Page 1

SERIES 24

MODELS 24A-AF, 24B-BF-BP

HOT WATER SANITIZING UNDERCOUNTER

DISHMACHINE

FROM SERIAL NO. 23000

INSTRUCTION MANUAL

INCLUDES:

-Warranty Policy -Specifications

-Installation Requirements -Care and Cleaning

-Operating Instructions -Troubleshooting

-Illustrated Parts -Optional Drain Pump

-Service Agencies -Wiring Diagram

Highway 25E

P.O. Box 1060

Barbourville, KY 40906

1-888-800-JSMC(5762)

FAX (606) 523-9196

September 21, 1998 P/N 7610-100-35-00 Rev A

Page 2

INDEX

WARRANTY Inside Front Cover

SPECIFICATIONS 2

CONCEALED DAMAGE 4

GENERAL INSTRUCTIONS (Installation) 5

INSTALLATION CHECKLIST 9

GENERAL INSTRUCTIONS(Operation) 10

GENERAL INSTRUCTIONS (Preventive Maintenance) 11

REMOVAL of RINSE and/or WASH HEAD ASSEMBLIES

(General Instructions) 12

TIMER for SERIES 24 DISHWASHERS 14

FUNCTION of SWITCHES, CIRCUIT BREAKER

and INDICATING LIGHTS 15

THERMOSTAT ADJUSTMENT 16

RINSE TANK HEATER SYSTEM 17

WASH TANK HEATERSYSTEM 19

WATER LEVEL CONTROL 20

SERVICE NSTRUCTIONS(lncomingWaterSolenoidValve) 21

BEWARE of COUNTERFEIT PARTS 22

TROUBLESHOOTING GUIDE 23

PICTORIALS:

FRONT VIEW 26

BACK VIEW 27

LEFT SIDE VIEW 28

RIGHT SIDE VIEW 29

PAN STRAINER, VACUUM BREAKER, DOOR SWITCH

and LATCH ASSEMBLY, INCOMING PLUMBING 30

RINSE TANK, WASH ASSEMBLY, WASH or RINSE

THERMOSTAT, WASH or RINSE THERMOMETER 31

BOOSTER TANK HEATER ELEMENT, ELEMENT

GASKET, THERMOSTATIC OVERLOAD 32

PUMP and MOTOR ASSEMBLY 33

DRAIN VALVE, CUTAWAY VIEW, PANEL 34

WIRING DIAGRAMS 35

PUMP DRAIN OPTION 40

FUNCTIONAL BREAKDOWN of the FOUR MAIN PARTS of the

24BP and 24AP PUMP DRAIN SYSTEM 46

GENERAL INSTALLATION INSTRUCTIONS of MACHINE DRAIN LINE 48

PARTS LIST for the PUMP DRAIN SYSTEM 53

COMPLETE PARTS LIST for SERIES 24 54,55

PARTS DISTRIBUTORS Inside Back Cover

Page 3

Overall Product, in P

lace

RINSE TANK CAPACITY

MODEL

24

(No Booster)

•Total automatic cycle is 2 minutes 25

seconds

• Up to 50% more wash time than other

undercounter dishwashers

• Door activated cycle start switch

• Electric wash tank heater with low water

protection maintains proper wash

temperature

•Simplified controls for ease of operation

•Automatic fill

• Automatic drain

• Manual wash switch for deliming

• 100% fresh water rinse eliminates

problems of rinse water contamination

associated with re-circulating rinse

machines

• (18-8) 304 series stainless steel construction. 18 gauge material is used for

extra durability and years of reliable

service

• No switches or wiring in door

• One dish rack and one combination cup,

bowl and silver rack included

• 115 v/60 Hz/1 phase only

• Optional pumped drain

MODEL 24B

• Same Standard Features as above except

the Model 24B includes a 6.2 KW built-in

booster heater

• Built-in booster is sized to raise incoming

water 40°-50°F

• 208-230 v/60 Hz/1 phase only

• Optional pumped drain

MODEL 24F and MODEL 24BF

•Same Standard Features as above except

"F" models include (18-8) 304 series 18

gauge stainless steel top and side

panels for free standing installations

•Optional pumped drain

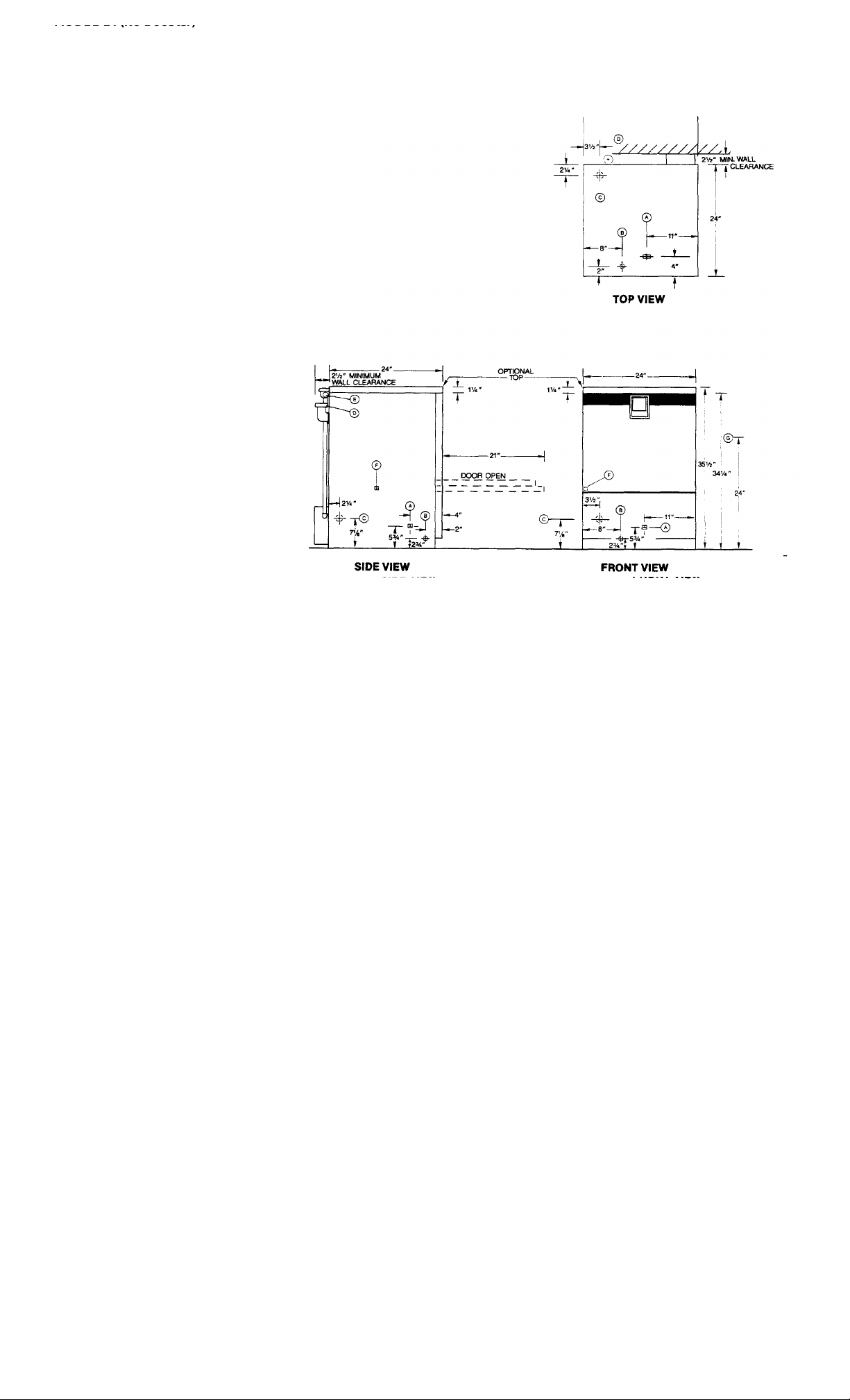

Dimensions

Height w/Top 36 1/4" ± 1/2"

Height w/o Top 341/2 a V1/2"

Width 24"

Depth 24"

Minimum Distance from

Wall to Machine 2 1/2"

Standard Table Height 34 1/2"

Maximum Clearance tor Dishes 14"

Legend

A. Electrical Connection.

B. Water Inlet - 1/2" Female Pipe

Thread. 2 1/2" High.

C. Drain Connection - 1 1/2" O.D.

D. Vented on Back. Cover underside of

countertop or table that will be affected

by moisture with suitable protective

material.

E. Rinse agent feeder connection.

F. Detergent feeder connection.

G. Maximum wall drain height with pumped

drain option.

NOTE: All dimensions from floor can be increased 1" with adjustable feet supplied.

Power/Connections

Model Model

24(F) 24B(F)

WASH PUMP MOTOR

Horsepower ELECTRIC HEAT WASH 1/2 1/2 OPERATING CAPACITY 24(F) 24B(F)

KW 1.0 1.0 Racks per Hour 21 21

ELECTRIC HEAT RINSE

KW N/A 6.2 Glasses per Hour 525 525

STANDARD RACK SIZE

Electrical Ratings 19 3/4 x 19 3/4 1 1

Model Volts Cycle* Phase Amps

15.5

1 (2

24,24F 115 60 24B,24BF 115/208-230 60

*50 cycle available

Water Requirements

Inlet Temperature— "F 180 140 WASH PUMP CAPACITY

Gal. per Hour 52.3 52.3 GalIons per Minute 60 60

Plow Pressure PSI 20 20 THERMOMETERS

Flow GPM 7.1 7.1 Wash-°F 140-160 140-160

Inlet—IPS 1/2" V2” Rinse- °F 180-195 180-195

Drain—O.D. 1/2" ½” SHIPPING WEIGHT - Pounds

(Gravity Feed Drain)

All specifications subject to change without notice.

wire)

1 (3

wire)

34.9 @

208v

37.8 @

230v

Performance/Capacities

Model Model

Dishes per Hour 525 525

OPERATING CYCLE

Wash Time-Seconds

Rinse Time-Seconds

Total Cycle-Seconds

WASH TANK CAPACITY

Gallons

Gallons

BASIC MODELS (Approx.) 200 200

CARTON SIZE (W x D x H) 30"x30"x38"

121

15 145

5.65

N/A

121

15

145

5.65

3

Page 4

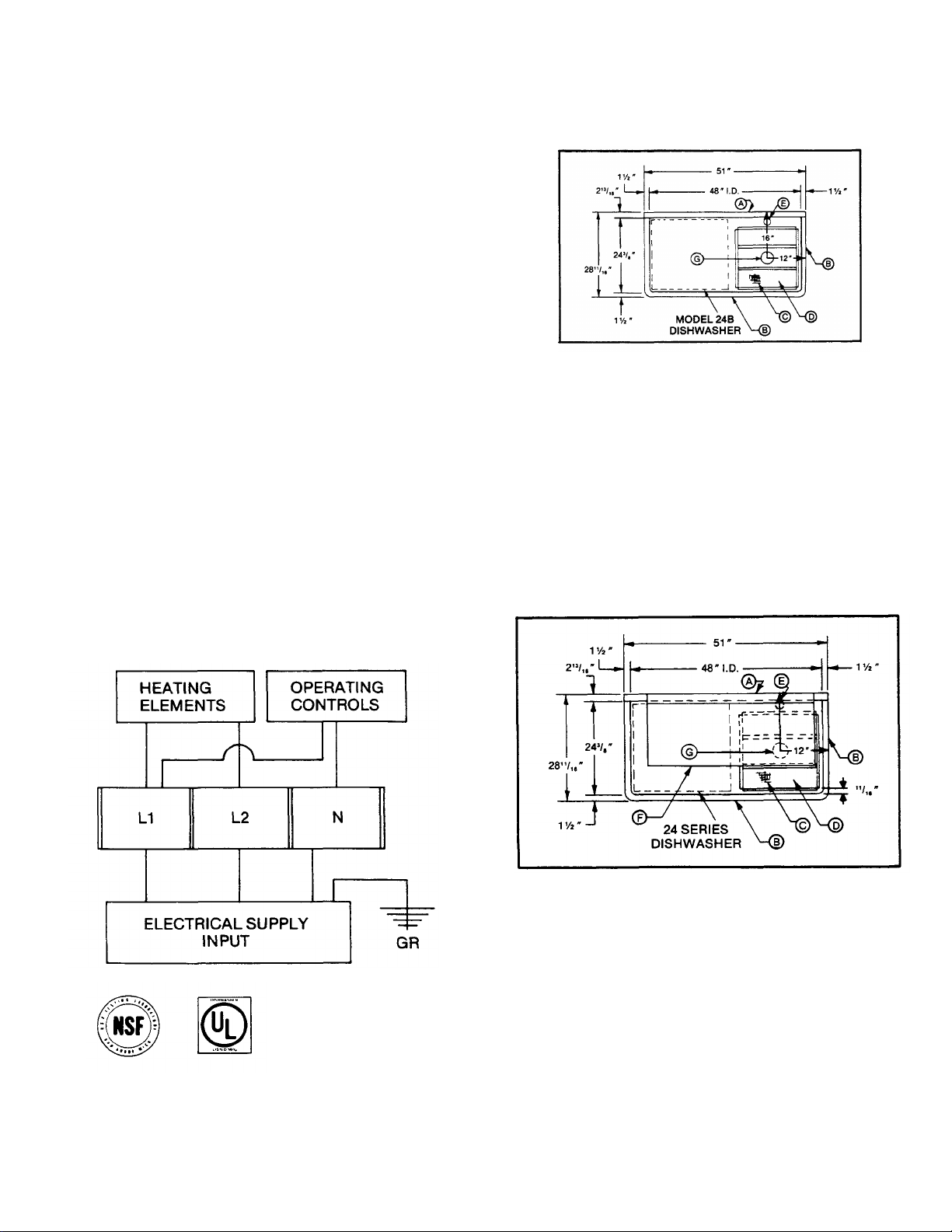

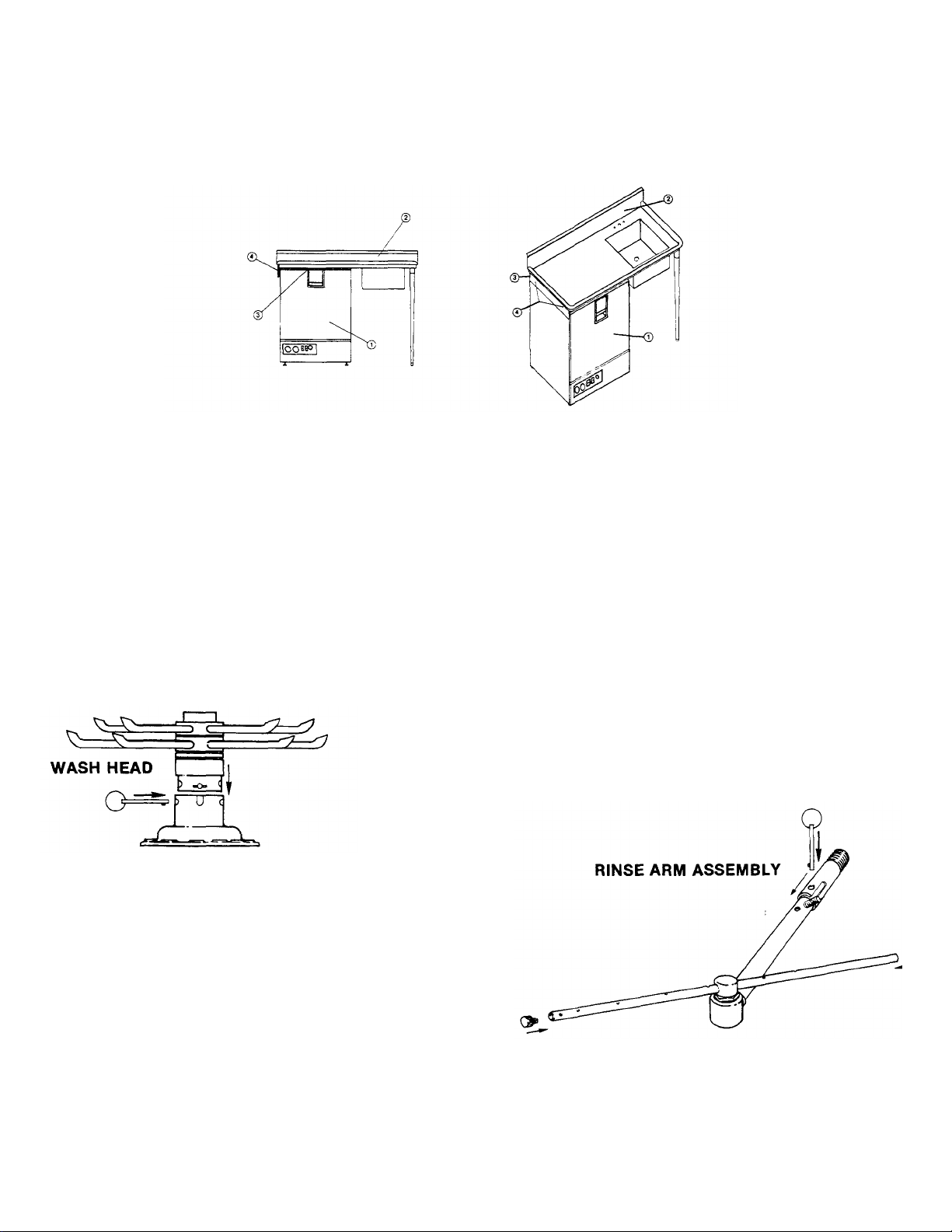

MODEL 24 TABLE PACKAGE OPTIONS

GENERAL INFORMATION 24.1 PACKAGE

• The system combines the 24 or 24B dishwasher with a standard

Dishtable.

• 42" wall mounted overshelf in 1-X package.

• The Dishtable and overshelf are constructed of 18-8 304 series 16

gauge stainless steel.

• Heavy duty pre-rinse spray.

• 20"x20"x6" deep pre-rinse sink with molded scrap basket and rack

slide.

• C33/16" high backsplash.

• Left and right side panels for machine.

NOTES:

A. 633/16" High Backsplash, 33/4" " Turnback

at 45°.

B. 3" High, 1 1/2" Dia. Rolled Edge.

C. Scrap Basket & "H" Bars.

D. 20 " x 20 " x 6" Deep Pre-Rinse Sink. Drain Connection 25 1/2 ± 1/2" from Floor.

E. Heavy Duty Pre-Rinse 13/16" Hole Size.

F. Slanted Wall Mounted Overshelf. 20" x 42" Long.

G. 3 1/2" Hole for Drain, Basket Assembly.

16 GA. s/s N.S.F.

CONSTRUCTION 24-1X PACKAGE

ELECTRICAL

CONNECTION DETAILS MODEL 24B ONLY

Page 5

CONCEALED DAMAGE

IMPORTANT: FOR YOUR PROTECTION, PLEASE READ AND OBSERVE THE FOLLOWING:

This merchandise has been thoroughly inspected and carefully packed before leaving our warehouse.

If it is found that the shipment has concealed damage, PLEASE DO NOT RETURN IT TO US, but notify and file a

claim with the carrier at once, as follows:

CONCEALED LOSS OR DAMAGE:

Concealed loss or damage means loss or damage which does not become apparent until the merchandise has

been unpacked. The contents may be damaged in transit due to rough handling even though the carton may not

show external damage. When the damage is discovered upon unpacking, notify the carrier within forty-eight (48)

hours by phone and in writing, asking them to send their agent to fill out an inspection report. Save the cartons so

he may see them and be sure to note in the report any black marks, creases, tears, crushed corners or any other

marks indicating rough handling.

DO NOT RETURN DAMAGED MERCHANDISE TO US. FILE YOUR CLAIM AS ABOVE.

Page 6

GENERAL INSTRUCTIONS

(INSTALLATION)

REFER TO SPECIFICATION SECTION FOR FURTHER DETAILS.

Note: Read the following instructions carefully. Proper installation of your Jackson

Dishwasher will assure proper machine operation.

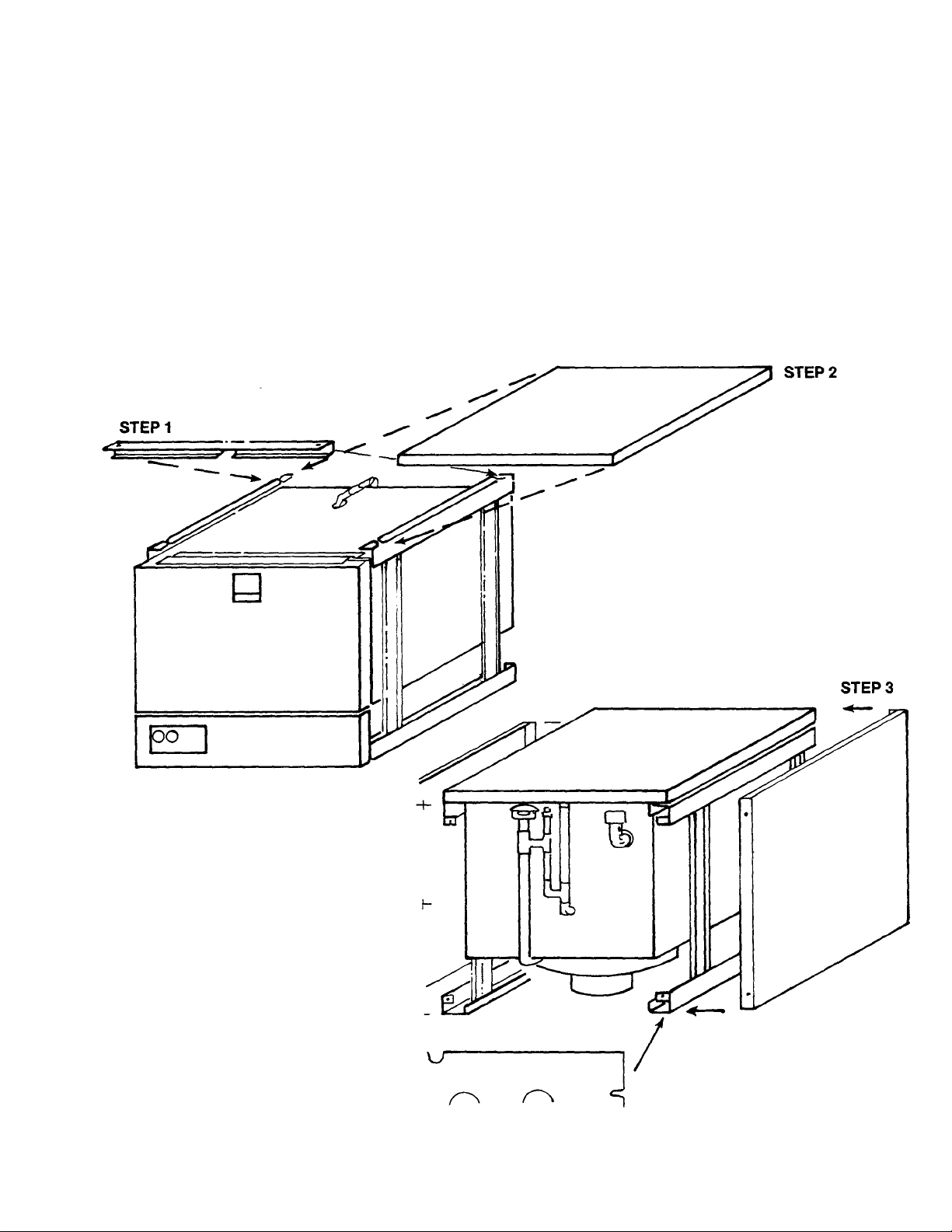

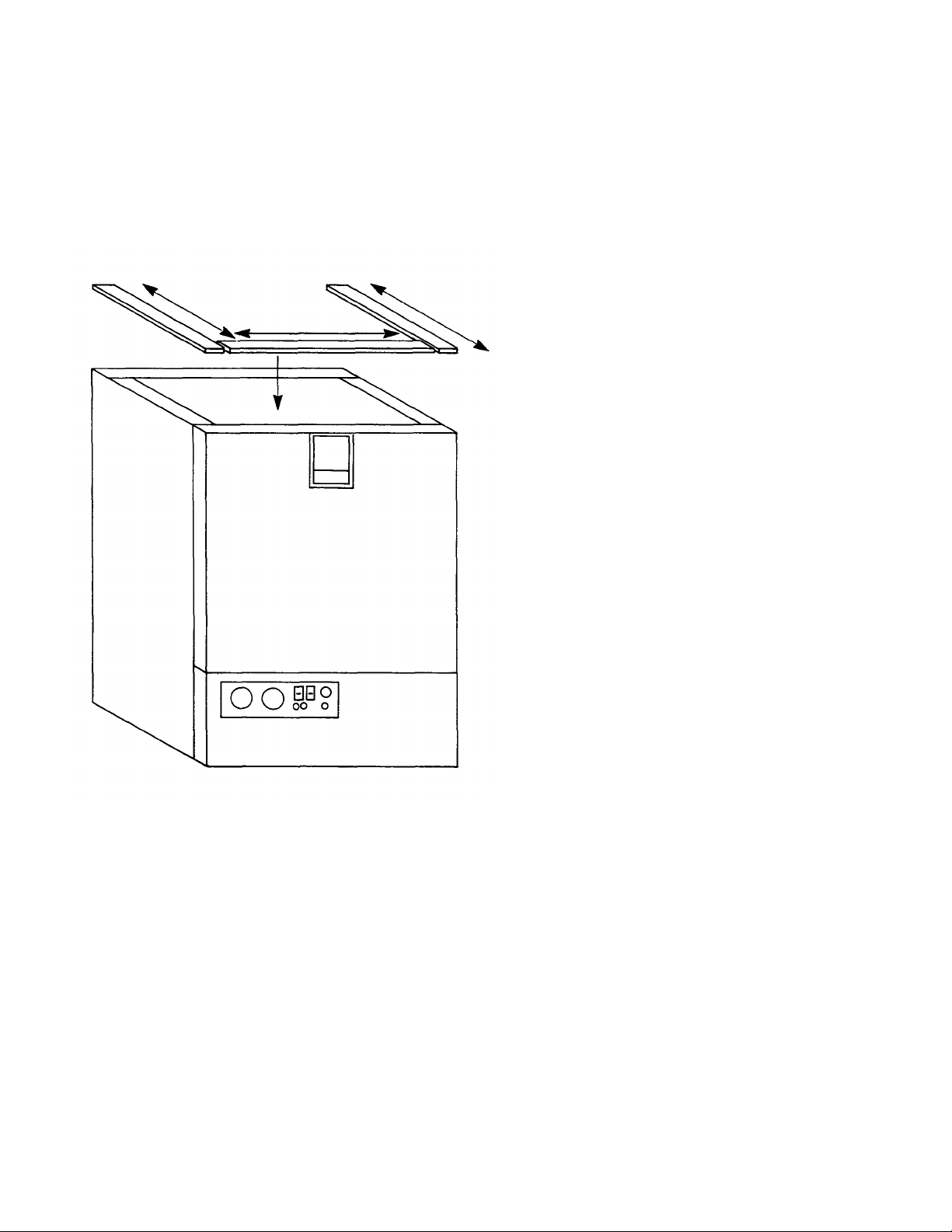

Uncrating 24:

1. Remove wooden blocks from carton.

2. Slide carton sleeve upward over top of dishwasher, set to one side.

3. Remove bolts holding wooden base to machine and screw in adjustable feet supplied. (Feet are

inside of dishwasher.)

4. Set dishwasher in place, ready for installation

Note: NSF base cradle must be field installed on all 'F' and 'P' models. Cradle goes under

machine and must be sealed in place using silicone sealant.

Installation Instructions:

1. The dishwasher can be leveled to the proper height by adjusting the feet on the four corners. The

front of the unit must be 1/4" to 1/2" higher than the back.

2. Refer to the dimensional data sketch for connections.

3. The drain from the machine is a GRAVITY DRAIN SYSTEM and should have the proper drop from

the machine to an open floor drain, vented to atmosphere. The drain connection is located to the left

rear of the machine when facing the machine's door. The drain fitting is I 1/2" OD tube size, 7" from

floor.

4. IMPORTANT — PLEASE READ — Located on the back upper left corner of the unit is a steam

equalizing vent. This vent in no way should be blocked or prevented from allowing steam to be

vented to the outside of the unit or from under the cabinet in which the unit is installed. Never pipe

the steam downward toward the floor. (SEE PAGE 5 IF IT IS BEING INSTALLED UNDER A

COUNTER.)

5. The electrical connections should be made to the terminal board located at the center front. The

terminals are marked L1, L2, and Neutral. Install proper circuit breaker and conduit size to conform

with local and/or national codes (standards). USE COPPER WIRE ONLY (#8 AWG).

Page 7

Installation of Top and Sides on 'F' and 'P' Models:

1. Insert rear barrier with angle facing out. Install prior to placing top on uit.

2. Place top on unit, making sure front lip is under flange, but does not interfere with latch or switch

mechanism. Place studs in holes on back of unit. Use 1/4-20 nuts.

NOTE: For 'P' models, omit steps 1 and 2.

3. Remove kickplate. Open door and place side panel lip at door opening. Work panel under top by

pushing with palm of hand. Put self-tapping screws in four places. Both side panels are installed in the

same way. Note: If unit being installed is an 'F' model, do not put the bottom rear self-tapping screw in

each panel until step 4.

4. 'F' models require a back panel. For installation, slide back panel behind lip of side panels and secure

with the two remaining self-tapping screws.

Page 8

Installation of Model 24 Top and Table gasket:

These instructions are to be used for applying the adhesive backed sponge rubber strip to the top of the

machine prior to setting the table in place.

Included with the Model 24 table is a 6 foot length of 1/4" thick x 1" wide sponge rubber adhesive backed

stripping.

Instructions for applying gasket:

1. Place one end of the stripping along the complete

side of the leg support flange and cut it off.

2. Repeat the same procedure along the other side.

3. Place the remaining piece along the front edge, fit it

in between the side pieces and cut it to length.

4. Remove the backing and set the strips in place.

Instructions for installation under a porous

counter top:

1. If possible, a hole should be cut through the counter

top directly above the equalizing vent. A piece of 1

1/4" OD pipe is then inserted through the hole into the

vent opening and piped to the outside.

2. If cutting a hole in the counter is not possible, then a

piece of stainless steel 36" wide by 36" long bend in

the middle at 90 should be centered directly over the

vent to allow the steam to condense on it when it

comes out of the vent.

3. It is very important that this vent be kept open and

cool air allowed to circulate around the unit.

Installation of Model 24 Dishwasher Under Dishtable:

1. On the end of the table, locate bracket #4 opposite the sink end.

2. A square rubber gasket #3 is supplied and should be secured to top frame of dishwasher with

caulk or suitable adhesive.

3. Place dishtable #2 where it is to be installed and support the machine's end.

4. Slide dishwasher #1 underneath dishtable #2 so that the outside of machine is positioned against

the guide bracket #4. Make sure dishtable and dishwasher are in desired permanent location.

Page 9

5. Using the two holes in bracket #4 as a guide, drill two holes 9/64" diameter in the side panel of

machine. Note: Drill through first thickness of metal only.

6. Using the self-tapping screws supplied, screw them through bracket #4 and into the side panel of

machine until screws are tight.

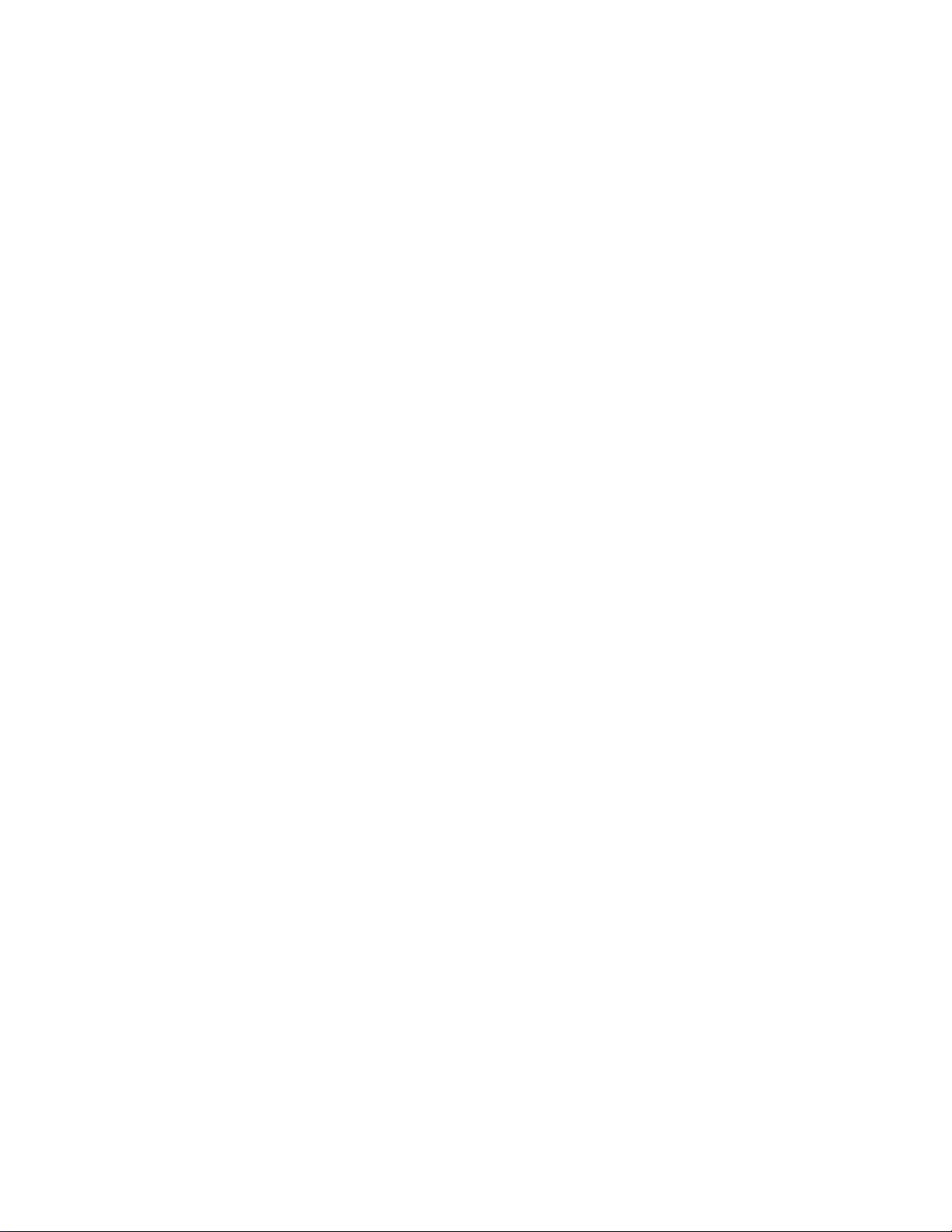

Removal of Pan Strainer for Cleaning: (Wash and rinse head assemblies must be removed prior to

removing strainer.)

1. Turn machine off and drain by depressing drain switch and releasing.

2. Remove holding pin from rinse feed pipe, remove rinse head assembly by pulling forward.

3. Remove holding pin from upper pump housing, wash head may now be lifted out.

4. Pan strainer now accessible, lift out and clean thoroughly.

5. Clean around pump intake with bristle brush.

6. Replace stainer pan.

7. Re-install wash and rinse head assemblies.

8. Clean strainer pan daily or as needed to insure proper machine operation.

Installation of Wash Head and Rinse Arm Assemblies: (Items disassembled for shipment)

1. Line holes up on wash head assembly to match slots in pump housing.

2. Insert wash head assembly down into upper pump housing as far as

possible.

3. Insert retaining pin to secure wash head to pump housing.

1. Line up stud to match with slot in nipple.

2. Insert rinse arm assembly into female receptical

protruding through back of machine.

3. Insert lanyard pin to secure rinse arm assembly

properly.

4. Make certain end plugs are secured properly in

rinse tubes.

Page 10

INSTALLATION CHECKLIST

Please check off the following items as they are completed. All items must be completed and checked off

before proceeding to machine operation.

In the event that installation information is needed, please call one of Jackson Products authorized

service agencies, dealership where purchased or Jackson Products Company Technical Assistance

(813) 985-8144.

1. Is machine pitched up 11/4-11/2 inch in front than rear?

2. For gravity drain systems — is machine's gravity drain connected to a open floor drain "vented to atmosphere"?

3. Is machine service voltage at L1 and L2 208-230 volts?

4. Is machine service voltage at L1 and neutral 104-120V?

5. Is machine properly grounded?

6. Is machine service breaker properly sized to total amp load as specified on data plate?

7. Is machine supplied with 140°F hot water at 20 PSI flow pressure with capacity of 52.3 gallons per hour?

8. Is water supply line to machine a minimum of 1/2 inch?

9. Is a pressure reducing valve installed on inlet water line for pressures greater than 20 PSI flow?

10. Is equalizing vent vented to atomopshere?

11. Is pump intake strainer installed?

12. Is lower rinse spray arm installed?

13. Is wash spray head installed?

Page 11

GENERAL INSTRUCTIONS

(OPERATION)

Note: Read the following instructions carefully. Proper operation of your Jackson

Dishwasher will assure clean and sanitized glasses and dishes, at optimum efficiency. Dish

Preparation:

1. Scrape dishes thoroughly.

2. Pre-wash dishes by soaking or with hose.

3. Place dishes and cups in dish rack, cups upside down.

4. Place glasses and silverware in combination glass-silverware rack, glasses upside down. Scatter silverware

loosely on bottom.

Note: Silverware in the upright position washes and rinses better than lying flat. These silverware

compartment racks are available through your dealer or Service Agency.

24B/BF Operating Instructions:

1. Install pan strainer and the wash and rinse arms. Close the door and push until the handle latches.

2. Push the On/Fill-Off/Drain switch to the up 'ON/FILL' position. The machine power light will come on and so will

the rinse heaters. The machine will begin to fill automatically and stop by itself.

3. After the machine has completed filling, open the door and put in a rack of soiled dishes. Close the door.

4. After the door has been closed, the cycle light will come on. There will be a 2-second delay before the wash

cycle begins.

5. The machine will wash for 130 seconds and rinse for 15 seconds. After the cycle has finished, the cycle light will

go out.

6. Open the door and remove the sanitized dishes. The machine is ready for another cycle.

7. To manually wash, push the manual wash switch to the up 'Manual' position. The machine will wash indefinitely.

This function can also be used to delime. To resume normal operation, push the manual wash switch to the

down 'Auto' position.

8. To drain the machine, close the door and latch. Push the On/Fill-Off/Drain switch to the 'OFF' position. All

machine functions will be off. Push On/Fill-Off/Drain switch down to the momentary drain position. This will begin

the drain cycle. After the machine is drained, it will turn itself off.

9. Open the door. Remove and clean the pan strainer and the wash arms.

10. Wash heater protection is provided by two means. Primary protection is given by the water level control which

senses the water level with a probe. If this should fail due to excessive build up on the probe, the secondary

thermal protection will cut out the wash heater before damage occurs.

11. When the secondary heater protection has been used, it will be indicated by the illuminated red reset light.

The following steps are necessary in this situation:

A. Turn off power supply.

B. Open the door and remove the wash and rinse arms and the pan strainer.

C. Locate the probe. It is in the wash sump on the left hand side.

D. Using a deliming compound and a brush, clean the probe.

E. Reinstall the wash and rinse arms and the pan strainer.

F. Push the reset button, located above the reset light.

G. Push On/Fill-Off/Drain switch to the 'ON/FILL' position. The machine should begin

to fill. If it does not and the reset light comes on again, call an authorized service

agency.

Detergent Recommendations and Rinse Additives:

We suggest that you contact your local Detergent Specialist for the correct detergent and rinse additives for your

area. Dump the detergent on the pan strainer. This may have to be increased or decreased to obtain satisfactory

results.

VERY IMPORTANT: Do not use a domestic type detergent in this machine at any time. This type of detergent may

damage and/or obstruct pump operation and may cause corrosion to tank.

10

Page 12

GENERAL INSTRUCTIONS

(PREVENTIVE MAINTENANCE)

USER SERVICEABLE AREAS

(THE FOLLOWING IS TO BE PERFORMED DAILY OR AS NEEDED.)

Note: Read the following instructions carefully. Proper maintenance of your Jackson Dishwasher

must be conducted for warranty consideration.

1. Remove all lime and corrosion deposits.

a. Fill the machine with wash water as would ordinarily be done for washing.

b. Open door and place one cup or less of de-liming compound into the water. The

compound is available from your detergent supplier.

c. Turn on the manual wash switch and allow to wash for five minutes.

d. Open door and examine the interior. All lime should be removed and parts should be

shiny. If not, allow to wash for longer period.

e. After the interior is clean, with door closed, empty the wash water by turning switch to

the "off/drain" position. Refill machine and allow to run for two minutes, then again

drain the wash reservoir.

2. Clean around overflow strainers and drain hole.

a. Clean around overflow and strainer pan.

b. Clean around pump intake (toothbrush makes excellent tool for cleaning).

3. Clean Y-strainer on incoming water line. (Water to machine must be turned off for this operation)

a. Remove plug and clean strainer.

4. Clean rinse tubes.

a. Remove rinse assembly by disconnecting rinse feed pipe and removing end plugs on

lower rinse.

b. Clean all rinse tubes and feed pipes with special brush supplied.

c. If spray holes in the rinse tubes are clogged, they may be cleaned with a pointed

object.

5. Clean water level probe in sump with brush to remove any scale or build-up.

6. Clean wash head assembly.

a. Remove pin holding wash head assembly to pump.

b. Clean assembly at sink by flushing water through spray jets.

c. If spray jets are still plugged, use sharp object to dislodge and flush again.

d. Reinstall wash and rinse assemblies. (See page with instructions.)

7. Clean any deposits which may have built up on exterior moving parts.

a. Clean around door gasket.

b. Using a soft bristle brush, clean around switches on exterior of control panel. (Use no

water.)

c. Use soft bristle brush, dip in wash tank water and scrub inside door around gasket

and hinges. Use clean cloth or paper towel to wipe off loose residue.

HARD WATER AREAS

Very Important: Areas known to have hard water (7-10.5 grains per gallon) or very hard water (10.5 + grains

per gallon) must consider installing a water softner system to prevent scaling of heater

elements and water probes which could cause damage not covered under normal warranty

conditions.

Page 13

REMOVAL of RINSE and/or WASH

HEAD ASSEMBLIES

(GENERAL INSTRUCTIONS)

USER SERVICEABLE PARTS

(THE FOLLOWING IS TO BE PERFORMED DAILY OR AS NEEDED.)

1. Drain unit by placing switch in the off/drain position.

2. Open the door and allow the unit a few minutes to cool off.

3. Remove the pin holding the rinse feed pipe. Pull the feed pipe out of the nipple and lay it to one

side.

4. Remove wash head assembly by pulling out the holding pin and lifting assembly. Place the wash

head on a table for disassembly.

5. Locate Allen head set screw in the wash head cap, insert Allen wrench and loosen screw by turning

counterclockwise.

6. Turn wash head cap counterclockwise until cap is removed and put cap in safe place.

7. Remove 1/4" stainless ball bearings carefully and put it in a receptacle in a safe place.

8. Lift and remove small manifold with short tubes. Put it in a safe place.

9. Remove 1/4" ball bearing in similar method to step #7.

10. Lift and remove large manifold with large length tubes similar to step #8.

11. Clean ball bearings by soaking in de-liming solution.

12. Ball bearing race ways may be cleaned by either brushing with de-liming solution

(toothbrush makes excellent tool) or gently clean by rubbing with fine sandpaper or emery cloth.

13. Rinse ball bearings and manifolds thoroughly.

14. To reassemble, first fill lower race to capacity with 1/4" ball bearings, then remove one. This will

give proper movement needed during rotation of assembly.

15. Replace lower manifold and fill race fully with 1/4" ball bearings. Repeat, removing one only.

16. Replace upper manifolds and repeat necessary parts of step #14.

17. Replace wash cap by screwing on center shaft clockwise, finger tight.

18. Back off wash cap about 1/4 turn and tighten Allen set screw.

19. Rotate manifolds in opposite directions; see if they rotate freely. A rule of thumb is to select the

longest tube in the bottom manifold and make sure it moves up and down at least 1/8" and no more

than 1/4".

20. Replace wash head assembly and rinse arm.

21. Close the front door and refill dishwasher.

22. Run through several cycles and recheck wash arms for easy movement. Adjust if necessary.

Note: It Is Important that the wash head and rinse arm be kept clean and free from

obstruction. Improper maintenance to these assemblies may create problems not

covered under normal warranty conditions.

Page 14

ITEM

w/TUBES

w/TUBES

1. 0186500 WASH HEAD CAP WITH RACE 6. 0187500 WASH HEAD CENTER SHAFT

2. 0187000 WASH HEAD CAP SET SCREW 7. 0193601 WASH HEAD FIXED RACE

3. 0194000 WASH HEAD BEARING 1/4" SIS

4. 0189000 WASH HEAD SMALL MANIFOLD 9. 0188601

5. 0189500 WASH HEAD LARGE MANIFOLD

P/N DESCRIPTION ITEM P/N DESCRIPTION

8. 0109600 UPPER PUMP HOUSING

WASH HEAD ASSEMBLY

RETAINING PIN w/RING

ITEM

1. 0125200 RINSE HEAD ARM 5. 0126500 RINSE HEAD SNAP RINGS S/S

2. 0126800 RINSE HEAD END PLUGS 6. 0137301 RINSE FEED PIPE LANYARD PIN

3. 0126000 RINSE HEAD NYLATRON WASHER 7. 0137200 RINSE FEED PIPE (LOWER)

4. 0125500 RINSE HEAD HEX BRUSHING S/S 8. 0137202 RINSE FEED PIPE NIPPLE

P/N DESCRIPTION ITEM

P/N DESCRIPTION

Page 15

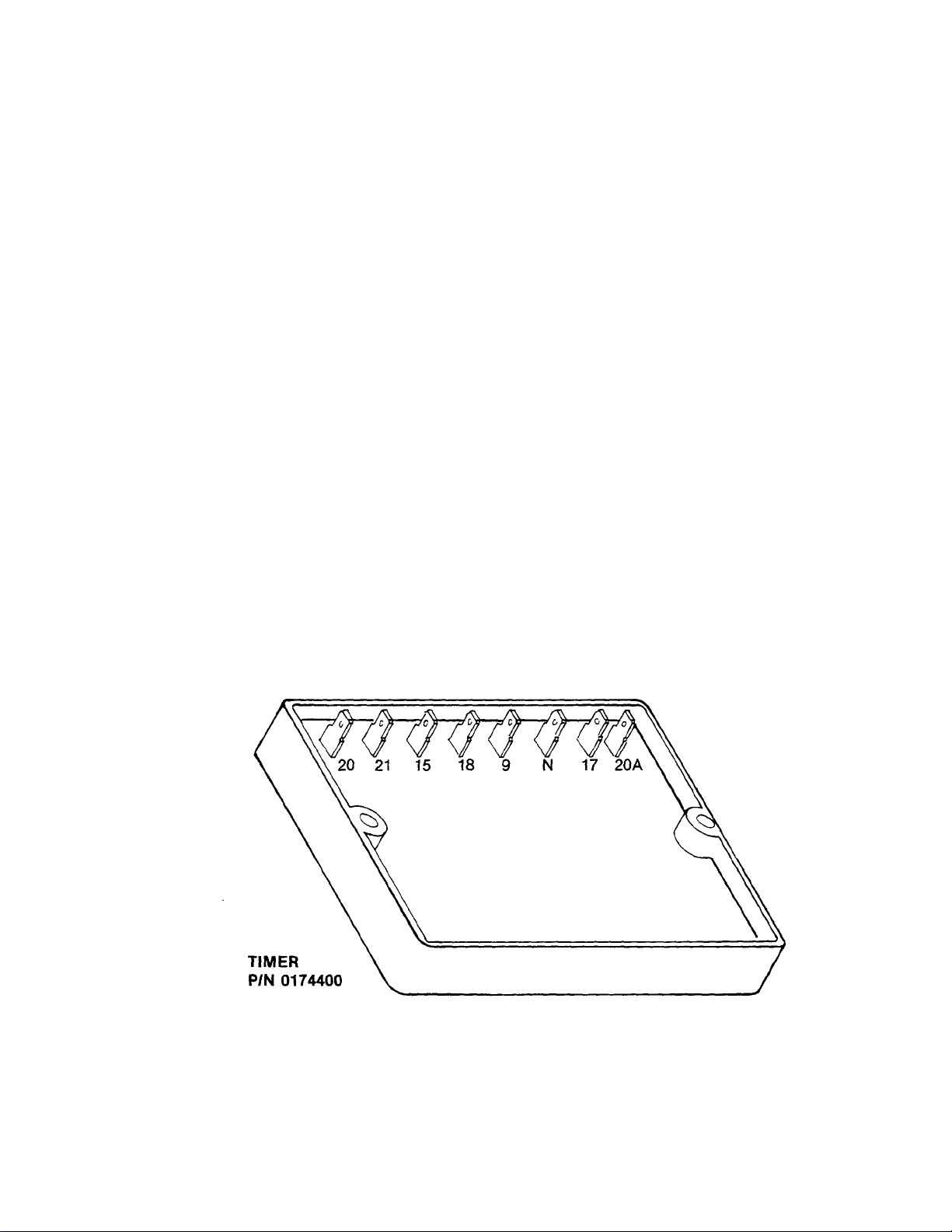

TIMER for MODEL 24

DISHWASHERS

General Description:

The timer is a solid state, 4 channel CMOS device with a 120V, 50 or 60 cycle, 1 amp rating. All

components are environmentally encapsulated and quick connect terminals are marked for

corresponding wires.

Principle of Operation:

Wash cycle function: (Machine must fill before cycle will start.) Upon closure of door switch,

cycle light will come on and remain on for the 150-second cycle. At the same time, a 2-second

rinse preheat interval will begin. After the preheat, the wash cycle will start and last 130

seconds. Between wash and rinse, there is a 4-second dwell followed by a 15-second rinse.

Cycle by opening and closing door switch at the end of cycle or at any point in the cycle.

Drain cycle function: (Power switch must be in off position and door switch closed.) When

power switch is pushed to the drain position and released, a holding circuit is established

between R4 drain relay and the timer. The machine will drain for 60 seconds and then break the

holding circuit. Cycle is reset by opening and closing door switch and pushing power switch to

drain and releasing.

Very Important: At no time are there to be any aftermarket equipment electric

connections made to any Input or load circuits of this timer. Consult

factory for further information.

Page 16

FUNCTION of SWITCHES, CIRCUIT

BREAKER and INDICATING LIGHTS

On/Fill

Off/Drain

Switch: P/N

0155600

Power Light:

P/N 0083518

Door Switch:

P/N 0164000

Cycle Light: P/N

0083507

Manual Wash

Switch:

P/N 0159700

Heater Reset

Button:

P/N 0169601

This switch serves as the main control for the unit. When pressed into the 'on' position, it

activates the heater controls, the automatic fill and readies the unit for the wash cycle.

When turned off, all power is off. When pushed to drain position and released, the unit

will drain and turn itself off.

This light comes on when the unit is turned on and goes off when the unit is turned off.

Located on top of the unit, behind the latch bracket, this switch serves three functions.

When the door is opened, it will reset the timer to the cycle starting position. When door

is closed, it will start the automatic cycle. If door should be opened during a cycle, it

would act as a safety switch by turning the unit off.

This green light comes on only when the automatic cycle is in progress and goes off

when the cycle is complete.

This switch is used to bypass the timer and operate the wash pump manually. The wash

pump will run as long as this switch is 'on'. Its prime purpose is to extend the wash

period for heavily soiled dishes, but it may be used for deliming.

This is the reset button on a thermostatic overload. Its purpose is to provide a secondary

protection for the wash tank heater element. If the heater element should come on while

the wash tank is empty, this button would pop out, turning off the element and signaling

a problem with the automatic fill.

Reset Light:

P/N 0083518

This light comes on only when the heater reset trips off. Its purpose is to signal that

there is a problem.

Page 17

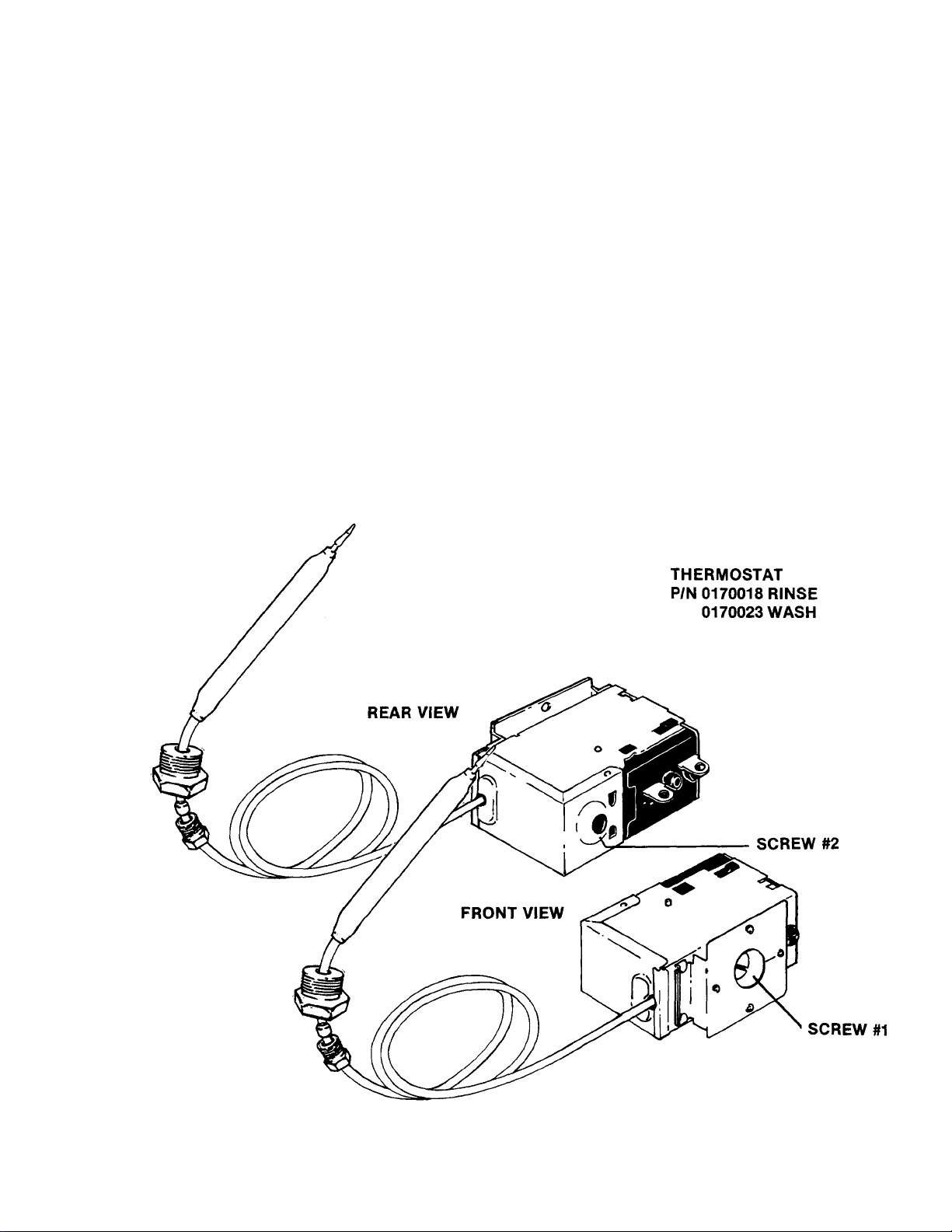

THERMOSTAT ADJUSTMENT

The thermostat can be adjusted by turning screw #1 (see picture) on the thermostat control box cover.

(Remember the present setting, in case the problems are elsewhere in the control circuit.) A CW rotation is

used to obtain a lower temperature setting and a CCW rotation is used to obtain a higher temperature setting.

A 1/8 turn of screw #1 changes the temperature approximately 15 °F. If screw #1 is turned all the way to its

stop in either direction, adjust screw #2 as follows.

Note: Do not touch the screw sealed with red paint. When adjusting screw #2, power should be

disconnected during adjustment.

Set screw #1 so that it can be turned equal distances in either direction, then:

— if screw #1 stopped while turning in CW direction, turn screw #2 in CW direction, slowly and only 1/8 of a

turn or less per complete cycle of the unit.

— if screw #1 stopped while turning in CCW direction, turn screw #2 in CCW direction, slowly and

only 1/8 of a turn or less per complete cycle of the unit.

Three-fourths of a turn will bring the thermostat to approximately the same setting obtained where screw #1

stopped. Check the present temperature setting before attempting any further adjustments. Use screw #1 for

any further adjustments.

Making large moves in adjusting may cause misalignment, thus increasing chances that further adjustment

cannot be made and thermostat will have to be replaced.

Page 18

RINSE TANK HEATER SYSTEM

Function:

The Rinse Tank Heater System is electrically connected in the circuit with the control system functioning

on 110/130V and the power system functioning on 208/230V for both systems. The heat circuit is

controlled by the 'on/fill' switch (mounted on front panel) and a thermostat (mounted near thermometer)

which activates the coil on the heat relay. When higher temperature is required, power is applied to the

heaters when the contacts of the heat relay are closed. Should the rinse tank thermometer read either

too high or too low, follow checkout below.

Checkout of Heater System for Rinse Tank: (Refer to drawing, Figure #2)

Note: The following checkout should be done by a qualified service person or electrician.

1. Turn off power to machine by tripping circuit breaker to 'off position.

2. Remove front kick plate below door.

3. Make sure rinse temperature is below 180°.

4. Reapply power and observe heat relay (2-pole) letter G, figure 2, as 'on/fill' switch is turned on and

off several times.

AA If heat relay contacts do not close, with 'on/fill' switch on:

1. Check power supply at Position 1 on terminal board X. Voltage should be 110VAC.

2. Check Position 3; there should be 'zero' volts there. If not, readjust thermostat per thermostat

instructions.

3. If voltage is being applied to Position 1, then the relay should be replaced; coil on relay probably

defective.

BB To determine if elements are working:

1. There's an insulated movable bar on the heat relay across the top of the two

contacts. With an insulated probe, depress the bar and observe rinse thermometer;

the temperature should rise noticeably in a minute or two. If it moves very slowly, it

would indicate that one element is defective. If it moves consistently higher at a

good rate, the elements are okay.

Note: A check with an amp probe, if available, can be made.

The element should draw 22-25 amps. Replace element if found defective.

CC If the heat relay closes:

1. Check power supply at Position 4 on terminal board X, right hand view. It should be 220V

approx. If not, check circuit breaker at customer's panel; replace if defective.

2. Check power at Position 5; voltage should be 220V. If not, check connections and wires for

breaks; replace as necessary.

3. With 'on/fill' switch on and relay closed, check power at Position 6; voltage should be 220V. If

not, replace heat relay.

4. If No. 3 above checks out okay, check at Position 7; voltage should be 220V. If not, check wiring

from heat relay to elements for loose connections or broken wires;

repair as necessary.

Page 19

A - ON/FILL SWITCH F - RESET LIGHT

B - WATER LEVEL CONTROL G -RELAY

C -THERMOSTAT H - RINSE HEATER

D - (WASH) RING HEATER X - TERMINAL BOARD

E - THERMOSTATIC OVERLOAD

Page 20

WASH TANK HEATER SYSTEM

Function:

The Wash Tank Heater system is electrically connected in the circuit, with the control system functioning

on 110V and the power system functioning on 208/230V. (On models without built-in booster, power

circuit is 110V.) The heat circuit is controlled by the water level control (mounted right side of control

panel), thermostat (mounted near thermometers), and thermostatic overload (located beside manual

wash switch), and wash heat relay (R-2). When higher temperature is required, power is applied to the

heater when the contacts of the heat relay are closed. Should the wash tank thermometer read either too

high or too low, follow checkout below.

Checkout of Heater System for Wash Tank: (Refer to drawing, Figure 1.)

Note: The following checkout should be done by qualified service personnel or electrician.

1. Turn off power to machine by turning circuit breaker to 'off position.

2. Remove front kickplate below door.

3. Turn circuit breaker back on.

4. With door closed and latched, turn the 'on/fill' switch to the 'on/fill' position. Machine should start to fill

automatically. Observe the water level control, letter B. When machine has filled for approximately

25 seconds, contact points in clear plastic relay should move, and an automatic cycle should start.

Note: This will happen everytime 'on/fill' switch is turned off and back on.

AA If water level control relay doesn't close, refer to page on Water Level Control function and checkout.

BB If water level control is functioning properly:

1. Check voltage at Position 1 on terminal board X. Voltage should be 110.

2. Check Position 3, Figure 1; there should be no voltage. If there is voltage, then adjust thermostat

(refer to page on Thermostat Adjustment).

3. Check reset light. If light is on, push reset button.

4. Check voltage at Position 2. There should be no voltage. If there is voltage, relay should be

replaced; coil is probably defective.

5. Check Position 5, Figure 1. Voltage should be 220. If not, check Position 8. There should be

220V.

6. Temperature should rise slowly. A check with an amp probe would indicate if the element is

working. Replace element if defective.

Page 21

WATER LEVEL CONTROL

AS USED ON 24

P/N 0204400 (110V, 60 cycle)

Function:

The water level control device is utilized on this machine to automatically control the filling of the

wash tank and the activation of the wash tank heater.

Note: All electrical checks should be made by qualified service personnel.

The control is a single probe resistance sensing device designed to maintain water level. When

water level reaches the probe and covers it, a fixed time delay of 25 seconds is initiated. When

the delay times out, the electromechanical relay energizes, opening the 'Auto/Fill' circuit and

closing the wash heater circuit. If the water level drops below the probe, the relay will deenergize, opening the wash heater circuit and closing the 'Auto/Fill' circuit.

Symptoms of Level Control Failure:

1. 'Auto/Fill' will not shut off when water reaches the proper level. (Check sensitivity

adjustment.)

2. Machine will partially fill.

Proceed with Checkouts:

1. Remove power source to machine by moving circuit breaker to 'OFF' position.

2. Remove screws holding lower kick plate to the front of machine and locate water level

control. (See sketch below.)

3. Remove, mark and insulate (for easy replacement), wires going to pin numbers 4 and 5.

4. Re-apply power. Turn on 'ON/FILL' switch. With an insulated wire, connect jumper wire

between pins 4 and 5. (12 volt system)

5. Wait for 25 seconds. The electromechanical relay will energize. If this occurs, control can be

deemed operational; then other causes should be explored.

6. If relay doesn't operate, check GND and input voltages. Replace if needed.

7. Remove power source once again and replace wires that were removed in step three to

original pins. (See trouble shooting section for other possible causes.)

Page 22

SERVICE INSTRUCTIONS

(INCOMING WATER SOLENOID VALVE)

SOLENOID VALVE

P/N 0142100

(110V, used on 60 cycle machine)

To take the valve apart:

Disassembly — These valves may be taken apart by

unscrewing the bonnet and the enclosing tube assembly

from the valve body assembly. See Fig. 3. After

unscrewing, carefully lift off the bonnet and enclosing

tube assembly. Don't drop the plunger. The "O" ring seal

and diaphragm cartridge can now be lifted out.

Be careful not to damage the machined faces while the

valve is apart.

To Reassemble — Place the diaphragm cartridge in the

body with the pilot port extension UP. Hold the plunger

with the synthetic seat against the pilot port. Make sure

the "0" ring is in place, then lower the bonnet and

enclosing tube assembly over the plunger. Screw

bonnet assembly snugly down on the body assembly.

Possible Problems

Pilot Port extension #1 clogged Hole #2

clogged

Remedy

Pass heated straight pin through hole #2 or

clean hole #1

Page 23

BEWARE of COUNTERFEITING!

No, not money, but counterfeiting of parts that could cost you hundreds of dollars.

The only difference between this form of counterfeiting and monetary counterfeiting is that is may be

legal. In our economy it's called competitive business. However, as an end user, are you aware of your

liability if such a part fails and causes injury to one of your customers or employees? Your customer may

bring suit against you, and your employee may file a workmen's compensation claim. In such a case, do

you have sufficient recourse against the company from which you bought the part? Do you realize that

many of these companies may not carry adequate liability insurance to protect themselves from such a

claim?

Factory Authorized parts are purchased directly from the manufacturer that produces the equipment.

Typically, the manufacturer assumes responsibility for the replacement parts, when installed correctly.

These parts have passed numerous rigid tests and are either UL (electrical), AGA (gas), or NSF (all)

approved.

Most manufacturers will void the warranty of equipment if counterfeit parts are installed. In some cases

installation of counterfeit parts will relieve the manufacturer from liability for the equipment. No one can

argue that counterfeit parts are competitively priced — although sometimes at the expense of quality.

The companies that manufacture counterfeit parts often do not have the same overhead as the

manufacturer that produces the original equipment — expenses incurred for continuous rigid testing,

inspection, insurance, warranty service and the like.

The next time you purchase a replacement part for "the best price", ask if it is a FACTORY

AUTHORIZED part. Then you can consider if the risk is worth the "savings".

If you are uncertain whether you have purchased a counterfeit part, please bring it to us for inspection.

We are pleased to help you reduce your liability — and costs — whenever we can.

GENUINE PARTS PROTECT YOU ALWAYS.

Page 24

TROUBLE SHOOTING GUIDE

PROBLEM CAUSE SOLUTION

Water overflow out bottom of Machine not level. Level machine.

front door when wash pump

is operating. Overflow drain clogged. Remove obstruction, checking

Wash motor doesn't operate on Wires broken or loose. Check all wires in the motor and

manual wash.

Note: The motor starting relay is utilized to insert a starting field in the wash pump motor, once the

motor has gained speed, the running winding will then take over and the starting winding will be

removed when the relay kicks out.

Motor runs on manual wash but Defective timer. Replace timer.

doesn't operate on automatic

(rinse operates okay on both

manual and automatic cycles.) Defective circuit in manual Replace switch.

No water comes through the Hand water valve to machine Turn on water valve.

rinse arms when the 'on/fill' not turned on.

switch is depressed.

Little or no water coming Limed up rinse heads or Begin by cleaning rinse heads

through rinse assemblies. piping. using instructions for de-liming.

Water level in machine's Solenoid valve not closing at

wash reservoir too high. end of fill or rinse cycle

Detergent foaming. Reduce quantity of detergent.

Equalizing vent blocked. Allow free steam flow.

Defective manual wash Replace.

switch.

Bad bearing, noticeable by Replace.

noisy bearings or locked

drive shaft.

Defective motor starting Replace.

relay. (Typical - motor

hums.)

wash switch.

Defective coil on Replace coil.

solenoid valve.

Probes are dirty or coated. Clean probes.

Defective water level control. Replace.

Water pressure low. Increase pipe size to machine.

Slight tilt to rear

inside of machine first.

causing excessive water

problem.

reconnect as necessary.

If this isn't satisfactory, then

clean the rinse feed pipes.

Page 25

TROUBLE SHOOTING GUIDE

PROBLEM CAUSE SOLUTION

Rinse doesn't operate on Timer defective. Replace.

automatic during timed cycle

(but does operate on auto/fill

operation).

Rinse water runs continuously Defective plunger in Replace plunger.

with circuit breaker controlling solenoid valve.

machine turned off.

Defective diaphragm in Check both holes in diaphragm

solenoid valve. cartridge to insure that they

Note: In disassembling solenoid valve, use instructions shown on separate page.

Rinse water runs con- Defective water level control. Replace.

tinuously with power applied

to machine, but when circuit

breaker to machine is turned Probes are dirty or coated. Clean probes.

off, water stops.

are open. The one on the outside

perimeter should be the size of an

ordinary straight pin. If it's not,

heat a straight pin and put it

through this hole to enlarge. If

this fails to correct situation,

replace diaphragm.

Note: Excessive water line pressure can cause water to continually run even though the power to the machine is

turned off. Check specifications for required pressure.

Wash temperature not at Defective thermometer. Using a thermometer (fast

required reading on

thermometer.

Rinse temperature not at Check out rinse heat using

required temperature, causing heater checkout system page

wash temperature to be in manual.

lowered during rinse cycle.

Note: Any switches, water level controls, heater elements, relays or contactor that have to be checked out, can be

done using the heater checkout system page.

reading type that's known

to be correct), insert in wash

rerservoir and check reading

against wash thermometer on

machine. If machine thermometer

isn't correct within three or four

degrees, replace.

Page 26

TROUBLE SHOOTING GUIDE

PROBLEM CAUSE SOLUTION

Thermostat defective. Adjust using instructions on thermostat

Water level protection control defective. Replace. (Auto/fill would run continuously.)

Heater element defective. Replace.

R-2 defective. Replace.

page and heater system's checkout page.

Replace if necessary.

Rinse water not at required temperature

range.

After filling machine with water, leakage

began at lower front panel without machine

operating or at end of rinse cycle.

Machine doesn't drain when

'off/drain' switch is depressed.

Thermometer's defective. Replace.

Thermostat defective. Adjust using instructions on thermostat

page and heater system's checkout page.

Replace if necessary.

Defective heater relay on contactor. If defective, replace. See note on heater

system above.

Overflow drain clogged. Clean away obstruction.

Drain solenoid clogged. Defective switch. Remove obstruction. Replace.

Defective motor or motor start relay. Replace.

Defective drain solenoid. Replace.

Note: The drain pump of this machine is part of wash motor, so if was motor operates properly drain system should work.

Defective timer. Replace timer.

Defective relay. Replace.

Page 27

FRONT VIEW

ITEM P/N DESCRIPTION

1. 0052700 DOOR HANDLE ASSEMBLY

2. SWITCHES

3. 0052600 FRONT DOOR

4. 0125100 RINSE ASSEMBLY, UPPER

4A. 0125200 RINSE ASSEMBLY, LOWER

5. 0188900 WASH ASSEMBLY

6. 0005700 BOOSTER TANK

7. 0060000 HEATER ELEMENTS

8. 0142100 SOLENOID, (110V, used on 60 cycle machines)

9. 0185000 VALVE FOR HEALTH INSPECTOR GAUGE

10. 0153600 "Y" STRAINER

11.

12.

13. 0169100 THERMOMETERS

14. 0170018 THERMOSTAT, RINSE

(or)

0170023 THERMOSTAT, WASH

ELECTRIC PANEL

INCOMING WATER CONNECTION

Page 28

ITEM

1. 0184101 VACUUM BREAKER ASSEMBLY

2. 0108100 PUMP & MOTOR ASSSEMBLY, (110V, 60 cycle)

3. DRAIN — GRAVITY FEED

4. 0005700 BOOSTER TANK

5. EQUALIZING VENT

6. INCOMING WATER CONNECTION

P/N DESCRIPTION

BACK VIEW

Page 29

DRAIN SOLENOID VALVE, (110V, used on

60

cycle

ITEM P/N DESCRIPTION

1. 0184101 VACUUM BREAKER ASSEMBLY

2. 0052700 DOOR HANDLE ASSEMBLY

3. 0052600 FRONT DOOR, OUTER

4. 0054902 KICK PANEL

5.

6. 0083400 ADJUSTING FEET

7. 0108100 PUMP & MOTOR ASSEMBLY, (110V, 60 cycle)

8.

9. 0142400

10. 0004001 SIDE FRAME & BRACE, LEFT HAND

LEFT SIDE VIEW

INCOMING WATER CONNECTION

DRAIN — GRAVITY FEED

Page 30

RIGHT SIDE VIEW

ITEM P/N DESCRIPTION

1. 0184101 VACUUM BREAKER ASSEMBLY

2. 0125100 RINSE ASSEMBLY, UPPER

2A. 0125200 RINSE ASSEMBLY, LOWER

3. 0004000 SIDE FRAME & BRACE, RIGHT HAND

4. 0188900 WASH ASSEMBLY

5. 0005700 BOOSTER TANK

6. 0083400 ADJUSTING FEET

7. 0054902 KICK PANEL

8. 0052600 FRONT DOOR

9. 0052700 DOOR HANDLE ASSEMBLY

10. 0054700 OPTIONAL TOP

Page 31

ITEM

1. 0153600 "Y" STRAINER

2. REMOVABLE FILTER

3. 0185000 VALVE FOR HEALTH INSPECTOR

4. 0142100 SOLENOID VALVE 1/2" (110V, used

5. PIPE UNION

P/N DESCRIPTION

on 60 cycle machine)

Page 32

RINSE TANK

ITEM P/N DESCRIPTION

1. 0005700 BOOSTER TANK

2. 0060001 BUS BAR

3. 0060000 BOOSTER HEATER ELEMENT

4.

5. 0060002 HEATER ELEMENT GASKET

6.

7.

8. WATER OUTLET

THERMOSTAT COUPLING

WATER INLET

THERMOMETER COUPLING

ITEM P/N DESCRIPTION

1. 0056900 WASH TANK RING ELEMENT

2. 0125200 RINSE ASSEMBLY, LOWER

3. 0188900 WASH ASSEMBLY

4.

5. HOLES FOR WASH TANK ELEMENT

WASH RESERVOIR

Page 33

1. BOOSTER TANK

HEATER ELEMENT

2. ELEMENT GASKET P/N 0060002

P/N 0060000

Page 34

ITEM KIT# DESCRIPTION

1.

2. 0108501 MOUNTING PLATE

3. 0108501 STATIONARY SEAL ASSEMBLY

4. 0108501 SHIM WASHERS

5. 0108501 ROTATING CERAMIC

6. 0108501 PROPELLER FOR DRAIN PUMP

7. 0109501 "O" RING SEAL

8. 0109501 DRAIN INLET PLATE

9. 0109501 SUCTION ADAPTER PLATE

10. 0108501 IMPELLER FOR WASH PUMP (ALSO 0109000)

11. 0109501 TRUSS HEAD SCREW

12. 0109501 DIFFUSER

13. 0109501 UPPER PUMP HOUSING

14. 0109700 FILL HEAD MACHINE SCREW (SHORT)

15. 0109800 FILL HEAD MACHINE SCREW (LONG)

PUMP AND MOTOR ASSEMBLY

MOTOR (11)

Page 35

ITEM

1. 0169100 THERMOMETERS, WASH AND RINSE

2. 0170018 THERMOSTAT, RINSE

2. 0170023 THERMOSTAT, WASH

3. DETERGENT FUSE BLOCK

4. 0155600 POWER SWITCH

5. 0083518 POWER LIGHT

6. 0083507 CYCLE LIGHT

7. 0159700 MANUAL/AUTO SWITCH

8. 0083518 HEATER RESET LIGHT

9. 0122701 MOTOR RELAY (R-3)

10. 0169601 THERMOSTATIC OVERLOAD

11. 0165600 TERMINAL BOARD, INCOMING ELECTRICAL CONNECTION

12. 0124400 DRAIN RELAY (R-4)

13. 0120701 MOTOR STARTING RELAY

14. 0120500 RINSE HEATER RELAY

15. 0204400 WATER LEVEL CONTROL

16. 0121300 WASH HEATER RELAY

P/N DESCRIPTION

Page 36

NOTE: ALL WIRES MTW 2/64 INSULATION TEMP RATED 90 C/194 F DEGREES

Rl RINSE HEATER RELAY WM WASH MOTOR PL POWER LIGHT HRL HEATER RESET LIGHT

R2 MASH HEATER RELAY RUN MAIN RUN WINDING RTHS RINSE THERMOSTAT M/A SW MANUAL/AUTOMATIC SWITCH

R3 WASH MOTOR RELAY C.N. WASH START WINDING LLC1 LIQUID LEUEL CONTROL F1-F2 DETERGENT FUSE CONNECTIONS

R4 DRAIN RELAY C.C.N. DRAIN START NINDING LLP LON LEVEL PROBE CL CYCLE LIGHT

RH RINSE HEATER IOL INTERNAL OVER LOAD GND GROUND CONNECTION R/F SOL RINSE/FILL SOLENOID

MH WASH HEATER DSW DOOR SWITCH WTHS WASH THERMOSTAT SST SOLID STATE TIMER

SR START RELAY PSW POWER SWITCH THOL THERMAL OVERLOAD DR SOL DRAIN SOLENOID

Page 37

Page 38

Page 39

LEGEND

RH RINSE HEATER

WH WASH HEATER

SR START RELAY

RUN RUN MOTOR WINDING

CW WASH START WINDING

CCW DRAIN START WINDING

O.L. MOTOR OVERLOAD

R1 RINSE HEAT CONTACTOR

R2 WASH HEAT RELAY

R3 WASH MOTOR RELAY

R4 DRAIN CYCLE RELAY

LLC1 LIQUID LEVEL CONTROL

LLP LOW LEVEL PROBE

PSW POWER SWITCH

DSW DOOR SAFETY SWITCH

M/ASW MANUAL/AUTO SWITCH

WTHS WASH THERMOSTAT

WHOL WASH HEAT OVERLOAD

HRL HEATER RESET LIGHT

F1 DETERGENT FUSE 1

F2 DETERGENT FUSE 2

SST SOLID STATE TIMER

R/FSOL RINSE/FILL SOLENOID

CL CYCLE LIGHT

DRSOL DRAIN SOLENOID

RTHS RINSE THERMOSTAT

PL POWER LIGHT

WIRING DIAGRAM

MODEL 24B

SOLID STATE TIMER

115-208/230 VOLT

60 CY 1 PH

Drain Sol.

Page 40

WIRING DIAGRAM

MODEL 24B SOLID STATE

TIMER 115-208/230

VOLT 60 CY 1 PH

Page 41

OPTIONAL PUMP

DRAIN APPENDIX

INDEX

FOUR MAIN AREAS of the PUMP DRAIN SYSTEM (DrawingA-4)

AIR GAP DRAIN MOUNTING (Drawing A-5)

DRAIN PUMP MOTOR (DrawingA-6)

PUMP INTAKE HOSE ASSEMBLY to SUMP (DrawingA-T)

WATER LEVEL FLOAT INSTALLATION (Drawing A-8)

FUNCTIONAL BREAKDOWN of the FOUR MAIN PARTS of the 24BP and 24AP

PUMP DRAIN SYSTEM

DRAIN LINE POINT of CONNECTION (Drawing A-9)

GENERAL INSTALLATION of MACHINE DRAIN LINE

DRAIN LINE INSTALLATION (Drawing A-10)

TWO SAMPLES of IMPROPER DRAIN LINE INSTALLATION (Drawing A-11)

PUMP DRAIN COMPONENT LAYOUT (Drawing A-12)

24BP AUTO/PUMP DRAIN WIRE DIAGRAM (Drawing A-13)

24BP AUTO/PUMP DRAIN INTERCONNECTION DIAGRAM (Drawing A-14)

PARTS LIST for PUMP DRAIN SYSTEM

Page 42

Page 43

AIR GAP DRAIN MOUNTING

1.) 0052110 ----- AIR GAP

2.) 0052124 ----- DRAIN HOSE CLAMP

3.) 0052101 ----- DRAIN HOSE

4.) 0052120 ----- DRAIN BARB REDUCER

5.) 0052102 ----- DRAIN HOSE

6.) 0052122 ----- DRAIN HOSE CLAMP

Page 44

1.)

2.) 3.) 4.)

DRAWING A

-6

0052100 ----- DRAIN PUMP MOTOR

6.)

0052112 ----- DRAIN PUMP MOTOR VENT CLAMP

5.)

0052122 ----- DRAIN HOSE CLAMP

0052102 ----- DRAIN HOSE

0052108 ----- DRAIN HOSE

0052123 ----- DRAIN HOSE CLAMP

7.)

0052111 ----- DRAIN PUMP MOTOR VENT CAP

8.)

0052113 ----- DRAIN RELAY TIME DELAY

9.)

0052114 ----- RELAY ADJUSTMENT POD

10.)

0052119 ----- DRAIN PUMP MOTOR CAP

Page 45

1.)

0052106 ----- DRAIN ELBOW FROM SUMP TO PUMP INTAKE

4.)

0052124 ----- DRAIN HOSE CLAMP

2.)

0052120 ----- DRAIN BARB REDUCER

3.)

0052123 ----- DRAIN HOSE CLAMP

5.)

6.)

0052107 ----- DRAIN HOSE

0052108 ----- DRAIN HOSE

DRAWING A-7

Page 46

1.) 0052103 DRAIN FLOAT SWITCH 2.) 0052105 DRAIN FLOAT COVER

3.) 0052104 DRAIN CORD CLIPS

DRAWING A-8

Page 47

FUNCTIONAL BREAKDOWN

of the FOUR MAIN PARTS

of the 24BP and 24AP

PUMP DRAIN SYSTEM

Note: Refer to Drawing A-4.

A.) With machine properly leveled, by adjusting the feet on all comers, the front of the unit should be 1/4" to 1/2"

higher than the back of the unit.

B.) With machine filled and power switch on, proceed as follows:

1.) Insert rack.

2.) Close door.

3.) Cycle will begin with two seconds of rinse water. Then, the wash cycle will begin.

4.) About half way through the cycle, there is another two seconds of rinse water.

5.) Note: At this time, water level in the machine may be higher than normal.

C.) At this level, the float switch will come into operation.

1.) The float switch rises, thus energizing the drain-time delay relay. This will in turn activate the drain pump

motor. The amount of time that the drain pump will run is determined by the setting on the adjustment pod,

located on the drain time-delay relay. The longer the pump runs, the more water will be removed from the

machine.

D.) Run machine through three or four cycles. Between each cycle, check water level to determine if it is too high or

too low. Accurate water level is obtained by setting the adjustment pod between each cycle until the water is at

its correct level.

Page 48

Page 49

GENERAL INSTALLATION

INSTRUCTIONS of

MACHINE DRAIN LINE

STEP 1: LOCATION OF DRAIN LINE CONNECTION Note:

Refer to Drawing A-1.

The drain line connection on this machine is located at rear of machine in the upper-right-hand comer.

Connection size is 3/4“. Use 3/4" reinforced hose.

STEP 2: DRAIN LINE INSTALLATION Note:

Refer to Drawing A-2.

Drain should slope downward on an incline to customer's drain connection. For every 24 inches of drain line,

the drop should be 3" to 4".

Please reference Drawing A-3 to note the IMPROPER drain line installation. Once the drain line is sloping

downward, DO NOT slope the drain line upward again. Doing this would prevent the pump from draining

properly.

DRAIN LINE INSTALLATION FOR MODEL 24BP OR 24AP

DRAWING A-10

Page 50

Page 51

PUMPED DRAIN

COMPONENT LAYOUT (Solid State Timer)

1.) 0052100 DRAIN, PUMP MOTOR 6.) 02044 00 WATER LEVEL CONTROL

2.) 0052113 DRAIN, TIME DELAY RELAY 7.) 0120500 RELAY RINSE HEATER

3.) 0046523 DISPENSER CONNECTION FUSE PLATE 8.) 0124400 RELAY DRAIN CYCLE

4.) 0121300 RELAY 110V, FOR PUMP MOTOR & WASH TANK HEATER 9.) 0174400 TIMER SOLID STATE

5.) 0120701 MOTOR START RELAY 10.) 0052114 DRAIN, RELAY ADJUSTING POD

DRAWING A-12

Page 52

Page 53

Page 54

PARTS LIST for the

PUMP DRAIN SYSTEM

This Parts List includes parts (only) for the Pump Drain System of the Model 24BP.

PART NUMBER DESCRIPTION

0052100 DRAIN PUMP ASSEMBLY

0052101 DRAIN HOSE, 1/2 " ID (AIR VENT)

0052102 DRAIN HOSE, 3/4" x 27"

0052103 DRAIN FLOAT SWITCH

0052104 DRAIN CORD CLIPS

0052105 DRAIN FLOAT COVER

0052106 DRAIN ELBOW FROM SUMP TO PUMP INTAKE

0052107 DRAIN HOSE, 1/2 " ID FROM PUMP TO TEE

0052108 DRAIN HOSE, 1" ID

0052110 DRAIN AIR GAP

0052111 DRAIN PUMP MOTOR VENT CAP

0052112 DRAIN PUMP MOTOR VENT CAP HOSE CLAMP

0052113 DRAIN TIME DELAY RELAY

0052114 DRAIN RELAY ADJUSTMENT POD

0052119 DRAIN PUMP MOTOR CAP

0052120 DRAIN BARB REDUCER, 3/4 " to 1/2 "

0052121 DRAIN TEE BARB, 1" x 1" x 1/2 "

0052122 DRAIN HOSE CLAMP (MEDIUM SIZE)

0052123 DRAIN HOSE CLAMP (LARGE SIZE)

0052124 DRAIN HOSE CLAMP (SMALL SIZE)

Page 55

COMPLETE PARTS LIST for SERIES 24

0005700 Booster Tank (stripped) 1

0051700 Door Latch and Switch Bracket 1

0052300 Door Gasket 1

0052400 Door Gasket, Clamp Assembly 1

0052600 Door, Front, Outer only (stripped) 1

0052700 Door Handle 1

0053400 Drain Hose-Pump to Solenoid Valve, short 1

0053500 Drain Hose Clamps 4

0053600 Drain Hose-Solenoid Valve to Drain, long 1

0054400 Door Spring 2

0054500 Enclosure Panel, righthand side 1

0054600 Enclosure Panel, lefthand side 1

0054700 Enclosure Panel, top 1

0054902 Enclosure Panel, Lower Kickplate 1

0056900 Heater Element, ring-style, 1000W, 220V, P/N 0056700,115V, 1000W 1

0060000 Heater Element, Flange Type, 208/230V, 6200W 1

0060001 Heater Element, Flange Type, Bus Bars 2

0060002 Heater Element, Flange Type, Gasket 1

0083507 Light, Indicator, Green 1

0083518 Light, Indicator, Red 2

0084300 Probe, Lundy, small 1

0108100 Pump Assembly, complete with motor, 115V, 60 cycle 1

0108400 Pump Gasket 1

0108500 Pump Propeller Mounting Plate and Seal Assembly, kit 1

0108700 Pump Diffuser (only) 1

0109000 Pump Impeller, kit 1

0109500 Pump, Upper Housing, kit 1

0109600 Pump, Upper Housing, (only) 1

0109700 Pump Fill Head Machine Screws, short 4

0109800 Pump Fill Head Machine Screws, long 4

0117500 Rack,square,19 3/4" x 193/4"(cup,bowl, glass) 1

0117800 Rack,square,19 3/4" x 193/4"(dish-molded) 2

0120500 Relay, 110V, 2-pole, HW Heat Circuit 1

0120701 Relay, 110V, Motor Starting 1

0121300 Relay, Motor, replaced by 0122701; use 0121300 for Heat Relay 1

0124400 Relay, Drain, 3PDT 1

0125100 Rinse Head Assembly,upper 1

0125200 Rinse Head Assembly, lower 1

0125300 Rinse Head End Plug,knurled 2

0125500 Rinse Head, Hex Bushing 2

0126000 Rinse Head, Nylatron Washer 2

0126500 Rinse Head, Snap Ring,s/s 2

0131000 Rinse Head Brush, Tube Cleaning 1

0137301 Rinse Feed Pipe Lanyard Pin, P/N - 6137200 Lower Feed Pipe 1

0142100 Solenoid Valve ½”, JE, 110V 1

0142400

0143600 Solenoid Valve Coil,110V, JE 1

0145000 Solenoid Valve Diaphragm Cartridge and "0" Ring, JE 1

0147500 Solenoid Valve "0" Ring,JE 1

0148600 Solenoid Valve, Plunger Assembly, JE 1

0149500 Solenoid Valve, Strainer Screen, JE 1

0153100 Strainer, Pan-Type 1

0155600 Switch, On/Fill, Off, Drain 1

0164000 Switch, Door,SPDT 1

0159700 Switch,Manual Wash 1

Drain Valve, Dole 1/2", 110V, (Valve only)

1

Page 56

COMPLETE PARTS LIST for SERIES 24

0165600 Terminal Board, 3-pole 1

0169100 Thermometer, 36" Cap, Rinse 1

0169601 Thermostatic Overload, Heater 1

0170018 Thermostat, Rinse, 180°, fixed 1

0170023 Thermostat, Wash, 150°, fixed 1

0174400 Timer, Solid State 1

0177500 Timer Micro Switches, Plastic Module-Type 3

0184101

0184200

0186500 Wash Head Cap w/Race 1

0187000 Wash Head Cap Set Screw 1

0187500 Wash Head Center Shaft 1

0188600 Wash Head Holding Pin 1

0188601 Wash Head, Disconnect Pin 1

0188900 Wash Head Assembly, complete 1

0189000 Wash Head, Small Manifold w/Tubes 1

0189500 Wash Head, Large Manifold w/Tubes 1

0193601 Wash Head Fixed Race 2

0194000 Wash Head Bearings, V4" s/s 57

0204400 Water Level Control, 110V, w/25 Second Time Delay 1

0054904 Gauge Panel, Black Plastic 1

0056900

0060000 Heater Element, Rinse, (Booster Tank)

0060002 Heater Gasket

0108200 Pump Assembly, Complete (w/Motor, 220V, 50 HZ, 1 PH)

0121100 Relay, DPDT, Drain 220V, Coil

0121400 Relay, Motor Start, 220V, 50 HZ, 1 PH

0121800 Contactor, Heater, 220V Coil

0123300 Relay, SPDT,220V Coil

0142200 Solenoid, Valve Drain,220V

0142500 Solenoid, Valve Coil, 220V, Incoming Water

0174500 Timer, Solid State, 8 Pin, 220V, 50 HZ, 1 PH

0204600 Water Level Control, SSAC, 220V, 50 HZ 6680-200-0821

Vacuum Breaker, 1/2" Conbraco

Vacuum Breaker Repair Kit, 1/2 " Conbraco

MODEL 24B PARTS LIST 220V, 50HZ,1 PH

Heater Element, Wash, (Ring Style)

1

1

Loading...

Loading...