Jackson / Dalton Dishwasher Conserver-XL2 Service Manual

CONSERVER XL2

DOUBLE RACK, CHEMICAL SANITIZING

DISHMACHINE

INSTALLATION AND OPERATIONINSTALLATION AND OPERATION

MANUALMANUAL

Visit Jackson on the Internet at:

www.jacksonmsc.com

February 8, 2001 P/N 7610-002-18-35 (Revision B)

MANUFACTURERS WARRANTY

ONE YEAR LIMITED PARTS & LABOR WARRANTY

ALL NEW JACKSON DISHWASHERS ARE WARRANTED TO THE ORIGINAL PURCHASER TO BE FREE FROM

DEFECTS IN MATERIAL OR WORKMANSHIP, UNDER NORMAL USE AND OPERATION FOR A PERIOD OF (1) ONE

YEAR FROM THE DATE OF PURCHASE, BUT IN NO EVENT TO EXCEED (18) EIGHTEEN MONTHS FROM THE DATE

OF SHIPMENT FROM THE FACTORY.

Jackson MSC agrees under this warranty to repair or replace , at its discretion, any original part which fails under normal use due to faulty

material or workmanship during the warranty period, providing the equipment has been unaltered, and has been properly installed, maintained and operated in accordance with the applicable factory instruction manual furnished with the machine and the failure is reported to

the authorized service agency within the warranty period. This includes the use of factory specified genuine replacement parts, purchased

directly from a Jackson authorized parts distributor or service agency. Use of generic replacement parts may create a hazard and void warranty certification.

The labor to repair or replace such failed part will be paid by Jackson MSC, within the continental United States, Hawaii and Canada, dur ing the warranty period provided a Jackson MSC authorized service agency, or those having prior authorization from the factory, performs

the service. Any repair work by persons other than a Jackson MSC authorized service agency is the sole responsibility of the customer.

Labor coverage is limited to regular hourly rates, overtime premiums and emergency service charges will not be paid by Jackson MSC.

Accessory components not installed by the factory carry a (1) one year parts warranty only. Accessory components such as table limit

switches, pressure regulators, pre rinse units, etc. that are shipped with the unit and installed at the site are included. Labor to repair or

replace these components is not covered by Jackson MSC.

This warranty is void if failure is a direct result from shipping, handling, fire, water, accident, misuse, acts of god, attempted repair by unauthorized persons, improper installation, if serial number has been removed or altered, or if unit is used for purpose other than it was originally intended.

TRAVEL LIMITATIONS

Jackson MSC limits warranty travel time to (2) two hours and mileage to (100) one hundred miles. Jackson MSC will not pay for travel time

and mileage that exceeds this, or any fees such as those for air or boat travel without prior authorization.

WARRANTY REGISTRATION CARD

The warranty registration card supplied with the machine must be returned to Jackson MSC within 30 days to validate the warranty.

REPLACEMENT PARTS WARRANTY

Jackson replacement parts are warranted for a period of 90 days from the date of installation or 180 days from the date of shipment from

the factory, which ever occurs first.

PRODUCT CHANGES AND UPDATES

Jackson MSC reserves the right to make changes in design and specification of any equipment as engineering or necessity requires.

THIS IS THE ENTIRE AND ONLY WARRANTY OF JACKSON MSC. JACKSON’S LIABILITY ON ANY CLAIM OF ANY KIND, INCLUDING

NEGLIGENCE, WITH RESPECT TO THE GOODS OR SERVICES COVERED HEREUNDER, SHALL IN NO CASE EXCEED THE PRICE

OF THE GOODS OR SERVICES OR PART THEREOF WHICH GIVES RISE TO THE CLAIM.

THERE ARE NO WARRANTIES, EXPRESSED OR IMPLIED, INCLUDING FOR FITNESS OR MERCHANTABILITY, THAT ARE NOT SET

FORTH HEREIN, OR THAT EXTEND BEYOND THE DURATION HEREOF. UNDER NO CIRCUMSTANCES WILL JACKSON MSC BE

LIABLE FOR ANY LOSS OR DAMAGE, DIRECT OR CONSEQUENTIAL, OR FOR THE DAMAGES IN THE NATURE OF PENALTIES,

ARISING OUT OF THE USE OR INABILITY TO USE ANY OF ITS PRODUCTS.

ITEMS NOT COVERED

This warranty does not cover adjustments to timer cams or thermostats, cleaning wash arms or strainers, or replacement of wear items such

as curtains, squeeze tubes, drain balls, door guides, or gaskets beyond 30 days from installation of unit. Also not covered are conditions

caused by the use of incorrect (non commercial) grade detergents, excessive supply water temperature or pressure, or hard water conditions.

i

TABLE OF CONTENTS

GENERAL PAGE

Specifications ............................................................................................... 1

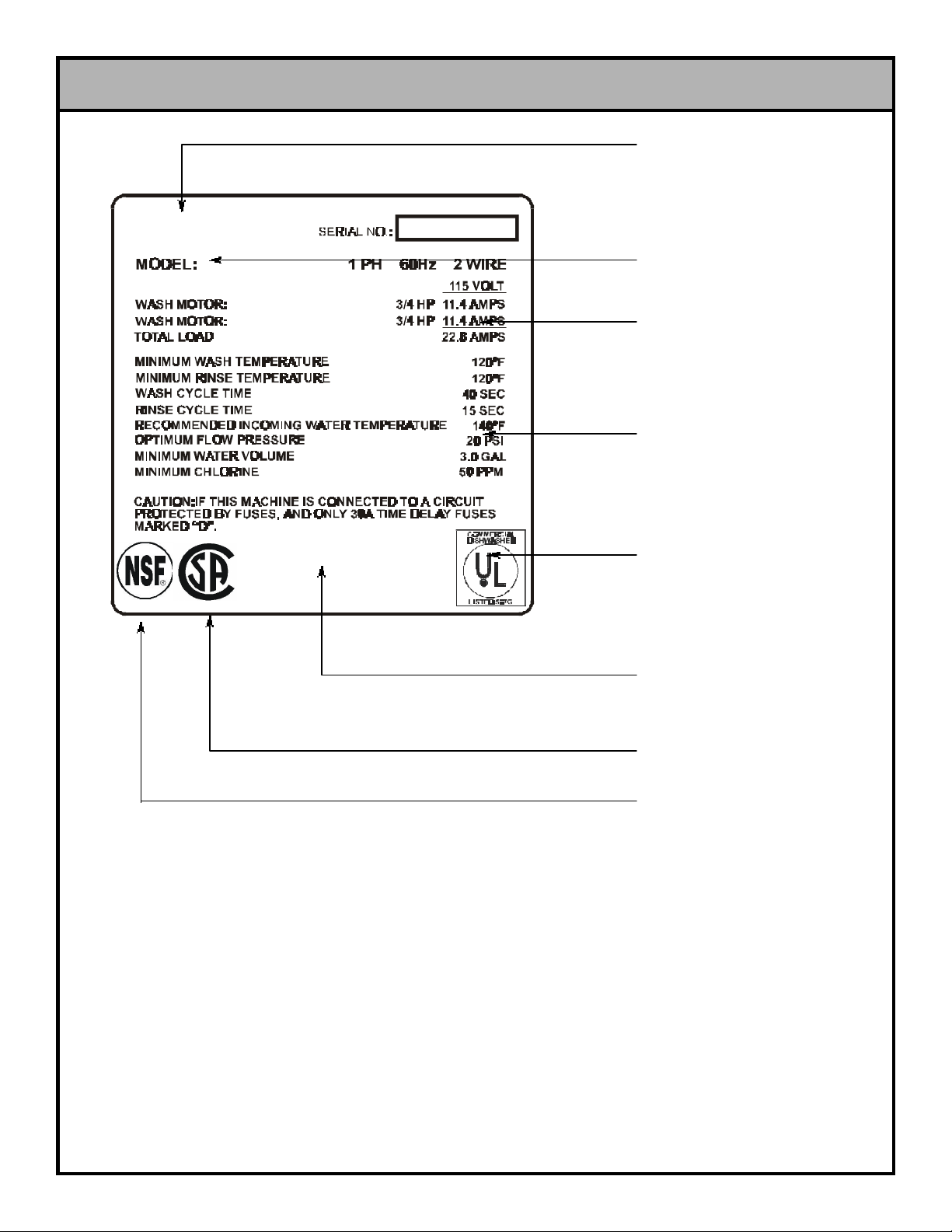

Detail of the Data Plate................................................................................. 2

General Notes............................................................................................... 3

INSTALLATION INSTRUCTIONS.............................................................................. 4

INSTALLATION CHECKLIST..................................................................................... 5

OPERATION INSTRUCTIONS................................................................................... 6

UNIT OPERATION

Cam Timer Operation................................................................................... 7

Timing Sequence ......................................................................................... 8

Detergent Control.......................................................................................... 9

PARTS DRAWINGS

Drawing and Dimensions ............................................................................. 10

Table Dimensions.......................................................................................... 11

115 V, 60 Hz, 1 Phase Schematic................................................................. 12

JACKSON MAINTENANCE AND REPAIR CENTERS .............................................. 13

IMPORTANT INFORMATION DATA SHEET.............................................................. 21

i

SPECIFICATIONS for the CONSERVER XL2

PERFORMANCE/CAPABILITIES

OPERATING CAPACITY (RACKS/HOUR)

RACKS PER HOUR 80

RACKS PER HOUR (OPTION) 96

DISHES PER HOUR 2000

GLASSES PER HOUR 2000

OPERATING CYCLE (SECONDS)

WASH TIME 35

RINSE TIME 20

TOTAL CYCLE TIME 90

TOTAL CYCLE TIME (OPTION) 72

TANK CAPACITY (GALLONS)

WASH TANK (MINIMUM) 3.1

WASH PUMP CAPACITY

GALLONS PER MINUTE 61

ELECTRICAL REQUIREMENTS

(2) WASH PUMP MOTOR HORSEPOWER 3/4 ea.

VOLTS PHASE AMPS

115 1 25.0

WATER REQUIREMENTS

INLET TEMPERATURE (Minimum) 120

INLET TEMPERATURE (Recommended)

GALLONS PER HOUR 160

GALLONS PER HOUR (OPTION) 192

WATER LINE SIZE I.P.S. (Minimum) 3/4”

DRAIN LINE SIZE I.P.S. (Minimum) 2”

FLOW PRESSURE P.S.I. (Optimum) 20

MINIMUM CHLORINE REQUIRED (PPM) 50

FRAME DIMENSIONS

WIDTH 44 1/8”

DEPTH 25 13/16”

140

°F

°F

TEMPERATURES

WASH--WASH--RINSE ---°F 120

RINSE

°F (MINIMUM) 120

°F (RECOMMENDED) 140

---

°F (RECOMMENDED) 140

HEIGHT 66 1/4”

STANDARD TABLE HEIGHT 34”

MAXIMUM CLEARANCE 19”

1

DETAIL of the CONSERVER XL2 DATA PLATE

MANUFACTURER’S

LOGO

MODEL DESIGNATION

(I.E. “CONSERVER XL2”)

AMPERAGE LOAD

INFORMATION

MINIMUM PARAMETERS

(SEE NOTE 1)

UL LOGO (SEE NOTE 2)

MANUFACTURERS

ADDRESS INFORMATION

CSA LOGO (SEE NOTE 4)

NSF LOGO (SEE NOTE 3)

The data plate is located (standing before the unit) on the right side front corner, directly under the tub lip. Under no circumstances

should the data plate be removed from the unit. The data plate is essential in identifying the particular characteristics of your machine

and is of great benefit to installers, operators, and maintenance personnel. It is recommended that, in the event the data plate is

removed, you copy down the essential information on the final page in this manual for reference before installation. Do not use the

above data plate to represent your dishmachine. The data plate above is a generic representation used only to show you where to

locate information.

2

GENERAL NOTES SECTION

Before connecting, operating, or adjusting any of the dishmachines covered in this manual, please carefully read through the entire

manual to familiarize yourself with the machine and its proper operation. This manual contains important operating, safety, and maintenance information concerning your dishmachine. You must follow the instructions and guidelines provided in this manual to ensure

that your warranty remains in effect.

FOR SERVICE PERSONNEL: Jackson MSC Inc. provides technical support for all of the dishmachines detailed in this manual. We

strongly recommend that you refer to this manual before making a call to our technical support staff. Please have this manual with you

when you call so that our staff can refer you, if necessary, to the proper page. Technical support is avaliable from 8:00 a.m. to 5:00 p.m.

(EST), Monday through Friday. Technical support is not available on holidays. Contact technical support toll-free at 1-888-800-5672.

Please remember that technical support is available for service personnel only. Non-service personnel should refer to the list of provided service agencies in this manual for local service support.

NOTES CONCERNING THE CONSERVER XL2 MODEL DATA PLATES:

NOTE 1: This area of the data plate denotes the minimum parameters that must be met in order for your dishmachine to operate at the

designed level of efficiency. Not meeting the required parameters can result in substandard performance of the dishmachine. Do not

refer to the data plate example in this manual for the parameters of your machine; instead, refer to the data plate affixed to the machine.

Not every model operates the same way. If you are unsure of whether or not you are meeting the required minimum parameters, contact your nearest Jackson authorized service agency.

NOTE 2: The UL logo on the data plate indicates that this machine is Listed by Underwriters Laboratories Inc. Representative samples

of this product have been evaluated by UL and meet applicable UL Standards and requirements. Dishmachines are evaluated under

UL Standard 921. For more information concerning the UL logo and UL standards in general, you may write to: Underwriters

Laboratories Inc., 333 Pfingsten Road, Northbrook, IL., 60062; or you may visit their website at www.ul.com.

NOTE 3: The NSF logo on the data plate indicates that this machine has been approved to be listed under NSF Standard 3 by NSF

International Inc. All of Jackson MSC’s Standard 3 approved dishmachines are listed on the NSF website at www.nsf.org. For more

information concerning NSF International, their testing procedures and their standards in general, you may write to: NSF International

Inc., 789 Dixboro Road, Ann Arbor, MI., 48105.

NOTE 4: The CSA logo on the data plate indicates that this machine has been approved to bear this mark by CSA International Inc.

CSA International evaluates and approves equipment for installation and operation in Canada. Representative samples of this product

have been made available to CSA for inspection to ensure that they meet all applicable Canadian safety standards and regulations.

For more information concerning the CSA mark and CSA standards in general, you may write to: CSA International Inc., 178 Rexdale

Blvd, Rexdale (Toronto), Ontario, Canada, M9W 1R3; or you may visit their website at www.csa-international.org.

3

INSTALLATION INSTRUCTIONS

VISUAL INSPECTION: Before installing the unit, check the container and machine for damage. A damaged container is an indicator that there may be some damage to the machine. If there is

damage to both the container and machine, do not throw away the

container. The dishmachine has been inspected and packed at

the factory and is expected to arrive to you in new, undamaged

condition. However, rough handling by carriers or others may

result in there being damage to the unit while in transit. If such a

situation occurs, do not return the unit to Jackson; instead, contact

the carrier and ask them to send a representative to the site to

inspect the damage to the unit and to complete an inspection

report.. You must contact the carrier within 48 hours of receiving

the machine. Also, contact the dealer through which you purchased the unit.

UNPACKING THE DISHMACHINE: Once the machine has been

removed from the container, ensure that there are no missing

parts from the machine. This may not be obvious at first. If it is discovered that an item is missing, contact Jackson immediately to

have the missing item shipped to you.

LEVEL THE DISHMACHINE: The dishmachine is designed to

operate while being level. This is important to prevent any damage to the machine during operation and to ensure the best

results when washing ware. The unit comes with adjustable bullet

feet, which can be turned using a pair of channel locks or by hand

if the unit can be raised safely. Ensure that the unit is level from

side to side and from front to back before making any connections.

PLUMBING THE DISHMACHINE: All plumbing connections must

comply with all applicable local, state, and national plumbing

codes. The plumber is responsible for ensuring that the incoming

water line is throroughly flushed prior to connecting it to any component of the dishmachine. It is necessary to remove all foreign

debris from the water line that may potentially get trapped in the

valves or cause an obstruction. Any valves that are fouled as a

result of foreign matter left in the water line, and any expenses

resulting from this fouling, are not the responsibility of the manufacturer.

In areas where the water pressure fluctuates or is greater than the

recommended pressure, it is suggested that a water pressure regulator be installed. The Conserver XL2 does not come with a

water pressure regulator as standard equipment.

Do not confuse static pressure with flow pressure. Static pressure

is the line pressure in a “no flow” condition (all valves and services

are closed). Flow pressure is the pressure in the fill line when the

fill valve is opened during the cycle.

It is also recommended that a shock absorber (not supplied with

the Conserver XL2) be installed in the incoming water line. This

prevents line hammer (hydraulic shock), induced by the solenoid

valveas it operates, from causing damage to the equipment.

PLUMBING CHECK: Slowly turn on the water supply to the

machine after the incoming fill line and the drain line have been

installed. Check for any leaks and repair as required. All leaks

must be repaired prior to placing the machine in operation.

ELECTRICAL POWER CONNECTION: Electrical and grounding

connections must comply with the applicable portions of the

National Electrical Code ANSI/NFPA 70 (latest edition) and/or

other electrical codes.

Disconnect electrical power supply and place a tag at the disconnect switch to indicate that you are working on the circuit.

The dishmachine data plate is located on the right side and to the

front of the machine. Refer to the data plate for machine operat ing requirements, machine voltage, total amperage load and serial number.

To install the incoming power lines, open the control box. This will

require opening the control box lid. Install 3/4” conduit into the prepunched holes in the back of the control box. Route power wires

and connect to power block and grounding lug. Install the service

wires (L1 & N) to the appropriate terminals as they are marked on

the terminal block. Install the grounding wire into the lug provided.

Tighten the connections and check that they are secure.

CONNECTING THE DRAIN LINE: The drain for the Conserver

XL2 is a gravity disharge drain. All piping from the 2” MNPT connection on the waste accumulator must be pitched (1/4” per foot)

to the floor or sink drain. All piping from the machine to the drain

must be a minimum 2” I.P.S. and shall not be reduced. There must

also be an air gap between the machine drain line and the floor

sink or drain. If a grease trap is required by code, it should have a

flow capacity of 5 gallons per minute.

WATER SUPPLY CONNECTION: Ensure that you have read the

section entitled “PLUMBING THE DISHMACHINE” above before

proceding. Install the water supply line (3/4” pipe size minimum) to

the dishmachine line strainer using copper pipe. It is recommended that a water shut-off valve be installed in the water line between

the main supply and the machine to allow access for service. The

water supply line is to be capable of 25 PSI “flow” pressure at the

recommended temperature indicated on the data plate.

It is recommended that “DE-OX” or another similar anti-oxidation

agent be used on all power connections.

VOLTAGE CHECK: Ensure that the power switch is in the OFF

position and apply power to the dishmachine. Check the incoming

power at the terminal block and ensure it corresponds to the volt age listed on the data plate. If not, contact a qualified service

agency to examine the problem. Do not run the dishmachine if the

voltage is too high or too low. Shut off the service breaker and

mark it as being for the dishmachine. Advise all proper personnel

of any problems and of the location of the service breaker.

Replace the control box cover and tighten down the screws.

4

Loading...

Loading...