WARNING: If incorrectly used this machine can cause severe

injury. Those who use and maintain this machine should be

trained in its proper use, warned of its dangers and should

read the entire manual before attempting to set up, operate,

adjust or service the machine.

Parts and Maintenance Manual

RJ 100 / 032004

24560G-BE (rev.2)

G-Plex III

Series: DP - Engine type: Kubota D722

Product code: USAD001

Series: DN - Engine type: Briggs & Stratton 350447

Product code: USAG001

© 2004, Ransomes Jacobsen Limited. All Rights Reserved

GB-1

JACOBSEN G-PLEX III Series: DN & DP

MAINTENANCE AND PARTS MANUAL

GB

1 CONTENTS

2 INTRODUCTION

2.1 PRODUCT IDENTIFICATION .................................................................................... 2

2.2 SPARES STOCKING GUIDE .................................................................................... 2

2.3 HOW TO USE THE PARTS MANUAL ...................................................................... 3

3 SAFETY INSTRUCTIONS

3.1 OPERATING INSTRUCTIONS .................................................................................. 4

3.2 SAFETY SIGNS ........................................................................................................ 4

3.3 STARTING THE ENGINE .......................................................................................... 4

3.4 DRIVING THE MACHINE .......................................................................................... 4

3.5 TRANSPORTING ..................................................................................................... 4

3.6 LEAVING THE DRIVING POSITION ......................................................................... 5

3.7 SLOPES ................................................................................................................... 5

3.8 BLOCKED CUTTING CYLINDERS ........................................................................... 5

3.9 ADJUSTMENTS, LUBRICATION AND MAINTENANCE............................................ 5

4 SPECIFICATION

4.1 ENGINE SPECIFICATION......................................................................................... 7

4.2 MACHINE SPECIFICATION ...................................................................................... 7

4.3 CUTTING UNIT......................................................................................................... 7

4.4 DIMENSIONS ........................................................................................................... 7

4.5 VIBRATION LEVEL .................................................................................................. 8

4.6 SLOPES ................................................................................................................... 8

4.7 RECOMMENDED LUBRICANTS ............................................................................... 8

4.8 CUTTING PERFORMANCE ...................................................................................... 8

4.9 TORQUES ................................................................................................................ 9

5 LUBRICATION AND MAINTENANCE

5.1 LUBRICATION AND MAINTENANCE CHART.......................................................... 10

5.2 ENGINE ACCESS .................................................................................................... 11

5.3 ENGINE OIL - DIESEL ............................................................................................. 11

5.4 ENGINE OIL FILTER- GASOLINE ........................................................................... 12

5.5 ENGINE OIL - GASOLINE ....................................................................................... 12

5.6 ENGINE OIL FILTER - DIESEL ................................................................................ 13

5.7 ENGINE FUEL FILTER - DIESEL ............................................................................. 13

5.8 AIR FILTER - DIESEL .............................................................................................. 14

5.9 AIR FILTER - GASOLINE ........................................................................................ 15

5.10 ENGINE FUEL FILTER - GASOLINE ....................................................................... 16

5.11 FAN BELT TENSION - DIESEL ................................................................................ 16

5.12 HYDRAULIC FILTER ............................................................................................... 16

5.13 HYDRAULIC OIL ..................................................................................................... 17

5.14 BRAKES .................................................................................................................. 17

5.15 BATTERY ................................................................................................................ 18

5.16 REAR SWING OUT ARM ........................................................................................ 19

6 ADJUSTMENTS

6.1 LEVELING LINKAGE FOR THE FRONT CUTTING HEADS .................................... 20

6.2 MOW/TRANSPORT SPEED CONTROL .................................................................. 21

6.3 SPEED CONTROL PEDAL ...................................................................................... 22

6.4 CUTTING HEAD LIFT AND LOWER TIMING .......................................................... 24

6.4 BLEEDING THE FUEL SYSTEM - DIESEL .............................................................. 24

6.5 BACKLAPPING ....................................................................................................... 25

7 TROUBLESHOOTING

7.1 GENERAL ................................................................................................................ 26

8 SCHEMATICS

8.1 HYDRAULIC CIRCUIT ............................................................................................. 28

8.2 ELECTRICAL CIRCUIT............................................................................................ 30

PARTS LIST

GB-2

GB

JACOBSEN G-PLEX III Series: DN & DP

MAINTENANCE AND PARTS MANUAL

2 INTRODUCTION

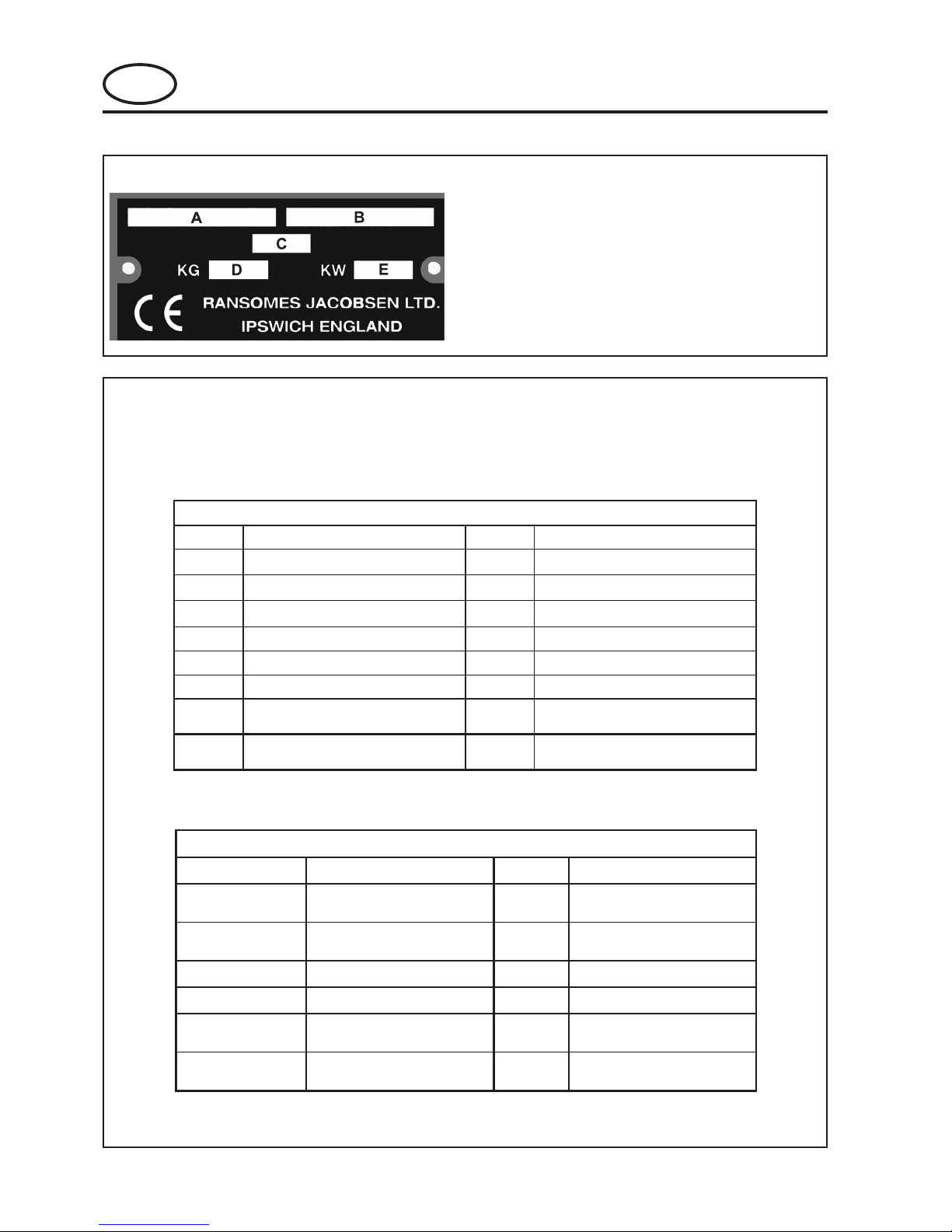

2.2 Spares Stocking Guide

To keep your equipment fully operational and productive, Ransomes suggests you maintain a stock of the

more commonly used maintenance items. We have included part numbers for the additional support

materials and training aids.

2.1 PRODUCT IDENTIFICATION

A Machine Name

B Serial Number

C Year of Manufacture

D Machine Weight

E Engine Power

straPecivreS

oNtraPnoitpircseD.oNtraPnoitpircseD

415248gulPkrapS061048retliFliOenignE,leseiD

115248retliFliOenignE,enilosaG161048yradnoceS,retliFleuF,leseiD

215248,enilosaGretliFleuFenignE916528yramirP,retliFleuFenignE,leseiD

705248,enilosaGtnemelErenaelCriA2530480tnemelErenaelCriA,leseiD

605248tnemelErenaelC-erPriA,enilosaG261048tleBnaF,leseiD

010298eguaGtuCfothgieH5430072ertil5.0,egnarOnesbocaJ,tniaPpuhcuoT

219828AhctiwSnoitingI1530072

59.0,egnarOnesbocaJ,tniaPpuhcuoT

ertil

8976314retliFciluardyH492418

,kcalB,tniaPpuhcuoT

ertil5.0

lairetaMtroppuSecivreS

oNtraPnoitpircseD.oNtraPnoitpircseD

08930-89879launaMstraPenignEleseiDG26542

srotarepOdnaytefaSenihcaM

E-BGlaunaM

leseiDsrotarepOenignE

launaM

launaMecivreSenignEleseiD

2002/8-C5-3622SMlaunaMstraPenignEenilosaG

20/9-863572

srotarepOenignEenilosaG

launaM

ecivreSenignEenilosaG

launaM

GB-3

JACOBSEN G-PLEX III Series: DN & DP

MAINTENANCE AND PARTS MANUAL

GB

2 INTRODUCTION

2.3 HOW TO USE THE PARTS MANUAL

ITEM NUMBER

Each part which is identified in the illustrations has an item number. Parts which do not have an item number

may not be readily identified in the illustration but are usually closely associated with the immediately adjacent

part.

ASSEMBLIES

A complete assembly, e.g. a wheel motor or hydraulic motor or roll assembly, is listed as a complete item with

subsequent individual components listed separately.

The assembly is listed under it's part number with component parts being listed offset to the right, e.g:-

ITEM PART NO. DESCRIPTION QTY REMARKS

4295 MBG2504 BRACKET 1

4296 MBG3848 LATCH 2

4298 450865 SCREW, M8 x 20, SCKT CSK HD 2

4300 450378 NUT, M8 NYLOC 2

4301 Wl001 Set Of Wheels 1

4301.1 008162130 Wheel & Hub Assy 1 (Rear)

4301.2 008170390 Tyre 1

4301.3 008161830 Rim 1

4301.4 008169140 Hub Assy. 1

4301.5 008169150 Cap 1

4301.6 002993010 Lubricator 1

4301.7 008161990 Wheel & Tyre 2 (Front)

4301.8 008170780 Tyre 2

4301.9 008161250 Rim 2

4302 001341110 Wheel Nut 12

It may not be possible to illustrate every item. With certain items purchased from outside suppliers some

component parts may not be available from Ransomes and may need to be specially ordered from the supplier.

QUANTITIES

Quantities shown are for one assembly or sub-assembly.

USING THE PARTS LIST

Determine the function and application of the part required. Turn to the main index page and select the

appropriate section. Locate the part on the illustration and parts list and read off the quantity from the

appropriate MODEL column.

NUMERICAL INDEX

This is a summary of all part numbers used in the manual arranged in numerical sequence and showing the

page and item number under which the parts appear.

ORDERING OF SPARE PARTS

When ordering replacement parts, it is most important to quote the SERIAL NUMBER of the machine, PART

NUMBER, DESCRIPTION and QUANTITY required.

Any arbitrary modifications carried out on this machine may relieve the manufacturer of liability for any resulting

damage or injury.

ABBREVIATIONS

N/A Not Available

AR As Required

GB-4

GB

JACOBSEN G-PLEX III Series: DN & DP

MAINTENANCE AND PARTS MANUAL

3 SAFETY INSTRUCTIONS

This safety symbol indicates important safety

messages in this manual. When you see this

symbol, be alert to the possibility of injury, carefully

read the message that follows, and inform other

operators.

3.1 OPERATING INSTRUCTIONS

Ensure that the instructions in this book

are read and fully understood.

No person should be allowed to operate

this machine unless they are fully

acquainted with all the controls and the

safety procedures.

Never allow children or people unfamiliar

with these instructions to usethis

machine. Local regulations may restrict

the age of the operator.

3.2 SAFETY SIGNS

It is essential all safety labels are kept

legible, if they are missing or illegible they

must be replaced. If any part of the

machine is replaced and it originally

carried a safety label, a new label must be

affixed to the replacement part. New

safety labels are obtainable from

Ransomes dealers.

3.3 STARTING THE ENGINE

Before starting the engine check that the

brakes are applied, drives are in neutral,

guards are in position and intact, and

bystanders are clear of the machine.

Do not run the engine in a building without

adequate ventilation.

3.4 DRIVING THE MACHINE

Before moving the machine, check to

ensure that all parts are in good working

order, paying particular attention to

brakes, tyres, steering and the security of

cutting blades.

Replace faulty silencers, mow only in

daylight or good artificial light

Always observe the Highway Code both

on and off the roads. Keep alert and

aware at all times. Watch out for traffic

when crossing or near roadways.

Stop the blades rotating before crossing

surfaces other than grass.

Remember that some people are deaf

or blind and that children and animals

can be unpredictable.

Keep travelling speeds low enough for

an emergency stop to be effective and

safe at all times, in any conditions.

Remove or avoid obstructions in the

area to be cut, thus reducing the

possibility of injury to yourself and/or

bystanders.

When reversing, take special care to

ensure that the area behind is clear of

obstructions and/or bystanders. DO

NOT carry passengers.

Keep in mind that the operator or user is

responsible for accidents or hazards

occurring to other people or their

property.

When the machine is to be parked,

stored or left unattended, lower the

cutting means unless the transport

locks are being used.

While mowing, always wear substantial

footwear and long trousers. Do not

operate the equipment when barefoot or

wearing open sandals.

Check the grass catcher frequently for

wear or deterioration. After striking a

foreign object. Inspect. the lawnmower

for damage and make repairs before

restarting and operating the equipment.

If the machine starts to vibrate

abnormally, check immediately.

3.5 TRANSPORTING

Ensure that the cutting units are

securely fastened in the transport

position. Do not transport with cutting

mechanism rotating.

Drive the machine with due

consideration of road and surface

conditions, inclines and local

undulations.

Sudden decelerating or braking can

cause the rear wheels to lift.

Remember that the stability of the rear

of the machine is reduced as the fuel is

used.

GB-5

JACOBSEN G-PLEX III Series: DN & DP

MAINTENANCE AND PARTS MANUAL

GB

3 SAFETY INSTRUCTIONS

3.6 LEAVING THE DRIVING POSITION

Park the machine on level ground.

Before leaving the driving position, stop

the engine and make sure all moving

parts are stationary. Apply brakes and

disengage all drives. Remove the starter

key.

3.7 SLOPES

TAKE EXTRA CARE WHEN WORKING ON

SLOPES

Local undulations and sinkage will change

the general slope. Avoid ground

conditions which can cause the machine

to slide.

Keep machine speeds low on slopes and

during tight turns.

Sudden decelerating or braking can

cause the rear wheels to lift. Remember

there is no such thing as a safe slope.

Travel on grass slopes requires particular

care.

DO NOT USE ON SLOPES GREATER THAN 15°

IMPORTANT: When working on any slope set the

weight transfer, if fitted to its maximum (+) setting.

3.8 BLOCKED CUTTING CYLINDERS

Stop the engine and make sure all moving

parts are stationary.

Apply brakes and disengage all drives.

Release blockages with care. Keep all parts

of the body away from the cutting edge.

Beware of energy in the drive which can

cause rotation when the blockage is

released.

Keep other people away from the cutting

units as rotation of one cylinder can cause

the others to rotate.

3.9 ADJUSTMENTS, LUBRICATION AND

MAINTENANCE

Stop the engine and make sure all moving

parts are stationary.

Apply brakes and disengage all drives.

Read all the appropriate servicing

instructions.

Use only the replacement parts supplied

by the original manufacturer.

When adjusting the cutting cylinders take

care not to get hands and feet trapped

when rotating cylinders.

Make sure that other people are not

touching any cutting units, as rotation of

one cylinder can cause the others to

rotate.

To reduce the fire hazard, keep the engine,

silencer and battery compartments free of

grass, leaves or excessive grease.

Replace worn or damaged parts for safety.

When working underneath lifted parts or

machines, make sure adequate support Is

provided.

Do not dismantle the machine without

releasing or restraining forces which can

cause parts to move suddenly.

Do not alter engine speed above maximum

quoted in Engine Specification. Do not

change the engine governor settings or

overspeed the engine. Operating the

engine at excessive speed may increase

the hazard of personal injury.

When refuelling, STOP THE ENGINE, DO

NOT SMOKE. Add fuel before starting the

engine, never add fuel while the engine is

running.

Use a funnel when pouring fuel from a can

into the tank.

Do not fill the fuel tank beyond the bottom

of the filler neck.

Replace all fuel tank and container caps

securely.

Store fuel in containers specifically

designed for this purpose.

Refuel outdoors only and do not smoke

while refuelling.

If fuel is spilled, do not attempt to start the

engine but move the machine away from

the area of spillage and avoid creating any

source of ignition until fuel vapours have

dissipated.

Allow the engine to cool before storing in

any enclosure.

Never store the equipment with fuel in the

tank inside a building where fumes may

reach an open flame or spark.

If the fuel tank has to be drained, this

should be done outdoors.

Do not spill fuel onto hot components.

When servicing batteries, DO NOT

SMOKE, and keep naked lights away.

Do not place any metal objects across the

terminals.

GB-6

GB

JACOBSEN G-PLEX III Series: DN & DP

MAINTENANCE AND PARTS MANUAL

Hydraulic Fluid escaping under pressure

can penetrate skin and do serious

damage. Immediate medical assistance

must be sought.

WARNING

Batteries produce explosive gases and

contain corrosive acid and supply levels

of electrical current high enough to cause

burns.

WARNING

DO NOT USE ON SLOPES GREATER THAN 15°

WARNING

3 SAFETY INSTRUCTIONS

DANGER - Indicates an imminently hazardous

situation which, if not avoided, WILL result in

death or serious injury.

WARNING - Indicates a potentially hazardous

situation which, if not avoided, COULD result

in death or serious injury.

CAUTION - Indicates a potentially hazardous

situation which, if not avoided, MAY result in

minor or moderate injury and property

damage. It may also be used to alert against

unsafe practices.

IMPORTANT: Transport speed is for highway

use only. Never select transport speed

on grass areas or uneven or unsurfaced

roads or tracks.

The operating Instructions for the Cutting Units are

contained in a separate Publication .

California Proposition 65

Engine Exhaust, some of its constituents,

and certain vehicle components contain

or emit chemicals known to the state of

California to cause cancer and birth

defects or other reproductive harm.

WARNING

Before releasing transport latches it is

important that all cutting units are fully

raised.

1. Park the machine on level ground.

2. With the engine running at operating

speed raise the cutting units to their

maximum position by operating lift

levers whilst seated in the driving

position.

3. Disengage drives, stop the engine and

make sure all moving parts are

stationary. Apply brakes and remove

the starter key.

4. transport latches can now be released.

WARNING

Battery posts, terminals and related

accessories contain lead and lead

compounds.

WASH HANDS AFTER HANDLING

WARNING

GB-7

JACOBSEN G-PLEX III Series: DN & DP

MAINTENANCE AND PARTS MANUAL

GB

4 SPECIFICATIONS

4.1 ENGINE SPECIFICATION

TYPE:TYPE: Kubota 15.5KW @ 3600 RPM,

3 cylinder Dioesel engine, 4

stroke, water cooled, 719cc

with 12V electric start.

Model: D722-E

Maximum Speed: 3400 RPM (No load)

Idle Speed: 1500 RPM

Oil Sump Capacity:3.2 litres

Firing Order: 1, 3, 4, 2.

Fuel: No. 2-D Diesel fuel (ASTM D975)

4.1.1 ENGINE SPECIFICATION

TYPE:TYPE: Briggs & Stratton 13.5KW @

3600 RPM, V twin gasoline

engine, 4 stroke, air cooled,

719cc with 12V electric start.

Model: Vanguard 350447 Type 1294

Maximum Speed: 3400 RPM (No load)

Idle Speed: 1500 RPM

Oil Sump Capacity:1.4 litres

Fuel: Unleaded Gasoline Minimum 85

octane

4.2 MACHINE SPECIFICATION

Frame construction:

Heavy duty fabricated steel

chassis.

Transmission:

Variable displacement

hydrostatic pump with high

speed low torque wheel motors.

Cutting unit drive:

Direct drive hydrostatic and reel

drive pumps, bi-directional

hydraulic gear motor with reel

control valve and backlap control

valve.

Speeds:

Cutting: 6 km/h

Transport: 12 kp/h

Reverse: 3 kp/h

Steering: Rear Wheel Steering. Power

Steering, 2.5 turns lock to lock

330mm dia. Steering Wheel

Ground pressure: 1.0 kg/cm

Brakes, Service: Positive hydostatic braking.

Parking: 152 mm Caliper Disk

Capacities:

Cooling System: 3.8 litres

Fuel Tank: 31 litres

Hydraulic Tank: 18.2 litres

Total System 25.7 litres

Battery: 12 volt, Type 093

Alternator Diesel 40amp

Gasoline 15amp

4.3 CUTTING UNIT

Type: Three 559mm wide steerable

floating head.

Reel: 127mm diameter, 7 / 9 / 11

knife.

Rolls: Smooth rear roll, smooth or

grooved front /rear rolls optional.

Bedknife to reel

adjustment: Opposed set screw.

Height of cut

adjustment: Micro-adjusters on front roll.

height of cut: 2.5mm to 16mm Standard blade

2mm to 16mm Tournament

blade.

4.4 DIMENSIONS

Width of cut: 1.57 metres

Overall width with reels: 1.9 metres

Overall height: 1.3 metres

Overall length with reels: 2.1 metres

Overall length with catchers: 2.5 metres

Overall weight of machine

With Reels

Diesel: 630kg

Gasoline: 574kg

Without Reels

Diesel: 535kg

Gasoline: 478kg

Wheel Track: 1.2 metres

Wheel Base: 1.3 metres

SERUSSERPERYT

tcudorP

leehWtnorF leehWraeR

eziSeryTepyTeryTerusserPeryTeziSeryTepyTeryTerusserPeryT

IIIxelP-G021-00.01x02

rp2htoomSnatiTisp9rab26.0

021-00.01x02

rp2htoomSnatiTisp9rab26.0

GB-8

GB

JACOBSEN G-PLEX III Series: DN & DP

MAINTENANCE AND PARTS MANUAL

emaNenihcaM

##seireS

noitareleccAmrA/dnaH

level

HRroHLxaM

s/msnoitareleccA

2

qeAXqeAYqeAZ

2.344.262.1

eulaVtnanimoD2.3

emaNenihcaM

##seireS

ydoBelohW

noitareleccA

level

noitacoLroolF

s/msnoitareleccA

2

noitacoLtaeS

s/msnoitareleccA

2

xyzxyz

naeM4320.09940.0901.00500.05520.01610.0

4.5 VIBRATION LEVEL

The machine was tested for whole body and hand/

arm vibration levels. The operator was seated in the

normal operating postion with both hands on the

steering mechanism. The engine was running and

the cutting device was rotating with the machine

stationary.

Standard ISO 5349: 1986 Mechanical vibration.

Guidelines for the measurement and the

assessment of human exposure to handtransmitted vibration.

Standard ISO 2631-1: 1985 Evaluation of human

exposure to whole body vibration -- Part 1:

General requirements.

4.8 CUTTING PERFORMANCE

Cutting Frequency

7-knife reel - 7.4mm at 6km/h

9-knife reel - 5.7mm at 6km/h

11-knife reel - 4.7mm at 6km/h

4.6 SLOPES

DO NOT USE ON SLOPES GREATER THAN 15°

The slope 15° was calculated using static stability

measurements according to the requirements of

EN 836.

4.7 RECOMMENDED LUBRICANTS

Engine oil:

Diesel: Should be to MIL-L-2104C

or to A.P.I. Classification CD

Gasoline: A.P.I. Classification SE/SF

Hydraulic Oil: GreensCare 68

Grease: Lithium based.

ERUTAREPMETYTISOCSIVLIO

)F°93(C°4EVOBA03EAS

)F°93(C°4WOLEB03-W01ro03-W5EAS

GB-9

JACOBSEN G-PLEX III Series: DN & DP

MAINTENANCE AND PARTS MANUAL

GB

4 SPECIFICATIONS

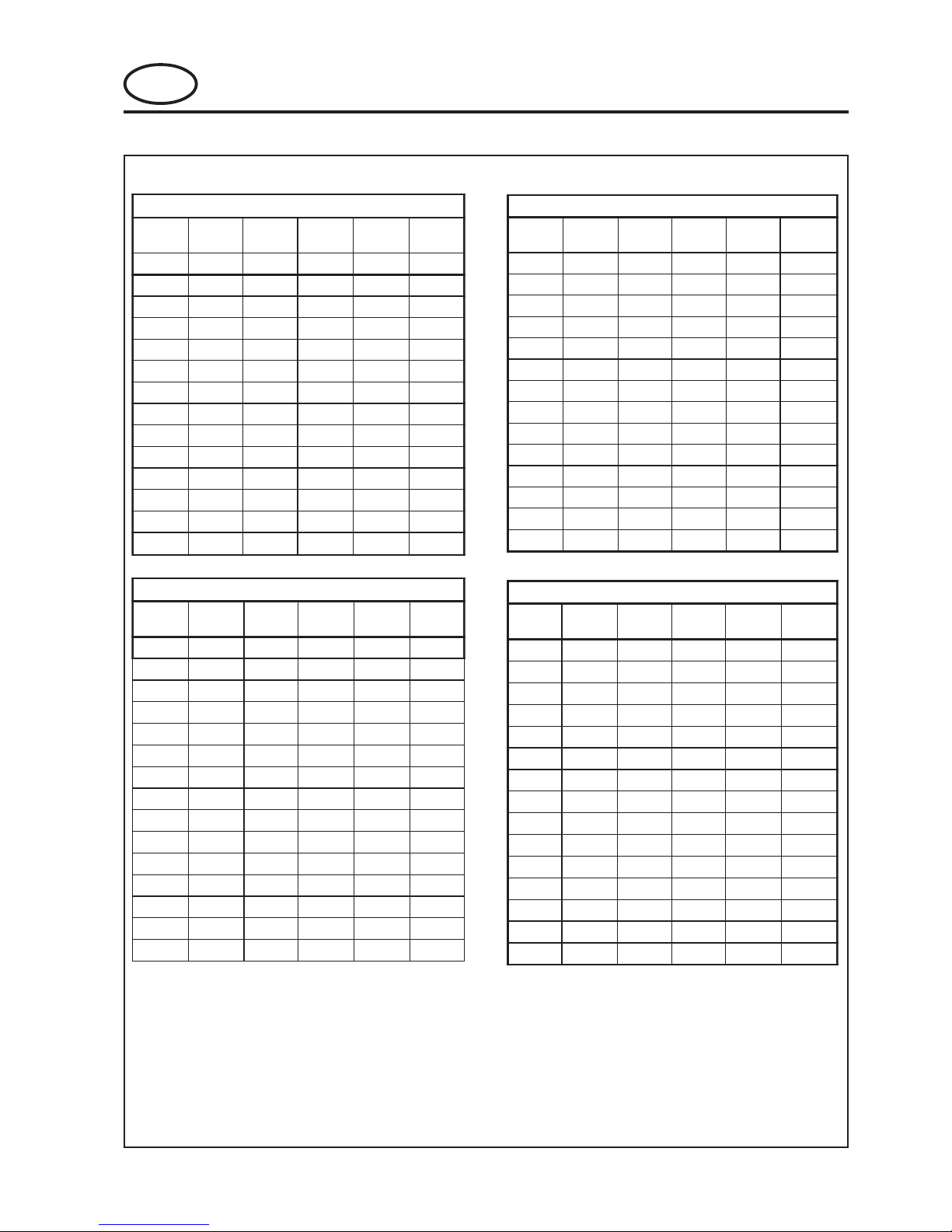

4.9 TORQUES

SDAERHTCIRTEMHCTIPESROC

aiD

)mm(

EDARG

6.4

EDARG

8.4

EDARG

8.8

EDARG

9.01

EDARG

9.21

)mN()mN()mN()mN()mN(

656 217112

81151032415

0122039548001

219325401641571

412628561232872

6169921752263434

02881152205607748

226521433860692511

4252343486802214641

72674536962158712412

03646268327142428092

332287901391248031073

6392116051210353242805

SDAERHTCIRTEMHCTIPENIF

aiD

)mm(

EDARG

6.4

EDARG

8.4

EDARG

8.8

EDARG

9.01

EDARG

9.21

)mN()mN()mN()mN()mN(

600000

82161235445

0142133688601

212475311951191

417609971252203

61301731472583264

02902972755387049

2218257305755016621

4245327444972313951

72415686173182914132

03517459809138629123

334696821275261630434

6369114951981348441835

SDAERHTCNU

)ni(aiD

EDARG

A

EDARG

S

EDARG

T

EDARG

V

EDARG

X

)tf.fbl()tf.fbl()tf.fbl()tf.fbl()tf.fbl(

4/14.32.99.96.212.51

61/579.814.028.523.13

8/33.215.331.638.545.55

61/77.915.358.752.377.88

2/11.036.1888211531

61/93.34711721161591

8/58.95261571222962

4/3601882013493774

8/7171464005536967

16525969470592511

8/11363489260174312361

4/111157831794199810032

8/310760281369109427103

2/119884142506230332004

SDAERHTFNU

)ni(aiD

EDARG

A

EDARG

S

EDARG

T

EDARG

V

EDARG

X

)tf.fbl()tf.fbl()tf.fbl()tf.fbl()tf.fbl(

4/18.34.013.113.413.71

61/57.78.025.225.825.43

8/39.317.737.046.155.26

61/79.125.952.464.186.89

2/17.335.197.89521251

61/92.84131141971712

8/54.76381791052303

4/3811913443734925

8/7881905055796548

197275771863015521

8/115049901681140513281

4/113659251056139025352

8/319571602422212828143

2/116993072719299632844

GB-10

GB

JACOBSEN G-PLEX III Series: DN & DP

MAINTENANCE AND PARTS MANUAL

5 LUBRICATION AND MAINTENANCE

5.1 LUBRICATION AND MAINTENANCE CHART

serudecorpecnanetniampohskrowerastnioptellubetihwdnaskcehcrotarepoerastnioptellubkcalB

tsriF

8-5

sruoh

yliaD

yrevE

52

sruoh

05tsriF

sruoh

ylkeeW

ro

yrevE

05

sruoh

yrevE

001

sruoh

yrevE

002

sruoh

yrevE

052

sruoh

yrevE

004

sruoh

yevE

006

rosruoh

dnE

fo

nosaeS

noitceS

ENIGNE

leveLliOkcehC

l

5.5/4.5

enignEleseiDliOegnahC

£

5.5

enignEenilosaGliOegnahC

££

3.5

enignEleseiDtnemelEretliFriAkcehC

l

enilosaGtnemelEretliFriAnaelC&kcehC

enignE

l

tnemelEretliFriAecalpeR

£

9.5/8.5

enignEleseiDretliFliOecalpeR

£

6.5

enignEenilosaGretliFliOecalpeR

£

4.5

leseiD-retlifleufenilnicitsalpecalpeR

£ l

01.5

leseiD-noitanimatnocretawrofretlifleufkcehC

£

7.5

leseiD-tnemelEretlifleufecalpeR

£

7.5

enilosaG-retlifleufecalpeR

£

01.5

enignEenilosaGecnaraelCevlaVtsujdA&kcehC

£

enignEeeS

launaM

sniFgnilooCnaelC

l

ENIHCAM

erusserPeryTkcehC

l

skaeLciluardyHrofkcehC

l

sedalBleeR&efinkdeBkcehC

l

tnemtsujdAefinkdeBotleeRkcehC

l

leveLdiulFciluardyHkcehC

l

neercSrelooCliOkcehC

l

sniFrelooCliOnaelC

l

sirbeDrofyaBenignEkcehC

£

ssenthgiTrofstloB&stuNkcehC

£

ssenthgiTrofsgnittiFciluardyHkcehC

£

noitidnoCyrettaBkcehC

£

noisneTtleBkcehC

£

11.5

retliFciluardyHegnahC

££

21.5

liOciluardyHegnahC

£

31.5

sgniniLekarBkcehC

£

41.5

esaergdesabmuihtiLahtiwgniwollofehtetacirbuL

sgniraeBleeRtinUgnittuC

£

srelloRraeR&tnorFtinUgnittuC

£

toviPdaeHgnittuC

£

tnuoMdaeHgnittuC

£

toviPmrAtfiL

£

toviPlortnoCdeepS/woM

£

toviPladePtfiL/woM

£

stoviPrednilyCgnireetS

£

GB-11

JACOBSEN G-PLEX III Series: DN & DP

MAINTENANCE AND PARTS MANUAL

GB

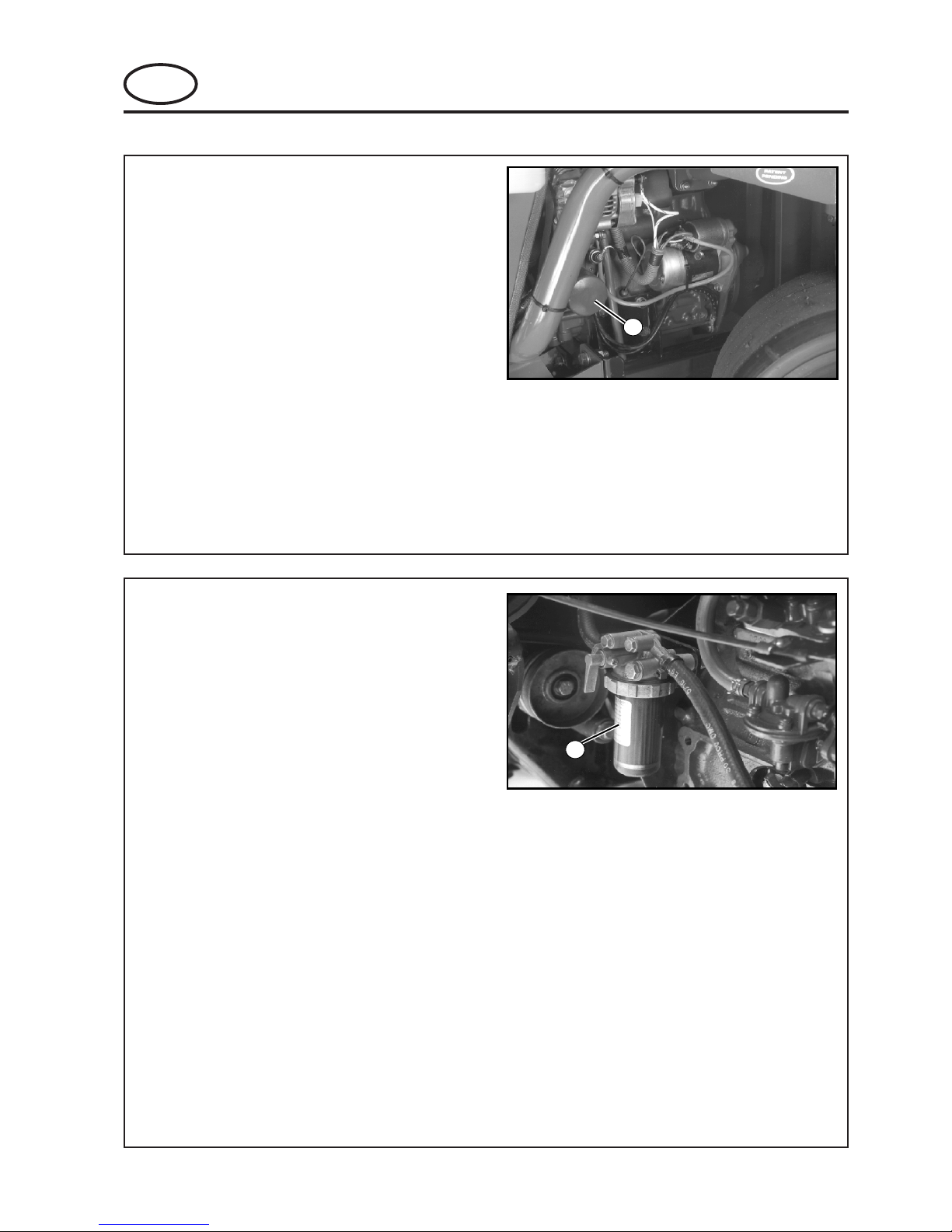

5.3 ENGINE OIL - GASOLINE

Change engine oil.

1 After first warming up the engine remove

the drain plug (Fig. 5.3.2) and drain all the

oil from the crankcase sump.

2 Clean plug and replace.

3 Remove the filler cap (Fig. 5.3.1) and refill

with fresh oil up to the maximum level on

the dipstick (Fig. 5.3.1).

See Specification for oil grade and

amount.

4 Replace filler cap securely.

NOTICE

DO NOT overfill. Engine overheating and

damage may result.

5 LUBRICATION AND MAINTENANCE

5.2 ENGINE ACCESS

The rear section of the unit can be raised for better

access to the engine. Loosen the two handknobs

above the rear fork. Raise the fuel tank frame.

Support it by pivoting the rod beneath the fuel tank

down and securing it in the cup next to the fork pivot

(See Fig. 5.2).

Figure 5.2

Rear Section of Unit Raised

DO NOT remove the fuel tank cap while

the tank is in the raised position.

WARNING

1

Figure 5.3.2

1. Filler Cap

2. Dipstick

Figure 5.3.2

1. Drain Plug

GB-12

GB

JACOBSEN G-PLEX III Series: DN & DP

MAINTENANCE AND PARTS MANUAL

5 LUBRICATION AND MAINTENANCE

5.5 ENGINE OIL - DIESEL

Change engine oil.

1 After first warming up the engine remove

the drain plug and drain all the oil from

the crankcase sump.

2 Clean plug and replace.

3 Remove the filler cap (Fig. 5.5.2) and refill

with fresh oil up to the maximum level on

the dipstick (Fig. 5.5.1).

See Specification for oil grade and

amount.

4 Replace filler cap securely.

NOTICE

DO NOT overfill. Engine overheating and

damage may result.

1

Figure 5.5.1

1. Dipstick

1

Figure 5.5.2

1. Oil Filler Port

5.4 ENGINE OIL FILTER- GASOLINE

Change Engine Oil Filter

1. Drain engine oil and remove oil filter.

2. Before installing new filter, lightly oil filter

gasket with fresh, clean oil.

3. Screw filter on by hand until gasket

contacts filter head. Tighten 1/2 to 3/4

turn more.

4. Add fresh oil. Fill to FULL line on dipstick.

5. Start and run engine at idle and check for

leaks.

6. Stop engine, leave for 15 minutes, recheck oil level. Add oil if required.

Fig. 5.4.1

A. Oil Filter

GB-13

JACOBSEN G-PLEX III Series: DN & DP

MAINTENANCE AND PARTS MANUAL

GB

5 LUBRICATION AND MAINTENANCE

5.6 ENGINE OIL FILTER - DIESEL

Change oil filter cartridge

(a) Remove cartridge from engine by

unscrewing and discard.

(b) Clean area on crankcase.

(c) Apply a thin film of oil to the gasket and

screw in the new cartridge by hand,

securely.

(d) After replacing the new cartridge the

engine oil level will drop, run the engine for

a short period and after ensuring that no

leaks appear, top up with fresh oil to the

level indicated on the dipstick.

NOTICE

DO NOT use a wrench when installing the

filter, use hand pressure ONLY.

5.7 ENGINE FUEL FILTER - DIESEL

Replace fuel filter element

(a) Unscrew locking ring and remove filter

element (2 Fig. 5.7.1) and discard.

(b) Place new filter element in filter bowl

locating on spring. Position bowl against

gasket in filter head and fit locking ring.

(c) Vent the fuel system.

In-line fuel filter

(a) Release clamp bands either side of in-line

filter and remove fuel pipes.

(b) Fit new in-line filter to fuel pipes, noting

direction of flow and replace clamp

bands.

1

Figure. 5.7.1

1. Fuel Filter Element

1

Figure. 5.6.1

1. Oil Filter Canister

GB-14

GB

JACOBSEN G-PLEX III Series: DN & DP

MAINTENANCE AND PARTS MANUAL

5 LUBRICATION AND MAINTENANCE

5.8 AIR FILTER - DIESEL

Clean Air Filter Element

1. As the element (A) of the air cleaner

employedon this engine is a dry type,

never apply oil to it.

2. Open the evacuator valve once a week

under ordinary conditions-or daily when

used in a dusty place-to get rid of large

particles of dust and dirt.

3. Avoid touching the element except when

cleaning.

4. When dry dust adheres to the element,

blow compressed air from the inside

turning the element. Pressure of

compressed air must be under 7kgf/cm

2

(100psi)

5. When carbon or oil adheres to the

element, soak the element in detergent for

30 minutes then wash it several times in

water, rinse with clean water and dry it

naturally. After the element is fully dried,

inspect inside of the element with a

light and check if it is damaged or not.

(refering to the instructions on the label

attached to the element.)

1

2

3

3

Fig. 5.8.1

1. Cover, 2. Evacuator valve

3. Clips

GB-15

JACOBSEN G-PLEX III Series: DN & DP

MAINTENANCE AND PARTS MANUAL

GB

5 LUBRICATION AND MAINTENANCE

5.9 AIR FILTER - GASOLINE

NOTICE

DO NOT use bent or dented air cleaner housing. DO

NOT use bent or dented air cleaner elements.

IMPORTANT!

WE RECOMMEND THAT THE FILTER ELEMENT

BE REPLACED BEFORE ENGINE PERFORMANCE

IS AFFECTED. THIS MAY OCCUR AT 250 HOURS

OF SERVICE UNDER VERY DUSTY CONDITIONS

OR AT 500 HOURS UNDER NORMAL OPERATING

CONDITIONS. WE DO NOT RECOMMEND

CLEANING THE FILTER ELEMENT BECAUSE OF

THE POSSIBILITY OF DAMAGING IT.

CHECKING THE ELEMENT

To check for damage, pin holes, etc. shine a light

source into the end of the element. If light CANNOT

be seen through the paper, a new element should be

installed. Likewise, if pinholes of bright light appear

in the paper, the element should be replaced (See

Fig. 5.9.1).

Pre-Cleaner

To clean the pre cleaner, seperate it from the

cartridge and wash in liquid detergent and water.

Squeeze dry in a clean cloth.

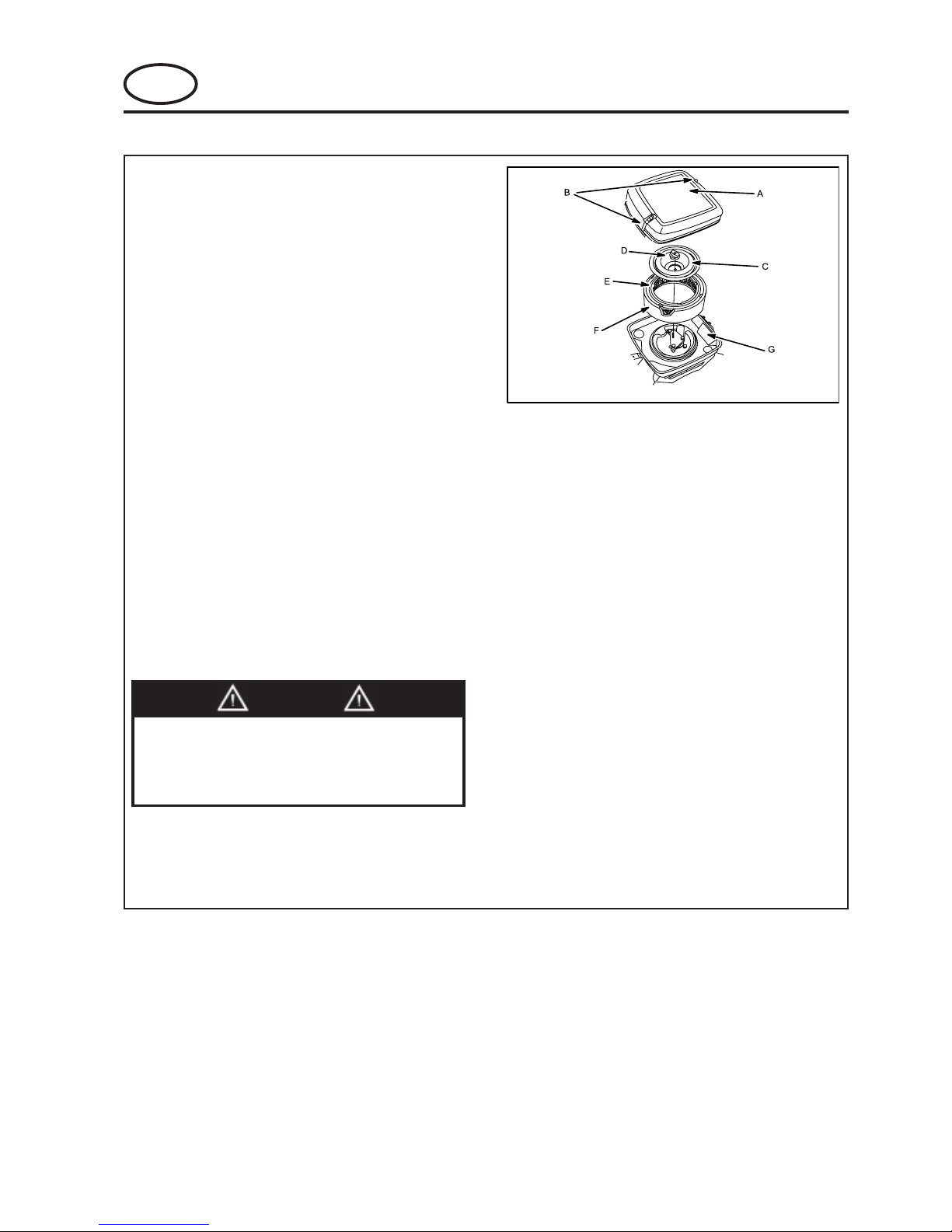

Fig. 5.9.1

A. Cover, B. Clips, C. Plate, D. Knob

E. Cartidge, F. Foam Pre-Cleaner, G. Body

Removing / Installing Air Cleaner

1. Unhook clips on both sides of cover and

remove cover.

2. Remove knob and plate. Carefully remove

air cleaner assembly to prevent debris

from entering carburettor.

3. Reassemble clean (or new) pre-cleaner on

clean (or new) cartridge.

4. Reinstall air cleaner assembly, plate and

knob.

5. Replace cover and reattach clips to body.

DO NOT use pressurized air or solvents to

clean cartridge. Pressurized air can

damage cartridge; solvents will dissolve

cartridge.

CAUTION

GB-16

GB

JACOBSEN G-PLEX III Series: DN & DP

MAINTENANCE AND PARTS MANUAL

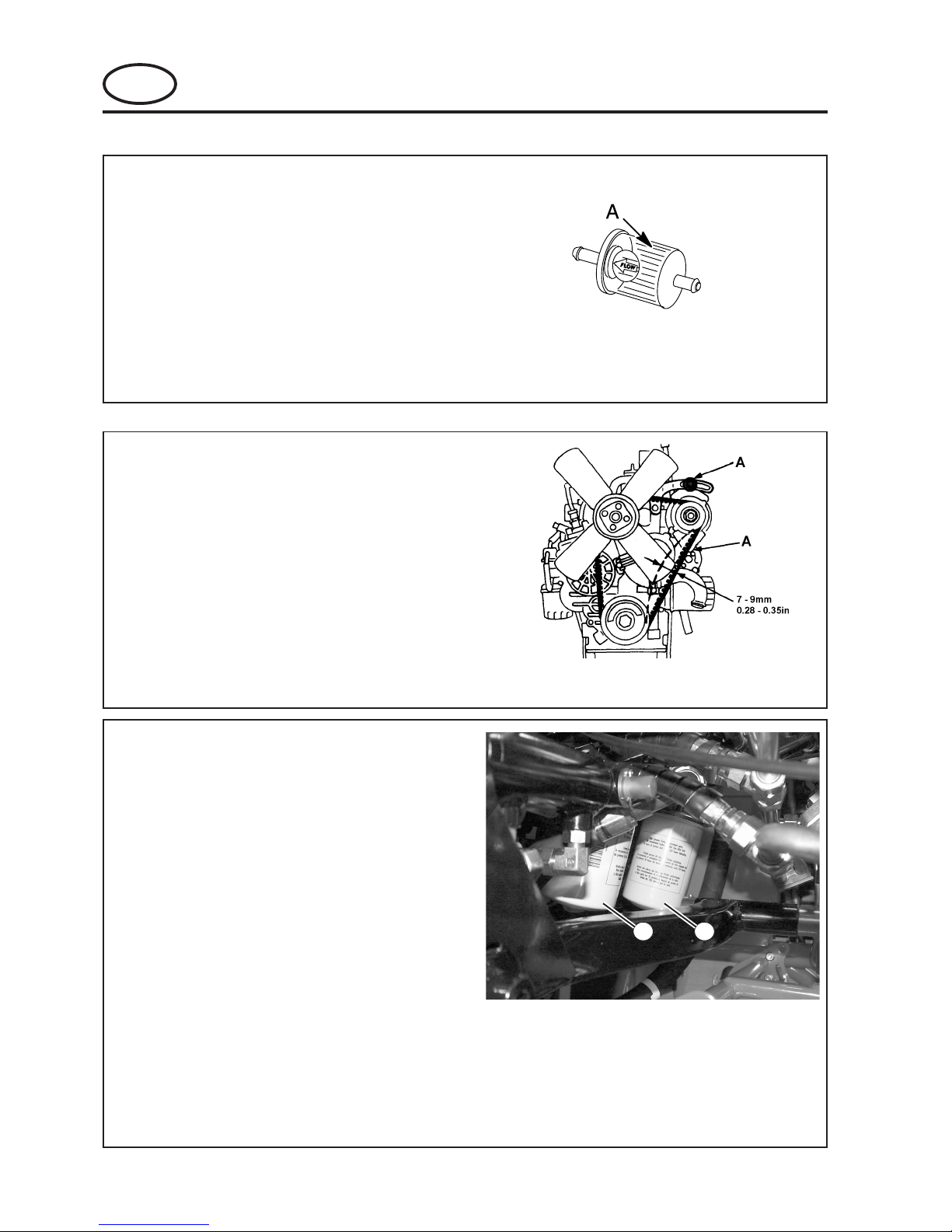

5.11 FAN BELT TENSION - DIESEL

The tension on the belt is correct when the belt can

be depressed 7 to 9mm (0.28 - 0.35in) under a load

of 10kgf (22lbs) midway between the crankshaft

pulley and the alternator pulley.

To adjust:

(a) Release the two bolts (A Fig. 5.11.1)

holding the alternator and adjust alternator

until the tension is correct.

(b) Re-tighten the bolts securely after

adjusting.

5 LUBRICATION AND MAINTENANCE

Figure. 5.11.1

5.10 ENGINE FUEL FILTER - GASOLINE

Replace fuel filte

(a) Release clamp bands either side of in-line

filter and remove fuel pipes.

(b) Fit new in-line filter to fuel pipes and

replace clamp bands.

Fig. 5.10.1

A. Fuel filter

5.12 HYDRAULIC OIL FILTER

The hydraulic oil filter MUST be replaced when:

250 hours of operation occurs.

Yearly.

After a major component failure.

If you notice the presence of water or foam

in the oil.

A rancid odor is detected (indicating

excessive heat).

Always replace the hydraulic filters when changing

oil.

When replacing the hydraulic oil filter, apply a light

film of clean oil to the rubber seal. Screw filter on

until the seal contacts the oil filter base, then tighten

1/2 turn more.

NOTE: DO NOT use wrench when replacing

the filter, use hand pressure ONLY.

11

Figure. 5.12.1

GB-17

JACOBSEN G-PLEX III Series: DN & DP

MAINTENANCE AND PARTS MANUAL

GB

5 LUBRICATION AND MAINTENANCE

5.13 HYDRAULIC OIL

The hydraulic oil MUST be drained and replaced

when:

250 hours of operation occurs.

Yearly.

After a major component failure.

If you notice the presence of water or foam

in the oil.

A rancid odor is detected (indicating

excessive heat).

Always replace the hydraulic filters when changing

oil.

To drain the hydraulic oil, remove the hydraulic oil

filters.

Once the hydraulic oil is replaced, the air must be

purged from the system. Operate the unit for five

minutes to stabilize the oil level.

Once the air is purged and the oil level is stabilized,

fill the tank to its proper level.

The hydraulic fluid reservoir is filled at the factory

with biodegradable hydraulic oil.

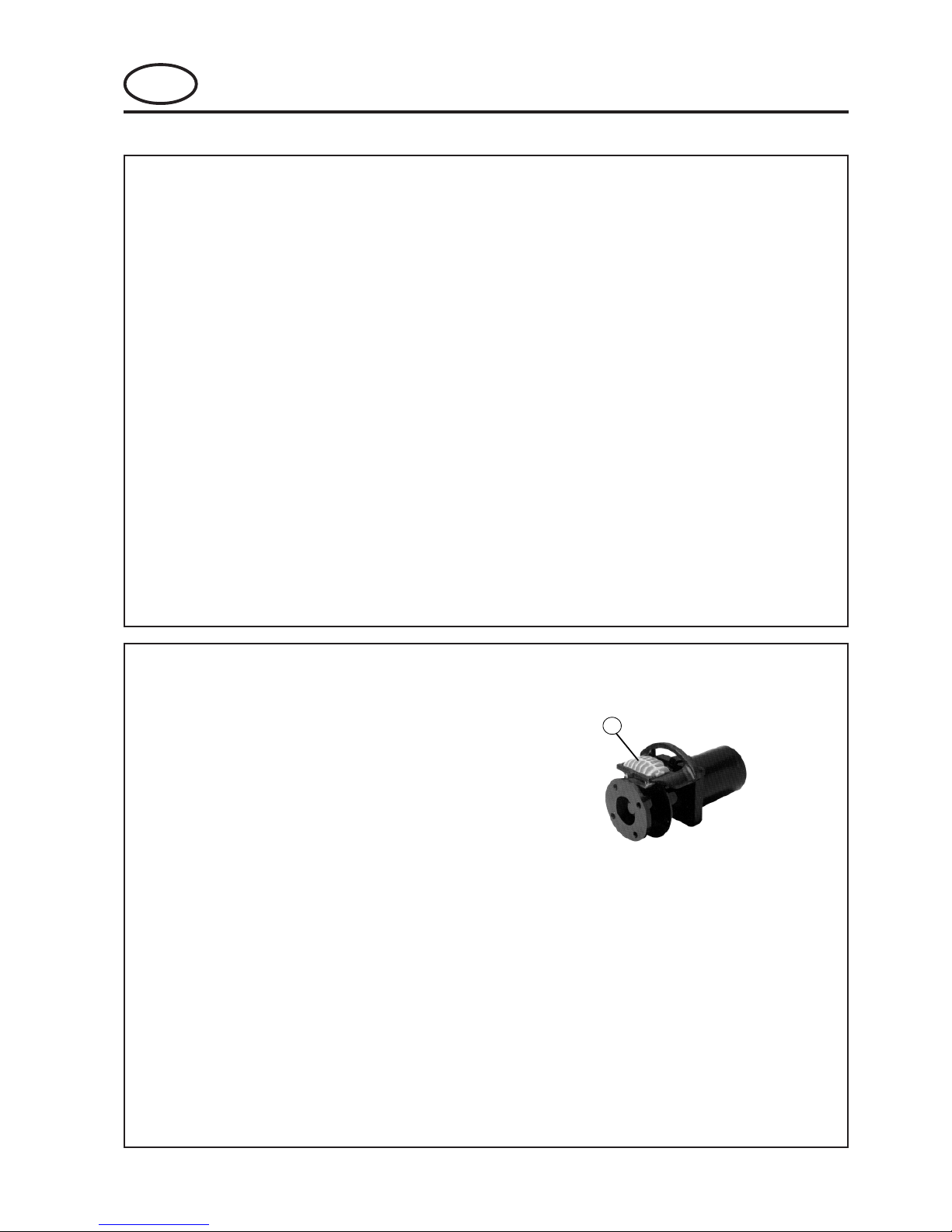

5.14 BRAKES

If desired, mineral oil may be used in place of the

biodegradable hydraulic oil.

NOTE: Use of mineral oil will compromise all

biodegradable properties of the biodegradable

hydraulic oil.

When changing to mineral oil, drain the reservoir and

replace the hydraulic oil filters. The system does not

have to be flushed out when changing over. As a

mineral oil alternative to the biodegradable hydraulic

oil, a straight-viscosity ISO 68 type fluid is

recommended for higher temperature environment.

Place the front axle on axle stands and remove the

front wheels. Inspect the Discs and pads for wear

and replace if necessary. Remove all debris from

around the brake assemby and ensure the caliper is

free to float

1

Figure. 5.14.1

1. Caliper

GB-18

GB

JACOBSEN G-PLEX III Series: DN & DP

MAINTENANCE AND PARTS MANUAL

5 LUBRICATION AND MAINTENANCE

Battery posts, terminals and related

accessories contain lead and lead

compounds.

WASH HANDS AFTER HANDLING

WARNING

5.15 BATTERY

UNTRAINED/UNAUTHORIZED persons

should NEVER attempt to service or

recharge the battery in this unit.

WARNING

Battery electrolyte is an acidic solution

and should be handled with care. If

electrolyte is splashed on any part of the

body, immediately flush the exposed

area with liberal amounts of water and

obtain medical aid immediately.

WARNING

NOTICE

Keep top of battery clean and free of

corrosion by washing with a solution of

baking soda and water OR ammonia and

water. Rinse with clean water. Batteries

with heavy corrosion should be removed

and cleaned with solution.

Battery cables should be disconnected

before using a Battery Charger.

GB-19

JACOBSEN G-PLEX III Series: DN & DP

MAINTENANCE AND PARTS MANUAL

GB

6 ADJUSTMENT

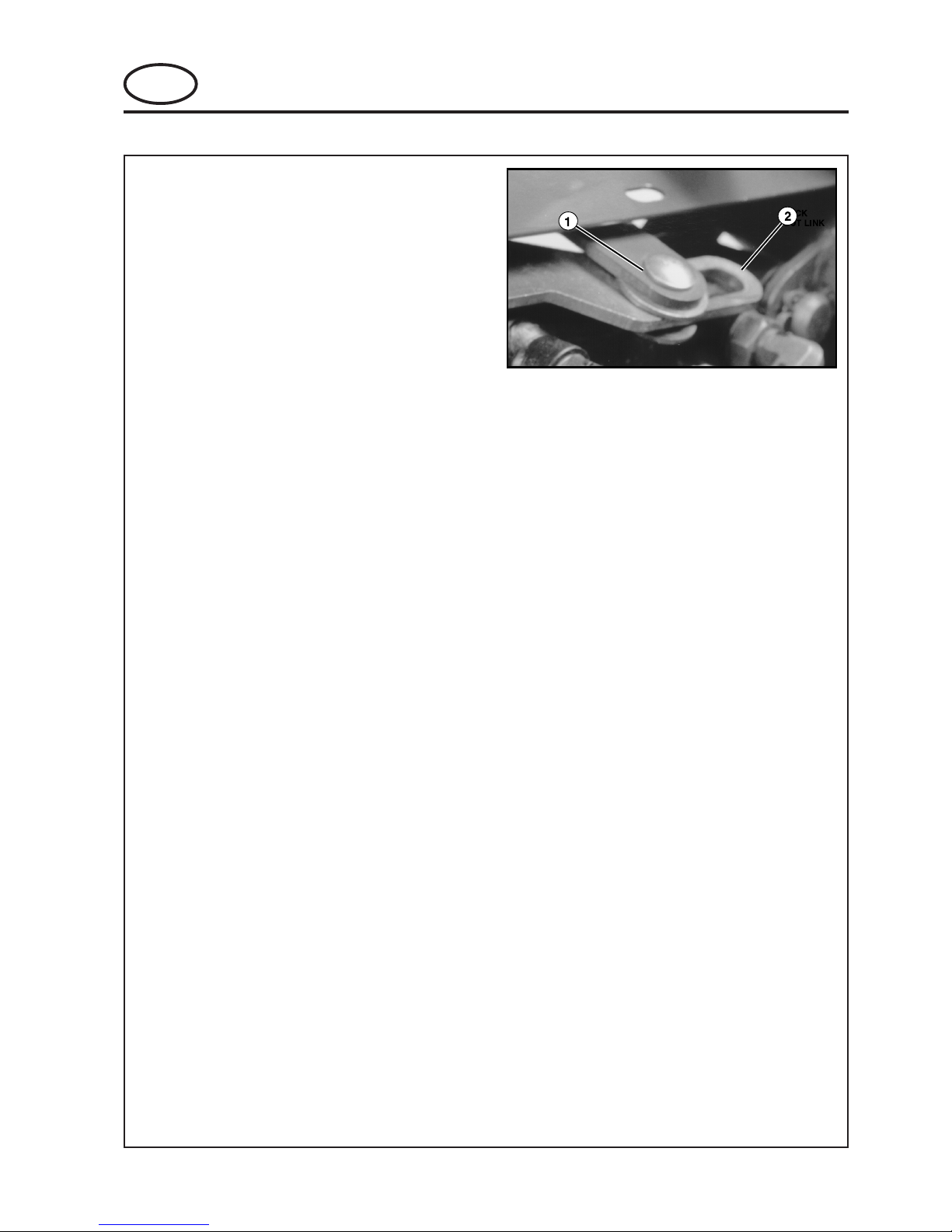

5.16 REAR SWING OUT ARM

NOTE: The rear swing out arm is to allow you

easy access to the rear cutting head. The cutting

heads must be in the raised position. DO NOT

swing the arm out with the cutting heads in the

lowered position.

1. The grass catcher MUST BE removed

before you swing the arm out.

2. Release the draw latch (See Fig. 5.16.1).

3. Pull the handle and swing the rear arm and

cutting head out.

4. After you are properly seated in the

operator's seat, restart the unit and lower

the cutting heads.

5. Shut off the unit and remove the rear

cutting head for service.

6. After you have completed your servicing,

secure the cutting head to the rear arm.

7. After you are properly seated in the

operator's seat, restart the unit and raise

the cutting heads.

8. Shut off the unit and swing the rear arm

back under the unit and secure the arm

with the draw latch (See Fig. 5.16.1).

9. Install the grass catcher.

1

2

Figure 5.16.1

1. Draw Latch

2. Handle

To avoid the possibility of serious injury,

ALWAYS be properly seated in the operator's

seat while the engine is running.

NEVER attempt to drive the machine while

the rear arm is not secured by the draw latch.

Driving the machine with the rear arm out, will

result in damage to the machine and/or cause

serious injury or death of the operator and/or

bystanders.

WARNING

GB-20

GB

JACOBSEN G-PLEX III Series: DN & DP

MAINTENANCE AND PARTS MANUAL

6 ADJUSTMENT

6.1 LEVELING LINKAGE FOR THE FRONT

CUTTING HEADS

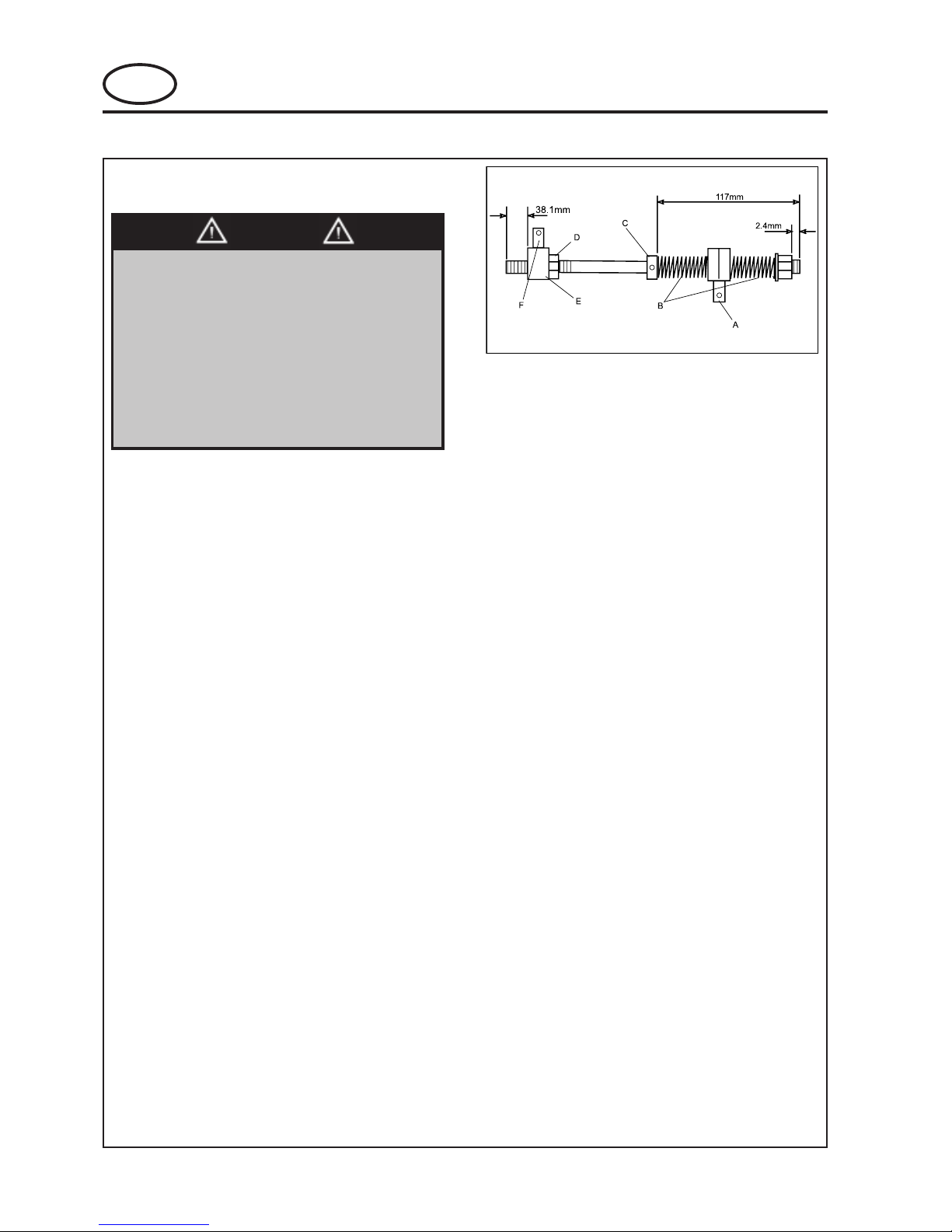

Fig. 6.1.1

A. Connector to main frame (DO NOT adjust)

B. Springs

C. Lock collar

D. Jam nut

E. Adjusting connector

F. Adjusting connector secures to lift arm

This procedure must be performed as

specified and only by properly trained

service personnel.

During this entire procedure the reel

enable switch must be in the off position.

Turning on the reel enable switch will

result in damage to the unit and/or

serious personal injury or death to you

the operator or bystanders

WARNING

NOTICE

The dimensions in figure 6.1.1 are factory

preset and the leveling linkage should not

need adjusting. After some time the

linkage may require some adjusting. If it

is required, only make adjustments on the

adjusting connector (E Fig. 6.1.1).

1. With the unit on a level surface

(recommend concrete surface), place

cardboard underneath all three of the

cutting heads.

2. An additional person is needed to stand 3

meters in front of the unit to check on how

level the front heads are when lowering.

Lower the cutting heads and ensure the

entire width of the front heads are parallel

with the level surface as the heads touch

the cardboard.

3. If they do not touch evenly, make an

adjustment using the adjusting connector.

Repeat procedure as needed until the two

front heads touch evenly on the level

surface.

GB-21

JACOBSEN G-PLEX III Series: DN & DP

MAINTENANCE AND PARTS MANUAL

GB

6.2 MOW/TRANSPORT SPEED CONTROL

When cutting heads are raised completely, the

wheel drive speed range is 0 7.5 mph (0 12 Km/

hr). Speed is controlled by use of the direction/

speed control pedal as described in control pedals

section.

When cutting heads are lowered, the forward

movement of the direction/speed control pedal is

restricted by the automatic mow speed control

linkage (the bellcrank stop screw contacts the foot

pedal tab which rotates the pedal upward. This in

turn reduces the ground speed of the unit for

mowing). The mow speed range is 0 3.8 mph (0

6.1 Km/hr).

ADJUSTING MOW SPEED

To determine mow speed, run a time check on how

fast the unit travels in a distance of 50 (15.24 M).

Prepare a level surface with enough room to start

and end beyond the 50 marks.

Place a stake in the ground where you want to begin

timing the unit. Measure and place another stake at

a distance of 50 (15.24 M). Lower the cutting heads

and press the direction pedal forward so the unit is

traveling at full throttle (the cutting heads should be

in the neutral position when timing the unit).

Begin timing the unit when the center of the front tire

aligns with the first stake. Stop timing when the

center of the front tire aligns with the stake placed at

50 (15.24 M). Estimated time for 3.8 mph (6.1 Km/

hr) will be approximately 8.8 to 9.2 seconds. If there

is a significant difference in the times listed above,

you can adjust the mow speed as follows.

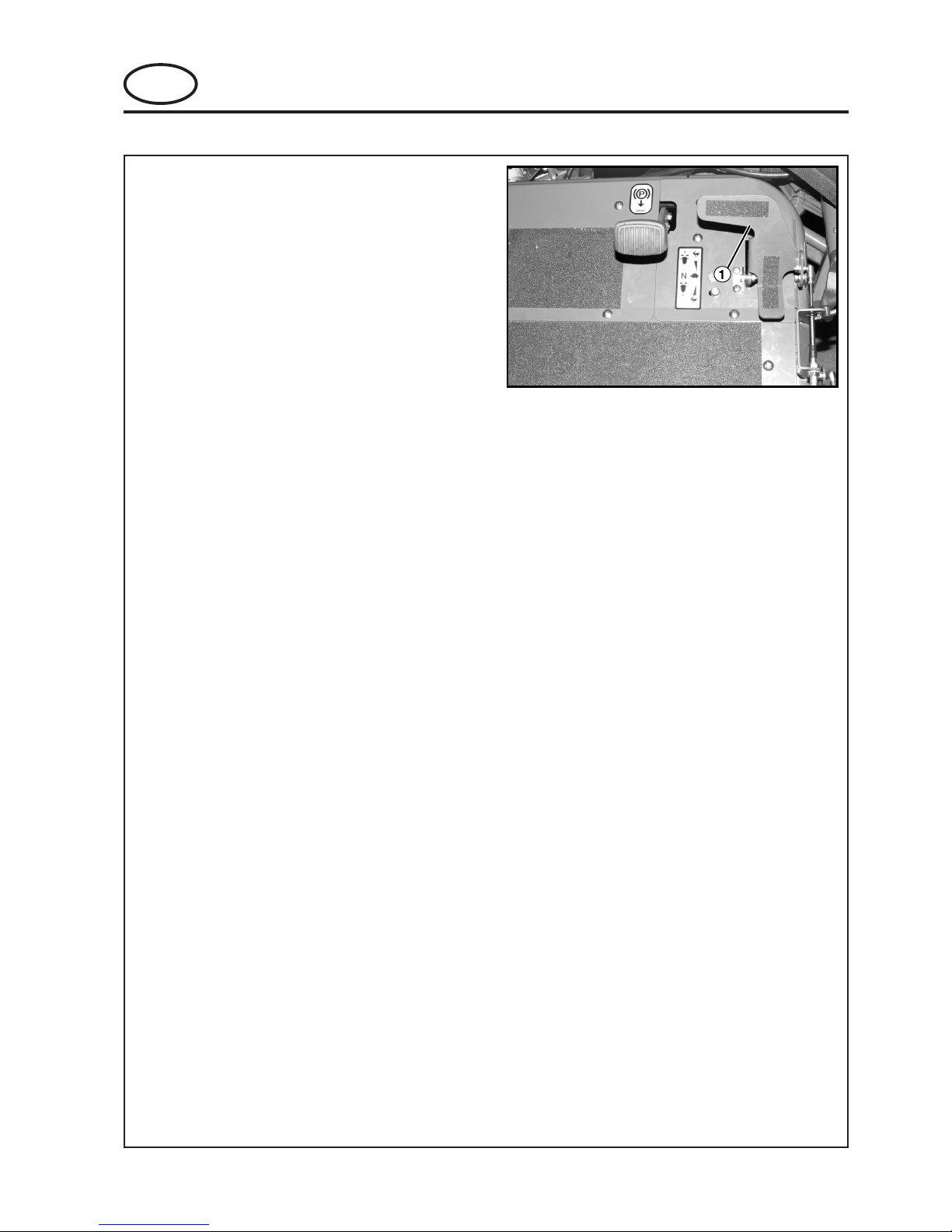

Figure 6.2.1

1. Direction/Speed Pedal

6 ADJUSTMENT

GB-22

GB

JACOBSEN G-PLEX III Series: DN & DP

MAINTENANCE AND PARTS MANUAL

6.3 SPEED CONTROL PEDAL

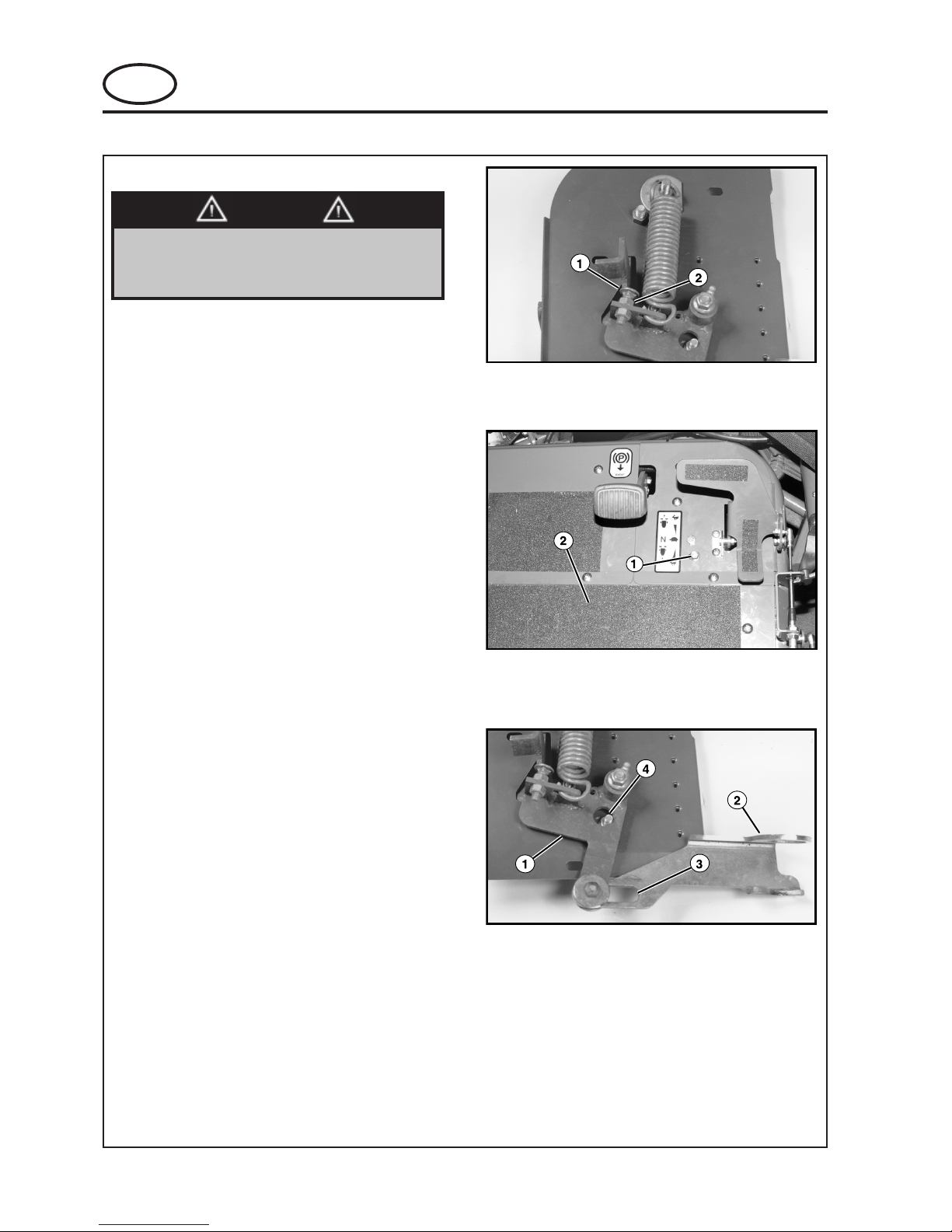

Figure 6.3.1

1. Mow Speed Adjustment Screw

2. Locking Nut

Figure 6.3.2

1. Bellcrank Stop Screw

2. Center Foot Panel

Figure 6.3.3

1. Bellcrank

2. Lockout Link Angle

3. Lockout Link slot

4. Bellcrank Stop Screw

This procedure MUST be performed as

specified and only by properly trained

service personnel.

WARNING

Adjusting the speed control screw out (increasing

length) will reduce the mow speed. Adjusting the

speed control screw in (shortening length) will

increase mow speed.

Determine which direction to adjust the mow speed

screw. Loosen the locking nut and adjust speed

control screw, snug up the locking nut and run the

time test again, repeat as necessary. When correct

mow speed has been obtained, tighten the locking

nut (See Fig. 6.3.1).

TO SET BELLCRANK STOP SCREW:

NOTICE

The bellcrank stop screw has been set at the factory

and should NOT require adjustment. If stop screw is

loosened or removed, it MUST be properly installed

and adjusted prior to unit operation.

Remove the screws securing the center foot panel

and remove panel (this will allow access to the

lockout link angle).

Loosen the nut on the bellcrank stop screw just

enough to allow the screw to be slid to the left of the

slot (See Fig. 6.3.3).

6 ADJUSTMENT

GB-23

JACOBSEN G-PLEX III Series: DN & DP

MAINTENANCE AND PARTS MANUAL

GB

Figure 6.3.4

Position Bushing to Left of Slot

Rotate bellcrank clockwise (as viewed from above)

and hold the bushing on the lockout link angle to the

left end of the lockout link slot (See Fig. 6.3.4).

Slide the bellcrank stop screw to the left of the slot

located in the foot panel (See Fig. 6.3.2) making

sure the bellcrank contacts the stop screw.

With the screw held tightly against the bellcrank,

tighten the stop screw nut.

Install the center foot panel.

6 ADJUSTMENT

GB-24

GB

JACOBSEN G-PLEX III Series: DN & DP

MAINTENANCE AND PARTS MANUAL

6.4 BLEEDING THE FUEL SYSTEM - DIESEL

This procedure MUST be performed as

specified and only by properly trained

service personnel.

WARNING

The fuel system must be bled when:

Starting the engine for the first time.

The fuel tank becomes completely empty.

The engine has not been used for an

extended period of time.

The fuel filter and/or fuel lines have been

loosened, removed or replaced.

1. Fill the fuel tank.

2. Open the air vent on top of the fuel filter

(See Fig. 6.5.1).

3. Without preheating the glow plugs, turn

the ignition switch to START to operate

the fuel pump. Allow the starter to run the

pump until a steady stream of fuel is

coming out of the fuel filter air vent. Stop

the starter and close the air vent.

4. Open the air vent on top of the injection

pump, open air vent only when engine is

NOT running (See Fig. 6.5.2).

5. Without preheating the glow plugs, turn

the ignition switch to START to operate

the fuel pump. Allow the starter to run the

pump until a steady stream of fuel is

coming out of the injection pump air vent.

Stop the starter and close the air vent.

Catch fuel and dispose of

properly.

To avoid a fire hazard, clean up

any spilled fuel.

WARNING

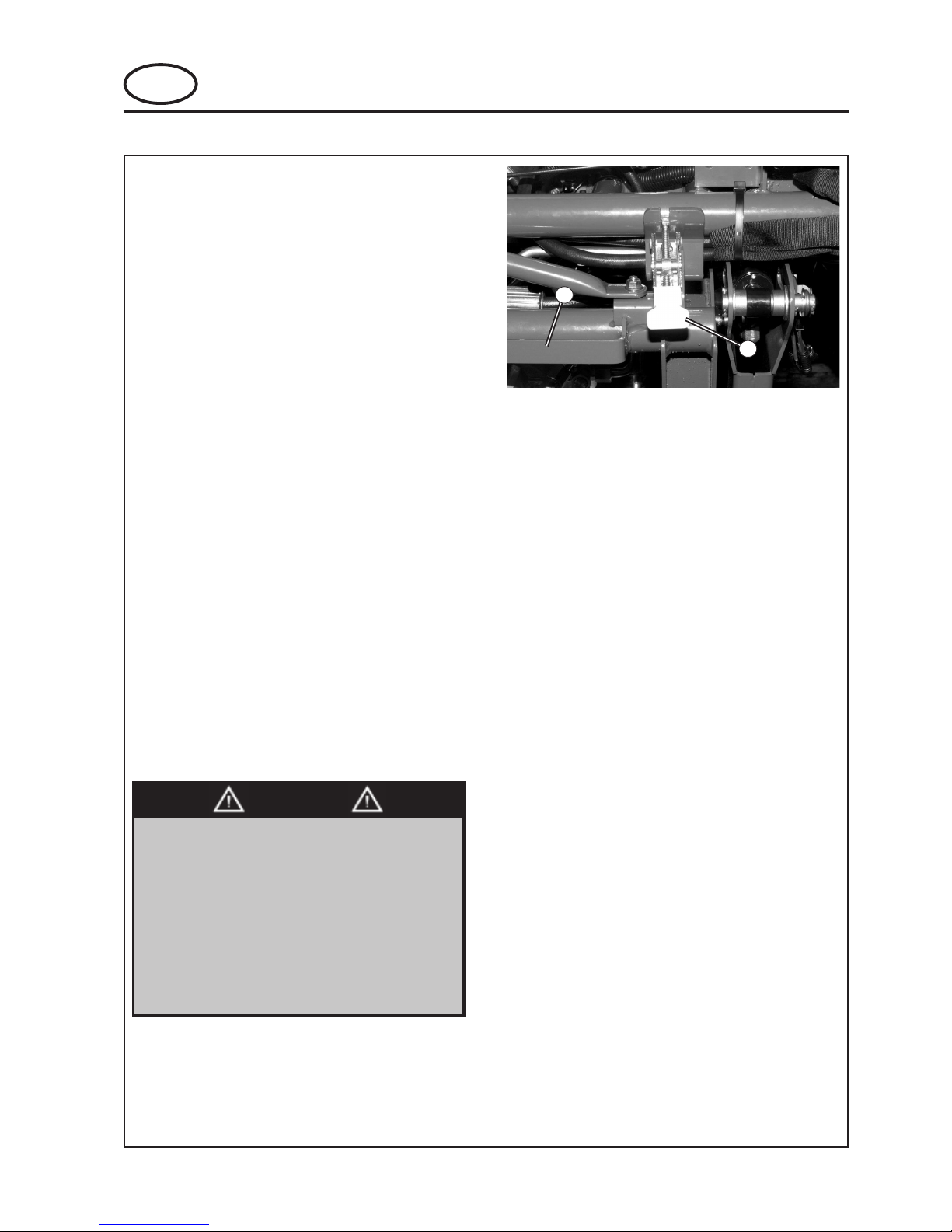

Figure 6.5.1

1. Fuel Filter Air Vent

2. Secondary fuel filter

Figure 6.5.2

1. Injection Pump Air Vent

6 ADJUSTMENT

GB-25

JACOBSEN G-PLEX III Series: DN & DP

MAINTENANCE AND PARTS MANUAL

GB

6.5 BACKLAPPING

Backlapping on a regular basis will help keep the

cutting edges sharp and extend the life of the reel.

Backlapping may be performed on one cutting head

only, two heads, or all three heads simultaneously. If

backlapping one or two cutting heads is desired,

back off slightly on the bedknifetoreel clearance on

the head(s) not requiring backlapping. This will

eliminate contact between bedknife and reel,

avoiding the possibility of damaging the reel or

bedknife during the backlap process. Always make

bedknife adjustments with the Engine Off.

NOTICE

Make sure the bedknife adjustment is

correct before backlapping. Refer to

Bedknife Adjustment .

2. Slowly turn the restriction valve knob

clockwise until the desired reel rotation

speed is attained. It should be slow

enough so that the reel will not throw off

the backlapping compound as it spins.

3. Apply an even coat of backlapping

compound to the entire length of each

blade of the reel. Use a brush with a long

enough handle to keep you away from the

rotating blades. For best results, use a

handle length which will permit application

of compound while standing in front of the

unit.

4. Once all the blades on the reel are

uniformly sharp, shut off the engine and

switch the reel enable switch to the off

position. Set the reel valve control to the

mow position and close the restriction

valve (all the way clockwise).

NOTICE

To ensure proper reel rotation, make sure

the restriction valve is completely closed.

5. Wash all of the backlapping compound

from all of the heads. Once they are

thoroughly cleaned and dry, apply a light

film of oil to the cutting edges to help

prevent rust.

6. After backlapping, the bedknife adjustment

should be made again.

1

3

2

A

B

N

Figure 6.6.1

2. Backlap Valve

3. Reel Control Lever

A. Mow Position

B. Backlap Position

N. Neutral Position

ALWAYS open the restriction

valve before setting the reel

control lever to BACKLAP

position. DO NOT set the reel

control lever to the BACKLAP

position before opening the

needle valve in the bypass

circuit. This will cause the reels

to start turning IMMEDIATELY at

full speed.

Keep hands, feet and clothing

away from all three reels

whenever the reel control lever

is placed in the backlap position.

When backlap restriction valve is

closed or being closed, all three

reels will rotate in the backlap

direction.

WARNING

1. Open the restriction valve on the reel valve

by turning the knob counterclockwise as

far as it will go (See Fig. 6.6.1).

2. Set the reel control lever to the right for the

backlap position (See Fig. 6.6.1).

1. Start the engine and set the throttle to low

idle. Switch the reel enable switch to the

on position. Lower heads by operating the

paddle or the footswitch.

6 ADJUSTMENT

GB-26

GB

JACOBSEN G-PLEX III Series: DN & DP

MAINTENANCE AND PARTS MANUAL

7.1 GENERAL

The troubleshootijng chart below lists basic problems that may occur during start-up and operation. For more

detailed information regarding the hydraulic and electrical systems contact your area Jacobsen Distributor.

7 TROUBLESHOOTING

smotpmySsesuaCelbissoPnoitcAnoitceS

.tratstonlliwenignE

.tuodemittonsahgulPwolG.1

otgulpwolgwolladnahctiwsnoitingiteseR.1

.enignegniknarcerofebtuoemit

roegrahcnowolyrettaB.2

.evitcefed

yrettabdnayrettabfonoitidnoctcepsnI.2

.snoitcennoc

leufroytpmeknatleuF.3

.detanimatnoc

niarD,retlifegnahC.leufhserfhtiwknatlliF.3

.senilmorfriadeelB,lwobthgismorfretawyna

7.5

.esuFnwolB.4.esuFecalpeR.4

.yaleRretratSevitcefeD.5.yraseccenfiyalerecalperdnatseT.5

deilppatonekarbgnikraP.6ekarbgnikrapylppA.6

otteshctiwsegagnewoM.7

.tuc

.hctiwswomdetnuomhsadegagnesiD.7

tratsotdrahenignE

.ylroopsnurro

leufroytpmeknatleuF.1

.detanimatnoc

niarD,retlifegnahC.leufhserfhtiwknatlliF.1

.senilmorfriadeelB,lwobthgismorfretawyna

7.5

.ytridrodekcolbrenaelCriA.2

saecalperdnarotacidnirenaelcriakcehC.2

.yraseccen

.pmupleuf,srotcejnI.3.launamenignetlusnoC.3

melborPenignErehtO.4.ediuggnitoohselbuortenignetlusnoC.4

.spotSenignE

ytpmeknatleuF.1senildeelbdnaleufhserfhtiwlliF.15.6

erofebtestonskcolretnI.2

taessrotarepognivael

gnivaelerofebnoitisopffoothctiwswomteS.2

.taes

.gnitaehrevOenignE

wolleveltnalooC.1

finoitulosezeerfitna05/05ddadnatcepsnI.1

.deriuqer

detcirtserekatniriarotaidaR.2.rotaidartadraughsemeriwnaelC.2

rotlebrotanretla/pmupretaW.3

.nekorbroesooltlebnaf

.tlebnafdnatlebrotanretla/pmupretawtcepsnI.3

.yraseccenfinethgiT

11.5

gnidlohtonyrettaB

thgilyrettaB.egrahc

.no

yrettabdedorrocroesooL.1

.slanimret

sanethgitdnanaelc,slanimrettcepsnI.1

.deriuqer

nileveletylortcelewoL.2

.yrettab

retawdelletsidhtiwyrettabllifeR.251.5

roesooltlebrotanretlA.3

.nekorb

finethgiT.lebrotanretla/pmupretawtcepsnI.3

.yraseccen

11.5

.evitcefedrotanretlA.4.aunamenigneeeS.4

tucsrednilyC

.ylnevenu

tonedalbmottobotrednilyC.1

.ylreporpdetsujda

.tnemtsujdaedalbmottobotrednilyctcepsnI.1

.wolootdeepsenignE.2 .elttorhtlluftaenignenur,deepsenignekcehC.2

detsujdatondeepsrednilyC.3

.snoitidnocfrutrof

.tuctsebrofdeepsrednilyctsujdA.3

tesrevelnoitceridrednilyC.4

.esreverni

.noitatordrawrofotrevelnoitceridrednilycteS.4

yltcerrocnithgiewdnuorG.5

detsujda

tcerrocllitevlavlortnocthgiewdnuorgtsujdA.5

.deveihcasidnuorg

GB-27

JACOBSEN G-PLEX III Series: DN & DP

MAINTENANCE AND PARTS MANUAL

GB

GB-28

GB

JACOBSEN G-PLEX III Series: DN & DP

MAINTENANCE AND PARTS MANUAL

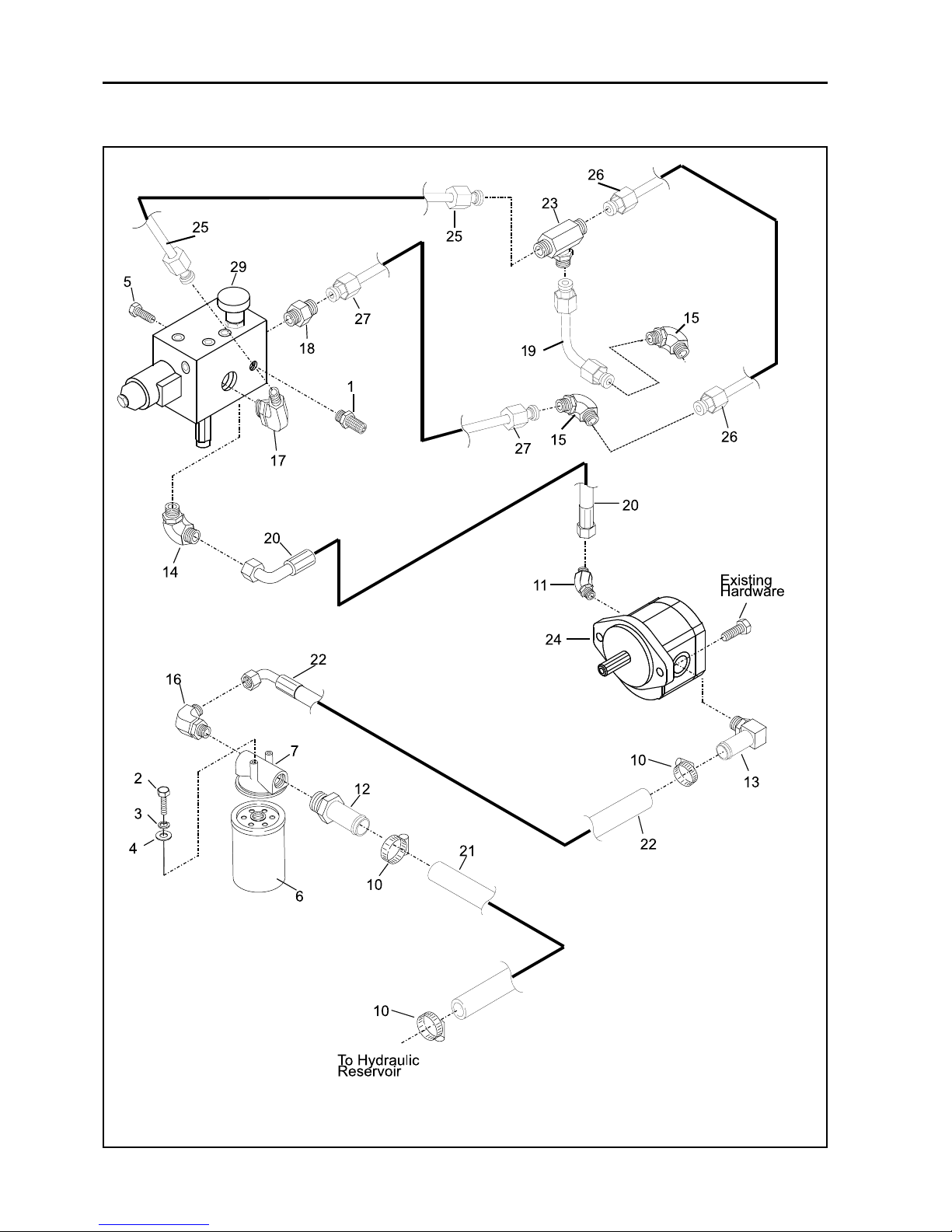

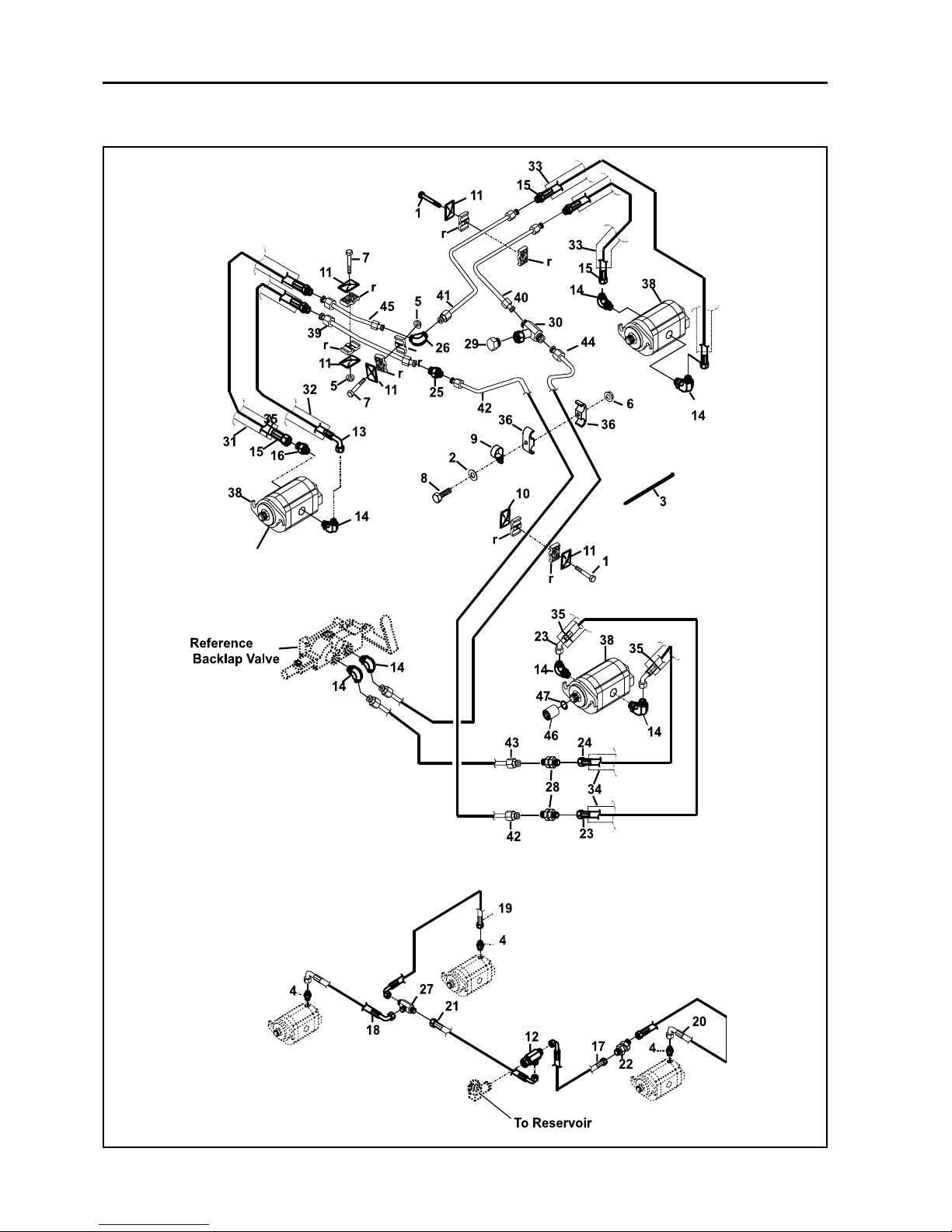

8.1 HYDRAULIC CIRCUIT

8 SCHEMATICS

GB-29

JACOBSEN G-PLEX III Series: DN & DP

MAINTENANCE AND PARTS MANUAL

GB

8 SCHEMATICS

8.1 HYDRAULIC CIRCUIT

1. Inlet Filter

2. Hydrostat Pump

3. Right Hand Wheel Motor

4. Left Hand Wheel Motor

5 Three Wheel Drive Accessory

6. Power Steering Valve

7. Steering Cylinder

8. Inlet Filter

9 Reel Pump

10. Reel Drive Valve

11. Backlap Valve Accessory

12. Rear Reel Motor

13. Left Reel Motor

14. Right Wheel Motor

15. Ball Valve Accessory

16. Lift Valve

17. Divider / Combiner Valve

18. Left Lift Cylinder

19. Right Lift Cylinder

20. Sequence Valve

21. Rear Lift Cylinder

22. Oil Cooler

23. Reservoir

GB-30

GB

JACOBSEN G-PLEX III Series: DN & DP

MAINTENANCE AND PARTS MANUAL

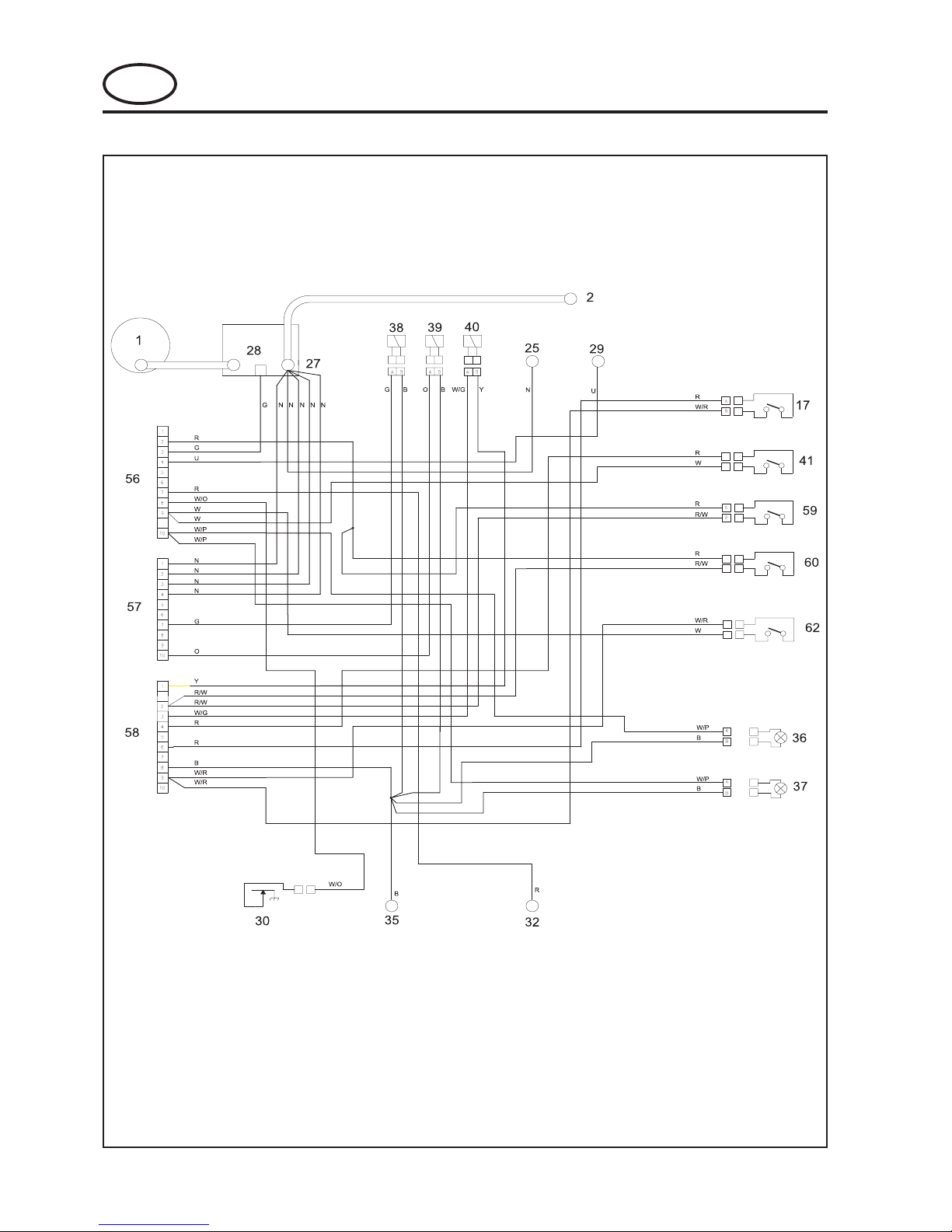

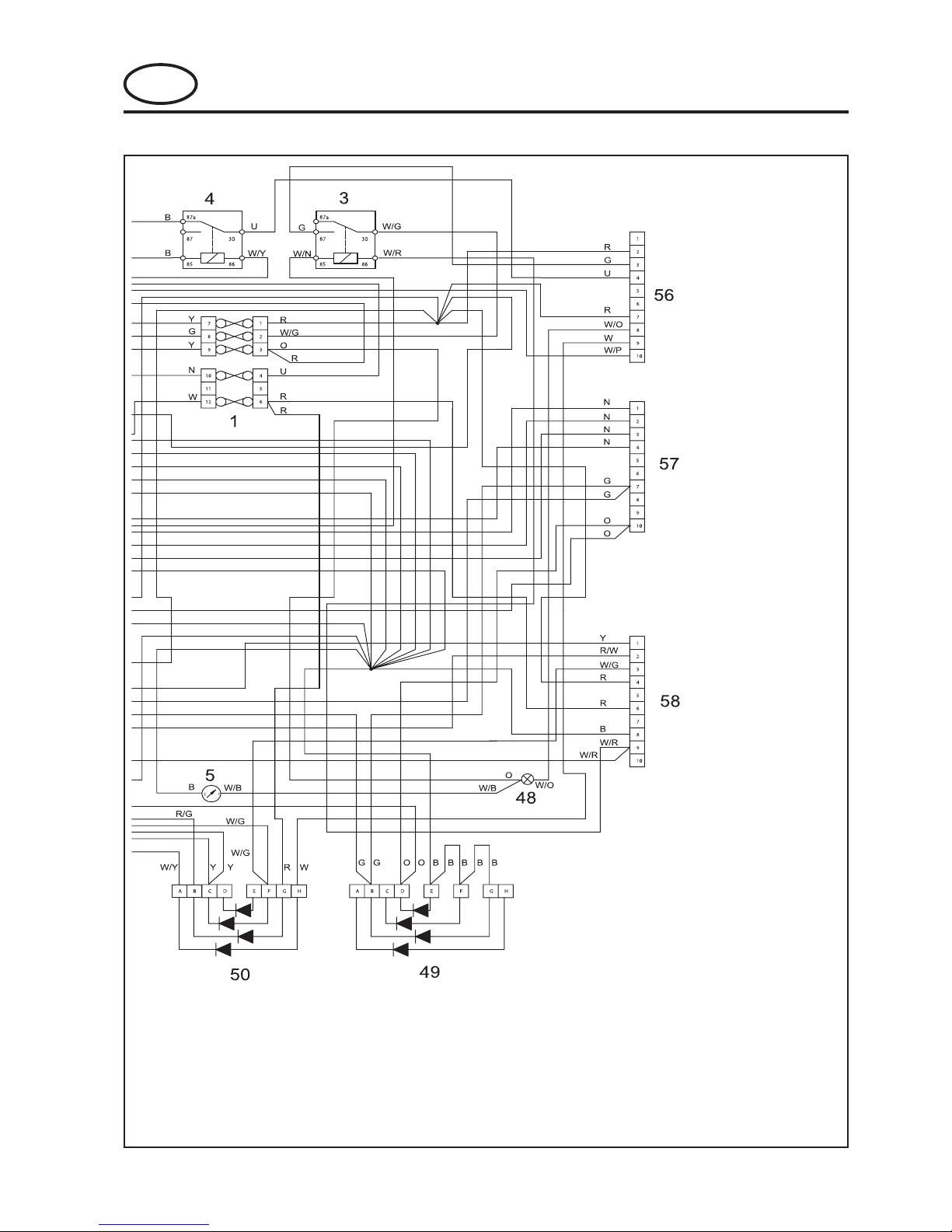

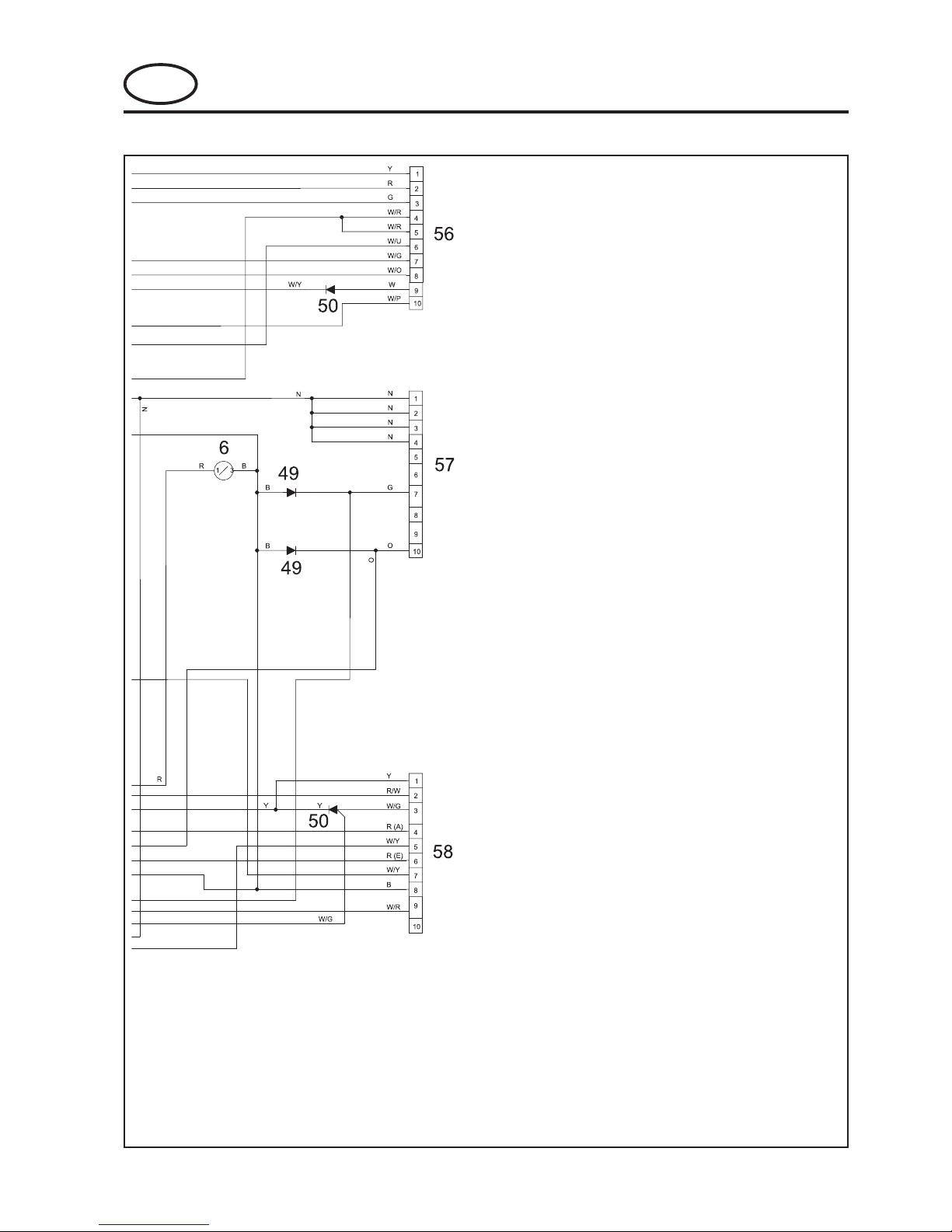

8.2 ELECTRICAL CIRCUIT MAIN HARNESS - GASOLINE

GB-31

JACOBSEN G-PLEX III Series: DN & DP

MAINTENANCE AND PARTS MANUAL

GB

CABLE COLOUR CODE

R Red

G Green

O Orange

S Grey

B Black

W White

K Pink

P Violet

Y Yellow

UBlue

N Brown

BG Black Green

BO Black Orange

NU Brown Blue

WG White Green

WY White Yellow

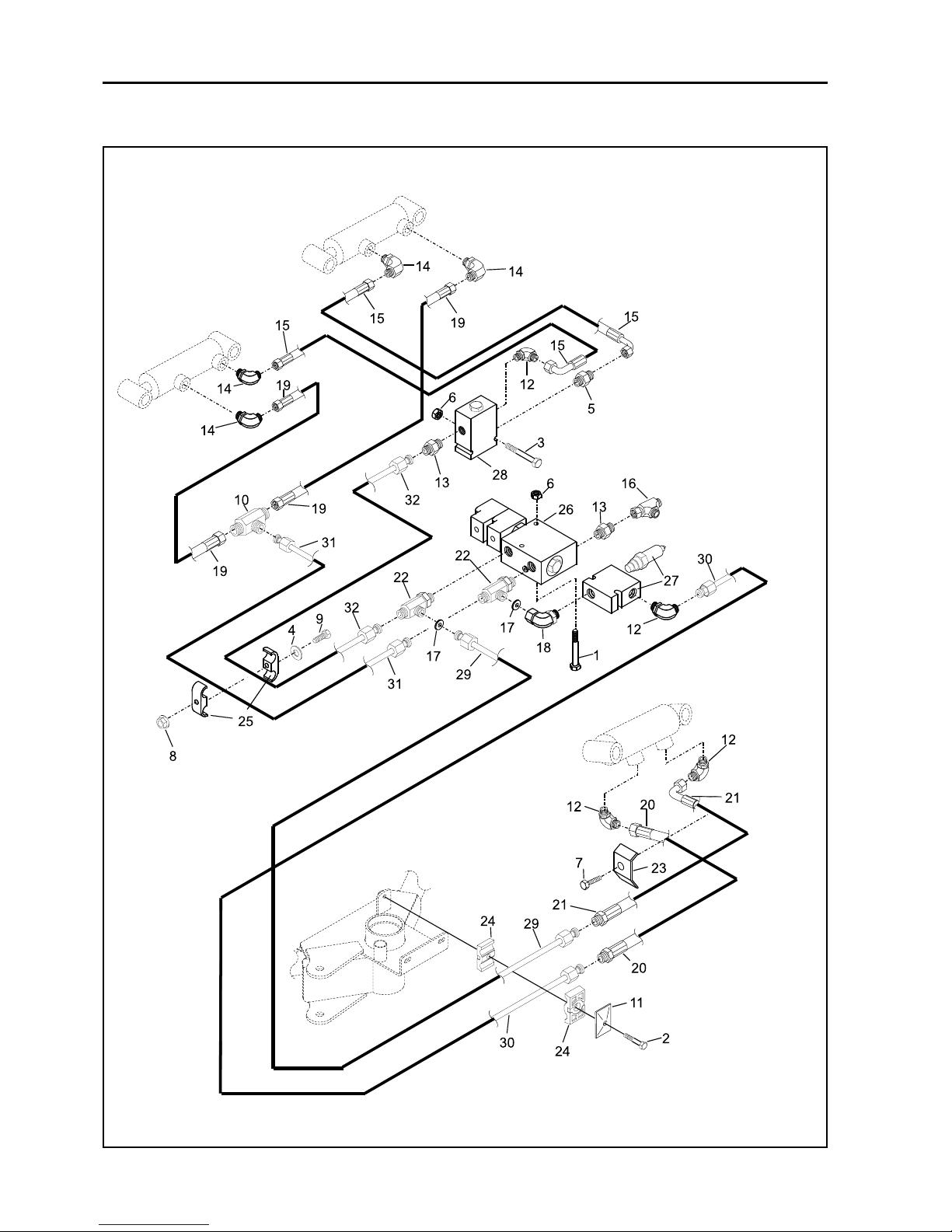

7 SCHEMATICS

1 Starter Motor

2 Battery +ve Terminal

17 Backlap Switch

25 Alternator

27 Starter Solenoid Batt +ve Terminal

28 Starter Solenoid

29 Engine Kill

30 Oil Pressure Sender

32 Carburetor Solenoid

35 Solenoid Ground

36 Headlight

37 Headlight

38 Raise Solenoid

39 Lower Solenoid

40 Reel Solenoid

41 Seat Switch

56 Instrument Connector 1

57 Instrument Connector 2

58 Instrument Connector 3

59 Paddle Switch

60 Foot Switch

62 Parking Brake / Neutral Switch

GB-32

GB

JACOBSEN G-PLEX III Series: DN & DP

MAINTENANCE AND PARTS MANUAL

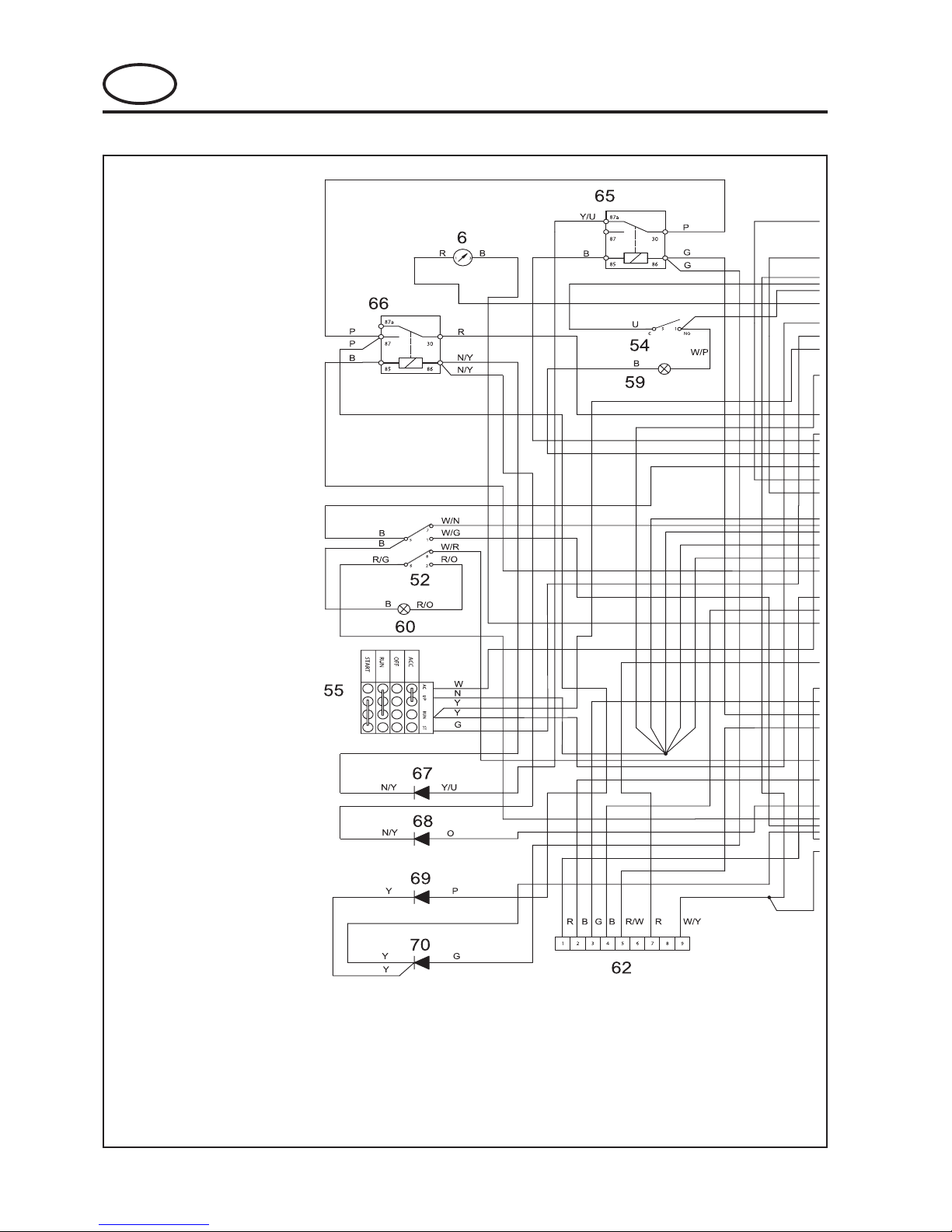

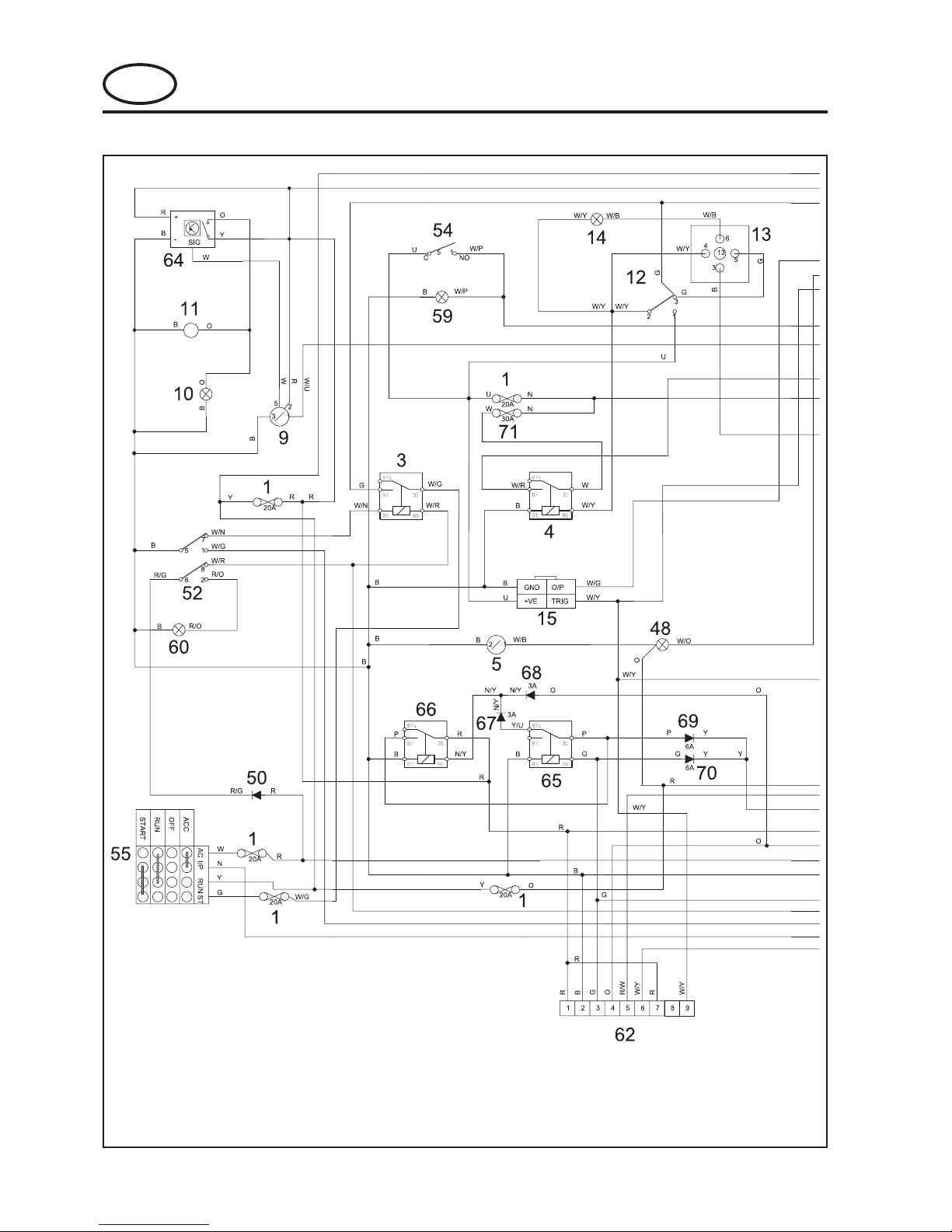

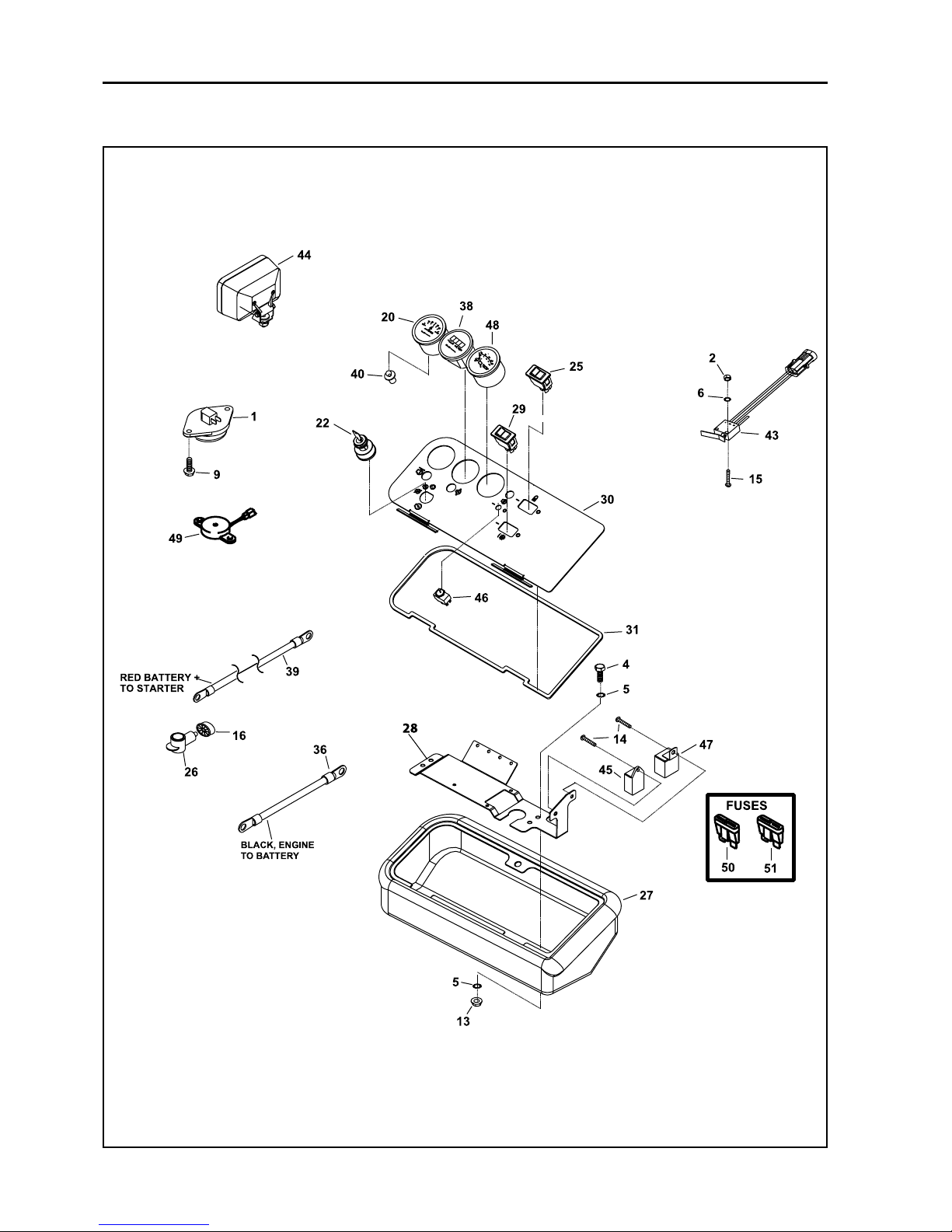

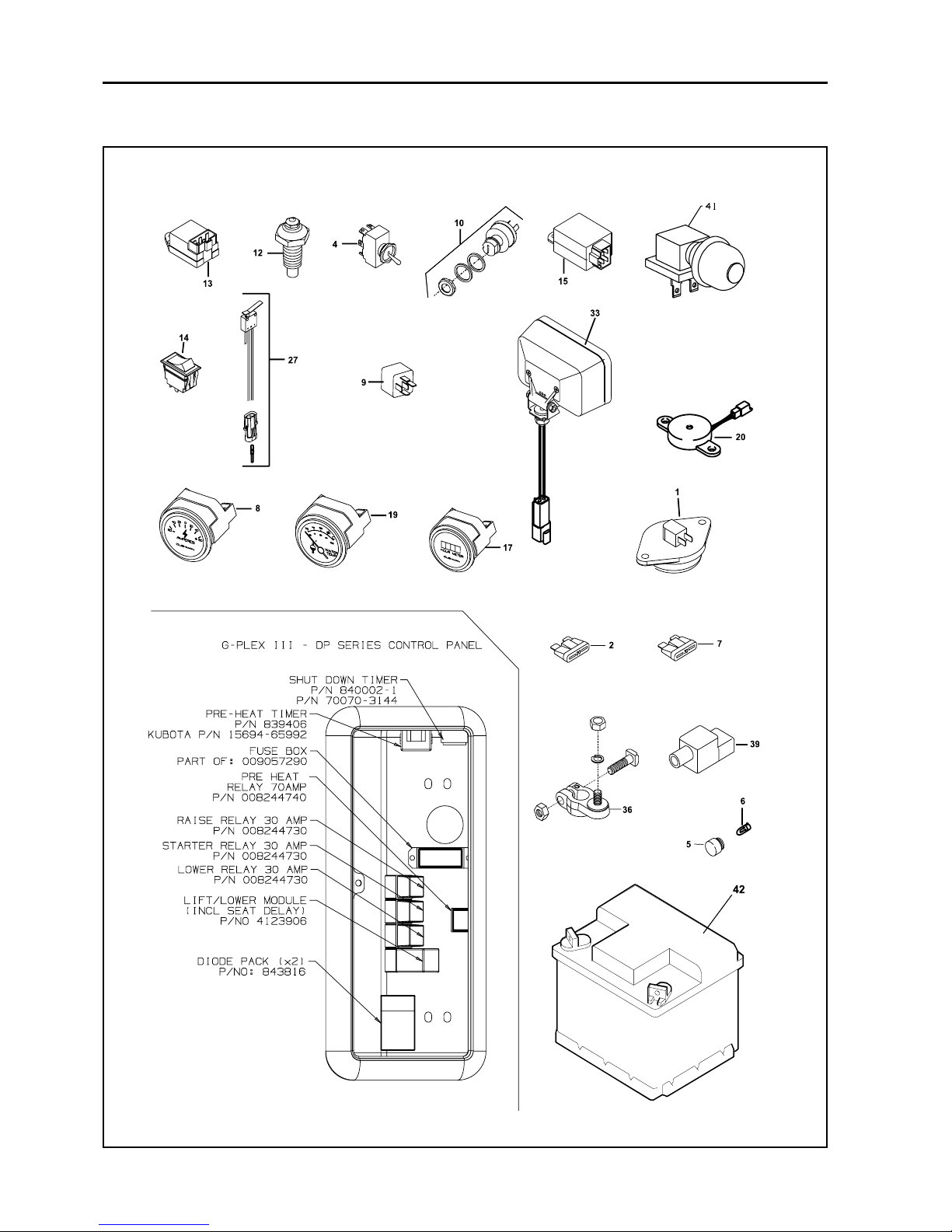

8.3 ELECTRICAL CIRCUIT CONTROL PANEL - GASOLINE

1 Fuse Box

3 Starter Relay

4 Ignition Relay

5 Hour Meter

6 Volt Meter

48 Oil Pressure Light

49 Diode Array 2

50 Diode Array 1

52 Reel Enable Switch

54 Headlight Switch

55 Key Switch

56 Instrument Connector

1

57 Instrument Connector

2

58 Instrument Connector

3

59 Headlight Switch Light

60 Reel Enable Switch

Light

62 Lift / Lower Modual

65 Raise Relay

66 Lower Relay

67 Diode

68 Diode

69 Diode

70 Diode

GB-33

JACOBSEN G-PLEX III Series: DN & DP

MAINTENANCE AND PARTS MANUAL

GB

CABLE COLOUR CODE

R Red

G Green

O Orange

S Grey

B Black

W White

K Pink

P Violet

Y Yellow

U Blue

N Brown

BG Black Green

BO Black Orange

NU Brown Blue

WG White Green

WY White Yellow

GB-34

GB

JACOBSEN G-PLEX III Series: DN & DP

MAINTENANCE AND PARTS MANUAL

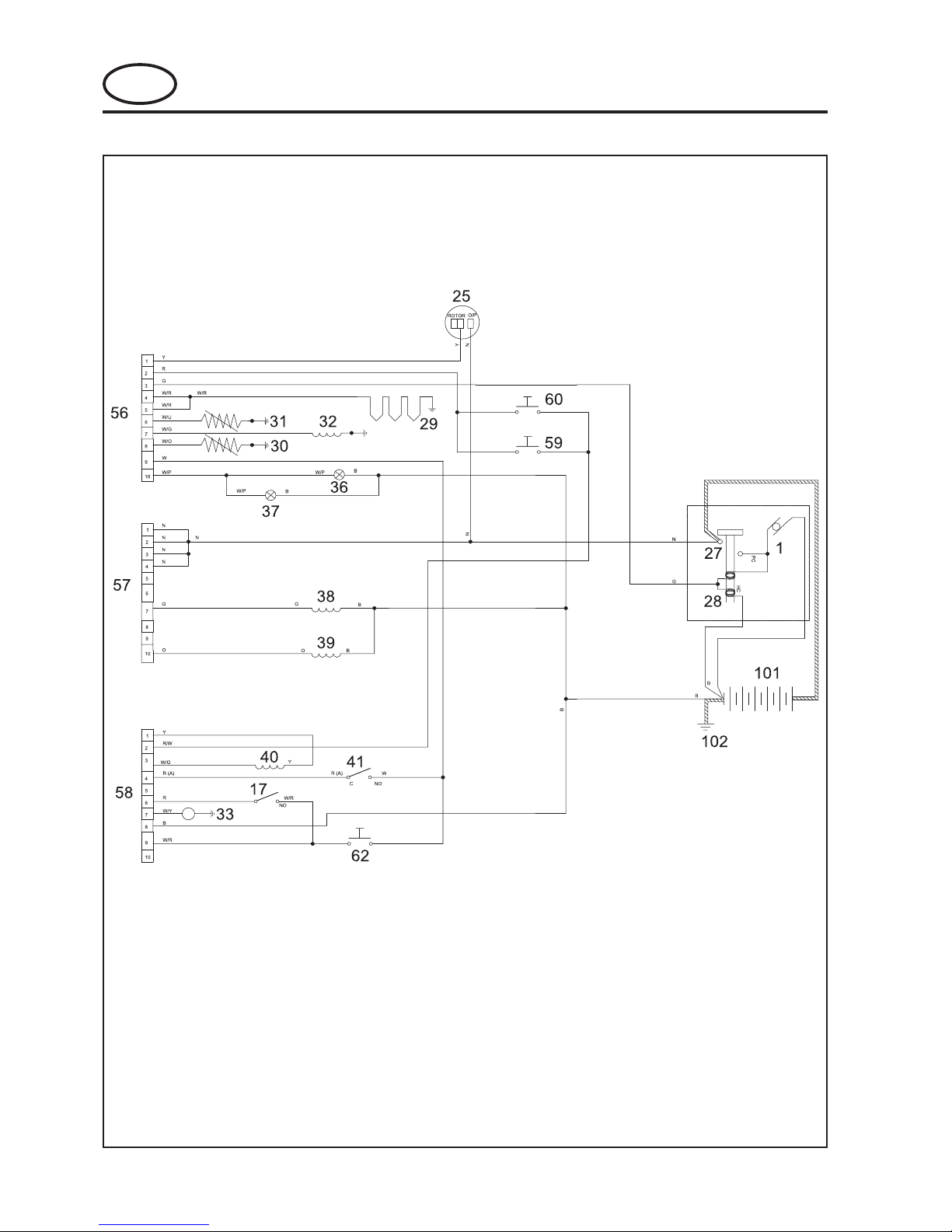

8.4 ELECTRICAL CIRCUIT MAIN HARNESS - DIESEL

GB-35

JACOBSEN G-PLEX III Series: DN & DP

MAINTENANCE AND PARTS MANUAL

GB

CABLE COLOUR CODE

R Red

G Green

O Orange

S Grey

B Black

W White

K Pink

P Violet

Y Yellow

UBlue

N Brown

BG Black Green

BO Black Orange

NU Brown Blue

WG White Green

WY White Yellow

1 Starter Motor

17 Backlap Switch

25 Alternator

27 Starter Solenoid Batt +ve Terminal

28 Starter Solenoid

29 Glow Plugs

30 Oil Pressure Sender

31 Water Temperature Sender

32 Fuel Solenoid

33 Fuel Pump

36 Headlight

37 Headlight

38 Raise Solenoid

39 Lower Solenoid

40 Reel Solenoid

41 Seat Switch

56 Instrument Connector 1

57 Instrument Connector 2

58 Instrument Connector 3

59 Paddle Switch

60 Foot Switch

62 Parking Brake / Neutral Switch

101 Battery

102 Battery Ground

GB-36

GB

JACOBSEN G-PLEX III Series: DN & DP

MAINTENANCE AND PARTS MANUAL

8.5 ELECTRICAL CIRCUIT CONTROL PANEL - DIESEL

GB-37

JACOBSEN G-PLEX III Series: DN & DP

MAINTENANCE AND PARTS MANUAL

GB

CABLE COLOUR CODE

R Red

G Green

O Orange

S Grey

B Black

W White

K Pink

P Violet

Y Yellow

U Blue

N Brown

BG Black Green

BO Black Orange

NU Brown Blue

WG White Green

WY White Yellow

1 Fuse 20Amp

3 Starter Relay

4 Ignition Relay

5 Hour Meter

6 Volt Meter

9 Water Temperature Gauge

10 Water Temperature Lamp

11 Water Temperature Buzzer

12 Preheat Switch

13 Preheat Timer

14 Preheat Lamp

15 Shut Down Timer

48 Oil Pressure Light

49 Diode Array 2

50 Diode Array 1

52 Reel Enable Switch

54 Headlight Switch

55 Key Switch

56 Instrument Connector 1

57 Instrument Connector 2

58 Instrument Connector 3

59 Headlight Switch Light

60 Reel Enable Switch Light

62 Lift / Lower Module

64 Water Temperature Gauge Relay

65 Raise Relay

66 Lower Relay

67 Diode

68 Diode

69 Diode

70 Diode

71 Fuse 30Amp

GB-38

GB

JACOBSEN G-PLEX III Series: DN & DP

MAINTENANCE AND PARTS MANUAL

NOTES

Parts-1

JACOBSEN G PLEX III Series: DN & DP

MAINTENANCE AND PARTS MANUAL

PARTS INDEX

1 CHASSIS AND COVERS ................................................................................... 3

2 POWER ASSY DIESEL ..................................................................................... 5

3 POWER ASSY GASOLINE ................................................................................ 7

4 RADIATOR (DIESEL) ......................................................................................... 9

5 AIR CLEANER (DIESEL) ................................................................................... 11

6 FUEL & HYDRAULIC RESERVOIRS & SUPPORT FRAME ............................... 13

7 HYDRAULIC TANK FITTINGS ........................................................................... 15

8 FUEL SYSTEM DIESEL .................................................................................... 17

9 FUEL SYSTEM GASOLINE ............................................................................... 19

10 OIL COOLER MOUNTING DIESEL .................................................................... 21

11 OIL COOLER MOUNTING GASOLINE .............................................................. 23

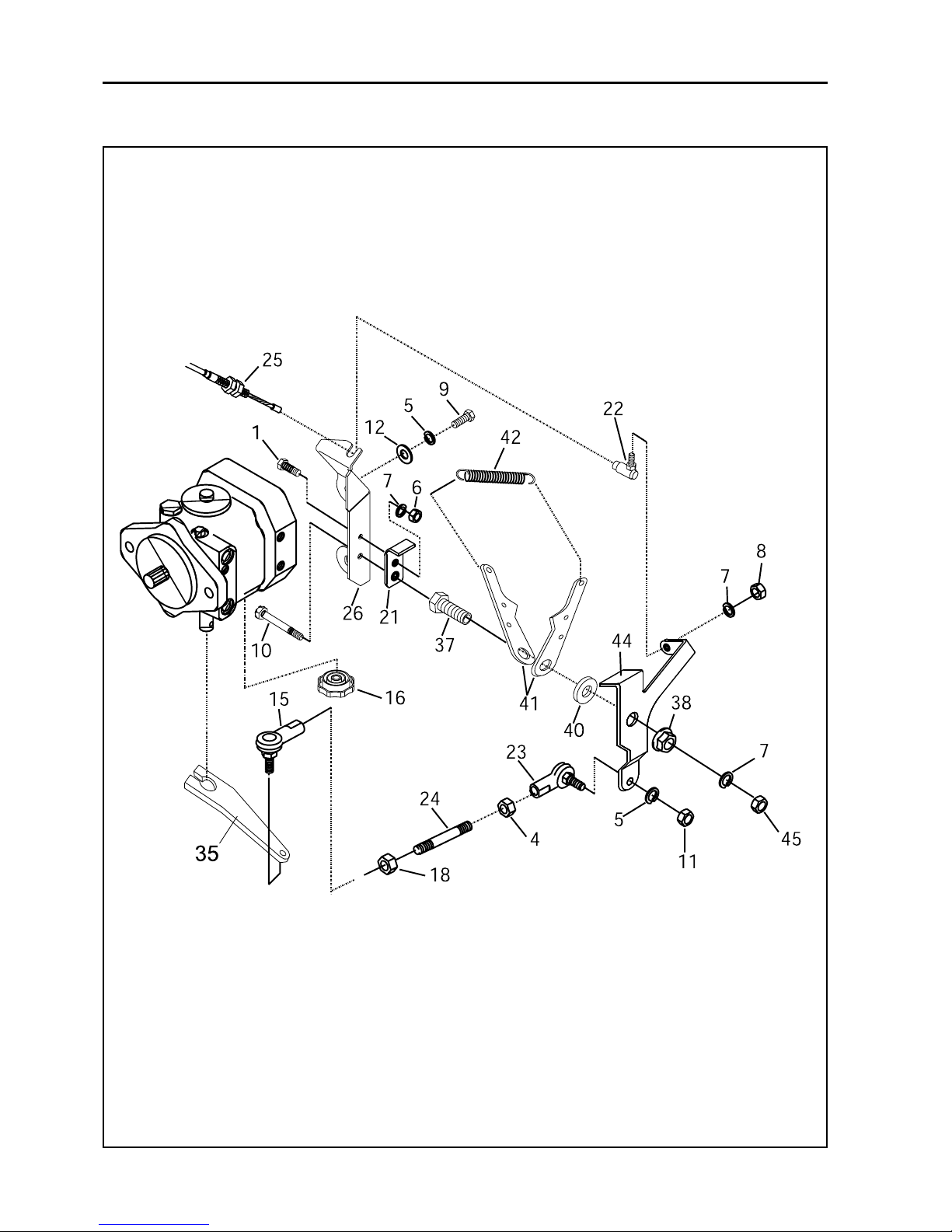

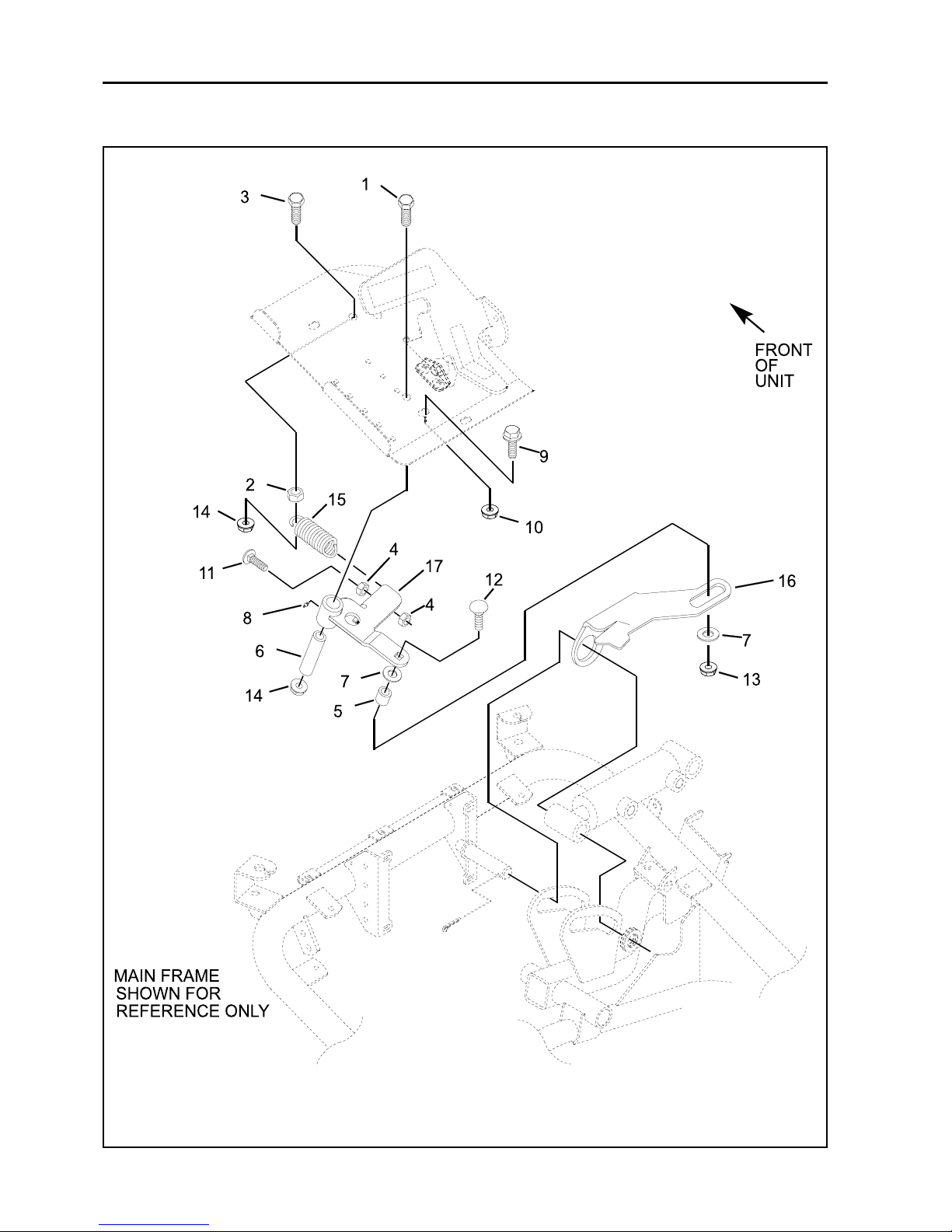

12 PUMP CONTROL LINKAGE ............................................................................. 25

13 HYDRAULIC PUMP AND VALVES - DIESEL ..................................................... 27

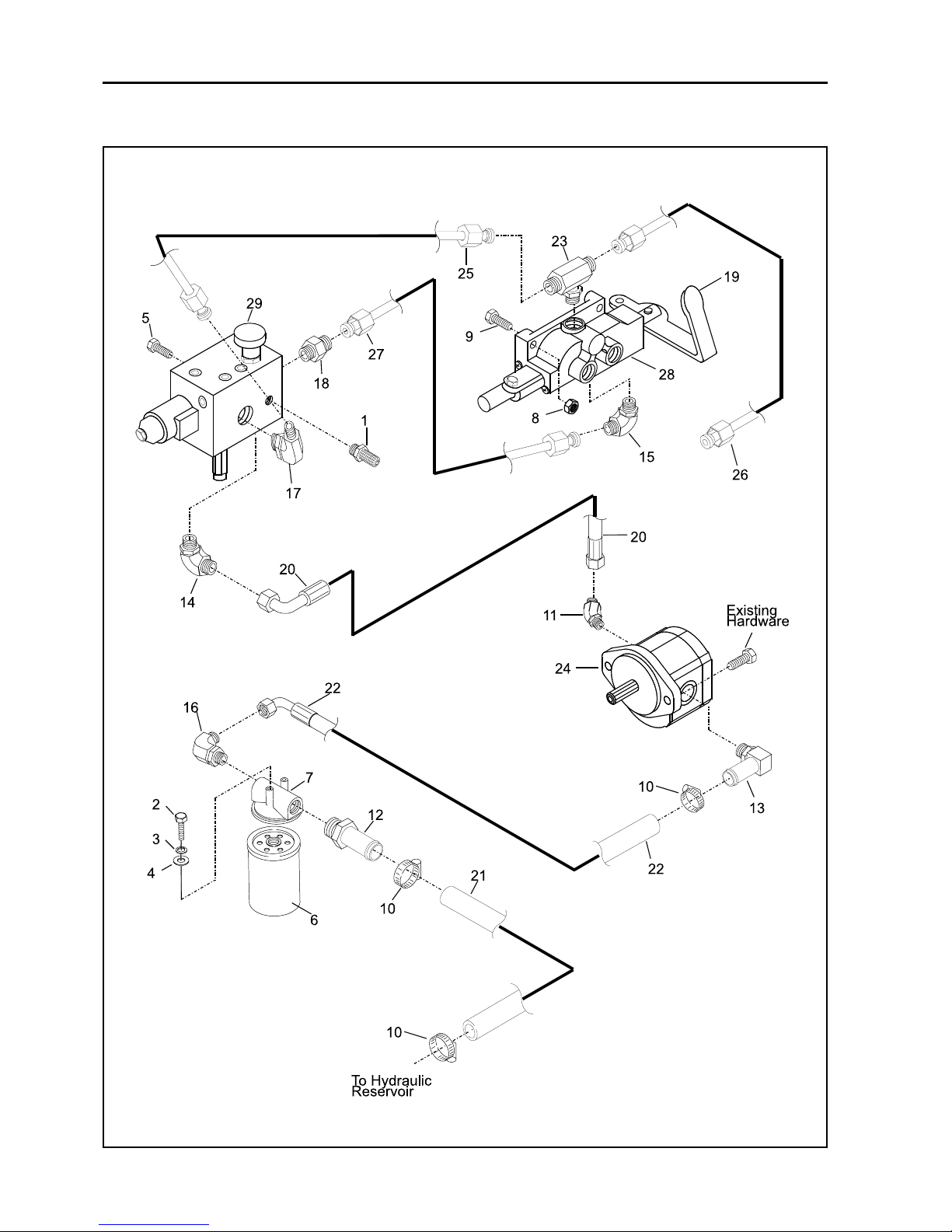

14 HYDRAULIC PUMP AND VALVES - GASOLINE ................................................ 29

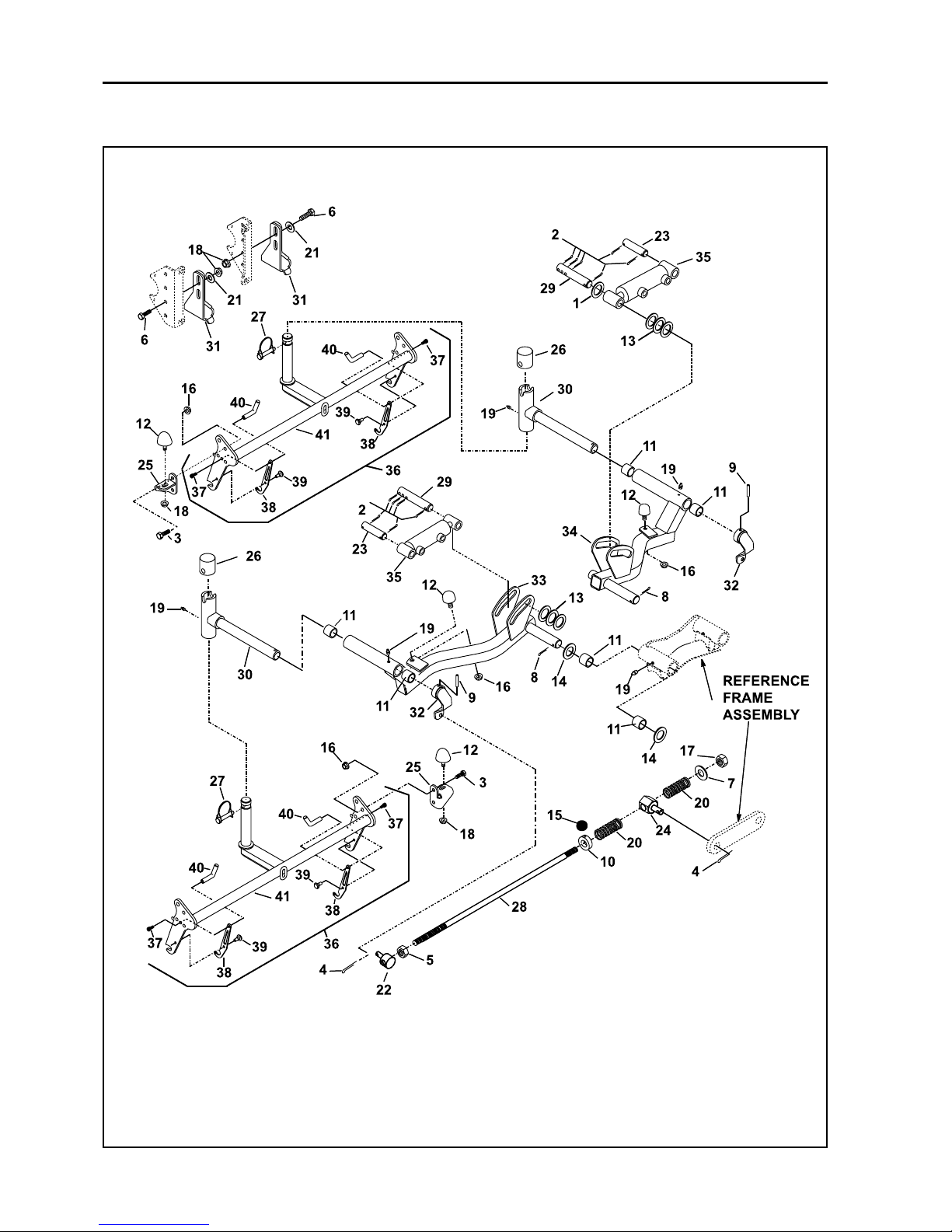

15 HYDRAULIC LIFT CIRCUIT ............................................................................... 31

16 HYDRAULIC REEL CIRCUIT ............................................................................. 33

17 HYDRAULIC WHEEL DRIVE CIRCUIT ............................................................... 35

18 HYDRAULIC POWER STEERING ..................................................................... 37

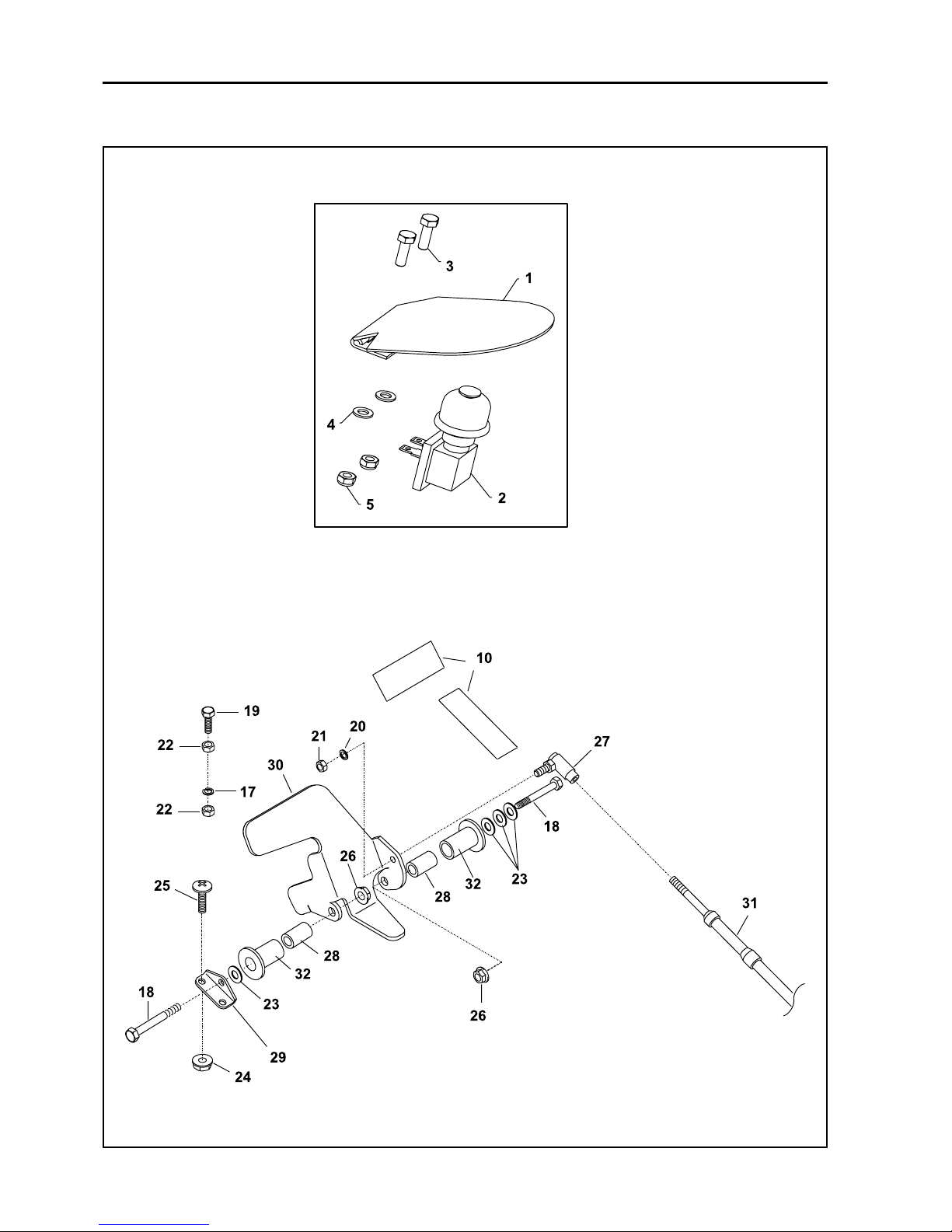

19 CONTROL ARM ............................................................................................... 39

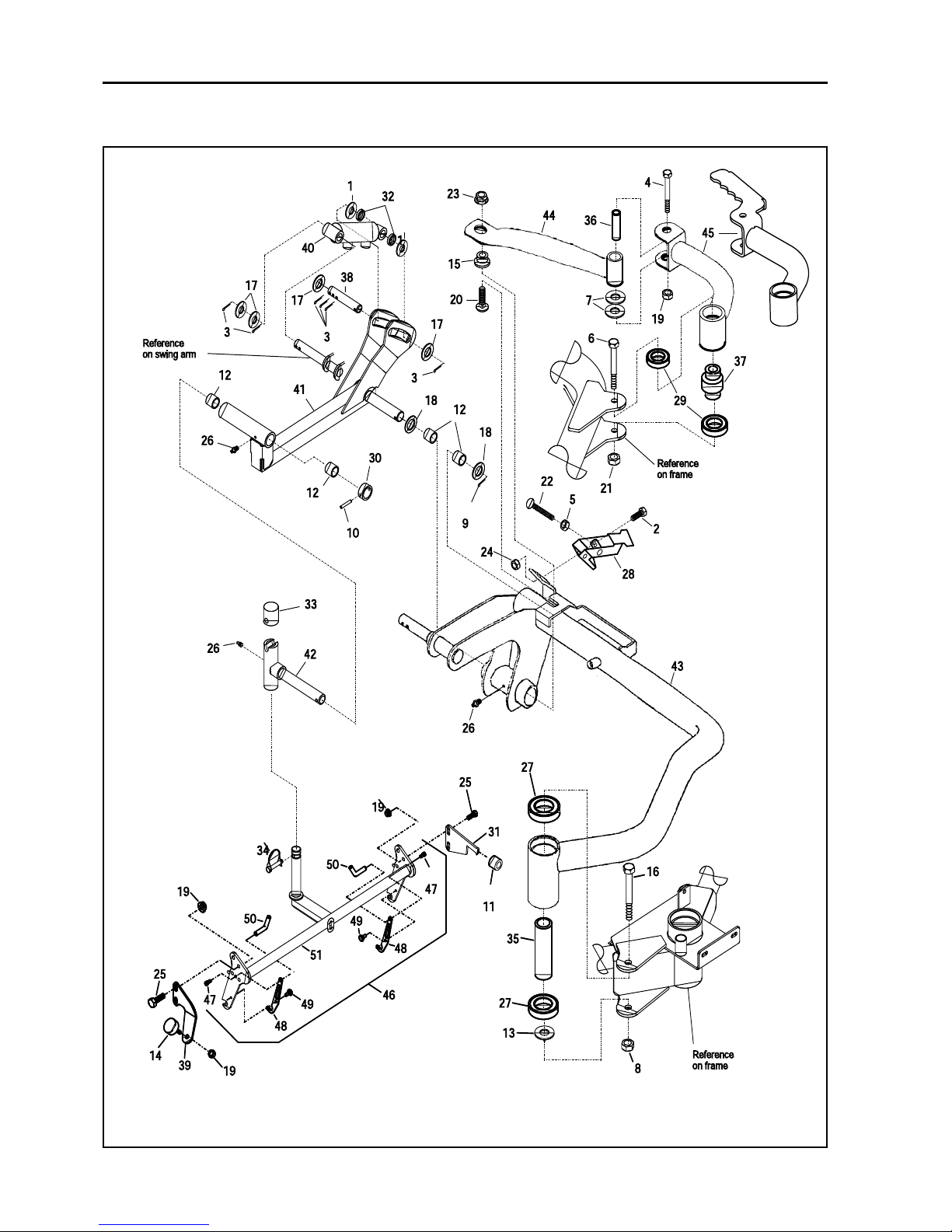

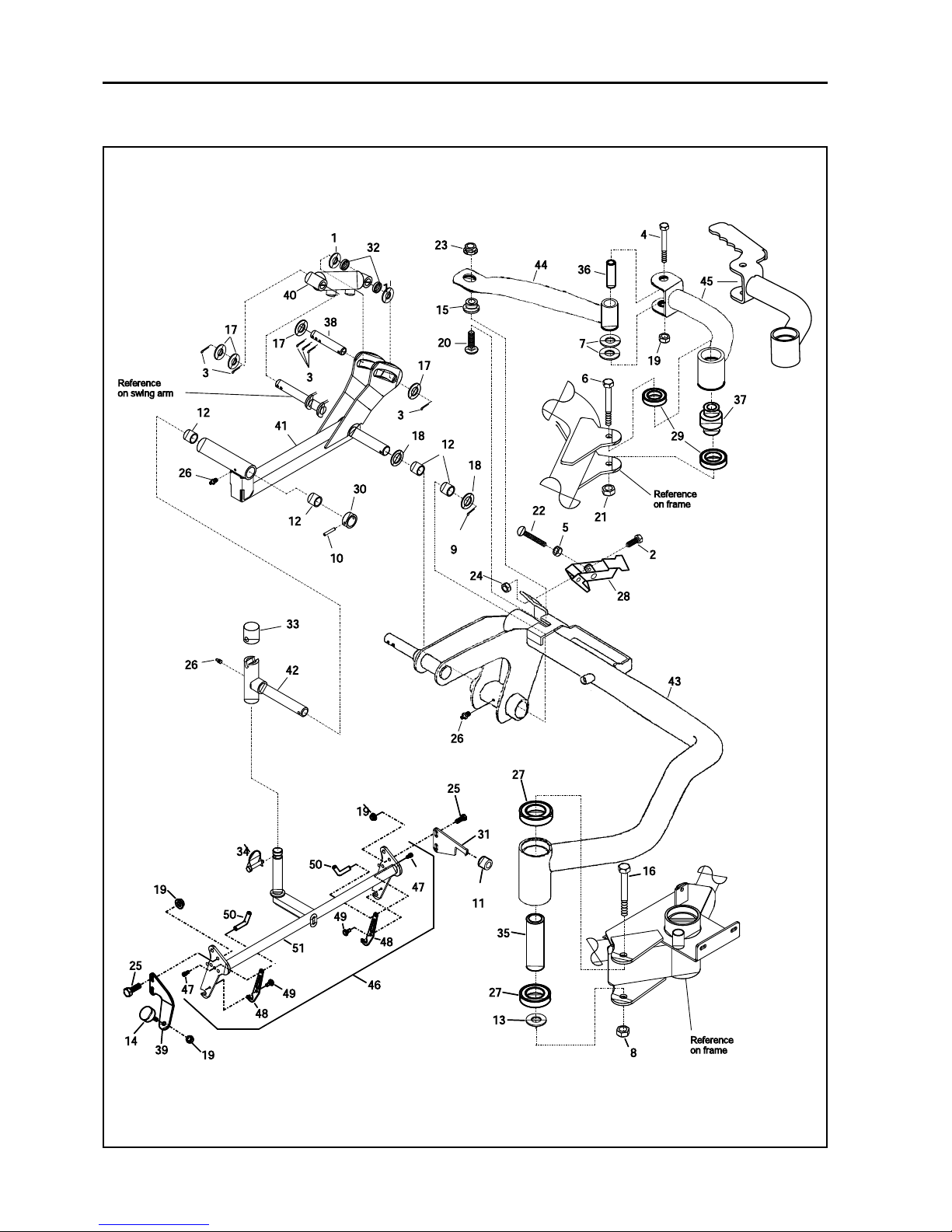

20 LIFT ASSEMBLY - FRONT CUTTING HEADS .................................................... 41

21 LIFT ASSEMBLY - REAR CUTTING HEAD ........................................................ 43

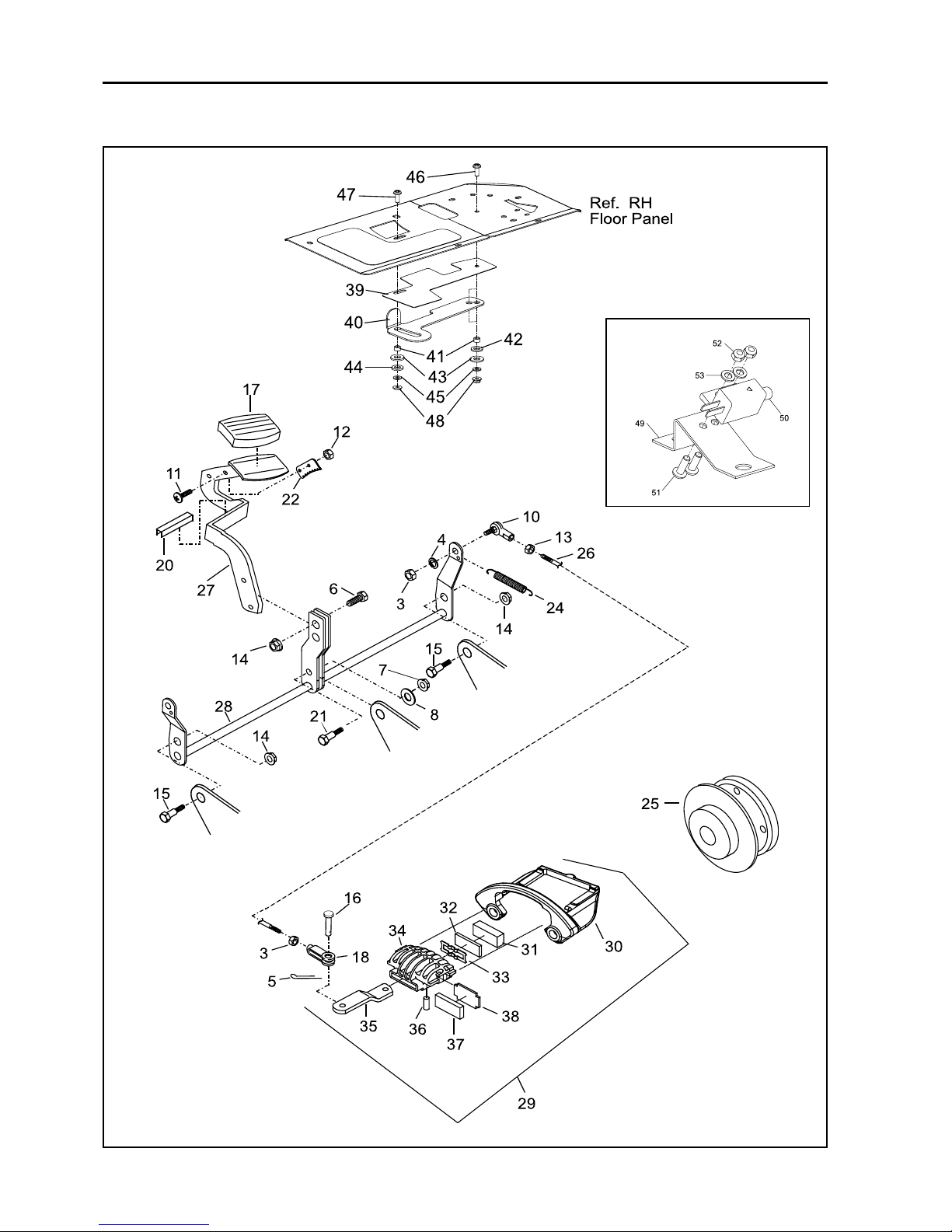

22 MOW / RAISE SWITCH AND SPEED CONTROL PEDAL ................................. 47

23 MOW SPEED CONTROL ................................................................................. 49

24 BRAKE PEDAL ................................................................................................. 51

25 SEAT ................................................................................................................ 53

26 DECALS ........................................................................................................... 55

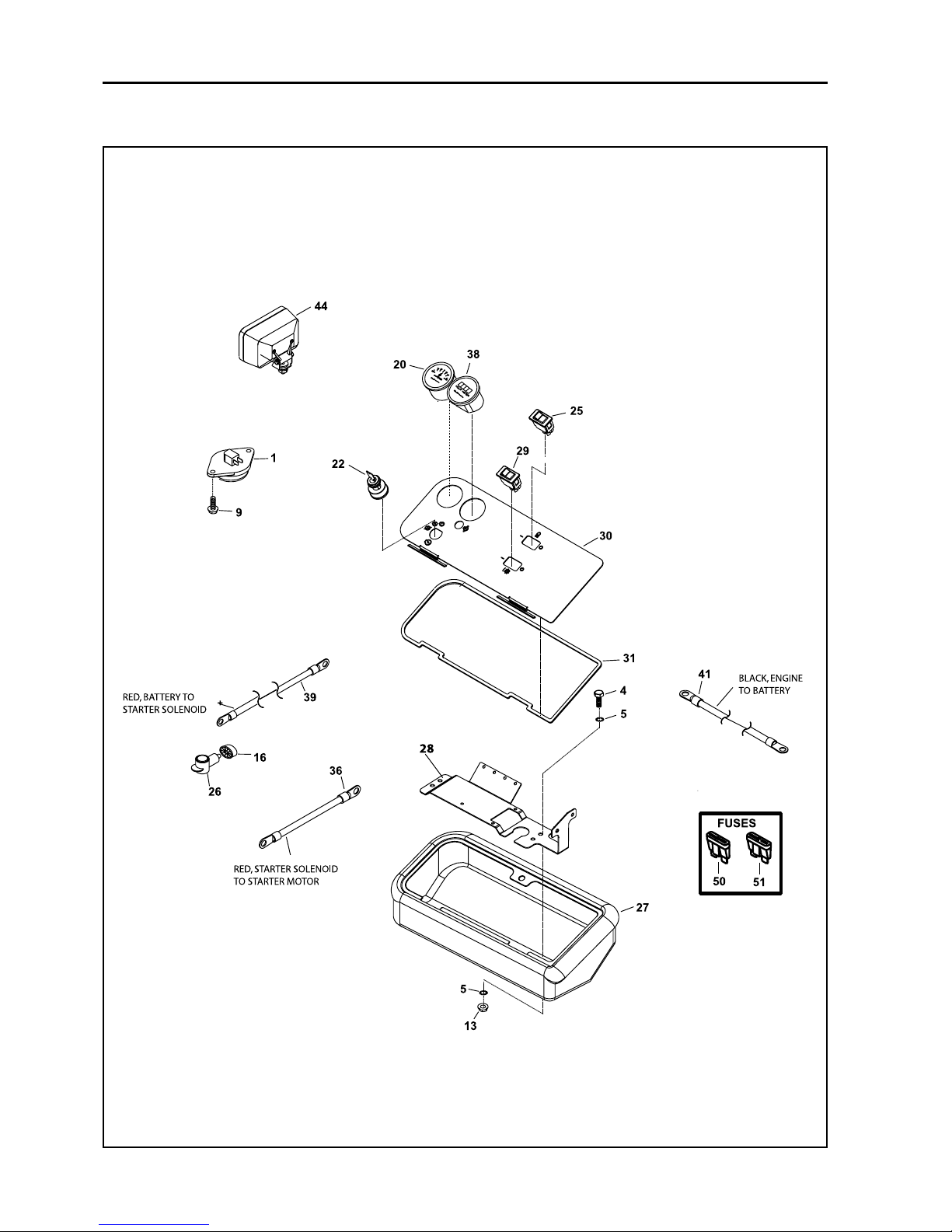

27 CONTROL PANEL AND ELECTRICAL COMPONENTS DIESEL........................ 57

28 CONTROL PANEL AND ELECTRICAL COMPONENTS GASOLINE .................. 59

29 ELECTRICAL COMPONENTS DIESEL ............................................................. 61

30 ELECTRICAL COMPONENTS GASOLINE ........................................................ 63

31 WHEELS AND REAR HUB ................................................................................ 65

32 MOTOR MOUNTING ......................................................................................... 67

33 CUTTING HEAD ................................................................................................ 69

34 REAR ROLLERS .............................................................................................. 7 1

35 VERTICUT HEAD .............................................................................................. 73

36 REAR ROLLER & SCRAPER VERTICUT .......................................................... 75

37 ACCESORY - ROTARY REAR BRUSH 068643 ................................................ 77

38 FRONT & REAR ROLLS ................................................................................... 79

39 FRONT ROLL 2" SMOOTH & SCRAPER ......................................................... 81

40 TURF GROOMER ............................................................................................. 83

41 TURF GROOMER DRIVE ASSEMBLY ............................................................... 85

42 TURF GROOMER DRIVEN ASSEMBLY ............................................................ 87

43 TURF GROOMER BLADE ASSEMBLY .............................................................. 89

44 TURF GROOMER ROLLER ASSEMBLY ........................................................... 91

45 TURF GROOMER QUICK HEIGHT ADJUSTER ................................................. 93

46 GRASS CATCHER ............................................................................................ 95

47 NUMBERICAL INDEX ....................................................................................... 96

Parts-2

JACOBSEN G PLEX III Series: DN & DP

MAINTENANCE AND PARTS MANUAL

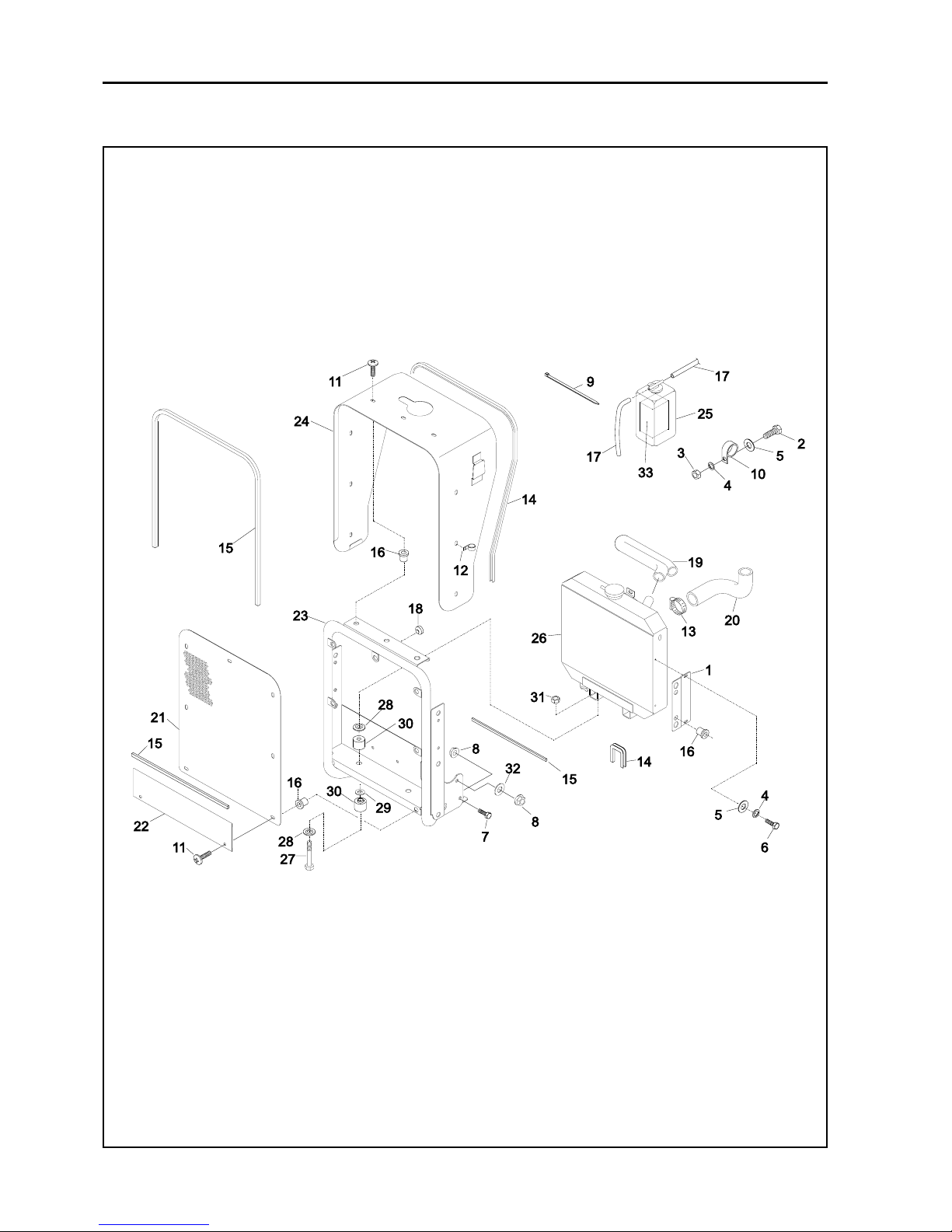

1 CHASSIS AND COVERS

Parts-3

* Not Illustrated

LIST OF PARTS

ITEM RANSOMES DESCRIPTION QTY REMARKS

PART NO

JACOBSEN G PLEX III Series: DN & DP

MAINTENANCE AND PARTS MANUAL

1 CHASSIS AND COVERS

1 450390 Washer M8 5

2 456110016 Screw, 1/4-20 x 3/4" 6

3 450411 Lockwasher M8 9

4 450120013 Nut, 1/4-20 16 (M6 - P/N 450323)

5 450410 Lockwasher M6 16

6 456110359 Screw, 5/16-18 x 1" 5

6 450192 Screw, M8 x 25, Hex 2 Used battery tray

7 450120021 Nut, 5/16-18 5

8 450389 Washer M6 6

9 523169 Tread, pedal, 1 131/2" x 3"(343 x 76mm)

10 523171 Tread, pedal, 1 8 3/4" x 6"(222 x 152mm)

11 523224 Bumper, rubber 2

12 A119003 Screw, 5/16-18 x 3/4" 4

13 A139305 Nut, 1/4-20 flange 4

14 A139301 Nut, 5/16-18 flange 2

15 800019 Screw, P.T.H., 1/4-20 x 1/2" 14 (M6 - P/N 450539)

16 800177 Screw, T.H., 5/16-18 x 3/4" 16

17 A149604 Rivet, pop, 1

18 825824 Retainer 1

19 835039 Fastener, snap 1

20 4132871 Clamp, battery 1 replaces 839391

21 840170.07 Box, tool/step 1

22 840171.07 Cover,box 1

23 840172 Hinge, box 3

24 MBG6052 Panel, floor, LEFT 1

25 842880.07 Panel, floor, RIGHT 1

26 MBG6471 Panel, foot, CENTER 1

27 842882.06 Panel, line cover 1

28 MBG6472 Panel, floor, CENTER 1

29 842932.06 Panel, control 1

30 843196.06 Bracket, lift valve 1

31 843402.07 Cover, battery 1

32 843404A.06 Bracket, fitting mount 1

33 843412 Bracket, Switch mounting 1 Diesel Only

34 843886 Cover 1

35 843887.07 Strap, cover 1

36 844076 Strap 1

37 844107 Tread, pedal, 1 25 1/2" x 5" (645 x 127mm)

38 893791.06 Frame, main 1

39 894237.06 Tray, battery 1

40 310854 Nut,jam,1-14 2

41 452000627 Washer, 1" i.d. 1

42 A203607 Bearing, Ball 2

43 892913.06 Fork 1

44 4132872 Battery Tray Cover Stop 1 replaces MBG5930.06

* 450369 Nutsert 4

Parts-4

JACOBSEN G PLEX III Series: DN & DP

MAINTENANCE AND PARTS MANUAL

2 POWER ASSY DIESEL

Parts-5

* Not Illustrated

LIST OF PARTS

ITEM RANSOMES DESCRIPTION QTY REMARKS

PART NO

JACOBSEN G PLEX III Series: DN & DP

MAINTENANCE AND PARTS MANUAL

2 POWER ASSY DIESEL

892258 Engine 1 Kubota D772-E

1 4124180 Manifold 1

* 4132107 Manifold Guard 1

* 4132108 Screw M6 x 8 2

2 452200134 Lockwasher 4

3 A109001 Screw,3/8-16x2 2

4 456110016 Screw, 1/4-20 x 3/4 8

5 4123644 Spacer 1

6 4124496 Gasket 2

7 450120013 Nut, 1/4-20 8

8 452200029 Lockwasher, 1/4 8

9 450192 Screw 3

10 450411 Lockwasher 3

11 450120039 Nut, 3/8-16 4

12 4124181 Muffler 1

13 450633 Screw 3

14 A682055 Screw, M10 -1.25 x 30mm 4

15 452692 Screw 4

16 452000326 Washer, 3/8 4

17 826218 Mount, motor 4

18 4124175 Muffler Guard 1

19 4123646 Muffler Bracket 1

20 001990399 U-Clamp 1

21 842539.06 Bracket, engine mount 2

22 842540.06 Bracket, engine rear 1

* MBG5275A Guard, Muffler Support 2

24 W148270 Sender,watertemperature 1

25 A691149 Housing, coupling and Hub 1

25a 844496 Hub 1

25b 844497 Coupling 1

28 120052 Lockwasher,#10 2

29 800296 Screw, #10-24 x 3/4 2

30 306531 Nut, #10-24 2

31 547610 Cable, control (throttle) 1

32 800868 Washer, polyethylene, 2

33 827821 Knob, ball 1

34 A109001 Screw, 3/8-16 x 2" 2

35 A119032 Screw,M10-1.25 x 20mm 2

Parts-6

JACOBSEN G PLEX III Series: DN & DP

MAINTENANCE AND PARTS MANUAL

3 POWER ASSY GASOLINE

Parts-7

* Not Illustrated

LIST OF PARTS

ITEM RANSOMES DESCRIPTION QTY REMARKS

PART NO

JACOBSEN G PLEX III Series: DN & DP

MAINTENANCE AND PARTS MANUAL

3 POWER ASSY GASOLINE

1 450388 Washer, M5 2

2 120166 Lockwasher,1/2" 2

3 450412 S.L.Washer, M12 4

4 4123564 Rear Engine Bracket 1

5 4123566 Engine Mount Plate 1

6 4117098 Muffler 1

7 2701768.8 Tailpipe 1

8 2701808 Throttle Control & Cable 1

9 4123773 Muffler Shield 1

10 450032 Screw, M10 x 50 2

11 2702239 Housing, Coupler & Adaptor 1

Coupler 1

Adaptor 1

12 2702384 Seal, Cooler 1 Up to Serial Number DN000xxx

12 4142825 Seal, Cooler 1 From Serial Number DN000xxx

13 4123676 Heat Shield 1

14 456110016 Screw, 1/4-20 x 3/4" 8

15 450120398 Nut, 3/8"-20 1

16 450120013 Nut, 1/4"-20 8

17 452200029 S.L.Washer, 1/4" 8

18 450017 Screw, M8 x 45 4

19 450376 Nut, M5, Staytite 2

20 450379 Nut, M10, Staytite 4

21 456110448 Screw, 3/8"-16 x 1/4" 4

22 450032 Screw, M10 x 50 2

23 453003341 Square Key, 1/4" x 1 3/4" 1

24 450529 Screw, M5 x 20, Pan Hd 2

25 450378 Nut, M8, Staytite 4

26 800770 Screw, 1/2"-13 x 3/4" 2

27 452692 Screw, M6 x 12, Taptite 1

28 450391 Washer, M10 10

29 001990399 Clamp 1

30 814065 Choke Cable (152cm) 1

32 451126 Screw, No.6 x 9.5, Rec. Pan Hd. 1

33 826218 Motor Mount 4

34 827821 Ball Knob 1

35 894103 Pump 1

547731 Service Kit 1

36 2701736 Engine, Briggs & Stratton 1 Model 350447 Up to DN000xxx

36 4142405 Engine, Briggs & Stratton 1 Model 356447 From DN000xxx

37 Gasket 2 Briggs & stratton

38 Screw 4 Briggs & stratton

* W48412 Clamp 1 Secures Harness to engine

Parts-8

JACOBSEN G PLEX III Series: DN & DP

MAINTENANCE AND PARTS MANUAL

4 RADIATOR (DIESEL)

Parts-9

* Not Illustrated

LIST OF PARTS

ITEM RANSOMES DESCRIPTION QTY REMARKS

PART NO

JACOBSEN G PLEX III Series: DN & DP

MAINTENANCE AND PARTS MANUAL

4 RADIATOR (DIESEL)

1 841160.06 Bracket, radiator 2

2 456110016 Screw, 1/4-20 x 3/4" 1

3 450120013 Nut, 1/4-20 1

4 452200029 Lockwasher, 1/4" 5

5 452100019 Washer, 1/4" 5

6 450168 Screw, M6 x 16 mm 4

7 456110595 Screw, 3/8-16 x 3/4" 2

8 450120267 Nut, crowniock flange, 3/8-16.... 4

9 A199203 Tie, cable, 7 1/2" (191 mm) 3

10 523213 Clip 1

11 450551 Screw, P.T.H. 16

12 815058 Clamp 1

13 A192540 Clamp, tubing 4

14 821893 Trim, push-on, 12' (3.6M) As Reqd

15 830355 Weatherseal, 35' (1 0.6M). As Reqd

16 A139924 Nut, isolation M8 16

17 835805 Hose, overflow 4' (1 .2M) . As Reqd

18 810149 Bumper, rubber 1

19 A912176 Hose, radiator, top 1

20 839953 Hose, radiator, bottom 1

21 839973.07 Panel, screen 1

22 840062.07 Panel, radiator 1

23 894077.06 Frame, radiator 1

23 4131290 Frame radiator 1 From M/C DP000486

24 892633.06 Cover, radiator 1

25 15531-72-403 Bottle, overflow 1 Ex Kubota

26 16676-72-061 Radiator 1 Ex Kubota

27 450034 Screw, M10 x 60 mm 2

28 15111-72202 Washer 4 Ex Kubota

30 15111-72181 Bushing, rubber 2 (with spigot) Ex Kubota

30 15111-72191 Bushing, Rubber 2 Ex Kubota

31 450325 Nut, M10 -1.25 2

32 452000326 Washer, 3/8" 2

33 523930 Foam 1

Parts-10

JACOBSEN G PLEX III Series: DN & DP

MAINTENANCE AND PARTS MANUAL

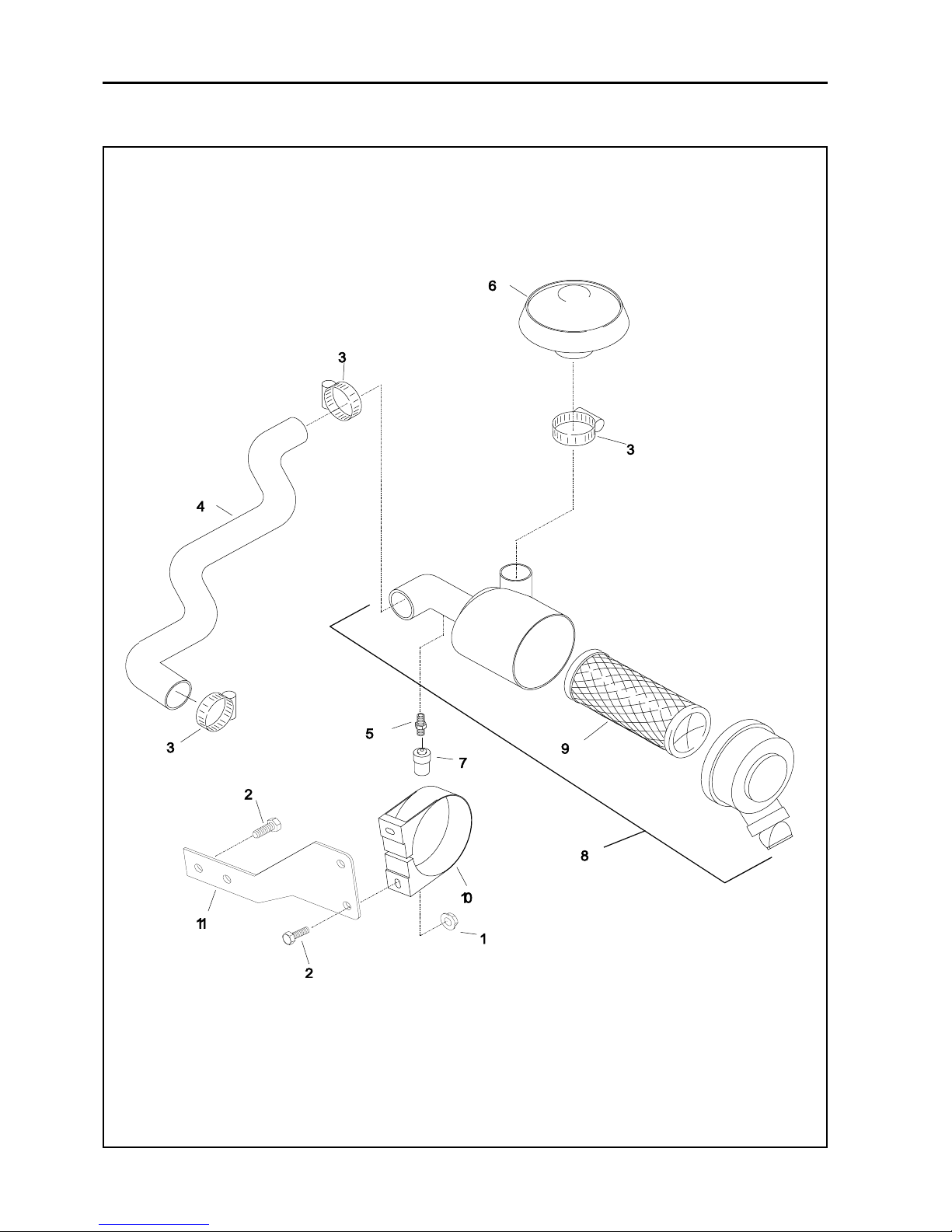

5 AIR CLEANER (DIESEL)

Parts-11

* Not Illustrated

LIST OF PARTS

ITEM RANSOMES DESCRIPTION QTY REMARKS

PART NO

JACOBSEN G PLEX III Series: DN & DP

MAINTENANCE AND PARTS MANUAL

5 AIR CLEANER (DIESEL)

1 A139322 Nut, flange crownlock 5/16-18 2

2 456110359 Screw, 5/16-18 x 1" 4

3 A192557 Clamp, hose, worm drive 3

4 844045 Hose, air intake 1

5 840346 Adaptor, gauge 1

6 4132265 Hood, inlet 1 Replaces 840347

* 4132266 Sleeve 1

7 888036 Gauge, restriction 1

8 893182 Filter,air,complete 1

9 0840352 Element, air filter 1

10 A819028 Bracket, filter 1

11 844044.06 Bracket, air filter 1

Parts-12

JACOBSEN G PLEX III Series: DN & DP

MAINTENANCE AND PARTS MANUAL

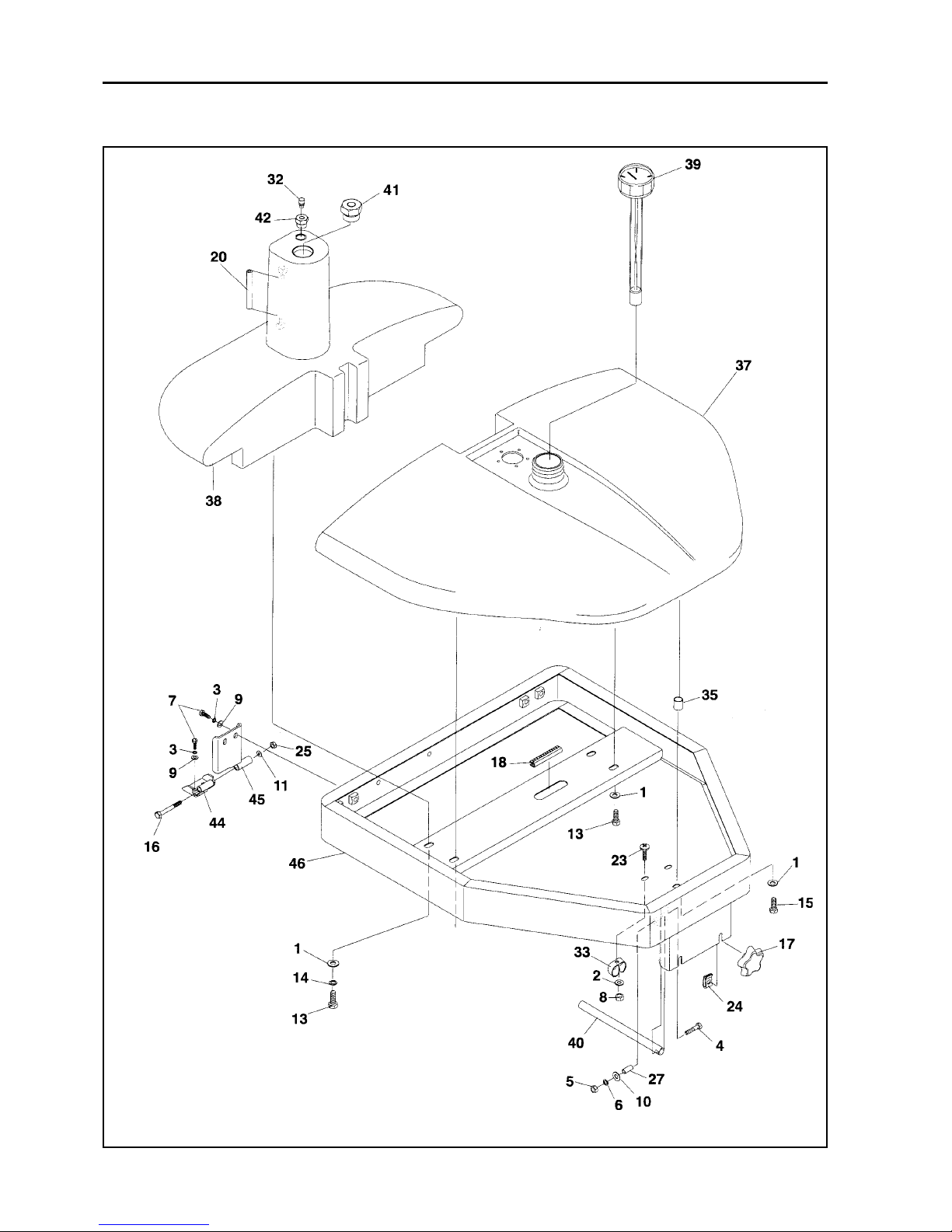

6 FUEL & HYDRAULIC RESERVOIRS & SUPPORT FRAME

Parts-13

* Not Illustrated

LIST OF PARTS

ITEM RANSOMES DESCRIPTION QTY REMARKS

PART NO

JACOBSEN G PLEX III Series: DN & DP

MAINTENANCE AND PARTS MANUAL

1 450390 Washer,M8 4

2 450409 Lockwasher,M5 1

3 452200134 Lockwasher, 3/8 8

4 A109011 Screw, 1/420 x 1 1/2 1

5 450120013 Nut, 1/420 1

6 452200029 Lockwasher, 1/4 1

7 456110066 Screw,3/816x1 4

* 450214 Screw M10 x 25 4

8 A139325 Nut, #10 1

9 450391 Washer, M10 8

10 452100019 Washer, 1/4 8

11 450392 Washer, M12 2

14 450411 Lockwasher, M8 2

15 452390 Bolt, M8 x 30 1

16 450061 Screw, M12 x 120 2

17 A907947 Knob, nut, M8 2

18 821893 Trim, pushon, 12(3.7 M) AR

20 158122 Tubing, polyurethane, 1

23 A119109 Screw,#1024x3/4 1

24 A907948 Nut, Speed M8 2

25 450380 Nut, M12 2

27 820529 Spacer 1

32 836852 Breather 1

33 838225 Clip 1

35 839876 Bushing 1

37 843267 Tank, fuel 1

38 843268 Reservoir, oil 1

39 843401 Cap, fuel with gauge 1

40 843696 Tube, support, 8 (203 mm) 1

41 843885 Plug 1

42 844080 Adapter 1

44 894352.06 Hinge, lower 1

45 894353.06 Hinge, upper 1

46 894354.06 Frame, tank support 1

6 FUEL & HYDRAULIC RESERVOIRS & SUPPORT FRAME

Parts-14

JACOBSEN G PLEX III Series: DN & DP

MAINTENANCE AND PARTS MANUAL

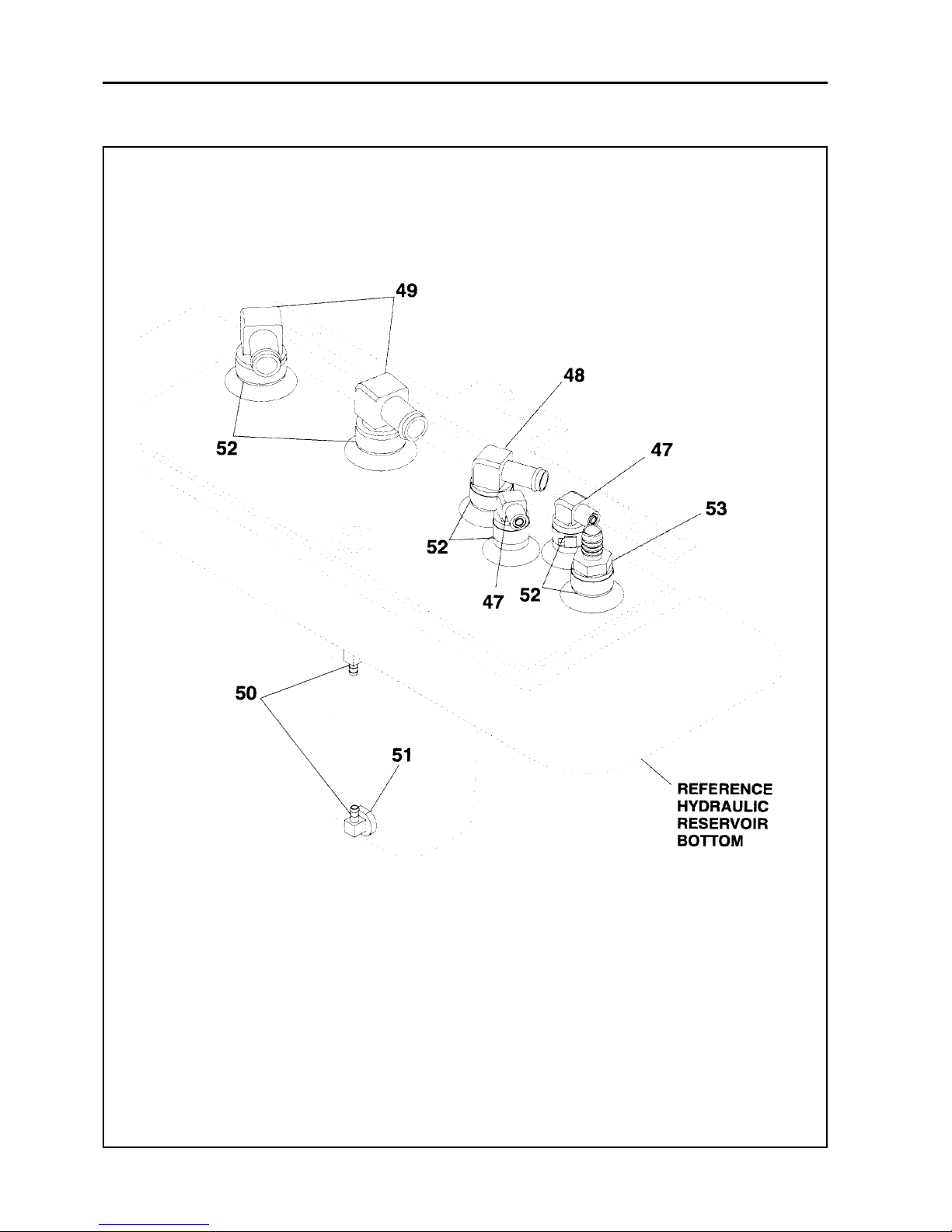

7 HYDRAULIC TANK FITTINGS

Parts-15

* Not Illustrated

LIST OF PARTS

ITEM RANSOMES DESCRIPTION QTY REMARKS

PART NO

JACOBSEN G PLEX III Series: DN & DP

MAINTENANCE AND PARTS MANUAL

47 843556 Elbow, 90, 11/16 x 1/2 NPT 1

48 843557 Elbow, 90, 3/4 x 3/4 NPT 1

49 843558 Elbow, 90, 1 x 1 NPT 1

50 148231 Fifting, 3/16, elbow 1

51 48310 Bushing 1

52 836206 Clamp 1

53 869037 Fitting, 3/4 x 3/4 NPT 1

7 HYDRAULIC TANK FITTINGS

Parts-16

JACOBSEN G PLEX III Series: DN & DP

MAINTENANCE AND PARTS MANUAL

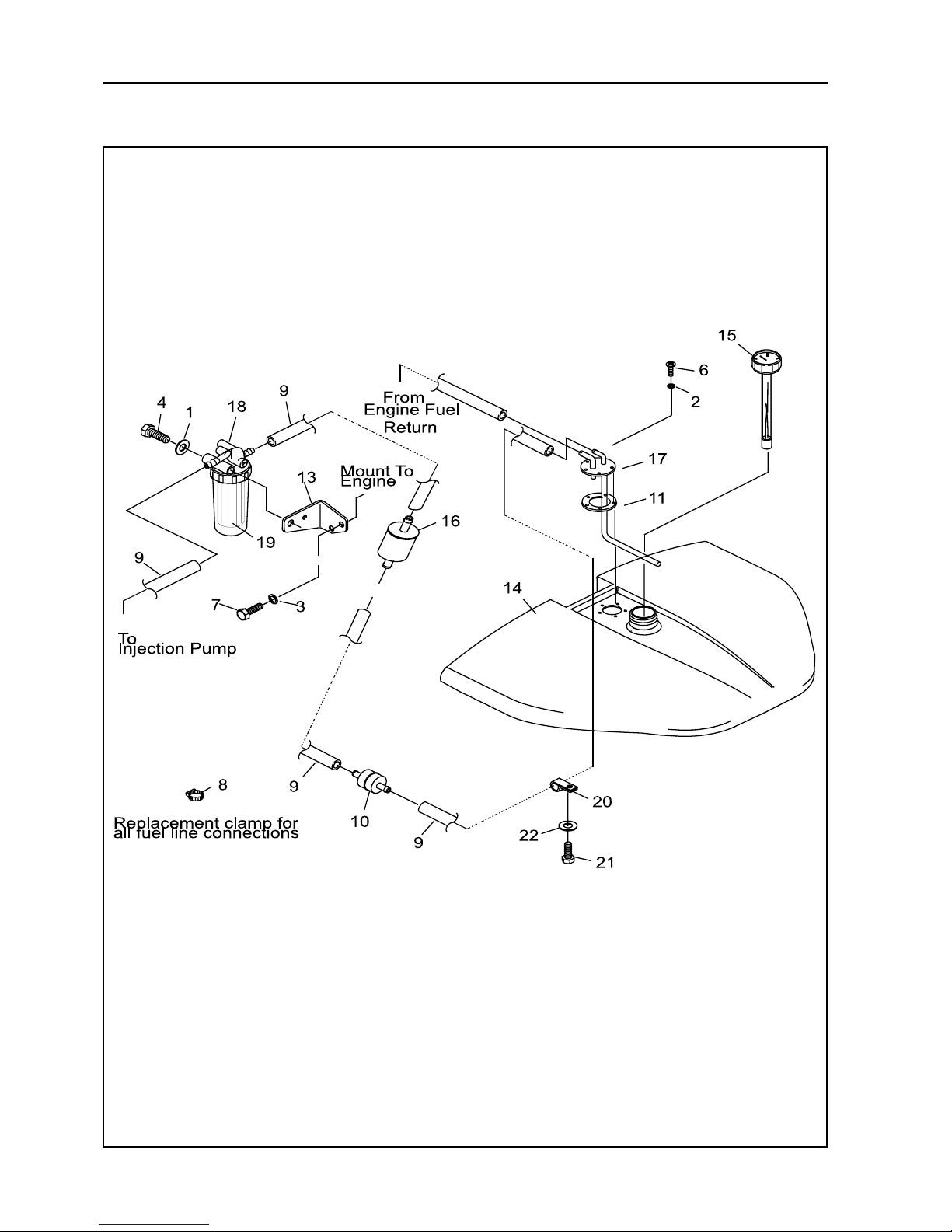

8 FUEL SYSTEM DIESEL

Parts-17

* Not Illustrated

LIST OF PARTS

ITEM RANSOMES DESCRIPTION QTY REMARKS

PART NO

JACOBSEN G PLEX III Series: DN & DP

MAINTENANCE AND PARTS MANUAL

8 FUEL SYSTEM DIESEL

1 450390 Washer, M8 1

2 450409 Lockwasher, M5 5

3 450411 Lockwasher, M8 2

4 A109043 Screw,5/16-18x23/4" 1

5 450120021 Nut, 5/16-18 1

6 A119004 Screw, #10-24 x 1/2" 5

7 450191 Screw,M8-1.25x20mm 1

8 A192516 Clamp, hose As Reqd

9 A912175 Hose, fuel, 5/16 As Reqd

* A912182 Hose - Fuel 3/16 1