Parts & Maintenance

Manual

When Performance Matters.

™

WARNING

If incorrectly used, this machine can cause severe injury. Those who use

and maintain this machine should be trained in its proper use, warned of its

dangers, and should read the entire manual before attempting to set up,

operate, adjust, or service the machine.

4189623-Rev C

Tri King® Triplex Mower with ROPS

67069 – Kubota D722-E3B Engine

GB

11524 WILMAR BLVD,

CHARLOTTE, NC 28273

®

kg kW

1 800 848 1636 (US)

PRODUCT OF U.S.A.

A Textron Company

FOREWORD

This manual contains adjustment, maintenance,

troubleshooting instructions and parts list for your new

Jacobsen machine. This manual should be stored with

the equipment for reference during operation.

Before you operate your machine, you and each operator

you employ should read the manual carefully in its

entirety. By following the safety, operating and

maintenance instructions, you will prolong the life of your

equipment and maintain its maximum efficiency.

If additional information is needed, contact your

Jacobsen Dealer.

The serial plate is located on the left rear frame rail.

Jacobsen recommends you record these numbers below

for easy reference.

Suggested Stocking Guide

To Keep your Equipment fully operational and productive, Jacobsen suggests you maintain a stock of the more

commonly used maintenance items. We have included part numbers for additional support materials and training aids.

To order any of the following material:

1. Write your full name and complete address on your

order form.

2. Explain where and how to make shipment:

3. Order by the quantity desired, the part number, and

the description of the part.

4. Send or bring the order to your authorized Jacobsen

Dealer.

❑ UPS ❑ Regular Mail

❑ Overnight ❑ 2nd Day

Service Parts

Qty. Part No. Description Qty. Part No. Description

550489 Fuel Filter, Diesel Engine 549579 Hydraulic Oil Filter (2 Req’d)

5000913 Air Filter, Diesel Engine 3001950 Pump Drive Belt

502644 Oil Filter, Diesel Engine 1001958 Ignition Key Switch

Service Support Material

Qty. Part No. Description

4189624 Safety & Operation Manual

4189623 Parts & Maintenance

4189622 Engine Parts Catalog

4191622 DVD, Operator Training

Qty. Part No. Description

4171674 Service Manual

These are the original instructions verified by

Jacobsen, A Textron Company.

© 2012, Jacobsen A Textron Company/Textron Innovations Inc.

“All rights reserved, including the right to reproduce this material

2

or portions thereof in any form.”

Proposition 65 Warning

This product contains or emits

chemicals known to the State of

California to cause cancer and birth

defects or other reproductive harm.

LITHO IN U.S.A. 5-2012

Table of Contents

1 Safety

1.1 Operating Safety ........................................... 4

1.2 Important Safety Notes ................................. 5

2 Specifications

2.1 Product Identification .................................... 6

2.2 Engine ........................................................... 6

2.3 Cutting Units: ................................................ 6

2.4 Mower ........................................................... 6

2.5 Weights and Dimensions .............................. 7

2.6 Accessories & Support Literature ................. 7

2.7 Declaration of Conformity ............................. 8

3 Adjustments

3.1 General ....................................................... 10

3.2 Fan Belt ....................................................... 10

3.3 Pump Drive Belt .......................................... 10

3.4 Neutral and 3WD Switches ......................... 11

3.5 Parking Brake Switches .............................. 11

3.6 Lift Limit Switch ........................................... 11

3.7 Traction Pedal Neutral ................................ 12

3.8 Traction Pedal Forward Stop ...................... 12

3.9 Lift / Lower Pedal Stop ................................ 12

3.10 Parking Brake ............................................. 13

3.11 Rear Lift Arm ............................................... 13

3.12 Down Pressure ........................................... 13

3.13 Reel To Bedknife ........................................ 14

3.14 Reel to Bedknife Adjustment ....................... 14

3.15 Cutting Modes ............................................. 15

3.16 Cutting Height Adjustment .......................... 15

3.17 Removing the Cutting Unit .......................... 16

3.18 Cutting Height - Fixed Mode ....................... 16

3.19 Cutting Height - Floating Mode ................... 17

3.20 Torque Specification ................................... 18

3.21 Specific Torque ........................................... 18

4 Maintenance

4.1 General ....................................................... 19

4.2 Engine ......................................................... 19

4.3 Engine Oil ................................................... 20

4.4 Air Filter ....................................................... 20

4.5 Fuel ............................................................. 21

4.6 Fuel System ................................................ 21

4.7 Battery ......................................................... 21

4.8 Jump Starting .............................................. 22

4.9 Charging Battery ......................................... 22

4.10 Hydraulic Hoses .......................................... 22

4.11 Hydraulic Oil ................................................ 23

4.12 Hydraulic Oil Filters ..................................... 23

4.13 Electrical System ........................................ 23

4.14 Muffler and Exhaust .................................... 24

4.15 Tires ............................................................ 24

4.16 Wheel Mounting Procedure ........................ 24

4.17 Care and Cleaning ...................................... 25

4.18 Radiator ...................................................... 25

4.19 Backlapping ................................................ 26

4.20 Storage ....................................................... 27

5 Troubleshooting

5.1 General ....................................................... 28

6 Maintenance & Lubrication Charts

6.1 General ........................................................ 29

6.2 Lubrication Chart .........................................29

6.3 Maintenance Charts ..................................... 30

7Parts Catalog

7.1 Table Of Contents........................................ 31

3

1 SAFETY

!

1.1 OPERATING SAFETY ______________________________________________________

WARNING

EQUIPMENT OPERATED IMPROPERLY OR BY UNTRAINED PERSONNEL CAN BE DANGEROUS.

Familiarize yourself with the location and proper use of all controls. Inexperienced operators should receive

instruction from someone familiar with the equipment before being allowed to operate the machine.

1. Safety is dependent upon the awareness, concern,

and prudence of those who operate or service the

equipment. Never allow minors to operate any

equipment.

2. It is your responsibility to read this manual and all

publications associated with this equipment (Safety

and Operation Manual, Engine Manual, and

attachments/accessories instruction sheets). If the

operator cannot read English it is the owner’s

responsibility to explain the material contained in this

manual to them.

3. Learn the proper use of the machine, the location and

purpose of all the controls and gauges before you

operate the equipment. Working with unfamiliar

equipment can lead to accidents.

4. Never allow anyone to operate or service the machine

or its attachments without proper training and

instructions; or while under the influence of alcohol or

drugs.

5. Wear all the necessary protective clothing and personal

safety devices to protect your head, eyes, ears, hands,

and feet. Operate the machine only in daylight or in

good artificial light.

6. Evaluate the terrain to determine what accessories and

attachments are needed to properly and safely perform

the job. Only use accessories and attachments

approved by Jacobsen.

7. Stay alert for holes in the terrain and other hidden

hazards.

8. Inspect the area where the equipment will be used.

Pick up all the debris you can find before operating.

Beware of overhead obstructions (low tree limbs,

electrical wires, etc.) and also underground obstacles

(sprinklers, pipes, tree roots, etc.). Enter a new area

cautiously. Stay alert for hidden hazards.

9. Never direct discharge of material toward bystanders,

nor allow anyone near the machine while in operation.

The owner/operator can prevent and is responsible for

injuries inflicted to themselves, to bystanders, and

damage to property.

10. Do not carry passengers. Keep bystanders and pets a

safe distance away.

11. Never operate equipment that is not in perfect working

order or is without decals, guards, shields, discharge

deflectors, or other protective devices securely fastened

in place.

12. Never disconnect or bypass any switch.

13. Do not change the engine governor setting or

overspeed the engine.

14. Carbon monoxide in the exhaust fumes can be fatal

when inhaled. Never operate the engine without proper

ventilation or in an enclosed area.

15. Fuel is highly flammable; handle with care.

16. Keep the engine clean. Allow the engine to cool before

storing and always remove the ignition key.

17. Disengage all drives and engage parking brake before

starting the engine (motor). Start the engine only when

sitting in operator’s seat, never while standing beside

the unit.

18. Equipment must comply with the latest federal, state,

and local requirements when driven or transported on

public roads. Watch out for traffic when crossing or

operating on or near roads.

19. Local regulations may restrict the age of the operator.

20. Operate the machine up and down the face of slopes

(vertically), not across the face (horizontally).

21. To prevent tipping or loss of control, do not start or stop

suddenly on slopes. Reduce speed when making sharp

turns. Use caution when changing directions.

22. Always use the seat belt when operating mowers

equipped with a Roll Over Protective Structure (ROPS).

Never use a seat belt when operating mowers

without a ROPS.

Accessory operator protective structures will

continue to be offered for all equipment currently

covered. This allows for the outfitting of any

machines without previous ROPS installations or

replacement of damaged structures.

23. Keep legs, arms, and body inside the seating

compartment while the vehicle is in motion.

24. Disconnect battery and controller electrical connectors

before performing any welding on this mower.

This machine is to be operated and maintained as specified in this manual and is intended for the professional

maintenance of specialized turf grasses. It is not intended for use on rough terrain or long grasses.

4

SAFETY 1

!

!

1.2 IMPORTANT SAFETY NOTES ________________________________________________

This safety alert symbol is used to alert you to potential hazards.

DANGER - Indicates an imminently hazardous situation which, if not avoided, WILL result in death or serious injury.

WARNING - Indicates a potentially hazardous situation which, if not avoided, COULD result in death or serious

injury.

CAUTION - Indicates a potentially hazardous situation which, if not avoided, MAY result in minor or moderate injury

and property damage. It may also be used to alert against unsafe practices.

NOTICE - Indicates a potentially hazardous situation which, if not avoided, MAY result in property damage. It may

also be used to alert against unsafe practices.

For pictorial clarity, some illustrations in this manual may show shields, guards or plates open or removed. Under no

circumstances should this equipment be operated without these devices securely fastened in place.

WARNING

The Interlock System on this mower prevents the mower from starting unless

the brake lever is engaged, reel switch is off, and traction pedal is in Neutral.

The system will stop the engine if the operator leaves the seat without

engaging the parking brake or setting the reel switch off.

NEVER operate mower unless the Interlock System is working.

WARNING

1. Before leaving the operator’s position for any reason:

a. Return traction pedal to Neutral.

b. Disengage all drives.

c. Lower all implements to the ground.

d. Engage parking brake.

e. Stop engine and remove the ignition key.

2. Keep hands, feet, and clothing away from moving parts. Wait for all

movement to stop before you clean, adjust, or service the machine.

3. Keep the area of operation clear of all bystanders and pets.

4. Never carry passengers, unless a seat is provided for them.

5. Never operate mowing equipment without the discharge deflector

securely fastened in place.

By following all instructions in this manual, you will prolong the life of your machine and maintain its maximum

efficiency. Adjustments and maintenance should always be performed by a qualified technician.

If additional information or service is needed, contact your Authorized Jacobsen Dealer who is kept informed of the

latest methods to service this equipment and can provide prompt and efficient service.

5

2 SPECIFICATIONS

619 13.2 XXXX

67069001651

2.1 PRODUCT IDENTIFICATION_________________________________________________

67069.............................. Tri-King Mower, 3-WD, 17.7 hp

diesel engine with ROPS. Without

front lift arms or mowers.

PRODUCT OF U.S.A.

A Textron Company

®

11524 WILMAR BLVD,

CHARLOTTE, NC 28273

1 800 848 1636 (US)

Serial Number ................An identification plate, like the one

shown, listing the serial number, is

kg kW

attached to the frame of the

mower and is located to the

operator’s left just behind the front

wheel motor. Always provide the

serial number of the unit when

ordering replacement parts or

Product

EEC Sound

Power

Sound Pressure

Level

Operator Ear

Vibration M/S

Arms Body

requesting service information.

67069 99 dba 86 dba 3.78 0.016

2.2 ENGINE__________________________________________________________________

Make ...............................Kubota

Model ..............................D722-E3B

Horsepower..................... 17.7 hp (13.2 kW) @ 3200 rpm

Note: Actual sustained horsepower will likely be lower

than listed in specifications due to operating limitations

and environmental factors

Displacement .................. 43.88 cu. in. (719 cc)

Torque............................. 26 ft. lbs. (35 Nm) @ 2600 rpm

Fuel:

Type ..........................No. 2 Low or Ultra-Low Sulfur

Diesel

Rating ....................... Min. Cetane rating 45

Capacity.................... 6.5 U.S. Gal. (24.6 liters)

Governor......................... Ball Type Governor

Low Idle ................... 1450 RPM

High Idle ................... 3400 RPM

Lubrication:

Capacity.................... 3.4 quarts (3.2 liter) with filter

Type .......................... SAE 20W, SAE 30W

API Classification ..... CD, CE

Air Filter .......................... Dry type with evacuator valve and

service indicator

Alternator ........................ 40 amp

2

2.3 CUTTING UNITS: __________________________________________________________

Reel ................................ 3 Reels, 26 in. (660 mm) wide or,

3 Reels, 30 in. (762 mm) wide.

Reel Diameter................. 7 in. (178 mm)

Bearings.......................... Self adjusting tapered roller

bearings

Blade Options .................7 blades

Cutting Width:

2.4 MOWER _________________________________________________________________

Tires:

Front ......................... 20 x 10 - 10 tubeless

Rear .........................20 x 10 - 8 tubeless

Pressure:

Front.......................... 10-12 psi (0.69-0.82 BAR)

Rear ..........................8-10 psi (0.55-0.69 BAR)

Battery:

Type ..........................12 Volt Lead/Acid

Group........................ 22 NF

Parking Brake ................. Mechanical front wheel disk

6

Hand lever actuated

26 in. Reels............... 72 in. (1828 mm)

30 in. Reels............... 84 in. (2134 mm)

Overall Width:

26 in. Reels............... 78.5 in. (1994 mm)

30 in. Reels............... 90.5 in. (2298 mm)

Cutting Frequency:

7 Blade ..................... 0.151 in./mph (3.8 mm/kph)

Speed:

Mow ......................... 0 - 5 mph (8 kph)

Transport ................. 0 - 8.5 mph (13.7 kph)

Reverse .................... 0 - 2.3 mph (3.7 kph)

Hydraulic System:

Capacity.......................... 5.5 U.S. gal. (20.8 liters) System

Fluid Type ....................... GreensCare 68 Biodegradable

Charge Filter................... 10 micron

Return Line Filter ............ 10 micron

Steering ......................... Hydrostatic power steering

SPECIFICATIONS 2

!

2.5 WEIGHTS AND DIMENSIONS ________________________________________________

Dimensions: Inches (mm)

Length ............................................................. 99 (2519)

Height........................................................... 51.5 (1308)

Width - Wheel .............................................. 64.5 (1638)

Weights:...................................................... Lbs. (kg)

67069 (Base Mower, No Reels).................. 1445 (655)

2.6 ACCESSORIES & SUPPORT LITERATURE _____________________________________

Contact your area Jacobsen Dealer for a complete listing of accessories and attachments.

CAUTION

Use of other than Jacobsen authorized parts and accessories may cause personal injury or damage to the

equipment.

Accesories

Air Blow Gun ...........................................................JAC5098

Orange Touch-up Paint (12 oz. spray) ...................... 554598

2-Post ROPS with Seat Belt........................................ 69157

Light Kit ....................................................................... 69149

Arm Rest ................................................................. 4139431

Grass Catchers for 26 in. Reel.................................... 69151

Grass Catchers for 30 in. Reel.................................... 69150

600 RPM Reel Kit (Diesel Units)............................. 5003062

Down Pressure Kit .................................................. 1002588

Reels

7 Blade, 26 in. Left Hand Reel .................................... 67114

7 Blade, 26 in. Right Hand Reel.................................. 67115

7 Blade, 26 in. Center Reel......................................... 67116

7 Blade, 30 in. Left Hand Reel .................................... 67123

7 Blade, 30 in. Right Hand Reel.................................. 67124

7 Blade, 30 in. Center Reel......................................... 67125

Vertical Mower, 26 in. Left Hand ................................. 67139

Vertical Mower, 26 in. Right Hand ............................... 67140

Vertical Mower, 26 in. Center ...................................... 67141

Rollers

Grooved Front Roller (Steel) for 26 in. Reel.................67731

Grooved Front Roller (Steel) for 30 in. Reel.................67729

Solid Roller for 26 in. Reel ......................................... 132639

Solid Roller for 30 in. Reel ......................................... 132640

Grooved Front Roller Scraper for 26 in. Reel...............69147

Grooved Front Roller Scraper for 30 in. Reel...............69148

Rear Roller Scraper for 26 in. Reel..............................67909

Rear Roller Scraper for 30 in. Reel..............................67910

Support Literature

Safety & Operation Manual......................................4189624

Parts & Maintenance Manual...................................4189623

Diesel Engine Parts Catalog.................................... 4189622

Operator Training DVD............................................. 4191622

Service & Repair Manual ......................................... 4171674

7

2 SPECIFICATIONS

2.7 DECLARATION OF CONFORMITY ____________________________________________

DECLARATION OF CONFORMITY ▪ ДЕКЛАРАЦИЯ ЗА СЪОТВЕТСТВИЕ ▪ PROHLÁŠENÍ O SHODĚ ▪

OVERENSSTEMMELSESERKLÆRING ▪ CONFORMITEITSVERKLARING ▪ VASTAVUSDEKLARATSIOON ▪

VAATIMUSTENMUKAISUUSVAKUUTUS ▪ DECLARATION DE CONFORMITE ▪ KONFORMITÄTSERKLÄRUNG ▪

ΔΗΛΩΣΗ ΣΥΜΜΟΡΦΩΣΗΣ ▪ MEGFELELŐSÉGI NYILATKOZAT ▪ DICHIARAZIONE DI CONFORMITÀ ▪ ATBILSTĪBAS

DEKLARĀCIJA ▪ ATITIKTIES DEKLARACIJA ▪ DIKJARAZZJONI TAL-KONFORMITÀ ▪ DEKLARACJA ZGODNOŚCI ▪

DECLARAÇÃO DE CONFORMIDADE ▪ DECLARAŢIE DE CONFORMITATE ▪ VYHLÁSENIE O ZHODE ▪ IZJAVA O

SKLADNOSTI ▪ DECLARACIÓN DE CONFORMIDAD ▪ DEKLARATION OM ÖVERENSSTÄMMELSE

Business name and full address of the manufacturer ▪ Търговско име и пълен адрес на производителя ▪ Obchodní jméno a plná adresa výrobce ▪

Producentens firmanavn og fulde adresse ▪ Bedrijfsnaam en volledig adres van de fabrikant ▪ Tootja ärinimi ja täielik aadress ▪

Valmistajan toiminimi ja täydellinen osoite ▪ Nom commercial et adresse complète du fabricant ▪ Firmenname und vollständige Adresse des Herstellers ▪

Επωνυμία και ταχυδρομική διεύθυνση κατασκευαστή ▪ A gyártó üzleti neve és teljes címe ▪ Ragione sociale e indirizzo completo del fabbricante ▪

Uzņēmuma nosaukums un pilna ražotāja adrese ▪ Verslo pavadinimas ir pilnas gamintojo adresas ▪ Isem kummerċjali u indirizz sħiħ tal-fabbrikant ▪

Nazwa firmy i pełny adres producenta ▪ Nome da empresa e endereço completo do fabricante ▪ Denumirea comercială şi adresa completă a

producătorului ▪ Obchodný názov a úplná adresa výrobcu ▪ Naziv podjetja in polni naslov proizvajalca ▪ Nombre de la empresa y dirección completa del

fabricante ▪ Tillverkarens företagsnamn och kompletta adress

Product Code ▪ Код на пр

▪ Termékkód ▪ Codice prodotto ▪ Produkta kods ▪ Produkto kodas ▪ Kodiċi tal-Prodott ▪ Kod produktu ▪ Código do Produto ▪ Cod produs ▪ Kód výrobku ▪

Oznaka proizvoda ▪ Código de producto ▪ Produktkod

Machine Name ▪ Наименование на машината ▪ Název stroje ▪ Maskinnavn ▪ Machinenaam ▪ Masina nimi ▪ Laitteen nimi ▪ Nom de la machine ▪

Maschinenbezeichnung ▪ Ονομασία μηχανήματος ▪ Gépnév ▪ Denominazione della macchina ▪ Iekārtas nosaukums ▪ Mašinos pavadinimas ▪ Isem talMagna ▪ Nazwa urządzenia ▪ Nome da Máquina ▪ Numele echipamentului ▪ N

Designation ▪ Предназначение ▪ Označení ▪ Betegnelse ▪ Benaming ▪ Nimetus ▪ Tyyppimerkintä ▪ Pažymėjimas ▪ Bezeichnung ▪ Χαρακτηρισμός ▪

Megnevezés ▪ Funzione ▪ Apzīmējums ▪ Lithuanian ▪ Denominazzjoni ▪ Oznaczenie ▪ Designação ▪ Specificaţie ▪ Označenie ▪ Namen stroja ▪ Descripción

▪ Beteckning

Serial Number ▪ Сериен номер ▪ Sériové číslo ▪ Serienummer ▪ Serienummer ▪ Seerianumber ▪ Valmistusnumero ▪ Numéro de série ▪ Seriennummer ▪

Σειριακός αριθμός ▪ Sorozatszám ▪ Num

serie ▪ Sériové číslo ▪ Serijska številka ▪ Número de serie ▪ Serienummer

Engine ▪ Двигател ▪ Motor ▪ Motor ▪ Motor ▪ Mootor ▪ Moottori ▪ Moteur ▪ Motor ▪ Μηχανή ▪ Modulnév ▪ Motore ▪ Dzinējs ▪ Variklis ▪ Saħħa Netta Installata ▪

Silnik ▪ Motor ▪ Motor ▪ Motor ▪ Motor ▪ Motor ▪ Motor

Net Installed Power ▪ Нетна инсталирана мощност ▪ Čistý instalovaný výkon ▪ Installeret nettoeffekt ▪ Netto geïnstalleerd vermogen ▪ Inst

netovõimsus ▪ Asennettu nettoteho ▪ Puissance nominale nette ▪ Installierte Nettoleistung ▪ Καθαρή εγκατεστημένη ισχύς ▪ Nettó beép tett teljesítmény ▪

Potenza netta installata ▪ Paredzētā tīkla jauda ▪ Grynoji galia ▪ Wisa’ tal-Qtugħ ▪ Moc zainstalowana netto ▪ Potência instalada ▪ Puterea instalată netă ▪

Čistý inštalovaný výkon ▪ Neto vgrajena moč ▪ Potencia instalada neta ▪ Nettoeffekt

Cutting Width ▪ Широчина на рязане ▪ Šířka řezu ▪ Skærebredde ▪ Maaibreedte ▪ Lõikelaius ▪ Leikkuuleveys ▪ Largeur de coupe ▪ Schnittbreite ▪

Μήκος μισινέζας ▪ Vágási szélesség ▪ Larghezza di taglio ▪ Griešanas platums ▪ Pjovimo plotis ▪ Tikkonforma mad-Direttivi ▪ Szer

Largura de Corte ▪ Lăţimea de tăiere ▪ Šírka záberu ▪ Širina reza ▪ Anchura de corte ▪ Klippbredd

Conforms to Directives ▪ В съответствие с директивите ▪ Splňuje podmínky směrnic ▪ Er i overensstemmelse med direktiver ▪ Voldoet aan de richtlijnen ▪

Vastab direktiividele ▪ Direktiivien mukainen ▪ Conforme aux directives ▪ Entspricht Richtlinien ▪ Ακολουθήστε πιστά τις Οδηγίες ▪ Megfelel az irányelveknek

▪ Conforme alle Direttive ▪ Atbilst direktīvām ▪ Atitinka direktyvų reikalavimus ▪ Valutazzjoni tal-Konformità ▪ Dyrektywy związane ▪ Cumpre as Directivas ▪

Respectă Directivele ▪ Je v súlade so smernicami ▪ Skladnost z direktivami ▪ Cumple con las Directivas ▪ Uppfyller direktiv

Conformity Assessment ▪ Оценка за съответствие ▪ Hodnocení plnění podmínek ▪ Overensstemmelsesvurdering ▪ Conformiteitsbeoordeling ▪

Vastavushindamine ▪ Vaatimustenmukaisuuden arviointi ▪ Evaluation de conformité ▪ Konformitätsbeurteilung ▪ Διαπίστωση Συμμόρφωσης ▪

Megfelelőség-értékelés ▪ Valutazione della conformità ▪ Atbilstības novērtējums ▪ Atitikties įvertinimas ▪ Livell tal-Qawwa tal-Ħoss Imkejjel ▪ Ocena

zgodności ▪ Avaliação de Conformidade ▪ Evaluarea conformităţii ▪ Vyhodnotenie zhodnosti ▪ Ocena skladnosti ▪ Evaluación de conformidad ▪

Bedömning av överensstämmelse

Measured Sound Power Level ▪ Измерено ниво на звукова мощност ▪ Naměřený akustický výkon ▪ Målte lydstyrkeniveau ▪ Gemeten geluidsniveau ▪

Mõõdetud helivõimsuse tase ▪ Mit

Σταθμισμένο επίπεδο ηχητικής ισχύος ▪ Mért hangteljesítményszint ▪ Livello di potenza sonora misurato ▪ Izmērītais skaņas jaudas līmenis ▪

Išmatuotas garso stiprumo lygis ▪ Livell tal-Qawwa tal-Ħoss Iggarantit ▪ Moc akustyczna mierzona ▪ Nível sonoro medido ▪ Nivelul măsurat al puterii

acustice ▪ Nameraná hladina akustického výkonu ▪ Izmerjena raven zvočne moči ▪ Nivel de potencia sonora medido ▪ Uppmätt ljudeffektsnivå

Guaranteed Sound Power Level ▪ Гарантирано ниво на звукова мощност ▪ Garantovaný akustický výkon ▪ Garanteret lydstyrkeniveau ▪

Gegarandeerd geluidsniveau ▪ Garanteeritud helivõimsuse tase ▪ Taattu äänitehotaso ▪ Niveau de puissance sonore garanti ▪ Garantierter

Schalldruckpegel ▪ Εγγυημένο επίπεδο ηχητικής ισχύος ▪ Szavatolt hangteljesítményszint ▪ Livello di pote

jaudas līmenis ▪ Garantuotas garso stiprumo lygis ▪ Livell tal-Qawwa tal-Ħoss Iggarantit ▪ Moc akustyczna gwarantowana ▪ Nível sonoro farantido ▪

Nivelul garantat al puterii acustice ▪ Garantovaná hladina akustického výkonu ▪ Zajamčena raven zvočne moči ▪ Nivel de potencia sonora garantizado ▪

Garanterad ljudeffektsnivå

Conformity Assessment Procedure (Noise) ▪ Оценка за съответствие на процедурата (Шум) ▪ Postup hodnocení plnění podmínek (hluk) ▪

Procedure for overensstemmelsesvurdering (Støj) ▪ Procedure van de conformiteitsbeoordeling (geluid) ▪ Vastavushindamismenetlus (müra) ▪

Vaatimustenmukaisuuden arviointimenettely (Melu) ▪ Procédure d’évaluation de conformité (bruit) ▪ Konformitätsbeurteilungsverfahren (Geräusch) ▪

Διαδικασία Αξιολόγησης Συμμόρφωσης (Θόρυβος) ▪ Megfelelőség-értékelési eljárás (Zaj) ▪ Procedura di valutazione della conformità (rumore) ▪

Atbilstības novērtējuma procedūra (troksnis) ▪ Atitikties įver

Procedura oceny zgodności (poziom hałasu) ▪ Processo de avaliação de conformidade (nível sonoro) Procedura de evaluare a conformităţii (zgomot) ▪

Postup vyhodnocovania zhodnosti (hluk) ▪ Postopek za ugotavljanje skladnosti (hrup) ▪ Procedimiento de evaluación de conformidad (ruido) ▪

Procedur för bedömning av överensstämmelse (buller)

UK Notified Body for 2000/14/EC ▪ Нотифициран орган в Обединеното кралство за 2000/14/ЕО ▪ Úřad certifikovaný podle směrnice č. 2000/14/EC ▪

Det britiske bemyndigede organ for 2001/14/EF ▪ Engels adviesorgaan voor 2000/14/EG ▪ Ühendkuningriigi teavitatud asutus direktiivi 2000/14/EÜ

mõistes ▪ Direktiivin 2000/14/EY mukainen ilmoitettu tarkastuslaitos Isossa-Britanniassa ▪ Organisme notifié concernant la directive 2000/14/CE ▪

Britische benannte Stelle für 2000/14/EG ▪ Κοινοποιημένος Οργανισμός Ηνωμένου Βασιλείου για 2000/14/ΕΚ ▪

2000/14/EK – egyesült királyságbeli bejelentett szervezet ▪ Organismo Notificato in GB per 2000/14/CE ▪ 2000/14/EK AK reģistrētā organizācija ▪

JK notifikuotosio

14/WE ▪ Entidade notificada no Reino Unido para 2000/14/CE ▪ Organism notificat în Marea Britanie pentru 2000/14/CE ▪

Notifikovaný orgán Spojeného kráľovstva pre smernicu 2000/14/ES ▪ Britanski priglašeni organ za 2000/14/ES ▪

Cuerpo notificado en el Reino Unido para 2000/14/CE ▪ Anmält organ för 2000/14/EG i Storbritannien

Operator Ear Noise Level ▪ Оператор на нивото на доловим от ухото шум ▪ Hladina hluku v oblasti uší operátora ▪ Støjniveau i førers ørehøjde ▪

Geluidsniveau oor bestuurder ▪ Müratase operaatori kõrvas ▪ Melutaso käyttäjän korvan kohdalla ▪ Niveau de bruit à hauteur des oreilles de l’opérateur ▪

Schallpegel am Bedienerohr ▪ Επίπεδο θορύβου σε λειτουργία ▪ A kezelő fülénél mért zajszint ▪ Livello di potenza sonora all’orecchio dell’operatore ▪

Trokšņa līmenis pie operatora auss ▪ Dirbančiojo su mašina patiriamo triukšmo lygis ▪ Livell tal-Ħoss fil-Widna tal-Operatur ▪

Dopuszczalny poziom hałasu dla o

Hladina hluku pôsobiaca na sluch operátora ▪ Raven hrupa pri ušesu upravljavca ▪ Nivel sonoro en el oído del operador ▪ Ljudnivå vid förarens öra

одукта ▪ Kód výrobku ▪ Produktkode ▪ Productcode ▪ Toote kood ▪ Tuotekoodi ▪ Code produit ▪ Produktcode ▪ Κωδικός προϊόντος

ázov stroja ▪ Naziv stroja ▪ Nombre de la máquina ▪ Maskinens namn

ero di serie ▪ Sērijas numurs ▪ Serijos numeris ▪ Numru Serjali ▪ Numer seryjny ▪ Número de Série ▪ Număr de

alleeritud

okość cięcia ▪

attu äänitehotaso ▪ Niveau de puissance sonore mesuré ▪ Gemessener Schalldruckpegel ▪

nza sonora garantito ▪ Garantētais skaņas

tinimo procedūra (garsas) ▪ Proċedura tal-Valutazzjoni tal-Konformità (Ħoss) ▪

s įstaigos 2000/14/EC ▪ Korp Notifikat tar-Renju Unit għal 2000/14/KE ▪ Dopuszczona jednostka badawcza w Wielkiej Brytanii wg 2000/

peratora ▪ Nível sonoro nos ouvidos do operador ▪ Nivelul zgomotului la urechea operatorului ▪

Jacobsen, A Textron Company

11524 Wilmar Blvd.

Charlotte, NC 28273, USA

67069

Tri-King 3WD

Lawnmower, Article 12, Item 32

6706901651-6706902500

Kubota D722-E3B Diesel

13,2 kW @ 3200 RPM

83 / 213 cm

2004/108/EC

2006/42/EC

200

0/14/EC, 2005/88/EC

2006/66/EC

2006/42/EC Annex VIII

99 dB(A) LWA

99 dB(A) LWA

2000/14/EC Annex VI, Part 1

Sound Research Laboratories Limited

86 dB(a) Leq (2006/42/EC)

Number: 1088

Holbrook House, Little Waldingfield

Sudbury, Suffolk CO10 0TH

8

SPECIFICATIONS 2

Harmonised standards used ▪ Използвани хармонизирани стандарти ▪ Použité harmonizované normy ▪ Brugte harmoniserede standarder ▪

Gebruikte geharmoniseerde standaards ▪ Kasutatud ühtlustatud standardid ▪ Käytetyt yhdenmukaistetut standardit ▪ Normes harmonisées utilisées ▪

Angewandte harmonisierte Normen ▪ Εναρμονισμένα πρότυπα που χρησιμοποιήθηκαν ▪ Harmonizált szabványok ▪ Standard armonizzati applicati ▪

Izmantotie saskaņotie standarti ▪ Panaudoti suderinti standartai ▪ Standards armonizzati użati ▪ Normy spójne powiązane ▪ Normas harmonizadas usadas

▪ Standardele armonizate utilizate ▪ Použité harmonizované normy ▪ Uporabljeni usklajeni standardi ▪ Estándares armonizados utilizados ▪

Harmoniserade standarder som används

Technical standards and specifications used ▪ Използвани технически стандарти и спецификации ▪ Použité technické normy a specifikace ▪

Brugte tekniske standarder og specifikationer ▪ Gebruikte technische standaards en specificaties ▪ Kasutatud tehnilised standardid ja spetsifikatsioonid ▪

Käytetyt tekniset standardit ja eritelmät ▪ Spécifications et normes techniques utilisées ▪ Angewandte technische Normen und Spezifikationen ▪

Τεχν ι κ ά πρό

Izmantotie tehniskie standarti un specifikācijas ▪ Panaudoti techniniai standartai ir techninė informacija ▪ Standards u speċifikazzjonijiet tekniċi użati ▪

Normy i specyfikacje techniczne powiązane ▪ Normas técnicas e especificações usadas ▪ Standardele tehnice şi specificaţiile utilizate ▪

Použité technické normy a špecifikácie ▪ Uporabljeni tehnični standardi in specifikacije ▪ Estándares y especificaciones técnicas utilizadas ▪

Tekniska standarder och specifikationer som används

The place and date of the declaration ▪ Място и дата на декларацията ▪ Místo a datum prohlášení ▪ Sted og dato for erklæringen ▪

Plaats en datum van de verklaring ▪ Deklaratsiooni väljastamise koht ja kuupäev ▪ Vakuutuksen paikka ja päivämäärä ▪ Lieu et date de la déclaration ▪

Ort und Datum der Erklärung ▪ Τόπ ο ς και ημερομηνία δήλωσης ▪ A nyilatkozat kelte

Deklarācijas vieta un datums ▪ Deklaracijos vieta ir data ▪ Il-post u d-data tad-dikjarazzjoni ▪ Miejsce i data wystawienia deklaracji ▪ Local e data da

declaração ▪ Locul şi data declaraţiei ▪ Miesto a dátum vyhlásenia ▪ Kraj in datum izjave ▪ Lugar y fecha de la declaración ▪ Plats och datum för

deklarationen

Signature of the person empowered to draw up the declaration on behalf of the manufacturer, holds the technical documentation and is authorised to

compile the technical file, and who is established in the Community.

Подпис на човека, упълномощен да състави декларацията от името на производителя, който поддържащ техническата документация и е

оторизиран да изготви техническия файл и е регистриран в общността.

Podpis osoby oprávněné sestavit prohlášení jménem výrobce, držet technickou dokumentaci a osoby oprávněné sestavit technické soubory a založené v

rámci Evropského společenství.

Underskrift af personen, der har fuldmagt til at udarbejde erklæringen på vegne af producenten, der er indehaver af dokumentatio

at udarbejde den tekniske journal, og som er baseret i nærområdet.

Handtekening van de persoon die bevoegd is de verklaring namens de fabrikant te tekenen, de technische documentatie bewaart en bevoegd is om het

technische bestand samen te stellen, en die is gevestigd in het Woongebied.

Ühenduse registrisse kantud isiku allkiri, kes on volitatud tootja nimel deklaratsiooni koostama, kes omab tehnilist dokumentatsiooni ja kellel on õigus

koostada tehniline toimik.

Sen henkilön allekirjoitus, jolla on valmistajan valtuutus vakuutuksen laadintaan, jolla on hallussaan tekniset asiakirjat, joka on valtuutettu laatimaan

tekniset asiakirjat ja joka on sijoittautunut yhteisöön.

Signature de la personne habilitée à rédiger la déclaration au nom du fabricant, à détenir la documentation technique, à compiler les fichiers techniques et

qui est implantée dans la Communauté.

Unterschrift der Person, die berechtigt ist, die Erklärung im Namen des Herstellers abzugeben, die die technischen Unterlagen aufbewahrt und berechtigt

ist, die technischen Unterlagen zusammenzustellen, und die in der Gemeinschaft niedergelassen ist.

Υπογραφή ατόμου εξουσιοδοτημένου για την σύνταξη της δήλωσης εκ μέρους του κατασκευαστή, ο οποίος κατέχει την τεχνική έκθεση και έχει την

εξουσιοδότηση να ταξινομήσει τον τεχνικό φάκελο και ο οποίος είναι διορισμένος στην Κοινότητα.

A gyártó nevében meghatalmazott személy, akinek jogában áll módosítania a nyilatkozatot, a műszaki dokumentációt őrzi, engedéllyel rendelkezik a

műszaki fájl összeállításához, és aki a közösségben letelepedett személy.

Firma della persona autorizzata a redigere la dichiarazione a nome del fabbricante, in possesso Della documentazione tecnica ed autorizzata a costituire

il fascicolo tecnico, che deve essere stabilita nella Comunità.

Tās personas paraksts, kura ir pilnvarota deklarācijas sastādīšana

reģistru un kura ir apstiprināta Kopienā.

Asmuo, kuris yra gana žinomas, kuriam gamintojas suteikė įgaliojimus sudaryti šią deklaraciją, ir kuris ją pasirašė, turi visą techninę informaciją ir yra

įgaliotas sudaryti techninės informacijos dokumentą.

Il-firma tal-persuna awtorizzata li tfassal id-dikjarazzjoni f’isem il-fabbrikant, għandha d-dokumentazzjoni teknika u hija awtorizzata li tikkompila l-fajl

tekniku u li hija stabbilita fil-Komunità.

Podpis osoby upoważnionej do sporządzenia deklaracji w imieniu producenta, przechowującej dokumentację techniczną, upoważnioną do stworzenia

dokumentacji technicznej oraz wyznaczonej ds. wspólnotowych.

Assinatura da pessoa com poderes para emitir a declaração em nome do fabricante, que possui a documentação técnica, que está autorizada a compilar

o processo técnico e que está estabelecida na Comunidade.

Semnătura persoanei împuternicite să elaboreze declaraţia în numele producătorului, care deţine documentaţia tehnică, este autorizată să compileze

dosarul tehnic şi este stabilită în Comunitate.

Podpis osoby poverenej vystavením vyhlásenia v mene výrobcu, ktorá má technickú dokumentáciu a je oprávnená spracovať technické podklady a ktorá

je umiestnená v Spoločenstve.

Podpis osebe, pooblaščene za izdelavo izjave v imenu proizvajalca, ki ima tehnično dokumentacijo in lahko sestavlja spis tehnične

sedež v Skupnosti.

Firma de la persona responsable de la declaración en nombre del fabricante, que posee la documentación técnica y está autorizada para recopilar el

archivo técnico y que está establecido en la Comunidad.

Undertecknas av den som bemyndigad att upprätta deklarationen å tillverkarens vägnar, innehar den tekniska dokumentationen och är bemyndigad att

sammanställa den tekniska informationen och som är etablerad i gemenskapen.

Certificate Number ▪ Номер на сертификат ▪ Číslo osvědčení ▪ Certifikatnummer ▪ Certificaatnummer ▪ Sertifikaadi number ▪ Hyväksyntänumero ▪

Numéro de certificat ▪ Bescheinigungsnummer ▪ Αριθμός Πιστοποιητικού ▪ Hitelesítési szám ▪ Numero del certificato ▪ Sertifikāta numurs ▪

Sertifikato numeris ▪ Numru taċ-Ċertifikat ▪ Numer certyfikatu ▪ Número do Certificado ▪ Număr certificat ▪ Číslo osvedčenia ▪ Številka certifikata ▪

Número de certificado ▪ Certifikatsnummer

τυπα και προδιαγραφές που χρησιμοποιήθηκαν ▪ Műszaki szabványok és specifikációk ▪ Standard tecnici e specifiche applicati ▪

(hely és idő) ▪ Luogo e data della dichiarazione ▪

nen og er bemyndiget til

i ražotāja vārdā, kurai ir tehniskā dokumentācija, kura ir pilnvarota sagatavot tehnisko

dokumentacije, ter ima

BS EN ISO 20643

BS EN ISO 5349-1

BS EN ISO 5349-2

BS EN 836

B71.4

ISO 2631-1

SAE J1194

Jacobsen, A Textron Company

11524 Wilmar Blvd.

Charlotte, NC 28273, USA

May 7th, 2012

2006/42/EC Annex II 1.A.2

Tim Lansdell

Technical Director

Ransomes Jacobsen Limited

West Road, Ransomes Europark,

Ipswich, IP3 9TT, England

2006/42/EC Annex II 1 A.10

Vasant Godhalekar

VP of Engineering

Jacobsen, A Textron Company

11524 Wilmar Blvd,

Charlotte, NC 28273, USA

4189623 Rev C

GB BG CZ DK NL EE FI FR DE GR HU

българскиEnglish čeština dansk Nederlands eesti suomi français Deutsch Ελληνικά magyar

IT LV LT MT PL PT RO SK SI ES SE

italiano lietuvių

latviešu

valoda

kalba

Malki polski português Română slovenčina slovenščina Ελληνικά Svenska

9

3 ADJUSTMENTS

!

!

A

B

D

E

C

3.1 GENERAL________________________________________________________________

adjustment cannot be made, contact an authorized

WARNING

To prevent injury, lower implements to the ground,

disengage all drives, engage parking brake, stop engine,

and remove key from ignition switch before making any

adjustments or performing maintenance.

Jacobsen Dealer.

2. Replace, do not adjust, worn or damaged components.

3. Do not wear jewelry or loose fitting clothing when

making adjustments or repairs.

Make sure the mower is parked on a solid and level

surface. Never work on a mower that is supported only

by the jack. Always use jack stands.

If only the front or rear of the mower is raised, place

chocks in front of and behind the wheels that are not

raised.

1. Adjustments and maintenance should always be

performed by a qualified technician. If proper

Be careful to prevent entrapment of the hands and

fingers between moving and fixed components of the

machine.

4. Do not change governor settings or overspeed the

engine.

CAUTION

3.2 FAN BELT________________________________________________________________

Inspect and adjust new belt after first ten hours of

operation. Adjust every 100 hours thereafter.

1. Adjust alternator pulley so belt (B) deflects 9/32 to

11/32 in. (7 to 9 mm) with a 22 lb. (10 kg) push at

midspan between pulleys.

2. If tension is incorrect, loosen alternator mounting

bolts (A), and adjust alternator until proper belt

tension is achieved. Tighten hardware (A).

3.3 PUMP DRIVE BELT ________________________________________________________

Adjust reel pump belt (C) to deflect 1/4 in. (6 mm) with a

force of 5-7 lb. (2-3 kg) applied at midspan.

1. Loosen hardware (D and E).

2. Move pump/clutch assembly down to increase

tension on belt (C) then tighten hardware (D and E).

3. Torque hardware (D and E) to 27 - 33 ft. lb. (37-45

Nm).

10

Figure 3A

Figure 3B

ADJUSTMENTS 3

G

H

F

K

L

M

3.4 NEUTRAL AND 3WD SWITCHES _____________________________________________

1. Check traction pedal adjustment.

2. Use a volt/ohm meter to determine when switch

opens or closes.

a. Adjust switch (G) so “finger” of actuating arm (F)

is centered over sensing portion of switch.

Switch contacts should be closed with traction

pedal in neutral and open with minimal pedal

travel in forward or reverse direction.

b. Adjust 3WD switch (H) so contacts are open with

traction pedal in neutral, and contacts close with

minimal pedal travel in forward direction.

Figure 3C

3.5 PARKING BRAKE SWITCHES________________________________________________

Loosen screws (K) and adjust both switches so contacts

just close as the brake lever is moved to the engaged

position then tighten screws.

Figure 3D

3.6 LIFT LIMIT SWITCH ________________________________________________________

The lift limit switch must be adjusted so the reels stop

turning before the cutting plane between the reel and

ground reach 15-3/4 in. (400 mm). To adjust, loosen

screw (L), and adjust arm (M).

Figure 3E

11

3 ADJUSTMENTS

O

N

N

Front

P

P

Q

S

R

3.7 TRACTION PEDAL NEUTRAL________________________________________________

1. If the mower “creeps” in either direction when the

engine is running, but the traction pedal is not

depressed, adjust spring tension so that the pedal

always returns to neutral when released.

Note: The mower may “creep” when the hydraulic oil

is cold. Operate the mower for 15 minutes before

determining if adjustment is required.

2. Use extreme caution when making this adjustment

as the wheels will be off the ground and the engine

will be running.

3. Engage parking brake, stop the engine, open hoods,

then lubricate all linkage pivot points.

4. Chock the rear wheel, and place the front of the

mower on jackstands.

5. Loosen all nuts (N) and adjust rear spring to

position traction arm in neutral.

a. Lock rear nuts and adjust front nuts (N) to

maintain 3/8 in. (9 mm) of extension in spring

(O).

b. Start the engine and check for “creep” then

repeat the process if necessary.

Figure 3F

3.8 TRACTION PEDAL FORWARD STOP__________________________________________

Loosen nuts (P) move the traction pedal to its maximum

forward position. Adjust screw (Q) until the head just

touches the traction pedal arm. Return traction pedal to

neutral and turn screw (Q) out one full turn. Tighten nuts

(P).

Important: Screw (Q) must stop traction pedal before the

internal stops in the hydrostatic transmission are

contacted.

Figure 3G

3.9 LIFT / LOWER PEDAL STOP_________________________________________________

Adjust bolts (R and S) to stop spool valve from hitting the

internal stops, while maintaining the full stroke of the

spool.

Figure 3H

12

ADJUSTMENTS 3

!

T

U

V

X

W

3.10 PARKING BRAKE__________________________________________________________

1. Check linkage cables and pivots to ensure they are

operating smoothly.

2. Park the mower on a 30% slope (16.7°) near the

bottom of the hill, with the front of the mower facing

downhill. Engage the parking brake and stop the

engine.

a. The mower should stay on the hill without

creeping.

b. If the brakes do not hold, start the engine,

disengage the brake, and drive to the bottom of

the hill.

DO NOT disengage the brakes with the engine off.

3. With parking brake disengaged, turn adjusting knob

in a clockwise direction, applying and releasing

brake every quarter turn, until a definite “snap over

center” action is achieved.

4. Repeat the test on the hill if required.

Note: Over adjustment causes hard lever action, but

does not increase brake efficiency.

3.11 REAR LIFT ARM ___________________________________________________________

1. Rear lift arm position is properly adjusted when the

rear mower bumpers are putting slight pressure

against the underside of the foot rests.

2. Disconnect lift chain (T) from crank and adjust ball

joint (U) as required.

CAUTION

3.12 DOWN PRESSURE_________________________________________________________

1. Place mowers in the Fixed Mode (Section 3.18) and

lower the mowers onto a scale, capable of weighing

250 lb. (113 kg). The rear roller of the mower must

rest on the scale.

2. To adjust pressure on rear mower loosen nuts (V)

and adjust to obtain the desired pressure.

3. To adjust pressure on front mowers, loosen nut (W)

and adjust bolt (X). Minimum thread engagement

should be 1/2 in. (13 mm).

4. To maintain a consistent height of cut, the down

pressure should be adjusted evenly on all three

mowers.

5. Jacobsen, recommends the mower weight for

Floating Mode at 60 lb. (27 kg), and for Fixed Mode

at 90 lb. (41 kg).

Figure 3K

Figure 3I

Figure 3J

13

3 ADJUSTMENTS

!

5 -6

93

5/32 in.

°

°

Leading

Edge of Reel

Normal

Rotation

A

B

C

E

D

F

G

3.13 REEL TO BEDKNIFE _______________________________________________________

(Pre-adjustment Check)

1. Check the reel bearings for end play or radial play. If

there is any abnormal movement of the reel, up and

down or side to side, adjust or replace components as

needed.

CAUTION

To prevent personal injury and damage to the cutting

edges, handle the reel with extreme care.

2. Inspect the reel blades and bedknife to insure good

sharp edges without bends or nicks.

a. The cutting edges of the reel blades and bedknife

must be sharp, free of burrs, and show no signs of

rounding off.

b. The bedknife and bedknife backing must be

securely tightened. The bedknife must be straight

and sharp.

c. A flat surface of 5/32 in. (4 mm) minimum must be

maintained on the front face of the bedknife. Use a

standard flat file to dress the bedknife.

maintained across the entire length of the reel and

bedknife.

5. The reel must be parallel to the bedknife. An

improperly adjusted reel will lose its sharp edges

prematurely and may result in serious damage to the

reel and bedknife.

6. Grass conditions will also affect the adjustment.

a. Dry, sparse conditions will require a wider gap to

prevent heat buildup and damage to the reel and

bedknife.

b. High quality grass with a good moisture content

requires a closer gap (near zero).

Figure 3L

3. If wear or damage is beyond the point where the reel

or bedknife can be corrected by the lapping process,

they must be reground.

4. Proper reel-to-bedknife adjustment is critical. A gap of

0.001 to 0.003 in. (0.025 to 0.076 mm) must be

3.14 REEL TO BEDKNIFE ADJUSTMENT __________________________________________

1. Read Section 3.13 before making the adjustment.

2. Start adjustment at the leading edge of the reel,

followed by the trailing end. The leading end of the

blade is the end that passes over the bedknife first

during normal rotation.

3. Loosen nut (C) 1/4 turn on both ends of the cutting

unit.

a. Turn adjuster (A) in 1/16 to 1/8 turn increments.

b. Slide a feeler gauge or shim stock.001 in. (.025

mm) between the reel blade and the bedknife.

Do not turn reel.

c. Adjust the trailing end of the reel in the same

manner then recheck the adjustment at the

leading end.

d. Tighten all hardware and recheck the

adjustment.

e. When properly adjusted, the reel will spin freely,

and you should be able to cut a piece of

newspaper along the full length of the reel, when

the paper is held at 90°.

Figure 3N

14

ADJUSTMENTS 3

H

H

H

Tether

3.15 CUTTING MODES__________________________________________________________

1. The mower may be operated in the Fixed Mode or

the Floating Mode.

2. Fixed Mode is generally used for cutting heights

greater than 1 in. (25 mm) and the mower does not

require a front roller unless the terrain is rough and

uneven.

If a front roller is required, the roller should be raised

1/4 in. (6 mm) higher than the rear roller and used for

anti-scalp purposes only.

3. Floating Mode is generally used for cutting heights

less than one inch (25 mm) and a front roller is

required.

If a 2-1/2 in. (63 mm) solid front roller is used, the

cutting height will range from 3/8 to 2-1/8 in. (9 to

54 mm).

If a 3 in. (76 mm) grooved front roller is used, the

cutting height will range from 3/8 to 2-1/4 in. (9 to

57 mm).

4. To convert the mower from Fixed to Floating Mode,

remove hardware (H) from each side of the three

mower frames.

Install a front roller and store hardware (H) for future

conversion to fixed mode.

5. To convert the mower from Floating to Fixed Mode,

assemble hardware (H) as shown and remove or

raise the front roller.

Figure 3O

3.16 CUTTING HEIGHT ADJUSTMENT_____________________________________________

1. Raise and lock the lift arms in transport mode.

2. For easier access to the height adjusters on the

motor end of the front reels, Jacobsen recommends

raising the front end of the mower just a few inches

off the ground then, being careful not to damage the

hydraulic hoses, tilt the front mowers 90 degrees,

and tether the mowers together.

3. On the rear mower (center) remove the pin and

collar on the shaft and slide the mower backwards.

4. Always make the reel-to bedknife adjustment

(Sections 3.13 and 3.14) before making the cutting

height adjustment.

5. Select Fixed or Floating Mode and convert the

mower accordingly.

6. Loosen skid mounting hardware (D - Figure 3N)

then adjust the cutting height. (A special tool is

provided with the mowers. A 5/8 in. socket and

ratchet are required).

Figure 3P

15

3 ADJUSTMENTS

!

1

2

3

4

5

6

7

8

N

M

N

M

U

T

S

R

B

E

F

G

G

J

F

E

A

B

3.17 REMOVING THE CUTTING UNIT _____________________________________________

1. To prevent contamination of the hydraulic system, as

well as loss of oil, do not disconnect the hoses from

the motor.

CAUTION

Disconnect lift springs before removing mowers.

2. Raise and lock the lift arms in transport mode

(Section 3.4) and disconnect the down pressure

springs.

3. Remove transport pin then lower the lift arms to the

ground.

4. Remove hardware securing motor to drive housing

and carefully pull the motor away.

5. Place motor in a clean plastic bag and cover the

opening in the gear box.

6. Remove pin and collar from center (rear) lift arm

and pull the center cutting unit away from the

mower.

7. Remove the hardware securing the front lift arms to

the cutting units, and slide the mowers out of the

way.

3.18 CUTTING HEIGHT - FIXED MODE ____________________________________________

Follow the procedures outlined in Section 3.16.

1. Reposition the rear roller adjuster.

a. For cutting heights from 3/8 to 1-3/4 in. (9 to

44 mm), use holes (M) on the mower frame, and

two holes (shown in black) of the height adjuster

(F) as shown.

b. For cutting heights greater than 1-3/4 inches

(44 mm), disassemble adjuster (F) and turn the

mounting bracket upside down; then use holes

(N) of the frame, and the two holes (shown in

black) of the adjuster (F).

2. Remove the tether, and lower the cutting units to

the ground.

Figure 3Q

3. Place spacers of the desired height (J) under each

end of the reel, adjacent to the front edge of the

bedknife.

4. Loosen nut (G) and lower rear roller to the ground.

Tighten nut (E) against the adjuster then recheck

the setting on both side of the reel. Readjust if

necessary.

5. Assemble the front roller adjuster (B) (If a roller is

required) to holes number 2 and 4 only of the

mower frame. Do not use holes number 1 and 3.

Set roller to 1/4 in. (6 mm) above rear roller.

16

Figure 3R

ADJUSTMENTS 3

1

2

3

4

5

6

7

8

N

M

N

M

U

T

S

R

B

E

F

G

Front Roller

P

Rear Roller

X-Cutting Height

K

L

3.19 CUTTING HEIGHT - FLOATING MODE _________________________________________

Follow the procedures outlined in Section 3.16.

1. Assemble the front roller adjuster (B) to holes num-

ber 2 and 4 only of the mower frame. Do not use hole

numbers 1 and 3. Refer to the chart below for correct

hole of front roller adjuster to use.

2. Reposition the rear roller adjusters (F).

a. For cutting heights from 3/8 to 1-3/4 in. (9 to

44 mm), use holes (M) on the mower frame, and

two holes (shown in black) of adjuster (F) as

shown.

b. For cutting heights greater than 1-3/4 in.

(44 mm), disassemble adjuster (F) and turn the

mounting bracket upside down; then use holes

(N) of the frame, and the two holes (shown in

black) of adjuster (F).

3. Loosen nut (L) and adjust screw (K) to obtain

desired cutting height (X) then lock nut (L) against

gauge (P).

Figure 3S

4. Place one end of the gauge under the front roller at

either end of the reel, and slide the head of screw

(K) over the bedknife.

a. Adjust nut (G) to lower the rear roller to the

gauge, then tighten nut (E) against the adjuster.

b. Move the gauge to the other end of the reel and

repeat Steps 4a and 4b.

Range of Cut

Grooved Roller

Inches Millimeters

3/8 - 3/4 10 - 19 3/8 - 5/8 10 - 16 R M

3/4 - 1-1/4 19 - 32 5/8 - 1-1/8 16 - 29 S M

1-1/4 - 1-3/4 32 - 44 1-1/8 - 1-5/8 29 - 41 T M

1-3/4 - 2-1/4 44 - 57 1-5/8 - 2-1/8 41 - 54 U N

Solid Roller

Inches Millimeters

Front

Rear

Figure 3T

17

3 ADJUSTMENTS

4.6

8.8

10.9

12.9

3.20 TORQUE SPECIFICATION___________________________________________________

NOTICE

All torque values included in these charts are approximate and are for reference only. Use of these torque values is

at your sole risk. Jacobsen is not responsible for any loss, claim, or damage arising from the use of these charts.

Extreme caution should always be used when using any torque value.

Jacobsen uses Grade 5 Plated bolts as standard, unless otherwise noted. For tightening plated bolts, use the value

given for lubricated.

AMERICAN NATIONAL STANDARD FASTENERS

SIZE UNITS GRADE 5 GRADE 8 SIZE UNITS GRADE 5 GRADE 8

Lubricated Dry Lubricated Dry Lubri-

cated

#6-32 in-lb (Nm) – 20 (2.3) – – 7/16-14 ft-lb (Nm) 37 (50.1) 50 (67.8) 53 (71.8) 70 (94.9)

#8-32 in-lb (Nm) – 24 (2.7) – 30 (3.4) 7/16-20 ft-lb (Nm) 42 (56.9) 55 (74.6) 59 (80.0) 78 (105)

#10-24 in-lb (Nm) – 35 (4.0) – 45 (5.1) 1/2-13 ft-lb (Nm) 57 (77.2) 75 (101) 80 (108) 107 (145)

#10-32 in-lb (Nm) – 40 (4.5) – 50 (5.7) 1/2-20 ft-lb (Nm) 64 (86.7) 85 (115) 90 (122) 120 (162)

#12-24 in-lb (Nm) – 50 (5.7) – 65 (7.3) 9/16-12 ft-lb (Nm) 82 (111) 109 (148) 115 (156) 154 (209)

1/4-20 in-lb (Nm) 75 (8.4) 100 (11.3) 107 (12.1) 143 (16.1) 9/16-18 ft-lb (Nm) 92 (124) 122 (165) 129 (174) 172 (233)

1/4-28 in-lb (Nm) 85 (9.6) 115 (13.0) 120 (13.5) 163 (18.4) 5/8-11 ft-lb (Nm) 113 (153) 151 (204) 159 (215) 211 (286)

5/16-18 in-lb (Nm) 157 (17.7) 210 (23.7) 220 (24.8) 305 (34.4) 5/8-18 ft-lb (Nm) 128 (173) 170 (230) 180 (244) 240 (325)

5/16-24 in-lb (Nm) 173 (19.5) 230 (26.0) 245 (27.6) 325 (36.7) 3/4-10 ft-lb (Nm) 200 (271) 266 (360) 282 (382) 376 (509)

3/8-16 ft-lb (Nm) 23 (31.1) 31 (42.0) 32 (43.3) 44 (59.6) 3/4-16 ft-lb (Nm) 223 (302) 298 404 315 (427) 420 (569)

3/8-24 ft-lb (Nm) 26 (35.2) 35 (47.4) 37 (50.1) 50 (67.8) 7/8-14 ft-lb (Nm) 355 (481) 473 (641) 500 (678) 668 (905)

Dry Lubri-

cated

Dry

SIZE UNITS

Lubricated Dry Lubricated Dry Lubricated Dry Lubricated Dry

M4 Nm (in-lb)––––––3.83 (34)5.11 (45)2.0 (18)

M5 Nm (in-lb) 1.80 (16) 2.40 (21) 4.63 (41) 6.18 (54) 6.63 (59) 8.84 (78) 7.75 (68) 10.3 (910 4.0 (35)

M6 Nm (in-lb) 3.05 (27) 4.07 (36) 7.87 (69) 10.5 (93) 11.3 (102) 15.0 (133) 13.2 (117) 17.6 (156) 6.8 (60)

M8 Nm (in-lb) 7.41 (65) 9.98 (88) 19.1 (69) 25.5 (226) 27.3 (241) 36.5 (323) 32.0 (283) 42.6 (377) 17.0 (150)

M10 Nm (ft-lb) 14.7 (11) 19.6 (14) 37.8 (29) 50.5 (37) 54.1 (40) 72.2 (53) 63.3 (46) 84.4 (62) 33.9 (25)

M12 Nm (ft-lb) 25.6 (19) 34.1 (25) 66.0 (48) 88.0 (65) 94.5 (70) 125 (92) 110 (81) 147 (108) 61.0 (45)

M14 Nm (ft-lb) 40.8 (30) 54.3 (40) 105 (77) 140 (103) 150 (110) 200 (147) 175 (129) 234 (172) 94.9 (70)

3.21 SPECIFIC TORQUE ________________________________________________________

1. Tie rod ball joints: (2) 30 - 35 ft. lb. (41 - 47 Nm)

2. Engine drain plugs: 22 ft. lb. (30 Nm)

3. Steering ball joints: 50 - 55 ft. lb. (68 - 75 Nm)

18

METRIC FASTENERS

Non Critical

Fasteners

into

Aluminum

4. Steering wheel nut: 30-40 ft. lb (41 - 51 Nm)

5. Wheel hardware:65 - 85 ft. lb. (88 - 116 Nm)

MAINTENANCE 4

!

4.1 GENERAL ________________________________________________________________

b. Keep all moving parts properly adjusted and lubri-

WARNING

Before you clean, adjust, or repair this equipment,

disengage all drives, lower implements to the ground,

engage parking brake, stop engine, and remove key from

ignition switch to prevent injuries

Make sure the mower is parked on a solid and level

surface. Never work on a mower that is supported only

by the jack. Always use jack stands.

1. Adjustment and maintenance should always be

performed by a qualified technician. If proper

adjustments cannot be made, contact an Authorized

Jacobsen Dealer.

2. Inspect the equipment on a regular basis, establish a

maintenance schedule, and keep detailed records.

a. Keep the equipment clean.

3. Do not wear jewelry or loose fitting clothing when

4. Use the illustrations in the Parts Catalog as reference

5. Recycle or dispose of all hazardous materials

cated.

c. Replace worn or damaged parts before operating

the machine.

d. Keep all fluids at their proper levels.

e. Keep shields in place and all hardware securely fas-

tened.

f. Keep tires properly inflated.

making adjustments or repairs.

for the disassembly and reassembly of components.

(batteries, fuel, lubricants, anti-freeze, etc.) according

to local, state, or federal regulations.

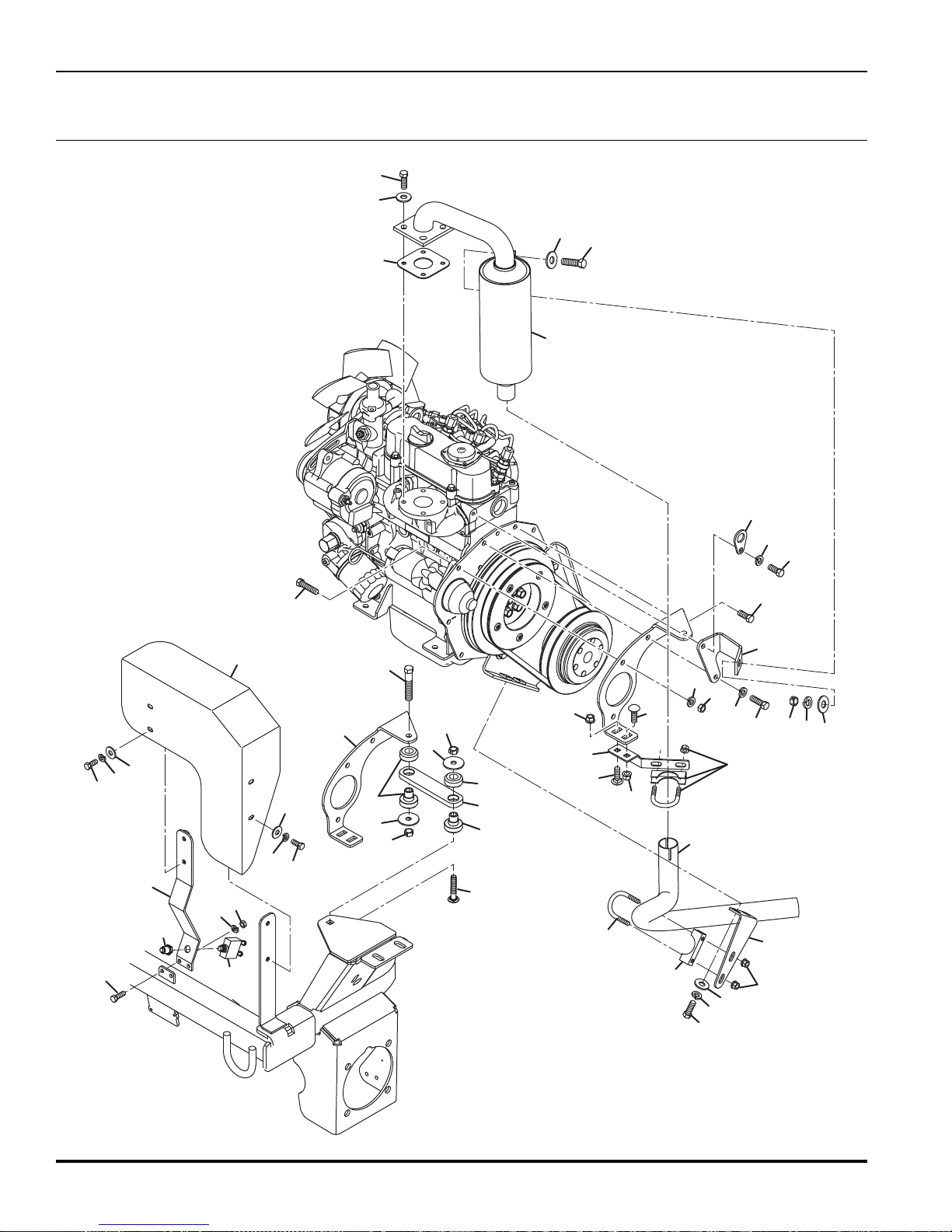

4.2 ENGINE _________________________________________________________________

IMPORTANT: A separate Engine Manual, prepared by

the engine manufacturer, is supplied with this mower.

Read the Engine Manual carefully until you are familiar

with the operation and maintenance of the engine.

Proper attention to the engine manufacturer’s

directions will assure maximum service life of the

engine. To order replacement engine manuals contact

the engine manufacturer.

The proper break-in of a new engine can make a

considerable difference to the performance and life of the

engine.

5. Refer to Section 6.3 and Engine Manual for specific

maintenance intervals.

If the injection pump, injectors, or the fuel system require

service, contact an authorized Jacobsen Dealer.

NOTICE

The mower is designed to operate and cut most

efficiently at the preset governor setting. Do not change

the engine governor settings or overspeed the engine.

During the break-in period, Jacobsen recommends the

following:

1. During the first 50 hours of operation, a new engine

should be allowed to reach an operating temperature of

at least 140°F (60°C) prior to operation at full load.

2. Check the engine oil level twice daily during the first 50

hours of operation. Higher than normal oil consumption

is not uncommon during the initial break-in period.

3. Change engine oil and oil filter element after first 50

hours of operation.

4. Check and adjust fan and alternator belts.

19

4 MAINTENANCE

Safe Operating Range

⎧

⎨⎪⎪

⎪

⎪

⎩

C

D

E

4.3 ENGINE OIL ______________________________________________________________

Check the engine oil at the start of each day, before starting

the engine. If the oil level is low, remove oil filler cap, and

add oil as required.

Perform initial oil change after first 50 hours of operation and

every 100 hours thereafter. See Engine Manual.

Use only engine oils with API classification CD/CE.

Above 77°F (25°C) SAE 30W or SAE10W30/10W40

32 to 77°F (0 to 25°C) SAE 20W or SAE 10W30/10W40

Below 32° (0°C) SAE10W or SAE 10W30/10W40

Figure 4A

4.4 AIR FILTER_______________________________________________________________

Check the service indicator daily. If red band appears in the

window (C) replace the element.

Do not remove the element for inspection or cleaning.

Unnecessary removal of the filter increases the risk of

injecting dust and other impurities into the engine.

When service is required, first clean the outside of the filter

housing; then remove the old element as gently as possible

and discard.

1. Carefully clean the inside of the filter housing without

allowing dust into the air intake.

2. Inspect the new element. Do not use a damaged

element and never use an incorrect element.

3. Assemble the new element and make sure it seats

properly. Reset the indicator by depressing button (D).

4. Reassemble cap making sure it seals completely

around the filter housing. Dust evacuator (E) must be

facing down.

Figure 4B

5. Check all hoses and air ducts. Tighten hose clamps.

20

MAINTENANCE 4

!

!

!

4.5 FUEL ____________________________________________________________________

Handle fuel with care - it is highly flammable. Use an

approved container, the spout must fit inside the fuel filler

neck. Avoid using cans and funnels to transfer fuel.

WARNING

Never remove the fuel cap from the fuel tank, or add fuel,

when the engine is running or while the engine is hot.

Do not smoke when handling fuel. Never fill or drain the

fuel tank indoors.

Do not spill fuel and clean spilled fuel immediately.

Never handle or store fuel containers near an open flame

or any device that may create sparks and ignite the fuel

or fuel vapors.

Be sure to reinstall and tighten fuel cap securely.

• Fill the fuel tank to within 1 in. (25 mm) of the bottom of

the filler neck.

• Store fuel according to local, state, or federal ordinances

and recommendations from your fuel supplier.

• Never overfill or allow the tank to become empty.

• Check fuel lines and clamps every 50 hours. Replace fuel

lines and clamps at the first sign of damage.

• Use clean, fresh, #2 Diesel fuel. Minimum Cetane rating

45. Refer to Engine Manual for additional information.

4.6 FUEL SYSTEM ____________________________________________________________

Refer to Section 6.3 for specific maintenance intervals.

Before replacing any filter, thoroughly clean the filter housing

and the area around the filter. Dirt must not be allowed to

enter into fuel system.

For diesel engines, bleed the fuel system after the fuel filter

and lines have been removed, or the fuel tank has become

empty. See Engine Manual.

4.7 BATTERY ________________________________________________________________

Make absolutely certain the ignition switch is OFF and the

key has been removed before servicing the battery.

CAUTION

Always use insulated tools, wear protective glasses or

goggles and protective clothing when working with

batteries. You must read and obey all battery

manufaturer’s instructions.

Tighten cables securely to battery terminals and apply a

light coat of silicone dielectric grease to terminals and cable

ends to prevent corrosion. Keep vent caps and terminal

covers in place.

Check the electrolyte level every 100 hours. Keep the cable

ends, battery, and battery posts clean.

Verify battery polarity before connecting or disconnecting

the battery cables.

1. When installing the battery, always assemble the RED,

positive (+) battery cable first, and the ground, BLACK,

negative (-) battery cable last.

2. When removing the battery, always remove the ground,

BLACK, negative (-) cable first, and the RED, positive

(+) cable last.

3. Make sure battery is properly installed and secured to

the battery tray.

WARNING

Battery posts, terminals, and related accessories

contain lead and lead compounds, chemicals known

to the State of California to cause cancer and

reproductive harm. Wash your hands after

handling

.

21

4 MAINTENANCE

!

!

!

4.8 JUMP STARTING __________________________________________________________

Before attempting to “jump start” the mower, check the

condition of the discharged battery. Section 4.7

WARNING

Batteries generate explosive hydrogen gas. To reduce

the chance of an explosion, avoid creating sparks near

battery. Always connect the negative jumper cable to the

frame of the mower with the discharged battery, away

from the battery.

When connecting jumper cables:

1. Stop the engine on the vehicle with a good battery.

2. Connect RED jumper cable to the positive (+) terminal

on the good battery and to the positive (+) terminal on

the “discharged” battery.

3. Connect the BLACK jumper cable from the negative

(-) terminal on the good battery to the frame of the

mower with the discharged battery.

After cables have been connected, start the engine on the

vehicle with the good battery then start the mower.

4.9 CHARGING BATTERY _____________________________________________________

1. Refer to Section 4.7. Read the Battery and Charger’s

WARNING

Charge battery in a well ventilated area. Batteries

generate explosive gases. To prevent an explosion, keep

any device that may create sparks or flames away from

the battery.

To prevent injury, stand away from battery when the

charger is turned on. A damaged battery could explode.

manual for specific instructions.

2. Whenever possible, remove the battery from the

mower before charging. If battery is not sealed, check

that the electrolyte covers the plates in all the cells.

3. Make sure the charger is Off Then connect the charger

to the battery terminals as specified in the charger’s

manual.

4. Always turn the charger Off before disconnecting

charger from the battery terminals.

4.10 HYDRAULIC HOSES _______________________________________________________

IMPORTANT: The hydraulic system can be

WARNING

To prevent serious injury from hot, high pressure oil,

never use your hands to check for oil leaks, use paper or

cardboard.

Hydraulic fluid escaping under pressure can have

sufficient force to penetrate skin. If fluid is injected into

the skin it must be surgically removed within a few hours

by a doctor familiar with this form of injury or gangrene

may result.

1. Always lower implements to ground, disengage all

drives, engage parking brake, stop engine, and remove

key before inspecting or disconnecting hydraulic lines or

hoses.

2. Check visible hoses and tubes daily. Look for wet

hoses or oil spots. Replace worn or damaged hoses

and tubes before operating the machine.

3. The replacement tube or hoses must be routed in the

same path as the existing hose, do not move clamps,

brackets, and ties to a new location.

permanently damaged if the oil becomes

contaminated. Before disconnecting any hydraulic

component, clean the area around fittings and hose

ends to keep impurities out of the system.

a. Before disconnecting any hydraulic component, tag

or mark the location of each hose then clean the

area around the fittings.

b. As you disconnect the component, be prepared to

assemble plugs or caps to the hose ends and open

ports. This will keep impurities out of the hydraulic

system and also prevent oil spills.

c. Make sure “O” rings are clean and hose fittings are

properly seated before tightening.

d. Keep the hose from twisting. Twisted hoses can

cause couplers to loosen as the hose flexes during

operation resulting in oil leaks.

e. Kinked or twisted hoses can restrict the oil flow

causing the system to malfunction and the oil to

overheat and also lead to hose failure.

4. Thoroughly inspect all tubes, hoses, and connections

every 250 hours.

22

MAINTENANCE 4

!

4.11 HYDRAULIC OIL___________________________________________________________

Refer to Section 6.3 for specific maintenance intervals.

The hydraulic reservoir on this machine is filled with

Jacobsen Greens Care 68 Biodegradable fluid.

Drain and replace the hydraulic oil after a major component

failure, or if you notice the presence of water or foam in the

oil, or a rancid odor (indicating excessive heat).

Always replace the hydraulic filter when changing oil.

To change hydraulic oil:

1. Clean the area around the oil cap to prevent impurities

from entering and contaminating the system.

a. Oil temperature should be at 60° to 90°F (16° -

32°C). Do not check oil level when oil is hot.

b. The hydraulic oil level should never fall below the

lower line on the dipstick or be above the top line on

dipstick.

2. Remove drain plug from bottom of tank and loosen or

remove breather cap on top of tank. Check and clean

the breather cap, replace as necessary.

3. After oil has drained install drain plug and fill with

Jacobsen GreensCare 68 Biodegradable Fluid.

4. Purge air from system.

a. Operate all mower functions for about 5 minutes to

purge air out of the system and stabilize the oil

level.

b. Once the level has stabilized and the air is purged,

fill the tank to the full mark on dipstick.

4.12 HYDRAULIC OIL FILTERS___________________________________________________

The hydraulic system is protected by two 10 micron filters.

To replace hydraulic oil filter:

1. Remove the old filters.

2. Fill new filter with oil then install new filter. Hand tighten

only.

3. Operate engine at idle speed with hydraulic system in

neutral for five minutes.

4. Check hydraulic oil level in reservoir and fill to full mark

on dipstick.

4.13 ELECTRICAL SYSTEM _____________________________________________________

6. Do not wash or pressure spray around electrical

connections and components.

CAUTION

Always turn the ignition switch off and remove the

negative battery cable (BLACK) before inspecting or

working on the electrical system.

General precautions that can be taken to reduce electrical

problems are listed below.

1. Make certain all terminals and connections are clean

and properly secured.

2. Check the operator backup system, fuses, and circuit

breakers regularly.

If the operator backup does not function properly and

the problem cannot be corrected, contact an authorized

Jacobsen Dealer.

3. Keep the wire harness and all individual wires away

from moving parts to prevent damage.

4. Make sure the seat switch harness is connected to the

main wire harness.

5. Check the battery and battery charging circuit.

23

4 MAINTENANCE

!

!

!

4.14 MUFFLER AND EXHAUST __________________________________________________

To protect from carbon monoxide poisoning, inspect the

WARNING

Exhaust fumes contain carbon monoxide that is toxic and

can be fatal when inhaled.

NEVER operate an engine without proper ventilation.

4.15 TIRES ___________________________________________________________________

1. Keep tires properly inflated to prolong tire life. Check

inflation pressure while the tires are cool. Inspect tread

wear.

2. Check the pressure with an accurate, low pressure

tire gauge.

3. Keep tires inflated to:

Front: - 10-12 psi (0.69-0.83 BAR).

Rear: - 8-10 psi (0.55-0.69 BAR).

complete exhaust system regularly and always replace a

defective muffler.

If you notice a change in the color or sound of the exhaust,

stop the engine immediately. Identify the problem and have

the system repaired.

Torque all exhaust manifold hardware evenly. Tighten or

replace exhaust clamps.

CAUTION

Unless you have the proper training, tools, and

experience, DO NOT attempt to mount a tire on a rim.