Page 1

MODEL 44 CE/RPW

40906

JUNE 1985

SINGLE TANK RACK CONVEYOR

DISHWASHERS

SERVICE MANUAL

INCLUDES:

-Warranty Policy -Sequence of Operation

-Installation Requirements -Basic Functions of Dishwasher

-Operating Instructions -Maintenance and Care

-Table Dimensions -Illustrated Parts List

-Wiring Diagrams -What's Not Covered by Warranty

-Troubleshooting Guide

WORLD HEADQUARTERS & MANUFACTURING OPERATIONS

Highway 25E, P.O. Box 1060

Barbourville, KY

888/800-JMSC

FAX 606/523-9196

November 6,1998 P/N 7610-100-21-00 Rev A

Page 2

INDEX

SPECIFICATIONS

3

GENERAL INSTRUCTIONS (Operation)

6

REPLACEMENT of SWITCHES in CONTROL PAN EL

9 THERMOSTAT ADJUSTMENT.

10

REPLACING SEAL and CERAMIC on WASH PUMPS

12

TROUBLESHOOTING GUIDE

14

CONVEYOR DRIVE ASSEMBLY and MOTOR

27

LOAD SENSOR HOLE LOCATION

32 WIRING of LOAD SENSOR SWITCH CIRCUIT

33

WARRANTY INSIDE FRONT COVER

GENERAL INSTRUCTIONS (Installation) 4

GENERAL INSTRUCTIONS (Preventive Maintenance) 7

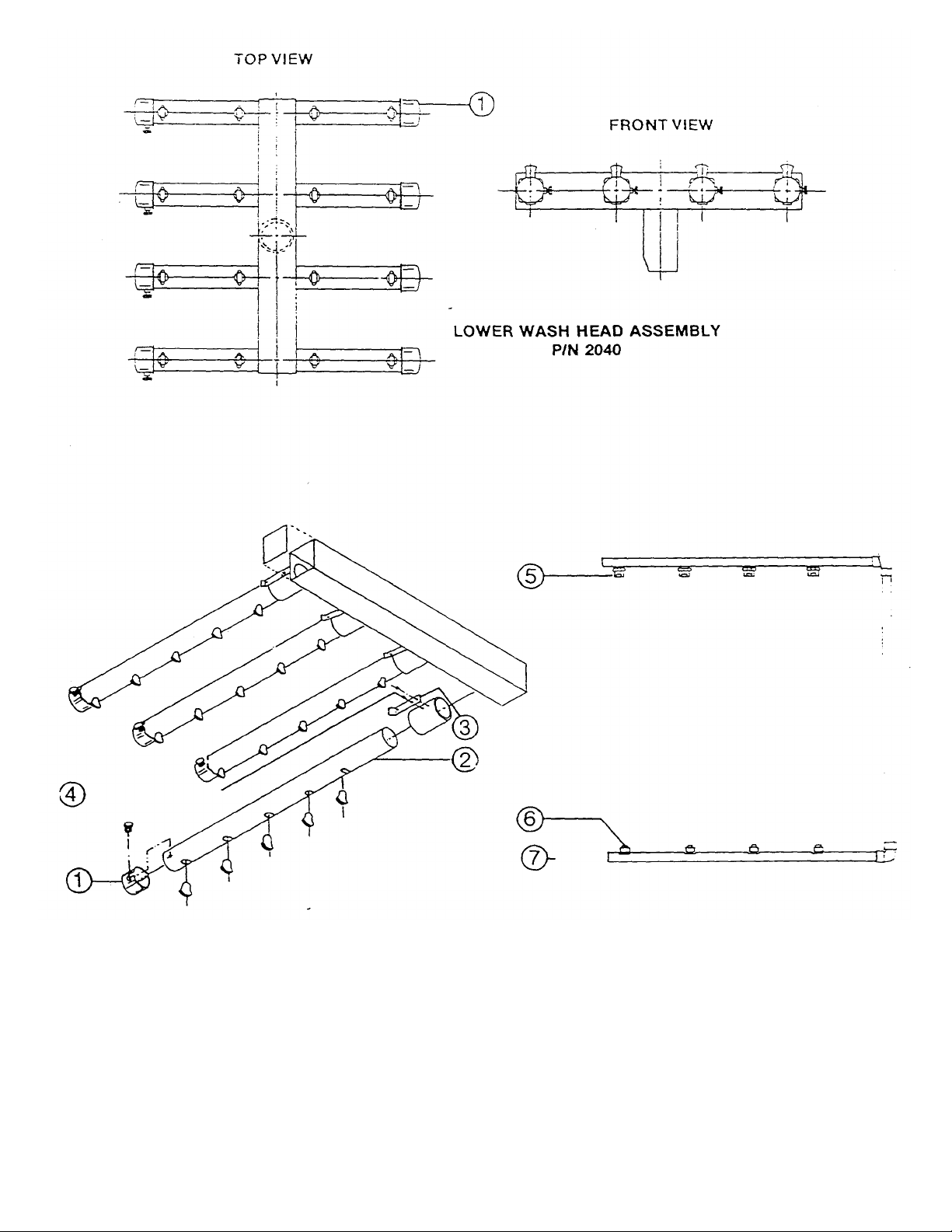

LOWER WASH HEAD ASSEMBLY 8

UPPER WASH ASSEMBLY 8

FINAL RINSE ASSEMBLY 8

SERVICE INSTRUCTIONS (lncoming Water Solenoid Valve) 11

WASH PUMP ASSEMBLY 13

TORQUE-TAMER 22

PAWL BAR ASSEMBLY 26

CAM and CLUTCH ASSEMBLY 28

LOAD SENSOR SWITCH CONVERSION 29

CONVEYOR DRIVE ASSEMBLY 31

LOAD SENSOR SWITCH DETAILS 32

ELECTRICAL DRAWINGS 34

PARTS LIST 38

PARTS DISTRIBUTORS INSIDE BACK COVER

Page 3

SPECIFICATIONS

OPERATING CAPACITY

Racks per hour (NSF Rated) 198

Dishes per hour 5000

Glasses per hour 5000

CONVEYOR SPEED

Feet per minute 5.5

WASH TANK CAPACITY

Gallons 24

WASH PUMP CAPACITY

Gallons per minute 240

THERMOMETER

Wash-°F 140-160

Rinse-°F 180-195

WATER REQUIREMENTS (NSF Rated)

Inlet Temperature °F 180

Gallons per hour 414

Flow pressure PSI 20

Flow GPM 6.9

Inlet-lPS 3/4"

Drain-IPS 1-1/2"

WASH PUMP MOTOR

Horsepower 1

CONVEYOR MOTOR

Horsepower 1/16

ELECTRIC HEAT WASH

KW 13

DIMENSIONS

Length (table to table) 44"

Width 25"

Height 55"

Standard table height ± 1/2" 34"

Maximum height for dishes 16"

STANDARD RACKS

Dish 19-3/4x19-3/4 4

Combination 2

SHIPPING WEIGHT BASIC MODELS

(approx.) 600

ELECTRICAL RATING

Volts: 208/220

Phase:1/3

Amps: (approx.)

Specifications subject to change without notice.

Page 4

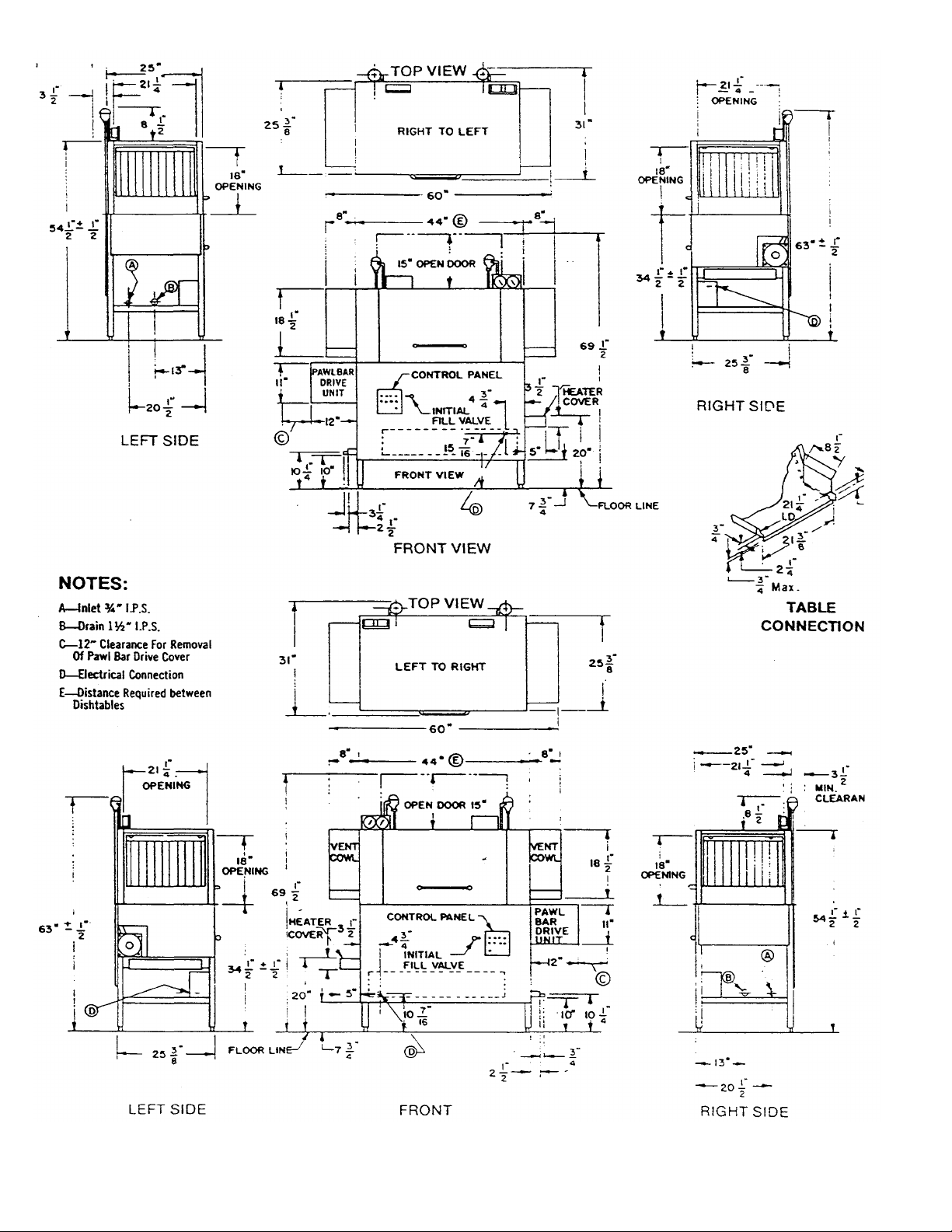

GENERAL INSTRUCTIONS

(INSTALLATION/DIMENSIONS) for 44CE SERIES

Note: Read the following instructions carefully. Proper installation of your

Jackson Dishwasher will assure proper machine operation.

1. Open the front door (hook open) and remove dish, cup, and glass racks, and set to one side for later use.

Remove the tape holding the overflow strainer, the pump intake strainer, and the wash head assembly

that are inside the machine.

2. Cut straps holding machine to base of crate, ease machine on to floor and slide into place of

installation.

3. Connect drain to bottom of machine (1 1/2" IPS female fitting on bottom of wash sump) with proper slope

to conform with local and/or national codes. Drain is a gravity feed system from machine.

4. Connect incoming 3/4" water line with capacity to supply 6.9 gallons per minute flow, at 20 PSI at a

temperature of 180°F+. This connection is just before the Y-strainer. Connect to conform with local

and/or national codes (STANDARDS).

5. Electrical connections should be made through hole in back of control box to terminal board inside (to the

left lower side of control box). This terminal board is accessible by removing the lower cover plate. The

terminals are marked L1, L2 (requiring 208—230V, single phase), or L1, L2, L3 (requiring 208—230V,

three phase). There is a grounding lug inside of the control box on the bottom left. Be sure all

connections made are tightened properly. Refer to data plate for Voltage and Amperage totals.

6. Install the proper circuit breaker, wire, and conduit size to conform with local and/or national codes. Refer

to data plate for electrical loads.

7. DO NOT APPLY POWER UNTIL STEP 10.

8. Insert pump intake strainer, overflow strainer, runoff sheets, and lower wash manifold, then close door.

9. Turn on hand valve controlling water supply to machine; check for any leaks in plumbing and

connections.

10. To energize electrically, proceed as follows:

a. Turn on customer's circuit breaker controlling machine.

b. Check voltage at incoming terminal L1, L2, and L3 (if applicable). It should match data

plate voltage. Voltage at L1 and L2 should be checked to ground individually to ensure

that a high (or wild) leg is not connected to L1 or L2. (Voltage exceeding 150V to

ground would indicate high leg.)

c. If voltages are in required range, turn on 15 amp circuit breaker. The 15 amp circuit

breaker protects and controls the motors and control circuit only; it is not meant to protect or control

the wash heaters.

d. Insert a rack into the machine, be sure the curtains are in place.

e. Turn the fill handle on the front of the machine to supply the unit with water. It should

take less than four minutes to fill the wash tank. When the desired level is reached turn

the handle back to the original position.

f. Open the front door and check the water level. It should be 1/4" below overflow level. If

not, check the incoming water line making sure that the valve fully opens and closes as

the handle is turned on and off.

g. If the water is the proper level, close the front door and turn on the heat switch. The

heaters are in the wash tank and are utilized to maintain the wash water temperature at

150°.

h. Turn on the conveyor switch. This will set the conveyor pawl bar into motion to pull the

rack of ware through the unit.

i. The unit is now ready to proceed with the washing of dishes in accordance with the

operating instructions in this manual, and the instruction sticker on the front door of

the dishwasher.

Note: As the racks leave the unit do not allow them to accumulate more than three in a row.

Page 5

Page 6

GENERAL INSTRUCTIONS

(OPERATION) 44CE

Note: Read instructions carefully. Proper operation of your Jackson Dishwasher will assure

clean and sanitized glasses and dishes at optimum efficiency.

Dish Preparation

1. Scrape the dishes thoroughly.

2. Pre-rinse the dishes by soaking or by spraying off with a pre-rinse hose.

3. Place the dishes and cups in the dish rack with cups upside down.

4. Place the glasses and silverware in the combination glass-silverware rack with the

glasses upside down. Scatter the silverware loosely on the bottom of the rack. Do not put glasses on top

of the silverware.

NOTE: When silverware is in an upright position, it washes and rinses better than lying flat. These

compartment silverware racks are available through your dealer or service agency.

Machine Operation

1. Open the front door and insert the pump intake strainer, overflow strainer, runoff sheets, and lower wash

manifold.

2. Close the door.

3. Turn the fill valve handle on the front of the unit- It should take less than four minutes for the water level

to reach the top of the overflow. When the desired level is reached turn the handle back to the original

position.

4. Turn on the heat switch, letting the wash temperature reach 150°.

5. Slide in a rack of dirty dishes.

6. Add detergent* (see Detergent Recommendation). If an automatic detergent dispenser is used, follow

the manufacturer's instructions.

7. Start the wash cycle of the dishwasher by flipping the start switch in a up position.

8. To set the conveyor pawl bar assembly in motion flip the conveyor switch in the up position. The pawl

bar assembly automatically pulls the rack through the machine once it enters the opening.

9. When the rack leaves the other end of the machine it should be removed or not allowed to accumulate

more than three racks on the table. This will prevent the clutch from burning out.

10. Once the wash cycle is activated there is no need to turn it off until the end of the meal period. Repeat

steps 6, 8, and 9 for each rack of ware.

11. At the end of a meal period or the end of the day, shut off the heater, wash, and conveyor switch. Drain

the machine by removing the overflow strainer. Clean both strainers, the overflow and the inside

strainer, of all foreign debris and build-up and flush out the unit.

* Detergent Recommendation and Rinse Additives:

We suggest you contact your local detergent specialists for the correct detergent and rinse additives for the

area. To help until one can be reached, we suggest that you use a non-foaming dishwasher detergent,

approximately one-quarter cup in wash tank, when machine is filled the first time, then one level tablespoon

each cycle (or load) thereafter. This may have to be increased or decreased to obtain satisfactory results.

6

Page 7

GENERAL INSTRUCTIONS

(PREVENTIVE MAINTENANCE)

(THE FOLLOWING IS TO BE PREFORMED AS NEEDED.)

Note: Read carefully. Proper maintenance of your Jackson Dishwasher will ensure optimum

1. To remove all lime and corrosion dep osits.

g. Refill as it is ready for regular operation.

2. Clean strainers.

3. Clean Y -strainer on incoming water line. (Water to machine must be turned off for this operation).

a. Remove plug and clean strainer.

4. Clean rinse tubes.

c. If spray holes in the rinse tubes are clogged, they may be cleaned with a pointed tool.

5. Clean wash head assembly.

service with a minimum of down time.

a. Fill the machine with wash water as would ordinarily be done for washing.

b. Open door and place one cup or more of de-liming compound into the water. (Be sure

to follow manufacturer's directions if they vary from these being given) which is

available from your detergent supplier.

c. Turn on wash switch and allow to wash for five minutes.

d. Open door-and examine the interior. All lime should be removed and parts should be

shiny. If not, allow to wash for longer periode. After the interior is clean, empt y the wash water by removing overflow strainer.

f. Replace overflow strainer. Refill machine and allow to run for two minutes, then, again

drain the wash reservoir.

a. Clean around overflow and pump intake strainer holes.

b. Clean around pump intake (toothbrush makes excellent tool for cleaning).

a. Remove end plugs on lower and upper rinse.

b. Clean all rinse tubes with special brush supplied.

a. If spray jets are plugged, use pointed tool to dislodge and flush with water.

b. If lodged items still remain in wash tubes, remove wash assembly by first removing

rinse assembly.

c. Clean assembly at sink by flushing water through spray jets. d. Reinstall wash and rinse

assemblies. (See page with instructions).

6. Clean any deposits which may have built up on exterior moving parts.

7

Page 8

UPPER WASH ASSEMBLY

P/N 1990

ITEM P/N DESCRIPTION

1. 2035 WASH HEAD TUBE CAP

2. 2020 WASH HEAD TUBE

3. 2025 WASH HEAD SPRING CUP

4. 2030 WASH HEAD SCREWS

0203700 TUBE CAP W/"O" RING

FINAL RINSE ASSEMBLY

P/N 6137500

ITEM PIN DESCRIPTION

5. 1390 RINSE ASSEMBLY UPPER NOZZLES

6. 1395 RINSE ASSEMBLY LOWER NOZZLES

7. 1400 RINSE ASSEMBLY END PLUGS

8

Page 9

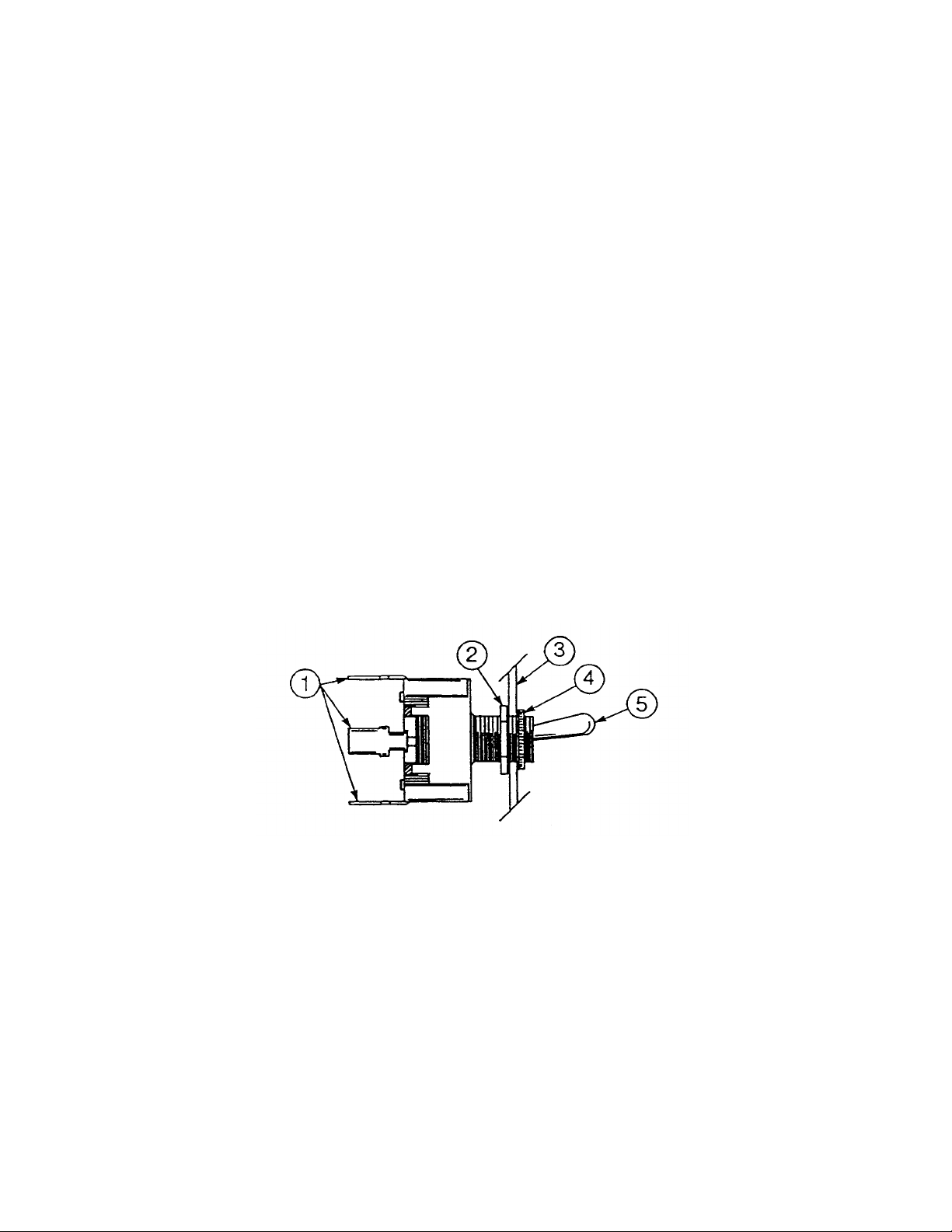

REPLACEMENT of SWITCHES In

CONTROL PANEL

There are three switches installed in the control box cover panel. These are the conveyor, wash, and

heater switches.

Before working on machine, it is important that power be turned off at customer's circuit breaker to prevent

the possibility of electrical shock, trip breaker to "off" position. Then turn machine breaker "on" located right

side of control box.

Remove the control panel from the control box. The three switches are mounted in individual round holes

with a keyway. By using a pair of pliers or open end wrench, it is possible to loosen the inside nut enough

to allow the outside nut holding the switch to be removed by fingers. Push switch out of hole.

If a switch is found to be defective, replacement can be achieved by placing the new switch next to the old

one. To make sure the new switch is not upside down, line up with the keyways. Transfer wires one at a

time to the new switch. If this is not practical, pull wires off, one at a time and tag them for proper

replacement.

Put switches back into panel, make sure switch protrudes through panel properly, tighten both nuts, and

replace control panel on control box. Power can now be applied to dishwasher and run through cycles

checking all operations.

P/N 1575

1. CONNECTION TERMINALS

2. INSIDE NUT

3. PANEL PLATE

4. OUTSIDE NUT

5. BAT OR TOGGLE HANDLE

9

Page 10

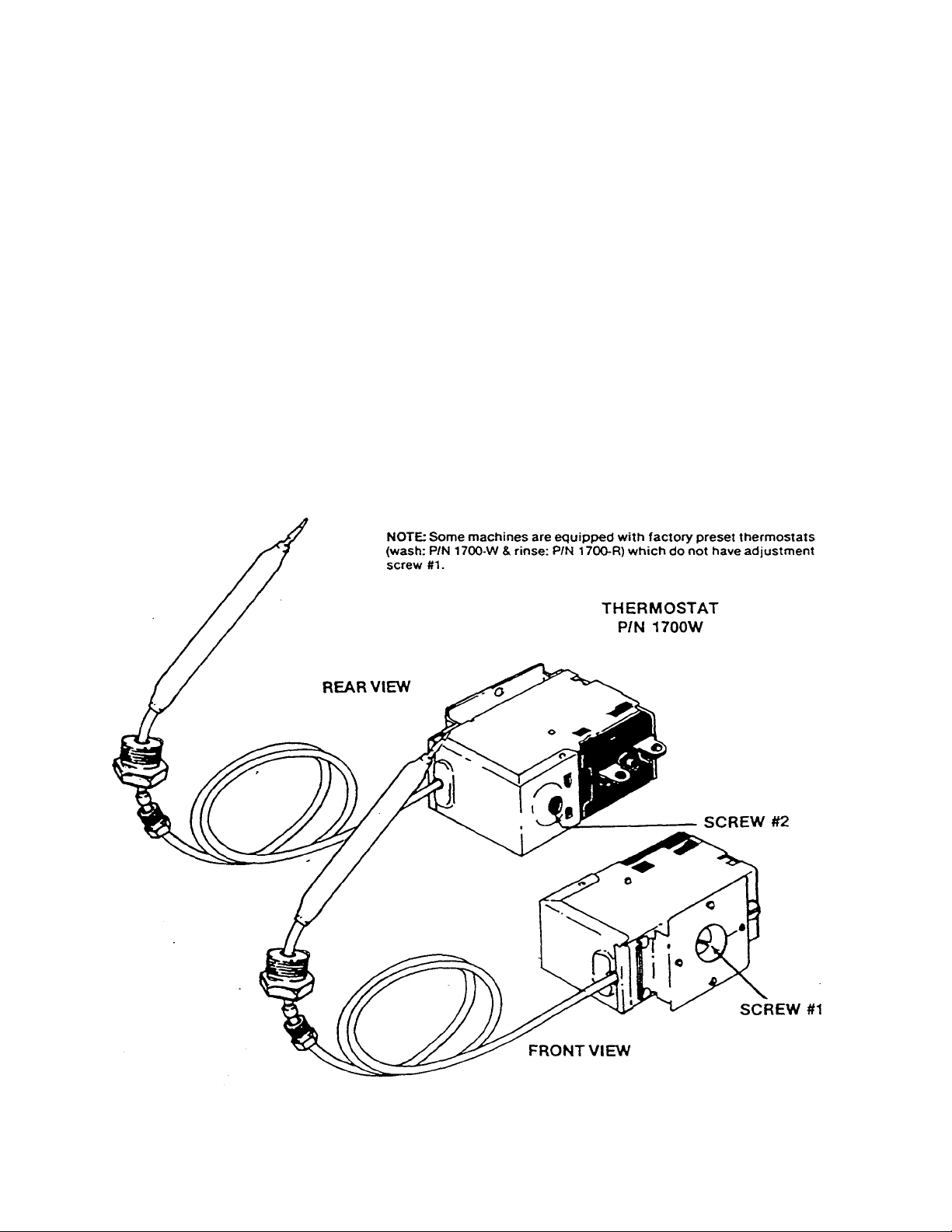

THERMOSTAT ADJUSTMENT

The thermostat can be adjusted by turning screw #1 (see picture) on the thermostat control box cover.

(Remember the present setting, in case the problems are elsewhere in the control circuit). A CW rotation

is used to obtain a lower temperature setting and a CCW rotation is used to obtain a higher temperature

setting. A 1/8 turn of screw #1 changes the temperature approximately 15°F. If screw #1 is turned all the

way to its stop in either direc tion; adjust screw #2 as follows. DO NOT TOUCH THE SCREW SEALED

WITH RED PAINT. When adjusting screw #2 power should be disconnected during adjustment.

Set screw #1 so that it can be turned-equal distances in either direction, then:

— if screw #1 stopped while turning in CW direction, turn screw #2 in CW direction slowly and only

1/8 of a turn or less per complete cycle of the unit.

— if screw #1 stopped while turning in CCW direction, turn screw #2 in CCW direction slowly and

only 1/8 of a turn or less per complete cycle of the unit.

Three-fourths of a turn will bring the thermostat to approximately the same setting obtained where

screw #1 stopped. Check the present temperature setting before attempting any further adjustments.

Use screw #1 for any further adjustments.

NOTE: Making large moves in adjusting may cause misalignment thus increasing

the chances that further adjustment cannot be made and the thermostat

will have to be replaced.

10

Page 11

SERVICE INSTRUCTIONS

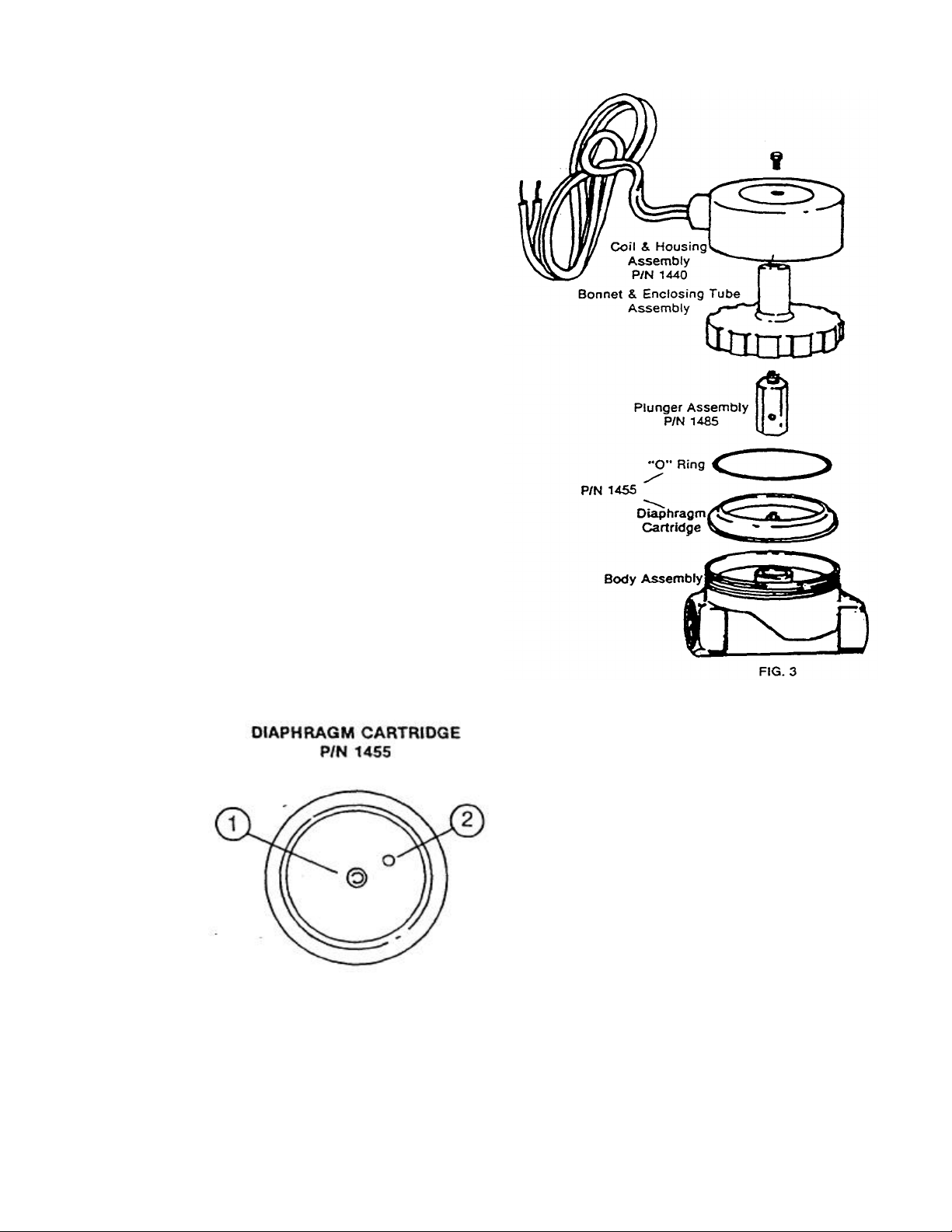

(INCOMING WATER SOLENOID VALVE)

To Take The Valve Apart

Disassembly - These valves may be taken apart by unscrewing the

bonnet and the enclosing tube assembly from the valve body assembly.

See Fig. 3. After unscrewing, carefully lift off the bonnet and enclosing

tube assembly. Don't drop the plunger. The "0" ring seal and diaphragm

cartridge can now be lifted out.

Be careful not to damage the machined faces while the valve is apart.

To Reassemble - Place the diaphragm cart ridge in the body with the

pilot port extension UP. Hold the plunger with synthetic seat against the

pilot port. Make sure the "0" ring is in place, then lower the bonnet and

enclosing tube assembly over the plunger. Screw bonnet assembly

snugly down on the body assembly.

11

Possible Problems

Pilot Port extension #1 clogged

Hole #2 clogged

Remedy

Pass heated straight pin through hole #2 or

clean hole #1

Page 12

REPLACING SEAL and CERAMIC

on WASH PUMPS

Function:

The pump is part of the total motor-pump system and utilizes one shaft seal and ceramic to prevent the

pump from leaking around the impeller and shaft. One gasket is used to prevent leakage between the

pump mounting plate and the machine pump plate.

Replacement of Seal and/or Ceramic:

1. Remove the power source to the machine by turning the circuit breaker to its "off" position on the side of

the control box.

2. Drain the machine by removing the overflow strainer in the wash tank.

3. Support the motor—remove the four nuts holding the pump/motor to the machine's pump plate.

4. Carefully pull motor outward, move from side to side as required to remove from machine.

5. Set motor and pump on a sturdy stand clos e to machine or remove wires and conduit to allow

motor/pump to be moved to a better work station.

6. Insert a firm object into the blades of the fan and use 1 5/16" ratchet to remove bolt holding impeller.

After the bolt is removed, pull the impeller up and off of the shaft.

7. The ceramic is imbedded in the pump mounting plate and usually does not need

replacement, but the seal normally would when water leaks around the motor shaft area.

If replacement of either is required, proceed as follows:

a. Remove the four bolts holding the pump mounting plate to the motor.

b. Slide the mounting plate up and off of the shaft and motor. The imbedded ceramic and shaft seal will

be removed with the mounting plate.

c. Turn over the plate and push the seal and/or ceramic out of the housing carefully. It may be

necessary to break the ceramic to remove it.

d. Clean the hole where the ceramic was installed.

e. Lightly coat with a lubricant around the new ceramic's edges and "0" ring. Gently press the ceramic

into place against the snap ring in the housing. Make sure that the grooved side of the ceramic faces

the motor and housing snap ring, leaving the smooth side toward the impeller.

f. Make sure that the woodruff key is in place in the shaft and then set the plate back

on the motor over the shaft.

Note: A field tool can be made (to ease installation of seal) from a pipe or tube (3/4" CPVC

typical example) that has proper outside and inside dimensions. It must fit over step

down in shaft, but be close to larger shaft size on outside - To accommodate woodruff,

cut long slot in tube. Lubricate tube slip seal over tube onto shaft.

g. Lightly coat with a lubricant the new seal face and gently press it into place over the shaft with seal

face against the ceramic. SEE NOTE ABOVE.

h. Place the spring over the shaft with the metal cap up. Press the impeller down onto the shaft, aligning

the keyway of the impeller with the woodruff key.

i. Tighten the impeller washer, lockwasher, and bolt into place. Replace the four bolts that hold the

mounting plate to the motor.

8. Reinstall the pump and motor in the unit by reversing steps one through eight (it is suggested that a new

pump gasket be installed).

Impeller Rotation:

When facing the impeller after mounting it on the motor shaft, the impeller should turn in a CCW

direction.

12

Page 13

3.

WASHER, RUBBER

ITEM P/N DESCRIPTION

1. 1027 PUMP MOTOR

2. 1065 WOODRUFF KEY

4. 1080 SNAP RING

5. 1050 CERAMIC FACE W/"O" RING

6. 1045 PUMP MOUNTING PLATE

7. 1050 SEAL FACE

8.

9. 1050

10. 1055 PUMP IMPELLER

11. 1075 IMPELLER WASHER

12. 1070 IMPELLER BOLT & LOCKWASHER

13. 1060 PUMP MOUNTING GASKET

PLATE TO MOTOR MOUNTING BOLTS &

LOCKWASHERS

SEAL ASSEM BLY (SEAL SPRING & CUP

WASHER)

13

Page 14

TROUBLE SHOOTING GUIDE

Temperature readings not within required

Spray tubes clogged with paper towels, toothpicks,

any obstructions in the pump intake hole,

The information contained herein is intended to help you solve some problems that may exist on your dishwasher from time to time.

Anything not covered in this guide should be referred to the factory. References to section drawings within this book will be made

throughout this "Trouble Shooting Guide." Refer to these section drawings to help you in correcting the problems.

PROBLEM CAUSE SOLUTION

1. Check thermometer by using a

range.

1. Thermometer is defective.

thermometer known to be accurate. If

defective, replace.

Final Rinse switch

Washing action does not get dishes

clean.

2. Heat switch contactor, elements, thermostats,or

low-water level control.

1. Refer to incoming water and rinse section for

solution.

1.

etc.

2. Pump intake strainer clogged.

3. Scrap basket full; will not allow water to return to

tank.

4. Overflow and drain tube not solid in drain fitting,

not allowing pump sufficient water, for pumping

action.

5- Pump clogged.

2. Refer to bottom drawing and electrical

drawing.

1. Remove upper spray tubes and clean,

remove lower assembly and clean

spray tubes by removing tube caps.

2. Remove pump intake strainer and

clean.

3. Remove scrap basket and clean.

4. Remove overflow and drain tube and

replace solidly in drain fitting.

5. With pump intake strainer off, check. If

remove.

Water in wash tank

excessively high.

Pawl bar not operating to push dishes

through dish washer.

Unable to maintain heat in wash tank.

6. Pump impeller not turning; therefore, motor is not

turning and pumping.

1. Overflow and drain tube clogged or covered with

napkin, etc.

1. Something jammed between pawl bar and clean

dish side of dishwasher.

2. With pawl bar removed, drive rod doesn't

operate.

1. Water too low in wash tank and does not touch

probe.

2. Low-water cutoff system not operating. (Probe is

part of this system.)

14

6. Refer to Pump/Motor Section.

1. Drain tank and refill to ensure clean

water.

1. Remove obstruction.

2. Check section "Conveyor Drive

and Motor."

1.Turn fill valve on refill machine (make

sure overflow and drain tube are

securely in drain).

2. Refer to "Electrical Section Drawing."

Read Electrical Checkout.

Page 15

TROUBLE SHOOTING GUIDE

Rinse temperature not within required

solenoid valve according to instructions

Rinse trip assembly is not tripping final rinse limit

dishwasher and make sure there are no

obstructions and no extreme number of

PROBLEM CAUSE SOLUTION

3. Thermostat not functioning properly. 3. Follow 6A.

4. Heaters not functioning. 4. Follow 6A.

Vacuum breaker is allowing water to

escape and spray on top of machine

and against wall.

range.

Little or no water coming from final

rinse nozzles when machine is in

operation.

1. Vacuum breaker is defective.

2. Gasket on poppet split or worn.

1. See "Top Section" for correction action.

1. 3/4" solenoid valve not opening to allow flow of

water.

2. Final rinse limit switch faulty.

3.

switch.

4. Water on incoming plumbing supplied by

customer not sufficient.

1. Remove top of vacuum breaker by

unscrewing. Lift poppet out and clean.

2. Replace rubber gasket and washer on

poppet completely.

1. Dismantle, clean and check out

on solenoid sheet Replace solenoid if

necessary.

2. Check switch to see that it has

continuity when in "on" position, if not

replace.

3. Make sure that coupling between

vertical rod from final rinse paddle is

tight and turns final rinse limit switch, if

not tighten. If vertical rod is bent,

straighten.

4. Check flow of water. If water isn't

sufficient, check line coming to

branches off from this line that could

steal water.

Can't fill machine. 1. Water to machine not turned on. 1.Tum water supply on.

5. Rinse nozzles clogged.

15

5. Unscrew rinse nozzles and clean. With

nozzles out, activate machine to see if

good amount of water flows. If not,

check plumbing.

Page 16

ring in

re

getting power into the switch and out of

se connections

TROUBLE SHOOTING GUIDE

PROBLEM CAUSE SOLUTION

Wash tank runs out of water. (This is

covered on previous page and is

continuation.)

Final rinse catch basin overflowing. 1. Crumb cup in drain clogged. 1. Remove crumb cup and clean.

Water level too high or low in wash

tank.

Pawl bar moves with no load but does

not move when loaded.

Pump/motor doesn't run. 1. Wash motor switch is defective.

Conveyor motor doesn't operate. 1. Conveyor push button switch is defective.

1. 1/4" Solenoid valve not operating.

2. Final rinse limit switch is defective.

1. Check previous Section for solution.

2. "O" ring not in drain fitting or damaged.

1. Clutch slipping.

2. Loose wires or connections.

3. Pump jammed.

1. Check Solenoid valve to see that it is

operating, if it doesn't operate, replace.

2. Check final rinse limit switch out to see

if it has continuity across the normally

closed contacts. If not, replace switch.

2. Check to see that there is an "0"

the drain fitting and it is not damaged.

Replace if necessary.

1. Adjust clutch. (See page insert for

instructions of Torque Tamer).

1. With switch on, check to see that you'

the switch, check back to circuit

breaker on dishwasher. If you are, but

not out of the switch, replace switch.

2. Check all wiring to and from motor to

see that there are no loo

or broken or frayed wires. Repair or

replace as necessary.

3. See previous instructions "Bottom

Section."

1. Check to see that power is going into

the switch for the conveyor and is

coming out the other side or turn off

power and check the continui ty by

pushing switch in and out to see that it

does turn the system on and off. If

switch's defective, replace.

16

Page 17

TROUBLE SHOOTING GUIDE

thermostat up or down as needed. If this

sulated wire, short

pass

level control have power coming to them,

If low water control is operating, the contacts

PROBLEM CAUSE SOLUTION

Heat circuit does not operate (wash

tank not at required temperature).

2. Loose wires or connection.

3. Motor is defective.

1. Water level in wash tank below low-water cutoff

probe.

2.Thermostat is out of adjustment or defective.

2. Check all wiring for breaks, loose

terminals and connections, and repair

accordingly.

3. Motor hums or doesn't operate at all.

Defective, replace motor.

1.FiII wash tank to overflow level.

2. By turning adjustment screw, adjust

doesn't increase or decrease the heat,

with a small piece of in

the two terminals on the thermostat out

with the heat switch on. This will by the thermostat action and if the water

temperature rises, the thermostat is

defective and should be replaced.

3. With heat switch on, check to see that

the terminals L1 and L2 on the water-

3. Water level control is defective.

4. Water-level control checked out okay on 9C, but

heat circuit still does not operate.

17

then with a short link of insulated wire.

Jump terminals 'L' and 'H'. These

terminals are on the low voltage (24V)

system.

in the little plastic-coated relay will work or

move. (Before attempting above, remove a

wire to Water-level probe).

4. Make sure that the probe wire has been

replaced.

Page 18

Item No. P/N DESCRIPTION

1. 453 CURTAIN

2.

3.

4.

5.

6. 1635

1691 WASH THERMOMETER

1377A RINSE ACTUATOR HELPER SPRING

1378 RINSE ACTUATOR COUPLING

1377B RINSE LIMIT SWITCH BRACKET

1636 RINSE LIMIT SWITCH

ITEM P/N DESCRIPTION

7. 1692 RINSE THERMOMETER

8. 526 DOOR FRONT CATCH

9. 1379 RINSE ACTUATOR ROD BRACKET

10. 1376 RINSE ACTUATOR PADDLE & ROD

11. 844 PROBE COVER

12. 525 FRONT DOOR

13. 530 FRONT DOOR HANDLE

18

Page 19

ITEM P/N DESCRIPTION

1. 1700 THERMOSTAT

2. 605 WASH TANK HEATER (6 EA.)

3. 843 LOW WATER PROBE

4. 1805 BACK CONVEYOR TRACK

5. 1410 LARGE RUNOFF SHEET

6. 1405 SMALL RUNOFF SHEET

7. 425 CONVEYOR PAWL BAR ASSEMBLY

8- 2035 WASH HEAD TUBE CAP

9. 2020 WASH HEAD SPRAY TUBE

19

ITEM P/N DESCRIPTION

10. 2025 WASH HEAD SPRING LOCK

11.

12. 2040 WASH HEAD MANIFOLD COVER

13. 1530 LARGE OVERFLOW TUBE

14. 1525 PUMP INTAKE STRAINER

15. 1535 TRACK & SCRAP STRAINER ASS'Y

16. 1790A FRONT TRACK LARGE SECTION

17. 1790B FRONT TRACK SMALL SECTION

TRANSFER SHEET

Page 20

ITEM P/N DESCRIPTION

1. 1414 DRAIN CRUMB CUP

2. 1530 OVERFLOW TUBE

3. 540 DRAIN "O" RING

21

ITEM P/N DESCRIPTION

4. 0002826 WASH DRAIN FITTING

5.

DRAIN OUTLET 1 1/2" IPS

Page 21

TORQUE-TAMER

clutch

FACTORY SERVICE BULLETIN #91

Model: 44 Clutch Adjustment

A.) Drive Bar Clearance Adjustment:

This instruction should be used to adjust the conveyor drive clutch, should the following problems arise:

1.) Cam follower bearing requires replacement due to damaged or broken stud

2.) Cam follower bearing jumps out of the slot in the drive arm and jams the drive system

Instructions (Refer to Figure I):

1.) Check the clearance between the top of the cam wheel and the drive arm. This clearance should be

1/32" or less, but also should not bind. If the clearance is more than 1/32", the following steps should

be performed:

a.) Measure the clearance between the top of the Cam Wheel and the drive arm, and between the

bottom of the clutch and the shoulder on the motor shaft.

b.) Remove Drive Motor from unit or pivot downward.

(This can most easily be accomplished by removing three of the motor mounting plate bolts &

allowing the motor assembly to pivot on the fourth bolt.)

c.) Remove Cam Wheel by loosening (3) allen head screws and lifting off.

d.) Loosen set screw at top of clutch.

e.) Remove clutch assembly from shaft.

f.) Place the proper combination of spacer washers on the shaft that will be equal to (or up to 1/32"

less than) the total of the clearances measured in step (a.).

NOTE: If cam follower bearing needs to be replaced, apply "Loctite 242" (or equiv.) to threads of

the new bearing. Tighten bearing securely and tighten locking set -screw. (Do not use

"Loctite" on the set -screw.)

g.) Replace clutch assembly on shaft, making sure that clutch assembly bottoms out on

the spacer washers.

h.) Retighten set -screw.

i.) Replace Cam Wheel

j.) Replace motor on unit and check clearance.

k.) Repeat, if necessary, until proper clearance is obtained.

22

Page 22

3.) Torque Adjustment:

This instruction should be used to adjust the conveyor drive clutch, should the following problems arise:

1.) Excessive slippage of clutch, resulting in racks not being pushed through machine.

2.) Damage to cam follower bearing or other conveyor drive parts due to clutch not slipping when

jammed or overloaded.

Instructions (Refer to Figure II):

1.) Loosen the three tension screws at least three turns. (They should not protrude through the adjusting

nut.)

2.) Loosen the adjusting nut set-screw at least six turns.

3.) To obtain initial setting, turn the adjusting nut by hand as tightly as possible — do not use a tool. Now,

back the adjusting nut off (counter-clockwise) one and one-half (1 1/2) turns — this will correspond to

nine notches. Tighten set -screw into closet spline notch at this location.

4.) Retighten the three tension screws - The tension screws should be tightened alternately and evenly

until heads bottom.

5.) Check torque adjustment again by exerting hand pressure against the rack. It should slip only under

heavy pressure such as a jam; however, it should move at least three heavily loaded racks without

slipping.

6.) If necessary repeat steps 1 & 2 and readjust adjusting nut as required — rotating the nut one notch

only (CCW to loosen, CW to tighten). Continue with steps 4, 5, & 6.

23

Page 23

FACTORY SERVICE BULLETIN #97

Clutch Conversion For

Series-44 Conveyor System

This conversion is to be used on all 44-Series units that develop recurring conveyor drive problems due to

breaking-off or stripping-out of the cam follower bearing. (For machines with persistent problems, it is

recommended that this conversion be performed in conjunction with Factory Service Bulletin #96.) Tools

Required:

Wrench Set

Hex Key Wrench Set

Torque Wrench, 3/8" drive, 30-200 Ib-in, ("Snap-on" #QC-217 or equiv.)

Crowfoot Wrench, 1 1/4" x 3/8" drive, ("Snap-on" #FC-40 or equiv.)

Tube or bottle of "Loctite 242" or equiv.

Parts Required:

(1) - Drive Hub

(1)- Friction Plate

(1)- Shaft Extender

(1)- Motor Riser

(1) - Torque Limiter Assembly

(1) - Cam Follower Bearing

(1) - "Oilite" Bearing

(1) - 3/8 - 16 x 1 1/4" long Hex Socket Head Cap Screw

(3) - 10-32 x 1 1/ 4" long Hex Socket Head Cap Screws

(1) - Locknut (thin series) 5/16-24NF

Procedure:

1.) Disconnect power to machine.

2.) Remove cover from conveyor drive assembly.

3.) Remove bolts that hold gear-motor riser to machine frame and lower gear-motor assembly away

from drive assembly.

4.) Remove motor riser from gear-motor and discard.

5.) Install new motor riser with four outer holes positioned closer to top, us ing existing hardware.

6.) Remove clutch and cam wheel assembly from gear-motor shaft and discard.

7.) Assemble clutch and drive hub assembly as per (Figure I.). Use "Loctite 242" or equiv. on cam

follower lock nut (be sure to remove all grease from screw threads first). Tighten all hardware, except

clutch adjustment nut, securely.

8.) Remount gear-motor assembly on machine frame, using existing hardware.

9.) Loosen setscrews in clutch adjustment nut so that nut turns freely.

10.) Using torque wrench with crowfoot adaptor, carefully adjust nut to a torque reading of: 30 in-lb.

11.) If machine is equipped with a "load sensor" switch, temporarily defeat this switch with a jumper wire

to facilitate adjusting the clutch.

12.) Jam conveyor drive bar by placing a piece of 2" x 4" between pawl bar support and machine wall

(with the conveyor OFF). Turn conveyor on and allow clutch to slip for at least 3 minutes "to burn in"

the clutch surfaces. (Note: if thermal overload cuts out during this period, allow time to cool and reset

in order to accumulate the total time required.)

13.) Allow clutch to cool and carefully reset with torque wrench to 30 in-lb. Clutch should not slip unless

jammed as in step #12. If further adjustment is required, make changes in 5 in-lb. increments and

recheck. Securely tighten the setscrews after attaining the final set ting.

14.) Test again to make sure clutch will still slip when jammed.

15.) If machine is equipped with a "load sensor" switch, remove the jumper wire installed in step #11.

Test to verify that switch will now stop drive motor before clutch slips, when drive bar is jammed.

16.) With machine turned off, replace all covers and hardware.

24

Page 24

25

Page 25

ITEM P/N DESCRIPTION

1. 450 PAWL BAR DOG STOP

2. 430 PAWL BAR PAWL (DOG)

3. 447 PAWL BAR NUT (NYLON INSERT)

4. 112 LOCK WASHER 1/4 X 20 S/S

5. 435 PAWL BAR SPACER PIN

6. 440 PAWL BAR SPACER BUSHING

7. 445 PAWL BAR CONNECTOR PIN

8. 446 PAWL BAR BOLT 1/4" X 20 X 3/4" S/S

9. 0003534 PAWL BAR SIDE RAILS

10. 0113283 PAWL BAR W/ ULTRA WEIGHTS

26

Page 26

ITEM P/N DESCRIPTION

1. 390 CLUTCH ADAPTER PLATE

2. 370 CAM WHEEL SET SCREW

3. 365 CAM WHEEL

4. 380 CAM FOLLOWER BEARING

5. 353 DRIVE ARM

6. 410 SHOULDER SCREW 1/ 4"

ITEM P/N DESCRIPTION

7. 355 ARM LINKAGE

8. 405 ROD WIPER

9. 400 DRIVE ROD BEARING

10. 360 DRIVE ROD ARM

11. 345 DRIVE MOTOR AND GEAR HEAD

27

Page 27

ITEM P/N DESCRIPTION

1-9 385 DODGE TORQUE TAMER #25

10. 415 10-24 X 3/8" LONG SET SCREW

11. 380 CAM FOLLOWER BEARING

12. 422 3/16" KEY

13. 350 SHAFT ADAPTER

14. 395 BUSHING .879" 00 X .752" ID

15. 365 CAM WHEEL

16.

17. 39001 CLUTCH ADAPTER PLATE

CAM AND CLUTCH ASSEMBLY

10-32 X 7/16" MACH. SCREW

28

Page 28

FACTORY SERVICE BULLETIN

#96

"Load Sensor" Switch Conversion

(FOR SERIES 44 CE & 44CL CONVEYOR SYSTEM)

This conversion is to be used on all 44-Series units that develop recurring conveyor drive problems due to

overloading or Jamming of the system.

Tools Required:

Wrench Set

Hex Key Wrench Set

3/8" Electric Drill

Drill Bits, sizes: 9/64, 13/64, & 9/32

1/4 - 20 Tap and Tap Handle

Center Punch

7/8" Greenlee Chasses Punch (May be needed, if additional conduit hold is required.)

Screwdrivers - Slotted & Phillips

Wire Strippers

Terminal Crimping Tool

Tube or Bottle of "Loctite 242 " or equivalent

Template for locating hole centers

1/4" Nut Driver

Parts Required:

(1) Actuator Assembly

(1) Switch, flange mounted

(1) Connecting Link

(2) Bushings (1) Clevis Pin (1) Cotter Pin (4) Spring Washers

(1) Shoulder Screw, ss (8') 3/8" Flexible Conduit (20') Wire, 18ga.,red (ea.) Assorted Terminals

(2) #8 Hex Head Sheet Metal Screws (2) 3/8" Straight Conduit Fittings

Procedure:

1.) Disconnect power to machine.

2.) Remove cover from conveyor drive assembly.

3.) Remove the drive rod arm, linkage, and linkage bracket (see Fig. I). Discard the linkage and linkage

bracket.

4.) Remove the drive rod support bracket.

5.) Using the 1" diameter hole in the base plate as a reference, center punch the hole locations for the

four new holes. (The use of the hole template is recommended.)

6.) Drill two 9/64 diameter holes, one 13/64 diameter hole, and one 9/32 diameter hole as shown. Top

the 13/64 diameter hole with a 1/4 - 20 tap.

7.) Replace the drive rod support bracket.

8.) Connect wires to the COM and NO terminals of switch (using ring terminals) and connect conduit to

switch with straight connector.

9.) Mount switch to base plate, using two #8 sheet metal screws.

29

Page 29

10.) Mount actuator to base plate, using spring washers and shoulder screw (as shown in Fig. 111). NOTE:

SPRING WASHERS MUST BE INSTALLED EXACTLY AS SHOWN FOR PROPER OPERATION. USE

LOCTITE ON THREADS OF SHOULDER SCREW—IF OIL WAS USED WHEN DRILLING OR TAPPING % 20 HOLE, REMOVE ALL TRACES BY USING A SOLVENT CLEANER.

11.) Assemble connecting link to actuator assembly by using spacers, clevis pin, and cotter pin, as shown.

12.) Reinstall drive arm, making sure all parts are in proper alignment without binding, etc.

13.) Route other end of conduit and wire into main electrical box of machine. (If all 7/8" diameter hole

openings are used up, an additional one will have to be added.)

14.) Connect switch wiring in main electrical box as per appropriate wiring diagram (i.e." Model 44CE or

44CL).

15.) Replace all electrical covers.

16.) Turn on power to machine.

17.) Test operation of load sensor by:

a.) Jamming conveyor drive bar by placing a piece of 2" by 4" between the pawl bar support and

machine wall (with the conveyor OFF). Turn conveyor on—it should stop immediately upon

binding, and before clutch slips. (If clutch slips first, it needs adjustment.)

b.) Test conveyor for normal operation. It should transport at least three loaded racks

under normal conditions without cutting out. if switch cuts out prematurely, check the 2 21/32

measurement of the actuator arm (see Fig. Ill) and bend as required; however, if this is

necessary, REPEAT STEP 17-a.)

18.) With machine turned OFF, replace all covers and hardware.

30

Page 30

CONVEYOR DRIVE ASSEMBLY

31

Page 31

"LOAD SENSOR" SWITCH DETAILS

32

Page 32

WIRING OF "LOAD SENSOR" SWITCH CIRCUIT

MODEL 44CE

33

Page 33

Page 34

Page 35

Page 36

Page 37

COMPLETE PARTS LIST for MODEL

44

120 Circuit Breaker, 15 amp (specify number from Part)

194 Control Box comp. wired

195 Control Box comp. wired

345 Conveyor Drive Motor 115/230V, 1/6HP; 29 rpm output

350 Conveyor Drive Shaft Adaptor, for motor

353 Conveyor Drive Arm

355 Conveyor Drive arm linkage 479-AD2922

360 Conveyor Drive rod arm 477-BA2914

365 Conveyor Drive cam wheel 549-AD3069

370 Conveyor Drive set screw, cam wheel

375 Conveyor Drive bolts, cam wheel socket head screw

380 Conveyor Drive cam follower bearing

385 Conveyor Drive clutch, torque tamer

390 Conveyor Drive clutch adaptor plate 550-AD-3070

395 Conveyor Drive bushing for cam wheel

400 Conveyor Drive bearing, for drive rod

405 Conveyor Drive wiper, for rod

410 Conv eyor Drive shoulder screw, 1/4"

415 Conveyor Drive shoulder screw, 3/8"

417 Conveyor shoulder bolt, 1/2"

420 Conveyor Drive shoulder screw, 3/4"

422 Conveyor Drive Key 554-BA3117M

423 Conveyor Pawl Bar Idler Roller

424 Conveyor Pawl Bar Idler Roller Bushing

425 Conveyor Pawl Bar assembly

429 Pawl Drive Connector Pin

430 Conveyor Pawl Bar pawl (dog)

435 Conveyor Pawl Bar spacer pin

440 Conveyor Pawl Bar spacer bushing

445 Conveyor Pawl Bar connection pin

446 Conveyor Pawl Bar bolts

447 Conveyor Pawl Bar nut (nylon insert)

450 Conveyor Pawl Bar dog stop

451 Conveyor Cutoff Switch KIT (table mount) w/ instructions

452 Curtain rod

453 Curtain

525 Door, front

526 Door, front catch

530 Door handle, front

540 Drain 'O' ring

560 Gauge, pressure, 0-60, bottom connection

587 Heater socket ONLY for heater element removal screw plug type

588 Heater bus bars, 3 hole

589 Heater bus bars, 2 hole

605 Heater element. Immersion, screw plug type, 230V, 2500W

608 Element for hard water application 220V, 2180W

835 Light indicator

843 Probe, Lundy, Small

1020 Pump assy. comp. JET 1 HP 1725 rpm 115/208-230V

1025 Pump motor, JET, 100/200V, 1 HP 1725 rpm w/adapter shaft (use 1027

1026 Pump motor ONLY, JET Special 1 HP 1725 rpm 220V 50 cycle for JL 100

1027 Pump motor, 1 HP 1725 rpm 115/208-230V

1030 Pump motor, JET, 115/230V, 1 HP 1725 rpm w/ adapter shaft

1035 Pump adapter shaft (for parts 1020; 1025; 1030)

1036 Pump motor bearing front (368C034H 63)WH

1037 Pump motor bearing rear (368C945H 19)WH

1040 Pump rolled pin (for parts 1020; 1025; 1030)

1045 Pump mounting plate (for part 1020)

1050 Pump seal and ceramic (for part 1020)

1055 Pump impeller (for part 1020)

1060 Pump gasket, (for part 1020) (mounting)

0087812 Pump Seal, New Style

Page 38

COMPLETE PARTS LIST for MODEL

44

1065 Pump, Woodruff Key (for part 1020)

1070 Pump bolt, Impeller, s/s 5/16-1" (for part 1020)

1075 Pump washer, Impeller (for part 1020)

1080 Pump snap ring (for part 1020)

1180 Rack, Square (dish) moulded w/conveyor rungs

1182 Rack, Square (cup, bowl & glass) moulded w/conveyor

1210 Relay, 220V, 2-pole HW (used on motor circuits)

1230 Relay, 220V, 3-pole, HW (used on heat circuit, three phase)

1240 Relay. 220V, 4-pole, HW (used on heat circuit, single phase)

1247 Relay Overload (for conveyor motor) w/heaters

1375 Rinse head assembly, final, complete

1376 Rinse Actuator Paddle and Rod

1377 Rinse Actuator Rod Bushing

1377A Rinse Actuator Helper Spring

1377B Rinse Limit Switch Bracket

1378 Rinse Actuat or Coupling

1379 Rinse Actuator Rod Bracket

1380 Rinse assembly, final, upper

1381 Rinse Actuator Assembly w/o Switch

1382 Rinse Actuator Assembly w/Switch (Specify Direction)

1385 Rinse assembly, final, lower

1390 Rinse Spray nozzles, final, upper

1395 Rinse Spray nozzles, final, lower

1400 Rinse End Plugs, 1/2" pipe plugs

1405 Runoff sheet, small

1410 Runoff sheet, large

1414 Crumb cup assy. for drain on tables and 44CE

1417 1/8" Asco Detex BX

1419 Asco valve, 1/4", 220V

1525 Strainer, pump intake

1530 Strainer, large overflow tube

1535 Strainer, track scrap, large

1537 Strainer, 'Y', ¾”

1539 Switch boot or cover (used on 10; 50; JL & some 39's)

1540 Switch, rinse/fill (All) (SPDT) momentary slip disconnect

1555 Switch, manual wash (DPDT) (All) slip disconnect

1575 Switch, master (DPST) (All) slip disconnect (used on wash, heat & conveyor on 39's)

1635 Switch, limit (final rinse) L/R machine

1636 Switch, limit (final rinse) R/L machine

1691 Thermometer, 3' long capillary, 2" dial

1692 Thermometer, 6' long capillary, 2" dial

1700W Thermostat, wash, 150°

1702 Thermostat, longer capillary

1790A Track, Front Large Section

1790B Track, Front Small Section

1805 Track, front and back

1848 Handle for 1/2" fill valve (complete) specify direction

1849 Valve. 1/2" fill

1850 Valve, 1/4" (for Health Inspector's gauge)

2015 Wash head assembly, upper fixed

2020 Wash head, removable spray tubes, upper

2025 Wash head spring clip for spray tubes, upper & lower

2030 Wash head screws, for spring lock, upper & lower

2035 Wash head tube cap, upper & lower

2040 Wash head assembly, complete, lower

2050 Water level control, Curtis, 220V

2055 Water level control, relay ONLY, Curtis

2060 Water level control, printed board ONLY, Curtis, 220V

39

Loading...

Loading...