Page 1

BUILDER/COMFORT BATH SERIES

INST ALLA TION AND OPERA TING INSTRUCTIONS

SERIE DE TINAS BUILDER/COMFORT

MANUAL DE INSTALACIÓN Y OPERACIÓN

Installer: Leave this manual for homeowner.

Homeowner: Read this manual and keep for future reference.

Instalador: Deje este manual para el propietario.

Propietario: Lea este manual y guardelo para referencia en el futuro.

©1996 Jacuzzi Whirlpool Bath K272000AC 12/04

Page 2

IMPORTANT SAFETY INSTRUCTIONS

READ AND FOLLOW ALL INSTRUCTIONS

SAVE THESE INSTRUCTIONS

ENGLISH

CAUTION: TEST THE GROUND FAULT CIRCUIT INTERRUPTER PROTECTING THIS APPLIANCE PERIODI-

CALLY IN ACCORDANCE WITH MANUFACTURER'S INSTRUCTIONS.

WARNING: RISK OF ACCIDENTAL INJURY OR DROWNING; CHILDREN SHOULD NOT USE HYDROMASSAGE

BATHTUB WITHOUT ADULT SUPERVISION.

WARNING: TO AVOID INJURY, EXERCISE CAUTION WHEN ENTERING OR EXITING THE HYDROMASSAGE

BATHTUB

WARNING: RISK OF ACCIDENTAL INJURY OR DROWNING; DO NOT USE HYDROMASSAGE BATHTUB

UNLESS ALL SUCTION GUARDS ARE INSTALLED TO PREVENT BODY AND HAIR ENTRAPMENT.

WARNING: KEEP BODY AND HAIR A MINIMUM OF 6" AWAY FROM SUCTION FITTING AT ALL TIMES WHEN

THE WHIRLPOOL SYSTEM IS OPERATING. HAIR LONGER THAN SHOULDER LENGTH SHOULD BE SECURED

CLOSE TO THE HEAD.

WARNING: NEVER DROP OR INSERT ANY OBJECT INTO ANY OPENING.

WARNING: RISK OF ELECTRICAL SHOCK; DO NOT PERMIT ELECTRICAL APPLIANCES (SUCH AS HAIR

DRYER, LAMP, TELEPHONE, RADIO OR TELEVISION) WITHIN 60" (1.5 M) OF THIS HYDROMASSAGE

BATHTUB.

WARNING: RISK OF ACCIDENTAL INJURY OR DROWNING; DO NOT USE DRUGS OR ALCOHOL BEFORE OR

DURING THE USE OF HYDROMASSAGE BATHTUB EQUIPPED WITH A HEATER TO AVOID UNCONSCIOUSNESS AND POSSIBLE DROWNING.

WARNING: RISK OF FETAL INJURY; PREGNANT OR POSSIBLY PREGNANT WOMEN SHOULD CONSULT A

PHYSICIAN BEFORE USING A HYDROMASSAGE BATHTUB EQUIPPED WITH A HEATER.

WARNING: RISK OF HYPERTHERMIA AND POSSIBLE DROWNING; DO NOT USE A HYDROMASSAGE

BATHTUB EQUIPPED WITH A HEATER IMMEDIATELY FOLLOWING STRENUOUS EXERCISE.

WARNING: RISK OF HYPERTHERMIA AND POSSIBLE DROWNING; WATER TEMPERATURE IN EXCESS OF

104°F (40°C) MAY BE INJURIOUS TO YOUR HEALTH. CHECK AND ADJUST WATER TEMPERATURE BEFORE

USE.

WARNING: RISK OF HYPERTHERMIA; PEOPLE USING MEDICATIONS AND/OR HAVING AN ADVERSE

MEDICAL HISTORY SHOULD CONSULT A PHYSICIAN BEFORE USING A HYDROMASSAGE BATHTUB

EQUIPPED WITH A HEATER.

THIS UNIT MUST BE CONNECTED ONLY TO A SUPPLY CIRCUIT(S) THAT IS PROTECTED BY A GROUND

FAULT CIRCUIT INTERRUPTER (GFCI). SUCH A GFCI SHOULD BE PROVIDED BY THE INSTALLER AND

SHOULD BE TESTED ON A ROUTINE BASIS. TO TEST THE GFCI, PUSH THE TEST BUTTON. THE GFCI

SHOULD INTERRUPT POWER. PUSH THE RESET BUTT ON. POWER SHOULD BE RESTORED. IF THE GFCI

FAILS T O OPERA TE IN THIS MANNER, THERE IS A GROUND CURRENT FLOWING , INDICATING A POSSIBILITY OF AN ELECTRIC SHOCK. DO NOT USE THIS UNIT. DISCONNECT THE UNIT AND HAVE THE PROBLEM

CORRECTED BY A QUALIFIED ELECTRICIAN BEFORE USING.

A PRESSURE WIRE CONNECTOR IS PROVIDED ON THE EXTERIOR OF THE MOTOR TO PERMIT CONNECTION OF AN NO. 8 AWG (8.4 MM) SOLID COPPER BONDING CONDUCTOR BETWEEN THIS UNIT AND

ALL OTHER ELECTRIC EQUIPMENT AND EXPOSED METAL IN THE VICINITY, AS NEEDED TO COMPLY WITH

LOCAL REQUIREMENTS.

Page 3

PRECAUTIONS

• Do not operate the whirlpool system unless the bath is filled with water to at least 1" above the highest jet.

• Do not immerse the control panel by overfilling the bath.

• Do not use oil-based bath additives in your whirlpool bath.

• When cleaning your bath, do not use abrasive substances which will damage the bath’s surface.

• To prevent discoloration of the acrylic finish, do not fill the bath with water in excess of 140°F (60°C).

• The whirlpool system should be purged at least twice a month. For your convenience, we have devel-

oped a plumbing system cleaner (Systems Clean™) specifically for whirlpool baths. For availability call

1-800-288-4002.

• Use this unit only for its intended purpose as described in this manual. Do not use attachments not

recommended by the manufacturer.

• A pressure wire connector is provided on the exterior of the motor to permit connection of an No. 8 AWG

(8.4 mm) solid copper bonding conductor between this unit and all other electric equipment and exposed

metal in the vicinity, as needed to comply with local requirements.

• This unit should be electrically grounded and installed by a licensed contractor , electrician, and plumber .

• For built-in and drop-in units, install to permit access for servicing.

Note: This is a professional grade product. A knowledge of construction techniques, plumbing and electrical installation according to codes are required for proper installation and user satisfaction. We recommend that a licensed contractor perform the installation of all Jacuzzi Whirlpool Bath products. Our warranty does not cover improper installation related problems.

ENGLISH

Page 4

ADDENDUM

r

Safety Instructions Change

IMPORTANT SAFETY INSTRUCTIONS

READ AND FOLLOW ALL INSTRUCTIONS

SAVE THESE INSTRUCTIONS

INSTRUCTIONS PERTAINING TO A RISK OF FIRE, ELECTRIC

SHOCK, OR INJURY TO PERSONS

WARNING — WHEN USING THIS UNIT, BASIC PRECAUTIONS SHOULD ALWAYS BE FOLLOWED,

INCLUDING THE FOLLOWING:

DANGER: TO REDUCE THE RISK OF INJURY, DO NOT PERMIT CHILDREN TO USE THIS UNIT

UNLESS THEY ARE CLOSELY SUPERVISED AT ALL TIMES.

WARNING — USE THIS UNIT ONL Y FOR ITS INTENDED USE AS DESCRIBED IN THIS MANUAL. DO

NOT USE ATTACHMENTS NOT RECOMMENDED BY THE MANUFACTURER.

WARNING — NEVER DROP OR INSERT ANY OBJECT INTO ANY OPENING.

WARNING — DO NOT OPERATE THIS UNIT WITHOUT THE GUARD OVER THE SUCTION FITTING.

WARNING — THIS UNIT MUST BE CONNECTED ONLY TO A SUPPLY CIRCUIT THAT IS PROTECTED

BY A GROUND FAULT CIRCUIT INTERRUPTER (GFCI). SUCH A GFCI SHOULD BE PROVIDED BY

THE INSTALLER AND SHOULD BE TESTED ON A ROUTINE BASIS. TO TEST THE GFCI, PUSH THE

TEST BUTTON. THE GFCI SHOULD INTERRUPT POWER. PUSH THE RESET BUTTON. POWER

SHOULD BE RESTORED. IF THE GFCI FAILS TO OPERATE IN THIS MANNER, THE GFCI IS

DEFECTIVE. IF THE GFCI INTERRUPTS POWER TO THE BATHTUB WITHOUT THE TEST BUTTON

BEING PUSHED, A GROUND CURRENT FLOWING, INDICATING A POSSIBILITY OF AN ELECTRIC

SHOCK. DO NOT USE THIS HYDROMASSAGE BATHTUB. DISCONNECT THE HYDROMASSAGE

BATHTUB AND HAVE THE PROBLEM CORRECTED BY A QUALIFIED SERVICE REPRESENTATIVE

BEFORE USING.

WARNING: (FOR PERMANENTLY CONNECTED UNITS) A GREEN COLORED TERMINAL (OR A WIRE

CONNECTOR MARKED “G”, “GR”, “GROUND”, OR “GROUNDING”) IS PROVIDED WITHIN THE TERMINAL

COMPARTMENT. TO REDUCE THE RISK OF ELECTRIC SHOCK, CONNECT THE TERMINAL OR

CONNECTOR TO THE GROUNDING TERMINAL OF YOUR ELECTRIC SERVICE OR SUPPLY PANEL WITH

A CONDUCTOR EQUIVALENT IN SIZE TO THE CIRCUIT CONDUCTORS SUPPLYING THIS EQUIPMENT.

OPERA TING INSTRUCTIONS

WARNING — PROLONGED IMMERSION IN HOT WATER MAY INDUCE HYPERTHERMIA. HYPER-

THERMIA OCCURS WHEN THE INTERNAL TEMPERA TURE OF THE BODY REACHES A LEVEL SEV ERAL DEGREES ABOVE THE NORMAL BODY TEMPERATURE OF 98.6°F. THE SYMPTOMS OF

HYPERTHERMIA INCLUDE AN INCREASE IN THE INTERNAL TEMPERATURE OF THE BODY, DIZZINESS, LETHARGY, DROWSINESS AND FAINTING. THE EFFECTS OF HYPERTHERMIA INCLUDE:

A) FAILURE TO PERCEIVE HEAT

B) FAILURE TO RECOGNIZE THE NEED TO EXIT THE SPA OR HOT TUB,

C) UNAWARENESS OF IMPENDING HAZARD,

D) FETAL DAMAGE IN PREGNANT WOMEN,

E) PHYSICAL INABILITY TO EXIT THE SPA OR HOT TUB, AND

F) UNCONSCIOUSNESS RESULTING IN DANGER OF DROWNING.

WARNING — THE USE OF ALCOHOL, DRUGS OR MEDICATION CAN GREATLY INCREASE THE

RISK OF FATAL HYPERTHERMIA.

WARNING — DO NOT TAMPER WITH USER-OPERATED CONTROLS OR SUCH DEVICES.

©

Printed on Recycled Pape

2005 Jacuzzi Whirlpool Bath DA38000A 06/05

Printed in the U.S.A.

Page 5

INST ALLATION INSTRUCTIONS

r

WARNING — WHEN USING THIS UNIT, BASIC PRECAUTIONS SHOULD ALWAYS BE FOLLOWED,

INCLUDING THE FOLLOWING:

DANGER — RISK OF ELECTRIC SHOCK. CONNECT ONLY TO A CIRCUIT PROTECTED BY A GROUND

FAULT CIRCUIT INTERRUPTER (GFCI).

CAUTION

PERIODICALLY IN ACCORDANCE WITH MANUFACTURER’S INSTRUCTIONS.

WARNING

USE ATTACHMENTS NOT RECOMMENDED BY THE MANUFACTURERS.

WARNING

WARNING

WHEN THE HYDROMASSAGE SYSTEM IS OPERATING. HAIR LONGER THAN SHOULDER LENGTH

SHOULD BE SECURED CLOSE TO THE HEAD.

WARNING

DRYER, LAMP, TELEPHONE, RADIO OR TELEVISION) WITHIN 60" (1.5 M) OF THIS HYDROMASSAGE BATHTUB.

WARNING

BEFORE OR DURING THE USE OF HYDROMASSAGE BATHTUB EQUIPPED WITH A HEATER TO AVOID

UNCONSCIOUSNESS AND POSSIBLE DROWNING.

WARNING

CONSULT A PHYSICIAN BEFORE USING A HYDROMASSAGE BATHTUB EQUIPPED WITH A HEATER.

WARNING

BATHTUB EQUIPPED WITH A HEATER IMMEDIATELY FOLLOWING STRENUOUS EXERCISE.

WARNING

EXCESS OF 104°F (40°C) MAY BE INJURIOUS TO YOUR HEALTH. CHECK AND ADJUST WATER

TEMPERATURE BEFORE USE.

WARNING

MEDICAL HISTORY SHOULD CONSULT A PHYSICIAN BEFORE USING A HYDROMASSAGE BATHTUB

EQUIPPED WITH A HEATER.

— TEST THE GROUND FAULT CIRCUIT INTERRUPTER PROTECTING THIS APPLIANCE

— USE THIS UNIT ONLY FOR ITS INTENDED USE AS DESCRIBED IN THIS MANUAL. DO NOT

— TO AVOID INJURY, EXERCISE CAUTION WHEN ENTERING OR EXITING THE HYDROMASSAGE BATHTUB.

— KEEP BODY AND HAIR A MINIMUM OF 6" AWAY FROM SUCTION FITTING AT ALL TIMES

— RISK OF ELECTRICAL SHOCK; DO NOT PERMIT ELECTRICAL APPLIANCES (SUCH AS HAIR

— RISK OF ACCIDENTAL INJURY OR DROWNING; DO NOT USE DRUGS OR ALCOHOL

— RISK OF FETAL INJURY; PREGNANT OR POSSIBLY PREGNANT WOMEN SHOULD

— RISK OF HYPERTHERMIA AND POSSIBLE DROWNING; DO NOT USE A HYDROMASSAGE

— RISK OF HYPERTHERMIA AND POSSIBLE DROWNING; WATER TEMPERATURE IN

— RISK OF HYPERTHERMIA; PEOPLE USING MEDICATIONS AND/OR HAVING AN ADVERSE

FOR BUILT-IN AND DROP-IN UNITS, INSTALL TO PERMIT ACCESS FOR SERVICING.

THIS UNIT SHOULD BE ELECTRICALLY GROUNDED AND INSTALLED BY A LICENSED CONTRACTOR,

ELECTRICIAN, AND PLUMBER.

BUILDING MATERIALS AND WIRING SHOULD BE ROUTED AWAY FROM THE MOTOR/PUMP OR

BLOWER OR OTHER HEAT PRODUCING COMPONENTS OF THIS UNIT.

A PRESSURE WIRE CONNECTOR IS PROVIDED ON THE EXTERIOR OF THE MOTOR/PUMP AND

HEATER TO PERMIT CONNECTION OF AN NO. 8 AWG (8.4 MM) SOLID COPPER BONDING CONDUCTOR

BETWEEN THIS UNIT AND ALL OTHER ELECTRIC EQUIPMENT AND EXPOSED METAL IN THE VICINITY,

AS NEEDED TO COMPLY WITH LOCAL REQUIREMENTS.

PRECAUTIONS

••

• Do not operate the hydromassage system unless the bath is filled with water to at least 1" above the highest jet.

••

••

• Do not immerse the control panel by overfilling the bath.

••

••

• Do not use oil-based bath additives in your hydromassage bath.

••

••

• When cleaning your bath, do not use abrasive substances which will damage the bath's surface.

••

••

• To prevent discoloration of the acrylic finish, do not fill the bath with water in excess of 140°F (60°C).

••

NOTE: This is a professional grade product. A knowledge of construction techniques, plumbing and electrical installation according to codes are required for proper installation and user satisfaction. W e recommend

that a licensed contractor perform the installation of all Jacuzzi Whirlpool Bath© products. Our warranty

does not cover improper installation related problems.

PRODUCT SPECIFICATIONS ARE SUBJECT TO CHANGE WITHOUT NOTICE.

USE INSTALLATION INSTRUCTIONS SUPPLIED WITH PRODUCT.

The Company has obtained applicable code (standards) listings generally available on a national basis for products of this type.

It is the responsibility of the installer/owner to determine specific local code compliance prior to installation of the product. The

Company makes no representation or warranty regarding, and will not be responsible for any code compliance.

©

Printed on Recycled Pape

2005 Jacuzzi Whirlpool Bath DA38000A 06/05

Printed in the U.S.A.

Page 6

CONTENTS

Specifications _________________________________________________________________________ 1-5

Roughing-in Reference _________________________________________________________________ 6-11

ENGLISH

Installation Instructions __________________________________________________________________ 12-18

Framing and Support _________________________________________________________________ 12

Skirts______________________________________________________________________________ 13

Service Access _____________________________________________________________________ 14

Electrical Connections ________________________________________________________________ 15

Plumbing and Water Supply ___________________________________________________________ 16

UnderMount Installation Instructions _____________________________________________________ 17-18

Operation ____________________________________________________________________________ 19-20

Maintenance __________________________________________________________________________ 21

General Troubleshooting Guide ___________________________________________________________ 22

Repair Parts __________________________________________________________________________ 23-28

Authorized Service _____________________________________________________________________ 30

Warranty _____________________________________________________________________________ 31-32

Save These Instructions for Future Use.

Owner's Record

Date Purchased ____________________________________________________________

Purchased From ____________________________________________________________

Installed By ________________________________________________________________

Serial Number _____________________________________________________________

Model ____________________________________________________________________

NOTE: To obtain a referral for a service agent in your area call 800-288-4002 . You may also visit our web site at

http://www.jacuzzi.com/. To find the service agent listing, click on For The Trade.

Then click on Repair Services in the left hand box.

Depending on the problem, click on Electrical/Mechanical Repairs or Finish, Surface or Shell-Related Problems or

Repair Parts or Accessories for a listing of authorized agents, contractors, or distributors.

Page 7

SPECIFICATIONS

Important: Read complete instructions before beginning installation.

Each whirlpool bath arrives ready for installation, completely equipped with motor/pump assembly and plumbing and fittings necessary for

whirlpool operation. An optional drain/overflow kit is available for installation on the bath.

Remove the bath from the carton. Retain the shipping carton until satisfactory inspection of the product has been made. Do not lift the bath

by the plumbing at any time; handle by the shell only.

Immediately upon receipt, inspect the shell before installing. Should inspection reveal any damage or defect in the finish, do not install the

bath. Damage or defect to the finish claimed after the bath is installed is excluded from the warranty . Jacuzzi Whirlpool Bath's responsibility for

shipping damage ceases upon delivery of the products in good order to the carrier. Refer any claims for damage to the carrier. For definitions of

warranty coverage and limitations, refer to the published warranty information packed with the product.

All bath units are factory tested for proper operation and watertight connections prior to shipping. Note: Prior to installation, the bath must

be filled with water and operated to check for leaks that may have resulted from shipping damage or mishandling. Jacuzzi Whirlpool

Bath is not responsible for any defect that could have been discovered, repaired, or avoided by following this inspection and testing procedure.

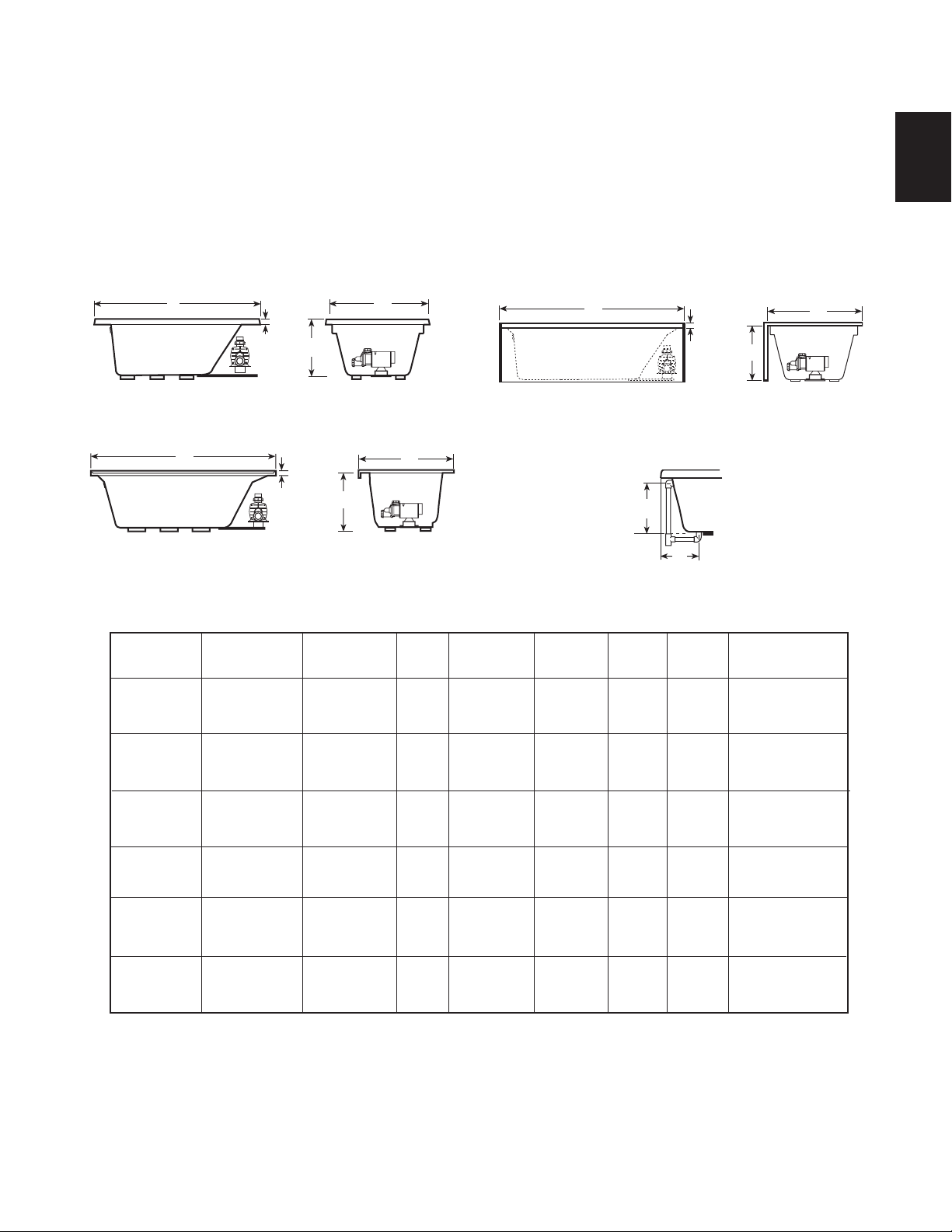

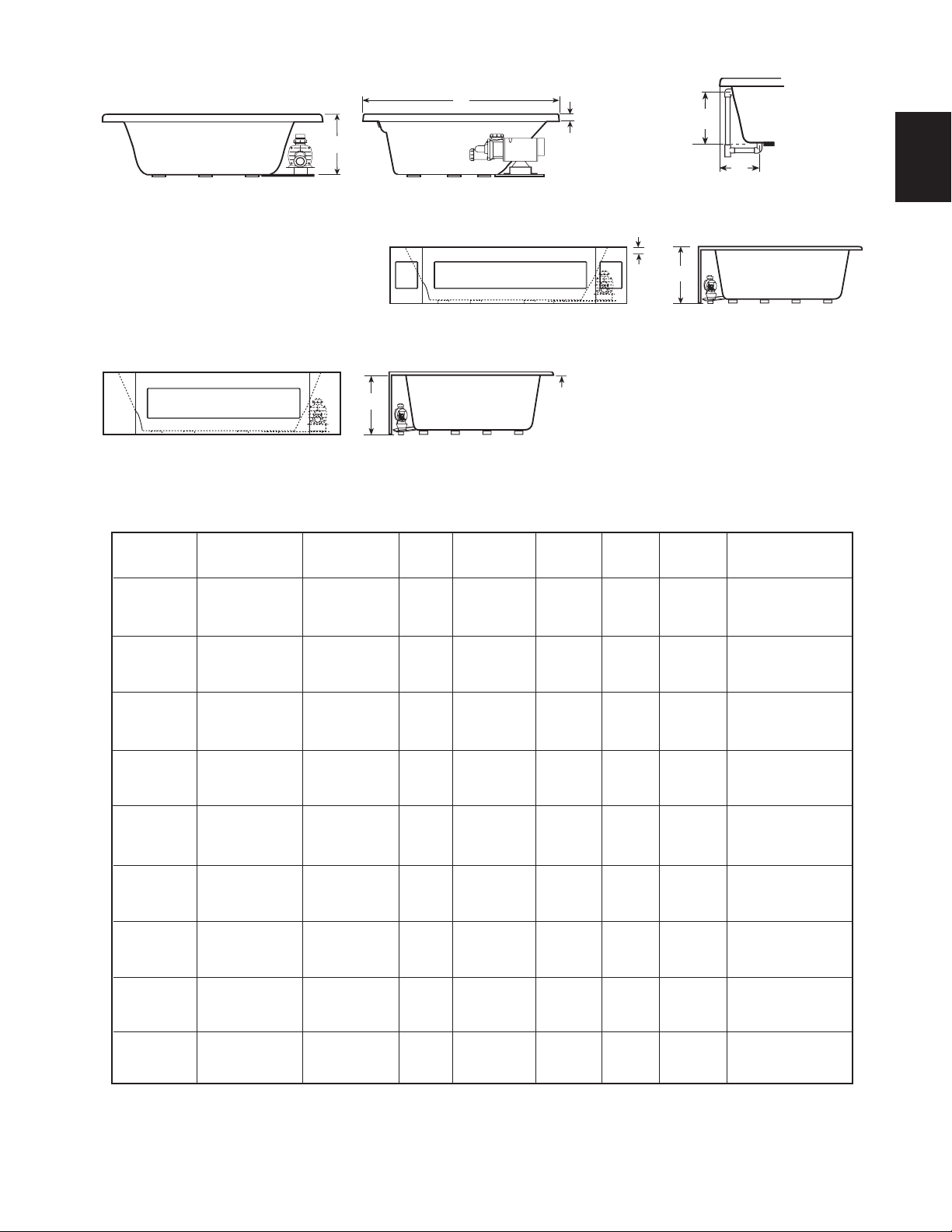

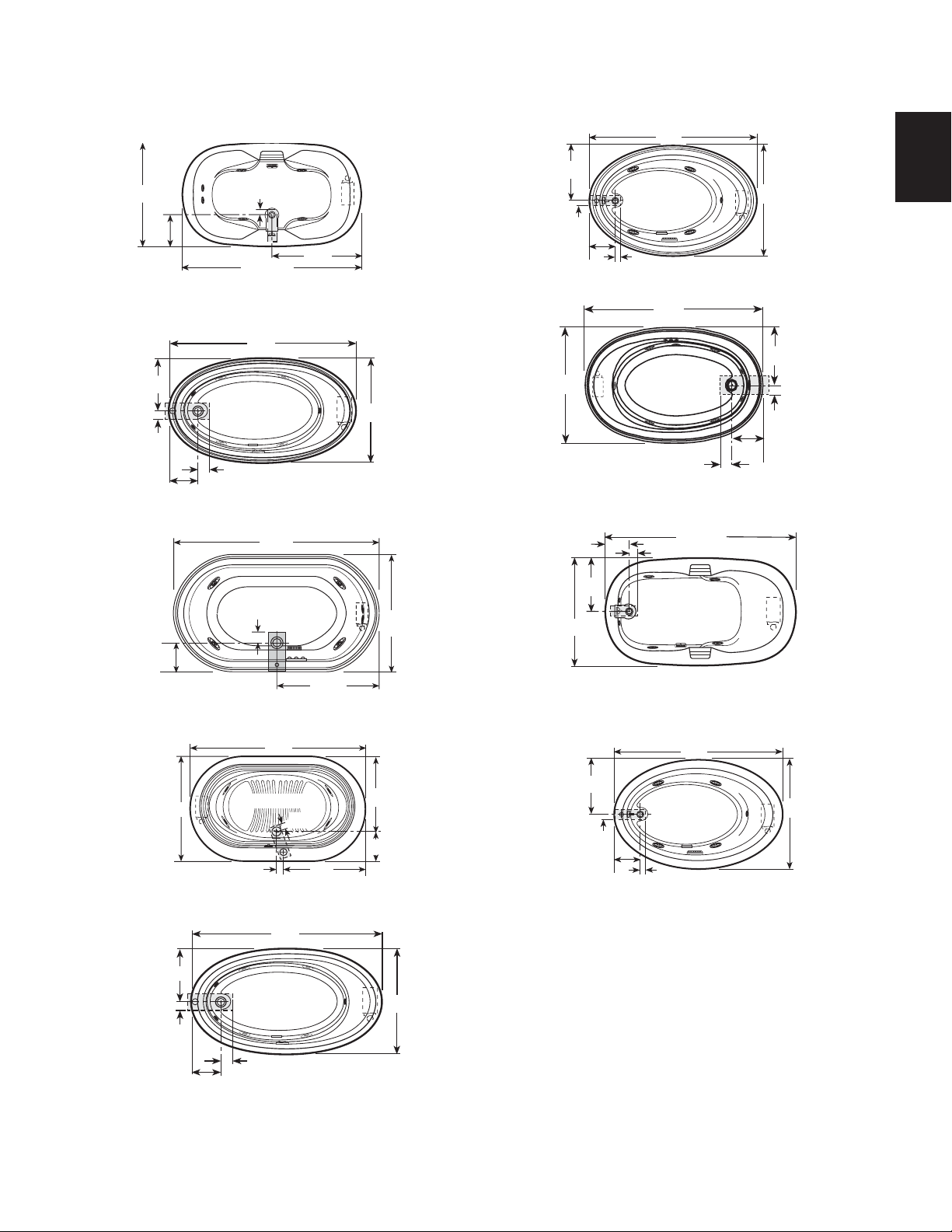

RECTANGULAR BATHS

ENGLISH

L

2"

(51 mm)

H

SIDE VIEW

BATHS WITHOUT INTEGRAL SKIRT

L

(25 mm)

W

END VIEW

L

(25 mm)

1"

SIDE VIEW

BATHS WITH INTEGRAL SKIRT

W

1"

SIDE VIEW

BATHS WITH 3-SIDED TILE FLANGE

H

END VIEW

A

B

DRAIN/OVERFLOW

SPECIFICATIONS (Rectangular)

OPERATING

GALLONAGE

50 U.S. gal

(186 liters)

50 U.S. gal

(186 liters)

73 U.S. gal

(276 liters)

46 U.S. gal

(174 liters)

43 U.S. gal

(163 liters)

48 U.S. gal

(181 liters)

PRODUCT

WEIGHT

105 lb

(48 kg)

129 lb

(59 kg)

135 lb

(61 kg)

94 lb

(43 kg)

89 lb

(41 kg)

92 lb

(42 kg)

SKIRT &

MOUNTING

Optional,

U-Frame

Integral

Optional,

U-Frame

Integral

Optional

U-Frame

Optional

U-Frame

NA

NA

58"

X

30-1/4"

58"

X

34-1/4"

TOTAL WEIGHT/

FLOOR LOADING

772 lb

(351 kg)/

43 lb/sq. ft.

(210 kg/sq. m)

796 lb

(362 kg)/

44 lb/sq. ft.

(214 kg/sq. m)

993 lb

(451 kg)/

41 lb/sq. ft.

(200 kg/sq. m)

727 lb

(330 kg)/

55 lb/sq. ft.

(268 kg/sq. m)

697 lb

(317 kg)/

53 lb/sq. ft.

(259 kg/sq. m)

742 lb

(337 kg)/

50 lb/sq. ft.

(244 kg/sq. m)

MODEL

AMIGA™

AMIGA™

WITH INTEGRAL

SKIRT

©

BIANCA

©

CETRA

WITH INTEGRAL

SKIRT

CETRA© 532

CETRA© 536

DIMENSIONS

72" (1829 mm) L*

36" ( 914 mm) W

20-3/4" ( 533 mm) H

72" (1829 mm) L*

36" ( 914 mm) W

20-3/4" ( 533 mm) H

72" (1829 mm) L*

48" (1219 mm) W

20-1/2" ( 521 mm) H

60" (1524 mm) L*

32" ( 813 mm) W

20-1/2" ( 521 mm) H

60" (1524 mm) L*

31-7/8" ( 791 mm) W

21-1/4" ( 553 mm) H

60" (1524 mm) L*

36" ( 914 mm) W

21-1/4" ( 553 mm) H

DRAIN/OVERFLOW

DIMENSIONS

16-7/8" (429 mm) A

14" (356 mm) B

16-7/8" (429 mm) A

14" (356 mm) B

16" (406 mm) A

8-1/2" (216 mm) B

17-7/8" (454 mm) A

9-3/8" (238 mm) B

18-1/2" ( 470 mm) A

9" ( 229 mm) B

18-1/2" ( 470 mm) A

9" ( 229 mm) B

CUTOUT

70" x 34"

70" x 46"

*Add 1/4" to this dimension when roughing-in for 3-wall niche.

NOTE: The overall dimensions are nominal with a tolerance of +0 and -1/4".

FOR ALL UNITS: Electrical Service Requirements: All require a dedicated GFCI protected separate circuit.

RapidHeat: 115 VAC, 15 AMP, 60 Hz. dedicated GFCI protected separate circuit.

Motor/Pump: 115 VAC, 15 Amp, 60 Hz. dedicated GFCI protected separate circuit.

W

H

END VIEW

HEATER READY

FOR FIELD

INSTALLATION

Yes

(S750000 HEATER KIT)

Yes

(S750000 HEATER KIT)

Yes

(S750000 HEATER KIT)

Yes

(S750000 HEATER KIT)

Yes

(S750000 HEATER KIT)

Yes

(S750000 HEATER KIT)

1

Jacuzzi Whirlpool Bath© K272000AC 12/04

Page 8

ENGLISH

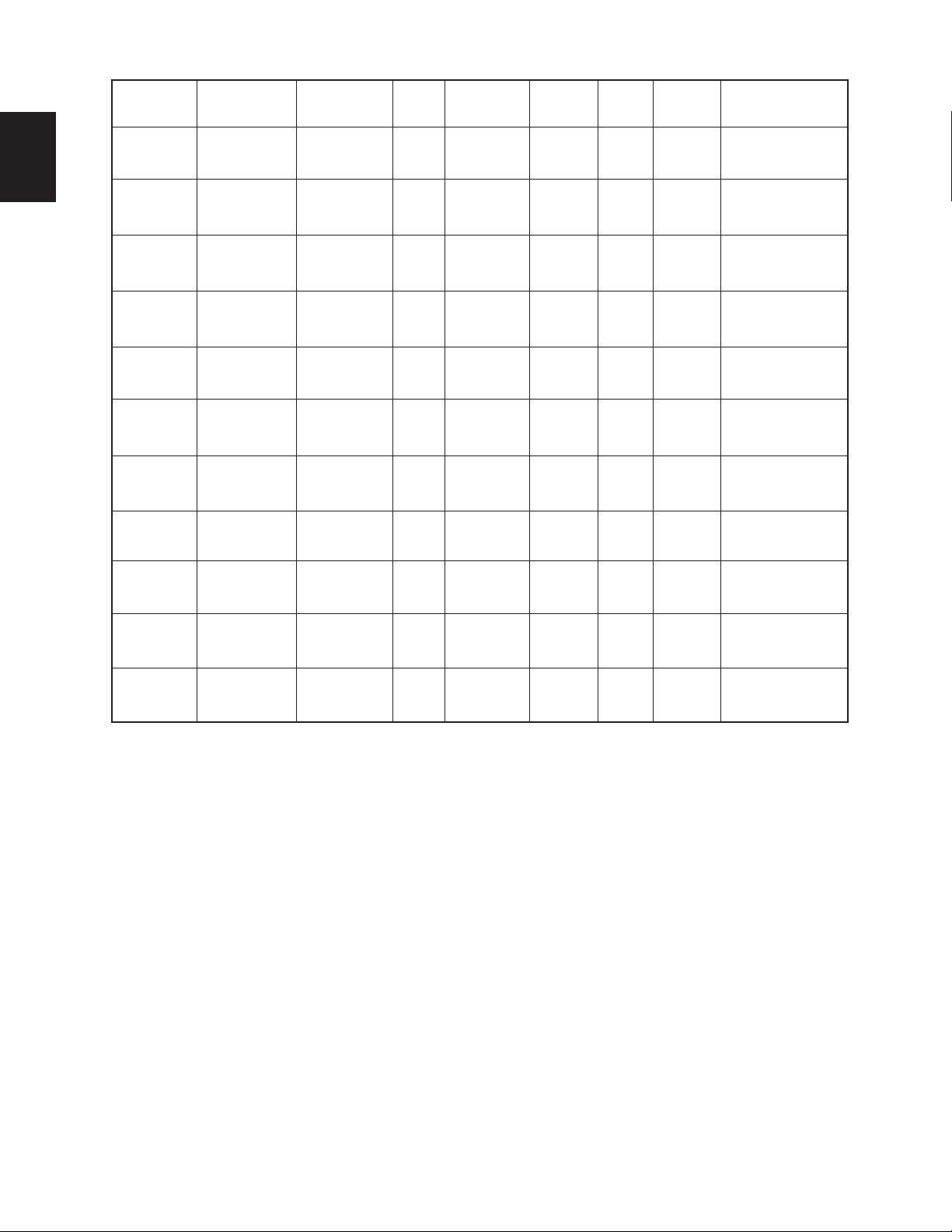

SPECIFICATIONS (Rectangular)

MODEL

CETRA© 536

WITH INTEGRAL

SKIRT

LUXURA™ 5

LUXURA™ 5

WITH INTEGRAL

SKIRT

LUXURA™ 5.5 66" (1676 mm) L*

WITH INTEGRAL

SKIRT

MAJORA© 5

MAJORA© 6

MAJORA© 6

WITH INTEGRAL

SKIRT

MITO© 5

MITO© 6 17-1/2" (445 mm) A

NOVA© 5

DIMENSIONS

60" (1524 mm) L*

36" ( 914 mm) W

21-1/4" ( 553 mm) H

60" (1524 mm) L

32" ( 813 mm) W

20-1/4" ( 514 mm) H

60" (1524 mm) L

32" ( 813 mm) W

20-1/4" ( 514 mm) H

34" ( 864 mm) W

20" ( 508 mm) H

60" (1524 mm) L*

30" ( 762 mm) W

20-1/4" ( 483 mm) H

60" (1524 mm) L*

42" (1067 mm) W

19-1/2" ( 495 mm) H

72" (1829 mm) L*

42" (1067 mm) W

19-3/4" ( 502 mm) H

72" (1829 mm) L*

42" (1067 mm) W

19-3/4" ( 502 mm) H

60" (1524 mm) L*

42" (1067 mm) W

21" ( 533 mm) H

72" (1829 mm) L*

42" (1067 mm) W

21-1/2" ( 546 mm) H

60" (1524 mm) L*

42" (1067 mm) W

18-1/2" ( 470 mm) H

DRAIN/OVERFLOW

DIMENSIONS

18-1/2" ( 470 mm) A

9" ( 229 mm) B

*

15-1/4" (387 mm) A

8-1/4" (210 mm) B

15-1/4" (387 mm) A

8-1/4" (210 mm) B

15-1/4" (387 mm) A

8-3/8" (213 mm) B

16-3/4" (425 mm) A

9-1/4" (235 mm) B

15" (381 mm) A

8-3/4" (222 mm) B

15-5/8" (397 mm) A

10-1/2" (267 mm) B

15-5/8" (397 mm) A

10-1/2" (267 mm) B

17-1/2" (445 mm) A

11-7/8" (302 mm) B

11-7/8" (302 mm) B

14-3/4" (375 mm) A

8-1/2" (216 mm) B

CUTOUT

NA

Molded-in

Tile Flange

NA

64" x 32"

NALUXURA™ 530

58" x 40"

70" x 40"

NA

58" x 40"

70" x 40"

58" x 40"

TOTAL WEIGHT/

FLOOR LOADING

742 lb

(337 kg)/

50 lb/sq. ft.

(244 kg/sq. m)

697 lb

(264 kg)/

52 lb/sq. ft.

(254 kg/sq. m)

700 lb

(318 kg)/

53 lb/sq. ft.

(259 kg/sq. m)

823 lb

(374 kg)/

53 lb/sq. ft.

(259 kg/sq. m)

662 lb

301 kg)/

53 lb/sq. ft.

(259 kg/sq. m)

728 lb

(331 kg)/

42 lb/sq. ft.

(205 kg/sq. m)

937 lb

(423 kg)/

44 lb/sq. ft.

(215 kg/sq. m)

947 lb

(430 kg)/

45 lb/sq. ft.

(220 kg/sq. m)

866 lb

(394 kg)/

50 lb/sq. ft.

(244 kg/sq. m)

993 lb

(451 kg)/

47 lb/sq. ft.

(229 kg/sq. m)

722 lb

(328 kg)/

41 lb/sq. ft.

(200 kg/sq. m)

OPERATING

GALLONAGE

48 U.S. gal

(181 liters)

44 U.S. gal

(167 liters)

42 U.S. gal

(159 liters)

58 U.S. gal

(220 liters)

38 U.S. gal

(144 liters)

46 U.S. gal

(172 liters)

70 U.S. gal

(265 liters)

70 U.S. gal

(265 liters)

62 U.S. gal

(235 liters)

76 U.S. gal

(288 liters)

45 U.S. gal

(170 liters)

PRODUCT

WEIGHT

92 lb

(42 kg)

80 lb

(36kg)

100 lb

(45 kg)

90 lb

(41 kg)

95 lb

(43 kg)

95 lb

(43 kg)

104 lb

(47 kg)

114 lb

(52 kg)

100 lb

(45 kg)

110 lb

(50 kg)

97 lb

(44 kg)

SKIRT &

MOUNTING

IntegralNA

Optional,

U-Frame

Integral

Optional,

U-Frame

Integral

Not

Available

Not

Available

Integral

Optional,

U-Frame

Not

Available

Optional,

U-Frame

HEATER READY

FOR FIELD

INSTALLATION

Yes

(S750000 HEATER KIT)

Yes

(S750000 HEATER KIT)

Yes

(S750000 HEATER KIT)

Yes

(S750000 HEATER KIT)

Yes

(U395000 HEATER KIT)

Yes

(S750000 HEATER KIT)

Yes

(S750000 HEATER KIT)

Yes

(S750000 HEATER KIT)

Yes

(S750000 HEATER KIT)

Yes

(S750000 HEATER KIT)

Yes

(S750000 HEATER KIT)

*Add 1/4" to this dimension when roughing-in for 3-wall niche.

NOTE: The overall dimensions are nominal with a tolerance of +0 and -1/4".

FOR ALL UNITS: Electrical Service Requirements: All require a dedicated GFCI protected separate circuit.

RapidHeat: 115 VAC, 15 AMP, 60 Hz. dedicated GFCI protected separate circuit.

Motor/Pump: 115 VAC, 15 Amp, 60 Hz. dedicated GFCI protected separate circuit.

2

Jacuzzi Whirlpool Bath© K272000AC 12/04

Page 9

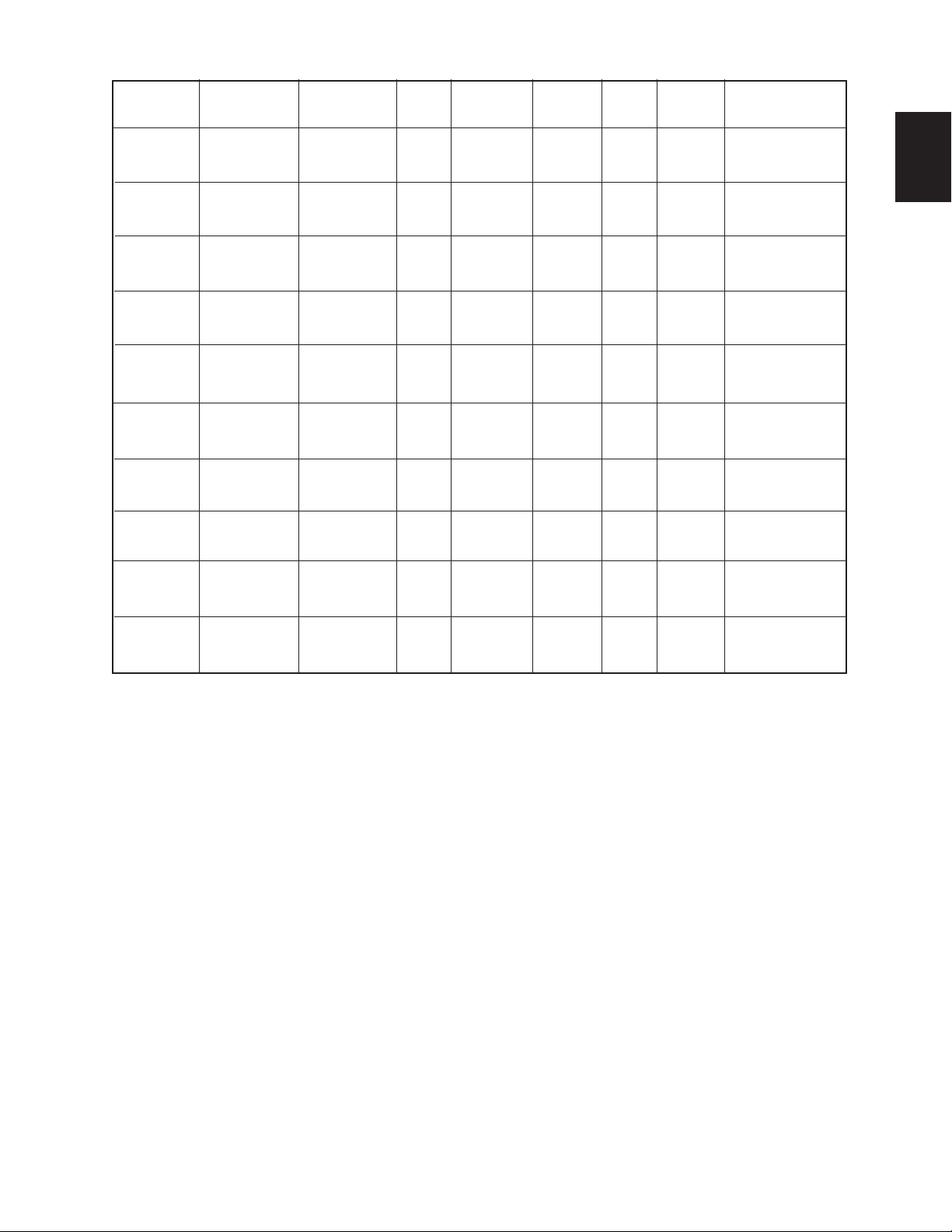

SPECIFICATIONS (Rectangular)

MODEL

©

5

NOVA

WITH INTEGRAL

3-SIDED TILE

FLANGE

©

5

NOVA

WITH INTEGRAL

SKIRT

NOVA© 6

NOVA© 536

©

NOVA

536

WITH INTEGRAL

SKIRT

©

636

NOVA

WITH INTEGRAL

SKIRT

©

SIGNA

5

SIGNA© 5 WITH

INTEGRAL SKIRT,

FRONT RIGHT

MOTOR/PUMP

SIGNA© 5

WITH INTEGRAL

3-SIDED TILE

FLANGE

SIGNA© 6

DIMENSIONS

60" (1524 mm) L

42" (1067 mm) W

18-1/2" ( 470 mm) H

60" (1524 mm) L

42" (1067 mm) W

18-1/2" ( 470 mm) H

72" (1829 mm) L*

42" (1067 mm) W

20-1/2" ( 521 mm) H

60" (1524 mm) L*

36" ( 914 mm) W

19-1/4" ( 489 mm) H

60" (1524 mm) L*

36" ( 914 mm) W

19-1/4" ( 489 mm) H

72" (1829 mm) L

36" ( 914 mm) W

19" ( 483 mm) H

60" (1524 mm) L*

42" (1067 mm) W

22" ( 559 mm) H

60" (1524 mm) L*

42" (1067 mm) W

22" ( 559 mm) H

60" (1524 mm) L*

42" (1067 mm) W

22" ( 559 mm) H

72" (1829 mm) L*

42" (1067 mm) W

22" ( 559 mm) H

DRAIN/OVERFLOW

DIMENSIONS

14-3/4" (375 mm) A

*

8-1/2" (216 mm) B

15-7/8" (403 mm) A

*

9-1/4" (235 mm) B

14-3/4" (375 mm) A

8-1/2" (216 mm) B

15-1/8" (384 mm) A

9" (229 mm) B

14-5/8" (372 mm) A

9" (229 mm) B

14-5/8" (372 mm) A

*

9-3/8" (238 mm) B

17-1/2" (445 mm) A

12-1/2" (318 mm) B

17-7/8" (451 mm) A

12-3/4" (330 mm) B

17-1/2" (445 mm) A

12-1/2" (318 mm) B

16-7/8" (429 mm) A

14" (356 mm) B

CUTOUT

NA

NA

70" x 40"

58" x 34"

NA

NA

58" x 40"

NA

NA

70" x 40"

TOTAL WEIGHT/

FLOOR LOADING

722 lb

(328 kg)/

41 lb/sq. ft.

(200 kg/sq. m)

737 lb

(335 kg)/

42 lb/sq. ft.

(205 kg/sq. m)

876 lb

(398 kg)/

42 lb/sq. ft.

(205 kg/sq. m)

683 lb

(310 kg)/

46 lb/sq. ft.

(224 kg/sq. m)

698 lb

(317 kg)/

47 lb/sq. ft.

(229 kg/sq. m)

824 lb

(375 kg)/

47 lb/sq. ft.

(229 kg/sq. m)

708 lb

(321 kg)/

40 lb/sq. ft.

(195 kg/sq. m)

723 lb

(329 kg)/

41 lb/sq. ft.

(200 kg/sq. m)

708 lb

(321 kg)/

40 lb/sq. ft.

(195 kg/sq. m)

826 lb

(375 kg)/

39 lb/sq. ft.

(190 kg/sq. m)

OPERATING

GALLONAGE

45 U.S. gal

(170 liters)

45 U.S. gal

(170 liters)

62 U.S. gal

(235 liters)

42 U.S. gal

(159 liters)

42 U.S. gal

(159 liters)

56 U.S. gal

(223 liters)

42 U.S. gal

(159 liters)

42 U.S. gal

(159 liters)

42 U.S. gal

(159 liters)

55 U.S. gal

(208 liters)

PRODUCT

WEIGHT

97 lb

(44 kg)

112 lb

(51 kg)

110 lb

(50 kg)

83 lb

(38 kg)

98 lb

(45 kg)

108 lb

(49 kg)

108 lb

(49 kg)

126 lb

(56 kg)

108 lb

(49 kg)

118 lb

(54 kg)

SKIRT &

MOUNTING

Not

Available

Integral

Optional,

U-Frame

Not

Available

Integral

Integral

Optional,

U-Frame

Integral

Optional,

U-Frame

Not

Available

HEATER READY

FOR FIELD

INSTALLATION

Yes

(S750000 HEATER KIT)

No

Yes

(S750000 HEATER KIT)

No

No

Yes

(S750000 HEATER KIT)

Yes

(S750000 HEATER KIT)

Yes

(U395000 HEATER KIT)

Yes

(S750000 HEATER KIT)

Yes

(S750000 HEATER KIT)

ENGLISH

*Add 1/4" to this dimension when roughing-in for 3-wall niche.

NOTE: The overall dimensions are nominal with a tolerance of +0 and -1/4".

FOR ALL UNITS: Electrical Service Requirements: All require a dedicated GFCI protected separate circuit.

RapidHeat: 115 VAC, 15 AMP, 60 Hz. dedicated GFCI protected separate circuit.

Motor/Pump: 115 VAC, 15 Amp, 60 Hz. dedicated GFCI protected separate circuit.

3

Jacuzzi Whirlpool Bath© K272000AC 12/04

Page 10

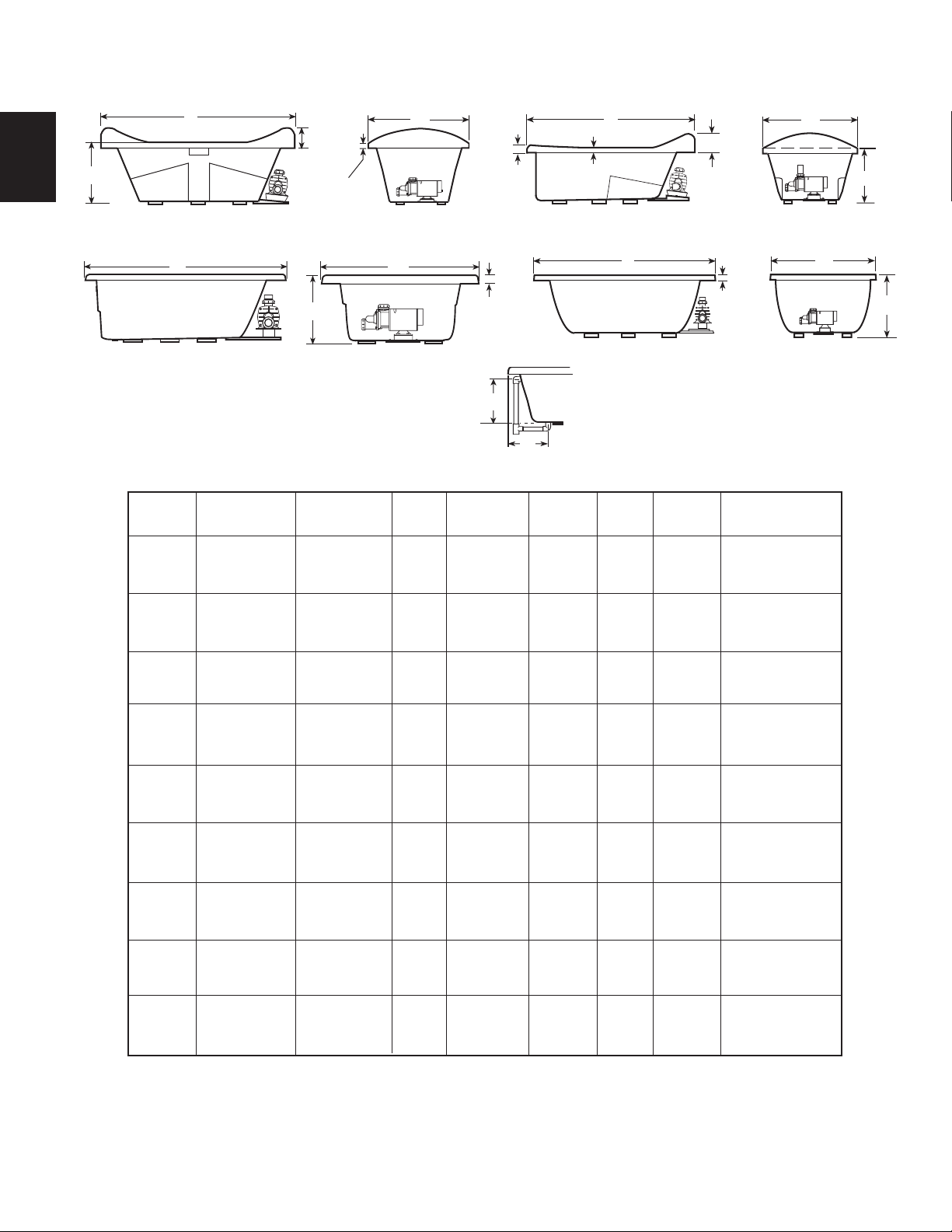

RIMLESS OVAL BATHS

H

ENGLISH

L

SIDE VIEW

FRESCO

L

SIDE VIEW

RIVA 5 & RIVA 6

GALLERY 5 OVAL & GALLERY 6 OVAL

SPECIFICATIONS (Oval)

MODEL

©

FRESCO

GALLERY™ 5

OVAL

GALLERY™ 6

OVAL

GALLERY™ 6

OVAL

UNDERMOUNT

LUNA™

MILANO™ 72" (1829 mm) L

OPALIA™ 72" (1829 mm) L

RIVA© 5 62" (1575 mm) L

RIVA© 6

DIMENSIONS

71-1/2" (1816 mm) L

42" (1067 mm) W

26-1/4" ( 603 mm) H*

62" (1575 mm) L

43" (1092 mm) W

19" ( 483 mm) H

72" (1829 mm) L

42" (1067 mm) W

20-1/2" ( 521 mm) H

72" (1829 mm) L

42" (1067 mm) W

20-1/2" ( 521 mm) H

72" (1829 mm) L

42" (1118 mm) W

23" ( 584 mm) H

40" (1016 mm) W

20-3/4" ( 527 mm) H

44" (1118 mm) W

22-1/4" ( 565 mm) H

43" (1092 mm) W

19" ( 483 mm) H

72" (1829 mm) L

42" (1067 mm) W

20-1/2" ( 521 mm) H

7-1/2"

(191 mm)

2"

(51 mm)

H

DRAIN/OVERFLOW

DIMENSIONS

20-1/8" (511 mm) A

11-3/4" (299 mm) B

14-3/4" (375 mm) A

9-1/2" (241 mm) B

16" (406 mm) A

11-1/2" (292 mm) B

16" (406 mm) A

11-1/2" (292 mm) B

19-1/8" (486 mm) A

11" (279 mm) B

18-1/2" (470 mm) A

11" (279 mm) B

18-3/4" (476 mm) A

12" (305 mm) B

14-3/4" (375 mm) A

9-1/2" (241 mm) B

16" (406 mm) A

11-1/2" (292 mm) B

END VIEW

W

END VIEW

CUTOUT

Template

Provided

P188000

Template

Provided

P186000

Template

Provided

P186000

Template

Provided

P186000

Template

Provided

P819000

Template

Provided

P188000

Template

Provided

P186000

Template

Provided

P186000

Template

Provided

P186000

W

P/N

P/N

P/N

P/N

P/N

P/N

P/N

P/N

P/N

3-1/2"

(89 mm)

2''

(51 mm)

A

DRAIN/OVERFLOW

TOTAL WEIGHT/

FLOOR LOADING

921 lb

(419 kg)/

44 lb/sq. ft.

(220 kg/sq. m)

746 lb

(339 kg)/

40 lb/sq. ft.

(195 kg/sq. m)

871 lb

(395 kg)/

42 lb/sq. ft.

(205 kg/sq. m)

871 lb

(395 kg)/

42 lb/sq. ft.

(205 kg/sq. m)

1221 lb

(555 kg)/

58 lb/sq. ft.

(283 kg/sq. m)

893 lb

(406 kg)/

45 lb/sq. ft.

(220 kg/sq. m)

978 lb

(445 kg)/

45 lb/sq. ft.

(220 kg/sq. m)

746 lb

(339 kg)/

40 lb/sq. ft.

(195 kg/sq. m)

871 lb

(396 kg)/

42 lb/sq. ft.

(205 kg/sq. m)

B

OPERATING

GALLONAGE

63 U.S. gal

(239 liters)

48 U.S. gal

(182 liters)

62 U.S. gal

(235 liters)

62 U.S. gal

(235 liters)

96 U.S. gal

(364 liters)

60 U.S. gal

(227 liters)

70 U.S. gal

(265 liters)

48 U.S. gal

(182 liters)

62 U.S. gal

(235 liters)

L

2'' (51 mm)

SIDE VIEW

SIDE VIEW

PRODUCT

WEIGHT

146 lb

(66 kg)

96 lb

(44 kg)

105 lb

(48 kg)

105 lb

(48 kg)

(55 kg)

143 lb

(65 kg)

145 lb

(66 kg)

96 lb

(44 kg)

105 lb

(48 kg)

L

121 lb

MILANO

LUNA

SKIRT &

MOUNTING

Not

Available

Not

Available

Not

Available

Not

Available

Not

Available

Not

Available

Not

Available

Not

Available

Not

Available

8"

(203 mm)

2"

(51 mm)

HEATER READY

FOR FIELD

INSTALLATION

(S750000 HEATER KIT)

(S750000 HEATER KIT)

(S750000 HEATER KIT)

(S750000 HEATER KIT)

(S750000 HEATER KIT)

(S750000 HEATER KIT)

(S750000 HEATER KIT)

(S750000 HEATER KIT)

(S750000 HEATER KIT)

W

H

END VIEW

W

H

END VIEW

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

* For Fresco™ models H551, H549, and H550 this height is 23-3/4"

NOTE: The overall dimensions are nominal with a tolerance of +0 and -1/4".

FOR ALL UNITS: Electrical Service Requirements: All require a dedicated GFCI protected separate circuit.

RapidHeat: 115 VAC, 15 AMP, 60 Hz. dedicated GFCI protected separate circuit.

Motor/Pump: 115 VAC, 15 Amp, 60 Hz. dedicated GFCI protected separate circuit.

4

Jacuzzi Whirlpool Bath© K272000AC 12/04

Page 11

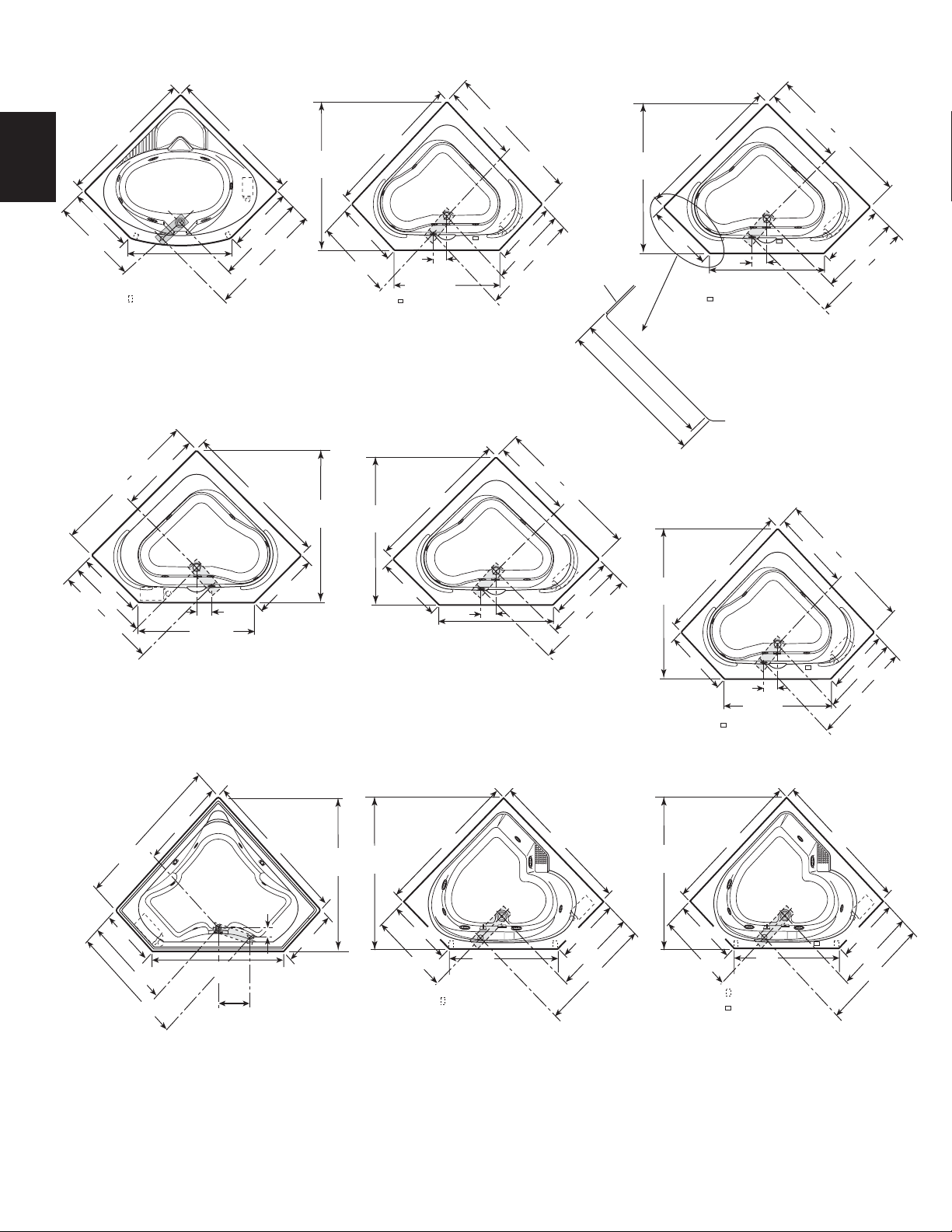

CORNER BATHS

SIDE VIEW

H

CORNER SIDE BATH

L

END VIEW

2"

(51 mm)

1"

(25 mm)

A

B

DRAIN/OVERFLOW

H

ENGLISH

FRONT VIEW

CAPELLA 55, CAPELLA 60, & TARA WITH INTEGRAL SKIRT

1"

(25 mm)

FRONT VIEW

H

SIDE VIEW

CAPELLA SPACESAVER WITH INTEGRAL SKIRT

SPECIFICATIONS (Corner)

MODEL

CAPELLA© 55

CAPELLA© 55

WITH INTEGRAL

SKIRT

©

CAPELLA

SPACESAVER

WITH INTEGRAL

SKIRT

CAPELLA© 60

FRONT LEFT

MOTOR/PUMP

CAPELLA© 60 60" (1524 mm) L

CAPELLA© 60

WITH INTEGRAL

SKIRT

GALLERY™

CORNER

TARA™

TARA™

WITH INTEGRAL

SKIRT

DIMENSIONS

55" (1397 mm) L

55" (1397 mm) L

20-1/4" ( 514 mm) H

55" (1397 mm) L

55" (1397 mm) L

20-1/2" ( 521 mm) H

60" (1524 mm) L

60" (1524 mm) L

20-1/2" ( 521 mm) H

60" (1524 mm) L

60" (1524 mm) L

20-1/2" ( 521 mm) H

60" (1524 mm) L

20-1/2" ( 521 mm) H

60" (1524 mm) L

60" (1524 mm) L

20-1/2" ( 521 mm) H

60" (1524 mm) L

60" (1524 mm) L

22-1/2" ( 572 mm) H

60" (1524 mm) L

60" (1524 mm) L

20-3/4" ( 527 mm) H

60" (1524 mm) L

60" (1524 mm) L

20-3/4" ( 527 mm) H

DRAIN/OVERFLOW

DIMENSIONS

17-1/2" (445 mm) A

9-5/8" (245 mm) B

18" (457 mm) A

12-1/8" (308 mm) B

18" (457 mm) A

12-3/8" (308 mm) B

18" (457 mm) A

12-1/8" (308 mm) B

18" (457 mm) A

12-1/8" (308 mm) B

18" (457 mm) A

12-1/8" (308 mm) B

18-1/8" (451 mm) A

12" (305 mm) B

16" (406 mm) A

12-3/8" (314 mm) B

16" (406 mm) A

12-3/8" (314 mm) B

CUTOUT

See

Page 11

NA

NA

See

Page 11

See

Page 11

NA

See

Page 11

See

Page 11

NA

TOTAL WEIGHT/

FLOOR LOADING

791 lb

(360 kg)/

38 lb/sq. ft.

(185 kg/sq. m)

833 lb

(379 kg)/

40 lb/sq. ft.

(195 kg/sq. m)

880 lb

(400 kg)/

35 lb/sq. ft.

(171 kg/sq. m)

870 lb

(395 kg)/

35 lb/sq. ft.

(171 kg/sq. m)

870 lb

(395 kg)/

35 lb/sq. ft.

(171 kg/sq. m)

880 lb

(400 kg)/

35 lb/sq. ft.

(171 kg/sq. m)

984 lb

(447 kg)/

39 lb/sq. ft.

(244 kg/sq. m)

984 lb

(447 kg)/

39 lb/sq. ft.

(190 kg/sq. m)

999 lb

(454 kg)/

40 lb/sq. ft.

(195 kg/sq. m)

OPERATING

GALLONAGE

51 U.S. gal

(193 liters)

55 U.S. gal

(208 liters)

60 U.S. gal

(227 liters)

60 U.S. gal

(227 liters)

60 U.S. gal

(227 liters)

60 U.S. gal

(227 liters)

74 U.S. gal

(280 liters)

74 U.S. gal

(280 liters)

74 U.S. gal

(280 liters)

PRODUCT

WEIGHT

116 lb

(53 kg)

125 lb

(54 kg)

130 lb

(59 kg)

120 lb

(54 kg)

120 lb

(54 kg)

130 lb

(59 kg)

118 lb

(54 kg)

118 lb

(54 kg)

133 lb

(61 kg)

NOTE: The overall dimensions are nominal with a tolerance of +0 and -1/4".

FOR ALL UNITS: Electrical Service Requirements: All require a dedicated GFCI protected separate circuit.

RapidHeat: 115 VAC, 15 AMP, 60 Hz. dedicated GFCI protected separate circuit.

Motor/Pump: 115 VAC, 15 Amp, 60 Hz. dedicated GFCI protected separate circuit.

SKIRT &

MOUNTING

Optional

Integral

Integral

Not

Available

Not

Available

Integral

Not

Available

Optional

Integral

SIDE VIEW

HEATER READY

FOR FIELD

INSTALLATION

Yes

(S750000 HEATER KIT)

No

No

No

No

No

Yes

(S750000 HEATER KIT)

Yes

(S750000 HEATER KIT)

No

5

Jacuzzi Whirlpool Bath© K272000AC 12/04

Page 12

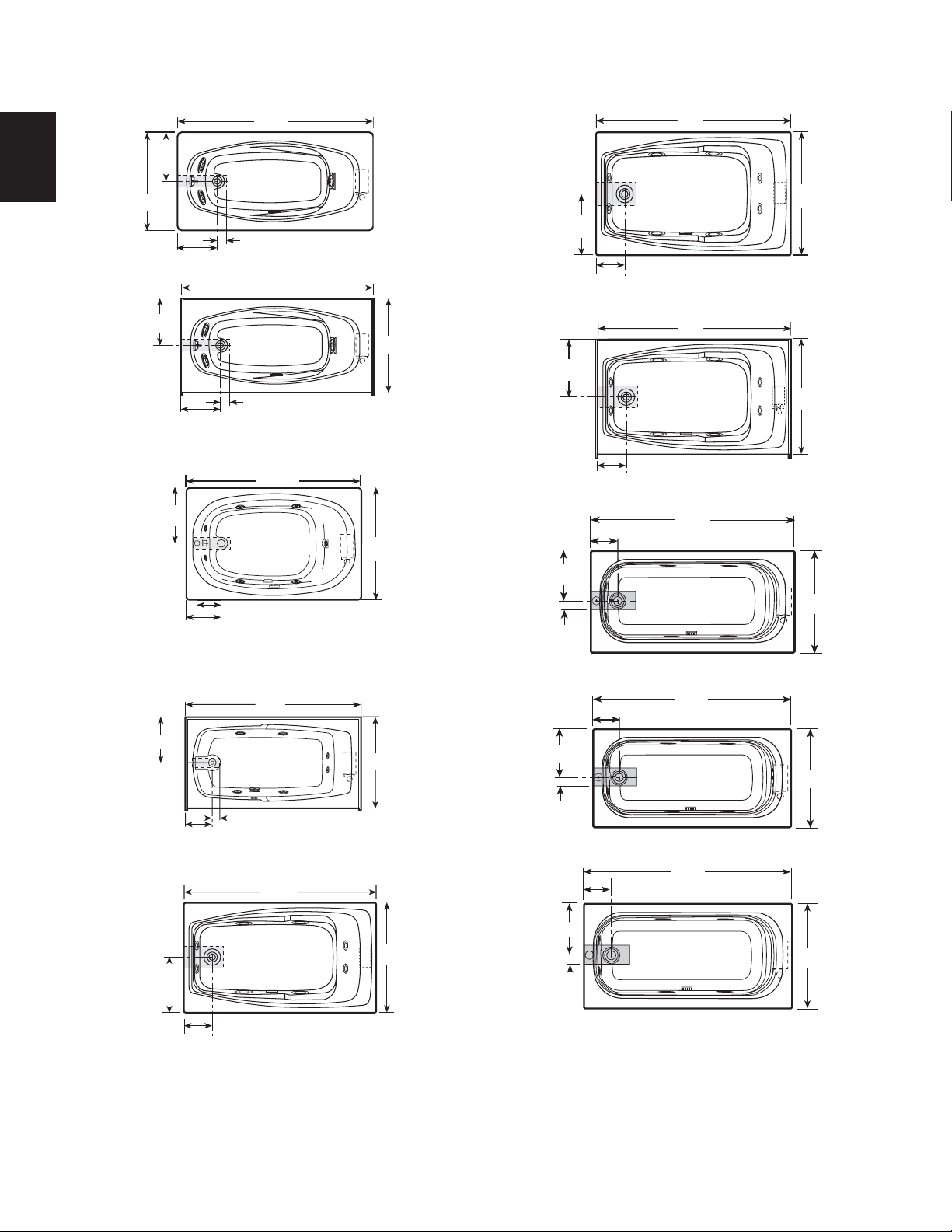

ROUGHING-IN REFERENCE (RECTANGULAR)

Note: Baths shown are left-hand unless otherwise specified. Right-hand is a mirror image.

ENGLISH

18''

36''

17-3/8''

24"

*72''

16'' x 4''

2''

14''

14-1/2''

AMIGA

*72''

16'' x 4''

2''

AMIGA WITH INTEGRAL SKIRT

* 72"

13-1/2" x 4"

48"

36''

12" x 4"

18"

9"

CETRA 536

17-3/8"

12" x 4"

9"

CETRA 536 WITH INTEGRAL SKIRT

*60"

8-1/4"

60"

36"

*60"

36"

8-1/2"

13-3/4"

(Left-hand only as shown.)

15-5/8"

2"

9-3/8"

CETRA WITH INTEGRAL SKIRT

16"

9"

BIANCA

*60"

10" x 4"

*60"

12" x 4"

CETRA 532

32"

32"

16"

15" x 5"

2-1/2"

LUXURA 5

*60"

9-1/4"

15-5/8"

15" x 5"

2-1/2"

LUXURA 5 WITH INTEGRAL SKIRT

*66"

8-3/8"

17"

15" x 5"

2-1/2"

LUXURA 5.5

32"

32"

34"

*Add 1/4" to this dimension when roughing-in for 3-wall niche.

Note: 1. THE OVERALL DIMENSIONS ARE NOMINAL WITH A TOLERANCE OF +0 AND -1/4".

2. Measurements inside each unit represent cutout in floor to allow for drain/overflow.

3. All measurements are in inches. To convert to millimeters, multiply inches by 25.4.

6

Jacuzzi Whirlpool Bath© K272000AC 12/04

Page 13

ROUGHING-IN REFERENCE (RECTANGULAR)

Note: Baths shown are left-hand unless otherwise specified. Right-hand is a mirror image.

*60"

9-1/8"

14-1/2"

15" x 5"

2-1/2"

30"

11-7/8"

*72"

10" x 4"

2"

ENGLISH

42"

LUXURA 530 WITH INTEGRAL SKIRT

8-3/4"

21"

10-1/2"

21"

8-1/2"

*60"

2"

10" x 4"

MAJORA 5

*72"

2"

12" x 4"

MAJORA 6

*72"

2"

42"

42"

36"

(Right hand shown.

Left hand is a mirror image.)

MITO 6

*60"

21''

11" x 4"

2''

8-1/2''

21''

2''

8-1/2''

NOVA 5 WITH 3-SIDED TILE FLANGE

2''

NOVA 5

*60"

11" x 4"

2''

*60"

42''

42''

20-1/2"

12" x 4"

42"

20''

2''

MAJORA 6 WITH INTEGRAL SKIRT

*60"

10" x 4"

2"

11-7/8"

30"

(Right hand shown.

Left hand is a mirror image.)

MITO 5

*Add 1/4" to this dimension when roughing-in for 3-wall niche.

Note: 1. THE OVERALL DIMENSIONS ARE NOMINAL WITH A TOLERANCE OF +0 AND -1/4".

2. Measurements inside each unit represent cutout in floor to allow for drain/overflow.

3. All measurements are in inches. To convert to millimeters, multiply inches by 25.4.

42"

9-7/8''

NOVA 5 WITH INTEGRAL SKIRT

21''

2''

10-7/8''

7

Jacuzzi Whirlpool Bath© K272000AC 12/04

11" x 4"

2''

14" x 4"

2''

NOVA 6

42''

*72''

42''

Page 14

ROUGHING-IN REFERENCE (RECTANGULAR)

Note: Baths shown are left-hand unless otherwise specified. Right-hand is a mirror image.

*60"

*60"

ENGLISH

18"

17-1/4"

18-1/8"

10" x 4"

2"

9"

9-3/4"

NOVA 536 WITH INTEGRAL SKIRT

NOVA 536

*60"

10" x 4"

2"

*72"

10" x 4"

36"

36"

36"

42"

6-3/4"

(Right hand only as shown.)

SIGNA 5 WITH INTEGRAL SKIRT

Front Right Motor/Pump

42"

5"

Left hand is a mirror image.)

SIGNA 5 WITH 3-SIDED FLANGE

42"

16" x 5"

4-1/4"

*60"

13" x 5"

4-1/4"

(Right hand shown.

*72"

18-1/2" x 5"

30"

30"

12-3/4"

12"

2"

10-1/8"

NOVA 636 WITH INTEGRAL SKIRT

1/4"

11-

5"

(Right hand shown.

Left hand is a mirror image.)

*60"

42"

13" x 5"

5"

12"

4-1/4"

30"

(Right hand shown.

Left hand is a mirror image.)

SIGNA 5

*Add 1/4" to this dimension when roughing-in for 3-wall niche.

Note: 1. THE OVERALL DIMENSIONS ARE NOMINAL WITH A TOLERANCE OF +0 AND -1/4".

2. Measurements inside each unit represent cutout in floor to allow for drain/overflow.

3. All measurements are in inches. To convert to millimeters, multiply inches by 25.4.

12-1/2"

36"

SIGNA 6

Jacuzzi Whirlpool Bath© K272000AC 12/04

8

Page 15

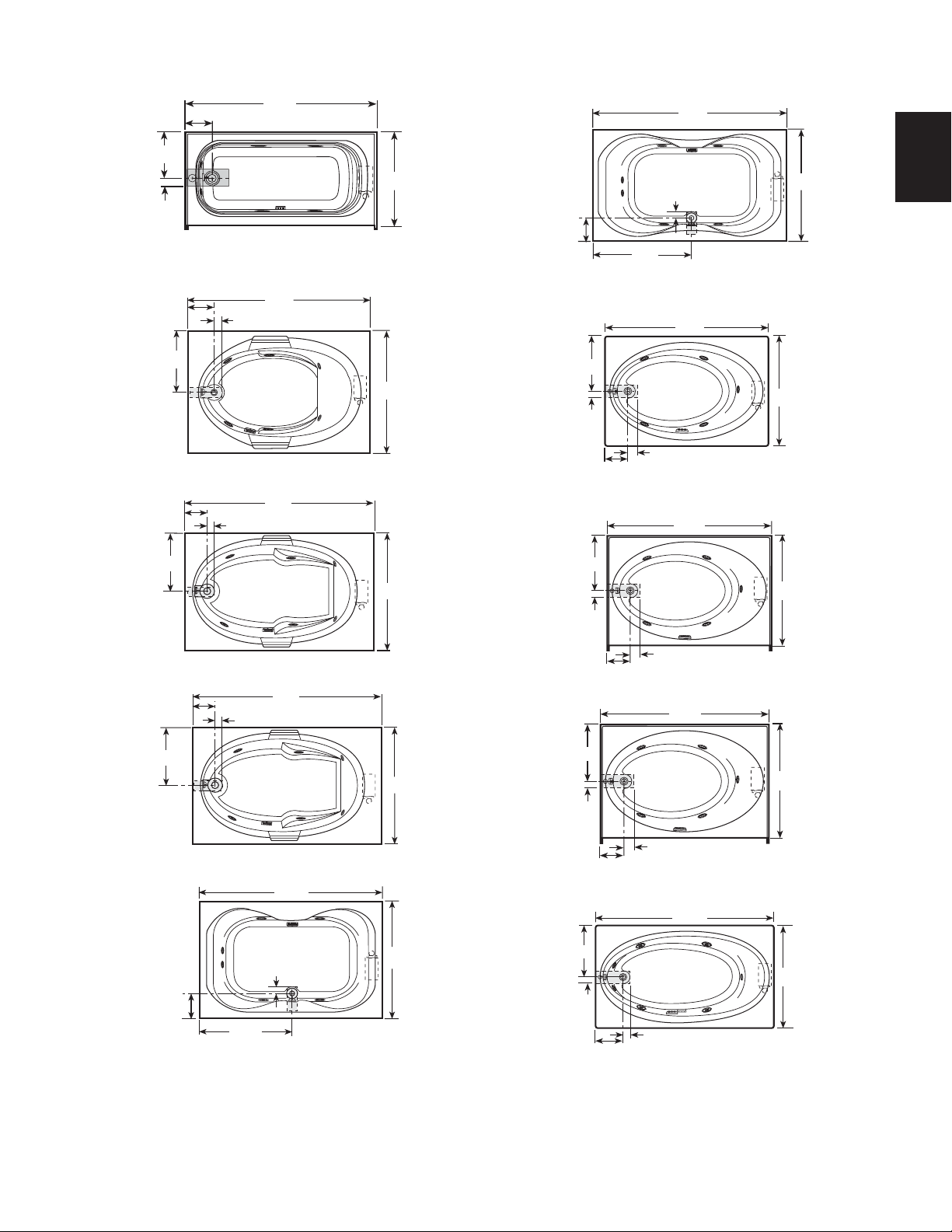

ROUGHING-IN REFERENCE (OVAL)

Note: Baths shown are left-hand unless otherwise specified. Right-hand is a mirror image.

These units have been provided with cutout templates included in shipping carton.

See CUTOUT information for each model on page 4.

62"

ENGLISH

43"

11-3/4"

(Right hand shown.

Left hand is a mirror image.)

FRESCO

21"

14" x 4"

2"

12-1/2"

12" x 4"

2"

71-1/2"

36"

72"

2"

GALLERY 6 OVAL

72"

13" X 6"

3"

42"

42"

21-1/2"

9-1/2"

42"

40"

12" x 4"

2"

2"

GALLERY 5 OVAL

72"

14" x 4"

GALLERY 6 UNDERMOUNT

11 "

71-1/2"

2"

20"

12" x 4"

43"

21"

2"

12-1/2"

2"

11"

36"

(Right-hand only.)

LUNA

72"

21-1/2"

2"

9-1/2"

44"

13" X 4"

3"

4"

(Left-hand unit shown.)

OPALIA

36"

32"

12"

72"

21"

14" x 4"

42"

2"

2"

11-1/2"

RIVA 6

NOTE: THE OVERALL DIMENSIONS ARE NOMINAL WITH A TOLERANCE OF +0 AND -1/4".

MILANO

62"

12" x 4"

2"

(Left-hand only as shown.)

RIVA 5

43"

9

Jacuzzi Whirlpool Bath© K272000AC 12/04

Page 16

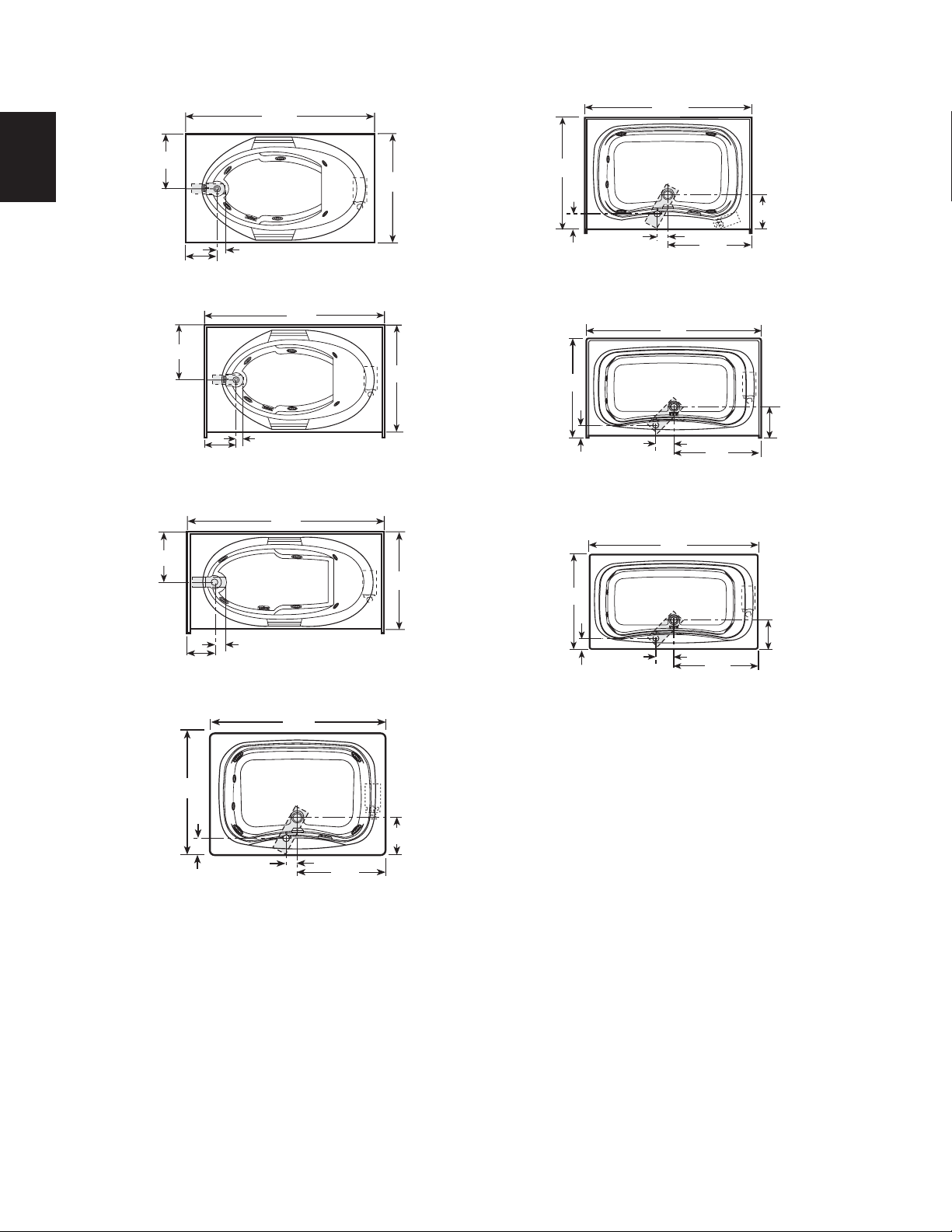

ROUGHING-IN REFERENCE (CORNER)

"

"

Note: Baths shown are left-hand unless otherwise specified. Right-hand is a mirror image.

ENGLISH

36 1/2"

34-15/16"

43-1/8"

55"

12" x 4"

27"

39 1/2"

- 2" x 4" Stud

(Right-hand only as shown.)

CAPELLA 55

33-1/2"

60"

14" X 4"

27"

46-5/8"

55"

6"

27"

36 1/2"

44 1/2"

60"

27"

57-1/4"

Ref.

61-1/2

Ref.

32-1/4"

55"

16" X 4"

26"

29-3/8"

CAPELLA 55 WITH INTEGRAL SKIRT

61-1/2"

Ref.

9-7/8"

40-7/16"

- Junction Box

(Right-hand only as shown.)

60"

14" X 4"

27"

6"

46-5/8"

55"

26"

32-1/2"

43-7/8"

33-1/2"

60-1/4"

Ref.

TILE

FLANGE

To Beginning of Radius

23-7/16"

25-1/4"

60"

27"

34-15/16"

43-1/8"

25-1/4"

61-1/2"

Ref.

33-13/16"

60"

14" X 4"

6"

49"

- Junction Box

(Capella right hand shown.)

CAPELLA SPACESAVER

33-1/2"

60"

14" X 4"

60"

25-1/4"

33-13/16

41-9/16"

60"

CAPELLA 60 w/Front Left Motor/Pump

34"

60"

60"

19" X 4"

7-1/2"

24"

34"

47-3/4"

50-1/4"

13"

(Right hand shown. Left hand is a mirror image.)

GALLERY CORNER

24"

(Right hand shown. Left hand is a mirror image.)

CAPELLA 60

60"

61-5/8"

59-1/2"

Ref.

Ref.

14" x 4"

27-1/4"

35"

46"

- 2" x 4" Stud

(Right hand shown. Left hand is a mirror image.)

TARA

60"

27-1/4"

35"

44"

27"

6"

46-5/8"

- Junction Box

(Right-hand only as shown.)

CAPELLA 60 WITH INTEGRAL SKIRT

61-5/8"

Ref.

60"

14" x 4"

27-1/4"

35"

46"

- 2" x 4" Stud

- Junction Box

(Right hand only as shown.)

TARA WITH INTEGRAL SKIRT

27"

34-15/16"

43-1/8"

60"

27-1/4"

35"

44"

Note: 1. THE OVERALL DIMENSIONS ARE NOMINAL WITH A TOLERANCE OF +0 AND -1/4".

2. Measurements inside each unit represent cutout in floor to allow for drain/overflow.

3. All measurements are in inches. To convert to millimeters, multiply inches by 25.4.

10

Jacuzzi Whirlpool Bath© K272000AC 12/04

Page 17

CUTOUT- CORNER BATHS

ENGLISH

(1346 mm)

25-3/4"

(654 mm)

57-5/8"

Ref.

23-1/2"

(597 mm)

53"

(1473 mm)

2-3/4"

(70 mm)

CAPELLA 55

58"

(1224 mm)

CAPELLA SPACESAVER

48"

R = 70"

53"

(1346 mm)

25-3/4"

(654 mm)

58"

(1473 mm)

23-1/2"

(597 mm)

59"

1499 mm

59"

Ref.

25-1/2"

(648 mm)

58"

(1473 mm)

58"

(1473 mm)

25-1/2"

(648 mm)

45-9/16"

(1157 mm)

CAPELLA 60

CAPELLA 60 W/ FRONT LEFT MOTOR/PUMP

(Motor/Pump position not shown.)

3" RADIUS

CORNERS

(5 PLACES)

58"

(1473 mm)

57"

Ref.

90°

22-5/8"

(575 mm)

50"

(1270 mm)

GALLERY CORNER

58"

(1473 mm)

90°

22-5/8"

(575 mm)

11

59"

Ref.

(648 mm)

58"

(1473 mm)

25-1/2"

45-9/16"

(1157 mm)

TARA

Jacuzzi Whirlpool Bath© K272000AC 12/04

58"

(1473 mm)

25-1/2"

(648 mm)

Page 18

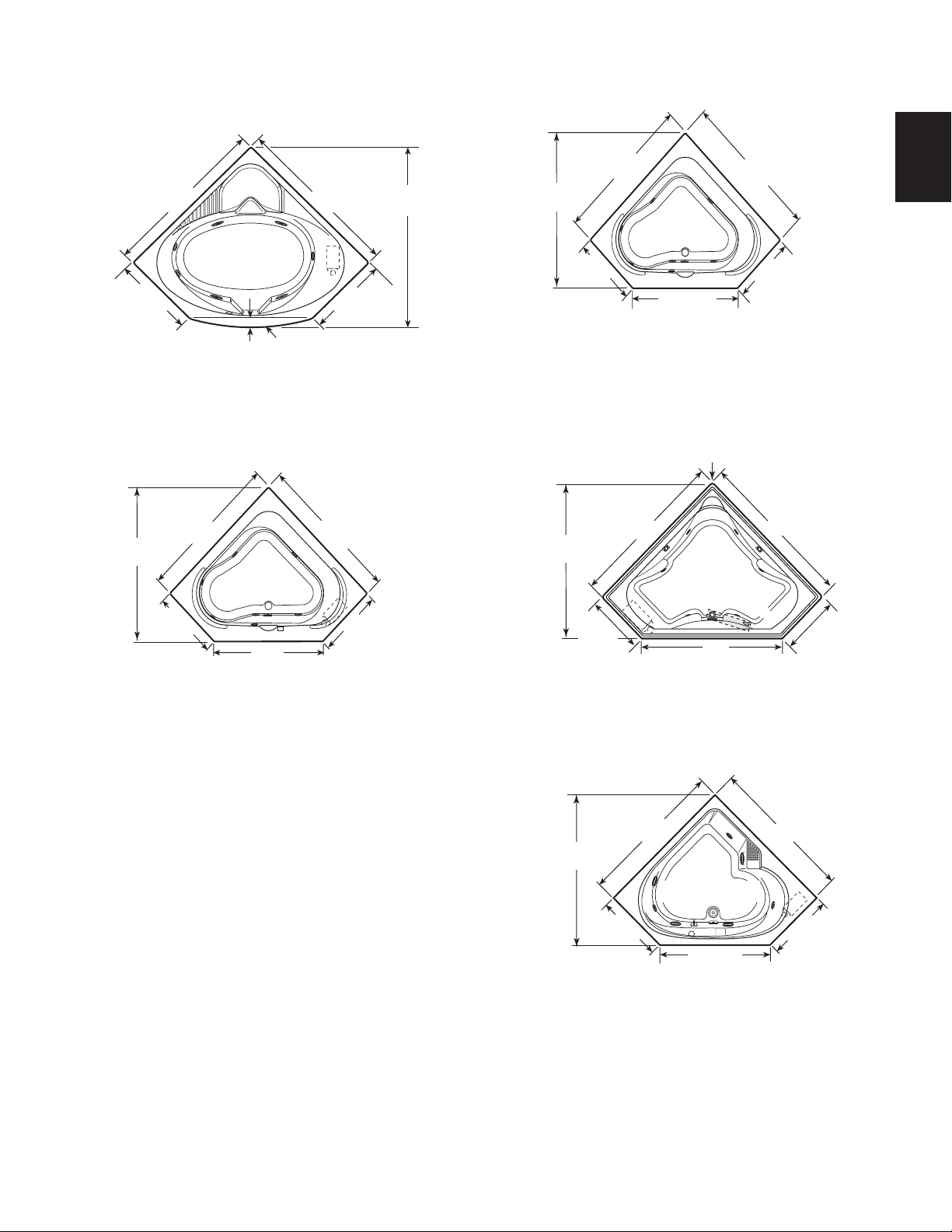

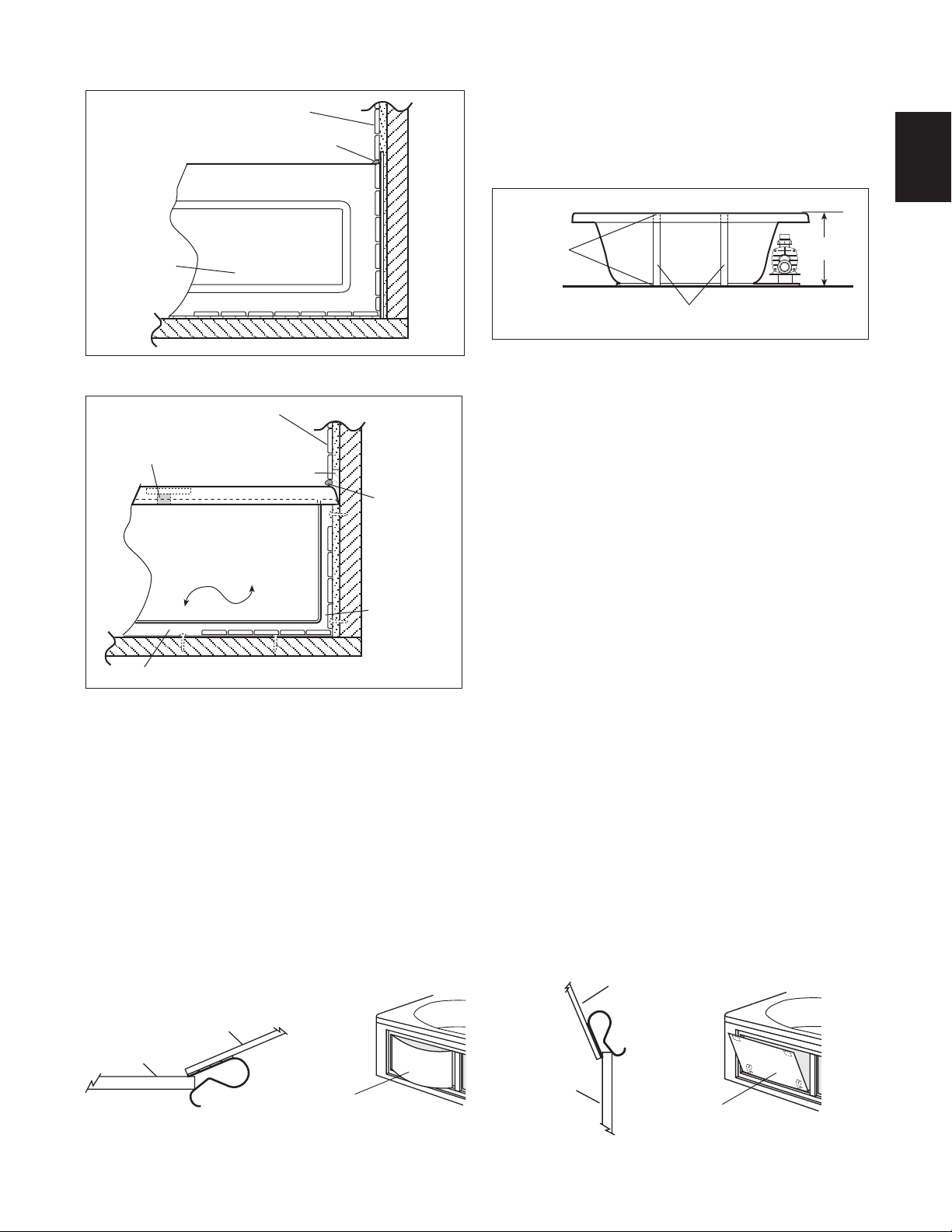

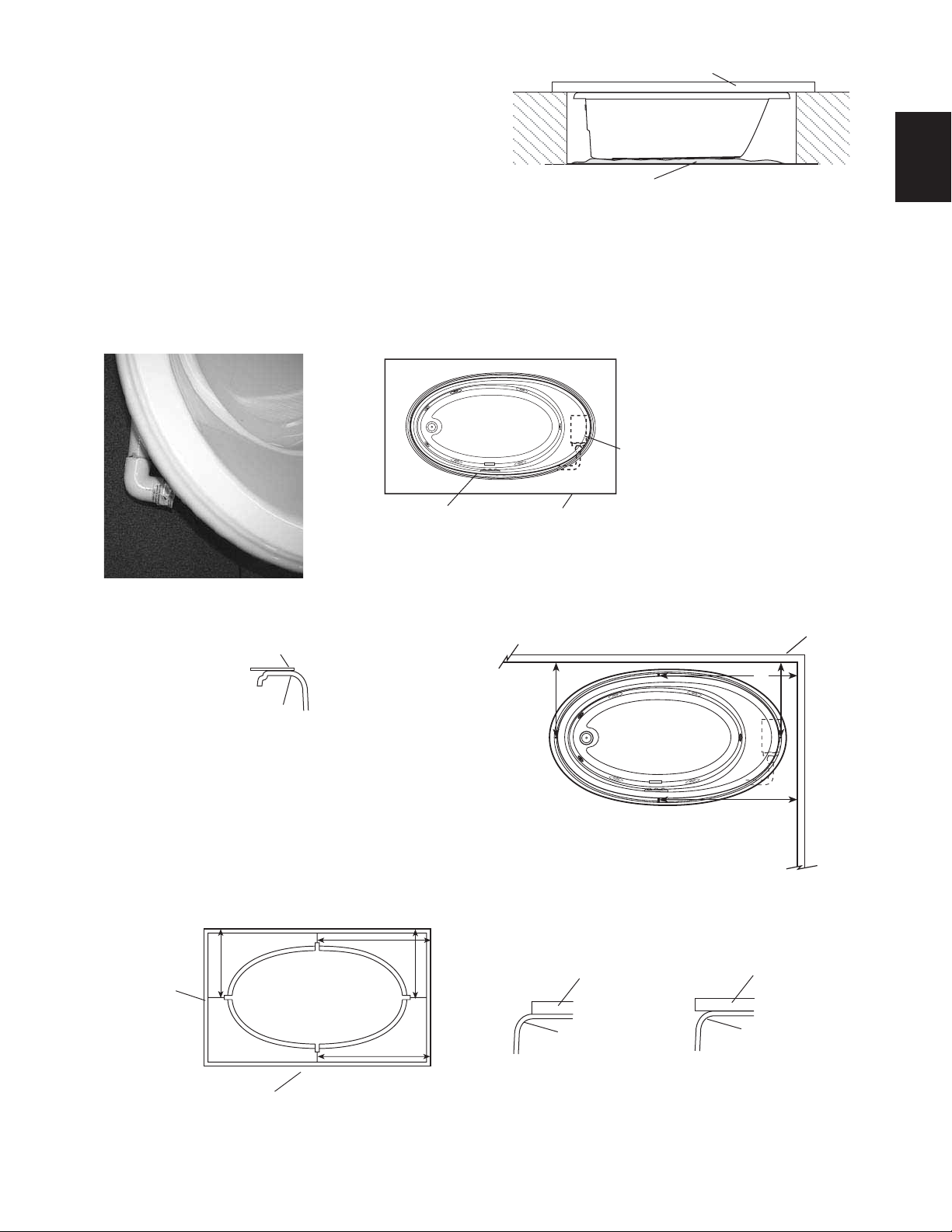

Framing and Support

The drain/overflow of the bath extends below the bottom of the bath. Note that this requires a cutout in the floor.

The floor structure beneath the bath must be able to support a total weight of bath, water , and bather. Refer to the t able under tota l

weight for your model. The unit must be supported from the bottom of the bath and not from the bath rim or tile flange. If the subfloor is level

and a continuous surface, no other preparation is necessary . You can proceed to install the bath. If the subfloor is not level, you MUST level the

entire surface prior to installing the bath. The use of materials that shim or provide a level installation are allowed provided the method used will

insure a level bath that is supported from the bottom. Materials that may be used are a floor leveling compound, mortar, plaster or minimal

expansion structural foam having a density of a minimum of 5 lbs./cubic ft.; however the bath must remain level in order for it to drain properly

and all foam feet must make full contact with the leveling material. Both sides of a joint or splice of subfloor should be level to each other. When

ENGLISH

attaching baths with flanges to stud wall, use shims to fill any gaps between the bath flange and studs.

The rim of the bath is not designed to support weight. If finish material is to overlap or contact the bath, the added weight must be fully self-

supporting.

The protective film liner inside the bath is used to prevent damage to the finish during installation. Before installation, remove liner

to inspect for any defects, reapply and do not remove until final cleanup.

Important: If a skirt is to be used, it must be installed at the time of unit installation – refer to skirt installation instructions. Install

optional trim parts when all installation has been completed.

TYPICAL INSTALLATIONS

MORTAR OR ADHESIVE

FLASHING

TILE

MORTAR OR ADHESIVE

SEALANT

SEALANT

TILE

PLASTER

FILLER

FLANGE

FINISHING

MATERIAL

MORTAR

CEMENT

BOARD

BATH RIM

NAIL

OR

SCREW

STUD

WALL

SILICONE

SEALANT

1" X 4" (NOT FOR

SUPPORT)

OPTIONAL TILE FLANGE KIT

1" X 4" (NOT FOR SUPPORT)

FLUSH TO WALL

SUB-FLOOR

FLASHING

1" X 4" (NOT FOR SUPPORT)

SEMI-SUNKEN

NOTE: ON the Riva 5 and Riva 6, the discharge plumbing extends slightly beyond the bath rim. When installing either bath as semisunken, lower the pump/motor side in first into the cutout.

TYPICAL FLANGE MOUNTING DETAIL

SHIM IF

NECESSARY

TO FILL GAPS

BETWEEN

STUD

AND FLANGE

STUD

FLANGE

CAULKING

1/8" GAP

TILE

CEMENT

BOARD

TILE

ADHESIVE

ATTACH WITH

SCREWS

PROVIDED

STUD

FLANGE

SHIM IF

NECESSARY

TO FILL GAPS

BETWEEN

STUD

AND FLANGE

STUD

CAULKING

FLANGE

1/8" GAP

TILE

CEMENT

BOARD

TILE

ADHESIVE

ATTACH WITH

SCREWS

PROVIDED

STUD

FLANGE

1"X 4"

(NOT FOR

SUPPORT)

UNDERMOUNT INST ALLATION OPTIONS

The undermount gives the opportunity to be flexible in the design and location of the bath. Examples are shown for possible

installations. Refer to pages 17-18 for undermount installation instructions.

FREE STANDINGCORNER NICHE

12

Jacuzzi Whirlpool Bath© K272000AC 12/04

Page 19

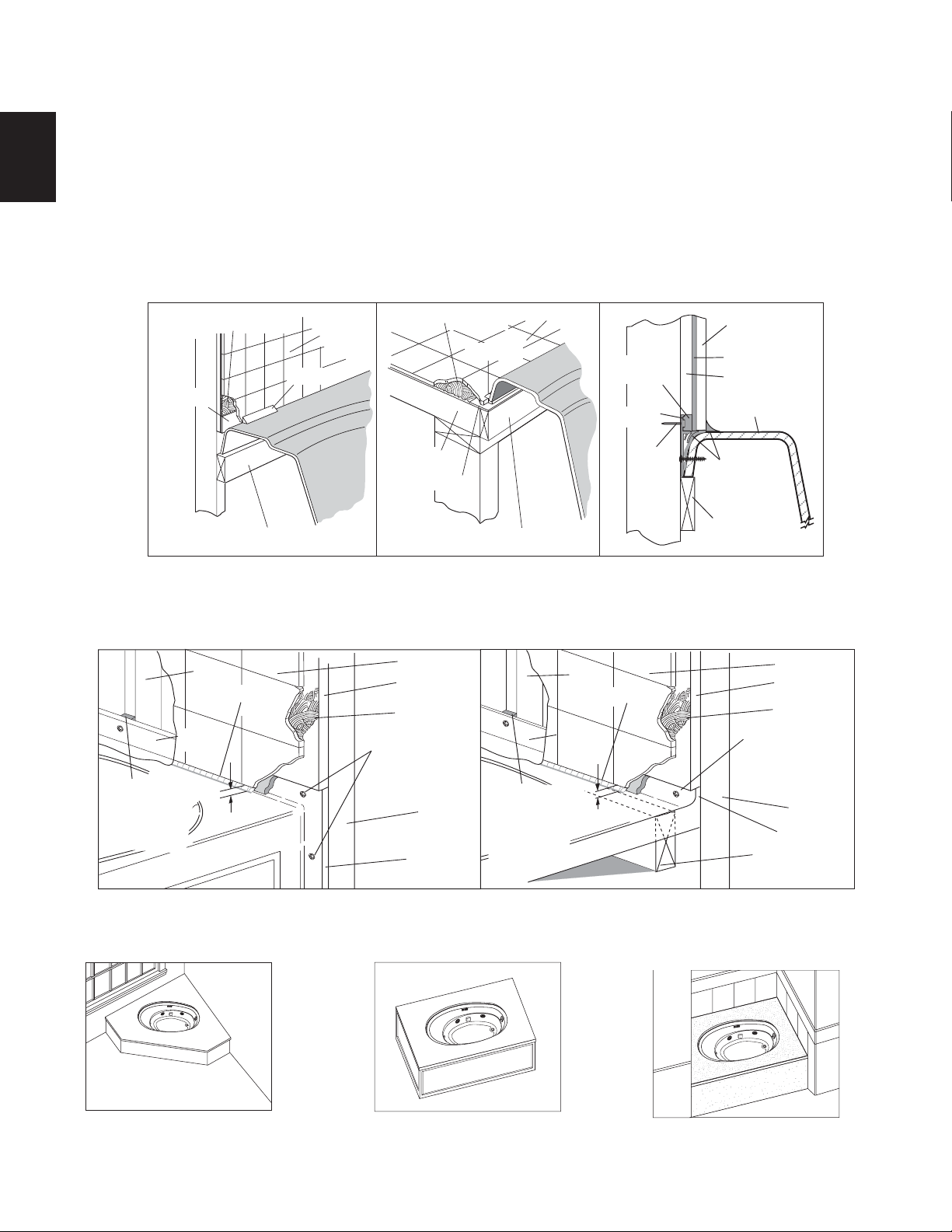

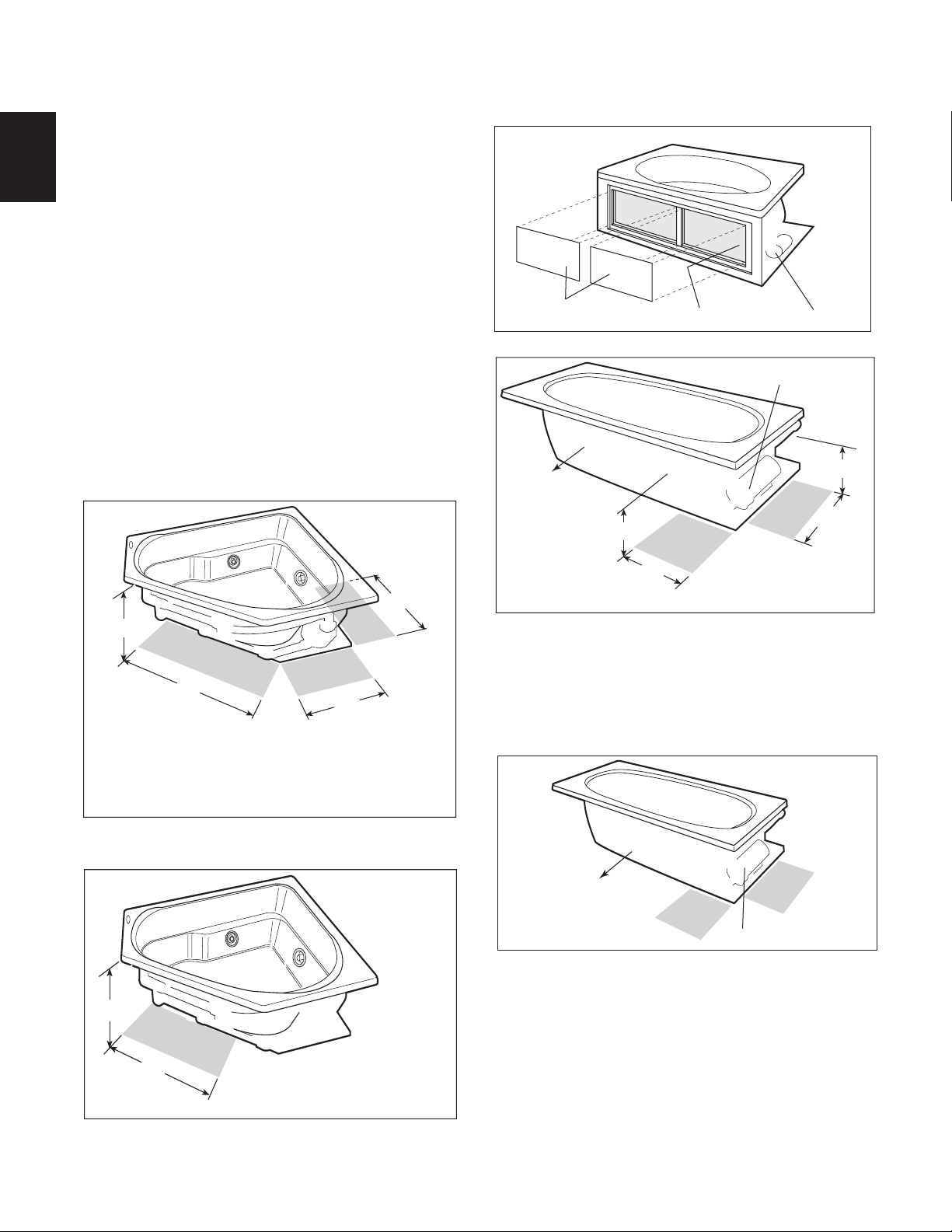

Skirts

INTEGRAL SKIRT MOUNTING DETAIL

FINISHING

MATERIALS

CAULKING BEAD

Corner Baths with Skirt

If an optional skirt is used on a corner bath, additional support is

necessary in the front of the unit. Measure the height from the floor to

the underside of the bath rim. Cut two 2" x 4" studs, apply adhesive

to both ends and install (See Specifications in reference).

SUPPORT FOR CORNER BATHS

ENGLISH

SKIRT

PANEL

U FRAME SKIRT MOUNTING DETAIL

FINISHING MATERIALS

SECURE SHELL CLIP

UNDER CENTER

BATH RIM

FILLER (Optional)

SKIRT

PANEL

SECURE BOTTOM OF FRAME TO FLOOR

CAULKING

BEAD

SKIRT

FRAME

APPLY

ADHESIVE

H

2" x 4" STUD

Reinstalling Removable Skirt Panel

Hold at an angle to the skirt and insert clip under edge of skirt

opening. Bow the panel outward and insert clip on other side.

ACCESS

PANEL

SKIRT

BOW

ACCESS

PANEL

Or slide clips over bottom lip of skirt opening and tilt up until velcro

tabs make contact.

ACCESS

PANEL

SKIRT

ACCESS

PANEL

13

Jacuzzi Whirlpool Bath© K272000AC 12/04

Page 20

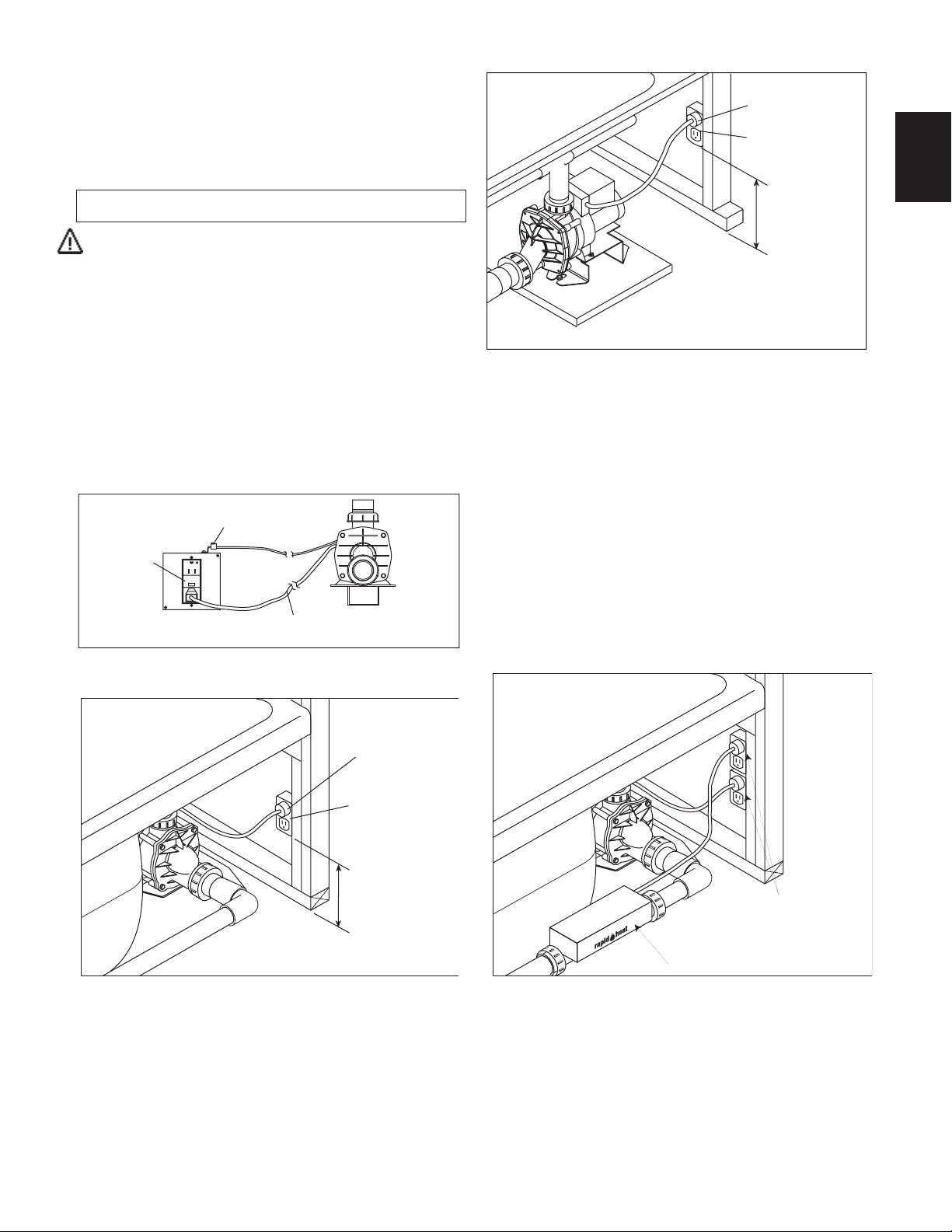

Service Access

For partially or fully sunken installations, allow for access to service connections. It is the installer's responsibility to provide sufficient service access. The recommended minimum dimensions allowable for service to the bath are shown in the "Service Access"

illustration.

Provide adequate area around unit for air circulation for cooling

the motor and to supply sufficient air to the jets. Do not insulate this

area or around motor.

ENGLISH

Optional RapidHeat Service Access

Where tubs have been ordered with the optional RapidHeat

heater consider an additional service access.

If service access has not been provided, it is the home owners

responsibility to remove the bath and provide the required

access, should a repair become necessary.

Service Access with Skirt

An optional skirt fits along the side of the bath for above-floor

installations and is also an access panel for servicing. Allow a sp ace

of at least 8 inches away from the bath for skirt removal.

The skirt is designed to accommodate the added height of the

tile, linoleum, or other floor coverings up to 1-1/4 inches above the

floor, and will be flush with the floor when installed.

More detailed instructions on skirt installation are provided with

the optional skirt assembly.

SERVICE ACCESS

(CORNER BATHS)

Service Access with Integral Skirt

Service access is through the removable skirt panels.

SERVICE ACCESS

REMOVABLE SKIRT

ACCESS PANELS

SERVICE ACCESS

FRONT

(WITH INTEGRAL SKIRT)

ACCESS AREA

(WITHOUT SKIRT)

MOTOR

MOTOR

12"

18"

C

36"

RIGHT HAND UNIT SHOWN

A - Preferred access

B - Acceptable alternative if access A is not possible

C - Optional access for equipment

NOTE: Left hand unit access is on the opposite

side (mirror Image).

B

A

24"

SERVICE ACCESS

(BG55 CAPELLA CORNER BATH ONLY)

20"

12"

ALTERNATE

ACCESS

In some cases, access may not have been provided because of

the design of the bath environment and having full understanding that

in this case, it may be necessary to remove the unit for service.

If this is the case, diagnosing a problem may not be possible without complete access to the plumbing system. This would necessitate

the removal of the unit. Although this practice is not commonly implemented, it is an acceptable method.

FRONT

18"

AREA

18"

PREFERRED

ACCESS

A

AREA

B

MOTOR

12"

18"

Preferred access area

Jacuzzi Whirlpool Bath© K272000AC 12/04

In some cases access may have been provided in Area A but

service is required in Area B which requires the unit to be pulled for

service and reinstalled.

If service access has not been provided, it is the home owners

responsibility to remove the bath and provide the required access, should a repair become necessary.

14

Page 21

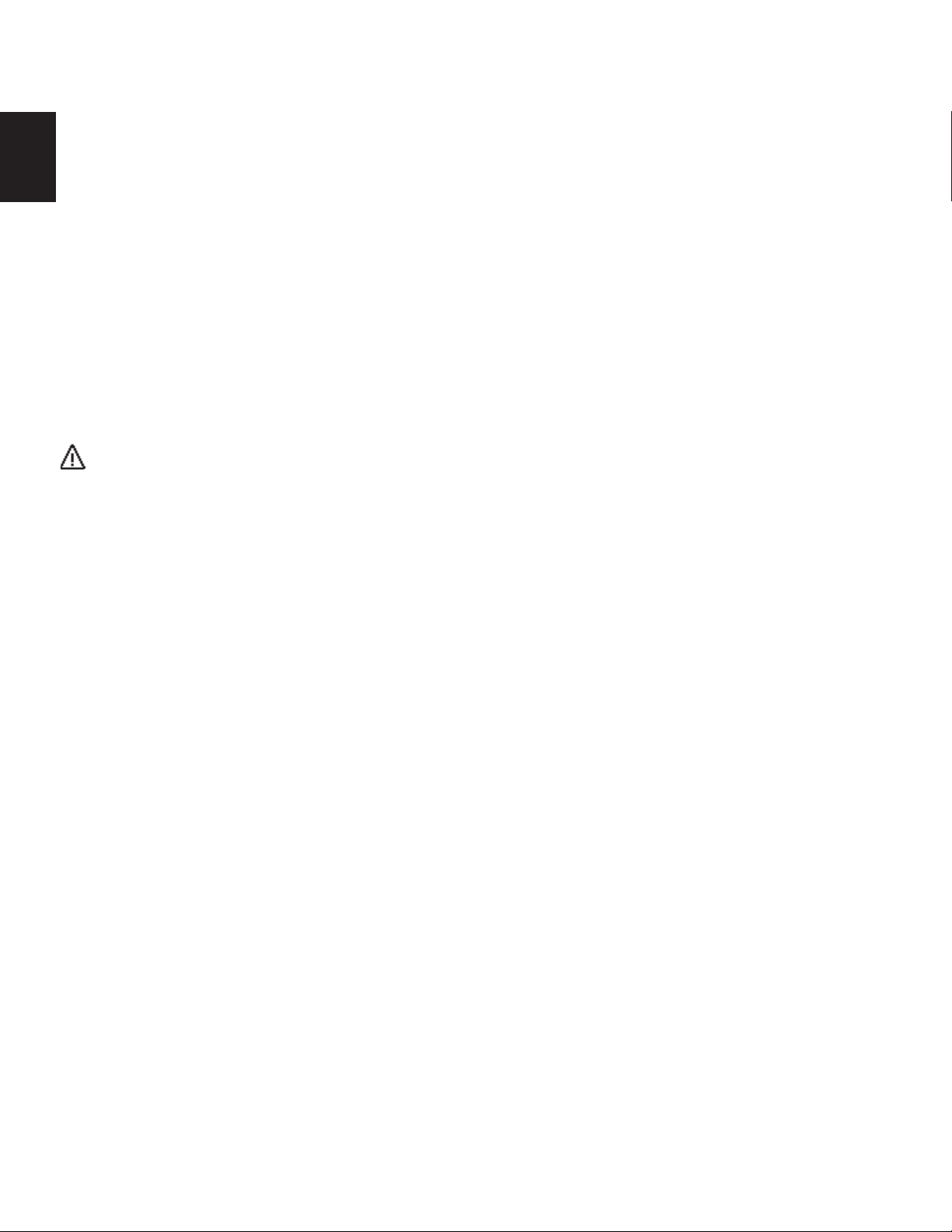

T

M

INSTALL SEPERATE

GFCI PROTECTED CIRCUITS

HEATER

ELECTRICAL CONNECTION RAPIDHEAT

Electrical Connections

A separate circuit, which must be protected by a Ground Fault

Circuit Interrupter (GFCI), is required. Install a duplex outlet to the

studwall underneath the bathtub, at least 4 inches above the floor.

The duplex outlet is not provided. Because these units are manufactured with a safe, convenient Magic Touch whirlpool ON/OFF switch

on the bath itself, no remote switch or timer is necessary. If an optional timer is desired, one is available from Jacuzzi Whirlpool Bath

for 115 VAC operation.

DANGER: RISK OF ELECTRIC SHOCK. Connect only to a circuit

protected by a Ground Fault Circuit Interrupter.

CAUTION: Operating the motor/pump without enough water in

the bath can cause leaking and permanent damage to the pump.

Before power is applied to the installation, make sure the switch

is in the OFF position to avoid pump damage.

ELECTRICAL CONNECTION

(FOR CORNER BATHS)

3 PRONG

PLUG

ENGLISH

DUPLEX

RECEPT.*

4" MIN.

OR IN

ACCORDANCE

WITH LOCAL

BUILDING OR

ELECTRICAL

CODES

FLOOR

On the Capella 55 with integral skirt, Capella 60 with integral skirt,

Capella Spacesaver with integral skirt and Tara with integral skirt a

duplex junction box has been provided. To access, remove skirt access panel. See top views for location.

A separate GFCI protected outlet* (not provided) is required for

pump/motor and is to be installed in the junction box. The junction

box is to be hard wired. The motor is bonded to the junction box at

the factory.

CAPELLA 55, CAPELLA 60, CAPELLA SPACESAVER

& TARA JUNCTION BOX

BONDING TO PUMP/MOTOR

*GFCI

POWER CORD

TO MOTOR

ELECTRICAL CONNECTION

(FOR SIDE/END DRAIN BATHS)

3 PRONG

PLUG

*(NOT PROVIDED)

Electrical Connection RapidHeat

Before installing electrical connection, inspect the heater nameplate and determine if you have a 120 VAC or a 240 VAC unit (240

VAC unit not available in U.S.A.).

Install a separate 120 VAC 15 AMP or 240 VAC 15 AMP dedicated circuit with GFCI protection. With a #8 solid copper wire, bond

the heater to the house electrical panel or approved local bond. A

bonding lug is provided on the heater.

At initial start-up and before each use thereafter with power ON,

push the GFCI test button. The reset button should pop out. Push

this button in to reset. If the interrupter fails to operate in this manner,

there is a ground current flowing or a device malfunction, indicating

the possibility of electrical shock. Turn off power and do not use

the bath until the source of the problem has been identified and

corrected.

*(NOT PROVIDED)

FLOOR

DUPLEX

RECEPT.*

4" MIN.

OR IN

ACCORDANCE

WITH LOCAL

BUILDING OR

ELECTRICAL

CODES

15

Jacuzzi Whirlpool Bath© K272000AC 12/04

Page 22

Plumbing and Water Supply

Drain Information

A drain/overflow assembly (sold separately) must be installed on the bath, water tested, and connected to the sanitary system of the house.

After opening the carton, inspect for damage and verify that the kit is of the proper finish. In the Jacuzzi Whirlpool Bath drain/overflow kit, note that

the waste flange, strainer, overflow cover and cover screws are packaged in a separate p ackage within the kit to protect the trim finish. Follow the

installation instructions provided with your drain/overflow kit. After the drain is fully installed, test for proper drainage. If the unit does not drain

properly, rectify this condition before proceeding with the inst allation. Jacuzzi Whirlpool Bath is not responsible for removal and or reinst allation

ENGLISH

costs.

NOTE: Watertight installation of the drain is the installer's responsibility. Drain leakage is excluded from the Jacuzzi Whirlpool

Bath warranty of this product.

Plumbing

Pump, jets, and suction fittings for the whirlpool system are factory plumbed in Schedule 40 PVC piping.

All Jacuzzi Whirlpool Bath products are factory tested for proper operation and watertight connections prior to shipping. If leaks are detected,

notify Jacuzzi Whirlpool Bath. Do not install the unit.

Water Supply

Consult local authorities for plumbing code requirements in your area.

IMPORTANT: Proper installation of the fill spout plumbing and compliance with local codes are the responsibility of the installer.

Jacuzzi Whirlpool Bath does not warrant connections of water supply fittings and piping, fill systems, or drain/overflow systems. Nor

is it responsible for damage to the bath which occurs during installation.

CAUTION: A nonflammable protective barrier must be placed between soldering work and bath unit to prevent damage to the bath.

Clean-Up After Installation

To avoid dulling and scratching the surface of the bath, never use abrasive cleaners. A mild liquid detergent and warm water w ill clean soiled

surfaces.

Remove spilled plaster with a wood or plastic edge. Metal tools will scratch the surface. Spots left by plaster or grout can be removed if lightly

rubbed with detergent on a damp cloth or sponge.

Major scratches and gouges which penetrate the acrylic surface will require refinishing. Contact your Jacuzzi Whirlpool Bath dealer for

special instructions.

Jacuzzi Whirlpool Bath© K272000AC 12/04

16

Page 23

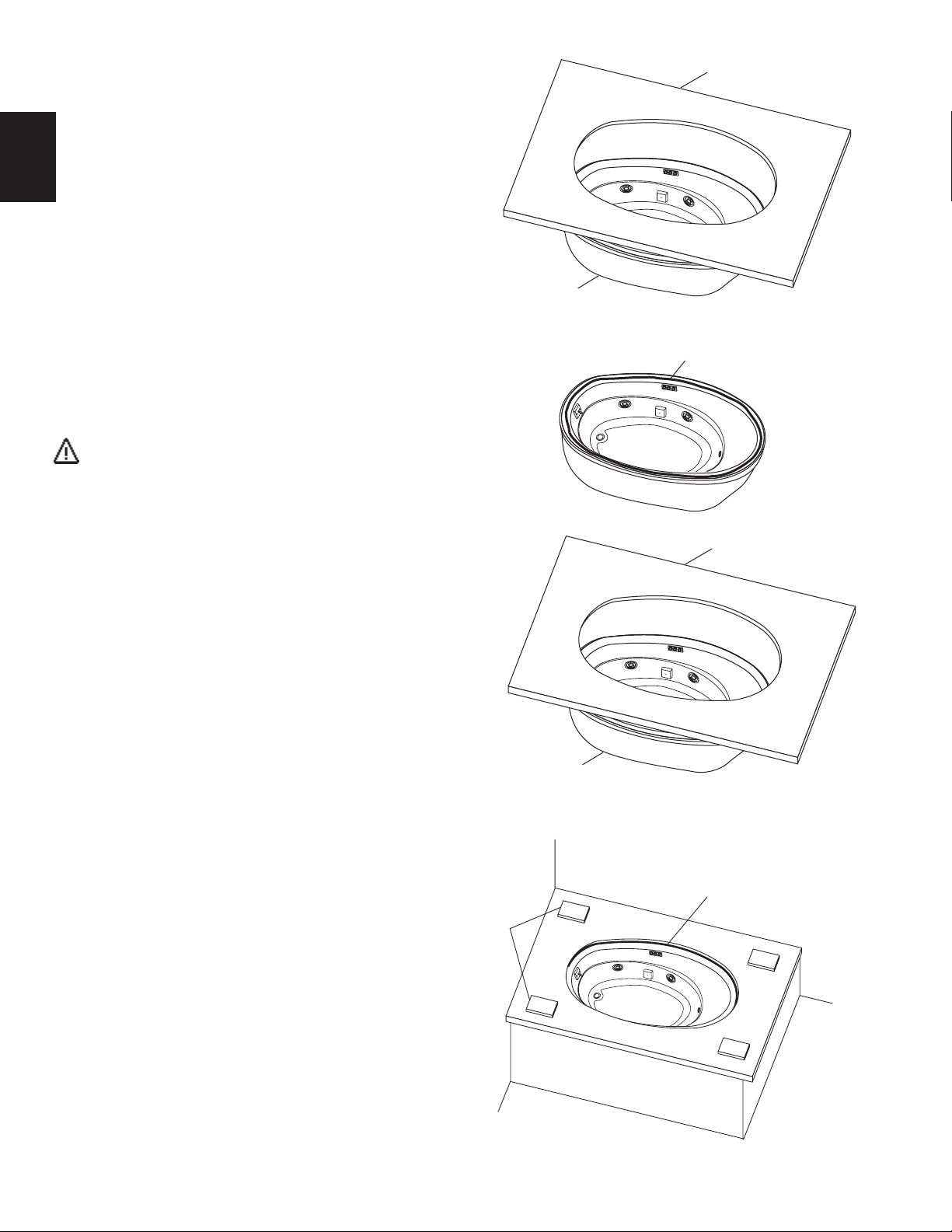

UNDERMOUNT INSTALLA TION INSTRUCTIONS

T

TEMPLATE

STUD WALL

COUNTER

COUNTER

Installation

A typical installation will have these construction characteristics.

MORTAR*

Unit Protection

*MORTAR MUST BE IN CONTACT WITH ALL FOAM FEE

If protective film has been removed, reapply film. For added protection, place a drop cloth or other material in the bottom

of bath for protection. Be careful not to scratch the bath surface.

Counter Preparation

NOTE: On pump/motor side of bath, the counter should extend a minimum of 4" past the outer edge of bath, in order

to clear the pump/motor plumbing extending beyond the rim of the bath.

MOTOR/PUMP

COUNTER

ENGLISH

INSIDE EDGE

OF RIM

COUNTER

Position the template so that the cutout oval aligns with

the rim edge.

A

BATH RIM

B

C

In this position, using a grease pencil, mark on the bath

the center line positions through the cut out slots. Remove template. Measure from marked center lines to a

D

fixed point such as a wall.

MEASURE FROM

CENTERLINE

MARKS TO WALL

Transfer these measurements to counter and mark center lines positions. Position template and cut counter for the

desired offset.

A

TEMPLATE

B

C

D

COUNTER

BATH RIM

OFFSET

After cutting is complete, perform any needed routing, edge work or polishing to the counter.

17

Jacuzzi Whirlpool Bath© K272000AC 12/04

BATH RIM

Page 24

UNDERMOUNT INSTALLATION INSTRUCTIONS

APPLY SILICONE

P

T

Position the counter on top of the bath to ensure correct

fit and appearance. Make any adjustments that may be

necessary. Remove the counter.

ENGLISH

Adhering Counter to Bath

Clean any dirt or debris from the bath rim. Do not use

abrasive cleaners.

Where the counter will make contact with top of the bath

rim, apply a bead of silicone sealant.

CAUTION: Do not use an adhesive or adhesive

sealant to secure the counter to the bath rim. If

maintenance or remodelling is required the counter

may have to be removed. Adhesive will permanently

bond the counter to the bath. This will make removal

difficult and costly and may cause damage to the

counter or bath.

COUNTER

BATH

SEALANT TO TO

OF BATH RIM

COUNTER

Carefully position the counter onto the bath rim. The

counter will need to be held in place while the sealant

cures. Follow the manufacturer's instructions to determine time required for curing.

Apply a continuous bead of silicone sealant around the

entire seam between the counter and bath rim. Allow

sealant to skin over or cure before cleaning the counter

or bath.

BATH

APPLY SILICONE SEALAN

WEIGHTS

Jacuzzi Whirlpool Bath© K272000AC 12/04

18

Page 25

T

OPERATING INSTRUCTIONS

Operation

Note: These instructions pertain to all bath products manufactured by Jacuzzi Whirlpool Bath. Not all features discussed

in this instruction pamphlet apply to all baths.

All baths manufactured by Jacuzzi Whirlpool Bath are designed

for "fill and drain," which means the bath should be drained after each

use and filled with fresh water by the next bather. This is a health

precaution, as these baths are not designed to hold water continuously like pools or spas.

Once the bath is installed, remove any residue or foreign materials left over from construction. Use turpentine or paint thinner to remove stubborn stains, paint or tar. Other dirt can be cleaned off with

a mild liquid detergent on a damp cloth. Scrape off plaster with a

wooden or plastic edge; do not use metal scrapers, wire brushes

or other metal tools, as they will damage the bath's surface.

Water Level

Close the drain and fill the bath until water is at least 1" above the

highest jet (see water line indicated in the illustration). Do not turn

on the whirlpool system at any time if the jets are not completely

immersed in water. Running the whirlpool system when there is

insufficient water in the bath could result in water spraying outside

the bath area. Running the whirlpool system without water will damage the recirculating pump.

Do not immerse the control panel by overfilling the bath.

FILL TO AT LEAST

1" ABOVE HIGHEST JET

Magic Touch® Whirlpool Switch

The Magic Touch Whirlpool ON/OFF switch, conveniently located

on the bath, allows you to turn the whirlpool system on and off while

in the bath. Simply push down on the switch button to turn on the

whirlpool system. To turn the system off, push down on the button

again.

If your bath has an optional Jacuzzi Whirlpool Bath wall mounted

timer, set it for the amount of time you wish the whirlpool to operate.

Note: When you desire less than 10 minutes of whirlpool action, it is

necessary to turn the timer knob clockwise past the number 10 and

then back to the desired amount. If the whirlpool action does not

begin when the timer is correctly set, it is necessary to push the

Magic Touch switch button.

WHIRLPOOL ON/OFF SWITCH

P

L

O

R

I

ON/OFF

O

L

DEPRESS CENTER ON/OFF

W

H

RapidHeat Operation

Once the heater is installed and the whirlpool pump is operating,

the heating function is totally automatic. The heater will help maintain the temperature of the water in the bath.

ENGLISH

Vacuum Switch

The heater is equipped with a preset vacuum switch which will not

1"

allow the heater to turn ON if the pump is not running with water

flowing through the whirlpool system.

High-Limit Switch

The heater includes an exclusive High-Limit switch. This safety

circuit will not false trip from hot tap water. It will only turn off the

heater if the thermostat fails. To reset, press the button. If the highlimit trips frequently, contact your Authorized Electrical/Mechanical

Service Provider. Visit our web site at http://www.jacuzzi.com/ to

find a Service Provider.

YPICAL BATH FITTINGS

MAGIC TOUCH WHIRLPOOL

ON/OFF SWITCH

AIR CONTROL

KNOBS

FULLY ADJUSTABLE JETS

SUCTION

COVER

High-Limit RESET SWITCH

WATER RAINBOW

FILL SPOUT (OPTIONAL)

DRAIN/OVERFLOW

(OPTIONAL)

19

Jacuzzi Whirlpool Bath© K272000AC 12/04

Page 26

Controlling Whirlpool Action

T

The whirlpool action in your bath is influenced by three factors –

direction of flow, force of water, and force of air. All whirlpool baths

manufactured by Jacuzzi Whirlpool Bath are equipped with adjustable PowerPro® jets, that may be adjustable for one or more of the

three factors.

Direction: To change the direction of the water flow, swivel the

jet nozzle to the desired angle. The jets can be directed individually

ENGLISH

toward any location on your body to provide a hydromassage. The

jets can also be adjusted so that they all point in the same direction

(clockwise or counterclockwise) to circulate the water in a circular

motion around the bath, causing a total whirlpool effect.

Water Force: The high volume, fully adjustable jets can be adjusted to control the force of the water coming into the bath. For

robust action, increase the force of the flow by rotating the jet handles

to the left (counterclockwise). For a more gentle effect, rotate the

handles to the right (clockwise). Never run the whirlpool system

with all the jets closed.

Force of Air: T wo knobs located on the bath serve as controls for

the air induction system. The intensity of the hydromassage whirlpool action is determined by the amount of air inducted into the water.

As the amount of air is increased, the hydromassage action increases.

For maximum air induction, rotate the control knobs fully counterclockwise to the largest circles. For fewer air bubbles, decrease the

amount of air induction by rotating the control knob clockwise. When

the knobs are turned to the smallest circles, only water is being circulated.

JETS

DIRECTIONALLY

ADJUSTABLE

AIR INDUCTION CONTROLS

URN CLOCKWISE TO

REDUCE AIR FLOW

FULLY

ADJUSTABLE

TURN COUNTER-CLOCKWISE

TO INCREASE AIR FLOW

20

Jacuzzi Whirlpool Bath© K272000AC 12/04

Page 27

MAINTENANCE INSTRUCTIONS

Cleaning the Bath

To clean your bath, simply use a mild, nonabrasive liquid detergent solution. Y ou can protect and restore the gloss to a dulled acrylic

surface by applying an acrylic polish or automotive paste wax.

Never use abrasive household cleaners on any Jacuzzi Whirlpool Bath product.

Repairs to the Surface

Major scratches and gouges which penetrate the acrylic surface

will require refinishing. Contact your Jacuzzi Whirlpool Bath dealer

for special instructions.

Purging the Whirlpool System

NOTE: THE WHIRLPOOL SYSTEM SHOULD BE PURGED AT

LEAST TWICE A MONTH

To remove accumulations of bath residue from the whirlpool system,

it is recommended that the whirlpool bath be purged at least twice a

month. For best results, however, we recommend that you purge your

whirlpool bath after each use using our exclusive two-part plumbing

system cleaner made specifically for whirlpool baths.

Systems Clean ™ i s available through an authorized Jacuzzi Whirlpool Bath Distributor or by calling us direct at 1-800-288-4002.

Instructions for use: Immediately after bathing and exiting the

whirlpool bath, leave the bath water in the tub and add hot water, if

necessary, so the water is at least 2" above the highest jet. Turn on

the unit without the aerator. Pour the contents of the Systems Clean

Packet 1 (taking care not to get the material on yourself) into the bath

near the intake for the circulation pump. Repeat same process with

Systems Clean Packet 2. It is important to use Packet 1 before

Packet 2 to avoid a strong odor. Run the bath for 5 to 10 minutes.

Drain completely and rinse any residue.

If you have followed the standard purging instructions above and still

have an excess accumulation of bath residue and desire an alternative

cleaning mechanism, we recommend SUPER SYSTEMS CLEAN

PLUS manufactured by Stearns Packaging to rectify this condition.

This may be obtained by contacting us at l-800-288-4002. It is

recommended that you follow the instructions provided by the manufacturer with the product. Repeated use may be necessary. SUPER

SYSTEMS CLEAN PLUS does not replace the necessity to regularly

purge your whirlpool system with Systems Clean as recommended.

(For additional information about water content, contact us for a copy

of the Jacuzzi Water Quality Primer.)

Suction Cover/Strainer Maintenance

Clean the suction cover/strainer of hair and debris when necessary. To do this, remove the center screw and detach the square

cover. Clean the cover by backflushing debris from the holes. Replace the suction cover immediately after cleaning. When reinstalling, orient the cover/strainer with the small notch at the bottom. The

gasket must be inserted into the groove of the cover/strainer before

reinstalling onto the suction fitting.

CAUTION: Keep hair a minimum of 6 inches away from the suction fitting at all times when the whirlpool system is operating.

Hair longer than shoulder length should be secured close to the

head, or a bathing cap should be worn. Do not operate the whirlpool system with the suction cover removed! It is a safety device and must always be in place on the suction fitting to minimize the potential hazard of hair and body entrapment.

SUCTION COVER/STRAINER ASSEMBLY

COVER STRAINER

SUCTION

FITTING

SCREW

NOTCH

GASKET

Lamp

An optional lamp kit is available from your Jacuzzi Whirlpool Bath

dealer for installation on your bath.

When the bulb burns out, replace it from the back of the lamp

fitting, on the underside of the shell, by pulling out the bulb receptacle. Replacement bulbs (12V, 7W) are available from your Jacuzzi

Whirlpool Bath dealer.

LIGHT BULB REPLACEMENT

LOCKING NUT

ENGLISH

Bath Additives

NOTE: DO NOT USE OIL OR OIL BASED BATH ADDITIVES.

If you want to use any kind of bath additive, use only a small amount

of low-foaming powder or crystal substance; the whirlpool action

intensifies the foaming properties of soaps.

The use of certain bath oils, bubble baths and bath additives may

increase the level of accumulations of bath residue in the whirlpool

system. If excess accumulations persist, you should discontinue use

of these products.

LIGHT BULB

BULB RECEPTACLE

LIGHT BEZEL

SHELL

21

Jacuzzi Whirlpool Bath© K272000AC 12/04

Page 28

General Whirlpool Bath Troubleshooting Guide

PROBABLE CAUSES PROBLEM REMEDY

ENGLISH

Pump/Motor does not start.

Pump/Motor operates but no fully

adjustable jets are functioning.

Pump/Motor operates but air is not

injected into water.

Pump/motor does not shutoff.

No power to pump/motor.

Pump/motor not plugged in.

Magic Touch switch - air tube not

connected to switch or to air switch

on pump/motor.

Pump/motor faulty.

Jets are closed.

Suction cover may be clogged.

Air valves closed.

Magic Touch switch - air tube not

connected to switch or to air switch

on pump/motor.

If a wall timer is used, the timer is

defective

Reset GFCI.

Insert plug fully into outlet.

Reconnect tube to Magic Touch switch

or to air switch pump/motor.

Replace pump/motor assembly.

Open jets by rotating counterclockwise.

With motor turned off, remove safety

cover and remove any debris. Replace

suction cover before operating.

Open air control valves.

Reconnect tube to Magic Touch switch

or to air switch pump/motor.

Replace timer.

Water leakage from pump unions.

Pump/motor shuts off by itself or with

wall timer, before set time elapses.

Note: If unit is within the warranty period, contact Jacuzzi Whirlpool Bath Service Support at 1- (800)- 288-4002 with bath's serial

number before work is started. The Serial Number is located on the Specification/Serial Number Plate. See page 30.

Overtightened, O-ring may be

pinched or improperly seated, under

tightened.

Motor thermal protection has deactivated pump/motor due to overheating. (Supply voltage low.)

GFCI tripped.

Inadequate supply wiring.

Untighten unions check and reseat Oring. If O-ring has been pinched out of

shape, replace (refer to Service Support

number below). When tightening union

nuts, hand tighten only.

Let motor cool; thermal protection will

reset. Check for proper ventilation.

(Check supply voltage.)

Reset GFCI. If it continues to trip do not

use this unit. Disconnect the unit and

have the problem corrected by a

licensed electrician before using.

Consult a licensed electrician to correct

wiring to unit.

Jacuzzi Whirlpool Bath© K272000AC 12/04

22

Page 29

REPAIR PARTS

(When ordering parts substitute a color code for the XXX.)

BMH JET

BMH JET ASSEMBLY 8489XXX

RETAINER NOZZLE 8412XXX*

NOZZLE BMH 8413XXX*

O RING 8488000

INTERNAL O RING SEAT 8487XXX*

JET BODY 8411XXX*

HTC JET

ENGLISH