Jackson 44CE Service Manual

SERVICE MANUAL

MAY 1990

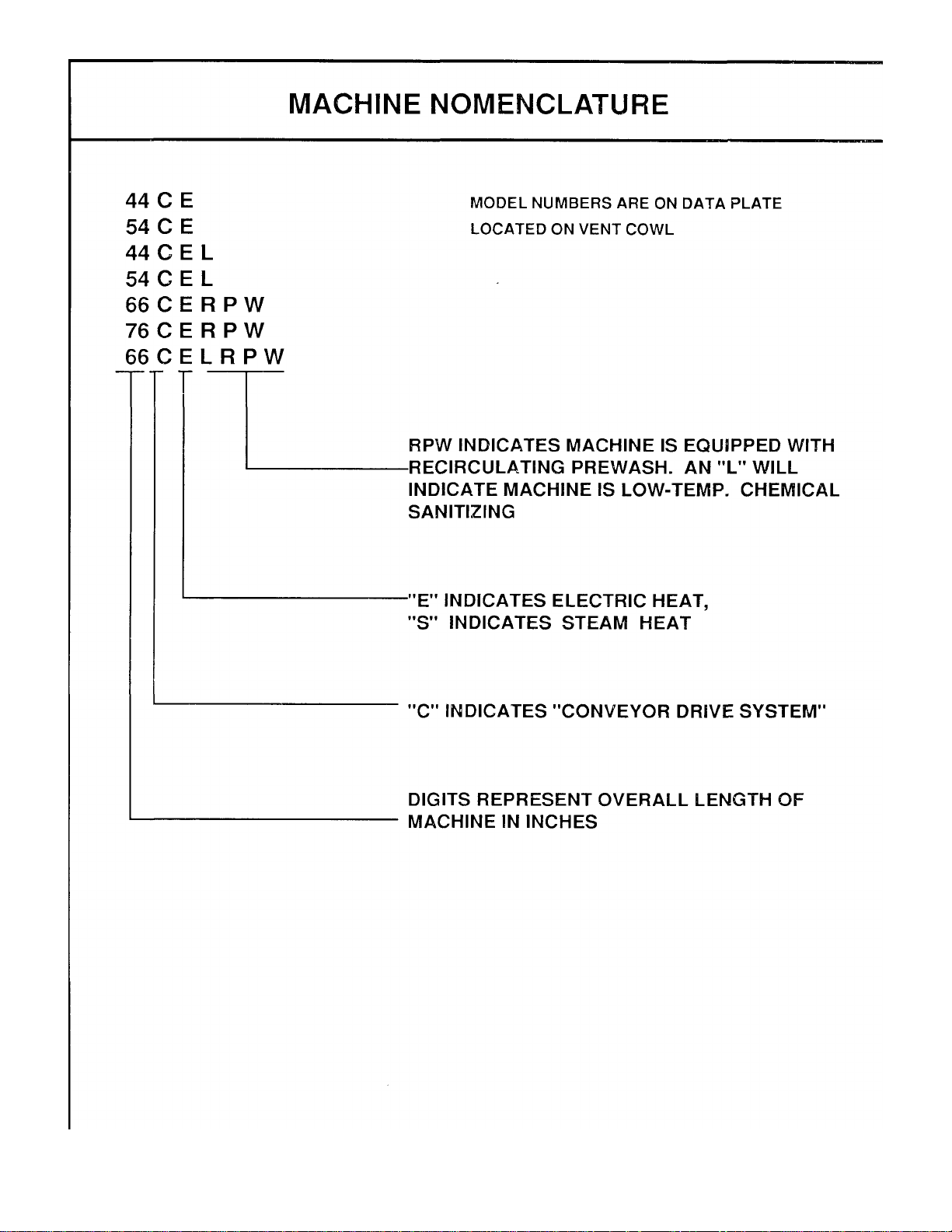

SINGLE - TANK RACK CONVEYER SERIES

MODELS 44CE- 44CEL - 54CE - 54CEL

66CERPW - 66CELRPW - 76CERPW - 76CELRPW

7610-100-41-00

BEFORE CONNECTING, OPERATING OR ADJUSTING THIS PRODUCT, PLEASE READ THIS INSTRUCTION MANUAL

CAREFULLY AND COMPLETELY.

FOR YOUR CONVENIENCE, THIS BOOKLET CONSISTS OF THE FOLLOWING SECTIONS IN THIS ORDER:

1. TABLE OF CONTENTS

2. GENERAL...............

Safety precautions

Certification

3. SPECIFICATIONS ..........

Operating capacity

Water requirements

Dimensions

Tank capacities

Pump and motors

Electric heat

Standard racks

Shipping weight, dimensions

Electrical requirements

Nomenclature

4. INSTALLAT ION .............

Unpacking

Electrical requirements

Electrical connections

Plumbing and water flow diagram

Plumbing requirements for Hot Water Sanitizing

Plumbing requirements for Chemical Sanitizing

Chemical dispensing equipment

5. GUIDE TO OPERATIONS ................

System Start - Up/Check Dispensing

equipment

6. MAINTENANCE AND CARE ..........

Daily cleaning Weakly cleaning Preventive

maintenance Energy saving tips

Lubrication of conveyor motor

JACKSON PRODUCTS CO.

-3-

7. REPLACEMENT PART PROCEDURES ......

Water solenoids

Wash heater

Wash motor and pump

Pre-wash motor and pump

Conveyor motor

Conveyor motor drive clutch

Vacuum breaker

Manual lever - drain

Paddle limit switches

Control Box Electrical Components

Thermal overload relays

Thermal overload heaters

Indicator lights

Service disconnect switch

Control transformer

Circuit breaker

Digital temperature display / controller

Water level control

Auto cycle timer and calibration

8. ILLUSTRATED PARTS LIST ..........

Wash arm assembly

Conveyor motor drive assembly

Wash motor and pump

Pre-wash motor and pump

Incoming plumbing

Paddle switches

Table limit switch

Manual lever drain assembly

Strainers

Overflow / drain tubes

Conveyor pawl bar drive assembly

Control box electrical components

9. TROUBLESHOOTING GUIDE ........

Quick - reference diagnostic chart

Step - by - step troubleshooting flowcharts

Conveyor drive system

Wash motor system

Wash heat system

Auto fill system

Auto cycle system

10. WIRING SCHEMATICS .......

Model - 44 CE Model - 66 CERPW

Model - 44 CEL Model - 66 CELRPW

11. WARRANTY. .............

12. PART DISTRIBUTORS .........

-4 -

SAFETY PRECAUTIONS

NEVER TRY TO REPAIR OR REPLACE ANY PART OF THE DISHWASHER UNLESS IT IS SPECIFICALLY RECOMMENDED IN THIS

MANUAL. ALL SERVICING SHOULD BE DONE BY A FACTORY AUTHORIZED SERVICE TECHNICIAN DURING WARRANTY

PERIOD, THERE ARE NO USER SERVICEABLE PARTS. SAFETY PRECAUTIONS IN THIS MANUAL ARE PRECEDED BY THE WORDS

"WARNING" OR "CAUTION" AND ARE VERY IMPORTANT. WARNING MEANS THERE IS THE POSSIBILITY OF PERSONAL INJURY

TO YOURSELF OR OTHERS. CAUTION MEANS THERE IS THE POSSIBILITY OF DAMAGE TO THE UNIT.

CERTIFICATION

THE UL MARK INDICATES THIS PRODUCT IS LISTED WITH THE UNDERWRITERS

LABORATORY. THIS AGENCY CONDUCTS TESTS AND EVALUATIONS OF PRODUCT

COMPLIANCE TO UL STANDARDS FOR SAFETY.

THE NSF SEAL IS WIDELY RECOGNIZED AS A SIGN THAT THE ARTICLE TO WHICH IS IS

AFFIXED COMPLIES WITH ALL PUBLIC HEALTH AND SAFETY CODES FOR FOODSERVICE EQ.

APPENDIX SECTION

THE APPENDIX SECTION IN THIS MANUAL WILL CONTAIN AND COLLECT SUPPLEMENTAL INFORMATION ADDED TO UPDATE AND KEEP THIS MANUAL CURRENT TO THE PRODUCT IT REPRESENTS. IT ALSO PROVIDES PERTINENT IN FORMATION

REGARDING ALL PRODUCT CHANGES AND NEW PRODUCT DEVELOPMENTS. PLEASE READ THESE SUPPLEMENTS

CAREFULLY AND COMPLETELY FOR THEY MAY REPLACE OR SUPERCEDE INSTRUCTIONS ALREADY CONTAINED IN THIS

MANUAL.

PRODUCT RECORD

FOR FUTURE USE, PLEASE RECORD THE INFORMATION IN THE SPACES PROVIDED BELOW:

JACKSON PRODUCTS CO.

-5-

SPECIFICATIONS

THE SPECIFICATION SECTION IN THIS MANUAL WILL CONTAIN ALL PERTINENT DATA COVERING THE SINGLETANK RACK CONVEYOR SERIES DISHWASHING MACHINES.

PLEASE REFER TO THIS SECTION FOR ALL DETAILS CONCERNING:

OPERATING HOT WATER CAPACITY

HOT WATER REQUIREMENTS

OVERALL MACHINE DIMENSIONS

TANK CAPACITIES

PUMP AND MOTORS

ELECTRIC HEAT

STANDARD RACKS

SHIPPING WEIGHT

ELECTRICAL REQUIREMENTS

ALL SPECIFICATIONS ARE SUBJECT TO CHANGE WITHOUT NOTICE.

-6-

JACKSON PRODUCTS CO.

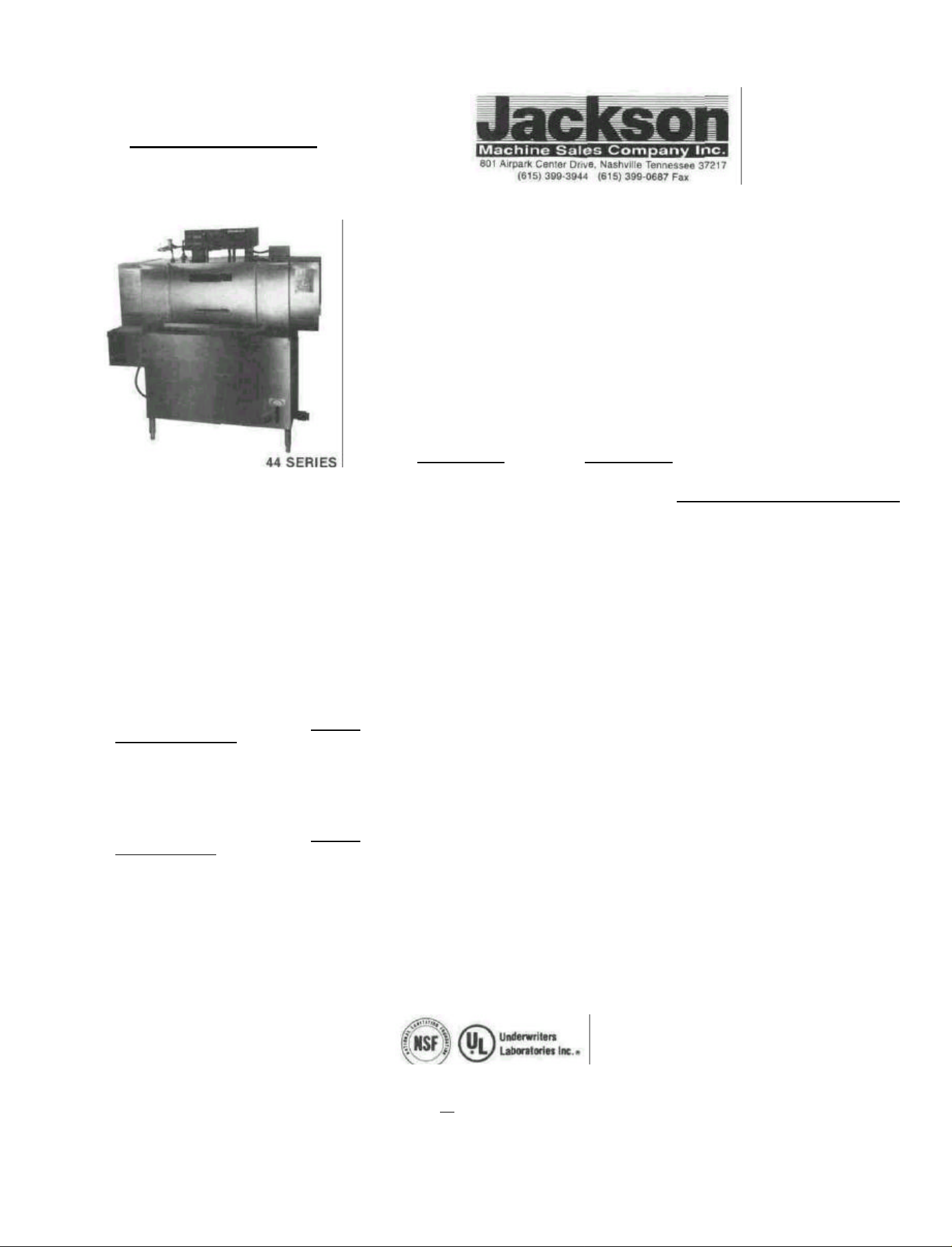

SINGLE-TANK

Jackson's 44 Series is made up of

SPECIFICATIONS

L

MODELS

44CE&44CS

MODELS

EL&44CSL

Operating Capacity

Racks per Hour

205

205

Dishes or glasses per Hour

5125

5125

Incoming Waterline Size

1/2" IPS

1/2" IPS

Flow Pressure

20 PSIG

20 PSIG

Flow Rate a) 20 PSI

4.8 GPM

4.8 GPM

Final Rinse Consumption & 20 PSI flow

pressure

Final Rinse Temperature

180-195°F

140-150-F

Wash Tank Temperature

160°F

140°F

Electric Tank Heat

Models 44CE & 44CEL

13KW

Steam Coil Tank Heat

Models 44CS & 44CSL

Steam coiI size

3/4"IPS

Steam flow pressure requirement

10-15PSIG

Steam Consumption Q 15PSI

60 Lbs/Hr.

Length - between dishtables

44"

Width

25-1/2"

Maximum Dish Clearance

18"

Venting

18"

Input End

200 CFM

Output End

400 CFM

Tank Capacity

Wash Tank

20 Gals

Wash Motor

1-1/2 HP

Wash Pump Capacity

270 GPM

Conveyor Motor

1/4 HP

Conveyor Speed (feet/minute)

5.70

Standard Racks - 19-3/4" x 19-3/4"

4

Combination racks (open type)

2

Shipping Weight (approx.)

600 Lbs

Shipping Dimensions (L x D x H)

71"x41"x77"

Cubic Feet

130

RACK CONVEYOR

DISHWASHER

MANDATORY SPECIFICATIONS

The following information must be specified when placing an order.

Sanitizing Method: (select one)

Hi-temp sanitizing Low-temp (chemical) sanitizing

Voltage: (Select One)

208V/60HZ/1 Ph 230V/60HZ/1 Ph

208V/60HZ/3 Ph 230V/60HZ/3 Ph

460V/60HZ/3 Ph

50 Hz also available in these voltages as well as 380V/50Hz/3 Ph

Tank Heat: (Select One)

13 KW Electric - Immersion-type heating elements with primary and secondary low

water protection. Regulated Steam - Wash tank steam coils with low water protection.

Requires 10-15 PSI steam supply. Above 15 PSI install a steam pressure regulator.

Direction of Rack Flow: (select one)

From Right to Left_____________From Left to Right

the following models.

MODEL 44CE - Electric tank heat,

44CEL - Electric tank heat,

MODEL 44CS - Steam coil tank heat,

44CSL - Steam coil tank heat,

STANDARD FEATURES

o High output with NSF rated 205 racks

per hour.

o Can be ordered as an energy efficient

high temperature sanitizing or low

temperature (chemical) sanitizing

mode I.

o Heavier gauge construction for extra

ruggedness and durability. 14 gauge

tank vs. 16 gauge on competitive machines.

o Stainless steel frame, legs, bullet

feet, vent cowls and front panel are

all standard features, not optional

extras.

o Uses less energy than competitive

machines.

o Low water consumption: only 1.4 gal-

lons per rack.

o Lower water consumption allows the

use of a lower KW booster when operated as a high temperature unit. For

a 40 F rise a 30W booster heater is

recommended.

o Exclusive "Energy Guard" control

system and excellent separation of the

wash and rinse sprays, produces superior results.

o Convenient, externally operated,

lever drains.

o Positive manual fill valve. Auto-

matic fill is available as an option.

o A.S.S.E. approved vacuum breaker.

Hi-temp rinse MODEL

Low-temp rinse

Hi-temp rinse MODEL

Low-temp rinse

Operating Requirements

Dimensions

Pumps and Motors

Dish racks (peg type)

ALL SPECIFICATIONS SUBJECT TO CHANGE WITHOUT NOTICE

288 GPH

288 GPH

-7-

Performance: Fully automatic, single tank, rack

conveyor dishwasher designed to wash, rinse and

the machine. Two dispensing point locations (1/4"

sanitize tableware and utensils commonly associated

with the preparation and consumption of food items

in a commercial foodservice operation. The unit

conveys standard 19-3/4" x 19-3/4" racks through

a recirculating wash section where 270 GPM of

detergent laden water is pumped over the rack to

remove food soil. The rack is then conveyor

driven into a rinse section where a fresh water

final rinse spray system removes residual detergent and sanitizes. Sanitization can be

accomplished by one of two methods: 1) high

temperature sanitization or 2) low temperature

sanitization. For high temperature sanitization

the unit must be installed on a potable water line

capable of supplying 288 gallons per hour of

water at: 180 F. minimum, 195 F. maximum. In

some cases an external booster heater sized for the

necessary temperature rise must be installed

to reach this sanitizing temperature

requirement. For low temperature sanitization the

unit must be installed on a potable water line

capable of supplying 288 gallons per hour of

water at: 140 F. minimum, 150 F. maximum. A

chemical feeder system must be supplied and

installed by others to inject 50 PPM minimum

sodium hypochlorite (chlorine) to meet

sanitization requirements.

Caution: Use of sodium hypochlorite (chlorine)

may have an adverse effect on materials including,

but not limited to, silver and silver plate,

pewter and aluminum.

Construction: All stainless steel components are

18-8 304 series stainless steel. Frame is 2" x 2"

x 1/8" stainless steel angle satin finish. Tank is

formed and heliarc welded 14 gauge #3 finish. The

wash tank on units specified for use as low

temperature sanitizing will be put through a

passivation process to increase chemical

resistance. Hood is 16 gauge #3 finish. Legs and

feet are stainless steel and are adjustable *_

1/2".

Wash Tank: 20 gallon capacity with skimming type

overflow tube. Lever operated drain valve for

draining tank. washing action is

accomplished by recirculating detergent laden

water in the wash tank through upper and lower

wash arms to strip away food soil. 7/8" round

knockouts are provided to allow easy installation

of detergent concentration sensor and dispenser

tube by others. A 19" span of 48 wash jets provides unsurpassed wash pattern. Tank and hood

design provides 17" of distance between wash and

rinse jets to insure excellent separation of wash

and rinse sprays. This greater separation

virtually eliminates spotting and poor results

caused by wash water splashing into rinse

section. Make-up water comes from the final rinse

reservoir and is spilled into wash tank at a

controlled rate.(approximately 2.0 GPM.)

Final Rinse: Rinse water enters the machine

through a brass "Y" strainer and solenoid valve

and approved vacuum breaker (supplied) and is

plumbed to upper and lower final rinse arms located

at the output end of

NPT plugs) are provided for dispensing equipment

connection by others. One point should be used for

rinse agent injection into the final rinse water.

The other connection point should be used for

injection of sodium hypochlorite on low

temperature sanitizing models.

Wash Pump: is integral with motor and is flange

mounted to wash tank and manifold. Wash

water is recirculated from the tank, through the

pumping system and back to the tank at the rate of

270 GPM.

Wash Pump Motor: is a 1-1/2 HP open

drip-proof type. Capacitor start, induction run

with bimetallic thermal overload protection.

Motor shaft is supported by permanently lubricated,

grease packed ball bearings.

Conveyor: Center mounted pawl bar with counter

weighted, wide surface pawls is driven by 1/4 HP

motor and worm drive reduction gear unit. Motor

is open, drip-proof type and is thermally

protected. Pawl bar drive unit is mounted at

the output end of machine and is enclosed with

removable stainless steel cover. Conveyor speed

is 5.7 feet per minute.

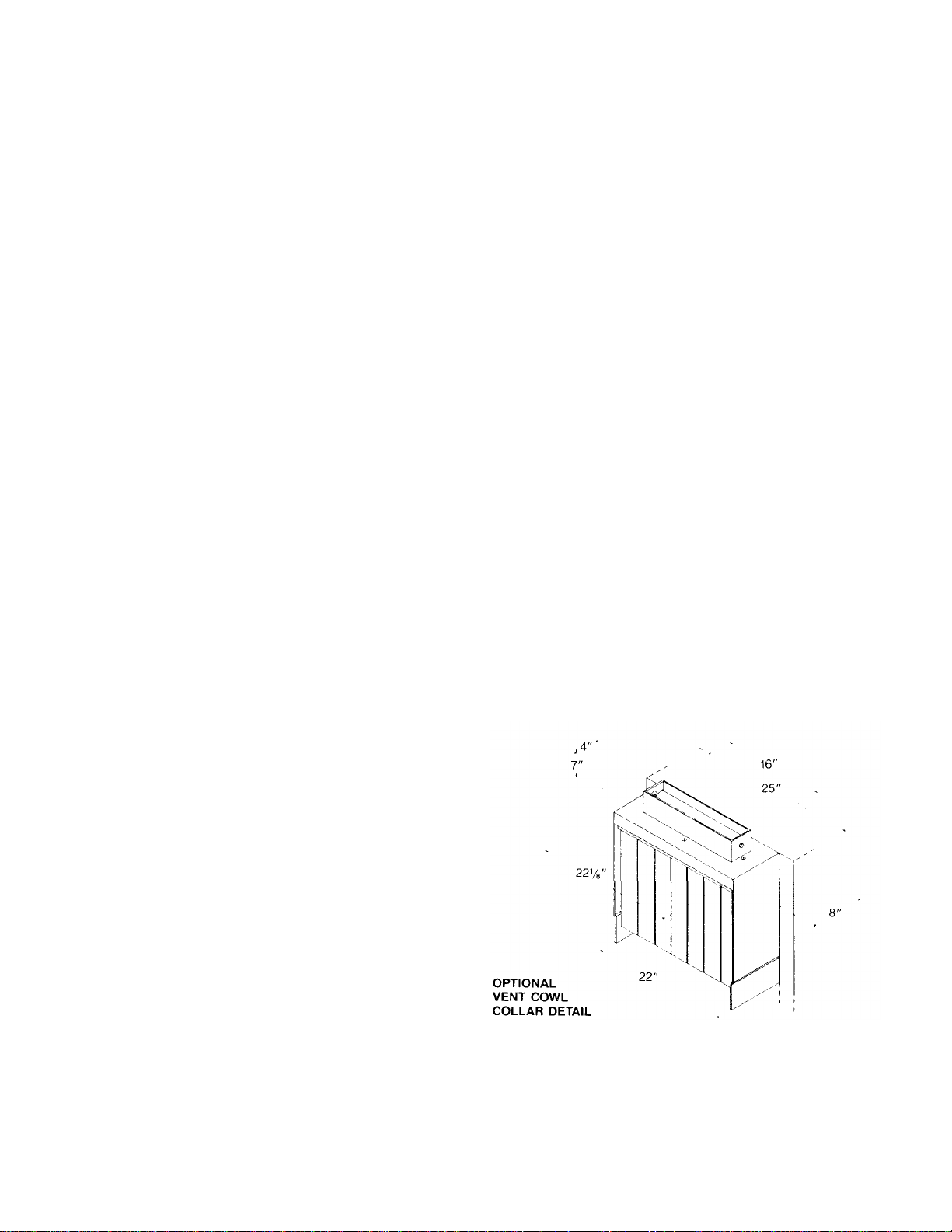

Vent Cowls: Unit comes standard with 8" vent cowls

on each end. Tops of cowls have 4" x 16" openings

(covered with removable plates) for connection to

exhaust duct. Available at additional cost are 4"

x 16" x 7" high vent cowl collars with adjustable

and lockable damper style flaps.

MANDATORY SPECIFICATIONS Tank Heating

Equipment

13 KW Electric - High efficiency Firebar immersion

type heating element is mounted in wash tank and

is protected by a solid state low-water cutoff

system. Tank temperature is monitored by a PTC

thermistor and controlled by fast reacting, solid

state thermostats. Available in 208V/60HZ/1 or 3

Phase, 230V/60Hz/1 or 3 Phase, 460V/60HZ/3 Phase.

50Hz available in these voltages as well as

380V/50HZ/3 Phase. 50Hz voltages are not UL

listed.

Regulated Steam Coil - stainless steel

steam coil is mounted in wash tank and is protected

by a solid state low-water cutoff system.

Incoming steam passes through a steam pressure

regulator and "Y" strainer. A steam solenoid

valve regulates flow of steam through coil.

Tank temperature is monitored by a PTC thermistor

and controlled by a fast reacting, solid state

thermostat. Requires 10-15 PSI flowing steam supply. Install with steam pressure regulator if

steam supply exceeds 15 PSI.

-8-

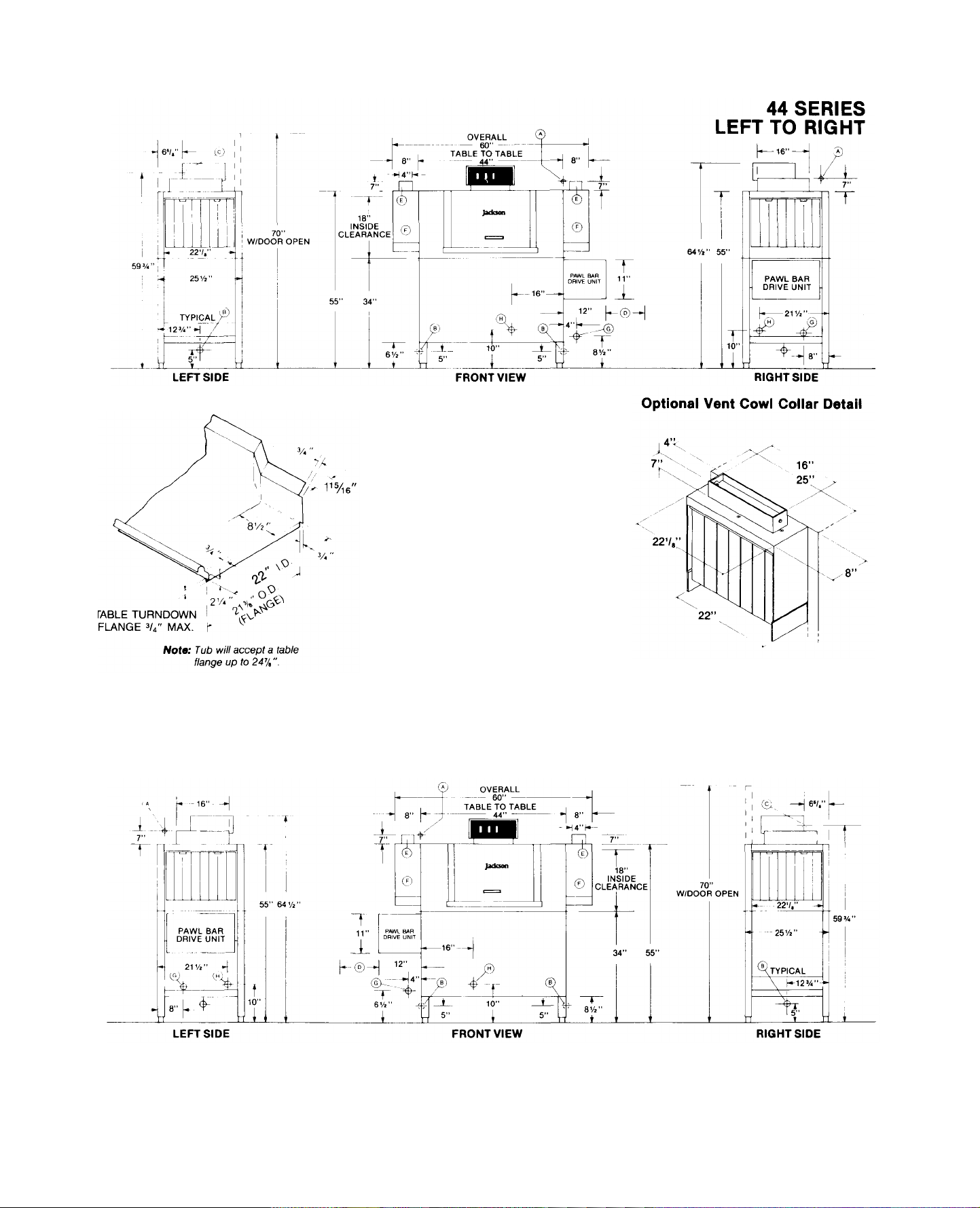

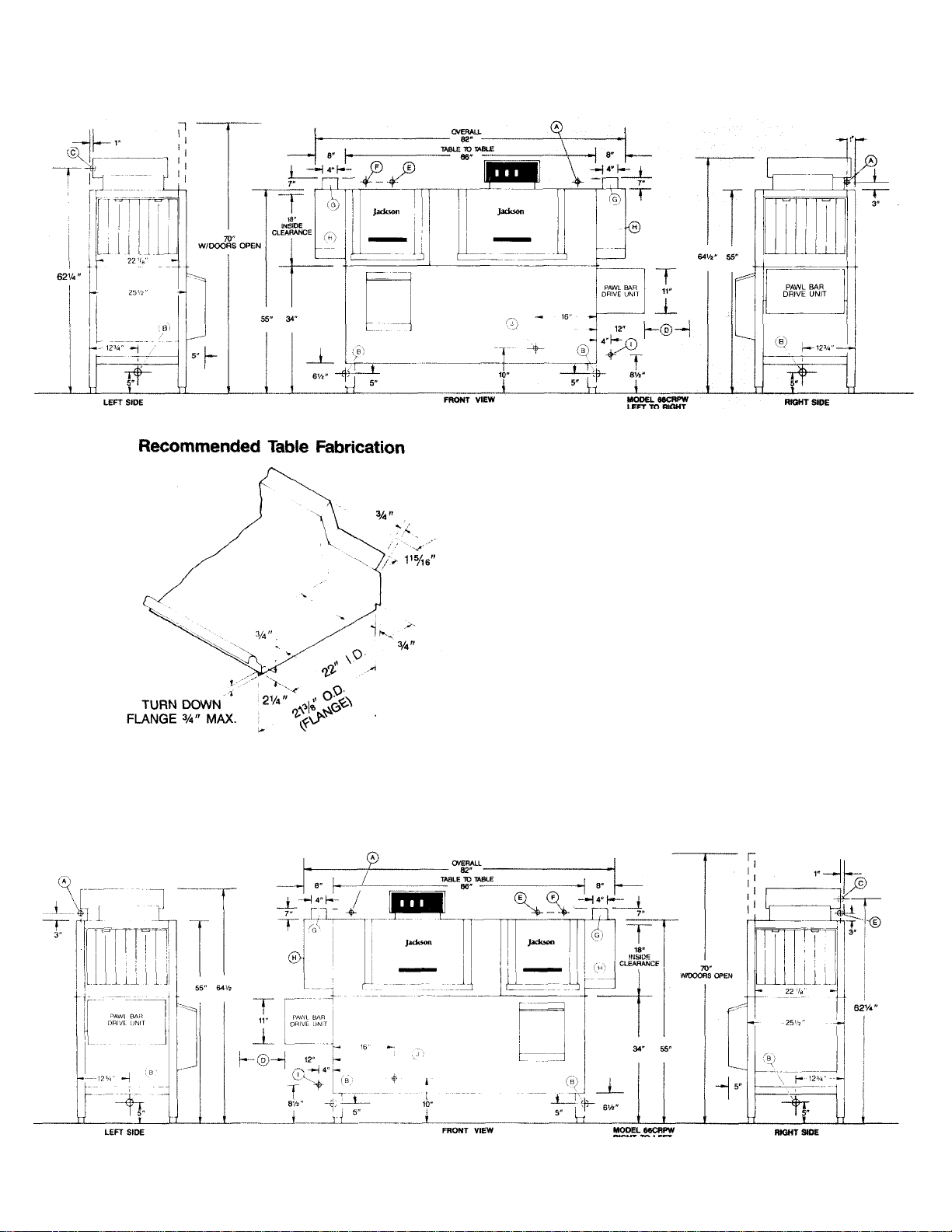

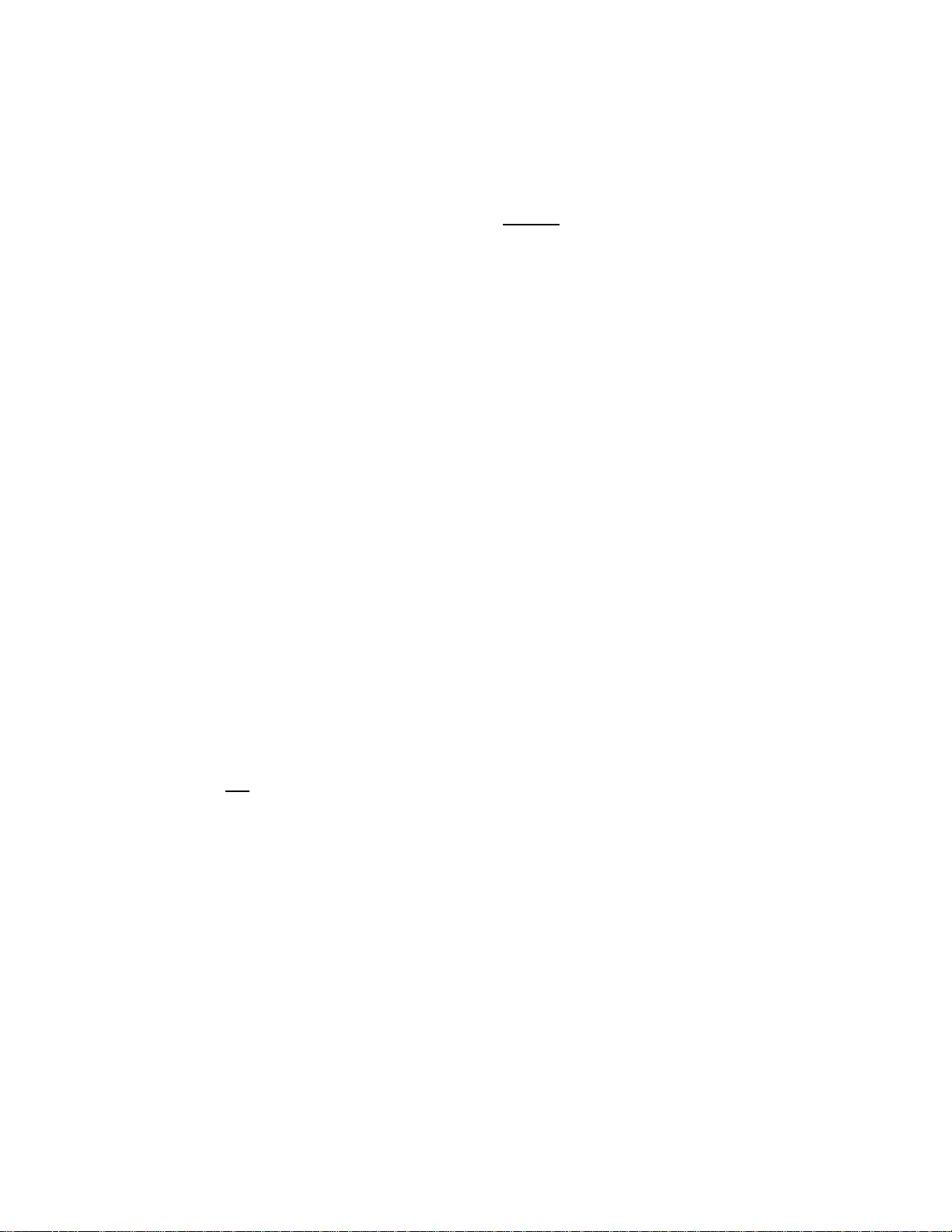

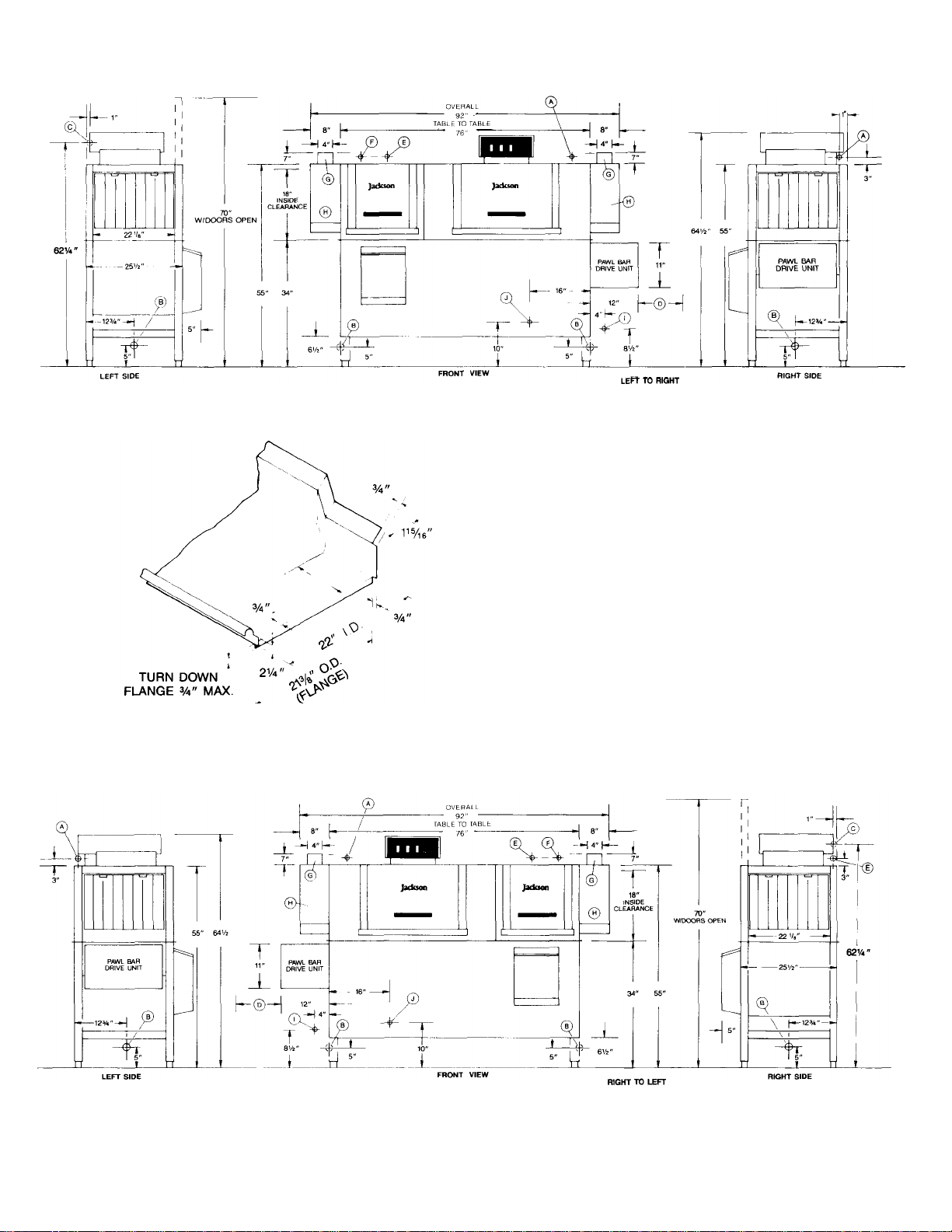

Recommended Table Fabrication

Legend To Drawings

A—Machine water inlet 1/2" I.P.S., 180°F mm.

58" above finished floor.

B—Drain connection 2" I.P.S. Drain can be

connected to either end.

C—Electrical connection.

D—Allow 12 " for removal of pawl bar drive

unit cover.

E —Vent collar 4" x 16" x 3" tall, optional.

F— Vent cowl, standard.

*G—Incoming steam connection, optional. 3/4"

FPT. (Gate valve supplied.)

*H—Condensate return connection V FPT.

(Return to boiler or open drain.)

* Steam Tank Heat Only

Note: All dimensions from floor are ± 1/2" due to adjustable bullet feet.

44 SERIES RIGHT

TO LEFT

-9-

COMMITMENT TO EXCELLENCE

44 SERIES

EP 1/92

7610-200-16-00

Single Tank Rack Conveyor

Optional Features and Accessories

Automatic Tank Fill - includes soieniod

valve that is controlled by water level sensors mounted in wash tank.

Function is activated by pressing a desiginated switch on the control

panel.

Booster Heaters:

36 KW electric Booster Heater -

boosts incoming 140°F water to 180 F for sanitizing rinse. Custom

features include castone lined tank, low water cut-off, pressure relief

valve, pressure reducing valve and two temperature/pressure gauges.

Pre-plumbed to be located at output side of machine. Unit is supplied

with a stainless steel stand with 6" legs and bullet feet. Unless

specified otherwise, electrical characteristics of the booster heater will

be the same as that of the dishwasher.

Steam Booster Heater - sized for a

40 F temperature rise. Therefore, unit must be connected to a 140°F

waterline in order to insure 180 F minimum sanitizing requirements.

The steam booster heater is designed to operate at flowing steam

pressures from 10 PSIG to 15 PSIG and is equipped with a steam

pressure reducing valve. Unit is externally mounted on a stainless

steel base with 6" stainless steel legs and bullet type feet. Preplumbed for connection at output end of a 44 Series machine.

50 Cycle Electrical Characteristics - are available in 208V/1 or 3

Ph, 230V/1 or 3 Ph, 380V/3 Ph and 460V/3 Ph.

Higher Than Standard Hood - 5"

increase in interior clearance through machine to 23'-Allows washing

a variety of larger sized trays and bun pans.

Incoming Water Pressure Reducing

Valve ~ factory installed on incoming

plumbing system. Not required when ordering the electric

booster heater option.

Incoming Water Pressure

Regulating Kit - factory installed package consisting of a pressure

reducing valve with a built-in line strainer, 0-60 psi guage and water

shock arrester. Gives full range control over flow pressure, water consumption and damaging water hammer.

Sideloader ~ is factory installed on input end of machine. This

option allows the machine to be installed in a corner and maximize

the use of dishroom space. It is available both hooded and unhooded.

Table Limit Switch - factory wired to machine and mounted to the

backsplash of the table in the field. Prevents damage to conveyor

drive system, racks and dishes due to racks backing up on the output

end of the machine. Highly recommended for clean dishtables less

than 10 feet in length.

Vent COWl Collar - 4" X 16" X 7" high collar installed in the vent cowl

to allow easy connection of "pant-leg" type exhaust duct. Includes an

adjustable and lockable damper flap for fine tuning exhaust system.

APPROXIMATE TOTAL LOAD AMPERES

44 SERIES

ELECTRICAL DATA

ELECTRIC TANK HEAT STEAM TANK HEAT

MODELS 44CE & 44CEL MODELS 44CS & 44CSL

OPTIONAL 36KW

ELECTRIC BOOSTER

1-PH 3-PH 1-PH 3-PH 1-PH 3-PH

208 VOLTS 75 44 12

230 VOLTS 69 40 12

7

7

173 100

157 90

380 VOLTS N/A 22 N/A 7 N/A 55

460 VOLTS N/A 18 N/A 5 N/A 45

HEATER

SHORT FORM SPECIFICATIONS AND PRODUCT DESCRIPTION 44 SERIES RACK

CONVEYOR DISHWASHER - ITEM#

Shall be Jackson 44 Series, Single-Tank Rack Conveyor Dishwasher. Sanitization shall be accomplished by using ___a high temperature (180 F

min.) rinse, ___a low temperature (140°F min. + chlorine) rinse. Electrical characteristics shall be ___208V, ___230V, ___380V(50Hz Only),

___460V/ ___60Hz, ___50Hz/ 1 Phase(208V & 230V Only), ___3 Phase. Tank heating shall be ___13KW electric element, ___3/4" steam coil.

Direction of rack flow shall be ___left to right, ___right to left. Frame, hood and tank shall be constructed of 18-8 304 series stainless steel.

14 gauge material shall be used in the construction of the tank. Unit shall be supplied with stainless steel, adjustable, bullet-type feet for

leveling, stainless steel front panel,stainless steel vent cowls with strip-type curtains on each end, lever operated drain, 4 peg-type dish racks

and 2 open-type combination racks as standard equipment. Unit shall be equipped with "Energy Guard" automatic controls and a manual control backup

system. Unit shall be NSF listed with a final rinse flow rate not to exceed 288 GPM 3 20 psig flow pressure, an operating capacity of not less than

205 racks per hour and a conveyor speed not less than 5.70 feet per minute. Final rinse water consumption shall not exceed 1.4 gal Ions per

rack.

Unit shall have the following features as optional extras: ___automatic tank fill, ___36KW externally mounted electric booster heater to provide

a 40 F temperature rise, ___steam booster heater to provide a 40 F temperature rise, ___5" higher than standard hood, ___incoming water pressure

reducing valve, ___incoming water pressure reducing kit, ___hooded sideloader, ___unhooded sideloader, ___table limit switch, ___vent cowl

collar at input end of unit, ___vent cowl collar at output end of unit.

- 10-

SINGLE-TANK RACK

Jackson's

66

Series is made up of the following

Racks per Hour

205 205

"

IPS 1/2" IPS

IPS

Flow Pressure

20

PSIG

20 PSIG

GPM

Flow Pressure

288

GPH

288

GPH

-

Steam Coil Size

3/4" IPS

Width —

at widest point

33"

Input End

200

CFM's

Pre-Wash Motor

1

HP

Wash Motor

1-1/2 HP

Conveyor Motor

1/4 HP

ALL SPECIFICATIONS SUBJECT TO CHANGE WITHOUT NOTICE

CONVEYOR

DISHWASHER

66 SERIES

MANDATORY SPECIFICATIONS

The following information must be specified when placing an order.

Sanitizing Method: (Select One)

Hi-temp sanitizing Low-temp (chemical) sanitizing

Voltage: (Select One)

208V/60HZ/1 Ph 230V/60HZ/1 Ph

208V/60Hz/3 Ph 230V/60Hz/3 Ph

460V/60HZ/3 Ph

50 Hz also available in these voltages as well as 380V/50Hz/3 Ph

Tank Heat: (Select One)

13 KW Electric — Immersion-type heating elements with primary and secondary low

water protection.

Regulated Steam — Wash tank steam coils with low water protection. Requires 10-15

PSI steam supply. Above 15 PSI install a steam pressure regulator.

Direction of Rack Flow: (Select One)

From Right to Left From Left to Right

models.

MODEL 66CERPW - Electric tank heat,

Hi-temp rinse

MODEL 66CELRPW - Electric tank heat,

Low-temp rinse

MODEL 66CSRPW - Steam coil tank heat,

Hi-temp rinse

MODEL 66CSLRPW - Steam coil tank heat,

Low-temp rinse

STANDARD FEATURES

• Recirculating pre-wash feature virtually eliminates

manual pre-rinsing and saves on labor.

• High output with NSF rated 205 racks per hour.

• Can be ordered as an energy efficient high

temperature sanitizing or low temperature

(chemical) sanitizing model. Low temperature

model has a passivated tank for extra chemical

resistance.

• Heavier gauge construction for extra rugged-ness

and durability. 14 gauge tank vs. 16 gauge on

competitive machines.

• Stainless steel frame, legs, bullet feet, vent cowls

and front panel are all standard features, not

optional extras.

• Uses less energy than competitive machines.

• Low water consumption: only 1.4 gallons per rack.

• Lower water consumption allows the use of a lower

KW booster when operated as a high temperature

unit. For a 40°F rise a 30 KW booster heater is

recommended.

• Exclusive "Energy Guard" control system and

excellent separation of the wash and rinse sprays,

produces superior results.

• Convenient, externally operated, lever drains.

• Positive manual fill valve. Automatic fill is available

as an option.

• A.S.S.E. approved vacuum breaker.

SPECIFICATIONS

Operating Capacity

Dishes or Glasses per Hour 5125 5125

Operating Requirements

Incoming Waterline Size — Pre-Wash

Incoming Waterline Size — Machine

Flow Rate @ 20 PSI 4.8 GPM 4.8

Final Rinse Consumption @ 20 PSI

Final Rinse Temperature 180-195°F 140-150

Wash Tank Temperature 160°F 140°F

Pre-Wash Tank Temperature (Maximum) 140°F. 140°F

Electric Tank Heat

Models 66CERPW & 66CELRPW 13 KW

Steam Coil Tank Heat

Models 66CSRPW & 66CSLRPW

Steam Flow Pressure Requirement 10-15 PSIG

Steam Consumption @ 15 PSI 60 Lbs./Hr.

Dimensions

Length — between dishtables 66"

Maximum Dish Clearance 18"

Venting

Output End 400 CFM's

Tank Capacity

Wash Tank 20 Gals.

Pumps and Motors

Pre-Wash Pump Capacity 120 GPM

Wash Pump Capacity 270 GPM

Conveyor Speed (feet/minute) 5.70

Standard Racks — 19-3/4" x 19-3/4"

Dish Racks (peg-type) 4

Combination Racks (open-type) 2

Shipping Weight (approx.) 700 Lbs.

Shipping Dimensions (L x D x H) 93" x 41" x 77"

Cubic Feet

MODELS MODELS

1/2

1/2" IPS 1/2"

170

-11 -

Performance: Fully automatic, single tank, rack conveyor dishwasher

with a recirculating pre-wash designed to wash, rinse and sanitize

to upper and lower spray arms. The pre-wash pump recirculates 120

tableware and utensils commonly associated with the preparation and

consumption of food items in a commercial foodservice operation. The

unit conveys standard 19-3/4" x 19-3/4" racks through a recirculating prewash section where 120 GPM of water is pumped over the rack to

mechanically prepare the ware for washing. Next the rack is conveyordriven into a power wash section where 270 GPM of detergent-laden

water is pumped over the ware to remove food soil. Finally, the rack is

conveyor-driven into a rinse section where a fresh water final rinse spray

system removes residual detergent and sanitizes. Sanitization can be

accomplished by one of two methods:

1) high temperature sanitization, or 2) low temperature sanitization. For

high temperature sanitization, the unit must be installed on a potable

water line capable of supplying 288 gallons per hour of water at: 180°F.

minimum, 195°F. maximum. In some cases an external booster heater

sized for the necessary temperature rise must be installed to reach this

sanitizing temperature requirement. For low temperature sanitization, the

unit must be installed on a potable water line capable of supplying 288

gallons per hour of water at: 140°F. minimum, 150°F. maximum. A

chemical feeder system must be supplied and installed by others to inject

50 PPM minimum sodium hypochlorite (chlorine) to meet sanitization

requirements.

Caution: Use of sodium hypochlorite (chlorine) may have an

adverse effect on materials including, but not limited to, silver

and silver plate, pewter and aluminum.

GPM over the rack of ware.

Pre-Wash Pump Motor: is a 1 HP open drip-proof type. Capacitor start,

induction run with bi-metallic thermal overload protection. Motor shaft is

supported by permanently-lubricated, grease-packed ball bearings.

Wash Pump: is integral with motor and is flange-mounted to wash tank

and manifold. Wash water is recirculated from the tank, through the

pumping system and back to the tank at the rate of 270 GPM.

Wash Pump Motor: is a 1-1/2 HP open drip-proof type. Capacitor start,

induction run with bi-metallic thermal overload protection. Motor shaft is

supported by permanently-lubricated, grease-packed ball bearings.

Conveyor: Center-mounted pawl bar with counter-weighted, wide surface

pawls is driven by 1/4 HP motor and worm drive reduction gear unit. Motor

is open, drip-proof type and is thermally protected. Pawl bar drive unit is

mounted at the output end of machine and is enclosed with removable

stainless steel cover. Conveyor speed is 5.7 feet per minute.

Vent Cowls: Unit comes standard with 8" vent cowls on each end. Tops

of cowls have 4" x 16" openings (covered with removable plates) for

connection to exhaust duct. Available at additional cost are 4" x 16" x 7"

high vent cowl collars with adjustable and lockable damper-style flaps.

Construction: All stainless steel components are 18-8 304 series

stainless steel. Frame is 2" x 2" x 1/8" stainless steel angle satin finish.

Tank is formed and heliarc welded 14 gauge #3 finish. The wash tank on

units specified for use as low temperature sanitizing will be put through a

passivation process to increase chemical resistance. Hood is 16 gauge

#3 finish. Legs and feet are stainless steel and are adjustable ± ^1/2".

Pre-Wash Tank: 12-gallon capacity with skimming-type overflow tube

and large externally removable scrap basket. Pre-washing action is

accomplished by pumping the water in the pre-wash tank through upper

and lower spray arms which removes heavy soil and deposits it in an

outside deep well scrap basket. Make-up water comes from detergent

wash.

Wash Tank: 20-gallon capacity with skimming-type overflow tube. Leveroperated drain valve for draining tank. Washing action is accomplished

by recirculating detergent-laden water in the wash tank through upper

and lower wash arms to strip away food soil. 77/8" round knockouts are

provided to allow easy installation of detergent concentration sensor and

dispenser tube by others. A 19" span of 48 wash jets provides

unsurpassed wash pattern. Tank and hood design provides 17" of

distance between wash and rinse jets to insure excellent separation of

wash and rinse sprays. This greater separation virtually eliminates

spotting and poor results caused by wash water splashing into rinse

section. Make-up water comes from the final rinse reservoir and is spilled

into wash tank at a controlled rate (approx. 2 GPM).

Final Rinse: Rinse water enters the machine through a brass "Y"

strainer and solenoid valve and approved vacuum breaker (supplied) and

is plumbed to upper and lower final rinse arms located at the output end

of the machine. Two dispensing point locations (1/4" NPT plugs) are

provided for dispensing equipment connection by others. One point

should be used for rinse agent injection into the final rinse water. The

other connection point should be used for injection of sodium

hypochlorite on low temperature sanitizing models.

MANDATORY SPECIFICATIONS

Tank Heating Equipment

13 KW Electric — High efficiency Firebar™ immersion-type heating

element is mounted in wash tank and is protected by a solid state low

water cutoff system. Tank temperature is monitored by a PTC thermistor

and controlled by fast-reacting, solid state thermostats. Available in

208V/60Hz/1 or 3 Phase, 230V/60Hz/1 or 3 Phase, 460V/60Hz/3 Phase.

50Hz available in these voltages as well as 380V/50Hz/3 Phase. 50Hz

voltages are not UL listed.

Regulated Steam Coil — Stainless steel steam coil is mounted in wash

tank and is protected by a solid state low water cutoff system. Incoming

steam passes through a steam pressure regulator and "Y" strainer. A

steam solenoid valve regulates flow of steam through coil. Tank

temperature is monitored by a PTC thermistor and controlled by a fastreacting, solid state thermostat. Requires 10-15 PSI flowing steam supply.

Install with steam pressure regulator if steam supply exceeds 15 PSI.

Pre-Wash Pump: is integral with motor and mounted to the machine's

frame. The pump intake is plumbed to the pre-wash tank and is protected by a removable screen. The output side of the pump is plumbed

- 12-

66 SERIES LEFT TO

Note:

Tub will accept a table

66

SERIES

RIGHT

Legend To Drawings

A—Machine water inlet 1/2" I.P.S., 180°F min.

58" above finished floor.

B—Drain connection 2" I.P.S. Drain can be connected to

either end.

C—Electrical connect ion.

D—Allow 12" for removal of pawl bar drive unit cover.

E—Pre-wash water inlet 1/2" I.P.S. 140.

F—Cold water thermostat option 1/2" I.P.S. ambient

temperature water connection.

G—Vent collar 4" x 16" x 7" tall, optional.

H—Vent cowl, standard.

I—Incoming steam connection, optional. 3/4" FPT.

(Gate valve supplied.)

∗ J —Condensate return connection V FPT. (Return to

boiler or open drain.)

∗ Steam tank heat only.

Note: All dimensions from floor are ± 1/2" due to adjustable bullet feet.

flange up to 24-7/8"

RIGHT TO LEFT

- 13-

66

SERIES

Single Tank Rack Conveyor

COMMITMENT TO EXCELLENCE

Optional Features and Accessories

Automatic Tank Fill — includes solenoid valves that are controlled by

water level sensors mounted in the pre-wash and wash tanks. Function

is activated by pressing a designated switch on the control panel.

Booster Heaters:

30 KW Electric Booster Heater — boosts incoming 140°F water to

180°F for sanitizing rinse. Custom features include castone-lined tank,

low water cutoff, pressure relief valve, pressure reducing valve and two

temperature/pressure gauges. Preplumbed to be located at output side

of machine. Unit is supplied with a stainless steel stand with 6" legs and

bullet feet. Unless specified otherwise, electrical characteristics of the

booster heater will be the same as that of the dishwasher.

Higher Than Standard Hood — 5" increase in interior clearance

through machine to 23". Allows washing a variety of larger-sized trays

and bun pans.

Incoming Water Pressure Reducing Valve — factory-installed on

incoming plumbing system. Not required when ordering the electric

booster heater option.

Incoming Water Pressure Regulating Kit — factory-installed package

consisting of a pressure reducing valve with a built-in line strainer, 0-60

PSI gauge and water shock arrestor. Gives full range control over flow

pressure, water consumption and damaging water hammer.

Steam Booster Heater — sized for a 40°F temperature rise. Therefore,

unit must be connected to a 140°F waterline in order to insure 180°F

minimum sanitizing requirements. The steam booster heater is designed

to operate at flowing steam pressures from 10 PSIG to 15 PSIG and is

equipped with a steam pressure reducing valve. Unit is externally

mounted on a stainless steel base with 6" stainless steel legs and bullettype feet. Pre-plumbed for connection at output end of a 66 Series

machine.

Cold Water Thermostat — provides an accurate method of controlling

pre-wash tank heat to prevent "baking on" food soil in the pre-wash

section. This feature is especially valuable for high protein soil loads

such as eggs and cheese.

50-Cycle Electrical Characteristics — are available in 280V/1 or 3 Ph,

230V/1 or 3 Ph, 380V/3 Ph and 460V/3 Ph.

APPROXIMATE TOTAL LOAD AMPERES

ELECTRIC TANK HEAT STEAM TANK HEAT

66 SERIES ELECTRICAL DATA

MODELS - 66CERPW 66CELRPW

1-PH 3-PH 1-PH 3-PH 1-PH 3-PH

208 VOLTS 79 46 15 15 173 100

230 VOLTS 72 42 15 15 157 90

380 VOLTS N/A 24 N/A 9 N/A 55

460 VOLTS N/A 20 N/A 7 N/A 45

Sideloader — is factory-installed on input end of machine. This option

allows the machine to be installed in a corner and maximize the use of

dishroom space. It is available both hooded and unhooded.

Table Limit Switch — factory-wired to machine and mounted to the

backsplash of the table in the field. Prevents damage to conveyor drive

system, racks and dishes due to racks backing up on the output end of

the machine. Highly recommended for clean dishtables less than 10 feet

in length.

Vent Cowl Collar — 4" x 16" x 7" high collar installed in the vent cowl to

allow easy connection of "pant-leg" type exhaust duct. Includes an

adjustable and lockable damper flap for fine-tuning exhaust system.

OPTIONAL 30 KW ELECTRIC

MODELS — 66CSRPW

66CSLRPW

BOOSTER HEATER

SHORT FORM SPECIFICATIONS AND PRODUCT DESCRIPTION 66 SERIES

RACK CONVEYOR DISHWASHER — ITEM #________

Shall be Jackson 66 Series, Single-Tank Rack Conveyor Dishwasher with Recirculating Pre-Wash. Sanitization shall be accomplished by using ___ a

high temperature (180°F min.) rinse, ___ a low temperature (140°F min. + chlorine) rinse. Electrical characteristics shall be ___ 208V, ___ 230V, ___ 380V

(50Hz only), ___ 460V/ ___ 60Hz, ___ 50 Hz/1 Phase (208V and 230V only), ___ 3 Phase. Tank heating shall be ___ 13 KW electric element, ___ 3/4"

steam coil. Direction of rack flow shall be ___left to right, ___right to left. Frame, hood and tank shall be constructed of 18-8 304 series stainless steel. 14

gauge material shall be used in the construction of the tank. Pre-wash section shall be equipped with upper and lower spray arms. Unit shall be supplied

with stainless steel, adjustable, bullet-type feet for leveling, stainless steel front panel, stainless steel vent cowls with strip-type curtains on each end, leveroperated drain, 4 peg-type dish racks and 2 open-type combination racks as standard equipment. Unit shall be equipped with "Energy Guard" automatic

controls and a manual control backup system. Unit shall be NSF listed with a final rinse flow rate not to exceed 288 GPH @ 20 PSIG flow pressure, an

operating capacity of not less than 205 racks per hour and a conveyor speed not less than 5.70 feet per minute. Final rinse water consumption shall not

exceed 1.4 gallons per rack.

Unit shall have the following features as optional extras: ___ automatic tank fill, ___ 30 KW externally-mounted electric booster heater to provide a 40°F

temperature rise, ___ steam booster heater to provide a 40°F temperature rise, ___ cold water thermostat for pre-wash section, ___ 5" higher than

standard hood, ___ incoming water pressure reducing valve, ___ incoming water pressure reducing kit, ___ hooded sideloader, ___ unhooded Sideloader,

___ table limit switch, ___ vent cowl collar at input end of unit, ___ vent cowl collar at output end of unit.

- 14-

SINGLE-TANK

Jackson's

54

Series is made up of the following

MODELS MODELS

Operating Capacity

Racks per Hour

270 270

Flow Pressure

20 PSIG

20

PSIG

Flow Rate

@ 20

PSI

5.85

GPM

5.85

GPM

Final Rinse Consumption

@

20

PSI flow

pressure

Final Rinse Temperature

180-195°F 140

-

150°F

Wash Tank Temperature

160°F 140

-F

Electric Tank Heat

Models

54CE & 54CEL

15KW

Steam Coil Tank Heat

Models

54CS & 54CSL

Steam coil size

3/4"

IPS

Steam flow pressure re

quirement

10-15 PSIG

Steam Consumption

3 15PSI

72 Lbs/Hr

Dimensions

Length

- between dishtables

54" Width

25-

1/2"

Maximum Dish Clearance

18"

Venting

Soiled End

200

CFM

Clean End

400 CFM

Tank Capacity

Wash Tank

24 Gals.

Pumps and Motors

Wash Motor

2 HP

Wash Pump Capacity

300 GPM

Conveyor Motor

1/4

HP

Conveyor Speed (feet/minute)

7.5

Standard Racks

- 19-3/4"

x

19-3/4"

Dish racks (peg type)

4

Shipping Weight (approx.)

670

Lbs.

Shipping Dimensions

(

L

x D x H

) 81"

x 41" x 77"

Cubic Feet

148

All specifications subject to change without notice.

RACK CONVEYOR

DISHWASHER

MANDATORY SPECIFICATIONS

The following information must be specified when placing an order.

Sanitizing Method: (select one)

Hi-temp sanitizing Low-temp (chemical) sanitizing

Voltage: (Select One)

208V/60HZ/1 Ph 230V/60HZ/1 Ph

208V/60HZ/3 Ph 230V/60HZ/3 Ph

460V/60HZ/3 Ph

50 Hz also available in these voltages as well as 380V/50HZ/3 Ph

Tank Heat: (Select One)

15 KW Electric - Immersion-type heating elements with

primary and secondary low water protection.

Regulated Steam • Wash tank steam coils with low water

protection. Requires 10-15 PSI steam supply. Above 15 PSI

install a steam pressure regulator. Do not use steam

coils with less than 10 PSI flowing steam pressure.

Direction of Rack Flow: (select one)

From Right to Left From Left to Right

models.

MODEL 54CE - Electric tank heat,

Hi-temp rinse

MODEL 54CEL - Electric tank heat,

Low-temp rinse

MODEL 54CS - Steam coil tank heat,

Hi-temp rinse

MODEL 54CSL - Steam coil tank heat,

Low-temp rinse

STANDARD FEATURES

o High output with 270 racks per hour.

o Can be ordered as an energy efficient high

temperature sanitizing or low temperature

(chemical) sanitizing model. Low temperature

model has a passivated tank for extra chemical

resistance.

o Heavier gauge construction for extra ruggedness

and durability. 14 gauge tank vs. 16 gauge on

competitive ma-ch i nes.

o Stainless steel frame, legs, bullet feet, vent cowls

and front panel are all standard features, not

optional extras.

o Uses less energy than competitive machines.

o Low water consumption: only 1.3 gallons per rack.

o Lower water consumption allows the use of a lower

KW booster when operated as a high temperature

unit. For a 40 F rise a 36kw booster heater is

recommended.

o Exclusive "Energy Guard" control

system and excellent separation of the wash and

rinse sprays, produces superior results.

I o Convenient, externally operated, lever drains.

o Positive manual fill valve. Automatic fill is available

as an option.

o A.S.S.E. approved vacuum breaker.

SPECIFICATIONS

Dishes or glasses per Hour 6750 6750

Operating Requirements

Incoming water Line Size 1/2" IPS 1/2" IPS

Combination racks (open type) 2

54CE & 54CS 54CEL & 54CSL

351 GPH 351 GPH

-15-

Performance: Fully automatic, single tank, rack

conveyor dishwasher designed to wash, rinse and

and lower final rinse arms located at the output

sanitize tableware and utensils commonly associated

with the preparation and consumption of food items

in a commercial foodservice operation. The unit

conveys standard 19-3/4" x 19-3/4" racks through

a recirculating wash section where 300 GPM of

detergent laden water is pumped over the rack to

remove food soil. The rack is then conveyor

driven into a rinse section where a fresh water

final rinse spray system removes residual detergent and sanitizes. Sanitization can be

accomplished by one of two methods: 1) high

temperature sanitization or 2) low temperature

sanitization. For high temperature sanitization

the unit must be installed on a potable water line

capable of supplying 351 gallons per hour of

water at: 180 F. minimum, 195 F. maximum. In

some cases an external booster heater sized for the

necessary temperature rise must be installed

to reach this sanitizing temperature

requirement. For low temperature sanitization the

unit must be installed on a potable water line

capable of supplying 351 gallons per hour of

water at: 140 F. minimum, 150 F. maximum. A

NSF recognised chemical feeder system must be

supplied and installed by others to inject 50

PPM minimum sodium nypochlorite (chlorine) to

meet sanitization requirements.

Caution; Use of sodium hypochlorite (chlorine)

may have an adverse effect on materials including,

but not limited to, silver and silver plate,

pewter and aluminum.

Construction: All stainless steel components are

18-8 304 series stainless steel. Frame is 2" x 2"

x 1/8" stainless steel angle satin finish. Tank is

formed and heliarc welded 14 gauge #3 finish. The

wash tank on units specified for use as low

temperature sanitizing will be put through a

passivation process to increase chemical

resistance. Hood is 16 gauge #3 finish. Legs and

feet are stainless steel and are adjustable +;

1/2".

Wash Tank: 24 gallon capacity with skimming type

overflow tube. Lever operated drain valve for

draining tank. Washing action is

accomplished by recirculating detergent laden

water in the wash tank through upper and lower

wash arms to strip away food soil. 7/8" round

knockouts are provided to allow easy installation

of detergent concentration sensor and dispenser

tube by others. A 24" span of 64 wash jets provides unsurpassed wash pattern. Tank and hood

design provides 20" of distance between wash and

rinse jets to insure excellent separation of wash

and rinse sprays. This greater separation

virtually eliminates spotting and poor results

caused by wash water splashing into rinse

section. Makeup water comes from the final rinse

reservoir and is spilled into wash tank at a

controlled rate. (approximately 2 g.p.m.)

Final Rinse: Rinse water enters the machine

through a brass "Y" strainer and solenoid valve

and approved vacuum breaker (supplied) and is

plumbed to upper

end of the machine. Two dispensing point locations

(1/4" NPT plugs) are provided for dispensing

equipment connection by others. One point should

be used for rinse agent injection into the final

rinse water. The other connection point should

be used for injection of sodium hypochlorite on

low temperature sanitizing models.

Wash Pump: is integral with motor and is flange

mounted to wash tank and manifold. Mash

water is recirculated from the tank, through the

pumping system and back to the tank at the rate of

300 GPM

Wash Pump Motor: is a 2 HP open,

drip-proof type. Capacitor start, induction run

with bimetallic thermal overload protection.

Motor shaft is supported by permanently lubricated,

grease packed ball bearings.

Conveyor: Center mounted pawl bar with counterweighted, wide surface pawls is driven by 1/4 HP

motor and worm drive reduction gear unit. Motor

is open, drip-proof type and is thermally

protected. Pawl bar drive unit is mounted at

the output end of machine and is enclosed with

removable stainless steel cover. Conveyor speed

is 7.5 feet per minute.

Vent Cowls: Unit comes standard with 8" vent cowls

on each end. Tops of cowls have 4" x 16" openings

(covered with removable plates) for connection to

exhaust duct. Available at additional cost are 4"

x 16" x 7" high vent cowl collars with adjustable

and lockable damper style flaps.

MANDATORY SPECIFICATIONS

Tank Heating Equipment

15 KW Electric - High efficiency Firebar™ immersion

type heating element is mounted in wash tank and

is protected by a solid state low-water cutoff

system. Tank temperature is monitored by a PTC

thermistor and controlled by fast reacting, solid

state thermostats. Available in 208V/60HZ/1 or 3

Phase, 230V/60HZ/1 or 3 Phase, 460V/60HZ/3 Phase.

50Hz available in these voltages as well as

380V/50HZ/3 Phase. 50Hz voltages are not UL listed.

Regulated Steam Coil - stainless steel

steam coil is mounted in wash tank and is protected

by a solid state low-water cutoff system.

Incoming steam passes through a steam pressure

regulator and "Y" strainer. A steam solenoid

valve regulates flow of steam through coil.

Tank temperature is monitored by a PTC thermistor

and controlled by a fast reacting, solid state

thermostat. Requires 10-15 PSI flowing steam supply. Install with steam pressure regulator if

steam supply exceeds 15 PSI. Do not use coils

with flowing steam pressures less than 10 PSI.

-16-

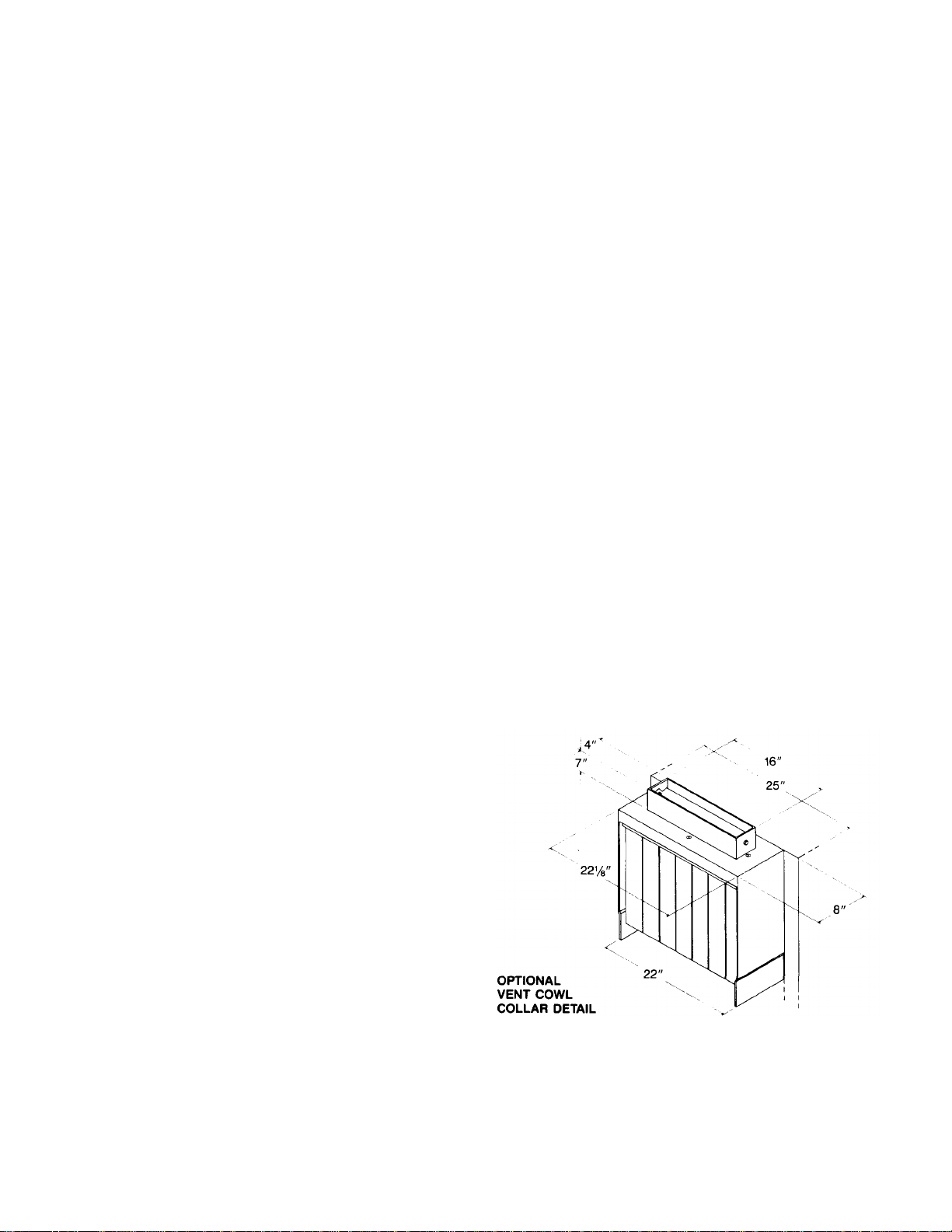

Recommended Table Fabrication Optional Vent Cowl Collar Detail

Legend To Drawings

A—Machine water inlet 4" I.P.S., 180*F

min. 58" above finished floor.

B—Drain connection 2" I.P.S. Drain can be

connected to either end.

C—Electrical connection.

D—Allow 12" tor removal of pawl bar

drive unit cover.

E—Vent collar 4" x 16" x 3 "tall, optional.

F—Vent cowl, standard.

*G—Incoming steam connection, optional.

3/4" FPT. (Gate valve supplied.)

*H—Condensate return connection V FPT.

(Return to boiler or open drain.)

* Steam Tank Heat Only

Note: All dimensions from floor are ± 1/2 " due to adjustable bullet test.

54 SERIES

RIGHT TO LEFT

54

SERIES

Single Tank Rack Conveyor

-18-

7610-200-18

-

Optional Features and Accessories

Automatic Tank Fill - includes solenoid

valve that is controlled by Mater level sensors mounted in wash tank.

Function is activated by pressing a designated switch on the control

panel.

Booster Heaters:

Electric:

36 KW - for a 40°F Rise

45 KW - for a 50-F Rise

Boosts incoming water temperature for sanitizing rinse. Custom features

include castone lined tank, low water cutoff, pressure relief valve, pressure

reducing valve and two temperature/pressure gauges. Preplumbed to be

located at output side of machine. Unit is supplied with a stainless steel

frame with 6" legs and bullet feet. Unless specified otherwise, electrical

characteristics of the booster heater will be the same as that of the

dishwasher.

Steam Booster Heater - sized for a

40 F temperature rise. Therefore, unit must be connected to a 140 F

waterline in order to insure 180 F minimum sanitizing requirements. The

steam booster heater is designed to operate at flowing steam pressures from

10 PSIG to 15 PSIG and is equipped with a steam pressure reducing valve.

Unit is externally mounted on a stainless steel base with 6" stainless steel

legs and bullet type feet. Pre-plumbed for connection at output end of

machine. Do not use steam booster with flowing steam supply pressure less

than 10 PSI.

50 Cycle Electrical Characteristics - are available in 208V/1 or 3

Ph, 230V/1 or 3 Ph, 380V/3 Ph and 460V/3 Ph.

APPROXIMATE TOTAL LOAD AMPERES

COMMITMENT TO EXCELLENCE

Higher Than Standard Hood - 5"i ncrease in interior clearance

through machine to 23". Allows washing a variety of larger sized trays

and bun pans.

Incoming Water Pressure Reducing

Valve — factory installed on incoming

plumbing system. Not required when ordering the electric

booster heater option.

Incoming Water Pressure

Regulating Kit - factory installed package consisting of a pressure reducing

valve with a built -in line strainer, 0-60 psi gauge and water shock arrestor.

Gives full range control over flow pressure, water consumption and

damaging water hammer.

Sideloader — is factory installed on input end of machine. This option

allows the machine to be in stalled in a corner and maximize the use of

dishroom space. It is available both hooded and unhooded.

Table Limit Switch - factory wired to machine and mounted to the

backsplash of the table in the field. Prevents damage to conveyor

drive system, racks and dishes due to racks backing up on the output

end of the machine. Highly recommended for clean dishtables less

than 10 feet in length.

Vent Cowl Collar - 4" X 16" X 7" high collar installed in the vent cowl

to allow easy connection of "pant-leg" type exhaust duct. Includes

an adjustable and lockable damper flap for fine tuning exhaust

system.

54 SERIES ELECTRICAL

DATA

208 VOLTS 87 51 14 9 173 100

230 VOLTS 79 47 14 9 156 90

380 VOLTS N/A 28 N/A 5 N/A 55

460 VOLTS N/A 23 N/A 5 N/A 45

ELECTRIC TANK HEAT STEAM TANK HEAT

MODELS 54CE & 54CEL MODELS 54CS 8 54CSL

1-PH 3-PH 1-PH 3-PH 1-PH 3-PH

OPTIONAL 36KW ELECTRIC

BOOSTER HEATER

SHORT FORM SPECIFICATIONS AND PRODUCT DESCRIPTION 54 SERIES RACK CONVEYOR

DISHWASHER - ITEM#_________

Shall be Jackson 54 Series, Single-Tank Rack Conveyor Dishwasher. Sanitization shall be accomplished by using ___a high temperature (180 F

min.) rinse, ___a low temperature (140 F min. + chlorine) rinse. Electrical characteristics shall be___208V, ___230V, ___380V(50Hz Only),

___460V/___60Hz, ___50Hz/___1 Phase(208V & 230V Only), .___3 Phase. Tank heating shall be ___15KW electric element, ___3/4" steam coil.

Direction of rack flow shall be ___left to right, ___right to left. Frame, hood and tank shall be constructed of 18-8 304 series stainless steel. 14 gauge

material shall be used in the construction of the tank. Unit shall be supplied with stainless steel adjustable, bullet-type feet for leveling, stainless steel

front panel, stainless steel vent cowls with strip-type curtains on each end, lever operated drain, 4 peg-type dish racks and 2 open-type combination

racks as standard equipment. Unit shall be equipped with "Energy Guard" automatic controls and a manual control backup system. Unit shall be NSF

listed with a final rinse flow rate not to exceed 351 GPM a 20 psig flow pressure, an operating capacity of not less than 270 racks per hour and a

conveyor speed not less than 7.5 feet per minute. Final rinse water consumption shall not exceed 1.3 gallons per rack.

Unit shall have the following features as optional extras: ___automatic tank fill, ___36KW externally mounted elec-tric booster heater to provide a 40 F

temperature rise, ___45KW externally mounted electric booster heater to provide a 50 F temperature rise, ___steam booster heater to provide a 40 F

temperature rise, ___5" higher than standard hood, ___incoming water pressure reducing valve, ___incoming water pressure reducing kit, ___hooded

sideloader, ___unhooded sideloader, ___table limit switch, ___vent cowl collar at input end of unit, ___vent cowl collar at output end of unit.

00

SINGLE

-

TANK

RACK CONVEYOR

Jackson's

76

Series is made up of the following

MODELS

76CELRPW & 76CSLRPW

ALL SPECIFICATIONS SUBJECT TO CHANGE WITHOUT NOTICE

-19-

DISHWASHER

models.

MODEL 76CERPW - Electric tank heat,

Hi-temp rinse

MODEL 76CELRPW - Electric tank heat,

Low-temp rinse

MODEL 76CSRPW Steam coil tank heat,

Hi-temp rinse

MODEL 76CSLRPW - Steam coil tank heat,

Low-temp rinse

STANDARD FEATURES

• Recirculating pre-wash feature virtually eliminates

manual pre-rinsing and saves on labor.

• High output of 270 racks per hour.

• Can be ordered as an energy efficient high

temperature sanitizing or low temperature (chemical)

sanitizing model. Low temperature model has a

passivated tank for extra chemical resistance.

• Heavier gauge construction for extra rugged-ness

and durability. 14 gauge tank vs. 16 gauge on

competitive machines.

• Stainless steel frame, legs, bullet feet, vent cowls

and front panel are all standard features, not optional

extras.

• Uses less energy than competitive machines.

• Low water consumption: only 1.3 gallons per rack.

• Lower water consumption allows the use of a lower

KW booster when operated as a high temperature

unit. For a 40°F rise a 36 KW booster heater is

recommended.

• Exclusive "Energy Guard" control system and

excellent separation of the wash and rinse

sprays, produces superior results.

• Convenient, externally operated, lever drains.

• Positive manual fill valve. Automatic fill is available

as an option.

• A.S.S.E. approved vacuum breaker.

MANDATORY SPECIFICATIONS

The following information must be specified when placing an order.

Sanitizing Method: (Select One)

Hi-temp sanitizing Low-temp (chemical) sanitizing

Voltage: (Select One)

208V/60HZ/1 Ph 230V/60Hz/1 Ph

208V/60HZ/3 Ph 230V/60HZ/3 Ph

460V/60HZ/3 Ph

50 Hz also available in these voltages as well as 380V/50HZ/3 Ph

Tank Heat: (Select One)

15 KW Electric — Immersion-type heating elements with primary and secondary low

water protection.

Regulated Steam — Wash tank steam coils with low water protection. Requires 1015 PSI steam supply. Above 15 PSI install a steam pressure regulator. Do not use

steam coils with flowing steam pressures less than 10 PSI.

Direction of Rack Flow: (Select One)

From Right to Left From Left to Right

SPECIFICATIONS

Operating Capacity

Racks per Hour 270 270

Dishes or Glasses per Hour 6750 6750

Operating Requirements

Incoming Waterline Size — Pre-Wash

Incoming Waterline Size — Machine

Flow Pressure 20 PSIG 20 PSIG

Flow Rate @ 20 PSI 5.85 GPM 5.85 GPM

Final Rinse Consumption @ 20 PSI

Flow Pressure 351 GPH 351 GPH

Final Rinse Temperature 180-195°F 140-150°F

Wash Tank Temperature 160°F 140°F

Pre-Wash Tank Temperature (Maximum) 140°F 140°F

Electric Tank Heat

Models 76CERPW & 76CELRPW 15 KW

Steam Coil Tank Heat

Models 76CSRPW & 76CSLRPW

Steam Coil Size

Steam Flow Pressure Requirement 10-15 PSIG

Steam Consumption @ 15 PSI 72 Lbs./Hr.

Dimensions

Length — between dishtables 76"

Width — at widest point 33"

Maximum Dish Clearance 18"

Venting

Input End 200 CFM's

Output End 400 CFM's

Tank Capacity

Wash Tank 24 Gals.

Pre-Wash Tank 12 Gals.

Pumps and Motors

Pre-Wash Motor 1 HP

Pre-Wash Pump Capacity 120 GPM

Wash Motor 2 HP

Wash Pump Capacity 300 GPM

Conveyor Motor

Conveyor Speed (feet/minute) 7.5

Standard Racks — 19-3/4" x 19-3/4"

Dish Racks (peg-type) 4

Combination Racks (open-type) 2

Shipping Weight (approx.) 900 Lbs.

Shipping Dimensions (L x D x H) 115" x 41" x 77"

Cubic Feet 210

76CERPW & 76CSRPW

1/2" IPS

1/2" IPS 1/2"" IPS

3/4" IPS

1/4 HP

MODELS

1/2" IPS

Performance:

Fully automatic, single tank, rack conveyor dishwasher

with a recirculating pre-wash designed to wash, rinse and sanitize

to upper and lower spray arms. The pre

-

wash pump recirculates

120

tableware and utensils commonly associated with the preparation and

consumption of food items in a commercial foodservice operation. The

unit conveys standard 19%" x 19%" racks through a recirculating prewash section where 120 GPM of water is pumped over the rack to

automatically prepare the ware for washing. Next the rack is conveyordriven into a power wash section where 300 GPM of detergent-laden

water is pumped over the ware to remove food soil. Finally, the rack is

conveyor-driven into a rinse section where a fresh water final rinse spray

system removes residual detergent and sanitizes. Sanitization can be

accomplished by one of two methods:

1) high temperature sanitization, or 2) low temperature sanitization. For

high temperature sanitization, the unit must be installed on a potable

water line capable of supplying 351 gallons per hour of water at: 180°F.

minimum, 195°F. maximum. In some cases an external booster heater

sized for the necessary temperature rise must be installed to reach this

sanitizing temperature requirement. For low temperature sanitization, the

unit must be installed on a potable water line capable of supplying 351

gallons per hour of water at: 140°F. minimum, 150°F. maximum. An NSF

listed chemical feeder system must be supplied and installed by others to

inject 50 PPM minimum sodium hypochlorite (chlorine) to meet

sanitization requirements.

Caution: Use of sodium hypochlorite (chlorine) may have an

adverse effect on materials including, but not limited to, silver

and silver plate, pewter and aluminum.

GPM over the rack of ware.

Pre-Wash Pump Motor: is a 1 HP open drip-proof type. Capacitor start,

induction run with bi-metallic thermal overload protection. Motor shaft is

supported by permanently-lubricated, grease-packed ball bearings.

Wash Pump: is integral with motor and is flange-mounted to wash tank

and manifold. Wash water is recirculated from the tank, through the

pumping system and back to the tank at the rate of 300 GPM.

Wash Pump Motor: is a 2 HP open drip-proof type. Capacitor start,

induction run with bi-metallic thermal overload protection. Motor shaft is

supported by permanently-lubricated, grease-packed ball bearings.

Conveyor: Center-mounted pawl bar with counter-weighted, wide surface pawls is driven by 1/4 HP motor and worm drive reduction gear unit.

Motor is open, drip-proof type and is thermally protected. Pawl bar drive

unit is mounted at the output end of machine and is enclosed with

removable stainless steel cover. Conveyor speed is 7.5 feet per minute.

Vent Cowls: Unit comes standard with 8" vent cowls on each end. Tops

of cowls have 4" x 16" openings (covered with removable plates) for

connection to exhaust duct. Available at additional cost are 4" x 16" x 7"

high vent cowl collars with adjustable and lockable damper-style flaps.

Construction: All stainless steel components are 18-8 304 series

stainless steel. Frame is 2" x 2" x 1/8" stainless steel angle satin finish.

Tank is formed and heliarc welded 14 gauge #3 finish. The wash tank on

units specified for use as low temperature sanitizing will be put through a

passivation process to increase chemical resistance. Hood is 16 gauge

#3 finish. Legs and feet are stainless steel and are adjustable ± 1/2".

Pre-Wash Tank: 12-gallon capacity with skimming-type overflow tube

and large externally removable scrap basket. Pre-washing action is

accomplished by pumping the water in the pre-was h tank through upper

and lower spray arms to prepare the ware for the wash. Makeup water

comes from detergent wash.

Wash Tank: 24-gallon capacity. Lever-operated drain valve for draining

tank. Washing action is accomplished by recirculating detergent-laden

water in the wash tank through upper and lower wash arms to strip away

food soil. 77/8" round knockouts are provided to allow easy installation of

detergent concentration sensor and dispenser tube by others. A 24"

span of 64 wash jets provides unsurpassed wash pattern. Tank and

hood design provides 20" of distance between wash and rinse jets to

insure excellent separation of wash and rinse sprays. This greater

separation virtually eliminates spotting and poor results caused by wash

water splashing into rinse section. Make-up water comes from the final

rinse reservoir and is spilled into wash tank at a controlled rate (approx.

2 GPM).

Final Rinse: Rinse water enters the machine through a brass "Y"

strainer and solenoid valve and approved vacuum breaker (supplied) and

is plumbed to upper and lower final rinse arms located at the output end

of the machine. Two dispensing point locations (1/4" NPT plugs) are

provided for dispensing equipment connection by others. One point

should be used for rinse agent injection into the final rinse water. The

other connection point should be used for injection of sodium

hypochlorite on low temperature sanitizing models.

Pre-Wash Pump: is integral with motor and mounted to the machine's

frame. The pump intake is plumbed to the pre-wash tank and is protected by a removable screen. The output side of the pump is plumbed

MANDATORY SPECIFICATIONS

Tank Heating Equipment

15 KW Electric — High efficiency Firebar™ immersion-type heating ele-

ment is mounted in wash tank and is protected by a solid state low water

cutoff system. Tank temperature is monitored by a PTC thermistor and

controlled by fast-reacting, solid state thermostats. Available in

208V/60Hz/1 or 3 Phase, 230V/60Hz/1 or 3 Phase, 460V/60Hz/3 Phase.

50Hz available in these voltages as well as 380V/50Hz/3 Phase. 50Hz

voltages are not UL listed.

Regulated Steam Coil — Stainless steel steam coil is mounted in wash

tank and is protected by a solid state low water cutoff system. A steam

solenoid valve regulates flow of steam through coil. Tank temperature is

monitored by a PTC thermistor and controlled by a fast-reacting, solid

state thermostat. Requires 10-15 PSI flowing steam supply. Install with

steam pressure regulator if steam supply exceeds 15 PSI.

-20-

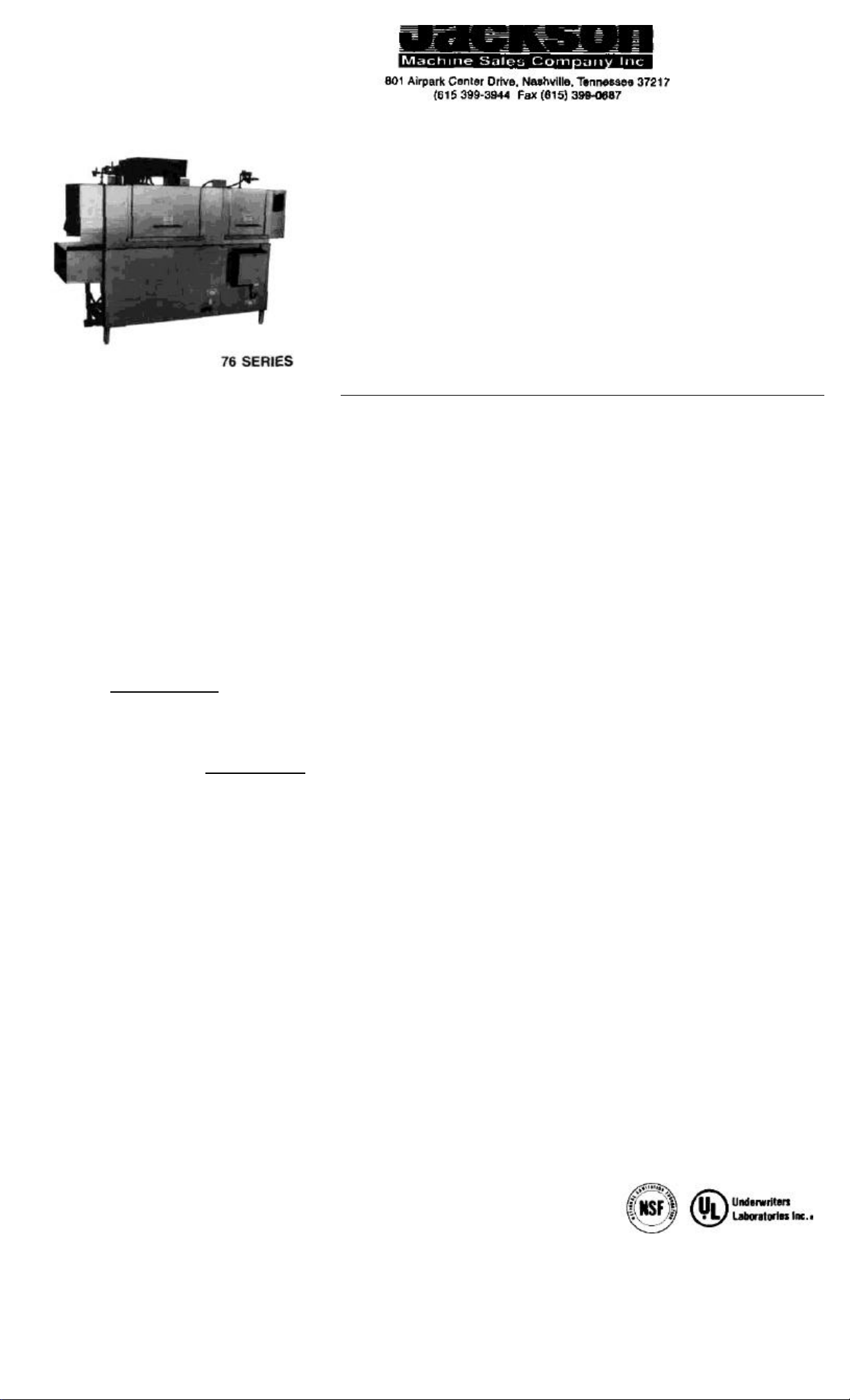

76

SERIES LEFT TO

Recommended Table Fabrication

Note:

Tub will accept a table

76

SERIES

Legend To Drawings

A—Machine water inlet 1/2" I.P.S., 180°F min.

58" above finished floor.

B—Drain connection 2" I.P.S. Drain can be connected to either

end.

C—Electrical connection.

D—Allow 12" for removal of pawl bar drive unit cover.

E—Pre-wash water inlet 1/2" I.P.S. 140°F. F—Cold water thermostat

option 1/2" I.P.S. ambient temperature water connection.

G—Vent collar 4" x 16" x 7" tall, optional.

H—Vent cowl, standard.

∗I —Incoming steam connection, optional. 3/4" FPT. (Gate valve

supplied.)

∗J —Condensate return connection 3/4" FPT. (Return to boiler or

open drain.)

∗Steam tank heat only

RIGHT

Note: All dimensions from floor are ± 1/2" due to adjustable bullet

feet.

flange up to 24 7/8".

RIGHT TO LEFT

-21 -

76

SERIES

Single Tank Rack Conveyor

COMMITMENT TO EXCELLENCE

EP 1/92

-22-

Optional Features and Accessories

Automatic Tank Fill — includes solenoid valves that are controlled by

water level sensors mounted in the pre-wash and wash tanks. Function

is activated by pressing a designated switch on the control panel.

Higher Than Standard Hood — 5" increase in interior clearance

through machine to 23". Allows washing a variety of larger-sized trays

and bun pans.

Booster Heaters:

36 KW — for a 40°F Rise

45 KW — for a 50°F Rise

Boosts incoming water temperature for sanitizing rinse. Custom features

include castone-lined tank, low water cutoff, pressure relief valve,

pressure reducing valve and two temperature/pressure gauges.

Preplumbed to be located at output side of machine. Unit is supplied with

a stainless steel stand with 6" legs and bullet feet. Unless specified

otherwise, electrical characteristics of the booster heater will be the

same as that of the dishwasher.

Steam Booster Heater — sized for a 40°F temperature rise. Therefore,

unit must be connected to a 140°F waterline in order to insure 180°F

minimum sanitizing requirements. The steam booster heater is designed

to operate at flowing steam pressures from 10 PSIG to 15 PSIG and is

equipped with a steam pressure reducing valve. Unit is externally

mounted on a stainless steel base with 6" stainless steel legs and bullettype feet. Pre-plumbed for connection at output end of a 76 Series

machine.

Cold Water Thermostat — provides an accurate method of controlling

pre-wash tank heat to prevent "baking on" food soil in the pre-wash

section. This feature is especially valuable for high protein soil loads

such as eggs and cheese.

50-Cycle Electrical Characteristics — are available in 280V/1 or 3 Ph,

230V/1 or 3 Ph, 380V/3 Ph and 460V/3 Ph.

76 SERIES ELECTRICAL DATA

ELECTRIC TANK HEAT STEAM TANK HEAT

MODELS — 76CERPW

76CELRPW

1-PH 3-PH 1-PH 3-PH 1-PH 3-PH

Incoming Water Pressure Reducing Valve — factory-installed on

incoming plumbing system. Not required when ordering the electric

booster heater option.

Incoming Water Pressure Regulating Kit — factory-installed package

consisting of a pressure reducing valve with a built-in line strainer, 0-60

PSI gauge and water shock arrestor. Gives full range control over flow

pressure, water consumption and damaging water hammer.

Sideloader — is factory-installed on input end of machine. This op-tion

allows the machine to be installed in a corner and maximize the use of

dishroom space. It is available both hooded and unhooded

Table Limit Switch — factory-wired to machine and mounted to the

backsplash of the table in the field. Prevents damage to conveyor drive

system, racks and dishes due to racks backing up on the out put end of

the machine. Highly recommended for clean dishtables less than 10

feet in length.

Vent Cowl Collar — 4" x 16" x 7" high collar installed in the vent cowl

to allow easy connection of "pant-leg" type exhaust duct. Includes an

adjustable and lockable damper flap for fine-tuning exhaust system.

APPROXIMATE TOTAL LOAD AMPERES

OPTIONAL 30 KW ELECTRIC

MODELS — 76CSRPW

76CSLRPW

BOOSTER HEATER

208 VOLTS 91 53 15 15 173 100

230 VOLTS 83 49 15 15 156 90

380 VOLTS N/A 29 N/A 9 N/A 55

460 VOLTS N/A 24 N/A 7 N/A 45

SHORT FORM SPECIFICATIONS AND PRODUCT DESCRIPTION 76 SERIES

RACK CONVEYOR DISHWASHER — ITEM #___

Shall be Jackson 76 Series, Single-Tank Rack Conveyor Dishwasher with Recirculating Pre-Wash. Sanitization shall be accomplished by using ___i

high temperature (180°F min.) rinse, ___ a low temperature (140°F min. + chlorine) rinse. Electrical characteristics shall be ___ 208V, ___ 230V, __ 380V

(50Hz only), ___ 460V/ ___ 60Hz, ___ 50 Hz/1 Phase (208V and 230V only), ___ 3 Phase. Tank heating shall be ___ 15 KW electric element ___ 3/4"

steam coil. Direction of rack flow shall be___left to right, ___right to left. Frame, hood and tank shall be constructed of 18-8 304 series stainless steel. 14

gauge material shall be used in the construction of the tank. Pre-wash section shall be equipped with upper and lower spray arms. Unit shall be supplied

with stainless steel, adjustable, bullet-type feet for leveling, stainless steel front panel, stainless steel vent cowls with strip-type curtains on each end, lever

operated drain, 4 peg-type dish racks and 2 open-type combination racks as standard equipment. Unit shall be equipped with "Energy Guard" automatic

con controls and a manual control backup system. Unit shall be NSF listed with a final rinse flow rate not to exceed 351 GPH @ 20 PSIG flow pressure,

an operating capacity of not less than 270 racks per hour and a conveyor speed not less than 7.5 feet per minute. Final rinse water consumption shall not

exceed 1.3 gallons per rack

Unit shall have the following features as optional extras: ___ automatic tank fill, ___ 36 KW externally-mounted electric booster heater to provide a 40°F

temperature rise, ___ 45 KW externally-mounted electric booster heater to provide a 50°F temperature rise, ___ steam booster heater to provide a 40°F

temperature rise, ___ cold water thermostat for pre-wash section, ___ 5" higher than standard hood, ___ incoming water pressure reducing valve, ___

incoming water pressure reducing kit, ___ hooded sideloader, ___ unhooded Sideloader, ___ table limit switch, ___ vent cowl collar at input end of unit,

___ vent cowl collar at output end of unit.

- 23 -

UNPACKING

BEFORE ANY CONNECTIONS ARE MADE, VISUALLY CHECK THE ENTIRE MACHINE FOR ANY POSSIBLE SHIPPING DAMAGE.

IF ANY DAMAGE IS FOUND, SAVE ALL SHIPPING MATERIAL AND NOTIFY CARRIER AND DEALER AT ONCE.

STEPS:

1. REMOVE ALL PROTECTIVE PACKING MATERIAL FROM MACHINE.

2. PLACE MACHINE IN ITS OPERATING LOCATION AND REMOVE SKID.

CAUTION: INSURE WEIGHT OF MACHINE IS EVENLY DISTRIBUTED WHEN REMOVING

FROM SKID INTO POSITION.

3. ADJUST ALL (4) ADJUSTABLE BULLET FEET SO CONTACT IS MADE TO FLOOR. SCREW

BULLET FEET IN OR OUT TO LEVEL MACHINE WHILE USING LEVEL. LEVEL FRONT OF

MACHINE FIRST, THEN REAR, AND SIDES.

ELECTRICAL CONNECTIONS

WARNING: ALL FIELD WIRING CONNECTIONS MUST CONFORM TO THE LOCAL AND

NATIONAL ELECTRICAL CODES. INSTALL PROPER CIRCUIT BREAKER, WIRE

AND CONDUIT SIZE.

MACHINE DATA PLATE is located at front of machine on vent cowl. Refer to data plate for machine voltage and amperage load.

REFER TO SPECIFICATION SECTION FOR FURTHER DETAILS IF NECESSARY.

STEPS : REFER TO FIGURE 1

1. Remove the cover from the electrical control box and lay aside.

2. Install conduit into access hole at rear of electrical control box as shown in figure (1).

3. Route wires and connect to service disconnect switch and grounding lug as shown. WARNING: Insure that machine

is properly grounded and complies to all local and national codes. Injury or death may occur from shock if

machine is not properly grounded.

4. Make connections to service disconnect switch as marked, LI and L2 for SINGLE PHASE, VOLTAGE MUST match

specified voltage on DATA PLATE, either 208 VAC or 220 VAC.

For THREE PHASE, make connections to LI, L2 AND L3. Voltage must match specified voltage in DATA PLATE,

either 208 VAC, 220 VAC or 460 VAC.

DO NOT APPLY POWER AT THIS TIME — PROCEED TO VOLTAGE CHECK

-24-

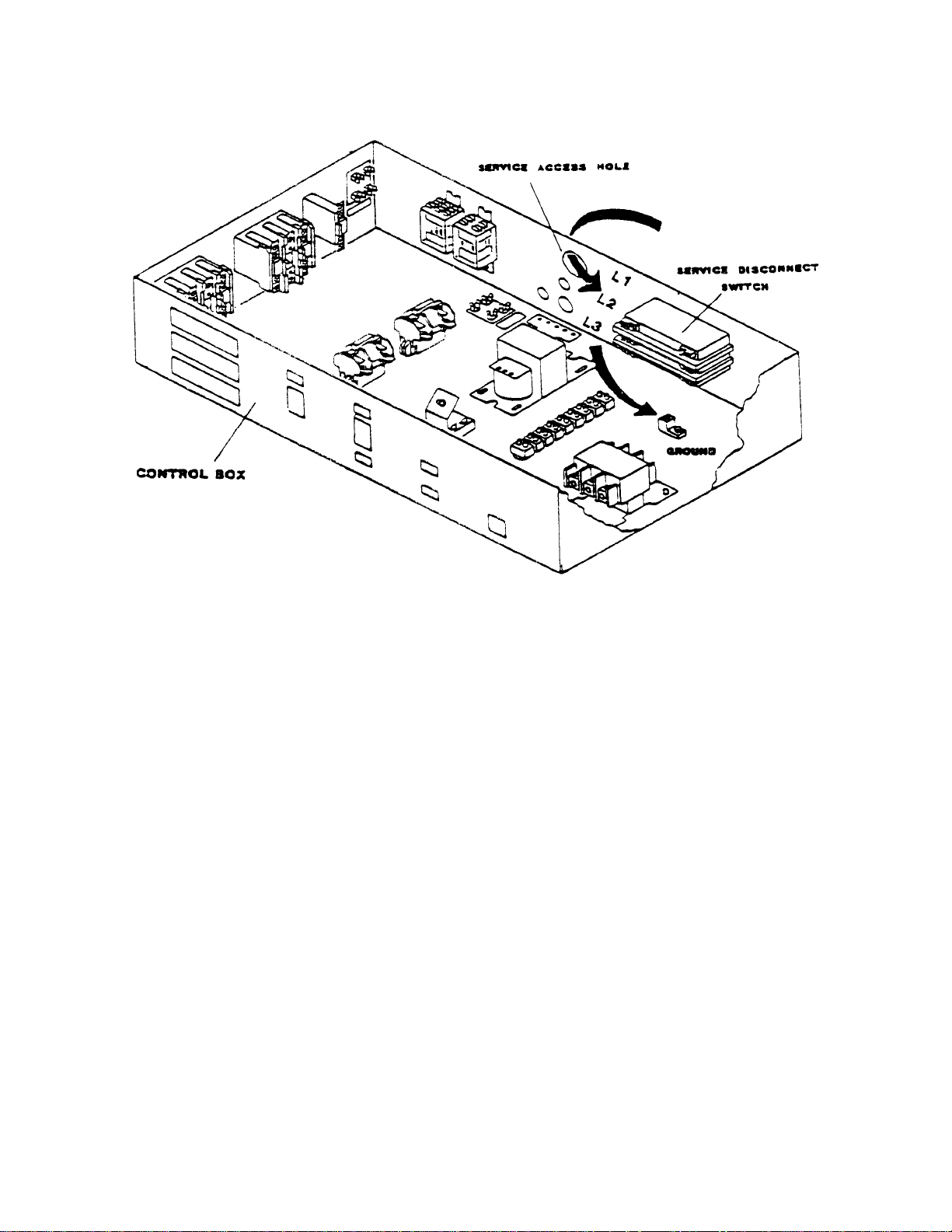

FIGURE 1

CONTROL BOX ELECTRICAL CONNECTIONS

25

STEPS:

1. Place the machine service disconnect switch in the "OFF" position.

2. Apply line power to the machine from the service breaker.

3. Check incoming service lines at terminals of disconnect switch for proper voltage per data plate.

NOTE: If applicable, check voltage at LI and L2 to ground individually to insure neither is

connected to a HIGH or WILD leg.

CAUTION: There is a possibility of damage to machine if not properly checked.

4. Turn off power at service breaker.

NOTE: Mark breaker for dishwasher and advise proper personnel.

DO NOT APPLY POWER OR TURN MACHINE ON AT THIS TIME ...

ALL PLUMBING AND WATER CONNECTIONS MUST BE COMPLETED BEFORE MACHINE

CAN BE OPERATED.

ALL PLUMBING CONNECTIONS MUST COMPLY WITH ALL SANITARY, SAFETY AND PLUMBING CODES.

REFER TO SPECIFICATION SECTION FOR FURTHER DETAIL IF NEEDED.

DRAIN CONNECTION

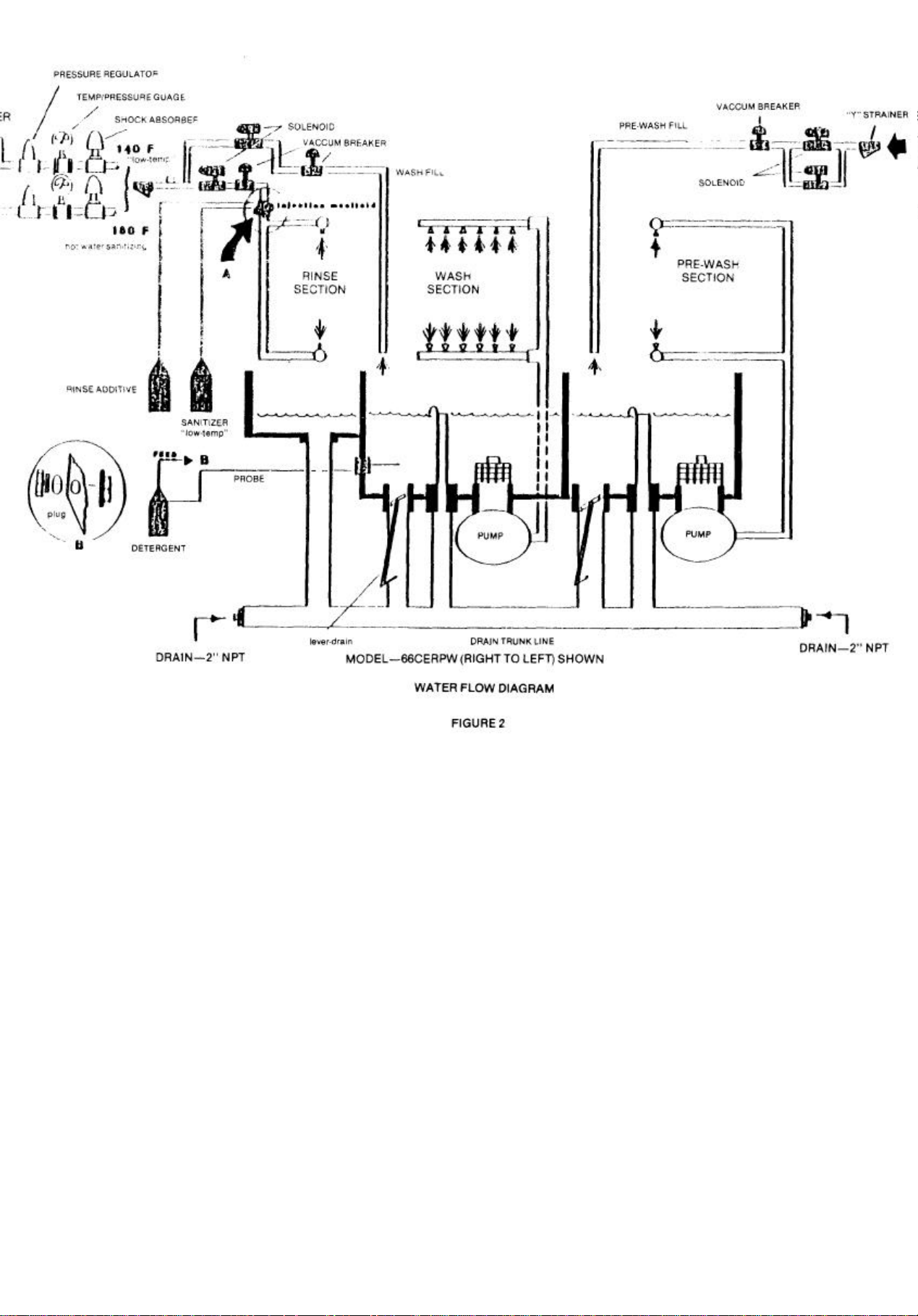

REFER TO FIGURE (2)

STEPS:

1. Remove the 2" plug from drain tank line at left or right end, only one connection is necessary.

2. Install a 2" DRAIN LINE with proper slope at this point.

NOTE: Drain is a GRAVITY FEED SYSTEM.

PROCEED TO PLUMBING AND HOT WATER REQUIREMENTS

-26-

Models 44CE, 54CE, 54CEL, 76CERPW, 44CEL, 66CERPW, and 66CELRPW DO NOT have an internal water heater to boost the regularly

available hot water (usually 140F.) up to 180F. Water at 180F can be used as sanitzing rinse water.

ALL HOT-WATER SANITIZING machines MUST have an external supply of 180F. HOT WATER to the machine.

All LOW-TEMPERATURE CHEMICAL SANITIZING machines will use the regularly available 140F. hot water along with

SANITIZER for sanitizing the final rinse water.

Before any connections are made, determine if machine is a HOT WATER SANITIZING or a LOW-TEMPERATURE CHEMICAL

SANITIZING machine.

This can easily be accomplished by comparing the MODEL NUMBER on the machine DATA PLATE to the lists below. REFER TO

NOMENCLATURE IN SPECIFICATION SECTION IF NECESSARY FOR FURTHER DETAILS.

The following machines are LOW-TEMPERATURE CHEMICAL SANITIZING:

44 C E L 54 C E L

66CELRPW 76CELRPW

The following machines are HOT-WATER SANITIZING:

44 C E 54 C E 66CERPWE

76CERPW

PROCEED TO THE APPROPRIATE HOT-WATER OR CHEMICAL SANITIZNG INSTRUCTIONS THAT FOLLOW.

HOT WATER SANITIZING MACHINES

STEPS: REFER TO FIGURE (2)

1. Connect a 180 F. MINIMUM constant HOT WATER 1/2" supply to the FINAL RINSE incoming water "Y"

STRAINER as shown in FIGURE (2).

WASH TANK WATER SUPPLY

Wash tank water is recirculating and is initially filled by same supply line as final rinse and no additional

connection is necessary.

NOTE:

ALL MACHINES require a MINIMUM of 20 PSI FLOW PRESSURE.

Do not confuse STATIC PRESSURE with FLOW PRESSURE. FLOW PRESSURE is the pressure

in the FINAL RINSE LINE when the rinse valve is OPEN, and machine is RINSING.

STATIC PRESSURE is line pressure with no flowing, all valves and service CLOSED.

CONTINUE TO NEXT PAGE

-28-

Loading...

Loading...