Page 1

TM

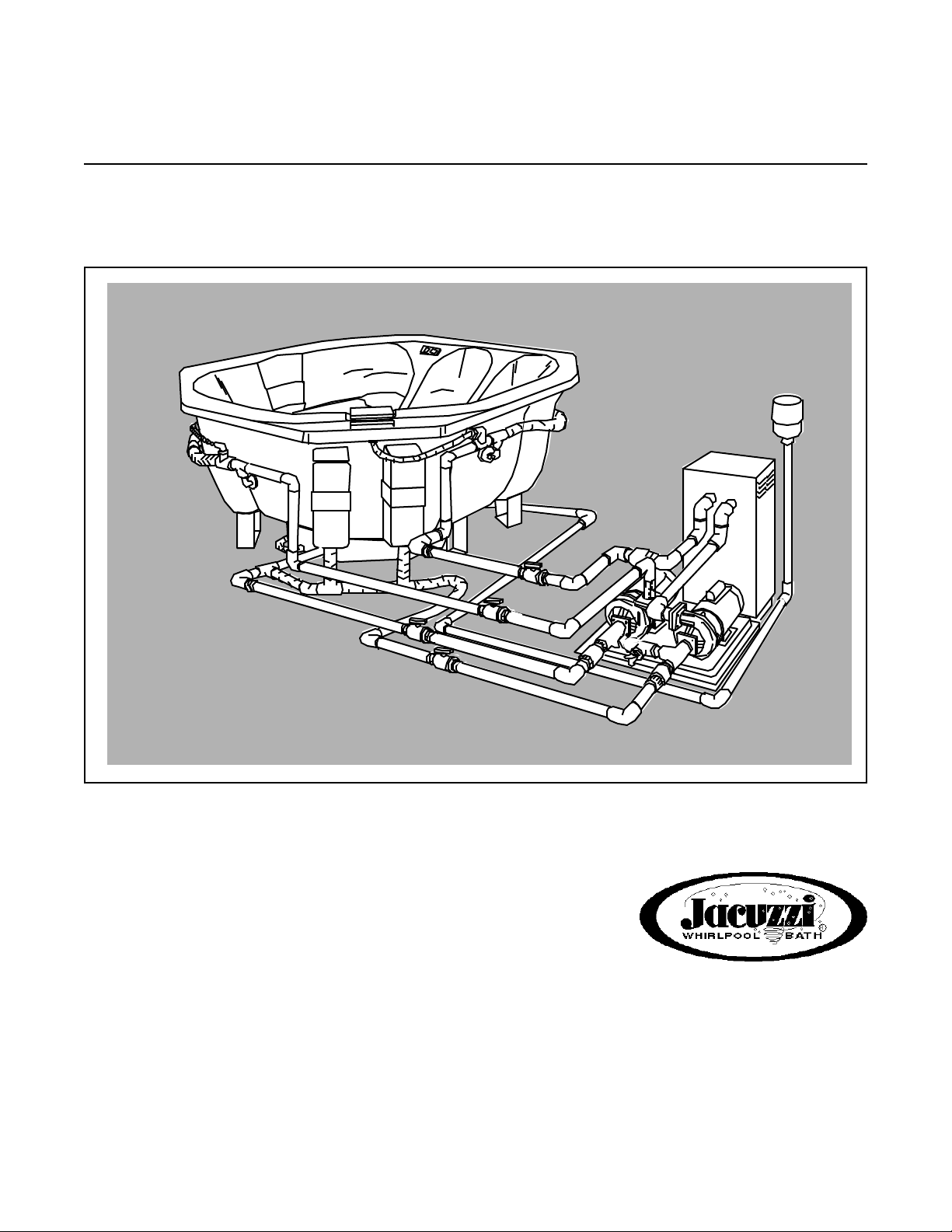

The Cirrus

IG

Owner's Manual

Page 2

IMPORTANT SAFETY INFORMATION

READ AND FOLLOW ALL INSTALLATION INSTRUCTIONS

Jacuzzi Whirlpool Bath does not recommend spa water

temperatures in excess of 104°F. High water temperatures

in excess of 104°F and/or prolonged periods of use can

raise the internal human body temperature excessively and

impair the body’s ability to regulate its internal temperature.

Limit your initial use of the spa to 10-15 minutes. High body

temperatures affect people differently; consult your physician about your safety and comfort before using the spa.

The elderly, the infirm, and children should not use the spa

unattended. Infants should not be permitted in the spa at

water temperatures over 100°F. Pregnant women and

people with heart conditions should consult their physicians

before using the spa at water temperatures over 100°F.

Extra care should be taken when using the spa and consuming alcoholic beverages. Alcohol, drugs, or certain medications such as tranquilizers affect a person’s ability to withstand high temperatures and may produce dangerous effects.

Keep body, hair, and clothing a minimum of 12 inches away

from suction fitting and skimmers at all times when the spa

is operating. Hair longer than shoulder length should be

secured close to the head, or a bathing cap should be worn.

Do not remove the suction grilles! They are safety devices

and must always be in place on the suction fitting to minimize

the potential hazard of hair entanglement or body entrapment.

While the optional spa cover is rigid, it is not designed to

support any weight. Therefore, as a safety precaution, do

not sit, stand or lie on it.

The spa must be installed with adequate electricalservice

access and water drainage system. (See Installation

Instructions.)

When using the electrical equipment, basic safety

precautions should always be followed:

Do not use electrically connected devices such as television, radio, or stereo speakers, lights, cooking devices, or

telephones within 5 feet of the spa while the spa is being

used. Lighting fixtures must not be located directly above

or within 5 feet of the spa. If located within 10 feet of the

spa, they must be on a circuit protected by a GFCI.

Do not apply power to the spa unless it is filled with water

to the normal water level, which is to the water level

indicator mark on the skimmer frame. Activating the spa

when there is an insufficient amount of water can damage

the circulation pump and may cause a fire.

Read manufacturer’s safety information provided with all

optional equipment.

The wet surface of the spa is slippery. Use care when

entering and exiting.

Save These Instructions for Future Use.

Owner's Record

Date Purchased

Purchased From

Installed By

Spa Serial Number Model # D500000

(See page 2 for location of serial number.)

Page 3

The Cirrus IG™ Whirlpool Spa

Owner's Manual

Model D500000

Contents

Page

Installation Instructions

Inspection and Shipping Claim

Unpacking

Indoor Installation,

Outdoor installation, Below Ground

Outdoor installation, Below Ground (cont).

Outdoor Istallation, Ground level or Above

Equipment Pack Site Preparation

Electrical Service

Plumbing

Heater and Air Channel Plumbing

Optional Air Blower

Seat Air Holes

Spa Set-up, Alternative use for Water Rainbow™

Operation Instructions

Equipment Set-up

Priming Procedure I

Priming Procedure II

Spa Controls, Normal Operation

Spa

Silent Air Induction

Water Rainbow™Spout

Maintenance

Water Quality and Water Chemistry

Filtration

Water Chemistry

Disinfecting

Balancing pH

Balancing Total Alkalinity

Water Quality Definitions

Water Level/Drain

Skimmer Basket Maintenance

Filter Maintenance

Automatic Filtration/Maintenance

Winterizing

Cleaning Your Spa

Covering Your Spa

Repairs to the Acrylic

3-14

3

3

4

5

6

7

8

9

10

11

12

13

14

15-19

15

16

17

18

19

19

19

20-24

20

20

20,21

21

21

21

21

22

22

22

23

23

24

24

24

Troubleshooting Guide

25-26

1

Page 4

The Cirrus IG Whirlpool Spa

Specifications

STANDARD FEATURES

• Three directionally-adjustable jets

• Six high volume fully-adjustable jets

• Water Rainbow Fill Spout

recirculating spout

• Two patented front load skimmer/filters

• Safety suction design

• Integrated steps

• Continuous contoured seating

• Separate equipment pack with:

2.0 hp whirlpool motor-pump and

0.75 hp heater/filter motor-pump

EQUIPMENT PACK

SUCTION EQUALIZER TUBE ASSEMBLY

(TO BE INSTALLED ON SITE)

WHIRLPOOL

MOTOR/PUMP

OPTIONS

• Air Blower

• Gas Heater

• Electric Heater

• Rigid Insulated

Spa Cover

• Air Switch/Timer

• Spa Pillows

HEATER/FILTER

MOTOR/PUMP

84"

15"

TYP.

15"

TYP.

84"

AIR CHANNEL HOLES TO

BE DRILLED ON SITE. (OPTIONAL)

84"

32"

SPECIFICATIONS

WHIRLPOOL

MODEL

Cirrus IG

(C500000)

Equipment

Pack

* Shipping weight includes equipment pack weight.

DIMENSIONS

84" (2134 mm) L.

84" (2134 mm)W.

36" (914 mm) H.

32" (81 mm) L.

20" (51 mm) W.

31" (79 mm) H.

MOTOR/PUMP

_

2.0 HP

230 VAC

10.0 AMPS

3450 RPM

Single Phase

60 Hz

32"

HEATER/FILTER

MOTOR/PUMP

_

0.75 HP

230 VAC

4.9 AMP

3450 RPM

Single Phase

60 Hz

PRODUCT SPECIFICATIONS ARE SUBJECT TO CHANGE WITHOUT NOTICE.

3"

36"

SERIAL NUMBER LOCATION

BLACK RECTANGLES IN ILLUSTRATION SHOW PLACEMENT OF WOOD SUPPORTS. SEE PAGE 4 OF

INSTALLATION INSTRUCTIONS.

LOCATE WOODEN SUPPORTS BENEATH OUTER

PERIMETER OF SEATING AREA.

PRODUCT

WEIGHT

321 lbs.

(145.6 kg.)

_

OPERATING

GALLONAGE

375 U.S. gal.

(1419 ltrs.)

_

SHIPPING

WEIGHT

615 lbs.*

(280kg)

_

ELECTRICAL

REQUIREMENTS

_

Two

230 VAC/15 AMP

Circuits

Page 5

INSTALLATION

Inspection and Shipping Claims

Check for shipping damage upon receipt of the spa. Jacuzzi Whirlpool Bath is not responsible for damage to the spa sustained

during shipping. If damage is evident before unpacking, see instructions regarding shipping claims on the outside of the carton and

immediately file a claim with the carrier.

Once the spa has been removed from the carton and before it is permanently installed (see below on this page for unpacking

instructions), check the spa completely for damage. Fill the shell with water and operate the system (see Operating Instructions) to

check for leaks which have resulted from shipping or handling. All Jacuzzi Whirlpool Bath spas are factory tested for proper operation

and water tight connections prior to shipping. If leaks or other problems are detected, immediately notify your Jacuzzi Whirlpool Bath

dealer or Authorized Service Agent, or call Jacuzzi Whirlpool Bath, (510) 938-7070 or (510) 938-7411 for Warranty Service.

Note: Damage or defects which could have been discovered and repaired prior to installation and which are claimed

after final installation of the spa, are excluded from our warranty.

Unpacking

1. Remove the outer carton by disassembling bracing and

side panels.

2. Remove the equipment pack from the pallet by removing

bolts and nuts securing the equipment pack base to the

pallet.

3. The spa should be moved to its final location on a dolly

in its upright position while still attached to its shipping

pallet.

4. When the spa has been moved to its final location,

preferably a concrete pad or other supported surfaces,

place a 4 x 4 x72" wooden block beside the base side

(bottom end) of the spa so it is parallel with the pallet.

5. Tip the spa over onto its bottom with the block supporting

the spa. Do not handle the spa by its plumbing;

handle it by the shell only.

6. Detach the spa from the shipping pallet by removing the

bolts from the pallet.

7. Leave the remaining plastic sheet attached to the spa

shell to keep the shell clean and free from debris during

installation.

8. Before installation begins, remove and retain the owner's

packet from the product accessory box. This packet

contains the Specifications and Installation Instructions,

and Operating Instructions. The accessory box also

contains filters cartridges, skimmer baskets, check valves,

and the equalizer tube assembly with installation hardware and connections to be installed on the equipment

pack. Set aside the filter cartridges in a dry place until it

is time to set up the spa equipment. Read all instructions

contained in both manuals before beginning installation.

9. Record the spa and equipment pack serial number on

the inside front cover of the Owner's manual. (See

illustration on page 2 for the serial number location.)

10. When unpacking optional equipment, keep enclosed

literature for owner's reference.

4 X 4 X 72"

BLOCK

FIBERBOARD

PALLET

REMOVE

BOLTS

BOLTS

4 X 4 BLOCK

3

Page 6

INSTALLATION

DRAIN HOSE HOOK-UP PERMAMENT DRAIN ASSEMBLY

Indoor Installation

Support

If you install your spa indoors, be sure to provide proper

support. The spa is very heavy when filled with water and

in use. The floor or deck it is placed on must be capable of

supporting a 4345 lbs. load, which includes weight of the

spa occupants, water and product. Consult an architect or

engineer to determine the adequacy of your floor or deck to

support this amount of weight. The Spa seating area and

foot well must be fully supported. Construct four 12 3/4" X

34" supports from 2 X 6 redwood or equivalent decayresistant or treated wood. The dimensions given are

approximate; supports should be cut to fit tightly between

the seat area and the floor. Locate the supports as shown

in the illustration on the inside front cover. Do not fill the

spa with water until the supports are installed.

Draining the Spa and Equipment Pack

Two methods of draining a spa installed indoors are

possible. You can install a permanent drain line in the

suction line of the spa, extending from the spa to the house

sewer line and using drain assembly fittings available at

most hardware or plumbing supply stores. Another method

is to install a drain valve in the suction line for hooking up a

garden hose which can be run to the house sewer line or to

an outside storm drain. Check local plumbing codes. See

Illustration below.

If you locate your equipment pack indoors, provide

drainage for that as well. You can attach a garden hose on

the hose bibb provided (once it is installed on the equalizer

tube between suction lines at the pumps) and run it to the

house sewer line when draining the equipment pack

2" X 6" MATERIAL

H

W

2" X 6" MATERIAL ~ REDWOOD OR WOOD

TREATED TO RESIST DETERIORIZATION

QTY SIZE

2 @ 11.0" H X 12.0" W *

1 @ 9.25" H X 12.0" W *

1 @ 9.50" H X 12.0" W *

1 @ 6.25" H X 6.0" W *

1 @ 6.50" H X 6.0" W *

* MATERIALS NOT PROVIDED

Surroundings

Water which splashes on the floor during use may cause

a walking hazard and/or structural damage unless good

drainage is provided and proper building materials are used

in the area surrounding and beneath the spa. Take into

consideration, also, the high room humidity which will exist

due to high spa water temperature. Providing natural or

forced ventilation of the room will help maintain comfort and

minimize moisture damage to the building. Jacuzzi Whirlpool

Bath is not responsible for damageresulting from excess

moisture or water spillage. Consult an architect or engineer

for aid in designing your indoor installation.

TEE*

WHIRLPOOL SUCTION

FROM SPA

HOSE BIB*

2-1/2" TO 3/4"

THREADED ADAPTER*

TEE*

WOODEN SUPPORTS

*PARTS SHOWN ARE NOT PROVIDED

REDUCER*

WHIRLPOOL SUCTION

FROM SPA

1" PVC VALVE*

1" PVC PIPE*

TO DRAIN

SYSTEM

Page 7

INSTALLATION

Outdoor Installation-Below Ground

The overall length of plumping between the spa and the equipment pack must be less than 20 ft. If you are installing your

spa below ground level, the base of the equipment pack must not be more than 9" above the spa rim.

Your spa should be installed so that the air intake opening on the air control assembly is not obstructed by backfill or

insulating material. If, however, your installation will cause the air intake to be restricted because of such obstruction, we

recommend that you construct a protective baffle around the intake to provide a fresh air passage to it.

Backfill Method

If your ground water level is low and drainage is good, you may use the backfill method to install your spa.

Dig a pit 6" deeper than the planned height of your spa and 6" around the outside walls. Since backfilling is below grade,

you should also trench out a plumbing run to the equipment pack at this time. Fill the bottom of the pit and level it. Make

sure the spa is at the desired height. All plumbing connections should be made at this time.

The plumbing system should be tested before completing backfill. (See "Plumbing.") Backfill beneath seat area and

perimeter, wetting the sand occasionally. Important: Use care when backfilling, both to avoid system damage and to prevent

sand from entering the air line system. The backfill should fully support the underside of the seat area and sides. Finishing

material around the spa, such as decking or patio, should not extend beneath the spa rim in such a way that the spa rim, after

shifting or settling of backfill sand, would become the main support of the spa. The spa rim is not designed to support the

weight of the spa. If the rim does support the spa, irreparable damage might occur which is not covered by the warranty.

Note: Do not use the backfill method if ground water level is high or drainage is poor, as hydrostatic pressure may lift the

spa out of the ground. If, because of heavy rains, the ground water level is temporarily high, ensure that the spa is filled

with water (except when cleaning) to compensate for the lifting force.

BACKFILL METHOD

BACKFILL WITH WETTED AND

COMPACTED SAND FOR SUPPORT

SPA RIM

6" MIN. DEPTH

Do not cover piping that is to be enclosed until having

completed a 24-hour leak test. Verify that the spa and

system, once filled with water and primed, are watertight for a 24 hour period before covering piping.

EQUIPMENT PACK BASE

(LOCATE LESS THAN 9"

ABOVE SPA RIM)

2" SHUT-OFF VALVES*

(LOCATE BELOW SPA

WATER LEVEL)

2" PVC PIPING*

*NOT PROVIDED

5

Page 8

INSTALLATION

Outdoor Installation — Below Ground (Continued)

Support Method

If your ground water is high and/or is poor, you will need to build a concrete pad at the bottom of the pit to support

your spa and prevent movement and slippage.

Build forms for a 60" X 72" X 4 " thick level concrete pad. Install a #10 gauge wire 6" X 6" steel reinforced grid. Then

pour concrete. Build wooden supports and fit them under the spa seating area as instructed in "indoor Installation." Refer

to "Support Method" illustration.

Draining the Spa

The spa can be drained to the level of the suction fittings if connected to a drain line or a gravel drain field. Whether the spa

is installed on a concrete pad or in a backfilled pit, install an accessible drain valve in the suction line and run a drain pipe

to a dry well, gravel drain field or storm drain. (See illustrations of suggested drain valve fittings on page 4.) If your spa is

installed lower than any drain field or storm drain, then it will be necessary to drain the spa by hand or by means of an electric

pump. When using an electric pump, observe caution and use a grounded cord, preferably with a plug-in GFCI (Ground Fault

Circuit Interrupter) available at your local hardware or electrical supply store. For maximum safety, do not use an electric

pump while the spa is occupied.

Air Blower Option

In the event that the air blower option may be added by the owner at a later date, we recommend that piping be

stubbed out from the air channel at this time. (See Optional Air Blower section.)

SUPPORT METHOD

BUILD 60" x 72" X 4"

CONCRETE PAD

DRAIN FIELD

SPA RIM

WOODEN

SUPPORTS*

2" SHUT-OFF VALVES*

(LOCATE BELOW SPA

WATER LEVEL)

ALTERNATE

DRAIN LINE

EQUIPMENT PACK BASE

(LOCATE LESS THAN 9"

ABOVE SPA RIM)

2" PVC PIPING

20 FT. MAX PLUMBING LINE

LENGTH BETWEEN SPA AND

EQUIPMENT PACK (INCLUDING

VERTICAL AND HORIZONTAL)

*

*

* NOT PROVIDED

Do not cover piping that is to be enclosed until

having completed a 24-hour leak test. Verify that the

spa and system, once filled with water and primed,

are watertight for a 24 hour period before covering

piping.

6

Page 9

INSTALLATION

CONCRETE PAD*

ABOVE GROUND LEVEL

WOODEN SUPPORTS*

*NOT PROVIDED

GROUND LEVEL

CONCRETE PAD*

2" SHUT-OFF VALVES*

(LOCATED BELOW

SPA WATER LEVEL)

20 FT. MAX. PLUMBING LINE LENGTH BETWEEN SPA AND EQUIPMENT PACK (INCLUDING VERTICAL AND

HORIZONTAL.)

*NOT PROVIDED

WOODEN SUPPORTS*

5' MAX.

VERTICAL

HEIGHT

SEE "SUPPORT METHOD" REQUIREMENTS ABOVE

SEE PAGE 5 (BOTTOM PAGE, BOLD TEXT)

20 FT. MAX. PLUMBING LINE LENGTH BETWEEN SPA AND EQUIPMENT PACK (INCLUDING VERTICAL AND

HORIZONTAL.)

Outdoor Installation — Ground Level or Above

You may install your spa and equipment pack so the spa is at ground level or above. The unique characteristic of the

equipment pack, which allows your spa system to be located away from the spa itself, is that it is designed to allow flexibility

in installation. This means that you can locate your spa on a level higher than the equipment pack, as long as the total

combined horizontal and vertical length of the plumbing lines between the equipment pack and the spa is no more than 20

feet, and as long as the equipment pack base is less than 5 feet below the spa rim.

Support Method

Particularly in deck installations, make sure the floor supporting the spa is strong enough to bear the load of the spa,

which is approximately 4345 lbs. which includes weight of spa occupants, water and product. Consult an architect or engineer

to determine the adequacy of your floor or deck to support this amount of weight. Build wooden seat supports as instructed

in "Indoor Installation".

Draining the Spa

As in other installations, you can install a permanent drain valve in the suction line; this will allow the spa to drain into

a sanitary drain, storm drain, or drain field, (See illustrations of suggested drain valve fittings on page 4.) Consult local codes.

Page 10

INSTALLATION

AIR BLOWER SUPPORT

OPTIONAL

AIR BLOWER*

SUGGESTED AREA

FOR CLASS I

ELECTRICAL

STUBOUT

(REFER TO NEXT

PAGE FOR

ELECTRICAL SERVICE

INFORMATION)

CHECK VALVE

(NOT INCLUDED)

OPTIONAL HEATER

EQUIPMENT PACK BASE

FROM SPA

FROM

SPA

TO

SPA

TO

SPA

FROM

SPA

TO

SPA

LOCATE HEATER WITHIN

5 FT. OF THE EQUIPMENT

PACK TO MINIMIZE

PERFORMANCE LOSS

24"

(36" FOR

GAS HEATER)

36" EQUIPMENT PACK ONLY

48" (FOR ELECTRICAL HEATER)

60" (FOR GAS HEATER)

MOUNT EQUIPMENT PACK

TO CONCRETE PAD

WITH 4 LAG SCREWS

(NOT PROVIDED)

LAG SCREW

(NOT PROVIDED)

EQUIPMENT

PACK BASE

LEAD ANCHOR

(NOT PROVIDED)

Equipment Pack Site Preparation

Locate the equipment pack on a level surface (at least 5 feet but not more than 20 feet from the spa) where there is

sufficient access to the equipment. Make sure the site selected will allow drainage of water away from the equipment pack.

We recommend that you build a concrete pad for the spa equipment. If an electric heater is to be used, the pad should

measure 48" X 24" X 3" thick; if a gas heater is to be used, make the pad 60" X 36" X 3" thick.* The heater must be located

within 5 feet of the equipment pack and on the same level. The pad should be reinforced with 6" X 6" #10 gauge steel wire

mesh grid Attach a #12 solid copper wire to the wire mesh grid with a ground clamp. This wire should be long enough to

reach the bond bar (See "Bonding" in the section on Electrical Service.)

After pouring concrete, and before it has set, locate holes for bolts or anchors to secure the equipment pack based to the

pad. Refer to the hole locations on the flange of the equipment pack base. Then secure the equipment pack base to the

pad. See illustrations on this page for details.

* Refer to heater manufacturer's installation instructions for proper placement and clearance around the heater, as well

as proper plumbing methods. Adjust pressure setting on heater according to manufacturer's instructions, if so equipped.

RECOMMENDED EQUIPMENT LAYOUT

8

Page 11

INSTALLATION

Electrical Service

Since most spa owners are not usually qualified to install the electrical hook-up to the equipment pack, we recommend

that you hire a professional electrician for a completely safe and functional installation. You or your electrician should obtain

whatever electrical permits may be required in your community and have the finished installation inspected by the local

building or electrical inspector. Consult your local building inspection department to determine local requirements. Your

electrician must size the wires to provide adequate amperage and voltage at the equipment pack. The type of wiring

insulation, amperage requirement, and distance from the service panel will determine the wire size (minimum 12 gauge

recommended). See also sections on grounding and bonding.

You will need to purchase a means of controlling your spa equipment pack. We recommend that you install an air switch/

timer such as that available as an option from your Jacuzzi Whirlpool Bath dealer. Follow switch manufacturer's instructions

when installing and refer to addendum sheet included with this product for wiring information. Provide a separate 230 VAC/

15AMP circuit to supply power to each of the motor/pumps. Additional circuits will be needed for any auxiliary equipment,

such as electric heater, air blower or chlorinator.

Note: When installing power wiring to the motors, refer to wiring diagram on motors or behind connection plate.

Bonding

Using a #8 solid copper wire, connect the equipment pack motors, current collector pipes (if an electric heater is used)

and air blower (if used) to a local bonding bar. Also connect all fixed metal objects (metal railings, window frames,

greenhouse structures, lamp poles, fence posts and gutters within 5 feet of the spa to the local bond bar. The local bond

bar must be connected to the house sub-panel or main electrical panel with a #8 solid copper bond wire. Consult your local

building inspection office for requirements. (See National Electrical Code Article 680-22.) Bonding lugs are available at

your local electrical supply store.

Grounding

The continuous service ground (minimum #14 copper) must run inside the electrical supply conduit from the main service

panel to the ground terminal in the equipment. Approved Local Ground. An approved local ground may be an 8 ft. long

ground rod, a ground plate electrode, or a buried metallic water pipe with at least 10 ft. or more of buried pipe. See Article

250 of the NEC or consult your local building code for additional approved grounding methods.

CAUTION

Your equipment pack is an electrical device. It has been made to operate as safely as possible

with many safeguards designed in. It complies with the NEC (National Electrical Code). It must

be installed at least 5 feet away from the spa and grounded properly in order to maintain these

safeguards. (See "Approved Local Ground".) All fixed metals within 5 feet of the spa must be

bonded (see Bonding). Electrical receptacles must be at least 10 feet from inside the rim of the

spa and be of a GFCI (Ground Fault Circuit Interrupter) type, or in a GFCI circuit. Area lighting

must not be located over the spa and must be at least 5 feet horizontally away from the spa rim,

at least 5 feet above the floor or ground. If within 10 feet of spa, it should be in a circuit protected

by a GFCI (see National Electrical Code, Article 680-6).

Without proper grounding and bonding, a system malfunction may cause fatal shock!

9

Page 12

INSTALLATION

Plumbing

Preliminary Assembly

Once your equipment pack is installed, attach the suction

equalizer tube assembly provided to the suction inlets of the

CLEAR PIPE (2)

SUCTION

EQUALIZER

TUBE ASSEMBLY

2" PVC ELL

AIR VENT VALVE (2)

pumps. Align pump flange ends of the assembly and install

using gaskets, bolts and washers provided. Next, install the

1 1/2" x 3/4" reducing bushing and hose bibb provided onto

HOSE BIB

the tee on the equalizer tube. This hose bibb can be used

to drain the equipment pack, and if a garden hose is

attached between it and your water supply, it can help when

priming the pumps. Be sure there is an anti-siphon valve in

the water line to prevent fresh water contamination. Screwon anti-siphon valves are available for easy installation on

the house water spigot.

REDUCER BUSHING

BOLT (8)

PUMP FLANGE

GASKET (2)

PUMP FLANGE (2)

Install the two ells to the clear plastic pipes at the

discharge outlets of the pumps, orienting them in the

direction appropriate for your plumbing layout. Note that

(DOTTED LINES INDICATE PARTS

TO BE INSTALLED ON SITE.)

each ell has a predrilled hole so you can install the two air

vent valves provided. These are necessary to bleed air

from the lines during priming. Install the air vents at this

time.

EQUIPMENT PACK PRELIMINARY ASSEMBLY

Interconnecting Piping

Plumbing lines between the equipment pack and the spa must not be longer than a total of 20 ft., including vertical

and horizontal dimensions.

Use 2" schedule 40 PVC pipe, with as few fittings as possible and bond with PVC solvent cement. When laying out

plumbing lines, avoid making configurations which might cause air entrapment in the system. Four 2" shut-off valves (not

provided) must be installed as close as possible to the equipment pack unit, below the spa water level, and accessible for

normal operation and maintenance. We recommend that they be ball-type valves. Do not use excessive amounts of cement

when bonding the valves to piping. Use pipe primer where required by local codes or when the air temperature during

installation is below 70 degrees F.

Install 2" check valves (swing type) supplied with the spa in the suction line to each pump. These aid in priming and

prevent reverse flow through the heater/filter pump when only the whirlpool pump is running. The arrow on the side of the

check valves must point in the direction of flow. If the base of the equipment pack is to be situated more than 20" higher

than the bottom of the spa shell, locate the check valves in the vertical part of the lines, near the pump.

EQUIPMENT PACK WITH PIPING

SUCTION

SHUT-OFF

VALVES

HOSE BIB

CHECK

VALVES

10

DISCHARGE

AIR VENT VALVE (2)

TO HEATER

PUMP

BOLTS (4)

Page 13

PLUMBING LAYOUT

INSTALLATION

OPTIONAL

AIR BLOWER

OPTIONAL

HEATER

CHECK

VALVE

DISCHARGE

2" PIPING*

(OR LARGER)

20 FT. MAX. PLUMBING LINE LENGTH

BETWEEN SPA AND EQUIPMENT PACK

(INCLUDING VERTICAL AND HORIZONTAL)

SHUT-OFF VALVES*

(LOCATE BELOW

SPA WATER LEVEL)

*SHUT-OFF VALVES AND PLUMBING LINES

NOT PROVIDED BY JACUZZI WHIRLPOOL BATH

SUCTION

CHECK

VALVES

Heater Plumbing

Use at least 4 ft. of copper pipe in the inlet and outlet plumbing of a gas heater (refer to local codes). Install a current

collector in each water line to the heater if an electric heater is used. Piping should be 1 1/2" or larger. You must install a

swing check valve after heater discharge. To minimize performance loss, locate the heater no farther than 5 ft. away from

the equipment pack and at the same elevation. Refer to heater manufacturer's instructions and the "Recommended

Equipment Layout" on page 8.

Air Channel Plumbing

Use 2" PVC schedule 40 pipe for the plumbing line between the optional air blower and the 2" fitting located under the

spa near the skimmer wall. See page 12 for detailed air blower instructions.

Automatic Chlorinators

There are several brands and types of automatic chlorinators available. Automatic chlorinators should be installed

downstream of the heater (all types) with a check valve in the line to ensure that the chlorine solution does not enter the heater

and cause corrosive damage. Your Jacuzzi Whirlpool Bath dealer will be glad to assist you in making your selection.

Note: Use of an automatic chlorinator does not ensure proper water quality. Check and adjust water quality frequently to

prevent corrosive damage, which is not covered by the Jacuzzi Whirlpool Bath warranty.

11

Page 14

2" PVC PIPE

12"

BOTTOM

DISCHARGE

BLOWER

RIGID

SUPPORT FOR

PLUMBING

AIR

CHANNEL

FITTING

INSTALLATION

Optional Air Blower

Two channels under the seating area of your Cirrus IG receive air from the air blower and distribute the air throughholes

in the seating area (to be drilled according to instructions on the following page). As the pressurized air is released from

the holes, tiny bubbles are formed. These bubbles travel upward through the water and expand until they reach the surface,

whereupon they burst. The visual effect of the bursting bubbles contributes to the overall hydromassage experience.

Consult your Jacuzzi Whirlpool Bath dealer for the air blowers available. The minimum rating of the air blower you use

should be 110 cfm, 2.6 psi. For best performance, the blower you select should not exceed this rating by more than 10

percent. See the illustration on page 8 for its recommended location. A bottom discharge blower should be mounted directly

onto a vertical 2" diameter PVC pipe (see illustration on this page). Side discharge blowers that are installed lower than 12"

above the spa's rim must be plumbed with a loop, as illustrated on this page. Some air blower manufacturers recommend

that a check valve also be installed, but use of a check valve instead of a loop is not recommended. Follow blower

manufacturer's instructions when installing.

CAUTION: Wait 24 hours before turning on the air blower, as the PVC cement fumes remaining in the plumbing

are flammable and may explode when the blower is started.

SIDE DISCHARGE BLOWER

LOOP

TYPICAL BOTTOM DISCHARGE

AIR BLOWER ORIENTATION

*LOOP MUST BE AT LEAST

12" ABOVE SPA RIM

12"

12"

2" PVC PIPE

DISCHARGE

BLOWER

SIDE

12

Page 15

INSTALLATION

Seat Air Holes

Because the air blower is an optional feature of the Cirrus IG, air holes are not factory drilled in the seating area. Included

with your spa are an air hole drill guide and a 5/32" diameter drill bit with which to drill the 59 holes required. The drill guide

is shaped to fit the contour of the spa. We recommend that you apply masking tape to the underside of the guide to prevent

scratching the spa surface.

Locate the dimples imprinted in the surface of the seat. (The dimples indicate the center of the air channel located beneath

the seat.) Align the drill guide so that it fits the contour of the spa and is positioned against the footwell wall, and the hole

is over one of the dimples.

Insert the drill bit provided into the drill chuck so that only 1" to 1 1/2" of the drill bit extends out of the chuck. With the

drill guide in place, insert the bit into the guide and proceed to drill with light pressure at low speed through the acrylic,

increasing to high speed to drill through the fiberglass. Continue marking and drilling holes around the seat of the spa until

all holes are drilled at 1 3/4" intervals. (See illustration below.)

Use care when drilling! Failure to use the drill guide or drill bit provided may cause the bit to drill through bottom

of the air channel or cause permanent damage to the shell.

SEAT AIR HOLE DRILLING (WHEN OPTIONAL AIR BLOWER IS INSTALLED)

HAND DRILL

1-1/2" MAX

DIMPLE

DRILL GUIDE

LOCATE AIR HOLE

1-3/4" APART

*Number and size of the holes may vary if a blower other than that recommended on page 12 is used.

13

Page 16

14

Alternate Use of Water Rainbow Spout as Fill Spout

You can use your Water Rainbow spout as a fill spout by permanently plumbing it to a fresh water supply if codes permit.

Local plumbing codes may require the use of an anti-siphon valve for such a connection. Do not interconnect water supply

with recirculating system of the spa.

To make the connections necessary to use the Water Rainbow as a fill spout, follow this procedure:

• Make sure power to the equipment pack is disconnected and spa is drained to below seat level.

• Cut 3/4" flexible piping as shown in illustration below and unscrew connecting fitting at spout.

• Cap off piping by cementing a 3/4" PVC cap where cut has been made.

• Connect permanent plumbing line to the spout.

FRONT ACCESS

SKIMMER/FILTER

Spa Set-Up

Remove the protective plastic rim cover on the

spa. Use care. Stepping into the spa with shoes

will scratch the acrylic surface.

Remove any packing materials from the spa.

Remove each filter cartridge and skimmer basket

from plastic bags.

Pull open each skimmer/filter door by the handle

located in the middle of the door. Insert the filter

cartridge into the filter housing and insert the

skimmer basket so it is in place over the filter

cartridge. Then close the skimmer/filter door.

Clean the interior of the spa of any remaining

construction debris. Remove stubborn stains,

paint or tar with turpentine, isopropyl alcohol or

paint thinner. A mild liquid dishwashing detergent

on a damp cloth is fine for cleaning off other dirt.

Plaster can be removed by scraping with a wooden

edge; do not use a metal scraper, wire brush, or

other metal tools, as they will damage the spa's

surface.

INSTALLATION

SKIMMER BASKET

NYLON ROPE LOOP

WEIR

DOOR

FILETR CARTRRIDGE

WATER RAINBOW SPOUT

INSTALL AND CEMENT3/4" PVC CAP

CUT PIPING HERE (LEAVE 1-1/2" -2")

TEE ON DISCHARGE PIPING

SPA SHELL

3/4" FLEXIBLE PIPING

Page 17

OPERATION

Equipment Set-Up

Important: Your spa equipment pack must have two professionally installed 230 VAC 15 AMP electrical circuits from your

house electrical panel. Additional power will be required for optional equipment, such as heater, air blower, or chlorinator.

A proper ground wire run to a ground approved by your local building or electrical inspector is also required. Make sure the

equipment is properly bonded as instructed in Installation Instructions.

1. Turn OFF all power to the equipment pack by turning off

circuit breakers at the main electrical service panel.

Warning! Turn off all power to the equipment pack

before priming, draining the spa, or performing any

equipment maintenance.

At no time should the whirlpool or filter pump motors

be activated until the pumps are primed and the spa is

filled with water to its normal operating level. Running

the pump dry will cause irreparable damage to the

pump, and the warranty will become void.

EQUIPMENT PACK

CLEAR PIPE (2)

SUCTION

EQUALIZER

TUBE ASSEMBLY

2. Turn on the circuit breakers at the service panel.

3. Follow Priming Procedure, I or II, depending on your

installation type, and check pipes, pumps, and fitting for

leaks.

4. Set thermostat at heater (see heater manufacturer's

operating instructions.)

5. Test for proper water chemistry; then add treatment

chemicals to ensure proper levels. See "Water Quality"

section for details.

2" PVC ELL

AIR VENT VALVE (2)

HOSE BIB

REDUCER BUSHING

PUMP FLANGE

GASKET (2)

BOLT (8)

PUMP FLANGE (2)

(DOTTED LINES INDICATE PARTS

TO BE INSTALLED ON SITE.)

15

Page 18

OPERATION

Priming Procedure I

Use this priming procedure if your installation is such that the base of the equipment pack is level with or above

the rim of the spa (see illustration.)

1. Turn all switches to OFF. Turn OFF circuit breakers at service panel.

2. Open the air vent valves on the plastic elbows.

3. Fill the spa with water with a garden hose to the

spa's normal operating level, which is at the

water level indicator mark on the filter/skimmer

frame.

4. Close the four shut-off valves in the suction and

discharge plumbing.

5. Connect hose to hose bibb on the equalizer tube

between the two pumps. (Make sure anti-siphon

valve is installed at the water source to prevent

contamination of the water supply.)

PRIMING PROCEDURE 1

(ABOVE WATER LEVEL)

6. Open the hose bibb and fill the piping system with

water until water can be seen through clear pipes

on discharge piping.

7. Close the air vent valves when water starts to

flow from them.

8. Close hose bibb and disconnect garden hose.

9. Open four shut-off valves in suction and discharge

piping.

10 Turn ON circuit breakers at the service panel.

11.Turn ON pumps one at a time.

Important: If either pump is not visibly pumping

water at this point, turn off the motor immediately.

Then repeat priming procedures steps.

SPA RIM

SHUT-OFF VALVES AND PIPING NOT PROVIDED BY JACUZZI WHIRLPOOL BATH

BASE

16

EQUIPMENT

PACK

Page 19

OPERATION

Priming Procedure II

Use this priming procedure if your installation is such that the base of the equipment pack is lower than the rim of

the spa (see illustration.)

1. Turn all switches to OFF. Turn OFF circuit breakers at

service panel.

2. Open shut-off valves in the suction and discharge system plumbing.

3. Open the air vents in the plastic elbows.

4. Close the hose bibb located in the equalizer tube between suction lines.

5. Fill the spa with water (using a garden hose) up to its

normal operating level, which is at the water indicator

mark on the skimmer/filter frame. As the water level in

the spa rises, it will bleed air out of the vent valves. When

water flows from the air vents, close them and continue

filling the spa to water indicator mark.

6 .Turn ON the circuit breaker at the service panel.

7. Turn ON the pumps one at a time.

PRIMING PROCEDURE II

(BELOW WATER LEVEL)

SPA RIM

SHUT-OFF VALVES AND PIPING NOT PROVIDED BY JACUZZI WHIRLPOOL BATH

EQUIPMENT

PACK

BASE

17

Page 20

SILENT AIR

CONTROLS

OPERATION

Spa Control

Your Spa and equipment pack installation must include a control system such as an air switch and/or timer system

which will turn the two motor/pumps on and off and provide control of whirlpool, heater and filter functions. Follow

switch manufacturer's instructions for operation.

Warning! At no time should the whirlpool or filter pump motors be activated until the pumps are primed and the spa is

filled with water to its normal operating level. Running the pump dry will cause irreparable damage to the pump,

and the warranty will become void.

All spa heaters have adjustable thermostat settings. The recommended water temperature range for whirlpool bathing

is 90°-98° F. (104° F. max.) . Following the heater manufacturer's instructions, set your heater thermostat to a point which

is comfortable for you within that range. (See Safety Information on the inside front cover.)

Normal Operation

Whirlpool System:

You can enjoy the Cirrus IG spa with or without activating

the whirlpool. Either way, bathing in your spa can be

pleasurable, as well as therapeutic. After a busy, stressful

day, you can look forward to soaking in your spa in still

water with no turbulence—only the gentle warmth of the

soothing and relaxing water.

DIRECTIONALLY ADJUSTABLE

WHIRLPOOL JETS

For a more invigorating spa experience, you can take

advantage of the built-in whirlpool system. To do this,

select the WHIRLPOOL mode at the system control

switch. Sit or recline in the spa so you are comfortable.

Since all the jets are directionally adjustable, you can direct

a jet toward an area where muscles feel tense or stiff. The

warmth of the water and the stimulating water flow from the

jet will pleasantly increase circulation.

For the total whirlpool effect and all-over feeling of well

being, you can adjust all jets so they point in a clockwise or

counterclockwise direction to circulate the air and water

mixture in a circular motion all about the spa.

WATER RAINBOW

SPOUT

SKIMMER/

FILTERS

WATER LEVEL

MARK

SUCTION

COVERS

FULLY ADJUSTABLE

WHIRLPOOL JETS

DIRECTIONALLY

ADJUSTABLE JET

FULLY

ADJUSTABLE

WHIRLPOOL

JET

SILENT

AIR

CONTROL

18

Page 21

OPERATION

™

Water Rainbow

The Water Rainbow spout will add the soothing sound of

a waterfall to your bathing pleasure, as well as provide a

beautiful cascade of shimmering water for an exciting visual

effect.

Activate the waterfall feature by first turning on the

WHIRLPOOL function, then rotate downward the flow control lever located on the left side of the spout. Use this lever

to adjust the amount of water flowing through the Water

Rainbow spout.

CAUTION: The water circulating through the Water

Rainbow spout is not fresh water and therefore is not

suitable for drinking.

Silent Air Induction

The intensity of the whirlpool action is determined by how much air is induced into the water. You have control of this

by adjusting the air induction control knobs (See illustration below). For maximum air induction, rotate each control knob

fully counter clockwise. For fewer air bubbles, decrease the amount of air induction by rotating the control knobs clockwise.

When the knobs are turned fully clockwise, only water is being circulated.

INCREASE AIR FLOW

(COUNTER CLOCKWISE)

DECREASE AIR FLOW

(CLOCKWISE)

CONTROLS

FOR FULLY ADJUSTABLE JETS

INCREASE AIR FLOW

(COUNTER CLOCKWISE)

FOR ADJUSTABLE NECK JETS

DECREASE AIR FLOW

(CLOCKWISE)

CONTROL

19

Page 22

MAINTENANCE

Water Quality and Water Chemistry

Maintaining water quality and water chemistry in your spa is extremely important and should be a regular part of your spa

maintenance program, as a neglected spa can be a breeding place for dangerous bacteria.

The water quality of your spa is maintained by a combination of filtration and chemistry. The spa’s integral filter system

helps maintain the water cleanliness and clarity by trapping most solid materials such as hair and other debris resulting from

normal use. However, the most important part of maintaining water chemistry is keeping the proper level of disinfectant in

the water at all times. This is accomplished by adding chlorine or bromine to the water, which will control particles too small

to be trapped by the filter, such as bacteria and algae, and will oxidize any organic materials. Follow instructions provided

here, and with water quality products, for the health and safety of spa users, as well as to make your spa bathing as enjoyable

as possible.

Filtration

The filtration system of your spa will keep your water

clear and clean if used properly. We recommend that you

run your filter system for at least two hours each day. The

filter cartridge elements will trap most solid materials and

debris in the water. However, the presence of materials

such as body oils or other particles which are too small to

be captured in the filters may bring about various undesirable water quality conditions. These conditions can be

corrected with the use of spa treatment chemicals which

are available from your Jacuzzi Whirlpool Bath dealer.

Such conditions include the following:

Foaming: A de-foamer is available to minimize foaming of

the water. This condition is usually caused by the addition

of soaps or oils, or other fatty substances to the spa water.

The interaction of these with hot water, especially at high

pH (more alkaline) levels, will cause the water to foam.

(See Water Quality Definitions.)

Oil Film or Cloudy Water: Add clarifier to congeal oil film

on the water surface into globules sufficiently large to be

trapped by the system’s filter. Cloudiness is caused by

particles that are too small to be trapped in the filter and is

also due to the presence of human body oils, lotions, and

cosmetics. During normal use, these materials can accumulate on the filter element and clog its pores. The addition

of clarifier will make the water clearer, but may clog filters

which must be cleaned as prescribed under the section

entitled “Filter Maintenance” in this manual.

Water Chemistry

You can ensure better water chemistry by testing your

spa water every day and adjusting the chemical balance

frequently. Obtain a water quality test kit, designed

especially for spas, from your Jacuzzi Whirlpool bath

dealer. The test kit must be of the type which allows you

to test for the disinfectant (chlorine) level, pH, and total

alkalinity. Make sure, also, that the chemicals used in your

spa are especially for spa use, and not for swimming pool,

as water quality maintenance of spas and swimming pools

is very different.

Set up a daily program at first to check the disinfectant

level, pH, and total alkalinity of the water to familiarize your

self with the amount of chemicals to add and to determine

how often to make chemical adjustments during normal

use. Remember that the more heavily the spa is used, the

more often you should check the water chemistry.

When adding any chemicals, always run the filter

system to ensure complete dilution with the water. DO

NOT ADD CHEMICALS DIRECTLY IN THE SKIMMER

OPENING.

Hard Water: Add a de-mineralizer to break down or de-

ionize mineral particles present in the spa water.

Follow the “Filter Maintenance” procedure described in

this manual to ensure optimum performance of your spa’s

filtration system.

20

Page 23

MAINTENANCE

Water Chemistry (continued)

Disinfecting:

Add a disinfectant to the water on a regular basis to help

control the amount of bacteria, algae and organic materials.

Such bacterial contaminants, if not controlled, could cause

skin rashes or other physical problems. To disinfect the spa

for normal use, first establish the amount of chlorine or

bromine to add and determine how often you need to add

it.

We recommend that you maintain a free chlorine level of

2.0-5.0 ppm at all times except when you must exceed that

during the initial purge/sanitizing procedure or during superchlorination (see “Water Quality Definitions” below).

Superchlorinate your spa every two weeks with heavy use.

If using sodium dichlor, add one heaping tablespoon for

each 150 gallons of spa water. Scrub the spa surfaces with

this solution to remove any oily deposits. This will ensure

that any bacteria or algae which are resistant to the normal

disinfectant level are killed. After adding the disinfectant,

run the filter system and allow the free chlorine level to

return to the 2.0 to 5.0 ppm range before using the spa

again. Do not install a rigid cover until the disinfectant

level is back to normal. High concentrations of chlorine

or bromine will damage metallic plated finishes if the

cover is in place.

Balancing pH:

For good hygiene and equipment longevity, maintain the

pH of your spa water according to the instructions provided.

pH is the measure to determine if the spa water is too acid

(low pH) or too alkaline or basic (high pH). The ideal range

for spa water is 7.2 to 7.6 pH. For excessive acidity (below

7.2 pH) add soda ash or sodium bicarbonate to the spa

water. For excessive alkalinity above 7.6 pH add dry acid to

the spa water. Caution: Refer to the spa chemical

manufacturer’s instructions for the initial amount of chemicals to add for the gallonage of your spa. Low pH can cause

equipment damage, as acidic water will dissolve metals,

while high pH can cause scale or calcium deposits to build

up in the system or on the shell. After adding chemicals, run

the filter system for at least 30 minutes before testing water

quality again for accurate readings.

Balancing Total Alkalinity:

Total alkalinity is the measure of base materials in the

water. The recommended range for total alkalinity is between 80 ppm and 150 ppm. If the chemistry of the water

is not within this range, you will have difficulty adjusting the

pH level, which will affect your adjustments for the proper

amount of free available chlorine. If the alkalinity of your spa

water is high, it is advisable to drain the water from the spa,

refill and begin the balancing process over again. Purge

and sanitize your spa (according to instructions in "Equipment Set-Up" section of the "Installation Instructions") and

clean the spa surfaces thoroughly before refilling with fresh

water. Then re-establish water chemistry. If the spa is used

heavily, change the water at least every month.

WATER QUALITY DEFINITIONS

pH: A chemical term used in expressing relative acidity or

alkalinity in numeric values, with 7.0 usually regarded as

neutral, and for purposes of this manual, indicating pure

water. From 7 to 0 indicates increasing acidity, and 7 to 14

indicates increasing alkalinity.

PPM: Parts per million.

Free chlorine: Chlorine that has not combined with other

chemicals and that is available to destroy bacteria in the spa

water.

Trichlor: A form of chlorine used in pool or spa water

treatment; usually supplied in tablet form. Not recommended

because of its higher acidic nature and slow dissolving action.

Prolonged contact with the spa shell may bleach or permanently mark the shell.

Sodium dichlor: The type of chlorine that is recommended

for spa use, as it is available in fast dissolving granular form.

It is neither excessively acid nor alkaline in character and does

not readily dissipate in higher water temperatures.

Calcium hypochlorite: A granular chlorine product that is

inexpensive and effective but not recommended because

it often tends to form calcium deposits on heater parts and

plumbing fittings and leaves an unattractive film on the spa at

the water line.

Sodium hypochlorite: A liquid chlorine product that is

inexpensive and effective but not recommended because the

liquid is readily spilled onto the spa or a surrounding area,

causing permanent damage. It has limited effectiveness at

high water temperatures and readily affects pH balance.

Total alkalinity: The measure of the amount of alkaline

materials (such as carbonates, bicarbonates and hydroxides) in the water. High alkalinity inhibits the effectiveness of

chemicals to change the pH. If the alkalinity of your spa water

is high (above 150 ppm), it is advisable to drain the water from

the spa and begin the balancing process over again. Low

total alkalinity (below 60 ppm) could be corrosive and damage your spa system.

Superchlorination: (Also referred to as “shock treatment”.)

The addition of an above-normal level of disinfectant to kill

any bacteria or algae that might have become resistant to

normal levels of disinfectant.

21

Page 24

22

Replacement cartridges are available through your

Jacuzzi Whirlpool Bath Dealer.

The suction covers located in the foot well area should be

checked at least once a week for collected debris, such as

leaves, hair, etc., and cleaned as necessary. It may not be

necessary to remove the suction cover to clean it, but if you

need to, remove the center screw with a Phillips type

screwdriver and clean the cover by flushing with water from

a hose.

CAUTION: Be sure to replace the suction cover imme-

diately after cleaning. It is a safety device and must be

in place over the suction fitting to minimize potential

hazard of hair and body entrapment.

If heavy rains raise the spa water level, drain the spa to

its normal level.

The optional rigid spa cover , when in place over the spa,

will help reduce evaporation and control the amount of

debris entering the spa when the spa is not occupied. In

addition, its use will reduce energy consumption.

NORMAL WATER LEVEL

Skimmer Basket Maintenance

The basket located in the skimmer of the spa should be

checked at least once a week for collection of debris, such

as leaves, hair, etc., and cleaned as necessary. To clean

the basket, remove it from the skimmer by pulling it out; then

backflush it with a garden hose and reinstall.

MAINTENANCE

Water Level/Drain

The water level in the spa must be maintained at its

normal level. Evaporation and splashing will cause the

water level to drop.

When concentrations of impurities from evaporation,

water quality chemicals, body oils, perfumes, dirty feet, and

winds, etc., accumulate in the spa and cannot be filtered

out, it is necessary to drain your spa and refill it with fresh

water. This should be done every 2 months or more often

depending on the amount of use.

After draining the spa, clean the spa shell, suction

covers, skimmer, and filter, then close the drain valve and

refill the spa with fresh water. Check the pH level and

maintain water quality.

FRONT ACCESS

SKIMMER/FILTER

SKIMMER BASKET

NYLON ROPE LOOP

WEIR

DOOR

NORMAL WATER

LEVEL MARKER

FILETR CARTRRIDGE

Filter Maintenance

The filters should be checked periodically. In normal

use, check the filters at least once a month. Keep the filters

clean; obstructed filters reduce water quality and inhibit

proper system performance.

A removable filter cartridge is located inside each skimmer. To remove it, pull open the skimmer door by the handle

located in the middle of the door. Slide the basket out, then

pull the filter cartridge upward and out of the housing by the

loop at the top of the filter. Clean the filter by separating the

folds of the filter and spraying with fresh water from a garden

hose. Then reinstall the cartridge in the housing and

replace the basket, reversing the above procedure.

Oils will coat the filter, resulting in a reduced flow. To

remove such materials, soak the cartridge in a plastic pail

containing a commercial filter cleaning solution (available

from your Jacuzzi Whirlpool Bath dealer or most pool

supply stores). Follow the manufacturer’s instructions for

use. Another method is to soak the filter cartridge in a

plastic pail containing a mild solution of trisodium phosphate (TSP) and water. An hour of soaking time is usually

required to break down oil coatings from the cartridge. Use

a stronger solution of TSP and water to remove algae. Most

hardware or paint stores stock TSP. Use the same method

of cleaning when the cartridge becomes plugged with clay

or vegetation.

Page 25

MAINTENANCE

Automatic Filtration/Maintenance

The spa should be covered to keep out debris. The filter cycle should be run at least two hour per day to maintain water quality.

If your equipment pack has a timer installed, the timer may turn on the filter automatically each day for you in your absence.

Your timer may also function to turn on the heater to maintain a certain water temperature. (Refer to optional switch/timer

instructions.)

During prolonged periods of no use, the evaporation of water from the spa will cause the water level to fall below the

skimmer level.* Long periods (two weeks or more) without water quality maintenance are not recommended. If spa water

care cannot be maintained, turn off the main service panel switch (or sub-panel switch), drain and cover the spa.

Another means of maintaining minimum water quality while you are away for less than two weeks is to follow the procedure

outlined for winterizing your spa in a warm climate. (See Winterizing.) Note: We do not recommend using this procedure

if you are absent during the summer, when algae build-up is most likely.

Always keep your spa covered when not in use to reduce heat loss and evaporation and to prevent debris from falling in.

*Warning: If motor/ pump(s) is activated when the spa water is low, when the spa has been drained, or when the

pump has lost its prime, the pump could become irreparably damaged.

Winterizing

In a climate where winter temperatures are below

freezing, follow this procedure when the spa will NOT

be used:

Note: If the spa is to be used during winter in a cold

climate, see warm climate instructions below.

1. Turn off the power to the equipment pack.

2. Drain the spa and equipment.

Note: If your spa is installed below ground and the

ground water level in your area is high or drainage is

poor, do not drain the spa (except for cleaning), as

hydrostatic pressure may lift the spa out of the ground.

Follow warm climate instructions for winterizing.

3. Remove the filter cartridges, clean them, and store

them dry.

4. Remove the lower 1/4" plugs from the face of each

pump housing, drain the pumps, then replace the plugs.

5. Obtain pure glycerine (Glycerol) from a druggist or other

source. Mix 2 parts of glycerine to 1 part water and pour

approximately one cup into each pump at the upper

drain plug opening. A syringe or other similar device

may speed up this process. Re-insert upper drain plug.

Do not use automotive anti-freeze.

In a warm climate where there are occasional freezing

temperatures, follow this procedure:

1. Set the thermostat on the heater to its minimum

temperature which, typically, is between 45°-65° F.

2. Run filter cycle daily during freezing conditions.

4. Maintain a chemical balance. (See Water Quality section.)

4. Use optional rigid spa cover for increased energy efficiency. This procedure allows usage of the spa during

winter months with a minimum energy requirement.

CAUTION: Not winterizing will cause irreversible

damage (at freezing temperatures) to the pump and

or plumbing lines.

After the spa has drained keep water and debris out by

covering with a water-proof cover.

Before using the spa again, see filling instructions in

appropriate Priming Procedure.

PLUG

PLUG

23

Page 26

MAINTENANCE

Cleaning Your Spa

Your Cirrus IG spa shell consists of two layers of plastic

materials. Its smooth top surface of acrylic is tough and

durable and contains concentrated color. This is supported

by a substantial thickness of fiberglass-reinforced polyester resin. A catalyst causes a chemical reaction during

manufacturing that bonds these layers permanently into a

hard, strong material. With a minimum amount of care and

cleaning, your whirlpool spa will look new for years.

To clean your spa, simply use a mild, non-abrasive liquid

detergent, isopropyl alcohol, or commercially prepared spa

cleaner. Do not use abrasive cleaners. You can protect

and restore the gloss to a dulled surface by applying

Meguiar’s #10 Mirror Glaze, which is a product specifically

designed for use on acrylic finishes. If Meguiar’s is not

available, an acrylic polish of equal quality or automotive

paste wax will do.

Use a spa cleaner for residue buildup at the water level

of the spa surface. This may be applied to the acrylic

surface with a soft cloth and wiped clean. Use sparingly in

small amounts to avoid contaminating the spa water. If the

spa is heavily soiled, it may be advisable to lower the water

level 2 - 3 inches before cleaning, then refill to normal level.

Covering Your Spa

An optional rigid spa cover is available to place on top of

the spa. The use of this cover will help to reduce energy

costs by minimizing heat loss and evaporation from your

spa. In addition, the attractive spa cover is an effective

means of preventing debris such as leaves and dirt from

entering your spa when not in use. Follow the instructions

for use and care provided with the spa cover.

CAUTION: While the spa cover is rigid it is not designed to support any weight. Therefore, as a safety

precaution and to preserve the life of your cover, you

must not sit, stand, or lie on it; nor should you place

objects of any kind on top of it.

Jacuzzi Whirlpool Bath does not guarantee or warranty

this cover. Refer to spa cover manufacturer's information provided with the cover.

Repairs to the Acrylic

Minor scratches which do not penetrate the color finish

(acrylic) can be removed with 600-grit wet/dry sandpaper.

Restore the glossy finish with Meguiar's #10 Mirror Glaze or

comparable automotive paste wax.

Major scratches or gouges which penetrate the acrylic

surface will require refinishing. Ask your Jacuzzi Whirlpool

Bath Dealer for special instructions.

24

Page 27

TROUBLESHOOTING GUIDE

PROBLEM REMEDYPROBABLE CAUSE

1. Water will not heat.

2. Water not clean.

3. Abnormal water usage.

4. Low water flow

from jets.

A. No power to the heater.

B. Thermostat set too low.

C. Pressure switch set too high

on gas heater.

D. Failure of heater thermostat.

E. Filter pump not on.

A. Filters clogged (dirty).

B. Skimmer basket clogged.

C. Clogged or blocked suction

strainer.

D. Improper maintenance.

E. High content of solids in

water.

A. Excess evaporation..

B. Leak in plumping line.

A. Only filter pump running.

B. Only whirlpool pump running.

C. Dirty filter(s).

D. Plugged strainers.

E. Low water level.

F. Shut-off valves closed.

G. Suction, skimmer, or

discharge partially clogged.

H. Worn or damaged pump seal.

I. Foreign object lodged in pump.

A. Check circuit breaker.

B. Reset thermostat.

C. Adjust pressure switch.

D. *

E. Check circuit breaker.

A. Clean or replace.

B. Clean.

C. Clean.

D. See Maintenance/Water

Chemistry.

E. Drain and refill spa.

A. Use spa thermal cover.

B. Repair leak.

A. Turn on whirlpool pump.

B. Turn on filter pump.

C. Clean and replace.

D. Clean.

E. Fill spa to middle of skimmer

opening.

F. Open valves.

G. Clean strainers or skimmer baskets.

H. *

I. *

5. No water flow from jets.

6. Noisy pump and motor.

* Note: The skills and tools necessary for the safe repair of this spa require the services of qualified service

personnel. Contact your Jacuzzi Whirlpool Bath Authorized Service Agent or Dealer.

A. Circuit breaker tripped.

B. Shut-off valve closed.

C. Low water level.

D. Leak in suction line,

discharge line or connections.

E. Pump or motor faulty.

F. Pumps lost prime.

A. Leakage of air into suction.

B. Blocked suction.

C. Vibrating parts attached to

motor or support brackets.

E. Damaged or worn motor

bearings.

F. Impeller rubbing inside case.

G. Debris inside pump.

A. Reset circuit breaker.

B. Open valves.

C. Fill spa to middle of skimmer

opening.

D. Repair leaks.

E. *

F. Prime pumps

A. Locate and repair leaks.

B. Clean suction strainers.

C. Tighten fasteners.

E. *

F. *

G. *

25

Page 28

26

* Note: The skills and tools necessary for the safe repair of this spa require the services of qualified service personnel.

Contact your Jacuzzi Whirlpool Bath Authorized Service Agent or Dealer.

TROUBLESHOOTING GUIDE

REMEDYPROBABLE CAUSEPROBLEM

7. Water leakage at pump

shaft. (rotating connection

between pump and motor).

8. Motor will not start.

9. Motor stops.

A. Worn or damaged pump seal.

B. Foreign matter trapped

in pump.

A. Optional timer or switch

set at OFF.

B. Circuit breaker tripped or in

OFF position.

C. Locked shaft or impeller.

D. Disconnected or defective

wiring.

E. Defective starting switch inside

motor.

F. Motor winding burned out.

G. Auxiliary switch malfunction.

A. Optional timer or switch set

at OFF.

B. Circuit breaker tripped or in

off position.

C. Switch failure.

D. Motor overload condition.

E. Auxiliary switch malfunction.

A. *

B. *

A. Turn to ON.

B. Reset circuit breaker.

C. *

D. *

E. *

F. *

G. *

A. Turn to ON.

B. Turn to ON.

C. *

D. Let cool for one hour. Motor

overload will reset, then start

again. If problem persists,

contact your Jacuzzi Whirlpool

Bath dealer for service.

E. *

10. Will not hold prime.

A. Air leak through faulty or

open vent valves.

B. Water or air leak in system

plumbing.

C. Low water level.

D. Faulty check valves.

A. Close or repair vent valve.

B. Repair leak.

C. Fill spa to middle of skimmer

opening.

D. Replace valves.

Page 29

a

Printed on Recycled Paper

Jacuzzi Whirlpool Bath has obtained applicable code (standards) listings generally available on a national basis for products of this type.

It is the responsibility of the installer/owner to determine specific local code compliance prior to installation of this product. Jacuzzi Whirlpool

Bath makes no representation or warranty regarding, and will not be responsible for any code compliance.

PRODUCT SPECIFICATIONS ARE SUBJECT TO CHANGE WITHOUT NOTICE.

USE INSTALLATION INSTRUCTIONS SUPPLIED WITH PRODUCT.

Jacuzzi Whirlpool Bath National Headquarters

P.O. Drawer J, Walnut Creek, CA 94596 (510) 938-7070

Service Support: Call (800) 288-4002

©1993 Jacuzzi Whirlpool Bath D492000 9/93

Printed in the U.S.A.

Loading...

Loading...