Page 1

Certified for

Canada and U.S.A

Outdoor Gas Barbeque Owner’s Manual

This manual is for use with 700, 700BI and 850BI series grills

Warning: Please read and understand the contents of this manual fully before operating. Failure to

do so may result in fire or explosion. Homeowners should retain these instructions.

All barbecues and carts are designed for OUTDOOR use only and cannot be installed in or on boats.

This barbecue is CANNOT be installed in or on Recreational Vehicles. Not for commercial use.

Manufactured by:

Jackson Grills Inc.

2945 Jacob Road Phone: 1-250-715-0820

Duncan, B.C. V9L 6W4 Fax: 1-250-715-0821

Email: jacksongrills@shaw.ca

Page 2

TABLE OF CONTENTS:

SAFETY. 3

LP GAS CYLINDER REPLACEMENT. 4-5

OPD EQUIPPED CYLINDER. 6

HOSE AND REGULATOR. 6

LEAK TESTING. 7

INSTALLATION. 8

CLEARANCES. 9

ASSEMBLY. 10-13

GETTING TO KNOW YOUR GRILL 14

LIGHTING INSTRUCTIONS. 15

GAS CONVERSION. 16-18

MAINTENANCE. 19

GRILLING TIPS AND TECHNIQUES. 20

TROUBLE SHOOTING. 21

PARTS LIST. 22

EXPLODED VIEWS. 23

WARRANTY. 24

A MESSAGE TO OUR CUSTOMERS. 25

DO’S AND DON’TS

DO…

¾ Have propane cylinder (LP Units) filled by

an authorized LP supplier.

¾ Check all gas connections for leaks using

a soapy water solution before lighting,

tighten connections until the bubbles

disappear.

¾ Always open the hood before lighting.

¾ Pre heat the grills before using.

¾ After cooking, turn the grill OFF, then take

a long handled soft wire brush and brush

off the cooking grills, then turn off the gas

at the main fuel supply.

¾ Cook with the hood down when possible.

It is faster and more efficient. Trapped

smoke adds flavor.

¾ Turn the gas supply off immediately if you

are unable to light the grill. Wait 5 minutes

before attempting to light the grill again.

¾ Have proper tools. Tongs, mittens ready

prior to removing food.

¾ Trim excess fat from meats to minimize

flare-ups.

¾ Let the grill totally cool before cleaning or

removing any parts for cleaning or

servicing.

¾ Cover the grill with the cover when not in

use.

DON’T…

¾ Install the grill closer than 36 “ on the

sides and back to any combustible

materials.

¾ Attempt to adjust the Regulator, it has

been factory set and tested.

¾ Allow a LP gas cylinder to lie on its side.

Keep in an upright position.

¾ Turn a control valve on before the igniter

button has been depressed.

¾ Use plastic or un-tempered glass utensils

on or in the grill.

¾ Attempt to move an Aluminum foil pan

while it is still hot.

¾ Cover or block any air opening.

¾ Place aluminum foil in the grease pan to

catch the drippings.

¾ Wear long, loose flowing clothing around

the grill. Long flowing hair is also easily

ignited.

¾ Put food on the grill and leave it

unattended or unwatched for long periods

of time.

¾ Use CAUSTIC materials to clean the grill.

Example: Lye, or solvents.

¾ Never use the warming rack in place while

using the rear infrared burner.

2

Page 3

SAFETY:

Your new Jackson Grill barbeque is a safe, convenient appliance when used and maintained properly. As

with all gas-fired appliances, certain safety precautions must be observed. Failure to follow these

precautions may result in damage or injury. If you have any questions or concerns regarding the

assembly or operation of this appliance, you should contact your dealer, gas appliance technician or your gas

company.

NEVER OPERATE THIS BBQ WITHOUT THE PULL OUT MAIN DRIP TRAY IN PLACE.

FOR YOUR SAFETY:

If you smell gas:

1. Shut off gas to the appliance.

2. Extinguish any open flame.

3. Open lid.

4. If odor continues, immediately call your supplier or fire department.

DO NOT store or use gasoline or any other flammable liquid in the vicinity of this or any other

appliance.

An LP Cylinder not connected for use shall not be stored in the vicinity of this or any other appliance.

CAUTION:

1. For outdoor use only.

2. If stored indoors, detach and leave cylinder outdoors.

3. This appliance must not be operated unattended.

4. Special care must be taken to keep small children away from heated surfaces.

ELECTRICAL CAUTION:

1. If any accessory is used on this appliance with an external electrical power source, the accessory (when

installed) must be electrically grounded in accordance with local codes. In the absence of local codes,

the following standards apply:

(Canada) CSA C22.1 Canadian Electrical Code, and (USA) ANSI/NFPA No. 70 – Latest Edition.

2. Do not cut or remove the grounding prong from the plug.

3. Keep the electrical supply cord and fuel supply hose away from any heater surface.

3

Page 4

LP GAS CYLINDER PLACEMENT:

Cylinders must be installed according to assembly instructions. Install the gas cylinder into the tank hole

inside of the Jackson Pedestal.

LP GAS CYLINDER:

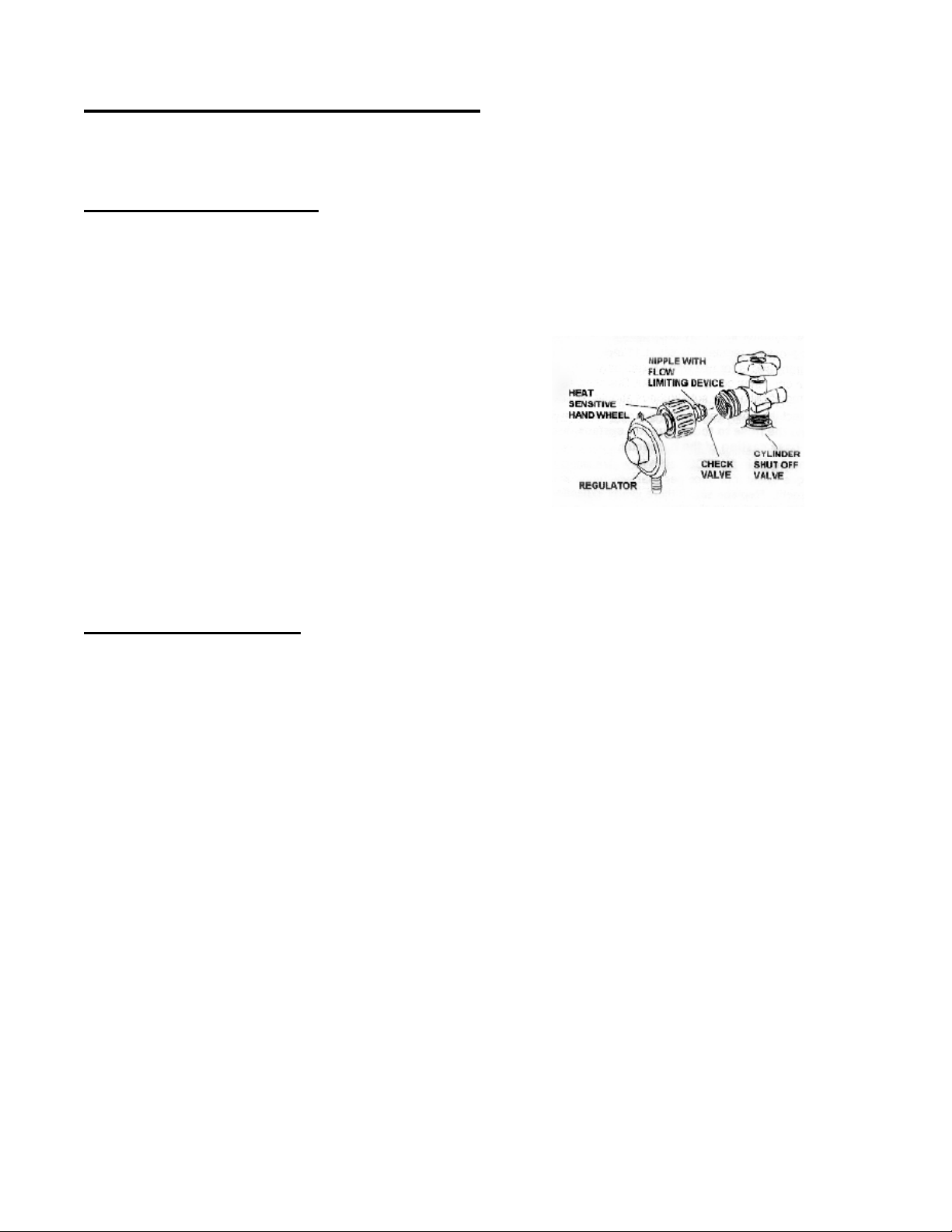

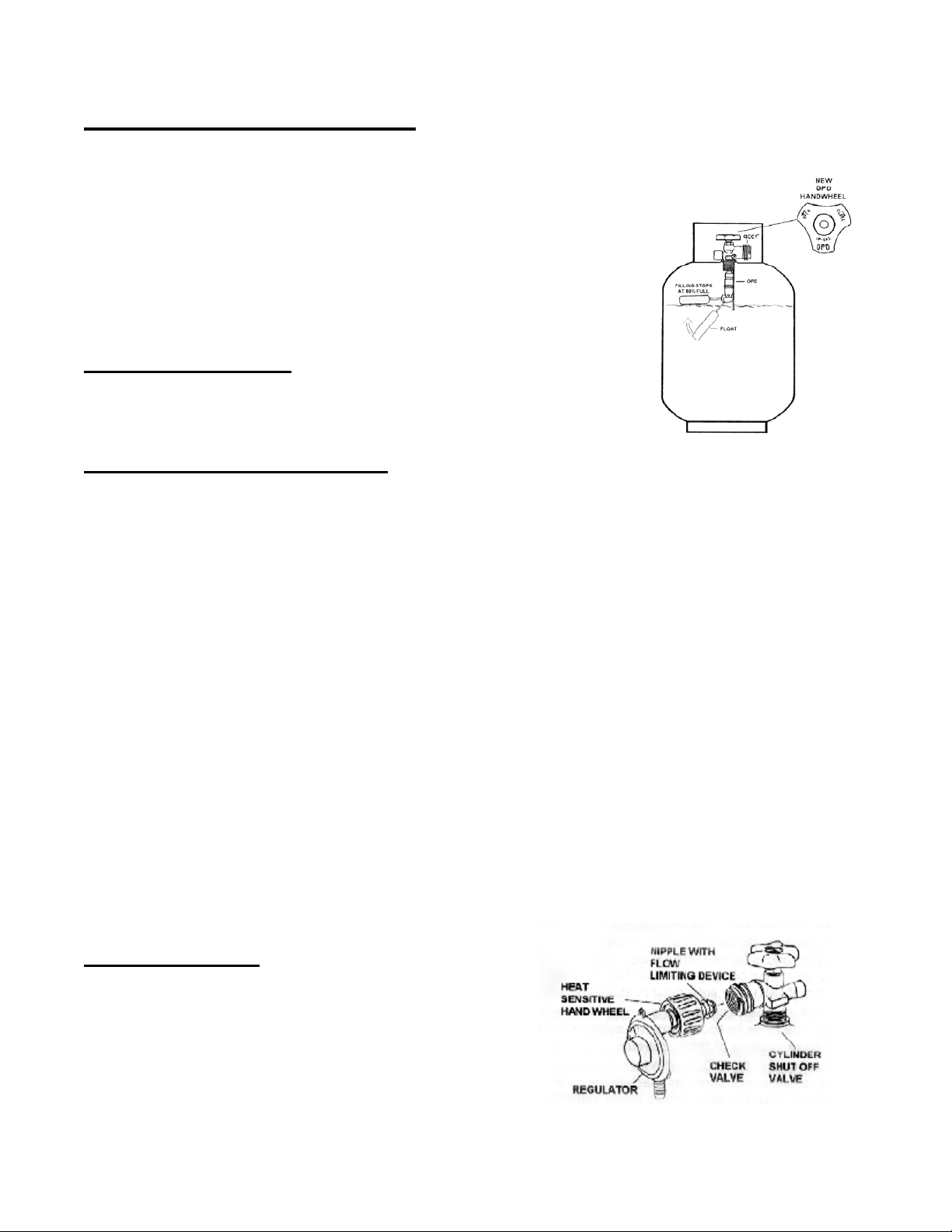

QCC-1 Quick Closing Coupling

Your grill is designed to be used with an LP gas cylinder equipped with the new QCC-1 Quick Closing

Coupling system. The QCC-1 system incorporates new safety features required by the Canadian Standards

Steering Committee and the American National Standards Institute (ANSI).

Gas will not flow until a positive connection has been made.

A thermal element will shut off flow of gas between 240

degrees and 300 degrees F. When activated, a flow-limiting

device will limit the flow of gas to 10 cubic feet per hour.

The LP Gas Cylinder is not included with the Gas Grill. Be

sure to purchase one with the QCC valve. The external threads on

the inlet port of the valve recognize this valve. QCC equipped

cylinders are available from your gas grill dealer. Any attempt to

connect the regulator, by use of adapters or any other means, to any other valve could result in

damage or fire, and may negate the important safety features designed into the QCC-1 system.

SPECIFICATIONS:

All LP gas cylinders used with this appliance must be constructed and marked with the specifications for LP

cylinders in accordance with the Canadian Transport Commission (CTC)

1. or the US Department of Transport (DOT) for use in the USA.

2. The LP gas cylinder used for this appliance must not have a capacity larger than 20 lb. (9 kg):

approximately 18” (46cm) high & 12” (30cm) diameter.

3. All LP gas cylinders used with this appliance should be inspected at every filling and re-qualified by a

licensed service outlet at the expiry date (10 years) in accordance with DOT (USA) and CTC (Canada)

codes for LP gas cylinders.

4. All LP gas cylinders used with the appliance must be provided with a shut off valve terminating in a

cylinder valve outlet No. 510, specified in the Standard for Compressed Gas Cylinder Valve Outlet and

Inlet Connections (USA) ANSI / CGA-V-11977 (Canada) CSA B96.

The cylinder supply system must be arranged for vapor withdrawal. The cylinder must also include a collar to

protect the cylinder valve. As well, the cylinder valve must include a safety relief device having direct

communication with the vapor space of the cylinder.

4

Page 5

HANDLING:

1. Government regulations prohibit shipping full LP gas cylinders. You must take your new cylinder to an LP

gas dealer for filling.

2. A filled LP gas cylinder is under very high pressure. Always handle with care and transport in the upright

position. Protect the valve from accidental damage.

3. Do not tip the LP gas cylinder while connecting it to the regulator. Fasten the cylinder securely during

transport, use and storage.

4. If the cylinder is tipped after it is connected to the regulator, shut off the gas, disconnect the regulator and

have it checked before using it again.

STORAGE:

1. Store the LP gas cylinders outdoors in a well-ventilated area.

2. Do not store the LP gas cylinders in direct sunlight or near a source of heat or combustion.

3. If you intend to store your grill indoors, disconnect and remove the LP gas cylinder first. Disconnected

cylinders must have plugs installed and must not be stored in a building, garage or any other enclosed

area.

4. Keep out of reach of small children.

5. When the LP gas cylinder is connected to the gas grill, the LP gas cylinder must be stored outside in a

well-ventilated area.

6. Keep the ventilation openings for the LP cylinder enclosure free and clear of debris.

OPERATION:

1. Never connect your gas grill to an LP cylinder without the regulator provided, and never to an

unregulated gas supply. The gas regulator supplied with the appliance must be used.

2. Always leak test the LP gas cylinder to regulator connection when connecting the LP gas cylinder to the

appliance. See “leak testing”.

3. Do not operate the appliance if the smell of LP gas is present. Extinguish all flame and determine the

source of LP gas before proceeding. Do not ignite the appliance until the LP gas leak has been found

and sealed.

4. Always shut off the LP gas cylinder valve when the appliance is not in use.

5

Page 6

OPD EQUIPPED CYLINDER:

Effective January 1, 1998, the standard for outdoor gas appliances, ANSI Z21.58/CAN CGA-1.6, requires that

appliances are to be used with cylinders equipped with an Overfill Prevention

Device (OPD).

The OPD is designed to reduce the potential for the overfilling of propane

cylinders, thus reducing the possibility of relief valve discharges of raw

propane. The new OPD causes a slower purge / fill operation. Some

consumers have been advised by filling stations that these cylinders are

“defective”. This is not a defect. Some propane filling stations may not be

aware of this new device and its effects on the purge / fill operation.

IDENTIFICATION:

To identify these cylinders, the new OPD hand wheel has been standardized

to the shape shown.

HOSE AND REGULATOR:

1. The QCC coupling contains a magnetic Flow Limiting Device which will limit the flow of gas should there

be a leak between the regulator and the appliance valve. This device will activate if the cylinder valve is

opened while the appliance valves are open. Be sure the appliance valves are off before the cylinder

valve is opened to prevent accidental activation.

2. The QCC coupling incorporates a heat sensitive hand wheel that will cause the back check module in the

QCC cylinder valve to close when exposed to temperatures between 240 degrees and 300 degrees F.

Should this occur, do not attempt to reconnect the nut. Remove the hose / regulator assembly and

replace with a new one.

The pressure regulator is set at 11” (water column) and is for use with LP

3. gas only. The hose and hose couplings comply with CGA Standard CAN 1.83. No modifications or

substitutions should be attempted.

4. Protect the hose from dripping grease and do not allow the hose to touch any hot surface, including

the base of the grill.

5. Inspect the seal in the QCC cylinder valve when replacing the LP gas cylinder or once per year, which

ever is more frequent. Replace the seal if there is any indication of cracks, creases or abr

6. Inspect the hose before each use of the appliance. If the hose is cracked, cut, damaged or abraded in

any way, the appliance must not be operated.

7. For repair or replacement of hose / regulator assembly, contact your dealer or approved service center.

CONNECTION:

1. Be sure the cylinder valve and appliance valves are “off”.

2. Place full LP gas cylinder on tank ring bracket.

3. Center the nipple in the cylinder valve and hold in place.

Using the other hand, turn the hand wheel clockwise until

there is a positive stop. Do not use tools. Hand tighten

only. When making the connection, hold the regulator in a straight line with the cylinder valve, so

as not to cross thread the connection.

6

Page 7

4. Leak test the connection. See “leak test”.

5. Refer to lighting instructions. To avoid activating the

Flow Limiting Device when lighting, open the cylinder

valve slowly with the appliance valves off. If the Flow

Limiting Device is accidentally activated, turn off

cylinder valve and appliance valves, wait 10 seconds to

allow the device to reset, open cylinder valve slowly,

then open the appliance valve.

IMPORTANT SAFETY INFORMATION;

THE PRESSURE REGULATOR AND HOSE ASSEMBLY SUPPLIED WITH THIS OUTDOOR COOKING

APPLIANCE MUST BE USED. REPLACEMENT PRESSURE REGULATORS AND HOSE ASSEMBLIES

MUST BE THOSE SPECIFIED BY THE OUTDOOR COOKING GAS MANUFACTURER.

A. Do not store a spare LP-gas cylinder under or near this appliance.

B. Never fill the cylinder beyond 80% full.

IF THE INFORMATION IN “A” AND “B” IS NOT FOLLOWED EXACTLY, A FIRE CAUSING DEATH OR

SERIOUS INJURY MAY OCCUR.

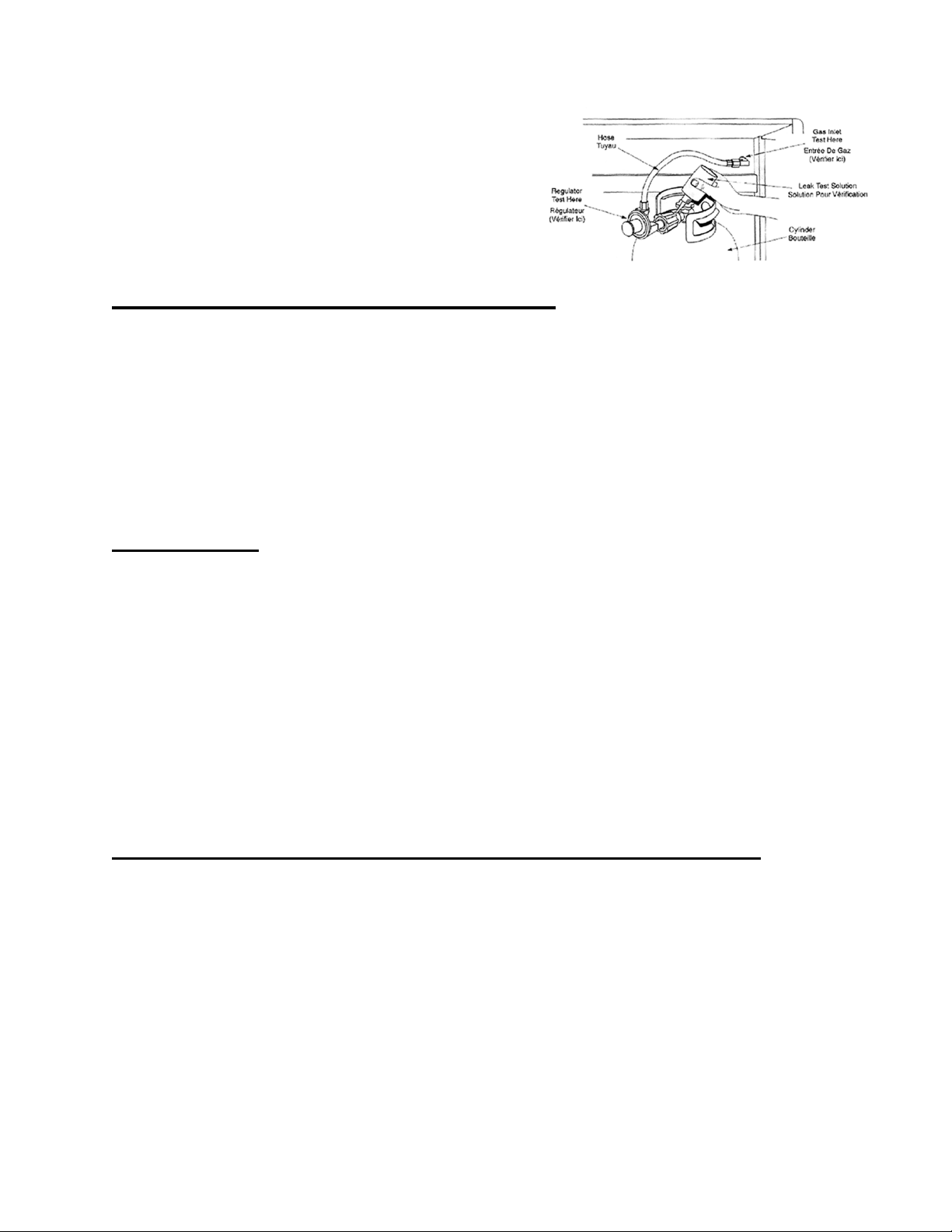

LEAK TEST:

1. DO NOT USE OR PERMIT SOURCES OF IGNITION IN THE AREA WHILE DOING THE LEAK TEST.

THIS INCLUDES SMOKING.

2. Leak testing should be done once per year or whenever the LP gas cylinder or any other gas system part

is replaced, whichever is more frequent.

3. The leak testing solution should be half liquid detergent and half water.

4. Apply the solution to the LP gas delivery system at points shown in the illustration.

5. Bubbles in the soap solution indicate that a leak is present.

6. The leak(s) must be stopped by tightening the loose joints, if possible, or by replacing the faulty parts(s)

with the part(s) recommended by the appliance manufacturer.

THE APPLIANCE IS NOT TO BE USED UNTIL ANY LEAK IS CORRECTED.

A gas appliance repairman or LP gas dealer should be called if attempts to stop the leak(s) are unsuccessful

and, in such case, the LP gas supply must be shut off at the cylinder valve or the cylinder must be removed

from the appliance until the leak(s) is corrected.

7

Page 8

INSTALLATION:

In Canada, this appliance must be installed in accordance with the local code and relevant CGA standards:

CAN/CGA-B149.1 LP Gas/Propane Installation Code and latest codes where applicable.

In the USA, this appliance must be installed in accordance with the local code and relevant national code:

ANSI Z223.1 – Latest Edition National Fuel Gas Code.

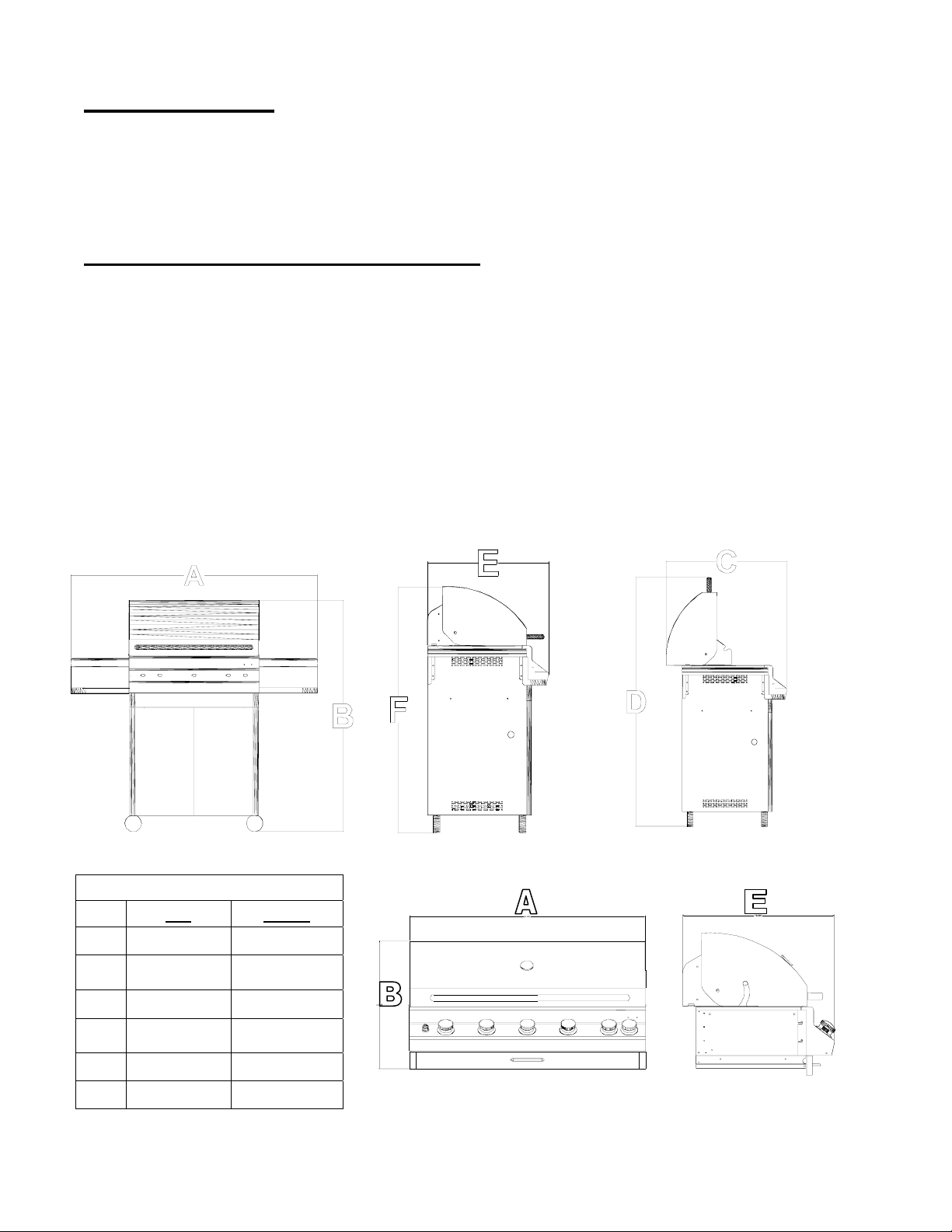

CLEARANCES and DIMENSIONS:

1. The appliance must have a minimum horizontal clearance from sides and back of unit to adjacent vertical

combustible construction below and extending above the top of the unit 36 inches from sides and 36

inches from back of unit.

2. Do not locate this appliance under any overhead, unprotected combustible construction.

3. This appliance is for OUTDOOR USE ONLY. Do not operate in garage, shed, balcony or other such

enclosed areas.

4. Do not restrict or obstruct the flow of combustible and ventilation air to the appliance.

5. Keep the area surrounding the appliance free of combustible materials, gasoline and all flammable liquids

and vapors.

6. This appliance is not to be installed in or on recreational vehicles and/or boats.

UNIT DIMENSIONS

850 BI

700

A 57.50” 40.5”

B 47.5” 21.75”

C 25.78”

D 56”

E 23.35” 23.375”

F 47.5”

850 Built In Model

8

Page 9

INSTALLING 700BI / 850BI INTO A NON COMBUSTIBLE ISLAND.

ALL DIMENSIONS ARE IN INCHES:

700BI

A 32.5 39.5

B 9.25” 9.25”

C 17” 17”

D 10.25” 10.25”

E 3” 3”

F 17.25” 17.25”

G 24.25” 24.25”

H 24” min. 24” min.

I 18.5” 18.5”

J 5.5” min 5.5” min

850 BI

INSTALLING 700BI / 850BI INTO A COMBUSTIBLE ISLAND.

NOTE: IMPORTANT!!!

If these units are to be installed into a COMBUSTIBLE island a Zero Clearance Box MUST be installed.

These Zero Clearance boxes are only available through your local dealer or Jackson Grills Inc.

Use Part numbers: #ZCAN700 / #ZCAN850 for installations into Combustible Islands.

700BI ZC

850 BI ZC

A 34.75*** 41.75***

B 9.25” 9.25”

C 17” 17”

D 10.25” 10.25”

E 3” 3”

F 17.25” 17.25”

G 24.25” 24.25”

H 24” min. 24” min.

I 19.5*** 19.5***

J 5.5” min 5.5” min

*** Difference between Non Combustible and Combustible Island Installations.

Ensure that the constructed island is well secured and that this island is level in all directions.

Place the grill into the cut out located in the island. Connect the gas line to the gas grill located on the left

hand side of this grill. Perform a gas leak test on this connection to ensure a gas leak is not present.

NOTE:

PLEASE ENSURE ALL PACKAGING MATERIALS HAVE BEEN REMOVED FROM ALL SURFACES.

9

Page 10

ASSEMBLY:

Please ensure the proper tools are used for ease of installation.

Some assembly will be required if this unit is installed in a pedestal.

Please remove all components from the packaging and inspect all components to ensure there is no damage

to any components in the packaging. If damage is present please contact you local dealer for replacement

components. Please replace all damaged components with original manufacturer’s parts only no substitutions

will be permitted. Please remove all packaging from all components of the gas grill before operating.

TOLLS REQUIRED FOR ASSEMBLY:

# 2 Phillips Screwdriver

8 mm Open Ended Wrench

2- 3/4” Open Ended Wrenches

Adjustable Wrench

SIDE SHELF INSTALLATION.

¾ Remove the securing straps from the front of the Display Panel and the pedestal side ( X 2). Do not

throw away these fasteners.

¾ Remove the 4 Phillips head screws from each side of the pedestal.

¾ Loosen the 2- 8 mm bolts at the top of each pedestal side. (Do Not Remove)

¾ Carefully remove the Side Shelves from the packaging.

¾ The Side Shelf that contains the Side Burner will ALWAYS be installed on the Left hand side of the

Grill as you are facing the grill.

¾ Install the side shelves buy dropping the Side Shelf over the 8 mm bolts. (do not tighten these 8 mm

bolts).

¾ Install the 4 Phillips head screws to secure the Side Shelf in place.

¾ Tighten the 2 – 8 mm bolts to finish the side shelf installation.

¾ Repeat for the other side.

Connect the gas line from the inside of the pedestal to the Side Burner outlet located under the Left Side

Shelf. Use 2 - 3/4” wrenches to properly secure the gas line to the Side Burner Gas Valve assembly.

NOTE: The Condiment bin is already attached to the side shelf as an assembly.

2 –8mm bolts. Loosen but Do Not remove

4 – Phillips head Screws. Remove and reinstall after side shelf

has been installed on the 2 8 mm bolts at the top

10

Page 11

After the Side Shelves have been installed, ensure the Grill Head is pushed back in the pedestal as far as

possible.

With the screws removed from the securing straps, place a screw through the side of the Condiment bins and

secure the Condiment Bins to the Display Panel.

Secure the Condiment

Bins to the Display Panel

using the screws from the

securing plates.

ROTISSERIE KIT INSTALLATION (If Equipped)

1 Install the Motor Mounting Bracket supplied to the Right hand side of the Inner Hood. (If not

already installed)

2 Install the Motor on the Motor Bracket.

3 Place the Rotisserie Rod into the Motor. Slide the Rotisserie Rod Bushing over the opposite end

of the Rod and drop into the cut out provided in the inner Hood Side. Tighten the thumb-screw

provided with the Rotisserie Rod Bushing.

4 Place the forks and Counter Balance on the Rotisserie Rod in the desired location.

5 When in use, spin the rod with your desired food until the weight of the food is at

the bottom. Install the Counter Balance Straight up to effectively balance the

Rotisserie system.

Rotisserie Rod Handle

1

Rotisserie Rod Bushing

2

Counter Balance

3

Rotisserie Forks X 2

4

Rotisserie Rod

5

Rotisserie Motor Mount

6

Rotisserie Motor

7

11

Page 12

Rotisserie Kit Completed Installation

Rotisserie Rod Bushing Placed on the

cut out provided on the Inner Hood

Upper Flavor Shield, Cooking Grid Installation.

Remove the Upper Flavor Shields form the Packaging. Please ensure that all protective plastic has been

removed from these parts.

These Upper Flavor shields should be placed on the pins provided on the Firebox Front and Rear. Ensure

that all of the Upper Flavor Shields have been installed correctly on the pins provided or the unit will not work

correctly. See diagram below.

Once the Upper Flavor Shield have been installed the Cooking Grids can be installed into the Grill. Place the

cooking grills on the upper ledge of the firebox as shown below.

Upper Flavor Shield installation.

Place the Upper Flavor Shields on the pins

provided on the Firebox Front and Rear

Cooking Grid Installation.

Place the Cooking Grids X 2 on the upper

ledge as shown.

12

Page 13

Main Gas Line Connections for Propane Gas and Natural Gas.

The main Fuel supply gas line is connected to a Manifold Tee securely mounted inside the pedestal located

on the left hand side of the pedestal.

Remove the Propane hose and regulator assembly from the packaging. Please ensure that there is no debris

inside the brass flare connection or inside the rubber hose. Using a ¾” wrench and an adjustable wrench

tighten the Hose to the connection provided inside the pedestal.

If this unit is to be connected to Natural Gas, place the Natural Gas hose through the hole provided in the

lower left hand rear corner of the pedestal. This hole should have a rubber grommet around the hole to

protect the Hose from getting damaged. See diagram below.

Place the Propane Hose

and regulator on the

Manifold located inside

the pedestal.

For Natural Gas hose

installations, place the

hose through the hole in

the back of the pedestal

and connect in the same

location as the Propane

Hose location.

Once the Main Gas line has been connected, connect the fuel line to the Gas supply being used. Turn the gas

on SLOWLY, if the gas is turned on too quickly the Regulator could lock up and not work correctly. By turning

the main gas supply on slowly this will prevent this problem form happening.

When the gas supply has been turn on, perform a Leak Check on ALL connections inside the pedestal using

a Soapy water solution as described on Page 7 of this manual.

13

Page 14

Getting To Know Your Grill.

1

2

3

4

5

6

7

8

9

10

Outer Hood Handle

Hood Thermometer

Outer Hood

Cooking Grids

Side Shelf

Condiment Bins X 2

Pedestal

Pedestal Doors X 2

Propane Tank Slide out

Pedestal Gas manifold

11

12

13

14

15

16

Pull Out Grease Tray

Main Control Knobs / Display Panel

Electronic Ignition

Side Burner Side Shelf

Warming Rack

Infrared Rear Burner

14

Page 15

MAIN BURNER LIGHTING

To light the Main Burners always start with the Left Hand Burner first. Turn the Left hand Control Knob to HI

and Depress the Igniter Button. Once this burner has lit, simply turn the next Control Knob to the right to high

and this burner will light, repeat this step for the remaining burners. The Ignition button will only be used to

light the first Left Hand Burner.

1. Always open the lid when lighting the burners.

2. Turn the left burner to HI. Press and hold igniter button until the burner lights. Simply turn the next Burner

to the left to HI and the next burner will light. Repeat this step for the remaining burners.

3. If the burner does not immediately light, turn the valve to OFF. Wait 5 minutes then repeat lighting

procedures.

NOTE:

Once all burners are lit you may turn any of the burners OFF to achieve the desired temperature.

Always light the burners from Left to Right using the Electronic Ignition to lit the Left hand Burner only.

LIGHTING INSTRUCTIONS

1) Read operating instruct ions BEFORE LIGHTING BARBECUE.

2) Always open the lid before lighting.

3) Main Burners: Push and turn Control Knob to HIGH.

Push and hold IGNITOR button until burner lights.

4) If ignition does not take place immediately. Turn valve to OFF,

Wait five (5) minutes and repeat lighting procedure.

5) To shut OFF: turn gas supply valve to OFF.

Allow gas line to burn out and turn Control Knob OFF.

CAUTION: FOR OUTDOOR USE ONLY

I

H

M

E

D

O

W

Turn the Left hand

Control Knob to

HI.

L

Depress The

Ignitor Button until

the Burner Lights.

H

I

M

E

W

O

L

D

MANUAL BURNER LIGHTING MAIN BURNER

See your local dealer for service if your grill igniter is not functioning.

1. Remove the cooking grates and the flame tamers that are over each burner.

2. Turn the burner you are lighting to high / light and place a long match near the side gas ports of the

burner.

3. If the burner does not immediately light, turn the valve to OFF. Wait 5 minutes then repeat lighting

procedures.

REAR BURNER LIGHTING (If equipped)

1. To Light the Rear Burner, Depress the Ignition Button and then turn the Rear Burner Control Knob to HI.

I

H

M

E

D

H

I

L

O

M

E

W

O

L

D

W

2. If the burner does not immediately light, turn

Control Knob to OFF. Wait 5 minutes then repeat

lighting procedures.

Turn the Rear

Burner Control

Knob to HI.

Depress The

Ignitor Button until

the Burner lights.

15

Page 16

Operating The Rear Burner

When operating the Rear Burner please ensure that the Warming Rack is REMOVED. The Warming Rack will

become damaged if NOT removed while the Rear Infrared Burner is in use.

The rear burner is specially designed to be used with the Rotisserie Kit, and should ONLY be used when

using the Rotisserie Kit.

MAIN BURNER USE

When searing foods, preheating is recommended by operating all main burners in the HI position with the lid

closed for approximately 10 minutes.

Cooking with the lid closed will ensure a more even temperature that will reduce cooking time and cook more

evenly.

Food that has a cooking time longer than 30 minutes, such as roasts, may be cooked indirectly (with the burner lit

opposite the food placement).

When cooking very lean meats, such as chicken breasts or lean pork, the grids can be oiled before cooking to

prevent sticking.

Cooking meat with a high degree of fat content may create flare-ups. Either trim some fat or reduce temperatures

to prevent this. Should a flare up occur, move the food away from the flames, reduce heat and leave the lid open.

NATURAL GAS INSTALLATIONS.

Tools Required to Convert this grill from Propane Gas to Natural Gas:

# 2 Phillips screwdriver

9 and 7 mm wrenches

13 mm wrench

¾” wrench

Adjustable Wrench

The outdoor cooking gas appliance and its’ individual shut off valve must be disconnected from the gas

supply piping system during any pressure testing of that system at test pressures in excess of ½ psi (3.5

kPa).

The outdoor cooking gas appliance must be isolated from the gas supply by closing its’ individual manual shut

off valve during any pressure testing of the gas supply piping system at test pressures equal to or less than ½

psi (3.5 kPa).

CONVERTING FROM PROPANE GAS(LP) TO NATURAL GAS

A qualified gas installer should perform all gas conversion. This appliance should only be converted

with conversion kit NG-CONVERSION KIT

. This conversion kit is supplied with this grill.

MAIN BURNER ORIFICES

1 Remove the Cooking Grids and Upper Flavor Shields.

2 Using a # 2 Phillips Screw Driver remove the screw that hold the main burners to the firebox rear

wall.

3 Pull the Grease Pan all the way out. Press on the 2 Blue clips on the side of the Grease pan and

totally remove the Grease Pan.

16

Page 17

4 Using a 13 mm wrench undo all of the main

burner orifices from the underside of the

Display Panel. Place then aside form any

other orifices included in the Natural Gas

Conversion Kit.

5 Using an approved thread sealant, replace

the Main Burner Orifices with the NEW

Natural Gas orifices supplied.

6 Before reinstalling the Main Burner tubes,

using a # 2 Phillips screwdriver, loosen the

screw at the Air Shutter on the Main Burner.

CLOSE the Air Shutter to a distance of 1/16”

OPEN and retighten the Air Shutter

adjustment screw.

7 Reinstall the Main Burners ensuring that the

Burner is properly placed over the Main

Burner orifice and reinstall the Main Burner screw on the firebox rear wall.

8 Reinstall the Grease Pan, Upper Flavor Shields and Cooking Grids.

REAR BURNER.

1 Using a # 2 Phillips

screwdriver undo the 4

screws that hold the Back

Cover plate to the Inner

Hood.

2 Once the Cover has been

removed use a 7 mm

wrench to remove the Rear

Burner Orifice from the

Rear Burner.

3 Install the new Rear

Burner orifice using an

approved thread sealant.

Remove Propane Gas Orifice and

reinstall Natural Gas Orifice

Remove the 4 screws that hold the Back

Cover plate using a # 2 Phillips screwdriver

Undo the Rear Burner Orifice using a

7 mm wrench.

Reinstall the new Natural Gas Orifice

using an approved thread sealant.

4 Reinstall the Rear Burner Cover Plate using the 4 screw previously removed.

NOTE:

Gas.

There is NO air adjustment required when converting the rear burner from Propane Gas to Natural

17

Page 18

SIDE BURNER

1 Open the side burner lid and remove the grate over

the burner head.

2 Undo the 2 Phillips head screws that hold the Flame

Thrower (burner ignition) and VERY Carefully move

away from the burner Head.

3 Undo the 3 screws that hold the Burner Head onto

the Side Shelf base.

4 Remove the 2 main orifices and place away from the

Natural Gas conversion kit so the orifices will not get

mixed up with the new orifices.

5 Replace the 2 orifices using an approved thread

sealant.

6 Reinstall the Burner head using the 3 screws

previously removed.

7 Reinstall the Flame Thrower ensuring that the tip is

properly placed inside the bottom of the Burner Head.

Open the Side

Burner Lid and

Remove the

Grate above the

Burner head.

Burner Head

screws X 3

Flame

Thrower

screws X 2

Undo the 3 screws that hold the Burner Head to the

base plate and carefully move Burner Head off of

the 2 Side Burner orifices

NOTE:

Side Burner Gas Valve. And the larger orifice is to be installed on the right hand outlet of the Gas Valve.

These 2 orifices look the same. The smaller size orifice is to be installed in the center outlet of the

Remove the 2 orifices from the Side

Burner Valve and replace with the

new Natural gas Orifices supplied in

the Natural gas conversion kit

Carefully move the Flame Thrower

(Burner ignition) away from the

Burner Head.

18

Page 19

GAS LINE

Remove the 3/8” flare fitting that

attaches the propane hose from the

Manifold block inside of the pedestal

and replace with an approved 10’

Natural Gas Hose neoprene hose.

Part # NGHOSE

REMEMBER TO LEAK CHECK ALL

FITTINGS AND ORIFICES AFTER

ALL OF THE CONVERSION IS

COMPLETED, LEAK CHECK ALL

FITTINGS AND TEST FIRE ALL

BURNERS TO ENSURE PROPER,

SAFE OPERATION.

Remove

Propane hose

and regulator

assembly and

Install new

Natural gas

Hose

MAINTENANCE

Burner Inspection: Please inspect these burners once a year.

Periodically inspect the burners for blockage or corrosion. These burners can be cleaned using a small piece

of wire and a wire brush. Be careful not to damage the ceramic spark electrode. Have the burner replaced if

there are any signs of deterioration.

BURNER REMOVAL FOR CLEANING

1. Ensure the gas supply is off and grill is cool.

2. Remove Cooking Grids and Upper Flavor Shields.

3. Remove the burner mounting screw located at the very back of burner near the rear of the firebox.

4. Remove burners by lifting up and out of firebox on an angle. Repeat for all burners.

5. Clean the outside of the burners with a Brass Bristle wire brush and make sure all gas ports are clear.

Use a straight coat hanger to clear any obstructions.

6. Use a flashlight to look into the venturi end of the burner to check for blockages. If necessary, use a

straight coat hanger to clear any obstructions.

7. Inspect and clean the venturi end of the burner by removing the venturi set screw on the end of the

burner and removing the venturi shutter. Once removed, make sure the burner is thoroughly cleaned and

the venturi shutter is re-installed with an opening of 1/8” for Natural Gas and ¼” for Propane. (NOTE:

ensure that the venturi set screw is tight after setting the correct air shutter opening.

8. Re-install and secure burner.

9. Re-mount flame tamers and cooking grids.

10. Light each burner to ensure they are operating correctly.

Note: When installing burners, it is very important to center the burner over the gas orifice. You should look

under the main control panel with a flashlight once installed to make sure they are in the proper position.

Failure to clean and install burners correctly could result in fire or explosion.

19

Page 20

FOOD SAFETY TIPS AND TECHNIQUES

We want to enjoy healthy and safe grill cooking, so here are some tips for basic barbecue hygiene:

Bacteria are living organisms that grow and multiply rapidly in warm moist foods. Marinate meat in the refrigerator

and take it out one half hour before grilling, if you want to grill your prepared meat at room temperature.

A marinade should never be saved for a later day. If you want to use this marinade to serve with your meat please

bring the marinade top a boil before using.

Professional grilling requires HIGH heat to brown and sear the meat to seal in the juices. Most foods will be cooked

on “HI” setting through the entire cooking time. Some large cuts of meat may require the heat be turned down after

initial browning to ensure the cut is cooked without burning the outside. Also foods that need to be cooked for a

long time or foods that have been basted in a sugary marinade may need to be cooked slower and longer in order

to stop the cut from being burnt on the outside.

Before grilling, check to be sure the drip tray is in place. Light the grill according to the lighting instructions. Turn the

control knobs to “HI” and preheat the grill for 15 minutes with the lid closed. Place the food to be grilled on the

cooking grids until desired doneness, adjust the heat setting if necessary. A meat thermometer is helpful in

determining hoe long the food should be cooked. Cooking time is affected by shape and type of cut as well as

thickness.

To achieve the juiciest meats, use a spatula instead of tongs or a fork to turn the meat, and only turn the meat once

during cooking. Turn the meat just when the juices begin to bubble to the surface. Add seasoning or salt only after

the cooking has been completed, add sauces only at the end of the cooking time, this will prevent the sauce from

being burnt.

Trim excess fat from the meats prior to grilling, this will help prevent flare-ups. Cutting the fat at 2 inch intervals will

prevent the cuts from shrinking during the grilling time.

ROTISSERIE COOKING:

NOTE: Always remove the Warming Rack before using the Rear Burner for Rotisserie Cooking.

To place the meat or poultry on the spit, slide one of the forks onto the spit and secure the Thumb screw. Then,

insert the spit rod in the center of the meat or poultry, lengthwise. The food should then be centered on the spit rod

and the remaining fork and secure the Thumb screw. Place the spit rod in the grill and let the heavy side fall to the

bottom, set the counter balance to the top and fasten in place. Periodically check the meat to ensure the spit rod is

turning smoothly while cooking. Adjust the counter balance if necessary.

The only accurate way to tell when the meat is done is to use a meat thermometer. Insert the thermometer into the

center of the meat. Do not allow the thermometer to touch a bone as this will not give an accurate reading on the

meat thermometer.

Remove the Cooking Grids and place a drip pan on top of the upper flavor shields and position the pan directly

beneath the food on the spit rod. Depending on the flavor you desire, place liquid in the pan such as, water, juices

or wine, chop up onions or add garlic, As the juices fall from the meat they will mix with the liquid and evaporate

directly into the meat, this will prevent you from basting as this is a self-basting system.

Do not let the drip tray dry out.

20

Page 21

TROUBLE SHOOTING

PROBLEM POSSIBLE CAUSES SOLUTION

Low heat or low flame when

valve turned to high.

For natural gas – undersized

For both gases – improper pre-

Excessive flare-ups or

un-even heat.

Burners burn with yellow

flame, accompanied by smell

of gas.

For propane – improper lighting

procedure.

supply line.

heating.

Flame tamers installed

incorrectly.

Improper pre-heating. Pre-heat grill with all main

Excessive food waste on sear

plates and in drip pan.

Possible spider web or other

debris.

Ensure lighting procedure is

followed carefully. All gas grill

valves must be in the off position

when the tank valve is turned on.

Turn tank on for all pressure to

equalize. See lighting

instructions.

Pipe must be sized according to

installation code.

Pre-heat grill with all main

burners on high for 10-15

minutes.

Ensure flame tamers are located

on pins in front and rear of

firebox and inline with burners.

burners on high for 10-15

minutes.

Clean flame tamers and drip pan

regularly. Do not line pan with

aluminum foil.

Thoroughly clean burner by

removing. See maintenance

instructions.

Burner will not light with

igniter but will light with

match.

Humming Regulator.

Dead battery in igniter. Change battery by turning igniter

cover clockwise to remove.

Install one AA battery.

Loose electrode wire. Check electrode wire is firmly

pushed onto the terminal on the

back of the igniter.

Improper gap at electrode tip. Ensure the collector box is tight

and the gap between the

electrode end and the collector

box is between 1/8” and 3/16”.

The gap can be adjusted by

bending the box in or out.

Normal occurrence on hot days. This is not a defect. It is caused

by internal vibrations in the

regulator and does not effect the

performance or safety of the gas

grill.

21

Page 22

- PARTS LIST

Part

Number Part Description Quantity

1 07-400 Outer Hood 1

2 04-3403 Warming Rack Bracket 2

3 07-402 Hood Handle 1

4 07-4505 Thermometer 1

5 07-403 Inner Hood 1

6 07-404 Rear Burner Mount 1

7 07-4508 Inner Hood Back Cover 1

8 07-405 Warming Rack 1

9 04-34510 Collector Box 1

10 07-4506 Upper Flavor Shields 4

11 07-407 Large/ Cooking Grids 2

12 07-4512 Control Knobs 5

13 04-34514 Electronic Igniter 1

14 07-408 Display Panel 1

15 07-4516 Gas Valves 5

16 07-4517 Main Burners 4

17 07-409 Gas Manifold 1

18 07-410 Grease Pan 1

19 07-411 Firebox Front 1

20 07-412 Firebox Back 1

21 07-419 Firebox Side left 1

22 07-420 Firebox Side Right 1

23 07-413 Firebox Back Cover 1

24 07-4547 Cross Lighters 3

25 04-3423 Grease Cup 1

26 07-4524 Grease Pan Handle 1

27 04-3425 Grease Cup Rails 2

28 04-3426 Rear Burner Cell 1

29 07-4530 Rear Burner Orifice 1

30 07-4531 Grease Pan Glides 2

32 07-432 Pedestal Side Right 1

33 07-433 Pedestal Side Left 1

34 07-416 Pedestal Back 1

35 07-417 Pedestal Heat Shield 1

36 07-418 Pedestal Base 1

37 07-419 Pedestal Door Right 1

38 07-420 Pedestal Door Left 1

39 07-421 Condiment Bin Right 1

40 07-422 Condiment Bin Left 1

41 07-423 Side Shelf Utensil Holders 2

42 07-424 Door Hinges 4

Gas Manifold Bracket and

43 07-425

44 07-426 Castors Locking Swivel 2

45 07-427 Castors 2

46 07-428 Side Shelf Right 1

47 07-429

48 07-430 Door Handle 2

49 07-431 Tank Slide out (assembly) 1

50 07-432 Rotisserie Kit 1

Rotisserie Rod 1

Rotisserie Forks 2

Rotisserie Rod Bushing 1

Rotisserie Motor 1

Rotisserie Motor Mount 1

Fitting

Side Shelf Left (side

burner) 1

Rotisserie Counter

balance

1

1

22

Page 23

1

EXPLODED VIEW

18

26

11

12

4

3

8

2

5

6

28

7

2

14

50

10

30

47

9

13

24

16

30

34

32

46

41

35

49

39

25

42

33

43

37

36

48

41

40

42

23

45

44

38

Page 24

Jackson Grills Limited Lifetime Warranty

Jackson Grills Inc. warrants the following materials and workmanship to be free of defects

for as long as you own the grill. This covers the following components: main stainless steel

outer hood, stainless steel cooking grills, stainless steel outer pedestal system, stainless

steel handle, Stainless Steel Burners and Stainless Steel cross lighters. Subject to the

following conditions: During the first 5 years Jackson Grills will replace or repair at our

option the defective parts free of charge. From 6 years to lifetime Jackson Grills will

provide replacement parts at 50% of the current retail price.

Inner stainless hood, firebox, Flame Diffusers and warming shelf come with a 10-year

warranty. During the first 5 years Jackson Grills will replace or repair at our option the

defective parts free of charge. From 6 to 10 years Jackson Grills will provide replacement

parts at 50% of the current retail price. The hardwood cart option (if equipped) is warranted

for a period of one year.

Other components: hose and regulator, thermometer, gas valves, knobs, fasteners, igniter

and electrode, and all accessories will be provided free of charge during the two years of

the limited warranty.

Limited Warranty subject to the following conditions and limitations:

- This factory warranty is non transferable and may not be extended whatsoever by any of our

representatives.

- Jackson Grills Inc. warrants its products to the original purchaser only (NO EXCEPTIONS)

- This Limited Warranty does not cover any damage caused by misuse, lack of maintenance, hostile

environments, accident, alterations, abuse or neglect, and parts installed by other manufacturers will

nullify the warranty.

- This Limited Warranty does not cover and scratches, dents, corrosion, or discoloring by heat (all

stainless steel will discolor), abrasive and chemical cleaners will also damage grill and grill surface.

- Should deterioration occur to the point of non-performance within the duration of the warranted

coverage, a replacement will be provided in the first year only. This warranty extends to the repair or

replacement of warranted parts that are defective in materials or workmanship provided that the

product has been operated in accordance with the operation instructions and under normal

conditions.

- After the first year Jackson Grills Inc. reserves the right to fully disengage all obligations with respect

to this Limited Warranty by refunding the original warranted purchaser the original wholesale

purchase price of the warranted parts.

- A licensed, authorized, service technician or contractor must install the gas grill. Installation must be

done in accordance with the installation instructions included with the product.

- Jackson Grills Inc. or its parties will not be responsible for the installation, labor or any other costs or

expenses related to the re installation of the warranted part, and such expenses are not covered by

this warranty.

- Notwithstanding any provision contained in this Limited Warranty, Jackson Grills Inc. responsibility

under this warranty is defined as above and it shall not in any event extend to any incidental,

consequential, or indirect damages.

- Jackson Grills Inc. neither assumes, nor authorizes any third party to assume, on its behalf, any other

liabilities with respect to the sale of this product.

- The bill of sale and proof of original ownership and serial number will be required when making any

warranty claims from your authorized dealer. The warranty registration card must be returned within

30 days to register your warranty.

- Jackson Grills Inc. reserves the right to inspect any parts prior to approving warranty claim.

- Jackson Grills or its representatives shall not be liable for ANY transportation charges, labor charges

or duties.

24

Page 25

A special message to our customers

Thank you for choosing the Jackson Grill for your new gas grill. This appliance is designed with quality

components and we are confident that it will provide you with years of excellent operation. Please take the

time to read the whole manual and familiarize yourself with all of the features of the Jackson Grill. This

manual also contains important safety information and operation instructions. Ensure that this manual

remains handy to the barbeque for quick reference. If you need to obtain replacement parts for your Jackson

Grill, contact your local dealer.

NOTE: It is normal for stainless steel surfaces to discolor due to high heat given off from the barbeque

burners.

Please take the time to fill out and return the Ownership and Registration Card below. It can be mailed to:

Jackson Grills Inc.

2945 Jacob Road, Duncan, B.C.

V9L 6W4

Or Fax: 1-250-715-0821

Please complete and return within 10 days. Thank you.

Mr. Mrs. Ms. Miss

First Name: Initial: Last Name:

Street: Apt. #:

City: State/Province: Zip/Postal:

Phone: Email:

Date of Purchase: Dealer:

Model: Serial #:

Comments:

Thank you for taking the time to fill out this Ownership and Registration Card

25

Loading...

Loading...