Super LF 1880™ Fairway Mower

67923 – Kubota D1105-E, 2WD

67924 – Kubota D1105-E, 4WD

67938 – Kubota D1105-TE, 4WD

4102144-SE rev A

Safety & Operation Manual

Handbok för säkerhet och drift

GB-2

CONTENTS

1 CONTENTS

1 Contents

2 Safety

2.1 Operating Safety.................................................. 3

2.2 Important Safety Notes ........................................ 4

3 Decals

3.1 Decals................. ...... ...... ....... ...... ....... ...... ....... .... 5

4 Controls

4.1 Icons ......................................................... ....... .... 6

4.2 Controls ............................................................... 8

4.3 Opening The Hood .............................................. 9

4.4 Steering Console Cover ....................................... 9

5 Operation

5.1 Daily Inspection ................................................. 10

5.2 Interlock System ................................................ 10

5.3 Operating Procedures ....................................... 11

5.4 Starting .............................................................. 12

5.5 Stopping / Parking ............................................. 12

5.6 To Drive / Transport ........................................... 13

5.7 Hillside Operation .............................................. 13

5.8 Mowing .............................................................. 14

5.9 Towing / Trailering ............................................. 14

5.10 Daily maintenance ............................................. 15

Proposition 65 Warning

Engine exhaust from this product

contains chemicals kno wn to the State

of California to cause cancer, birth

defects, and other reproductive harm

© COPYRIGHT 2002, TEXTRON INC.

“All rights reserved, including the right to reproduce this book or portions thereof in any form”.

A

ll information in this publication is based on information available at time of approval for printing. Textron Golf, Turf &

S

pecialty Products reserves the right to make changes at any time without notice and without incurring any obligation

.

LITHO IN U.S.A. 2-2003

SAFETY 2

GB-3

2 SAFETY

2.1 OPERATING SAFETY _____________ ___ __ __ ___ _________________________ ___ __ _

1. Safety is dependent upon the awareness, concern

and prudence of those who operate or service the

equipment. Never allow minors to operate any

equipment.

2. It is your responsibility to read this manual and all

publications associated with this equipment (Parts

and Maintenance Manual, Engine Manual,

accessories and attachments). If the operator can

not read English it is the owner’s responsibility to

explain the material contained in this manual to

them.

3. Learn the proper use of the machine, the location

and purpose of all the controls and gauges before

you operate the equipm ent. Working with unfamiliar

equipment can lead to accidents.

4. Never allow anyone to operate or service the

machine or its attachments without proper training

and instructions; or while under the influence of

alcohol or drugs.

5. Wear all the necessary protective clothing and

personal safety devi ces to protect your head, eyes,

ears, hands and feet. Operate the machine only in

daylight or in good artificial light.

6. Inspect the area where the eq uipment will be used.

Locate and remove all debris in the operating area

before using equipment. Beware of overhead

obstructions (low tree limbs, electrical wires, etc.)

and also underground obstacles (sprinklers, pipes,

tree roots, etc.) Enter a new area cautiously. Stay

alert for hidden hazards.

7. Never direct discharge of material toward

bystanders, nor allow anyone near the machine

while in operation. The owner/operator can prevent

and is responsible for injuries inflicted to

themselves, to bystanders and damage to property.

8. Never operate equipment that has been modified,

does not meet factory specifications, or is without

decals, guards, shields, discharge deflectors or

other protective devices securely fastened in place.

9. Never disconnect or bypass any switch or interlock.

10. Carbon monoxide in t he exhaust fumes c an be fatal

when inhaled. Never operate the engine without

proper ventilation.

11. Fuel is highly flammable, handle with care.

12. Keep the engine clean. Allow the engine to cool

before storing and always remove the ignition key.

13. Disengage all drives and engage parking brake

before starting the engine (motor). Start the engine

only when sitting in operator’s seat, never while

standing beside the unit.

14. Equipment must comply with the latest federal,

state, and local requirements when driven or

transported on public roads.

15. Never use your hands to search for oil leaks.

Hydraulic fluid under pressure can penetrate the

skin and cause serious injury.

16. Operate the machine up and down the face of the

slopes (vertically), not across the face (horizontally).

17. To prevent tipping o r loss of control, do not start or

stop suddenly; reduce speed when making sharp

turns. Use caution when changing direction on

slopes.

18. Keep legs, arms and body inside the seating

compartment while the vehicle is in motion.

This machine is to be operated and maintained as specified in this manual and is intended for the pr ofession al

maintenance of specialized turf grasses. It is not intended for use on rough terrain or long grasses.

WARNING

EQUIPMENT OPERATED IMPROPERLY OR BY UNTRAINED PERSONNEL CAN BE DANGEROUS.

Familiarize yourself with the location and proper use of all controls. Inexperienced operator’s should receive

instruction from someone familiar with the equipment before being allowed to operate the machine.

!

2 SAFETY

GB-4

2.2 IMPORTANT SAFETY NOTES________________________________________________

This safety alert symbol is used to alert you to potential hazards.

DANGER - Indicates an imminently hazardous situation which, if not avoided, WILL result in death or serious injury.

WARNING - Indicates a potentially hazardous situation which, if not avoided, COULD result in death or serious

injury.

CAUTION - Indicates a potenti ally haz ardous situa tion whi ch, i f not av oided, MAY result in minor or moderat e inju ry

and property damage. It may also be used to alert against unsafe practices.

For pictoral clar ity, some illustrations in this manua l may show shield s, guards or plat es open or removed. U nder no

circumstances should this equipment be operated without these devices securely fastened in place

By following all instructions in this manual, you will prolong the life of your machine and maintain its maximum

efficiency. Adjustments and maintenance should always be performed by a qualified technician. If additional

information or service is needed, contact your Authorize d Textron Golf, Turf & Specialty Products Dealer who is kept

informed of the latest methods to service this equipment and can provide prompt and efficient service.

Use of other than original or Authorized Textron Golf, Turf & Specialty Products Accessories will void the

warranty.

WARNING

The Interlock System on this tractor pre vents the tractor from starting un less

the brake lever is engaged, mower switch is off and traction pedal is in

neutral. The system will stop the engine if the operator leaves the seat

without engaging the parking brake or setting the mower switch off.

NEVER operate tractor unless the Interlock System is working.

!

!

WARNING

1. Before leaving the operator’s position for any reason:

a. Return traction pedal to neutral.

b. Disengage all drives.

c. Lower all implements to the ground.

d. Engage parking brake.

e. Stop engine and remove the ignition key.

2. Keep hands, feet, hai r and clothin g away from mov ing parts. Wait for all

movement to stop before you clean, adjust or service the machine.

3. Keep the area of operation clear of all bystanders and pets.

4. Never carry passengers, unless a seat is provided for them.

5. Never operate mowing equipment without the discharge deflector

securely fastened in place.

!

DECALS 3

GB-5

3 DECALS

3.1 DECALS _ __ ___ __ _________________________________________________________

Familiarize yourself with the decals they are critical to the safe operation of the machine.

REPLACE DAMAGED DECALS IMMEDIATELY.

1. Leer el manual del operador. No permitir que personas

no capacitadas para ello usen la maquina.

2. Mantener los escudos en su lugar y la tornilleria

debidamente fijada.

3. Antes de limpiar, ajustar o reparar este equipo,

desengranar todas los mandos, aplicar el freno de

estacionamiento y apagar el motor.

4. Mantener las manos, los pies y la ropa alejados de las

piezas en movimiento.

5. No viajar como pasajero ni llevar pasajeros en

maquinas sin asiento para ello.

6. Mantener a las demas personas alejadas.

7. Si no sabe leer ingles, solictarle a otra persona que le

lea y explique el contenido de las etiquetas y del

manual de le maquina.

! ADVERTENCIA

340623

To avoid injury when working with battery:

1. Always connect the black ground (-) cable last and

remove it first.

2. Keep sparks and flames away, and avoid contact

with acid.

To avoid injury when jumping battery:

1. Connect positive (+) terminal to positive (+)

terminal.

2. Connect negative (-) terminal on good battery to

frame of vehicle that has dead battery.

! DANGER

3001435

To prevent injury, disengage

all drives, engage parking

brake and stop engine before

working on machine or

emptying grass catcher s.

! DANGER

361877

RADIATOR IS UNDER PRESSURE. REMOVE

CAP SLOWLY TO AVOID BODILY INJURY.

! WARNING

365956

To prevent cuts use

socket wrench or Turf

Groomer® knob to

turn reel.

1000997

! WARNING

• Read operator’s manual. Do not allow

untrained operators to use machine.

• Keep shields in place and hardware

securely fastened.

• Before you clean, adjust or repair this

equipment, disengag e all driv es, engag e

parking brake and stop engine.

• Keep hands, feet and clothing away from

moving parts.

• Never carry passengers.

• Keep bystanders away.

• Do not use on slopes greater than 20°.

Model - Engine power - Vehicle Mass with Reels

– – – – – – – – – – – – – – – – – – – – – – – –

LF 1880 - 26.5 hp (19.7 kW) - 2115 lbs (959 kg)

LF 1880 - 35 hp (26 kW) - 2200 lbs. (998 kg)

! WARNING

4102682

4 CONTROLS

GB-6

4 CONTROLS

4.1 ICONS______________________________________________________________ _____

WARNING

Never attempt to drive the trac tor unless you have read the Safe ty and Operation Manua l

and know how to operate all controls correctly.

Familiarize yourself with the icons shown above and what they represent. Learn the

location and purpose of all the controls and gauges before operating this tractor.

Coolant

Temperatur

D

Read Manual Engine Throttle

High Low

Hour Meter

Trac tion Pedal

Forward Reverse

Fuel

Diesel

Cutting Units

Forward Off Reverse

(Cut) (Backlap)

Horn

Engine

Off Run Glow Plug Start

Engine Oil

Pressure

Parking Brake

Engaged Disengaged

LightsMowers

Lower Raise

Hydraulic

Oil Level

!

CONTROLS 4

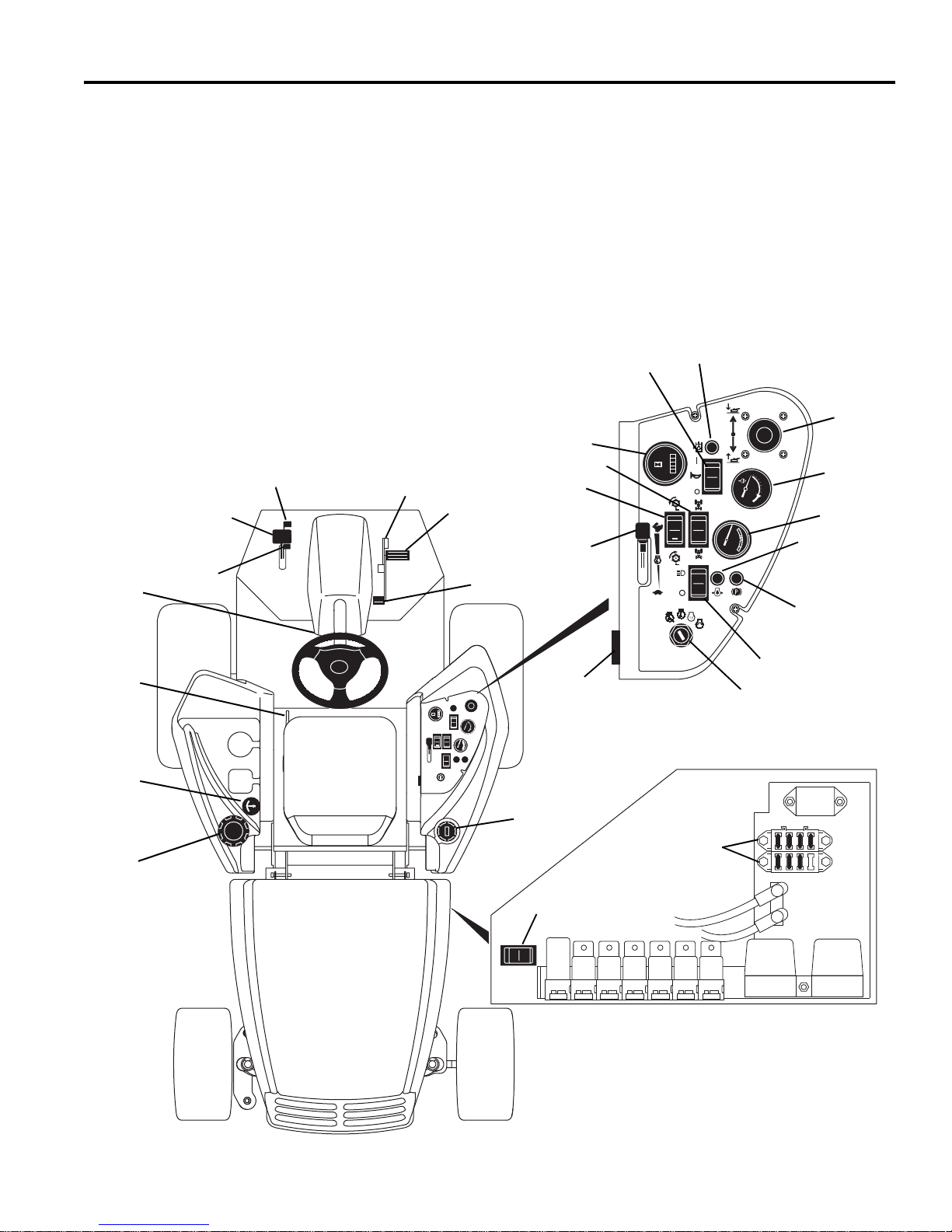

GB-7

10

12

14

16

A Tilt Steering Lever

B1 Parking Brake Lock

B2 Parking Brake Release

C Parking Brake Pedal

D Mow Speed Stop

E Traction Pedal - Forward

F Traction Pedal - Reverse

G Seat Adjus tme nt

H Hydraulic Oil Cap

I Hydraulic Oil Light

J Fuel Cap

K Fuel Level Gauge

L Backlap Switch

M Hour Meter

N Water Temperature Gauge

O Volt Meter

P Engine Oil Light

Q Horn

R 2WD / 4WD Switch

S Raise / Lower Joystick

T Reel Switch

U Light Switch

V Ignition Switch

W Throttle

X Parking Brake Light

Y Fuse Blocks

Z Horn Switch

A

B

1

C

D

E

F

G

H

J

K

L

M

N

O

P

Q

R

S

T

U

V

W

X

Y

B

2

I

Z

4 CONTROLS

GB-8

4.2 CONTROL DESCRIPTIONS__________________________________________________

A. Steering Tilt Control

Pull lever up to release steering column. Tilt column

up or down to positi on des ired. Re lease lev er to lock

steering column in place.

B. Parking Brake Lock / Release

To lock parking brake, hold brake pedal (C) down and

press lock (B

1

) until it enga ges. To disengage, press

brake pedal release (B

2

).

C. Parking Brake

To engage parking brake press pedal down.

D. Mow Speed Stop

Limits forward speed while mowing. To operate at

lower travel speed while mowing, rotate lever so it

contacts stop screw (D1) on floor board when

forward travel pedal is pressed. To travel at full

speed, set lever in p osition shown (D3). Stop screw

(D2) can be adjusted to set specific mow speeds.

See the Parts & Maintenance manual.

Figure 4A

E. Forward Travel (Traction Pedal)

Press front of pedal down for forward travel. Release

pedal to slow tractor and stop. Do not press traction

pedal when parking brake is set and parking brake light

(W) is lit.

F. Reverse Travel (Traction Pedal)

Press rear of pedal down for reverse travel. Release

pedal to slow tractor and stop. Allow tractor to come to a

complete stop before reversing directions. Do not press

traction pedal when parking brake is set and parking

brake light (W) is lit.

G. Seat Adjustment

Pull left side lever out to adjust seat forward or

backward. To adjust spring tension under seat, turn

adjusting knob on front of seat.

H. Hydraulic Oil Cap

Fill to “green” area on gauge using clean hydraulic fluid

while machine is cool. Do not overfill

I. Hydraulic Oil Light

Alerts the operator of a low fluid level in

hydraulic tank. This light operates in

combination with the alarm. See Section 4.3.

J. Fuel Cap

Fill fuel tank with No. 2 diesel fuel, minimum cetane

rating of 45. Section 5.10

K. Fuel Level Gauge

Indicates current fuel level. Check fuel gauge daily

before starting machine.

Fill only to “‘green’ area on

gauge, do not top off tank.

Do not allow machine to run

out of fuel.

L. Backlap Switch

The backlap switch allows the mowers to rotate in

reverse for backlapping.

Forward - For normal operation (mowing) the

switch must be set to the FORWARD (cut)

position.

Reverse - When backlapping the mower must be

operated in the reverse direction. Set switch to

the REVERSE (backlap) position.

When backlapping the parking brake must be set and

both the reel switch (S) and backlap switch (L) must be

set to reverse. See Parts & Maintenance Manual

M. Hour Meter

Records engine operating hours. Use hour meter to

schedule periodic maintenance.

N. Temperature Gauge

Indicates engine coolant temperature. Normal operating

temperature should be between 160° - 230°F (71°110°C). If temperature rises above 230° (110°F), alarm

will sound. See Section 4.3.

O. Voltmeter

Indicates battery condition. During normal operation

meter should never be in the red area.

P. Engine Oil Pressure Light

The indicator will light if engine oil pressure drops

below 7 PSI (48 kPa). Stop engine immediately,

determine the cause, and co rrect the problem bef ore

resuming operation.

CAUTION

Never adjust steering while tractor is moving. Stop

unit and set parking brake before adjusting.

!

Full Speed Reduced Speed

D

1

D

2

D

3

E

F

CONTROLS 4

GB-9

Q. Horn

The alarm sounds to alert the operator to conditions

requiring immediate attention. See Section 4.3.

R. 2 WD / 4 WD Switch

Sets tractor into two or four wheel drive.

S. Raise / Lower Joystick

The joystick raises and lowers the mowers. Push

forward to lower mowers, pull back to raise mowers.

T. Reel Switch

The reel switch is a 3-position rocker type switch with a

neutral locking tab. It sets the mowers for either forward

or reverse rotation. Set mower switch in its OF F (center)

position when starting the tractor.

Forward - To mow, press switch to the

FORWARD (cut) position. With the switch in this

position, mowers will start automatically when

they are lowered and stop when they are raised. Return

switch to its center position to disable mowers.

Reverse - The mower can be operated in the

reverse direction for backlapping, running

vertical mowers, removing grass build-up in

mowers or dislodging objects binding mowers. To

reverse blade rotation, press switch to the REVERSE

position.

When backlapping, the parking brake must be set,

traction pedal in neutral and both the reel switch (Q) and

backlap switch (K) must be set to REVERSE. See Parts

& Maintenance Manual.

U. Light Switch

Controls operation of work lights.

V. Ignition Switch

The ignition switch has four positions. OFF - RUN GLOW PLUG - START. See Section 5.4.

W. Throttle

Controls engine speed. Run machine at full throttle

during normal machine operation.

X. Parking Brake Light

Indicates that the parkin g brake i s engaged. Par king

brake must be disengaged before depressing

traction pedal.

Y. Fuse Blocks

Used to provide circuit protection for electrical

systems. See Parts & Maintenance Manual.

Z. Horn Switch

This switch is used to test the alarm system or disable

the alarm after a low oil level has been detected. Keep

switch in its ON position when starting and operating

tractor. To test alarm, set switch to OFF and turn ignition

key to RUN. See

Section 4.3.

4 CONTROLS

GB-10

4.3 OPERATOR ALERTS_______________________________________________________

The machine monitors vital machine systems. It uses an

audible alarm and warning lights to alert the operator of

conditions requiring immediate action. When an alert

occurs, follow the general guidelines listed in the chart

below, and any specific actions outlined by the grounds

superintendent or service manager.

To test alarm system:

Turn ignition switch to RUN. Engine oil light will come on for

one second or more.

This system monitors:

1. Engine oil pressure

2. Engine coolant temperature

3. Hydraulic oil level

Alert Action

1. Engine Oil Pressure - Oil pressure

light comes on. Oil pressure low.

Stop tractor immediately, lower implements and shut off engine! Inspect oil

level in engine. If oil light remains on with oil at proper level, shut off engine and

tow or trailer tractor back to a service area. NEVER operate engine with oil light

on, severe damage to the engine can occur.

2. Engine Coolant Temperature

Alarm sounds. Engine coolant

temperature high.

Stop tractor immediately, lower implements and shu t off engine! Remove

debris such as leaves and grass clippings that may be restricting air flow through

front screen and area between radiator and oil cooler. If engine continues to run

hot, return tractor to a service area.

CAUTION: Engine coolant is under pressure. Turn engine off and allow

fluid to cool before checking fluid level or adding coolant to radiator.

3. Hydraulic fluid level - alarm

sounds and hydraulic fluid

warning light comes on.

Hydraulic fluid is below

recommended level.

Stop tractor immediately, lower implements and shut off engine! Visually

inspect tractor for obvious signs of leaks around connections, hoses and

hydraulic components. Return tractor to service area for maintenance.

CAUTION: Hydraulic fluid is under pressure. Turn engine off and allow

fluid to cool before checking fluid level or adding oil to hydraulic tank.

!

!

OPERATION 5

GB-11

5 OPERATION

5.1 DAILY INSPECTION______________________ ___ __ __________________________ __ _

1. Perform a visual i nspec tio n o f the entire unit, loo k for

signs of wear, loose hardware, and missing or

damaged components. Chec k for fuel or oil leaks to

ensure connections are tight and hoses and tubes

are in good condition.

2. Check the fuel supply, radiator coolant level,

crankcase oil and air cleaner indicator. All fluids

must be at the full level mark with engine cold.

3. Make sure all mowers are adjusted to the same

cutting height.

4. Check tires for proper inflation.

5. Test the Interlock System.

Note: For more detailed maintenance information,

adjustments and maintenance/lube charts, see the

Parts & Maintenance manual.

5.2 Interlock System_________________________________________________________________________

1. The Interlock System prevents the engine from

starting unless the parking brake is engaged, the

traction pedal is in neutral and the reel switch is OFF.

The system also stops the engine if the operator

leaves the seat with the reel switch ON, traction

pedal out of NEUTRAL, or parking brake

DISENGAGED.

2. Perform each of the following tests to insure the

Interlock System is functioning properly. Stop the

test and have the s ystem inspected and repaired if

any of the tests fail as listed below:

● the engine does not start in test 1;

● the engine does start during tests 2,3 or 4;

● the engine continues to run during tests 5 or 6.

3. Refer to the cha rt below for each t est and f ollow the

check (✔) marks across the chart. Shut engine off

between each test.

Test 1: Represents normal starting procedure. The

operator is seated, parking brake is engaged, the

traction pedal is in neutral, and the reel switch is

OFF. The engine should start.

Test 2: The engine must not start if the reel switch is

ON.

Test 3: The engine must not start if the parking brake

is DISENGAGED.

Test 4: The engine must not start if traction p edal is

not in neutral.

Test 5: Start the engine in the normal ma nner then

turn reel switch ON and lift your weight off the seat. ★

Test 6: Start the engine in the normal ma nner then

disengage parking brake an d lift your weight off the

seat. ★

★ Lift your weight off seat. The engine will shut down.

CAUTION

The daily inspection should be performed only when

the engine is off and all fluids are cold. Lower mowers

to the ground, engage the parking brake, Stop engine

and remove ignition key.

!

WARNING

Never operate equipment with the Interlock System

disconnected or malfunctioning. Do not disconnect or

bypass any switch.

!

Interlock System Check

Test Operator

Seated

Parking

Brake

Traction Pedal

in Neutral

Reel

Switch

Engine

Starts

Yes No Engaged Disengaged Yes No On Off Yes No

1 ✔✔ ✔ ✔✔

2 ✔✔ ✔✔ ✔

3 ✔✔✔✔✔

4 ✔ ✔ ✔✔✔

5 ✔

★

✔✔✔

★

6 ✔

★

✔✔ ✔

★

Loading...

Loading...