Page 1

Drive Motor & Gear

Reducer Replacement

07610-003-08-78 A

July 5, 2005

Rack Conveyor Dishmachine

Maintenance Instructions

Page 2

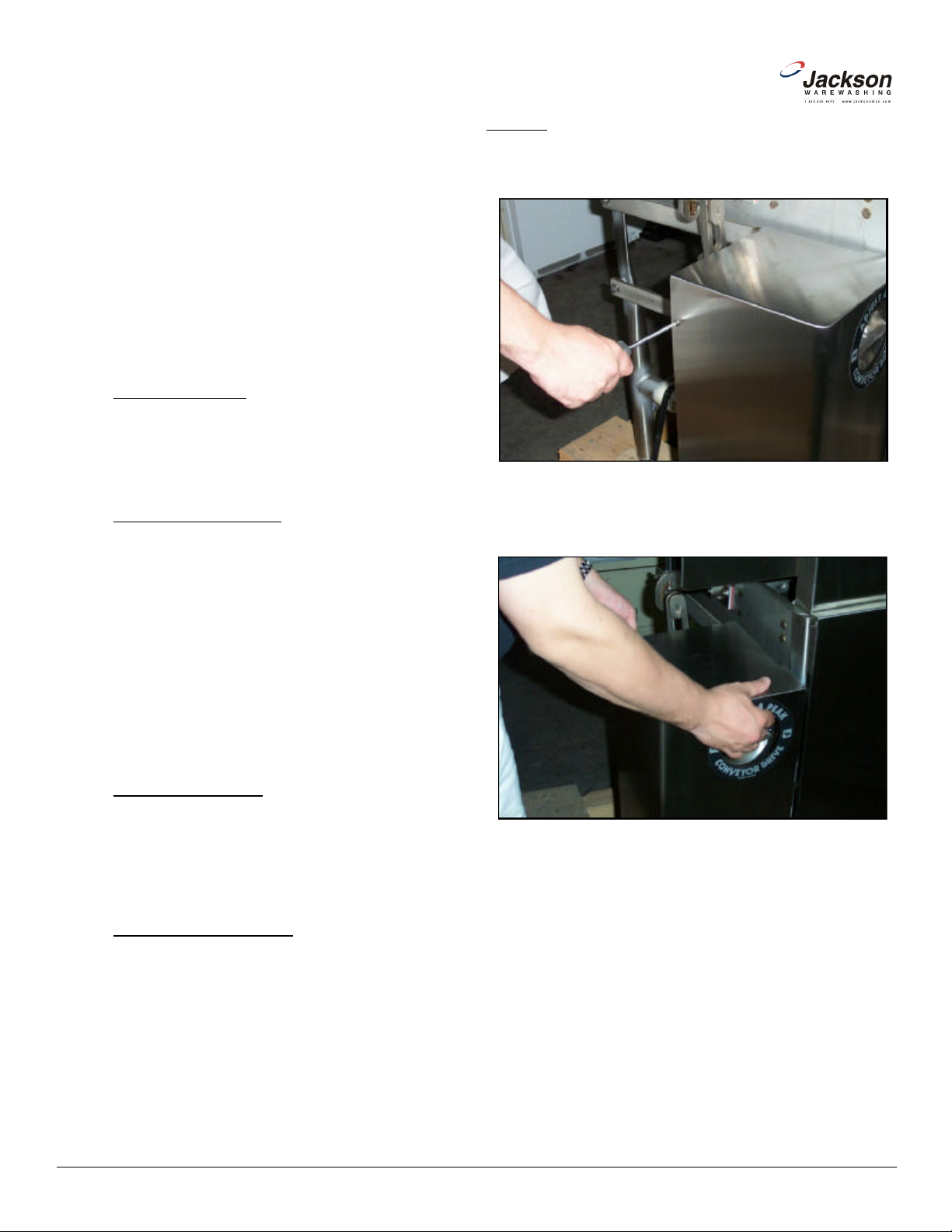

1. Remove the (2) screws that secure the top drive assembly cover

3. Set the top cover to the side and out of the way so that it does

not become a trip hazard. From here, the next step will be to

remove the bottom cover. This will require using the 7/16” socket

with ratchet and most likely the 7/16” combination wrench. Do not

lose the hardware for the covers as your repair kits do not come

with the hardware necessary to replace these. If you do require

hardware that is not present in your kits, do not hesitate to contact

www.jacksonmsc.com

The drive motor and the gear reducer of your Jackson

rack conveyor are responsible for moving racks of ware through

the dishmachine. If needed to be replaced, these instructions will

show you how to get your machine up and running in the shortest

possible time.

Jackson offers all of the repair parts necessary for performing this task.

The instructions provided here are for maintenance personnel only. Unauthorized persons should not attempt any of the

steps contained in these instructions.

Warning: many of the instructions and steps within

this document require the use of tools. Only authorized per sonnel should ever perform any maintenance procedure on

the dishmachine!

PREPARATION

1. Power must be turned off to the unit at the service

breaker. Tag or lock out the service breaker to prevent accidental

or unauthorized energizing of the machine.

TOOLS REQUIRED

The following tools will be needed to perform this mainte-

nance evolution:

1. 7/16” socket and ratchet with extension

2. 9/16” socket and ratchet with extension

3. 7/16” combination wrench

4. 9/16” combination wrench

5. 3/4” combination wrench

6. 1/8” Allen wrench

7. 1/4” nutdriver

8. Large flathead screwdriver

9. Medium phillipshead screwdriver

10. Medium hammer

11. Rubber mallet

STEPS

in place.

Removing the screws from the top cover.

2. Remove the top cover to expose the drive assembly.

TIME REQUIRED

It is estimated that it will take (1) person one and a quarter hours to replace the drive motor, one and a quarter hours to just

replace the gear reducer or two hours to do both at one time, not

including all of the items indicated in the section entitled “PREPA RATION”.

IMPORTANT NOTES

1. Read these instructions thoroughly before attempting

this maintenance procedure. Become familiar with the parts and

what actions need to be taken. This will save time in the long run!

2. The procedures demonstrated in this manual are

shown being performed on an AJ-44 rack conveyor dishmachine.

The actual maintenance steps, however, apply to any drive motor

or gear reducer found on a Jackson rack conveyor dishmachine.

Removing the top cover.

Jackson Technical Service for help.

2

Rack Conveyor Drive Motor and Gear Reducer Replacement Instructions

Revision A (07/05/2005)

Page 3

6. Once the bolts are removed, the motor should slide out of the

gear reducer. Remember to support and lay it gently on the floor or

some other surface in order to continue working on it. Be sure that

you get the key, checking the keyway on the motor shaft and in the

7. If the purpose of this maintenance action is to replace the drive

motor, continue to step 8. If you wish to replace the gear reducer,

8. With the motor laying on a level surface, you need to remove the

conduit from it. First, use the 1/4” nutdriver to remove the wiring

9. Once the cover is removed and the wiring is exposed, you may

want jot down how your motor is wired. You can also refer to the

schematic located on the motor itself because how the motor is

wired when you remove it is how you will wire it when you replace

it. If you have any questions regarding the wiring of your motor, do

10. pull the bundled wires out and remove the wire nuts. Set the

wire nuts to the side as you will need them when you wire up the

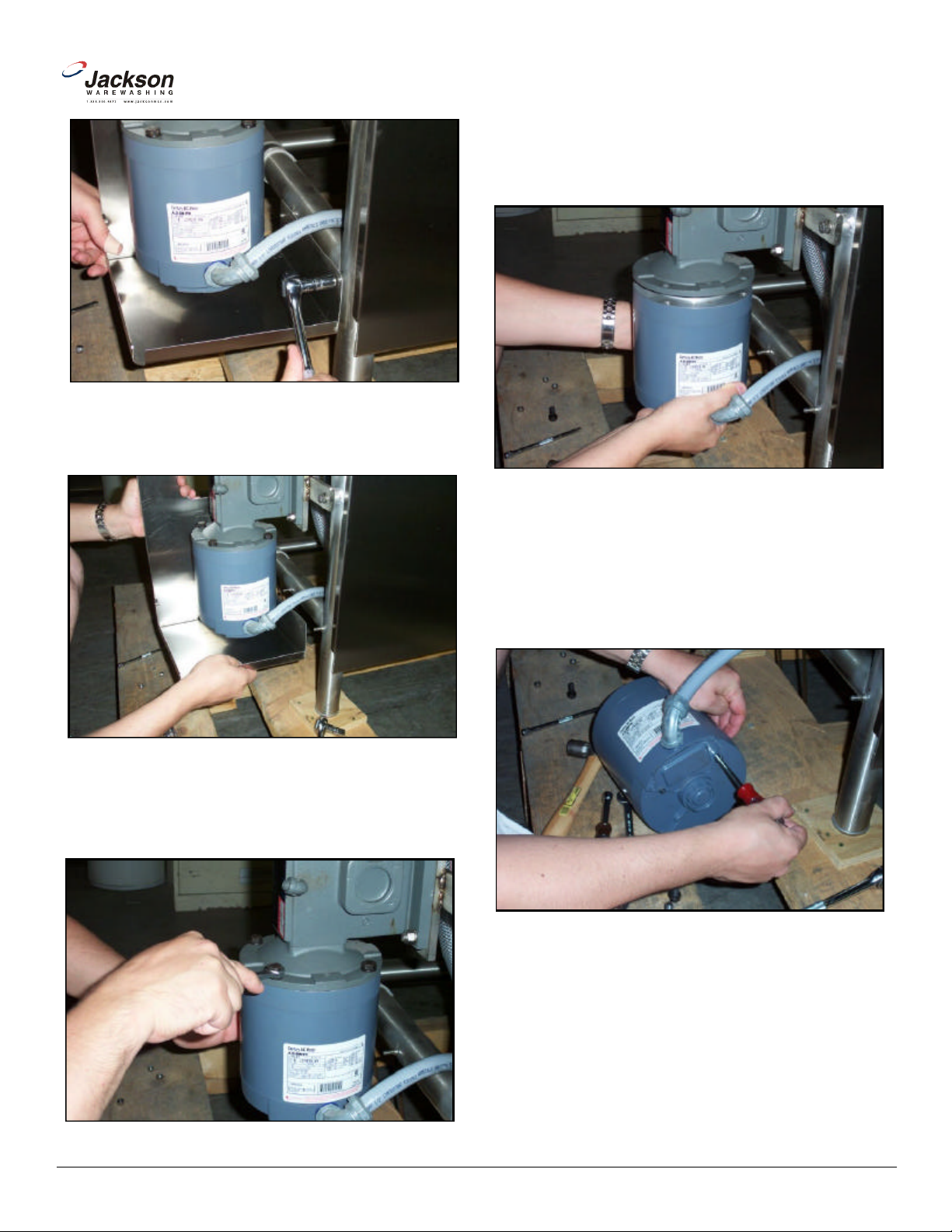

Removing the nuts securing the bottom cover.

4. Remove the bottom and set to the side so that it does not

become a trip hazard.

www.jacksonmsc.com

gear reducer.

Removing the drive motor.

Removing the bottom cover.

5. With the cover removed you may now remove the bolts used to

connect the drive motor to the gear reducer. Note: you need to

support the motor as you remove the bolts; failure to do so could

result in the motor falling to the ground and becoming damaged.

continue to step 21.

access cover on the back of the motor.

Removing the wiring access cover.

Removing the bolts holding the drive motor to the gear reducer.

Rack Conveyor Drive Motor and Gear Reducer Replacement Instructions

Revision A (07/05/2005)

not hesitate to contact Jackson Technical Service.

new motor.

3

Page 4

20. Proceed to the sections entitled “AFTER MAINTENANCE

21. (Continuing from step 7) To remove the gear reducer, first take

www.jacksonmsc.com

Removing the wire nuts.

11. Once the wire nuts are removed, separate the wires.

12. With the flathead screwdriver and the hammer, loosen the conduit nut. Once loosened, pull the conduit away from the motor. The

motor may now be disposed of.

13. Remove the access cover off of the new motor.

14. Attach the conduit and pull the wires through the hole provid ed. Tighten the conduit nut.

15. Using the wire nuts, wire the motor back the same way the old

one had been. Refer to the schematic on the motor itself or contact

Jackson Technical Service if you any questions.

16. Once the wiring is done, carefully push wires back into the

motor and put the access cover back on. Tighten down the screws

for securing it.

17. The drive motor now needs to be reattached to the gear reducer. There are two methods for doing this. The first is to try and and

reinsert the drive motor shaft into the gear reducer with it (gear

reducer) still attached to the unit. This is difficult but possible.

Ensure that the key is in the keyway when you mate the parts. The

second method and perhaps the easiest is to remove the gear

reducer, mate the two parts and bolt them together and then put

them on the unit at one time. This method takes a little more time.

If you wish to remove the gear reducer and assemble the two components continue on to step 27.

The WRONG way to mount the drive motor.

The Correct way to mount the drive motor.

19. Reattach the bottom and top drive assembly covers.

ACTIONS”.

the 3/4” combination wrench and remove the drive hub bolt.

18. Once the motor and gear reducer are mated, secure them with

the locknuts and bolts. Ensure the bolts are tight.

Note: Because of the way the covers for the drive assembly are

designed, it is imperative that you position the motor on the gear

reducer so that the conduit fitting is facing towards the front of the

dishmachine. If it is facing away from the machine, the covers may

not go back on.

Removing the drive hub bolt.

4

Rack Conveyor Drive Motor and Gear Reducer Replacement Instructions

Revision A (07/05/2005)

Page 5

22. Once the drive hub bolt & bearing are removed, loosen the set

25. Set the gear reducer on a flat surface. The drive hub needs

tobe removed. You have already loosened the set screw, but it may

take some more effort to remove it. You may have pry it off, or give

it some taps with a mallet to coax it off of the shaft. The liberal use

gear reducer. Ensure the key is in the keyway. Once it is on and

flush with the end of the shaft, tighten down on the set screw with

27. As you have both the drive motor and the gear reducer off of

the machine, it is much simpler to assemble them together prior to

mounting them. Ensuring that the key for the drive shaft of the drive

28. After the motor is mated against the gear reducer, turn the

motor so that the conduit fitting will face towards the front of the

dishmachine once both components are mounted to the frame.

This is to all the drive assembly covers to go back on. If you do not

do this, then there is a possibility the covers will not fit back on the

-

screw on the drive hub. There is no need to remove it.

Loosening the set screw with the 1/8 allen wrench.

www.jacksonmsc.com

of spray lubricants will also help.

23. Remove the gear drive by using the 9/16” socket and ratchet,

as well as the combination wrench as required, to remove the nuts

holding it to the mounting plate.

Removing the nuts holding the gear reducer on.

24. Gently remove the gear reducer, careful not to drop it.

Removing the drive hub.

26. Once the drive hub is removed, place it on the shaft of the new

the 1/8” allen wrench.

motor is in the keyway.

Removing the gear reducer.

Rack Conveyor Drive Motor and Gear Reducer Replacement Instructions

Revision A (07/05/2005)

Mounting the motor to the gear reducer.

unit. Refer to step 18 and the note following for more details.

29. Stand the assembly up and secure them using the lockwash

ers and bolts. Use the 9/16” combination wrench to tighten them

down.

5

Page 6

www.jacksonmsc.com

Reconnect the incoming water (if disconnected) and turn

-

utes, running an empty rack through the machine to ensure that it

is carried all of the way through. If you hear any grinding sounds

while the motor is running, immediately shut off the unit and secure

power and water. There is a serious problem that must be

addressed. If any problems arise you can contact Jackson

-

-

ning this or any other maintenance evolution on a unit under war

-

ranty, you should contact a certified Jackson technician or Jackson

Technical Service. You can find a list of qualified service agencies

Jackson MSC Inc. provides technical support for all of the

dishmachines detailed in this manual. We strongly recommend that

-

port staff. Please have this manual with you when you call so that

our staff can refer you, if necessary, to the proper page. Technical

support is available from 8:00 a.m. to 5:00 p.m. (EST), Monday

through Friday. Technical support is not available on holidays.

Contact technical support toll free at 1-888-800-5672. Please

remember that technical support is available for service personnel

Tightening the bolts to secure the drive motor to the gear reducer.

30. Once the motor is securely fastened to the gear reducer, carefully lift the assembly up and mount it on the fasteners. Be sure to

use proper lifting techniques to prevent injury.

AFTER MAINTENANCE ACTIONS

on. Then restore power to the unit. Run the unit for at least 10 min

Technical Service.

SPECIAL NOTES

Work performed on Jackson dishmachines by unautho

rized or unqualified personnel may void the warranty. Before begin

in the back of you unit’s installation manual.

SPECIAL PARTS

31. Once mounted, secure with the lockwashers and locknuts.

32. Reinstall the drive hub bearing and drive hub bolt, tightening

down with the 7/8” combination wrench.

33. Reattach the bottom and top assembly covers.

AJ-44/66/80 Machines:

Gear Reducer: 6105-011-71-88

Drive Motor Replacement Kit:

50 Hz: 6401-003-08-41

60Hz/1 Ph: 6401-003-08-42

60 Hz/3 Ph: 6401-003-08-40

600 V/60 Hz/3 Ph: 6401-003-08-43

AJ-54/76/90 Machines:

Gear Reducer: 6105-011-87-20

Drive Motor Replacement Kit:

50 Hz: 6401-003-08-41

60 Hz/1 Ph: 6401-003-08-42

60 Hz/3 Ph: 6401-003-08-40

600 V/60 Hz/3 Ph: 6401-003-08-43

AJ-64/86/100 Machines:

Gear Reducer: 6105-011-87-20

Drive Motor Replacement Kit:

50 Hz: 6401-003-08-41

60 hz/1 Ph: 6401-003-08-42

60 Hz/3 Ph: 6401-003-08-40

600 V/60 Hz/3 Ph: 6401-003-08-43

CONTACT INFORMATION

you refer to this manual before making a call to our technical sup

only.

6

Rack Conveyor Drive Motor and Gear Reducer Replacement Instructions

Revision A (07/05/2005)

Page 7

Drive Assembly (with Adjust-A-Peak)

www.jacksonmsc.com

Mounting Plate

Gear Reducer

Drive Hub Bearing & Bolt

Drive Motor

Rack Conveyor Drive Motor and Gear Reducer Replacement Instructions

Revision A (07/05/2005)

7

Loading...

Loading...