Jackson 230 1 15 06401-003-10-22, 600 3 15 06401-003-10-33, 208 1 10 06401-003-12-94, 230 3 10 06401-003-12-95, 220 3 15 06401-003-10-22 User Manual

...Page 1

Heater Replacement

07610-003-12-01 A

October 14, 2005

Rack Conveyor Dishmachine

Maintenance Instructions

Page 2

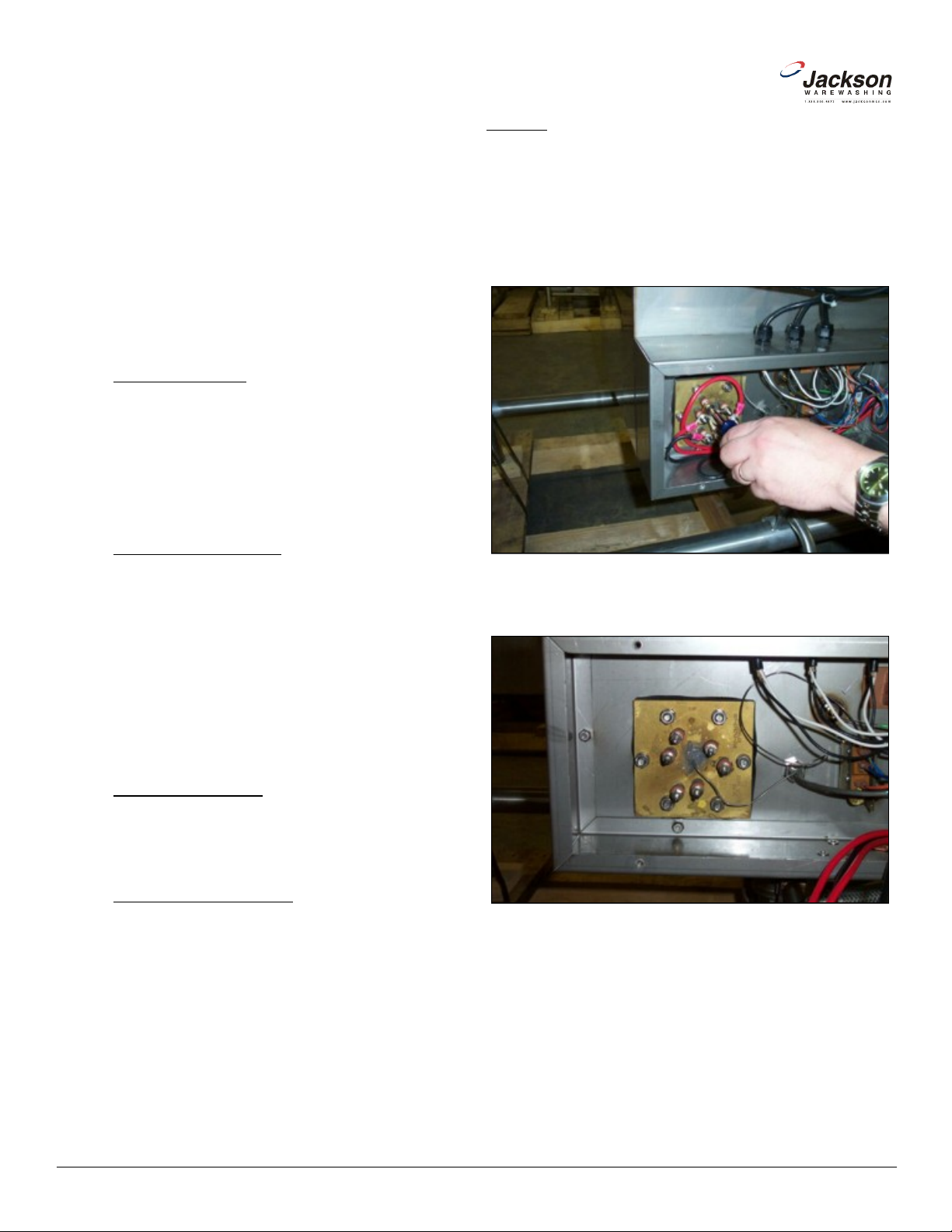

2. Remove the heater box cover to expose the heater. Set the

3. Remove the incoming electrical lines from the heater. Set the

5. The thermostat probe needs to be removed from the well inside

the heater. The probe is secured in place with silicone that must be

peeled away prior to attempting to remove it. It is important that

you do not damage the probe during this part of the maintenance

action. If you do, then the thermostat will have to be replaced as

6. Using your hand or needlenose pliers, remove the silicone so

www.jacksonmsc.com

Jackson rack conveyor machines come equipped with

heaters to ensure proper ware washing results. Occasionally,

some of these components may need replacing to maintain opti mum performance.

Jackson offers all of the repair parts necessary for performing this task.

The instructions provided here are for maintenance personnel only. Unauthorized persons should not attempt any of the

steps contained in these instructions.

Warning: many of the instructions and steps within

this document require the use of tools. Only authorized per sonnel should ever perform any maintenance procedure on

the dishmachine!

PREPARATION

1. Power must be secured to the unit at the service breaker. Tag or lock out the service breaker to prevent accidental or

unauthorized energizing of the machine.

2. Ensure that incoming water to the machine is secured

either by use of a shut-off valve or disconnecting the incoming

water line.

3. The unit must be drained completely.

TOOLS REQUIRED

The following tools will be needed to perform this mainte-

nance evolution:

1. 3/8” Nutdriver

2. Ratchet

3. 1/2” Socket

4. 3/8” Socket

5. Phillipshead Screwdriver

6. Needlenose Pliers

7. Torque Wrench

8. Siliconee Sealant

9. Amp Meter

STEPS

1. Remove the front dress panel.

cover and hardware to the side.

hardware to the side.

Removing the power lines.

4. Push the incoming electrical lines out of the way.

TIME REQUIRED

It is estimated that it will take (1) person ninety minutes to

perform this task, not including all of the items indicated in the section entitled “PREPARATION”.

IMPORTANT NOTES

1. Read these instructions thoroughly before attempting

this maintenance task. Become familiar with the parts and what

actions need to be taken. This will save time in the long run!

Heater without power lines attached.

well.

that the thermostat probe may be gently removed.

2

Heater Replacement Instructions

Revision A (10/14/2005)

Page 3

9. Remove the gasket.

10. Before proceeding any further, it is important to verify that the

tub wall is free of any excess debris so that when the new gasket

is applied, there are no gaps that could lead to leaking around the

-

washers and nuts. Tighten the nuts by hand and then use the

torque wrench set to 154 in-lbs to ensure that the nuts are secure.

13. The thermostat probe needs to be placed into the well of the

new heater. Again, use caution when doing this so that the probe

or the capillary tube do not become broken. If this occurs, then the

www.jacksonmsc.com

Removing silicone from thermostat well

7. With the thermostat probe out of the way, use the 1/2” socket

and ratchet to remove the nuts holding the heater to the tub.

Remove all nuts and lockwashers.

Removing the nuts and lockwashers

8. Remove the heater from the tub weldment.

Removing the gasket

heater.

11. Apply the new heater gasket from your service kit.

12. Slide the heater onto the studs and apply by hand the lock

Removing the heater

Heater Replacement Instructions

Revision A (10/14/2005)

Applying the torque wrench to the nuts

thermostat will have to be replaced.

3

Page 4

16. Using the torque wrench or a torque nutdriver (if available)

torge the nuts holding the wires, jumpers and bus bars to 16 in-lbs.

17. Ensuring that all non-essential personnel are clear of the area,

close the drain valve(s) and restore power and water to the unit.

18. Verify that there are no leaks around the heater. If there are,

attempt to tighten it down as the tub will change shape slightly as

19. Use the amp meter to take readings off of the power lines to the

20. Wait until the heater contactor kicks out (meaning that the tub

has reached the appropriate temperature) and place the unit in

DELIME mode by flipping the switch on the back of the control box.

Allow the unit to operate for at least ten minutes to verify that there

-

www.jacksonmsc.com

Putting the thermostat probe in the heater well Three phase wiring

14. Apply silicone to seal the well and hold the thermostat probe in

place.

Applying silicone to the heater well

15. Reattach the incoming power lines to the heater, ensuring that

you wire the heater correctly for either single or three phase operation.

Single phase wiring

Tightening the nuts holding the power lines

Turn the unit on and allow it to fill normally.

it heats up.

heater, verifying the amperage draw to the machine data plate.

are no leaks and that the heater is maintaining the tank tempera

ture.

21. If the unit appears to be operating correctly, return it to AUTO

mode and turn off.

4

Heater Replacement Instructions

Revision A (10/14/2005)

Page 5

Jackson MSC Inc. provides technical support for all of the

dishmachines detailed in this manual. We strongly recommend that

-

port staff. Please have this manual with you when you call so that

our staff can refer you, if necessary, to the proper page. Technical

support is available from 8:00 a.m. to 5:00 p.m. (EST), Monday

through Friday. Technical support is not available on holidays.

Contact technical support toll free at 1-888-800-5672. Please

remember that technical support is available for service personnel

www.jacksonmsc.com

22. Replace the heater box cover.

23. Replace the front dress panel.

AFTER MAINTENANCE ACTIONS

Service perosnnel may want to drain the machine and

allow it to cool down. Secure power to the unit at the service breaker and then verify the torque of all fasteners covered in this instruction.

SPECIAL NOTES

Work performed on Jackson dishmachines by unautho rized or unqualified personnel may void the warranty. Before beginning this or any other maintenance evolution on a unit under warranty, you should contact a certified Jackson technician or Jackson

Technical Service. You can find a list of qualified service agencies

in the back of you unit’s installation manual.

SPECIAL PARTS

Heater Replacement Kit Chart

Model Volts Phase KW Part Number

CONTACT INFORMATION

you refer to this manual before making a call to our technical sup

only.

All 208 1 15 06401-003-10-21

230 1 15 06401-003-10-22

200 3 15 06401-003-10-21

208 3 15 06401-003-10-21

220 3 15 06401-003-10-22

230 3 15 06401-003-10-22

380 3 15 06401-003-10-28

415 3 15 06401-003-10-28

440 3 15 06401-003-10-29

460 3 15 06401-003-10-31

575 3 15 06401-003-10-33

600 3 15 06401-003-10-33

208 1 10 06401-003-12-94

230 1 10 06401-003-12-95

200 3 10 06401-003-12-94

208 3 10 06401-003-12-94

230 3 10 06401-003-12-95

460 3 10 06401-003-12-96

575 3 10 06401-003-12-97

600 3 10 06401-003-12-97

Heater Replacement Instructions

Revision A (10/14/2005)

5

Loading...

Loading...