Installaon

Operaon

and

Maintenance

Instrucons

Built-In

Refrigerator/Freezer

TABLE OF CONTENTS

Secon Page

UNPACKING THE UNIT 1

PRE-INSTALLATION 2

INSTALLATION 3

CORNER INSTALLATION AND INSTALLING TWO UNITS SIDE BY SIDE 4

LEVELING THE UNIT 5

INSTALLING THE CABINET 6

INSTALLING THE MODULE 7

INSTALLING THE ICE MAKER 8

ALTITUDE ADJUSTMENT FOR TEMPERATURE CONTROL 8

INSTALLING THE GRILLE ASSEMBLY 9

HINGE AND GASKET ADJUSTMENT AND FACE MOUNTED DOOR HANDLES 10

INSTALLING THE SIDE PANELS AND KICK PLATE 11

CUSTOM DOOR PANELS AND SPECIFICATIONS 12

CUSTOM GRILLE PANELS AND SPECIFICATIONS 13

TRIMLESS OVERLAY DOOR PANELS AND SPECIFICATIONS 14

TRIMLESS OVERLAY GRILLE PANELS AND SPECIFICATIONS 15

EXTENDED PANELS AND SPECIFICATIONS 16/17

EXTENDED GRILLE PANELS AND SPECIFICATIONS 18/19

GLASS PANEL READY WOOD FRAME DOOR SPECIFICATIONS 20/21

INSTALLING A DOOR FRAME TO THE GLASS DOOR 22

INSTALLATION CHECKS/COMMON ERRORS/TROUBLESHOOTING 23

TROUBLESHOOTING 24

USE AND CARE GUIDE 25/27

WARRANTY 28

Before you begin - Read these instrucons completely and carefully.

IMPORTANT - Save these instrucons for local inspector’s use.

IMPORTANT - OBSERVE ALL GOVERNING CODES AND ORDINANCES.

Note to Installer - Be sure to leave these instrucons with the consumer.

Note to Consumer - Keep these instrucons for future reference.

UNPACKING THE UNIT

Remove Packaging

Your refrigerator/freezer has been packed for shipment

with all parts that could be damaged by movement securely fastened. Before using, be sure all packing materials

and tape have been removed.

Important

Keep your carton packaging unl your refrigerator/freezer

has been thoroughly inspected and found to be in good

condion. If there is damage, the packaging will be

needed as proof of damage in transit.

Note to Customer

This merchandise was carefully packed and thoroughly

inspected before leaving our plant. Responsibility for its

safe delivery was assumed by the retailer upon acceptance

of the shipment. Claims for loss or damage sustained in

transit must be made on the retailer as follows:

• Exterior and Concealed Damage

Any damage must be reported immediately to your retailer.

DO NOT RETURN DAMAGED MERCHANDISE TO THE

MANUFACTURER - FILE THE CLAIM WITH THE RETAILER.

Safety

Protect your kitchen oor. Remove all packing materials from cabinet and if there was no freight damage then

destroy cartoning, plasc bags and any exterior wrapping

material. Children should never use these items for play.

Remove all staples from your carton. Staples can cause severe cuts and destroy nishes if they come in contact with

other appliances or furniture. Carefully read and follow

the child safety precauons in the pamphlet enclosed with

your new refrigerator. It is published by the Associaon of

Home Appliance Manufacturers.

Tools to Have Available for Installaon

• Phillips Screwdriver

• Flat Blade Screwdriver

• 5/16 inch & 1/4 inch Hex head Nut driver

• Level

• Drill and Drill Bit (#6 - .204)

• 7/16 inch & 1/2 inch Open End Wrench

• Pliers

• Adjustable Wrench

• 1/4 inch Open End Wrench

• Tape Measure

1

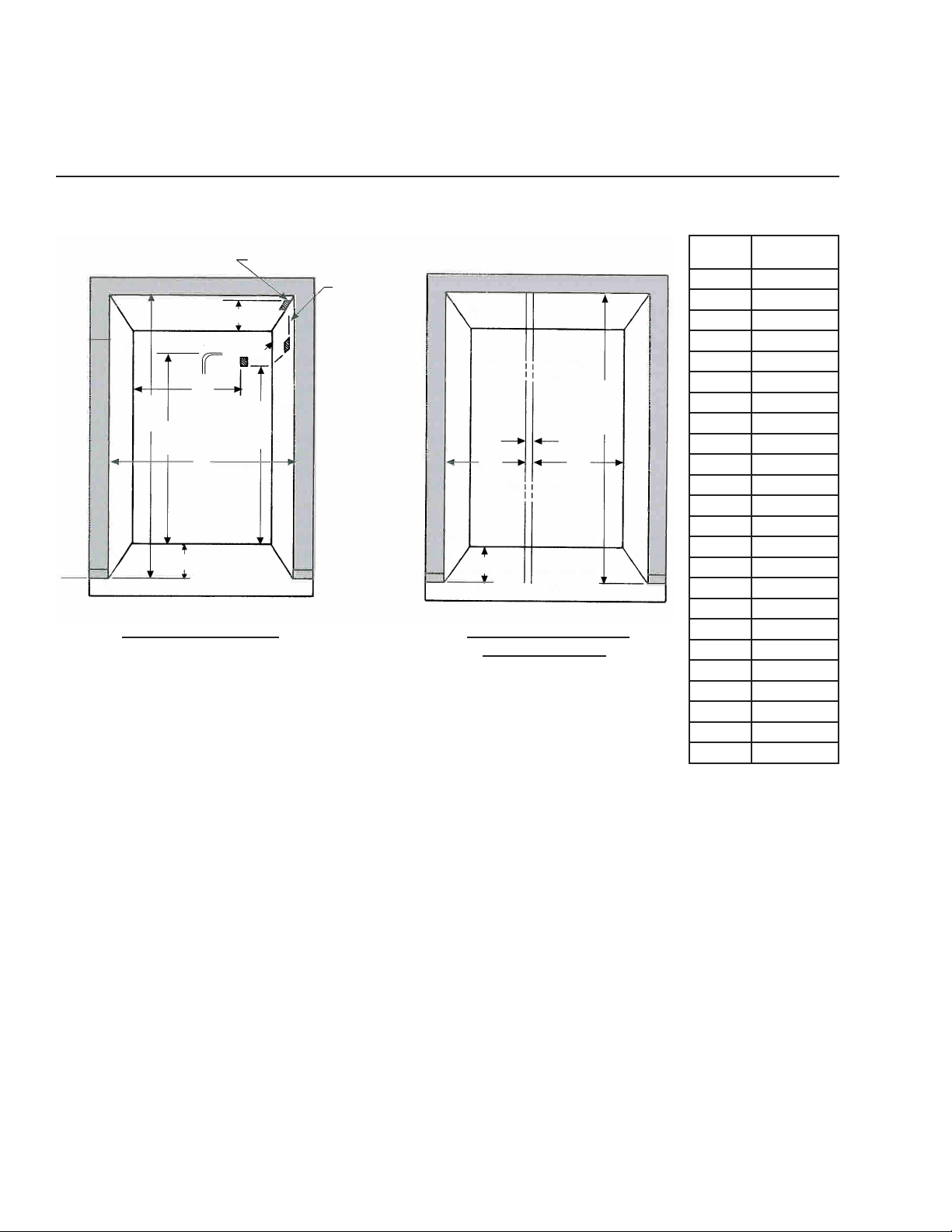

PRE-INSTALLATION

Receptacle must be placed in

this locaon for 18” models.

22”

Ice Maker

Tubing

20”

to

approx.

78”

Min. (typ)

*See note below.

78 1/2”

Min.

(typ)

83 3/4”

84 1/2”

A

24”

Cut-Out Detail for 1 Unit

Cut-Out Width = “A”

22”

83 3/4”

to

84 1/2”

1/2”

A A

24”

*Cut-Out Detail for 2 Units

Placed Side by Side

Cut-Out Width = “A” + “A” + 1/2”

Model

18AR 17 1/2

18AF 17 1/2

18TF 17 1/2

18WC 17 1/2

24AR 23 1/2

24AF 23 1/2

24TF 23 1/2

24WC 23 1/2

24BC 23 1/2

242Z 23 1/2

30AR 29 1/2

30AF 29 1/2

30TF 29 1/2

36AR 35 1/2

36AF 35 1/2

36TF 35 1/2

36SS 35 1/2

363D 35 1/2

42SS 41 1/2

48SS 47 1/2

54SS 53 1/2

60SS 59 1/2

66SS 65 1/2

72SS 71 1/2

Cut-Out Width

(inches)

Floor under product MUST be at or above the same level as the surrounding FINISHED oor, for ease of installaon and

removal.

Electrical: Provide 115 Volt, 60 Cycle, Single Phase, 15 Amp, AC Receptacle. It is recommended that a separate circuit, serving only this appliance, be provided. *Two (2) units side-by-side require separate circuits, except the 60SS and 72SS (see

Instrucon Sheet 34361-000). Electrical opening should be placed 78 1/2 inches minimum from the oor.

Plumbing: Ice maker water supply line (1/4 inch OD copper tubing) to come up the rear of cut-out opening approximately

78 inches o the oor depending on height adjustment. Tubing should then pass around the right side of the module and

around the front to the solenoid valve (see Installaon Instrucons provided with the unit).

NOTE: Allow for three (3) inch high removable ller panel for easy removal of power module.

2

INSTALLATION

Select Locaon

Locate the refrigerator/freezer in the coolest part of the

room, out of direct sunlight and away from heang ducts

or registers.

Do not place the refrigerator/freezer next to heat-producing appliances such as a range, oven or dishwasher. If this

is not possible, a secon of cabinetry or an added layer

of insulaon between the two (2) appliances will help the

refrigerator/freezer operate more eciently.

IMPORTANT

When installing the water line for the ice maker, be sure to

install a SHUT-OFF VALVE at a convenient locaon between

the refrigerator and the supply line.

Required water pressure range is 20 to 120 psi.

Also required is an in-line WATER FILTER between the

refrigerator and the supply line to prevent sediment from

blocking water ow through the water solenoid valve.

NOTE: Self-piercing water valves and plasc tubing are

NOT approved for water supply to ice maker.

Electrical Connecon

The module comes with a 3-prong power supply cord. It

must be plugged into a mang 115 volt, 60 Hz, 15 amp

separately fused, 3-prong grounded outlet serving only

this product, and wired in accordance with Naonal and

Local Electrical Codes and ordinances. A me delay fuse or

circuit breaker is recommended. DO NOT USE AN EXTENSION CORD OR ADAPTER PLUG.

DO NOT REMOVE THE GROUND PRONG FROM THE

POWER SUPPLY CORD UNDER ANY CIRCUMSTANCES!

If voltage varies by 10 percent or more, performance of

your refrigerator/freezer may be aected. Operang the

refrigerator/freezer with insucient voltage can damage

the compressor. Such damage is not covered under your

warranty. If you suspect your voltage is high or low, consult your power company for tesng.

Do NOT pinch, knot, or bend the power cord in any manner.

NEVER unplug the refrigerator/freezer by pulling on the

power cord. Always grip the plug rmly and pull straight

out from the receptacle. To avoid electrical shock, unplug

the refrigerator/freezer before cleaning and before replacing a light bulb.

NOTE: Turning the control to “OFF” turns o the compressor, but does not disconnect power to the light bulb or

other electrical components. The unit MUST be unplugged

or turned o at the circuit breaker.

3

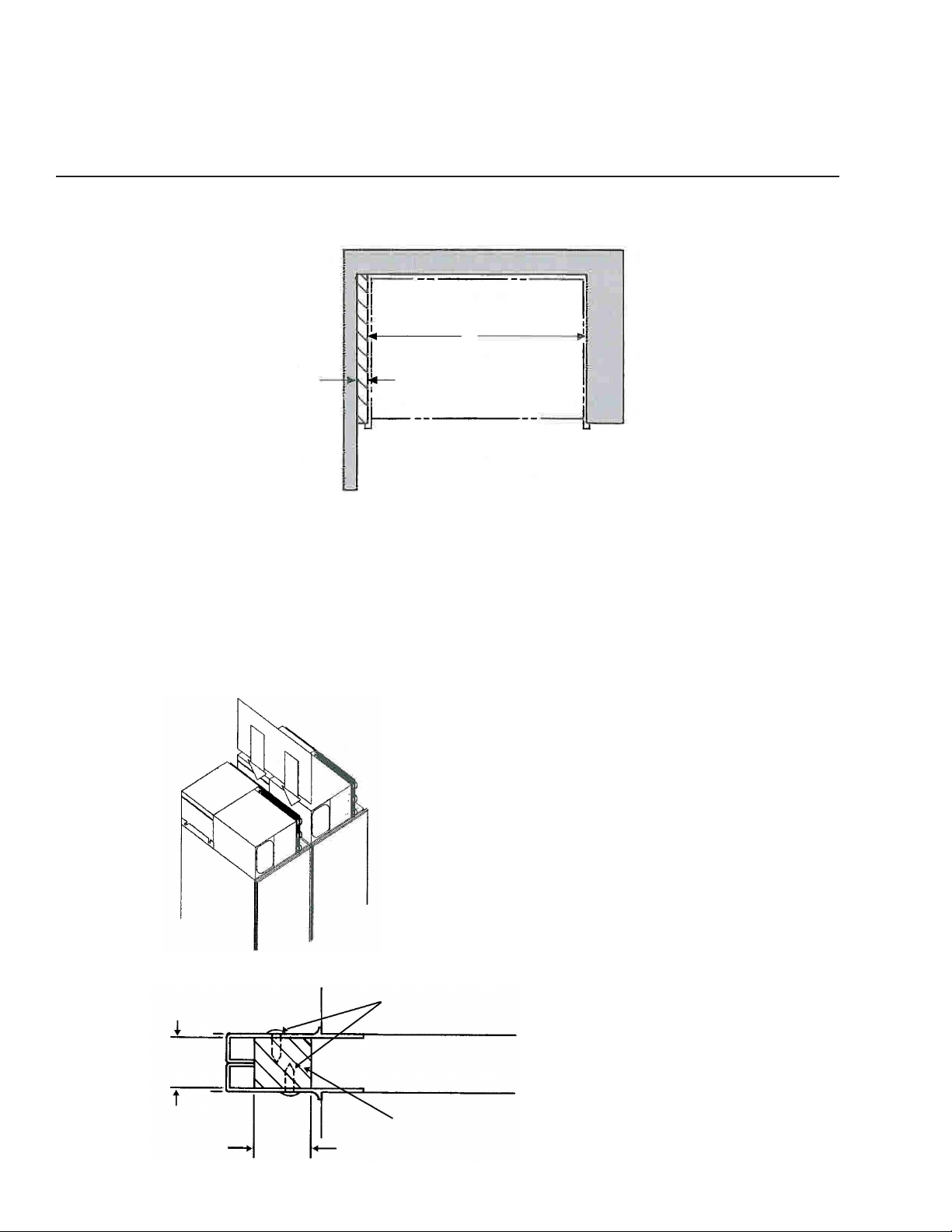

CORNER INSTALLATION AND INSTALLING TWO UNITS SIDE-BY-SIDE

A

1” or

3” Min.

Filler

Enclosure must permit refrigerator to be removed for

service.

PANEL READY UNITS: For corner installaons, a minimum one (1) inch ller must be used as shown above.

Cabinet Outline

7/8”

ANY UNIT WITH FACE MOUNTED HANDLE: Filler must

be three (3) inches minimum.

Installing Two Units Side-By-Side

When two (2) units are installed together, a 23 1/2 inch

x 12 inch (minimum) divider panel needs to be installed

between the two (2) modules (refer to Illustraon) with

self-tapping screws. The divider panel can be made of any

material available, (i.e. 1/32 inch aluminum, 1/8 - 1/4 inch

wood paneling), or you can order Kit # 34747-000 from

the AGA MARVEL Service Department. Locate the divider

panel approximately one (1) inch down from the top of the

cabinet and ush with the back of the cabinet. Drill three

(3) pilot holes approximately 1/2 inch up from the boom

of divider panel, through panel, and into cabinet. Secure

the panel to the cabinet with three (3) screws using pilot

holes previously drilled.

Drill three (3) holes each side equal

distance apart in vercal secon of

aluminum frame and install screws

as shown.

Wood Shim

7/8” x 1” x 68”

1”

• Install wood shim to one of the

cabinets before installing cut-out

cavity (not provided).

• Aer properly installing both

cabinets, drill trim and install pan

head screws (provided).

4

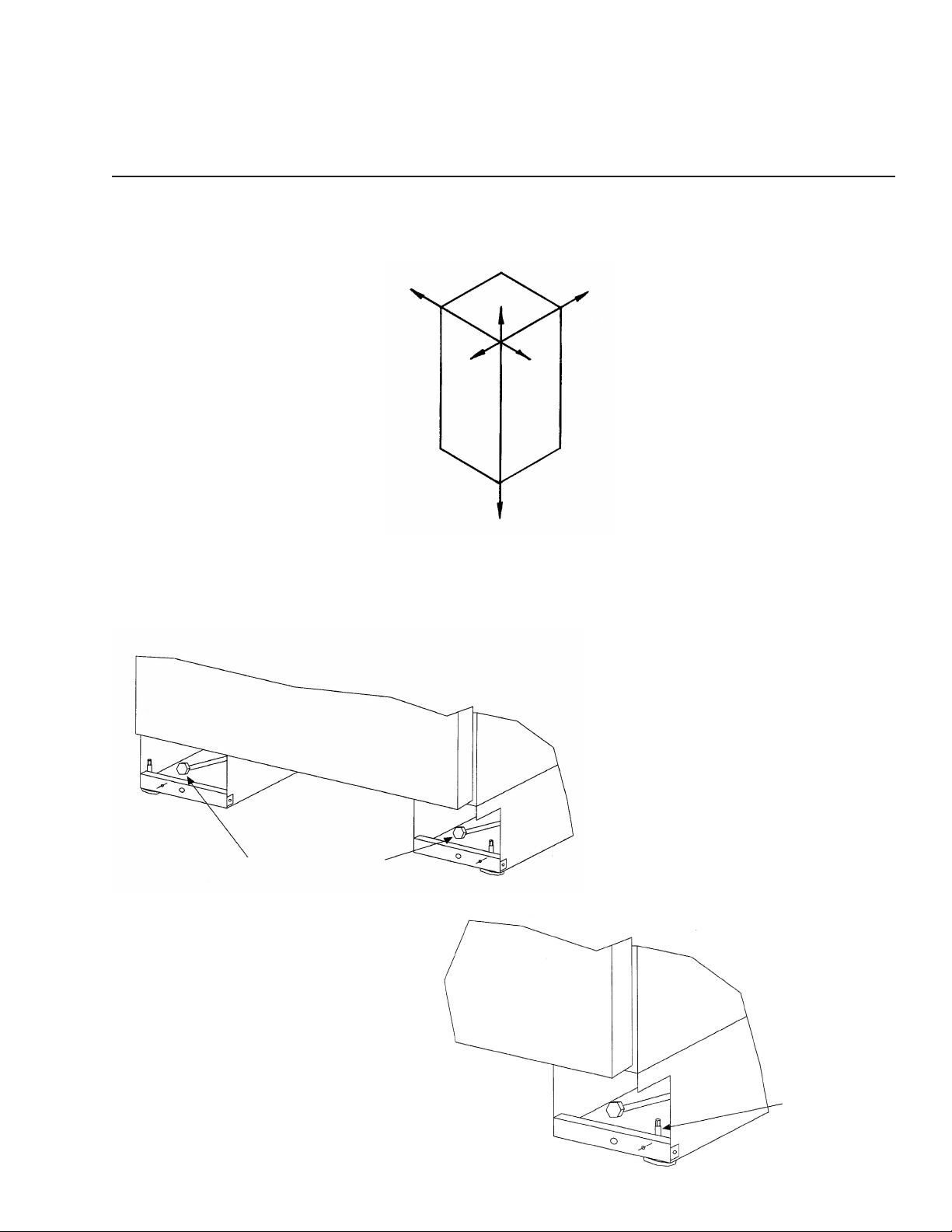

LEVELING THE UNIT

NOTE: Unit MUST be installed level in all planes, on a oor that is strong enough to support a fully loaded

refrigerator/freezer.

This unit is equipped with front and rear rollers. Rollers will aid during installaon. Rear rollers are adjustable from the

front of the unit. Total adjustment is + 5/16, - 5/16. Turn adjusng bolt clockwise to raise cabinet and counterclockwise to

lower cabinet. Front leveling legs must be adjusted to the oor for leveling and to prevent the unit from rolling during use.

Rear Roller Adjustment Bolt

Front leveling leg.

Use 1/4” wrench

to adjust height of

leveling legs.

5

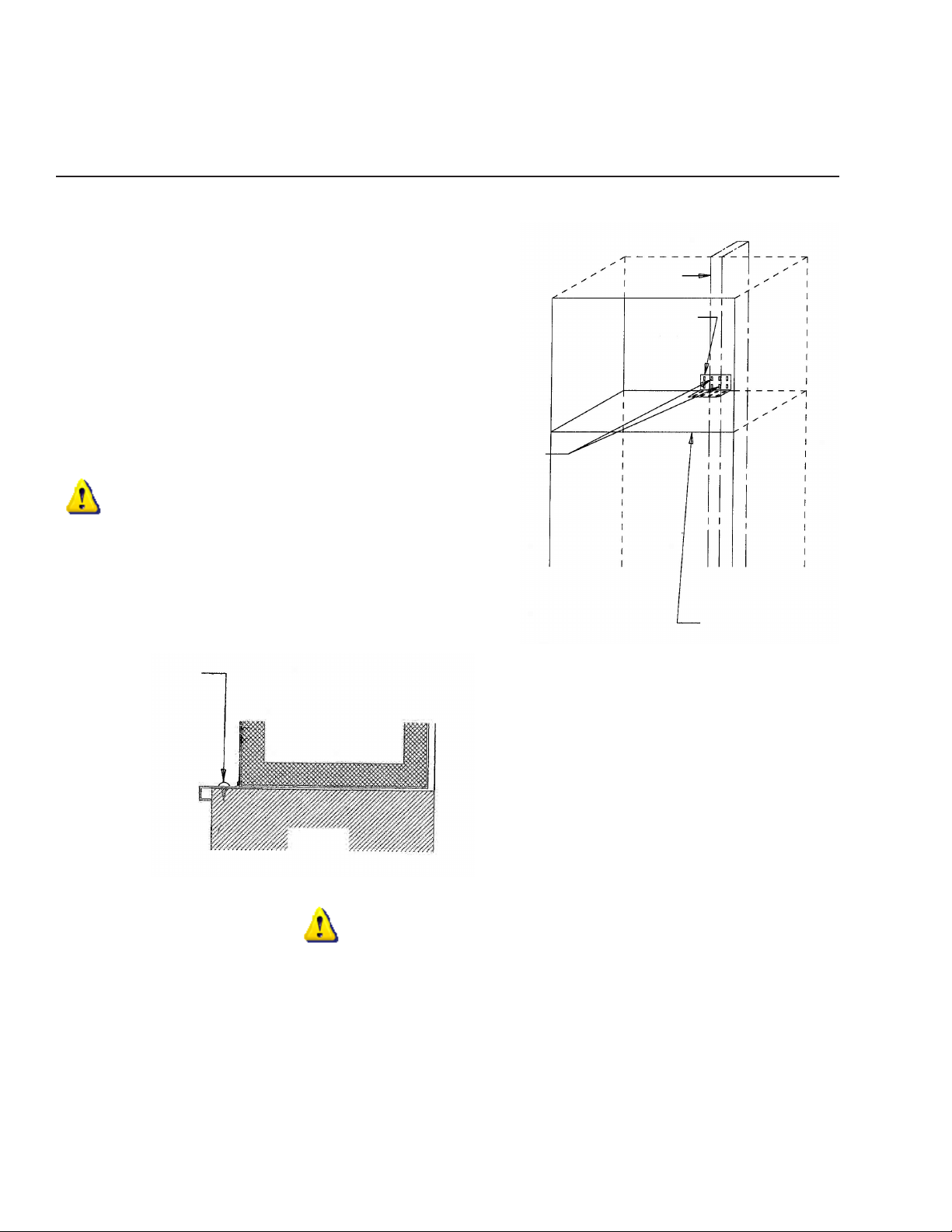

INSTALLING THE CABINET

Before placing the cabinet in opening, the depth of the

cut-out opening should be at least 24 inches. If the cut-out

opening depth is more than 24 inches, then a piece of

wood must be secured crosswise on the wall into the studs

at the height of the an-p bracket. Slide the cabinet into

posion and level the cabinet with adjustable rear roller

and front leveling legs. Locate and mark a center stud in

the back of the cut-out opening for the L-shaped an-p

bracket- (the bracket should t ght to the top of the cabinet). Install at least two screws through the bracket into

the stud located in the wall behind the cabinet. The front

leveling legs also prevent the unit from rolling during use.

Check t of toe kick and grille.

IMPORTANT

Drill and screw through the side trim into adjoining cabinets and/or walls for addional support.

Stud

An-Tip

Bracket

Install at least

two (2) screws

into studs.

Drill three (3) holes equal

distance apart in vercal

secon of aluminum

frame and install pan head

screws as shown.

Refrigerator

Cabinet

Do NOT install an-p bracket over the top of

the power module.

NOTE: 18 and 24 inch wide models have a full

an-p bracket across the back of the units.

The an-p bracket should be aached to the

Finished

Wall or

Cabinets

wall.

IMPORTANT

Recheck cabinet installaon for:

• Proper space le for grille installaon.

• Cabinet levelness.

• Door opening and closing appearance.

• SAFETY...To prevent unit from pping forward:

-Are screws installed securely through front trim

into adjoining cabinetry and/or walls?

-Is an-p mounng bracket secured to wall studs?

Cabinet Top

Aer above checks have been made, proceed with refrigeraon installaon.

6

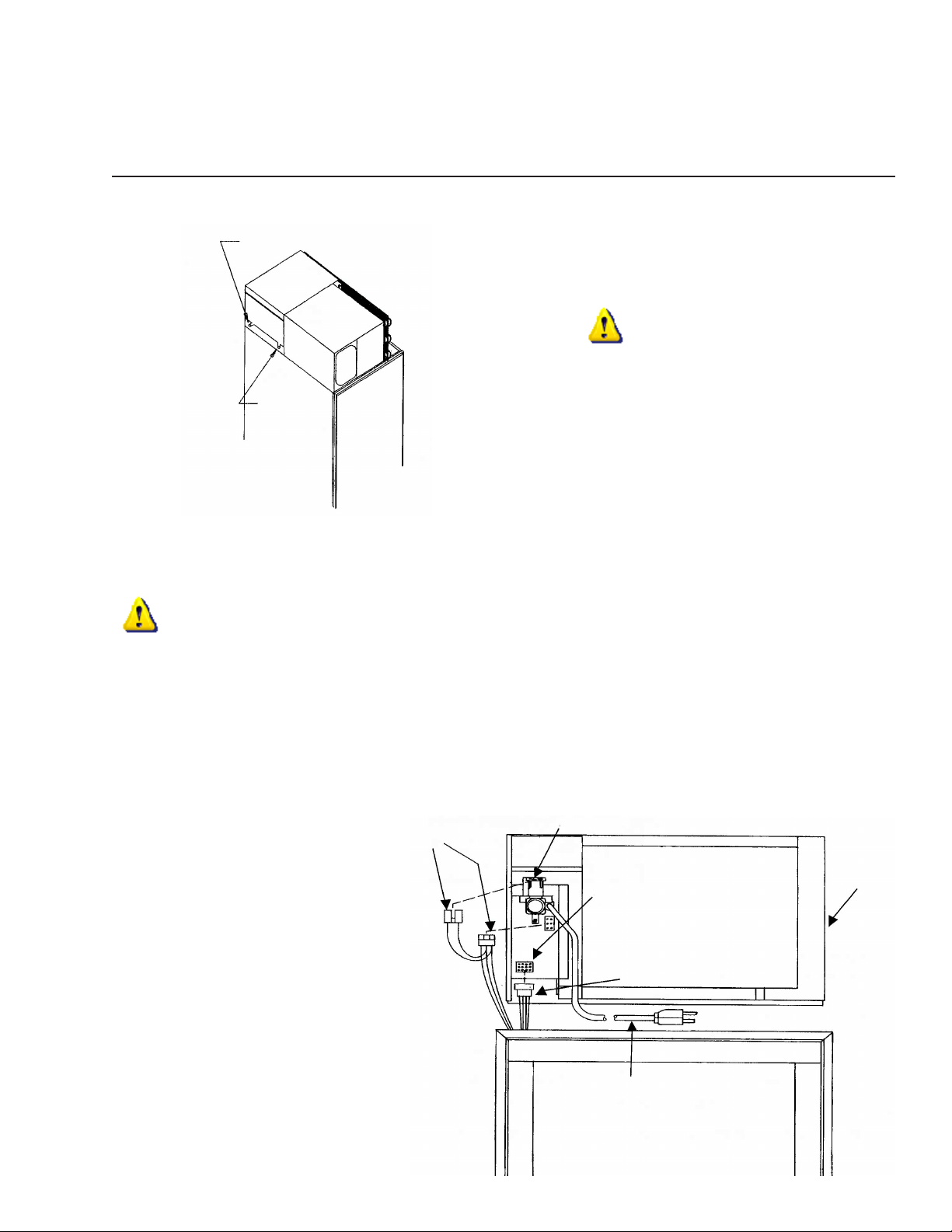

INSTALLING THE MODULE

Rear Shoulder Screw

CAUTION

Module NOT fastened to cabinet below. Remove before

Front

Shoulder

Screw

Place module on top of the cabinet with rear shoulder screws resng on the locator brackets behind the front slots. Slide

module toward the rear of the cabinet unl the rear shoulder screws engage the slots in the rear of the brackets. Rest the

front shoulder screws into the front slots of the brackets.

pping or transporng.

IMPORTANT

Check to make sure wiring and ice maker tubing is clear and not interfering with module seal. Do NOT start product during

construcon, as dust can block module condenser coils. If dust accumulates on coils, vacuum immediately, using a so

brush aachment.

Do NOT operate the refrigerator in the presence of explosive fumes.

Do NOT install the refrigerator where the temperature will drop below 60 degrees F (15 degrees C) or rise above 110 degrees F (43 degrees C). The compressor will NOT be able to maintain proper temperatures.

Ice Maker

Water Valve

Leads

Module

Juncon

Box

Make electrical connecons from the top

of the lower cabinet to the juncon box at

le side of module. If NO ice maker then

Cabinet

Leads

only one cabinet line will be protruding.

With ice maker, be sure to plug the ice

maker line into the module, and the solenoid valve as well. See module diagram on

the right.

Power Cord

7

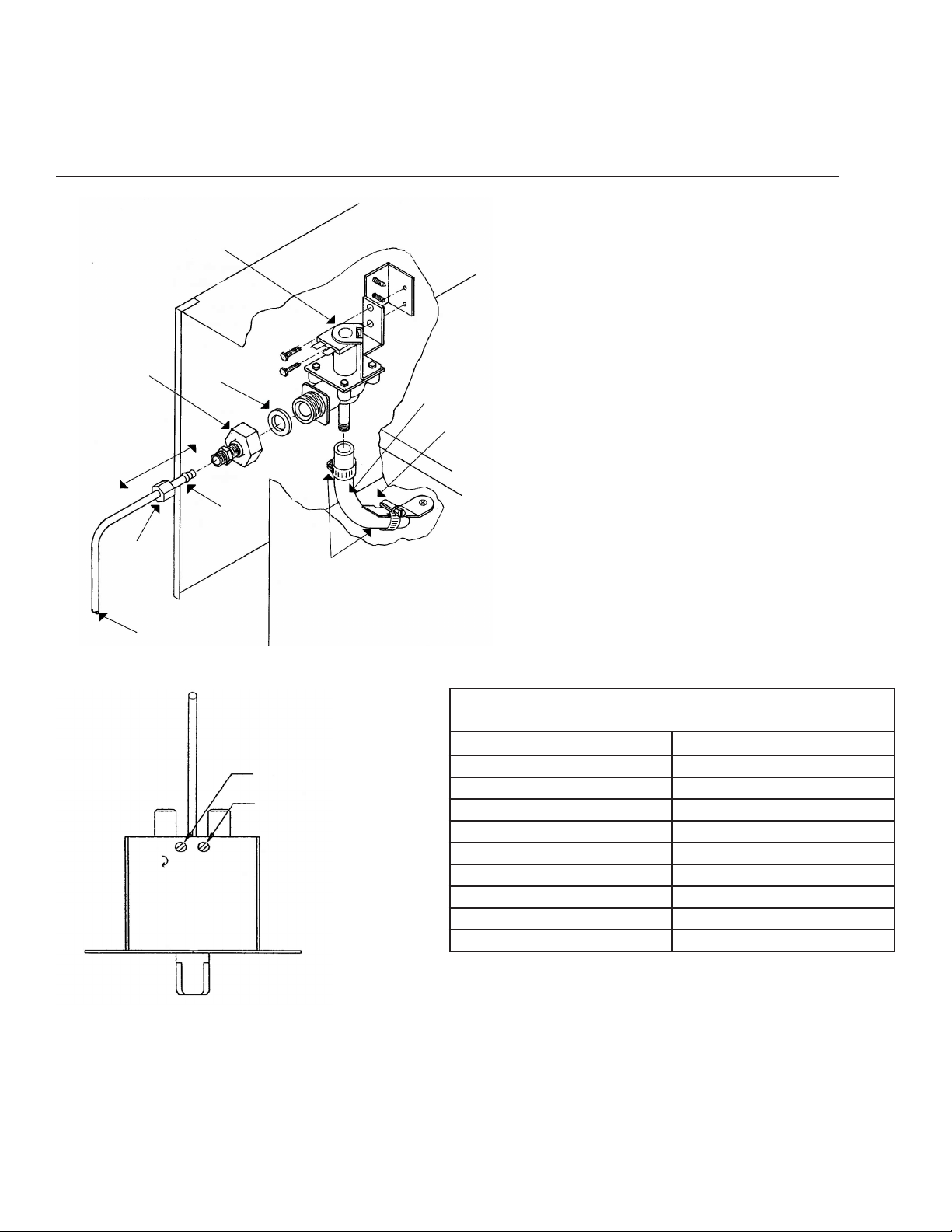

INSTALLING THE ICE MAKER WATER VALVE

Solenoid Wa-

ter Valve

Ice Maker (Solenoid) Connecon

Slip solenoid valve compression nut and

compression sleeve on copper tubing as

shown in diagram. Tighten nut onto water

valve with adjustable wrench. Turn on water

supply valve. Check ngs for leaks. Clamp

ice maker line from cabinet onto solenoid

Garden Hose

Fing

3 1/2”

Gasket

Fill hose to ice maker.

This clamp for tube posioning only.

Check to make sure tube is not collapsed or restricted aer connecng

opposite end to valve.

Sleeve

valve as shown. Tighten clamp securely.

NOTE: If a shuto valve is installed in the

water line do not use a self-piercing type

Compression

Nut

Copper Tubing

(by customer)

Tube Clamp (2)

valve.

ALTITUDE ADJUSTMENT FOR FREEZER/WINE CELLAR TEMPERATURE CONTROL

ALTITUDE CORRECTION

BOTH CUT-IN & CUT-OUT SCREWS MUST BE ADJUSTED.

ALTITUDE IN FEET COUNTERCLOCKWISE TURNS

2,000 7/60 = .12

3,000 13/60 = .22

4,000 19/60 = .32

5,000 25/60 = .42

6,000 31/60 = .52

7,000 37/60 = .62

8,000 43/60 = .72

9,000 49/60 = .82

10,000 55/60 = .92

In

Cut-In Screw

Cut-Out Screw

Out

Colder

1. Turn o power to refrigerator before servicing.

2. Remove screws holding freezer/wine cellar air return and drop air return grille to expose control assembly.

3. Locate cut-in and cut-out adjustment screws.

4. Determine the altude of your locaon and refer to the chart above for the number of counterclockwise turns to adjust

the control for proper calibraon. NOTE: Both cut-in and cut-out screws must be adjusted the same amount. (NEVER

exceed one full turn or damage to the control may occur.)

5. Reassemble the return air grille and plug in the refrigerator.

8

Edge of Cabinet

INSTALLING THE GRILLE ASSEMBLY

GRILLE MOUNTING - STYLE I BRACKET

3.81”

2.00”

.45” typ. (ref.)

Grille Top Trim

See Note #2.

2.06” from inside of

cabinet top trim to

centerline of holes.

Boom of grille

shown behind top

trim. See Note #4.

Cabinet Top Trim

GRILLE MOUNTING - STYLE II

SCREW

Fasten top of grille to enclosure

with screw provided. Cover screw

head with snap-on cap.

Grille Back

Drill four (4) holes 7/64” (.109) dia.

Mounng Brackets

(91180-000) # 8 - 5/8 P.H. Screws

See Note #1.

Instrucons for Installing Grille Brackets

1. Use the two (91180-000) screws to secure each bracket to the cabinet top.

2. Loosen the screws at the top of the mounng bracket. Leave .13 inches (2-3 screw

threads) scking through the bracket.

3. Install the grille by aligning the screws in the top of the bracket with the slots in the grille

top trim.

4. Grille is installed when boom of the grille ts behind the cabinet trim across the front.

5. Pull grille forward about an inch at the top and reghten the screws in the top of the

bracket.

GRILLE MOUNTING - STYLE III SPRING

Module

Spring

(81050-000)

24”, 30” & 36” wide units will use

one (1) spring (81050-000) and one

(1) L-bracket (30483-000) to secure

the facia.

L-Bracket

(30483-000)

Screw A

An-Tip

Bracket

Facia Bracket

Facia

Kappet Screw

(into enclosure)

Screw Cap

Instrucons for Installing Grille Mounng (STYLE III) Spring

1. Remove screw A in mounng bracket. Mount L-bracket with screw A.

2. Hook one end of spring (81050-000) through hole in L-bracket. Holding the facia in posion - stretch the

spring and secure the hook end to the facia through a square top hole in the facia.

42” & 48” wide units will

use two (2) springs (81050-

000) and two (2) L-brackets

(30483-000) to secure the

facia.

9

HINGE AND GASKET ADJUSTMENTS AND FACE MOUNTED DOOR HANDLES

Hinge and Gasket Adjustment

It is possible that doors may become out of adjustment in

shipment. See diagram on right.

Cabinet

If product is installed slightly “out of level”, doors may not

line up properly. Check this BEFORE adjusng hinges.

Adjustable Screws

NOTE: Door gaskets occasionally compress in shipment. If

Edge of Door Trim

gasket does not seal all around, warm slightly with a hair

dryer and pull outward soly unl magnet in gasket seals

against cabinet.

Door

Panel Ready Doors

To expose the concealed door screws, rst remove handle trim. Then slide trim over hinge toward handle side. If your unit

requires door panels, see “Custom Door Panel” secon, on page 14.

All hinge secons aached to doors, adjust le or right. Top and boom cabinet hinges are also adjustable in and out.

Change or Tighten Face Mounted Door Handles

1. Open the door - remove the interior door shelves.

2. Remove the screws that secure the shelf mounng rail

and the rail.

3. Remove the plug buons (exposing handle screws) make sure not to scratch the inner liner.

Stainless Steel Wrap Door Units

To expose concealed door hinge screws, remove plug

buons if present. All hinge secons aached to doors

adjust le or right. Top and boom cabinet hinges are

also adjustable in and out. See diagram (shown without

cabinet trim).

4. Remove the foam insert to expose the door handle

mounng screw.

5. Change handle/ghten screw and replace foam insert,

plug buon, shelf rail and door shelf.

10

Shelf Mounng

Rail and Screw

Foam

Handle Mounng

Screw

Door Shelf

Plug Buon

Foam Insert

Door Handle

Cabinet

Adjustable

Screws

Door

INSTALLING THE SIDE PANELS AND KICK PLATE

Instrucons for Fastening Side Panels to Refrigerator

1. Side panels should be 24 inches D (or 24 5/16

inches D when tucked into the front trim).

2. Panel height to match installaon height.

3. Install the side panels per drawings on the

right.

NOTE: To avoid damage to panels or ooring,

raise panels slightly, to clear oor when installing.

Drill three (3) holes equal distance apart in vercal secon of aluminum frame and install pan

head screws as shown.

Anchor side panel with screw as shown. Be sure

screw used goes no more than 1/2 inch deep into

product. Do NOT overghten.

“A”

“B”

“C”

“D”

Typ.

1 1/8”

3/16” Thick Back Up

1/8” Thick Back Up

2 3/16”

Typical Side Panel Installaons

1/4” Thick Baens

1/4” Plywood/Panel

3/16” Thick Baens

1/4” Plywood/Panel

24 5/16”

1/16” Rout

1/2” Plywood/Panel

11/32”

Metal Side Panel

24”

(Typ. Installaon Opening)

5/16”

Drill three (3) holes equal distance apart in vercal secon of aluminum frame and install # 6 - 3/8 pan head screws as

shown (provided).

Aach side panel to cabinet with screws as shown. Screws must not penetrate cabinet more than 1/2 inch.

Kick Plate Installaon

Use two (2) #8 sheet metal screws to facilitate holding your kick plate in place. Mount screws in holes in roller base. Notching of upper corners may be required to clear hinges.

Measure the distance between

mounng holes on roller base.

#8 Sheet

Metal Screw

11

CUSTOM DOOR PANELS AND SPECIFICATIONS

The AGA MARVEL Panel Ready Built-In design allows you to insert decorave material on the doors of your refrigerator/

freezer. If a panel thinner than 1/4 inch is being used, we recommend a ller be inserted behind it for a proper t, as frames

are designed to accept up to a 1/4 inch of material. If a raised panel is used, route edges to t the frame.

CAUTION

Door panels MUST NOT exceed 50 lbs. Do NOT use glass, mirrors, granite or similar heavy materials for panels. Panels

weighing more than 50 lbs. may cause product damage. We recommend that the door load (panel and food) NOT exceed 90

lbs.

For models:

All Refrigerator (AR), All Freezer (AF), Top Freezer (TF), Side-by-Side (SS), and Side-by-Side 3 Door (3D)

Model AR H W

18AR Custom Panel 68” 15 1/2”

24AR Custom Panel 68” 21 1/2”

30AR Custom Panel 68” 27 1/2”

36AR Custom Panel 68” 33 1/2”

Model AF H W

18AF Custom Panel 68” 15 1/2”

24AF Custom Panel 68” 21 1/2”

30AF Custom Panel 68” 27 1/2”

36AF Custom Panel 68” 33 1/2”

Model TF

18TF Custom Panel 22 1/4” 15 1/2” 45 1/8” 15 1/2”

24TF Custom Panel 22 1/4” 21 1/2” 45 1/8” 21 1/2”

30TF Custom Panel 22 1/4” 27 1/2” 45 1/8” 27 1/2”

36TF Custom Panel 22 1/4” 33 1/2” 45 1/8” 33 1/2”

Model SS

36SS Custom Panel 68” 15 1/2” 68” 17”

42SS Custom Panel 68” 17” 68” 21 1/2”

48SS Custom Panel 68” 17” 68” 27 1/2”

60SS Custom Panel 68” 21 1/2” 68” 33 1/2”

72SS Custom Panel 68” 33 1/2” 68” 33 1/2”

Model 3D

363D Custom Panel 22 1/4” 15 1/2” 68” 17” 45 1/8” 15 1/2”

Freezer Door Refrigerator Door

H W H W

Freezer Door Refrigerator Door

H W H W

Freezer Door Refrigerator Door Refrigerator Door 2

H W H W H W

W

3/8”

H

Min.

1/4”

Max.

Removing Protecve Film from Factory Installed Decorave Panels

• Cabinets are shipped with protecve lm over the exterior surface of

decorave panels (oponal).

• Do NOT remove protecve lm unl the cabinet has been completely

installed to prevent scratching or marring the decorave panels.

• To remove the protecve lm, rmly grasp the loose edge of the lm and

slowly pull the lm downward o the decorave panels.

• Decorave panels may be removed if necessary by removing the handle

screws and handle and then sliding the decorave panel out of the frame.

12

Screw

Screw

Cap

Handle

CUSTOM GRILLE PANELS AND SPECIFICATIONS

Custom Grille Panels

• Remove screws and handle.

• Slide custom panel into posion in door trim opening.

• Do ALL doors.

CAUTION

Grille panels MUST NOT exceed 20 lbs. Panels weighing

more than 20 lbs. may cause product damage.

• Do NOT replace handle unl hinge and gasket adjustments have been made. See page 12.

• Replace handle and screws and install plasc screw

caps provided.

For grille installaon refer to page 11, Grille Assembly Installaon, and see separate Instrucon Sheet, No. 31395-

000.

For models:

All Refrigerator (AR), All Freezer (AF), Top Freezer (TF), Side-by-Side (SS), and Side-by-Side 3 Door (3D)

Model AR H W

18AR Grille Panel 8 9/16” 14 13/16”

24AR Grille Panel 8 9/16” 20 13/16”

W

30AR Grille Panel 8 9/16” 26 13/16”

36AR Grille Panel 8 9/16” 32 13/16”

Model AF H W

H

3/8”

Min.

18AF Grille Panel 8 9/16” 14 13/16”

24AF Grille Panel 8 9/16” 20 13/16”

30AF Grille Panel 8 9/16” 26 13/16”

36AF Grille Panel 8 9/16” 32 13/16”

Model TF H W

18TF Grille Panel 8 9/16” 14 13/16”

24TF Grille Panel 8 9/16” 20 13/16”

30TF Grille Panel 8 9/16” 26 13/16”

36TF Grille Panel 8 9/16” 32 13/16”

Model SS H W

36SS Grille Panel 8 9/16” 32 13/16”

42SS Grille Panel 8 9/16” 38 13/16”

48SS Grille Panel 8 9/16” 44 13/16”

54SS Grille Panel 8 9/16” 50 13/16”

60SS Grille Panel 8 9/16” 56 13/16”

66SS Grille Panel 8 9/16” 62 13/16”

72SS Grille Panel 8 9/16” 68 13/16”

Model 3D H W

363D Grille Panel 8 9/16” 32 13/16”

NOTE: All center hinged doors CANNOT exceed 1/2 inch in

panel thickness from the door trim face.

1/4” Max.

Note: 1/2” Min. (Relief)

13

TRIMLESS OVERLAY DOOR PANELS AND SPECIFICATIONS

For models:

All Refrigerator (AR), All Freezer (AF), Top Freezer (TF), Side-by-Side (SS), and Side-by-Side 3 Door (3D)

Model 18AR & 18AF H W

Refrigerator or Freezer Overlay Panel 68 1/4” 15 3/4”

Refrigerator or Freezer Spacer Panel 66 3/4” 14 1/4”

Refrigerator or Freezer Backer Panel 68” 15 1/2”

Model 24AR & 24AF H W

Refrigerator or Freezer Overlay Panel 68 1/4” 21 3/4”

Refrigerator or Freezer Spacer Panel 66 3/4” 20 1/4”

Refrigerator or Freezer Backer Panel 68” 21 1/2”

Model 30AR & 30AF H W

Refrigerator or Freezer Overlay Panel 68 1/4” 27 3/4”

Refrigerator or Freezer Spacer Panel 66 3/4” 26 1/4”

Refrigerator or Freezer Backer Panel 68” 27 1/2”

Model 36AR & 36AF H W

Refrigerator or Freezer Overlay Panel 68 1/4” 33 3/4”

Refrigerator or Freezer Spacer Panel 66 3/4” 32 1/4”

Refrigerator or Freezer Backer Panel 68” 33 1/2”

Model 18TF H W

Refrigerator Overlay Panel 45 3/8” 15 3/4”

Refrigerator Spacer Panel 43 7/8” 14 1/4”

Refrigerator Backer Panel 45 1/8” 15 1/2”

H W

Freezer Overlay Panel 22 1/2” 15 3/4”

Freezer Spacer Panel 21” 14 1/4”

Freezer Backer Panel 22 1/4” 15 1/2”

Model 24TF H W

Refrigerator Overlay Panel 45 3/8” 21 3/4”

Refrigerator Spacer Panel 43 7/8” 20 1/4”

Refrigerator Backer Panel 45 1/8” 21 1/2”

H W

Freezer Overlay Panel 22 1/2” 21 3/4”

Freezer Spacer Panel 21” 20 1/4”

Freezer Backer Panel 22 1/4” 21 1/2”

Model 30TF H W

Refrigerator Overlay Panel 45 3/8” 27 3/4”

Refrigerator Spacer Panel 43 7/8” 26 1/4”

Refrigerator Backer Panel 45 1/8” 27 1/2”

H W

Freezer Overlay Panel 22 1/2” 27 3/4”

Freezer Spacer Panel 21” 26 1/4”

Freezer Backer Panel 22 1/4” 27 1/2”

Model 36TF H W

Refrigerator Overlay Panel 45 3/8” 33 3/4”

Refrigerator Spacer Panel 43 7/8” 32 1/4”

Refrigerator Backer Panel 45 1/8” 33 1/2”

H W

Freezer Overlay Panel 22 1/2” 33 3/4”

Freezer Spacer Panel 21” 32 1/4”

Freezer Backer Panel 22 1/4” 33 1/2”

Model 36SS H W

Refrigerator Overlay Panel 68 1/4” 17 1/4”

Refrigerator Spacer Panel 66 3/4” 15 3/4”

Refrigerator Backer Panel 68” 17”

H W

Freezer Overlay Panel 68 1/4” 15 3/4”

Freezer Spacer Panel 66 3/4” 14 1/4”

Freezer Backer Panel 68” 15 1/2”

Model 42SS H W

Refrigerator Overlay Panel 68 1/4” 21 3/4”

Refrigerator Spacer Panel 66 3/4” 20 1/4”

Refrigerator Backer Panel 68” 21 1/2”

H W

Freezer Overlay Panel 68 1/4” 17 1/4”

Freezer Spacer Panel 66 3/4” 15 3/4”

Freezer Backer Panel 68” 17”

Model 48SS H W

Refrigerator Overlay Panel 68 1/4” 27 3/4”

Refrigerator Spacer Panel 66 3/4” 26 1/4”

Refrigerator Backer Panel 68” 27 1/2”

H W

Freezer Overlay Panel 68 1/4” 17 1/4”

Freezer Spacer Panel 66 3/4” 15 3/4”

Freezer Backer Panel 68” 17”

Model 60SS H W

Refrigerator Overlay Panel 68 1/4” 33 3/4”

Refrigerator Spacer Panel 66 3/4” 32 1/4”

Refrigerator Backer Panel 68” 33 1/2”

Freezer Overlay Panel 68 1/4” 21 3/4”

Freezer Spacer Panel 66 3/4” 20 1/4”

Freezer Backer Panel 68” 21 1/2”

Model 72SS H W

Refrigerator Overlay Panel 68 1/4” 33 3/4”

Refrigerator Spacer Panel 66 3/4” 32 1/4”

Refrigerator Backer Panel 68” 33 1/2”

Freezer Overlay Panel 68 1/4” 33 3/4”

Freezer Spacer Panel 66 3/4” 32 1/4”

Freezer Backer Panel 68” 33 1/2”

Model 363D H W

Refrigerator 1 Overlay Panel 68 1/4” 17 1/4”

Refrigerator 1 Spacer Panel 66 3/4” 15 3/4”

Refrigerator 1 Backer Panel 68” 17”

Refrigerator 2 Overlay Panel 45 3/8” 15 3/4”

Refrigerator 2 Spacer Panel 43 7/8” 14 1/4”

Refrigerator 2 Backer Panel 45 1/8” 15 1/2”

Freezer Overlay Panel 22 1/2” 15 3/4”

Freezer Spacer Panel 21” 14 1/4”

Freezer Backer Panel 22 1/4” 15 1/2”

3/32”

Custom

Door

Panel

Front

H W

H W

H W

H W

Slot - panel ts in.

3/32” 5/8”

14

1/8”

Min.

1/4”

Max.

Typical Door Assembly with “Trimless” Panel

Door

Typical

All

Around

Panel

TRIMLESS OVERLAY GRILLE PANELS AND SPECIFICATIONS

For models:

All Refrigerator (AR), All Freezer (AF), Top Freezer (TF), Side-by-Side (SS), and Side-by-Side 3 Door (3D)

Model 18AR & 18AF H W

Refrigerator or Freezer Grille Overlay Panel 8 7/8” 15 1/8”

Refrigerator or Freezer Grille Spacer Panel 7 5/16” 13 9/16”

Refrigerator or Freezer Grille Backer Panel 8 9/16” 14 13/16”

Model 24AR & 24AF H W

Refrigerator or Freezer Grille Overlay Panel 8 7/8” 21 1/8”

Refrigerator or Freezer Grille Spacer Panel 7 5/16” 19 9/16”

Refrigerator or Freezer Grille Backer Panel 8 9/16” 20 13/16”

Model 30AR & 30AF H W

Refrigerator or Freezer Grille Overlay Panel 8 7/8” 27 1/8”

Refrigerator or Freezer Grille Spacer Panel 7 5/16” 25 9/16”

Refrigerator or Freezer Grille Backer Panel 8 9/16” 26 13/16”

Model 36AR & 36AF H W

Refrigerator or Freezer Grille Overlay Panel 8 7/8” 33 1/8”

Refrigerator or Freezer Grille Spacer Panel 7 5/16” 31 9/16”

Refrigerator or Freezer Grille Backer Panel 8 9/16” 32 13/16”

Model 18TF H W

Top Freezer Grille Overlay Panel 8 7/8” 15 1/8”

Top Freezer Grille Spacer Panel 7 5/16” 13 9/16”

Top Freezer Grille Backer Panel 8 9/16” 14 13/16”

Model 24TF H W

Top Freezer Grille Overlay Panel 8 7/8” 21 1/8”

Top Freezer Grille Spacer Panel 7 5/16” 19 9/16”

Top Freezer Grille Backer Panel 8 9/16” 20 13/16”

Model 30TF H W

Top Freezer Grille Overlay Panel 8 7/8” 27 1/8”

Top Freezer Grille Spacer Panel 7 5/16” 25 9/16”

Top Freezer Grille Backer Panel 8 9/16” 26 13/16”

Model 36TF H W

Top Freezer Grille Overlay Panel 8 7/8” 33 1/8”

Top Freezer Grille Spacer Panel 7 5/16” 31 9/16”

Top Freezer Grille Backer Panel 8 9/16” 32 13/16”

Model 36SS H W

Side-by-Side Grille Overlay Panel 8 7/8” 33 1/8”

Side-by-Side Grille Spacer Panel 7 5/16” 31 9/16”

Side-by-Side Grille Backer Panel 8 9/16” 32 13/16”

Model 363D H W

Three Door Grille Overlay Panel 8 7/8” 33 1/8”

Three Door Grille Spacer Panel 7 5/16” 31 9/16”

Three Door Grille Backer Panel 8 9/16” 32 13/16”

Model 42SS H W

Side-by-Side Grille Overlay Panel 8 7/8” 39 1/8”

Side-by-Side Grille Spacer Panel 7 5/16” 37 9/16”

Side-by-Side Grille Backer Panel 8 9/16” 38 13/16”

H

Model 48SS H W

Side-by-Side Grille Overlay Panel 8 7/8” 45 1/8”

Side-by-Side Grille Spacer Panel 7 5/16” 43 9/16”

Side-by-Side Grille Backer Panel 8 9/16” 44 13/16”

Model 54SS H W

Side-by-Side Grille Overlay Panel 8 7/8” 51 1/8”

Side-by-Side Grille Spacer Panel 7 5/16” 49 9/16”

Side-by-Side Grille Backer Panel 8 9/16” 50 13/16”

Model 60SS H W

Side-by-Side Grille Overlay Panel 8 7/8” 57 1/8”

Side-by-Side Grille Spacer Panel 7 5/16” 55 9/16”

Side-by-Side Grille Backer Panel 8 9/16” 56 13/16”

Model 66SS H W

Side-by-Side Grille Overlay Panel 8 7/8” 63 1/8”

Side-by-Side Grille Spacer Panel 7 5/16” 61 9/16”

Side-by-Side Grille Backer Panel 8 9/16” 62 13/16”

Model 72SS H W

Side-by-Side Grille Overlay Panel 8 7/8” 69 1/8”

Side-by-Side Grille Spacer Panel 7 5/16” 67 9/16”

Side-by-Side Grille Backer Panel 8 9/16” 68 13/16”

1/8”

Min.

Custom

Grille

Panel

Front

W

Typical Grille Assembly with “Trimless” Panel

3/32” 3/32” 5/8”

Grille Frame

1/4”

Max.

Typical All

Around Panel

15

EXTENDED PANELS AND SPECIFICATIONS

Finish this area of panel

1-5/16

Secon C-C

1/4 Max.

3/32

11/16

Finished Side of Door

1/8 Min.

Handle Side

A

H

1/8 Min.

3/32

1/4 Max.

1/8

3/4

A

Secon A-A

Finished Side of Door

Top of Door

5/8

1/4 Max.

Custom Door

Panel Dimensions

C

C

Finished Side of Door

3/32

1/8 Min.

Secon B-B

Hinge Side

B

Finished

B

Side of Door

D

D

Secon D-D

Boom of Door

W

Finished Side of Door

1/8 Min.

3/4

1/8

3/32

16

1/4 Max.

EXTENDED PANELS AND SPECIFICATIONS

For models:

All Refrigerator (AR), All Freezer (AF), Top Freezer (TF), Side-by-Side (SS), and Side-by-Side 3 Door (3D)

Model 18AR & 18AF H W

Refrigerator or Freezer Overlay Panel 68 1/4” 16 3/16”

Refrigerator or Freezer Spacer Panel 66 3/4” 14 1/4”

Refrigerator or Freezer Backer Panel 68” 15 1/2”

Model 24AR & 24AF H W

Refrigerator or Freezer Overlay Panel 68 1/4” 22 3/16”

Refrigerator or Freezer Spacer Panel 66 3/4” 20 1/4”

Refrigerator or Freezer Backer Panel 68” 21 1/2”

Model 30AR & 30AF H W

Refrigerator or Freezer Overlay Panel 68 1/4” 28 3/16”

Refrigerator or Freezer Spacer Panel 66 3/4” 26 1/4”

Refrigerator or Freezer Backer Panel 68” 27 1/2”

Model 36AR & 36AF H W

Refrigerator or Freezer Overlay Panel 68 1/4” 34 3/16”

Refrigerator or Freezer Spacer Panel 66 3/4” 32 1/4”

Refrigerator or Freezer Backer Panel 68” 33 1/2”

Model 18TF H W

Refrigerator Overlay Panel 45 3/8” 16 3/16”

Refrigerator Spacer Panel 43 7/8” 14 1/4”

Refrigerator Backer Panel 45 1/8” 15 1/2”

H W

Freezer Overlay Panel 22 1/2” 16 3/16”

Freezer Spacer Panel 21” 14 1/4”

Freezer Backer Panel 22 1/4” 15 1/2”

Model 24TF H W

Refrigerator Overlay Panel 45 3/8” 22 3/16”

Refrigerator Spacer Panel 43 7/8” 20 1/4”

Refrigerator Backer Panel 45 1/8” 21 1/2”

H W

Freezer Overlay Panel 22 1/2” 22 3/16”

Freezer Spacer Panel 21” 20 1/4”

Freezer Backer Panel 22 1/4” 21 1/2”

Model 30TF H W

Refrigerator Overlay Panel 45 3/8” 28 3/16”

Refrigerator Spacer Panel 43 7/8” 26 1/4”

Refrigerator Backer Panel 45 1/8” 27 1/2”

H W

Freezer Overlay Panel 22 1/2” 28 3/16”

Freezer Spacer Panel 21” 26 1/4”

Freezer Backer Panel 22 1/4” 27 1/2”

Model 36TF H W

Refrigerator Overlay Panel 45 3/8” 34 3/16”

Refrigerator Spacer Panel 43 7/8” 32 1/4”

Refrigerator Backer Panel 45 1/8” 33 1/2”

H W

Freezer Overlay Panel 22 1/2” 34 3/16”

Freezer Spacer Panel 21” 32 1/4”

Freezer Backer Panel 22 1/4” 33 1/2”

Model 36SS H W

Refrigerator Overlay Panel 68 1/4” 17 11/16”

Refrigerator Spacer Panel 66 3/4” 15 3/4”

Refrigerator Backer Panel 68” 17”

H W

Freezer Overlay Panel 68 1/4” 16 3/16”

Freezer Spacer Panel 66 3/4” 14 1/4”

Freezer Backer Panel 68” 15 1/2”

Model 42SS H W

Refrigerator Overlay Panel 68 1/4” 22 3/16”

Refrigerator Spacer Panel 66 3/4” 20 1/4”

Refrigerator Backer Panel 68” 21 1/2”

H W

Freezer Overlay Panel 68 1/4” 17 11/16”

Freezer Spacer Panel 66 3/4” 15 3/4”

Freezer Backer Panel 68” 17”

Model 48SS H W

Refrigerator Overlay Panel 68 1/4” 28 3/16”

Refrigerator Spacer Panel 66 3/4” 26 1/4”

Refrigerator Backer Panel 68” 27 1/2”

H W

Freezer Overlay Panel 68 1/4” 17 11/16”

Freezer Spacer Panel 66 3/4” 15 3/4”

Freezer Backer Panel 68” 17”

Model 60SS H W

Refrigerator Overlay Panel 68 1/4” 34 3/16”

Refrigerator Spacer Panel 66 3/4” 32 1/4”

Refrigerator Backer Panel 68” 33 1/2”

Freezer Overlay Panel 68 1/4” 22 3/16”

Freezer Spacer Panel 66 3/4” 20 1/4”

Freezer Backer Panel 68” 21 1/2”

Model 72SS H W

Refrigerator Overlay Panel 68 1/4” 34 3/16”

Refrigerator Spacer Panel 66 3/4” 32 1/4”

Refrigerator Backer Panel 68” 33 1/2”

Freezer Overlay Panel 68 1/4” 34 3/16”

Freezer Spacer Panel 66 3/4” 32 1/4”

Freezer Backer Panel 68” 33 1/2”

Model 363D H W

Refrigerator 1 Overlay Panel 68 1/4” 17 11/16”

Refrigerator 1 Spacer Panel 66 3/4” 15 3/4”

Refrigerator 1 Backer Panel 68” 17”

Refrigerator 2 Overlay Panel 45 3/8” 16 3/16”

Refrigerator 2 Spacer Panel 43 7/8” 14 1/4”

Refrigerator 2 Backer Panel 45 1/8” 15 1/2”

Freezer Overlay Panel 22 1/2” 16 3/16”

Freezer Spacer Panel 21” 14 1/4”

Freezer Backer Panel 22 1/4” 15 1/2”

Inside surface to be nished

These two (2)

surfaces are ush.

H W

H W

H W

H W

This door requires a face mounted

door handle

17

EXTENDED GRILLE PANELS AND SPECIFICATIONS

A

H

25/32

Finished Side of Grille

1/4 Maximum

1/8 Minimum

3/32

5/32

Secon A-A

29/32

1-17/32

A

B

W

B

1/4 Maximum

27/32

3/32

Finished Side of Grille

1/8 Minimum

1-15/32

18

1/4 Maximum

3/32

1/8 Minimum

Secon B-B

Typical

Both Sides

EXTENDED GRILLE PANELS AND SPECIFICATIONS

For models:

All Refrigerator (AR), All Freezer (AF), Top Freezer (TF), Side-by-Side (SS), and Side-by-Side 3 Door (3D)

Model 18AR & 18AF H W

Refrigerator or Freezer Grille Overlay Panel 9 5/8” 16 1/2”

Refrigerator or Freezer Grille Spacer Panel 7 5/16” 13 9/16”

Refrigerator or Freezer Grille Backer Panel 8 9/16” 14 13/16”

Model 24AR & 24AF H W

Refrigerator or Freezer Grille Overlay Panel 9 5/8” 22 1/2”

Refrigerator or Freezer Grille Spacer Panel 7 5/16” 19 9/16”

Refrigerator or Freezer Grille Backer Panel 8 9/16” 20 13/16”

Model 30AR & 30AF H W

Refrigerator or Freezer Grille Overlay Panel 9 5/8” 28 1/2”

Refrigerator or Freezer Grille Spacer Panel 7 5/16” 25 9/16”

Refrigerator or Freezer Grille Backer Panel 8 9/16” 26 13/16”

Model 36AR & 36AF H W

Refrigerator or Freezer Grille Overlay Panel 9 5/8” 34 1/2”

Refrigerator or Freezer Grille Spacer Panel 7 5/16” 31 9/16”

Refrigerator or Freezer Grille Backer Panel 8 9/16” 32 13/16”

Model 18TF H W

Top Freezer Grille Overlay Panel 9 5/8” 16 1/2”

Top Freezer Grille Spacer Panel 7 5/16” 13 9/16”

Top Freezer Grille Backer Panel 8 9/16” 14 13/16”

Model 24TF H W

Top Freezer Grille Overlay Panel 9 5/8” 22 1/2”

Top Freezer Grille Spacer Panel 7 5/16” 19 9/16”

Top Freezer Grille Backer Panel 8 9/16” 20 13/16”

Model 30TF H W

Top Freezer Grille Overlay Panel 9 5/8” 28 1/2”

Top Freezer Grille Spacer Panel 7 5/16” 25 9/16”

Top Freezer Grille Backer Panel 8 9/16” 26 13/16”

Model 36TF H W

Top Freezer Grille Overlay Panel 9 5/8” 34 1/2”

Top Freezer Grille Spacer Panel 7 5/16” 31 9/16”

Top Freezer Grille Backer Panel 8 9/16” 32 13/16”

Model 36SS H W

Side-by-Side Grille Overlay Panel 9 5/8” 34 1/2”

Side-by-Side Grille Spacer Panel 7 5/16” 31 9/16”

Side-by-Side Grille Backer Panel 8 9/16” 32 13/16”

Model 363D H W

Three Door Grille Overlay Panel 9 5/8” 34 1/2”

Three Door Grille Spacer Panel 7 5/16” 31 9/16”

Three Door Grille Backer Panel 8 9/16” 32 13/16”

Model 42SS H W

Side-by-Side Grille Overlay Panel 9 5/8” 40 1/2”

Side-by-Side Grille Spacer Panel 7 5/16” 37 9/16”

Side-by-Side Grille Backer Panel 8 9/16” 38 13/16”

Model 48SS H W

Side-by-Side Grille Overlay Panel 9 5/8” 46 1/2”

Side-by-Side Grille Spacer Panel 7 5/16” 43 9/16”

Side-by-Side Grille Backer Panel 8 9/16” 44 13/16”

Model 54SS H W

Side-by-Side Grille Overlay Panel 9 5/8” 52 1/2”

Side-by-Side Grille Spacer Panel 7 5/16” 49 9/16”

Side-by-Side Grille Backer Panel 8 9/16” 50 13/16”

Model 60SS H W

Side-by-Side Grille Overlay Panel 9 5/8” 58 1/2”

Side-by-Side Grille Spacer Panel 7 5/16” 55 9/16”

Side-by-Side Grille Backer Panel 8 9/16” 56 13/16”

Model 66SS H W

Side-by-Side Grille Overlay Panel 9 5/8” 64 1/2”

Side-by-Side Grille Spacer Panel 7 5/16” 61 9/16”

Side-by-Side Grille Backer Panel 8 9/16” 62 13/16”

Model 72SS H W

Side-by-Side Grille Overlay Panel 9 5/8” 70 1/2”

Side-by-Side Grille Spacer Panel 7 5/16” 67 9/16”

Side-by-Side Grille Backer Panel 8 9/16” 68 13/16”

19

GLASS PANEL READY WOOD FRAME DOOR SPECIFICATIONS

Model AR H W

18AR - WGP 68 1/8” 16 1/4” 2 1/2”

18AR - SGP 68 1/8” 16 1/4” 2 1/2”

24AR - WGP 68 1/8” 22 1/4” 2 1/2”

24AR - SGP 68 1/8” 22 1/4” 2 1/2”

30AR - WGP 68 1/8” 28 1/4” 2 1/2”

30AR - SGP 68 1/8” 28 1/4” 2 1/2”

36AR - WGP 68 1/8” 34 1/4” 2 1/2”

36AR - WGP 68 1/8” 34 1/4” 2 1/2”

Model WC H W

18WC - SGP 68 1/8” 16 1/4” 2 1/2”

24WC - SGP 68 1/8” 22 1/4” 2 1/2”

Model 2Z H W

242Z - SGP 68 1/8” 22 1/4” 2 1/2”

Model BC H W

24BC - SGP 68 1/8” 22 1/4” 2 1/2”

Model SS H W

60SS - WGP 68 1/8” 34 1/4” 2 1/2”

60SS - SGP 68 1/8” 34 1/4” 2 1/2”

72SS - WGP 68 1/8” 34 1/4” 2 1/2”

72SS - SGP 68 1/8” 34 1/4” 2 1/2”

Frame with

Min.

Frame with

Min.

Frame with

Min.

Frame with

Min.

Frame with

Min.

20

GLASS PANEL READY WOOD FRAME DOOR SPECIFICATIONS

W

2.50” Typ.

All Around

H

.50”

1.38” Typ.

(2) Plcs.

.33” Typ.

(2) Plcs.

21

INSTALLING A DOOR FRAME TO THE GLASS DOOR

The door frame can be mounted to the glass door with the glass door on or o the unit. The door handle needs to be

mounted to the door frame before the frame is mounted to the glass door.

Glass Door On the Unit

1. Lay the unit on its back.

2. Open the glass door 180 degrees and support the glass door during installaon.

3. Pull the door gasket back along the top and boom of the glass door to expose the mounng holes for the door frame.

There are twelve (12) total mounng holes on the door - four (4) on each side and two (2) on the top and boom of the

door. Screws will be mounted around the outside diameter of the door on the gasket side.

4. Line up the door frame that is to be mounted to the unit and mark the hole locaons on the door frame. Drill 1/8” pilot

holes, 1/4” deep to aid during mounng of the door frame.

5. Recommended screws to use to mount the door frame are 1 1/4” long wood screws.

6. Aer installing the mounng screws, press the door gasket back into the gasket retainer. Make sure the gasket is seated

into the corners to retain proper door gasket seal.

Glass Door O the Unit

1. Remove the four (4) hinge bolts from the door- two (2) at the top and two (2) at the boom of the door. Retain the two

(2) hinge spacers. One (1) at the top and one (1) at the boom of the door.

2. Lay the glass door on a surface that will protect the door frame during assembly of the frame to the glass door.

3. Complete Steps 3 through 6 as listed in the above secon “Glass Door On the Unit”.

4. Mount the door to the unit using the hinge spacers and hinge bolts that were removed when taking the glass door o

the unit.

22

Door Gasket

(shown pulled up)

Screws to mount the door

frame to the glass door.

Door Frame

INSTALLATION CHECKS/COMMON ERRORS

Installaon Checks

• An-p mounng bracket must be installed correctly and anchored to prevent cabinet from pping

forward.

• Module should be engaged in the slots on the module

posioning brackets and seated on the foam seal

without air gaps. Module posioning brackets should

not be removed.

• All wires from the lower cabinet to module must be

securely connected. If a problem is suspected, inspect

both male and female plugs and insure that the terminals in the plug are suciently forward to engage.

• Cabinet must be level both side-to-side and frontto-back. Front leveling legs should rest rmly on the

oor. Cabinetry on both sides of the cabinet must be

secure and level to prevent the cabinet from shiing

when the doors are opened.

• Doors must not hit adjacent walls or countertops.

• Gaskets must seal completely. If gaskets seal well, no

further adjustments need to be made.

• On models with ice makers, check water connecons

for leaks. If water is not yet connected, the plasc

water ll tube to the freezer compartment must either

be aached to the solenoid or sealed to prevent air

leaking into the cabinet.

• Brown and white wires should be connected to the

solenoid. The remaining Molex connector plugs into

the power module.

• Do NOT overcrowd the shelves or block cold air ducts.

• Do NOT install a refrigerator shelf closer than 8 inches

from the interior top.

• Do NOT allow packages to overhang sides or rear of

shelves as this will block air circulaon, making the

refrigerator less ecient.

Common Installaon Errors

• Any air leaks between the module and the cabinet will

keep the cabinet from operang eciently.

• The water supply line and electric outlet must be located in a manner that will not interfere with module

to cabinet alignment when the unit is pushed into

place.

• Power cord to outlet sing under the power module

will create an air leak.

• Ice maker ll tube (plasc) not connected or loose

creang a water and/or air leak.

• Plugs from cabinet not connected to the ice maker

and/or power module.

• Floor under products lower than nished oor making

the unit inaccessible for service. Floor under product

must be strong enough to support weight of fully

loaded refrigerator.

• Product not anchored properly (to prevent pping).

Bracket not secured to rear wall studs or screws

through product side trim into adjoining cabinets or

walls.

23

TROUBLESHOOTING

Troubleshoong

If product does not start when plugged in, check the following:

• Does the light bulb go on when the refrigerator door is

opened? If NOT, check bulb, then...

• -Is the cord from the lower cabinet plugged

into the module?

• -Is the power cord plugged in at the receptacle?

• -Is the circuit breaker or fuse ”on”? Check

by plugging another electric device into the

outlet.

• If light bulb DID go on when the door was opened...

• -Turn the defrost mer clockwise (might be in

“defrost”) unl compressor starts.

• If motor “hums”, but does not start...

• -Check for adequate line voltage at the outlet.

• -The module may have been transported or

stored on its side or upside down, causing

temporary displacement of motor oil. Let rest

24 hours, then plug in again.

24

USE AND CARE GUIDE FOR YOUR REFRIGERATOR/FREEZER

CONGRATULATIONS! You are now the proud owner of a

superb, beauful and durable addion to your kitchen.

The following informaon will help you get the most pleasure from your purchase.

Using your refrigerator...

Cool owing air keeps your refrigerated foods fresh. Large

containers placed close together may restrict the ow of

air. Space food so cool air can ow around it.

To retain maximum moisture and avor, cover containers

or seal food in moisture proof wrap. Odorous foods which

might aect others should always be covered.

Meat, sh and poultry can be stored safely in the refrigerator secon for a few days, but as a general rule, the freezer

should be ulized for longer storage.

Vegetables and fruits should be washed, dried and stored

in the slide-out crisper. They will last longer in closed plasc containers or wrapped in plasc lm.

Cover le-overs and use within a couple of days.

Shelves adjust to many posions, allowing versale storage and maximum use of space. The adjustable door

shelves hold abundant storage, even tall boles. Firmly

lock shelves in place before use.

Varying amounts of frost will form occasionally in the

freezer compartment, especially in areas near the top air

return. This is normal adjunct of the moist cold air circulang in the refrigerator secon to help food stay fresh

longer.

If your freezer has an icemaker...

First buckets may contain contaminaon from new installaon. Throw away the rst two harvests or unl the ice is

free of discoloraon and taste.

The icemaker makes ice once the freezer is cold. It will

turn o automacally when the ice bucket is full, provided

the bucket is properly posioned.

Li the Stop Arm up out of the way when removing and

replacing the container.

CAUTION

Never place ngers, foreign objects or food packages near

the Ejector Blade.

Motor

Ejector Blade

NOTE: Do NOT block air coming into the refrigerator secon. Food or liquids can freeze if placed too close to inlet

air.

All refrigerator crispers, and also the freezer basket supplied on the side-by-side models, are designed to be at the

very BOTTOM of their compartments.

Using your freezer...

Meats, sh and poultry pre-packed in plasc (self-service)

wrap can be stored in the freezer for a couple of weeks.

For longer freezer storage, wrap food in foil or other vaporproof, moisture-proof freezer wrap. Frozen food containers should be sealed ghtly. If food is wrapped in “Butcher

Paper”, remove and rewrap.

For more even temperature, space food so as not to restrict air ow, especially at rear.

Light frost may form on shelves when freezer door is open.

Aer the door is closed, the air stream gradually removes

the frost.

Form

Stop Arm

Ice

Bucket

Shelf

Typical cycle of icemaker:

1. The icemaker lls with water.

2. When the water freezes, the motor rotates Ejector

Blade against the ice. The blade stops when it touches

the ice.

3. The heater releases the ice from the form.

4. The motor starts again. The blade moves ice from the

form into the bucket. The Ejector Blade makes two

(2) revoluons and then the icemaker lls with water

again.

25

USE AND CARE GUIDE FOR YOUR REFRIGERATOR/FREEZER

When the bucket is full and in the proper (highest possible) posion, the Stop Arm senses the ice and stops ice

making.

To stop the icemaker, whether full or not, simply raise the

Stop Arm to “up” posion. To restart, lower the Stop Arm.

TIME PER CYCLE... Varies due to door openings, water

temperatures, etc.

NORMAL ICEMAKER OPERATION

• Sounds to be expected: motor hum; creaking of the

Ejector Blade; ice dropping into the bucket; running

water; water supply valve snapping open.

• Frost formaons in area of the icemaker: Since

fresh water enters the form, frost build-up near the

icemaker occurs. This will not aect the operaon of

your freezer.

• Ice in the bucket for long periods may freeze together

and acquire odors. Discard stale pieces... Your icemaker will make more.

Temperatures...

are automacally controlled by thermostats. You may

adjust your refrigerator compartment without adversely

aecng freezer temperatures, and vice versa. The refrigerator and the freezer compartment each have their own

temperature control. The freezer control is located in the

roof of the freezer. The refrigerator control is either on

the upper le side wall (side-by-side models), or in the

roof area of the refrigerator. “3” is a good seng to start

out with... Lower numbers for warmer temperatures and

higher numbers for coldest temperatures.

NOTE: To help keep food fresh longer, some moisture is desirable in the food storage compartments. You may see it

on the walls, or in the form of droplets of ice or “icicles”...

especially in hot or humid weather, or when frequent or

extended door openings occur. This is normal, and not in

any way harmful. If occasional “spot” build-ups occur, it

is usually the result of the above, or of “overcrowding” of

food. Occasionally remove such accumulaon.

Defrosng...

is automac. It takes place in the Power Module, above

and away from your food. For several minutes each day

the compressor and interior fan will shut o, while any ice

accumulaon is removed from the coils.

Cleaning...

It’s easy to keep your Built-In refrigerator/freezer clean.

Occasionally, clean the interior walls, shelves, door interiors and gaskets with a soluon ot two (2) teaspoons of

baking soda dissolved in a quart of lukewarm water. Harsh

abrasives and cleaning powders are unnecessary and

should never be used. Do not place parts in the dishwasher.

It is recommended that circuit breakers be shut o before

cleaning. Wring excess moisture from sponge or cloth and

avoid excess moisture, especially when cleaning in the

vicinity of switches, lights or controls.

If your unit has a stainless steel interior, shelves or exterior

door then use a stainless steel cleaner and a cloth to clean.

Condenser cleaning procedure...

The condenser is located behind the top grille. It is a part

of the Power Module on its very right hand side. It has

horizontal tubes with small diameter vercal wires and

it is black in color. It is away from oor dust, however, it

should be examined for dust accumulaon at least two

(2) mes a year, and cleaned and/or vacuumed as neces-

sary. Remember to shut o the circuit breaker before

removing the grille and before exposing, cleaning, and/or

vacuuming the condenser.

There are three (3) styles of grille assemblies and each one

can be removed. Two (2) have removable facia assemblies

and the third one is the louvered grille. The rst two (2)

grille facia assemblies can be removed by rst, liing the

decorave/stainless steel grille panel up approximately

one (1) inch which will free it from the grille back, then

place the panel aside. The louvered grille is all one assembly.

There are three (3) ways to remove the grille back. The

rst style is with mounng brackets behind the grille back.

Pull the grille forward about one (1) inch to expose the the

top screw in the brackets. Unscrew the screw to loosen it

but do not remove it. Do this to each bracket. CAUTION,

when the screw is loosened, the grille back will be loose,

do not allow it to fall. Grasp the grille back on each side

and lt the top forward and li upward to free the grille

back from its mounng.

26

USE AND CARE GUIDE FOR YOUR REFRIGERATOR/FREEZER

The second style is with a screw mount. Locate the capit screw in the center of the grille back and pry o the

plasc cap with a wide at screw driver, then unscrew the

mounng screw. CAUTION, when the screw is removed,

the grille back will be loose, do not allow it to fall. Grasp

the grille back on each side and lt the top forward and li

upward to free the grille back from its mounng.

The third style of mounng is with springs. The spring(s)

are located behind the grille back. The spring(s) are

mounted to the top of the cabinet and hook to the square

holes in the grille back. To remove the grille, pull the grille

forward and reach down to the spring and unhook it from

the grille back. The grille

back will be free to be removed. The louvered grille is

heavy so use care when removing. Now you can inspect

the condenser for dust accumulaon.

Be sure to refasten top grille aer cleaning to avoid injury,

as grille could fall if not properly fastened.

Power Module

Condenser

(behind top grille)

Energy Saving Tips...

• Do not open doors more oen than necessary.

• Close the doors as soon as possible, parcularly in

hot, humid weather.

• Be sure the doors are closed ghtly.

• Before leaving the house or rering for the night,

check to be sure doors have not been le ajar inadvertently.

• Store only those foods requiring refrigeraon in your

refrigerator.

• Allow hot foods to cool to room temperature before

storing them.

• Keep all foods covered to reduce moisture build-up.

• Do not waste ice cubes by leng many melt while

only using a few.

• Do not turn controls colder than needed.

If you need service...

If your unit will not operate correctly then:

1. Take the necessary steps to preserve food. Remove

and store at a neighbor’s house or other facility if

needed.

2. The doors should be kept closed if possible unl the

unit is back in service.

3. Call your dealer or Service Agency. Please have bill of

sale, model and serial number available.

NOTE: Be sure to fully ll out and mail back your registraon card without delay. Failure to do so may void your

warranty.

Lower Cabinet

(food storage)

Record both the Module model number and cabinet

model number and serial numbers on the card and below

for future reference.

The module serial plate is located on the front of the module. The cabinet serial plate can be located on the inside

right side wall near the boom, or on the ceiling of the

compartment.

For Your Records

Date of Purchase

Dealer’s name

Dealer’s Address

Dealer’s City

Dealer’s State and Zip Code

Cabinet Serial Number

Cabinet Model Number

Module Serial Number

Module Model Number

Date Warranty Card Sent (Must be

within 10 days of purchase).

27

WARRANTY

Enre Product - Limited One Year Warranty

AGA MARVEL warrants that it will supply all necessary

parts and labor to repair or replace in your home, any

component which proves to be defecve in materials or

workmanship, subject to the condions and exclusions

stated below, for the period of one year from date of sale.

Enre Product - Limited Second Year Addional Warranty

During the second year, from date of sale, AGA MARVEL

will provide all necessary parts only to repair or replace

any component which proves to be defecve in materials

or workmanship, subject to the condions and exclusions

below.

Sealed System - Limited Six Year Addional

Warranty

During the second through seventh year, from date of sale,

AGA MARVEL will supply all necessary parts and labor to

repair or replace in your home, any poron of the hermecally sealed refrigeraon system, which consists of: the

compressor, condenser, evaporator, dryer and all connecting tubing, which proves to be defecve in materials or

workmanship, subject to the condions and exclusions

below.

Inner Liner - Limited Second Through Tenth Year Warranty

During the second through tenth year, from date of sale,

AGA MARVEL will provide all necessary parts to repair

or replace the refrigerator/freezer inner liner if the paint

chips or rusts and proves to be defecve in materials or

workmanship.

The above warranes do not cover:

1. Customer educaon or instrucons on how to use the

refrigerator/freezer.

2. Any food loss due to product failure.

Nor do the above warranes cover failure of this product

or its components due to:

3. Transportaon or subsequent damages.

4. Use commercially or use other than normal household.

5. Improper installaon, misuse, abuse, accident or

alteraon, use on wiring not conforming to electrical

codes, low voltage, failure to provide necessary maintenance or other unreasonable use.

6. Parts or service not supplied or designated by the

factory.

The above warranes also do not apply if:

1. The original Bill of Sale, delivery date or serial number

cannot be veried.

2. The product is moved from place of original installaon.

THE WARRANTIES, SET FORTH HEREIN ARE THE ONLY

WARRANTIES EXTENDED BY AGA MARVEL. ANY IMPLIED

WARRANTIES, INCLUDING THE IMPLIED WARRANTY OF

MERCHANTABILITY, ARE LIMITED TO THE DURATION

OF THESE EXPRESS WARRANTIES. IN NO EVENT SHALL

AGA MARVEL BE LIABLE FOR ANY CONSEQUENTIAL OR

INCIDENTAL DAMAGES OR EXPENSES RESULTING FROM

BREACH OF THESE OR ANY OTHER WARRANTIES, WHETHER EXPRESSED OR IMPLIED. Some states do not allow the

exclusion or limitaon of consequenal damages or limitaons on how long an implied warranty lasts, so the above

exclusion or limitaon may not apply to you. This warranty

gives you specic legal rights and you may also have other

rights which may vary from state to state.

No person, rm or corporaon is authorized to make any

other warranty or assume any other obligaon for AGA

MARVEL. These warranes apply only to products used in

any of the y states of the United States and the District

of Columbia.

To obtain performance of this warranty, report any defects

to:

1260 E. VanDeinse St.

Greenville, Michigan 48838

For quesons regarding coverage, contact your selling

dealer or local distributor.

28

NOTES

1260 E. VanDeinse St.

Greenville, MI

48838

800.223.3900

35256-000 revD

02/07/12

www.agamarvel.com

All specicaons and product designs subject to change without noce. Such revisions do not entle the

buyer to corresponding changes, improvements, addions, replacements or compensaon for previously

purchased products.

Loading...

Loading...