Technical Manual

4325163-Rev B

HoverKing

32251 – 20 Inch (50.8 cm) HoverKing

32252 – 20 Inch (50.8 cm) Metal Blade Kit

32253 – 20 Inch (50.8 cm) Plastic Blade Kit

32254 – 20 Inch (50.8 cm) String Cutter Kit

32255 – 20 Inch (50.8 cm) Handle Extension Accessory

32257 – 16 Inch (40.6 cm) HoverKing

32258 – 16 Inch (40.6 cm) Metal Blade Kit

32259 – 16 Inch (40.6 cm) Plastic Blade Kit

32260 – 16 Inch (40.6 cm) String Cutter Kit

32261 – 16 Inch (40.6 cm) Handle Extension Accessory

32256 – Wheel Kit

™

WARNING

Warning: If incorrectly used, this machine can

cause severe injury. Those who use and maintain

this machine should be trained in its proper use,

warned of its dangers, and must read the entire

manual before attempting to set up, operate, adjust,

or service the machine.

GB

FOREWORD

This manual contains safety, operating, adjustment,

maintenance, troubleshooting instructions and parts list

for your new Jacobsen machine. This manual should be

stored with the equipment for reference during operation.

The serial plate is located on the deck housing. Jacobsen

recommends you record these numbers below for easy

reference.

Before you operate your machine, you and each operator

you employ should read the manual carefully in its

entirety. By following the safety, operating and

maintenance instructions, you will prolong the life of your

equipment and maintain its maximum efficiency.

If additional information is needed, contact your

Jacobsen Dealer.

A Textron Company

CHARLOTTE NC PRODUCT OF U.S.A.

®

Suggested Stocking Guide

To Keep your Equipment fully operational and productive, Jacobsen suggests you maintain a stock of the more

commonly used maintenance items. We have included part numbers for additional support materials and training aids.

To order any of the following material:

1. Write your full name and complete address on your

order form.

2. Explain where and how to make shipment:

❑ UPS ❑ Regular Mail

❑ Overnight ❑ 2nd Day

3. Order by the quantity desired, the part number, and

the description of the part.

4. Send or bring the order to your authorized Jacobsen

Dealer.

Service Parts

Qty. Part No. Description Qty. Part No. Description

4325116 Metal Blade (Package of 3) 4325134 1/2” HOC Spacer

4325126 Plastic Blade (Package of 6) 4325117 Blade Bolt, Metal Blade (Black)

4325146 String Cutter (Package of 50) 4325126 Blade Bolt, Plastic Blade (Silver)

4325118 20 Inch (508 mm) Blade Disk Washer

4325148 16 Inch (406 mm) Blade Disk Washer

Service Support Material

Qty. Part No. Description

4325163 Technical Manual

© 2015, Jacobsen, A Textron Company/Textron Innovations Inc.

“All rights reserved, including the right to reproduce this material

or portions thereof in any form.”

Qty. Part No. Description

Proposition 65 Warning

This product contains or emits

chemicals known to State of California

to cause cancer and birth defects or

other reproductive harm.

2

LITHO IN U.S.A. 7-2015

Table of Contents

Introduction

1.1 Important............................................................................. 1

1.2 Product Identification ..........................................................2

1.3 Serial Number .....................................................................2

1.4 Guidelines for the Disposal of Scrap Products ...................3

Safety

2.1 How to Operate Safely........................................................ 4

Specifications

3.1 Engine Specifications..........................................................8

3.2 Dimensions and Weights ....................................................9

3.3 Cutting Unit Specification.................................................. 11

3.4 Recommended Lubricants ................................................11

3.5 Accessories.......................................................................11

3.6 Support Literature .............................................................12

Decals

4.1 Safety Decals.................................................................... 13

Set-up

5.1 General .............................................................................14

5.2 Initial Inspection ................................................................14

5.3 Engine Oil .........................................................................14

5.4 Handle Assembly ..............................................................15

5.5 Handle Mounting Holes.....................................................15

5.6 Blade Disk Torque ............................................................15

Controls

6.1 Handle Controls ................................................................16

6.2 Engine Controls ................................................................17

Operation

7.1 Daily Inspection.................................................................19

7.2 OPC System .....................................................................19

7.3 Operating Procedure.........................................................20

7.4 Starting The Engine ..........................................................21

7.5 To Stop The Engine..........................................................22

7.6 Mowing..............................................................................22

Maintenance and Lubrication Charts

8.1 Maintenance Chart............................................................23

Maintenance

9.1 General Precautions .........................................................24

9.2 Engine...............................................................................24

9.3 Engine Oil .........................................................................25

9.4 Engine Air Filter ................................................................25

9.5 Fuel ...................................................................................26

9.6 Engine Exhaust.................................................................26

9.7 Inspecting Cutter Disk.......................................................27

9.8 Care and Cleaning ............................................................28

9.9 Mower Storage..................................................................29

Adjustments

10.1 General Precautions .......................................................30

10.2 Height of Cut (HOC)........................................................30

10.3 Bail Cable Adjustment (20 inch Mowers) ........................31

10.4 Torque Specification .......................................................32

Problem Solving

11.1 General ...........................................................................33

Notes

Parts List

13.1 How To Use The Parts Catalog ......................................36

13.2 To Order Parts ................................................................36

13.3 Parts Catalog Table of Contents.....................................36

1 INTRODUCTION

1Introduction

1.1 IMPORTANT______________________________________________________________

The Jacobsen HoverKing is a walk behind rotary mower.

If you follow all instructions in this manual, you increase the life of your mower and keep its maximum performance. The

adjustments and maintenance must always be done by an approved technician.

IMPORTANT: Do the maintenance included in this manual to make sure that the quality of cut is kept at a high level.

This SAFETY, OPERATION AND MAINTENANCE MANUAL is part of the mower and must stay with the mower always.

Suppliers of both original and used mowers need to keep the documentation that comes with the mower.

You must use the mower to cut the grass and not for any other purpose. Compliance with the conditions or operation,

service and repair specified by the manufacturer, are understood to be part of the correct use.

ALL operators MUST read through this manual and understand the Safety Instructions, controls, lubrication and

maintenance procedures.

Make sure that you obey all safety and road traffic regulations.

You must not make any changes to the mower that the manufacturer does not approve. This type of change can

release the manufacturer from the liability for any damage or injury.

When you discard worn parts, know the environmental result and use the systems available in the country where the

mower is used. When the mower is at its end of life, there are guidelines in this manual for the removal of the mower

from use.

Use only Jacobsen approved parts.

2006/42/EC

The instructions recorded here are the original instructions confirmed by Jacobsen, A Textron Company.

en-1

INTRODUCTION 1

1.2 PRODUCT IDENTIFICATION _________________________________________________

Mower Serial number plate

The serial number plate is found on the deck housing near the air filter.

®

A Textron Company

CHARLOTTE NC PRODUCT OF U.S.A.

1.3 SERIAL NUMBER__________________________________________________________

Record the mower and engine numbers shown below:

Mower Number:_________________________

en-2

1 INTRODUCTION

1.4 GUIDELINES FOR THE DISPOSAL OF SCRAP PRODUCTS _______________________

1.4.1 DURING SERVICE LIFE ____________________________________________________

The used oil is hazardous material. Follow the recommended procedures for their safe removal.

If a fluid leaks, contain the spill to make sure that the leak does not flow into the ground or drainage system. Follow the

local laws to make sure that leaks are controlled safely.

The maintenance procedures in this manual make sure that the damage that the mower can cause in the local

environment is controlled safely.

Take these actions after the mower complete its full service life.

1.4.2 END OF SERVICE LIFE _____________________________________________________

Use these guidelines with applicable Health, Safety and Environmental laws. Always use the approved local waste

disposal and agencies for recycled materials.

• Park the mower in a location to use all of the necessary lifting equipment.

• Use the correct tools and Personal Protective Equipment (PPE) and take instruction from the technical manuals

applicable to the mower.

• Remove and keep correctly

1. Fuel

2. Engine Oil

Disassemble the structure of the mower and refer to the technical manuals. Give attention to parts that have

mechanical pressure or tension applied to the part in the mower, including springs.

• Separate items that continue to have service life and returned to storage.

• Separate items that are worn into the material groups and removed according to the agencies for the recycled

materials that are available. Common types are as shown:

• Steel

• Non ferrous metals

• Aluminum

• Brass

• Copper

• Plastic Materials

• Identified

• Can be recycled

• Can not be recycled

• Not Identified

• Rubber

• Electrical and Electronic Components

• Add items that can not be easily separated into different materials to the “General discarded materials” area.

• Do not burn the discarded materials

Change the mower records to show that the mower is not in service and is discarded. Supply this serial number to

Jacobsen Warranty Department to close their records.

en-3

SAFETY 2

2Safety

2.1 HOW TO OPERATE SAFELY ______________________________________________________

!

WARNING

EQUIPMENT OPERATED INCORRECTLY OR WITHOUT TRAINING CAN BE DANGEROUS.

Know the location and correct operation of controls. Operators without experience must receive instruction from

another person that knows the correct operation of the equipment before you operate the mower.

Only use parts, accessories and attachments approved by Jacobsen.

2.1.1 SAFE OPERATION

a Read the Operator’s Manual and other training material. If the operator or technician can not read this manual,

the owner is responsible to describe this material to the operators and technicians. Manuals in additional

languages may be available on the Jacobsen or RansomesJacobsen website.

a Read all of the instructions for this mower carefully. Know the controls and the correct operation of the

equipment.

b Children or persons who do not understand these instructions must not use the mower. The local regulations can

limit the age of the operator.

c Never use a mower near persons, including children or animals.

d Remember that the operator or owner is responsible for accidents or hazards that occur to other persons or their

property.

e Never allow persons to operate or service the mower or its attachments without correct instructions.

f Do not operate equipment while tired, sick or after you use alcohol or drugs.

2.1.2 PREPARATION

a When you operate the mower, wear correct clothing, slip resistant work shoes or boots, work gloves, hard hat,

safety glasses and hearing protection. Long hair, loose clothing or jewelry can be caught in moving parts.

b Do not operate the equipment with the OPC System disconnected or the system does not operate correctly. Do

not disconnect or prevent the operation of any switch.

c Never operate equipment that is not in correct order or without decals, guards, shields, deflectors or other

protective devices fastened.

d Inspect the mower before you operate the mower. Check the engine oil level. Fuel is flammable. Use caution

when you add the fuel to the mower.

e Operate the mower in daylight or in good artificial light. Use caution when you operate the mower during bad

weather. Never operate the mower with lightning in the area.

f Inspect the area to select the accessories and attachments that are needed to correctly and safely do the job.

Only use parts, accessories and attachments approved by Jacobsen.

g Be careful of holes in the terrain and other hazards that are not visible.

h Inspect the area where the equipment is operated. Remove all objects you can find before you operate. Be

careful of obstructions above the ground (low tree limbs, electrical wires) and also underground obstacles

(sprinklers, pipes, tree roots). Enter a new area carefully. Look for possible hazards.

i Inspect the cutting system before you start the mower. Make sure the blades are free to rotate.

en-4

2 SAFETY

2.1.3 OPERATION

a Never operate the engine without enough ventilation or in an enclosed area. The carbon monoxide in the exhaust

fumes can increase to dangerous levels.

b Keep other persons or animals away from the mower.

c Only start the engine with the operator in the locations indicated. Never start the engine with persons near the

mower.

d Keep your hands and feet away from the cutting blades.

e Do not use on the slopes greater than the safe slope limit for the equipment.

f To guard against loss of control:

– Operate the mower across the face (horizontally), but not up and down on the face of slopes (vertically).

– Do not start or stop suddenly on slopes.

– Decrease the speed when you operate on slopes or when you must turn. Use caution when you change

direction. Turf condition can change the mower stability.

– Use caution when you operate the mower near drop-offs, ditches or embankments.

– Be careful of holes in the terrain and other hazards that are not visible.

g Always operate at speeds that allow you to have complete control of the machine. Make sure of your footing keep

a tight grip on the handle and walk. Never run when you operate the mower.

h Use caution when you go near corners, trees or other objects that can prevent a clear view.

i Before you move across or operate on the paths or roads, release the OPC handle and lift the mower. Look for

traffic.

j Stop the engine when the mower is on any surface that is not grass.

k Do not release the cut grass in the direction of persons or allow persons near the mower while in operation.

l Do not operate the mower with damaged guards or without safety devices in position.

m Do not change the engine governor setting or over-speed the engine. Never change or tamper with adjusters that

are closed with a seal for the engine speed control.

n Before you leave the mower, for any reason:

– Release the OPC handle to stop the engine and allow the mower to settle to the ground.

o When you hit an object or mower starts to cause the vibration that is not normal, inspect the mower for damage

and make repairs.

p Do not use this equipment for uses that the mower was not made for.

2.1.4 SAFE HANDLING OF FUELS

a The fuel and the fuel vapors are flammable. Use caution when you add the fuel to the mower. The fuel vapors

can cause an explosion.

b Never use the containers that are not approved to keep or transfer fuel.

c Never keep the mower or fuel containers near an open flame or any device that can cause the ignition of fuel or

fuel vapors.

d Never fill the fuel containers inside a vehicle or on a truck or trailer with a plastic liner. Always put the fuel

container on the ground away from your vehicle before you fill the container.

en-5

SAFETY 2

e Refuel the mower before you start the engine. When the engine is in operation or while the engine is hot, never

remove the fuel cap or add fuel to the mower.

f Refuel outdoors only and do not smoke when you add fuel. Extinguish all types of ignition.

g The fuel nozzle must touch the rim of the fuel tank when you add fuel to the mower. Do not use a device to lock

the fuel nozzle in the open position.

h Do not over fill the fuel tank. Leave at least 1 inch (25 mm) below the filler neck.

i Always tighten the fuel tank cap and container cap after you add fuel.

j If the fuel spills on your clothing, change your clothing immediately.

2.1.5 MAINTENANCE AND STORAGE

a Before you clean, adjust or repair this equipment, stop the engine and disconnect the spark plug wire. Keep the

wire away from the plug to prevent the engine to start.

b Make sure the mower is stored on a solid and level surface.

c Never allow persons to service the mower or its attachments without correct instructions.

d When you put the mower on a trailer or put the mower in storage, close the fuel valve. Do not keep fuel near

flames or drain the fuel inside a building.

e Be careful and wear gloves when you check or service the cutting unit blades. Replace any damaged blades, do

not try to correct a damaged blade.

f Keep your hands and feet away from parts that move. Do not adjust the mower with the engine in operation,

unless the adjustment needs the engine in operation.

g Keep the mower and the engine clean.

h Allow the engine to become cool before storage.

i Keep all nuts, bolts and screws tight to make sure the equipment is in safe condition.

j Replace worn or damaged parts for safety. Replace damaged or worn decals. Only use parts, accessories and

attachments approved by Jacobsen.

k To decrease the fire hazard, remove materials that burn from the engine, muffler, battery tray and fuel tank area.

2.1.6 WHEN YOU PUT THE MOWER ON A TRAILER

a Use straps, chains, cables or ropes to fasten the mower to the trailer.

2.1.7 CHILDREN

Children are often attracted to the mower when you are mowing. If the operator does not know that children in the area,

accidents can occur. You must never assume that children will continue to stay where you last saw them.

a When you operate the mower, keep children away. Children must be watched by an adult other than the operator.

b Stop the mower immediately if a child enters the area of operation.

c Never allow children to operate the mower.

en-6

2 SAFETY

2.1 IMPORTANT SAFETY NOTES _______________________________________________

This safety alert symbol is used to alert you to potential hazards.

DANGER - Indicates an imminently hazardous situation which, if not avoided, WILL result in death or serious injury.

WARNING - Indicates a potentially hazardous situation which, if not avoided, COULD result in death or serious

injury.

CAUTION - Indicates a potentially hazardous situation which, if not avoided, MAY result in minor or moderate injury

and property damage. It may also be used to alert against unsafe practices.

NOTICE - Indicates a potentially hazardous situation which, if not avoided, MAY result in property damage. It may

also be used to alert against unsafe practices.

For pictorial clarity, some illustrations in this manual may show shields, guards or plates open or removed. Under no

circumstances should this equipment be operated without these devices securely fastened in place.

!

WARNING

The Interlock System on this machine will stop the engine if the operator

releases the OPC (Operator Presence Control) bail.

To protect the operator and others from injury, never operate equipment with

the Interlock System disconnected or malfunctioning.

!

WARNING

1. Before leaving the operator’s position for any reason, release the OPC

bail. Allow the mower to settle to the ground.

2. Keep hands, feet, and clothing away from moving parts. Wait for all

movement to stop before you clean, adjust, or service the machine.

3. Keep the area of operation clear of all bystanders and pets.

4. Never operate mowing equipment without the guards securely fastened

in place.

By following all instructions in this manual, you will prolong the life of your machine and maintain its maximum

efficiency. Adjustments and maintenance should always be performed by a qualified technician.

If additional information or service is needed, contact your Authorized Jacobsen Dealer who is kept informed of the

latest methods to service this equipment and can provide prompt and efficient service.

en-7

SPECIFICATIONS 3

3Specifications

3.1 ENGINE SPECIFICATIONS __________________________________________________

20 in. HoverKing 16 in. HoverKing

Make Honda Honda

Model GCV160 GXV57

Type Four cycle, overhead Cam Four cycle, overhead valve

Number of Cylinders 1 1

Bore and Stroke 2.5 in. (6.4 cm) x 2.0 in. (5.0 cm) 1.77 in. (4.5 cm) x 1.42 in. (3.6 cm)

Total Displacement

Intake System Naturally Aspirated Naturally Aspirated

Net Power 4.4 hp (3.3 kW) @ 3600 rpm 2.0 hp (1.5 kW)@ 4800 rpm

Torque 6.9 ft.Lb. (9.4 Nm) @ 2500 rpm 2.4 ft.Lb. (3.2 Nm) @ 4500 rpm

Maximum Speed 3600 ± 50 rpm (No Load) 4600 ± 50 rpm (No Load)

Low Idle 1400 ± 150 rpm (No Load) 2500 ± 200 rpm (No Load)

9.8 in

3

(0.160 l) 3.5 in3(0.057 l)

Rotation Counter-clockwise viewed at PTO shaft Counter-clockwise viewed at PTO shaft

Fuel Unleaded Gasoline, 87 Octane Minimum Unleaded Gasoline, 87 Octane Minimum

Fuel Tank Capacity 0.25 U.S. Gallon (0.93 l) 0.071 U.S. Gallon (0.27 l)

Engine Oil (API Class) 10W30 (SJ) 10W30 (SJ)

Oil Capacity 18.6 oz. (0.55 l) 8.4 oz. (0.25 l)

Start Method Recoil Start Recoil Start

Cooling System Forced Air Forced Air

Ignition System Transistorized Magneto Transistorized Magneto

Dry Weight 22 lb. (9.8 kg) 11.9 lb. (5.4 kg)

Dimensions

(Length x Width x Height)

14.4 x 13.0 x 13.7 in.

(36.7 x 33.1 x 34.7 cm)

9.8x 11.3 x 9.4 in.

(24.9 x 28.6 x 24.0 cm)

en-8

3 SPECIFICATIONS

3.2 DIMENSIONS AND WEIGHTS ________________________________________________

20 Inch HoverKing 16 Inch HoverKing

A - Width of Cut 20 inch (50.8 cm) 16 inch (40.6 cm)

B - Maximum Width 23.4 inch (59.4 cm) 19.5 inch (49.5 cm)

C - Height (Standard Handle)

Handle at 30° angle from ground

D - Height (Extended Handle)

Handle at 30° angle from ground

E - Length (Standard Handle)

Handle at 30° angle from ground

F - Length (Extended Handle)

Handle at 30° angle from ground

G - Handle Length (Standard Handle) 50 inch (127 cm) 50 inch (127 cm)

H - Handle Length (Extended Handle) 67 inch (170 cm) 67 inch (170 cm)

Weight of unit, fuel tank filled x x

Weight of unit, fuel tank empty x-1.278 x-.45369

36.7 inch (93.2 cm) 32 inch (81.3 cm)

46.5 inch (118.1 cm) 41.8 inch (106.2 cm)

59 inch (149.9 cm) 59 inch (149.9 cm)

76 inch (193.04 cm) 76 inch (193.04 cm)

en-9

20 inch (50.8 cm)

HoverKing

(Standard Handle)

SPECIFICATIONS 3

C

C

G

E

16 inch (40.6 cm)

HoverKing

(Standard Handle)

G

E

A

B

A

B

20 inch (50.8 cm)

HoverKing

(Extended Handle)

D

H

F

en-10

3 SPECIFICATIONS

3.3 CUTTING UNIT SPECIFICATION _____________________________________________

Blade Length 4 in. (10.2 cm)

Number of blades 3

Height of cut 1 to 3 in. (2.5 to 7.6 cm)

Height of cut adjustment 1/2 in. (1.3 cm) spacers put between impeller

and blade disk.

3.4 RECOMMENDED LUBRICANTS______________________________________________

Engine Oil:

Must meet MIL-L-46152 or API Classification grades SJ

Temperature Viscosity

Above 50° F (10° C) SAE 10W-30 or SAE 30

Below 50° F (10° C) SAE 10W-30

3.5 ACCESSORIES ___________________________________________________________

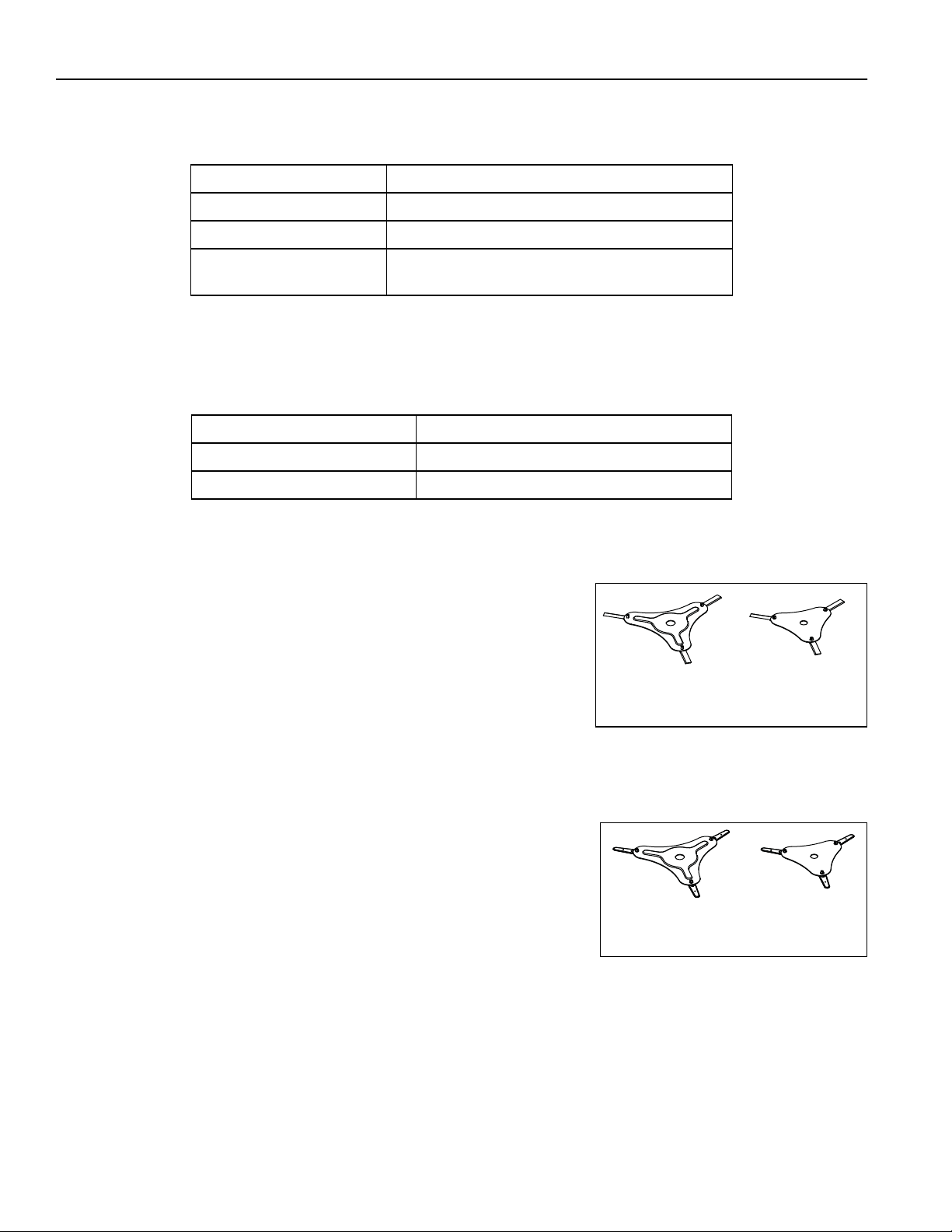

3.5.1 METAL BLADE KIT ________________________________________________________

20 inch (50.8 cm) Kit number 32252

16 inch (40.6 cm) Kit number 32258

20 inch

(50.8 cm)

16 inch

(40.6 cm)

3.5.2 PLASTIC BLADE KIT_______________________________________________________

20 inch (50.8 cm) Kit Number 32253

16 inch (40.6 cm) Kit number 32259

20 inch

(50.8 cm)

16 inch

(40.6 cm)

en-11

SPECIFICATIONS 3

3.5.3 STRING CUTTER KIT _______________________________________________________

20 inch (50.8 cm) Kit Number 32254

16 inch (40.6 cm) Kit number 32260

20 inch

(50.8 cm)

3.5.4 HANDLE EXTENSION KIT ___________________________________________________

20 inch (50.8 cm) HoverKing Kit number 32255

Includes longer bail and throttle control cables.

16 inch (40.6 cm) HoverKing Kit number 32261

Includes longer OPC switch harness.

16 inch

(40.6 cm)

3.5.5 WHEEL KIT _______________________________________________________________

Kit number 32256

3.6 SUPPORT LITERATURE ____________________________________________________

Contact your Jacobsen Dealer for a complete listing of literature available for your mower.

Technical Manual: 4325163

Engine Manual

en-12

4 DECALS

4Decals

4.1 SAFETY DECALS _________________________________________________________

Understand the purpose of these decals. The decals are important to the safe operation of the mower. REPLACE THE

DAMAGED DECALS IMMEDIATELY.

DANGER

Injury or death can occur from contact with the

blade or from the objects discharged from the

mower.

WARNING

Read the manual.

Wear safety glasses, hearing protection and other required safety equipment.

Be careful of discharged objects. When the mower is in operation, keep persons and animals away.

Be careful when you operate the mower on slopes. To prevent slips or falls, only mow when the grass is dry.

Your hands or feet can be injured from contact with the blades. To prevent injury, disconnect the spark plug wire before

you service the mower.

Stay away from hot surfaces and moving parts. Never operate equipment that is not in correct order or without decals,

guards, shields, deflectors or other protective devices fastened.

en-13

SET-UP 5

5Set-up

5.1 GENERAL ________________________________________________________________

A qualified technician must always do the assembly, adjustment and mower tests. The technician must know the

correct operation of this equipment.

Completely read each instruction and make sure you understand the instructions before continue with the assembly.

Look for possible hazards and obey all safety precautions.

The RIGHT and LEFT, FRONT and BEHIND the machine are given from the operator’s position.

Order the accessories not included with this product separately. See the accessory instructions accessory for

installation and parts.

!

CAUTION

Do not operate the mower unless you know this type of equipment and know how to operate all controls correctly.

5.2 INITIAL INSPECTION _______________________________________________________

Do a visual inspection of the mower. Look for indications of wear or loose hardware. Look for any components that are

not included on the mower or damaged components. Inspect paint and decals for damage or scratches. Decals provide

important safety and operating information. Replace all missing or hard to read decals.

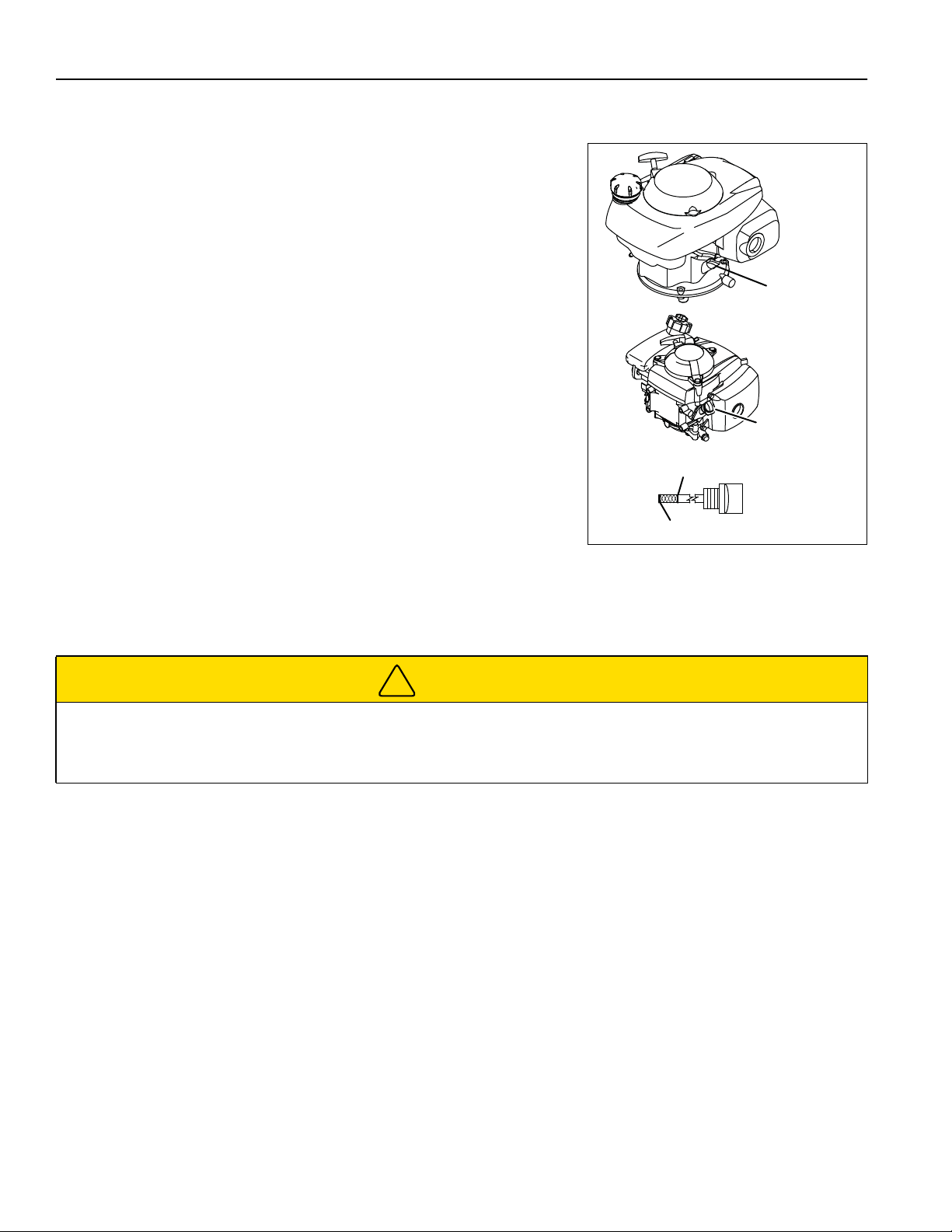

5.3 ENGINE OIL______________________________________________________________________

NOTICE

Your mower was shipped from the factory without oil in the engine crankcase. Make certain the engine oil is

added before you start the engine. The damage caused by low or no oil in the engine is not covered under

the warranty.

1. Place the mower on a flat and level surface.

2. Remove the oil cap/dipstick. Check to make sure there is no oil in the

crankcase.

3. Slowly add the correct amount of engine oil. Do not overfill the engine.

• 20 inch (50.8 cm) HoverKing - 18.6 oz. (0.55 l)

• 16 inch (40.6 cm) HoverKing - 8.4 oz. (0.25 l)

4. Wait three to five minutes and check the engine oil level.

• Clean the dipstick with a lint-free cloth.

• Insert the dipstick until the cap touches the engine base. Do not

screw the cap into the engine.

• Remove the dipstick. Engine oil must be between the upper and

lower level marks.

• If the engine oil level is above the upper level mark, remove the

excess engine oil.

• If the engine oil level is below the lower limit mark, add more engine

oil. Check the oil level again. Do not overfill the engine.

5. Insert the dipstick and hand tighten the oil cap.

6. Change the engine oil after the first 5 hours of operation.

Upper Limit Mark

20 inch

HoverKing

Engine

Oil cap and

dipstick

16 inch

HoverKing

Engine

Oil cap and

dipstick

Lower Limit Mark

en-14

5 SET-UP

5.4 HANDLE ASSEMBLY ______________________________________________________

The handle was shipped with the upper handle

disconnected from the bottom handle.

1. Align the holes in the bottom handle with the holes in

the upper handle.

2. Insert the four carriage bolts from the upper handle

side. Secure with the four nylon insert hex flange

nuts.

3. Secure the handle control cable(s) to the bottom

handle using cable ties.

4. 20 Inch (50.8 cm) HoverKing: Make sure the bail

cable is inserted in the correct slot in the throttle

lever.

• When the standard handle is installed, the bail

cable must be in the upper slot.

• When the optional tapered handle is installed, the

bail cable must be in the lower slot.

5. Handle cables must be routed down handle and on

the right side of the engine. Do not wrap cables

around the left side of the engine.

NOTE: 20 inch (50.8 cm) HoverKing standard handle

shown. 16 inch (40.6 cm) HoverKing handle and optional 20 inch (50.8 cm) HoverKing tapered handle is assembled the

same way.

Handle

Cables

Bottom

Handle

Upper Slot

Lower Slot

Upper

Handle

Carriage

Bolts

Nylon Insert Hex

Flange Nuts

5.5 HANDLE MOUNTING HOLES ________________________________________________

The HoverKing has two mounting positions for the handle. Handle

positions are only recommendations. The handle should be

mounted so the operator has the best control of the mower based

on specific mowing conditions.

20 Inch (50.8 cm) HoverKing: The back hole is recommended for

operation on steep inclines. The front hole is recommended for

operation on more level terrain.

16 Inch (40.6 cm) HoverKing: The back hole is recommended for

operation on more level terrain. The front hole is recommended for

operation on steeper inclines.

Front Hole

Front Hole

20 inch

HoverKing

Back Hole

16 inch

HoverKing

Back Hole

5.6 BLADE DISK TORQUE______________________________________________________

Check torque on the blade disk. Do not over torque blade disk bolt or damage to the impeller bushing can result.

20 inch (50.8 cm) HoverKing - 38-40 ft. lb. (51-54 Nm)

16 inch (40.6 cm) HoverKing - 12-14 ft.lb. (16-19 Nm)

en-15

CONTROLS 6

6Controls

6.1 HANDLE CONTROLS_______________________________________________________

20 inch

HoverKing

Handle

6.1.1

6.1.2

16 inch

HoverKing

Handle

6.1.1

6.1.1 BAIL HANDLE ____________________________________________________________

The bail handle controls the operation of the OPC (Operator Presence Control) system. The bail handle must be closed

before the engine will start. When the bail handle is released, the engine must stop within 3 seconds.

6.1.2 THROTTLE LEVER (20 INCH (50.8 CM) HOVERKING ONLY) _______________________

The throttle lever is to control the engine speed. Push the throttle lever forward to increase the engine speed. Pull the

throttle lever to decrease the engine speed. When you operate the mower, Jacobsen recommends that the engine

speed is at full throttle.

When you start a cold engine, pull the throttle lever completely toward the operator to close the choke plate. Slowly

push the throttle lever forward to increase the engine speed as the engine becomes warm.

en-16

6 CONTROLS

6.2 ENGINE CONTROLS _______________________________________________________

6.2.2

6.2.5

20 inch

HoverKing

Engine

6.2.4

6.2.7

6.2.4

6.2.1

6.2.5

6.2.2

6.2.1

6.2.6

6.2.3

16 inch

HoverKing

Engine

6.2.3

6.2.1 FUEL SHUT-OFF VALVE ____________________________________________________

Rotate the fuel shut off valve 90°to the CLOSED position to stop the flow of fuel to

the carburetor. The fuel valve must be in the OPEN position for the engine to

operate.

When the mower is not used or before you service the mower, close the fuel shut-off

valve.

OPEN

Position

CLOSED

Position

6.2.2 STARTER HANDLE ________________________________________________________

The starter handle is used to start the engine. Slowly pull on handle until resistance is felt, then pull firmly. Do not allow

the starter handle to snap back into the recoil starter.

6.2.3 DIPSTICK/OIL CAP ________________________________________________________

The dipstick/oil cap is used to check the engine crankcase oil level and add oil to the engine.

6.2.4 AIR FILTER COVER________________________________________________________

The air filter cover holds the air filter in position to prevent dirt and debris being pulled into the engine.

6.2.5 FUEL TANK CAP __________________________________________________________

Remove the fuel tank cap to add fuel to the mower. When the engine operates, do not remove the fuel tank cap. Do not

start the engine unless the fuel cap is installed.

en-17

CONTROLS 6

6.2.6 FUEL CAP BREATHER (16 INCH (40.6 CM) HOVERKING ONLY) ___________________

The fuel cap breather must be turned two to three turns to the left before you start the engine. When the mower is not

used, close the fuel cap breather.

6.2.7 CHOKE LEVER (16 INCH (40.6 CM) HOVERKING ONLY) __________________________

When you start a cold engine, move the CHOKE lever to the choke position.

Slowly push the choke lever to the RUN position as the engine becomes

warm.

RUN

Position

Choke

Position

en-18

7 OPERATION

7Operation

7.1 DAILY INSPECTION________________________________________________________

!

CAUTION

The inspection must be done each day when the engine is stopped.

Do a visual inspection of the mower. Look for indications of wear or loose hardware. Look for any damaged

components.

Check the fuel supply and crankcase oil level. When the engine is cold, all fluids must be at the full level mark.

Test the OPC system.

7.2 OPC SYSTEM_____________________________________________________________

The OPC System prevents the engine to start unless the bail handle is closed. The system stops the engine if the

operator releases the bail handle.

!

WARNING

Do not operate the equipment with the OPC System disconnected or the system does not operate correctly. Do not

disconnect or prevent the operation of any switch.

Do each of these tests to make sure the OPC System operates correctly. If any of the tests fail, stop the test and have

the system inspected and repaired as shown below:

• The engine does not start during test 1

• The engine does start during test 2

• The engine continues to run during test 3

Refer to the chart below for each test and follow the check (✔) marks across the chart. Turn off the engine between

each test.

TEST 1: The test shows the normal engine start procedure. The bail handle is closed. The engine will start.

TEST 2: The engine must not start if the bail handle is open.

TEST 3: Start the engine with the normal procedure. Release the bail handle. The engine and mower blades must

stop..

Test Bail Handle

Closed

Yes No Yes No

1 ✔✔

2 ✔✔

3 ✔★★

Engine Starts

en-19

★ Start the engine with the normal procedure,

release the bail.

The engine must stop and the cutting unit blades

must not rotate after three (3) seconds.

OPERATION 7

7.3 OPERATING PROCEDURE __________________________________________________

!

CAUTION

To prevent injury, always wear safety glasses, leather work shoes or boots, a hard hat and ear protection.

1. Never operate the engine without enough ventilation or in an enclosed area. The carbon monoxide in the exhaust

fumes can increase to dangerous levels.

2. Keep your hands and feet away from moving parts and the cutting units. When possible, do not adjust the mower

with the engine started.

3. Do not operate the mower with loose or damaged components. All components must be correctly fastened to the

mower. Mow when the grass is dry to get the best results.

4. First cut in a test area so that you completely understand the operation of the mower and controls.

5. Inspect the area to find the safest procedure for the mower. Check the height of the grass, the type of terrain and

the conditions of the surface. Each condition needs the correct adjustments and precautions.

6. Do not release the cut grass in the direction of persons or allow persons near the mower while in operation. The

owner and operator are responsible for injuries caused to persons near the mower and any damage to their

property.

!

CAUTION

Remove all objects you can find before you operate the mower. Carefully enter a new area and always operate at

speeds that allow you to control the mower safely.

7. Be careful when you operate near to gravel areas (roads, parking areas, cart paths). Stones released from the

equipment can cause injuries to persons and cause damage to the equipment.

8. When you are not mowing grass, always stop the engine.

9. When you hit an object or mower starts to cause vibration that is not normal, inspect the mower for damage and

make repairs.

!

WARNING

Before you clean, adjust or repair this equipment, always stop the engine, close the fuel shut-off valve and

disconnect the spark plug wire..

10. Walk slowly and be careful when you operate on the slopes or near sharp edges.

11. Never use your hands to clean the blades. Use a brush to remove the grass clippings from the blades. The

blades are sharp and can cause injuries.

en-20

7 OPERATION

7.4 STARTING THE ENGINE ____________________________________________________

20 Inch (50.8 cm) HoverKing:

Start the engine with the operator behind or on the right side of the mower.

Check the engine oil level.

Check fuel level. Make sure fuel shut-off valve is in the OPEN position

When you start a cold engine, pull the throttle lever completely toward the

operator to close the choke plate.

Pull and hold the bail handle against the upper handle. Move the handle to

the upright position.

Place your foot firmly on the rear surface of the deck.

Slowly pull on the starter handle until resistance is felt, then pull firmly. Do

not allow the starter handle to snap back into the recoil starter. Repeat

until the engine starts.

When the engine starts, slowly push the throttle lever forward to increase

the engine speed as the engine becomes warm.

16 Inch (50.8 cm) HoverKing:

Bail

Handle

Throttle

Lever

Starter

Handle

Fuel Shut-Off

Valve

Start the engine with the operator behind or on the right side of the

mower.

Check the engine oil level.

Check fuel level. Make sure fuel shut-off valve is in the OPEN

position. Turn the fuel cap breather two to three turns to the left.

When you start a cold engine, move the choke lever to the CHOKE

position.

Pull and hold the bail handle against the upper handle. Move the

handle to the upright position.

Place your foot firmly on the rear surface of the deck.

Slowly pull on the starter handle until resistance is felt, then pull firmly.

Do not allow the starter handle to snap back into the recoil starter.

Repeat until the engine starts.

When the engine starts, slowly move the choke lever to the RUN

position as the engine becomes warm.

Fuel Cap

Breather

Choke

Lever

Bail

Handle

Starter

Handle

Fuel Shut-Off

Valve

en-21

OPERATION 7

7.5 TO STOP THE ENGINE ______________________________________________________

1. Release the bail lever to stop the engine. Allow the engine to settle to the ground and all movement stop.

2. Move the fuel shut-off valve to the closed position.

3. 16 inch (40.6 cm) HoverKing: Close the fuel cap breather valve.

7.6 MOWING_________________________________________________________________________

!

WARNING

To prevent injuries, when the blades rotate, keep your hands, feet and clothing away from the cutting unit.

NEVER use your hands to clean the cutting units. Use a brush to remove grass from the blades. The blades can be

sharp and can cause injury.

Only mow when the grass is dry.

Make sure of your footing when you operate on slopes. Operation on slopes needs caution. If you are not

comfortable when you operate on a slope, do not mow the slope.

Always stay above the mower when you mow on slopes. Keep the mower pointing down when you mow on slopes.

Never mow by pushing the hover mower up a slope.

Mow across slopes horizontally, not vertically.

To m o w:

1. Move the mower to the area to be mowed. Start the engine.

2. To get the best results and highest quality of cut, start at the outer edge of the area to be mowed. Mow from the

left side to the right side in decreasing sized half circles starting at the edge of your turf and work inwards. When

you follow this pattern, the mulching performance of the mower improves.

3. Do not cut off more than 1/3 of the length of the blade of grass. Cutting more than 1/3 of the blade length can

damage the health of your turf. Hover mowers do an excellent job mowing grass over mixed surfaces, make sure

that the surfaces are level to each other and are free from branches, rocks and debris.

4. You can trim around the trees and bushes in half circle motions.

5. Use caution and be aware of your footing when you operate the mower on slopes. Move the hover mower from

the right to the left side along the slope. Stand at the top of the hill. Start at the bottom of the slope and work your

way to the top. When you must mow on steep or deep slopes, use the handle extension kit for easy and safe

operation.

Always stay above the mower when you mow on slopes.

6. To mow around sand trap and flower bed edges: Walk forward while you pull the hover mower towards you in a

clockwise direction around the edge. Mow from the left side to the right side so that the rotation of the blades

throws any grass or debris away from the bed or sand trap. The hover mower deck must never be more than 3 to

4 inches (7.5 to 10 cm) over the edge of the bed or sand trap edge.

7. To trim around surface transitions: When the turf is the same level as the path, move the hover mower slowly

towards the grass edge, the airflow will raise the overhanging grass and it will create a neat and quality cut

.

en-22

8 MAINTENANCE AND LUBRICATION CHARTS

8Maintenanceand Lubrication Charts

8.1 MAINTENANCE CHART

Mower Service Interval Chart

Interval Item Section

First 5 Hours

or First Month

1

• Replace the engine oil

• Check all blades and blade bolts.

• Check engine shaft bolt and blade disk

Each day • Check OPC System

• Check the engine oil level

• Check the air filter

• Check the blades, blade bolts and blade disk for damage or

loose hardware

• Clean any grass or dirt from blades and mower housing.

• Make sure air inlet around engine base is not blocked.

• Inspect the mower for hardware that is loose or missing.

• Inspect the mower for damage.

Each 25 hours

or 3 Months

1

Each 50 Hours

or 6 Months

1

Each 100 Hours

or Year

1

Each 200 Hours

or 2 Years

1

Whichever occurs first. Log hours of operation to determine proper maintenance intervals.

1

• Clean the air filter

• Replace the engine oil

• Check the spark plug. Replace if needed.

• Replace spark plug

• Replace air filter

2

3

2

Clean the air filter more often when used in dusty areas.

3

Change engine oil every 25 hours when used under heavy load or in high ambient temperatures.

en-23

MAINTENANCE 9

9Maintenance

9.1 GENERAL PRECAUTIONS ________________________________________________________

!

WARNING

Before you clean, adjust or repair this equipment, stop the engine, close the fuel shut-off valve and disconnect the

spark plug wire.

Make sure the mower is parked on a solid and level surface. Only tilt the mower so the air cleaner and carburetor

are above the crankcase.

A qualified technician must always do adjustments and maintenance. If the correct adjustments can not be made,

contact your Jacobsen Dealer.

Inspect the equipment according to the maintenance schedule and keep complete records.

a Keep the equipment clean.

b Keep all moving parts correctly adjusted and lubricated.

c Replace worn or damaged parts before you operate the mower.

d Keep all fluids at the correct level.

When you make the adjustments or repairs, do not wear jewelry or loose fitting clothing.

Refer to the illustrations in the Parts Manual for the removal and assembly of parts.

When you discard hazardous materials (engine oil, fuel), follow your local, state or federal-recommended procedures.

9.2 ENGINE __________________________________________________________________

IMPORTANT - The mower includes a separate Engine Manual prepared by the engine manufacturer. Read the Engine

Manual and know the operation and maintenance of the engine. When you follow the engine manufacturer instructions,

you will make sure of the maximum service life of the engine. The replacement engine manuals are available from the

engine manufacturer.

Refer to the Engine Manual as an aid when you check or change the oil or service the air cleaner.

The operation and maintenance during the first 5 hours of a new engine can make a difference to the performance and

life of the engine.

During the first 5 hours of operation, Jacobsen recommends the following.

• Allow the engine to reach a temperature of at least 140° F (60° C) before operation at full load.

• Check the engine oil level two times each day. Higher than normal oil use can occur during the first 5 hours.

• Change the engine oil and oil filter after the first 5 hours of operation.

• Check the air filter.

• Refer to the Engine manual for specified maintenance intervals.

NOTICE

The mower operates and cuts correctly at the preset governor setting. Do not change the engine governor setting

or over speed the engine.

en-24

9 MAINTENANCE

9.3 ENGINE OIL ______________________________________________________________

Check engine oil level

Check the engine oil level before you start the engine or at least five minutes

after you stop the engine.

a Place the mower on a level surface.

b Remove the oil cap and dipstick. Clean the dipstick with a clean cloth.

c Insert the dipstick until the cap touches the engine base. Do not screw

the cap into the engine.

d Remove the dipstick. Engine oil must be between the upper and lower

level marks.

e If the engine oil level is above the upper level mark, remove the excess

engine oil.

f If the engine oil level is below the lower limit mark, add more engine

oil. Check the oil level again. Do not overfill the engine.

Change Engine Oil

a Start the engine to increase the temperature, then stop the engine.

Turn the fuel shut-off valve to the CLOSED position and disconnect

the spark plug wire.

b Remove the drain plug from the bottom of the crankcase and clean with a cloth.

c Drain the engine oil into a container.

20 inch

HoverKing

Engine

Oil cap and

dipstick

16 inch

HoverKing

Engine

Oil cap and

dipstick

Upper Limit Mark

Lower Limit Mark

d Replace the drain plug and fill the engine with the correct quantity and grade of oil through the filler.

!

CAUTION

The engine oil can damage your skin. Use gloves when you use engine oil. If engine oil touches your skin, clean the

area immediately.

Discard used engine oil as shown in local regulations.

9.4 ENGINE AIR FILTER _______________________________________________________

Clean the outside of the filter cover. Remove the cover and the air filter.

Clean the inside of the filter housing and cover. Make sure dust and other particles do not get into the carburetor inlet.

20 inch (50.8 cm) HoverKing: Tap the filter several times on a hard surface to remove dirt. Never try to brush off dirt.

16 inch (40.6 cm) HoverKing: Clean the filter in warm soapy water. Rinse and allow to dry completely. Dip the filter in

clean engine oil. Squeeze out all excess oil. When started, the engine will smoke if too much oil is left in the filter.

When you replace the filter, inspect the new filter. Do not use a damaged filter and never use an incorrect filter.

Assemble the filter and cover to the filter housing.

en-25

MAINTENANCE 9

9.5 FUEL ____________________________________________________________________

Gasoline is flammable. Use caution when you add the fuel to the mower. Only use an approved container. The

spout on the container must fit inside the fuel filler neck. Never use the containers that are not approved to keep or

transfer fuel.

!

WARNING

Refuel the mower before you start the engine. When the engine is in operation or while the engine is hot, never

remove the fuel cap or add fuel to the mower.

Refuel outdoors only and do not smoke when you add fuel.

If the fuel spills, do not try to start the engine, but move the mower away from the area. Until fuel vapors are

removed, do not allow the sparks, open flame or other types of ignition.

Never keep fuel containers near an open flame or any device that can cause the ignition of fuel or fuel vapors.

Always tighten the fuel tank cap and container cap after you add fuel.

Fill the fuel tank to less than 1 inch (2.5 cm) below the filler neck.

Use clean unleaded gasoline with a 87 octane rating minimum.

Check fuel hoses and clamps each year. Replace fuel hoses and clamps at first indication of wear or damage.

Keep fuel according to your local, state or federal regulations and instructions from your fuel supplier.

9.6 ENGINE EXHAUST _______________________________________________________________

!

WARNING

The exhaust fumes contain carbon monoxide. The carbon monoxide in the exhaust fumes can increase to

dangerous levels. To protect you from carbon monoxide poisoning, inspect the complete exhaust system every

month and replace damaged components immediately.

NEVER operate the engine without enough ventilation.

The temperature of the exhaust components can be greater than 300° F (149° C). To prevent the burns, do not

touch a hot exhaust system.

If you sense a change in the color or sound of the exhaust, stop the engine immediately. Identify the problem and have

the system repaired.

en-26

9 MAINTENANCE

9.7 INSPECTING CUTTER DISK _________________________________________________

A bent or unbalanced cutter disc can cause excessive vibration. Always mow with a flat and balanced cutter disc and

non worn blades. Make sure that the cutter disc insert nuts, blade bolts and blades are properly securely fastened to

the disc.

1. Stop the engine and wait for all moving parts to stop. Turn the fuel shut-off valve to the closed position and

disconnect the wire from the spark plug.

2. Rotate and tip the lawn mower onto its left edge with the carburetor and air cleaner facing up and away from the

ground.

3. Remove the blade attachment bolts and the blades.

4. Remove the engine shaft bolt and washer.

5. Remove blade disc from the mower and place on a flat level surface with the blade side facing down.

6. Inspect for a consistent gap at each of the three blade disc ends where blades are attached.

7. If an inconsistent gap is seen between the flat surface and the surface of the blade disc, or if the disc is warped or

damaged in any way, replace the blade disc.

!

WARNING

Never operate the mower with a bent or damaged blade disc. A bent or damaged disc will cause excessive vibration

and unsafe operating conditions including loose components or thrown objects. Loose components can be thrown

causing serious injury or death.

8. Inspect the disc insert nuts to ensure they are properly secure and tight. If the insert nuts are loose or damaged,

the blade disk must be replaced. Do not attempt to tighten the insert nuts if they are loose.

9. Inspect the blade attachment bolts for excessive wear and to ensure they are properly tightened. Make sure the

correct blade bolts are used. Using incorrect blade bolts can result in injury or death. The blade bolts used with

the metal blades are black in color. The blade bolts used with the plastic blades are silver in color. Never use

incorrect blade bolts.

10. Tighten, blade bolts to 7 ft. lb. (9.5 Nm). Replace worn or damaged bolts. Loose or damaged bolts can cause

blades or blade bolts to be thrown into the operator mowing area causing serious injury or death.

11. Inspect the blades for wear or damage. Replace worn and damaged blades immediately. Worn or damaged

blades can cause objects be thrown into operator mowing area causing serious injury or death.

!

WARNING

Always replace all three blades at the same time. Never replace only one or two blades. When you replace less than

all three blades at the same time can cause your mower to become unbalanced and can cause excessive vibration.

Excessive vibration can create unsafe operating conditions resulting in loose or thrown objects which can result in

serious injury or death.

en-27

MAINTENANCE 9

9.8 CARE AND CLEANING _____________________________________________________

Clean the mower after each use. To prevent damage to the engine, do not wash the mower with the engine in

operation. When possible, clean the mower with compressed air.

NOTICE

Do not wash any part of the mower that is hot. Do not use the high-pressure spray or steam. Use cold water and

automotive cleaners.

!

WARNING

Never use your hands to clean the blades. Use a brush to remove grass clippings from the blades. The blades are

sharp and can cause injuries.

Keep the top and bottom of the deck housing clean and free of grass and debris. Never block the impeller air intake

openings around the base of the engine. Tilt the mower on the left edge so the air filter and carburetor face up and

away from the ground to clean the bottom of the deck housing.

Use compressed air to clean the engine. Do not pressure wash engine.

Use clean water to wash your equipment.

NOTICE

To use salt water or drain water is known to cause rust and corrosion of metal parts and can cause damage or

failure. This damage is not included by the factory warranty.

Clean all plastic or rubber parts with a weak soap solution or use commercially available rubber cleaners.

Repair damaged metal surfaces and use Jacobsen touch-up paint. Apply wax to the equipment for maximum paint

protection.

!

CAUTION

To prevent fire, clean grass clippings and dirt from the cutting disk, engine and exhaust components.

en-28

9 MAINTENANCE

9.9 MOWER STORAGE ________________________________________________________

General

• Clean the mower. Repair and paint damaged or exposed metal.

• Inspect the mower, tighten all hardware, replace worn or damaged components.

• Keep the mower and all accessories clean, dry and protected from the elements. Never keep the mower near an

open flame or spark which can cause ignition of the fuel or fuel vapors.

Engine

• Drain the fuel from the mower. Start the engine. Allow the engine to operate until it runs of fuel and stops. Try to

start the engine again. When you can no longer start the engine, the fuel system is completely empty.

• While the engine is warm, remove the drain plug and drain the oil from the crankcase. Install the drain plug and

fill the engine with oil.

• Remove the spark plug and add 1 ounce (29 ml) of clean engine oil into the spark plug hole. Slowly pull the

starter rope several times to distribute the engine oil on the cylinder walls. Install the spark plug.

• Clean the outside surface of the engine. Paint bare metal or apply a thin layer of rust preventative oil.

Blades

• Completely clean the blade disk and blades. Paint any damaged or bare metal surfaces.

• Apply a thin layer of rust preventative oil to the sharpened edges of the blades.

!

CAUTION

The blades have sharp edges. To prevent injury, use caution when you service or hold the blade.

After Storage

• Remove the spark plug. Place a clean rag over the spark plug hole and pull the starter handle quickly to remove

excess oil from the cylinder. Install the spark plug.

• Check or service the air filter

• Check the level of engine oil.

• Fill the fuel tank with fuel.

• Remove all oil from the blades. Adjust the cutting height.

• Start the engine and allow the engine to become warm and lubricated.

!

WARNING

Never operate the engine without enough ventilation or in an enclosed area. The carbon monoxide in the exhaust

fumes can increase to dangerous levels.

en-29

ADJUSTMENTS 10

10Adjustments

10.1 GENERAL PRECAUTIONS ________________________________________________________

!

WARNING

Before you clean, adjust or repair this equipment, stop the engine, close the fuel shut-off valve and disconnect the

spark plug wire.

Make sure the mower is parked on a solid and level surface. Only tilt the mower so the air cleaner and carburetor

are above the crankcase.

A qualified technician must always do adjustments and maintenance. If the correct adjustments can not be made,

contact your Jacobsen Dealer.

Inspect the equipment according to the maintenance schedule and keep complete records.

a Keep the equipment clean.

b Keep all moving parts correctly adjusted and lubricated.

c Replace worn or damaged parts before you operate the mower.

d Keep all fluids at the correct level.

When you make the adjustments or repairs, do not wear jewelry or loose fitting clothing.

Refer to the illustrations in the Parts Manual for the removal and assembly of parts.

When you discard hazardous materials (engine oil, fuel), follow your local, state or federal-recommended procedures.

10.2 HEIGHT OF CUT (HOC) _____________________________________________________

The height of cut is adjusted by adding or removing 1/2 inch (1.2 cm)

spacers between the blade disk and the impeller.

1. Stop the engine, close the fuel shut-off valve and disconnect the

spark plug wire.

2. Tilt the mower on the left edge so the air filter and carburetor face

up and away from the ground to access the bottom of the deck

housing.

3. Remove the engine shaft bolt, washer and blade disk.

!

CAUTION

The blades have sharp edges. To prevent injury, use caution when

you service or hold the blade.

4. Refer to the height of cut chart and install the correct number of spacers between the blade disk and the impeller.

5. Using the correct length engine shaft bolt for the height of cut, assemble the blade disk, washer and engine shaft

bolt. Tighten the shaft bolt to 38-40 ft. lb. (51-54 Nm) for the 20 inch (50.8 cm) HoverKing or 12-14 ft.lb. (16-19

Nm) for the 16 inch (40.6 cm) HoverKing.

6. Store remaining engine shaft bolt lengths and spacers for future use.

HOC Spacers

3 inch (7.6 cm) 0 3/8-24 x 3-1/2 inch (8.9 cm) 1/4-28 x 2-3/4 inch (7 cm)

2-1/2 inch (6.4 cm) 1 3/8-24 x 3-1/2 inch (8.9 cm) 1/4-28 x 3-1/4 inch (8.3 cm)

2 inch (51 cm) 2 3/8-24 x 4-1/2 inch (11.4 cm) 1/4-28 x 3-3/4 inch (9.5 cm)

1-1/2 inch (3.8 cm) 3 3/8-24 x 4-1/2 inch (11.4 cm) 1/4-28 x 4-1/4 inch (10.8 cm)

1 inch (2.5 cm) 4 3/8-24 x 4-1/2 inch (11.4 cm) 1/4-28 x 4-3/4 inch (12.1 cm)

Engine Shaft Bolt

20 inch (50.8 cm) HoverKing

Blade Disk

Washer

Engine Shaft Bolt

16 inch (40.6 cm) HoverKing

Spacer(s)

Shaft Bolt

en-30

10 ADJUSTMENTS

10.3 BAIL CABLE ADJUSTMENT (20 INCH MOWERS) _______________________________

Adjust the bail cable to remove excess movement.

Make sure the bail cable is inserted in the correct slot in the throttle

lever.

• When the standard handle is installed, the bail cable must be

in the upper slot.

• When the optional tapered handle is installed, the bail cable

must be in the lower slot.

Use the cable adjuster as required to adjust the cable length.

Test the operation of the OPC handle.

Upper Slot

Lower Slot

• When the bail is open, the engine must not start.

• When the bail is closed, the engine will start.

• When the bail is released, the engine must stop.

Cable

Adjuster

en-31

ADJUSTMENTS 10

10.4 TORQUE SPECIFICATION ___________________________________________________

NOTICE

The torque values included in these charts are approximate and are for reference only. Use these torque values at

your risk. Jacobsen is not responsible for any loss, claim or damage caused by these charts. Always use caution

with torque values.

Jacobsen uses Grade 5 (Inch) and Grade 8.8 (Metric) Plated bolts, unless a note is given. Always check the marks on

the head of the bolts for the bolt grade. For tightening plated bolts, use the value given for lubricated.

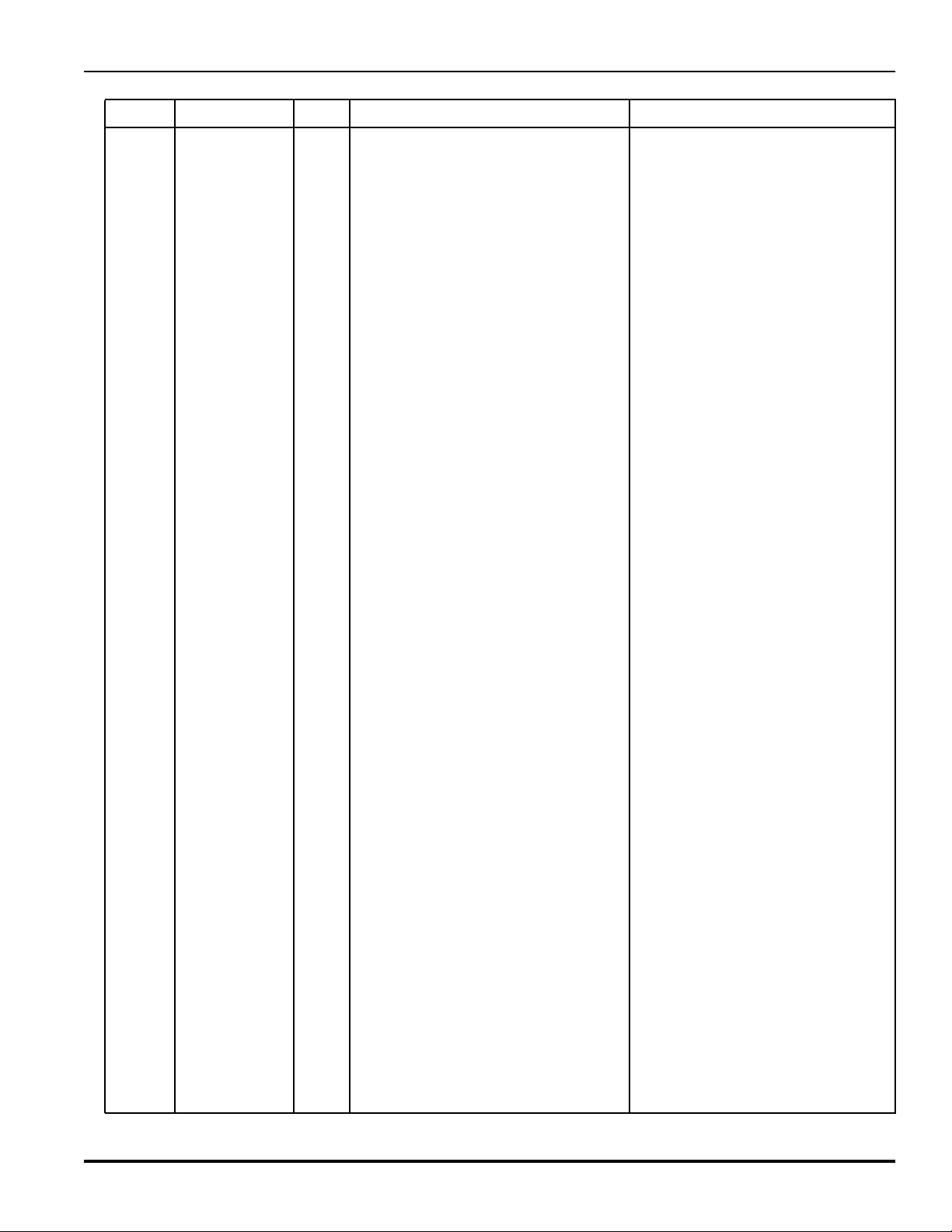

AMERICAN NATIONAL STANDARD FASTENERS

SIZE UNITS

SIZE UNITS

GRADE 5 GRADE 8

Lubricated Dry Lubricated Dry Lubri-

#6-32 in-lb (Nm) – 20 (2.3) – – 7/16-14 ft-lb (Nm) 37 (50.1) 50 (67.8) 53 (71.8) 70 (94.9)

#8-32 in-lb (Nm) – 24 (2.7) – 30 (3.4) 7/16-20 ft-lb (Nm) 42 (56.9) 55 (74.6) 59 (80.0) 78 (105)

#10-24 in-lb (Nm) – 35 (4.0) – 45 (5.1) 1/2-13 ft-lb (Nm) 57 (77.2) 75 (101) 80 (108) 107 (145)

#10-32 in-lb (Nm) – 40 (4.5) – 50 (5.7) 1/2-20 ft-lb (Nm) 64 (86.7) 85 (115) 90 (122) 120 (162)

#12-24 in-lb (Nm) – 50 (5.7) – 65 (7.3) 9/16-12 ft-lb (Nm) 82 (111) 109 (148) 115 (156) 154 (209)

1/4-20 in-lb (Nm) 75 (8.4) 100 (11.3) 107 (12.1) 143 (16.1) 9/16-18 ft-lb (Nm) 92 (124) 122 (165) 129 (174) 172 (233)

1/4-28 in-lb (Nm) 85 (9.6) 115 (13.0) 120 (13.5) 163 (18.4) 5/8-11 ft-lb (Nm) 113 (153) 151 (204) 159 (215) 211 (286)

5/16-18 in-lb (Nm) 157 (17.7) 210 (23.7) 220 (24.8) 305 (34.4) 5/8-18 ft-lb (Nm) 128 (173) 170 (230) 180 (244) 240 (325)

5/16-24 in-lb (Nm) 173 (19.5) 230 (26.0) 245 (27.6) 325 (36.7) 3/4-10 ft-lb (Nm) 200 (271) 266 (360) 282 (382) 376 (509)

3/8-16 ft-lb (Nm) 23 (31.1) 31 (42.0) 32 (43.3) 44 (59.6) 3/4-16 ft-lb (Nm) 223 (302) 298 404 315 (427) 420 (569)

3/8-24 ft-lb (Nm) 26 (35.2) 35 (47.4) 37 (50.1) 50 (67.8) 7/8-14 ft-lb (Nm) 355 (481) 473 (641) 500 (678) 668 (905)

METRIC FASTENERS

SIZE UNITS Non Critical

4.6 8.8 10.9 12.9

Lubricated Dry Lubricated Dry Lubricated Dry Lubricated Dry

M4 Nm (in-lb) ––––––3.83 (34) 5.11 (45) 2.0 (18)

M5 Nm (in-lb) 1.80 (16) 2.40 (21) 4.63 (41) 6.18 (54) 6.63 (59) 8.84 (78) 7.75 (68) 10.3 (910 4.0 (35)

M6 Nm (in-lb) 3.05 (27) 4.07 (36) 7.87 (69) 10.5 (93) 11.3 (102) 15.0 (133) 13.2 (117) 17.6 (156) 6.8 (60)

M8 Nm (in-lb) 7.41 (65) 9.98 (88) 19.1 (69) 25.5 (226) 27.3 (241) 36.5 (323) 32.0 (283) 42.6 (377) 17.0 (150)

M10 Nm (ft-lb) 14.7 (11) 19.6 (14) 37.8 (29) 50.5 (37) 54.1 (40) 72.2 (53) 63.3 (46) 84.4 (62) 33.9 (25)

M12 Nm (ft-lb) 25.6 (19) 34.1 (25) 66.0 (48) 88.0 (65) 94.5 (70) 125 (92) 110 (81) 147 (108) 61.0 (45)

M14 Nm (ft-lb) 40.8 (30) 54.3 (40) 105 (77) 140 (103) 150 (110) 200 (147) 175 (129) 234 (172) 94.9 (70)

GRADE 5 GRADE 8

Dry Lubri-

cated

cated

Dry

Fasteners into

Aluminum

en-32

11 PROBLEM SOLVING

11ProblemSolving

11.1 GENERAL________________________________________________________________

The problem solution chart lists basic problems that can occur during start and operation of the mower. For complete

information about the hydraulic and electrical systems, contact your Jacobsen Dealer.

Symptoms Possible Causes Action

Engine will not

start.

Engine hard to

start or looses

power.

Engine runs

poorly.

1. Spark plug wire is

disconnected.

2. The fuel cap breather hole

is plugged.

3. The air filter is dirty. 3. Clean or replace the air filter.

4. Air filter is soaked in

gasoline.

5. The spark plug gap is

incorrect.

6. The spark plug is pitted,

fouled or cracked

7. The fuel tank is empty Fuel

stale or dirty.

8. OPC System is not

functioning.

9. Throttle or choke lever not

in the CHOKE position

1. Fuel level low, fuel stale or

dirty.

2. Air filter dirty. 2. Clean or replace the air filter.

3. The fuel cap breather hole

is plugged.

4. Deck housing plugged with

grass clippings. Impeller air

intake blocked.

5. Engine oil too low, too high

or dirty.

6. Engine problem. 6. Consult engine manual.

1. Spark plug wire not full

connected to sprak plug

2. The spark plug gap is

incorrect.

3. The spark plug is pitted,

fouled or cracked

4. Air filter dirty. 4. Clean or replace the air filter.

5. Throttle or choke lever in

the CHOKE position.

1. Connect the spark plug wire.

2. Clean the fuel cap breather hole or replace the fuel cap.

4. Replace the air filter. Only tip the mower on the left side so

the air filter and carburetor is away from the ground.

5. Check the spark plug and adjust the gap.

6. Replace the spark plug

7. Drain and refill fuel tank with fresh gasoline.

8. Test, adjust, or repair OPC System.

9. Move throttle or choke lever to CHOKE position.

1. Fill with fresh fuel.

3. Clean the fuel cap breather hole or replace the fuel cap.

4. Remove grass clippings or dirt from bottom of deck

housing and impeller air intake around engine base.

5. Add or remove oil until the correct oil level is achieved.

Replace dirty engine oil.

1. Fully press the spark plug wire onto the spark plug.

2. Check the spark plug and adjust the gap.

3. Replace the spark plug

5. Move the throttle or choke lever to the RUN position.

en-33

Symptoms Possible Causes Action

The mower or

engine vibrates

more than normal.

1. The bottom of the deck

housing contains grass or

debris

2. The engine mounting bolts

are loose

3. Engine mount to deck

hardware is loose.

4. The blade bolts are loose

or missing.

5. The blade disk is bent or

warped.

6. One or more blades

missing.

7. A blade is bent or broken. 7. Install three new blades.

8. HOC spacers not installed

correctly.

9. Blade disk not properly

seated on impeller hub or

HOC spacer

10. Engine shaft bolt is loose. 10. Tighten the engine shaft bolt to 38 ft. lb. (51.5 Nm)

1. Clean bottom of deck housing.

2. Tighten the engine mounting bolts.

3. Tighten engine mount to deck hardware.

4. Tighten or replace all three blade bolts.

5. Replace the blade disk.

6. Install three new blades.

8. Remove and install HOC spacers properly.

9. Install blade disk so it properly seats on the hub or HOC

spacers.

PROBLEM SOLVING 11

en-34

12 NOTES

12Notes

en-35

PARTS LIST 13

13PartsList

13.1 HOW TO USE THE PARTS CATALOG__________________________________________

Abbreviations

N/S - Not serviced separately, can only be obtained by ordering main component or kit.

AR -Variable quantity or measurement is required to obtain correct adjustment.

Symbols such as ●, next to the item number, indicate that a note exists which contain additional information

important in ordering that part.

Indented Items

Indented items indicate component parts that are included as part of an assembly or another component. These parts

can be ordered separately or as part of the main component.

Item Part No. Qty Description Serial Numbers/Notes

● 1 123456 1 Mount, Valve Indicates a piece part

2 789012 1 Valve, Lift Includes Items 2 and 3

3 345678 1 • Handle Serviced part included with Item 2

4 N/S 1 • Seal Kit Non serviced part included with Item 2

5 901234 1 Screw, 1/4-20 x 2” Hex Head

13.2 TO ORDER PARTS _________________________________________________________

1. Write your full name and complete address on the order.

2. Explain where and how to make shipment.

3. Give product number, name and serial number that is stamped on the name plate or serial plate of your product.

4. Order by the quantity desired, the part number, and description of the part as given in the parts list.

5. Send or bring the order to an authorized Jacobsen Distributor.

6. Inspect all shipments on receipt. If any parts are damaged or missing, file a claim with the carrier before accepting.

7. Do not return material without a letter of explanation, listing the parts being returned. Transportation charges must

be prepaid.

13.3 PARTS CATALOG TABLE OF CONTENTS______________________________________

1.1.............................. 20 Inch HoverKing Handle........................................................................................................................... 37

2.1.............................. 16 Inch HoverKing Handle........................................................................................................................... 38

3.1.............................. 20 Inch HoverKing Deck Housing............................................................................................................... 39

4.1.............................. 16 Inch HoverKing Deck Housing............................................................................................................... 41

5.1.............................. Accessories .................................................................................................................................................. 43

en-36

HOVERKING

1.1 20 Inch HoverKing Handle

20 Inch (50.8 cm) HoverKing Mowers

Serial No. 32251 - All

7

8

1

5

3

4

4

6

3

9

10

10

Item Part No. Qty. Description Serial Numbers/Notes

1

2 4325129 1 Lower Handle

3 4325111 4 Carriage Bolt, 5/16-18 x 1-1/2”

4 4325123 4 Nut, 5/16-18 Nylon Insert Flange

5 4325122 1 Cable, Bail

6 4325121 1 Throttle Lever

7 4325110 1 Screw, 1/4-20 x 2-3/4” Hex Socket Stainless Steel

8 4325109 1 Nut, 1/4-20 Hex

9 4325119 2 Clevis Pin, 3/8 x 1-3/4”

10 4325147 2 Hair Pin

4325158 1 Upper Handle Includes Grip and Bail Handle

4325130 1 • Handle, Bail

2

9

37

> Change from previous revision

2.1 16 Inch HoverKing Handle

16 Inch (40.6 cm) HoverKing Mowers

HOVERKING

Serial No. 32257 - All

6

5

1

3

3

2

4

7

8

8

Item Part No. Qty. Description Serial Numbers/Notes

1

2 4325142 1 Lower Handle

3 4325111 4 Carriage Bolt, 5/16-18 x 1-1/2”

4 4325123 4 Nut, 5/16-18 Nylon Insert Flange

5 4325161 1 OPC Switch and Harness

6 4325108 1 Screw, 1/4-20 x 1-1/2” Hex Socket

7 4325119 2 Clevis Pin, 3/8 x 1-3/4”

8 4325147 2 Hair Pin

4325137 1 Upper Handle Includes Grip and Bail Handle

4325136 1 • Handle, Bail

4

7

> Change from previous revision

38

HOVERKING

3.1 20 Inch HoverKing Deck Housing

20 Inch (50.8 cm) HoverKing Mowers

Serial No. 32251 - All

14

15

™

HOVERKING

5

3

4

6

1

2

39

20

10

16 / 19

21

7

17

18

11

13

8

12

9

18

17

18

7

22

23

17

23

20

21

20

21

HOVERKING

Item Part No. Qty. Description Serial Numbers/Notes

1

2 4325113 1 • Decal, Banner Warning

3 4325114 1 • Decal, Blade Warning

4 4325115 1 Mount, Engine

5 N/S 1 Engine, Honda GCV160

6 4325112 4 Bolt, 3/8-16 x 1-1/8” Tri-Lobe

7 4325123 8 Nut, 5/16-18 Nylon Insert Flange

8 4325125 1 Key, 3/16” Square

9 4325120 1 Spacer, Impeller

10 4325124 1 Fan, Impeller

11 4325134 4 Spacer, HOC

12 4325152 1 Screw, 3/8-24 x 3-1/2” Grade 8 Used for 3-1/2” and 4” HOC

12 4325153 1 Screw, 3/8-24 x 4-1/2” Grade 8 Used for 2”, 2-1/2” and 3” HOC

13 4325118 1 Washer, Disk

14 4325155 1 Decal, HoverKing

15 4325156 1 Decal, Jacobsen

4325157 1 Deck, 20”

16 32252 1 20” Metal Blade Kit

17 4325116 3 • Blade, 4” Metal Package of 3 Blades

18 4325117 3 • Bolt, Blade Black Color

19 32253 1 20” Plastic Blade Kit

20 4325135 3 • Blade, 4” Plastic Package of 6 Blades