Page 1

MODEL 24 B/BF

HIGH TEMPERATURE UNIT

NOVEMBER 1984

AFTER S/N 14389

BEFORE S/N 21800

INSTALLATION/OPERATION

and

SERVICE MANUAL

INCLUDES:

-Warranty Policy -Basic Functions of Dishwasher

-Installation Requirements -Maintenance and Care

-Operating Instructions -Wiring Diagrams

-Description of Components

801 AIRPARK CENTER DRIVE

NASHVILLE, TN

(615)399-3944

1-800-736-8144

FAX(615)-366-9126

January 30,1998 7610-100-03-00 Rev A

Page 2

MANUFACTURERS WARRANTY

ONE YEAR LIMITED PARTS & LABOR WARRANTY

ALL NEW JACKSON DISHWASHERS ARE WARRANTED TO THE ORIGINAL PURCHASER TO BE FREE FROM DEFECTS IN

MATERIAL OR WORKMANSHIP, UNDER NORMAL USE AND OPERATION FOR A PERIOD OF (1) ONE YEAR FROM THE DATE OF

PURCHASE, BUT IN NO EVENT TO EXCEED (18) EIGHTEEN MONTHS FROM THE DATE OF SHIPMENT FROM THE FACTORY.

Jackson MSC agrees under this warranty to repair or replace , at its discretion, any original part which fails under normal use due to faulty

material or workmanship during the warranty period, providing the equipment has been unaltered, and has been properly installed, main

tained and operated in accordance with the applicable factory instruction manual furnished with the machine and the failure is reported to the

authorized service agency within the warranty period. This includes the use of factory specified genuine replacement parts, purchased

directly from a Jackson authorized parts distributor or service agency. Use of generic replacement parts may create a hazard and void

warranty certification.

The labor to repair or replace such failed part will be paid by Jackson MSC, within the continental United States, Hawaii and Canada, during

the warranty period provided a Jackson MSC authorized service agency, or those having prior authorization from the factory, performs the

service. Any repair work by persons other than a Jackson MSC authorized service agency is the sole responsibility of the customer. Labor

coverage is limited to regular hourly rates, overtime premiums and emergency service charges will not be paid by Jackson MSC.

Accessory components not installed by the factory carry a (1) one year parts warranty only. Accessory components such as table limit

switches, pressure regulators, pre rinse unit s, etc. that are shipped with the unit and installed at the site are included. Labor to repair or

replace these components is not covered by Jackson MSC.

This warranty is void if failure is a direct result from shipping, handling, fire, water, accident, mi suse, acts of god, attempted repair by unau

thonzed persons, improper installation, if serial number has been removed or altered, or if unit is used for purpose other than it was originally

intended.

TRAVEL LIMITATIONS

Jackson MSC limits warranty travel time to (2) two hours and mileage to (100) one hundred miles. Jackson MSC will not pay for travel time

and mileage that exceeds this, or any fees such as those for air or boat travel without prior authorization.

WARRANTY REGISTRATION CARD

The warranty registration card supplied with the machine must be returned to Jackson MSC within 30 days to validate the warranty.

REPLACEMENT PARTS WARRANTY

Jackson replacement parts are warranted for a period of 90 days from the date of installation or 180 days from the date of shipment from the

factory, which ever occurs first.

PRODUCT CHANGES AND UPDATES

Jackson MSC reserves the right to make changes in design and specification of any equipment as engineering or necessity requires.

THIS IS THE ENTIRE AND ONLY WARRANTY OF JACKSON MSC. JACKSON'S LIABILITY ON ANY CLAIM OF ANY KIND, INCLUD ING

NEGLIGENCE, WITH RESPECT TO THE GOODS OR SERVICES COVERED HEREUNDER, SHALL IN NO CASE EXCEED THE PRICE

OF THE GOODS OR SERVICES OR PART THEREOF WHICH GIVES RISE TO THE CLAIM.

THERE ARE NO WARRANTIES, EXPRESSED OR IMPLIED, INCLUDING FOR FITNESS OR MERCHANTABILITY, THAT ARE NOT SET

FORTH HEREIN, OR THAT EXTEND BEYOND THE DURATION HEREOF. UNDER NO CIRCUMSTANCES WILL JACKSON MSC BE

LIABLE FOR ANY LOSS OR DAMAGE, DIRECT OR CONSEQUENTIAL, OR FOR THE DAMAGES IN THE NATURE OF PENALTIES,

ARISING OUT OF THE USE OR INABILITY TO USE ANY OF ITS PRODUCTS.

ITEMS NOT COVERED

This warranty does not cover adjustments to timer cams or thermostats, cleaning wash arms or strainers, or replacement of wear items such

as curtains, squeeze tubes, drain balls, door guides, or gaskets beyond 30 days from installation of unit. Also not covered are conditions

caused by the use of incorrect (non commercial) grade detergents, excessive supply water temperature or pressure, or hard water

conditions.

Page 3

INDEX

TROUBLE SHOOTING GUIDE

22

FRONT VIEW

25

SPECIFICATIONS 2

ELECTRICAL RATING 2

GENERAL INSTRUCTIONS (Installation) 3

GENERAL INSTRUCTIONS (Operation) 6

GENERAL INSTRUCTIONS Preventive Maintenance) 7

REMOVAL of RINSE and/or WASH HEAD ASSEMBLIES (General Instructions) 8

DEFECTIVE TIMER MOTOR 11

FUNCTION OF SWITCHES, CIRCUIT BREAKER and INDICATING LIGHTS 12

REPLACEMENT OF SWITCHES la FRONT DOOR INTERLOCK SYSTEM 13

CHECKOUT 14

THERMOSTAT ADJUSTMENT 15

RINSE TANK HEATER SYSTEM 16

WASH TANK HEATER SYSTEM 18

WATER LEVEL CONTROL 19

SERVICE INSTRUCTIONS 20

REPLACING SEAL AND CERAMIC for PUMP SYSTEM 21

PICTORIALS

BACK VIEW 26

LEFT SIDE VIEW 27

RIGHT SIDE VIEW 28

PAN STRAINER, VACUUM BREAKER, OVERFLOW and INCOMING PLUMBING 29

RINSE TANK, WA SH ASSEMBLY. WASH OR RINSE THERMOSTAT. WASH or RINSE

THERMOMETER

PUMP and MOTOR ASSEMBLY 31

SWITCHES. DOOR SAFETY SWITCH and SAFETY SWITCH 32

DRAIN VALVE CUTAWAY VIEW and PANEL 33

WIRING DIAGRAMS 34

PARTS LIST 36

PARTS DISTRIBUTORS 38

30

Page 4

SPECIFICATIONS

JACKSON DISHWASHER MODEL 24 B - BP

OPERATING CAPACITY 100% 248

Racks per hour 21

Dishes per hour 525

Glasses per hour 525

OPERATING CYCLE

Wash Time — seconds 120

Rinse Time — seconds 15

Total Cycle — seconds 150

WASH TANK CAPACITY (Gallons) 5.65

RINSE TANK CAPACITY (Gallons) 3

WASH PUMP CAPACITY (GPM) 60

WATER REQUIREMENTS 100%

Inlet Temperature F 140 deg.

Gallons per hour 52.3

Row Pressure, PSI 20

Row, gallons per minute 7.1

Inlet size — IPS 1/2"

Drain size — 0.0. 1 1/2"

WASH PUMP MOTOR (HP) 1/2

WASH HEATER (kw) 1.0

RINSE HEATER (kw) 5.0

ELECTRICAL REQUIREMENTS (See below for details, under Electrical Rating)

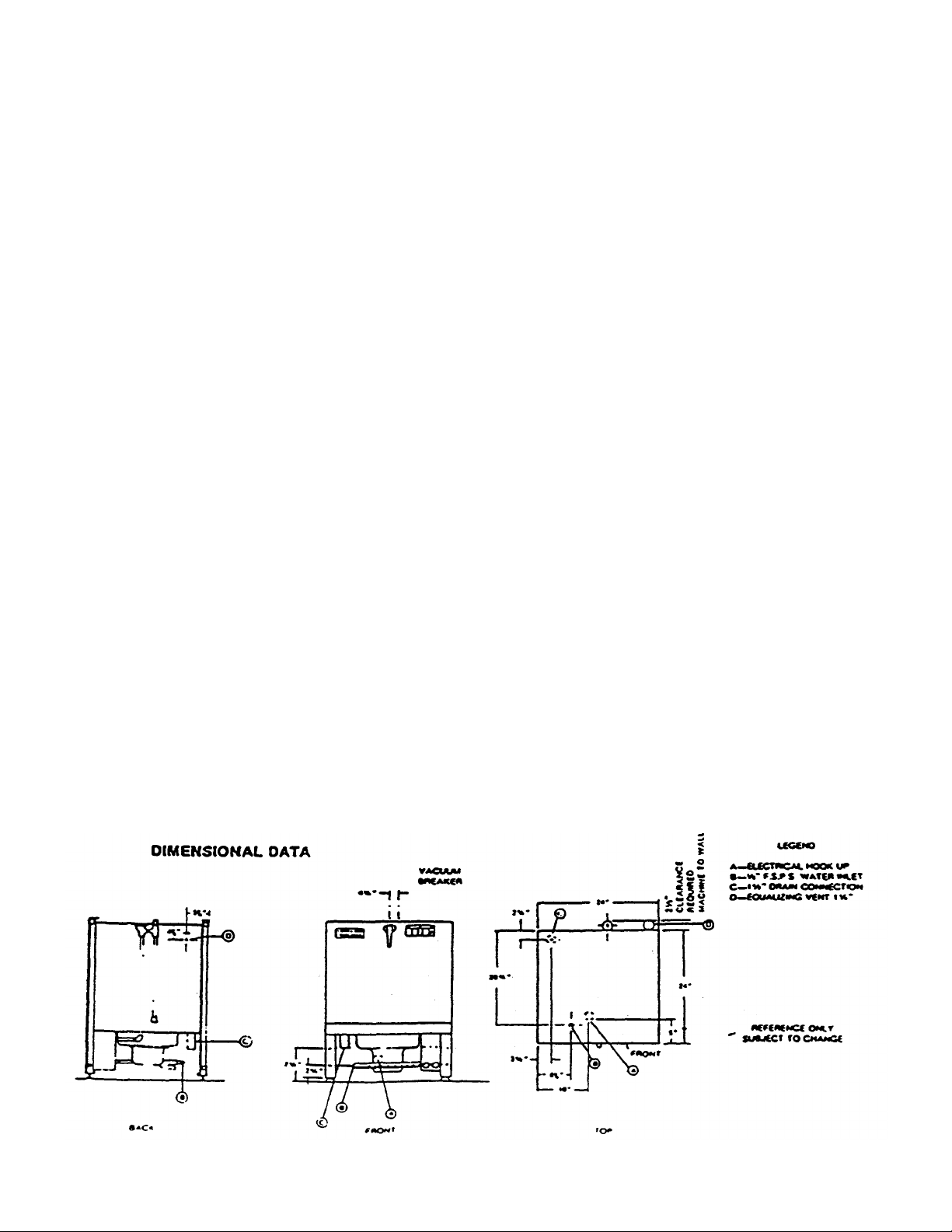

DIMENSIONS

Height with Top 36"

Height with no Top 34 1/2 "

Width 24"

Clearance, Wall to Machine 2 1/4"

Depth 24"

Maximum Height for Dishes 14"

Rack Size 19 3/4"

NOTE VENTED BACK

•ALL "F" MODELS ARE FREE STANDING (Top and Side Panels)

ELECTRICAL RATING

MODEL VOLTS CYCLE PHASE APPROX. TOTAL LOAD AMPS

24B 220 60 1 35 Refer to

248 208 60 1 35 Machine Data

248 208/220 50 1 28 Plate

Specifications subject to change without notice.

Page 5

GENERAL INSTRUCTIONS

(INSTALLATION)

Note: Read the following instruction carefully. Proper Installation of your Jackson

Dishwasher will assure proper machine operation.

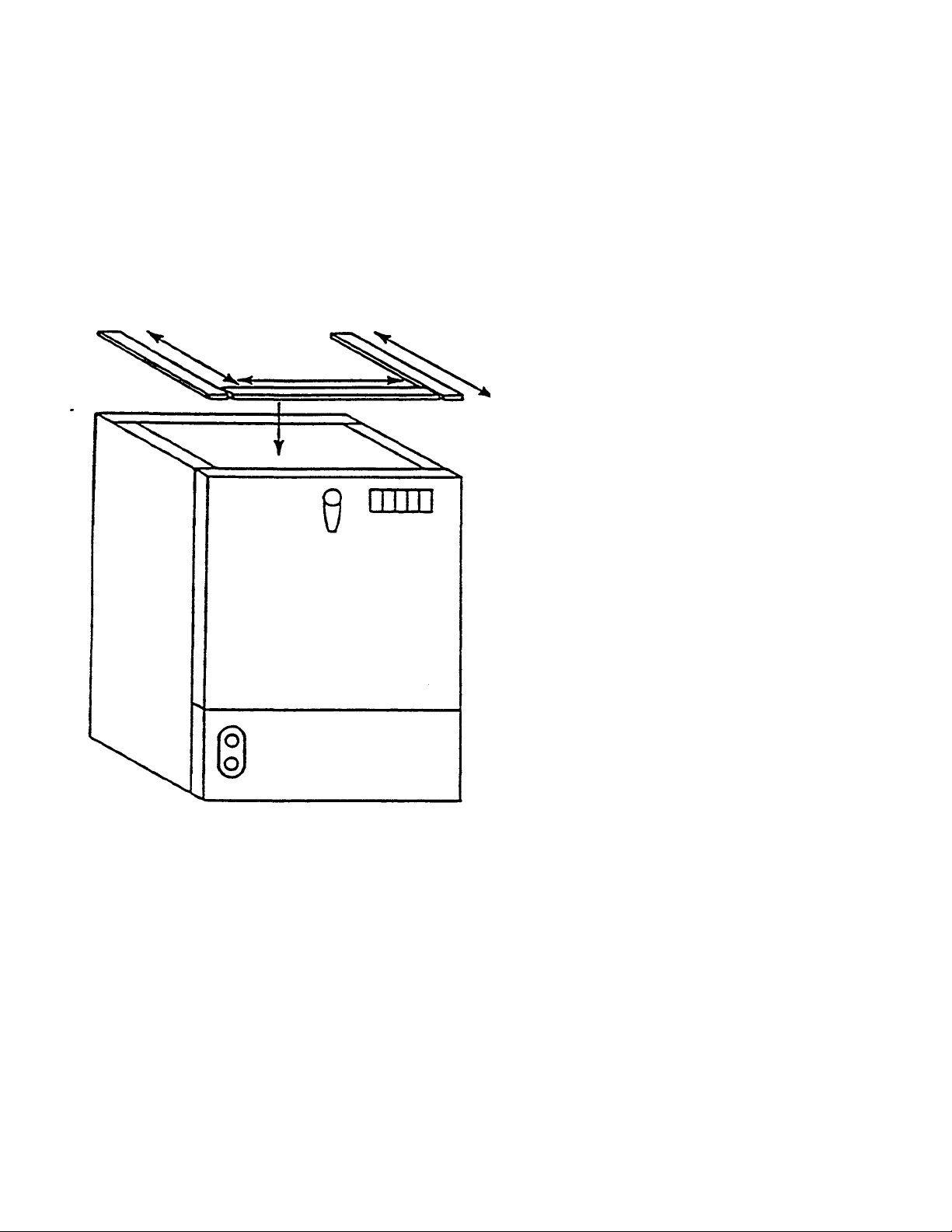

Uncrating 24:

1. Remove straps around carton.

2. Open top flaps of dishwasher carton.

3. Remove any packing from top and sides of machine that can be done with ease from top.

4. Slide carton sleeve upward over top of dishwasher, set to one side.

5. Lift dishwasher and wooden base from carton base.

6. Move dishwasher to general installation area.

7. Remove bolts holding wooden base to machine and screw In adjustable feet supplied.

8. Reassemble wash and rinse assemblies In machine using sketch and Instructions In this

manual.

9. Set dishwasher In place, ready for Installation.

Note: NSF base cradle Installation must be add Installed on all AF and BF models. Cradle goes

around bottom; secure la place using liquid adhesive.

Installation Instructions:

1. The dishwasher can be leveled to the proper height by adjusting the adjustable feet on the four

comers. The front of the unit should be 1/4" to 1/2" higher than the back.

2. Refer to the dimensional data sketch for connections.

3. The drain from the machine is a GRAVITY DRAIN SYSTEM and should, therefore, have the proper

drop from the machine to the kitchen's drain system. The drain connection is located to the left

rear of the machine when facing the machine's door. The drain fitting Is 1 1/2" 00 tube size, 7"

from floor.

4. IMPORTANT-PLEASE READ-Located on the back upper left comer of this unit Is a steam

equalizing vent. This vent in no way should be blocked off or prevented from allowing steam to

be vented to the outside of the unit or from under the cabinet In which the unit Is Installed.

Never pipe the steam downward toward the floor. (SEE PAGE 4 IF BEING INSTALLED UNDER A

COUNTER.)

5. The electrical connections should be made to the terminal board located at the left center front.

The terminals are marked LI. and NeutraL Install proper circuit breaker. wire and conduit size to

conform with local and/or national codes (standards).

Page 6

Installation of Model 24 Top and Table gasket

These Instructions are to be used for applying the adhesive backed sponge rubber strip to the top of

the machine prior to setting the table in place.

Included with the Model 24 table is a 6 foot length of 1/4 " thick x 1" wide sponge rubber

adhesive backed stripping.

Instructions for applying gasket:

1. Place one end of the tripping along the complete

side of the tog support flange and cut It off.

2. Repeat the same procedure along the other side.

3. Place the remaining piece along the front edge, fit

It In between the aide pieces and cut It to length.

4. Remove the backing and set the strips in place.

Instructions for Installation under a porous counter

top:

1. If possible, a hole should be cut through the

counter top directly above the equalizing vent. A

piece of 1 1/4" OD pipe Is then Inserted through

the hole into the vent opening and piped to the

outside.

2. If cutting a hole In the counter Is not possible,

then a piece of stainless steel 36" wide by 36"

long bend In the middle at 90 deg. should be

centered directly over the vent to allow the steam

to condensate on It when It comes out of the

vent.

3. It Is very Important that this vent be kept open and

cool air allowed to circulate around the unit.

Installation of Model 24 Dishwasher Under Dishtable:

1. On the end of the table, locate bracket #4 opposite the sink end.

2. A square rubber gasket #3 Is supplied and should be secured to top frame of dishwasher

with caulk or suitable adhesive.

3. Place dishtable #2 where It Is to be Installed and support the machine's end.

4. Slide dishwasher #1 underneath dishtable #2 so that the outside of machine Is

positioned against the guide bracket #4. Make sure dishtable and dishwasher are In desired

permanent location.

Page 7

5. Using the two holes In bracket #4 as a guide, drill two holes 9/64" diameter In the side panel

of machine. Note: Drill through first thickness of metal only.

6. Using the self-tapping screws supplied, screw them through bracket #4 and Into the side

pane l of machine until screws are tight

Removal of Pan Strainer for Cleaning: (Wash and rinse head assemblies must be removed prior to

removing strainer.)

1. Turn heat switch 'off' and drain machine by depressing drain switch for approximately 50

seconds.

2. Remove wing nut from rinse feed pipe, remove rinse head assembly by pulling forward.

3. Remove wing nut from upper pump housing, wash head may now be lifted out.

4. Pan strainer now accessible, lift out and dean thoroughly.

5. Clean around pump Intake with bristle brush.

6. Replace stainer pan.

7. Re -Install wash and rinse head assemblies.

8. Clean strainer pan daily or as needed to insure proper machine operation.

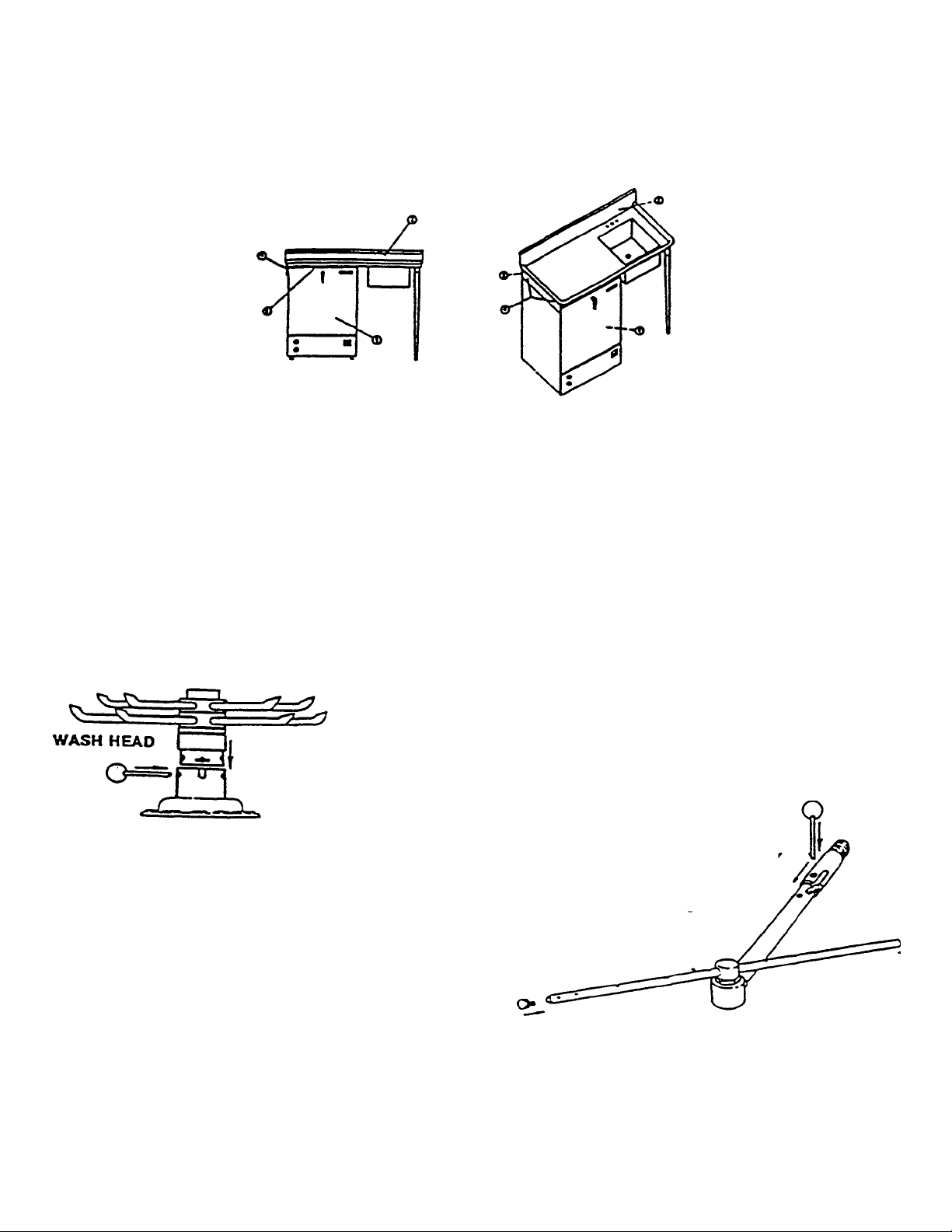

Installation of Wash Head and Rinse Ann Assemblies: (Items disassembled for shipment)

1. Line holes up on wash head assembly to match slots In pump housing.

2. Insert wash head assembly down Into upper pump housing as far as

possible

3. Insert retaining pin to secure wash head to pump housing.

RINSE ARM ASSEMBLE

1. Line up stud to match with slot In nipple.

2. Insert rinse arm assembly into female

recepticle protruding through back of

machine.

3. Insert lanyard pin to secure rinse arm

assembly properly.

4. Make certain end plugs are secured property

In rinse tubes.

Page 8

GENERAL INSTRUCTIONS

(OPERATION)

Note: Read the following instructions carefully. Proper operation of your Jackson

Dishwasher will assure clean and sanitized glasses and dishes, at optimum efficiency.

Dish Preparation:

1. Scrape dishes thoroughly.

2. Pre -wash dishes by soaking or with hose.

3. Place dishes and cups In dish rack, cups upside down.

4. Place glasses and silverware la combination glass-silverware rack. glasses upside down.

Scatter silverware loosely on bottom.

Note: Silverware In the upright position washes and rinses better than lying flat. These

silverware compartment racks an available through your dealer or Service Agency.

Operators Instructions:

1. Make sure dean pan strainer Is In place and slide empty rack In machine.

2. Place st art rocker switch In center position.

3. Close door and lock latch.

4. Push top of fill switch and hold approximately 45 seconds.

5. Turn heater switch on.

6. Open door and slide rack of dishes Into dishwasher.

7. Dispense proper amount of detergent In machine.

8. Start automatic wash and rinse cycle of dishwasher by pushing on top or bottom of start

switch (with indicating light): light will come on.

9. When light goes out, cycle has ended, Open door, slide out rack of clean dishes to air dry,

slide In rack of dirty dishes, add detergent, close door and push start switch.

10. At end of mealtime, shut off by placing start rocker switch In center position and heater

switch off, Drain machine by pressing top of drain switch approximately 50 seconds,

Remove pan strainer after removing lower rinse arm and wash head assembly. clean inside

of machine and replace clean strainer, wash head and lower rinse arm assembly. (See page

on Installation of Wash Head and Rinse Arm Assemblies — Removal of Pan Strainer for

Cleaning.)

Detergent Recommendations and Rinse Additives:

We suggest that you contact your local Detergent Specialist for the correct detergent and rinse

additives tor your area. To help you until one can be reached, we suggest that you use a nonfoaming dishwasher detergent, approximately three tablespoons in wash tank when machine Is

filled and one teaspoon each cycle or load thereafter. This may have to be increased or

decreased to obtain satisfactory results.

Page 9

GENERAL INSTRUCTIONS

(PREVENTIVE MAINTENANCE) (THE FOLLOWING IS TO BE

PERFORMED AS NEEDED.)

Note: Read the following Instructions carefully. Proper maintenance of your Jackcon

Dishwasher will ensure optimum service with a minimum of down time.

1. Remove all lime and corrosion deposits.

a. Fill the machine with wash water as would ordinarily be done for washing.

b. Open door and place one cup or less of de -liming compound Into the water. The

compound is available from your detergent supplier.

c. Turn on the manual wash switch and allow to wash for five minutes.

d. Open door and examine the interior. All lime should be removed and parts should

be shiny. If not, allow to wash for longer period.

e. After the Interior Is dean, with door closed, empty the wash water by depressing

drain switch for approximately 50 seconds. Refill machine and allow to run for two

minutes, then again drain the wash reservoir.

2. Clean around overflow strainers and drain hole.

a. Clean around overflow and strainer pan.

b. Clean around pump Intake (toothbrush makes excellent tool for cleaning).

3. Clean Y-strainer on Incoming water line. (Water to machine must be turned off for this

operation)

a. Remove plug and clean strainer.

4. Clean rinse tubes.

a. Remove rinse assembly by disconnecting rinse feed pipe and removing end plugs

on lower rinse.

b. Clean all rinse tubes and feed pipes with special brush supplied.

c. If spray holes in the rinse tubes are clogged, they may be cleaned with a pointed

object

5. Clean wash head assembly.

a. Loosen two wing nuts holding wash head assembly to pump.

b. Clean assembly at sink by flushing water through spray jets.

c. If spray jets are still plugged, use sharp object to dislodge and flush again.

d. Reinstall wash and rinse assemblies. (See page with Instructions.)

6. Clean any deposits which may have built up on exterior moving parts.

a. Clean around door gaske t.

b. Using a soft bristle brush, clean around switches on exterior of control panel. (Use

no water.)

c. Use soft bristle brush, dip in wash tank water and scrub inside door around gasket

and hinges. Use clean cloth or paper towel to wipe off loose residue.

Page 10

REMOVAL of RINSE and/or

WASH HEAD ASSEMBLIES

(GENERAL INSTRUCTIONS)

1. Before opening the door, hold the drain switch in and drain all of the water out of the

unit

2. Open the door and allow the unit a few minutes to cool off.

3. With your fingers, loosen the wing nut holding the rinse feed pipe. When it is loose, pull the

feed pipe out of the nipple and lay It to one side.

4. Locate Allen head set screw in the wash head cap, Insert Allen wrench and loosen screw by

turning counterclockwise.

5. Turn wash head cap counterclockwise until cap Is removed and put cap In safe place.

6. Remove 1/4" stainless ball bearings carefully and put it in a receptacle In a safe place.

7. Life and remove small manifold with short tubes. Put It In a safe place.

8. Remove 1/4" ball bearing In similar method to step 16.

9. Lift and remove large manifold with large length tubes similar to step #7.

10. The lower fixed race may be left in place.

11. Clean ball bearings by soaking in de -liming solution.

12. Ball bearing race ways may be cleaned by either brushing with de -liming solution

(toothbrush makes excellent tool) or gently clean by rubbing with fine sandpaper or emery

cloth.

13. Rinse ball bearings and manifolds thoroughly.

14. To reassemble, first fill lower race to capacity with 1/4" ball bearings, then remove one. This

will give proper movement needed during rotation of assembly.

15. Replace lower manifold and fill race fully with 1/4" ball bearings. Repeat, removing one only.

16. Replace upper manifolds and repeat necessary parts of step #14.

17. Replace wash cap by screwing on center shaft clockwise, finger tight.

18. Back off wash cap about 1/4 turn and tighten Allen set screw.

19. Rotate manifolds in opposite directions: see If they rotate freely. A rule of thumb Is to select

the longest tube in the bottom manifold and make sure It moves up and down at least V

and no more than 1/4".

20. Replace the rinse assembly and pipe by aligning the stud on the feed pipe with the slot in

the nipple. Push the feed pipe in gently as far as It will go and then secure It with the wing

nut.

21. Close the front door and refill dishwasher.

22. Run through several cycles and recheck wash arms for easy movement. Adjust if

necessary.

Page 11

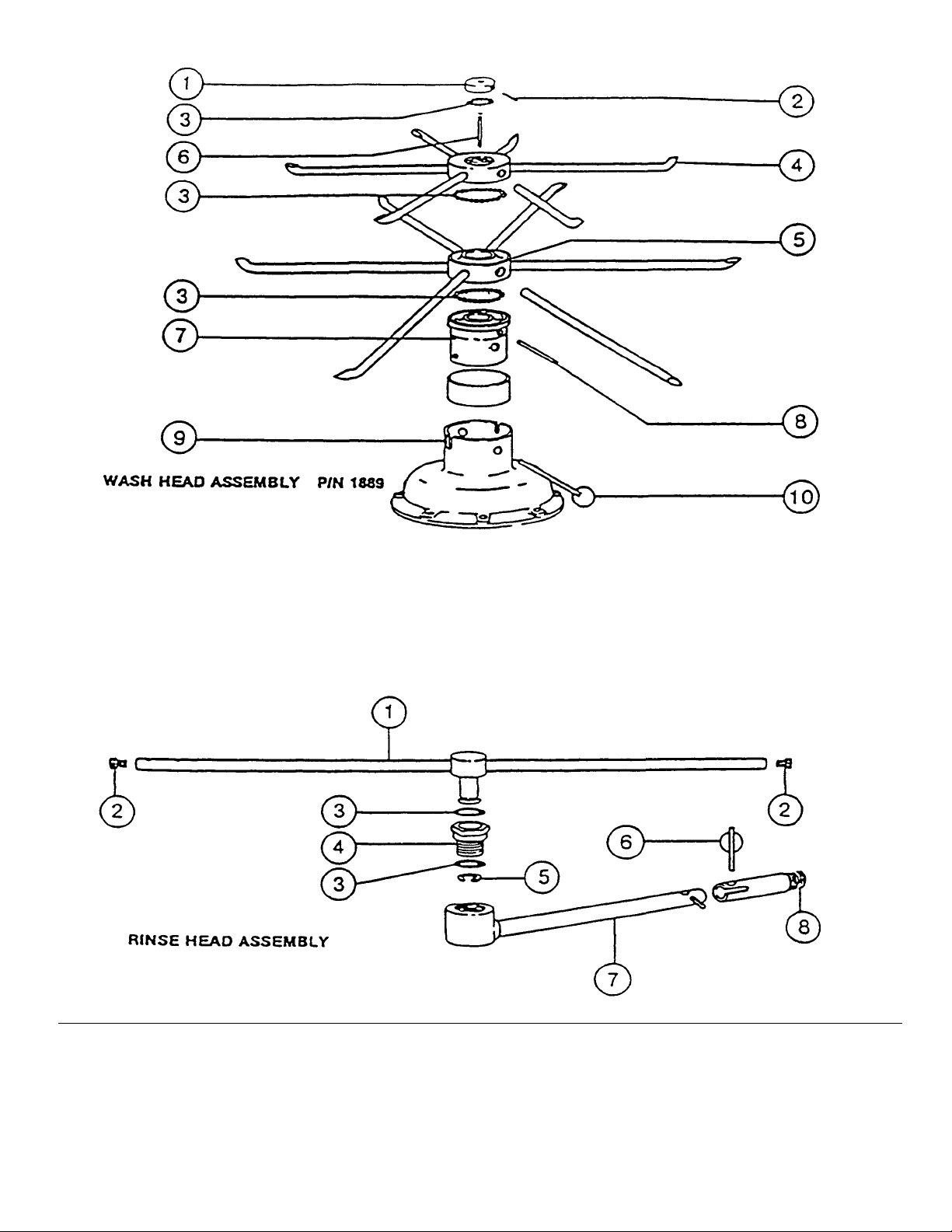

3. 0194004

WASH HEAD BEARING 1/4" S/S

7. 0193600

WASH HEAD FIXED RACE

9. 0109501

UPPER PUMP HOUSING

2. 0126800

RINSE HEAD END PLUGS

6. 0137301

RINSE FEED PIPE LANYARD PIN

ITEM P/N DESCRIPTION

1. 0186500 WASH HEAD CAP WITH RACE

2. 0187000 WASH HEAD CAP SET SCREW

4. 0189000

5. 0189500

WASH HEAD SMALL MANIFOLD

w/TUBES

WASH HEAD LARGE MANIFOLD

w/TUBES

ITEM P/N DESCRIPTION

6. 0187500 WASH HEAD CENTER SHAFT

8. 0188600 WASH HEAD SHAFT HOLDING PIN

10. 0189805

WASH HEAD ASSEMBLY RETAINING

PIN w/RING

ITEM P/N DESCRIPTION

1. 0125200 RINSE HEAD ARM

3. 0126000 RINSE HEAD NYLATRON WASHER

4. 0125500 RINSE HEAD HEX BRUSHING S/S

ITEM P/N DESCRIPTION

5. 0126500 RINSE HEAD SNAP RINGS S/S

7.

8. 0137202 RINSE FEED PIPE NIPPLE

6137200 RINSE FEED PIPE (LOWER)

Page 12

TIMER for MODEL 24

DISHWASHERS

General Description

The timer is a self-contained (frame mounted) timer of the repeating cycle type. It is mounted on

the control panel of Jackson Automatic Dishwashing Machines, to control the automatic

functions of these-machines. It consists of a dock motor which operates on 60 cycle, AC,

110VAC or 50 cycle, AC, 220VAC. In addition to the dock motor, the timer also contains a driven

cam arrangement which operates three micro switches.

Principle of Operation:

The timer controls various operations of the automatic washers as per wiring diagram for each

machine; however, the timing cycle and the micro switches are the same for each model. The

time for One Complete Revolution of the cam shaft Is approximately 300 seconds, allowing two

wash and two rinse operations for each complete revolution of the cam shaft. The micro switch

nearest the timer motor is the hold circuit and uses both the NO and NC contacts. The middle

micro switch controls the wash and uses the NO contact. The micro switch farthest away from

the timer motor controls the rinse and uses just the NC contact

Service Instructions:

Caution: Always remove the power to the machine before working on the control panel or while

servicing the components on the switch panel. All electrical checks should be made by

qualified personnel.

Timer operation can be observed after removing the machine's kickplate by loosening the two

screws holding it.

If It is determined that the timer Is defective. It is recommended that a new timer be installed. If a

new timer is not available, limited field maintenance can be accomplished by changing the micro

switch.

A frozen contact on a micro switch will be indicated If one function of the timer Is being executed

all the time or If there Is an absence of a click when the switch arm is actuated.

To Replace Micro Switch:

1. Remove all wires from the timer, properly tag them to assure proper replacement.

2. Remove the two screws which hold the timer to the control panel.

3. One screw holds the micro switches, cams and actuating arms In the frame. This screw

is seen on the side opposite the motor. Remove this screw.

Note: Be sure to note which cam goes with which micro switch. Cam nearest timer motor has

½ of Its edge raised; center cam has 2 large depressed areas; cam furthest from timer

motor has two smaller depressed areas.

4. The unit can now be taken apart and the defective micro switch replaced.

5. Reassemble.

Note: The flanges on the cams are such that they only mesh in one direction.

The timer's cam drive system is equipped with a clutch to enable one to view the operations of

the cams and micro switches. Remove power to machine before touching timer. Rotate cams by

turning with fingers; cams will turn in one direction only. Do not force them. As cams actuate

switches, listen for the "click"" of the switch or test the switches with an ohmmeter.

Page 13

DEFECTIVE TIMER MOTOR

TIMER

A defective motor is indicated by the fact that the cams do not rotate or the machine does not

perform the automatic operations, or performs a specific part of the cycle conti nuously, but

works okay on manual. Remember, the timer motor is controlled by the start switch and the hold

micro switch; check this complete circuit before changing motor.

To Replace Motor:

1. Remove motor loads from shorting bar and neutral.

2. Remove the two screws which hold the motor.

3. Replace with a new motor.

Note: It may be necessary to remove complete timer to replace motor; If so, foilow steps 1 and

2, previous page.

TYPICAL TIMER SWITCH P/N 1775

A . TO UPPER RIGHT TERMINAL START SWITCH

B . TO LOWER RIGHT TERMINAL START SWITCH

C . TO BOTTOM TERMINAL MANUAL WASH SWITCH

D . TO UPPER TERMINAL OF RINSE SWITCH

E. TO NEUTRAL TERMINAL

F. SHORTING BAR CONNECTED TO ALL THREE TIMER SWITCHES, THIS

TERMINAL

P/N 0171700 (110V, 60 cycle)

P/N 0171800 (220V, 50 cycle)

MOTOR ONLY

Page 14

FUNCTION of SWITCHES, CIRCUIT

ine through the rinse heads. It may

position to operate. The switch when activated causes the drain valve to open and

BREAKER and INDICATING LIGHTS

Start switch:

P/N 0158800

This switch controls the timer motor through two circuits. (See electrical

diagram.) It is a three-position switch, up position = start: middle position = off;

down position = start. To start, flip switch toggle in either up or down position;

Indicating light in center of panel will light verifying automatic cycle has started.

After cycle ends and you are ready to start a new cycle, flip toggle to opposite

position.

Cycle light

Manual wash

switch:

P/N 0155700

Rinse/fill switch-

P/N 0154300

Heat switch:

P/N 0157800

Heat light:

Drain switch:

P/N 0160900

This light comes on only when automatic cycle is in progress and extinguishes

when cycle is complete. It is located In the start switch.

This switch is used to by-pass the timer and operate the wash pump manually.

The wash pump will run as long as this switch is "on". The prime purpose of this

switch is to extend the wash period for extremely soiled dishes before putting

them through the normal automatic cycle. It may also be used as an emergency

back-up should the timer ever fall to operate. The required wash time is Indicated

on the control panel (front).

This switch is spring-loaded and must be held in its up position to operate. When

switch is operated, water Is allowed to fill mach

be used as an emergency back-up in case of timer failure for rinsing dishes. The

required rinse time is Indicated on the front control panel.

This switch applies power to the heat circuits which are composed of automatic

control devices that turn heaters on and off to maintain required temperatures.

This indicating light remains lit all the time the heat switch is on. It is located in

the heat switch.

This switch controls the manual draining of the unit at the end of a meal period or

at the end of the day. It is a spring-loaded switch and must be held in its up

the motor to go Into reverse, pumping the water out of the sump into the drain

line. This switch should be held for approximately 50 seconds.

Page 15

REPLACEMENT of SWITCHES

in FRONT DOOR

There are fly switches installed in the front door. These are the start, drain, manual wash, rinse fill

and heater switches.

Before working on the machine. It is important that the power be turned off at the customer's

circuit breaker to prevent the possibility of electrical shock; trip the breaker to the "Off" position.

The five rocker switches are mounted in a rectangular hole held in position by a bracket. These

switches, are designed to be released from the inside and pushed outward. The spring sides must

be depressed to release the switch and bracket from the hole. To remove the bracket from the

switch, wedge a screwdriver In between them then lift up and move off.

If the switch to found to be defective, mount a ne w one into the bracket and Insert It Into the hole In

the control box. Make sure that the tab on the switch is in the proper notch on the bracket for easy

operation of the switch. Replace the wires from the used switch terminal by terminal on to the new

switch.

Power can now be applied to the dishwasher and run through cycles checking all

operations.

1. CONNECTION TERMINALS

2. BRACKET SPRING SIDES

3. PANEL PLATE

4. BRACKET FRONT

5. ROCKER BUTTON

INTERLOCK SYSTEM

The Interlock System is designed to preve nt the machine from operating when the front door Is

opened or not latched property.

The Interlock System consists of two safety switches, one mounted so that the door latch has to be

closed to complete the circuit. The other switch is located so that a pin on the machine depresses a

safety switch mounted on the door, to complete the circuit. Either of these switches, if not

depressed, will prevent the machine from operating. Basically, the door must be closed and the door

latch locked in order for the machine to function.

Page 16

CHECKOUT

(INTERLOCK SYSTEM)

Note: All eletrical checks should be made by qualified service personnel.

If it's determined that the proper power is being applied to the machine's incoming terminal

blocks, then further check of the safety switch should be made.

Note: This checkout would only be performed if none of the systems of the machine

operate. This would mean that none of the switches, when depressed, will perform

the function noted for that switch.

Example: Drain, fill, start or manual wash switches.

Proceed with checkout

1. Remove power to the machine by turning circuit breaker that protects the machine to "off"

position.

2. Open the front door and remove screws holding inside panel of door.

3. Disconnect one wire from the switch closest to the door latch and using an ohmmeter,

depress the lever of the switch and check that there is continuity across that switch. If

there is no continuity, replace switch.

4. Check second safety switch located in top lefthand comer of door. Remove wire from one

side of the switch and check for continuity with ohmmeter when switch is depressed. If

there is no continuity, replace switch.

5. Replace Inside door panel.

6. Re -apply power & re-check operation.

Page 17

THERMOSTAT ADJUSTMENT

THERMOSTAT

The thermostat can be adjusted by turning screw #1 (see picture) on the thermostat control box

cover. (Remember the present setting, in case the problems are elsewhere in the control circuit.) A

CW rotation is used to obtain a lower temperature setting and a CCW rotation is used to obtain a

higher temperature setting. A 1/4 turn of screw #1 changes the temperature approximately 15 °F. If

screw #1 is turned all the way to its top in either direction, adjust screw #2 as follows.

Note: Do not touch the screw sealed with re d paint. When adjusting screw #2, power should be

disconnected during adjustment.

Set screw #1 so that it can be turned equal distances in either direction, then:

— If screw #1 stopped while turning in CW direction, turn screw #2 in CW direction, slowly and

only 1/4 of a turn or less per complete cycle of the unit.

— If screw #1 stopped while turning in CCW direction, turn screw #2 In CCW direction, slowly

and only 1/4 of a turn or less per complete cycle of the unit.

Three-fourths of a turn will bring the thermostat to approximately the same setting obtained when

screw #1 stopped. Check the present temperature setting before attempting any further

adjustments. Use screw #1 for any further adjustments.

Making large moves In adjusting may cause misalignment, thus increasing chances that further

adjustment cannot be made and thermostat will have to be replaced.

PAST: P/N 1700

PRESENT:

P/N 0170018 - Rinse (Shown)

and 0170023 - Wash

Page 18

RINSE TANK HEATER SYSTEM

Function:

The Rinse Tank Heater System is electrically connected in the circuit with the control system

functioning on 110/130V for 60 cycle and 220/240V (or 50 cycle system and the power system

functioning on 208/230V for both systems. The heat circuit is controlled by a heat switch

(mounted on coat door) and a thermostat (mounted near thermometer) which activates the coil

on the heat relay. When higher temperature is required, power is applied to the heaters when

the contacts of the heat relay are closed. Should the rinse tank thermometer read either too

high or too low, follow checkout below.

Checkout of Heater System for Rinse Tank: (Refer to drawing, Figure #2)

Note: The following checkout should be done by a qualified service person or electrician.

1. Turn off power to machine by tripping circuit breaker to "off" position.

2. Remove front kick plate below door.

3. Make sure rinse temperature is below 180°.

4. Reapply power and observe heat relay (2pole) letter E, figure 2, (next to timer) as heat

switch Is turned on and off several times.

1. If heat relay contacts do not close, with heat switch on:

a. Check power supply at Position 1 on terminal board X. Voltage should be 110VAC

on 60 cycle machine or 220VAC on 50 cycle machine (L1-L2).

b. Check Position 2; voltage should be 110V on 60 cycle machine or 220V on 50 cycle

machine. If not, check switch as necessary.

c. Check Position 3; there should be "zero" volts there. If not. read just thermostat per

thermostat Instructions.

d. If voltage is being applied to Positions 1 and 2, then the relay should be replaced;

coil on relay probably defective.

2. To determine If elements are working:

a. There's an Insulated movable bar on the heat relay across the top of the two

contacts. With an insulated probe, depress the bar and observe rinse thermometer:

the temperature should rise noticeably in a minute or two. If It moves very slowly. It

would indicate that one element Is defective. If It moves consistently higher at a

good rate, the elements are okay.

Note: A check with an amp probe. If available, can be made.

The elements together should draw 20 amps: one element will draw only 10 amps.

Replace element If found defective.

3. If the heat relay closes:

a. Check power supply at Position 4 on terminal board X, right hand view. It should be

220V approx. It not, check circuit breaker at customers panel: replace if defective.

b. Check power at Position 5; voltage should be 220V. If not, check connections and

wires for breaks: replace as necessary.

c. With heat switch on and relay closed, check power at Position 6: voltage should be

220V. If not, replace heat relay.

d. If No. 3 above checks out okay, check at Position 7: voltage should be 220V. If not,

check wiring from heat relay to elements for loose connections or-broken wires:

repair as necessary.

Page 19

E. RELAY

A . HEAT SWITCH

B . WATER LEVEL CONTROL

C . THERMOSTAT

D . (WASH) RING HEATER

F. RINSE HEATERS

G. BUS BARS

X . TERMINAL BOARD

Page 20

WASH TANK HEATER SYSTEM

Function:

The Wash Tank Heater Control system is electrically connected in the circuit to operate on

220V regardless whether system is 60 or 50 cycle. The heat circuit Is controlled by a heat

switch (mounted on front door), water level control (mounted middle of control panel), and

thermostat (mounted near thermometers). When higher temperature is required, power is

applied to the heater element through above controls. Should the wash tank thermometer read

either too high or too low, follow checkout below.

Checkout of Heater System for Wash Tank: (Refer to drawing. Figure 1.)

Note: The following checkout should be done by qualified service personnel or electrician.

1. Ready machine for normal dishwashing operation with wash tank water at proper level

2. Remove front kickplate below door.

Note: Power's still applied to circuit, so be careful.

3. Check power to machine at Position 1; terminal board X should read 110V on 60 cycle, or

220V. 50 cycle machine (L1-L2). If not, check customer's circuit breaker. If defective,

replace.

4. Wash temperature should be 130° or less to proceed.

5. Observe water level control, letter "B" (with front door closed and latched). Turn heat

switch on and off several times. Relay and contact points (Inside clear plastic case on

water level control) should move back and forth.

AA If water level control relay doesn't close, refer to page on Water Level Control's

function and checkout.

BB If water level control relay does close, proceed with heat switch on.

1. Check voltage at Position 1 on terminal board X. Voltage is 110 on 60 cycle machine or

220V on a 50 cycle machine (L1-L2).

2. Check Position 3, Figure 1: there should be no voltage. If there is voltage, then adjust

thermostat (refer to page on Thermostat Adjusting).

3. Check Position 2 at heat switch A. There should be 110V on 60 cycle. There should be

220V on 50 cycle.

4. Check Position 5. Figure 1, voltage should be 220. If not, check Position 8, there should

be 220V.

5. Temperature should rise slowly, a check with an amp probe would indicate If the

element Is drawing the correct amperage. Replace element if defective.

Page 21

WATER LEVEL CONTROL

AS USED ON 24

P/N 0204500 (110V, 60 cycle)

P/N 0205000 (220V, 50 cycle)

Function:

The water level control device to utilized on this machine to automatically control the cutoff of

the wash tank heater when water drains from the wash tank.

Note: All electrical checks should be made by qualified service personnel.

The control is designed to sense when the proper water level is maintained. At this time, the

relay in the clear plastic case will activate, closing the circuit to the thermostat which

completes the wash tank heat circuit as it closes. If one of the following problems exist, this

unit should be checked out as shown below.

Symptoms of Leve l Control Failure:

1. Wash heater circuit Is not activated with water at proper level (up to overflow level on

overflow pipe) In wash tank.

2. Wash heaters remain on when water drained from wash tank. (Sometimes caused by

deposits on probe)

Proceed with Checkouts:

1. Remove power source to machine by moving circuit breaker to "off" position.

2. Remove screws holding lower kick plate on front of machine and locate water level control

(sketch below).

3. Remove, mark and Insulate, for easy replacement, wires going to letters C & H.

4. Re -apply power, turn on heat switch. With an insulated wire. connect Jumper wire between

terminals C & H (24 volt system).

5. If relay operates, (he water level control action can be deemed operational; then other

causes sh ould be explored.

6. If relay doesn't operate, replace control.

7. Remove power source once again and replace wires that were removed in step three to

original terminals (see trouble shooting section for other possible causes).

Page 22

SERVICE INSTRUCTIONS

P/N

0143500 (60

cycle)

(INCOMING WATER SOLENOID VALVE)

SOLENOID VALVE

P/N 0142000 (110V, used on 60 cycle machine)

P/N 0142500 (220V, used on 50 cycle machine)

To take the valve apart

Disassembly — These valves may be taken apart by

unscrewing the bonnet and the enclosing tube

assembly from the valve body assembly. See Fig. 3.

After unscrewing, carefully lift off the bonnet and

enclosing tube assembly. Don't drop the plunger. The

"O" ring seal and diaphragm cartridge can now be

lifted out.

Be careful not to damage the machined faces while

the valve is apart

To Reassemble — Place the diaphragm cartridge in

the body with the pilot port detention UP. Hold the

plunger with the synthetic seat against the pilot port.

Make sure the "O" ring is in place, then lower the

bonnet and enclosing tube assembly over the

plunger. Screw bonnet assembly snugly down on the

body assembly.

P/N 0144000 (50 cycle)

DIAPHRAGM CARTRIDGE

Possible Problems

Pilot Port extension #1 clogged

Hole #2 clogged

Remedy

Pass heated straight pin through hole #2

or clean hole #1

Page 23

SEAL and CERAMIC for

1.

MOTOR

PUMP SYSTEM

(GENERAL INFORMATION)

The wash and drain pump are part of the total motor pump system. One seal and ceramic are

utilized to prevent the pump from leaking.

Replacement of Seal and/or Ceramic:

1. Drain machine either by depressing drain switch or by balling out

2. Turn Incoming power to machine off.

3. Open door — remove dolly, racks, rinse head assembly and wash head assembly.

4. Remove kickplate (located under front door).

5. Unplug motor at connector

6. Loosen eight screws holding pump in sump tank.

7. Disconnect drain hose from motor (must be done from underneath machine).

8. Pull motor and pump gently upward and move from side to side as required to remove unit.

(Old machine motor removed downward.)

9. Set pump and motor on bench and proceed.

10. Loosen eight screws holding upper pump housing, and remove housing.

11. Remove diffuser plate.

12. Loosen Impeller screw and remove Impeller.

13. Remove suction adapter plate.

14. Remove drain Inlet plate.

15. Remove propeller.

16. Remove mounting plate from motor (loosen 4 phillips head screws on bottom of plate).

17. Knock out old seal carefully and clean hole, re -insert new seal.

Note: Be sure not to ruffle edges of seal when inserting. Seal should contact all

resting surfaces at one time.

18. Ceramic is imbedded In propeller and normally does not wear or need replacement but

check for cracks.

19. Re -install motor and pump by reversing above process.

2. MOUNTING PLATE

3. STATIONARY SEAL

4. SHIM WASHERS

ON MOTOR SHAFT

5. CERAMIC

6. DRAIN PROPELLER

Page 24

TROUBLE SHOOTING GUIDE

PROBLEM

Water overflow out bottom of front door

when wash pump Is operating.

CAUSE

Machine not level

Overflow drain clogged.

SOLUTION

Level machine.

Slight tilt to rear

Remove obstruction, checking

Inside of machine fIrst

Wash motor doesn't operate on manual

wash.

Note: The motor starting relay Is utilized to insert a starting fiel d In the wash pump motor, once the motor has gained

speed, the running winding will then take over and the starting winding will be removed when the relay ki cks out.

This relay Is the amperage sensing type.

Motor runs on manual wash but doesn't

operate on automatic (rinse operates

okay on both manual and automatic

cycles.)

Water level in machine's wash reservoir

too high.

Detergent foaming.

Equalizing vent blocked.

Wires broken or loose.

Defective manual wash switch. Replace.

Bad bearing, noticeable by noisy bearings

or locked drive shaft.

Defective motor starting relay. (Typical •

motor hums.)

Defective center micro switch of

timer.

Defective circuit in manual wash

switch.

Solenoid valve not closing at end of

fill or rinse cycle causing excessive

water problem.

Reduce quantity of detergent

Allow free steam flow.

Check all wires In the motor a

reconnect as necessary.

Replace.

Replace.

Replace switch.

Replace switch.

No water comes through the rinse arms

when the rinse fill switch is depressed.

Little or no water coming through rinse

assemblies.

Hand water valve to machine not turned

on.

Defective coil on solenoid valve. Replace coil.

Broken or loose wires. Repair or reconnect.

Defective manual rinse (ill switch. Replace.

Limed up rinse heads or piping.

Water pressure low. Increase pipe size to machine

Turn on water valve.

Begin-by cleaning rinse head using

instructions (or de-lime If this isn't

satisfactory, there clean the rinse

feed pipes.

Page 25

TROUBLE SHOOTING GUIDE

PROBLEM CAUSE SOLUTION

Rinse doesn't operate on automatic

during timed cycle (but does operate

on manual rinse/fill operation).

Rinse water runs continuously with

circuit breaker controlling machine

turned off.

Micro switch defective (this is the micro

switch furthest from the timer motor on the

timer assembly).

Rinse fill switch defective on N.C. contacts,

Defective plunger in solenoid valve. Replace plunger.

Defective diaphragm in solenoid valve.

Note: In disassembling solenoid valve, use instructions shown on separate page.

Rinse water runs continuously with

power applied to machine, but when

circuit breaker to machine is turned off,

water stops.

Defective rinse/fill switch.

Defective timer that has

stopped in a position

keeping the rinse on.

Replace.

Replace.

Check both holes in diaphragm cartridge

to Insure that they are open, The one on

the outside perimeter should be the size

of an ordinary straight pin. If it's not,

heat a straight pin and put It through this

hole to enlarge. If this falls to correct

situation, replace diaphragm.

Replace.

Replace timer motor or

timer as necessary

Note: Excessive water line pressure can cause water to continually run even though the power to the machine is turned off.

Check specifications for required pressure.

Wash temperature not at required

reading on thermometer.

Note: Any switches, water level controls, heater elements, relays or contactor that have to be checked out, can be

done using the heater checkout system page.

Defective micro switch on timer assembly.

Defective thermometer.

Rinse temperature not at required

temperature, causing wash

temperature to be lowered during

rinse cycle.

Replace.

Using a thermometer (fast reading type

that's known to be correct). Insert in

wash rerservoir and check reading

against wash thermometer on machine.

If machine thermometer isn't correct

within three or four degrees, replace.

Check out rinse heat using heater

checkout system page in manual.

Page 26

TROUBLE SHOOTING GUIDE

PROBLEM CAUSE SOLUTION

Heater switch defective. Replace.

Rinse water not at required

temperature range.

After filling machine with water,

leakage began at lower front panel

without machine operating or at end of

rinse cycle.

Water level protection control defective. Replace.

Heater element defective. Replace.

Wires loose or burned off. Retighten or Replace.

Thermometer's defective. Replace.

Heater switch defective.

Thermostat defective.

Defective heater relay on contactor.

Overflow drain clogged. Clean away obstruction.

See page on heater system

checkout

Adjust using instructions on

thermostat page and heater

system's checkout page. Replace if

necessary.

If defective, replace. See note on

heater system above.

Machine doesn't drain when drain

switch is depressed.

Note: The drain pump of this machine is part of wash motor, so if wash motor operates property drain system should

work.

Drain solenoid dogged.

Defective switch.

Defective motor or motor start relay. Replace.

Defective drain solenoid. Replace.

Remove obstruction.

Replace.

Page 27

FRONT VIEW

2.

SWITCHES

4. 0125100

RINSE ASSEMBLY, UPPER

6. 0005700

BOOSTER TANK

7.

0060200

HEATER ELEME

NTS 8. 0142500

SOLENOID (220V, used on

50

cycle machines)

9. 0185000

VALVE FOR HEALTH INSPECTOR GAUGE

13. 01700

18 RINSE THERMOSTAT

ITEM P/N DESCRIPTION

1. 0051200 DOOR HANDLE ASSEMBLY

3. 486 FRONT DOOR (NLA)

4A. 0125200 RINSE ASSEMBLY, LOWER

5. 0188900 WASH ASSEMBLY

8. 0142000 SOLENOID (110V, used on 60 cycle machines)

10. 0153600 "Y" STRAINER

11. 0030500 ELECTRIC PANEL

12. INCOMING WATER CONNECTION

0170023 WASH THERMOSTAT

14. 0169100 THERMOMETERS

Page 28

2. 0108200

PUMP

&

MOTOR ASSEMBLY (220V,

50

cycle)

5. 0185900

EQUALIZING VENT

ITEM P/N DESCRIPTION

1. 0184101 VACUUM BREAKER ASSEMBLY

2. 0108100 PUMP & MOTOR ASSEMBLY (110V, 60 cycle)

3. DRAIN—GRAVITY FEED

4. 0005700 BOOSTER TANK

6.

BACK VIEW

INCOMING WATER CONNECTION

Page 29

2. 0051200

DOOR HANDLE ASSEMBLY

3.

0048700

FRONT DOOR, OUTER

6. 0083400

ADJUSTING FEET

9. 0142400

DRAIN SOLENOID VALVE (110V, used on

60

cycle machine)

9. 0142200

DRAIN SOLENOID VALVE (220V, used on

50

cycle machine)

ITEM P/N DESCRIPTION

1. 0184101 VACUUM BREAKER ASSEMBLY

4. 0054900 KICK PANEL

5. INCOMING WATER CONNECTION

7. 0108100 PUMP & MOTOR ASSEMBLY (110V, 60 cycle)

7. 0108200 PUMP & MOTOR ASSEMBLY (220V, 50 cycle)

8. DRAIN—GRAVITY FEED

10.

LEFT SIDE VIEW

SIDE FRAME & BRACE

Page 30

RIGHT SIDE VIEW

2. 0125100

RINSE ASSEMBLY, UPPER

2A. 0125200

RINSE ASSEMBLY, LOWER

4. 0188900

WASH ASSEMBLY

6. 0083400

ADJUSTING FEET

8. 0048700

FRONT DOOR OUTER ONLY

9.

0051200

DOOR HANDLE ASSEMBLY

ITEM P/N DESCRIPTION

1. 0184101 VACUUM BREAKER ASSEMBLY

3. SIDE FRAME & BRACE

5. 0005700 BOOSTER TANK

7. 0054900 KICK PANEL

10. 0054700 OPTIONAL TOP

Page 31

ITEM P/N DESCRIPTION

3. 0185000

VALVE FOR HEALTH INSPECTOR

1. 0153600 "Y" STRAINER

2. REMOVABLE FILTER

4. 0142000

4.

5.

0142500 SOLENOID VALVE 1/2" (220V, used on 50

SOLENOID VALVE 1/2" (110V, used on 60

cycle machine)

cycle machine)

PIPE UNION

Page 32

ITEM P/N DESCRIPTION

3. 0060200

BOOSTER HEATER ELEMENT

5.

HEATER COUPLINGS

6. WATER INLET

8.

WATER OUTLET

2. 0125200

RINSE ASSEMBLY, LOWER

3. 0188900

WASH ASSEMBLY

4.

WASH RESERVOIR

1. 0005700 BOOSTER TANK

2. 0058900 BUS BAR

ITEM P/N DESCRIPTION

1. 0056900 WASH TANK RING ELEMENT

5.

HOLES FOR WASH TANK

ELEMENT

4.

7. THERMOMETER COUPLING

THERMOSTAT COUPLING

Page 33

10. 0108501

IMPELLER FOR WASH PUMP

11. 0109501

TRUSS HEAD SCREW

13A. 0108400

GASKET

17. 0189700

WING NUT

21. 0108601

MOUNTING CLIPS

ITEM P/N DESCRIPTION

1. 0108100 MOTOR AND PUMP ASSEMBLY

2. 0108501 MOUNTING PLATE

3. 0108501 STATIONARY SEAL ASSEMBLY

4. 0109001 SHIM WASHERS

5. 0108501 ROTATING CERAMIC

6. 0108501 PROPELLER FOR DRAIN PUMP

7. 0109501 "O" RING SEAL

8. 0109501 DRAIN INLET PLATE

9. 0109501 SUCTION ADAPTER PLATE

12. 0109501 DIFFUSER (ALSO 1087)

13. 0109501 UPPER PUMP HOUSING (ALSO 1096)

14. 0193600 WASH HEAD BOTTOM ADAPTER AND FIX RACE

15. 0109700 FILL HEAD MACHINE SCREW (SHORT)

16. 0109800 FILL HEAD MACHINE SCREW (LONG)

18. 0188600 WASH HEAD SHAFT HOLDING PIN

19. 0108602 SEALING WASHERS

20. 0108400 PUMP GASKET

NOT SHOWN 0108600 PUMP TINNERMAN KIT (INCLUDES START

AND ITEM NUMBERS 14,15, 16,17, 18 (COMES WITH 0108100

(also 0109000-IMP only)

Page 34

4. 0155700

MANUAL WASH

-

SPST

ITEM P/N DESCRIPTION

1. 0158800 START—SPDT (lighted)

2. 0154300 RINSE FILL—SPDT (momentary)

3. 0157800 HEATER— DPST (lighted)

5. 0160901 DRAIN DPDT (momentary) 6-TERM.

5A. 0160900 DRAIN TPDT (momentary) 9-TERM.

SWITCHES

Page 35

ITEM P/N PANEL DESCRIPTION

2. 0170018

THERMOSTAT, RINSE

3. 0165600

TERMINAL BOARD, INCOMING ELECTRICAL CONNECTION

4.

0120701

STARTING RELAY (110V, for

60

cycle machine)

5. 0205000

WATER LEVEL CONTROL (220V, for

50

cycle machine)

6.

0121000

HEATER RELAY (110V, for

60

cycle machine)

7. 0171700

TIMER (110V, for

60

cycle machine)

8.

GROUND LUG

1. 0169100 THERMOMETERS, WASH & RINSE

2A. 0170023 THERMOSTAT, WASH

4. 0120900 STARTING RELAY (220V, for 50 cycle machine)

5. 0204500 WATER LEVEL CONTROL (110V, for 60 cycle machine)

6. 0120900 HEATER RELAY (220V, for 50 cycle machine)

7. 0171800 TIMER (220V. for 50 cycle machine) MOTOR ONLY

9. 0121300 MOTOR RELAY

Page 36

Page 37

Page 38

COMPLETE PARTS LIST FOR MODEL 24

0005700

Booster Tank (stripped) for

24B

1

0030500

Control Panel, wired (lower front) for 24B (specify

50

or

60

cycle machine)

1

0047200

Door, complete, stripped (obsolete)

1

0047300

Door, front, outer only, stripped (ob

solete)

1

0047400

Door insert, inner only, stripped

1 0051200

Door Handle Assembly

1

0051300

Door Handle Cam

1

0044700

Door Handle Cam Nut

2

0052300

Door Gasket

1 0052400

Door Gasket, Clamp Assembly

1

0053400

Drain Hose

-

Pump to Solenoid Valve,

Short

1

0053500

Drain Hose Clamps

4

0053600

Drain Hose

-

Solenoid Valve to Drain, long

1 0054400

Door Spring

2

0054600

Enclosure Panel, lefthand side

1

0054700

Enclosure Panel, top

1

0056900

Heater Element

, ring

-

style, 1000W, 220V

1

0058900

Heater Bus Bar, 2

-

hole, copper

2

0060200

Heater Element, short, 220V. 2500W

2 0060700

Heater Element, short, 208V,

2500W

2

0084300

Probe, Lundy, small

1

0108100

Pump Assembly, complete with motor, 115V,

60

cycle

1 0108200

Pump Assembly, complete with motor, 220V,

50

cycle

1

0108400

Pump Gasket

1

0108501

Pump Propeller Mounting Plate and Seal Assembly, kit

1 0108700

Pump Diffuser (only) NLA use

0109501

Kit

1

0109000

Pump Impeller, kit

1

0109501

Pump, Up

per Housing, kit

1

0109600

Pump, Upper Housing, (only) NLA use

0109501

kit 1

0109800

Pump Fill Head Machine Screws, long

4

0110200

Rack Trolley, movable, s/s (obsolete)

1

1003600

Rack, square,

19 3/4

x 10 3/4" (cup, bowl, glass)

1

0120500

Relay, 110V, 2

-

pole, HW Heat Circuit

1

0120701

Relay, 110V, Motor Starting

1 0120900

Relay, 220V, Motor Starting, (for

50

cycle machine)

1

0121000

Relay, 220

V, 2-pole. HW Heater Circuit, (for

50

cycle)

1 0121300

Relay Motor

1

0125100

Rinse Head Assembly, upper

1

0125200

Rinse Head Assembly, lower

1

0126800

Rinse Head End Plug

2

0125700

Rinse Head, upper. Dual Syste

ms (obsolete)

2

0126500

Rinse Head, Snap Ring,

sis 2

0130100

Lower Feed Pipe Knurled Holding Screw

1

0134000

Rinse Head Brush, Tube Cleaning

1 6137200

Rinse Head Feed Pipe, lower

1

0137301

Rinse Feed Pipe Lanyard Pin

1

0138700

Rinse Head Spray Nozzle, Dual System

6

0054500 Enclosure Panel, righthand side 1

0109700 Pump Pill Head Machine Screws, short 4

1003500 Rack, square, 19 3/4 x 19 3/4" (dish-molded) 2

0125500 Rinse Head, Hex Bushing 2

0126000 Rinse Head, Nylatron Washer 2

0137202 Rinse Feed Pipe Nipple 1

Page 39

COMPLETE PARTS LIST FOR MODEL 24

6142300

Drain Valve Kit, Includes Valve, Bracket, Hoses

1 0142400

Drain Valve, Dole 1/2 110V, (Valve only)

1

0143500

Solenoid Valve Coil.

1

10V, JE

1 0144000

Solenoid Valve Coil, 220V, JE (for

50

cycle machine)

1

0145000

Solenoid Valve Diaphragm Cartidge

& "0"

Ring, JE

1

0147500

Solenoid Valve

"0"

Ring

.JE 1 0148500

Solenoid Valve, Plunger Assembly, JE

1 0149500

Solenoid Valve, Strainer Screen, JE

1

0153100

Strainer, Pan

-

Type

1

0155700

Switch, Manual Wash (Rocker

-

type)

1

0157800

Switch, Heat (Illuminate

d rocker

-

type)

1

0158800

Switch, Start (Illuminated rocker

-

type)

1

0160901

Switch, Drain (Rocker

-

type),

9

Term.

1 0160900

Switch, Drain, 6 Term.

1 6161000

Switches wired w/harness

1 0164100

Switch interlock (side or latch)

1

0169100

Thermometer,

36"

Cap., Rinse

1

0170018

Thermostat, Rinse,

180 deg.,

fixed

1

0170023

Thermostat, Wash

150°,

fixed

1

017170

0 Timer, 115V w/wires,

60

cycles

1

0171800

Timer, 220V w/wires,

50

cycles, Motor Only

1

0172200

Timer Motor, 115V, for Module

-

Type Timer

1

0

184600

Vacuum Break

er, Sloan, Float and Seal Repair Kit

1 0186500

Wash Head Cap w/Race

1 0187000

Wash Head Cap Set Screw

1

0188600

Wash Head Holding Pin

1

0188900

Wash Head Assembly, complete

1 0189000

Small Manifold w/Tubes, Wash

Head

1

018950

0 Large Manifold w/Tubes, Wash Head

1 0199505

Wash Head Knurled Screw

2

0189805

Wash Head Assembly Retaining Pin w/Ring

1

0193600

Wash Head Fixed Race

2

Wash Head Bearings,

1/4" s/s, Pkg of

25

0204500

Water Level Control,

110V, Curtis

1

0142000 Solnoid Valve, 1/2",JE 110V 1

0142200 Drain Valve, Dole 1/2220V, (for 50 cycle machine) 1

0142500 Solenoid Valve, 1/2" JE, 220V, (for 50 cycle machine) 1

0154300 Switch, Rinse-Fill (Rocker-type) 1

0164300 Switch Bracket, for side interlock, use 6051500 1

0177500 Timer Micro Switches, Plastic Module-Type 3

0184101 Vacuum Breaker, Sloan, 1/2 1

0187500 Wash Head Center Shaft 1

0194004

0205000 Water Level Control, 220V, Curtis (for 50 cycle) 1

57

Loading...

Loading...