Safety & Operation Manual

When Performance Matters.

™

WARNING

If incorrectly used, this machine can cause severe injury. Those who use

and maintain this machine should be trained in its proper use, warned of its

dangers and should read the entire manual before attempting to set up,

operate, adjust or service the machine

GB

United

Kingdom

R-311T™ Rot ary Mower with folding ROPS

69171 – Kubota® V2403-M-T

4227680-GB-Rev A

FOREWORD

This manual contains safety a nd operating instructions for

your new Jacobsen mower. This manual should be stored

with the equipment for reference durin g op er a tion .

Before you operate your mower, you and each operator you

employ should read the manual carefully in its entirety. By

following the safety, operating, and maintenance

instructions, you will prolong the life of your equipment and

maintain its maximum efficiency.

If additional information is needed, contact your Jacobsen

Dealer.

CONTENTS

CONTENTS

CONTENTS.......................................................... 2

1 SAFETY................................................................ 3

1.1 Operating Safety ..................................... ... ... ........ 3

1.2 Important Safety Notes .................................. .... ... . 4

2 DECALS............................................................... 5

2.1 Decals................................................................... 5

3 CONTROLS........................................................ 10

3.1 Icons............. ....................................... ... ............ 10

3.2 Control Descriptions ............................................ 11

3.3 Control Panel Levers ........................................... 13

3.4 Control Panel Switches ....................................... 14

3.5 Gauges and Circuit Breakers ............................... 14

3.6 Warning Lights ....................................................15

4 OPERATION ......................................................17

4.1 Daily Inspection................................................... 17

4.2 Interlock System ............................................... .. 17

4.3 Operating Procedures ....................................... .. 18

4.4 Starting ............................................................... 19

4.5 Stopping / Parking ................................ ... ............20

4.6 To Drive / Transport ............................................. 20

4.7 Transport Latches ...............................................20

4.8 Hillside Operation ................................................ 21

4.9 Mowing ............................................................... 23

4.10 Folding ROPS .....................................................23

4.11 Towing / Trailering ...............................................23

4.12 Daily Maintenance .............................................. 24

The serial plate is located on the right rear frame rail.

Jacobsen recommends you record these numbers below

for easy reference.

P.O. BOX 7708,

®

CHARLOTTE,

NC 28241, USA

Jacobsen.com

1-800-848-1636 (US)

kg kg kg kW

5 QUALITY OF CUT ............................................. 25

5.1 Quality of Cut Troubleshooting............................. 25

5.2 Washboarding .................................................... 25

5.3 Step Cutting ........................................................ 26

5.4 Scalping.............................................................. 27

5.5 Stragglers ........................................ ................... 28

5.6 Streaks ............................................................... 29

5.7 Windrowing ........................................................ 30

5.8 Mismatched Cutting Units ................................... 31

6 NOTES............................................................... 32

2006/42/EC

These are the Original instructions verified by Jacobsen A

Textron Company.

© Copyright 2010, Jacobsen, A Textron Company. “All rights

reserved, including the right to r eproduce this material or portions

thereof in any form.”

en-2

Proposition 65 Warning

This product contains or emits chemicals

known to the State of California to cause

cancer and birth defects or other

reproductive harm.

Litho In U.S.A. 4-2010

SAFETY 1

!

1 SAFETY

1.1 OPERATING SAFETY ______________________________________________________

WARNING

EQUIPMENT OPERATED IMPROPERLY OR BY UNTRAINED PERSONNEL CAN BE DANGEROUS.

Familiarize yourself with the location and proper use of all controls. Inexperienced operators should receive instruction

from someone familiar with the equipment before being allowed to operate the machine.

1. Safety is dependent upon the awareness, concern, and

prudence of those who operate or service the

equipment. Never allow minors to operate any

equipment.

2. It is your responsibility to read this manual and all

publications associated with this equipment (Parts and

Maintenance Manual, Engine Manual, and

attachments/accessories instruction sheets). If the

operator cannot read English it is the owner’s responsibility to explain the material contained in this manual to

them.

3. Learn the proper use of the machine, the location and

purpose of all the controls and gauges before you

operate the equipment. Working with unfamiliar

equipment can lead to accidents.

4. Never allow anyone to operate or service the machine

or its attachments without proper training and

instructions; or while under the influence of alcohol or

drugs.

5. Wear all the necessary protective clothing and personal

safety devices to protect your head, eyes, ears, hands,

and feet. Operate the machine only in daylight or in good

artificial light.

6. Evaluate the terrain to de termine what accessories a nd

attachments are needed to properly and safely perform

the job. Only use accessories and attachments

approved by Jacobsen.

7. Stay alert for holes in the terrain and other hidden

hazards.

8. Inspect the area where the equipment will be used. Pick

up all the debris you can find before operating. Beware

of overhead obstructions (low tree limbs, electrical

wires, etc.) and also underground obstacles (sprinklers,

pipes, tree roots, etc.). Enter a new area cautiously.

Stay alert for hidden hazards.

9. Never direct discharge of material toward bystanders,

nor allow anyone near the machine while in operation.

The owner/operator can prevent and is responsible for

injuries inflicted to themselves, to bystanders, and

damage to property.

10. Do not carry passengers. Keep bystanders and pets a

safe distance away.

11. Never operate equipment that is not in perfect working

order or is without decals, guards, shields, discharge

deflectors, or other protective devices securely

fastened in place.

12. Never disconnect or bypass any switch.

13. Do not change the engine governor setting or

overspeed the engine.

14. Carbon monoxide in the exhaust fumes can be fatal

when inhaled. Never operate the engine without proper

ventilation or in an enclosed area.

15. Fuel is highly flammable; handle with care.

16. Keep the engine clean. Allow the engine to cool before

storing and always remove the ignition key.

17. Disengage all drives and engage parking brake before

starting the engine (motor). Start the engine only when

sitting in operator’s seat, never while standing beside

the unit.

18. Equipment must comply with the latest federal, state,

and local requirements when driven or transported on

public roads. Watch out for traffic when crossing or

operating on or near roads.

19. Local regulations may restri ct th e ag e of the operator.

20. Operate the machine up and down the face of slopes

(vertically), not across the face (horizontally).

21. To prevent tipping or loss of control, do not start or stop

suddenly on slopes. Reduce speed when making sharp

turns. Use caution when changing directions.

22. Always use the seat belt when operating mowers

equipped with a Roll Over Protective Structure (ROPS).

Never use a seat belt when operating mowers

without a ROPS or with the ROPS folded.

23. Keep legs, arms, and body inside the seating

compartment while the vehicle is in motion.

24. Disconnect battery and controller electrical connectors

before performing any welding on this mower.

This machine is to be operated and maintained as specified in this manual and is intended for the professional

maintenance of specialized turf grasses. It is not intended for use on rough terrain or long grasses.

en-3

1 SAFETY

!

!

1.2 IMPORTANT SAFETY NOTES________________________________________________

This safety alert symbol is used to alert you to potential hazards.

DANGER - Indicates an imminently hazardous situation which, if not avoided, WILL result in death or serious injury.

WARNING - Indicates a potentially hazardous situation which, if not avoided, COULD result in death or serious injury.

CAUTION - Indicates a potentially hazardous situation which, if not avoided, MAY result in minor or moderate injury and

property damage. It may also be used to alert against unsafe practices.

NOTICE - Indicates a potentially hazardo us situation which, if n ot avoided, MAY result in property damage. It may also be

used to alert against unsafe practices.

For pictorial clarity, some illustrations in this manual may show shields, guards, or plates open or removed. Under no

circumstances should this equipment be operated without these devices securely fastened in place.

WARNING

The Interlock System on this mower prevents the mower from starting unless the

parking brake is Engaged, PTO switch is off, and traction pedal is in Neutral. The

system will stop the engine if the operator leaves the seat without engaging the

parking brake or setting the PTO switch off.

NEVER operate mower unless the Interlock System is working.

WARNING

1. Before leaving the operator’s position for any reason:

a. Return traction pedal to Neutral.

b. Disengage all drives.

c. Lower all implements to the ground.

d. Engage parking brake.

e. Stop engine and remove the ignition key.

2. Keep hands, feet, and clothing away from moving parts. Wait for all

movement to stop before you clean, adjust, or service the machine.

3. Keep the area of operation clear of all bystanders and pets.

4. Never carry passengers, unless a seat is provided for them.

5. Never operate mowing equipment without the discharge deflector securely

fastened in place.

By following all instructions in this manual, you will prolong the life of your machine and maintain its maximum efficiency.

Adjustments and maintenance should alw ay s be performed by a qualified technician.

If additional information or service is needed, contact your Authorized Jacobsen Dealer who is kept informed of the latest

methods to service this equipment and can provide prompt and efficient service.

en-4

DECALS 2

4164381

DANGER

Serious injury or death can result from blade contact

or from objects being thrown very long distances.

• Do not operate machine with discharge chute or

guards flipped up or removed.

• Do not opera te m ach ine with bent or damaged

components or with cutting units in the raised

position.

• Keep yourself and others away from the mower

when in operation.

WARNING

Radiator is under pressure. Remove

cap slowly to avoid personal injury.

WARNING

Charge filter is under pressure.

Remove filter slowly to avoid bodily

injury.

CAUTION

Fill oil tank to 2 inches (51 mm) below

filler neck. Do not overfill.

WARNING

Seat belts must be worn whenever operating the mower with

the ROPS in the raised and locked position. Always keep

seat belt snugly adjusted. DO NOT use seat belts with the

ROPS folded down.

NEVER operate the mower with the ROPS folded down on

slopes, or near drop offs or water. Only operate in these

areas with the ROPS in the raised and locked position.

2 DECALS

2.1 DECALS _________________________________________________________________

Familiarize yourself with the following decals. They are critical to the safe operation of the

machine. REPLACE DAMAGED DECALS IMMEDIATELY.

4181863

4181862

en-5

2 DECALS

4199140

IMPORTANT

DO NOT USE STARTING ASSIST FLUIDS

Use of starting assist fluids in the air intake system

may be potentially explosive or cause a “runaway”

engine condition. This could result in serious engine

damage.

WARNING

To prevent burns, do not touch muffler or muffler

shield. Temperatures may exceed 150° F (66° C).

Weight Transfer

To transfer weight to mower, turn knob clockwise.

To transfer weight to cutting unit, turn knob counter-

clockwise.

PUSH TO LATCH

WING ARMS.

PULL TO RELEASE.

366608

USE AUTHORIZED

HYDRAULIC FLUID

SEE MANUAL FOR

SPECIFICATIONS

352487

4181861

4192000

en-6

DECALS 2

4181865

3002565

• Read operator's manual. Do not allow untrained

operators to use machine.

• Keep shields in place and hardware securely

fastened.

• Keep hands, feet, and clothing away from moving

parts.

• Before you clean, adjust, or repair this equipment,

disengage all drives, engage parking brake, and stop

engine.

• Never carry passengers.

• Keep bystanders away.

• Do not use on slopes greater than 14°.

Brake

Relay

Cruise

Relay

Not used Fuel

Solenoid

Relay

Horn

Button

Accessory

Relay

Horn

Relay

Familiarize yourself with the following decals. They are critical to the safe operation of the

machine. REPLACE DAMAGED DECALS IMMEDIATELY.

THIS RADIATOR CONTAINS

ANTI-FREEZE

PROTECTED TO -26°F (-32°C)

Mix equal parts of clean water and a premium quality

ethylene glycol based anti-freeze to maintain the boil

over, rust and corrosion protection.

Drain and discard coolant yearly. Read manual for

additional instructions.

363995

en-7

2 DECALS

3008004

J-

T

XXXXXX-XX

105

dB

L

WA

4205183

Parking Brake

Engage

Disengage

Traction Pedal

Forward

Reverse

WARNING

Do Not use for towing.

Sound Power Level

3008521

en-8

10 10 10 30 30 10

T

XXXX

DECALS 2

4221180

4221181

4181864

WARNING

Connecting Jumper Cables:

1. Connect positive cable to positive

remote terminal first.

2. Connect negative cable to negative

remote terminal last.

Disconnecting Jumper cables:

1. Remove negative cable first.

2. Remove positive cable last.

WARNING

Use caution when connecting and

disconnecting jumper cables.

Battery explosion may result if

remote terminals are shorted.

Danger

To avoid injury when working with battery:

1. Always connect the black (-) ground last and remove it

first.

2. Keep sparks and flames away, and avoid contact with

acid.

To avoid injury when jumping battery:

1. Connect positive (+) terminal to positive (+) terminal.

2. Connect negative (-) terminal on good battery to frame of

vehicle that has dead battery.

en-9

3 CONTROLS

Coolant

Temperature

D

Read Manual Engine Throttle

High Low

Hour Meter

Parking Brake Diesel Fuel Implement Position

Left Center Right

Cruise Control

Engine

Off Run Start

Service Brake

Drive Mode

2WD 4WD 4WD

Momentary

Engine Oil

Air Filter

Traction

Forward Reverse

PTO Switch

Engage Disengage

Filter ServiceLights

Work Road

Horn

Cutting Units

Raise Lower

Hydraulic Oil

Temperature Pressure

Glow Plug

Weight Transfer

to Decks

Increase Decrease

Engage

Disengage

Filter Service

!

3 CONTROLS

3.1 ICONS___________________________________________________________________

Never attempt to drive the mower unless you have read the Safety and Operation Manual and

know how to operate all controls correctly.

Familiarize yourself with the icons shown above and what they represent. Learn the location

and purpose of all the controls and gauges before operating this mower.

en-10

WARNING

CONTROLS 3

J-T XXXXXX-XXJ-T XXXXXX-XX

77

93

° C

170

200

° F

10 16

12 14

VOLTS

SOLID STATE

HOURS

00000

10 10 10 30 30 10

10 10 10 30 30 10

4192000

E

I

M

Q

U

Y

F

J

N

R

V

Z

G

K

O

S

W

A

AA

B

C

D

H

AB

H

L

P

T

X

A Steering Tilt Lever

B Traction Pedal

C Mow Speed Stop

D Brake Pedal

E Parking Brake Latch

F Weight Transfer

G Seat Tilt Lever

H Transport Latches

I Horn / Test Switch

J Left Wing Lift/Lower Lever

K Front Lift/Lower Lever

L Right Wing Lift/Lower Lever

M Throttle Lever

N PTO Switch

O Wing Deck Switch

P Front Deck Switch

Q Light Switch (Optional)

R 2WD / 4WD Switch

S Cruise Control Switch

T Ignition Switch

U Glow Plug Switch

V Warning Lights

W Fuel Gauge

X Volt Meter

Y Hour Meter

Z Circuit Breakers

AA Temperature Gauge

AB Remote Battery Terminals

3.2 CONTROL DESCRIPTIONS__________________________________________________

en-11

3 CONTROLS

!

B

1

B

2

C

1

C

2

C

3

Transport Speed Mow Speed

E

1

E

2

D

A. Tilt Steering Lever

Pull lever up to release steering column. Tilt

column up or down to position desired. Release

lever to lock steering column in place.

CAUTION

Never adjust steering while mower is moving. Stop unit

and engage parking brake switch before adjusting.

B. Traction Pedal

Press front of pedal (B

) down for forward travel.

1

Release pedal to slow mower and stop.

Press rear of pedal (B

) down for reverse travel.

2

Release pedal to slow mower and stop. Allow mower to

come to a complete stop before reversing directions.

NOTICE

Engine will stop if traction pedal is depressed in either

direction with the parking brake engaged.

Disengage parking braked before attempting to drive

mower.

D. Brake Pedal

Press pedal down to slow or stop the machine and to

disengage cruise control. Never press both service

brake pedal and traction pedal at the same time.

Figure 3B

E. Parking Brake Lock/Release

To lock parking brake, hold brake pedal (C) down and

press lock (E

brake pedal release (E

) until it engages. To disengage, press

1

).

2

F. Weight Transfer

Used to adjust the ground pressure of the decks. See

Parts & Maintenance Manual.

G. Seat Tilt Lever

Used to adjust the rear seat angle. Lift up on lever and tilt

seat back as required until seat is in the desired

position. Release the lever to lock the seat in position.

H. Transport Latches

Used to prevent accidental lowering of the wing cut ting

units during transport.

C. Mow Speed Stop

Limits forward speed while mowing. To operate at lower

travel speed while mowing, rotate lever (Position C

so it contacts stop screw on floor board when forward

travel pedal is pressed. To travel at full speed, set lever

in position shown (Position C

be adjusted to set specific mow speeds. See Parts &

Maintenance Manual.

I. Horn/Test Switch

Used to sound horn and test system warning lights.

Depress switch, horn should sound and all warning

lights, except for glow plug, engine oil and charge

pressure, should light.

Figure 3A

)

1

). Stop screw (C2) can

3

en-12

CONTROLS 3

M

J

K

L

3.3 CONTROL PANEL LEVERS__________________________________________________

J. Left Wing Lift/Lower Lever

Raises and lowers left wing deck. Push lever forward to

lower left wing deck. Pull lever back to raise left wing

deck. Deck will start automatically when lowered when

both PTO (N) and wing deck (O) switches are engaged.

K. Front Lift/Lower Lever

Raises and lowers front deck. Push lever forward to

lower front deck. Pull lever back to raise front deck.

Deck will start automatically when lowered when both

PTO (N) and front deck (P) switches are engaged.

L. Right Wing Lift/Lower Lever

Raises and lowers right wing deck. Push lever forward

to lower right wing deck. Pull lever back to raise right

wing deck. Deck will start automatically when lowered

when both PTO (N) and wing deck (O) switches are

engaged.

M. Throttle Lever

Regulates engine speed. Push lever forward to

increase speed or pull lever back to decrease speed.

Always operate mower at full throttle during normal

operation.

Figure 3C

en-13

3 CONTROLS

J-T XXXXXX-XX

77

93

˚ C

170

200

˚ F

10 16

12 14

VOLTS

SOLID STATE

HOURS

00000

10 10 10 30 30 10

10 10 10 30 30 10

M

Q

U

Y

J

N

R

V

Z

K

O

S

W

AA

L

P

T

X

3.4 CONTROL PANEL SWITCHES _______________________________________________

N. PTO Switch

Lift up and push switch lever forward to engage decks

and switches (O and P). Pull switch lever back to

disengage.

O. Wing Deck Switch

Used to engage or disengage both wing decks.

Depress front of switch to engage decks. Return switch

to center position to disengage decks. Pressing rear of

switch has no function. PTO switch (N) must be

engaged and cutting units lowered for switch to

operate.

P. Front Deck Switch

Used to engage or disengage front deck. Depress front

of switch to engage deck. Return switch to center

position to disengage deck. Pressing rear of switch has

no function. PTO switch (N) must be engaged and

cutting units lowered for switch to operate.

Q. Light Switch

Press front of switch for road lights. Press rear of switch

for work lights. Return switch to center position to shut

R. 2WD / 4WD Switch

Used to switch mower between 2WD and 4WD mo de.

Depress front of switch for 4WD in forward direction

only. Place switch in center position for 2WD. Depress

rear of switch for momentary 4WD in reverse. Do not

engage or disengage 4WD while mower is moving.

S. Cruise Control Switch

Depress traction pedal for desired speed and press

front of switch to engage cruise control. Depress

service brake pedal or press rear of switch to disengage

cruise control.

T. Ignition Switch

Used to start and stop the engine. The ignition switch

has three positions OFF, RUN, and START. To prevent

unauthorized use of this mower, remove ignition key

when not in use.

U. Glow Plug Switch

Used to energize the glow plugs before starting. Do no t

hold switch for more than 7 seconds. Glow Plug light will

be on when switch is depressed.

off lights.

3.5 GAUGES AND CIRCUIT BREAKERS __________________________________________

V. Warning Lights

Alerts the operator to conditions requiring immediate

action. See Section 3.6.

W. Fuel Gauge

Displays fuel level in tank. Do not allow mower to run out

of fuel.

X. Voltmeter

Displays electrical system voltage.

Y. Hour Meter

Records engine operating hours. The hour meter can

be used to time maintenance intervals or mowing

operations.

en-14

Z. Circuit Breakers

Used to protect electrical system. Push down on rubber

boot to reset circuit breaker.

AA.Temperature Gauge

Displays engine coolant temperature. Do not operate

mower if temperature is above 230° F (110° C).

AB.Remote Battery Terminals

Used for connecting jumper cables with wing decks in

raised position. Keep red boot of positive remote

terminal in place when not in use.

CONTROLS 3

T

1

T

9

T

2

T

3

T

4

T

5

T

6

T

7

T

8

T

9

3.6 WARNING LIGHTS _________________________________________________________

The R-311 mower monitors vital machine systems. It uses a

combination of warning lights and an audible alarm to alert

the operator of conditions requiring immediate action.

When an alert occurs follow the general guidelines listed in

the chart below, and any specific actions outlined by the

grounds superintendent or service manager.

To test alarm system:

Turn ignition switch to RUN. The engine oil light (T

charge pressure light (T

) should come on. All lights should

3

) and

1

go out once engine is started.

Press horn/test switch (I). Horn will sound and Engine

Coolant Temperature (T

Temperature (T

), Charge Filter (T6), and Air Filter (T7)

5

), Return Filter (T4), Hydraulic Oil

2

lights will come on.

With engine off, press glow plug switch (U). Glow plug light

) will come on.

(T

8

Turn signal lights (T

) are only used with the optional cab

9

installed.

This system monitors:

T1. Engine oil pressure

T2. Engine coo lant temperature

T3. Charge pressure

T4. Hydraulic return oil filter

T5. Hydraulic oil temperature

T6. Hydraulic charge filter

T7. Air filter

T8. Glow Plug

Alert Action

T1. Engine Oil Pressure - Alarm

sounds and oil pressure light

comes on. Oil pressure low.

T2. Engine Coolant Temperature

Horn sounds. Engine coolant

temperature high.

T3. Charge Pressure Light stays on

after starting engine or comes on

during operation. Indicates low

charge pressure in traction

system.

T4. Hydraulic Return Oil Filter -

Oil filter warning light comes on.

Figure 3D

Stop mower immediately, lower implements and shut off engine! Inspect

oil level in engine. If oil light remains on with oil at proper level, shut off engine and

tow or trailer mower back to service area. NEVER operate engine with oil light on,

severe damage to the engine can occur.

Stop mower immediately, lower implements and shut off engine!

Remove debris such as leaves and grass clippings that may be restricting air flow

through rear screen on hood and area between radiator and oil cooler. If engine

continues to run hot, return mower to service area.

CAUTION: Engine coolant is under pressure. Turn engine off and allow

fluid to cool before checking fluid level or adding coolant to radiator.

Stop mower immediately, lower implements and shut off engine! Check

hydraulic oil level in main tank. Visually inspect mower for obvious signs of leaks

around connections, hoses and tubes. Tow or trailer mower back to se rvice area.

Never operate mower with charge pressure light on, severe damage to hydraulic

system components can result.

CAUTION: Hydraulic system is under pressure. Turn engine off and allow

oil to cool before checking oil level or adding oil to tank.

Return mower to a service area as soon as possible. Change hydraulic

return oil filter.

Continued on next page

en-15

3 CONTROLS

Alert Action

T5. Hydraulic Oil Temperature

Horn sounds. Hydraulic oil

temperature high.

T6. Hydraulic Charge Oil Filter -

Oil filter warning light comes on.

T7. Air Filter - Air filter warning light

comes on.

T8. Glow Plug - Glow plug light

comes on.

Stop mower, disengage drives and lower implements. Run engine at low

idle for a few minutes until light goes off. If light remains on, shut off engine and

allow hydraulic system to cool. Remove debris such as leaves and grass

clippings that may be restricting air flow through rear screen on hood and area

between radiator and oil cooler. If hydraulics continues to run hot, return mower

to service area.

CAUTION: Hydraulic system is under pressure. Turn engine off and allow

oil to cool before checking oil level or adding oil to tank.

Return mower to a service area as soon as possible. Change hydraulic

charge oil filter.

Return mower to a service area as soon as possible. Change air filter.

Glow plug switch depressed. Do not energize glow plugs with engine running.

en-16

OPERATION 4

!

!

4 OPERATION

4.1 DAILY INSPECTION ________________________________________________________

2. Check the fuel supply, radiator coolant level, crankcase

CAUTION

The daily inspection should be performed only when the

engine is off and all fluids are cold. Lower decks to the

ground, engage the parking brake, stop engine, an d

remove ignition key.

1. Perform a visual inspection of the entire unit. Look for

signs of wear, loose hardware, and missing or

damaged components. Check for fuel or oil leaks to

ensure connections are tight and hoses and tubes ar e in

good condition.

4.2 INTERLOCK SYSTEM ______________________________________________________

1. The Interlock System prevents the engine from starting

unless the parking brake is Engaged, traction pedal is in

Neutral, and the PTO switch is OFF. The system also

stops the engine if the operator leaves the seat with the

PTO switch ON, traction pedal out of neutral, or parking

brake Disengaged.

WARNING

Never operate equipment with the Interlock System

disconnected or malfunctioning. Do not disconnect

or bypass any switch.

2. Perform each of the following tests to insure the

Interlock System is functioning properly. Stop the test

and have the system inspected and repaired if any of

the tests fail as listed below:

l the engine does not start in test 1;

l the engine does start during tests 2, 3, or 4;

l the engine continues to run during tests 5 or 6.

oil, and air cleaner indicator. All fluids must be at the full

level mark with engine cold.

3. Make sure all decks are adjusted to the same cutting

height.

4. Visually check tires for proper inflation.

5. Test the Interlock System.

Note: For more detailed maintenance information,

adjustments, and maintenance/lube charts, see the

Parts & Maintenance manual.

3. Refer to the chart below for each test and follow the

check (4) marks across the chart. Shut engine off

between each test.

Test 1: Represents normal starting procedure. The

operator is seated, parking brake is Engaged, traction

pedal is in Neutral, and the PTO switch is OFF. The

engine should start.

Test 2: The engine must not start if the PT O switch is

ON.

Tes t 3: The engine must not start if the par king brake is

Disengaged.

Test 4: The engine must not start if the traction pedal is

not in Neutral.

Test 5: Start the engine in the normal manner then turn

the PTO switch ON and lift your weight off the seat. H

Test 6: Start the engine in the normal manner then

disengage parking brake and lift your weight off the

seat. H

Test Operator

Seated

Yes No Engaged Disengaged Yes No On Off Yes No

1 44 4 44

2 44 44 4

3 44444

4 4

5 4

6 4

H

H

H Lift your weight off seat. The engine will shut down.

Interlock System Check

Parking

Brake

444

44 4

Traction Pedal in

Neutral

PTO

Switch

Engine

H

H

Starts

en-17

4 OPERATION

!

!

!

!

4.3 OPERATING PROCEDURES_________________________________________________

WARNING

A folding Roll Over Protection Structure (ROPS) is included with this mower. Seat belts must be worn whenever

operating the mower with the ROPS in the raised and locked position. Always keep seat belt snugly adjusted. DO NOT

use seat belts with the ROPS folded. See Section 4.12.

If the mower is overturning and the ROPS in the raised and locked position, hold onto the steering wheel. Do not attempt

to jump out or leave the seat.

CAUTION

To prevent injury, always wear safety glasses, leather work shoes or boots, a hard hat, and ear protection.

1. Under no circumstances should the engine be started

without the operator seated on the mower.

2. Do not operate mower or attachments with loose,

damaged, or missing components. Whenever possible

mow when grass is dry.

3. First mow in a test area to become thoroughly familiar

with the operation of the mower and control levers.

4. Study the area to determine the best and safest

operating procedure. Consider the height of the grass,

type of terrain, and condition of the surface. Each

condition will require certain adjustments or

precautions.

5. Never direct discharge of material toward bystanders,

nor allow anyone near the machine while in operation.

The owner/operator is responsible for injuries inflicted

to bystanders and/or damage to their property.

CAUTION

Before mowing, pick up all debris such as rocks, toys,

and wire which can be thrown by the machine. Enter a

new area cautiously. Always operate at speeds that

allow you to have complete control of the mower.

8. Disengage the drive motors and raise the decks when

crossing paths or roadways. Look out for traffic.

9. Stop and inspect the equipment for damage

immediately after striking an obstruction or if the

machine begins to vibrate abnormally. Have the

equipment repaired before resuming operation.

WARNING

Before you clean, adjust, or repair this equipment,

always disengage all drives, lower implements to the

ground, engage parking brake, stop engine, and remove

key from ignition switch to prevent injuries.

10. Slow down and use extra care on hillsides. Read

Section 4.8. Use caution when operating near drop

offs.

11. Look behind and down before backing up to be sure the

path is clear. Use care when approaching blind

corners, shrubs, trees, or other objects that may

obscure vision.

12. Never use your hands to clean blades. Use a brush to

remove grass clippings from blades. Blades are

extremely sharp and can cause serious injuries.

6. Use discretion when mowing near gravel areas

(roadway, parking areas, cart paths, etc.). Stones

discharged from the implement may cause serious

injuries to bystanders and/or damage the equipment.

7. Always turn PTO switch OFF to stop blades when not

mowing.

en-18

OPERATION 4

!

J-T XXXXXX-XX

77

93

˚ C

170

200

˚ F

10 16

12 14

VOLTS

SOLID STATE

HOURS

00000

10 10 10 30 30 10

10 10 10 30 30 10

M

U

N

T

4.4 STARTING________________________________________________________________

CAUTION

IMPORTANT: Do not use starting assist fluids. Use

of such fluids in the air intake system may be potentially

explosive or cause a “Runaway” engine condition and

could result in serious engine damage.

1. Make sure fuel shut off valve is completely open and the

tow valve (See Section 4.10) is closed.

2. Sit in operator’s seat, make sure the PTO switch (N) is

OFF, traction pedal is in Neutral, and the parking brake

(E) is Engaged.

3. Move throttle lever (M) between 1/4 to 1/3 throttle. Turn

ignition switch (T) to RUN.

4. Press glow plug switch (U) for about 3 to 7 seconds.

The colder the temperature, the longer it will take to

energize plugs. Do not press switch for more than 7

seconds. Energizing glow plugs is not necessary when

starting a warm engine.

5. Turn ignition switch (T) to START position. Release

switch as soon as engine starts. Do not hold key in start

position for more than 15 seconds at a time. If engine

does not start, turn ignition switch off, wait 30 seconds,

and try again.

6. Allow the engine to become warm and properly

lubricated before operating at high RPM.

Figure 4A

NOTICE

Allow engine to operate at low idle for at least one minute

before operating mower.

When starting engine at temperatures below 40° F (4°

C), operate the engine at low idle for five minutes to

prevent damage to engine or hydraulic system.

en-19

4 OPERATION

!

4.5 STOPPING / PARKING _____________________________________________________

To stop:

Remove your foot from traction peda l and stop the mower.

The mower will automatically brake when the traction pedal

returns to Neutral.

To park the mower under normal conditions:

1. Disengage the PTO switch, raise the decks, engage

transport latches, and move away from the area of operation.

Permanent damage to the turbocharger may occur if the

engine is shut down without allowing the turbocharger

time to cool.

To prevent damage, operate the engine with no load and

at half throttle for 3 to 5 minutes before shutting off

engine.

NOTICE

2. Select a flat and level area to park.

a. Release traction pedal to bring the mower to a com-

plete stop.

b. Disengage all drives, disengage transport latches,

lower decks to the ground, reduce throttle to slow,

and allow engine to operate at no load for a minute.

3. Engage parking brake, stop the engine, and always

remove the ignition key.

If an emergency arises and the mower must be parked in the

area of operation, follow the guidelines outlined by the

grounds superintendent. If the mower is parked on an

incline, chock or block the wheels.

4.6 TO DRIVE / TRANSPORT____________________________________________________

Read and follow all safety notes contained in this manual

when driving or transporting mower. Refer to Section 4.3

for general operating instructions. When operating in

reverse look behind you to ensure you have a clear path.

Important: If this mower is driven on public roads, it must

comply with federal, state, and local ordinances. Contact

local authorities for regulations and equipment

requirements.

1. Disengage all drives and raise implements to the transport position and engage transport latches when driving

to and from the area of operation.

2. Shift mower to 2WD.

3. Disengage parking brake and move throttle lever to

FAST. Depress traction pedal slowly.

4. Always bring the mower to a complete stop before

changing travel direction or shifting from 2WD to 4WD.

4.7 TRANSPORT LATCHES ____________________________________________________

1. The wing decks are equipped with a latch to prevent

accidental lowering of the cutting units during transport

or maintenance operations. The latch knobs are

located on the engine fire wall, behind and to the left and

right of the operator’s seat.

2. Fully raise the wing decks and push the latch knobs in

to secure the deck. The weight of the deck/lift arm must

not rest on the latch.

3. To release latch, pull the latch knob out and lower the

deck to the ground.

NOTICE

Do not transport with the arms resting on the latch.

Transport latches are only used to prevent accidental

lowering of the cutting units.

CAUTION

To prevent injury to bystanders, or damage to the

equipment, do not rest the weight of the deck and lift arm

on the latch. Weight of deck and lift arm may cause the

deck to fall when the latch is released.

en-20

OPERATION 4

!

!

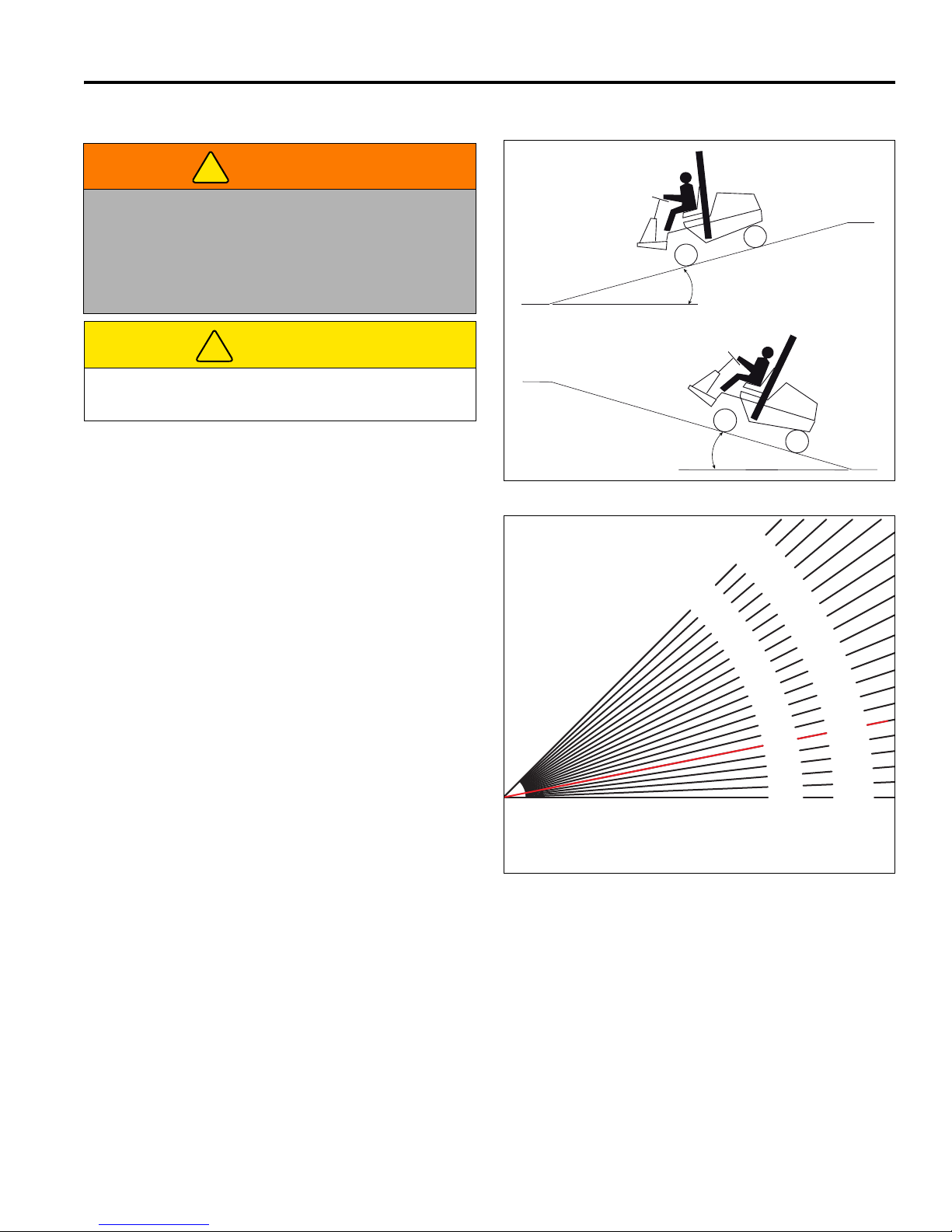

0°

Degrees are shown to nearest 1/4°

General Slope of Roadway Embankment - 45°

Steepest Grass Area - 31°

Slope of Average Roof - 19-1/4°

2nd Class Highway Maximum Grade - 4-1/2°

Toll Road or Freeway - 1-3/4°

0%

2-3/4°

5%

5-3/4°

10%

8-1/2°

15%

11-1/4°

20%

14°

25%

16-3/4°

30%

19-1/4°

35%

21-3/4°

40%

24-1/4°

45%

26-1/2°

50%

28-3/4°

55%

31°

60%

33°

65%

35°

70%

36-3/4°

75%

38-3/4°

80%

40-1/4°

85%

42°

90%

43-1/2°

95%

45°

100%

Degrees

Grade

4.8 HILLSIDE OPERATION _____________________________________________________

WARNING

To minimize the possibility of overturning, the safest

method for operating on hills and terraces is to travel up

and down the face of the slope (vertically), not across the

face (horizontally). Avoid unnecessary turns, travel at

reduced speeds, stay alert for hidden hazards, and drop

offs.

14°

25%

Maximum

CAUTION

Do not operate this mower on slopes greater than 14°

angle or 25% grade.

14°

Maximum

The mower has been designed for good traction and

stability under normal mowing conditions; however, use

caution when operating on slopes, especially over rough

terrain, or when the grass is wet. Wet grass reduces traction

and steering control.

25%

Figure 4B

1. Always mow with the engine at full throttle but reduce

forward speed for safe operation.

2. If the mower tends to slide or the tires begin to “mark”

the turf, angle mower into a less steep grade until

traction is regained or tire marking stops.

3. If mower continues to slide or mark the turf, the grade is

too steep for safe operation. Do not make another

attempt to climb, back down slowly.

4. When descending a steep slope, always lower

implements to the ground to reduce the risk of mower

overturning.

5. Correct tire pressure is essential for maximum traction.

Front - 16 to 20 psi (1.10 to 1.38 BAR)

Rear - 10 to 12 psi (0.69 to 0.83 BAR)

6. If additional traction is required, adjust the weight

transfer knob as described in the Parts and

Maintenance manual.

Figure 4C

en-21

4 OPERATION

C

A

B

D

How to calculate a slope:

Tools Required:

Level (A), either 1 yard, or 1 meter long.

Tape measure (B).

With the level (A) positioned horizontally, measure the

distance (C) with tape measure (B). Use the chart to

calculate either the slope angle or the % grade of the slope

(D).

Height (C) Result (D)

Inches with 1 Yard Level (A) Millimeters with 1 Meter Level (A) Slope in Degrees Slope Grade %

Figure 4D

en-22

3

100 5.7 10.0

150 8.5 15

6

200 11.3 20.0

7.5

225 12.7 22.5

9 250 14 25.0

275 15.4 27.5

10

300 16.7 30.0

11

325 18.0 32.5

12

350 19.3 35.0

13

375 20.6 37.5

14

400 21.8 40.0

15

425 23.0 42.5

16

475 25.4 47.5

18 500 26.6 50.0

20

600 31.0 60.0

25

800 38.7 80.0

30

900 42.0 90

36 1000 45.0 100

4.8 8.3

9.5 16.7

11.8 20.8

15.5 27.8

17.0 30.6

18.4 33.3

19.9 36.1

21.3 38.9

22.6 41.7

24 44.4

29.1 55.6

34.8 69.4

39.8 83.3

OPERATION 4

!

!

Normal

Operation

Tow

Position

Z

4.9 MOWING _________________________________________________________________

3. Move throttle lever to FAST then slowly depress

WARNING

To prevent serious injuries, keep hands, feet, and

clothing away from cutting unit when the blades are

moving.

NEVER use your hands to clean cutting units. Use a

brush to remove grass clippings from blades. Blades can

be sharp and could cause injuries.

To clear obstructions from cutting unit, disengage PTO

switch, engage parking brake, stop engine, and remove

key from ignition switch then remove obstruction.

To mow:

1. Start the engine and lower the decks to the ground.

2. Turn PTO switch to ON, depress front of desired deck

switch(es), shift mower to 4WD, and disengage

parking brake.

4.10 FOLDING ROPS ___________________________________________________________

A folding Roll Over Protection Structure (ROPS) is included

with this mower.

WARNING

There is no roll over protection with the ROPS

folded down. NEVER operate the mower with the

ROPS folded down on slopes, or near drop offs or water.

Only operate in these areas with the ROPS in the raised

and locked position.

traction pedal to the desired mowing speed.

a. For complete even cutting, overlap swaths by a few

inches.

b. When cutting tall grass, cut grass higher than

desired the first time so deck will clear unseen

obstructions and will not scalp if ground is rough.

c. Stop and raise the decks to the transport position

when crossing paths or roadways. Look out for traffic.

4. For better traction and handling, adjust weight transfer.

5. When operating in reverse and additional power is

required to climb out of a small depression, press and

hold the 2WD/4WD in the momentary 4WD Reverse

position.

Study the area of operation to determine if folding the ROPS

is required. Be aware of overhead obstructions and turf

conditions. Only operate the mower with the ROPS folded

down when absolutely necessary.

Seat belts must be worn whenever operating the mower

with the ROPS in the raised and locked position. Always

keep seat belt snugly adjusted. DO NOT use seat belts with

the ROPS folded down.

To fold ROPS, push top portion of ROPS towards front of

mower, remove pins, and fold ROPS towards rear of

mower. Secure ROPS in folded position with pins.

4.11 TOWING / TRAILERING _____________________________________________________

If the mower experiences problems and must be shut down

and removed from the area, it should be lo aded onto a trailer

for transport. If a trailer is not available, the unit can be towed

slowly short distances.

NOTE: Do not exceed 2 MPH (3.2 KPH) while towing.

Long distance towing is not recommended.

Use care when loading and unloading mower. Fasten

mower to trailer to prevent mower from rolling or shifting

during transport.

Before towing, open tow valve. The tow valve permits

moving the mower without starting the engine and prevents

possible damage to hydraulic components.

The tow valve (Z) is located on the drive pump beneath the

seat. Remove hardware and tilt seat towards left side

deck.To open valve, use a small wrench to turn the valve

counterclockwise 90°.

After towing, close tow valve completely and make certain

seat is closed and secured.

Figure 4E

en-23

4 OPERATION

!

4.12 DAILY MAINTENANCE _____________________________________________________

Important: For more detailed maintenance information,

adjustments, and maintenance/lubrication charts, see the

Parts & Maintenance manual.

1. Park the mower on a flat, level surface. Fully lower the

implements to the ground, engage parking brake, stop

the engine, and remove key from ignition switch.

2. Grease and lubricate all points if required. To prevent

fires, wash the cutting units and mower after each use.

a. Use only fresh water for cleaning your equipment.

Note: Use of salt water or effluent water has been

known to encourage rust and corrosion of met al p arts

resulting in premature deterioration or failure.

Damage of this nature is not cov ered by the factory

warranty.

b. Do not use high pressure spray.

c. Do not spray water directly at the instrument panel,

or any electrical components.

To prevent serious injury from hot, high pressure oil,

never use your hands to check for oil leaks, use paper or

cardboard.

Hydraulic fluid escaping under pressure can have

sufficient force to penetrate skin. If fluid is injected into

the skin, it must be surgically removed within a few hours

by a doctor familiar with this form of injury or gangrene

may result.

6. Inspect hydraulic hoses and tubes daily. Look for wet

hoses or oil spots and replace worn or damaged hoses

and tubes before operating the machine.

7. Check the engine oil and hydraulic oil at the start of

each day, before starting the engine. If the oil level is

low, remove the oil filler cap and add oil as required. Do

not overfill.

WARNING

d. Do not spray water into the cooling air intake or the

engine air intake.

NOTICE

Do not wash a hot or running engine. Use compressed

air to clean the engine and radiator fins.

3. Fill mower’s fuel tank at the end of each operating day

to within 1 in. (25 mm) below the filler neck.

Use clean, fresh #2 low or ultra-low sulfur diesel fuel.

Minimum Cetane Rating 45.

4. Handle fuel with care - it is highly flammable. Use an

approved container, the spout must fit inside the fuel

filler neck. Avoid using cans and funnels to transfer

fuel.

a. Never remove the fuel cap from the fuel tank, or add

fuel, when the engine is running or while the engine

is hot.

b. Do not smoke when handling fuel. Never fill or drain

the tank indoors.

c. Never overfill or allow the tank to become empty.

Do not spill fuel. Clean any spilled fuel immediately.

NOTICE

Care must be used at all times to avoid any

contamination of the hydraulic system. Follow

recommended maintenance practices and adhere to

scheduled intervals for hydraulic oil and filter changes.

Introduction of any type of contamination may result in

operating issues by causing valves to stick or leak

internally.

d. Never handle or store fuel containers near an open

flame or any device that may create sparks and

ignite the fuel or fuel vapors.

5. Store fuel according to local, state, or federal

ordinances and recommendations from your fuel

supplier.

en-24

QUALITY OF CUT 5

TN0159

5 QUALITY OF CUT

5.1 QUALITY OF CUT TROUBLESHOOTING _______________________________________

It is recommended that a “test cut” be performed to evaluate

the mower’s performance before beginning repairs.

Before performing a “test cut” to diagnose cut appearance

and mower performance, the following items should be

verified to ensure an accurate “test cut.”

An area should be available where “test cuts” can be made.

This area should provide known and consistent turf

conditions to allow accurate evaluation of the mower’s

performance.

1. Mowing (Ground) Speed

2. Blade Sharpness

3. Height-of-Cut (HOC)

Another “test cut” should be performed after the completion

of the repairs and/or adjustments to verify the mower’s

performance.

4. Decks Leveled

5. Blade Speed

6. Deck Rake not Set

5.2 WASHBOARDING__________________________________________________________

Washboarding is a cyclical pattern of varying cutting

heights, resulting in a wave-like cut appearance.

This condition is usually caused by the weight transfer not

set correctly.

Washboarding may also be caused by variations in the tu rf.

NOTE: Arrow indicates direction of travel.

Probable Cause Remedy

Decks have too much or too little weight on them. Adjust weight transfer valve to put more weight on decks.

(Refer to Parts & Maintenance Manual.)

en-25

5 QUALITY OF CUT

TN0221

5.3 STEP CUTTING ___________________________________________________________

Step cutting occurs when grass is cut taller on one side of a

deck than the other. This is usually caused by mechanical

wear or deck caster adjustment.

NOTE: Arrow indicates direction of travel.

Probable Cause Remedy

HOC (height-of-cut) settings are different from one side of a deck to

the other or from one deck to another.

Worn deck caster wheel bearings or fork bushings. Check/replace deck caster wheel bearings and fork bushings.

Tire pressure uneven. Check/adjust proper tire inflation pressure. (Refer to Parts &

Check HOC adjustment of decks. (Refer to Parts & Maintenance

Manual.)

Maintenance Manual.)

en-26

QUALITY OF CUT 5

TN0222

5.4 SCALPING _______________________________________________________________

Scalping is a condition in which areas of grass are cut

noticeably shorter than the surrounding areas, resulting in a

light green or even brown patch. This is usually caused by an

excessively low height-of-cut setting and/or uneven turf.

NOTE: Arrow indicates direction of travel.

Probable Cause Remedy

HOC (height-of-cut) settings are lower than normal. Check and adjust the HOC settings. (Refer to Parts & Maint enance

Manual.)

Turf too uneven for the mower to follow. Change mowing direction or raise HOC setting.

en-27

5 QUALITY OF CUT

TN0223

5.5 STRAGGLERS ____________________________________________________________

Stragglers are scattered blades of uncut or poorly cut grass.

NOTE: Arrow indicates direction of travel.

Probable Cause Remedy

Dull cutting blade(s). Sharpen blade(s). (Refer to Parts & Maintenance Manual.)

Mowing (ground) speed is too fast. Reduce mowing (ground) speed.

Grass is too tall. Mow more often.

Mowing in the same direction. Change mowing direction regularly.

Blade speed to slow Inspect and repair hydraulic system.

en-28

QUALITY OF CUT 5

TN0224

5.6 STREAKS ________________________________________________________________

A streak is a line of uncut grass. This is usually caus ed by a

damaged blade.

NOTE: Arrow indicates direction of travel.

Probable Cause Remedy

Damaged blade(s). Replace blade(s).

Turning too aggressively. Cutting units don’t overlap during turns or

on side hills.

Tire mats down grass before it is cut. Install high lift blades.

Blades installed incorrectly. Check for proper clockwise/counter-clockwi se blade installation.

Turn less aggressively to allow cutting units to overlap. Change

mowing direction or pattern on side hills.

en-29

5 QUALITY OF CUT

TN0225

5.7 WINDROWING ____________________________________________________________

Windrowing is the deposit of clippings concentrated at one

end of cutting unit(s) or between cutting units, forming line(s)

in the direction of travel.

NOTE: Arrow indicates direction of travel.

Probable Cause Remedy

Grass is too tall. Mow more often.

Mowing while grass is wet. Mow when grass is dry.

en-30

QUALITY OF CUT 5

TN1278

5.8 MISMATCHED CUTTING UNITS ______________________________________________

Mismatched decks is a pattern of varying cutting heights,

resulting in a stepped cut appearance, usually due to

mismatched HOC (height-of-cut) adjustment from one deck

to another.

NOTE: Arrow indicates direction of travel.

Probable Cause Remedy

HOC inconsistent from one deck to another. Check/adjust HOC on decks to same height. (Refer to Parts &

Maintenance Manual.)

Difference in blade speeds. Check operation of rotary cutting motor(s) and repair/replace as

necessary.

Difference in deck ride height side to side. Check/adjust tire inflation pressure. (Refer to Parts & Maintenance

Manual.)

Decks not level. Level decks. (Refer to Parts & Maintenance Manual.)

Deck rake not set. Adjust decks so that front of blade is 1/8 in. (1.25 mm) lower than rear of

blade. (Refer to Parts & Maintenance Manual.)

en-31

6 NOTES

6 NOTES

en-32

Jacobsen, A Textron Company

11108 Quality Drive, Charlotte, NC 28273

www.Jacobsen.com

800-848-1636

When Performance Matters.

™

World Class Quality, Performance and Support

Equipment from Jacobsen is built to exacting

standards ensured by ISO 9001 and ISO 14001

registration at all our manufacturing locations.

A worldwide dealer network and factory trained

technicians backed by Genuine Jacobsen Parts

provide reliable, high-quality product support.

Ransomes Jacobsen Limited

West Road, Ransomes Europark,

Ipswich, England, IP3 9TT

English Company Registration No. 1070731

www.ransomesjacobsen.com

Loading...

Loading...