Jackson 24P-NSU Service Manual

DISHWASHER MODEL 24P-NSU

SPECIFICATION:

440 VOLT - 60 HERTZ - 3 PHASE

HIGH TEMPERATURE SANITIZING

UNDERCOUNTER UNIT

SERVICE MANUAL

DGSC MANUAL NUMBER:

S6161 -A1 -FSC010-17228

INCLUDES:

-Warranty Policy -Installation Requirements

-Operating Instructions -Basic Functions of Dishwasher

-Description of Components -Maintenance and Care

-Troubleshooting Guide -Wiring Diagrams

MANUFACTURING OPERATIONS & WORLD HEADQUARTERS

Highway 25E, P.O. Box1060

Barbourville, KY 40906

888/800-JMSC

Fax: 606/523-9196

January 8, 1999 7610-100-37-00 Rev B

TABLE OF CONTENTS

ILLUSTRATED PARTS LIST

15-23

SPECIFICATIONS 1

INSTALLATION INSTRUCTIONS 2-5

SAFETY PRECAUTIONS 2

UNCRATING 2

INSTALLATION 2

DECK HARDWARE FOR SECURING DISHMACHINE 3

STRAINER INSTALLATION 4

WASH HEAD AND RINSE SPRAY ARM INSTALLATION 5

OPERATION 6

OPERATING INSTRUCTIONS 6

DETERGENT RECOMMENDATIONS 6

CARE AND CLEANING 7-8

GENERAL CLEANING 7

WASH HEAD AND RINSE ARM CLEANING 8

FUNCTIONAL INFORMATION 9-11

SOLID STATE TIMER 9

WATER LEVEL CONTROL 10

SWITCHES, CIRCUIT BREAKER AND INDICATOR LIGHTS 11

SERVICE AND ADJUSTMENTS 12-13

THERMOSTAT ADJUSTMENT 12

INCOMING WATER SOLENOID SERVICE. 13

TROUBLESHOOTING 14-16

PUMP AND MOTOR ASSEMBLY 15

RINSE TANK,WASH ASSY.,THERMOMETERS,THERMOSTATS 16

BOOSTER HEATER, THERMOSTATIC OVERLOAD 17

STRAINER,VACUUM BREAKER/DOOR SWITCH, PLUMBING 18

RIGHT-SIDE ILLUSTRATION 19

BACK-SIDE ILLUSTRATION 20

LEFT-SIDE ILLUSTRATION. 21

WASH AND RINSE ASSEMBLIES 22

DRAIN VALVE AND ELECTRICAL PANEL LAYOUT 23

COMPLETE PARTS LIST AND PART DISTRIBUTORS 24-25

PARTS DISTRIBUTOR LIST 26

WIRING DIAGRAM AND SCHEMATIC 27-28

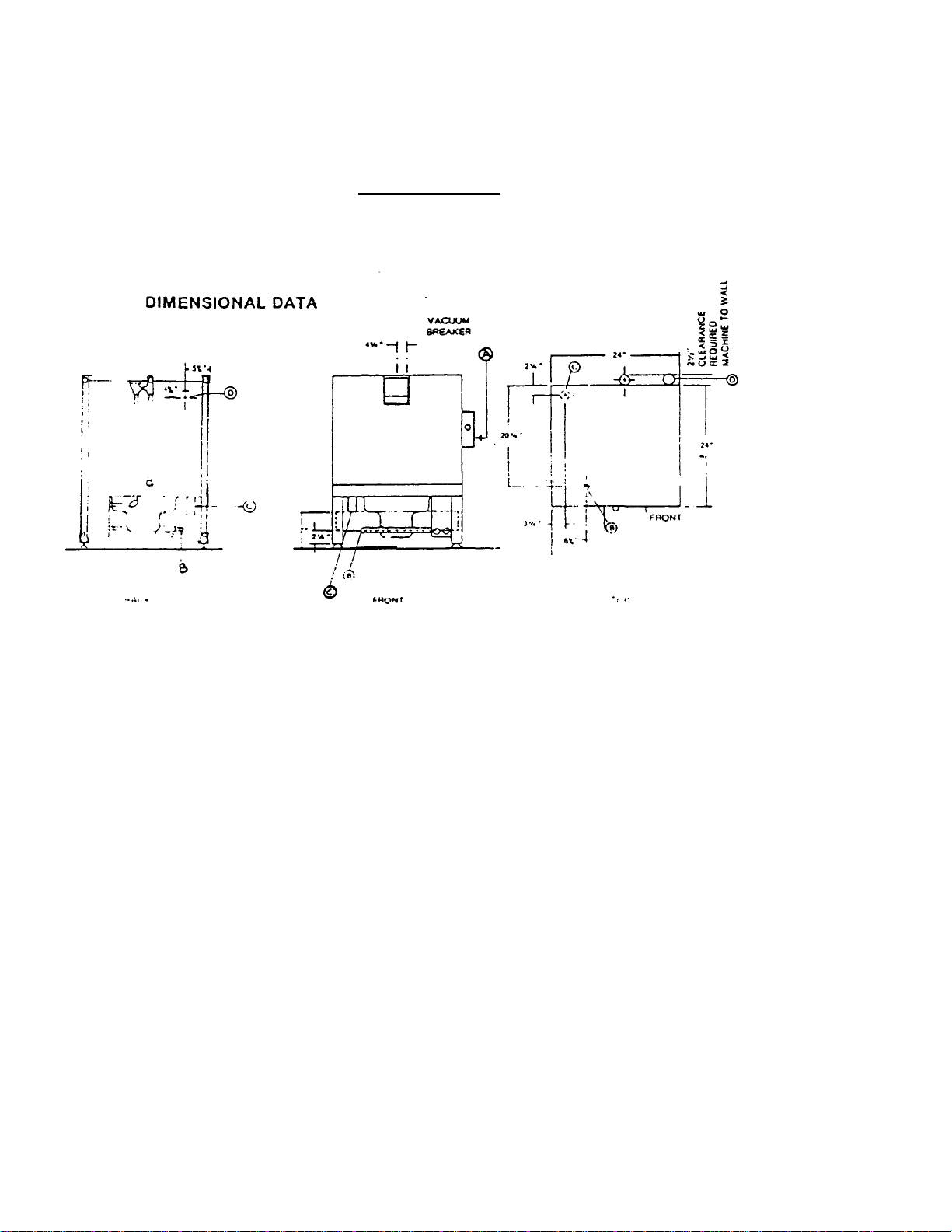

SPECIFICATIONS

OPERATING CAPACITY

Volts

440

Width

28-1/2

Racks per hour 21

Dishes per hour 525

Glasses per hour 525

OPERATING CYCLE

Wash time-seconds 120

Rinse time—seconds 15

Total Cycle-seconds 150

WASH TANK CAPACITY (Gallons) 5.65

RINSE TANK CAPACITY (Gallons) 3

WASH PUMP CAPACITY (GPM) 60

WATER REQUIREMENTS

Inlet Temperature F. 140

Gallons per hour 52.3

Flow pressure, PSI 20

Flow, gallons per minute 7.1

Inlet size, NPT 1/2"

Drain size, OD 1-1/2"

WASH PUMP MOTOR (HP) 1/2

WASH HEATER (KW) 1.0

RINSE HEATER (KW) 6.7

ELECTRICAL REQUIREMENTS

Phase 3

Cycle 60

TOTAL LOAD AMPS. 17.6

DIMENSIONS

Height, with Top 36"

Height, without Top 34-1/2

Clearance, Wall to Machine 2-1/4

Depth 24"

Maximum height for Dishes 14"

Rack size 19-3/4

[ PAGE 1 ]

INSTALLATION INSTRUCTIONS

SAFETY PRECAUTIONS

Never try to repair or replace any part of the dishwasher unless it is

specifically recommended in this manual. All servicing should be done by a

authorized service technician. There are no user serviceable parts. Safety

precautions in this manual are preceded by the words WARNING or CAUTION and

are very important. WARNING means there is the possibility of personal

injury to yourself or others. CAUTION means there is the possibility of

damage to the machine.

UNPACKING AND INSPECTION STEPS:

1. Remove wooden blocks securing carton to skid and lift box up

and off of machine.

2. Remove bolts securing machine to skid.

The following parts are supplied with the dishmachine and are packed inside

of machine:

1. INSTRUCTION MANUAL

2. STRAINER

3. COMPLETE WASH HEAD ASSEMBLY WITH RETAINING PIN

4. COMPLETE LOWER RINSE ARM ASSEMBLY

5. ADJUSTABLE FEET (4 EACH)

6. DECK MOUNTING TRACKS (2 EACH)

7. DECK MOUNTING TRACK CAPS (4 EACH)

8. TUBE BRUSH

9. RACKS (2 EACH)

[PAGE 2 ]

INSTALLATION INSTRUCTIONS

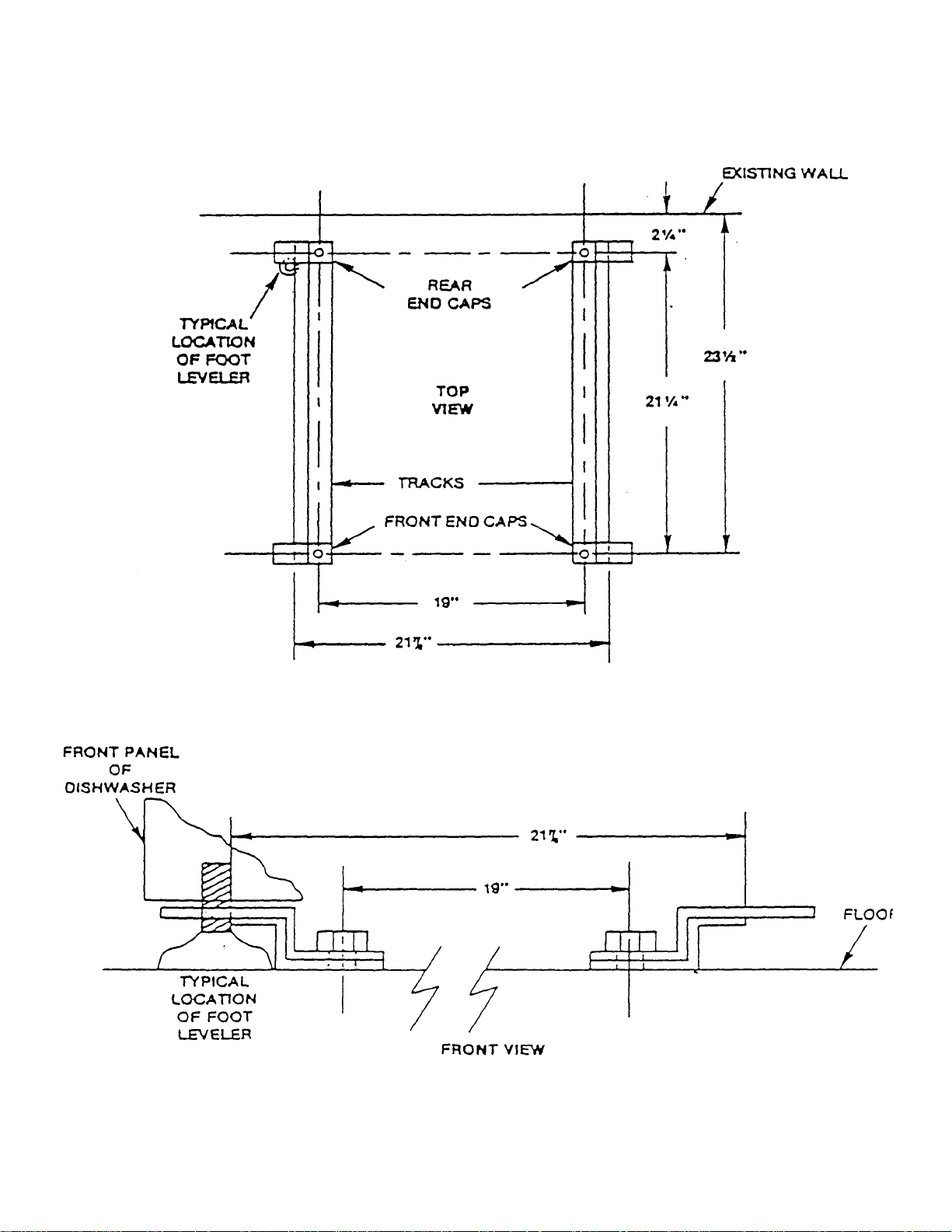

DECK MOUNTING OF DISHMACHINE

The dishmachine must be secured in place using the deck mounting tracks and caps

provided with machine.

STEPS : REFER TO FIGURE 1

1. Install the (4) adjustable feet provided into screw holes where shipping

bolts were removed earlier.

2. Adjust the level of the dishmachine by screwing the adjustable feet in or

out. The front of the machine should be adjusted 1/4" to 1/2" higher

than the back

3. Install the deck mounting hardware as shown in FIGURE 1 to the deck at

location where dishmachine will be permanently positioned. Install 3/8

inch stainless steel lug bolts to secure tracks and caps to deck.

4. Drill holes into deck as shown in FIGURE 1 and

insure rear holes are located 2-1/4 inch from wall.

5. The tracks and the rear end caps maybe tightened at this time.

6. Slide dishmachine onto tracks and into position at rear end caps.

7. Install front end caps into place and adjust if necessary to remove any

movement of machine, if possible, tack weld tracks to deck.

GRAVITY DRAIN SYSTEM

The drain from the dishmachine is a gravity drain system and should have the proper

drop from the machine to floor drain system.

STEPS : REFER TO FIGURE 2

1. Install hose to drain tube located at left rear of machine as shown in

FIGURE 2. Drain tube is 1-1/2 inches in diameter and 7 inches from floor.

[ PAGE 3 ]

FIGURE 1

INSTALLATION OF DECK HARDWARE TO SECURE DISHMACHINE

INSTALLATION INSTRUCTIONS

STEAM EQUALIZING VENT

The steam equalizing vent is located on the back upper left corner of the

dishmachine. The vent should not be blocked or prevented from venting steam

off from inside of unit. Under-counter machines installed inside of cabinet

are not excluded from this requirement.

STEPS : REFER TO FIGURE 2

1. Install 1-1/4 inch pipe to equalizing vent fitting and connect to

appropriate venting system. NOTE: Do not pipe steam line downward

toward floor, this will restrict venting of steam.

ELECTRICAL POWER CONNECTION

WARNING: All field wiring connections must conform to the Local and National

electrical codes. Install proper circuit breaker, wire and conduit size.

MACHINE DATA PLATE is located at top of inner door.

STEPS : REFER TO FIGURE 2

1. Remove control box side panel and lay aside.

2. Make electrical connection through conduit hole provided at rear of

box and connect 440 VOLT, 60 HZ, 3 PHASE service to terminal block marked

LI, L2 and L3. Connect GROUND WIRE to grounding lug provided.

CAUTION: INJURY OR DEATH MAY OCCUR FROM SHOCK IF MACHINE IS NOT PROPERLY

GROUNDED.

WARNING: DO NOT CONNECT WILD/HOT LEG OF 3 PHASE POWER TO LI OR L2 . CHECK LEGS

TO GROUND FOR PROPER VOLTAGES.

[ PAGE 4 ]

FIGURE 2

LEGEND

A—ELECTRICAL HOOK UP

B—1/2"- F.S.P S. WATER INLET

C—1 1/2" DRAIN CONNECTION

D—EQUALIZING VENT 1 1/4"

REFERENCE ONLY

SUBJECT to CHANGE

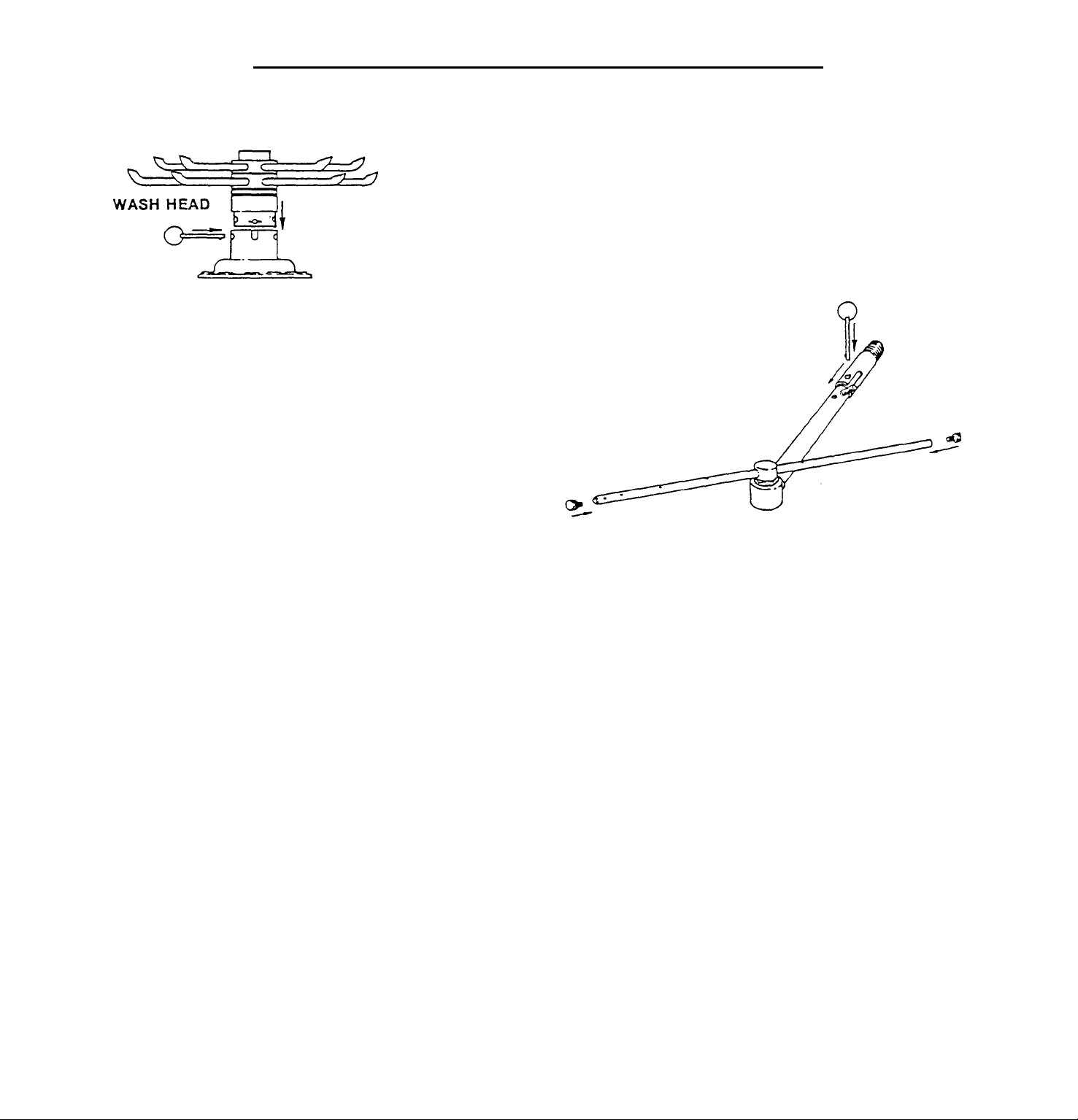

INSTALLATION OF WASH SPRAY HEAD AND RINSE SPRAY ASSEMBLIES

Installation of Wash Head and Rinse Arm Assemblies: (Items disassembled for shipment)

1. Line holes up on wash head assembly to match slots in pump housing.

2. Insert wash head assembly down into upper pump housing as far as possible.

3. Insert retaining pin to secure wash head to pump housing.

RINSE ARM ASSEMBLY

1. Line up stud to match with slot in nipple.

2. Insert rinse arm assembly into female receptacle protruding through back of

machine.

3. Insert lanyard pin to secure rinse arm assembly properly.

4. Make certain end plugs are secured properly in rinse tubes.

[ PAGE 5 ]

GENERAL INSTRUCTIONS

(OPERATION)

Note: Read the following instructions carefully. Proper operation of your Jackson

Dishwasher will assure clean and sanitized glasses and dishes, at optimum efficiency. Dish

Preparation:

1. Scrape dishes thoroughly.

2. Pre-wash dishes by soaking or with hose.

3. Place dishes and cups in dish rack, cups upside down.

4. Place glasses and silverware in combination glass-silverware rack, glasses upside down. Scatter

silverware loosely on bottom.

Note: Silverware in the upright position washes and rinses better than lying flat. These

silverware compartment racks are available through your dealer or Service Agency.

Operating Instructions:

1. Install pan strainer and the wash and rinse arms. Close the door and push until the handle latches.

2. Push the On/Fill-Off/Drain switch to the up 'ON/FILL' position. The machine power light will come on and

so will the rinse heaters. The machine will begin to fill automatically and stop by itself.

3. After the machine has completed filling, open the door and put in a rack of soiled dishes. Close the door.

4. After the door has been closed, the cycle light will come on. There will be a 2-second delay before the

wash cycle begins.

5. The machine will wash for 130 seconds and rinse for 15 seconds. After the cycle has finished, the cycle

light will go out.

6. Open the door and remove the sanitized dishes. The machine is ready for another cycle.

7. To manually wash, push -the manual wash switch to the up 'Manual' position. The machine will wash

indefinitely. This function can also be used to delime. To resume normal operation, push the manual

wash switch to the down 'Auto' position.

8. To drain the machine, close the door and latch. Push the On/Fill-Off/Drain switch to the 'OFF' position.

All machine functions will be off. Push On/Fill-Off/Drain switch down to the momentary drain position.

This will begin the drain cycle. After the machine is drained, it will turn itself off.

9. Open the door. Remove and clean the pan strainer and the wash arms.

10. Wash heater protection is provided by two means. Primary protection is given by the water level control

which senses the water level with a probe. If this should fail due to excessive build up on the probe, the

secondary thermal protection will cut out the was h heater before damage occurs.

11. When the secondary heater protection has been used, it will be indicated by the illuminated red reset

light. The following steps are necessary in this situation:

A. Turn off power supply.

B. Open the door and remove the wash and rinse arms and the pan strainer.

C. Locate the probe. It is in the wash sump on the left hand side.

D. Using a deliming compound and a brush, clean the probe.

E. Reinstall the wash and rinse arms and the pan strainer.

F. Push the reset button, located above the reset light.

G. Push On/Fill-Off/Drain switch to the 'ON/FILL' position. The machine should begin

to fill. If it does not and the reset light comes on again, call an authorized service

agency.

Detergent Recommendations and Rinse Additives:

We suggest that you contact your local Detergent Specialist for the correct detergent and rinse additives for

your area. To help you until one can be reached, we suggest that you use a non-foaming dishwasher

detergent, approximately three tablespoons in wash tank when machine is filled and one teaspoon each

cycle or load thereafter. Dump the detergent on the pan strainer. This may have to be increased or

decreased to obtain satisfactory results.

6

Loading...

Loading...