Page 1

TECHNICAL MANUAL

INSTALLATION MANUAL FOR EXPORT UNITS

SERVICE MANUAL FOR DOMESTIC UNITS

FOR JACKSON MODELS:

10A

10AB

10APRB

10U

HIGHER HOOD OPTION

Jackson MSC, INC.

P.O. BOX 1060

HWY. 25E

BARBOURVILLE, KY. 40906

1-888-800-5672

www.jacksonwws.com

10 SERIES, ELECTRICALLY HEATED, ROUND DISHMACHINES

February 11, 2014

P/N 07610-002-41-09 (Revision E)

Page 2

MANUFACTURERS WARRANTY

ONE YEAR LIMITED PARTS & LABOR WARRANTY

ALL NEW JACKSON DISHWASHERS ARE WARRANTED TO THE ORIGINAL PURCHASER TO BE FREE FROM DEFECTS IN

MATERIAL OR WORKMANSHIP, UNDER NORMAL USE AND OPERATION FOR A PERIOD OF (1) ONE YEAR FROM DATE OF

PURCHASE, BUT IN NO EVENT TO EXCEED (18) EIGHTEEN MONTHS FROM DATE OF SHIPMENT FROM THE FACTORY.

Jackson WWS agrees under this warranty to repair or replace, at its discretion, any original part which fails under normal use due to faulty material or

workmanship during the warranty period, providing the equipment has been unaltered, and has been properly installed, maintained and operated in

accordance with applicable factory instruction manual furnished with the machine and failure is reported to the authorized service agency within the

warranty period. This includes the use of factory specified genuine replacement parts, purchased directly from a Jackson authorized parts distributor or

service agency. Use of generic replacement parts may create a hazard and void warranty certification.

The labor to repair or replace such failed part will be paid by Jackson WWS, within the continental United States, Hawaii and Canada, during the warranty

period provided a Jackson WWS authorized service agency, or those having prior authorization from the factory, performs the service. Any repair work by

persons other than Jackson WWS authorized service agency is the sole responsibility of the customer. Labor coverage is limited to regular hourly rates;

overtime premiums and emergency service charges will not be paid by Jackson WWS.

Accessory components not installed by the factory carry a (1) one year parts warranty only. Accessory components such as table limit switches, pressure

regulators, pre-rinse units, etc. that are shipped with the unit and installed at the site are included. Labor to repair or replace these components is not covered

by Jackson WWS.

This warranty is void if failure is a direct result from shipping, handling, fire, water, accident, misuse, acts of God, attempted repair by authorized persons,

improper installation, if serial number has been removed or altered, or if unit is used for purpose other than originally intended.

TRAVEL LIMITATIONS

Jackson WWS limits warranty travel time to (2) two hours and mileage to (100) one hundred miles. Jackson WWS will not pay for travel time and mileage

that exceeds this, or any fees such as those for air or boat travel without prior authorization.

WARRANTY REGISTRATION

To register your product go to www.jacksonwws.com or call 1-888-800-5672. Failure to register your product will void the warranty.

REPLACEMENT PARTS WARRANTY

Jackson replacement parts are warranted for a period of 90 days from date of installation or 180 days from the date of shipment from the factory, whichever

occurs first.

PRODUCT CHANGES AND UPDATES

Jackson WWS reserves the right to make changes in design and specification of any equipment as engineering or necessity requires.

THIS IS THE ENTIRE AND ONLY WARRANTY OF JACKSON WWS. JACKSON’S LIABILITY ON ANY CLAIM OF ANY KIND, INCLUDING

NEGLIGENCE, WITH RESPECT TO THE GOODS OR SERVICES COVERED HEREUNDER, SHALL IN NO CASE EXCEED THE PRICE OF THE

GOODS OR SERVICES OR PART THEREOF WHICH GIVES RISE TO THE CLAIM.

THERE ARE NO WARRANTIES, EXPRESSED OR IMPLIED, INCLUDING FOR FITNESS OR MERCHANTABILITY, THAT ARE NOT SET FORTH

HEREIN, OR THAT EXTEND BEYOND THE DURATION HEREOF. UNDER NO CIRCUMSTANCES WILL JACKSON WWS BE LIABLE FOR ANY

LOSS OR DAMAGE, DIRECT OR CONSEQUENTIAL, OR FOR THE DAMAGES IN THE NATURE OF PENALTIES, ARISING OUT OF THE USE

OR INABILITY TO USE ANY OF ITS PRODUCTS.

ITEMS NOT COVERED

THIS WARRANTY DOES NOT COVER CLEANING OR DELIMING OF THE UNIT OR ANY COMPONENT SUCH AS, BUT NOT LIMITED TO,

WASH ARMS, RINSE ARMS OR STRA

INERS AT ANYTIME. NOR DOES IT COVER ADJUSTMENTS SUCH AS, BUT NOT LIMITED TO TIMER

CAMS, THERMOSTATS OR DOORS, BEYOND 30 DAYS FROM THE DATE OF INSTALLATION. IN ADDITION, THE WARRANTY WILL ONLY

COVER REPLACEMENT WEAR ITEMS SUCH AS CURTAINS, DRAIN BALLS, DOOR GUIDES OR GASKETS DURING THE FIRST 30 DAYS AFTER

INSTALLATION. ALSO, NOT COVERED ARE CONDITIONS CAUSED BY THE USE OF INCORRECT (NON-COMMERICAL) GRADE DETERGENTS,

INCORRECT WATER TEMPERATURE OR PRESSURE, OR HARD WATER CONDITIONS.

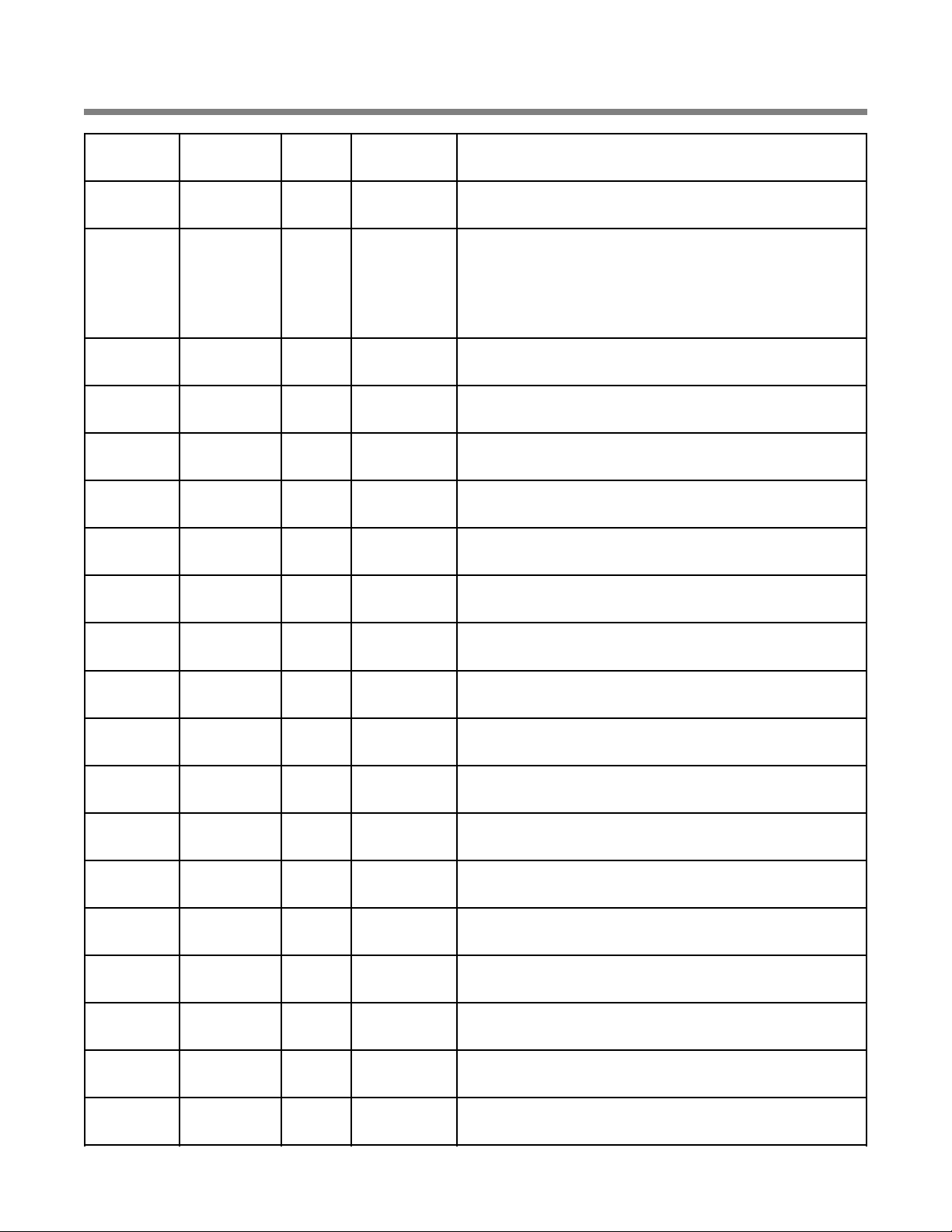

Page 3

i

REVISION

REVISION

DATE

MADEBYAPPLICABLE

ECN

DETAILS

D 02-24-04 MAW N/A

ADDED 10U PHOTO INSTALLATION GUIDE AND ALL 10U

INFORMATION

E 02-11-14 MHH QOF NDB

Updated manufacturer information and logos.

Updated manufacturer warranty.

Replaced figure 5 (pg. 7) that incorrectly showed 2 O-rings

in use instead of 1.

Replaced figure 8 (pg. 9) that showed internal vacuum breaker

being installed backward.

Page 4

ii

NOMENCLATURE FOR THE MODELS COVERED IN THIS MANUAL:

10 SERIES

10A = 10 without a booster tank

10AB = 10 with a booster tank

10APRB = 10 with a booster tank and a power rinse pump

10U = 10 with a booster tank, a 4” shorter hood, and 9” shorter legs

Higher Hood Option = A hood that is 5” higher than the standard hood

Model:

Serial No.:

Installation Date:

Service Rep. Name:

Phone No.:

Jackson MSC Inc. provides technical support for all

of the dishmachines detailed in this manual. We

strongly recommend that you refer to this manual

before making a call to our technical support staff.

Please have this manual with you when you call so

that our staff can refer you, if necessary, to the proper page. Technical support is available from 8:00

a.m. to 5:00 p.m. (EST), Monday through Friday.

Technical support is not available on holidays.

Contact technical support toll free at 1-888-800-

5672. Please remember that technical support is

available for service personnel only.

Page 5

iii

SECTION DESCRIPTION PAGE

I. SPECIFICATION INFORMATION

Operating & Electrical Requirements 2

10A Dimensions 3

10AB/10APRB/10U Dimensions 4

Table Dimensions 5

II. INSTALLATION/OPERATION INSTRUCTIONS

Visual Inspection/Unpacking the Dishmachine 7

Leveling the Dishmachine/Installing the Vacuum Breaker & Plumbing 8

Installing the Internal Vacuum Breaker/Hood Assembly 9

Plumbing the Dishmachine/Drain Line Connection/Electrical Connection 10

Final Check 11

Operation Instructions 12

Detergent Control 13

III. PREVENTATIVE MAINTENANCE

Preventative Maintenance 15

IV. SERVICE PROCEDURES

Rinse Head/Wash Head Assemblies 17

Timer for 10 Dishmachines 18

Function of Switches, Circuit Breaker & Indicating Lights 19

Replacement of Switches in Control Panel 19

Thermostat Adjustment 20

Rinse Tank Heater System 21

Wash Tank Heater System 22

Water Level Control 23

Water Level Control (APRB) 24

Replacing Seal & Ceramic on Wash and Rinse Pumps 25

V. TROUBLESHOOTING 26

VI. PARTS

10A Assembly 31

10AB/APRB Assembly 32

Control Box Assembly 33

Ordering Replacement Wire/Conduit Fittings 35

Ordering Replacement Conduit, Fittings & Hose 36

Tub Assembly 37

Bottom View Assembly 39

Wash Tank Cross View/Tub to Booster Connection 41

10AB/APRB Rinse Booster & Associated Parts 42

Pump & Motor Assembly 43

Thermostat Housing Assembly 44

Incoming Plumbing Assemblies 45

Solenoid Valve Repair Kit/Vacuum Breaker Repair Kit 46

Hood & Associated Assemblies 47

Vacuum Breaker/Connector Assemblies 10A Series 49

Vacuum Breaker/Connector Assemblies 10AB/10APRB/10U 50

Parts List for 10 Dishmachines 51

TABLE OF CONTENTS

Page 6

iv

TABLE OF CONTENTS

VII. ELECTRICAL SCHEMATICS

10A 208 - 220 V, 60 HZ, single phase 17

10AB 208 - 220 V, 60 HZ, single phase 17

10AB/10U 208 - 220 V, 60 HZ, three phase 17

10AB/APRB/10U 208 - 220 V, 60 HZ, single phase 17

10AB/APRB/10U 208 - 220 V, 60 HZ, three phase 17

WIRING DIAGRAMS

10A/10U 208 - 220 V, 60 HZ, single phase 18

10AB/10U 208 - 220 V, 60 HZ, single phase 19

10AB/10U 208 - 220 V, 60 HZ, three phase 20

10AB/APRB/10U 208 - 220 V, 60 HZ, single phase 21

10AB/APRB/10U 208 - 220 V, 60 HZ, three phase 22

VIII. JACKSON MAINTENANCE & REPAIR CENTERS 24

Page 7

1

SECTION 1:

SPECIFICATION INFORMATION

Page 8

2

SECTION 1: SPECIFICATION INFORMATION

10 SERIES SPECIFICATIONS

PERFORMANCE/CAPABILITIES

OPERATING CAPACITY (RACKS/HOUR)

RACKS PER HOUR 45

DISHES PER HOUR 950

GLASSES PER HOUR 950

OPERATING CYCLE (SECONDS)

WASH TIME 60

RINSE TIME 10

TOTAL CYCLE TIME 72

TANK CAPACITY (GALLONS)

WASH TANK 4.5

BOOSTER TANK (10AB/10APRB/10U ONLY) 3.0

PUMP CAPACITY (GALLONS)

WASH PUMP 70 GPM

TEMPERATURES

WASH---°F (MINIMUM) 150

RINSE---°F (MINIMUM) 180

ELECTRICAL REQUIREMENTS

WASH PUMP MOTOR HP 1/2

RINSE PUMP MOTOR HP (10APRB ONLY) 1/2

MODEL VOLTS HERTZ PHASE AMPS

10A 208 60 1 8.23

10A 220 60 1 8.23

10AB/10U 208 60 1 38.8

10AB/10U 208 60 3 25.6

10AB/10U 220 60 1 37.2

10AB/10U 220 60 3 24.6

10APRB 208 60 1 43.4

10APRB 208 60 3 30.2

10APRB 220 60 1 41.8

10APRB 220 60 3 29.2

WATER REQUIREMENTS

INLET TEMPERATURE (10A) 180°F

INLET TEMPERATURE (10AB/10ABPRB/10U) 140°F

WATER LINE SIZE NPT (MINIMUM) 1/2”

DRAIN LINE SIZE I.D (MINIMUM) 1 1/2”

GALLONS PER HOUR 58

FLOW PRESSURE P.S.I. (OPTIMUM) 20±5

FLOW RATE GPM 7.8

RACKS

DISH (17 1/2” DIAMETER ROUND) 1

GLASS AND SILVERWARE

(17 1/2” DIAMETER ROUND) 1

FOUR COMPARTMENT SILVERWARE 1

Page 9

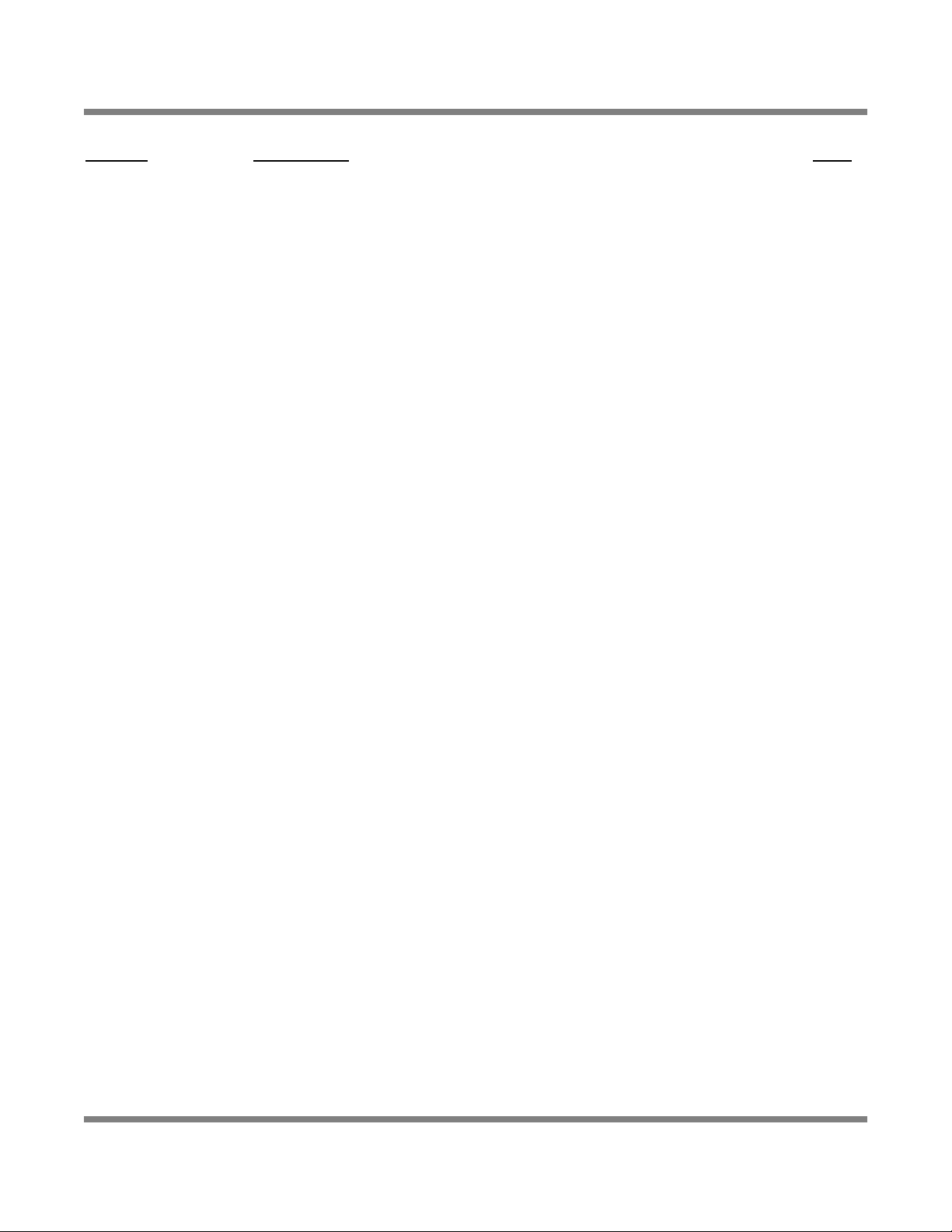

3

SECTION 1: SPECIFICATION INFORMATION

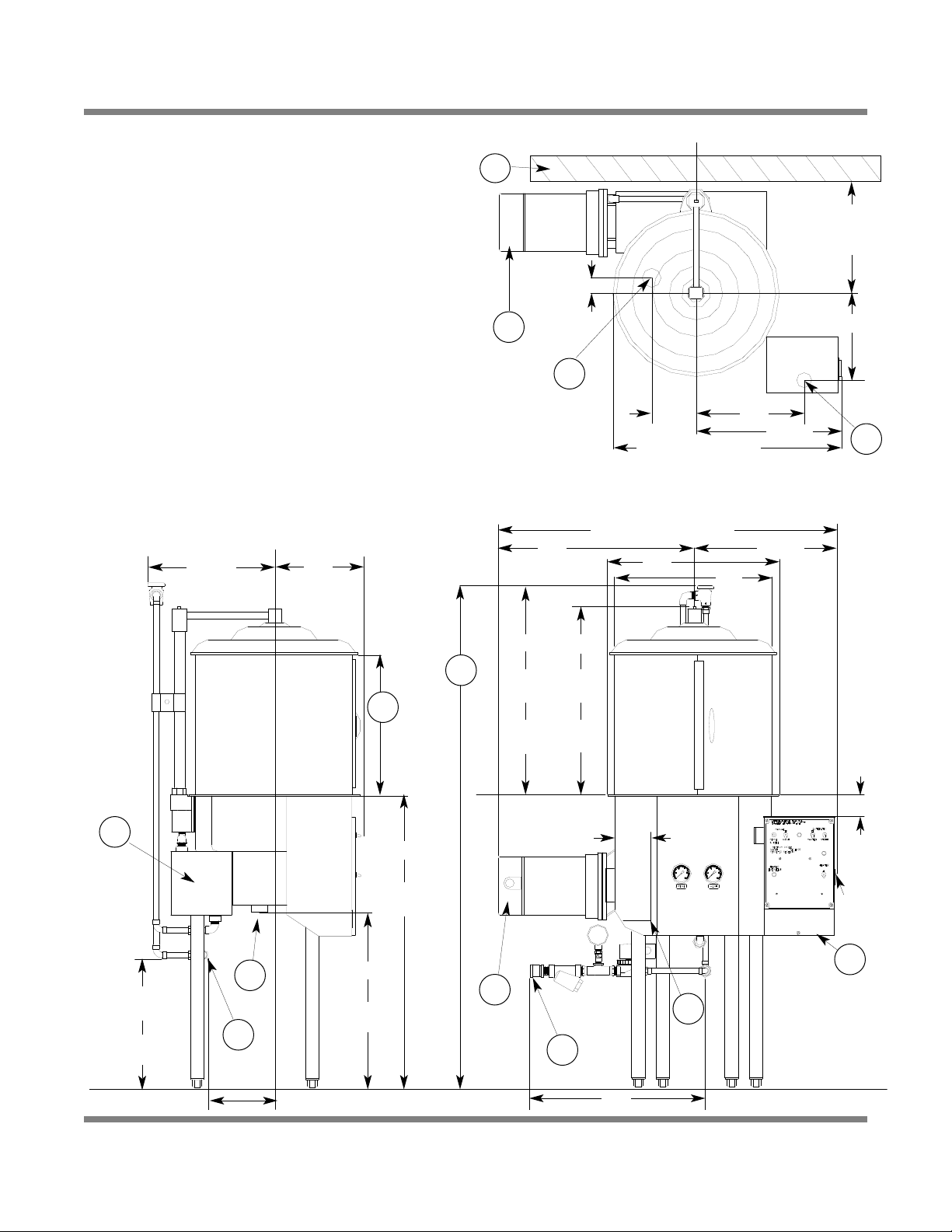

10A DIMENSIONS

NOTES:

A - Water inlet 1/2” NPT. Plumbing can be directed either left or

right.

B - Drain connection 1 1/2” NPT

C - Electrical connection

D - Clearance for dishes:

10” (10A 4” shorter hood)

14” (10A standard hood)

19” (10A 5” higher hood)

E - Machine height:

45 1/2” (9” shorter leg, 4” shorter hood)

58 1/4” (standard leg & hood)

63 1/4” (standard leg, 5” higher hood)

All dimensions in inches.

All vertical dimensions are +/- 1/2” from the floor

due to the adjustable bullet feet.

C

E

B

A

B

B

C

9”

13”

5 1/4”

1 13/16”

16 1/2”

27 1/2”

16 1/2”

14 7/8”

TO THE

WALL

21”

11”

14 1/2”

18”

19 1/4”

15 1/4”

4” SH

24 1/4”

5” HH

2 3/4”

CIRCUIT

BREAKER

4”

14” TO

INLET

5” 4” SH

ONLY

34”

22 1/4”

20 1/4”

4” SH

25”

4” SH

11 1/2”

4” SH

29 1/4”

5” HH

13 1/2”

28 3/4”

TOP VIEW

LEFT VIEW

FRONT VIEW

VACUUM

BREAKER

D

19”

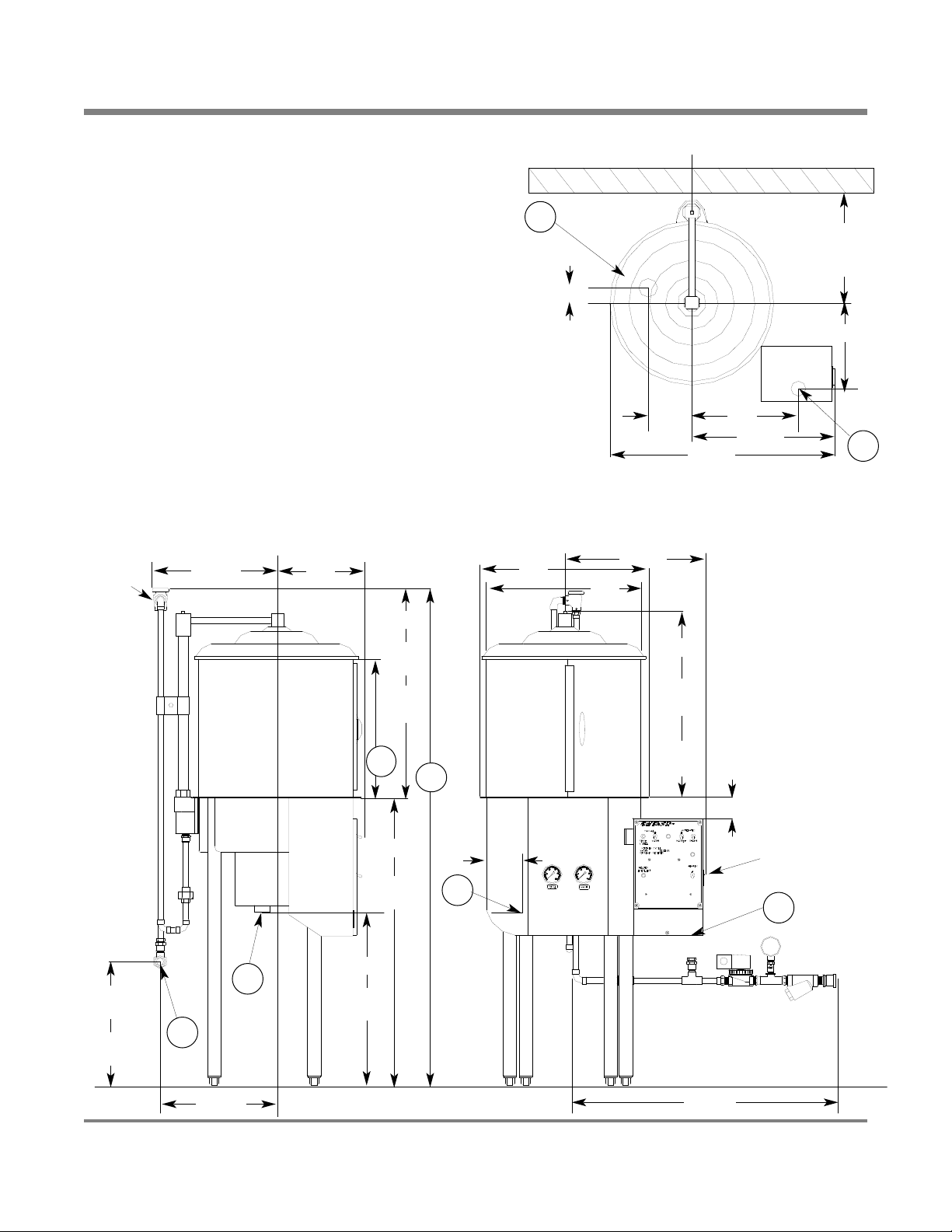

Page 10

4

SECTION 1: SPECIFICATION INFORMATION

10AB/10APRB/10U DIMENSIONS

NOTES:

A - Water inlet 1/2” NPT. Plumbing can be directed either left or

right.

B - Drain connection 1 1/2” NPT

C - Electrical connection

D - Clearance for dishes:

10” (10U/10AB/10APRB 4” shorter hood)

14” (10A/10AB/10APRB standard hood)

19” (10A/10AB/10APRB 5” higher hood)

E - Power rinse pump motor (10APRB only)

F - Booster tank (10AB/10APRB/10U only)

G - Machine height:

45 1/2” (10U/10AB/10APRB, 9” shorter leg, 4” shorter hood)

58 1/4” (10AB/10APRB standard leg & hood)

63 1/4” (10AB/10APRB, standard leg, 5” higher hood)

All dimensions in inches.

All vertical dimensions are +/- 1/2” from the floor

due to the adjustable bullet feet.

A

B

E

F

A

B

B

C

A

E

F

D

G

9”

13”

5 1/4”

1 13/16”

16 1/2”

27 1/2” (AB ONLY)

16 1/2”

14 7/8”

TO THE

WALL

21”

19”

35 1/2” (APRB ONLY)

11”

14 1/2”

18”

2 3/4”

4”

20 1/2”

34”

25”

10U ONLY

11 1/2”

10U ONLY

15 1/4”

10U

24 1/4”

5” HH

19 1/4”

5”

10U ONLY

14” TO

INLET

22 1/4”

20 1/4”

10U

29 1/4”

5” HH

5 1/2”

20”

TOP VIEW

LEFT VIEW

FRONT VIEW

CIRCUIT

BREAKER

Page 11

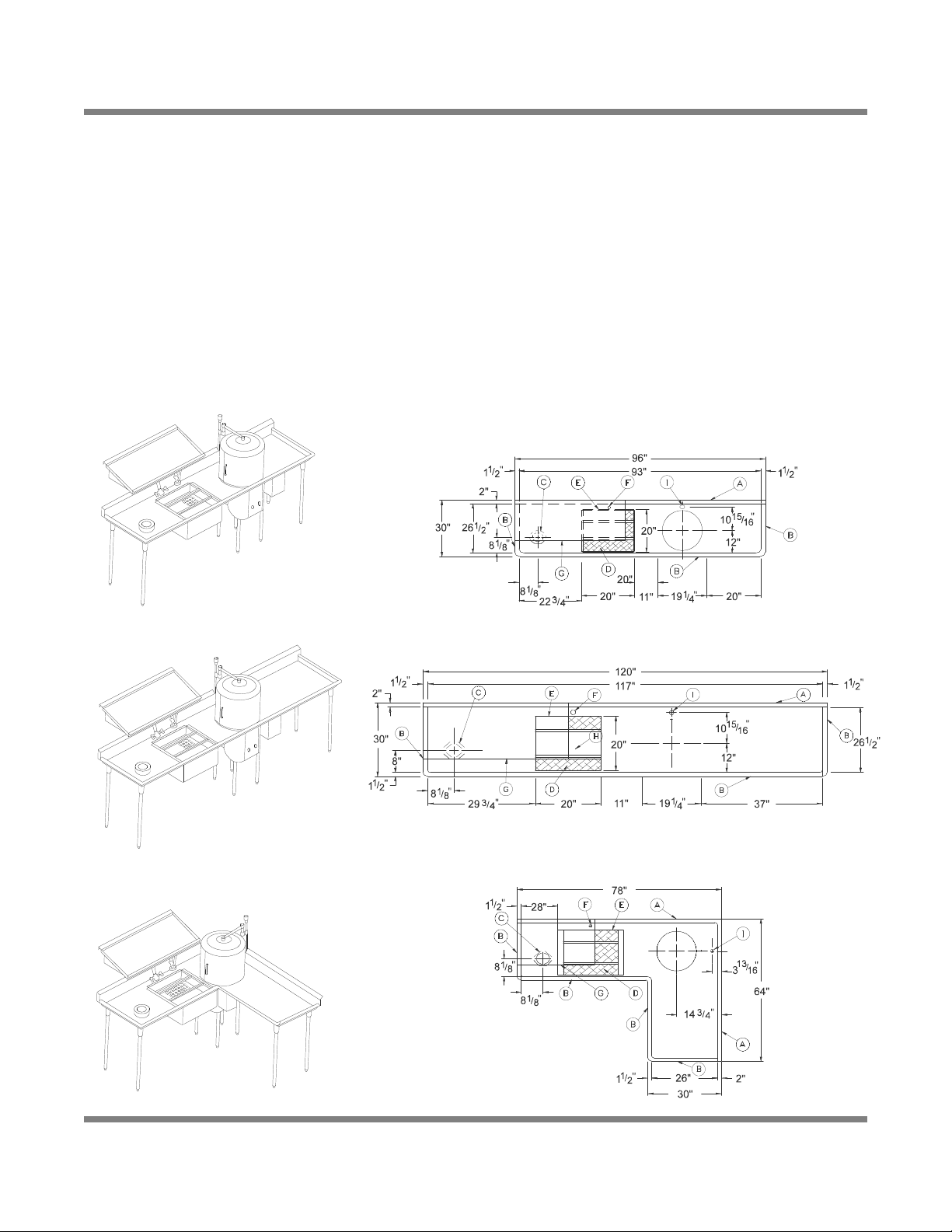

5

SECTION 1: SPECIFICATION INFORMATION

10 SERIES TABLE DIMENSIONS

10 1X PACKAGE

10 2X PACKAGE

10 3X PACKAGE

Legend

A - 10” High backsplash, 2” turnback at 45°

B - 3” High, 1 1/2” diameter rolled edge

C - Scrap block

D - Scrap basket with slide bars

E - 20” x 20” x 5” deep pre-rinse sink

F - Heavy duty pre-rinse

G - 20” Slanted wall mounted overshelf 42” long

H - 3 1/2” hole for sink drain with basket drain

I - 1 7/8” hole for hood support piping

Page 12

6

SECTION 2:

INSTALLATION/OPERATION

INSTRUCTIONS

Page 13

7

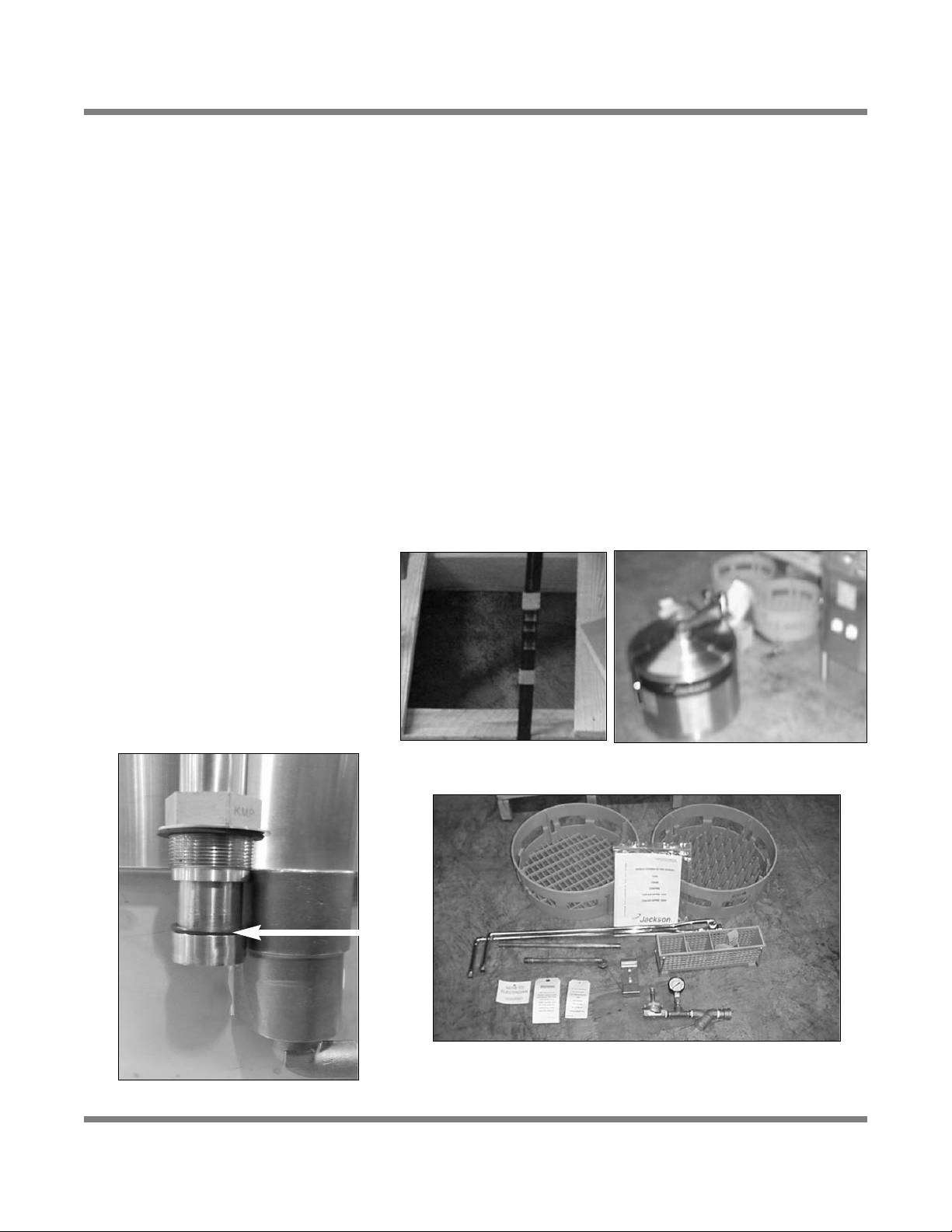

SECTION 2: INSTALLATION/OPERATION INSTRUCTIONS

INSTALLATION INSTRUCTIONS

Jackson WWS Inc. provides technical support for all of the dishmachines detailed in this manual and recommends that service

personnel have this manual on hand when calling technical support staff. Technical support is available from 8:00 a.m. to

5:00 p.m. (EST), Monday through Friday. Technical support is not available on holidays. Contact technical support toll

free at 1-888-800-5672. Please remember that technical support is available for service personnel only.

VISUAL INSPECTION: Before installing unit check container and machine for damage. A damaged container may be an indication of damage to the machine. If there is any type of damage to both container and unit, do not throw away the

container. The dishmachine has been inspected at the factory prior to shipping and is expected to arrive in new, undamaged

condition. However, rough handling by carriers or others may result in damage to the unit while it is in transit. If such a

situation occurs, do not return the unit to the manufacturer. Instead, contact the carrier and ask them to send a representative

to the site to inspect the damage, and request that an inspection report be completed.

Contact the carrier within 48 hours of receiving the machine (to report possible freight damage) and the dealer from whom the

unit was purchased.

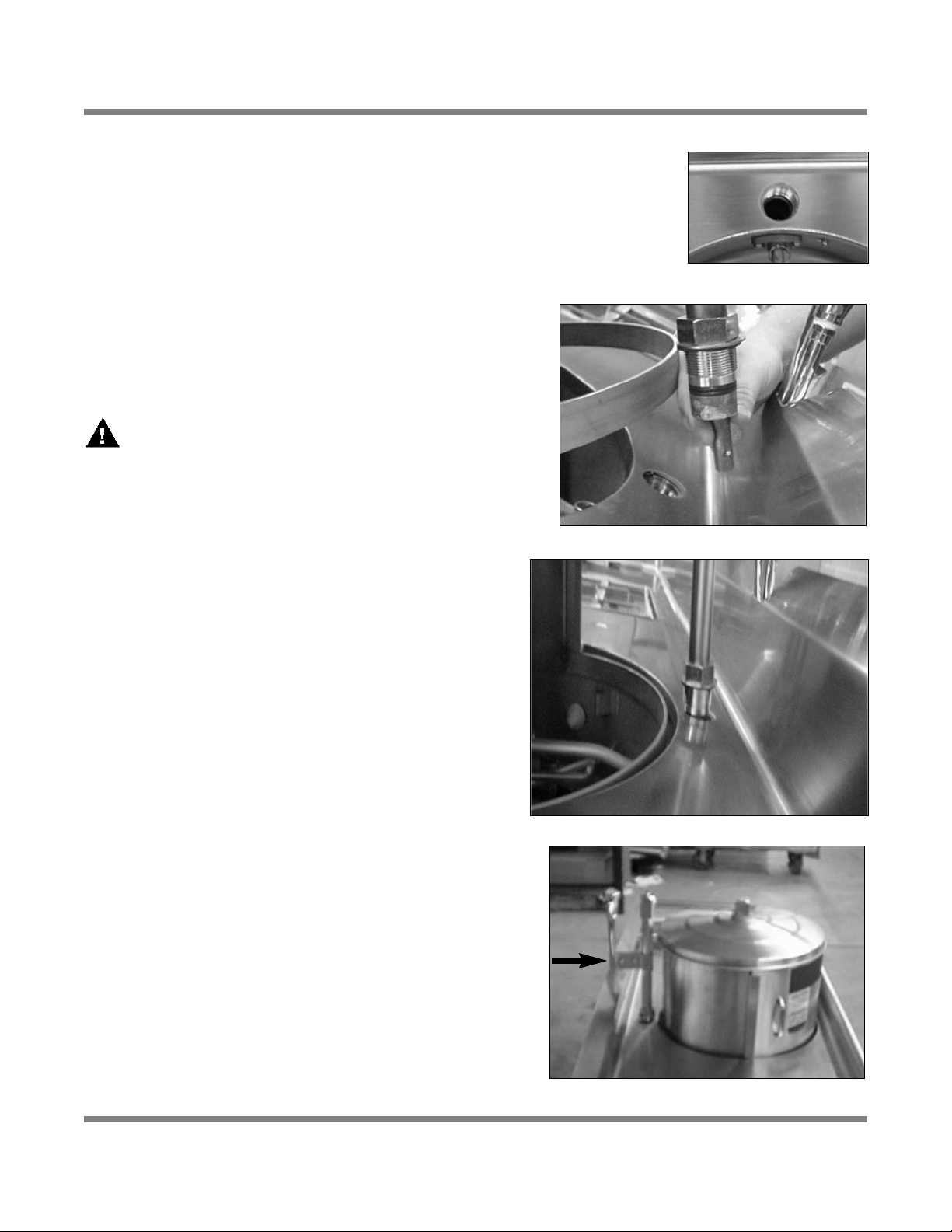

UNPACKING THE DISHMACHINE: Note: Be careful when cutting the hold down strap (Fig. 3), it is under tension. Remove

the hood (Fig. 4) and set to the side. Please note (Fig. 5) for the location of the O-ring. Once the machine has been removed

from the container, ensure that there are no missing parts (Fig. 5 & 6) from the machine. This may not be obvious at first. If it

is discovered that an item is missing, contact Jackson immediately to have the missing item shipped to you.

(Fig. 3) (Fig. 4)

(Fig. 5)

(Fig.

6)

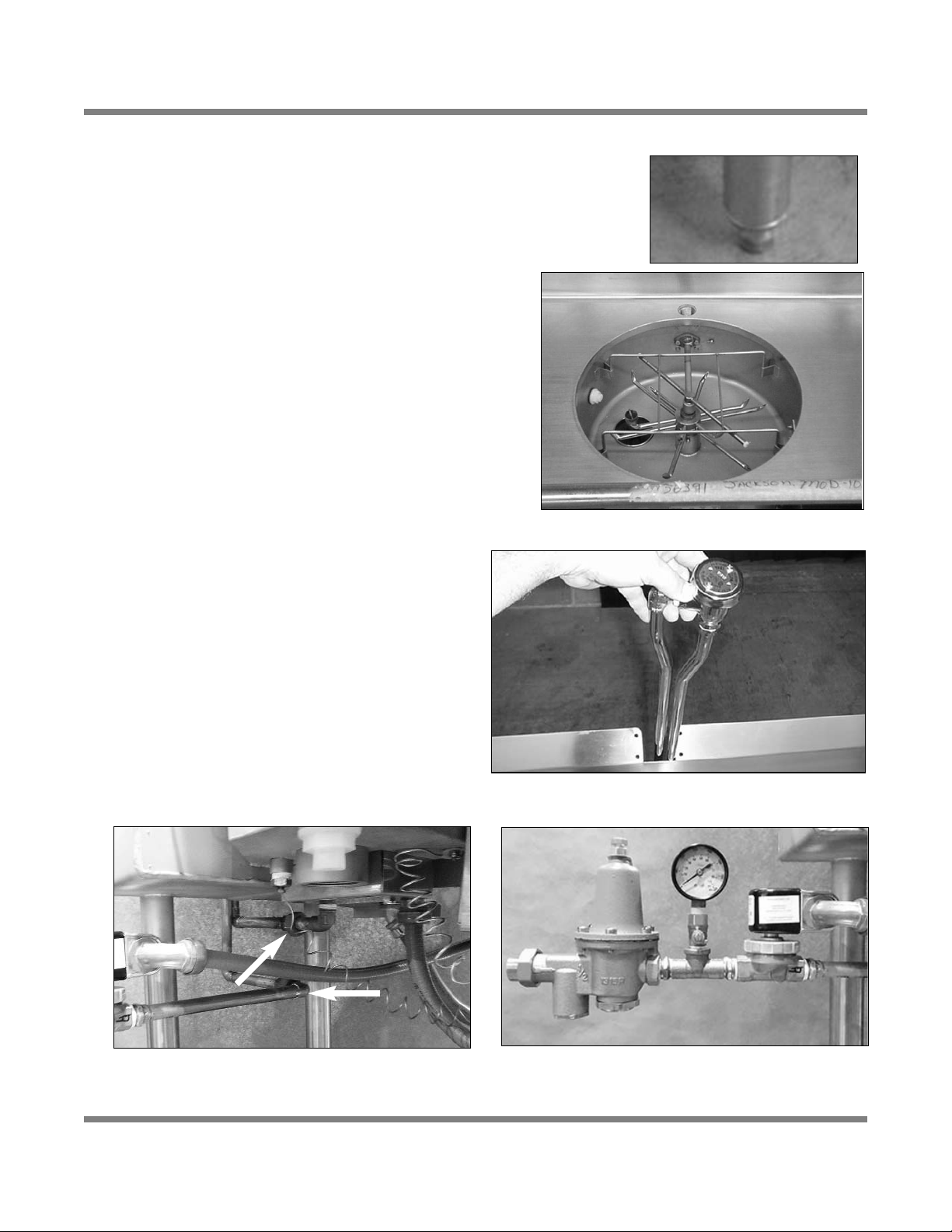

LEVEL

THE DISHMACHINE:

The dishmachine is

designed

to operate

while being level. This is important to prevent any damage to the machine during

operation and to ensure the best results when washing ware. The unit comes with

adjustable bullet feet, which can be turned using a pair of channel locks or by hand if the unit can be raised safely. Ensure that

Page 14

8

SECTION 2: INSTALLATION/OPERATION INSTRUCTIONS

INSTALLATION INSTRUCTIONS

the top of the tub is level from side to side and from front to back before making any connections.

INSTALLING THE DISHMACHINE: With the machine base set in place,

lift the table (Fig. 7) (with proper flange cutout) over and above machine

so that vertical flange on table cutout fits down inside of machine tub and

horizontal flange on machine tub fits up tight against underside of the

table.

(Fig. 7)

INSTALLING THE VACUUM BREAKER & PLUMBING: Ease vacuum

breaker piping (Fig. 8) supplied with the dishmachine down through the

square cutout in the backsplash of the table (directly behind the

machine). Connect vacuum breaker piping to machine. The top union connects to its matching half on the bottom of the rinse

booster tank (Fig.9). The bottom union of the piping connects to an adapter pipe which, in turn connects to the solenoid valve

(Fig. 10). The arrows on the solenoid valve indicate the direction

of water flow to the machine. Tighten both of the connections.

(Fig. 8)

(Fig. 9) (Fig. 10)

Page 15

9

SECTION 2: INSTALLATION/OPERATION INSTRUCTIONS

INSTALLATION INSTRUCTIONS

ALIGNING THE MACHINE: Adjust the machine base to line up hole in table with hole in sup-

port block (Fig. 11).

(Fig. 11)

INSTALLING THE INTERNAL VACUUM BREAKER: Insert internal vacuum breaker pipe into hood support block pin end down (Fig.12).

WARNING: Internal vacuum breaker pipe must be installed or

there will be a hazard to the operator.

(Fig. 12)

INSTALLING THE HOOD ASSEMBLY: Make sure there are two “Orings” (Fig. 5) on the lower support pipe near the end of the ring. While

also holding the internal vacuum breaker, lift the hood and hood support pipe up over table. Set hood support pipe down into the support

block hole (Fig. 13) and begin to work the hex nut into the hole. The

locating pin in the support block will insure proper line up. While holding the support pipe, start tightening nut by hand to prevent cross

threading. It should tighten considerable by hand. Then continue tightening with a wrench. It may be necessary to work support pipe back

and forth to seat nut properly. When the nut is tight, it should force flat

the stainless steel and rubber washers tight to the table top.

(Fig. 13)

Attach vacuum breaker support pipe clamp (Fig. 14) to the support pipe

and external vacuum breaker piping. Slide up about 12” from the table

and tighten securely. Position cover plate (supplied with table) over

square cutout in backsplash on table so that it fits tightly around piping

then snap in the four nylon fasteners (supplied) to hold in place.

Rotate the hood to insure it is free, if not, check level of machine, tightness of table to machine flange, centering of machine, level of table and

hood support pipe.

(Fig. 14)

Page 16

10

SECTION 2: INSTALLATION/OPERATION INSTRUCTIONS

INSTALLATION INSTRUCTIONS

PLUMBING THE DISHMACHINE: All plumbing connections must comply with all applicable local, state, and national plumb-

ing codes. The plumber is responsible for ensuring that the incoming water line is thoroughly flushed prior to connecting it to

any component of the dishmachine. It is necessary to remove all foreign debris from the water line that may potentially get

trapped in the valves or cause an obstruction. Any valves that are fouled as a result of foreign matter left in the water line, and

any expenses resulting from this fouling, are not the responsibility of the manufacturer.

CONNECTING THE DRAIN LINE: The drain for the dishmachine is a gravity discharge drain. Remove the overflow strainer

stopper from the tub and the unit will drain itself. There must also be an air gap between the machine drain line and the floor

sink or drain. If a grease trap is required by code, it should have a flow capacity of 5 gallons per minute.

WATER SUPPLY CONNECTION: Ensure that you have read the section entitled “PLUMBING THE DISHMACHINE” above

before proceeding. Install the water supply line (3/4” pipe size minimum) to the end of the Y-strainer. It is recommended that a

water shut-off valve be installed in the water line between the main supply and the machine to allow access for service. The

water supply line is to be capable of 25 PSI “flow” pressure at the recommended temperature indicated on the data plate. In

areas where the water pressure fluctuates or is greater than the recommended pressure, it is suggested that a water pressure

regulator be installed. The Model 10 does not come with water a pressure regulator as standard equipment.

Do not confuse static pressure with flow pressure. Static pressure is the line pressure in a “no flow” condition (all valves and

services are closed). Flow pressure is the pressure in the fill line when the fill valve is opened during the cycle.

It is also recommended that a shock absorber (not supplied with the dishmachine) be installed in the incoming water line. This

prevents line hammer (hydraulic shock), induced by the solenoid valve as it operates, from causing damage to the equipment.

PLUMBING CHECK: Slowly turn on the water supply to the machine after the incoming fill line and the drain line have been

installed. Check for any leaks and repair as required. All leaks must be repaired prior to placing the machine in operation.

ELECTRICAL POWER CONNECTION: Electrical and grounding connections must comply with the applicable portions of the

National Electrical Code ANSI/NFPA 70 (latest edition) and/or other electrical codes.

Disconnect electrical power supply and place a tag at the disconnect switch to indicate that you are working on the circuit.

Refer to the data plate for machine operating requirements, machine voltage, total amperage load and serial number.

To install the incoming power lines, first remove the lower control box cover (Fig. 15). Next, run the power lines through the

hole located in the bottom of the control box to the terminal board inside (Fig. 16). This board is accessible by removing the

lower cover plate on the control box. Attach lines (L1 and L2 (L3 for three phase)) on the terminal block at the lower front right

corner. There is no neutral wire on this machine. There is a grounding lug inside the control box on the bottom left. Be sure all

connections made are tightened properly. It is recommended that “DE-OX” or another similar anti-oxidation

agent be used on all power connections.

VOLTAGE CHECK: Ensure that the power switch is in

the OFF position and apply power to the dishmachine.

Check the incoming power at the terminal block and

ensure it corresponds to the voltage listed on the data

plate. If not, contact a qualified service agency to

examine the problem. Do not run the dishmachine if the

voltage is too high or too low. Shut off the service

breaker and mark it as being for the dishmachine.

Advise all proper personnel of any problems and of the

location of the service breaker. Replace the lower

cover and tighten down the screws.

Page 17

11

SECTION 2: INSTALLATION/OPERATION INSTRUCTIONS

INSTALLATION INSTRUCTIONS

(Fig. 15) (Fig. 16)

FINAL CHECK: Check all fittings and connections before and after first 10 cycles. Deliver Installation/Operation Manual to site

manager. Contact Jackson for free performance and installation check.

Page 18

SECTION 2: INSTALLATION/OPERATION INSTRUCTIONS

OPERATION INSTRUCTIONS

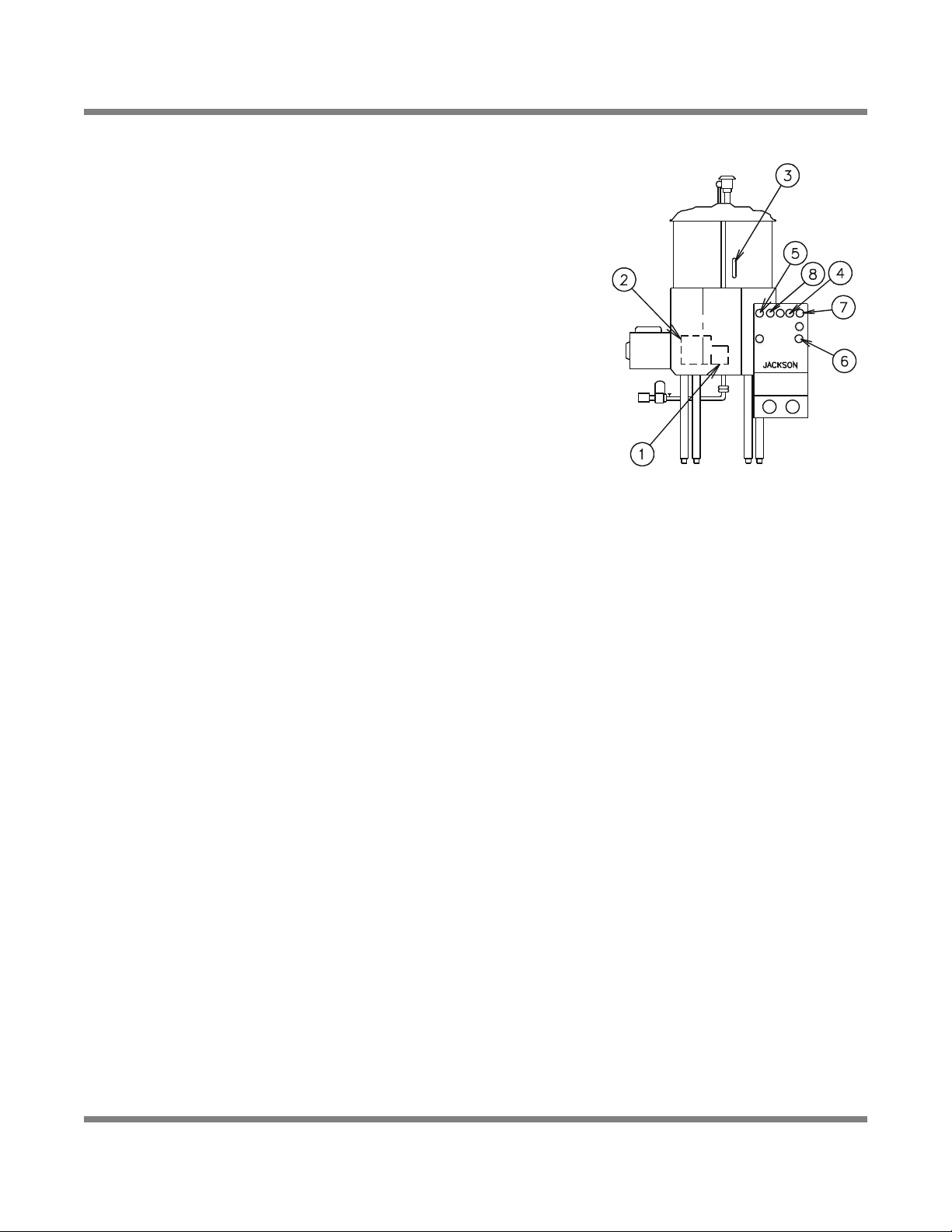

PREPARATION:

1. Ensure that the pump intake strainer (1) and basket overflow strainer (2) are

inserted and tight.

2. Ensure that the wash and rinse arms are installed and secure.

3. Remove all solid wastes in order to avoid obstructing filters, drain and wash and

rinse arms.

4. Ware that is encrusted with soil should be presoaked prior to being placed in the

machine.

5. When placing dishes into the racks, do not allow them to lean on each other.

6. Place the glasses upside down in the open rack. With the model 10 series, a four

compartment silverware rack is supplied. Place silver in compartment rack loosely

not allowing it to mix with other silverware of the same nature. Place the compartment rack in the open rack and wash with the cups and glasses.

DAILY MACHINE PREPARATION: Refer to the section entitled “PREPARATION” at the top of this page and follow the instructions there. Afterwards, check that all of the chemical levels are correct and/or that there is plenty of detergent available for the

expected workload.

WARM-UP CYCLE: At the beginning of each work day, a warm up cycle will need to be performed. Close the hood (3). Turn

on the master switch (4). Raise the fill switch (5) until the machine is filled to the top of the basket overflow strainer (2.) Once

the proper water level has been reached, turn on the heater switch (6). Observe the temperature gauges, the rinse temperature should rise to a specified level of 180°F within five minutes if the incoming water to the booster tank is 140°F. The wash

heater will take longer to reach 150°F as the element is designed for maintaining temperature, not heating. Once the proper

temperature has been reached, with the hood closed, turn on the manual wash switch. You should hear the water being

pumped as it strikes the top of the hood. Turn off the manual wash switch. The dishmachine is now ready to proceed with washing of the dishes.

WARE PREPARATION: Proper preparation of ware will help ensure good results and less re-washes. If not done properly, ware

may not come out clean and the efficiency of the dishmachine will be reduced. It is important to remember that a dishmachine

is not a garbage disposal and that throwing unscraped dishes into the machine will defeat the purpose altogether of washing

the ware. Scraps should be removed from ware prior to being loaded into a rack. Pre-rinsing and pre-soaking are good ideas,

especially for silverware and casserole dishes. Place cups and glasses upside down in racks so that they do not hold water

during the cycle. The dishmachine is meant not only to clean, but to sanitize as well, to destroy all of the bacteria that could be

harmful to human beings. In order to do this, ware must be properly prepared prior to being placed in the machine.

WASHING A RACK OF WARE: To wash a rack, open the hood completely (being careful for hot water that may drip from the

top of the hood), manually load detergent into the wash chamber, or if automatic detergent dispenser is used, follow the manufacturers instructions. Slide the rack of dishes into the dishmachine. Close the hood. Start the automatic wash and rinse cycle

of the dishmachine by flipping the start switch (7) either up or down (NOTE: The start switch, is a three position switch. Up =

Start, Center = Off, Down = Start) the indicating light (8) will come on at the start of the cycle. When the light goes off, the cycle

is complete. Open the hood, remove the rack of clean dishes to air dry. Repeat the cycle by adding another rack of soiled dishes, adding the detergent, close hood and flip start switch (8) in opposite direction.

SHUT DOWN AND CLEANING: At the end of meal time, shut off the dishmachine by placing the start switch in center position and turn heat switch off. Drain the dishmachine by removing the overflow strainer. Remove the pump intake strainer after

water has drained. Clean both strainers. Clean the inside of the unit. Clean wash head, upper and lower rinse arms and replace

the clean strainers. Replace all removed parts. The machine is now ready for refilling and operation.

12

Page 19

13

SECTION 2: INSTALLATION/OPERATION INSTRUCTIONS

DETERGENT CONTROL

Detergent usage and water hardness are two factors that contribute greatly to how efficiently your dishmachine will operate.

Using detergent in the proper amount can become, in time, a source of substantial savings. A qualified water treatment specialist can tell you what is needed for maximum efficiency from your detergent, but you should still know some basics so you’ll

understand what they are talking about.

First, you must understand that hard water greatly effects the performance of the dishmachine. Water hardness is the amount

of dissolved calcium and magnesium in the water supply. The more dissolved solids in the water, the greater the water hardness. Hard water works against detergent, thereby causing the amount of detergent required for washing to increase. As you

use more detergent, your costs for operating the dishmachine will increase and the results will decrease. The solids in hard

water also may build-up as a scale on wash and rinse heaters, decreasing their ability to heat water. Water temperature is

important in removing soil and sanitizing dishes. If the water cannot get hot enough, your results may not be satisfactory. This

is why Jackson recommends that if you have installed the machine in an area with hard water, that you also install some type

of water treatment equipment to help remove the dissolved solids from the water before it gets to the dishmachine.

Second, hard water may have you adding drying agents to your operating cycle to prevent spotting, when the real problem is

deposited solids on your ware. As the water evaporates off of the ware, the solids will be left behind to form the spotting and

no amount of drying agent will prevent this. Again, using treated water will undoubtedly reduce the occurrences of this problem.

Third, treated water may not be suitable for use in other areas of your operation. For instance, coffee made with soft water may

have an acid or bitter flavor. It may only be feasible to install a small treatment unit for the water going into the dishmachine

itself. Discuss this option with your qualified water treatment specialist.

Even after the water hardness problems have been solved, there still must be proper training of dishmachine operators in how

much detergent is to be used per cycle. Talk with your water treatment specialist and detergent vendor and come up with a

complete training program for operators. Using too much detergent has as detrimental effects as using too little. The proper

amount of detergent must be used for job. It is important to remember that certain menu items may require extra detergent by

their nature and personnel need to be made aware of this. Experience in using the dishmachine under a variety of conditions,

along with good training in the operation of the machine, can go a long way in ensuring your dishmachine operates as efficiently as possible.

Certain dishmachine models require that chemicals be provided for proper operation and sanitization. Some models even

require the installation of third-party chemical feeders to introduce those chemicals to the machine. Jackson does not recommend or endorse any brand name of chemicals or chemical dispensing equipment. Contact your local chemical distributor for

questions concerning these subjects.

Some dishmachines come equipped with integral solid detergent dispensers. These dispensers are designed to accommodate

detergents in a certain sized container. If you have such a unit, remember to explain this to your chemical distributor upon first

contacting them.

As explained before, water temperature is an important factor in ensuring that your dishmachine functions properly. The data

plate located on each unit details what the minimum temperatures must be for either the incoming water supply, the wash tank

and the rinse tank, depending on what model of dishmachine you have installed. These temperatures may also be followed by

temperatures that Jackson recommends to ensure the highest performance from you dishmachine. However, if the minimum

requirements are not met, the chances are your dishes will not be clean or sanitized. Remember, a dish can look clean, but it

may not be sanitized. Instruct your dishmachine operators to observe the required temperatures and to report when they fall

below the minimum allowed. A loss of temperature can indicate a much larger problem such as a failed heater or it could also

indicate that the hot water heater for your operation is not up to capacity and a larger one may need to be installed.

There are several factors to consider when installing your dishmachine to ensure that you get the best possible results from it

and that it operates at peak efficiency for many years. Discuss your concerns with your local chemical distributor and water

treatment specialist before there is a problem.

Page 20

14

SECTION 3:

PREVENTATIVE MAINTENANCE

Page 21

15

SECTION 3: PREVENTATIVE MAINTENANCE

PREVENTATIVE MAINTENANCE

Proper maintenance of your Jackson dishmachine will insure optimum service with a minimum of down time.

1. To delime the booster tank.

a. Remove the support pipe nut and lift the whole hood assembly away from the unit.

b. Loosen the fitting going into bottom side of booster tank.

c. Drain approximately 2 to 3 cups out of the tank.

d. Pour 1 to 2 cups of delimer into the hood support block opening, after tightening the booster tank union.

e. Replace the hood assembly.

f. Turn on the heat switch for 30 minutes.

g. Fill the machine with water.

h. Turn on manual wash switch and allow the unit to run for about 20 minutes.

i. Empty the machine and refill at least twice.

2. To remove all lime and corrosion deposits.

a. Fill the machine with wash water as would ordinarily be done for washing.

b. Open the door and place one cup or less of deliming compound into the water. (Be sure to follow their directions if they

vary from these being given) which is available from your detergent supplier. Read and follow the label instructions.

c. Turn on the manual wash switch and allow to wash for five minutes.

d. Open the door and examine the interior. All lime should be removed and parts should be shiny. If not, allow to wash for

a longer period.

e. After the interior is clean, empty the wash water be removing overflow strainer.

f. Replace the overflow strainer. Refill machine and allow to run for two minutes, then again drain the wash reservoir.

g. Refill as it is ready for regular operation.

3. Clean strainers.

a. Clean around overflow and pump intake strainer holes.

b. Clean around pump intake (a toothbrush makes a good cleaning tool).

4. Clean Y-strainer on the incoming water line. (Water to the machine must be turned off for this operation.)

a. Remove the plug and clean the strainer.

5. Clean rinse tubes.

a. Remove the end plugs on the lower and upper rinse arms.

b. Clean all rinse tubes with the special brush provided.

c. If spray holes in the rinse tubes are clogged, they may be cleaned with a pointed tool.

6. Clean the wash head assembly.

a. If the spray jets are plugged, use a pointed tool to dislodge and flush with water.

b. If lodged items still remain in the wash tubes, remove the wash assembly by first removing the rinse assembly.

c. Clean the assembly at the sink by flushing water through the spray jets.

d. Reinstall the wash and rinse assemblies.

7. Clean any deposits which may have built up on exterior moving parts.

Page 22

16

SECTION 4:

SERVICE PROCEDURES

Page 23

17

SECTION 4: SERVICE PROCEDURES

RINSE HEAD/ WASH HEAD ASSEMBLIES

1. Turn master switch to off position.

2. Open hood and drain machine by lifting overflow strainer.

3. When empty, replace overflow strainer.

4. Remove the pin holding the rinse feed pipe and remove the feed

pipe and rinse head assembly.

5. Locate the allen head set screw in the wash head cap and

loosen screw by turning counter-clockwise.

6. Turn the wash head cap counter-clockwise until the cap is

removed and put the cap in a secure area.

7. Carefully remove the 1/4” stainless steel ball bearings and place

in a container. Take special care to prevent any from falling through

the wash tub base for these will fall into the motor impeller. If any

should fall into this area, the motor will have to be removed to

retrieve the ball bearings. If any should drop in the machine, you will

be able to locate and retrieve these if you left the overflow strainer

in as suggested in step 3.

8. Lift and remove the small manifold with the short tubes and place

in a secure area.

9. Carefully remove the 1/4” stainless steel ball bearings and place

in a container.

10. Lift and remove the large manifold with the long tubes and place

in a secure area.

11. The lower fixed race may be left in place. 21. Replace the rinse

feed pipe and rinse head assembly. Replace the pin through the

rinse feed casting and rinse feed pipe.

12. Clean the ball bearings by soaking in a deliming solution.

13. The ball bearing raceways may be cleaned by either brushing

with deliming solution or gently cleaned by rubbing with fine sandpaper or emery cloth.

14. Rinse the ball bearings and manifolds thoroughly.

15. To reassemble, first fill the lower raceway to capacity with the

1/4” ball bearings, then remove one. This will allow proper movement needed during rotation of assembly.

16. Replace the lower large manifold and fill the raceway fully with

the bearings, then remove one.

17. Replace the upper small manifold and fill raceway fully with

bearings, then remove one.

18. Replace the wash cap by turning clockwise onto the center shaft

and finger-tighten.

19. Turn the wash cap counter-clockwise by a 1/4” turn and tighten

the allen set screw.

20. Rotate the manifolds in opposite directions and see if they rotate

freely. (Select the longest tube in the bottom manifold and make

sure it moves up and down at least 1/8” and no more than 1/4”.)

22. Close the hood doors and refill the dishwasher.

23. Run through several cycles and recheck the wash manifolds for

easy movement. Adjust if necessary.

Page 24

Timer Switch

Mfg. No.: 5945-306-02-00

COM

NC

NO

A

B C

F (on rear)

E

Timer, 220V

5945-303-19-00

D

Timer Motor, 220V

5945-306-06-00

18

SECTION 4: SERVICE PROCEDURES

TIMER FOR 10 DISHMACHINES

GENERAL DESCRIPTION: The timer is a self-contained (frame mounted) timer of the repeating cycle type. It is mounted

on the control panel of the control box to control the automatic functions of the machine. It consists of a clock motor which

operates on 60 cycle AC, 220 VAC. In addition to the clock motor, the timer contains a driven cam arrangement which

operates three microswitches.

PRINCIPLE OF OPERATION: The timer controls various operations of the dishmachine as per the wiring diagrams for each

machine, however, the timing cycle and the microswitches are the same for each model. The time for one complete revolution of the cam shaft is approximately 150 seconds, allowing two wash and two rinse operations for each complete revolution

of the cam shaft. The microswitch nearest the timer motor is the hold circuit and uses both the NO and NC contacts. The

middle microswitch controls the wash and uses the NO contact. The switch farthest away from the timer motor controls the

rinse and uses just the NC contact.

SERVICE INSTRUCTIONS: CAUTION: ALWAYS REMOVE THE POWER TO THE MACHINE BEFORE WORKING ON THE

CONTROL PANEL OR WHILE SERVICING THE COMPONENTS ON THE SWITCH PANEL. ALL ELECTRICAL CHECKS

SHOULD BE MADE BY QUALIFIED PERSONNEL.

Timer operation can be observed after removing the control panel from the control box by loosening the four screws holding

it. Hang the control panel using the two right-hand screws with the back side of the panel outward.

If it is determined that the timer is defective, it is recommended that a new timer be installed. However, limited field maintenance can be accomplished as follows: A frozen contact on a microswitch will be indicated by one function being executed all

the time or the absence of a click when the switch arm is actuated. To replace microswitch:

1. Remove all wires from the timer, properly tag them to assure proper replacement.

2. Remove the two screws which hold the timer to the control panel.

3. One screw holds the microswitches, cams and actuating arms in the frame. This screw is seen on the side

opposite the motor. Remove this screw. NOTE: Be sure to note which cam goes with which microswitch. Cam

nearest timer motor has 1/2 raised, cam center, larger depressed areas, cam farthest from timer motor, smallest

depressed areas.

4. The unit can now be taken apart and the defective microswitch replaced.

5. Reassemble. NOTE: The flanges on the cams are such that they only mesh in one direction. The shorter flange

on the cams always points toward the drive motor.

The timer’s cam drive system is equipped with a clutch to enable user to view the operations of the cams and microswitches.

Remove power to the machine BEFORE touching the timer. Rotate the cams by turning with fingers; cam will turn in one direction only. Do not force them. As cams actuate switches, listen for the click of the switch or test the switches with an ohm-meter.

A defective motor is indicated by the fact that the cams do not rotate or the machine does not perform the automatic operations or performs a specific part of the cycle continuously, but works okay on manual. Remember, the timer motor is controlled

by the start switch and the hold microswitch, check this complete circuit before changing the motor. NOTE: It may be necessary to remove complete timer to replace motor; if so, follow steps 1 and 2 for removing the microswitches.

To replace the motor:

1. Remove motor leads from connection points.

2. Remove the two screws which hold the motor.

3. Replace with the new motor.

4. Re-connect motor leads to proper points.

A. To upper right terminal start switch

B. To lower right terminal start switch

C. To right-central terminal manual wash switch

D. To upper terminal of rinse switch

E. To #5 terminal

F. Shorting bar or jumpers connected to all

three timer switches, this terminal

Page 25

19

SECTION 4: SERVICE PROCEDURES

FUNCTION OF SWITCHES, CIRCUIT BREAKER & INDICATING LIGHTS/REPLACEMENT OF SWITCHES

FUNCTION OF SWITCHES, CIRCUIT BREAKER & INDICATING LIGHTS

CIRCUIT BREAKER: Rated 15 amps, controls power to the control circuit only, i.e. timer, relays, solenoid valve, water level

control and motors. The circuit breaker does not cut off power in the control box at incoming terminal board and rinse heater

relay contacts. Power is still applied to them when the circuit breaker is in “off” position.

MASTER SWITCH: The switch interrupts all power going to the control circuit, this means that all switches on control panel

are inoperable until master switch is turned “on.”

START SWITCH: This switch controls the timer motor through two circuits (see electrical diagram) it is a three-position

switch, up position = start, middle position = off, down position = start. To start, flip switch toggle in either up or down

position; indicating light in center of panel will light verifying automatic cycle has started. After cycle ends and you are ready

to start a new cycle, flip toggle to opposite position.

CYCLE LIGHT: This light comes on only when automatic cycle is in progress and extinguishes when cycle is complete.

MANUAL WASH SWITCH: This switch is used to bypass the timer and operate the wash pump manually. The wash pump

will run as long as this switch is “on.” The prime purpose of this switch is to extend the wash period for extremely soiled

dished before putting them through the normal automatic cycle. It may also be used as an emergency backup in case of

timer failure for rinsing dishes. The required rinse time is indicated on the front control panel.

RINSE/FILL SWITCH: This switch is spring-loaded and must be held in its up position to operate. When the switch is

operated, water is allowed to fill machine through the rinse heads. It may be used as an emergency backup in case of timer

failure for rinsing dishes. The required rinse time is indicated on the front control panel.

HEAT SWITCH: This switch applies power to the heat circuits which are composed of automatic control devices that turn

heaters on and off to maintain required temperatures.

REPLACEMENT OF SWITCHES IN CONTROL PANEL

HEAT LIGHT: This indicating light remains lit all the time the heat switch is on.

There are five switches installed in the control box cover panel. These are the start, master, manual wash, rinse-fill and

heater switches.

Before working on the machine, it is important that power be turned off at the customer’s circuit breaker to prevent the

possibility of electrical shock, trip breaker to “off” position.

Remove control panel from the control box by removing the four screws holding it in place. Hang the control panel using

the two right-hand upper and lower screw receptacles on the control box with backside of panel facing outward. The five

switches are mounted in individual round holes with a keyway. By using a pair of pliers, or open-end wrench, it is possible to

loosen the inside nut enough to allow the outside nut holding the switch to be removed by fingers. Push switch out of hole.

If a switch is found to be defective, replacement can be achieved by placing the new switch next to the old one. To make the

new switch is not upside down, line up with the keyways. Transfer wires one at a time to the new switch. If this is not

practical, pull wires off, one at a time and tag them for proper replacement.

Put switches back into panel, make sure switch protrudes through panel

properly, tighten both nuts, and replace control panel on control box. Power

can now be applied to the dishmachine and run through cycles checking all

operations.

1. Connection terminals

2. Inside nut

3. Panel plate

4. Outside nut

5. Bar or toggle handle

2

1

3

4

5

Page 26

20

SECTION 4: SERVICE PROCEDURES

THERMOSTAT ADJUSTMENT

THERMOSTAT ADJUSTMENT: The thermostat can be adjusted by turning screw #1 (see diagram below) on the thermostat

housing cover. (Remember the preset setting in case the problems are elsewhere in the control circuit.) A clockwise rotation

is used to obtain a lower temperature setting and a counter-clockwise rotation is used to obtain a higher temperature setting.

A 1/8” turn of screw #1 changes the temperature approximately 15°F. If screw #1 is turned all the way to its stop in either

direction; adjust screw #2 as follows. DO NOT TOUCH THE SCREW SEALED WITH RED PAINT! When adjusting screw #2,

power should be disconnected during adjustment.

Set screw #1 so that it can be turned equal distances in either direction, then:

-if screw #1 stopped while turning in clockwise direction, turn screw #2 3/4” turn in a clockwise direction.

-if screw #1 stopped while turning in counterclockwise direction, turn screw #2 3/4” turn in a

counterclockwise direction.

This will bring the thermostat to approximately the same setting obtained where screw #1 stopped. Check the preset temperature setting before attempting any further adjustments. Use screw #1 for any further adjustments.

Thermostats can be ordered by using the following numbers:

Rinse Thermostat 05930-510-02-00

Wash Thermostat 05930-510-01-00

Screw #2

Screw #1

Page 27

21

SECTION 4: SERVICE PROCEDURES

RINSE TANK HEATER SYSTEM

The rinse tank heater system is electrically connected in the circuit and is controlled by a heat switch (mounted on the front

panel) and a thermostat (mounted near the right front leg underneath) which activates the coil on the heat relay, mounted in

the control box. When higher temperature is required, power is applied to the heaters (mounted on the right end of built-in

boosters) when the contacts of the heat relay are closed. Should the rinse tank thermometer read either too high or too low,

follow checkout below.

CHECKOUT OF HEATER SYSTEM FOR RINSE TANK (refer to diagram below)

NOTE: THE FOLLOWING CHECKOUT SHOULD BE DONE BY A QUALIFIED SERVICE PERSON OR ELECTRICIAN.

1. If temperature is too high, adjust thermostat using thermostat instructions in this manual.

2. If temperature is too low, adjust thermostat using thermostat instructions in this manual then:

a. Turn off power to machine by tripping customer circuit breaker to “off” position.

b. Remove lower cover plate on control box (held by a single screw).

c. Make sure rinse temperature is below 180°F (preferably about 140°F).

d. Re-apply power, turn on master switch and observe heat relay (2 pole mounted at the lower left inside

control box) letter “C” figure 1 as heat switch is turned on and off several times.

NOTE: ELECTRICAL POWER STILL APPLIED, SO BE CAREFUL. (See instructions in manual for removing control panel

front.Refer to replacement of switch in control panel.)

1. If heat relay contacts do not close: With heat switch on:

a. Check power supply at Position 1 on terminal board X. Voltage should be 208-230 VAC. If not, check

customer’s breaker, if defective, replace.

b. Check position 2, voltage should be 0 volts. If not, check thermostat, adjust per instructions, check

master and heat switch, if any items are defective, replace.

c. Check position 3, there should be 208-230 Volts there. If not, check wiring for breaks or poor

connections.

d. If voltage is being applied to Positions 1 and 3 and the relay doesn’t operate, it should be replaced, coil

on relay is probably open.

2. To determine if elements are working, if heat relay does not close:

a. There is an insulated movable bar on the heat relay across the top of the two contacts. With an

insulated probe, depress the bar and observe the rinse thermometer, the temperature should rise

noticeably in a minute or two. If it move VERY slowly, it would indicate that one element is defective.

If it moves consistently higher at a steady rate, elements are okay.

b. Check voltage at position 4. There should be 208-230 Volts. If not, check wiring.

NOTE: A CHECK WITH AN AMP PROBE (POSITION E), IF AVAILABLE, WOULD BE HELPFUL AT THIS POINT.

Clamp probe on single wire between heat relay

and heater elements. The elements together on a

single phase should draw 30 amps, one element

will draw only 10 amps. Replace element if found

inoperative.

3. If relay is closed, but elements do not

heat, use same general methods used in

step 2 above for checkout.

A. Heater switch

B. Thermostat

C. Heater Relay

D. Rinse Tank Heaters

E. Amprobe Test Position

X. Terminal board (9 terminals)

1

2

3

B

L1

L2

619

X

C

A

DDD

E

Page 28

22

SECTION 4: SERVICE PROCEDURES

WASH TANK HEATER SYSTEM

The wash tank heater control system is electrically connected in the circuit to operate on 208-230 Volts. The heat circuit is

controlled by a heat switch (mounted right front panel), water level control (mounted top inside control box), and thermostat

(mounted right front leg underneath). When higher temperature is required, power is applied to the heater element through

above controls. Should the wash tank thermometer read too high or too low, follow checkout below.

CHECKOUT OF HEATER SYSTEM FOR WASH TANK (refer to diagram below)

NOTE: THE FOLLOWING CHECKOUT SHOULD BE DONE BY A QUALIFIED SERVICE PERSON OR ELECTRICIAN.

1. Ready the machine for normal dishwashing operation with the wash tank water at proper level.

2. If temperature is too high, adjust thermostat using thermostat instructions in this manual.

3. If temperature is too low, adjust thermostat using thermostat instructions in this manual then:

NOTE: ELECTRICAL POWER STILL APPLIED, SO BE CAREFUL. (See instructions in manual for removing control panel

front. Refer to replacement of switch in control panel.)

A. With circuit breaker, master switch and heat switch on, check power to machine at position 1, terminal board “X”

should read 208-230 Volts, if not, check customer’s circuit breaker, if defective, replace.

B. Wash temperature should be 130°F or less to proceed.

C. Observe water level control, letter “D”. Turn hat switch on and off several timers. Relay and contact points (inside

clear case on heat water level control) should move back and forth.

1. If water level control relay doesn’t close, (contact points don’t move in “C” above.

a. Refer to page on Water Level Control’s function and checkout.

2. If water level control relay does close, proceed with heat switch on:

a. Check voltage at position 1 on terminal board “X”. Voltage is 208-230 Volts.

b. Check position 2, there should be no voltage. If there is voltage, then adjust thermostat (refer to

page on ThermostatAdjusting).

c. Check position 3, voltage should be 208-230 Volts. If not, check wiring for loose connections or

a break.

d. Temperature should rise slowly, a check with an amprobe would indicate if the element is

drawing the correct amperage. Replace element if defective.

NOTE: A CHECK WITH AN AMP PROBE (POSITION E), IF AVAILABLE, WOULD BE HELPFUL AT THIS POINT.

Clamp probe on a single wire between the thermostat and wash heater element. The element should draw 3 amps. If it does

not and everything above checked out okay, replace the element. This wash element is used to maintain wash water

temperature so temperature rise will be extremely slow - do not depend on this indication.

A. Heater switch

B. Thermostat

C. Heater Relay

D. Rinse Tank Heaters

E. Amprobe Test Position

X. Terminal board (9 terminals)

D

X 619

2

1

A

B

F

E

C

3

E

Page 29

23

SECTION 4: SERVICE PROCEDURES

WATER LEVEL CONTROL

WATER LEVEL CONTROL: This water level control is used on this machine in conjunction with a sensor, master switch,

thermostat all of which help control the action of the wash tank heater. The wash heater water level control is energized

when the master switch is turned on.

When the water level decreases in the wash tank, the sensor (probe) sends a signal to the control which deactivates the

plug-in relay (located on the control circuit board). When the relay deactivates, one set of its contacts return to a normally

open position. The thermostat and wash heater are connected in series with these contacts and at this time de-energizes the

wash tank heat circuit (thermostat & wash heaters). When the proper water level is restored the relay reactivates and closes

the normally open contacts to energize the wash-heat circuit. Note: The master & heat switch must be on and the wash tub

full to the probe level for the wash-heat circuit to work.

SYMPTOMS OF LEVEL CONTROL FAILURE:

1. Wash-heat circuit not energized by control. (Wash temperature not maintained by heater.)

2. Wash heater stays on with machine master and heat switch on yet no water in wash tub.

PROCEED WITH CHECKOUT:

1. Remove power to machine by turning circuit breaker to its “OFF” position.

2. Remove the 4 screws holding the control panel on the control box. Remove panel and attach to one side of

control box with 2 screws.

3. Locate wash-heat water level control board and disconnect wires going to terminals maked C & H. Mark and

insulate wires for replacement.

4. Re-apply power to machine. With an insulated jumper wire, touch jumper between terminals C & H, relay in clear

plastic cube should activate as wire touched to terminals, observe relay contacts, they should pull in.

5. If relay operates, the control can be deemed operational and other causes should be explored. EXAMPLE: Wash

element (open ore shorted) thermostat is defective or needs adjustment. See thermostat page for checkout.

6. If relay does not operate, replace control to see voltage is being applied to L1 - L2 marked on control.

7. In any case, always locate sensor (probe) inside wash tub and clean off all deposits (instruct customer, this

should be done on a weekly basis).

8. Other checks can be made using the wash tank heater system checkout shown on another page.

9. Remove power to machine and replace wires that were removed in the steps above.

SENSOR, LUNDY PROBE

Page 30

24

SECTION 4: SERVICE PROCEDURES

WATER LEVEL CONTROL (AS USED ON AN APRB)

WATER LEVEL CONTROL: The water control is used on this machine in conjunction with a sensing probe, to detect the

water level in the rinse tank, and to control the automatic refilling of it.

When the water level decreases as the rinse pump starts to push water through the rinse tubes, the probe then sends a

signal to the control which deactivates the plug-in relay (located on the control circuit board). When the relay deactivates, its

contacts return to a normally closed position. The solenoid valve is connected in series with these contacts and at this time

energizes to allow water to refill the rinse tank to the proper level. Then the relay activates and opens the normally closed

contacts to deactivate the solenoid valve.

SYMPTOMS OF LEVEL CONTROL FAILURE:

1. Water level in rinse tank is not maintained, indicated by diminishing rinse spray halfway through its cycle.

2. Water continues to run at the end of the rinse cycle or water continues to spray out of the rinse tubes.

PROCEED WITH CHECKOUT:

1. Remove power to machine by turning circuit breaker to its “off” position.

2. Remove 4 screws holding control panel on control box. Remove panel and attach to one side of control box

with 2 screws.

3. Locate water level control board and disconnect wires going to terminals marked C & H. Mark and insulated wires

for correct placement.

4. Re-apply power to machine. With an insulated jumper wire, touch jumper between terminals C & H, relay in clear

plastic cube should activate as wire touched to terminals, observe relay contacts, they should pull in.

5. If relay operates, the control can be deemed operational and other causes should be explored. EXAMPLE:

Solenoid valve not functioning properly, loose or broken wires in circuit, sensing probe malfunctioning, or loose

green ground wire.

6. If relay does not operate, replace control.

7. Remove sensing probe from rinse tank and clean any deposits that may have built up causing it to malfunction.

8. If solenoid valve does not open or remains open, see instructions on separate page to check, clean or repair.

9. Remove power to machine and replace wires that were removed in above steps.

Water Level Control Board

06680-200-01-19

Page 31

25

SECTION 4: SERVICE PROCEDURES

REPLACING SEAL & CERAMIC ON WASH & RINSE PUMPS

REPLACING SEAL AND CERAMIC ON WASH AND RINSE PUMPS

The pump is part of the total motor-pump system and utilizes one seal and ceramic to prevent the pump from leaking around

the impeller and shaft. One gasket is used to prevent leakage in between the pump and mounting plate and the machine

pump plate.

REPLACEMENT of SEAL and/or CERAMIC:

1. Remove power source to machine by turning circuit breaker to its off position on side of control box.

2. Drain machine by removing overflow strainer in wash tank.

3. Support motor, and remove the four nuts holding the pump/motor to the machine’s pump plate.

4. Carefully pull motor outward, move from side to side as required to remove from the machine.

5. Set motor and pump on a sturdy stand close to machine or remove wires and conduit to allow motor/pump to be

moved to a better work position.

6. Remove dust cap over end of motor shaft (opposite impeller end). This can be done by wedging with a screwdriver.

7. Remove impeller. Hold shaft by inserting screw driver in slotted end of shaft and unscrew impeller in counter

clockwise direction.

8. The ceramic is embedded in the impeller and normally does not need replacement, but it should be checked for

cracks or a worn out surface. If the ceramic does need replacement, proceed as follows.

a. With a pointed, flat tool, work the ceramic and rubber cap out of groove in impeller.

b. Clean groove of all residue.

c. Apply a small amount of adhesive in groove.

d. Press new ceramic gently into groove with rubber cap leading the way. (NOTE: THE CERAMIC HAS

ONE SIDE THAT IS HAS A GROOVE IN IT. THIS SIDE SHOULD BE FACING DOWN INTO THE RUBBER

CAP. THE SMOOTH SURFACE SHOULD BE FACING UP).

9. The seal is embedded in the pump mounting plate and usually will need replacement when water leaks around

the motor shaft area. If replacement is required proceed as follows.

a. Remove the four bolts holding the pump mounting plate to the motor, must done with an allen wrench.

b. Slide mounting plate up off of shaft and motor.

c. Press seal out of housing carefully.

d. Clean hole where seal was installed.

e. Apply a small amount of non-hardening sealant to the backside of seal. Insert new seal with a seal driver

to prevent ruffling the edges of the seal. Never use a screwdriver or similar tool to alternately force edge of

seal in place.

10. Reassemble pump and motor by reversing the above procedure.

Gasket

Impeller

Ceramic Seal

Crane Seal

Socket Head Cap Screw

Pump Mounting Plate Motor

Page 32

26

SECTION 5:

TROUBLESHOOTING SECTION

Page 33

27

SECTION 5: TROUBLESHOOTING

COMMON PROBLEMS

WARNING: Inspection, testing and repair of electrical equipment should only be performed by a qualified service

technician. Many of the tests require that the unit have power to it and live electrical components be exposed.

USE EXTREME CAUTION WHEN TESTING THE MACHINE.

Problem: Nothing on the machine operates.

1. No voltage to the dishmachine. Check to see if the customer’s fuse has blown or the circuit breaker has tripped.

Replace or reset.

2. Machine circuit breaker tripped or turned off. Turn on or reset.

3. Voltage to machine low or circuit to machine broken. Contact your electrician and/or power company for repair.

Problem: Machine will not fill with electrical power applied, even though other components work. (AB Model)

1. Water hand valve off. Turn hand valve on.

2. Master switch not on or faulty. Turn on or replace.

3. Fill switch faulty or loose wire connection. Replace switch or wire or connection terminal.

4. Solenoid valve does not operate. See instructions page concerning the solenoid valve.

5. Y-Strainer is clogged. Turn water to machine off, remove plug and strainer screen, clean and replace.

Problem: Machine will not fill with electrical power applied even though other components work. (APRB Model)

1. Water hand valve off. Turn hand valve on.

2. Master switch not on or faulty. Turn on or replace.

3. Fill switch faulty or loose wire connection. Replace switch or wire or connection terminal.

4. Rinse motor not operating. Check connection and voltage to motor repair or replace as necessary.

5. Water level control does not maintain the water level in the rinse tank. See instruction page concerning the water

level control for APRB Models.

6. Solenoid valve does not operate. See instructions page concerning the solenoid valve.

7. Y-Strainer is clogged. Turn water to machine off, remove plug and strainer screen, clean and replace.

Problem: Machine fills slowly and/or rinse is weak.

1. Low water pressure. Check water pressure by first, turning the heat and master switch off. Next, empty the wash

tub. Then turn the master switch on, and as you push up the fill switch, time the seconds it takes to fill the machine

to the top of the overflow tube. It should be 35 seconds. Any more than 5 seconds longer indicates the water supply

and pressure and insufficient.

2. Rinse head assemblies limed up or clogged with other deposits. Clean rinse head tubes by removing end plugs

and push the cleaning brush though to clean.

Problem: Rinse water runs continuously with power on.

1. Rinse switch sluggish or faulty. Replace.

2. Solenoid valve dirty or faulty. See special instructions page concerning the solenoid valve.

3. Water level control faulty. (APRB Models only) See special instructions page concerning the water level control

for APRB Models.

4. Rinse tank probe coated. (APRB Models only) Remove and clean probe then replace.

5. Breather tube plugged or bent closed. (APRB Model only) Clean or replace tube.

Problem: Rinse water runs with no electrical power applied to the solenoid (master switch is off).

1. Water pressure excessive. Check the pressure gauge during flow period, it should read 20 A 5 PSI. If it is

excessive, a pressure reducer can reduce the pressure.

2. Solenoid valve diaphragm breather hole clogged. See instructions page concerning the solenoid valve.

Problem: Rinse water temperature too low (less than 180°F).

1. Incoming water temperature under required 140°F. Check incoming water temperature by first turning off heat

switch, then drain the machine wash tub. Next, with the master switch, push the fill switch up and hold 1 and a half

minutes (90 seconds). Release the fill switch and read the rinse thermometer. The temperature should read 140°F

or higher. If it is not this temperature, then the customer’s supply water heater temperature must be adjusted to

provide proper temperature.

2. Heat switch, relay thermostat or elements faulty. See instructions page concerning Rinse Tank heater system.

Page 34

28

SECTION 5: TROUBLESHOOTING

COMMON PROBLEMS

Problem: Rinse water temperature too hot (over 200°F) and water may dribble out of the rinse heads from time to

time.

1. Thermostat needs adjustment or is faulty. See instructions page concerning thermostat adjustment.

2. Heat relay contacts welded or held shut. Remove power and alter cause, holding contacts closed or replace

relay if needed.

Problem: Vacuum breaker leaks.

1. Limed up. To disassemble: Use flat jaw wrench or channel locks. Remove the poppet. Clean poppet, top, and

body. Reassemble parts removed.

2. Faulty. Replace needed parts or whole vacuum breaker.

Problem: Wash arms spray water but do not rotate.

1. Wash cap adjusted too tight. See instructions page concerning removal of rinse and wash head assemblies.

2. Race ways where ball bearings rotate rough or full of food particles. See instructions page concerning removal of

rinse and wash head assemblies while apart. Clean race way with emery cloth or fine sandpaper. Soak ball

bearings in lime dissolving solution, rinse and dry with a lint free towel.

Problem: Wash water only spray up and out of tubes a couple of inches.

1. Overflow strainer clogged or pump intake strainer clogged. Remove overflow strainer. When the wash tub is

empty, reach in opening (where the overflow was) and remove the pump intake strainer and clean thoroughly.

2. Pump impeller worn or broken (only after many years of use). See instructions page concerning seal and ceramic

on wash and rinse pump for removal and inspection of impeller.

3. Obstruction in pump chute or wash manifold. Follow #2 above to remove pump then check chamber and

manifold.

Problem: Wash motor or rinse motor (APRB Model only) does not operate.

1. Faulty. Checkout and remove for motor repair if necessary.

Problem: Wash water temperature too low (below 150°F).

1. Rinse water temperature too low. Raise rinse water temperature to a max of 196°F using instruction page

concerning thermostat adjustment.

2. Thermometer faulty. Check thermometer and replace if necessary.

3. Water level control faulty. See instruction page concerning water level control (wash heat circuit).

4. Wash heater faulty. See instruction page concerning wash tank heater system.

5. Thermostat faulty. See instruction page concerning wash tank heater system.

Problem: Water flow near rinse tank indicating leak.

1. Hood support pipe does not have two (2) O-rings below the support nut. The hood must be removed to check

and replace the o-rings, but be sure the leak is coming from there before proceeding.

2. Hood support block (center back of wash tub) is leaking. Tighten the screws from the inside of the tub.

Sometimes you can remove the screws one at a time and fill the holes with a non-hardening, food zone safe

sealant and replace screws.

3. Hood support nut not down tight against washer, gasket, and table. Tighten down.

Problem: Hood scrapes when opened.

1. Machine not level. Make sure rim of dishwasher tight up against table all around by loosening or tightening bullet

feet on machine and table.

2. Hood not centered. Remove upper spray head assembly and insert a 1/2” by 9” or more nipple. With pressure on

nipple, force hood away from where it rubs.

3. Hood too low. Raise arm by using pressure on hood arm upward.

4. Inside adjustment nut too loose or tight. Turn washer lock tab up and rotate spanner nut to tighten or loosen then

bend tab to lock spanner in place.

Page 35

29

SECTION 5: TROUBLESHOOTING

COMMON PROBLEMS

Problem: Water sprays from lower rinse arms after end of each cycle.

1. Water pressure too high holding solenoid valve open. Check and install pressure reducer if necessary.

2. Water temperature set too high in rinse tank. See instructions page concerning thermostat adjustment.

3. Internal vacuum breaker pipe not in hood support arm. See illustration on page concerning hood support pipe.

Problem: Indicator lights do not glow at any time.

1. Lights faulty or poor connection. Replace or correct connection.

Problem: None of the automatic functions work (wash, rinse).

1. Start switch faulty. Check switch. Replace if necessary, see instructions page concerning replacement of switches

in control panel.

2. Wire connections poor. Correct the connection.

3. Timer rinse or wash microswitch faulty. See instructions page concerning timer and motor.

Problem: Rinse does not work when manual rinse fill switch operated, but does work during automatic cycle.

1. Normally open contact on rinse fill switch faulty. See instruction page concerning replacement of switches in

control panel.

2. Wire connection poor. Correct the connection.

Problem: Wash does not work on automatic cycle, but does on manual wash.

1. Normally closed contacts on wash switch faulty. See instruction page concerning replacement of switches in

control panel.

2. Wire connections poor. Correct the connection.

3. Timer rinse or wash microswitch faulty. See instructions page concerning timer and motor.

Problem: Wash does not work when manual wash switch operated but does work during the automatic cycle.

1. Normally open contact on wash switch faulty. See instruction page concerning replacement of switches in

control panel.

2. Wire connection poor. Correct the connection.

Problem: When master switch is turned on either it washes continuously or rinses continuously.

1. Timer motor faulty and cams are not turning holding it in the mode it is in. See instruction page on the timer &

timer motor.

Problem: Wash tub water level continuously lowers.

1. Large overflow strainer not seated properly. Remove and insert with a slight twisting action.

2. O-ring in drain fitting is missing. Replace. See illustration on page concerning overflow strainer and drain o-ring.

3. Deposit build up on drain fitting or O-ring. Clean.

4. Bottom of overflow strainer (conical end of tube) bent out of shape. Replace strainer.

Page 36

30

SECTION 6:

ASSEMBLY PARTS

Page 37

31

SECTION 6: ASSEMBLY PARTS

10A ASSEMBLY

ITEM QTY DESCRIPTION Mfg. No.

1 1 Hood Assembly N/A

2 1 Control Box Support Bracket 05700-000-24-76

3 1 Shroud 05700-000-24-77

4 4 Bullet Feet 05340-108-01-03

5 1 Complete Control Box Assembly N/A

6 1 Vacuum Breaker Assembly N/A

7 1 Motor and Pump Assembly 05700-002-60-91

8 1 Incoming Plumbing Assembly 05700-002-60-98

9 1 Outlet Connector 05700-002-61-19

10 1 Tub Weldment Assembly 10A 05700-002-60-95

10 1 Tub Weldment Assembly 10A (9” Shorter Leg) 05700-002-62-00

11 2 Bracket, Vacuum Breaker Support 05700-000-32-27

Refer to Vacuum

Breaker Assy. Page

Refer to Hood

Assembly Page

11

Refer to Control

Box Assy. Page

10

2

3

4

9

7

8

REAR VIEW ASSEMBLYFRONT VIEW ASSEMBLY

Page 38

32

SECTION 6: ASSEMBLY PARTS

10AB/10APRB/10U ASSEMBLY

ITEM QTY DESCRIPTION Mfg. No.

1 1 Hood Assembly N/A

2 1 Motor and Pump Assembly 05700-002-60-91

2a 1 Motor and Pump Assembly (APRB only) 05700-002-60-91

3 1 Shroud (without holes for gauges) 05700-000-24-77

3 1 Shroud (with holes for gauges) 05700-002-60-36

4 1 Control Box Support Bracket 05700-000-24-76

5 4 Bullet Feet 05340-108-01-03

6 1 Outlet Connector 05700-002-60-92

7 1 Complete Control Box Assembly N/A

8 1 Vacuum Breaker Assembly N/A

9 1 Rinse Tank Assembly 05700-000-24-84

9 1 Rinse Tank Assembly (APRB Only) 05700-000-24-80

10 1 Inlet Connector 05700-002-60-93

11 1 Incoming Plumbing Assembly 05700-000-15-25

12 1 Tub Weldment Assembly 10AB 05700-000-57-73

12 1 Tub Weldment Assembly 10AB (9” shorter leg)/10U 05700-002-60-94

12 1 Tub Weldment Assembly 10APRB 05700-000-57-74

12 1 Tub Weldment Assembly 10APRB (9” shorter leg) 05700-002-62-01

2a

12

1110

Refer to Vacuum

Breaker Assy. Page

2

9

FRONT VIEW ASSEMBLY

REAR VIEW ASSEMBLY

6

2a

5

Refer to Hood

Assembly Page

3

4

Refer to Control Box

Assy. Page

Page 39

2, 3, 4, 51 6

6 14

18, 19, 20, 10

30 31

4

7, 8, 9, 10, 11

5

16

17

29

24, 25, 9, 10, 11

26, 27, 28

32, 4

1

12

13

6

15

21, 22, 23

21, 22, 23

14

APRB only

The complete Control Box

attaches to the Control

Box Support Bracket with

2 of each item:

Locknut, 1/4"-20 S/S Hex

w/ Nylon Insert

5310-374-01-00

Washer, 1/4" I.D., S/S

5311-174-01-00

33

SECTION 6: ASSEMBLY PARTS

CONTROL BOX ASSEMBLY

Page 40

34

SECTION 6: ASSEMBLY PARTS

CONTROL BOX ASSEMBLY (CONTINUED)

ITEM QTY DESCRIPTION Mfg. No.

1 1 Control Box Panel with Decal 09905-500-07-10

2 1 Timer 05945-303-19-00

3 1 Bracket, Timer Mounting 05700-000-34-28

4 4 Screw, 10-32 x 3/8” Phillips Truss Head 05305-173-12-00

5 4 Locknut, 10-32 S/S Hex with Nylon Insert 05310-273-01-00

6 3 Light, Pilot 05945-504-02-18

7 1 Block, 9 Position Terminal 05940-500-06-19

8 1 Decal, Terminal Block 09905-100-87-62

9 2 Screw, 8-32 x 3/8” Round Head 05305-172-02-00

10 6 Lockwasher, #8 External Tooth 05311-272-01-00

11 2 Nut, Hex 8-32 05310-272-01-00

12 1 Switch, Rinse 05930-301-20-18

13 1 Switch, Wash 05930-301-21-18

14 2 Switch, Master 05930-301-22-18

15 1 Switch, Start 05930-301-23-18

16 1 Decal, Schematic, 10A 09905-002-57-63

16 1 Decal, Schematic, 10AB/10U, 1 Phase 09905-105-33-59

16 1 Decal, Schematic, 10AB/10U, 3 Phase 09905-105-34-47

16 1 Decal, Schematic, 10APRB, 1 Phase 09905-105-33-62

16 1 Decal, Schematic, 10APRB, 3 Phase 09905-105-34-50

17 1 Panel, Control Box Front & Bottom 05700-000-24-30

18 1 Circuit Breaker, 15 Amp 05925-105-10-01

19 1 Plate, Circuit Breaker 05927-113-13-01

20 2 Screw, 8-32 x 1/4” Round Head Slotted 05305-172-01-00