Page 1

AJ-54C Series Technical Manual 7610-002-30-91

Issued: 03-22-2006 Revised: N/A

SECTION 6: PARTS SECTION

AJ-54 CONTROL BOX ASSEMBLY

65

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16, 17

18

19

20

21

22

23

15

Page 2

AJ-54C Series Technical Manual 7610-002-30-91

Issued: 03-22-2006 Revised: N/A

SECTION 6: PARTS SECTION

AJ-54 CONTROL BOX ASSEMBLY (CONTINUED)

66

ITEM QTY DESCRIPTION Mfg. No.

1 1 Electrical Box Weldment 05700-041-88-43

2 1 Electrical Plate 05700-031-67-03

3 1 Light, Amber 05945-111-44-44

4 1 Ground Lug 05940-200-76-00

5 1 Terminal Block 05940-011-48-27

6 1 Light, Red 05945-111-44-45

7 1 Circuit Breaker (208 & 230 Volt Models Only) 05925-011-68-34

8 1 Motor Contactor 05945-111-68-38

9 1 Motor Contactor 05945-111-68-38

10 1 Switch, Manual Wash 05930-301-46-00

11 1 Overload See Chart

12 2 Heater Contactor (Electrically-Heated Models Only) 05945-002-24-70

13 1 Din Rail, 5-3/4” Long 05700-021-72-75

14 1 Transformer 05950-011-68-35

1 Transformer (575/600 Volt Models Only) 05950-002-23-77

15 2 Relay, Top Mount 05945-111-72-51

16 1 Fuse Holder (460/575/600 Volt Models Only) 05920-011-72-89

17 1 Fuse (460/575/600 Volt Models Only) 05920-011-72-88

18 1 Control Relay 05945-111-35-19

19 1 Terminal Board 05940-021-70-70

20 1 Control Box Decal 09905-021-72-29

21 1 Thermometer, Wash 06685-111-68-48

1 Decal, Wash 160°F 09905-003-00-69

22 1 Thermometer, Rinse 06685-111-68-49

1 Decal, Rinse 180°F 09905-002-97-62

23 1 Terminal Board, Screw Down 05940-021-89-41

Items not shown:

Grommet, 1/2” OD x 3/8” ID 05325-011-46-73

Bushing, Heyco SB100 05975-210-09-00

Plug, Heyco 2700 G-875 05975-011-47-81

Control Box Cover 05700-031-66-88

Control Box Cover Hinge Weldment 05700-021-68-57

Control Hinge Rod 05700-011-68-58

MANUAL/DELIME Switch (Located on rear of control box) 05930-301-22-18

MANUAL/DELIME Decal 09905-011-74-61

Copper Conductors Only Decal 09905-011-47-35

Control Box Leg 05700-011-71-47

Page 3

AJ-54C Series Technical Manual 7610-002-30-91

Issued: 03-22-2006 Revised: N/A

SECTION 6: PARTS SECTION

AJ-76 & AJ-90 CONTROL BOX ASSEMBLY

67

1

2

3, 4, 5

6

4, 7, 10, 11, 12

8

4, 9, 10

14

14

14

15

16

17

18

18

20, 21

22, 23

24, 25, 26

26, 27

26, 28

29

31

30

30

13, 26

19, 26

Page 4

AJ-54C Series Technical Manual 7610-002-30-91

Issued: 03-22-2006 Revised: N/A

SECTION 6: PARTS SECTION

AJ-76 & AJ-90 CONTROL BOX ASSEMBLY (CONTINUED)

68

ITEM QTY DESCRIPTION Mfg. No.

1 1 Electrical Box Weldment 05700-041-88-50

2 1 Decal, L1-L2-L3 09905-101-12-66

3 1 Terminal Block 05940-011-48-27

4 6 Lockwasher, #10 05311-273-02-00

5 2 Screw, 10-32 x 3/4” Long Phillips Trusshead 05305-011-62-17

6 1 Light, Amber 05945-111-44-44

7 1 Wire Lug, 2 AWG to 14 AWG 05940-200-76-00

8 1 Light, Red 05945-111-44-45

9 1 Din Rail 05700-021-94-96

10 3 Screw, 10-32 x 1/2” Long Phillips Trusshead 05305-011-39-36

11 1 Washer, Flat, 1/4” 05311-174-01-00

12 1 Decal, Ground 09905-011-86-86

13 1 Terminal Board 05940-021-70-70

14 3 Motor Contactor 05945-111-68-38

15 1 Circuit Breaker (208 & 230 Volt Models Only) 05925-011-68-34

16 1 See Motor Overloads Chart N/A

17 1 Switch, ON/FILL & OFF/DRAIN 05930-011-49-55

18 1 See Motor Overloads Chart N/A

19 1 Terminal Board 05940-021-89-41

20 2 Heater Contactor (Not Available on Steam Models) 05945-002-24-70

21 2 Screw, 10-32 x 3/8” Long Phillips Trusshead 05305-173-12-00

22 1 Transformer 05950-011-68-35

1 Transformer (575/600 Volt Models Only) 05950-002-23-77

23 4 Locknut, 10-24 with Nylon Insert 05310-373-01-00

24 1 Fuse Holder (460/575/600 Volt Models Only) 05920-011-72-89

25 1 Fuse (460/575/600 Volt Models Only) 05920-011-72-88

26 12 Screw, 6-32 x 3/8” Long Phillipshead 05305-171-02-00

27 3 Control Relay 05945-111-35-19

28 1 Relay 05945-111-72-51

29 1 Thermometer, Prewash 06685-111-68-49

30 2 Thermometer, Rinse/Wash 06685-111-87-13

1 Decal, Wash 160°F 09905-003-00-69

1 Decal, Rinse 180°F 09905-002-97-62

31 1 Decal, Gauge 09905-021-72-30

Items not shown:

Grommet, 1/2” OD x 3/8” ID 05325-011-46-73

Bushing, Heyco SB100 05975-210-09-00

Plug, Heyco 2700 G-875 05975-011-47-81

Control Box Cover 05700-031-66-88

Control Box Cover Hinge Weldment 05700-021-68-57

Control Hinge Rod 05700-011-68-58

MANUAL/DELIME Switch (Located on rear of control box) 05930-301-22-18

MANUAL/DELIME Decal 09905-011-74-61

Copper Conductors Only Decal 09905-011-47-35

Control Box Leg 05700-011-71-47

Page 5

AJ-54C Series Technical Manual 7610-002-30-91

Issued: 03-22-2006 Revised: N/A

SECTION 6: PARTS SECTION

MOTOR OVERLOADS

69

Model Volts Hz Phase Drive Motor Prewash Motor Wash Motor

AJ-54CE 208 60 1 N/A N/A N/A

AJ-54CE 230 60 1 N/A N/A N/A

AJ-54CE 208 60 3 05945-111-68-39 N/A 05945-111-68-40

AJ-54CE 230 60 3 05945-111-68-39 N/A 05945-111-68-40

AJ-54CE 460 60 3 05945-111-68-39 N/A 05945-111-68-40

AJ-54CE 575 60 3 05945-111-69-12 N/A 05945-111-68-41

AJ-54CE 600 60 3 05945-111-69-12 N/A 05945-111-81-33

AJ-54CS 208 60 1 N/A N/A N/A

AJ-54CS 230 60 1 N/A N/A N/A

AJ-54CS 208 60 3 05945-111-68-39 N/A 05945-111-68-40

AJ-54CS 230 60 3 05945-111-68-39 N/A 05945-111-68-40

AJ-54CS 460 60 3 05945-111-68-39 N/A 05945-111-68-40

AJ-54CS 575 60 3 05945-111-69-12 N/A 05945-111-68-41

AJ-54CS 600 60 3 05945-111-69-12 N/A 05945-111-81-33

AJ-76CE 208 60 1 N/A N/A N/A

AJ-76CE 230 60 1 N/A N/A N/A

AJ-76CE 208 60 3 05945-111-68-39 05945-111-68-41 05945-111-68-40

AJ-76CE 230 60 3 05945-111-68-39 05945-111-68-41 05945-111-68-40

AJ-76CE 460 60 3 05945-111-68-39 05945-111-68-41 05945-111-68-40

AJ-76CE 575 60 3 05945-111-69-12 05945-111-68-41 05945-111-68-41

AJ-76CE 600 60 3 05945-111-69-12 05945-111-68-41 05945-111-81-33

AJ-76CS 208 60 1 N/A N/A N/A

AJ-76CS 230 60 1 N/A N/A N/A

AJ-76CS 208 60 3 05945-111-68-39 05945-111-68-41 05945-111-68-40

AJ-76CS 230 60 3 05945-111-68-39 05945-111-68-41 05945-111-68-40

AJ-76CS 460 60 3 05945-111-68-39 05945-111-68-41 05945-111-68-40

AJ-76CS 575 60 3 05945-111-69-12 05945-111-68-41 05945-111-68-41

AJ-76CS 600 60 3 05945-111-69-12 05945-111-68-41 05945-111-68-41

AJ-90CE 208 60 1 N/A N/A N/A

AJ-90CE 230 60 1 N/A N/A N/A

AJ-90CE 208 60 3 05945-111-68-39 05945-111-68-41 05945-111-68-40

AJ-90CE 230 60 3 05945-111-68-39 05945-111-68-41 05945-111-68-40

AJ-90CE 460 60 3 05945-111-68-39 05945-111-68-41 05945-111-68-40

AJ-90CE 575 60 3 05945-111-69-12 05945-111-68-41 05945-111-68-41

AJ-90CE 600 60 3 05945-111-69-12 05945-111-68-41 05945-111-81-33

AJ-90CS 208 60 1 N/A N/A N/A

AJ-90CS 230 60 1 N/A N/A N/A

AJ-90CS 208 60 3 05945-111-68-39 05945-111-68-40 05945-111-68-40

AJ-90CS 230 60 3 05945-111-68-39 05945-111-68-40 05945-111-68-40

AJ-90CS 460 60 3 05945-111-68-39 05945-111-68-40 05945-111-68-40

AJ-90CS 575 60 3 05945-111-69-12 05945-111-68-41 05945-111-68-41

AJ-90CS 600 60 3 05945-111-69-12 05945-111-68-41 05945-111-81-33

Page 6

AJ-54C Series Technical Manual 7610-002-30-91

Issued: 03-22-2006 Revised: N/A

SECTION 6: PARTS SECTION

HEA TER ASSEMBLY

70

Heater Chart

Model Volts Phase KW Part Number

All* 208 1 10 06401-003-12-94

230 1 10 06401-003-12-95

208 3 10 06401-003-12-94

230 3 10 06401-003-12-95

460 3 10 06401-003-12-96

575 3 10 06401-003-12-97

575 3 18 04540-003-06-22

600 3 10 06401-003-12-97

* - AJ-54CGP, AJ-54CS, AJ-76CGP, AJ-76CS and AJ-90CS models do not use electric heaters in the wash tank or power rinse

tank.

SERVICE NOTE: When replacing the tub heaters, it is HIGHLY recommended that you also change out the gasket as well.

Once installed, gaskets become compressed and are subjected to extreme temperature changes. Replacing the gasket with a

new one when replacing the heater may prevent future leaks.

SERVICE NOTE: The nuts used to secure the heater to the tub should be torqued to 16 in-lbs. After tightening, the unit should

be allowed to heat up and operate normally for approximately 30 minutes. Secure power to the machine and check the nuts

once more to ensure that they are torqued to 16 in-lbs.

See Heater Chart Below

Heater Gasket

05330-011-47-79

5/16” Lockwasher

05311-275-01-00

5/16”-18 Hex Nut

05310-275-01-00

Page 7

AJ-54C Series Technical Manual 7610-002-30-91

Issued: 03-22-2006 Revised: N/A

SECTION 6: PARTS SECTION

HEA TER ASSEMBLY (CONTINUED)

71

The wash tank heater system is electrically connected in the circuit so that they are dependent upon the dishwasher being properly filled with and maintaining a safe water level, two thermostats (mounted in the heater box behind the dress panel), float

switch (mounted in the wash tank), and the heater relay (mounted in control box) with the heater being activated by the thermostats.

Once the dishwasher has been filled to the correct level, the heater should operate automatically. Should the tank heat be too

high, too low or no indication of temperatures at all, the following checkout should be made.

Note: The following checkout should be made by either a qualified service person or electrician.

A- Checkout of the heater system

1- If the temperature is too high, adjust thermostat using instructions on the page entitled “Thermostats”.

2- If temperature is too low, adjust thermostat as above, then:

a - Turn off power to machine by placing customer’s circuit breaker in the “OFF” position. Turn off machine

circuit breaker located on right side of control box.

b - Remove cover from control box on top of dishwasher.

c - Make sure water temperature is below 140° F.(preferably about 130°F.).

d - Turn on both circuit breakers. Observe heater relay (R1) while the power switch is turned “ON” and “OFF”.

If relay contacts move in and out, the heater relay is operating correctly: if not proceed to “C”.

B- If heater relay (R1) closes:

1 - Check power supply at incoming terminal board L1, L2 & L3. It should be the same voltage as indicated on

the machine data plate.

2 - Check power at connections on heater relay (R1). The voltage should agree with the voltage on the

machine data plate. If not, check wires for breaks or bad connections.

3 - Check power at terminals of heater which should agree with the data plate. If not check wires for breaks or

bad connections.

4 - Temperatures should rise as explained in “C-1”, and amperage may be checked according to those instructions. Replace any defective elements.

C - If heater relay (R1) does not close.

1 - There is an insulated movable insulated movable bar on relay across the top. With an insulated probe, depress

this bar and observe the thermometer: the temperature should rise noticeably in a minute or two. If it moves slowly, it would indicate that the element is faulty. If it moves constantly higher at a good rate, elements should be

good.

Note: A check with an amp probe at heater relay (R1) terminals should be made to verify the amp draw on each leg.

This should be appropriate for the voltage and phase indicated on the data plate

HEATER PROTECTION & AUTOMATIC FILL

This control is activated when the power switch is turned “ON”. The primary function is to automatically energize the wash tank

heat circuit. It will also cutoff the wash tank heat circuit should the water be accidently drained from the machine with the power

switch still “ON”. The power switch should always be turned-off before draining the unit.

This water level control consists of two (2) floats that operate when the power switch is turned on and works in conjunction with

the thermostats and heater relays.

When the power switch is turned “ON” water starts to enter the dishmachine. When it reaches the proper level the normally

open contacts in the water level float switch close activating the heating circuit for tank heat.

If the water level below the correct level while power is still on, the float switch will sense the lack of water and de-activate the

heater.

Page 8

AJ-54C Series Technical Manual 7610-002-30-91

Issued: 03-22-2006 Revised: N/A

SECTION 6: PARTS SECTION

THERMOST ATS/FRAME ASSEMBLY/DRESS PANELS

72

THERMOSTATS

The thermostat range is from 140°F to 240°F with a maximum bulb exposure temperature of 300°F.

Calibration:

Wash Thermostat:

Set Point: 165°F (Adjustable range)

Hi-LImit Thermostat:

Fixed set point: 210°F (Non-adjustable)

The hi-limit thermostat is used to protect the heater element in the event of a run away regulating thermostat or a dry fire situation. It is set for 210°F +0°F or -10°F with a fixed set point. This part is not adjustable.

The wash tank regulating thermostat will maintain the correct wash water temperature to meet NSF requirements. These specify that the wash be no lower than 160°F on hot water sanitizing machines.

To order the thermostats and corresponding decals:

Kit, Thermostat, Wash Regulating (CE Models) 06401-003-18-20

Kit, Thermostat, Wash Regulating (CS Models) 06401-003-18-21

Thermostat, High Limit Control 05930-011-49-43

1/4” Imperial Brass Fitting 05310-924-02-05

HEA

TER BOX COMPONENTS

Heater Box Weldment 05700-031-66-81

Heater Box Cover 05700-031-66-82

Terminal Board 05940-002-78-97

FRAME WELDMENTS

Model

Left to Right Part Number Right to Lef

t Part Number

AJ-54’s 05700-031-75-20 05700-031-75-20

AJ-54CGP 05700-002-65-68 05700-002-65-68

AJ-76’s 05700-031-75-25 05700-031-75-22

AJ-76CGP 05700-031-75-25 N/A

AJ-90’s 05700-031-75-26 05700-031-75-24

Bullet Feet (4 per model) - order using part number 5340-011-71-74.

FRONT DRESS P

ANELS

Model Left to Right Part Number Right to Left Part Number

AJ-54’s 05700-031-72-22 05700-031-72-22

AJ-54CGP 05700-002-63-12 05700-002-63-12

AJ-76’s 05700-031-71-85 05700-031-72-42

AJ-76CGP 05700-002-89-68 N/A

AJ-90’s 05700-031-74-06 05700-031-77-10

Page 9

AJ-54C Series Technical Manual 7610-002-30-91

Issued: 03-22-2006 Revised: N/A

SECTION 6: PARTS SECTION

73

PREWASH PLUMBING ASSEMBLY

Y-Strainer, 3/4” NPT,

Brass

04730-717-02-06

Nipple, 3/4”, Brass, Close

04730-207-34-00

Valve, Solenoid, 3/4”

04810-100-53-00

Nipple, 3/4”, Brass, Close

04730-207-34-00

Vacuum Breaker, 3/4”

04820-002-53-77

Elbow, 90°, 3/4” Brass

04730-206-04-34

Elbow, 90°, 3/4” Brass

04730-206-04-34

Nipple, 3/4” x 6” Long

05700-001-26-74

Fill Line Injector Replacement Kit

06401-003-09-93

A new gasket can be

ordered using part number 05330-111-42-81.

Replacement Kit Note:

The kit for the fill line injector comes

with the injector weldment, a new

gasket and the mounting hardware.

Page 10

AJ-54C Series Technical Manual 7610-002-30-91

Issued: 03-22-2006 Revised: N/A

SECTION 6: PARTS SECTION

74

WASH SECTION INCOMING PLUMBING ASSEMBLY

ITEM QTY DESCRIPTION Mfg. No.

1 1 Rinse Injector Replacement Kit 06401-003-11-88

1 Gasket 05330-111-42-81

2 3 Plug, Brass, 1/8” NPT 04730-209-07-37

3 2 Vacuum Breaker, 3/4” NPT 04820-002-53-77

4 3 Elbow, Street, 3/4” NPT 04730-206-04-34

5 1 Plug 04730-209-01-00

6 2 Union, Brass, 3/4” 04730-212-05-00

7 2 Solenoid Valve, 3/4” 04810-100-53-00

8 4 Nipple, Close, Brass, 3/4” NPT 04730-207-34-00

9 2 Fitting, 3/4” Male to Slip Copper 04730-401-11-01

10 1 Tube, Copper See Chart

11 1 Fill Injector Replacement Kit 06401-003-09-93

1 Gasket 05330-111-42-81

12 1 Tube, Copper See Chart

13 1 Gauge, Pressure, 0-100 PSI 06685-111-88-34

1 Decal, 15-25 PSI 09905-002-97-74

14 1 Valve, Ball, Test Cock, 1/4” NPT 04810-011-72-67

15 1 Tube, Copper See Chart

16 2 Tee, 3/4” x 3/4” x 1/2” 04730-411-03-01

17 1 Elbow, Brass, 90°, 3/4” Copper 04730-406-42-01

18 2 Tube, Copper See Chart

19 1 Regulator, Pressure, 3/4” NPT, Brass 06685-011-58-22

20 1 Nipple, Brass, 6” Long 05700-001-26-74

21 1 Tee, 3/4”, CUB x CUB x CUB 04730411-46-01

22 2 Fitting, Adapter, 1/2” to 1/4” 04730-401-41-01

1

3

2

4

20

4

7

7

6 8

8

15

17

8

6 9

10 21 12 162218 5, 16

22

13, 14

19

11 18 9

Left to right direction shown

Tube Length Chart

Item Length (Inches)

10 3/4” x 3-7/16”

12 3/4” x 2-5/8”

15 3/4” x 3”

18 3/4” x 2-13/16”

Replacement Kits Notes:

The rinse and fill injector

replacement kits come with

the injectors, gasket and

mounting hardware. The

rinse injector kit (item 1)

also has the (3) required

brass plugs.

Page 11

AJ-54C Series Technical Manual 7610-002-30-91

Issued: 03-22-2006 Revised: N/A

SECTION 6: PARTS SECTION

EXTERNAL ELECTRIC BOOSTER INCOMING PLUMBING ASSEMBLIES

75

ITEM QTY DESCRIPTION Mfg. No.

1 - Y-Strainer, 3/4” NPT, Brass 04730-717-02-06

2 - Arrestor, Water Hammer, 1/2” NPT 06685-100-05-00

3 - Regulator, Pressure, 3/4” NPT, Brass 06685-011-58-22

4 - Nipple, 3/4” NPT x 2” Long, Brass 04730-207-46-00

5 - Elbow, Brass, 90°, 3/4” 04730-206-13-00

6 - Nipple, 3/4” NPT, Close, Brass 04730-207-34-00

7 - Coupling, 3/4” FNPT x 3/4” FNPT, Brass 04730-011-87-95

8 - Adapter, 3/4” Male 04730-401-11-01

9 - Tube, Copper, 3/4” x 3-7/16” Long 05700-011-72-70

10 - Adapter, 1/2” NPT x Male 04730-401-07-01

11 - Tee, Copper, 3/4” x 3/4” x 1/2” 04730-411-03-01

1

8

9

11

9

8

2

10

3

4

5

6

7

1

3

4

7

5

6

Plumbing with Water Hammer Arrestor

Plumbing without Water Hammer Arrestor

6

Page 12

AJ-54C Series Technical Manual 7610-002-30-91

Issued: 03-22-2006 Revised: N/A

SECTION 6: PARTS SECTION

EXTERNAL ELECTRIC BOOSTER OPTION OUTLET PLUMBING

76

Elbow, Brass, 90°, 3/4”

04730-206-13-00

Nipple, 3/4” NPT x 2” Long, Brass

04730-207-46-00

Union, 3/4” NPT, Brass

04730-212-05-00

Adapter, 3/4”, Brass

04730-401-11-01

Tube, Copper, 3/4” x 24” Long

05700-021-76-53

Elbow, 3/4” Copper to Copper (Female)

04730-406-16-01

Tube, Copper, 3/4” x 49-1/2” Long

05700-031-87-98

Elbow, 3/4” Copper to Copper (Female)

04730-406-16-01

Elbow, 3/4”, 90°, Street, Copper to Copper

04730-406-40-01

Tube, Copper, 3/4” x 5-7/8” Long

05700-011-87-96

Page 13

AJ-54C Series Technical Manual 7610-002-30-91

Issued: 03-22-2006 Revised: N/A

SECTION 6: PARTS SECTION

WATER HAMMER ARRESTOR OPTION/WATER PRESSURE REGULATOR KIT OPTION

77

Nipple, 3/4” NPT,

Close, Brass

04730-207-34-00

Water Arrestor, 1/2” NPT

06685-100-05-00

Tee, 3/4” x 3/4” x 1/2”

04730-211-06-00

Water Arrestor, 1/2” NPT

06685-100-05-00

Bushing, 3/4” x 1/2”

04730-002-01-34

Tee, Brass, 3/4” x 3/4” x 3/4”

04730-211-01-34

Nipple, Close, 3/4”

04730-207-34-00

Regulator, Pressure, 3/4”

06685-011-58-22

WATER PRESSURE REGULATOR WITH ARRESTOR KIT OPTION

WATER HAMMER ARRESTOR OPTION

Page 14

AJ-54C Series Technical Manual 7610-002-30-91

Issued: 03-22-2006 Revised: N/A

SECTION 6: PARTS SECTION

78

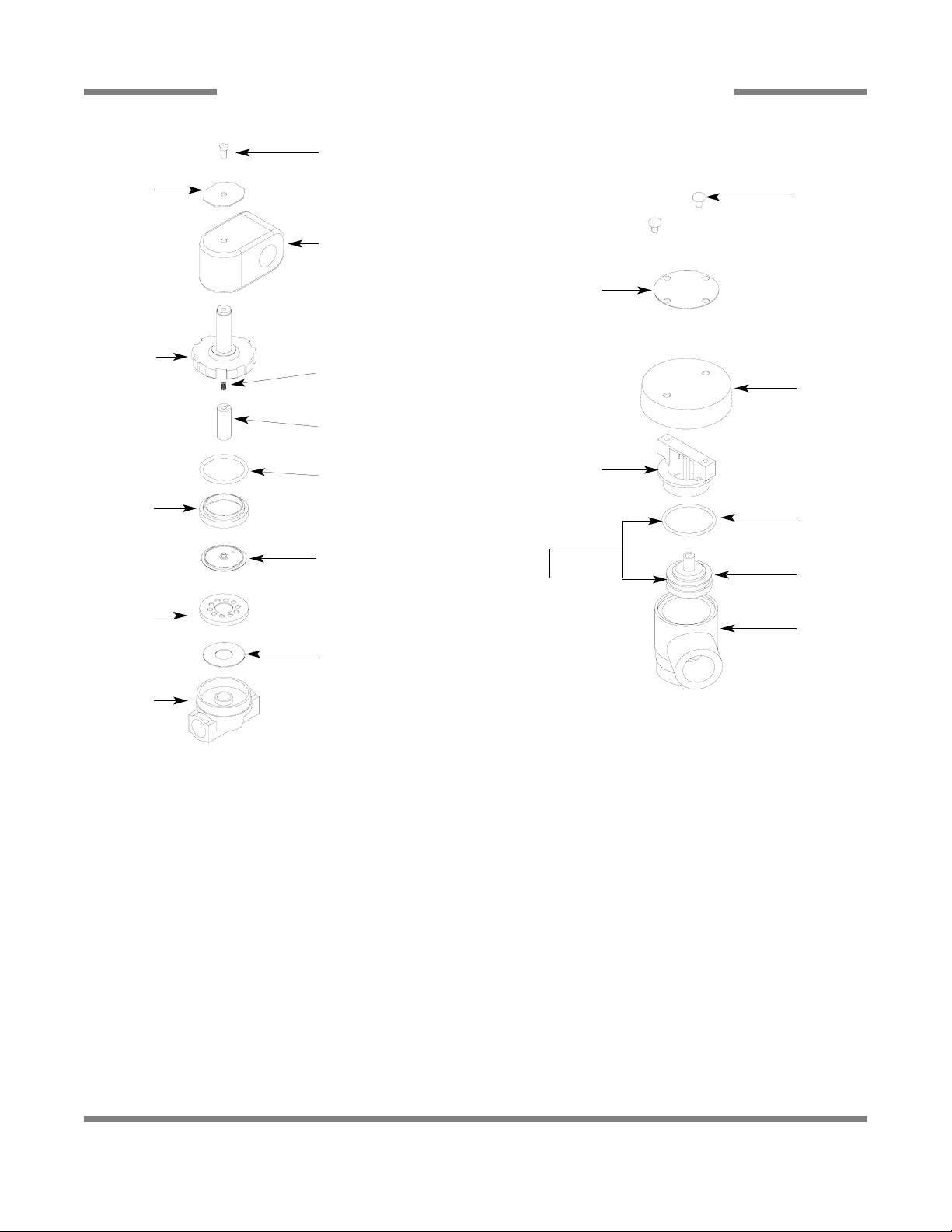

RINSE SOLENOID VALVE & VACUUM BREAKER REPAIR PARTS KITS

Complete 110 Volt Solenoid Valve Assembly, 3/4”

04810-100-53-00

Coil & Housing only, 3/4”

06401-003-07-43

Screw

Data Plate

Coil & Housing

Valve Bonnet

Spring

06401-003-07-40

Plunger

06401-003-07-40

Spring position is moved

for clarity.

Goes below the plunger.

O-Ring

06401-003-07-42

Diaphragm

Retainer

Diaphragm

06401-003-07-42

Screen

Retainer

Mesh Screen

Valve Body

Components of

Repair Kit

06401-003-06-24

Cap Screw

Data Plate

Cap

O-Ring

Plunger

Body

Cap Retainer

Complete Vacuum Breaker Assembly, 3/4” NPT

04820-002-53-77

Page 15

AJ-54C Series Technical Manual 7610-002-30-91

Issued: 03-22-2006 Revised: N/A

SECTION 6: PARTS SECTION

STEAM UNIT WASH TANK COIL ASSEMBLY

79

Order the entire assembly using part number

05700-002-11-78.

Coil Weldment

05700-002-84-03

Stand “C” Weldment

05700-002-74-84

Stand “D” Weldment

05700-002-74-85

Coil Nut

05310-011-17-85

Flat Washer

05700-001-17-87

Coil Gasket

05700-001-17-86

SERVICE NOTE: Jackson

HIGHLY recommends that the

Coil Gaskets be replaced any

time the Coil Weldment is

replaced or removed for an

extended period of time.

Stand “B” Weldment

05700-002-74-83

Page 16

AJ-54C Series Technical Manual 7610-002-30-91

Issued: 03-22-2006 Revised: N/A

SECTION 6: PARTS SECTION

STEAM PLUMBING (LEFT TO RIGHT)

80

ITEM QTY DESCRIPTION Mfg. No.

1 1 Reducer, 3/4” NPT to 1/2” NPT, Black Iron 04730-911-02-34

2 2 Union, 3/4” NPT, Black Iron 04730-912-01-00

3 4 Nipple, Close, 3/4” NPT, Black Iron 04730-907-01-00

4 1 Valve, Steam Solenoid, 3/4” NPT, 120V 04820-011-87-39

5 2 Elbow, 90°, 3/4” FNPT, Black Iron 04730-906-10-34

6 2 Elbow, Street, 90°, 3/4” NPT, Black Iron 04730-011-87-37

7 1 Y-Strainer, 3/4” NPT, Black Iron 04730-217-01-32

8 1 Valve, Gate, Steam, 3/4” NPT 04820-100-19-00

9 1 Plug, 3/8” NPT, Black Iron 04730-909-02-34

10 1 Nipple, 3/4” NPT x 47” Long 04730-021-89-26

11 1 Pipe, 3/4” NPT x 2” Long, Black Iron 04730-907-05-34

12 1 Steam Trap, 3/4” NPT 06680-500-02-77

2

3

4

10

5

3

6

8

3

7

9

15

6

11

2

3

12

STEAM INLET PLUMBING

STEAM OUTLET PLUMBING

Page 17

AJ-54C Series Technical Manual 7610-002-30-91

Issued: 03-22-2006 Revised: N/A

SECTION 6: PARTS SECTION

STEAM PLUMBING (RIGHT TO LEFT)

81

ITEM QTY DESCRIPTION Mfg. No.

1 2 Reducer, 3/4” NPT to 1/2” NPT, Black Iron 04730-911-02-34

2 2 Union, 3/4” NPT, Black Iron 04730-912-01-00

3 4 Nipple, Close, 3/4” NPT, Black Iron 04730-907-01-00

4 1 Valve, Steam Solenoid, 3/4” NPT, 120V 04820-011-87-39

5 1 Elbow, 90°, 3/4” FNPT, Black Iron 04730-906-10-34

6 1 Elbow, Street, 90°, 3/4” NPT, Black Iron 04730-011-87-37

7 1 Y-Strainer, 3/4” NPT, Black Iron 04730-217-01-32

8 1 Valve, Gate, Steam, 3/4” NPT 04820-100-19-00

9 1 Plug, 3/8” NPT, Black Iron 04730-909-02-34

10 1 Nipple, 3/4” NPT x 10” Long 04730-907-06-34

11 1 Reducer, 3/4” NPT to 1/2” NPT, Black Iron 04730-911-02-34

12 1 Elbow, 90°, 3/4” FNPT, Black Iron 04730-906-10-34

13 1 Elbow, Street, 3/4” NPT, Black Iron 04730-011-87-37

14 1 Steam Trap, 3/4” NPT 06680-500-02-77

8 9 63

7

10

5 3

3

4

1

2

1

3

2

14

STEAM INLET PLUMBING

STEAM OUTLET PLUMBING

Page 18

AJ-54C Series Technical Manual 7610-002-30-91

Issued: 03-22-2006 Revised: N/A

SECTION 6: PARTS SECTION

GAS COIL ASSEMBLY (CGP MODELS)

82

Other items used but not shown.

ITEM QTY DESCRIPTION Mfg. No.

1 1 Thermostat, High Limit 05930-011-49-43

2 1 Gasket 05330-200-02-70

3 1 Terminal Board 05940-002-78-97

4 1 Thermostat Bracket 05700-011-81-64

5 1 Decal, Thermostat Regulating 09905-011-84-31

6 1 Thermostat, Wash Regulating 06401-140-00-32

7 2 Fitting, 1/4”, Imperial Brass 05310-924-02-05

Gas Coil Weldment

05700-002-44-23

Connection point for:

Hose, Recirculating Discharge

(See “Hose Connections” page )

Connects with:

3/4” 90° Elbow Brass

04730-206-13-00

3/4” Close Brass Nipple

04730-207-34-00

Connection point for:

Hose, Wash Coil Assembly

(See “Hose Connections” page )

Connects with:

3/4” 90° Elbow Brass

04730-206-13-00

3/4” Close Brass Nipple

04730-207-34-00

Coil Box Weldment

05700-002-50-94

Gas Coil Box Cover

05700-002-48-50

Page 19

AJ-54C Series Technical Manual 7610-002-30-91

Issued: 03-22-2006 Revised: N/A

SECTION 6: PARTS SECTION

TANK, RINSE BOOSTER (CGP MODELS ONLY)

83

BOTTOM ANGLED VIEW

TOP ANGLED VIEW

ITEM QTY DESCRIPTION Mfg. No.

1 2 Plumbing Assembly, Inlet/Discharge, Rinse Tank 05700-002-51-24

2 1 Tube, Dispersion Weldment 05700-002-46-16

3 1 Tank, GP Rinse 05700-002-45-05

4 1 Bracket, Upper Rinse Tank 05700-002-67-13

5 1 Bracket, Lower Rinse Tank 05700-002-67-14

6 1 Nipple, 3/4” NPT x 4” Long 04730-207-05-00

7 3 Elbow, 3/4” NPT, 90° Brass 04730-206-13-00

8 1 Nipple, 3/4” NPT x Closed Brass 04730-207-34-00

1

7

4

8

7

6

6

2

7

1

6

Page 20

AJ-54C Series Technical Manual 7610-002-30-91

Issued: 03-22-2006 Revised: N/A

SECTION 6: PARTS SECTION

RECIRCULATING PUMP ASSEMBLY (CGP MODELS ONLY)

84

Nipple, 3/4” Close Brass

2 per

04730-207-34-00

Elbow, 3/4” 90° Brass

2 per

04730-206-13-00

Pump, Recirculating with Adapters

05700-002-51-28

Pump, Recirculating Modified

05700-002-81-22

Pump, Recirculating

06105-002-05-26

Mounting Bracket

05700-002-25-74

Mounting Bracket

05700-002-23-61

Used only on AJ-76CGP left to right units.

Used on AJ-54CGP, AJ-76CGP, AJ-90CGP units right to

left units and the AJ-54CGP left to right unit.

Page 21

AJ-54C Series Technical Manual 7610-002-30-91

Issued: 03-22-2006 Revised: N/A

SECTION 6: PARTS SECTION

HOSE CONNECTIONS (CGP MODELS ONLY)

85

HOSE ASSEMBLIES

AJ-54CGP (L-R & R-L)

AJ-76CGP (L-R)

*Each hose assembly includes 2, 3/4” Pushlock Fittings part number 04730-011-94-00.

A - Hose, Recirculating Discharge (39”) 05700-002-65-58 (31”) 05700-002-89-69

B - Hose, Recirculating Pump Suction (23 1/2”) 05700-002-65-57 (18”) 05700-002-51-38

C - Hose, Wash Coil Assembly (34”) 05700-002-52-76 (36”) 05700-002-89-72

D - Hose, Wash/Fill Supply (60”) 05700-003-03-97 (60”) 05700-003-03-97

E - Hose connection to existing gas booster outlet fitting.

F - Hose connection to existing gas booster inlet fitting.

Gas Booster Connection Kit 05700-002-51-73 includes:

18 Feet of 3/4” Hose

4 - 3/4” Push Lock Fittings

A

B

A

C

C

E

D

Recirculating Pump Assembly

Gas Coil Weldment Rinse Booster Tank

Rinse Header Plumbing Assembly

Wash/Fill Plumbing Assembly

B

F

D

Page 22

AJ-54C Series Technical Manual 7610-002-30-91

Issued: 03-22-2006 Revised: N/A

SECTION 6: PARTS SECTION

WASH/FILL PLUMBING ASSEMBLY (CGP MODELS)

86

1

5

2

3

3

4

19

6

6

7

8

9

18

6

18

5

21

15

20

10

14

11, 12

12, 13

8

16

47

ITEM QTY DESCRIPTION Mfg. No.

1 1 Rinse Injector Weldment 05700-002-57-87

1 Gasket 05330-111-42-81

2 3 Plug, 1/8” NPT, Brass 04730-209-07-37

3 2 Vacuum Breaker, 3/4” NPT 04820-002-53-77

4 2 Valve, Solenoid, 3/4” NPT, 110 Volt 04810-100-53-00

5 3 Elbow, 3/4” Street Brass 04730-206-04-34

6 4 Nipple, Close, Brass, 3/4” NPT 04730-207-34-00

7 4 Union, 3/4”, Copper to Copper 04730-212-05-00

8 2 Adapter, 3/4” Fitting x Male 04730-401-11-01

9 1 Elbow, 90° 3/4” Copper to MSPS 04730-406-42-01

10 1 Tee, 3/4”, CUB x CUB x CUB 04730-411-4601

11 2 Tee, 3/4” x 3/4” x 1/2” 04730-411-03-01

12 2 Fitting, Adapter, 1/2” to 1/4” 04730-401-41-01

13 1 Plug, 1/4” NPT, Brass 04730-209-01-00

14 1 Test Cock, Valve, Ball, 1/4” NPT 04810-011-72-67

15 1 Gauge, Pressure, 0-100 PSI 06685-111-88-34

1 Decal, 15-25 PSI 09905-002-97-74

16 1 Nipple, Brass, 6” Long 05700-001-26-74

17 1 Fill Injector 05700-011-67-99

1 Gasket 05330-111-42-81

18 1 Tube, Copper, 3/4” x 2 13/16” Long 05700-011-72-72

19 1 Tube, Copper, 3/4” x 3 7/16” Long 05700-011-72-70

20 1 Tube, Copper, 3/4” X 3” Long 05700-000-54-85

21 1 Tube, Copper, 3/4” x 2 5/8” Long 05700-011-72-71

22 1 Elbow, 3/4” NPT, 90° Brass 04730-206-13-00

To order the AJ-54CGP left to right or right to left model use part number

05700-002-51-17.

To order the AJ-76CGP left to right model as shown (right to left

model is not available) use part number 05700-002-51-17.

Page 23

AJ-54C Series Technical Manual 7610-002-30-91

Issued: 03-22-2006 Revised: N/A

SECTION 6: PARTS SECTION

RINSE HEADER PLUMBING ASSEMBLY (CGP MODELS)

87

Complete Plumbing Assembly

05700-002-51-16

Incoming Piping Assembly

05700-002-51-15

Incoming Plumbing Support Bracket

05700-002-50-70

Nipple, 3/4” Close Brass

04730-207-34-00

Solenoid Valve, 3/4” 110V

04810-100-53-00

Valve, 3/4” Pressure Reducing

04820-002-51-53

Y-Strainer, 3/4” Brass

04730-717-02-06

Inlet Plumbing Mounting Bracket

2 per

05700-002-51-41

Clamp, Pipe

2 per

05700-000-35-06

Elbow, 3/4” NPT 90° Brass

04730-206-13-00

Nipple, 3/4” Close Brass

04730-207-34-00

Page 24

AJ-54C Series Technical Manual 7610-002-30-91

Issued: 03-22-2006 Revised: N/A

SECTION 6: PARTS SECTION

AJ-54 SERIES DRAIN PLUMBING ASSEMBLIES

88

AJ-54 Series Ball Valve Handle Assembly

05700-021-83-53

AJ-54CGP Ball Valve Handle Assembly

05700-021-84-74

Ball Valve, 1-1/2” NPT

04820-111-71-46

Elbow, 1-1/2” Brass 90° Street

04730-206-32-00

AJ-54CGP Complete Drain Assembly

05700-002-52-71

AJ-54 Series Complete Drain Assembly

05700-031-70-10

Nipple, 1-1/2” Brass, Close

04730-207-40-00

Tee, 1-1/2” Brass

04730-011-69-93

Nipple, Rinse Weldment

05700-021-84-61

Fitting, Barbed, 1-1/2” NPT x 1-1/2”

04730-011-69-92

Page 25

AJ-54C Series Technical Manual 7610-002-30-91

Issued: 03-22-2006 Revised: N/A

SECTION 6: PARTS SECTION

AJ-76 DRAIN PLUMBING ASSEMBLIES

89

Tube, Copper, 1-1/2” x 10-1/8” Long

05700-002-99-00

Adapter, Male to Female, 1-1/2”

04730-401-25-01

Elbow, 1-1/2” FNPT, 90°, Brass

04730-011-73-77

Tube, Copper, 1-1/2” x 4-5/8” Long

05700-002-98-98

Tube, Copper, 1-1/2” x 6-3/8” Long

05700-002-98-99

Left to Right Plumbing

Assembly

Connector, No-Hub, 1-1/2”

4720-604-06-00

Valve, Ball, 1-1/2”

04820-111-71-46

Ball Valve Handle Assembly

05700-021-84-74

Nipple, Brass, Close, 1-1/2” NPT

04730-207-40-00

Nipple, Brass, 3” NPT

04730-011-87-04

Tee, Brass, 1-1/2” x 1-1/2” x 1-1/2”

04730-011-69-93

Tube, Copper, 1-1/2” x 6-3/8” Long

05700-002-98-99

Tube, Copper, 1-1/2” x 4-5/8” Long

05700-002-98-98

Tube, Copper, 1-1/2” x 10-1/8” Long

05700-002-99-00

Nipple, Rinse Weldment

05700-021-84-61

Elbow, Brass,

Street, 1-1/2” NPT

04730-206-32-00

Right to Left Plumbing

Assembly

All parts are common to both assemblies.

Page 26

AJ-54C Series Technical Manual 7610-002-30-91

Issued: 03-22-2006 Revised: N/A

SECTION 6: PARTS SECTION

AJ-90 DRAIN PLUMBING ASSEMBLIES

90

Tube, Copper, 1-1/2” x 17-1/4” Long

05700-021-88-16

Elbow, 1-1/2” FNPT, 90°, Brass

04730-011-73-77

Tube, Copper, 1-1/2” x 13-3/4” Long

05700-021-88-17

Valve, Ball, 1-1/2”

04820-111-71-46

Tube, Copper, 1-1/2” x 5-1/16” Long

05700-021-88-13

Left to Right Plumbing

Assembly

Adapter, Male to Female, 1-1/2”

04730-401-25-01

Tube, Copper, 1-1/2” x 5-1/16” Long

05700-021-88-13

Tube, Copper, 1-1/2” x 13-3/4” Long

05700-021-88-17

Connector, No-Hub, 1-1/2”

4720-604-06-00

Ball Valve Handle Assembly

05700-021-84-74

Nipple, Brass, Close, 1-1/2” NPT

04730-207-40-00

Nipple, Brass, 3” NPT

04730-011-87-04

Tee, Brass, 1-1/2” x 1-1/2” x 1-1/2”

04730-011-69-93

Nipple, Rinse Weldment

05700-021-84-61

Elbow, Brass, Street, 1-1/2” NPT

04730-206-32-00

Right to Left Plumbing

Assembly

All parts are common to both assemblies.

Tube, Copper, 1-1/2” x 17-1/4” Long

05700-021-88-16

Page 27

AJ-54C Series Technical Manual 7610-002-30-91

Issued: 03-22-2006 Revised: N/A

SECTION 6: PARTS SECTION

AJ-76CGP (LEFT TO RIGHT) DRAIN PLUMBING ASSEMBLY

91

ITEM QTY DESCRIPTION Mfg. No.

1 6 Adapter, Male to Female, 1-1/2” 04730-401-25-01

2 3 No-Hub Connector 4720-604-06-00

3 3 Tee, Brass, 1-1/2” FNPT 04730-011-69-93

4 2 Ball Valve, 1-1/2” FNPT 04820-011-71-46

* 2 Valve Handle Weldment Assembly (Not Shown) 05700-021-84-74

5 2 Nipple, Brass, Close, 1-1/2” NPT 04730-207-40-00

6 2 Elbow, Brass, 90°, 1-1/2” FNPT 04730-011-73-77

7 1 Tube, Copper, 1-1/2” x 1-3/4” Long 05700-000-75-57

8 1 Rinse Nipple Weldment 05700-021-84-61

9 2 Tube, Copper, 1-1/2” x 3-1/2” Long 05700-011-84-23

10 2 Tube, Copper, 1-1/2” x 7-1/2” Long 05700-002-50-98

11 1 Nipple, Brass, 1-1/2” NPT x 3” Long 04730-011-87-04

12 1 Tube, Copper, 1-1/2” x 4-1/4” Long 05700-011-88-40

1 Entire Assembly 05700-002-89-64

6

6

5 2

2

1

3

4*

8

5

9

9

4*

3 1

2

1

1

10

11

Plumbing, Prewash Overflow

05700-002-51-05

Plumbing, Prewash Drain

05700-002-51-06

12

Plumbing, Wash Tank Drain

05700-002-89-65

10

13

3

5

7

Plumbing, Drain Connection

05700-002-51-08

(Right to left model not available.)

Page 28

AJ-54C Series Technical Manual 7610-002-30-91

Issued: 03-22-2006 Revised: N/A

SECTION 6: PARTS SECTION

DRAIN QUENCH SYSTEM

92

From the existing drain, attach the two additional Tees (Item 7) using the 1-1/2” NPT Close Nipples (Item 8). Tighten the

Reducers (Items 6 & 9) into the Tees as shown above. Attach the Modified Compression Fitting (Item 10) into the 1-1/2” to 1/4”

Reducer (Item 9). Position the bulb of the thermostat (Item 1) so that it rests approximately 1/4” from the bottom of the Tee (Item

7). Tighten the Modified Compression Fitting (Item 10) as required.

Mount the Thermostat (Item 1) to the tub using the Thermostat Bracket (Item 2) and set it for 120

°

F - 140°F. Install the Solenoid

Valve (Item 3) to the second Tee (Item 7) and then attach to the incoming cold water line. Use pipe dope or thread tape as

required to prevent any leaks.

Thermostat

05930-121-67-72

Thermostat Bracket

05700-002-73-72

Solenoid Valve

04810-100-09-18

To Cold Water Supply

Nipple, Close, 1/2” NPT

04730-207-15-00

Valve, Check, 1/2”

04820-002-55-77

Reducer, 1-1/2” to 1/2”

04730-002-55-75

Tee, 1-1/2” x 1-1/2” x 1-1/2”

04730-011-69-93

Modified Compression

Fitting

05700-001-16-52

Reducer, 1-1/2” x 1/4”

04730-002-55-76

To Dishmachine Drain

To Drain

Nipple, 1-1/2” NPT

04730-207-40-00

Drain Quench Assembly

06401-002-44-07

Page 29

AJ-54C Series Technical Manual 7610-002-30-91

Issued: 03-22-2006 Revised: N/A

SECTION 6: PARTS SECTION

93

MOTOR ASSEMBLIES

WASH MOTOR CHART

Volts Phase Hz Motor Part Number Kit Part Number

208 - 230 1 60 06105-021-70-57 06401-003-09-97

200 - 230 3 60 06105-121-70-58 06401-003-09-98

460 3 60 06105-121-70-58 06401-003-09-98

575 3 60 06105-002-48-31 06401-003-09-99

600 3 60 06105-002-48-31 06401-003-09-99

PREW

ASH MOTOR CHART

Model(s) Volts Phase Hz Part Number Kit Part Number

AJ-76’s 208 1 60 06105-121-70-55 06401-003-10-40

230 1 60 06105-121-70-55 06401-003-10-40

200 3 60 06105-121-70-56 06401-003-10-38

220 3 60 06105-121-70-56 06401-003-10-38

230 3 60 06105-121-70-56 06401-003-10-38

460 3 60 06105-121-70-56 06401-003-10-38

575 3 60 06105-002-48-31 06401-003-10-41

600 3 60 06105-002-48-31 06401-003-10-41

AJ-90’s 208 1 60 06105-121-70-57 06401-003-10-42

230 1 60 06105-121-70-57 06401-003-10-42

200 3 60 06105-121-70-58 06401-003-10-43

220 3 60 06105-121-70-58 06401-003-10-43

230 3 60 06105-121-70-58 06401-003-10-43

460 3 60 06105-121-70-58 06401-003-10-43

575 3 60 06105-002-48-31 06401-003-10-41

600 3 60 06105-002-48-31 06401-003-10-41

See Motor

Chart Below

Key, 3/16” x 1” Long

Pump Plate

05700-021-71-83

Cap Screw, 3/8”-16 x 2”

05305-011-74-98

Wash Impeller Replacement Kit

06401-003-10-51

Prewash Impeller Replacement Kit

06401-003-10-55

Pump Seal

06401-003-06-73

Impeller Washer Bolt, 1/4”-20 x 3/4”

Motor Mounting Gasket

06401-003-06-75

Replacement Kit Notes:

The impeller replacement kits come with the

impeller, washer, key and bolt. The motor kits

come with everything detailed above as well as

two new mounting gaskets.

Kit, Motor Brkt Replace

06401-021-73-42

Clamp, 4 1/8” - 7” (Not Shown)

04730-002-32-15

Page 30

AJ-54C Series Technical Manual 7610-002-30-91

Issued: 03-22-2006 Revised: N/A

SECTION 6: PARTS SECTION

94

PREWASH & WASH PUMP WELDMENTS

Intake Suction Scoop Weldment

05700-021-87-60

Prewash Intake

Strainer Weldment

05700-021-74-96

Prewash Strainer

Bracket

05700-021-74-94

Prewash Pump Weldment

AJ-76/AJ-90 Right to Left models:

05700-002-11-96

Wash Pump

Weldment

05700-041-68-88

Prewash Pump Weldment

AJ-76/AJ-90 Left to Right models:

05700-002-10-62

Prewash Pump Weldment

AJ-76CGP Left to Right model

05700-002-43-56

Scoop, Intake Suction Wash

Weldment

05700-002-51-20

Pump Discharge

Weldment

05700-002-50-90

Gasket

05330-002-54-55

Wash Pump Weldment

05700-002-50-92

Prewash Pump Weldment

AJ-76CGP Right to Left model

05700-002-42-69

Page 31

AJ-54C Series Technical Manual 7610-002-30-91

Issued: 03-22-2006 Revised: N/A

SECTION 6: PARTS SECTION

95

PREWASH ARM/UPPER WASH ARM ASSEMBLY

Lanyard

05340-011-72-46

End Cap Replacement Kit

06401-003-10-19

Upper Wash Arm Manifold Weldment

05700-031-75-07

Cap, Wash Tube

05700-021-69-68

Service Note:

When replacing the 10-32 screws in the End Caps, it

is recommended that a thread locking fluid be used to

ensure that the screws do not back out during normal

operation.

Replacement Kit Note:

The replacement kit for the end cap

includes the endcap, lanyard, mounting

screw and the locknut.

Upper Wash Manifold Support Bracket

05700-021-73-97

End Cap

Replacement Kit

06401-003-10-19

Replacement Kit Note:

The replacement kit for the end cap

includes the endcap, lanyard, mounting

screw and the locknut.

Prewash Tube

Weldment

05700-001-16-89

Complete Prewash Arm Assembly

05700-021-74-65

Complete Upper Arm Assembly

05700-031-75-33

Page 32

AJ-54C Series Technical Manual 7610-002-30-91

Issued: 03-22-2006 Revised: N/A

SECTION 6: PARTS SECTION

LOWER WASH ARM ASSEMBLY

96

Screw, 10-32 x 3/8” Truss Head

05305-173-12-00

Complete Lower Wash Arm Assembly

05700-031-75-32

End Cap Replacement Kit

06401-003-10-19

Lanyard

6 per

5340-011-72-46

Locknut, 10-24 with Nylon Insert

05310-373-01-00

Lower Wash Arm Manifold Weldment

05700-031-75-06

Manifold Quick-Release Key

05700-011-94-45

SERVICE NOTE: When replacing the 10-32 screws in the End Caps, it is recommended that a thread locking fluid be used to

ensure that the screws do not back out during normal operation.

Lower Wash Arm Support Bracket

05700-011-71-20

Secured with Locknut, 1/4”-20 with Nylon Insert

05310-374-01-00

Replacement Kit Note:

The replacement kit for the end cap includes the endcap, lanyard, mounting screw and the locknut.

Page 33

AJ-54C Series Technical Manual 7610-002-30-91

Issued: 03-22-2006 Revised: N/A

SECTION 6: PARTS SECTION

97

CURTAINS/TUB MAGNETS

Curtain, 21” Long x 20-1/2” Wide

08415-131-73-45

Curtain, 12” Long x 20-1/2” Wide

08415-131-73-44

Curtain Rod

05700-021-73-43

Long Curtain Decal

09905-011-73-84

Short Curtain Decal

09905-011-73-82

Curtain, 24 1/2” Long x 20-1/2” Wide

CGP MODELS ONLY

08415-002-47-37

Extra Long Curtain Decal

CGP MODELS ONLY

09905-002-52-69

Middle Curtain Hook

05700-011-72-65

Curtain Hook

05700-011-83-54

Limit Switch Bracket

05700-021-71-18

Conveyor Switch Replacement Kit

06401-003-11-79

Replacement Kit Note:

The conveyor switch replacement kit

comes with the switch, a terminal and

a wire nut.

Service Note:

The cord for the conveyor switch needs to be cut to length in the field

and have the pink terminal applied there.

Page 34

AJ-54C Series Technical Manual 7610-002-30-91

Issued: 03-22-2006 Revised: N/A

SECTION 6: PARTS SECTION

98

FINAL RINSE ASSEMBLY

Final Rinse Manifold Weldment

05700-021-74-88

Upper Rinse Arm Replacement Kit

06401-003-10-08

Lower Rinse Arm Replacement Kit

06401-003-10-09

Rinse Pan Strainer Weldment

05700-041-85-09

Rinse Drain Control Plate

05700-011-68-70

Rinse Drain Control Plate

05700-011-68-70

Rinse Drain Overflow Plate

05700-002-53-62

Left Rinse Pan Locator Bracket

05700-021-92-38

Right Rinse Pan Locator Bracket

05700-021-92-37

Rinse Tray Weldment

(All models except CGP)

05700-031-66-75

Rinse Tray Weldment

(CGP models only)

05700-031-66-75

Optional Parts for CGP

Models

Locknut, 1/4”-20 with Nylon Insert

05310-374-01-00

End plugs can be ordered using

part number 04730-209-07-37.

O-Ring

05330-011-74-55

Retaining Ring (Not Shown)

05340-112-01-11

Gasket

05330-111-42-81

Rinse Arm

Support Bracket

05700-011-71-19

Replacement Kit Note:

The replacement kits for the rinse

arms have the rinse arms, end caps, orings and the retaining rings.

Page 35

AJ-54C Series Technical Manual 7610-002-30-91

Issued: 03-22-2006 Revised: N/A

SECTION 6: PARTS SECTION

DRIVE ASSEMBLY

99

1

2

3

4

11

12

13

18

17

14

15

16

5

6

7

8

9

10

See Detail A

Page 36

AJ-54C Series Technical Manual 7610-002-30-91

Issued: 03-22-2006 Revised: N/A

SECTION 6: PARTS SECTION

100

DRIVE ASSEMBLY (CONTINUED)

ITEM QTY DESCRIPTION Mfg. No.

1 1 Drive Plate and Rod Weldment 05700-021-67-44

Replacement Kit with Expansion Legs 06401-021-86-80

Replacement Kit with Expansion Legs/Adjuster Crank 06401-011-94-54

2 1 Adjuster Crank Assembly 05700-021-69-95

3 1 Skotch Yoke Weldment Replacement Kit 06401-003-08-48

4 2 Coupling & Expansion Leg Weldment 05700-021-67-50

5 1 Pawl Bar Drive Linkage Casting 09515-021-87-73

6 1 Spacer Plate 05700-011-67-58

7 2 Pillow Block Replacement Kit 06401-003-08-50

8 2 Shaft Collar 05700-011-89-18

9 1 Drive Socket 05700-021-67-39

10 1 Drive Plate 05700-021-67-42

11 2 Pillow Block 03120-021-71-87

12 1 Drive Spring 05315-011-83-51

13 2 Shaft Collar 05700-011-89-18

14 1 Drive Motor Mounting Bracket 05700-031-73-56

15 1 Adjuster Spring 05315-011-71-90

16 1 Adjusting Handle Weldment 05700-021-72-28

17 1 Drive Motor Replacement Kits

Drive Motor (50 Hz Models) 06401-003-08-41

1 Drive Motor (208-230 Volt, 60 Hz, Single Phase Models) 06401-003-08-42

Drive Motor (208-230 Volt, 60 Hz, Three Phase Models) 06401-003-08-40

Drive Motor (600 Volt, 60 Hz, Three Phase Models) 06401-003-08-43

18 1 Gear Drive 06105-011-87-20

19 1 Roller Bearing 03120-011-71-81

20 1 Drive Hub 05700-011-67-97

19

20

Detail A

Front Drive Motor Cover

Replacement Kit

06401-003-11-64

Rear Drive Motor Cover

Replacement Kit

06401-003-10-18

Replacement Kits Notes:

The replacement kits for the drive motor covers come

with the weldments and the mounting hardware.

Page 37

AJ-54C Series Technical Manual 7610-002-30-91

Issued: 03-22-2006 Revised: N/A

SECTION 6: PARTS SECTION

LUBRICATION CHART FOR DRIVE GEAR

101

Note: The maintenance procedures detailed here are manufacturer’s instructions for the WINSMITH brand of gear reducer

that is installed on the rack conveyors covered in this manual.

Ambient Temperature -30 - 15°F 16 - 50°F 51 - 95°F 51 - 95°F 96 - 131°F 96 - 131°F

Final Stage Worm Speed

1

up to 2000 FPM up to 2000 FPM up to 450 FPM above 450 FPM up to 450 FPM above 450 FPM

ISO Viscosity Grade 220 460 680 460 680 460

1

AGMA Lubricant No. 5S #7 Compounded #8 Compounded #7 Compounded 8S 7S

Mobil SHC 630 600W Super Extra Hecla Super 600W Super SHC 636 SHC 634

Cylinder Cylinder

American Lubricants SHC-90W AGMA #7 Gear Oil AGMA #8 Gear Oil AGMA#7 Gear Oil N/A N/A

Castrol Tribol 800/220 Tribol 1105-7C Tribol 1105-8C Tribol 1105-7C Tribol 800/680 Tribol 800/460

Chevron Tegra 220 Cylinder Oil W460 Cylinder Oil W680 Cylinder Oil W460 Tegra 680 Tegra 460

Conoco Syncon R & O Inca Oil 460 Inca Oil 680 Inca Oil 460 N/A Syncon R & O

220 460

Exxon (Esso) Teresstic SHP220 Spartan EP460 Spartan EP680 Spartan EP460 Teresstic SHP 680 Teresstic SHP

460

Fiske Brothers SPO-MG SPO-277 SPO-288 SPO-277 N/A N/A

Shell Omala RL 220 Valvata J 460 Valvata J 680 Valvata J 460 Omala RL 680 Omala RL 460

Texaco Pinnacle 220 Vanguard 460 Vanguard 680 Vanguard 460 Pinnacle 680 Pinnacle 460

(1) The sliding velocity in feet per minute (FPM) for standard ratios is determined by multiplying the speed of the worm in RPM by

the factor from the table below. For selecting proper lubricant, use the speed of the worm in the final stage (input RPM divided by

the first stage ratio).

Page 38

AJ-54C Series Technical Manual 7610-002-30-91

Issued: 03-22-2006 Revised: N/A

SECTION 6: PARTS SECTION

102

DOOR ASSEMBLIES

ITEM QTY DESCRIPTION Mfg. No.

1 1 Wash Door Weldment 05700-003-13-35

2 1 Prewash Door Weldment

Left to Right Model 05700-003-13-42

Right to Left Model 05700-003-13-40

3 1 Screw, 8-32 x 1/4” Long 05305-172-09-00

4 1 Door Switch Magnet 05700-111-51-68

5 1 Door Guide 05700-111-70-92

6 1 Door Stop Weldment, Right 05700-002-96-33

7 1 Door Stop Weldment, Left 05700-002-96-32

8 2 Locknut, 10-24 SS Hex with Nylon Insert 05310-373-01-00

9 2 Door Stop Weldment, Prewash 05700-002-05-46

Wash Door Handle Weldment

05700-011-82-63

Prewash Door Handle Weldment

05700-011-80-45

Wash Door Hood Support: 05700-031-84-13

22” Prewash Door Hood Support: 05700-031-84-14

Door Stiffener (Not Shown) 05700-031-83-43

Door Catch Weldment

05700-031-84-80

2

Locknut, 1/4”-20 with Nylon Insert

05310-374-01-00

1

5

7

8

8

6

3

4

Left Door Guide Weldment

05700-002-32-51

Right Door Guide Weldment

05700-031-76-44

Page 39

AJ-54C Series Technical Manual 7610-002-30-91

Issued: 03-22-2006 Revised: N/A

SECTION 6: PARTS SECTION

103

PAWL BAR MISCELLANEOUS COMPONENTS

Pawl Bar Gutter Weldment Replacement Kit

06401-003-09-95

Bottom Guide Block

Top Guide Block

Pawl Bar Gutter Gasket

05330-011-68-55

Replacement Kits Notes:

The pawl bar gutter weldment

replacement kit contains the weldment, a gasket and the mounting

hardware. The guide block kit contains both blocks and a gasket.

Service Note: It is highly recommended that when

changing out one guide block, that the other be changed

out as well, along with the gasket.

Guide Block Replacement Kit

06401-003-10-15

Pawl Bar Roller Replacement Kit

06401-003-11-80

Replacement Kit Notes:

The replacement kit for the pawl bar roller comes with the roller, roller

shaft, hardware and locknut as shown.

Pawl Bar Bracket (with studs) Weldment

05700-031-84-68

Pawl Bar Bracket (without tabs) Weldment

05700-031-92-36

Page 40

AJ-54C Series Technical Manual 7610-002-30-91

Issued: 03-22-2006 Revised: N/A

SECTION 6: PARTS SECTION

AJ-54 PAWL BAR ASSEMBLY

104

Pawl Bar Dog Casting

12 per

05700-021-69-00

Pawl Bar Spacer

24 per

05700-011-71-45

Pawl Bar Weldment

05700-031-75-09

AJ-54 Complete Assembly with Hardware

06401-131-81-01

AJ-54 Prison Assembly with Hardware

06401-231-81-01

Page 41

AJ-54C Series Technical Manual 7610-002-30-91

Issued: 03-22-2006 Revised: N/A

SECTION 6: PARTS SECTION

AJ-76 PAWL BAR ASSEMBLIES

105

Left to Right Assembly

Pawl Bar Weldment

05700-031-75-18

Pawl Bar Spacer

05700-011-71-45

Pawl Bar Dog Casting

05700-021-69-00

Pawl Bar Weldment

05700-031-82-00

Right to Left Assembly

AJ-76 Complete L-R Assembly

06401-141-81-04

AJ-76 Complete R-L Assembly

06401-241-81-04

AJ-76 Prison Assembly

06401-341-81-04

Page 42

AJ-54C Series Technical Manual 7610-002-30-91

Issued: 03-22-2006 Revised: N/A

SECTION 6: PARTS SECTION

AJ-90 PAWL BAR ASSEMBLIES

106

Left to Right Assembly

Bolt, 3/8”-16 x 1-3/4” Long

5306-011-36-94

Locknut, 3/8”-16 with Nylon Insert

05700-011-72-55

Pawl Bar Spacer

05700-011-71-45

Pawl Bar Dog Casting

05700-021-69-00

Pawl Bar Weldment

05700-031-74-19

Right to Left Assembly

All associated hardware, spacers and castings may be

ordered using the part numbers indicated in the above

assembly.

Pawl Bar Weldment

05700-041-82-01

Both assemblies contain 20 pawl bar dog castings. Please

note the direction of installation as indicated on the above

drawings. When replacing pawl bar dog castings, ensure to

re-install in the appropriate direction. If you do not, then the

rack will not be pulled through the machine during operation.

AJ-90 Complete L-R Assembly

06401-141-81-05

AJ-90 Complete R-L Assembly

06401-241-81-05

AJ-90 Prison Assembly

06401-341-81-05

Page 43

AJ-54C Series Technical Manual 7610-002-30-91

Issued: 03-22-2006 Revised: N/A

SECTION 6: PARTS SECTION

AJ-54 RACK RAIL ASSEMBLY

107

Spacer

6 per

05700-011-71-44

Limit Switch Actuator Assembly

1 per

05700-021-77-03

Actuator Switch Replacement Kit

06401-003-10-14

Rack Rail Weldment

05700-031-81-95

Opposite Rack Rail

05700-041-75-29

Replacement Kit Note:

The replacement kit for the actuator

switch comes with the switch, two spacers and the mounting hardware.

Page 44

AJ-54C Series Technical Manual 7610-002-30-91

Issued: 03-22-2006 Revised: N/A

SECTION 6: PARTS SECTION

AJ-76 RACK RAIL ASSEMBLIES

108

Rack Guide Weldment

05700-031-75-53

Actuator Switch

Replacement Kit

06401-003-10-99

Actuator Switch Replacement Kit

06401-003-10-14

Actuator Assembly

05700-002-91-11

Spacer

6 per

05700-011-71-44

Left to Right Assembly

Rack Guide Weldment

05700-041-75-47

Opposite Rack Rail

05700-041-75-46

Actuator Switch Replacement Kit

06401-003-10-86

Actuator Switch Replacement Kit

06401-003-10-14

Actuator Assembly

05700-021-77-03

Spacer

6 per

05700-011-71-44

Right to Left Assembly

Opposite Rack Rail

05700-041-75-46

Replacement Kit Notes:

The replacement kits for the actuator

switches come with the switch, two spacers

and the mounting hardware.

Page 45

AJ-54C Series Technical Manual 7610-002-30-91

Issued: 03-22-2006 Revised: N/A

SECTION 6: PARTS SECTION

AJ-90 RACK RAIL ASSEMBLIES

109

Rack Guide Weldment

05700-031-81-55

Opposite Rail

05700-041-75-99

Actuator Switch Replacement Kit

06401-003-10-14

Limit Switch Actuator Assembly

05700-002-91-11

Left to Right Assembly

Actuator Switch Replacement

Kit

Rack Guide Spacer

05700-011-71-44

Right to Left Assembly

Limit Switch Actuator Assembly

05700-021-77-03

Rack Guide Spacer

05700-011-71-44

Actuator Switch Replacement Kit

06401-003-10-85

Actuator Switch Replacement Kit

06401-003-10-14

Rack Guide Weldment

05700-031-81-56

Opposite Rail

05700-041-75-98

Replacement Kit Notes:

The replacement kits for the actuator switches come with the

switch, two spacers and the

mounting hardware.

Page 46

AJ-54C Series Technical Manual 7610-002-30-91

Issued: 03-22-2006 Revised: N/A

SECTION 6: PARTS SECTION

110

MISCELLANEOUS PARTS AND WELDMENTS

Run Off Sheet Weldment

05700-021-71-39

Plate, Right Water

Directional

05700-021-79-23

Plate, Left Water

Directional

05700-021-79-27

Splash Shield Weldment

05700-031-85-16

Hole Direction Plate Replacement Kit

06401-003-10-00

Replacement Kit Note:

The kit for the hole direction plate comes

with the plate, a new gasket and the

mounting hardware.

Pipe Clamp

05700-000-35-05

Rinse Drain Plate Replacement

Kit

(CGP Models Only)

06401-003-10-07

Rinse Drain Plug Replacement Kit

06401-003-10-06

Rinse Drain Weldment Replacement Kit

06401-003-10-05

Rinse Drain Plate Gasket

05330-011-72-27

Replacement Kits Notes:

The kits for the drain weldments and

drain plugs come with the

weldments/parts, a new gasket and the

mounting hardware.

Page 47

AJ-54C Series Technical Manual 7610-002-30-91

Issued: 03-22-2006 Revised: N/A

SECTION 6: PARTS SECTION

111

MANIFOLDS/STRAINER SUPPORT WELDMENTS

Prewash Manifold Weldment

AJ-66 Models Only

05700-031-69-70

Prewash Manifold Weldment

AJ-80 Models Only

05700-002-24-94

Prewash Manifold Weldment

(CGP Models Only)

05700-002-59-51

Wash Manifold Weldment

05700-031-71-13

Wash Manifold Weldment

(CGP Models Only)

05700-002-51-14

Shoulder Bolt Wingnut Weldment

05700-002-46-02

Wash Fill Tube Weldment

05700-021-71-21

Prewash Fill Tube Weldment

(AJ-66 & AJ-80 Models Only)

05700-021-74-76

Vellumoid Gasket

05330-111-42-81

Wash Strainer Separator Weldment

05700-031-84-38

Page 48

AJ-54C Series Technical Manual 7610-002-30-91

Issued: 03-22-2006 Revised: N/A

SECTION 6: PARTS SECTION

112

STRAINERS

Back Strainer Weldment

05700-021-85-11

Drain Guard

Strainer Weldment

05700-002-09-15

Front Strainer Weldment

05700-021-85-10

Screen Strainer

with Handle Weldment

05700-002-09-04

Overflow Strainer Support

05700-001-96-48

Tub Strainer Weldment (CGP Models)

05700-002-03-21

Wash Intake Strainer Weldment (CGP Models)

05700-002-51-52

Page 49

AJ-54C Series Technical Manual 7610-002-30-91

Issued: 03-22-2006 Revised: N/A

SECTION 6: PARTS SECTION

113

FLOAT SWITCH COMPONENTS/SCRAP BASKETS

Float Switch Support Bracket

Replacement Kit

06401-003-11-77

Float Switch Cover

05700-021-75-71

Scrap Basket Lid

Weldment

05700-002-56-55

Scrap Basket Assembly

06401-011-87-78

Wash Tank Float Switch Replacement Kit

06401-003-11-75

Prewash Tank Float Switch Replacement Kit

06401-003-11-76

Replacement Kit Note:

The float switch replacement kits contain the float switch with

associated terminals, the flat washer and the nut.

Service Agent Note:

Remember than when reinstalling the float switch that the flat

washer goes inside against the tub wall while the nut is on the

outside of the tub.

Replacement Kit Note:

The float switch support bracket replace-

ment kit contains the bracket and asso-

ciated hardware for mounting.

Page 50

AJ-54C Series Technical Manual 7610-002-30-91

Issued: 03-22-2006 Revised: N/A

SECTION 6: PARTS SECTION

114

VENT COWL ASSEMBLY/VENT SCOOP OPTION

Vent Cowl Cover Replacement Kit

06401-003-10-16

Gasket, Top Vent Cowl

05330-031-83-47

Vent Cowl Replacement Kit

06401-003-11-62

Gasket, Side Vent Cowl

05330-031-83-48

VENT SCOOP OPTION

Replacement Kit Note:

The kit for the vent cowl comes with the vent

cowl weldment, new gaskets and the locknuts needed to mount it.

Vent Scoop Assembly

05700-002-04-08

Page 51

AJ-54C Series Technical Manual 7610-002-30-91

Issued: 03-22-2006 Revised: 04-19-2007

SECTION 6: PARTS SECTION

115

EXHAUST FAN CONTROL/TABLE LIMIT SWITCH OPTIONS

Delay Timer

05945-011-65-44

2” Din Rail

05700-002-36-09

Kit, Exhaust Fan - Electric & Steam Models

05700-031-90-53

Kit, Exhaust Fan - Gas Models

05700-003-14-59

Terminal Board

05940-011-84-41

Whisker Switch Assembly

05700-002-23-94

Whisker Limit Switch & Lever

05930-303-40-01

Whisker Limit Switch

Mounting Bracket

05700-000-14-55

Limit Switch

05930-002-62-81

Striker Plate Limit Switch

Assembly

05700-002-62-94

Proximity Limit

Switch Sensor

06685-002-94-15

Bracket, Proximity Switch

05700-002-94-93

Photoelectric Limit Switch

Assembly

05700-002-93-81

FAN LOAD ON TIMER OUTPUT

5A, 1/4HP, 240 V AC MAX

Decal, Fan Load

09905-003-32-20

Page 52

AJ-54C Series Technical Manual 7610-002-30-91

Issued: 03-22-2006 Revised: N/A

SECTION 6: PARTS SECTION

116

SIDE LOADER TRACK ASSEMBLY/LEG REPLACEMENTS/STRAINER

ITEM QTY DESCRIPTION Mfg. No.

1 1 Track Weldment (Left to Right) 24” 05700-031-78-98

1 Track Weldment (Right to Left) 24” 05700-031-95-20

1 Track Weldment (Left to Right) 30” 05700-003-04-57

1 Track Weldment (Right to Left) 30” 05700-003-04-58

2 1 Actuator Switch Replacement Kit 06401-003-10-64

3 2 Spacer 05700-011-71-44

4 1 Leg Socket Replacement Kit 06401-003-09-79

5 1 Leg Support Replacement Kit 06401-003-09-80

6 1 Bullet Foot 05340-108-01-03

1

2

3

Side loader track assembly

(left to right model shown).

Replacement Kits Notes:

The actuator switch replacement kit comes with the

actuator weldment, mounting hardware and (2)

spacers.

The leg socket replacement kit has the leg socket,

mounting hardware and set screw.

The leg support replacement kit has the leg and the

bullet foot included.

4

5

6

Front Strainer Weldment

05700-021-85-10

Page 53

AJ-54C Series Technical Manual 7610-002-30-91

Issued: 03-22-2006 Revised: N/A

SECTION 6: PARTS SECTION

117

SIDE LOADER PAWL BAR ASSEMBLIES/PAWL BAR BRACKET/MAGNET

Pawl Dog Wing Weldment

05700-021-86-79

Pawl Bar Spacer

05700-011-71-45

Drive Linkage Replacement Kit (L-R)

06401-003-11-59

Drive Linkage Replacement (R-L)

06401-003-11-60

Kit, Pawl Bar Replacement: 06401-131-86-90

Kit, 30” Pawl Bar Replacement: 06401-231-86-90

Replacement Kit Note:

The kits for the pawl bars come with the bar

weldment, (3) dogs and the hardware.

Replacement Kit Note:

The replacement kits for the drive linkages come also

with the hardware for mounting them to the pawl bars.

Pawl Bar Roller Bracket

05700-031-77-94

Replacement Kit Note:

The conveyor switch replacement

kit comes with the switch, a terminal and a wire nut.

Service Note:

The cord for the conveyor switch needs to

be cut to length in the field and have the

pink terminal applied there.

See page entitled “Pawl Bar

Miscellaneous Components”

for other parts used on the

Side Loader.

Page 54

AJ-54C Series Technical Manual 7610-002-30-91

Issued: 03-22-2006 Revised: N/A

SECTION 6: PARTS SECTION

118

SIDE LOADER VENT COWL OPTION

VENT SCOOP OPTION

Vent Scoop Assembly

05700-002-04-08

ST ANDARD ASSEMBLY

Vent Cowl Cover Replacement Kit

06401-003-10-16

Vent Cowl Replacement Kit (Left to Right)

06401-003-11-81

Vent Cowl Replacement Kit (Right to Left)

06401-003-11-83

Replacement Kit Note:

The replacement kit(s) for the vent cowls come with the

cowls, the gaskets and mounting hardware.

Replacement Kit Note:

The cover kit contains the

cover and the hardware for

mounting it.

Vent Cowl Gasket, Top: 05330-031-83-47

Vent Cowl Gasket, Side: 05330-031-83-48

Service Note:

One of the side

gaskets that come

in the kit will need

to be cut to length

in order to fit properly on the unit

when replaced.

Vent Cowl Assembly for

Hooded Side Loader Option

05700-003-15-66

Page 55

AJ-54C Series Technical Manual 7610-002-30-91

Issued: 03-22-2006 Revised: N/A

SECTION 6: PARTS SECTION

D226 STEAM BOOSTER CONTROL BOX ASSEMBLY

119

10

Decal, Warning, Disconnect Power

09905-100-75-93

Decal, Schematic, D226 Booster (on the

inside of the control box cover)

09905-002-78-56

Cover, Control Box

05700-001-19-82

Decal, L1-L2

09905-002-78-67

Ground Lug

05940-200-76-00

Spacer, Terminal Block

05700-011-40-05

Decal, Ground

09905-011-86-86

Thermostat

06680-500-01-77

Conduit Fitting, .231” x.394”

05975-011-49-03

Terminal Block

05940-500-09-61

Control Box with Decal

06401-002-78-87

Decal Only

09905-021-44-97

Light, Red

05945-111-21-57

Power Switch

05930-011-49-55

Page 56

AJ-54C Series Technical Manual 7610-002-30-91

Issued: 03-22-2006 Revised: N/A

SECTION 6: PARTS SECTION

D226 STEAM BOOSTER PLUMBING ASSEMBLY

120

17

2

1

2 3 4

5

6

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

31

31

7

32

3330

Page 57

AJ-54C Series Technical Manual 7610-002-30-91

Issued: 03-22-2006 Revised: N/A

SECTION 6: PARTS SECTION

D226 STEAM BOOSTER PLUMBING ASSEMBLY (CONTINUED)

121

ITEM QTY DESCRIPTION Mfg. No.

1 1 Water Pressure Regulator, 3/4” 04820-100-01-06

2 2 Nipple, Brass, 3/4” NPT x 6” Long 05700-001-26-74

3 2 U-Bolt, 6”, 5/8”-11 Thread 5306-458-01-04

4 1 Platform Weldment 05700-002-78-02

5 1 Heat Exchanger 4420-100-01-05

6 1 Steam Trap, 3/4” 06680-500-02-77

7 1 Bushing, 2” NPT x 3/4” NPT, Black Iron 04730-902-06-34

8 2 Elbow, 3/4” NPT, Brass 04730-206-13-00

9 6 Nipple, 1” NPT, Close, Black Iron 04730-907-08-34

10 2 Union, 3/4” NPT, Brass 04730-212-05-00

11 2 Bushing, 2” NPT x 3/4” NPT, Brass 04730-202-18-00

12 4 Nipple, 3/4” NPT x 1-3/8” Long 04730-207-34-00

13 1 Bushing, Hex 3/4” M x 1/2” F, Brass 04730-002-56-27

14 1 Y-Strainer, 1” NPT, Black Iron 04730-217-02-32

15 2 Pressure Gauge 06685-111-88-34

16 1 Steam Relief Valve 04820-100-07-06

17 2 Nipple, 3/4” NPT x 4” Long, Brass 04730-207-05-00

18 2 Tee, 3/4” NPT x 3/4” NPT x 3/4” NPT, Brass 04730-211-01-34

19 1 Bushing, 2” NPT x 1” NPT, Black Iron 04730-002-94-51

20 3 Elbow, 90°, 1” NPT, Black Iron 04730-906-03-34

21 2 Nipple, 1” NPT x 4” Long, Black Iron 04730-907-09-34

22 1 Elbow, 90°, Street, 3/4” NPT, Black Iron 04730-011-87-37

23 1 Nipple, Pigtail, 1/4” NPT 04730-907-14-34

24 1 Coupling, 1/4” NPT x 1/4” NPT 04730-904-01-34

25 1 Steam Solenoid Valve, 240VA 04820-100-29-34

25 1 Steam Solenoid Valve, 200VA 04820-002-93-66

25 1 Steam Solenoid Valve (ASCO) 04820-002-90-26

26 1 Tee, 3/4” NPT x 3/4” NPT x 1/4” NPT, Brass 04730-211-04-00

27 1 Valve, Test Cock, 1/4” NPT 04810-011-72-67

28 1 Tee, 1” NPT x 1” NPT x 1” NPT, Black Iron 04730-911-01-34

29 1 Valve, Safety Relief 1” NPT 04820-100-01-35

30 1 Tee, 1” NPT x 1” NPT x 1/4” NPT, Black Iron 04730-911-01-00

31 2 Union, 3/4” NPT, Black Iron 04730-912-01-00

32 2 Nipple, 3/4” NPT x 2” Long, Brass 04730-207-46-00

33 2 Nipple, 3/4” NPT, Close, Black Iron 04730-907-01-00

Page 58

AJ-54C Series Technical Manual 7610-002-30-91

Issued: 03-22-2006 Revised: N/A

SECTION 6: PARTS SECTION

GO*BOX COMPONENTS

122

A GO*BOX is a kit of the most needed parts for a particular model or model family to successfully effect a repair in the first

call 90% or more of the time.

The following components may be ordered together using part number 06401-002-14-98.

QTY DESCRIPTION Mfg. No.

1 Drive Motor Contactor 05945-111-68-38

1 Contactor, Wash Heater, 3 ph, 3 pole 05945-002-24-70

1 Contactor, Wash Heater, 1 ph, 4 pole 05945-111-68-37

2 Final Rinse Arm End Cap 05700-011-35-92

1 Float Switch, Dual, Wash & Prewash 06680-121-70-71

1 Gasket, Pawl Bar Gutter 05330-011-68-55

1 Gauge, Pressure 06685-111-88-34

6 Glide, Door Edge 05700-111-70-92

2 Magnet, Door Reed Switch 05930-111-51-68

2 O Ring, Prewash Manifold 05330-400-12-08

2 O Ring, Wash Manifold 05330-011-74-56

1 Overload, Drive Motor 05945-111-68-39

1 Overload, Wash Motor 05945-111-68-40

1 Relay,120v, 3 PDT 05945-111-72-51

1 Relay,120v,50/60Hz 3AControl 05945-111-35-19

1 Repair Kit, 3/4" Vacuum Breaker 04820-001-60-57

4 Roller, Pawl Bar 05700-011-68-16

1 Seal Kit for Wash and Prewash pump 05330-011-71-98

2 Solenoid Valve, Fill & Rinse 04810-100-53-00

2 Switch, Power 05930-011-49-55

2 Switch, Reed, Actuator (NC) 05930-111-68-44

1 Switch, Reed, Door (NO) 05930-111-68-86

1 Thermometer, 48" Capillary 06685-111-68-48

1 Thermometer, 96" Capillary 06685-111-68-49

2 Thermostat, Wash High Limit 05930-121-71-36

2 Thermostat, Wash Regulating 05930-121-67-72

1 Transformer,150VA 05950-011-68-35

1 Valve, Ball 1 1/2" NPT 04820-111-71-46

Page 59

AJ-54C Series Technical Manual 7610-002-30-91

Issued: 03-22-2006 Revised: N/A

SECTION 6: PARTS SECTION

123

RINSE FILL OPTION

ITEM QTY DESCRIPTION Mfg. No.

1 Rinse Fill Motor Assembly 05700-002-40-25

1 1 Motor 06105-002-72-71

2 1 Bracket, Pump Mounting 05700-002-63-59

3 1 Clamp, Hose 5 5/8” to 6” 04730-011-34-90

4 1 Reducer Bushing, 1 1/4” to 1” 04730-002-73-62

5 1 Reducer Bushing 1” to 3/4” 04730-011-65-14

6 1 Elbow, 90 Deg., 1” Street 04730-002-11-99

7 1 Nipple, 1” NPT x 6” Long Brass 04730-002-12-00

8 1 Elbow, 90 Deg. Brass Female 04730-002-12-55

9 4 Lockwasher, 1/4” 05311-274-01-00

10 4 Bolt, 1/4”-20 x 1/2” Long 05305-274-02-00

11 4 Nut, Hex S/S 1/4”-20 05310-274-01-00

12 1 Rinse Motor Mounting Bracket 05700-002-38-90

3

12

5

10

9

1

2

4

6

7

8

11

Loading...

Loading...