Page 1

AJ-44C Series Technical Manual 7610-001-76-22

Issued: 03-21-2006 Revised: N/A

SECTION 2: INSTALLATION/OPERATION INSTRUCTIONS

CHANGING THE AJ-44CE/CS DIRECTION OF TRAVEL (CONTINUED)

38

22. Separate the rinse plumbing from the rest of the incoming

plumbing by loosening the union. Ensure that the gasket on

the bottom of the rinse injector stays with the assembly as you

remove it.

23. Remove the remaining half of the union from the incoming

plumbing.

24. Remove the incoming water pressure regulator from the

incoming plumbing and replace with the union half that was

removed in step 23. Place the water pressure regulator on the

end that the union half was removed from.

25. Place the removed rinse plumbing assembly (with the gasket) in the hole left open from when you removed the hole

cover weldment in step 21. Tighten the two halves of the union

together.

26. Place the hole cover weldment (with its gasket) over the

hole from where the rinse plumbing assembly was originally

installed. Tighten down with the locknuts.

27. Re-install the rinse manifold (with its gasket) by connecting it to the rinse injector weldment at its new location.

Remove the locknut from the stud for the bracket down near

the rack rails and then secure the bracket to the machine

using the same lock nut.

28. Re-install the lower wash arm support bracket to the pawl

bar support on the end of the tub opposite from where it was

removed.

29. Re-install the upper and lower rinse arms. Reinstall the

lower rinse arm support bracket.

30. Re-install the lower wash arm assembly, turning it 180°

and locking it in place with the locking screw.

31. Re-install the pawl bar. Ensure that the pawl bar is placed

so that when racks are placed in the unit, the pawl bar dogs

fold down.

32. Re-install the upper wash arm assembly. If you performed

all of the actions outlined in step 2, when you install it, it will be

directly over the lower wash arm assembly.

33. Remove the heater box cover by unscrewing the four

screws holding it on.

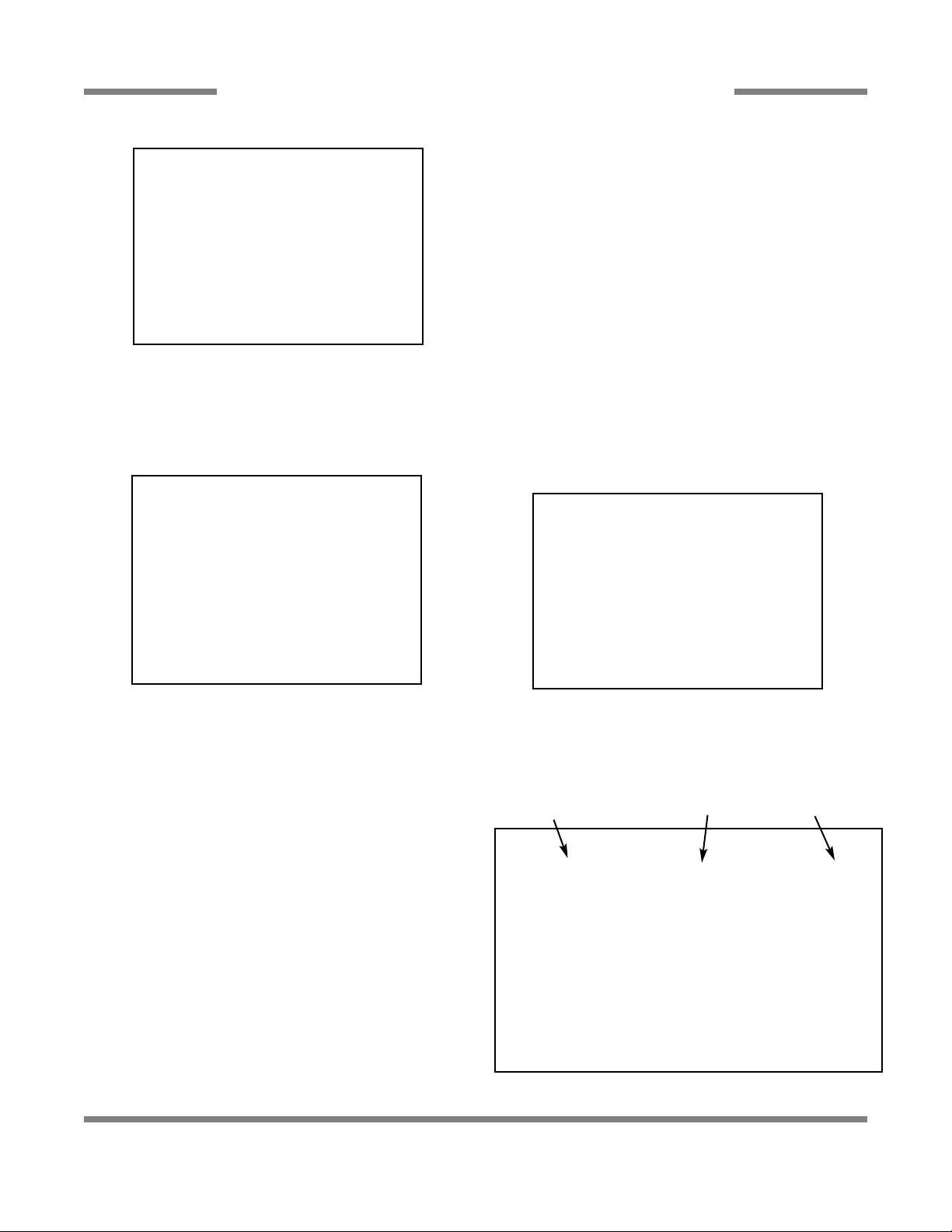

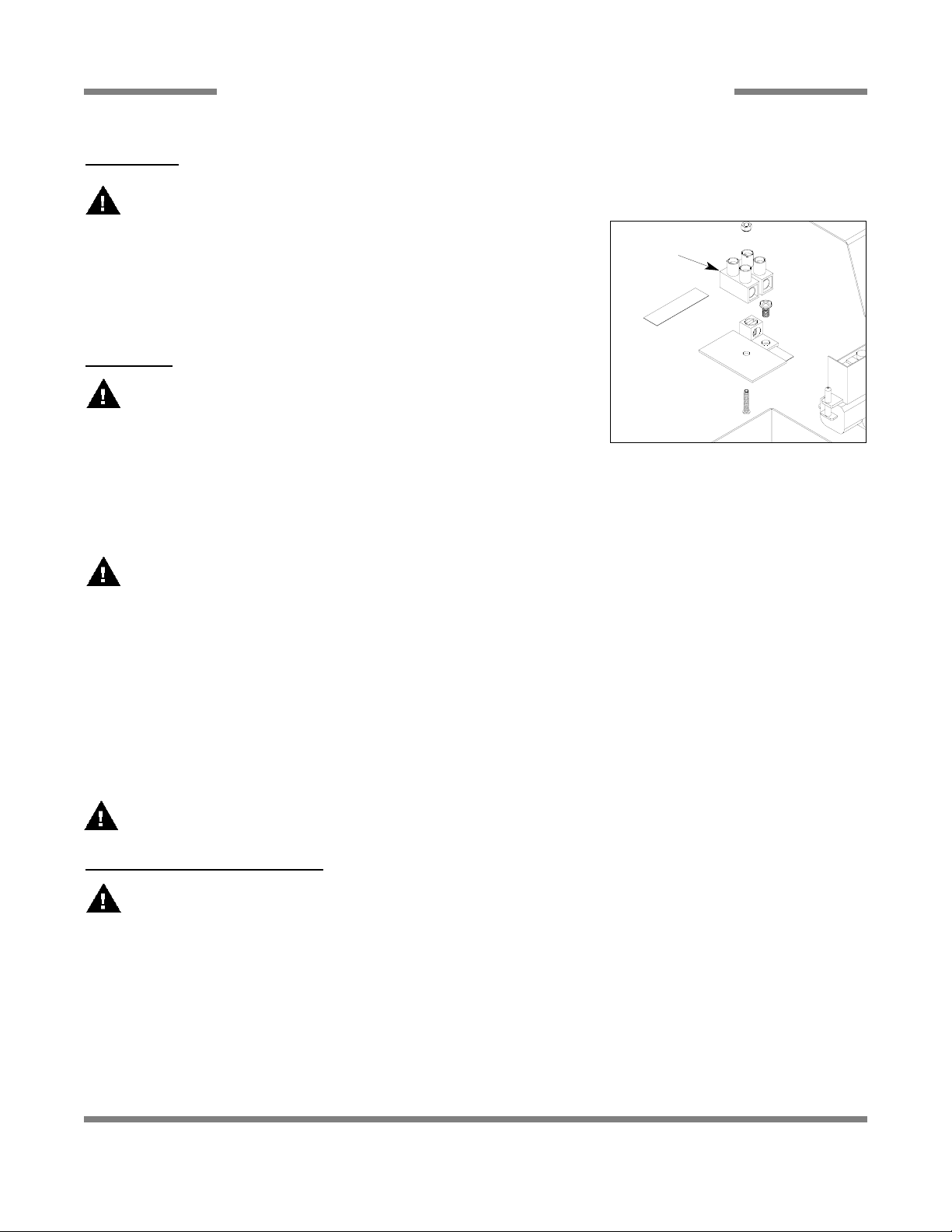

Removing the hole cover weldment

Loosening the union on the incoming plumbing

Removing the heater box cover

Front of rack conveyor showing the conveyor

switches

1

2

3

Page 2

AJ-44C Series Technical Manual 7610-001-76-22

Issued: 03-21-2006 Revised: N/A

SECTION 2: INSTALLATION/OPERATION INSTRUCTIONS

CHANGING THE AJ-44CE/CS DIRECTION OF TRAVEL (CONTINUED)

39

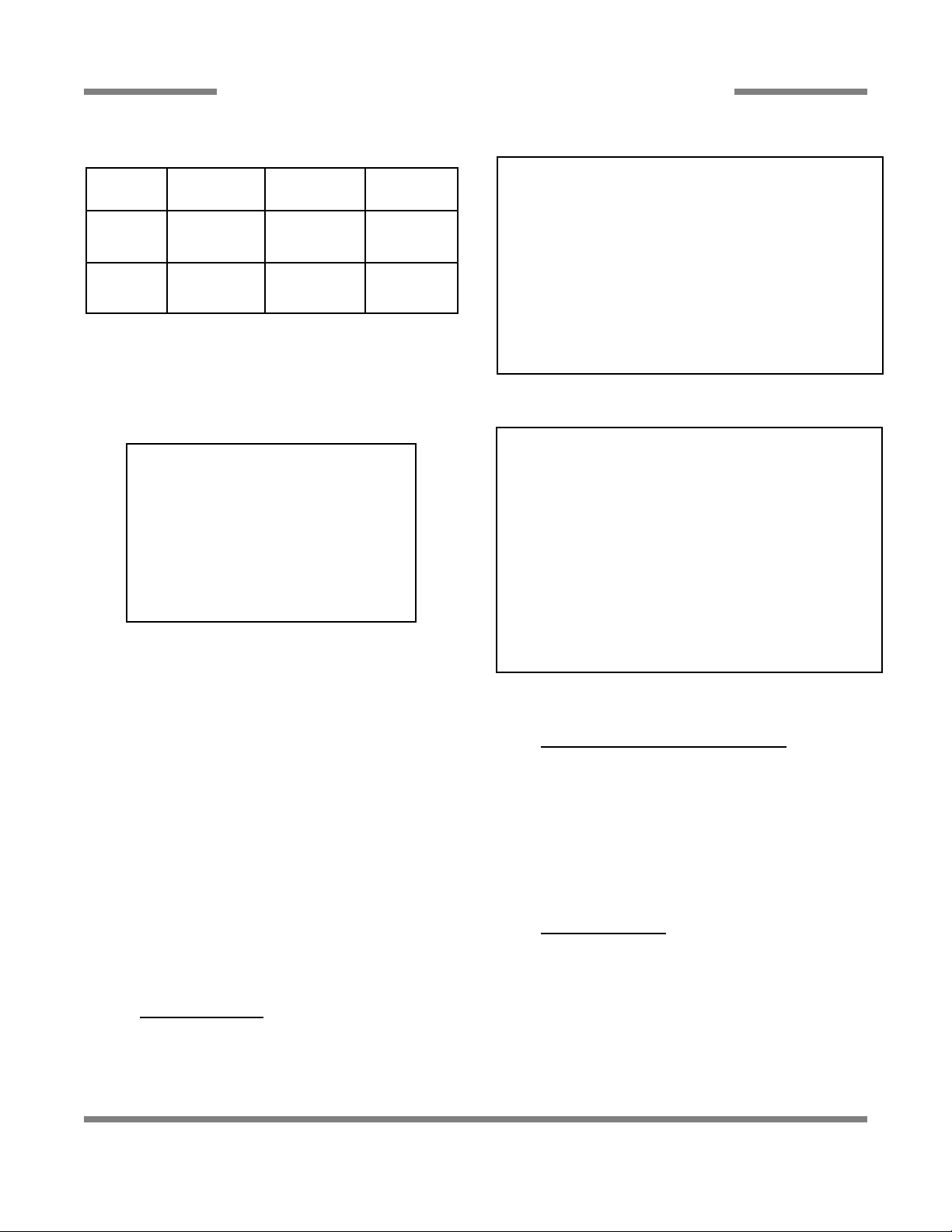

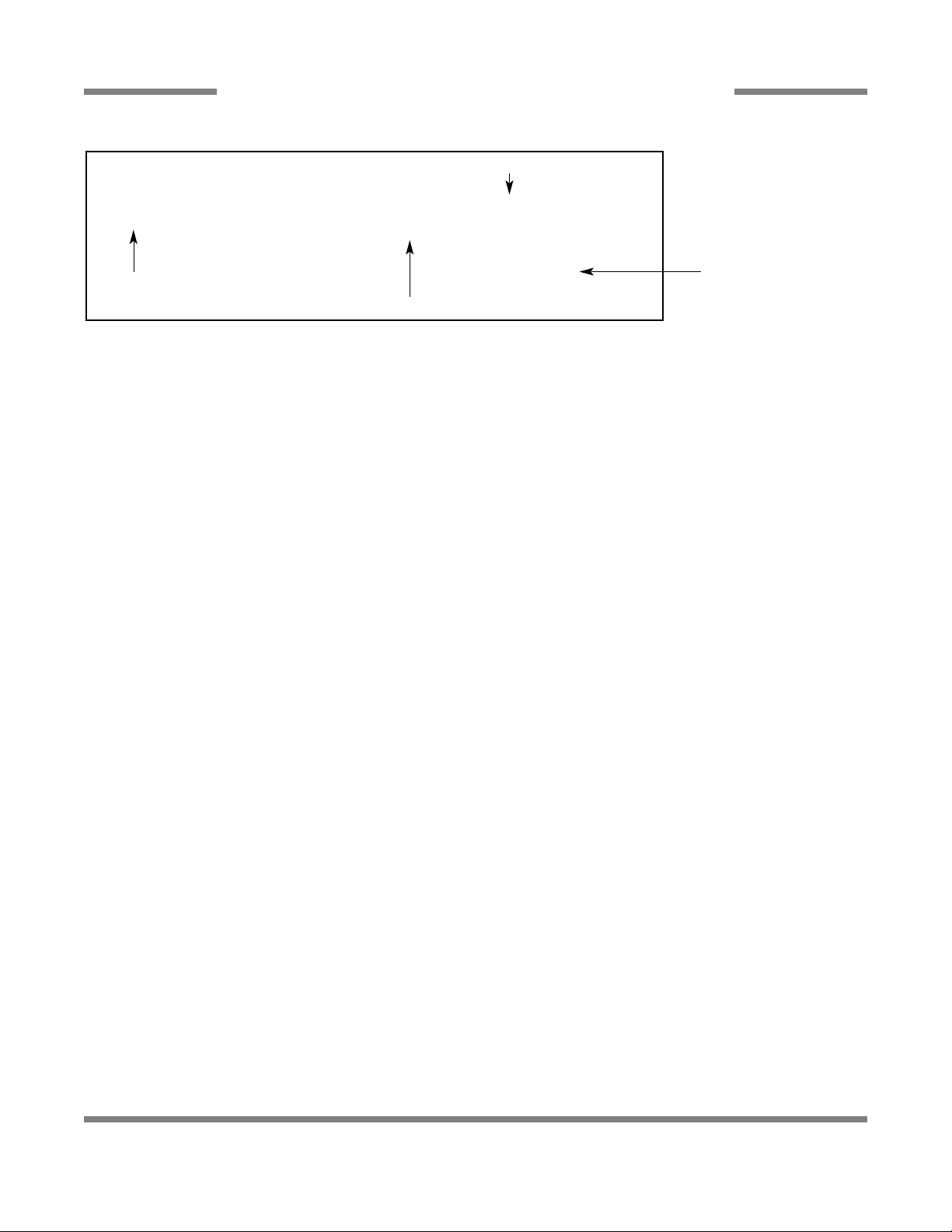

Conveyor Switch Chart:

The chart above lists the conveyor switches and their functions, depending on the direction of travel for the machine. As

you can see, when you change the direction of the conveyor,

you must also alter the way the conveyor switches operate.

There is no need to remove the switches, only to change the

wiring inside the heater box.

34. Note: Before beginning any part of this maintenance evolution that deals with the wiring of the machine, ensure that it

is performed by qualified technicians only. Always refer to the

machine schematic, located inside the control box, for any

questions.

Wash Switch #1 and the Rinse Switch need to have their wire

positions changed on the terminal board pictured above.

Locate the gray/yellow wire for Wash Switch #1 (do not confuse it with the gray/yellow wire for Wash Switch #2) and the

orange/yellow wire for the Rinse Switch. Exchange their positions on the terminal board.

35. Verify that the plumbing has been reassembled correctly

and that the hole cover weldment has been replaced and none

of the gaskets are torn or pinched as this could lead to leaking

when the machine operates.

35. Re-install the heater box cover.

SPECIAL PARTS

Gasket, Rinse Injector:

Mfg. No.: 05330-111-42-81

AFTER MAINTENANCE ACTIONS

1. Reconnect the incoming water and drain lines and

then restore power to the unit. Run the unit for at least 1/2

hour to ensure there are no leaks. Test the unit with an empty

rack to ensure that it pulls the rack all of the way through the

unit. If any problems arise you can contact your Jackson representative.

2. Replace the front dress panel once the unit is

ready for service again.

SPECIAL NOTES

1. There is a possibility that you may be required to

shorten or lengthen the conduit and wire lengths for the inlet

solenoid on the rinse plumbing once it is moved. This work

should be performed by qualified technicians who will do the

work according to applicable local, state and national codes.

Questions concerning this should be directed to your Jackson

representative.

Unit

Direction

Switch #1 Switch #2 Switch #3

Left to Right

Wash Switch#1Wash Switch

#2

Rinse Switch

Right to Left Rinse Switch

Wash Switch#2Wash Switch

#1

Terminal board inside the heater box

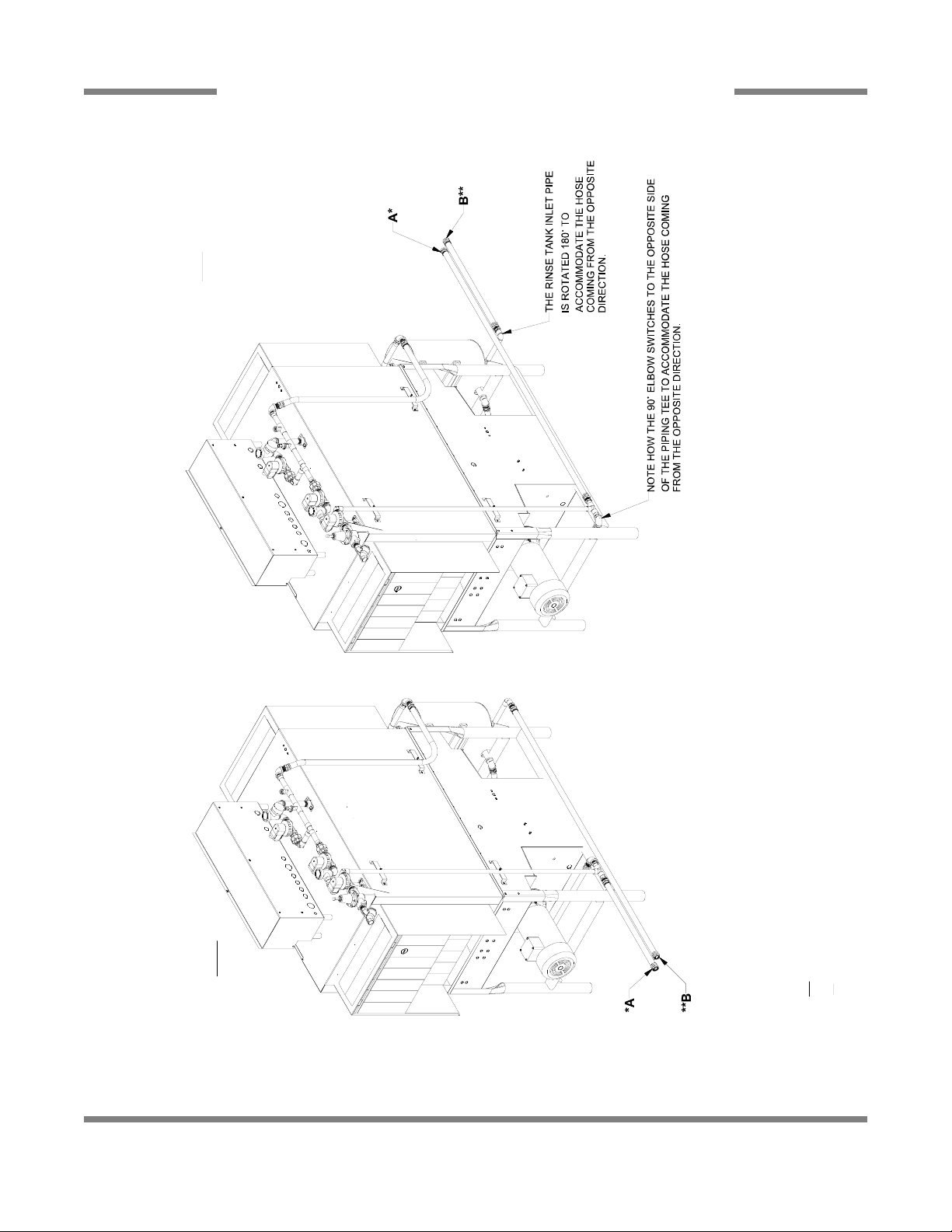

Incoming plumbing assembly for a Right to Left machine

(note hole cover weldment in upper left corner)

Incoming plumbing assembly for a Left to Right machine

(note hole cover weldment in lower right corner)

Page 3

AJ-44C Series Technical Manual 7610-001-76-22

Issued: 03-21-2006 Revised: N/A

SECTION 2: INSTALLATION/OPERATION INSTRUCTIONS

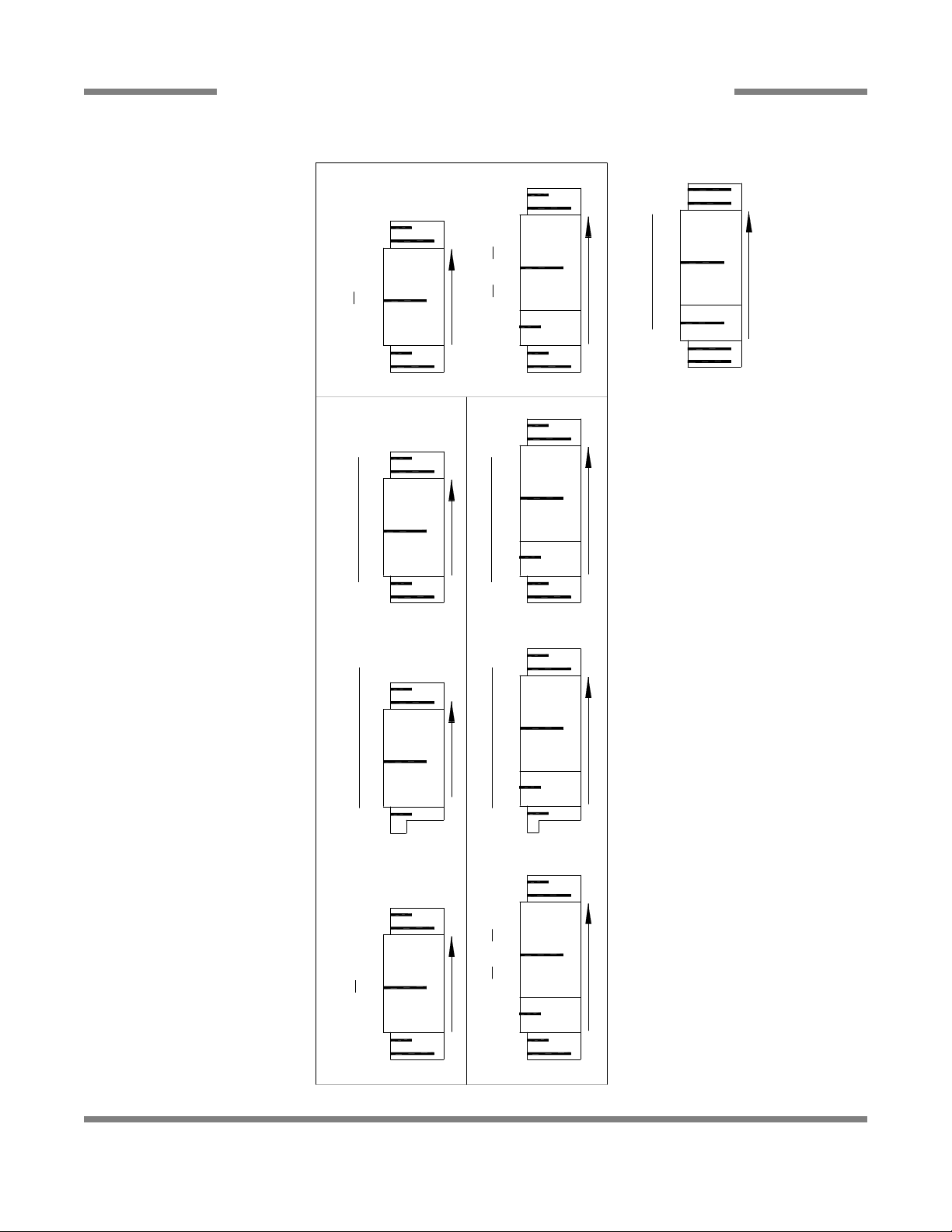

CURTAIN INSTALLATION DIAGRAMS

40

80 COUNTRY BUFFET

21"

L

L

21"

21"

L

OTHER

S

12"

L R

LS SLL

21"

12"

12"

21"21"

21" 21"

12"

12"

21"

LLSSL

RL

HOODED SIDE LOADER

UNHOODED SIDE LOADER

UNHOODED SIDE LOADER

HOODED SIDE LOADER

ELECTRIC & STEAM MACHINES

LLSSL

RL

66

12"

S

80

S

12"

L R

SSLL

12" 12"

21"21"

80

S

12"

66

L R

SSL

12" 12"

21"

21"

12"

12"

24.5"

LSSXL

RL

44

GAS MACHINES

XL

24.5"

24.5"

XL

24.5"

XL

L

21"

L

21"

21"

L

RL

44

L R

LS SLL

21"

12"

12"

21"21" 21" 21"

12"12"

LLSS

RL

21" 21"

12"

12"

21"

Please refer to the chart for

placement of the curtains.

Page 4

This accessory assists in the delivery of a full dish rack from the break down (scrapping) table to the dishmachine. It will convert the direction of travel 90°. Since the Side Loader is shipped mounted on the conveyor dishwasher there is no additional

installation required for this option. As it is operated mechanically by the dishwasher it does not require any plumbing or electrical connections.

This Side Loader does not require or add any additional electrical or mechanical devices to the unit which could create operational or maintenance problems. As designed the drive mechanism is powered by the conveyor drive motor on the dishmachine. An extension on the pawl bar provides the drive to push the racks into the unit.

PREPARATION: Before proceeding with the start-up of the unit, verify that the Side Loader pan strainer is installed.

WARE PREPARA TION:Proper preparation of ware will help ensure good results and less re-washes. If not done properly , ware

may not come out clean and the efficiency of the dishmachine will be reduced. It is important to remember that a dishmachine

is not a garbage disposal and that simply throwing unscraped dishes into the machine simply defeats the purpose altogether

of washing the ware. Scraps should be removed from ware prior to being loaded into a rack. Pre-rinsing and pre-soaking are

good ideas, especially for silverware and casserole dishes. Place cups and glasses upside down in racks so that they do not

hold water during the cycle. The dishmachine is meant not only to clean, but to sanitize as well, to destroy all of the bacteria

that could be harmful to human beings. In order to do this, ware must be properly prepared prior to being placed in the machine.

WASHING A RACK OF WARE: Once a rack is fully loaded it should be positioned against the front of the dish table. The rack

should then be moved into the Side Loader until it activates the actuator switch. Once the the machine is started, it should pull

the rack through the machine and push it out the unload end. Once a rack has started through, you may put another rack in.

OPERATIONALINSPECTION: Based upon usage, the pan strainer may become clogged with soil and debris as the workday

progresses. Operators should regularly inspect the pan strainer to ensure it has not become clogged. If the strainer does

become clogged, it will reduce the washing capability of the machine. Instruct operators to clean out the pan strainer at regular intervals or as required by work load.

SHUTDOWN AND CLEANING: At the end of the workday, remove the pan strainer and clean as required. Wipe out the inside

of the Side Loader and then reinsert the strainer.

AJ-44C Series Technical Manual 7610-001-76-22

Issued: 03-21-2006 Revised: N/A

SECTION 2: INSTALLATION/OPERATION INSTRUCTIONS

SIDE LOADER INSTALLATION & OPERATION INSTRUCTIONS

41

Page 5

CONCEALED DAMAGE OR MISSING P

ARTS:

IMPORTANT: FOR YOUR PROTECTION, PLEASE READ AND OBSERVE THE FOLLOWING:

This steam booster has been thoroughly inspected and carefully packed before leaving our warehouse.

Concealed loss or damage means loss or damage which does not become apparent until the booster has been unpacked. The

contents may be damaged in transit due to rough handling even though the carton may not show external damage.

If it is found that the shipment has concealed damage, PLEASE DO NOT RETURN IT TO JACKSON, but notify the carrier

(within 48 hours) asking them to send their agent to fill out an inspection report. Save the cartons so he may inspect them and

be sure to note in the report any black marks, creases, tears, crushed corners or any other marks indicating rough handling.

Also, notify your JACKSON dealer immediately.

If it is discovered that there are missing parts, please notify your JACKSON dealer immediately.

EQUIPMENT MOUNTING:

Your booster should come pre-assembled and will require that it be permanently mounted in place. The platform has prepunched holes to allow for mounting to the installation floor. NOTE: The D226 Booster must be properly mounted and level

before being used. Once the platform is secure to the floor, attach the water and steam lines in accordance with local and

national codes.

PLUMBING:

NOTE: ALL CONNECTIONS MUST COMPLY WITH ALL APPLICABLE LOCAL, STATE AND NATIONAL PLUMBING

CODES.

The plumber is responsible for ensuring that the water line is THOROUGHLY FLUSHED BEFORE connecting it to any manu-

al or solenoid valve. It is necessary to remove all foreign matter such as chips (resulting from cutting or threading pipes), pipe

joint compound or, if soldered fittings are used, bits of solder or cuttings from the lines. This debris, if not removed, may lodge

in the valves and render them inoperative.

The D226 Booster is designed to take incoming water from a minimum temperature of 110°F to approximately 180°F for use in

the final rinse of your Jackson dishmachine. In order to do this, water is supplied to the booster and is heated by tubes carrying 15-25 PSIG flow steam. Heat is transferred from the steam into the water, raising the temperature.

Install condensate drains in accordance with applicable codes.

The D226 Booster is designed to operate at a water flow rate of 20 ±5 PSI. The assembly comes with a water pressure reg-

ulator, which is preset at the factory. However, adjustment may be required so ensure that you verify the the flow pressure

before beginning operations. See the instructions regarding adjustment and maintenance of the water pressure regulator for

more information.

WARNING: The D226 Booster is designed to heat water to a minimum of 180°F and is extremely hot during operations.

Advise personnel of the dangers associated with touching booster components as burns or severe injury can occur.

This equipment is not recommend for use with deionized water or other aggressive fluids. Use of deionized

water or other aggressive fluids will result in corrosion and failure of materials and components. Use of deionized water or other aggressive fluids will void the manufacturer's warranty.

AJ-44C Series Technical Manual 7610-001-76-22

Issued: 03-21-2006 Revised: N/A

SECTION 2: INSTALLATION/OPERATION INSTRUCTIONS

D226 STEAM BOOSTER INSTALLATION & OPERATION INSTRUCTIONS

42

Page 6

ELECTRICAL:

WARNING: Electrical and grounding connections must comply with applicable portions of the National Electrical Code

ANSI / NFPA70 (latest edition) and/or other electrical codes.Disconnect electrical power supply and place a tag or lock

at the disconnect switch to indicate that you are working on the circuit.

To connect the incoming power, run the conduit for power wires through the open

hole in the back of the control box. Connect the power wires to the terminal block as

it is labeled (L1 and L2). Run the ground wire to the grounding lug marked “GND”.

Tight connections and conduit nuts and close the control box by putting the cover on

and securing with the 10-32 screws.

OPERA

TION:

WARNING: The heat exchanger used in the D226 Booster system is a pres-

sure vessel with very precise operating parameters. Safety equipment such as

relief valves should never be tampered with or disabled. These devices are meant to

protect the equipment and the operator from harm, damage and death.

1. Ensure that water, steam and any condensate drains are connected to the booster.

2. Start the water flow first, open the condensate drains and then begin steam flow.

3. On the control box, press the power switch and put it in the ON position. The power light should illuminate.

The unit should run normally now.

WARNING: Do not shock the system by applying the steam before the water. This can cause damage to the booster.

The following explanation describes the operation of the D226 Booster.

NOTE: This explanation assumes that water and steam have been connected to the machine.

1. When the power switch (S1) is placed in the ON position, power is provided to both the power light (E1) and the thermostat

(TS1).

2. The thermostat (TS1) will close when the water falls below the minimum setpoint, energizing the steam solenoid light (E2)

and the steam solenoid (FS1).

3. The steam solenoid (FS1) will remain open, allowing steam into the booster, until the water temperature reaches the desired

temperature. At that point, the thermostat (TS1) will open, de-energizing the steam solenoid (FS1) and the steam solenoid light

(E2).

IMPORTANT: Please remember that all of the components in the control box are under line voltage (208-240 volts).

Under no circumstance is the control box cover to be removed or opened during normal operations!

SHUTDOWN (FOR SER

VICE ONLY):

WARNING: The D226 Booster is designed to heat water to a minimum of 180°F and is extremely hot during operations.

Advise personnel of the dangers associated with touching booster components as burns or severe injury can occur.

1. Turn the power switch to the OFF position. The power light should extinguish.

2. Secure steam flow to the unit.

3. Secure water flow.

4. Close the condensate drains as required by procedure and/or code.

5. Do not attempt to clean, wipe down or perform any maintenance on the booster until it has been given a generous amount

of time to cool down.

AJ-44C Series Technical Manual 7610-001-76-22

Issued: 03-21-2006 Revised: N/A

SECTION 2: INSTALLATION/OPERATION INSTRUCTIONS

D226 STEAM BOOSTER INSTALLATION & OPERATION INSTRUCTIONS (CONTINUED)

43

10

Terminal Block

D226 Conrtol Box

Page 7

Due to the fact that each customer may have different requirements for the orientation of the gas booster heater relative to the

main dishmachine, the hose lengths that connect the two units must be customized during each installation. The appropriate

3/4” hosing, fittings and gaskets have been provided.

To prevent incorrect measurements of the hose, it is recommended to place one barbed hose fitting into the end of the uncut

length of hose coil and attach that fitting to an appropriate connection. Run the hose to the corresponding connection on the

other unit before cutting the hose. Use a barbed hose fitting that is screwed into the second connection on the other unit before

cutting the hose. Use a barbed hose fitting that is screwed onto the second connection to gauge the correct distance. Ensure

a smooth “flow” of hose without any sharp turns or kinks.

To aid in pushing the barbed hose fitting into the hose, place the fitting on a hard surface (i.e. the floor) with the barbed e nd of

the fitting pointing upward and push the hose down onto the fitting. Asmall amount of lubricant (i.e. petroleum jelly) may aid in

this process.

AJ-44C Series Technical Manual 7610-001-76-22

Issued: 03-21-2006 Revised: N/A

SECTION 2: INSTALLATION/OPERATION INSTRUCTIONS

GAS CONVEYOR HOSE INSTALLATION

44

Barbed Hose Fitting

Connection

Attach the hose fitting to this

connection before making the

cut at the other end of the

hose.

Hose

Cut the hose at the location

where the hose is even

with the yellow plastic stop.

Page 8

AJ-44C Series Technical Manual 7610-001-76-22

Issued: 03-21-2006 Revised: N/A

SECTION 2: INSTALLATION/OPERATION INSTRUCTIONS

GAS CONVEYOR HOSE INSTALLATION (CONTINUED)

45

TYPICAL RECIRCULATING WATER HOOK-UP

FOR ALL GAS HEATED CONVEYORS

HOOKUP WHEN GAS BOOSTER HEATER

IS LOCATED TO THE

RIGHT OF THE

DISHMACHINE

HOOKUP WHEN GAS BOOSTER HEATER

IS LOCATED TO THE

LEFT OF THE

DISHMACHINE

CONNECTION HOSES ARE CUT TO L ENGTH DURING INSTALLATION.

(ENOUGH HOSE IS PROVIDED TO L OCATE T HE GAS BO OT ER H EATER APPROXIMATELY 9 FEET

AWAY FROM THE DISHMACHINE. ADDITIONAL HO SE MUST BE OR DERED IF A GREATER DISTANCE

IS REQUIRED. DISTANCES GREATER THAN 20 F EET AWAY CAN AF FEC T TH E H EAT I N G PER F ORMANCE

OF THE UNIT)

* HOSES MARKED A IN THE ABOVE ILLUSTRATIONS CONNECT TO THE INLET WATER CONNECTION OF THE GAS BOOSTER HEATER

** HOSES MARKED B IN THE ABOVE ILLUSTRATIONS CONNECT TO THE OUTLET WATER CONNECTION OF THE GAS BOOSTER HEATER

Page 9

PREPARATION: Before proceeding with the start-up of the unit, verify the following:

1. Close door(s) on dishmachine.

2. Close the drain valve(s).

POWER UP (ELECTRICALLY-HEATED MODELS): To energize the unit, turn on the power at the service breaker. The volt-

age should have been previously verified as being correct. If not, the voltage will have to be verified.

POWER UP (STEAM-HEATED MODELS): To energize the unit, turn on the power at the service breaker. The voltage should

have been previously verified as being correct. If not, the voltage will have to be verified. Ensure that the steam service is connected and that steam is flowing to the machine. Without steam, the water will not reach the required minimum temperatures

that the machine is designed to operate at.

POWER UP (GAS-HEATED MODELS): T o energize the unit, turn on the power at the service breaker . The voltage should have

been previously verified as being correct. If not, the voltage will have to be verified. Ensure that the gas service is connected

and that gas is flowing to the machine. Without gas, the water will not reach the required minimum temperatures that the

machine is designed to operate at.

FILLING THE WASH TUB: Ensure that the delime switch is in the NORMAL position, and place the power switch into the ON

position. The machine should fill automatically and shut off when the appropriate level is reached (just below the pan strainer).

The wash tub must be completely filled before operating the wash pump to prevent damage to the component. Once the wash

tub is filled, the unit is ready for operation.

Machines equipped with prewash sections should not be run without water in those sections. This can cause

damage to components.

WARE PREPARATION: Proper preparation of ware will help ensure good results and less re-washes. If not done properly, ware

may not come out clean and the efficiency of the dishmachine will be reduced. It is important to remember that a dishmachine

is not a garbage disposal and that simply throwing unscraped dishes into the machine simply defeats the purpose altogether

of washing the ware. Scraps should be removed from ware prior to being loaded into a rack. Pre-rinsing and pre-soaking are

good ideas, especially for silverware and casserole dishes. Place cups and glasses upside down in racks so that they do not

hold water during the cycle. The dishmachine is meant not only to clean, but to sanitize as well, to destroy all of the bacteria

that could be harmful to human beings. In order to do this, ware must be properly prepared prior to being placed in the machine.

DAILY MACHINE PREPARATION: Refer to the section entitled “PREPARATION” at the top of this page and follow the instructions there. Afterwards, check that all of the chemical levels are correct and/or that there is plenty of detergent available for the

expected workload.

WASHING A RACK OF WARE: To wash a rack, simply slide a rack of soiled ware into the load end of the machine. Once the

the machine is started, it should pull the rack through the machine and push it out the unload end. Once a rack has started

through, you may put another rack in.

OPERATIONAL INSPECTION: Based upon usage, the pan strainers may become clogged with soil and debris as the workday progresses. Operators should regularly inspect the pan strainers to ensure they have not become clogged. If the strainers

do, they will reduce the washing capability of the machine. Instruct operators to clean out the pan strainers at regular intervals

or as required by work load.

NOTE: On units equipped with prewash sections (AJ-66 and AJ-80), operators should also t ake the time to inspect the prewash

section strainers and clean them as required by workload.

SHUTDOWN AND CLEANING (ELECTRICALLY-HEATED MODELS): At the end of the workday, place the power switch in

the OFF position and open the door(s). Open the drain valves and allow the machine to drain completely. Remove the pawl bar

assembly (clean as required). Remove the pan strainers and, if equipped, the prewash strainers, run off sheets and scrap basket strainer. Remove the wash and, if equipped, the prewash arms and verify that the nozzles and arms are free from obstructions. Flush the arms with fresh water. Remove the pump suction strainers and clean out as required. Remove the rinse tray

assembly and clean. Remove the curtains and scrub with a mild detergent and warm water. Wipe out the inside of the unit and

then reassemble with the components previously removed.

AJ-44C Series Technical Manual 7610-001-76-22

Issued: 03-21-2006 Revised: N/A

SECTION 2: INSTALLATION/OPERATION INSTRUCTIONS

DISHMACHINE OPERATING INSTRUCTIONS

46

Page 10

SHUTDOWN AND CLEANING (STEAM-HEATED MODELS): At the end of the workday, place the power switch in the OFF

position, secure the flow of steam to the machine and open the door(s). Open the drain valves and allow the machine to drain

completely. Remove the p awl bar assembly (clean as required). Remove the p an strainers and, if equipped, the prewash strainers, run off sheets and scrap basket strainer. Remove the wash and, if equipped, the prewash arms and verify that the nozzles

and arms are free from obstructions. Flush the arms with fresh water. Remove the pump suction strainers and clean out as

required. Remove the rinse tray assembly and clean. Remove the curtains and scrub with a mild detergent and warm water.

Wipe out the inside of the unit and then reassemble with the components previously removed.

SHUTDOWN AND CLEANING (GAS-HEATED MODELS): At the end of the work day, shut down the gas booster in accordance with manufacturer’s instructions. Place the power switch in the OFF position, secure the flow to the machine and open

the door(s). Open the drain valves and allow the machine to drain completely. Remove the pawl bar assembly (clean as

required). Remove the pan strainers and, if equipped, the prewash strainers, run off sheets and scrap basket strainer. Remove

the wash and, if equipped, the prewash arms and verify that the nozzles and arms are free from obstructions. Flush the arms

with fresh water. Remove the pump suction strainers and clean out as required. Remove the rinse tray assembly and clean.

Remove the curtains and scrub with a mild detergent and warm water. Wipe out the inside of the unit and then reassemble with

the components previously removed.

AJ-44C Series Technical Manual 7610-001-76-22

Issued: 03-21-2006 Revised: N/A

SECTION 2: INSTALLATION/OPERATION INSTRUCTIONS

DISHMACHINE OPERATION INSTRUCTIONS (CONTINUED)

47

Page 11

AJ-44C Series Technical Manual 7610-001-76-22

Issued: 03-21-2006 Revised: 05-03-2007

SECTION 2: INSTALLATION/OPERATION INSTRUCTIONS

CHANGING DUAL SANITIZATION MODE

48

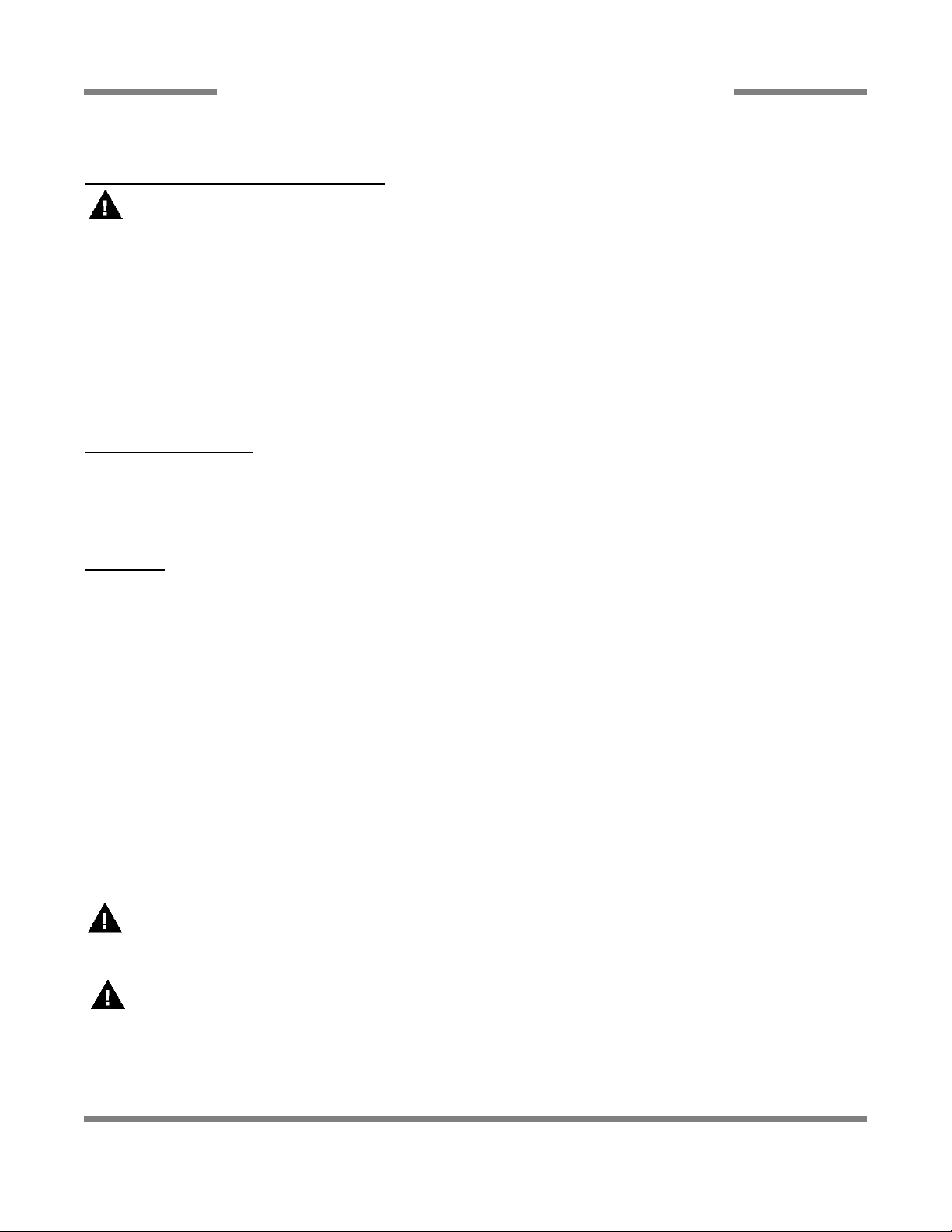

Figure 2

Figure 1: Drive Mechanism

MODEL: AJ-44CE

SERIAL #

60 HZ 3 PHASE 3 WIRE

2.0 HPWASH MOTOR

CONVEYOR SPEED

WASH TANK TEMPERATURE160° F MIN.

460 V

2.8 A

1/4 HPDRIVE MOTOR 0.6 A

15 KWWASH HEATER LOAD 18.8 A

TOTAL AMP LOAD 22.2 A

FINAL RINSE TEMPERATURE

180° F MIN.

FLOW PRESSURE 20 5 PSI

±

HOT WATER

SANITIZING

6.9 FPM

CHEMICAL

SANITIZING

6.5 FPM

140° F MIN.

140° F MIN.

20 5 PSI

±

230 V

5.6 A

1.1 A

37.7 A

44.4 A

208 V

5.6 A

1.1 A

41.7 A

48.4 A

An Company

Commercial

Dishwasher

597G

NOTE: SEE INSTRUCTION IN MANUAL FOR MODIFYING MODE OF

SANITIZATION.

US Patent Number(s):

6,012,567

Canadian Patent Number(s):

2,205,331

Made in the USA

Jackson MSC Inc.

P. O. Box 1060

Barbourville, KY. 40906

(606) 523-9795

09905-021-70-81 E

XXX XXXX X

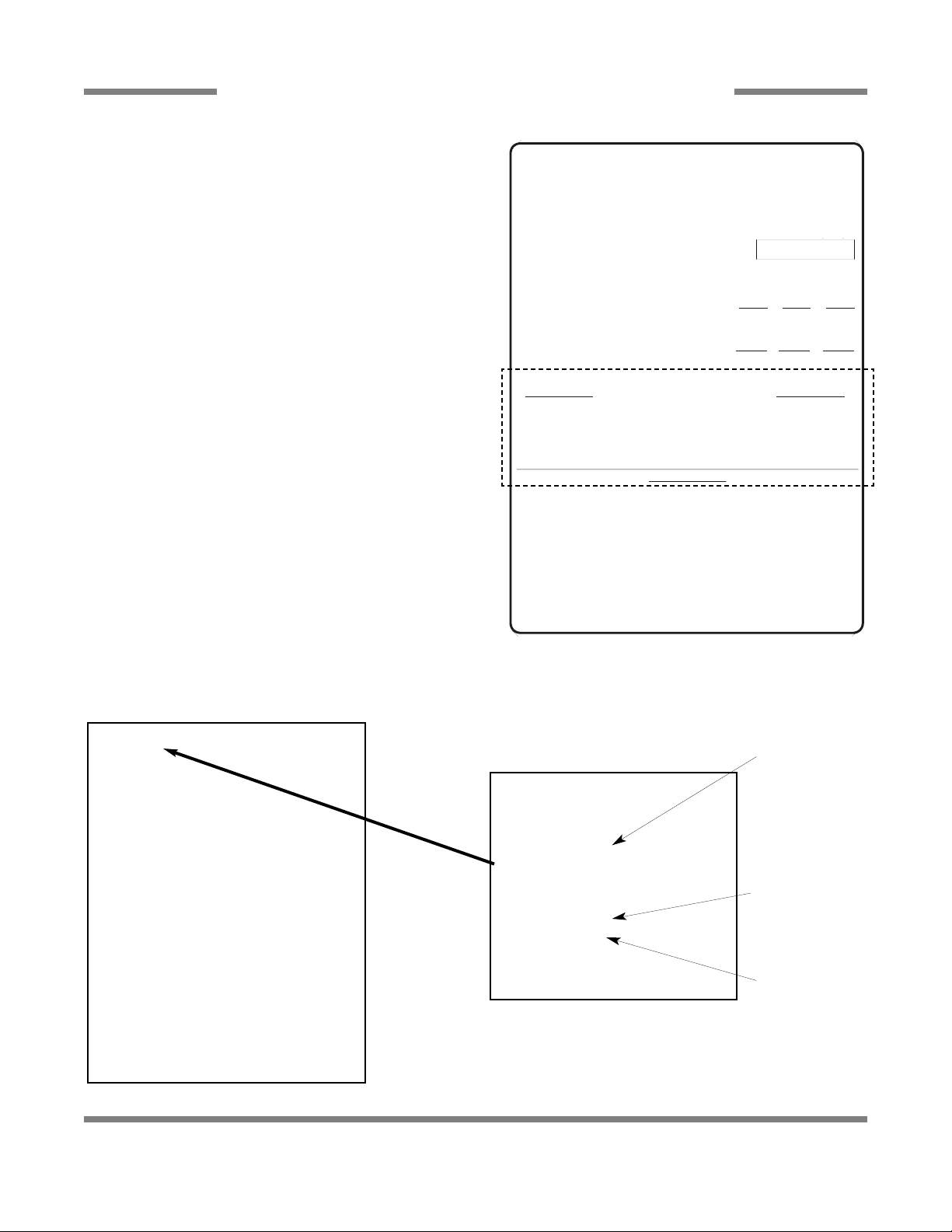

If the machine has a dataplate like the one shown, which indicates both Hot Water Sanitizing and Chemical Sanitizing

operation parameters (the area within dashed box), it is possible to change the sanitizing mode after the machine has left

the original manufacturer's facility. This change can only be

performed by an authorized Jackson service technician. If the

machine does not have a dataplate like the one shown, the

sanitization mode CAN NOT be changed.

Follow the instructions below to change the mode of sanitization. Failure to follow these instructions can result in a violation of applicable regulatory codes.

DRIVE MECHANISM MAXIMUM SPEED ADJUSTMENT:

Note: This adjustment is only required when changing from

hot water sanitizing to chemical sanitizing mode.

Locate the maximum speed adjustment mechanism at the top

of the conveyor drive mechanism (Figure 1). Figure 2 shows

an enlarged view of the maximum speed adjustment mechanism. Loosen the Bottom Jam Nut approximately one turn

counterclockwise. Move the Top Jam Nut down on the

threaded shaft by turning it approximately 1/2 turn counterclockwise. Tighten the Adjustment Nut by turning it clockwise.

Retighten the Bottom Jam Nut against the Top Jam Nut.

Bottom Jam Nut

Top Jam Nut

Adjustment Nut

Please note the parameters for both modes of sanitization. If your data

plate has this information, it is convertible from one mode to another.

XXXXXXXXX

Page 12

THERMOSTAT ADJUSTMENT: Remove the front dress

panel from the machine to expose the heater/thermostat box.

Remove the cover from the heater/thermostat box. Locate the

wash tank regulating thermostat (see diagram).

The wash tank regulating thermostat will maintain the correct

wash water temperature. NSF requirements specify that the

wash water during operation be 140ºF minimum in the chemical sanitizing mode and 160ºF minimum in the hot water sanitizing mode. Adjust the thermostat to achieve the required

minimum temperatures during operation. Turn the adjustment

screw clockwise to increase the temperature set point, counterclockwise to decrease the temperature set point.

Replace heater/thermostat box cover and front dress panel.

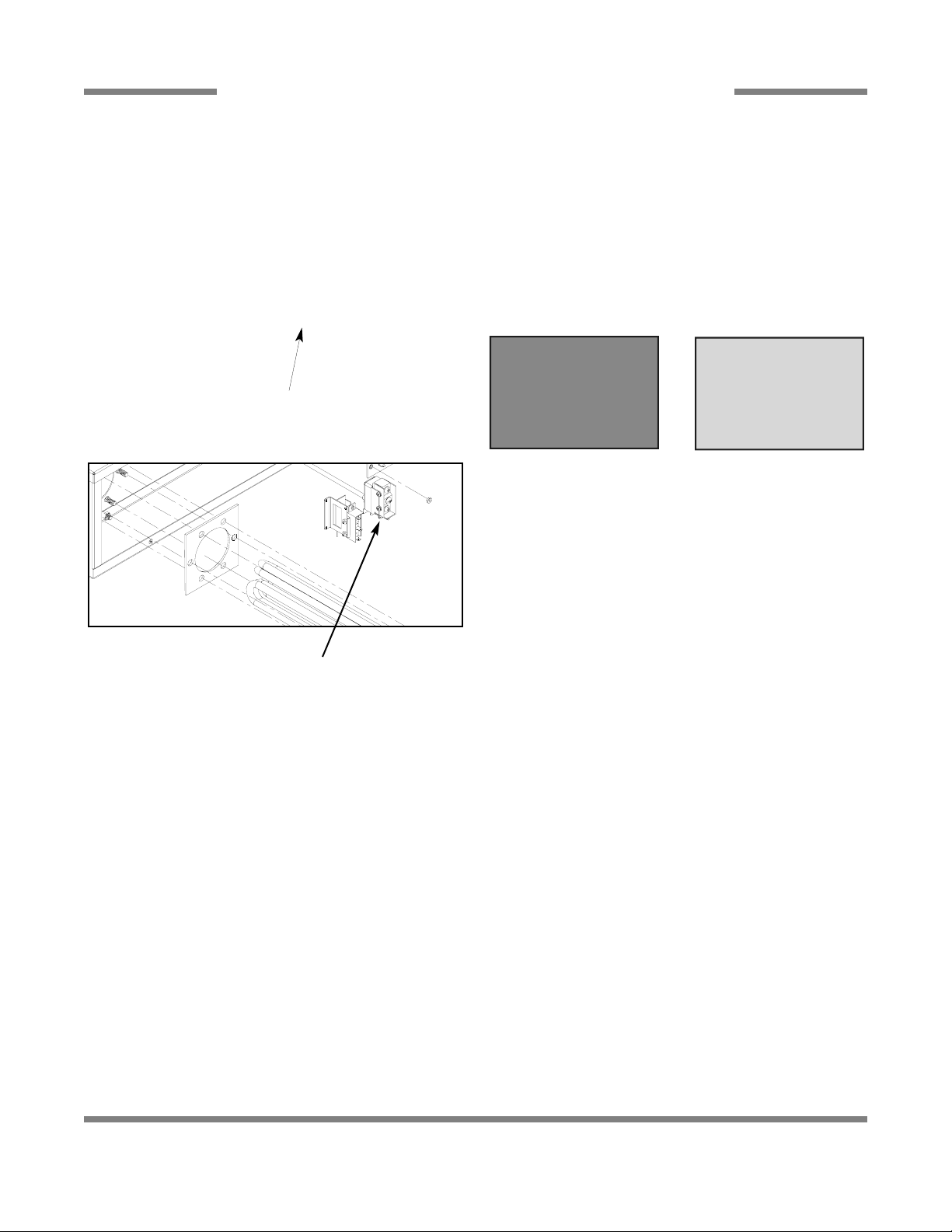

IDENTIFICATION OF SANITIZING MODE: Apply the correct

temperature gauge label to the face of the temperature

gauges. In the chemical sanitizing mode, the temperature

gauge labels must specify 140ºF minimum wash temperature

and 140ºF minimum rinse temperature. In the hot water sanitizing mode, the temperature gauge labels must specify

160ºF minimum wash temperature and 180ºF minimum rinse

temperature.

Apply the correct sanitizing mode label in a visible location on

the side of the control box.

INSTALL SANITIZER DISPENSER: For machines in the

chemical sanitizing mode, a NSF Standard 29 approved

chemical dispenser must be installed to dispense sanitizer

into the final rinse line. Follow instructions included with the

chemical dispenser. The system selected must be able to provide detergent and sanitizer in the required concentrations.

The minimum chlorine concentration for proper sanitization is

50 PPM. Furthermore, the selected feeder needs to be able to

operate against a head of 25 PSI and deliver 7.38 ml of a 10%

chlorine sanitizer per minute.

FINAL CHECK: Verify that the incoming water matches the

flow pressure and temperature requirements listed on the

machine data plate. Verify that minimum wash and rinse temperatures are maintained during operation.

AJ-44C Series Technical Manual 7610-001-76-22

Issued: 03-21-2006 Revised: 04-30-2007

SECTION 2: INSTALLATION/OPERATION INSTRUCTIONS

CHANGING DUAL SANITIZATION MODE (CONTINUED)

49

Wash Thermostat

Front Dress Panel

Control Box Gauge Location

NOTICE:

THIS MACHINE IS

CURRENTLY IN

HOT WATER SANITIZING

MODE!

09905-003-33-15

NOTICE:

THIS MACHINE IS

CURRENTLY IN

CHEMICAL SANITIZING

MODE!

09905-003-33-14

Orange background

Yellow background

Page 13

Detergent usage and water hardness are two factors that contribute greatly to how efficiently your dishmachine will operate.

Using detergent in the proper amount can become, in time, a source of substantial savings. A qualified water treatment specialist can tell you what is needed for maximum efficiency from your detergent, but you should still know some basics so you’ll

understand what they are talking about.

First, you must understand that hard water greatly effects the performance of the dishmachine. Water hardness is the amount

of dissolved calcium and magnesium in the water supply. The more dissolved solids in the water, the greater the water hardness. Hard water works against detergent, thereby causing the amount of detergent required for washing to increase. As you

use more detergent, your costs for operating the dishmachine will increase and the results will decrease. The solids in hard

water also may build-up as a scale on wash and rinse heaters, decreasing their ability to heat water. Water temperature is

important in removing soil and sanitizing dishes. If the water cannot get hot enough, your results may not be satisfactory. This

is why Jackson recommends that if you have installed the machine in an area with hard water, that you also install some type

of water treatment equipment to help remove the dissolved solids from the water before it gets to the dishmachine.

Second, hard water may have you adding drying agents to your operating cycle to prevent spotting, when the real problem is

deposited solids on your ware. As the water evaporates off of the ware, the solids will be left behind to form the spotting and

no amount of drying agent will prevent this. Again, using treated water will undoubtedly reduce the occurrences of this problem.

Third, treated water may not be suitable for use in other areas of your operation. For instance, coffee made with soft water may

have an acid or bitter flavor. It may only be feasible to install a small treatment unit for the water going into the dishmachine

itself. Discuss this option with your qualified water treatment specialist.

Even after the water hardness problems have been solved, there still must be proper training of dishmachine operators in how

much detergent is to be used per cycle. Talk with your water treatment specialist and detergent vendor and come up with a

complete training program for operators. Using too much detergent has as detrimental effects as using too little. The proper

amount of detergent must be used for job. It is important to remember that certain menu items may require extra detergent by

their nature and personnel need to be made aware of this. Experience in using the dishmachine under a variety of conditions,

along with good training in the operation of the machine, can go a long way in ensuring your dishmachine operates as efficiently as possible.

Certain dishmachine models require that chemicals be provided for proper operation and sanitization. Some models even

require the installation of third-party chemical feeders to introduce those chemicals to the machine. Jackson does not recommend or endorse any brand name of chemicals or chemical dispensing equipment. Contact your local chemical distributor for

questions concerning these subjects.

Some dishmachines come equipped with integral solid detergent dispensers. These dispensers are designed to accommodate

detergents in a certain sized container. If you have such a unit, remember to explain this to your chemical distributor upon first

contacting them.

As explained before, water temperature is an important factor in ensuring that your dishmachine functions properly. The data

plate located on each unit details what the minimum temperatures must be for either the incoming water supply, the wash tank

and the rinse tank, depending on what model of dishmachine you have installed. These temperatures may also be followed by

temperatures that Jackson recommends to ensure the highest performance from you dishmachine. However, if the minimum

requirements are not met, the chances are your dishes will not be clean or sanitized. Remember, a dish can look clean, but it

may not be sanitized. Instruct your dishmachine operators to observe the required temperatures and to report when they fall

below the minimum allowed. Aloss of temperature can indicate a much larger problem such as a failed heater or it could also

indicate that the hot water heater for your operation is not up to capacity and a larger one may need to be installed.

There are several factors to consider when installing your dishmachine to ensure that you get the best possible results from it

and that it operates at peak efficiency for many years. Discuss your concerns with your local chemical distributor and water

treatment specialist before there is a problem.

AJ-44C Series Technical Manual 7610-001-76-22

Issued: 03-21-2006 Revised: N/A

SECTION 2: INSTALLATION/OPERATION INSTRUCTIONS

DETERGENT CONTROL

50

Page 14

AJ-44C Series Technical Manual 7610-001-76-22

Issued: 03-21-2006 Revised: N/A

SECTION 2: INSTALLATION/OPERATION INSTRUCTIONS

STRIKER PLATE LIMIT SWITCH INSTALLATION INSTRUCTIONS

51

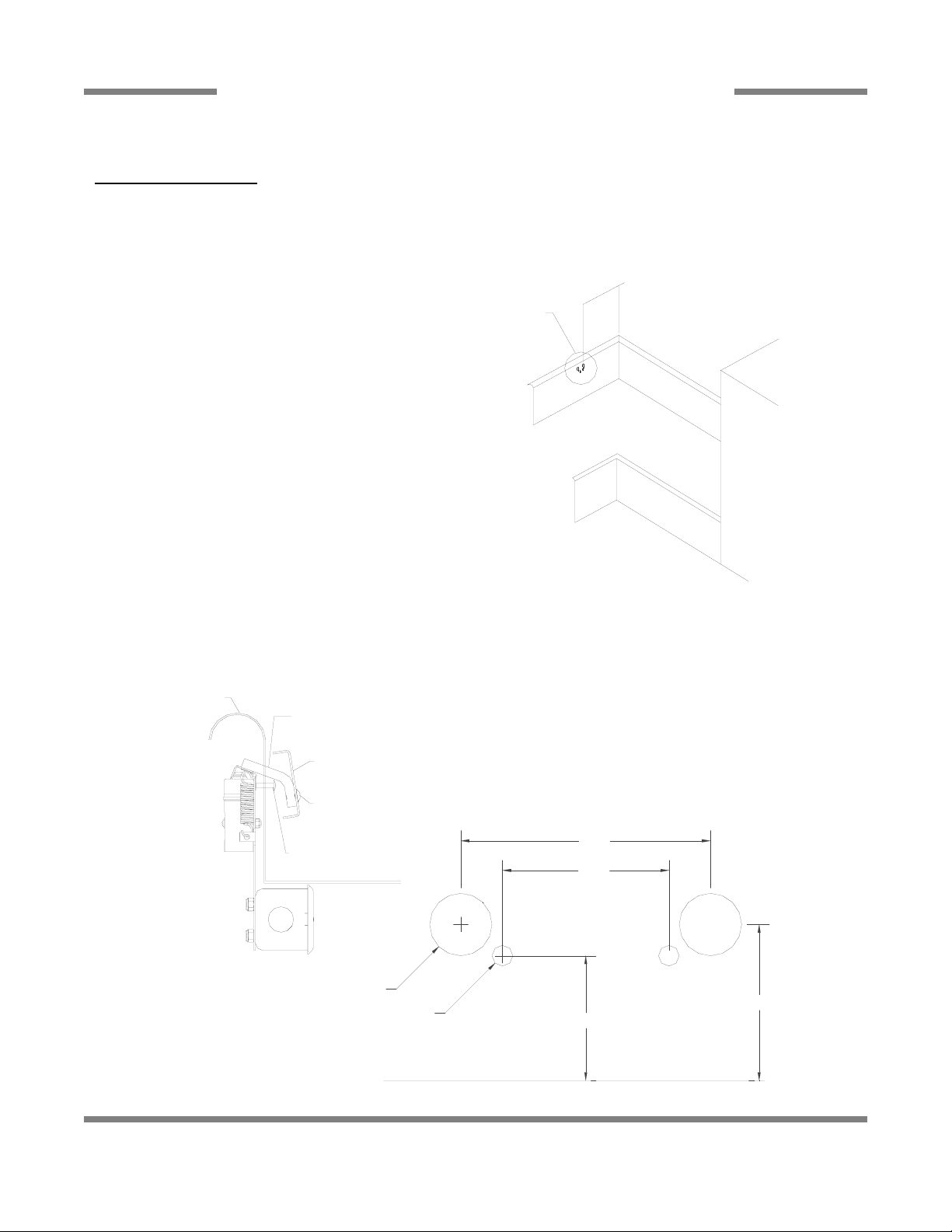

TABLE LIMIT SWITCH THROUGH ROD HOLES

TABLE

SWITCH RODS

STRIKE PLATE

STRIKE PLATE BOLTS

MOUNTING BOLTS

TABLE BOTTOM

3.00

2.00

Ø0.75

Ø0.25

1.50

TABLE BOTTOM

1.875

INSTALL AT FAR END OF TABLE

1/3 RACK WIDTH

Installation Instructions:

1. Wiring: The switch is wired common and normally open because of the hinge design. By

interrupting the line in series with the door

switches, the dishmachine ceases to operate.

Refer to the machine schematic for details on

how to wire the switch.

2. Parts of the table switch are mounted in the

dishtable, at the end of the table and under the

table. See the drawing(s) for the relationship of

the switch to the table.

3. Move the limit switch as far down on the two

slots as possible and see that the limit switch is

straight on the base plate. This might require

adjustment of the nut on the connector for the

limit switch.

4. Then adjust the inside and the outside connector nuts for the connector box so that it lines

up even with the limit switch and the base plate.

5. Tighten down the nuts for the seal so that

they are tight.

6. If you have any difficulty you might have to adjust the

connectors to the seal, screwing in or screwing out

until the installation is straight on the table and the limit

switch is actuated correctly by the rack.

Unless noted, all dimensions are in

inches.

Page 15

52

SECTION 3:

PREVENTATIVE MAINTENANCE

Page 16

The dishmachines covered in this manual are designed to operate with a minimum of interaction with the operator. However,

this does not mean that some items will not wear out in time. Jackson highly recommends that any maintenance and repairs

not specifically discussed in this manual should be performed by QUALIFIED SERVICE PERSONNELONLY. Performing maintenance on your dishmachine may void your warranty if it is still in effect, so if you have a question or concern, do not hesitate

to contact Jackson.

There are many things that operators can do to prevent catastrophic damage to the dishmachine. One of the major causes of

component failure has to do with prescrapping procedures. Adishmachine is not a garbage disposal; any large pieces of material that are put into the machine shall remain in the machine until they are either broken up (after spreading out on your ware!)

or physically removed. Strainers are installed to help catch debris, but they do no good if they are clogged. Have operators regularly inspect the pan strainers to ensure (1) that they are free of soil and debris and (2) they are laying flat in the tub.

When cleaning out strainers, do NOT beat them on waste cans. The strainers are made of metal and can be forgiving; but once

severe damage is done, it is next to impossible for the strainer to work in the way it was designed to. Wipe out strainers with

a rag and rinse under a faucet if necessary. For stubborn debris, a toothpick should be able to dislodge any obstructions from

the perforations. Always ensure that strainers are placed back in the machine before operation and that they lay flat in the tub.

You may wish to also refer to the page entitled “Detergent Control” in order to learn more about how your water hardness will

effect the performance of your machine. Hard water makes dishmachines work harder and decreases efficiency.

Again, it is important to remind operators that trying to perform corrective maintenance on the dishmachine could lead to larger problems or even cause harm to the operator. If a problem is discovered; secure the dishmachine using proper shut down

procedures as listed in this manual and contact Jackson.

Some problems, however, may having nothing to do with the machine itself and no amount of preventative maintanence is

going to help. Acommon problem has to do with temperatures being too low. Verify that the water temperatures coming to your

dishmachine match the requirements listed on the machine data plate. There can be a variety of reasons why your water temperature could be too low and you should discuss it with Jackson to determine what can be done.

By following the operating and cleaning instructions in this manual, you should get the most efficient results from your machine.

As a reminder, here are some steps to take to ensure that you are using the dishmachine the way it was designed to work:

1. Ensure that the water temperatures match those listed on the machine data plate.

2. Ensure that all strainers are in place before operating the machine.

3. Ensure that all wash and/or rinse arms are secure in the machine before operating.

4. Ensure that drains are closed/sealed before operating.

5. Remove as much soil from dishes by hand as possible before loading into racks.

6. Do not overfill racks.

7. Ensure that glasses are placed upside down in the rack.

8. Ensure that all chemicals being injected to machine have been verified as being at the correct concentrations.

9. Clean out the machine at the end of every workday as per the instructions in the manual.

10. Always contact Jackson whenever a serious problem arises.

11. Follow all safety procedures, whether listed in this manual or put forth by local, state or national codes/regulations.

AJ-44C Series Technical Manual 7610-001-76-22

Issued: 03-21-2006 Revised: N/A

SECTION 3: PREVENTATIVE MAINTENANCE

PREVENTATIVE MAINTENANCE

53

Page 17

WARNING: Maintenance should only be performed by authorized service personnel in order to ensure safe and

effective workmanship, while minimizing danger to operating personnel. The D226 Steam Booster is designed

to operate at temperatures capable of causing burns to personnel. Always allow the unit to cool down to an

acceptable temperature prior to performing any maintenance.

Very little maintenance is required to be performed on the D226 Booster. So long as the steam and water used with the unit

have the proper filtration and are operated at the correct temperature and pressures, then you should expect many years of

reliable service out of your system.

MAINTENANCE OF THE W

ATER PRESSURE REGULAT

OR:

Incoming water pressure can be regulated by adjusting the water pressure regulator on the system. In order to adjust pressure,

loosen the top nut on the regulator. This will allow you to turn the adjusting screw. Turn the adjusting screw clockwise to

increase pressure and counter-clockwise to decrease. Pressure can be read on the pressure gauge located on the water outlet side of the heat exchanger. Once the desired pressure is achieved, tighten the top nut to ensure that the adjustment cannot be accidently changed.

The water pressure regulator has an internal strainer that can be removed through the bottom hexagonal plug. This may need

to be periodically checked depending on the water quality. It is important that the water supply to the water pressure regulator

be secured prior to trying to clean the strainer.

MAINTENANCE OF THE RELIEF V

ALVES, SAFETY VALVES AND THERMOSTAT:

These components are shipped from the factory preset and should not be tampered with. None of these components are considered adjustable and no attempt should be made to do so. If a component does not appear to be working properly, then it

should be replaced immediately by an authorized service representative.

AJ-44C Series Technical Manual 7610-001-76-22

Issued: 03-21-2006 Revised: N/A

SECTION 3: PREVENTATIVE MAINTENANCE

D226 MAINTENANCE

54

Page 18

AJ-44C Series Technical Manual 7610-001-76-22

Issued: 03-21-2006 Revised: N/A

SECTION 3: PREVENTATIVE MAINTENANCE

LUBRICATION CHART FOR DRIVE GEAR

55

Note: The maintenance procedures detailed here are manufacturer’s instructions for the WINSMITH brand of gear reducer

that is installed on the rack conveyors covered in this manual.

Ambient Temperature -30 - 15°F 16 - 50°F 51 - 95°F 51 - 95°F 96 - 131°F 96 - 131°F

Final Stage Worm Speed

1

up to 2000 FPM up to 2000 FPM up to 450 FPM above 450 FPM up to 450 FPM above 450 FPM

ISO Viscosity Grade 220 460 680 460 680 460

1

AGMA Lubricant No. 5S #7 Compounded #8 Compounded #7 Compounded 8S 7S

Mobil SHC 630 600W Super Extra Hecla Super 600W Super SHC 636 SHC 634

Cylinder Cylinder

American Lubricants SHC-90W AGMA #7 Gear Oil AGMA #8 Gear Oil AGMA #7 Gear Oil N/A N/A

Castrol Tribol 800/220 Tribol 1105-7C Tribol 1105-8C Tribol 1105-7C Tribol 800/680 Tribol 800/460

Chevron Tegra 220 Cylinder Oil W460 Cylinder Oil W680 Cylinder Oil W460 Tegra 680 Tegra 460

Conoco Syncon R & O Inca Oil 460 Inca Oil 680 Inca Oil 460 N/A Syncon R & O

220 460

Exxon (Esso) Teresstic SHP220 Spartan EP 460 Spartan EP 680 Spartan EP 460 Teresstic SHP 680 Teresstic SHP

460

Fiske Brothers SPO-MG SPO-277 SPO-288 SPO-277 N/A N/A

Shell Omala RL 220 Valvata J 460 Valvata J 680 Valvata J 460 Omala RL 680 Omala RL 460

Texaco Pinnacle 220 Vanguard 460 Vanguard 680 Vanguard 460 Pinnacle 680 Pinnacle 460

(1) The sliding velocity in feet per minute (FPM) for standard ratios is determined by multiplying the speed of the worm in RPM by

the factor from the table below. For selecting proper lubricant, use the speed of the worm in the final stage (input RPM divided by

the first stage ratio).

Page 19

AJ-44C Series Technical Manual 7610-001-76-22

Issued: 03-21-2006 Revised: N/A

SECTION 3: PREVENTATIVE MAINTENANCE

DRIVE MOTOR GEAR REDUCER PREVENTATIVE MAINTENANCE

56

Note: The maintenance procedures detailed here are manufacturer’s instructions for the WINSMITH brand of gear reducer that is

installed on the rack conveyors covered in this manual.

Lubrication & Maintenance:

Factory filling - WINSMITH speed reducers are oil filled at the factory to the proper level for the standard mounting position that you will

find it in on the unit. The oil level should be checked and adjusted (if necessary) prior to operation, using the oil level plug provided and while

the unit is oriented in its operating position.

Ambient temperature - If the operating ambient temperature is other than 51 - 95°F, then refer to the lubrication chart and refill the unit with

the correct grade based on actual ambient temperature and operating speed. See “Oil changing” below for additional information.

Oil changing - When changing the oil for any reason, it should be remembered that oils of various types may not be compatible. Therefore,

when changing to a different oil, it is recommended that the housing be completely drained and thoroughly flushed with a light flushing oil

prior to refilling with the appropriate lubricant. The oil level should be rechecked after a short period of operation and adjusted, if necessary.

When changing double reduction models, each housing should be drained and filled independently, even though there may be a common

level.

Initial oil change: The new oil in a speed reducer should be changed at the end of 250 hours of operation. This is equivalent to

30 days of peration for 8 hours per day; 15 days of operation for 16 hours per day, or 10 days of operation for 24 hours per day.

Subsequent oil changes: Under normal conditions, after the initial oil change, the oil should be changed after every 2500 hours

of operation, or every 6 months, whichever occurs first. Under severe conditions (rapid temperature changes, moist, dirty or corrosive environment) it may be necessary to mchange oil at intervals of one to three months. Periodic examination of oil samples taken from the unit will

help establish the appropriate interval.

Synthetic oils: Synthetic lubricants can be advantageous over mineral oils in that they generally are more stable, have a much

longer life, and operate over a wider temperature range. These oils are appropriate for any application but are especially useful when units

are subjected to low start-up temperatures or high operating temperatures. However, continuous operation above 225°F may cause damage to seals or other components. It is recommended that the initial oil be changed or filtered after the first 1500 hours of operation to remove

metal particles that accumulate during break-in. Subsequent oil changes should be made after 5000 hours operation if units are operating

in a clean environment. This can be extended to 10,000 hours if using new reformulated Mobil SHC lubricants (orange in color) and the lubricant remains free of contamination over this period. See comments under “Subsequent oil changes” for discussion of severe ambient conditions.

Long term storage or infrequent operation: If a speed reducer is to stand idle for an extended period of time, either prior to

installation or during use, it is recommended that the unit be filled completely with oil to protect interior parts from rust and corrosion due to

internal condensation. Be sure to drain the oil to the proper level before placing the speed reducer in service.

Grease fittings: Some units are equipped with grease fittings to lubricate bearings not adequately lubricated by the oil splash.

These fittings must be lubricated every 3 - 6 months depending on operating conditions. bearing greases must be compatible with the type

of gear lubricant being used (i.e. mineral, synthetic, food grade, etc.). For mineral oils, use a high quality lithium base NLGOI #2 bearing

grease. For synthetic oils, use a synthetic bearing grease such as Mobil Synthetic Universal gease, Mobilith SHC 100 or a sutable equivalent. For food grade lubricants, use Chevron FM grease, NGLI 2, or equivalent.

Low input speeds (under 1600 RPM): When input speeds are less than 1600 RPM, grease fittings will be required to lubricate

any bearings not partially covered by the normal oil level.

Oil temperature: Speed reducers in normal operation can generate temperatures up to 200°F depending on the type of reducer

and the severity of the application 9loading, duration of service, ambient temperatures). Excessive oil temperatures may be the result of several factors including overloading, overfilling, underfilling or inadequate cooling.

Nominal Ratio

Size 5 7.5 10 15 20 25 30 40 50 60 80 100

920 0.347 0.263 0.225 0.216 0.202 0.191 0.215 0.200 0.188 0.182 0.164 0.161

Lubricant selections are provided by the lubricant manufacturer based on AGMArecommeded viscosity grades. Viscosity grades are based

on Lubrication Standard ANSI/AGMA 9005-D94.

Page 20

57

SECTION 4:

TROUBLESHOOTING SECTION

Page 21

WARNING: Inspection, testing and repair of electrical equipment should be performed only by qualified service per-

sonnel. Certain procedures in this section require electrical tests or measurements while power is applied to the

machine. Exercise extreme caution at all times. If test points are not easily accessible, disconnect power, attach

test equipment and reapply power to test. When replacing electrical parts, disconnect power at source circuit breaker

Problem: Nothing on dishmachine operates. The power switch is ON and the power indicator light is OFF.

1. Machine is not wired correctly to incoming power source. Have an electrician verify wiring.

2. Machine circuit breaker is tripped. Reset the circuit breaker. If it trips again, contact an electrician to verify the machine amp

draw.

3. Service breaker is tripped. Reset the service breaker. If it trips again, contact an electrician to verify the machine amp draw.

Problem: Machine will not fill. The power switch is ON and the power indicator light is ON.

1. No water supply to machine. Verify that water lines have been connected to the machine.

2. Dishmachine doors are not closed. Close doors completely.

3. Incoming water solenoid valve damaged/faulty. Verify that the valve is operating. If not, replace.

4. Tank floats faulty. Verify the wiring of the floats. Verify that no debris is jamming the floats. Replace if necessary.

Problem: Machine fills, but fill is weak.

1. Low incoming water pressure. Verify that incoming water pressure during fill is 20 ±5 PSI.

2. Incoming water solenoid is clogged. Verify that debris is not entrapped in valve. If so, remove debris.

Problem: Low wash tank temperature.

1. Low incoming water temperature. Verify that the incoming water temperature matches what is indicated on the machine data

plate.

2. Heater not energizing. Verify that the wash tank heater is operating. If not, replace.

3. Low incoming voltage. Have an electrician verify that the power coming to the machine is the same as indicated on the data

plate.

Problem: Low wash arm pressure, poor spray pattern.

1. Clogged wash arm nozzles. Verify that nozzles are not clogged with debris. If so, remove debris.

2. Clogged wash tank or wash pump strainers. Clean out strainers if necessary.

3. Worn wash pump impeller. Verify status of impeller, replace if necessary.

Problem: Low prewash arm pressure, poor spray pattern.

1. Clogged prewash arm nozzles. Verify that nozzles are not clogged with debris. If so, remove debris.

2. Clogged prewash tank or prewash pump strainers. Clean out strainers if necessary.

3. Worn prewash pump impeller. Verify status of impeller, replace if necessary.

Problem: Inadequate rinse.

1. Low incoming water pressure. Verify that incoming water pressure during fill is 20 ±5 PSI.

2. Incoming water solenoid is clogged. Verify that debris is not entrapped in valve. If so, remove debris.

Problem: Pawl bar moves with no load, but does not move when loaded.

1. Clutch on drive assembly is out of adjustment. Adjust as required.

AJ-44C Series Technical Manual 7610-001-76-22

Issued: 03-21-2006 Revised: N/A

SECTION 4: TROUBLESHOOTING

COMMON PROBLEMS

58

Page 22

Problem: Pawl bar does not move.

1. Failed or broken overload spring. Replace spring if necessary.

2. No power to the drive motor/failed drive motor. Verify power and wiring connections to the motor. If necessary, replace the

motor.

3. Pawl bar not properly installed. Verify that the pawl bar is installed correctly.

Problem: Racks go through the machine, but results are poor.

1. Verify that detergent is being dispensed into the machine at the appropriate quantities for the water volume. If not, get detergent to appropriate level and review results of washing ware.

2. Clogged strainers/scrap basket. Clean out strainers and scrap basket and replace.

3. Ware not being properly prescrapped. Review paragraph entitled “Ware Preparation” in Operating Instructions.

4. Wash or rinse arms missing end plugs or caps. Verify and replace as required.

5. Low tank heat.

6. Inadequate rinse.

7. Incorrect voltage coming to the machine. Verify that the voltage matches that on the machine data plate.

8. Wash pump cavitation due to low water level. Verify that the drains are shut and that the water level is correct.

Problem: Spotting of silverware, glasses and dishes.

1. Incorrect final rinse temperature. Verify that the rinse water temperature matches that which is listed on the machine data

plate.

2. Clogged wash and/or rinse nozzles and arms. Remove the arms and verify that they and their nozzles are from debris.

3. Excessively hard water. Install a water softener to reduce hardness.

4. Loss of water pressure due to clogged/obstructed wash pump. Turn the power off to the machine at the source. Drain the

wash tank of water and verify that the pump intake is free from debris.

5. Improper scrapping procedures. Review the paragraph entitled “Ware Preparation” in Operating Instructions.

6. incorrect detergent/chemcial concentrations. Verify that the detergent/chemical concentrations are correct for the associated water volume.

TORQUE SETTINGS

When replacing components either in the control box or the heater box area, the manufacturer has suggestions on how

much to torque the screws and nuts used in securing items to the machine. Refer to the table below for the torque specifictions:

ITEMS

TORQUE SPEC

Relays 16 In/lbs

Heater Contactor 35 In/lbs

Heater Nuts 16 In/lbs

Terminal Block 50 In/lbs

AJ-44C Series Technical Manual 7610-001-76-22

Issued: 03-21-2006 Revised: N/A

SECTION 4: TROUBLESHOOTING

COMMON PROBLEMS

59

Page 23

WARNING: Inspection, testing and repair of electrical equipment should be performed only by qualified service personnel. Certain procedures in this section require electrical tests or measurements while power is applied to the

machine. Exercise extreme caution at all times. If test points are not easily accessible, disconnect power, attach

test equipment and reapply power to test. When replacing electrical parts, disconnect power at source circuit breaker

Problem: Power light does not illuminate.

1. Power not connected to the unit through the control box. Open the control box cover and verify that incoming power lines

are connected and light.

2. Service breaker tripped or open. Verify that the breaker is closed.

3. Power switch connections could be loose. Ensure that the connections are of sound quality.

4. Power switch is faulty. Replace the power switch.

5. Power light is faulty. Replace the light.

Problem: Water pressure is too low.

1. Water pressure regulator is out of adjustment. Follow the instructions provided in the maintenance section and adjust so that

the flow pressure is 20 ±5 PSI.

2. Water pressure regulator internal strainer is clogged. Clean in accordance with the instructions provided in the maintenance

section.

3. Water pressure regulator is faulty. Replace the regulator.

4. Water pressure gauge is faulty or the cut off from the system. Verify that the test cock valve under the gauge is open to allow

for the sensing of line pressure. Replace gauge if necessary.

5. Heat exchanger is clogged. Replace the heat exchanger.

Problem: Solenoid valve is not opening/shutting.

1. Power not connected to the unit through the control box. Open the control box cover and verify that incoming power lines

are connected and light.

2. Service breaker tripped or open. Verify that the breaker is closed.

3. Power switch connections could be loose. Ensure that the connections are of sound quality.

4. Power switch is faulty. Replace the power switch.

5. Thermostat is faulty. Replace the thermostat.

6. Solenoid wires are loose or broken. Verify that the electrical connections are of sound quality.

7. Faulty solenoid coil. Replace the solenoid.

Problem: Outlet water temperature too low.

1. Power not connected to the unit through the control box. Open the control box cover and verify that incoming power lines

are connected and light.

2. Service breaker tripped or open. Verify that the breaker is closed.

3. Power switch connections could be loose. Ensure that the connections are of sound quality.

4. Power switch is faulty. Replace the power switch.

5. Thermostat is faulty. Replace the thermostat.

6. Solenoid wires are loose or broken. Verify that the electrical connections are of sound quality.

7. Faulty solenoid coil. Replace the solenoid.

8. Steam flow pressure is too low for the unit. Verify that the steam flow is 15-25 PSIG.

9. Water flow pressure is too high. Follow the instructions provided in the maintenance section and adjust so that the flow pressure is 20 ±5 PSI.

10. Heat exchanger is clogged. Replace the heat exchanger.

11. Insufficient volume of steam to unit. Check the line size and flow pressure.

AJ-44C Series Technical Manual 7610-001-76-22

Issued: 03-21-2006 Revised: N/A

SECTION 4: TROUBLESHOOTING

D226 COMMON PROBLEMS

60

Page 24

61

SECTION 5:

PARTS SECTION

Page 25

AJ-44C Series Technical Manual 7610-001-76-22

Issued: 03-21-2006 Revised: N/A

SECTION 5: PARTS SECTION

AJ-44 CONTROL BOX ASSEMBLY

62

1

2

4, 5

4, 8, 9, 10

11

12

13

14

15

10

16

17

17

4, 18, 29

19

20

21, 22

21, 22

21, 22

22, 23, 24

25, 26

22, 27

22, 28

7

6

3

Page 26

AJ-44C Series Technical Manual 7610-001-76-22

Issued: 03-21-2006 Revised: N/A

SECTION 5: PARTS SECTION

AJ-44 CONTROL BOX ASSEMBLY (CONTINUED)

63

ITEM QTY DESCRIPTION Mfg. No.

1 1 Electrical Box Weldment 05700-041-88-43

2 1 Terminal Block, 3 Pole 05940-011-48-27

3 1 Thermometer, 96” Lead 06685-111-68-49

4 6 Star Washer, External Tooth, 10-24 05311-273-02-00

5 6 Screw, 10-32 x 3/4” Long Phillips Trusshead 05305-011-62-17

6 1 Decal, Gauge 09905-021-72-29

7 1 Thermometer, 48” Lead 06685-111-68-48

8 1 Wire Lug, 2 AWG to 14 AWG 05940-200-76-00

9 1 Decal, Ground 09905-011-86-86

10 1 Screw, 10-32 x 1/2” Long Phillips Trusshead 05305-011-39-36

11 1 Decal, L1-L2-L3 09905-101-12-66

12 1 Light, Amber 05945-111-44-44

13 1 Light, Red 05945-111-44-45

14 1 Din Rail 05700-021-72-75

15 1 Circuit Breaker (200-380 Volt, 60 Hz Models Only) 5925-011-68-34

15 1 Circuit Breaker (CGP Models Only) 5925-111-64-18

16 1 Switch, ON/FILL - OFF/DRAIN 05930-301-46-00

17 2 Motor Contactor 05945-111-68-38

18 1 Heater Contactor 05700-011-71-44

19 1 Overload See Chart

20 1 Overload See Chart

21 3 Control Relay 05945-111-35-19

22 12 Screw, 6-32 x 3/8” Long Round Phillipshead 05305-171-02-00

23 1 Fuse (380 Volt-460 Volt, (all 60 Hz) Models Only) 5920-011-72-88

1 Fuse, 600 Volt Models Only 5920-002-75-95

24 1 Fuse Holder for (23) Above 5920-011-72-89

25 1 Transformer

200 Volt Model 05950-002-41-47

208-220-230-460 Volt Models 05950-011-68-35

208-220-230-460 Volt CGP Models 05950-002-46-10

380-415 Volt Models 05950-011-75-59

600 Volt Model 05950-002-23-77

26 4 Locknut, 10-24 with Nylon Insert 05310-373-01-00

27 1 Terminal Board 05940-002-78-97

28 1 Terminal Board 05940-021-89-41

29 3 Screw, 10-32 x 3/8” Long Phillips Trusshead 05305-173-12-00

30 2 Control Relay (CGP Models Only (Not Shown) 05945-111-72-51

MISCELLANEOUS PARTS NOT SHOWN:

Grommet, 1/2” OD x 3/8” ID 05325-011-46-73

Bushing, Heyco SB100 05975-210-09-00

Plug, Heyco 2700 G-875 05975-011-47-81

Control Box Cover 05700-031-66-88

Control Box Cover Hinge Weldment 05700-021-68-57

Control Hinge Rod 05700-011-68-58

Washer, Flat, S/S, 1/4” ID 05311-174-01-00

Cotter Pin 05315-011-68-56

MANUAL/DELIME Switch (located on rear of control box) 05930-301-22-18

MANUAL/DELIME Switch Decal (located on rear of control box) 09905-011-74-61

Copper Conductors Only Decal 09905-011-47-35

Control Box Leg 05700-011-71-47

Bolt, 1/4”-20 x 2-1/2” Long Hex Head 05306-011-83-52

Locknut, 1/4”-20 with Nylon Insert 05310-374-01-00

Component Mounting Plate (located inside the control box) 05700-031-67-03

Conduit Bracket 05700-021-70-88

Page 27

AJ-44C Series Technical Manual 7610-001-76-22

Issued: 03-21-2006 Revised: N/A

SECTION 5: PARTS SECTION

AJ-66 & AJ-80 CONTROL BOX ASSEMBLY

64

1

2

3

6

7, 12

8

9

14

14

14

15

16

17

18

19

20

22

24, 25

23

23

23

21

11

5

10

10

13

4

Page 28

AJ-44C Series Technical Manual 7610-001-76-22

Issued: 03-21-2006 Revised: N/A

SECTION 5: PARTS SECTION

AJ-66 & AJ-80 CONTROL BOX ASSEMBLY (CONTINUED)

65

ITEM QTY DESCRIPTION Mfg. No.

1 1 Electrical Box Weldment 05700-041-88-50

2 1 Decal, L1-L2-L3 09905-101-12-66

3 1 Terminal Block 05940-011-48-27

4 1 Terminal Board 05940-021-89-41

5 1 Decal, Gauge 09905-021-72-30

6 1 Light, Amber 05945-111-44-44

7 1 Wire Lug, 2 AWG to 14 AWG 05940-200-76-00

8 1 Light, Red 05945-111-44-45

9 1 Din Rail 05700-021-72-75

10 2 Thermometer, 96” Lead 06685-111-68-49

11 1 Thermometer, 48” Lead 06685-111-68-48

12 1 Decal, Ground 09905-011-86-86

13 1 Terminal Board 05940-002-78-97

14 3 Motor Contactor 05945-111-68-38

15 1 Circuit Breaker (200/208/230/360 Volt, 60 Hz Models Only) 5925-011-68-34

15 1 Circuit Breaker (CGP Models Only) 5925-111-64-18

16 1 Overload See Chart

17 1 Switch, ON/FILL & OFF/DRAIN 05930-301-46-00

18 1 Overload See Chart

19 1 Overload See Chart

20 1 Heater Contactor (for non-steam units) 05945-002-24-70

21 1 Relay 05945-111-72-51

22 1 Transformer (200 Volt Models Only) 05950-002-41-47

Transformer (208/220/230/460 Models Only) 05950-011-68-35

208-220-230-460 Volt CGP Models 05950-002-46-10

Transformer (380/415 Volt Models Only) 05950-011-75-59

Transformer (600 Volt Models Only) 05950-002-23-77

23 3 Control Relay 05945-111-35-19

24 1 Fuse Holder (380 (60 Hz)/460/600 Volt Models Only) 5920-011-72-89

25 1 Fuse (380 (60 Hz)/460 Volt Models Only) 5920-011-72-88

1 Fuse (600 Volt Models Only) 5920-002-75-95

26 2 Control Relay (CGP Models (Not Shown) 05945-111-72-51

MISCELLANEOUS PARTS NOT SHOWN:

Manual/Delime Switch 05930-301-22-18

Manual/Delime Switch Decal 09905-011-74-61

Decal, High Limit Warning Light 09905-002-49-48

Transformer, 150V, 60 Cycle 05950-011-68-35

Control Box Cover 05700-031-66-88

Control Box Leg 05700-011-71-47

Conduit Bracket 05700-021-70-88

Page 29

AJ-44C Series Technical Manual 7610-001-76-22

Issued: 03-21-2006 Revised: N/A

SECTION 5: PARTS SECTION

MOTOR OVERLOAD CHART

66

Model Volts Hz Phase Drive Motor Prewash Motor Wash Motor

AJ-44’S 208 50 3 05945-011-84-59 N/A 05945-111-68-40

220 50 3 05945-011-84-59 N/A 05945-111-68-40

230 50 3 05945-011-84-59 N/A 05945-111-68-40

380 50 3 05945-002-71-09 N/A 05945-111-68-40

415 50 3 05945-111-69-12 N/A 05945-111-81-33

440 50 3 05945-111-69-12 N/A 05945-111-81-33

208 60 1 N/A N/A N/A

230 60 1 N/A N/A N/A

200 60 3 05945-002-66-00 N/A 05945-002-65-99

208 60 3 05945-111-68-39 N/A 05945-111-68-40

230 60 3 05945-111-68-39 N/A 05945-111-68-40

380 60 3 05945-111-69-12 N/A 05945-111-81-33

460 60 3 05945-111-68-39 N/A 05945-111-68-40

600 60 3 05945-111-69-12 N/A 05945-111-81-33

AJ-66’S 200 50 3 05945-011-84-59 05945-002-65-98 05945-111-68-40

208 50 3 05945-011-84-59 05945-002-24-70 05945-111-68-40

220 50 3 05945-011-84-59 05945-002-24-70 05945-111-68-40

230 50 3 05945-011-84-59 05945-002-24-70 05945-111-68-40

380 50 3 05945-002-71-09 05945-002-24-70 05945-111-68-40

415 50 3 05945-111-69-12 05945-002-24-70 05945-111-81-33

440 50 3 05945-111-69-12 05945-002-24-70 05945-111-81-33

208 60 1 N/A N/A N/A

230 60 1 N/A N/A N/A

200 60 3 05945-002-66-00 05945-002-66-02 05945-002-65-99

208 60 3 05945-111-68-39 05945-111-68-41 05945-111-68-40

230 60 3 05945-111-68-39 05945-111-68-41 05945-111-68-40

380 60 3 05945-111-69-12 05945-002-24-70 05945-111-81-33

460 60 3 05945-111-68-39 05945-111-68-41 05945-111-68-40

600 60 3 05945-111-69-12 05945-111-81-33 05945-111-81-33

AJ-80’S 200 50 3 05945-011-84-59 05945-111-68-40 05945-111-68-40

208 50 3 05945-011-84-59 05945-111-68-40 05945-111-68-40

220 50 3 05945-011-84-59 05945-111-68-40 05945-111-68-40

230 50 3 05945-011-84-59 05945-111-68-40 05945-111-68-40

380 50 3 05945-002-71-09 05945-111-68-40 05945-111-68-40

415 50 3 05945-111-69-12 05945-111-81-33 05945-111-81-33

440 50 3 05945-111-69-12 05945-111-81-33 05945-111-81-33

208 60 1 N/A N/A N/A

230 60 1 N/A N/A N/A

200 60 3 05945-002-66-00 05945-002-65-99 05945-002-65-99

208 60 3 05945-111-68-39 05945-111-68-40 05945-111-68-40

230 60 3 05945-111-68-39 05945-111-68-40 05945-111-68-40

380 60 3 05945-111-69-12 05945-111-81-33 05945-111-81-33

460 60 3 05945-111-68-39 05945-111-68-40 05945-111-68-40

600 60 3 05945-111-69-12 05945-111-81-33 05945-111-81-33

Page 30

AJ-44C Series Technical Manual 7610-001-76-22

Issued: 03-21-2006 Revised: N/A

SECTION 5: PARTS SECTION

HEATER ASSEMBLY

67

Heater Replacement Kit Chart

Model Volts Phase KW Part Number

All* 208 1 15 06401-003-10-21

230 1 15 06401-003-10-22

200 3 15 06401-003-10-21

208 3 15 06401-003-10-21

220 3 15 06401-003-10-22

230 3 15 06401-003-10-22

380 3 15 06401-003-10-28

415 3 15 06401-003-10-28

440 3 15 06401-003-10-29

460 3 15 06401-003-10-31

600 3 15 06401-003-10-33

* - AJ-44CGP, AJ-44CS, AJ-44CSL, AJ-66CGP, AJ-66CS, AJ-66CSL, AJ-80CS and AJ-80CSL models do not use electric

heaters in the wash tank.

See Heater Chart Below

Heater Gasket

05330-200-02-70

5/16” Lockwasher

5/16”-18 Hex Nut

Replacement Kit Note:

All heater kits come with the

heater, the gasket, lockwashers

and locknuts.

SERVICE NOTE:

When replacing the tub heaters, it is HIGHLYrecommended that you also change out the gasket as well.

Once installed, gaskets become compressed and

are subjected to extreme temperature changes.

Replacing the gasket with a new one when replacing

the heater may prevent future leaks.

SERVICE NOTE:

The nuts used to secure the heater to the tub should be

torqued to 154 in-lbs. After tightening, the unit should be

allowed to heat up and operate normally for approximately 30

minutes. Secure power to the machine and check the nuts

once more to ensure that they are torqued to 154 in-lbs.

Page 31

AJ-44C Series Technical Manual 7610-001-76-22

Issued: 03-21-2006 Revised: N/A

SECTION 5: PARTS SECTION

HEATER ASSEMBLY (CONTINUED)

68

The wash tank heater system is electrically connected in the circuit so that they are dependent upon the dishwasher being properly filled with and maintaining a safe water level, two thermostats (mounted in the heater box behind the dress panel), float

switch (mounted in the wash tank), and the heater relay (mounted in control box) with the heater being activated by the thermostats.

Once the dishwasher has been filled to the correct level, the heater should operate automatically. Should the tank heat be too

high, too low or no indication of temperatures at all, the following checkout should be made.

Note: The following checkout should be made by either a qualified service person or electrician.

A- Checkout of the heater system

1- If the temperature is too high, adjust thermostat using instructions on the page entitled “Thermostats”.

2- If temperature is too low, adjust thermostat as above, then:

a - Turn off power to machine by placing customer’s circuit breaker in the “OFF” position. Turn off machine

circuit breaker located on right side of control box.

b - Remove cover from control box on top of dishwasher.

c - Make sure water temperature is below 140° F.(preferably about 130°F.).

d - Turn on both circuit breakers. Observe heater relay (R1) while the power switch is turned “ON” and “OFF”.

If relay contacts move in and out, the heater relay is operating correctly: if not proceed to “C”.

B- If heater relay (R1) closes:

1 - Check power supply at incoming terminal board L1, L2 & L3 (3 phase only). It should be the same voltage as

indicated on the machine data plate.

2 - Check power at connections on heater relay (R1). The voltage should agree with the voltage on the

machine data plate. If not, check wires for breaks or bad connections.

3 - Check power at terminals of heater which should agree with the data plate. If not check wires for breaks or

bad connections.

4 - Temperatures should rise as explained in “C-1”, and amperage may be checked according to those instructions. Replace any defective elements.

C - If heater relay (R1) does not close.

1 - There is an insulated movable insulated movable bar on relay across the top. With an insulated probe, depress

this bar and observe the thermometer: the temperature should rise noticeably in a minute or two. If it moves slowly, it would indicate that the element is faulty. If it moves constantly higher at a good rate, elements should be

good.

Note: A check with an amp probe at heater relay (R1) terminals should be made to verify the amp draw on each leg.

This should be appropriate for the voltage and phase indicated on the data plate

HEATER PROTECTION & AUTOMATIC FILL

This control is activated when the power switch is turned “ON”. The primary function is to automatically energize the wash tank

heat circuit. It will also cutoff the wash tank heat circuit should the water be accidently drained from the machine with the power

switch still “ON”. The power switch should always be turned-off before draining the unit.

This water level control consists of two (2) floats that operate when the power switch is turned on and works in conjunction with

the thermostats and heater relays.

When the power switch is turned “ON” water starts to enter the dishmachine. When it reaches the proper level the normally

open contacts in the water level float switch close activating the heating circuit for tank heat.

If the water level below the correct level while power is still on, the float switch will sense the lack of water and de-activate the

heater.

Page 32

AJ-44C Series Technical Manual 7610-001-76-22

Issued: 03-21-2006 Revised: N/A

SECTION 5: PARTS SECTION

HEATER ASSEMBLY (CONTINUED)/THERMOSTATS/DRESS PANELS

69

THERMOSTATS

The thermostat range is from 140°F to 240°F with a maximum bulb exposure temperature of 300°F.

Calibration:

Wash Thermostat:

Set Point: 165°F (Adjustable range)

Hi-LImit Thermostat:

Fixed set point: 210°F (Non-adjustable)

The hi-limit thermostat is used to protect the heater element in the event of a run away regulating thermostat or a dry fire situ-

ation. It is set for 210°F +0°F or -10°F with a fixed set point. This part is not adjustable.

The wash tank regulating thermostat will maintain the correct wash water temperature to meet NSF requirements. These spec-

ify that the wash be no lower than 140°F on chemical sanitizing models and no lower than 160°F on hot water sanitizing

machines.

To order the thermostats and corresponding decals:

Kit, Thermostat Wash Regulating (CE/CELModels) 06401-003-18-20

Kit, Thermostat Wash Regulating (CS/CSLModels) 06401-003-18-21

Thermostat, High Limit Control 05930-011-49-43

HEATER BOX COMPONENTS

Heater Box Weldment 05700-031-66-81

Heater Box Cover 05700-031-66-82

Terminal Board 05940-002-78-97

FRONT DRESS P

ANELS

Model Left to Right Part Number Right to Left Part Number

AJ-44’s 05700-031-72-22 05700-031-72-22

AJ-44CGP 05700-002-52-77 05700-002-52-77

AJ-66’s 05700-031-71-85 05700-031-72-42

AJ-66CGP 05700-002-51-22 05700-002-57-84

AJ-80’s 05700-031-74-06 05700-031-77-10

Page 33

AJ-44C Series Technical Manual 7610-001-76-22

Issued: 03-21-2006 Revised: N/A

SECTION 5: PARTS SECTION

PREWASH PLUMBING ASSEMBLY

70

Y-Strainer, 3/4” NPT,

Brass

04730-717-02-06

Nipple, 3/4”, Brass, Close

04730-207-34-00

Valve, Solenoid, 3/4”

04810-100-53-00

Nipple, 3/4”, Brass, Close

04730-207-34-00

Vacuum Breaker, 3/4”

04820-002-53-77

Elbow, 90°, 3/4” Brass

04730-206-04-34

Elbow, 90°, 3/4” Brass

04730-206-04-34

Nipple, 3/4” x 6” Long

05700-001-26-74

Fill Line Injector Replacement Kit

06401-003-09-93

A new gasket can be

ordered using part number 05330-111-42-81.

Replacement Kit Note:

The kit for the fill line injector comes

with the injector weldment, a new

gasket and the mounting hardware.

Page 34

AJ-44C Series Technical Manual 7610-001-76-22

Issued: 03-21-2006 Revised: N/A

SECTION 5: PARTS SECTION

WASH SECTION INCOMING PLUMBING ASSEMBLY

71

ITEM QTY DESCRIPTION Mfg. No.

1 1 Rinse Injector Replacement Kit 06401-003-11-88

1 Gasket 05330-111-42-81