Jacobsen Zero Turn Rotary Mower, ZT90009, ZT90013, ZT90014, ZT90017 Safety, Operation & Maintenance Manual

...

Safety, Operation, & Maintenance Manual

WARNING

Warning: If incorrectly used, this machine can

cause severe injury. Those who use and maintain

this machine should be trained in its proper use,

warned of its dangers, and must read the entire

manual before attempting to set up, operate, adjust,

or service the machine.

700489-Rev A

Zero Turn Rotary Mower

®

ZT90009 – RZT 3172KW, 72 Inch (183 cm) Cutting Unit

ZT90011 – RZT 2550KW, 50 Inch (127 cm) Cutting Unit

ZT90012 – RZT 2750EFI, 50 Inch (127 cm) Cutting Unit

ZT90013 – RZT 2760KW, 60 Inch (152 cm) Cutting Unit

ZT90014 – RZT 2760EFI, 60 Inch (152 cm) Cutting Unit

ZT90017 – RZT 3172EFI, 72 Inch (183 cm) Cutting Unit

GB

1 CONTENTS

1Contents

Contents

Introduction

2.1 Important.............................................................................2

2.2 Product Identification...........................................................3

2.3 Serial Numbers ...................................................................3

2.4 Guidelines for the Disposal of Scrap Products....................4

Safety

3.1 How to Operate Safely........................................................5

Specifications

4.1 Engine Specifications........................................................10

4.2 Dimensions and Weights ..................................................11

4.3 Mower Specification..........................................................13

4.4 Cutting Unit Specification..................................................13

4.5 Belt Specification...............................................................13

4.6 Recommended Lubricants ................................................14

4.7 Slopes ...............................................................................14

4.8 Accessories.......................................................................15

4.9 Support Literature .............................................................15

Decals

5.1 Safety Decals....................................................................16

5.2 Instruction Decals..............................................................18

Controls

6.1 Mower Controls.................................................................19

6.2 Control Panel ....................................................................20

6.3 Steering Control Levers ....................................................22

6.4 Parking Brake....................................................................22

6.5 Cutting Unit HOC Pedal ....................................................23

6.6 Lift Stop Lever...................................................................23

6.7 Operator Controlled Discharge Chute...............................23

Operation

7.1 Daily Inspection.................................................................24

7.2 Interlock System................................................................25

7.3 Operating Procedure.........................................................26

7.4 Starting The Engine ..........................................................27

7.5 To Stop The Engine ..........................................................27

7.6 Driving...............................................................................28

7.7 Height of Cut .....................................................................29

7.8 Mowing..............................................................................29

7.9 Mowing On Slopes............................................................30

7.10 Towing The Mower..........................................................32

Maintenance and Lubrication Charts

8.1 Maintenance Chart............................................................33

8.2 Lubrication Chart...............................................................34

8.3 Fluid Requirements...........................................................34

Maintenance

9.1 General Precautions .........................................................35

9.2 Engine...............................................................................35

9.3 Engine Oil .........................................................................36

9.4 Engine Air Filter ................................................................37

9.5 Engine Exhaust.................................................................37

9.6 Fuel ...................................................................................38

9.7 Charge the battery ............................................................38

9.8 Battery...............................................................................39

9.9 Hydraulic Hoses................................................................40

9.10 Hydraulic Fluid ................................................................41

9.11 Hydraulic Filter ................................................................41

9.12 Tires ................................................................................42

9.13 Wheel Mounting Procedure ............................................42

9.14 Folding ROPS .................................................................43

9.15 Air Cooling System .........................................................44

9.16 Inspecting Blades............................................................44

9.17 Sharpening Blades..........................................................45

9.18 Electrical System ............................................................45

9.19 Belts ................................................................................46

9.20 Care and Cleaning ..........................................................47

9.21 Mower Storage................................................................48

Adjustments

10.1 General Precautions .......................................................49

10.2 Belt Adjustment...............................................................49

10.3 Forward Speed Limit Screws ..........................................50

10.4 Torque Specification .......................................................51

Problem Solving

11.1 General ...........................................................................52

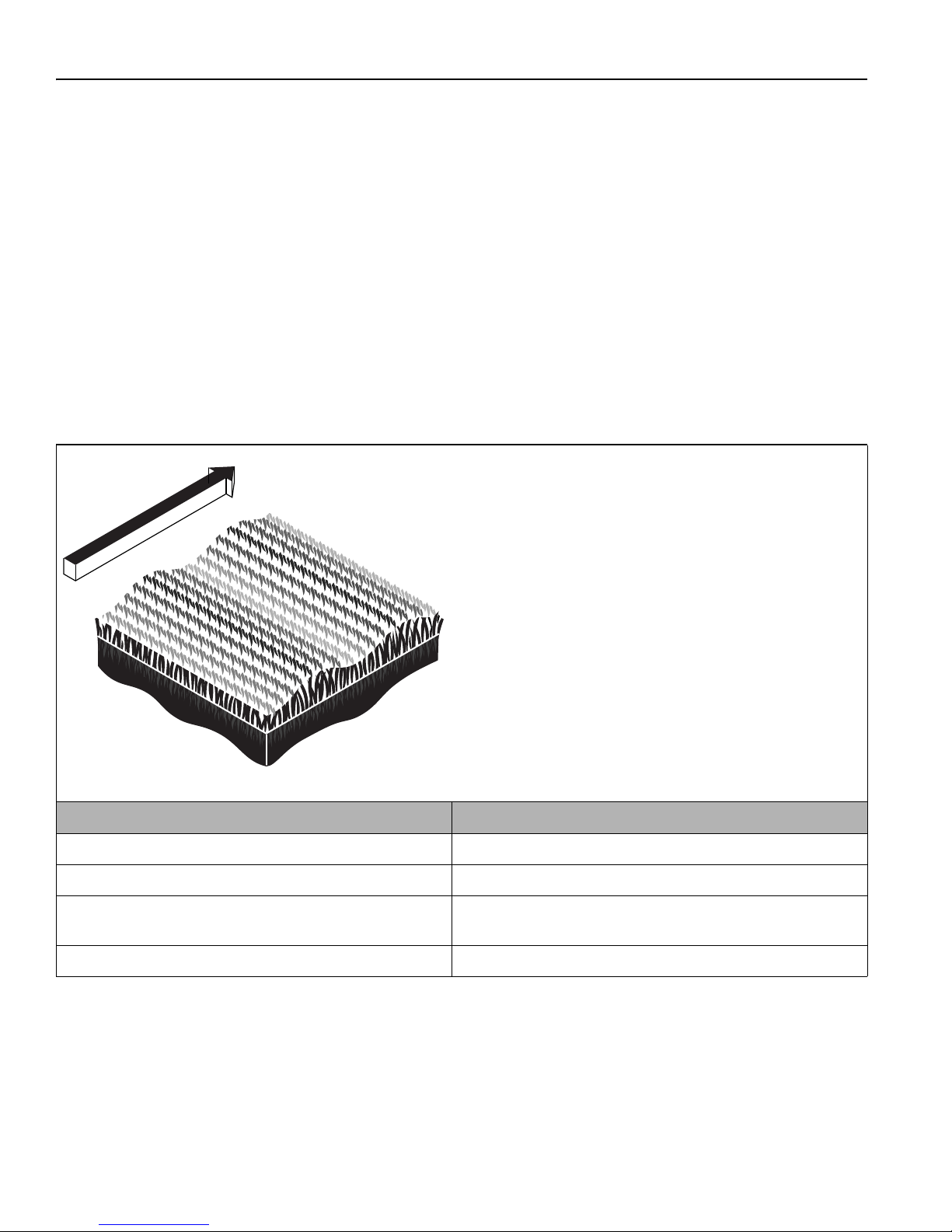

Quality of Cut

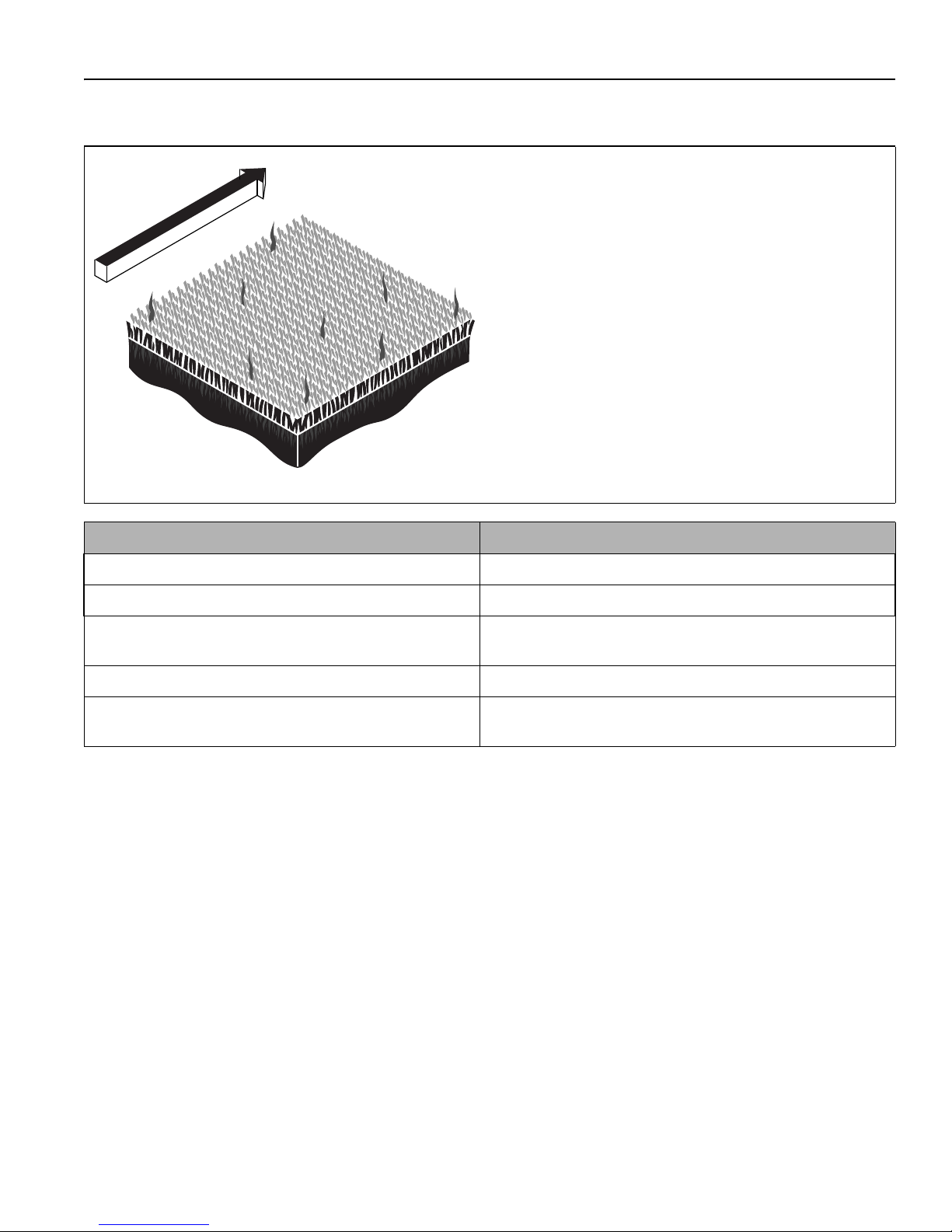

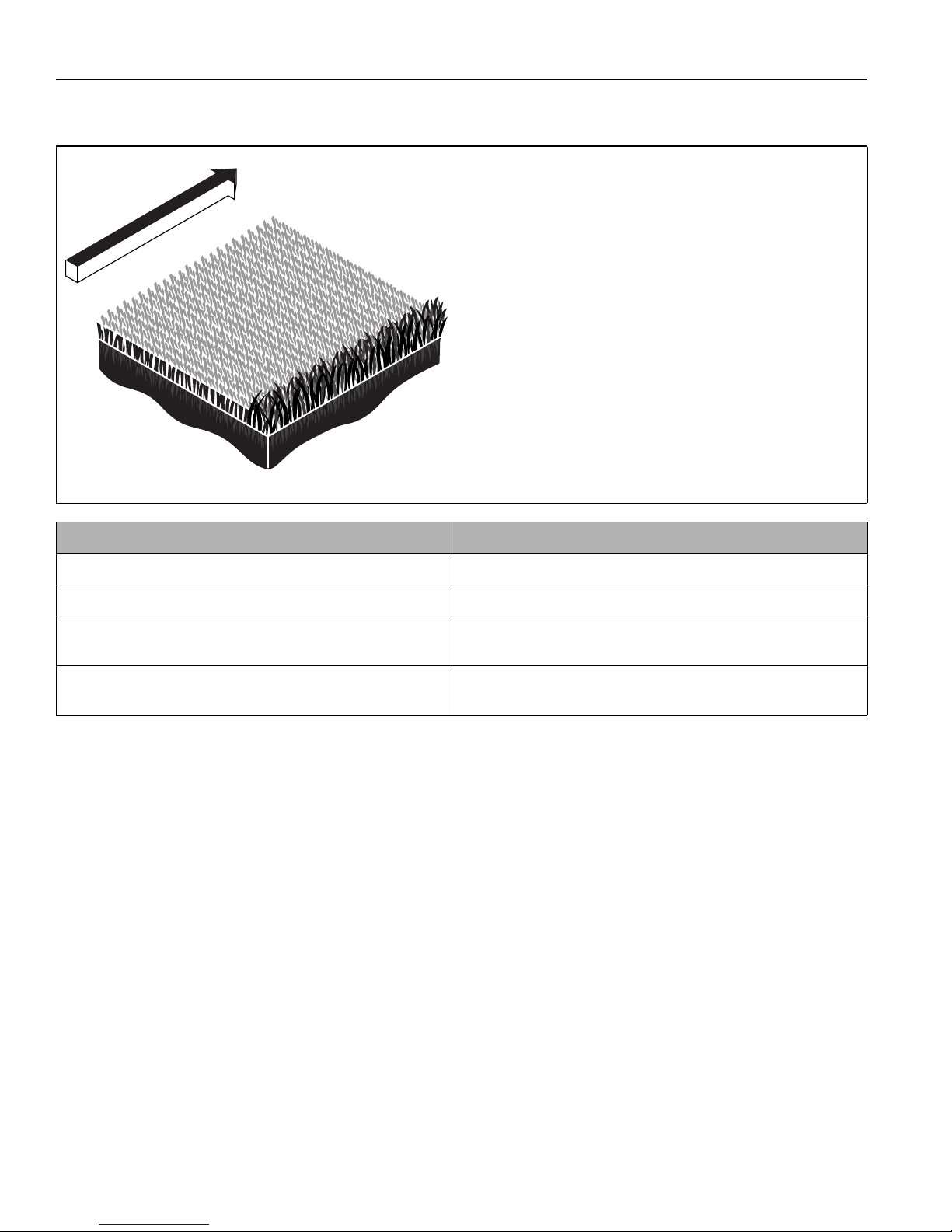

12.1 Quality of Cut Problem Solving .......................................53

12.2 Washboarding.................................................................53

12.3 Step Cutting ....................................................................54

12.4 Scalping ..........................................................................55

12.5 Stragglers........................................................................56

12.6 Streaks............................................................................57

12.7 Windrowing .....................................................................58

Notes

© 2015, Jacobsen, A Textron Company/Textron Innovations Inc.

“All rights reserved, including the right to reproduce this material

or portions thereof in any form.”

en-1

Proposition 65 Warning

This product contains or release

chemicals known to the State of

California to cause cancer and birth

defects or other reproductive harm.

Litho In U.S.A. 10-2015

INTRODUCTION 2

2Introduction

2.1 IMPORTANT ______________________________________________________________

The Jacobsen RZT 2550KW, RZT2750EFI, RZT2760KW, RZT 2760EFI, RZT 3172KW and RZT 3172EFI with a

Gasoline engine is a self propelled rotary mower.

If you follow all instructions in this manual, you increase the life of your mower and keep its maximum performance.

Adjustments and maintenance must always be done by an approved technician.

IMPORTANT: Do the maintenance included in this manual to make sure that the quality of cut is kept at a high level.

This SAFETY, OPERATION AND MAINTENANCE MANUAL is part of the mower and must stay with the mower always.

Suppliers of both original and used mowers need to keep the documentation that comes with the mower.

You must use the mower to cut the grass and not for any other purpose. Compliance with the conditions or operation,

service and repair specified by the manufacturer, are understood to be part of the correct use.

ALL operators MUST read through this manual and understand the Safety Instructions, controls, lubrication and

maintenance procedures.

Make sure that you obey all safety and road traffic regulations.

You must not make any changes to the mower that the manufacturer does not approve. This type of change can

release the manufacturer from the liability for any damage or injury.

When you discard worn parts, know the environmental result and use the systems available in the country where the

mower is used. When the mower is at its end of life, there are guidelines in this manual for the removal of the mower

from use.

Use only Jacobsen approved parts.

2006/42/EC

The instructions recorded here are the original instructions confirmed by Jacobsen, A Textron Company.

en-2

2 INTRODUCTION

MMMMMMMSSSSSS

BARCODE

Seven digit product code Six digit serial number

2.2 PRODUCT IDENTIFICATION_________________________________________________

Mower Serial number plate

A Product code and Serial number

Location of Mower Serial number plate

The serial number plate (A) is found on the right front caster wheel mount.

Engine Identification Numbers

The engine serial number is found on a label on the side of the engine.

2.3 SERIAL NUMBERS ________________________________________________________

Record the mower and engine numbers shown below:

Mower Number:_________________________

Engine Number:__________________________

en-3

INTRODUCTION 2

2.4 GUIDELINES FOR THE DISPOSAL OF SCRAP PRODUCTS _______________________

2.4.1 DURING SERVICE LIFE _____________________________________________________

The used oil, oil filters and engine coolant are hazardous materials. Follow the recommended procedures for their safe

removal.

If a fluid leaks, contain the spill to make sure that the leak does not flow into the ground or drainage system. Follow the

local laws to make sure that leaks are controlled safely.

The maintenance procedures in this manual make sure that the damage that the mower can cause in the local

environment is controlled safely.

Take these actions after the mower complete its full service life.

2.4.2 END OF SERVICE LIFE _____________________________________________________

Use these guidelines with applicable Health, Safety and Environmental laws. Always use the approved local waste

disposal and agencies for recycled materials.

• Park the mower in a location to use all of the necessary lifting equipment.

• Use the correct tools and Personal Protective Equipment (PPE) and take instruction from the technical manuals

applicable to the mower.

• Remove and keep correctly

1. Batteries

2. Fuel

3. Engine coolant

4. Oils

• Disassemble the structure of the mower and refer to the technical manuals. Give attention to parts that have

mechanical pressure or tension applied to the part in the mower, including springs.

• Separate items that continue to have service life and returned to storage.

• Separate items that are worn into the material groups and removed according to the agencies for the recycled

materials that are available. Common types are as shown:

• Steel

• Non ferrous metals

• Aluminum

• Brass

• Copper

• Plastic Materials

• Identified

• Can be recycled

• Can not be recycled

• Not Identified

• Rubber

• Electrical and Electronic Components

• Add items that can not be easily separated into different materials to the “General discarded materials” area.

• Do not burn the discarded materials

Change the mower records to show that the mower is not in service and is discarded. Supply this serial number to

Jacobsen Warranty Department to close their records.

en-4

3 SAFETY

!

3Safety

3.1 HOW TO OPERATE SAFELY ______________________________________________________

WARNING

EQUIPMENT OPERATED INCORRECTLY OR WITHOUT TRAINING CAN BE DANGEROUS.

Know the location and correct operation of controls. Operators without experience must receive instruction from

another person that knows the correct operation of the equipment before you operate the mower.

Only use parts, accessories and attachments approved by Jacobsen.

3.1.1 SAFE OPERATION

a Read the Operator’s Manual and other training material. If the operator or technician can not read this manual,

the owner is responsible to describe this material to the operators and technicians. Manuals in additional

languages may be available on the Jacobsen or RansomesJacobsen website.

a Read all of the instructions for this mower carefully. Know the controls and the correct operation of the

equipment.

b Children or persons who do not understand these instructions must not use the mower. The local regulations can

limit the age of the operator.

c Never use a mower near persons, including children or animals.

d Remember that the operator or owner is responsible for accidents or hazards that occur to other persons or their

property.

e Never carry passengers.

f Never allow persons to operate or service the mower or its attachments without correct instructions.

g Do not operate equipment while tired, sick or after you use alcohol or drugs.

3.1.2 PREPARATION

a When you operate the mower, wear correct clothing, slip resistant work shoes or boots, work gloves, hard hat,

safety glasses and hearing protection. Long hair, loose clothing or jewelry can be caught in moving parts.

b Do not operate the equipment with the Interlock System disconnected or the system does not operate correctly.

Do not disconnect or prevent the operation of any switch.

c Never operate equipment that is not in correct order or without decals, guards, shields, deflectors or other

protective devices fastened.

d Inspect the mower before you operate the mower. Check the tire pressure, the engine oil level, and the fuel level.

Fuel is flammable. Use caution when you add the fuel to the mower.

e Operate the mower in daylight or in good artificial light. Use caution when you operate the mower during bad

weather. Never operate the mower with lightning in the area.

f Inspect the area to select the accessories and attachments that are needed to correctly and safely do the job.

Only use parts, accessories and attachments approved by Jacobsen.

g Be careful of holes in the terrain and other hazards that are not visible.

h Inspect the area where the equipment is operated. Remove all objects you can find before you operate. Be

careful of obstructions above the ground (low tree limbs, electrical wires) and also underground obstacles

(sprinklers, pipes, tree roots). Enter a new area carefully. Look for possible hazards.

i Inspect the cutting system before you start the mower. Make sure the blades are free to rotate. When you rotate

one blade, other blades can rotate.

en-5

SAFETY 3

3.1.3 OPERATION

a Never operate the engine without enough ventilation or in an enclosed area. The carbon monoxide in the exhaust

fumes can increase to dangerous levels.

b Never carry passengers. Keep other persons or animals away from the mower.

c Disengage all drives and engage the parking brake before you start the engine. Only start the engine with the

operator in the seat. Never start the engine with persons near the mower.

d Keep your legs, arms and body inside the operator compartment while the mower is in operation. Keep your

hands and feet away from the cutting units.

e Do not use on the slopes greater than the safe slope limit for the equipment.

f To guard against over turning or loss of control:

– Operate the mower up and down on the face of slopes (vertically), but not across the face (horizontally).

– Do not start or stop suddenly on slopes.

– Decrease the speed when you operate on slopes or when you must turn. Use caution when you change

direction. Turf condition can change the mower stability.

– Use caution when you operate the mower near drop-offs, ditches or embankments.

– Be careful of holes in the terrain and other hazards that are not visible.

g When you drive in the reverse direction, look behind you and down to make sure the path is clear. Do not operate

the cutting unit when you drive in the reverse direction.

h Use caution when you go near corners, trees or other objects that can prevent a clear view.

i Equipment must meet the current regulations to be driven on the public roads.

j Before you move across or operate on the paths or roads, turn off the PTO switch, lift the cutting unit and travel at

decreased speed. Look for traffic.

k Stop the blades when the mower is on any surface that is not grass.

l Do not release the cut grass in the direction of persons or allow persons near the mower while in operation.

m Do not operate the mower with damaged guards or without safety devices in position.

n Do not change the engine governor setting or over-speed the engine. Never change or tamper with adjusters that

are closed with a seal for the engine speed control.

o Before you leave the operator compartment, for any reason:

– Disengage all the drives and lower the cutting unit to the ground.

– Engage the parking brake.

– Stop the engine and remove the key.

p When you hit an object or mower starts to cause the vibration that is not normal, inspect the mower for damage

and make repairs.

q Decrease the throttle setting before you stop the engine.

r Do not use this equipment for uses that the mower was not made for.

en-6

3 SAFETY

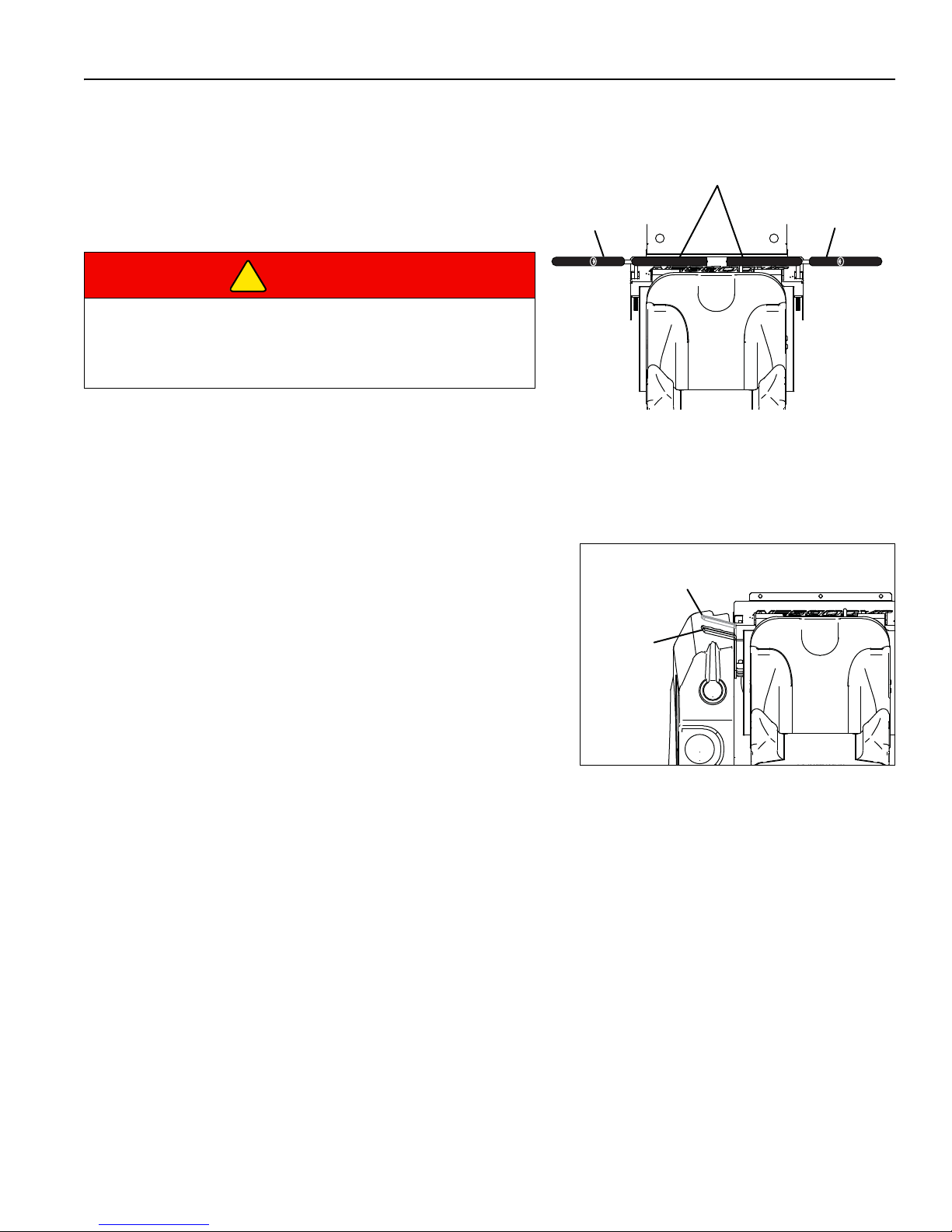

3.1.4 ROPS

a The ROPS is a safety device. Keep the ROPS in the vertical and locked position. Always use the seat belt when

you operate the mower. Make sure the seat belt can be released quickly in an emergency.

b Only operate the mower with the ROPS in the folded position on flat and level surfaces when necessary. Do not

operate the mower with the ROPS in the folded position on slopes, near sharp edges or near water. There is no

roll over protection with the ROPS in the folded position.

c Check for clearance before you drive below objects. Do not contact tree branches, electrical wires or other

objects with the ROPS.

d Do not use the seat belt with the ROPS in the folded position.

e Inspect the ROPS for damage. Keep the ROPS hardware fastened.

f Do not weld, drill, change or bend the ROPS. Replace a damaged ROPS. Do not try to correct a damaged

ROPS.

g Do not remove the ROPS from the mower.

h Jacobsen must approve any changes to the ROPS.

3.1.5 SAFE HANDLING OF FUELS

a The fuel and the fuel vapors are flammable. Use caution when you add the fuel to the mower. The fuel vapors

can cause an explosion.

b Never use the containers that are not approved to keep or transfer fuel.

c Never keep the mower or fuel containers near an open flame or any device that can cause the ignition of fuel or

fuel vapors.

d Never fill the fuel containers inside a vehicle or on a truck or trailer with a plastic liner. Always put the fuel

container on the ground away from your vehicle before you fill the container.

e Refuel the mower before you start the engine. When the engine is in operation or while the engine is hot, never

remove the fuel cap or add fuel to the mower.

f Refuel outdoors only and do not smoke when you add fuel. Extinguish all types of ignition.

g The fuel nozzle must touch the rim of the fuel tank when you add fuel to the mower. Do not use a device to lock

the fuel nozzle in the open position.

h Do not over fill the fuel tank. Leave at least 1 inch (2.5 cm) below the filler neck.

i Always tighten the fuel tank cap and container cap after you add fuel.

j If the fuel spills on your clothing, change your clothing immediately.

3.1.6 MAINTENANCE AND STORAGE

a Before you clean, adjust or repair this equipment, push PTO switch to the OFF position, lower the cutting unit to

the ground, engage the parking brake, stop the engine and remove the key.

b Make sure the mower is parked on a solid and level surface.

c Never work on a mower that is lifted only by the jack. Always use the jack stands.

d Never allow persons to service the mower or its attachments without correct instructions.

e When the mower is parked, put into storage or left without an operator, lower the cutting device unless a positive

mechanical lock is used.

f When you put the mower on a trailer or put the mower in storage, close the fuel valve. Do not keep fuel near

flames or drain the fuel inside a building.

en-7

SAFETY 3

g Disconnect the battery before you service the mower. Always disconnect the negative battery cable before the

positive battery cable. Always connect the positive battery cable before the negative battery cable.

h Charge the battery in an area with good airflow. The battery can release hydrogen gas that is explosive. To

prevent an explosion, keep any device that can cause sparks or flames away from the battery.

i Disconnect the battery charger from the power supply before you connect or disconnect the battery charger to

the battery. Wear protective clothing and use insulated tools when you service the battery.

j Be careful and wear gloves when you check or service the cutting unit blades. Replace any damaged blades, do

not try to correct a damaged blade.

k Keep your hands and feet away from parts that move. Do not adjust the mower with the engine in operation,

unless the adjustment needs the engine in operation.

l Carefully release the pressure from components with stored energy.

m To prevent injury from the hot, high pressure oil, never use your hands to check for oil leaks. Use the paper or

cardboard to find leaks.

n The hydraulic fluid pressure can have enough force to enter your skin. If hydraulic fluid has entered your skin, a

doctor must remove the hydraulic fluid surgically within a few hours or gangrene can occur.

o When you service the hydraulic system, make sure the hydraulic fittings, tubes and hoses are tightened to the

correct torque. Make sure the hydraulic system is in good condition before you start the engine.

p Keep the mower and the engine clean.

q Allow the engine to become cool before storage and always remove the ignition key.

r Keep all nuts, bolts and screws tight to make sure the equipment is in safe condition.

s Replace worn or damaged parts for safety. Replace damaged or worn decals. Only use parts, accessories and

attachments approved by Jacobsen.

t To decrease the fire hazard, remove materials that burn from the engine, muffler, battery tray and fuel tank area.

u Disconnect the battery and controller connectors before you weld on this mower.

3.1.7 WHEN YOU PUT THE MOWER ON A TRAILER

a Be careful when you load or unload the mower on a trailer. Trailer must be wider than the mower and can carry

the weight of the mower.

b Use a full-width ramp to load or unload the mower on a trailer.

c Use straps, chains, cables or ropes to fasten the mower to the trailer. Both front and rear straps must be sent

down and toward sides of trailer.

d Make sure that all latches are correctly fastened.

en-8

3 SAFETY

!

!

3.1.8 IMPORTANT SAFETY NOTES _______________________________________________

This safety alert symbol gives a warning of possible hazards.

DANGER - Indicates a dangerous condition that WILL cause death or injury unless it is prevented.

WARNING - Indicates a dangerous condition that CAN cause death or injury unless it is prevented.

CAUTION - Indicates a dangerous condition that can cause injury and property damage unless it is prevented. The

label can indicate work procedures that are not safe.

NOTICE - Indicates a condition that can cause damage to the property unless it is prevented. The label can indicate

work procedures that are not safe.

Some illustrations in this manual show the shields, guards or plates, removed. Do not operate this equipment without

these devices correctly fastened in position.

WARNING

The Interlock System on this mower prevents the operation of the mower

unless a.) The parking brake is engaged. b.) The PTO switch is in the OFF

position and c.) The steering control levers are in the Neutral position. The

system will stop the engine if the operator leaves the operator position

without:

a.) The parking brake engaged

b.) The steering control levers in the Neutral position and

b.) the PTO switch in the OFF position.

NEVER operate the mower unless the Interlock System operates correctly.

WARNING

1. Before you leave the operator position, for any reason:

a. Return the steering control levers to Neutral.

b. Disengage all drives.

c. Lower the cutting unit to the ground.

d. Engage the parking brake.

e. Stop the engine and remove the ignition key.

2. Keep your hands, feet and clothing away from moving parts. Wait for all

movement to stop before you clean, adjust or service the mower.

3. Keep persons and animals away from the area of operation.

4. Never carry passengers.

5. Never operate the equipment without a correctly fastened grass

deflector in position.

If additional information or service is needed, contact your Authorized Jacobsen Dealer. Your Dealer knows the current

methods to service this equipment.

en-9

SPECIFICATIONS 4

4Specifications

4.1 ENGINE SPECIFICATIONS __________________________________________________

RZT 2550KW / RZT 2760KW / RZT 3172KW RZT 2750EFI / RZT 2760EFI / RZT 3172EFI

Make Kawasaki Kohler

Model RZT 2550KW: FX801V

RZT 2760KW: FX850V

RZT 2750 EFI / RZT 2760EFI: ECV850

RZT 3172EFI: ECV870

RZT 3172KW: FX921V

Type Four cycle, air cooled, V-Twin, OHV Four cycle, air cooled, V-Twin, OHV

Number of Cylinders 2 2

Bore and Stroke 3.33 in. (8.45 cm) x 2.99 in. (7.6 cm)

3.39 in. (8.6 cm) x 2.79 in. (7.09 cm)

3.50 in. (8.91 cm) x 3.15 in. (8.0 cm)

Total Displacement

RZT 2550KW / RZT 2760KW: 52 in

RZT 3172KW: 61 in

3

(0.999 l)

3

(0.852 l)

50.3 in

3

(0.824 l)

Intake System Naturally Aspirated Naturally Aspirated

Gross Intermittent

Power

RZT 2550KW: 25.5 hp (19.0 kW) @ 3600 RPM

RZT 2760KW: 27.0 hp (20.1 kW) @ 3600 RPM

27 hp (20.1 kW) @ 3600 RPM

31 hp (23.1 kW) @ 3600 RPM

RZT 3172KW: 31.0 hp (23.1 kW) @ 3600 RPM

Compression Ratio RZT 2550KW / RZT 2760KW: 8.2:1

8.9:1

RZT 3172KW: 8.4:1

Maximum Speed 3600 ± 100 rpm (No Load) 3600 ± 100 rpm (No Load)

Low Idle 1550 ± 100 rpm (No Load) 1750 ± 100 rpm (No Load)

Rotation Clockwise viewed at flywheel Clockwise viewed at flywheel

Fuel System 2 Barrel Float Feed Carburetor Electronic Fuel Injection (EFI)

Fuel 87 Octane Gasoline

Maximum 10% Ethanol

87 Octane Gasoline

Maximum 10% Ethanol

Ignition System Two magnetos triggered by flywheel magnets Two ECU Controlled Dual Plug Ignition Coils

Spark Plug NGK BPR4ES

Spark Plug Gap 0.030 Inch (0.76 mm) 0.030 Inch (0.76 mm)

Engine Oil (API

SF, SG, SH, SJ or SL SJ or higher

Class)

Oil Pan Capacity 2.1 quarts (2.0 l) 2.7 quarts (2.6 l)

Starter 12 Volt Electric Start 12 Volt Electric Start

Alternator 12 Volt, 15 Amp 12 Volt, 20 Amp

Dry Weight RZT 2550KW / RZT 2760KW: 124 lb. (56.4 kg)

136 lb. (61.7 kg)

RZT 3172KW: 138 lb. (62.6 kg)

Dimensions

(Length x Width x

19.21 x 18.27 x 24.65 in.

(48.8 x 46.4 x 62.6 cm)

19.7 x 20.5 x 24 in.

(50.65 x 47.07 x 60.9 cm)

Height)

Emission Regulation

en-10

4 SPECIFICATIONS

4.2 DIMENSIONS AND WEIGHTS________________________________________________

RZT 2550KW / RZT 2750EFI RZT 2760KW / RZT 2760EFI RZT 3172KW / RZT 3172EFI

A - Width of Cut 50 inch (127 cm) 60 inch (152.4 cm) 72 inch (182.9 cm)

B - Maximum

Width

C - Height

(ROPS Up)

D - Height

(ROPS Folded)

E - Total length

(ROPS Up)

F - Total length

(ROPS Folded)

G - Wheel Base 44.75 inch (113.7 cm)

H - Front Wheel

Tr ack

J - Rear Wheel

Tr ack

Weight of unit 1104 lb. (500.8 kg) 1215 lb. (551.1 kg)

54 inch (137.2 cm) 65 inch (165.1 cm) 75 inch (190.5 cm)

73 inch (185.4 cm)

48 inch (121.9 cm)

74 inch (188.0 cm)

94 inch (238.8 cm)

38.9 inch (98.7 cm)

39.2 inch (95.5 cm)

Tire Specifications

Front Wheel Rear Wheel

Tire Size Type Tire Pressure Tire Size Type Tire Pressure

13 x 6.5-6 N/A 24 x 12-12 Turf 8-10 psi (0.55-0.69 BAR)

en-11

SPECIFICATIONS 4

E

G

D

A

H

J

ZT 2760KW

ZT 2760EFI

ZT 2550KW

ZT 2750EFI

B

A

H

J

B

F

C

en-12

4 SPECIFICATIONS

4.3 MOWER SPECIFICATION ___________________________________________________

Battery: 12V, 300 CCA

Service Brake: Dynamic braking through the traction circuit

Parking Brake: Drum brakes on wheel motor

Fuel Tank: 8 U.S. Gallons (30.3 l)

Steering: Hand lever speed and direction controls for left and right rear wheel

Traction Drive: Belt driven dual hydrostatic 0.73 in

Cutting Unit Drive: Belt drive with electric clutch

Ground Speed: 0-12 mph (0-19.3 kph)

Reverse Speed: 0-8 mph (0-12.87 kph)

RZT 2550KW / RZT 2750 EFI Cutting Performance: Up to 4.04 acres/hr. (1.64 hectares/hr) @8 mph (12.87 km/hr)

RZT 2760KW / RZT 2760 EFI Cutting Performance: Up to 4.85 acres/hr. (1.96 hectares/hr) @8 mph (12.87 km/hr)

RZT 3172KW / RZT 3172 EFI Cutting Performance: Up to 5.82 acres/hr. (2.35 hectares/hr) @8 mph (12.87 km/hr)

3

(12 cm3) pumps and 14.5 in3 (238 cm3) wheel motors.

4.4 CUTTING UNIT SPECIFICATION _____________________________________________

RZT 2550KW / RZT 2750 EFI RZT 2760KW / RZT 2760 EFI RZT 3172KW / RZT 3172 EFI

Blade Length 17 inch (43.2 cm) 20-1/2 inch (54.3 cm) 24 inch (61.0 cm)

Number of blades 3

Height of cut 1-1/2 to 5 in. (3.8 to 12.7 cm) in 1/4 in. (0.6 cm) increments

Height of cut

adjustment

A foot lever to lift or lower the cutting unit with a HOC stop installed in different slots for

specified HOC.

Blade Tip Speed

@ 3600 rpm engine

speed

295.2 feet/second (90.0

meters/second)

4.5 BELT SPECIFICATION _____________________________________________________

Traction Belt Part Number 2006B64R, B-Section, Raw, 64 in. EL Belt

50 in. Deck Belt Part Number 2006B112R, B-Section, Raw, 112 in. EL Belt

60 in. Deck Belt Part Number 2006B130R, B-Section, Raw, 130 in. EL Belt

72 in. Deck Belt Part Number 2006B160R, B-Section, Raw, 160 in. EL Belt

50 in. Engine to Deck Belt Part Number 2010B81W, B-Section Wrapped, 81 in. Belt

60 in. Engine to Deck Belt Part Number 2010B85W, B-Section Wrapped, 85 in. Belt

72 in. Engine to Deck Belt Part Number 2010B92W, B-Section Wrapped, 92 in. Belt

en-13

284.8 feet/second (86.8

meters/second)

282.7 feet/second (86.2

meters/second)

SPECIFICATIONS 4

4.6 RECOMMENDED LUBRICANTS ______________________________________________

Engine Oil:

Kawasaki FX801V and FX850V: API Classification grades SF, SG, SH, SJ or SL

Temperature Viscosity

Above 95° F (35° C) SAE 40

68° to 95° F (20° to 35° C) SAE 30 or SAE 10W-30 or SAE 10W-40 or SAE 40

32° to 68° F (0° to 20° C) SAE 30 or SAE 10W-30 or SAE 10W-40

-4° to 32° F (-20° to 0° C) SAE 5W-20 or SAE 10W-30 or SAE 10W-20

Below -4° F (-20° C) SAE 5W-20

Kohler ECV850: API Classification grades SJ or higher

Temperature Viscosity

Above 75° F (24° C) SAE 20W-50

50° to 75° F (10° to 24° C) SAE 30 or SAE 20W-50

32° to 50° (0° to 10° C) SAE 10W-30 or SAE 20W-50

0° to 32° F (-18° to 0° C) SAE 5W-30 or SAE 10W-30

Below 0° F (-18° C) SAE 5W-30

Hydraulic Fluid:

The standard hydraulic fluid is SAE 15W40 API Classification SL.

Grease:

Texaco Starplex 2EP Moly (NLGI Grade 2-EP Lithium Complex Grease containing Molybdenum Disulfide) or

equivalent.

4.7 SLOPES _________________________________________________________________

DO NOT USE ON SLOPES GREATER THAN 15°. The 15° slope was calculated with static stability measurements

according to the requirements of BS EN ISO 5395-3.

en-14

4 SPECIFICATIONS

4.8 ACCESSORIES ___________________________________________________________

4.8.1 STRIPING KIT ____________________________________________________________

Kit Number 300329

4.8.2 BLACK HARD TOP SUNSHADE ______________________________________________

Kit Number 902750

4.8.3 WHITE HARD TOP SUNSHADE ______________________________________________

Kit Number 902749

4.8.4 BLACK SOFT TOP SUNSHADE ______________________________________________

Kit Number 902748

4.8.5 WHITE SOFT TOP SUNSHADE _______________________________________________

Kin Number 902747

4.8.6 ELECTRIC DECK LIFT______________________________________________________

Kit Number 300407

4.8.7 REPLACMENT BLADES ____________________________________________________

Standard 17 inch (43.2 cm) X-Blade Part Number 30227-50X (For 50 inch (127 cm) cutting unit)

Standard 20-1/2 inch (54.3 cm) X-Blade Part Number 30227-60X (For 60 inch (152 cm) cutting unit)

Standard 24 inch (61.0 cm) X-Blade Part Number 30227-72X (For 72 inch (183 cm) cutting unit

Optional 17 inch (43.2 cm) Twist Blade Part Number 30227-50T (For 50 inch (127 cm) cutting unit)

Optional 20-1/2 inch (54.3 cm) Twist Blade Part Number 30227-60T (For 60 inch (152 cm) cutting unit)

Optional 24 inch (61.0 cm) Twist Part Number 30227-72T (For 72 inch (183 cm) cutting unit

4.8.8 SPRINGER FORKS ________________________________________________________

Kit Number 100200

4.8.9 MAGIC MULCHER KIT______________________________________________________

Kit Number 30302

4.8.10 RUN FLAT TIRE KIT_______________________________________________________

Kit Number 400130

4.9 SUPPORT LITERATURE ____________________________________________________

Contact your Jacobsen Dealer for a complete listing of literature available for your mower.

Operator’s Manual: 700457

Mower Parts Manual: 700531

en-15

DECALS 5

DANGER

DO NOT OPERATE

WITHOUT GUARDS

Use of fan on outside spindle without pulley guard may

result in serious injury or DEATH.

PELIGRO

NO FUNCIONE SIN

PROTECTORES

El uso del ventilador en huso exterior sin

protectir de la polea puede dar lugar a

leslon o a muerte serla.

800056

800817

Read the manual

before you operate the

mower

Pick up sticks, stones

and other debris that

can be thrown by the

mower.

Wear eye protection

when you operate the

mower.

Wear ear protection

when you operate the

mower.

Keep bystanders away

from the mower.

Be careful of debris

thrown by the mower.

Use caution when you

operate on slopes.

Only operate on slopes

with the ROPS in the

vertical position.

Do not carry

passengers.

Serious injury or death can result from blade contact or from contacting

the belts or pulleys with the engine running. Deck spindles may have a

fan installed above or below the pulleys.

Do not operate the mower with the discharge chute or belt guards

removed. Make sure the Interlock System is operates correctly.

5Decals

5.1 SAFETY DECALS __________________________________________________________

Understand the purpose of these decals. The decals are important to the safe operation of the mower. REPLACE THE

DAMAGED DECALS IMMEDIATELY.

30229

en-16

5 DECALS

800818

MAX. FILL

800848

DO NOT OPERATE WITHOUT OPERATOR CONTROLLED

DISCHARGE CHUTE (OCDC), DISCHARGE DEFLECTOR,

ENTIRE GRASS COLLECTION SYSTEM, OR MULCHING

KIT IN PLACE. DO NOT REMOVE GRASS CATCHER

UNTIL BLADES HAVE STOPPED.

The OCDC should be in the

downward position when vulnerable

objects or property are in the vicinity

of the machine during operation.

97072

DANGER

Only fill the fuel tank to the bottom of

the fuel filler neck. Do not overfill the

fuel tank.

en-17

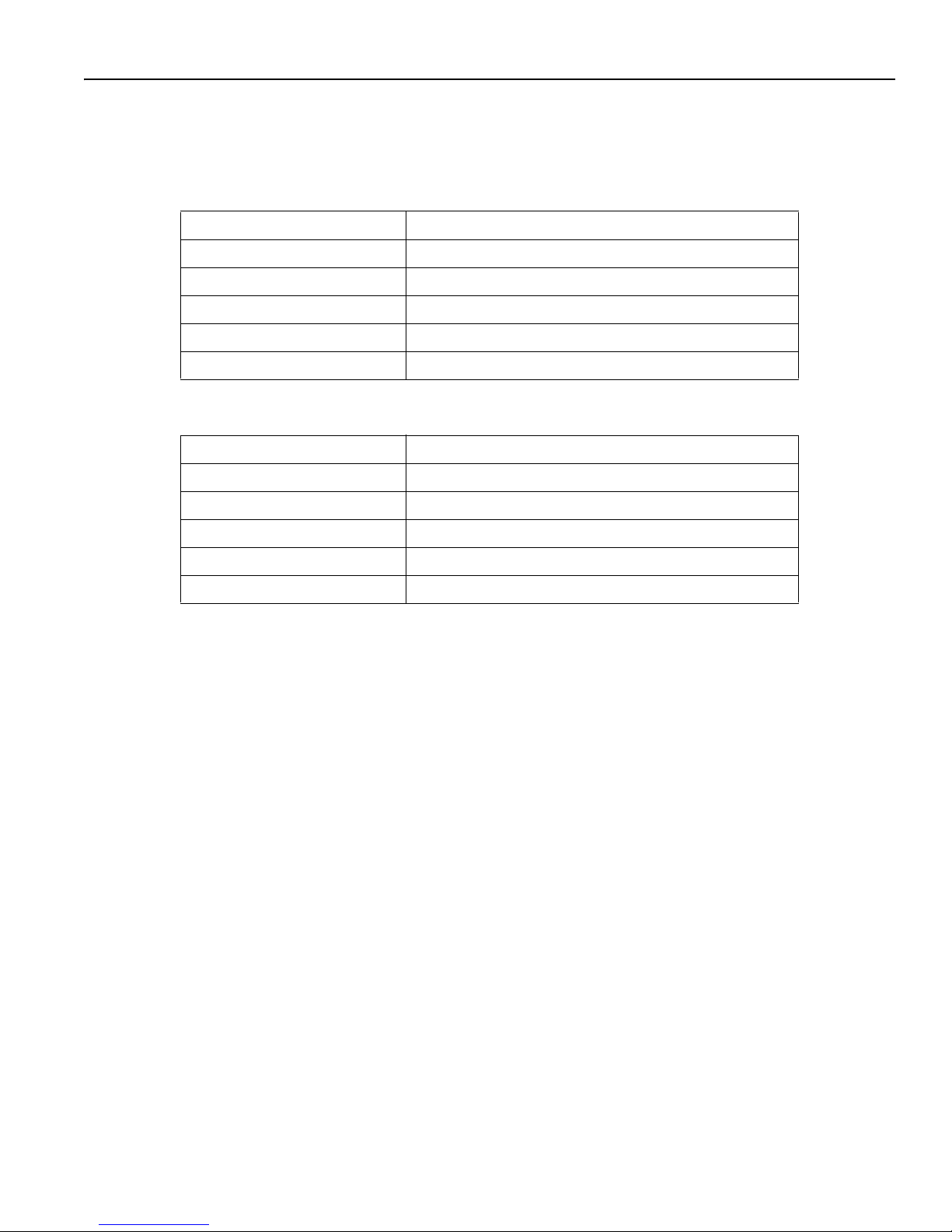

5.2 INSTRUCTION DECALS ____________________________________________________

800843

L

PARKING

BRAKE

800844

Fast Reverse

Slow Reverse

Slow Forward

Fast Forward

Neutral

Neutral Lock

Position

Neutral Lock

Position

Left Side

Steering Lever

Right Side

Steering Lever

Engaged

Position

Disengaged

Position

Fast

Slow

Engine

Throttle

R

800842

DECALS 5

DECK HEIGHT

INDICATOR

800846

DOWN STOP

1.75”

2.00”

2.25”

2.50”

2.75”

3.00”

3.25”

3.50”

3.75”

4.00”

4.25”

4.50”

DOWN STOP

800038

en-18

6 CONTROLS

6.2

6.4

6.5

6.6

6.7

6.3

6Controls

6.1 MOWER CONTROLS _______________________________________________________

en-19

CONTROLS 6

STOP

CHOKE

6.2.1

6.2.2

6.2.4

6.2.5

HR

6.2.3

OFF

RUN

START

6.2 CONTROL PANEL _________________________________________________________

6.2.1 IGNITION SWITCH _________________________________________________________

The ignition switch has three positions, OFF, RUN and START.

STOP

6.2.2 PTO SWITCH _____________________________________________________________

The PTO switch is a 2-position knob type switch to engage and to disengage the cutting unit. The

PTO switch must be in the OFF (down) position to start the engine.

Pull on the red knob to move the switch to the ON position. When the PTO switch is in the ON

position, the cutting unit is engaged.

Always mow with the throttle lever in the fast position.

en-20

6 CONTROLS

HR

Mode

Button

CHOKE

Choke

Position

Run

Position

6.2.3 HOUR METER ____________________________________________________________

The hour meter shows the hours of operation, voltmeter and engine speed.

Press and release the mode button to toggle between functions.

6.2.4 THROTTLE LEVER ________________________________________________________

The throttle lever controls the engine speed. Always operate the mower at full throttle during

normal operation.

6.2.5 CHOKE CONTROL_________________________________________________________

RZT 2550KW, RZT 2760KW and RZT 3172KW Only: When you start a cold

engine, pull the choke control to the choke position. Slowly push the choke

lever to the RUN position when the engine becomes warm.

NOTICE

The choke control is not necessary to start a warm engine.

en-21

CONTROLS 6

Operation

Position

Neutral

Position

Neutral

Position

Left Side Right Side

!

Engaged

Position

Disengaged

Position

6.3 STEERING CONTROL LEVERS ______________________________________________

The mower has separate wheel motors for each rear wheel. The

right-side control lever controls the operation of the right-side

wheel motor. The left-side control lever controls the operation of

the left-side wheel motor. See 7.6 for the operation of the steering

control levers.

DANGER

To prevent personal injury or death, do not quickly move the

steering control levers or suddenly start and stop the mower.

You must use more caution when you turn the mower or when

you operate on slopes.

To put the steering control levers in the Neutral position, move the

steering control levers toward the left and right sides.

The steering control levers must be in the Neutral position, the PTO switch must be in the OFF (down) position and the

parking brake engaged to start the mower.

6.4 PARKING BRAKE__________________________________________________________

The parking brake lever engages the rear wheel motor brakes to

prevent movement of the mower.

When the steering control levers are in the Neutral position, pull the

parking brake lever up to the engaged position to engage the parking

brake. Push the parking brake lever down to the disengaged position to

disengage the parking brake.

The steering control levers must be in the Neutral position, the PTO

switch must be in the OFF (down) position and the parking brake

engaged to start the mower.

en-22

6 CONTROLS

Lift Stop

Lever

HOC

Plate

HOC

Pedal

OCDC

Lever

Open

Closed

Discharge

Chute

!

6.5 CUTTING UNIT HOC PEDAL_________________________________________________

The cutting unit height of cut (HOC) pedal lifts and lowers the cutting

unit.

Install the HOC plate in the correct position for the cutting height. To

lower the cutting unit, press the pedal down, push the lift stop lever

forward and slowly allow the pedal to lift until the HOC plate touches

the lift stop. See 7.7 for the HOC plate position chart.

NOTICE

To prevent damage to the HOC mechanism or the cutting unit,

slowly allow the pedal to lift until the HOC plate touches the lift

stop. Do not allow the cutting unit to drop from the lifted position

against the HOC plate.

To lift the cutting unit, fully push the HOC pedal and pull the lift stop lever toward the seat. Release the lift pedal.

6.6 LIFT STOP LEVER_________________________________________________________

The lift stop lever is used to hold the cutting unit in the fully raised position and the desired HOC.

To lift the cutting unit, fully push the HOC pedal and pull the lift stop lever toward the seat. Release the lift pedal. The

rear part of the lift stop lever will hold the cutting unit in the fully raised position.

To lower the cutting unit, push on the pedal to release the pressure on the lift stop lever and push the lift stop lever

forward. When the cutting unit is lowered, the HOC plate will contact the front part of the lift stop lever.

6.7 OPERATOR CONTROLLED DISCHARGE CHUTE _______________________________

The operator controlled discharge chute (OCDC) lever opens and closes the

discharge chute. When you mow around flower beds or edges of paths, the

discharge chute can be closed to limit the discharge. Never mow with the

discharge deflector removed.

WARNING

The operator must be careful of persons and objects near the mower. Do not

release the cut grass in the direction of persons or allow persons near the

mower while in operation.

Never operate the mover with the discharge chute removed. The cutting unit

can discharge objects for long distances with the discharge chute removed.

Remember that the operator and/or owner are responsible for accidents or

hazards that occur to other persons or their property.

en-23

OPERATION 7

!

7Operation

7.1 DAILY INSPECTION ________________________________________________________

CAUTION

The inspection must be done each day when the engine is turned off and all fluids are cold. Lower the cutting units

to the ground, engage the parking brake, stop the engine and remove the ignition key.

Do a visual inspection of the mower. Look for indications of wear or loose hardware. Look for any components that are

not included on the mower or damaged components. Check for fuel and oil leaks to make sure the connections are

tight. Make sure that all hoses are in good condition.

Check the fuel supply and crankcase oil level. When the engine is cold, all fluids must be at the full level mark.

Check the engine oil cooler fins for dirt or grass. Clean with compressed air as required before you operate the mower.

Check all tires for the correct pressure.

Test the Interlock system.

en-24

7 OPERATION

!

7.2 INTERLOCK SYSTEM ______________________________________________________

The Interlock System prevents the engine to start unless the steering control levers are in the Neutral position, the

parking brake is engaged and the PTO switch is in the OFF (Down) position. The system stops the engine if the

operator leaves the seat with the PTO switch in the ON position, steering control levers out of the NEUTRAL position or

the parking brake disengaged.

WARNING

Do not operate the equipment with the Interlock System disconnected or the system does not operate correctly. Do

not disconnect or prevent the operation of any switch.

Do each of these tests to make sure the Interlock System operates correctly. If any of the tests fail, stop the test and

have the system inspected and repaired as shown below:

• The engine does not start during test 1

• The engine does start during tests 2, 3 and 4

• The engine continues to run during tests 5 and 6

Refer to the chart below for each test and follow the check () marks across the chart. Turn off the engine between

each test.

TEST 1: The test shows the normal engine start procedure. The operator is in the seat, parking brake is engaged, the

steering control levers are in the NEUTRAL position and the PTO switch is in the OFF (down) position. The engine will

start.

TEST 2: The engine must not start if the PTO switch is in the ON position.

TEST 3: The engine must not start if the parking brake is disengaged.

TEST 4: The engine must not start if the steering control lever(s) is out of the NEUTRAL position.

TEST 5: Start the engine with the normal procedure. Turn on the PTO switch and lift your weight off the seat. The

engine must stop. The cutting unit blades must not rotate after seven (7) seconds.

TEST 6: Start the engine with the normal procedure. Disengage the parking brake and lift your weight off the seat. The

engine must stop. The cutting unit blades must not rotate after seven (7) seconds.

Test

1

2

3

4

Operator Seated

YesNoYesNoYesNoYesNoYesNo

PTO Switch OFF Parking Brake

Engaged

Steering Control

Levers in Neutral

Engine Starts

5

6

Start the engine with the normal procedure, move position of the switch and lift your weight off the seat.

The engine must stop immediately and the cutting unit blades must not rotate after seven (7) seconds.

en-25

OPERATION 7

!

!

!

!

7.3 OPERATING PROCEDURE __________________________________________________

WARNING

This mower has a folding Roll Over Protection Structure (ROPS). Always wear the seat belt with the ROPS frame in

the vertical and locked position. Never wear the seat belt with the ROPS in the folded position.

If the mower is over turning and the ROPS is in the vertical and locked position, hold the steering wheel. Do not try

to move off the mower or leave the seat.

CAUTION

To prevent injury, always wear the safety glasses, leather work shoes or boots, a hard hat and ear protection.

1. Always start the engine with the operator in the seat, never while next to the mower. Never start the engine with

persons near the mower.

2. Never operate the engine without enough ventilation or in an enclosed area. The carbon monoxide in the exhaust

fumes can increase to dangerous levels.

3. Keep your hands and feet away from moving parts and the cutting units. When possible, do not adjust the mower

with the engine started.

4. Do not operate the mower with loose or damaged components. All components must be correctly fastened to the

mower. Mow when the grass is dry to get the best results.

5. First cut in a test area so that you completely understand the operation of the tractor and controls.

6. Inspect the area to find the safest procedure for the mower. Check the height of the grass, the type of terrain and

the conditions of the surface. Each condition needs the correct adjustments and precautions.

7. Do not release the cut grass in the direction of persons or allow persons near the mower while in operation. The

owner and operator are responsible for injuries caused to persons near the mower and any damage to their

property.

CAUTION

Remove all objects you can find before you operate the mower. Carefully enter a new area and always operate at

speeds that allow you to control the mower safely.

8. Be careful when you operate near to gravel areas (roads, parking areas, cart paths). Stones released from the

equipment can cause injuries to persons and cause damage to the equipment.

9. When you are not mowing grass, always turn off the PTO switch.

10. Before you move across or operate on the paths or roads, turn off the PTO switch, lift the cutting unit and travel at

decreased speed. Look for traffic.

11. When you hit an object or mower starts to cause vibration that is not normal, inspect the mower for damage and

make repairs.

WARNING

Before you clean, adjust or repair this equipment, always turn off the PTO switch, lower the cutting unit to the

ground, turn on the parking brake switch, stop the engine and remove the ignition key.

12. Travel at decreased speed and be careful when you operate on the slopes or near sharp edges.

13. When you drive in the reverse direction, look behind you and down to make sure the path is clear. Use caution

when you go near corners, trees or other objects that can prevent a clear view.

14. Never use your hands to clean the cutting units. Use a brush to remove the grass clippings from the blades. The

blades are sharp and can cause injuries.

en-26

7 OPERATION

Throttle

Lever

Hour Meter

Ignition

Switch

Choke

PTO

Switch

7.4 STARTING THE ENGINE____________________________________________________

Start the engine with the operator in the seat, steering controls

levers in the Neutral position, the PTO switch in the OFF position

and the parking brake engaged.

Set the throttle lever to half throttle.

RZT 2550KW and RZT 2760KW: If the engine is cold, move the

HR

choke to the choke position.

Turn the ignition switch to the RUN position. The hour meter will

show the engine operation hours.

Turn the ignition switch to the START position. Release the key

STOP

CHOKE

when the engine starts. Allow 30 seconds between start tries to

allow the starter motor to become cool.

NOTICE

Do not hold the ignition switch in the START position for more

than 5 seconds.

When the engine starts, move the choke to the RUN position. Allow the engine to become warm before you operate the

engine at full throttle.

7.5 TO STOP THE ENGINE _____________________________________________________

To stop and park the mower in normal conditions:

1. Turn the PTO switch to the OFF position. Drive the mower to a flat and level area to park the mower.

2. Put the steering control levers in the Neutral position.

3. Lower the cutting unit to the ground. Engage the parking brake.

4. Turn the ignition switch to the OFF position and remove the key before you leave the mower.

If an emergency occurs and you must park the mower in the area of operation, follow the guidelines set by the grounds

manager. If the mower is parked on a slope, chock or block the wheels.

en-27

OPERATION 7

!

Neutral Forward Forward Left

Tu r n

Forward Right

Tu r n

Zero Radius

Left Turn

Neutral Reverse Reverse Left

Tu r n

Reverse Right

Tu r n

Zero Radius

Right Turn

7.6 DRIVING _________________________________________________________________

Read and follow all safety instructions contained in this manual when you operate the mower. When you operate in the

reverse direction, look behind you to make sure you have a clear path. Do not mow in reverse.

Slowly and equally push both the right-side and left-side control levers forward to drive the mower in the forward

direction. The more the levers are pressed the more the forward speed is increased.

DANGER

To prevent personal injury or death, do not quickly move the steering control levers or suddenly start and stop the

mower. You must use more caution when you turn the mower or when you operate on slopes.

Slowly and equally pull both the right-side and left-side control levers toward you to drive the mower in the reverse

direction. The more the levers are pulled the more the reverse speed is increased. Press the levers against the reverse

stop for the maximum reverse speed.

To turn the mower to the left, push the right-side drive lever more than the left-side drive lever. The greater the

difference in lever position, the sharper the mower will turn. To do a zero radius left turn, press the right-side lever

forward and pull the left-side lever toward you.

To turn the mower to the right, push the left-side drive lever more than the right-side drive lever. The greater the

difference in lever position, the sharper the mower will turn. To do a zero radius right turn, press the left-side lever

forward and pull the right-side lever toward you.

en-28

7 OPERATION

2

1

AB

4

3

6

5

7

Front

!

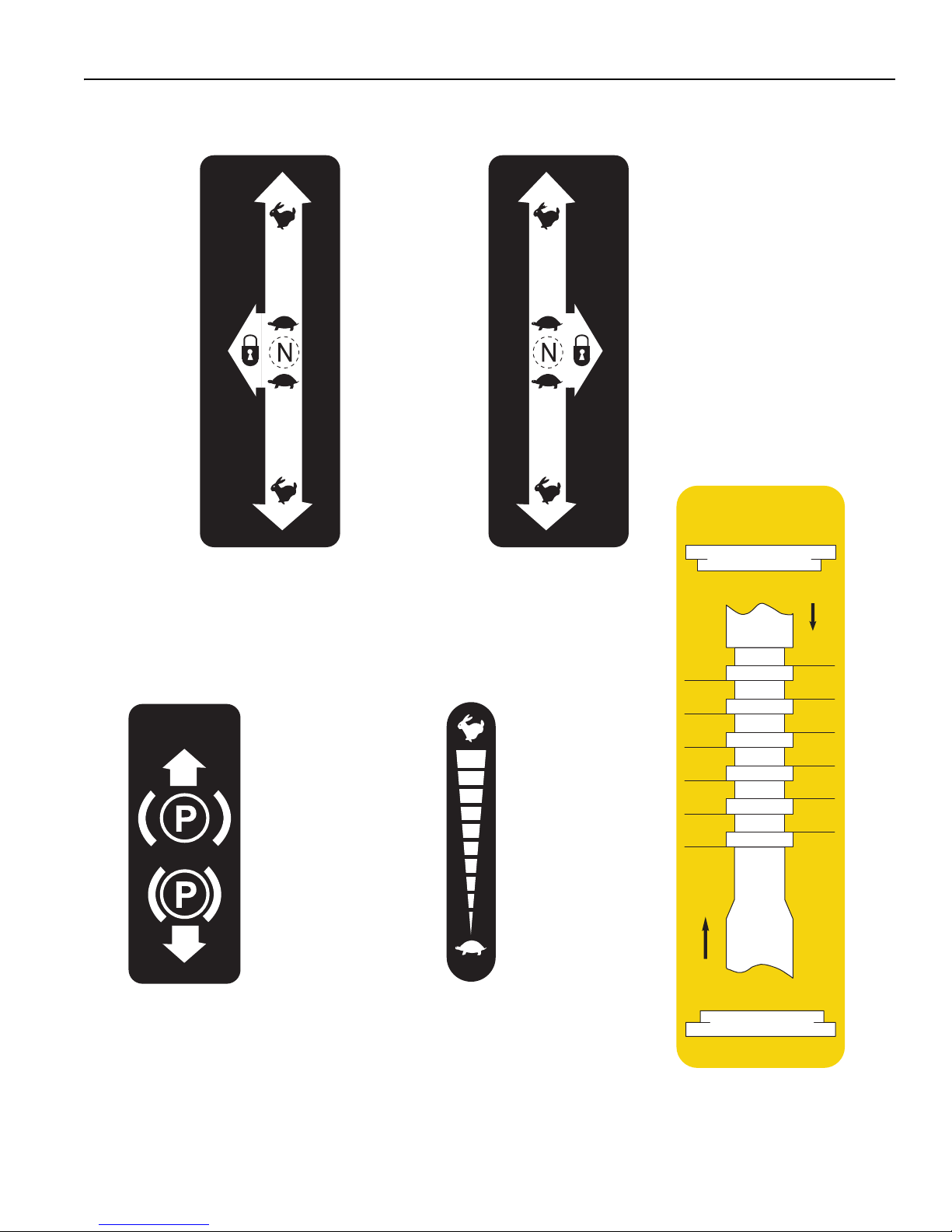

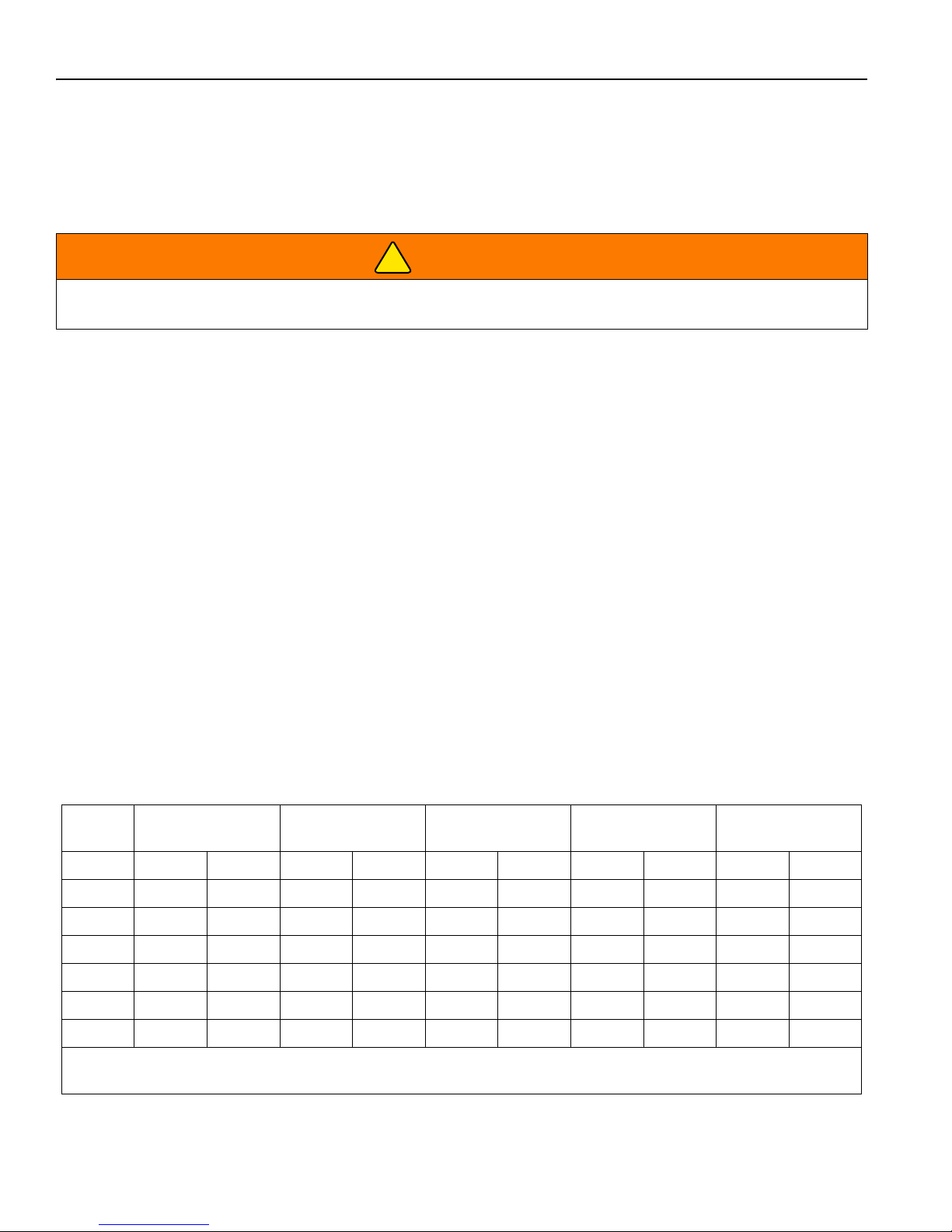

7.7 HEIGHT OF CUT __________________________________________________________

The height of cut is determined by the position and orientation of the HOC plate. Engage the parking brake, stop the

engine and remove the key before you change the HOC. Fully raise the cutting unit and pull the lift lever stop toward the

seat for 5 inch (12.7 cm) HOC.

Use the chart to find the correct cutting height slot and plate orientation for the necessary HOC.

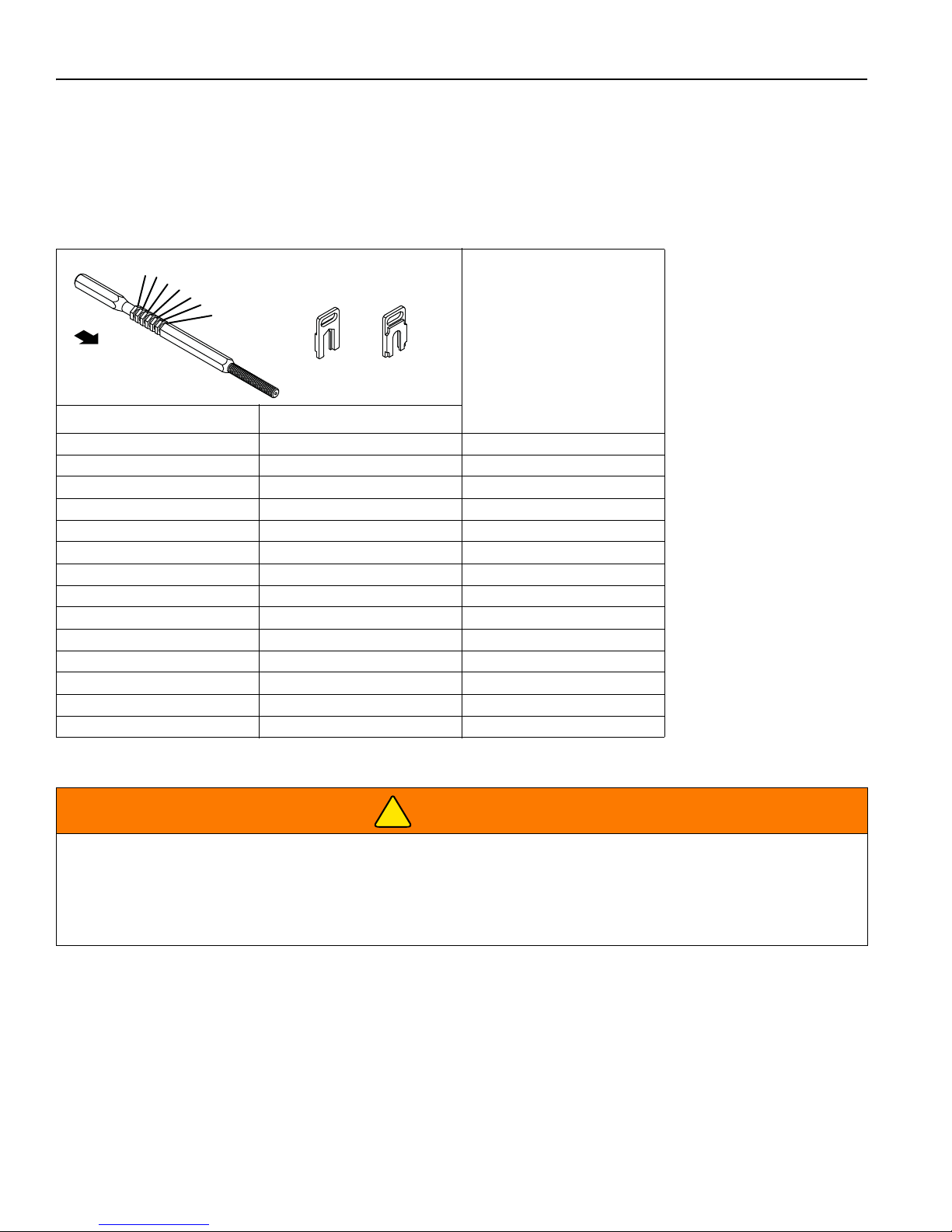

HOC

Slot HOC Plate Orientation

1A1-1/2 Inch (3.8 cm)

1B1-3/4 Inch (4.4 cm)

2A2 Inch (5.1 cm)

2B2-1/4 Inch (5.7 cm)

3A2-1/2 Inch (6.4 cm)

3B2-3/4 Inch (7.0 cm)

4A3 Inch (7.6 cm)

4B3-1/4 Inch (8.3 cm)

5A3-1/2 Inch (8.9 cm)

5B3-3/4 Inch (9.5 cm)

6A4 Inch (10.2 cm)

6B4-1/4 Inch (10.8 cm)

7A4-1/2 Inch (11.4 cm)

7B4-3/4 Inch (12.1 cm)

7.8 MOWING_________________________________________________________________________

To prevent injuries, when the blades rotate, keep your hands, feet and clothing away from the cutting unit.

NEVER use your hands to clean the cutting unit. Use a brush to remove grass from the blades. The blades can be

sharp and can cause injury.

DO NOT operate the cutting unit with the discharge chute removed.

To m ow :

1. Put the PTO switch in the ON position. The blades will start turning.

2. Lower the cutting unit.

3. Push the steering control levers forward to drive the mower. Never mow in the reverse direction.

4. Slow down when you turn the mower or mow on slopes.

en-29

WARNING

OPERATION 7

!

!

0°

0%

2-3/4°

5%

5-3/4°

1

0%

8-

1

/2°

15%

11-1/4°

20

%

1

4°

25%

16-3/4°

30%

19-1/4°

35%

2

1-3/

4°

40%

24-1/4°

45%

26-1/2°

50%

28-3/4°

55%

31°

60%

33°

65%

35°

70%

36-3/4°

75%

38-3/4°

80%

40-1/4°

85%

42°

90%

43-1/2°

95%

45°

100%

General slope of roadway embankment - 45°

Steepest Grass Area - 31°

Slope of the average roof - 19-1/4°

2nd Class highway maximum grade 4-1/2°

Toll road or freeway - 1-3/4°

Grade

Degrees

7.9 MOWING ON SLOPES ______________________________________________________

The mower is made to have good traction and to have good

balance. Operate the mower with caution when you drive on a

slope. If you drive on wet grass, the traction and steering

control of the mower is decreased.

WARNING

To make sure that the mower does not turn over, the safest

method to drive on a slope is to drive vertically. Travel at a

slow speed and do not make turns that are not necessary.

Check for hazards on the road that are not visible to the

drivers. Keep the cutting unit lowered when you operate on

the slopes.

CAUTION

Do not operate the mower on the slopes greater than 15°

or a 26.8% slope.

1. Always cut the grass with the engine at full throttle.

Control the forward speed with the steering control

levers to keep the correct performance.

2. If the mower moves to the side or the tires damage the

turf, drive the mower on a slope with a decreased

angle.

3. If the mower continues to move to the side and damage

the turf, the slope is at an angle that is not safe. Do not

continue to drive toward the top of the slope. Carefully

drive toward the bottom of the slope.

4. When you drive toward the bottom of a slope with a

high angle, lower the cutting unit to the ground. This

procedure makes sure the mower does not turn upside

down.

5. Correct tire pressure is necessary for maximum

traction.

Rear - 8-10 psi (0.55-0.69 BAR)

15° Maximum

15° Maximum

en-30

7 OPERATION

C

A

B

D

How to calculate a slope:

Tools Required:

Level (A), either 1 yard, or 1 meter long.

Tape measure (B).

Use the level (A) and position it horizontally to measure the

distance (C) with tape measure (B). Use the chart to

calculate the slope angle or the percentage grade of the

slope (D).

Height (C) Result (D)

Inches with 1 Yard Level (A) Millimeters with 1 Meter Level (A) Slope in Degrees Slope Grade %

3

100 5.7 10.0

150 8.5 15

6

200 11.3 20.0

7.5

225 12.7 22.5

9 250 14 25.0

275 15.4 27.5

10

300 16.7 30.0

11

325 18.0 32.5

12

350 19.3 35.0

13

375 20.6 37.5

14

400 21.8 40.0

15

425 23.0 42.5

16

475 25.4 47.5

18 500 26.6 50.0

20

600 31.0 60.0

25

30

36 1000 45.0 100

800 38.7 80.0

900 42.0 90

4.8 8.3

9.5 16.7

11.8 20.8

15.5 27.8

17.0 30.6

18.4 33.3

19.9 36.1

21.3 38.9

22.6 41.7

24 44.4

29.1 55.6

34.8 69.4

39.8 83.3

en-31

OPERATION 7

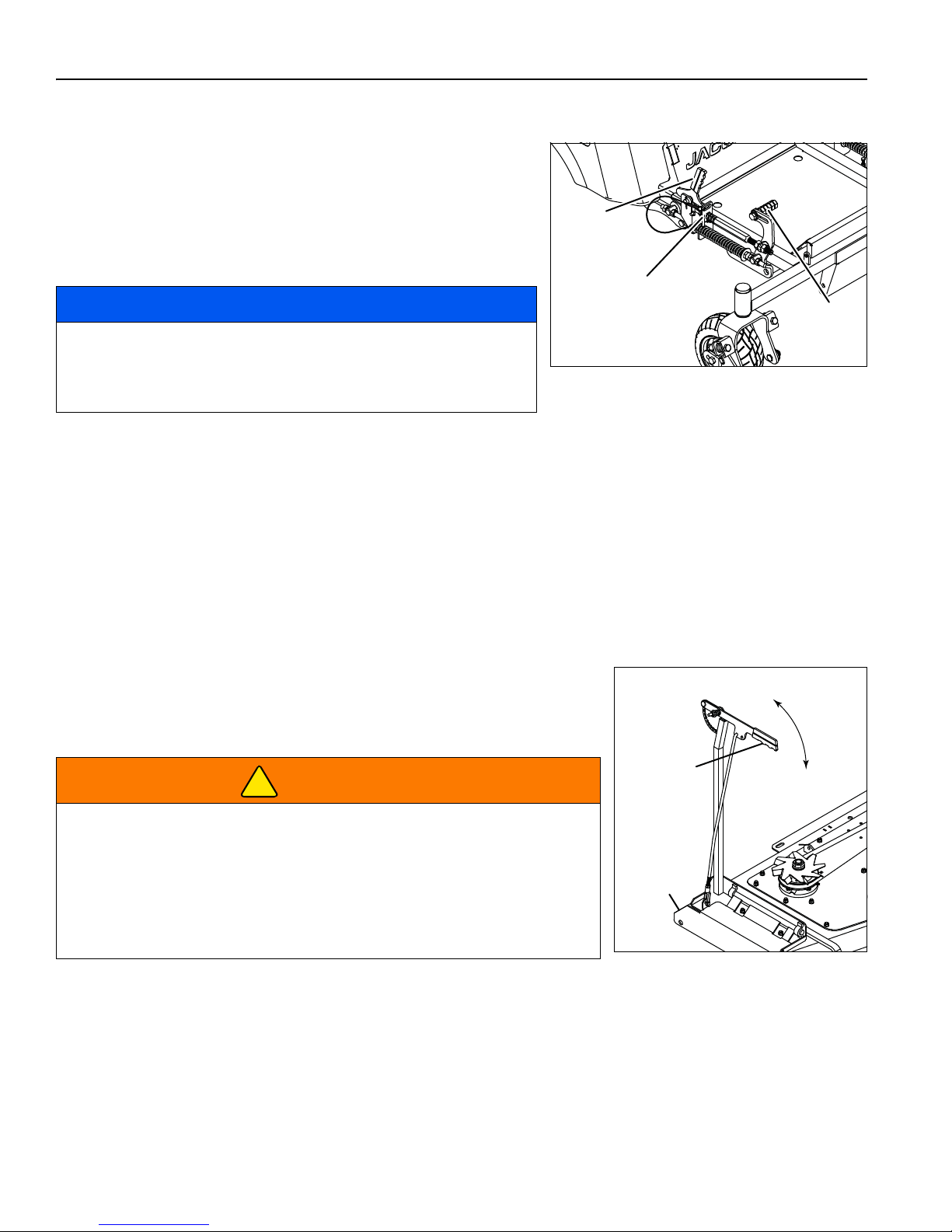

Bypass

Valves

Left Pump

Right Pump

7.10 TOWING THE MOWER ______________________________________________________

If the mower has a problem and can not drive to the service area, open the bypass valve and load the mower on a

trailer. If a trailer is not available, tow the mower at a slow speed for short distances.

Be careful when you load or unload the mower on the trailer. Fasten the mower to the trailer to prevent the mower to

move on the trailer. Engage the parking brake.

If the trailer is moved on the highway, inflate the tires to the maximum pressure recorded on the tire before you fasten

the mower to the trailer. Decrease the tire pressure after the mower is removed from the trailer.

Tilt the seat forward. Open the bypass valve on both pumps

before you tow the mower. The bypass valve lets the mower be

moved without the engine started and to prevent possible

damage to hydraulic components.

The bypass valve is found on the front side of the left and right

traction pumps below the operator seat. To open the valve, use

a wrench to turn the bypass valve counterclockwise two full

turns (720°).

Before towing, disengage the parking brake and make sure

the cutting unit is lifted.

NOTICE

When you tow the mower, do not drive more than 2 mph

(3.2 km/hr). Jacobsen recommends that you do not tow the

mower for long distances.

When the mower gets to the service area, engage the parking brake and turn the bypass valves clockwise two full turns

(720°). Torque the bypass valves to 84-120 in. lb. (7-10 ft. lb.) (9.5-13.5 Nm).

en-32

8 MAINTENANCE AND LUBRICATION CHARTS

8Maintenance and Lubrication Charts

8.1 MAINTENANCE CHART ____________________________________________________

Mower Service Interval Chart

Interval Item Section

First 8 Hours • Replace engine oil

• Replace engine oil filter

• Check electrical wiring

• Lubricate spindles and casters

Each day (10 Hours) • Check Safety Interlock System

• Check engine oil level

• Clean engine oil cooler

• Check hydraulic oil level

• Clean area around muffler and controls

Each week (50 Hours) • Check fuel lines and fittings

• Inspect parking brake and steering control lever linkage

• Inspect deck and drive belts

• Check for loose components

• Lubricate grease fittings

First 75 Hours • Replace drive axle fluid and filter (Two per mower) See 9.9

Each Two weeks (100

Hours)

• Clean engine oil cooler fins and cylinder cooling fins

• Check and clean primary air filter element

1

1

• Check engine exhaust system

• Replace engine oil and filter

• Replace EFI fuel filter (Kohler Engine)

1

1

• Clean and regap spark plugs (Kawasaki Engine)

See 9.3

See 9.3

See 9.18

See 8.2

See 7.2

See 9.3

See 9.6

See 8.2

See 9.15

See 9.4

See 9.9

See 9.3

Each month (250 Hours) • Check electrical wiring

1

1

300 Hours

• Replace primary air filter element

• Check secondary air filter element

• Clean combustion chamber (Kawasaki Engine)

• Check and adjust valve clearance (Kawasaki Engine)

• Clean and lap valve seating surface (Kawasaki Engine)

Each two months (400

Hours

Yearly or 500 Hours

• Replace fuel filter

• Replace drive axle fluid See 9.9

• Replace secondary air filter element

• Replace spark plugs

1

1

• Replace hydraulic fluid

600 Hours

• Check and adjust valve lash (Kohler Engines)

3

Grease Fittings

1. Caster Pivot (2) 2. Deck Spindle (3) 3. Deck Lift Pivot (4)

1

Perform more frequently under severe, dusty, dirty conditions.

2

Have a Kawasaki authorized dealer perform this service

See 9.18

2

2

2

See 9.4

en-33

MAINTENANCE AND LUBRICATION CHARTS 8

3

Have a Kohler authorized dealer perform this service

8.2 LUBRICATION CHART _____________________________________________________

1

2

2

2

1

3

8.3 FLUID REQUIREMENTS ____________________________________________________

Fluid Requirements

Quantity Type

Engine Oil with Filter 2.06 to 2.12 quarts (1.95 to 2.01 l) SAE 10W-30 API Classification SJ

Hydraulic System with Filters 1.75 gallons (6.62 liter) SAE 15W-40 API Classification SL

Fuel 16 U.S. Gallons (60.6 l) 87 Octane Gasoline

Maximum 10% Ethanol

en-34

9 MAINTENANCE

!

9Maintenance

9.1 GENERAL PRECAUTIONS ________________________________________________________

WARNING

Before you clean, adjust or repair this equipment, push PTO switch to the OFF position, lower the cutting unit,

engage the parking brake, stop the engine and remove the key.

Make sure the mower is parked on a solid and level surface. Never work on a mower that is lifted only by the jack.

Always use the jack stands.

A qualified technician must always do adjustments and maintenance. If the correct adjustments can not be made,

contact your Jacobsen Dealer.

Inspect the equipment according to the maintenance schedule and keep complete records.

a Keep the equipment clean.

b Keep all moving parts correctly adjusted and lubricated.

c Replace worn or damaged parts before you operate the mower.

d Keep all fluids at the correct level.

e Keep the shields in position and all hardware tight.

f Keep the tires correctly inflated.

When you make the adjustments or repairs, do not wear jewelry or loose fitting clothing.

Refer to the illustrations in the Parts Manual for the removal and assembly of parts.

When you discard hazardous materials (batteries, lubricants, fuel, anti-freeze), follow your local, state or federalrecommended procedures.

9.2 ENGINE _________________________________________________________________

IMPORTANT - The mower includes a separate Engine Manual prepared by the engine manufacturer. Read the Engine

Manual and know the operation and maintenance of the engine. When you follow the engine manufacturer instructions,

you will make sure of the maximum service life of the engine. The replacement engine manuals are available from the

engine manufacturer.

The operation and maintenance during the first 8 hours of a new engine can make a difference to the performance and

life of the engine.

During the first 8 hours of operation, Jacobsen recommends the following.

• Allow the engine to reach a temperature of at least 140° F (60° C) before operation at full load.

• Check the engine oil level two times each day. Higher than normal oil use can occur during the first 8 hours.

• Change the engine oil and oil filter after the first 8 hours of operation.

• Refer to the Engine manual for specified maintenance intervals.

NOTICE

The mower operates and cuts correctly at the preset governor setting. Do not change the engine governor setting

or over speed the engine.

en-35

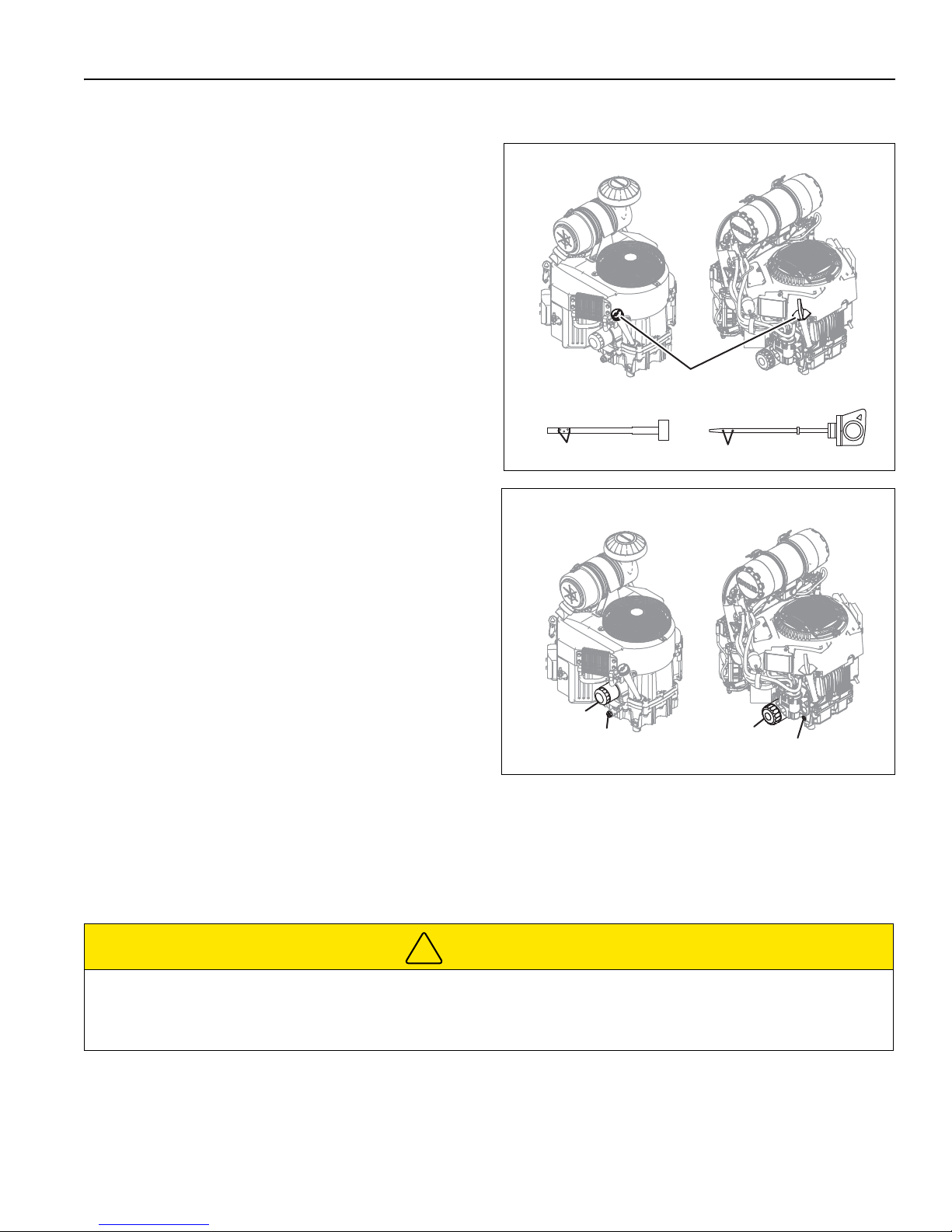

MAINTENANCE 9

Dipstick

Level Indicator Level Indicator

Kohler EngineKawasaki Engine

Drain Plug

Filter

Drain Plug

Filter

Kohler EngineKawasaki Engine

!

9.3 ENGINE OIL ______________________________________________________________

Check engine oil level

Check the engine oil level before you start the engine or at

least five minutes after you stop the engine.

a Park the mower on a level surface.

b The dipstick is found at the right front corner of the

engine behind the seat. Remove the dipstick. Clean

the dipstick with a cloth and replace in position.

c Remove the dipstick and check the oil level. The oil

level must be between the two level indicators on the

dipstick.

ADD FULL

Change Engine Oil and Filter

a Start the engine to increase the temperature, then

stop the engine.

b Place a container capable of holding one gallon

under the engine.

c Remove the oil drain plug and allow the engine oil to

drain into a container.

d Remove the oil filter.

e Let the engine oil flow into a container.

f Clean the filter area on the engine.

g Apply a thin layer of oil to the gasket on new filter.

Install the oil filter.

h Tighten the filter until the gasket contacts the oil filter adapter, then tighten an additional 1/2 to 3/4 turn. Only use

your hand to tighten the filter.

i Replace the oil drain plug and fill the engine with the correct quantity and grade of oil through the dipstick tube.

j Start the engine and check around the oil filter gasket for leaks.

k Stop the engine and check the engine oil level.

The engine oil can damage your skin. Use gloves when you use engine oil. If engine oil touches your skin, clean the

area immediately.

CAUTION

Discard used engine oil as shown in local regulations.

en-36

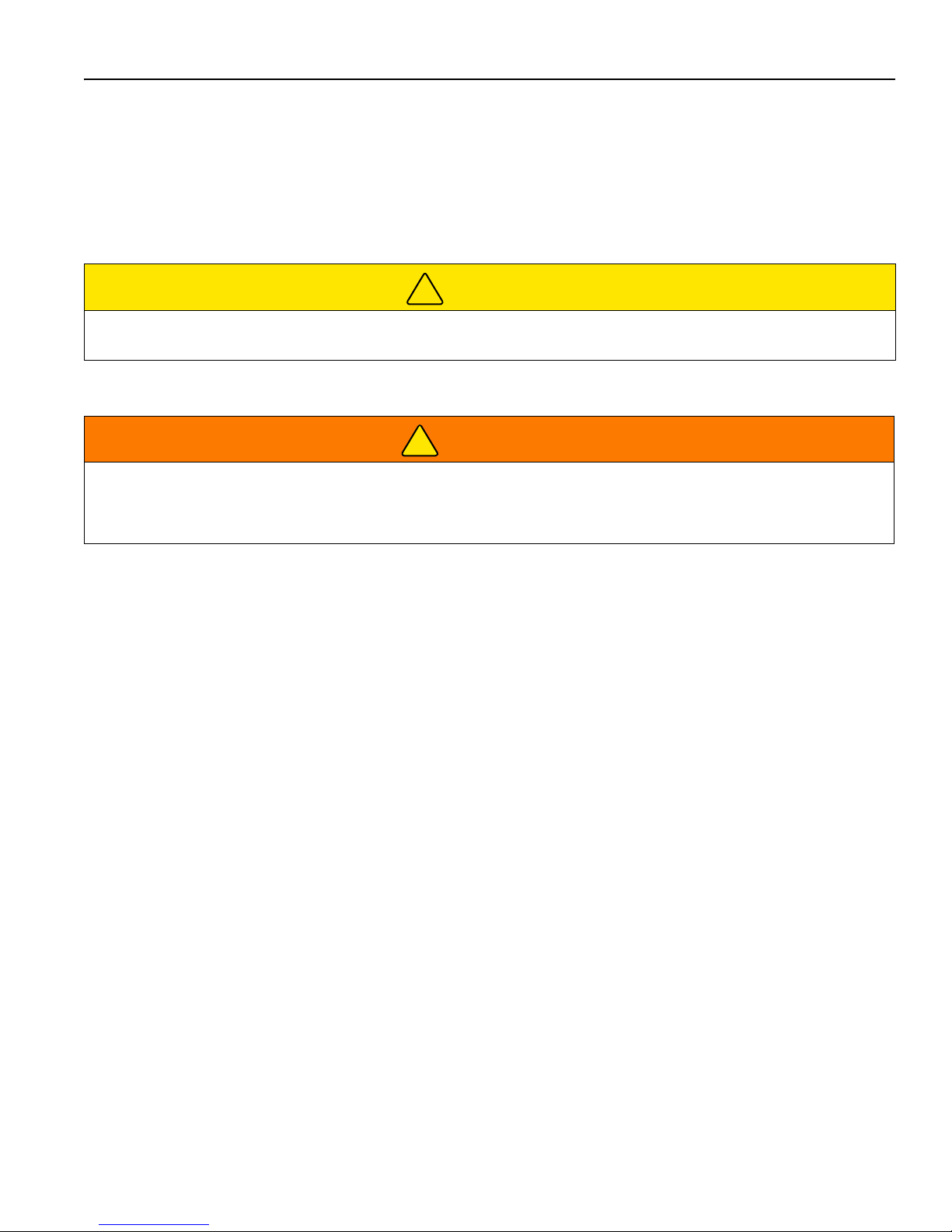

9 MAINTENANCE

Val ve

Cap

Outer

Element

Inner

Element

Cap

Outer

Element

Inner

Element

!

9.4 ENGINE AIR FILTER _______________________________________________________

Do not remove the elements to inspect or clean.

Removal of the filter that is not necessary increases

the risk of dust and other particles to enter the

engine.

Clean or replace the outer filter element every 100

hours. Replace the inner element every third change

of the outer filter.

When service is needed, first clean the outside of the

filter housing, then remove the outer element. Only

remove the inner element if replacement is needed.

Clean the inside of the filter housing. Make sure dust and other particles do not get into the engine inlet hose.

Inspect the new elements. Do not use a damaged element and never use an incorrect element.

Assemble the inner and outer filter elements. Make sure the elements seat correctly.

RZT 2550KW, RZT 2760KW and RZT 3172KW: Assemble the cap to the filter housing. Make sure the cap seals

around the filter housing. The dust valve on the cap must be at the bottom of the filter. Fasten the cap with the two clips.

RZT 2750EFI, RZT 2760EFI and RZT 3172EFI: Assemble the cap to the filter housing. Make sure the cap seals

around the filter housing. The dust ejector area on the cap must be at the bottom of the filter. Fasten the cap with the

two clips.

Check the air filter hoses for wear or damage. Make sure the hose clamps are tight and hold the hoses in position.

9.5 ENGINE EXHAUST _______________________________________________________________

WARNING

The exhaust fumes contain carbon monoxide. The carbon monoxide in the exhaust fumes can increase to

dangerous levels. To protect you from carbon monoxide poisoning, inspect the complete exhaust system every

month and replace damaged components immediately.

NEVER operate the engine without enough ventilation.

The temperature of the exhaust components can be greater than 300° F (149° C). To prevent the burns, do not

touch a hot exhaust system.

If you sense a change in the color or sound of the exhaust, stop the engine immediately. Identify the problem and have

the system repaired.

Torque all exhaust manifold hardware equally. Tighten or replace the exhaust clamps.

en-37

MAINTENANCE 9

!

!

9.6 FUEL ____________________________________________________________________

Gasoline is flammable. Use caution when you add the fuel to the mower. Only use an approved container. The

spout on the container must fit inside the fuel filler neck. Never use the containers that are not approved to keep or

transfer fuel.

WARNING

Refuel the mower before you start the engine. When the engine is in operation or while the engine is hot, never

remove the fuel cap or add fuel to the mower.

Refuel outdoors only and do not smoke when you add fuel.

If the fuel spills, do not try to start the engine, but move the mower away from the area. Until fuel vapors are

removed, do not allow the sparks, open flame or other types of ignition.

Never keep fuel containers near an open flame or any device that can cause the ignition of fuel or fuel vapors.

Always tighten the fuel tank cap and container cap after you add fuel.

Fill the fuel tank to the bottom of the filler neck.

Do not use premium gasoline or an oil-gasoline mixture. Use clean, fresh, regular unleaded gasoline, 85 octane

minimum. When using blended fuel, do not use a blend with more than 10% ethanol. Under no circumstances should

you use a blend with methanol. Refer to the engine’s operator manual for fuel recommendations when using blended

fuel.

Check fuel hoses and clamps every 50 hours. Replace fuel hoses and clamps at first indication of wear or damage.

Keep fuel according to your local, state or federal regulations and instructions from your fuel supplier.

Never allow the tank to become empty.

9.7 CHARGE THE BATTERY __________________________________________________________

WARNING

Charge the battery in an area with good airflow. The battery can release hydrogen gas that is explosive. To prevent

an explosion, keep any device that can cause sparks or flames away from the battery.

When the battery charger is turned on, to prevent injury, stay away from the battery. A battery that is damaged can

cause an explosion.

Read the battery charger manual for specified instructions on the operation of the charger.

When possible, remove the battery from the mower before you charge the battery. If the battery is not sealed, check

and make sure the level of the electrolyte is above the plates in all of the cells.

Make sure the battery charger is turned OFF, then connect the battery charger to the battery terminals as specified in

the battery charger manual.

Always turn OFF the battery charger before you disconnect the battery charger from the battery terminals.

en-38

9 MAINTENANCE

!

!

!

!

9.8 BATTERY ________________________________________________________________

Before you service the battery, make sure the ignition switch is in the OFF position and the key is removed.

CAUTION

When you service the battery, always use the tools with insulation, wear protective glasses and protective clothing.

Discard used batteries as shown in your local regulations.

WARNING

The battery contains corrosive acid. Prevent contact with the battery acid.

Always wash your hands after you service a battery.

WARNING

The battery posts, battery terminals and related accessories contain lead and lead compounds, chemicals known to

the State of California to cause cancer and other reproductive harm.

Tighten the battery cables on the battery terminals, To prevent corrosion, apply a layer of silicone dielectric grease to

battery terminals and ends of cables. Keep the vent caps and battery terminal covers in position.

Before you do any welding operation on the mower, always disconnect the battery cables from the battery and the

connectors from the controllers.

Confirm the battery polarity before you connect or you disconnect the battery cables.

When you install the battery, always connect the positive (RED) battery cable before the negative (BLACK) battery

cable.

When you remove the battery, always disconnect the negative (BLACK) battery cable before the positive (RED) battery

cable.

Jump-Starting the Mower

a Before you try to jump-start the mower, check the condition of the drained battery.

b Connect the positive (+) battery terminal of the charged battery to positive battery terminal of the drained battery.

c Connect the negative (–) battery terminal of the charged battery to frame of vehicle with the drained battery.

WARNING

The battery can release hydrogen gas that is explosive. To decrease the risk of an explosion, prevent sparks near

the battery. Always connect the negative jumper cable to the frame of the mower with the drained battery.

d When the cables are connected, start the engine on the vehicle with the good battery, then start the mower.

en-39

MAINTENANCE 9

!

9.9 HYDRAULIC HOSES ______________________________________________________________

WARNING

To prevent injury from the hot, high pressure oil, never use your hands to check for oil leaks. Use paper or cardboard

to find leaks.

The hydraulic fluid pressure can have enough force to enter your skin. If hydraulic fluid has entered your skin, a