Page 1

MODEL 100 B/PRB

6

JMSC

HIGH TEMPERATURE DOOR

TYPE DISHWASHER

SERVICE MANUAL

INCLUDES:

-Warranty Policy -Basic Functions of Dishwasher

-Installation Requirements -Maintenance and Care

-Operating Instructions -Illustrated Parts List

-Description of Components -Electrical Diagrams

WORLD HEADQUARTERS & MANUFACTURING OPERATIONS

Highway 25E, P.O. Box 1060

Barbourville, KY 4090

888/800-

FAX 606/523-9196

March 12,1999 (Reprinted without change) 7610-100-02-00 Rev A

Page 2

INDEX

SPECIFICIATIONS 2

GENERAL INSTRUCTIONS (Installation/Dimensions) 4

GENERAL INSTRUCTIONS (Operation) 6

GENERAL INSTRUCTIONS (Preventive Maintenance) 7

REMOVAL OF RINSE and/or WASH HEAD ASSEMBLIES 8

TIMER FOR MODEL 100 DISHWASHERS 10

DEFECTIVE TIMER MOTOR 11

FUNCTION of SWITCHES. CIRCUIT BREAKER and

INDICATING LIGHTS 12

REPLACEMENT of SWITCHES in CONTROL PANEL 13

THERMOSTAT ADJUSTMENT 14

SERVICE INSTRUCTIONS 15

RINSE TANK HEATER SYSTEM 16

WASH TANK HEATER SYSTEM 18

REPLACING SEAL and CERAMIC on WASH PUMPS 20

REPLACING SEAL and CERAMIC on RINSE PUMPS 22

INSTRUCTIONS for ADJUSTING TENSION of CANTILEVER 24

APPLYING NYLATRON STRIP TO 100 SERIES DOOR 26

WATER LEVEL CONTROL (For Rinse Tank) 27

WATER LEVEL CONTROL (Initial Fill and Wash-Heat

Circuit) 28

TROUBLE SHOOTING GUIDE 30

PICTORIALS

FRONT VIEW OF MACHINE 37

BACK VIEW OF MACHINE 38

RIGHT SIDE OF MACHINE 39

LEFT SIDE OF MACHINE 40

BOTTOM VIEW OF MACHINE 41

HIGH LEVEL. LOW LEVEL PROBE, VACUUM BREAKER

and INCOMING PLUMBING 42

WASH TANK SUMP W/STRAINERS and ELEMENTS 43

BOOSTER TANK WITH ELEMENT 44

BOOSTER TANK HEATER ELEMENT. WASH TANK

HEATER ELEMENT 45

CONTROL BOX AND CONTROL PANEL COMPONENTS 46

ELECTRICAL DRAWINGS 47

PARTS LIST 52

PARTS DISTRIBUTORS 55

Page 3

SPECIFICATIONS

SPECIFICATIONS 100 SERIES ITEM #_________

MODEL 100 100B 100PRB

Operating Capacity

Racks per hour

(NSF Rated)

Dishes per hour 1375 1375 1375

Glasses per hour 1375 1375 1375

Operating Cycle

Wash Time-Sec 48 48 48

Rinse Time-Sec 10 10 10

Total Cycle-Sec 60 60 60

Wash Tank Capacity

Gallons 12 12 12

Rinse Tank Capacity

Gallons N/A 3 3

Wash Pump Capacity

Gal Per Min 188 188 188

Thermometers

Wash- F 140-160 140-160 140-160

Rinse -F 180-195 180-195 180-195

Water Requirements

(NSF Rated)

Inlet Temperature — °F 180 140 140

Gal per hour 110 110 97

Flow Pressure PSI 20 20 20

Flow GPM 12 12 10.5

Inlet-I.P.S. 3/4" 3/4" 3/4"

Drain - I.P.S. 1 - 1/2" 1 - 1/2" 1 -1/2"

Wash Pump Motor

Horsepower 1 1 1

Rinse Pump Motor

Horsepower N/A N/A 1/2

Electric Heat Wash

KW 1.5 1.5 1.5

Electric Heat Rinse

KW N/A 13 13

55 55 55

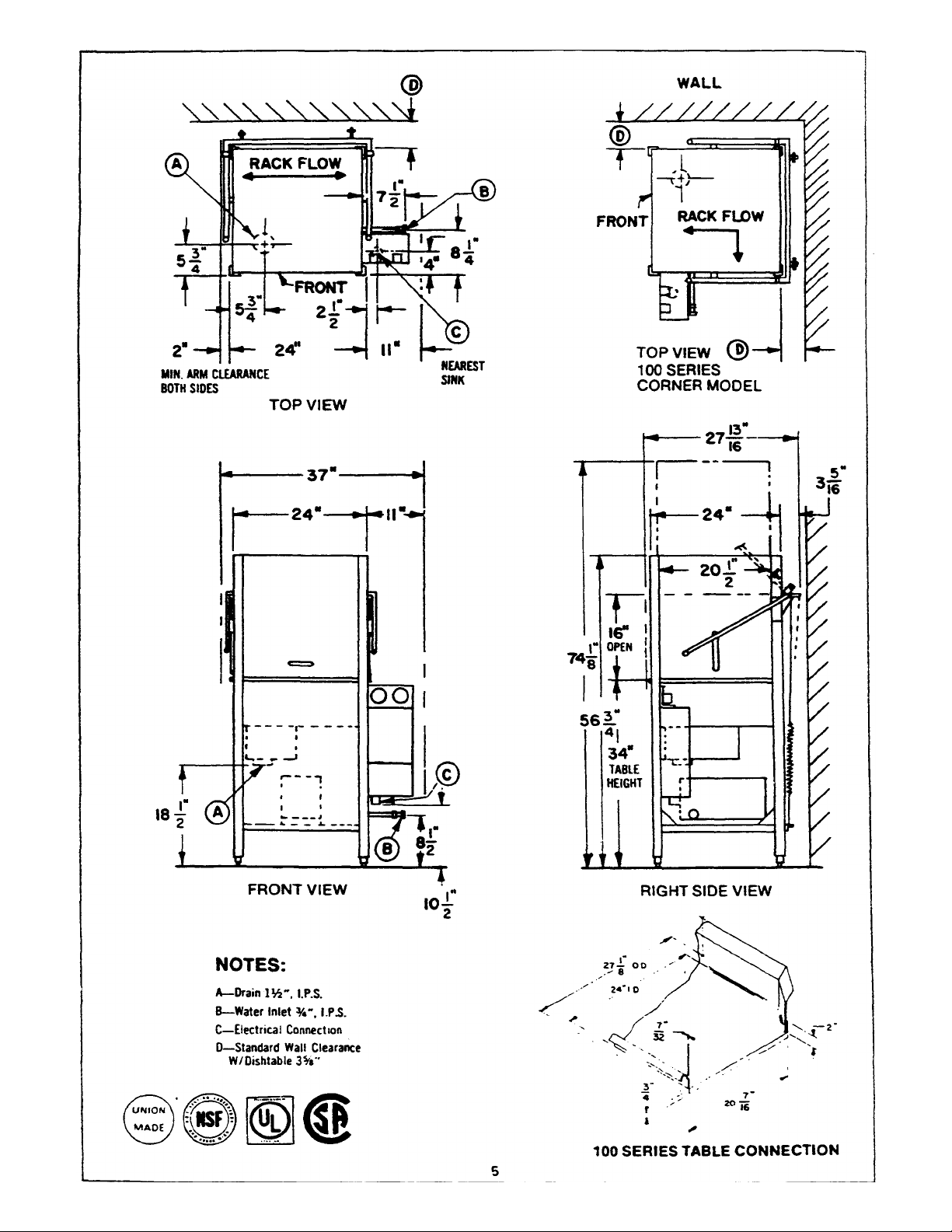

Page 4

Specifications 100 Series, cont'd

Dimensions

Length 24" 24" 24"

Width 24" 24" 24"

Height 57" 57" 57"

Standard table height 34" 34" 34"

Maximum Clearance

for Dishes 15" 15" 15"

Standard Eq. Racks

Dish 19-3/4 x 19-3/4 2 2 2

Combination 2 2 2

Shipping Weight

Approximate

basic model 400 400 400

Electrical Rating

Model

Volts Cycle Phase Maximum

Total Load Amps

100 208 or 220 60 1 16

100B 208 or 220 60 1 80

100PRB 208 or 220 60 1 80

100B 208 or 220 60 3 58

100PRB 208 or 220 60 3 58

100B 208 or 220 50 1 80

100PRB 208 or 220 50 1 80

Specifications subject to change without notice.

3

Page 5

GENERAL INSTRUCTIONS

(INSTALLATION / DIMENSIONS) FOR 100B, PRB SERIES

NOTE: Read the following instructions carefully. Proper installation of your Jackson Dishwasher will assure proper

machine operation.

1. Open side doors, the front door (hook open) and remove dish, cup, and glass racks, and set to one side for

later use. Remove the tape holding the overflow strainer, the pump intake strainer, the wash head assembly

and the rinse head that are inside the machine.

2. Cut straps holding machine to base of crate, ease machine on to floor and slide into place of installation.

3. Connect drain to bottom of machine (1 1/2" IPS female fitting on bottom of wash sump) with proper slope to

conform with local and/or national codes. Drain is a gravity feed system from machine.

4. The incoming water line to the unit must be 3/4" with the capacity to supply 12 gallons per minute with a flow

rate of 20 PSI. The temperature at the unit must be 140° F. • This connection is just before the Y-strainer.

Connect to conform with local and/or national codes (STANDARDS).

5. Electrical connections should be made through hole in bottom of control box to terminal board inside (to the

right lower side of control box). This terminal board is accessible by removing the lower cover plate on control

box. The terminals are marked L1, L2 (requiring 208-230V, single phase), or L1, L2, L3 (requiring 208-230V,

three phase). There is a grounding lug inside of the control box on the bottom left. Be sure all connections

made are tightened properly. Refer to data plate for Voltage and Amperage totals and whether machine is

designed for 50 or 60 cycle operation.

6. Install the proper circuit breaker, wire, and conduit size to conform with local and/or national codes. Refer to

data plate for electrical loads.

7. DO NOT APPLY POWER UNTIL STEP 10.

8. Insert pump intake strainer and overflow strainer, then close door.

9. Turn on hand valve controlling water supply to machine; check for any leaks in plumbing

and connections.

10. To energize electrically, proceed as follows:

a. Turn on customer's circuit breaker controlling machine.

b. Check voltage at incoming terminal L1, L2, and L3 (if applicable). It should match

data plate voltage. Voltage at L1 and L2 should be checked to ground individually to

ensure that a high (or wild) leg is not connected to L1 or L2. (Voltage exceeding 150V

to ground would indicate high leg).

c. If voltages are in required range, turn on 15 amp circuit breaker on side of control box.

The 15 amp circuit breaker protects and controls the motors and control circuit only;

it is not meant to protect or control the rinse heaters.

d. Insert a rack into the machine and close all doors.

e. Turn on the master switch; this supplies voltage to the operating controls. Then lift up on the rinse/fill

switch. The unit will automatically fill the wash tub with water to a specific level.

f. Open the front door and check the water level. It should be 1/4" below overflow level.

If not, close doors, check the incoming water line making sure that the solenoid valve

fully opens and closes as the switch is turned on and off.

g. If the water is at the proper level, with the front door closed, turn. on the heat switch.

Observe the temperature gauges; the rinse temperature should rise to the specified level

of 180° within five minutes if the incoming water temperature is 140° to the booster

tank.

h. The wash heater will take longer to reach 150°F, as the element is designed for maintaining

temperature, not heating.

i. Turn the manual wash switch on with the door closed. You should hear the water being pumped as it

strikes the top of the machine. Turn off the manual wash switch.

j. The unit is now ready to proceed with the washing of dishes in accordance with the

operating instructions in this manual, and the instruction sticker on the front door of

the dishwasher.

4

Page 6

Page 7

GENERAL INSTRUCTIONS

(OPERATION) 100B, PRB

READ INSTRUCTIONS CAREFULLY: Proper operation of your Jackson Dishwasher will assure clean and

sanitized glasses and dishes at optimum efficiency.

DISH PREPARATION

1. Scrape the dishes thoroughly.

2. Pre-rinse the dishes by soaking or by spraying off with a pre-rinse hose.

3. Place the dishes and cups in the dish rack with the cups upside down.

4. Place the glasses and silverware in the combination glass-silverware rack with the glasses upside down.

Scatter the silverware loosely on the bottom of the rack. Do not put glasses on top of the silverware.

NOTE: When silverware is in an upright position, it washes and rinses better than lying flat. These compartment

silverware racks are available through your dealer or service agency.

MACHINE OPERATION

1. Open the front door and insert the pump intake strainer and overflow strainer.

2. Close all of the doors.

3. Turn the master switch on. Lift the rinse/fill switch up and release. The machine wilt now automatically fill

the wash tank and energize the wash and rinse heater control circuit.

4. Turn on the heat switch, letting the temperatures rise to the required temperatures on the wash (150°) and

rinse (180-195°) gauges.

5. Raise up the side doors. Slide in a rack of dirty dishes.

6. Add detergent* (see Detergent Recommendation). If an automatic detergent dispenser is used, follow the

manufacturer's instructions.

7. Lower all of the doors.

8. Start the automatic wash and rinse cycle of the dishwasher by flipping the start switch in a full up or down

position. For the next cycle, the switch must go in the opposite direction all of the way. The center position is

off. The light in the top center of the panel will go on when the cycle starts.

9. When the light goes out, open the side doors, slide out the rack of clean dishes, slide in

another rack of dirty dishes, and then repeat steps 6,7. and 8.

10. At the end of a meal period or the end of the day, shut off the heater switch and the master switch. Drain the

machine by removing the overflow strainer. Clean both strainers, the overflow and the inside strainer, of all

foreign debris and build-up and flush out the unit.

*DETERGENT RECOMMENDATION AND RINSE ADDITIVES: We suggest you contact your local detergent

specialists for the correct detergent and rinse additives for the area. To help until one can be reached, we suggest

that you use a non-foaming dishwasher detergent, approximately one-quarter cup in wash tank, when machine is

filled the first time, then one level table-spoon each cycle (or load) thereafter. This may have to be increased or

decreased to obtain satisfactory results.

When manually dispensing powdered detergent in wash tub always distribute over a sufficient area to prevent build

up. Some detergent, when dispensed in a small or concentrated area. may cause deterioration of the stainless tub

or sump.

6

Page 8

GENERAL INSTRUCTIONS

e must be turned off for this operation) (Semi Annually)

(PREVENTIVE MAINTENANCE)

(The following is to be performed as needed.)

READ CAREFULLY: Proper maintenance of your Jackson Dishwasher will insure optimum service with a minimum of down

time.

1. To remove all lime and corrosion deposits. (As needed or at least weekly)

a. Fill the machine with wash water as would ordinarily be done for washing.

b. Open door and place one cup or less of de-liming compound into the water. (Be

sure to follow their directions if they vary from these being given) which is available

from your detergent supplier.

c. Turn on the manual wash switch and allow to wash for five minutes.

d. Open door and examine the interior. All lime should be removed and parts should

be shiny. If not, allow to wash for longer period.

e. After the interior is clean, empty the wash water by removing overflow strainer.

f. Replace overflow strainer. Refill machine and allow to run for two minutes, then,

again drain the wash reservoir.

g. Refill as it is ready for regular operation.

2. Clean strainers. (Three times per day)

a. Clean around overflow and pump intake strainer holes.

b. Clean around pump intake (toothbrush makes excellent tool for cleaning).

3. Clean Y-strainer on incoming water line. (Water to machin

a. Remove plug and clean strainer.

4. Clean rinse tubes. (Daily)

a. Remove end plugs on lower and upper rinse.

b. Clean all rinse tubes with special brush supplied.

c. If spray holes in the rinse tubes are clogged, they may be cleaned with a pointed tool.

5. Clean wash head assembly. (Daily, or as needed)

a. If spray jets are plugged, use pointed tool to dislodge and flush with water.

b. If lodged items still remain in wash tubes, remove wash assembly by first

removing rinse assembly.

c. Clean assembly at sink by flushing water through spray jets.

d. Reinstall wash and rinse assemblies. (See page with instructions)

6. Clean any deposits which may have built up on exterior moving parts. (Weekly)

7

Page 9

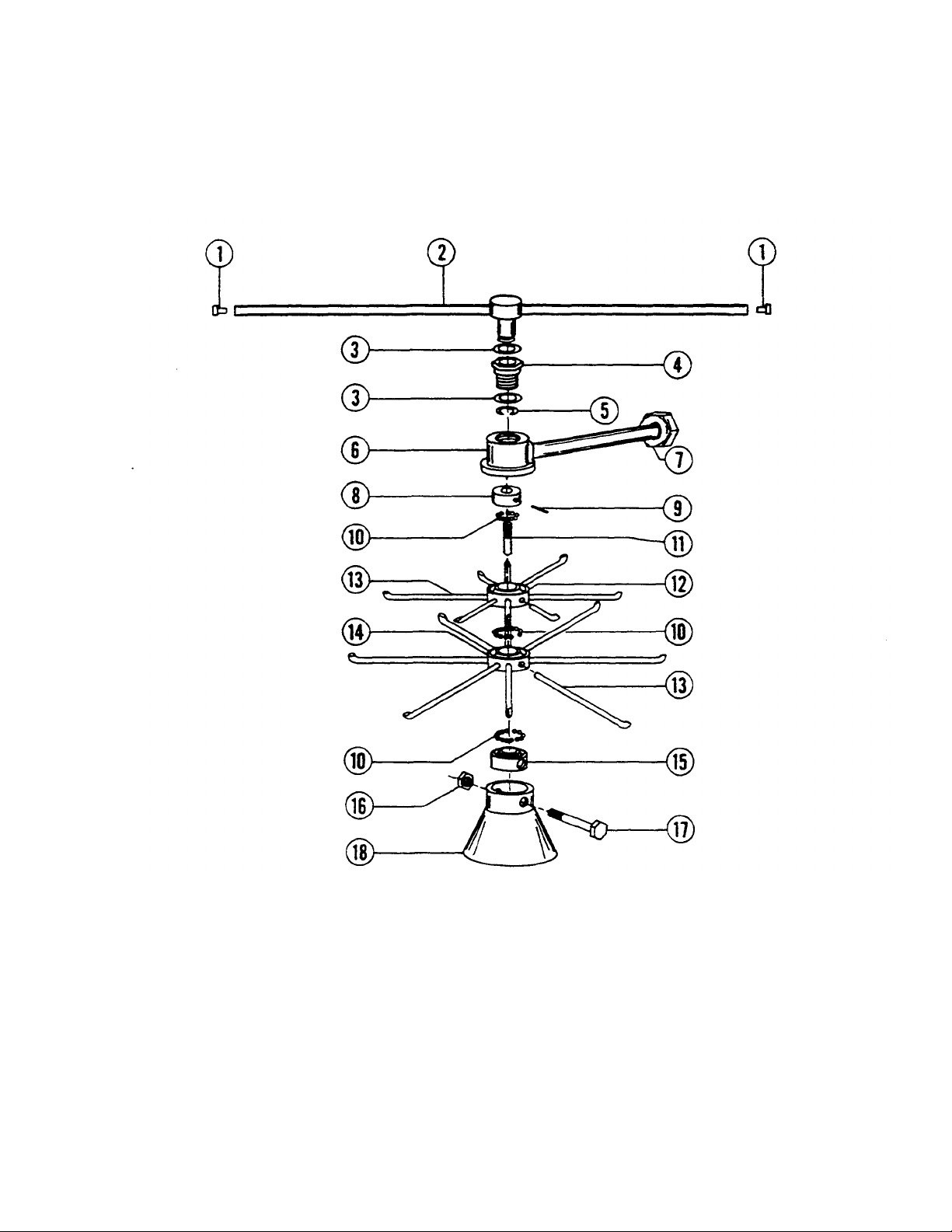

REMOVAL of RINSE and/or

WASH HEAD ASSEMBLIES

GENERAL INSTRUCTIONS

1. Turn master switch to off position.

2. Open door and drain machine by lifting overflow strainer.

3. When empty, replace overflow strainer.

4. With wrench, remove pipe fitting holding lower rinse feed pipe to machine and remove feed pipe and rinse head

assembly.

5. Locate Allen head set screw in wash head cap, insert Allen wrench and loosen screw by turning counterclockwise.

6. Turn wash head cap counterclockwise until cap is removed and put cap in safe place.

7. Remove 1 /4" stainless ball bearings carefully and put in a receptacle in a safe place. if any should drop in machine,

you will be able to locate and retrieve if you left the overflow strainer in as suggested in step #3 above.

8. Lift and remove small manifold with short tubes. Put in safe place.

9. Remove 1/4" ball bearing in similar method to step #7.

10. Lift and remove large manifold with long length tubes similar to step #8.

11. The lower fixed race may be left in place.

12. Clean ball bearings by soaking in de-liming solution.

13. Ball bearing race ways may be cleaned by either brushing with de-liming solution (toothbrush makes excellent tool) or

gently clean by rubbing with fine sandpaper or emery cloth.

14. Rinse bail bearings and manifolds thoroughly.

15. To reassemble, first, fill lower race to capacity with 1/4" ball bearings then remove one. This will give proper

movement needed during rotation of assembly.

16. Replace lower manifold and fill race fully with 1/4" ball bearings. Repeat, removing one only.

17. Replace upper manifolds and repeat necessary parts of step #15.

18. Replace wash cap by screwing on center shaft clockwise, finger tight.

19. Back off wash cap about 1/4 turn and tighten Allen set screw.

20. Rotate manifolds in opposite directions; see if they rotate freely. A rule of thumb is to select the longest tube in the

bottom manifold and make sure it moves up and down at least 1/8" and no more than 1/4".

8

Page 10

21. Replace rinse assembly and feed pipe.

22. Close all doors and refill dishwasher.

23. Run through several cycles and recheck wash arms for easy movement. Adjust if necessary.

24. If removal of upper wash or rinse assembly is necessary, then extra care must be taken to support

assembly. It will drop as one unit, but will be subject to falling apart as wash cap is removed.

ITEM P/N DESCRIPTION ITEM P/N DESCRIPTION ITEM P/N DESCRIPTION

1 0126800 End Plug 7 0137000 Rinse feed pipe coupling or nut 13 0194500 Spray tube (16)

2 0136000 Rinse arm body 8 0186500 Wash cap 14 0201000 Large manifold

3 0133000 Nylatron washer (2) 9 0187000 Wash cap set screw 15 0193500 Fixed race

4 0132500 Hex nut 10 0194000 Ball bearings (3) 16 0044700 Holding nut

5 0133500 Snap ring 11 0187500 Center shaft 17 0188500 Holding bolt

6 0137000 Lower rinse feed pipe 12 0200500 Small manifold 18

Wash head base

9

Page 11

TIMER FOR MODEL 100 DISHWASHERS

General Description

The timer is a self-contained (frame-mounted) timer of the repeating cycle type. It is mounted on

the control panel of Jackson Automatic Dishwashing machines, to control the automatic functions of

these machines. It consists of a clock motor which operates on 60 cycle AC, 220 VAC. In addition to the

clock motor, the timer also contains a driven cam arrangement which operates three micro switches.

Principle of Operation

The timer controls various operations of the automatic washers as per wiring diagram for each

machine, however, the timing cycle and the micro switches are the same for each model. The time for

ONE COMPLETE REVOLUTION of the cam shaft is approximately 120 seconds, allowing two wash

and two rinse operations for each complete revolution of the cam shaft. The micro switch nearest the

timer motor is the hold circuit and uses both the NO and NC contacts. The middle micro switch controls

the wash and uses the NO contact. The micro switch farthest away from the timer motor controls the

rinse and uses just the NC contact.

Service Instructions

CAUTION: ALWAYS REMOVE THE POWER TO THE MACHINE BEFORE WORKING ON THE

CONTROL PANEL OR WHILE SERVICING THE COMPONENTS ON THE SWITCH

PANEL. ALL ELECTRICAL CHECKS SHOULD BE MADE BY QUALI-FIED PERSONNEL.

Timer operation can be observed after removing the control panel from the control box by

loosening the four screws holding it. Hang the control panel using the two right hand screws with the

back side of the panel outward.

If it is determined that the timer is defective, it is recommended that a new timer be installed. However, limited field maintenance can be accomplished as follows:

A frozen contact on a micro switch will be indicated by one function being executed all the time or

the absence of a click when the switch arm is actuated. The micro switch is replaced by:

1. Remove all wires from the timer, properly tag them to assure proper replacement.

2. Remove the two screws which hold the timer to the control panel.

3. One screw holds the micro switches, cams and actuating arms in the frame. This screw

is seen on the side opposite the motor. Remove this screw. NOTE: Be sure to note which

cam goes with which micro switch. Cam nearest timer motor has % raised, cam center,

larger depressed areas, cam farthest from timer motor, smallest depressed areas.

4. The unit can now be taken apart and the defective micro switch replaced.

5. Reassemble. NOTE: The flanges on the cams are such that they only mesh in one

direction. The shorter flange on the cams always points toward the drive motor.

The timers cam drive system is equipped with a clutch to enable one to view the operations of the

cams and micro switches. Remove power to machine BEFORE touching timer. Rotate cams by turning

with fingers; cams will turn in one direction only. Do not force them. As cams actuate switches, listen

for the click of the switch or test the switches with an ohmmeter.

10

Page 12

DEFECTIVE TIMER MOTOR

A defective motor is indicated by the fact that the cams do not rotate or the machine does not perform the

automatic operations or performs a specific part of the cycle continuously, but works okay on manual. Remember, the

timer motor is controlled by the start switch and the hold micro switch, check this complete circuit before changing

motor. The motor is replaced by:

1. Remove motor leads from connection points.

2. Remove the two screws which hold the motor.

3. Replace with new motor.

4. Re-connect motor leads to proper points.

NOTE: It may be necessary to remove complete timer to replace motor; if so, follow steps 1 and 2 previous page.

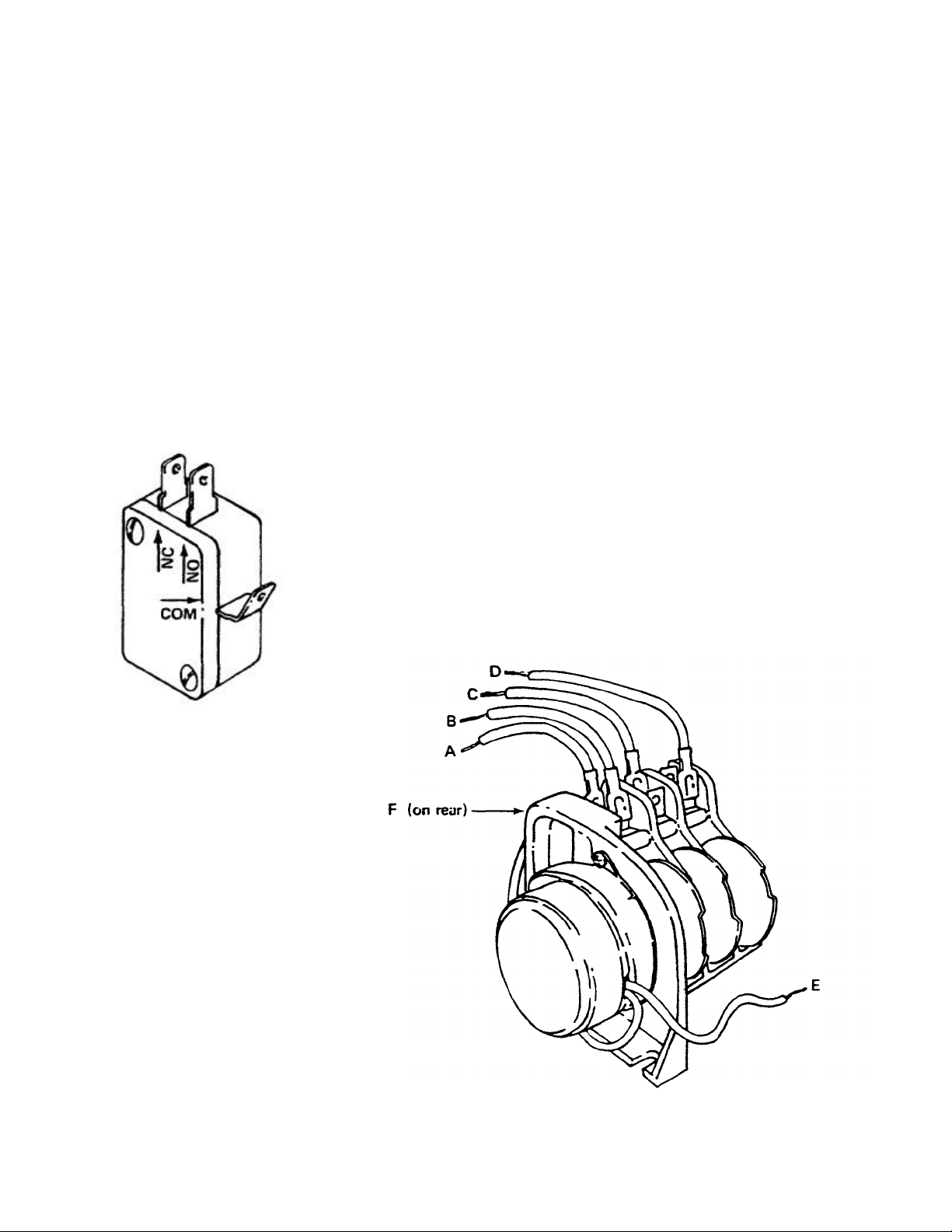

TYPICAL TIMER SWITCH P/N 0177500

A. To upper right terminal start switch

B. To lower right terminal start switch C.

To right-central terminal manual wash switch. D. To

upper terminal of rinse switch E. To

#5 terminal

F. Snorting bar or jumpers connected to all three timer

switches, this terminal

TIMER P/N 0171300, 50 Cycle

P/N 0171500, 60 Cycle

Page 13

FUNCTION of SWITCHES, CIRCUIT

BREAKER and INDICATING LIGHTS

Circuit breaker

P/N 0012000

Master switch

P/N 0157500

Start switch

P/N 0162500

Cycle light

P/N 0083500

Manual wash switch

P/N 0155500

Rated 15 amps, controls power to control circuit only, I.E. timer, relays. solenoid valve,

water-level control and motors. Circuit breaker does not cutoff power in control box at

incoming terminal board and rinse heater or its relay contacts. Power is still applied to them

when the circuit breaker is in "off" position.

This switch interrupts all power going to the control circuit, this means that all switches on

control panel are inoperable until master switch is turned "on."

This switch controls the timer motor through two circuits (see electrical diagram) it is a threeposition switch, up position = start, middle position = off, down position = start. To start, flip

switch toggle in either up or down position; indicating light in center of panel will light

verifying automatic cycle has started. After cycle ends and you are ready to start a new

cycle, flip toggle to opposite position.

This light comes on only when automatic cycle is in progress and extinguishes when cycle is

complete.

This switch is used to by-pass the timer and operate the wash pump manually. The wash

pump will run as long as this switch is "on." The prime purpose of this switch is to extend the

wash period for extremely soiled dishes before putting them through the normal automatic

cycle. It may also be used as an emergency back-up should the timer ever fail to operate.

The required wash time is indicated on the control panel (front).

Rinse/fill switch

P/N 0154000

Heat switch

P/N 0157500

Heat light

P/N 0083500

This switch is spring-loaded and must be held in its up position to operate. When switch is

operated, water is allowed to fill machine through the rinse heads. It may be used as an

emergency back-up in case of timer failure for rinsing dishes. The required rinse time is

indicated on the front control panel.

This switch completes the heat circuit which is composed of automatic control devices that

turn heaters on and off to maintain required temperatures.

This indicating light remains lit all the time the heat switch is on.

12

Page 14

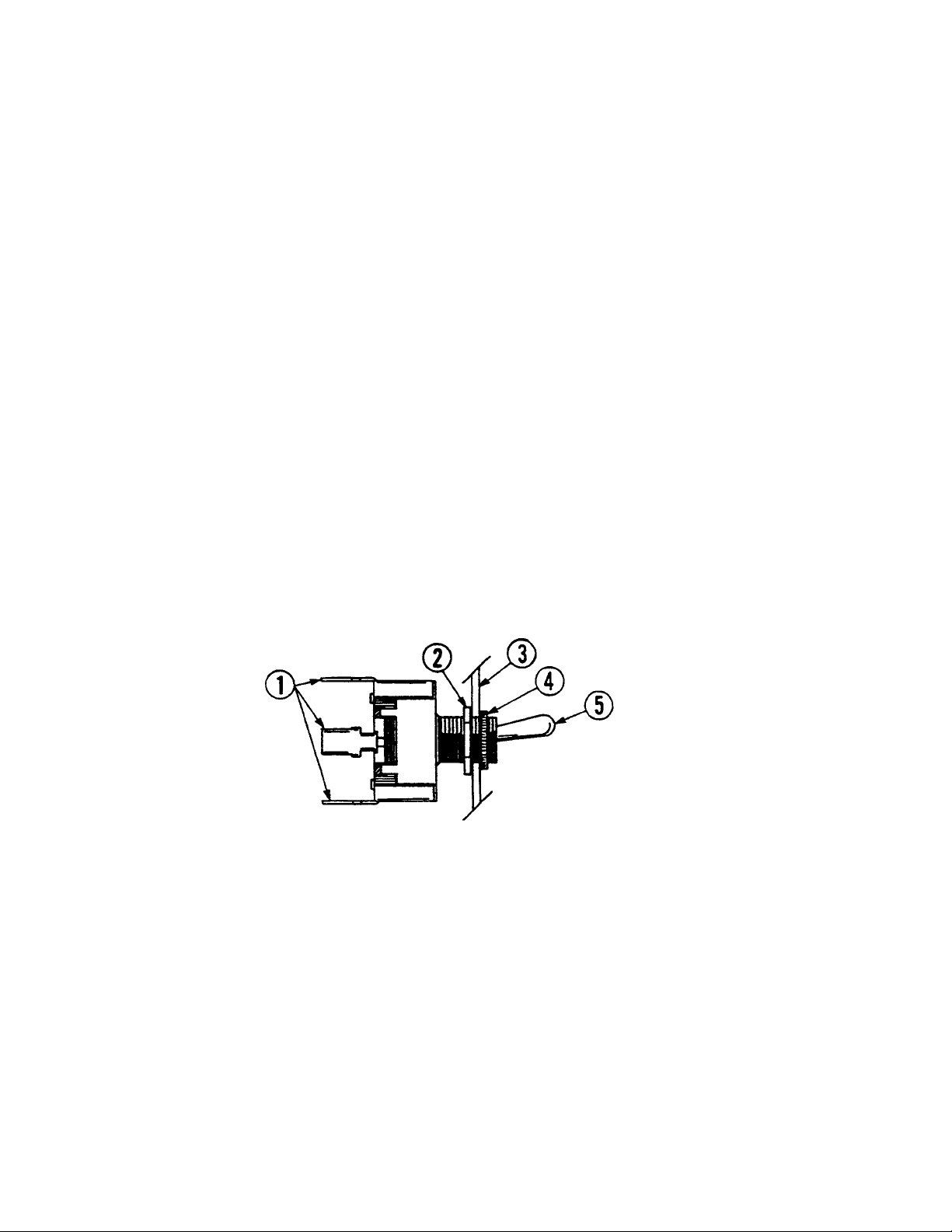

REPLACEMENT of SWITCHES in CONTROL

PANEL

There are five switches installed in the control box cover panel. These are the start, master, manual wash,

rinse/fill and heater switches.

Before working on machine, it is important that power be turned off at customer's circuit breaker to prevent the

possibility of electrical shock, trip breaker to "off" position. Then turn machine breaker "on" located right side of

control box.

Remove control panel from control box by removing the four screws holding it in place. Hang the control panel

using the two right hand upper and lower screw recepticles on the control box with backside of panel facing

outward. The five switches are mounted in individual round holes with a keyway. By using a pair of pliers or open

end wrench, it is possible to loosen the inside nut enough to allow the outside nut holding the switch to be removed

by fingers. Push switch out of hole.

If a switch is found to be defective, replacement can be achieved by placing the new switch next to the old one. To

make sure the new switch is not upside down. line up with the keyways. Transfer wires one at a time to the new

switch. If this is not practical, pull wires off, one at a time and tag them for proper replacement.

Put switches back into panel, make sure switch protrudes through panel properly, tighten both nuts, and replace

control panel on control box. Power can now be applied to dishwasher and run through cycles checking all

operations.

13

1. CONNECTION TERMINALS

2. INSIDE NUT

3. PANEL PLATE

4. OUTSIDE NUT

5. BAT OR TOGGLE HANDLE

Page 15

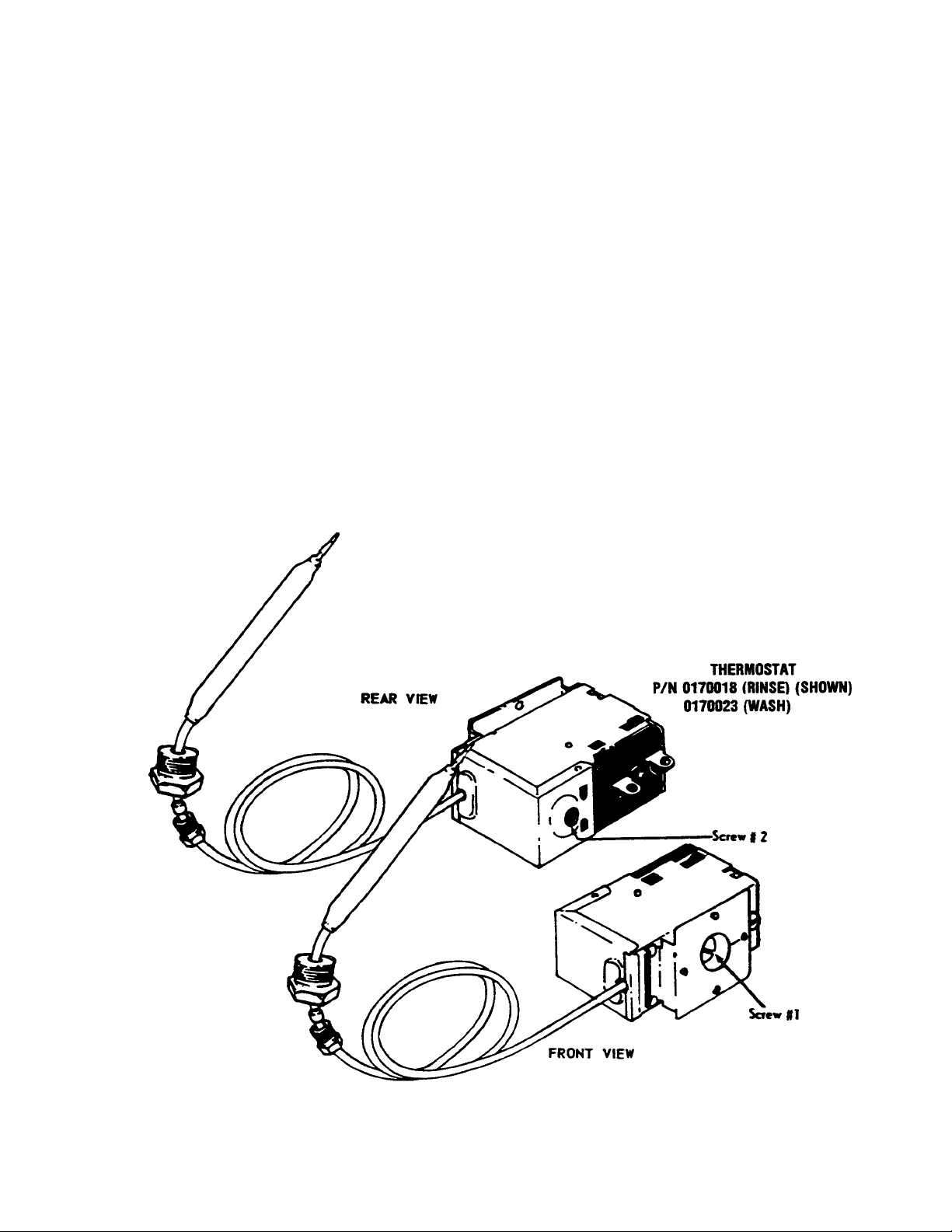

THERMOSTAT ADJUSTMENT

The thermostat can be adjusted by turning screw # 1 (see picture) on the thermostat control box cover.

(Remember the present setting, in case the problems are elsewhere in the control circuit.) A CW rotation is

used to obtain a lower temperature setting and a CCW rotation is used to obtain a higher temperature

setting. A 1/8 turn of screw # 1 changes the temperature approximately 15° F. If screw # 1 is turned all the

way to its stop in either direction; adjust screw #2 as follows. DO NOT TOUCH THE SCREW SEALED WITH

RED PAINT. When adjusting screw #2 power should be disconnected during adjustment.

Set screw # 1 so that it can be turned equal distances in either direction, then:

- - -if screw # 1 stopped while turning in CW direction, turn screw #2 in CW direction

slowly and only 1/8 of a turn or less per complete cycle of the unit.

- - -if screw # 1 stopped while turning in CCW direction, turn screw #2 in CCW direction

slowly and only 1/8 of a turn or less per complete cycle of the unit.

Three-fourth's of a turn will bring the thermostat to approximately the same setting obtained where

screw # 1 stopped. Check the present temperature setting before attempting any further adjustments. Use

screw # 1 for any further adjustments.

NOTE:

Making large moves in adjusting may cause misalignment

thus increasing the chances that further adjustment cannot be

made and the thermostat will have to be replaced.

NOTE: Some machines were equipped with factory preset

thermostats (wash: P/N 1700-W & rinse: P/N 1700-R) which do not

have adjustment screw #1.

Page 16

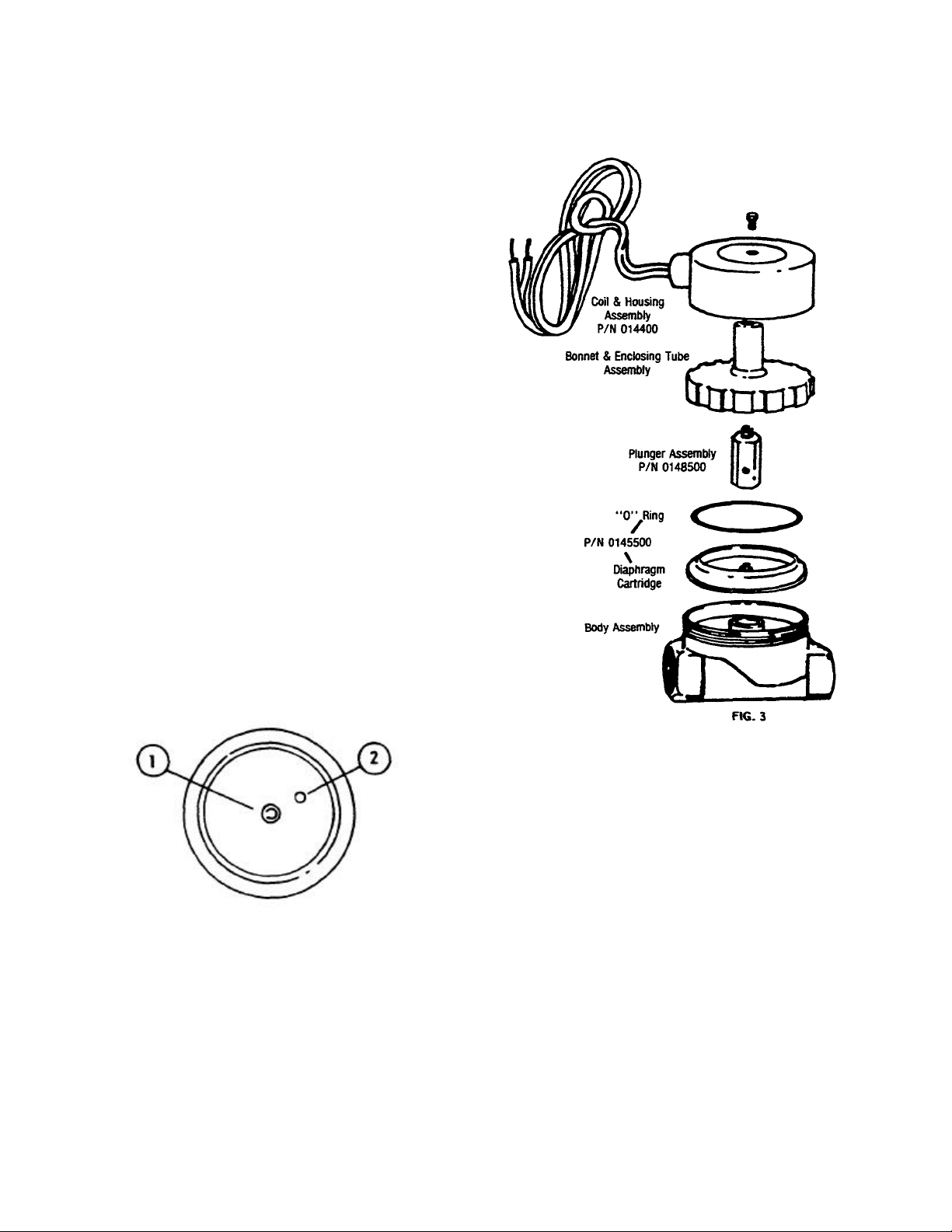

SERVICE INSTRUCTIONS

(INCOMING WATER SOLENOID VALVE)

SOLENOID VALVE

TO TAKE THE VALVE APART

DISASSEMBLY - These valves may be taken apart by unscrewing

the bonnet and the enclosing tube assembly from the valve body

assembly. See Fig. 3. After unscrewing, carefully lift off the bonnet

and enclosing tube assembly. Don't drop the plunger. The "O" ring

seal and diaphragm cartridge can now be lifted out.

Be careful not to damage the machined faces while the valve is

apart.

TO REASSEMBLE - Place the diaphragm cartridge in the body with

the pilot port extension UP. Hold the plunger with the synthetic seat

against the pilot port. Make sure the "O" ring is in place, then lower

the bonnet and enclosing tube assembly over the plunger. Screw

bonnet assembly snugly down on the body assembly.

DIAPHRAGM CARTRIDGE

P/N 0145500

POSSIBLE PROBLEMS

Pilot Port extension #1 clogged

Hole #2 clogged

REMEDY

Pass heated straight pin through hole #2 or

clean hole # 1

15

Page 17

RINSE TANK HEATER SYSTEM

FUNCTION

The Rinse Tank Heater System is electrically connected in the circuit so that it is dependent upon the

dishwasher being properly filled with and maintaining a safe water level. The automatic fill system, therefore, should

operate properly before the heat system can be engaged. The circuit is controlled by a heat switch (mounted on the

front control panel), a thermostat (mounted behind the lower front panel), a water level control (mounted in the

control box), and a heater relay (mounted in the control box), with the coil being activated by the thermostat.

INDICATORS OF POSSIBLE MALFUNCTION

Once the machine, has been properly filled and the heat system engaged, the heat circuit should operate by

merely turning on the heat switch. Should the rinse tank heat, be it either too high, too low, or no indication of

temperature at all, the following checkouts should be made.

CHECKOUT OF HEATER SYSTEM FOR RINSE TANK (Refer to drawing, figure 1)

NOTE: THE FOLLOWING CHECKOUTS SHOULD BE DONE BY A QUALIFIED SERVICE PERSON OR

ELECTRICIAN.

1. If temperature is too high: adjust thermostat, using thermostat instructions in this manual.

2. If temperature is too low, adjust thermostat as above, then:

a. Turn off power to machine by tripping customer circuit breaker to "off" position.

Turn off machine circuit breaker located on right side of control box.

b. Remove lower cover plate on control box (held by single screw).

c. Make sure rinse temperature is below 180° (preferably about 140°).

d. Reapply power. Turn on master switch and observe heat relay (4 pole mounted lower left inside control

box) while heat switch is turned "on" and "off". If relay contacts move in and out, see instructions under

"B"; if not, proceed with "A".

A. If heat relay does not close:

1. There is an insulated movable bar on the relay across the top of the four contacts. With insulated

probe, depress this bar and observe the rinse thermometer; the temperature should rise noticeably

in a minute or two. If it moves very slowly, it would indicate that one or more elements are faulty. If it

moves constantly higher at a good rate, elements are okay.

NOTE: A check with an amp probe at position E, if available, can be made. Each row of elements should draw 30

amps with a total approximate amperage draw of 60 amps for both rows of elements. (Single phase). Replace any

defective elements.

A. 2. With master and heat switches on:

a. Check position 1, figure 1. Voltage should be 220V; if not, checkout heat

switch and replace if necessary.

b. Check position 2; there should be no voltage.

If there is, readjust thermostat per thermostat adjustment instructions.

c. Check position 3; voltage should be approximately 120V to ground. d. If voltage being applied

on positions 1, 2. and 3 check out okay. then the relay should be replaced. Coil is probably defective.

16

Page 18

B. If heat relay closes:

1. Check power supply at incoming terminal board L1 and L2. It should be 220V, approximately.

2. Check power at positions 4 and 5, figure 1. Voltage should read approximately 220V; if not,

check wires for breaks or bad connections.

3. Check power at positions 6 and 7. Voltage should be approximately 220V. If not, check wires for

breaks or bad connections.

4. Temperature should rise as explained in A1 and amperages may be checked according to those

instructions. Replace any defective elements.

FIGURE NO. 1 RINSE HEATER SYSTEM

A. HEATER SWITCH

B. WATER LEVEL CONTROL

C. THERMOSTAT

D. HEATER RELAY

E. RINSE TANK HEATERS

F. AMPROBE TEST POSITION

X. TERMINAL BOARD (9 TERMINALS)

17

Page 19

WASH TANK HEATER SYSTEM

FUNCTION

The Wash Tank Heater System is electrically connected in the circuit so that it is dependent upon the

dishwasher being properly filled with and maintaining a safe water level. The automatic fill system, therefore, should

operate properly before the heat system can be engaged. The circuit is controlled by a heat switch (mounted on the

front control panel), a water level control (mounted in the control box), a thermostat (mounted behind the lower front

panel), and a heater relay (mounted behind the lower front panel), and a heater relay (mounted in the control box),

with the coil being activated by the thermostat.

INDICATORS OF POSSIBLE MALFUNCTION

Once the machine has been properly filled and the heat system engaged, the heat circuit should operate by

merely turning on the heat switch. Should the wash tank be either too high, too low, or no indication of temperature

at all, the following checkouts should be made.

CHECKOUT OF HEATER SYSTEM FOR WASH TANK (Refer to drawing, fig. 2)

NOTE: THE FOLLOWING CHECKOUTS SHOULD BE DONE BY A QUALIFIED SERVICE PERSON OR

ELECTRICIAN.

1. If temperature is too high: adjust thermostat, using thermostat instructions in this manual.

2. If temperature is too low: adjust thermostat, using thermostat instructions in this manual.

3. If step one or two does not correct the problem, proceed as follows:

a. Turn off power to machine by tripping customer circuit breaker to "off" position.

Turn machine circuit breaker on right side of control box to "off".

b. Remove control panel from control box. Remount panel to right side, using two

screws, with the backside of panel facing you. c. Reapply

power to unit.

d. Wash tank must be emptied, then refilled for each checkout.

e. Wash temperature must be 130 degrees or less. Observe wash heater open switching

relay (two pole; only one pole used), located top relay on left side. With master

switch on, turn heat switch on and off; if relay contacts move in and out. see instructions

under BB. if not. proceed.

AA - - If heat relay doesn't close:

1. There's an insulated bar across the top of two contacts. With insulate probe, depress this bar and

observe wash thermometer; temperature should rise slowly. Watch for approximately five minutes; if

temperature doesn't rise, replace element. If amprobe E is used, the element should draw

approximately 7 amps.

2. With master and heat switches on:

a. Check position 1, figure 2. Voltage should be 220V. If not, check out and replace heat switch.

b. Check position 2; there should be no voltage. If there is, readjust thermostat

per thermostat adjustment instructions.

b. Check position 3; voltage should be approximately 120V to ground.

d. If voltage being applied on positions 1, 2, and 3 checks out okay, then the

relay should be replaced. Coil is probably defective.

18

Page 20

BB - - If heat relay does close:

1. Check power supply at terminal board #2 between terminals #5 and #7; it should be approximately 220V.

2. Check power at position 4; there should be no voltage.

3. Check position 5; voltage should be approximately 120V to ground.

4. Check power at position 6; voltage should be 220V approximately; if not. check wires for breaks and bad

connections.

5. Temperature should rise as explained in AA1 and amperages may be checked according to those instructions.

Replace any defective elements.

FIGURE NO. 2 WASH HEATER SYSTEM

A. HEATER SWITCH D. HEATER RELAY

B. WATER LEVEL CONTROL E. AMPROBE TEST POSITION

C. THERMOSTAT F. WASH TANK HEATER

X. TERMINAL BOARD (9 TERMINALS)

19

Page 21

REPLACING SEAL and

CERAMIC on WASH PUMPS

FUNCTION

The pump is part of the total motor-pump system and utilizes one shaft seal and ceramic to prevent

the pump from leaking around the impeller and shaft. One gasket is used to prevent leakage between the

pump mounting plate and the machine pump plate.

REPLACEMENT OF SEAL AND/OR CERAMIC

1. Remove the power source to the machine by turning the circuit breaker to its "off" position on the side

of the control box.

2. Drain the machine by removing the overflow strainer in the wash tank.

3. Support the motor - - remove the four nuts holding the pump/motor to the machine's pump plate.

4. Carefully pull motor outward, move from side to side as required to remove from machine.

5. Set motor and pump on a sturdy stand close to machine or remove wires and conduit to allow

motor/pump to be moved to a better work station.

6. Insert a firm object into the blades of the fan and use a 5/16" ratchet to remove bolt holding impeller.

After the bolt is removed, pull the impeller up and off of the shaft.

7. The ceramic is imbedded in the pump mounting plate and usually does not need replacement, but the

seal normally would when water leaks around the motor shaft area. If replacement of either is

required, proceed as follows:

a. Remove the four bolts holding the pump mounting plate to the motor.

b. Slide the mounting plate up and off of the shaft and motor. The imbedded ceramic and

shaft seal will be removed with the mounting plate.

c. Turn over the plate and push the seal and/or ceramic out of the housing carefully. It

may be necessary to break the ceramic to remove it.

d. Clean the hole where the ceramic was installed.

e. Lightly coat with a lubricant around the new ceramic's edges and "0" ring. Gently press

the ceramic into place against the snap ring in the housing. Make sure that the grooved

side of the ceramic faces the motor and housing snap ring, leaving the smooth side toward

the impeller.

f. Make sure that the woodruff key is in place in the shaft and then set the plate back on the

motor over the shaft.

NOTE: A field tool can be made (to ease installation of seal) from a pipe or tube (3/4" CPVC typical

example) that has proper outside and inside dimensions. It must fit over step down in shaft, but be

close to larger shaft size on outside. To accommodate woodruff, cut long slot in tube. Lubricate tube

slip seal over tube onto shaft.

g. Lightly coat with a lubricant the new seal face and gently press it into place over the shaft

with the seal face against the ceramic. SEE NOTE ABOVE.

h. Place the spring over the shaft with the metal cap up. Press the impeller down onto the

shaft, aligning the keyway of the impeller with the woodruff key.

i. Tighten the impeller washer, lockwasher, and bolt into place. Replace the four bolts

that hold the mounting plate to the motor.

8. Reinstall the pump and motor in the unit by reversing steps one through eight (it is suggested that a

new pump gasket be installed).

IMPELLER ROTATION:

WHEN FACING THE IMPELLER AFTER MOUNTING IT ON THE MOTOR SHAFT, THE

IMPELLER SHOULD TURN IN A CCW DIRECTION.

20

Page 22

ITEM P/N DESCRIPTION

1 0102600 PUMP MOTOR, 50 Cycle

1 0102700 PUMP MOTOR, 60 Cycle

2 0106500 WOODRUFF KEY

3 3691300 WASHER, RUBBER

4 0108000 SNAP RING

5 0105000 CERAMIC FACE w/ "O" RING

6 0104500 PUMP MOUNTING PLATE

7 0105000 SEAL FACE

8 PLATE TO MOTOR MOUNTING

BOLTS & LOCKWASHERS

9 0105000 SEAL ASSEMBLY (SEAL SPRING

& CUP WASHER)

10 0105500 PUMP IMPELLER

11 0107500 IMPELLER WASHER

12 0107000 IMPELLER BOLT & LOCKWASHER

13 0106000 PUMP MOUNTING GASKET

Page 23

REPLACING SEAL and

CERAMIC on RINSE PUMPS

FUNCTION

The pump is part of the total motor-pump system and utilizes one seal and ceramic to prevent the pump from leaking

around the impeller and shaft. One gasket is used to prevent leakage in between the pump mounting plate and the machine

pump plate.

REPLACEMENT OF SEAL AND/OR CERAMIC

1. Remove power source to machine by turning circuit breaker to its off position on side of control box.

2. Drain machine by removing overflow strainer in wash tank.

3. Support motor - remove the four nuts holding the pump/motor to the machine's pump plate.

4. Carefully pull motor outward, move from side to side as required to remove from machine.

5. Set motor and pump on a sturdy stand close to machine or remove wires and conduit to allow motor/pump to be moved to

a better work station.

6. Remove dust cap over end of motor shaft (opposite impeller end). This can be done by wedging with a screwdriver.

7. Remove impeller - hold shaft by inserting screw driver in slotted end of shaft and unscrew impeller in counterclockwise

direction.

8. The ceramic is embedded in the impeller and normally does not need replacement, but it should be checked for cracks or

a worn out surface. If ceramic does need replacement, proceed as follows.

(a) With a pointed, flat tool, work the ceramic and rubber cup out of groove in impeller.

(b) Clean groove of all residue.

(c) Apply small amount of adhesive in groove.

(d) Press new ceramic gently into groove with rubber cup leading the way. (NOTE:

THE CERAMIC HAS ONE SIDE THAT IS GROOVED. THIS SIDE SHOULD BE FACING DOWN INTO THE

RUBBER CUP. THE SMOOTH SURFACE SHOULD BE FACING UP).

9. The seal is embedded in the pump mounting plate and usually will need replacement when water leaks around motor

shaft area. If replacement is required proceed as follows.

(a) Remove four bolts holding pump mounting plate to motor, must be done with Allen wrench.

(b) Slide mounting plate up off of shaft and motor.

(c) Press seal out of housing carefully.

(d) Clean hole where seal was installed.

(e) Apply a small amount of non-hardening sealant to backside of seal. Insert new seal with a seal driver to prevent

ruffling the edges of seal. Never use screwdriver or similar tool to alternately force edge of seal in place.

10. Reassemble pump and motor by reversing the above procedure.

22

Page 24

ITEM P/N DESCRIPTION

1 0086100 PUMP MOTOR, 50 Cycle

1 0086000 PUMP MOTOR, 60 Cycle

2 0088000 PUMP MOUNTING PLATE

3 0089000 PUMP CERAMIC FACE w/RETAINER CUP

4 0087500 PUMP IMPELLER SEAL

5 0089500 PUMP IMPELLER

6 0090000 PUMP MOUNTING GASKET

7 0090500 PUMP PLATE TO MOTOR MOUNTING BOLTS

8 0091000 MOUNTING PLATE LOCKWASHERS

9 0091000 PUMP MOUNTING PLATE TO BASE LOCKWASHERS

10 0091500 PUMP MOUNTING PLATE TO BASE NUTS

Page 25

INSTRUCTIONS for ADJUSTING TENSION

of CANTILEVER

PROBLEM: Doors raise hard, but lower easily.

SOLUTION: 1. Back off (loosen) upper adjusting nuts (F) on both eyebolts (E) about two or three complete turns.

2. Tighten lower adjusting nuts (G) on both eyebolts (E) a complete turn.

3. Check door for easy operation. Adjust further, if necessary.

4. When adjustment is completed, tighten upper adjusting nuts (F) down against angle to lock in position. Check

both eyebolts.

PROBLEM: Doors raise easily, but lower hard.

SOLUTION: 1. Back off lower adjusting nuts (G) carefully, making sure there is still some thread on eyebolt available (both

eyebolts).

2. Check door for easy operation. Adjust further, if necessary.

3. When adjustment is complete, tighten upper adjusting nuts (F) down against angle to lock in position. Check

both eyebolts.

PROBLEM: Doors sticking, or are hard to move up and down.

SOLUTION: 1. Raise doors.

2. Clean inside door channels on machine with a good cleaning compound. It may be necessary to remove

doors to completely clean channel. If so, remove only one door at a time. Make sure cantilever has stop to

prevent pulling other door up and out of channel. If it does not have stop, secure cantilever arm to machine

with doors in the closed position.

3. Build up should be completely removed so it may be necessary to use an abrasive pad (non-metallic) to clean.

4. While you have the door out of channel, make sure it is not dented or crooked. If channel is crooked or

dented, use 1/2" wide block to spread to proper opening.

5. Clean nylatron runners on the doors or replace nylatron, if excessively worn. See instructions on door runners.

6. Check door channels on machine for evenness and burrs.

7. After replacing doors, check for proper operation by raising and lowering with cantilever.

PROBLEM: One side of door higher than other and does not close completely.

SOLUTION: 1. Straighten cantilever arm.

2. This can sometimes be accomplished while arm is on machine by forcing down on the arm connected to the

high door while the other side of the cantilever is pulled up.

3. If step two cannot be accomplished on machine, cantilever will have to be removed and straightened.

24

Page 26

Page 27

APPLYING NYLATRON STRIP TO

100 SERIES DOOR

P/N 0051800

INSTRUCTIONS FOR INSTALLING NEW DOOR GUIDES

ITS IMPORTANT WHEN REMOVING THE OLD DOOR GUIDES THAT THE SURFACE BE

CLEANED THOROUGHLY. THIS CAN BE DONE WITH A SOLVENT THAT WILL DISSOLVE

THE REMAINING GLUE AND/OR THE USE OF A FINE SANDPAPER TO SCRATCH THE

SURFACE WHERE THE DOOR GUIDE WOULD MAKE CONTACT WITH THE STAINLESS

STEEL DOOR.

AFTER THIS IS ACCOMPLISHED AND YOU ARE QUITE CONVINCED THAT THE SURFACE

IS CLEANED OF ALL OIL. GLUE. DIRT. DETERGENT ETC.. THEN THE DOOR GUIDE

SHOULD BE PLACED ON A FLAT SURFACE AND A BEAD OF A SILICONE ADHESIVE OR

ANY GOOD NON-HARDENING GLUE SHOULD BE LAID ON THE INSIDE OF THE DOOR

GUIDE'S SURFACE (TOP AND BOTTOM, MAKING SURE THAT NONE OF THE EXPOSED

SURFACE TO THE OUTSIDE HAS ANY GLUE ON IT).

TAKE THE DOOR GUIDE AND SNAP IT OVER THE DOOR'S EDGE AS DESCRIBED IN THE

ATTACHED SKETCH. 00 NOT SLIDE UP THE EDGE. LET THIS DOOR SET FOR AT LEAST

ONE HOUR BEFORE USE SO THAT THE GLUE OR ADHESIVE HAS A CHANCE TO SET

SOMEWHAT.

IF THESE INSTRUCTIONS ARE FOLLOWED. THE DOOR GUIDES SHOULD ADHERE TO

THE DOOR.

Fig. 1 - PUT A STREAM OF SILASTIC

OR NON-HARDENING ADHESIVE IN

INSIDE CORNER OF STRIP.

Fig. 2-SIDE VIEW OF

NYLATRON STRIP.

Fig. 3-SNAP STRIP ON DOOR

LIP.

NOTE: DO NOT SLIDE STRIP

FROM END ALWAYS SNAP

ON.

Fig. 4 - PRESS DOWN WITH

THUMB AND INWARD WITH

FINGERS.

Fig. 5- FINISHED

APPLICATION -END

VIEW.

Page 28

WATER LEVEL CONTROL(ELS)

(FOR RINSE TANK) P/N 0205000

FUNCTION

The Water Level Control device utilized on power rinse (PRB) models only, automatically maintains

the water level in the rinse tank. The rinse tank water level control is energized by the master switch. The

control is designed to sense when the proper water level is maintained. At this time. the relay in the clear

plastic case will activate, opening the normally closed circuit to the solenoid, which stops the water flow

to the rinse tank.

When water is removed from the tank by the rinse pump, the sensing probe will alert the water level

control by signal to deactivate and return the contact points on relay (in clear plastic case) to the normally

closed position, allowing power to be reapplied to the solenoid valve. Water will again flow into rinse tank

until proper level is reached and maintained.

CHECKOUT

NOTE: ALL ELECTRICAL CHECKS SHOULD BE MADE BY QUALIFIED SERVICE PERSONNEL

OR ELECTRICIAN.

If one of the following problems exist, this control should be checked out as shown below:

1. Water to rinse tank runs continually with the master switch on.

2. Water does not flow into rinse tank when required.

PROCEED WITH CHECKOUTS:

1. Remove power source to machine by moving breaker to "off" position.

2. Remove 4 screws holding control pane! to control box and fasten to control box on right side,

using 2 screws with backside of panel outward.

3. Locate the water level control for the rinse tank circuit (sketch below). Remove, mark. and insulate

for easy replacement wires going to letters C and H on control.

4. Reapply power and turn on master switch.

5. With insulated wired, connect jumper wire between terminals C and H (24 Volt system).

6. If relay (inside clear plastic case marked "X" on drawing below) operates, then the water level

control action can be deemed operational, and other causes should be explored (see

troubleshooting section).

7. If relay doesn't operate, then check relay coil continuity. Replace relay or complete control, as

necessary.

8. Remove power source once again and replace wires removed in (3) to original terminals or new

control, if replacement was made.

27

Page 29

WATER LEVEL CONTROL (ELS)

(INITIAL FILL AND WASH-HEAT CIRCUIT) P/N 0205000

FUNCTION

This control is activated when the master switch is turned on. The primary function is to automatically

control the proper initial filling of the wash tank, then to activate the wash and rinse tank heat circuit It will

also provide cutoff of the wash and rinse heat circuit, should the water be accidentally drained from the

machine (with the master switch still on). The master switch should be turned off before draining.

This water level control is used in conjunction with two probes (sensors), master switch, fill

switch, rinse relay, thermostat(s). heat relay(s), solenoid or rinse motor.

When the master switch is turned on, the normally closed circuit in the plug-in relay is energized. As the

fill switch is pushed upward and released, the rinse relay contacts close, and the solenoid (or rinse pump on

PRB model) opens and water flows into wash tub. As the water rises in the wash tub, it will cover first the

lower probe (directly above wash element) then reach the upper probe. At this time, the plug-in relay coil will

be activated and open the normally closed contacts, de-energizing the solenoid (or rinse pump).

Simultaneously, the contacts will close on the normally open circuit, energizing the wash-rinse heat circuit.

(Checkout and information concerning that part of the circuit are in the wash heater system or rinse heater

system instruction page of this manual.)

If the water should be drained from the machine while the master switch is still on, the lower probe

will sense the lack of water and de-energize the plug-in relay, which will de-energize the wash-rinse heat

circuit. DO NOT DEPEND ON THIS - - always turn master switch off before draining.

SYMPTOMS OF LEVEL CONTROL FAILURE:

1. Fill does not take place unless rinse switch is held upward until full.

2. Initial fill does not stop when it reaches overflow, but continues.

3. Wash-rinse heat circuit does not activate.

4. Wash heater remains on (if wash water accidentally emptied with master switch on.)

PROCEED WITH CHECKOUT:

1. Remove power to machine by turning customer circuit breaker to its "off" position. Turn machine

circuit breaker, located on right side on control box. to "off".

2. Remove 4 screws holding control panel on control box. Remove panel and attach to one side of

control box with 2 screws, with back side facing toward you.

3. Locate initial fill and wash-heat circuit water level control board and disconnect wires going to

terminals marked C, H, and L. Mark and insulate wires for replacement.

28

Page 30

4. Be sure wash tank is empty and master switch and heat switch are off. Carefully reapply power to machine.

Begin by turning master switch on. With an insulated jumper wire, touch jumper between terminals C & H; relay

in clear plastic cube should activate as wire is touched to terminals. Observe relay contacts - - they should pull

in. If they do, remove wire and they should return to original position. Repeat several times to verify action.

Reconnect wires removed.

5. If relay operates, the control can be deemed operational and other causes should be explored. EXAMPLES: 1.

Loose or broken wire to probe or ground (green wire).

2. Dirty probe(s).

3. Solenoid faulty (see instruction page concerning solenoid).

4. Thermostat faulty or needs adjustment (see instruction page concerning thermostat).

5. Wash element faulty (see instruction page concerning wash-heat checkout).

6. If relay does not operate, check voltage being applied to LI - L2 marked on control. It should be 208-230V.

Replace control, if necessary.

7. In any case, always locate sensor (probes) inside wash tub and clean off all deposits (instruct customer; this

should be at least a weekly project).

8. Remove power to machine and replace panel and any wires that were not replaced previously.

Page 31

TROUBLE SHOOTING GUIDE

PROBLEM

1- No Voltage to dishwasher,

Nothing on machine a. Customer's fuse blown or a. Replace or reset.

operates. circuit breaker tripped.

Will not fill with electrical 1- Water hand valve off. 1- Turn hand valve on.

power applied even though

other components work. 2- Master switch not on or 2- Turn on or replace.

(B Model) faulty.

Will not fill with electrical 1- Customer's water hand 1-Tum hand valve on.

power applied even though valve off.

other components work

(PRB Model) 2- Master switch not on or 2- Turn on or replace.

screen, clean & replace.

30

2- Machine circuit breaker 2- Turn on or reset.

tripped or turned off.

3- Voltage to machine low or 3- Contact your electrician

circuit to machine broken. and/or power company for

3- Fill switch faulty or loose 3- Replace switch or wire or

wire connection. connection terminal.

4- Solenoid valve does not 4- See instruction page

operate. concerning the Solenoid

5- Water level control faulty 5- See page on water.

6- Y strainer clogged. 6- Turn water to machine

faulty.

3- Fill switch faulty or loose 3- Replace switch or wire or

wire connection. connection terminal.

4- Rinse motor not operating. 4- Check connection and

5- Water level control does not 5- See instruction page

maintain the water level in the concerning the water level

rinse tank. control for PRB Models.

6- Solenoid Valve does not 6- See instruction page con-

operate cerning Solenoid Valve.

7- Y-strainer clogged. 7- Turn off water to machine,

CAUSE SOLUTION

repair.

valve.

off, remove plug & strainer

screen, clean & replace.

voltage to motor repair or

replace as necessary.

remove plug. prepare to

catch hot water & strainer

Page 32

TROUBLE SHOOTING GUIDE

PROBLEM CAUSE SOLUTION

Fills slowly and/or rinse is 1- Low water pressure. 1- Check water pressure by:

weak.

Rinse water runs continu- 1- Rinse switch sluggish 1- Replace.

ously with power on. or faulty.

Rinse water runs with 1- Water pressure exces- 1- Check using pressure

no electrical power sive. gauge during flow

applied to solenoid

(Master Switch off).

2- Rinse head assemblies limed 2- Clean rinse head tubes.

up or clogged with other See instruction page

deposits. on preventive maintenance.

2- Solenoid valve dirty 2- See special instruc-

or faulty. tions page concerning

3- Water level control 3- See special instruc-

faulty (PRB Models tions page concerning

only). water level control

4- Rinse tank probe 4- Remove & clean probe

coated (PRB Model) then replace.

5- Breather tube plugged 5- Clean tube or repair.

or bent closed (PRB

Model only).

2- Solenoid Valve diaphragm 2- See instructions

breather hole clogged. page concerning

31 Solenoid Valve.

a. Turn heat and master

switch off.

b. Empty wash tub.

c. Replace overflow

strainer, close doors.

d. Turn on master switch.

e. As you push up fill

switch, time the seconds it

takes to fill machine to

within 1/4of top of the

overflow tube. It should be

60 seconds. Any more than

5 seconds longer indicates

the water supply &

pressure insufficient.

Solenoid Valve.

for PRB Models.

period (solenoid

valve open) should

read 20 PSI. if in ex cess installation of a

Pressure Reducer can

reduce pressure.

Page 33

TROUBLE SHOOTING GUIDE

PROBLEM CAUSE SOLUTION

Machine won't work on automatic. Wash

and rinse work only on manual.

1- Timer motor faulty. 1- Pull control panel and observe timer

operation. See instruction page for

changing timer motor.

2- Master or start switch faulty. 2- Replace switch.

3- Start switch in middle position. 3- Position switch up or down fully.

Machine will not automatically fill. 1- Power is off. 1- Check incoming line fuses circuit

breakers.

2- Wire loose or broken to L1 and L2. 2- Check line voltage at L1 and L2 on water

level control and control panel.

3- Master switch faulty. 3- Replace.

4- Water level control faulty. 4- To check water level control, see special

instructions on water level control.

Wash motor does not operate on

automatic or manual but machine rinses

properly.

5- High fill probe. 5- Clean or short out probe end to tank, this

will cause the relay on the water level

control to close and return, if this does not

happen, check for loose wire especially a

loose ground wire.

6- Electric solenoid valve not opening. 6- Check electric solenoid valve, see special

information section under solenoid valve

1 - Wash switch faulty.

2- Broken or loose wire from

terminal board to motor.

3- Wash motor faulty. 3- Repair or replace.

32

1- Replace.

2- Check for loose or broken

short circuit.

Page 34

TROUBLE SHOOTING GUIDE

PROBLEM CAUSE SOLUTION

Wash motor does not 1-Wash micro switch in timer 1- Check timer, see instruc-

operate on automatic. faulty tion page on timer

but rinses on automatic

and washes on manual

Machine begins to 1- Timer motor, micro switch 1- Check timer, see instruc-

wash when master faulty tion page on timer

switch is turned on

without operating 2- Start switch faulty 2- Replace

start switch

Machine goes through 1- Wash micro switch faulty 1- Check timer, see instruc-

entire cycle and

shuts off but washes

through complete cycle

Wash reservoir does 1- Large overflow strainer 1- Check '0' ring in drain

not remain full not properly seated. fitting - Put strainer in

2- Bottom of strainer (conical 2- Replace strainer

end of tube) bent out of

shape

3- Dirt or mineral deposits in 3- See instruction page on

strainer hole Preventive Maintenance

Wash motor runs but 1- Wash temperature of 150°- 1- Adjust thermostat on wash

machine fails to wash 160° is not maintained tank, check wash heater

satisfactorily

2- Inadequate or improper de- 2- Use recommended deter-

tergent being used gent, see machine's opera

3- Pump intake strainer is dirty 3- See Preventive Maintenance

4- Wash tubes not turning 4- The wash assembly can usually

wash head assemblies.

33

tion page on timer

tightly

element.

tion instructions

be freed by bearing down on

the wash assembly and rotating

back and forth. If the as

sembly can't be freed in this

manner, take the wash assembly

apart and the bearing races,

using care not to lose the bear

ings or drop them into the

machine. Clean scale off part

with recommended scale solvent.

See Preventive Maintenance &

instruction for removal of

Page 35

PROBLEM

Wash Pump leaks

TROUBLE SHOOTING GUIDE

CAUSE

1- Impeller seal is worn (leaks

around shaft)

1- Remove and inspect pump and motor

assembly, see instruction page on pump

seals and ceramic replacement

SOLUTION

Rinse and fill switch is on but water does not

come through rinse tubes

When master switch is on rinse runs

continually

Machine goes through entire cycle and shuts

off, but rinses throughout the cycle

2- Pump assembly is not seated to base of

machine (leaks around mounting plate).

1- Valve in water line is not open

2- Rinse tubes are clogged

3- Strainer in water line is full of scale 3- See Preventive Maintenance

4- Rinse and fill switch faulty 4- Check rinse and fill switch

5- Electric solenoid diaphram or plunger not

operating

6- Coil on the solenoid valve is burned out.

7- Insufficient or excessive pressure 7- Check flow pressure which should not

1- Water level control faulty 1- Check instruction page on water level

1- Defective rinse microswitch 1 - Check timer, instruction page

2- Replace gasket. Make sure mounting

nuts are tight

1- Check to make sure all valves are open

2- See Preventive Maintenance

5- Remove diaphram and plunger, flush

and clean. see instruction page on

Solenoid Valves

6- See #5 above

exceed 25 PSI or go below 15 PSI

controls

Master switch off, rinse runs continually as

soon as power is applied to machine

Extremely high rinse temperature indication 1 - Thermostat set too high. 1- Adjust thermostat control, see instruction

34

- Master & rinse switch faulty

- Loose green ground wire from

water level control

2- Thermostat faulty 2- Replace

1- Replace rinse and/or master switch 2-

Tighten ground wire or see instruction

page on solenoids

page on thermostat

Page 36

TROUBLE SHOOTING GUIDE

PROBLEM

CAUSE

SOLUTION

Low rinse temperature 1- Machine using more water 1- If this trouble occurs, it

indication than normal by rinse running should be determined that

Water leaks from 1- Spray arms are not moving 1 - See instruction page on

top of door freely or ends bent down preventive maintenance -

Machine wash and 1- Timer defective and stopped 1 - Move start switch to middle

rinse do not operate in timed cycle position (start switch is

Machine does not 1- Circuit breaker tripped 1-Reset circuit breaker on

operate at all

35

throughout wash cycle, caused the rinse is running during

by faulty rinse microswitch in the wash cycle by in

timer specting the rinse sole

noid and by disconnecting

the wash motor lead at

the terminal board on the

control panel. See instruction page on timer

2- Incoming water supply not 2- Provide adequate supply of

hot enough hot water, see specifica-

3- Heater switch faulty 3- Check heater switch

4- Setting on thermostat con- 4- Try new setting. Move the

trol has been moved from thermostat control clock original factory setting wise for higher setting.

5- Thermostat faulty 5- Check thermostat, see

6- Heater faulty 6- Check heater, see instruction

7- Contactor faulty 7- Check contactor, see instruc-

8- Thermometer faulty 8- Remove thermometer and

ward pull upward on ends of

tions sheet

instruction page

page

tion page

check in hot water against

an accurate thermometer

longest wash spray arms ½.

three position) UP - Start

CENTER-Off, DOWN Start. See instruction

page on timer.

wall panel. Check voltage

to machine at L1 and L2

at terminal board #TB2

Page 37

TROUBLE SHOOTING GUIDE

PROBLEM

CAUSE

SOLUTION

Rinse pump leaks. 1- Impeller seal is worn. 1- See instruction page on

PRB Models only.

Indicator light(s) do 1- Lights faulty or poor connec- 1- Replace or correct

not glow at any time. tion. connection.

None of the automatic 1- Start switch faulty. 1-Check switch. Replace if

functions work (wash, rinse).

Vacuum breaker leaks 1- Limed up. 1- Disassemble:

2- Impeller ceramic is worn or 2- Same as 1.

scored.

2- Wire connections poor. 2- Correct connection.

3- Timer rinse or wash micro- 3- See instruction page

switch faulty. concerning timer &

2- Faulty. 2-Replace needed parts or

ceramic replacement

necessary, see instructions

page concerning replace

ment of switches in control

panel.

motor.

a. Remove top using

flat jaw wrench or

channel locks.

b. Remove poppet.

c. Clean poppet & V.B.

top & body.

d. Replace parts removed.

whole VB.

36

Page 38

FRONT VIEW

ITEM P/N DESCRIPTION ITEM P/N DESCRIPTION

1 0068000 BOOSTER TANK 10 0019900 CONTROL BOX & PANEL

2 0058000 WASH TANK HEATER 11 0169400 THERMOSTAT BOX

3 0151000 INSIDE PUMP STRAINER 12 0012000 CONTROL CIRCUIT PROTECTION DEVICE

4 0152000 LARGE OVERFLOW STAINER 13 0101800 WASH PUMP & MOTOR, 50 Cycle

0047000 WASH PUMP & MOTOR, 60 Cycle

5

6

0050900 CUSTOMER'S ELECTRICAL CONNECTION

6A

0051000 CUSTOMER'S WATER CONNECTION

0055100 RINSE PUMP & MOTOR (PRB ONLY) 50 Cycle

7

6007900 RINSE PUMP & MOTOR (PRB ONLY), 60 Cycle

8

0184301

FRONT DOOR

DOOR HANDLE

HANDLE JL MODELS

BOTTOM FRONT PANEL (NOT SHOWN)

CANTILEVER ARM CONV. KIT

VACUUM BREAKER

13 0102000

14 0165500

15

16 0085100

16 0085000

17 0083300

ADJUSTABLE FOOT

9 0169100 WASH & RINSE THERMOMETERS 18 RINSE ADDITIVE FITTING

37

Page 39

ITEM P/N DESCRIPTION ITEM P/N DESCRIPTION

1 0085100 RINSE PUMP & MOTOR (PRB ONLY), 50 Cycle 11 0008700 CANTILEVER SPRING RODS

1 0085000 RINSE PUMP & MOTOR (PRB ONLY), 60 Cycle 12 0011501 CANTILEVER DOOR COUPLER

2

CUSTOMER'S WATER CONNECTION 13 0007500 BREATHER TUBE (PRB ONLY)

3 0019900 CONTROL BOX & PANEL 14 0009000 CANTILEVER SPRINGS

4 0012000 CONTROL CIRCUIT PROTECTION DEVICE 15 0084500 WATER LEVEL PROBE (PRB ONLY)

5 0101800 WATER PUMP & MOTOR, 50 Cycle 16 0068000 BOOSTER TANK

5 0102000 WASH PUMP & MOTOR, 60 Cycle 17 0009400 CANTILEVER EYE BOLTS

6

0169100 WASH & RINSE THERMOMETER 19

DETERGENT DISPENSER FITTING 18 0083300 ADJUSTABLE FOOT

RINSE ADDITIVE FITTING

6007900 CANTILEVER ARM 20 0009100 YOKE ASSEMBLY

9 0184301 VACUUM BREAKER 21 0049000 SPACER

10

EXTERNAL VACUUM BREAKER PIPING 22 0010000 SLEEVE

38

Page 40

RIGHT SIDE VIEW

ITEM P/N DESCRIPTION ITEM P/N DESCRIPTION

1

2 0165500 CUSTOMER'S ELECTRICAL CONNECTION 13

CUSTOMER'S WATER CONNECTION 12

DETERGENT DISPENSER FITTING

EXTERNAL VACUUM BREAKER PIPING

3 0019900 CONTROL BOX & PANEL 14 0009000 CANTILEVER SPRING

4 0012000 CONTROL CIRCUIT PROTECTION DEVICE 15 0101800 WASH PUMP & MOTOR, 50 Cycle

5 0084300 HIGH WATER PROBE 15 0102000 WASH PUMP & MOTOR, 60 Cycle

6 0169100 WASH & RINSE THERMOMETERS 16 0007500 BREATHER TUBE (PRB ONLY)

7 0011500 CANTILEVER DOOR COUPLER 17 0084500 WATER LEVEL PROBE (PRB ONLY)

8 6007900 CANTILEVER ARM 18 0085000 RINSE PUMP & MOTOR (PRB ONLY) 60 Cycle

9 0048000 SIDE DOOR 18 0085100 RINSE PUMP & MOTOR (PRB ONLY) 50 Cycle

10 0184300 VACUUM BREAKER 19 0083300 ADJUSTABLE FOOT

11 0008700 CANTILEVER SPRING ROD 20

RINSE ADDITIVE FITTING

39

Page 41

ITEM P/N DESCRIPTION ITEM P/N DESCRIPTION

1 0006800 BOOSTER TANK 10 6007900 CANTILEVER ARM

2

3 0009000 CANTILEVER SPRING 12 0136000 LOWER RINSE HEAD ASSEMBLY

4

5 0008700 CANTILEVER SPRING ROD 14

6 0136000 UPPER RINSE HEAD ASSEMBLY 15

7 0200000 UPPER WASH HEAD ASSEMBLY 16 0083300 ADJUSTABLE FOOT

8 0184301 VACUUM BREAKER 17

9 0048000 SIDE DOOR 18 0182100 PLUMBING VACUUM BREAKER TO HOOD

DETERGENT SENSOR FITTING 11 0011500 CANTILEVER DOOR COUPLER

EXTERNAL VACUUM BREAKER PIPING 13 0200000 LOWER WASH HEAD ASSEMBLY

WASH TANK (NLA)

DRAIN OUTLET

DETERGENT DISPENSER FITTING

40

Page 42

BOTTOM VIEW

ITEM P/N DESCRIPTION ITEM P/N DESCRIPTION

1 0083300 ADJUSTABLE FOOT 7 0012000 CONTROL CIRCUIT PROTECTION DEVICE

2 0006800 BOOSTER TANK 8 0153700 'Y' STRAINER

3

4

5

6 0019900 CONTROL BOX & PANEL 11 0085000 RINSE PUMP & MOTOR (PRB ONLY), 60 Cycle

DETERGENT SENSOR FITTING 9 0143000 SOLENOID VALVE

WASH TANK 10 0101800 WASH PUMP & MOTOR, 50 Cycle

DRAIN OUTLET 10 0102000 WASH PUMP & MOTOR, 60 Cycle

11 0085100 RINSE PUMP & MOTOR (PRB ONLY), 50 Cycle

41

Page 43

HIGH LEVEL

PROBE

VACUUM BREAKER P/N

0184301

P/N 0084300

1 NUT, 6/32 S/S

2 WASHER RUBBER

3 PORCELAIN, OUTER

4 INSERT, SILASTIC

5 PORCELAIN, INNER

6 STEM

LOW LEVEL

PROBE

P/N 0084500

1 PROBE BOOT

2 NUTS

3 LOCKWASHER

4 PROBE

5 TANK COUPLING

ITEM P/N DESCRIPTION

1

2 0184700 DISK

3 0184700 GASKET

4 0184700 POPPET

5 BODY

BONNET

42

ITEM P/N DESCRIPTION

1 0153700 ‘Y’ STRAINER

2

3 0185000 VALVE FOR HEALTH INSPECTOR

4 0055500 FLOW CONTROL, 3/4"

5 0143000 SOLENOID VALVE 3/4"

6

REMOVABLE FILTER

PIPE UNION

Page 44

CUTAWAY VIEW OF WASH SUMP

ITEM P/N DESCRIPTION

1

2 0005400 DRAIN '0' RING

3 0152000 OVERFLOW STRAINER

4 0058000 WASH TANK HEATER ELEMENT

5 015100 INSIDE PUMP STRAINER

6

7

DRAIN FITTING

WASH TANK THERMOSTAT SHEATH

SUMP WALL

ITEM P/N DESCRIPTION

1

2 0054000 DRAIN '0' RING

3 0151000 INSIDE PUMP STRAINER

4 0152000 LARGE OVERFLOW STRAINER

DRAIN FITTING WELDED

TO WASH SUMP BOTTOM

43

Page 45

ITEM P/N

BOOSTER TANK

END VIEW BOOSTER

1 0006800 BOOSTER TANK (B MODEL)

2

3

4 0058800 HEATER BUS BARS (1 PHASE CONNECTION)

5 0060500 HEATER ELEMENTS (6 EACH)

6

DESCRIPTION

(NEW STYLE-NOT SHOWN)

EXTERNAL VACUUM BREAKER FITTING

THERMOSTAT PROBE, FITTING

HEATER ELEMENT COUPLING (6 EACH)

WITH ELEMENTS

(1 PHASE HOOKUP)

TANK

(3 PHASE HOOKUP)

ITEM P/N DESCRIPTION

1

2

3

4 0060500 BOOSTER HEATER ELEMENTS

5 0058800 HEATER ELEMENT BUS BARS

& 0058900 (3 PHASE CONNECTION)

THERMOSTAT PROBE FITTING

THERMOMETER PROBE FITTING

INCOMING WATER FITTING

44

Page 46

BOOSTER TANK HEATER

ELEMENT P/N 0060500

WASH TANK HEATER ELEMENT

P/N 0058000

45

Page 47

CONTROL BOX AND CONTROL PANEL COMPONENTS

ITEM P/N DESCRIPTION ITEM P/N DESCRIPTION

1 GROUNDING LUG 10 0157500 HEATER SWITCH

2 0165500 CUSTOMER'S ELECTRIC CONNECTION 11 0162500 START SWITCH

3 0123000 HEATER RELAY (3 POLE/3 PHASE) 12 0157500 MASTER SWITCH

0124000 (4 POLE/1 PHASE) 13 0083500 AUTOMATIC INDICATOR LIGHT

4 0121000 RINSE/FILL RELAY 14 0155500 MANUAL WASH SWITCH

5 0121000 WASH MOTOR RELAY 15 0154000 MANUAL RINSE SWITCH

6 0122000 WASH HEATER RELAY 16 0083500 HEATER INDICATOR LIGHT

7 0012000 CONTROL CIRCUIT PROTECTION DEVICE 17 0171300 AUTOMATIC TIMER ASSEMBLY 50 Cycle

8 0205000 RINSE TANK WATER LEVEL CONTROL 17 0171500 AUTOMATIC TIMER ASSEMBLY 60 Cycle

(PRB ONLY) 18 0167000 TERMINAL BOARD

9 0205000 WASH HEATER WATER LEVEL CONTROL 19 GROUNDING STUD

46

Page 48

R1 & R2: CONTACTORS

M SW: MASTER SWITCH ON-OFF

1-ELS, CONTROL, HIGH LEVEL FILL,

LOW LEVEL CUT-OFF IN WASH

TANK & RINSE TANK, LOW

VOLTAGE SENSOR, 24V. TO

PROBE

H.SW: HEAT & LIGHT SWITCH

THS: INDEPENDENT THERMOSTAT

CONTROL

WASH HEATER: (1)-1500W.

S-SW: START SWITCH • STARTS THE

AUTOMATIC CYCLE WHEN

THROWN TO THE CLOSE SIDE OF

TH: TIMER HOLD • TIMER MOTOR

RUNS ONE HALF CYCLE, THEN

OPENS • TH • TO COMPLETE ONE

MACHINE CYCLE.

TW: TIMER WASH & TR: TIMER RINSE •

CONTROLLED BY CAMS DRIVEN BY

THE TIMER MOTOR

MW SW MANUAL OPERATION WASH

SWITCH • IN THE OFF POSITION

FOR AUTOMATIC OPERATION, ON •

FOR MANUAL OPERATION.

MR-SW: MANUAL RINSE & FILL

SWITCH, SPRING RETURN, LOCKS

IN R2 THROUGH 1-ELS, UNTIL

MACHINE FILLS TO HIGH LEVEL

PROBE IN WASH TANK.

Page 49

RINSE HEATERS

(6) 2200

W HC:

CONTACTOR

CB 1: OVER CURRENT CIRCUIT

BREAKERS-15A.

R1&2: CONTACTOR M SW: MASTER

SWITCH ON OFF

1 ELS, CONTROL, HIGH LEVEL FILL,

LOW LEVEL CUT OFF IN WASH

TANK & RINSE TANK HEAT. LOW

VOLTAGE SENSOR, 24V. TO

PROBE

H SW: HEAT & LIGHT SWITCH

W THS & R-THS: INDEPENDENT

THERMOSTAT CONTROL WASH &

RINSE TANK HEAT WASH

HEATER. (1) 1500 W.

S-SW: START SWITCH - STARTS THE

AUTOMATIC CYCLE WHEN

THROWN TO THE CLOSE SIDE OF

TH: TIMER HOLD, - TIMER MOTOR

RUNS ONE HALF CYCLE, THEN

OPENS - TH TO COMPLETE ONE

MACHINE CYCLE,

TW: TIMER WASH & TR: TIMER RINSE

CONTROLLED BY CAMS DRIVEN

BY THE TIMER MOTOR

MW-SW: MANUAL OPERATION WASH

SWITCH IN THE OFF POSITION

FOR AUTOMATIC OPERATION. ON

FOR MANUAL OPERATION.

MR-SW: MANUAL RINSE & FILL

SWITCH, SPRING RETURN, LOCKS

IN R2 THROUGH 1-ELS, UNTIL

MACHINE FILLS TO HIGH LEVEL

PROBE IN WASH TANK.

48

Page 50

RINSE HEATERS

(6) 2500

W HC:

CONTACTOR (HEATER)

CB.1: OVER CURRENT CIRCUIT

BREAKERS. 15 AMPS RATING

R1, R2 & R3: CONTACTORS (WASH &

RINSE MOTORS, AND WASH

HEATER)

M-SW: MASTER SWITCH ON-OFF

1 ELS, CONTROL, HIGH LEVEL FILL,

LOW LEVEL CUT-OFF IN WASH

TANK & RINSE TANK HEAT, LOW

VOLTAGE SENSOR, 24V. TO

PROBE

H-SW: HEAT & LIGHT SWITCH

W-THS & R-THS: INDEPENDENT

THERMOSTAT CONTROL OF

WASH & RINSE TANK HEAT

WASH HEATER, (1) 1500W.

S-SW: START SWITCH STARTS THE

AUTOMATIC CYCLE WHEN

THROWN TO THE CLOSE SIDE OF .

TH: TIMER HOLD, TIMER MOTOR

RUNS ONE HALF CYCLE, THEN

OPENS TH TO COMPLETE ONE

MACHINE CYCLE.

TW & TR TIMER WASH & TIMER RINSE

CONTROLLED BY CAMS DRIVEN BY

THE TIMER MOTOR

MW SW MANUAL OPERATION WASH

SWITCH IN THE OFF POSITION FOR

AUTOMATIC OPERATION, ON FOR

MANUAL OPERATION.

MR-SW: MANUAL RINSE & PILL

SWITCH, SPRING RETURN, LOCKS

IN R2 THROUGH 1.ELS. UNTIL

MACHINE FILLS TO HIGH LEVEL

PROBE IN WASH TUB.

Page 51

RH RINSE HEATERS ((6)

2500

W

HC: CONTACTOR (HEATE R) CB 1

OVER CURRENT, CIRCUIT

BREAKER 15AMP RATING

Rl & R2 CONTACTORS (WASH &

RINSE MOTOR)

M SW MASTER SWITCH ON OFF

1 ELS. CONTROL. HIGH LEVEL FILL,

LOW LEVEL CUT-OFF IN WASH

TANK & RINSE TANK HEAT, LOW

VOLTAGE SENSOR, 24 V. TO

PROBE

H SW: HEAT & LIGHT SWITCH

W THS & R THS INDEPENDENT

THERMOSTAT CONTROL WASH &

RINSE TANK HEAT. WASH

HEATER. (1)1500 W.

R3. CONTACTOR (WASH HEATER)

S.SW: START SWITCH, STARTS THE

AUTOMATIC CYCLE WHEN

THROWN TO THE CLOSE SIDE OF

TH

TH: TIMER HOLD: TIMER MOTOR

RUNS ONE HALF CYCLE, THEN

OPENS TH TO COMPLETE ONE

MACHINE CYCLE

TW & TR: TIMER WASH & TIMER

RINSE: CONTROLLED BY CAMS

DRIVEN BY THE TIMER MOTOR

MW-SW: MANUAL OPERATION WASH

SWITCH: IN THE OFF POSITION

FOR AUTOMATIC OPERATION ON

FOR MANUAL OPERATION. ON

LOCKS OUT RINSE MOTOR

MR SW: MANUAL RINSE & FILL

SWITCH. SPRING RETURN,

LOCKS IN R-2 THROUGH 1 ELS,

UNTIL MACHINE FILLS TO HIGH

LEVEL PROBE IN WASH TUB

2 ELS: CONTROLS THE WATER LEVEL

IN THE RINSE TANK THROUGH

LOW VOLTAGE SENSOR. 24 V. TO

PROBE FOR OPENING THE

SOLENOID VALVE

50

Page 52

HC: CONTACTOR (HEATER) RH: RINSE

HEATERS. (6) 2500 W.

CB-1: OVER CURRENT, CURRENT

CIRCUIT BREAKER,

15AMPS RATING R1 & R2:

CONTACTORS (WASH &

RINSE MOTORS)

M-SW: MASTER SWITCH ON-OFF

1 ELS: CONTROL, HIGH LEVEL FILL,

LOW LEVEL CUT-OFF IN WASH

TANK & RINSE TANK HEAT, LOW

VOLTAGE SENSOR, 24 V. TO

PROBE

H-SW: HEAT & LIGHT SWITCH R-3:

CONTACTOR (WASH HEATER) W-THS &

R-THS: INDEPENDENT THERMOSTAT

CONTROL WASH & RINSE TANK HEAT;

WASH HEAT WH: WASH

HEATER (1)1500 W.

S-SW: START SWITCH, STARTS THE

AUTOMATIC CYCLE WHEN

THROWN TO THE CLOSE SIDE OF

TH

TH: TIMER HOLD: TIMER MOTOR RUNS

ONE HALF CYCLE, THEN OPENS

TH TO COMPLETE ONE MACHINE

CYCLE

TW & TR: TIMER WASH & TIMER RINSE

CONTROLLED BY CAMS DRIVEN

BY THE TIMER MOTOR.

MW-SW: MANUAL OPERATION WASH

SWITCH: IN THE OFF POSITION

FOR AUTOMATIC OPERATION: ONFOR-MANUAL OPERATION, ON

LOCKS OUT RINSE MOTOR

MR-SW: MANUAL RINSE & PILL

SWITCH, SPRING RETURN, LOCKS

IN R-2 THROUGH 1-ELS, UNTIL

MACHINE FILLS TO HIGH LEVEL

PROBE IN WASH TUB.

2-ELS: CONTROLS THE WATER LEVEL

IN THE RINSE TANK THROUGH

LOW VOLTAGE SENSOR, 24 V. TO

PROBE FOR OPENING THE

SOLENOID VALVE

51

Page 53

PARTS LIST FOR MODEL 100

B/PRB DISHWASHERS

PART

NUMBER

0006800 Booster Tank for machine (stripped) B All 1

0006900 Booster Tank for machine (stripped) PR All 1

0006900 Booster Tank for machine (stripped) PRB All 1

6007900 Cantilever Assy Comp. (includes pans 79; 83; 87; 90; 94; 96

100; 103; 106; 109; 112) N/S (Conversion Kit) All 1

0008901 Cantilever Ann, ONLY N/S (1" Dia.) Old Style was 3/4" All 1