Page 1

目录 CONTENTS

工业缝纫机伺服控制系统用户手册 ......................................................................................... - 2 -

1. 产品规格(SPECIFCATIONS) ........................................................................................ - 2 -

2.机头安装方法(INSTALLATION OF MACHINE HEAD) ............................................ - 3 -

3.加油方法(LUBRICATION) .............................................................................................. - 3 -

4.机针安装方法 (ATTACHING THE NEEDLE) .............................................................. - 4 -

5.针杆罩的安装方法 (ATTACHING THE NEEDLE BAR GUARD) ............................. - 4 -

6.纽扣盘的安装方法(ATTACHING THE BUTTON TRAY ASSEMBLY) ................... - 4 -

7.上线穿线方法(THREADING THE MACHINE )........................................................... - 5 -

8.线张力(THREAD TENSION ADJUSTMENT) ............................................................. - 5 -

9.线调节杆的调整(ADJUSTMENT OF THE THREAD PULL -OFF LEVER) ............ - 6 -

10.针导向器的位置(POSITION OF THE NEEDLE GUIDE ) ........................................ - 6 -

11.机针和弯针的关系(NEEDLE -TO-LOOPER RELATION) ....................................... - 6 -

12.爪扣装置的高度(HEIGHT OF THE BUTTON CLAMP) ........................................... - 7 -

13. 拨针器的调整(ADJUSTMENT OF THE NIPPER ) ................................................... - 8 -

14. 压脚压力的调节(WORK PRESSING FORCE ) ........................................................ - 8 -

15. 压脚压力的调节(ADJUSTMENT OF THE BUTTON CLAMP STOP LEVER) ... - 8 -

16. 松线同步时间的调整(TIMING OF THREAD TENSION RELEASE) ................... - 9 -

17. 切线装置(AUTOMATIC THREAD TRIMMER) .................................................... - 10 -

18. 电控部分(ELECTRIC CONTROL PART) ............................................................. - 10 -

19.第1章 产品接口(CHAPTER 1 PRODUCT INTERFACE) .......................................... - 12 -

1. 1 接口插头连接(INTERSACE PLUG CONNETTION) ......................................... - 12 -

1.2 接线与接地(WIRING AND GROUNDING) ........................................................ - 13 -

20.第2 章 操作面板使用说明(CHAPTER 2 OPRATION PANEL INSTRUTIONS) .... - 13 -

2.1 操作面板的显示说明(THE OPRATION PANEL DISPLAY) ........................... - 13 -

2.2 操作面板各按键功能说明(OPRATION PANEL KEY-PRESS FUNCTION) . - 14 -

22.第3章 系统参数设置说明(SYSTEM PARAMETER SETUP INSTRUCTION) ........ - 16 -

3.1 技术员参数表(THE TECHNICIAN PARAMETER TABLE) ........................... - 16 -

3.2 系统员参数表(SYSTEM PARAMETER TABLE) ............................................ - 18 -

3.3 监控参数表(MONITORRING PARAMETER TABLE) .................................... - 18 -

3.4 故障代码表(THE FAULT CODE TABLE) ......................................................... - 19 -

23.第4章 特殊功能操作说明(SPECIAL FUNCTION INSTRUCTION) ......................... - 22 -

4.1 上停针位调整(THE NEEDLE ON AN ADJUSTMENT) ................................... - 22 -

4.2 一键恢复机头厂家参数值(A KEY PARAMETER VALUES) ........................... - 22 -

4.3 自动测试(AUTOMATIAC TEST ) ...................................................................... - 23 -

24.零件样本(THE SAMPLE PARTS) .................................................................................. - 25 -

- 1 -

Page 2

工业缝纫机伺服控制系统用户手册

前言

使用前请详细阅读本用户手册及所搭配的缝制设备说明书,配

!

注意

安全说明

· 在使用本产品之前,请先阅读《产品说明书》及所搭配的缝纫机机械说明书。

· 本产品必须由接受过专业培训的人员来安装或操作。

· 请尽量远离电弧焊接设备,以免产生的电磁波干扰本控制器而发生误动作。

· 请不要在室温45°以上或者0°以下的场所使用。

· 请不要在湿度30%以下或者95%以上或者有露水和酸雾的场所使用。

· 安装控制箱及其他部件时,请先关闭电源并拔掉电源插头。

· 为防止干扰或漏电事故,请做好接地工程,电源线的接地线必须以牢固的方式与大地有效连

接。

· 所有维修用的零部件,须由本公司提供或认可,方可使用。

· 在进行任何保养维修动作前,必须关闭电源并拔掉电源插头。控制箱里有高压危险,必须关闭

电源五分钟后方可打开控制箱。

合正确使用,并须由接受过专业培训的人员来安装或操作。

· 本手册中标有

符号之处为安全注意点,必须注意并严格遵守,以免造成不必要的损害。

1. 产品规格(SPECIFCATIONS)

控制器型号 AHE59

电源电压 AC 220±20% V

输出功率 550W

电机低速最大转矩 3Nm

电源频率 50HZ/60HZ

电机最大转速(r/min) 最高1500(常用1300~1400)

针数 8针、16针、32针(更改凸轮后可6、12、24针)

送布量 横向送布2.5~6.5mm 纵向送布0、2.5~6.5mm

纽扣尺寸 10~28mm

机针 TQ×1#16(#14~#18) TQ×7#16(#14~#20)

机油 NO.1新机油

The controller model

The power supply voltage

The output power

Low-speed maximum power frequency motor

Power frequency

Sewing speed 最高1500(常用1300~1400)

Number of stitches 8针、16针、32针(更改凸轮后可6、12、24针)

Feed amount 横向送布2.5~6.5mm 纵向送布0、2.5~6.5mm

Button size 10~28mm

Needle

Lubricating oil NO.1新机油

AC 220±20% V

AHE59

550W

3Nm

50HZ/60HZ

TQ×1#16(#14~#18) TQ×7#16(#14~#20)

- 2 -

Page 3

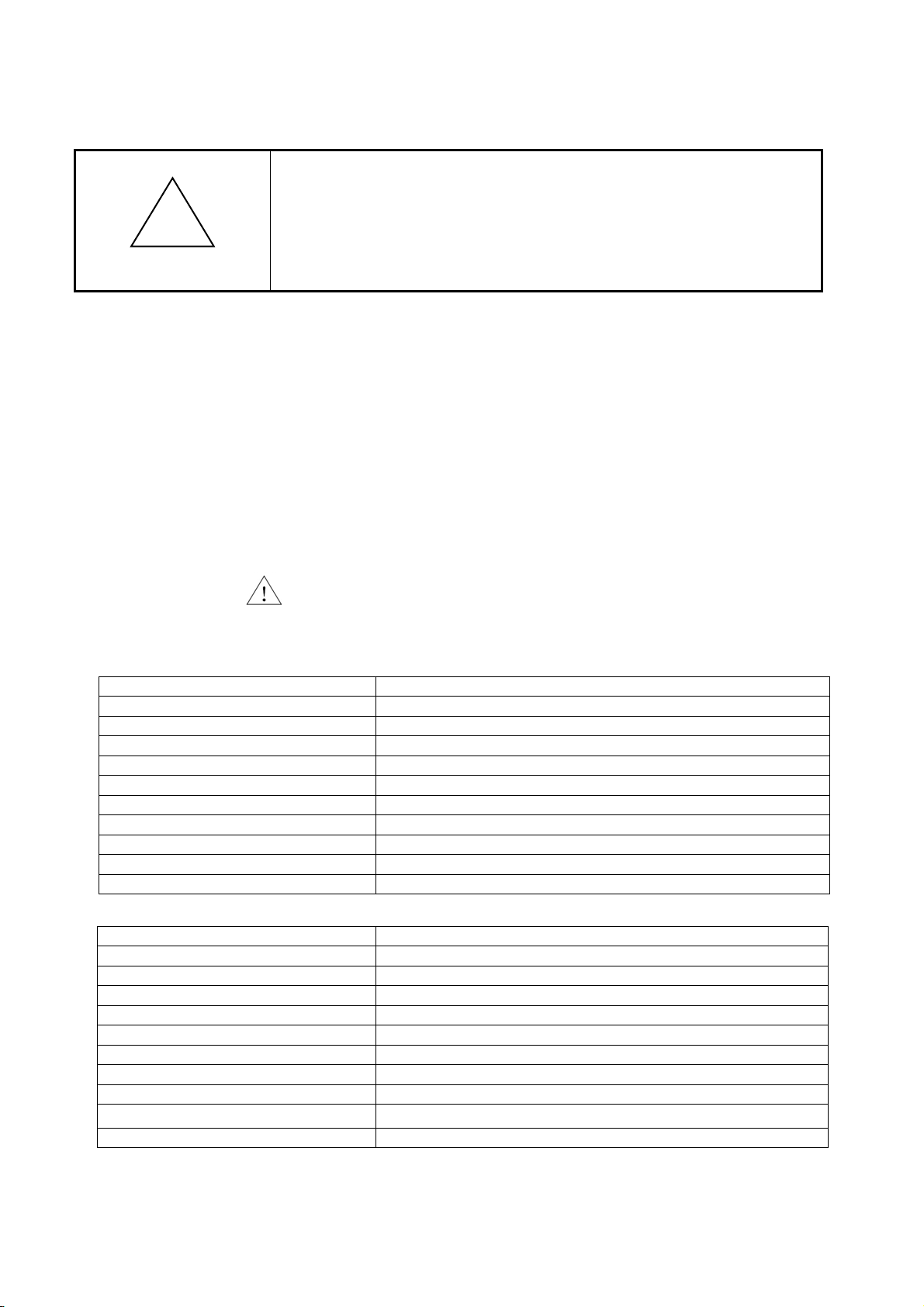

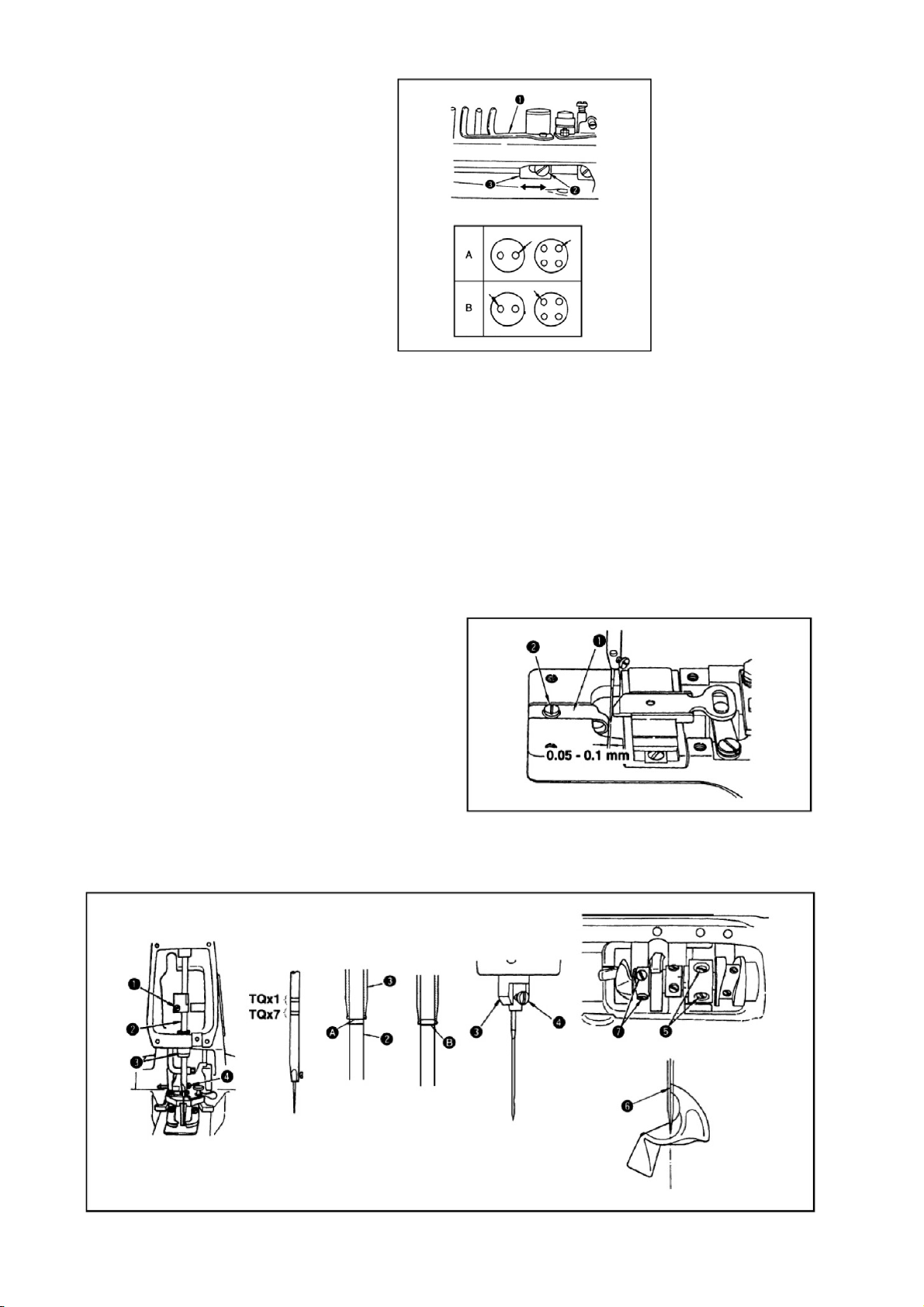

2.机头安装方法(INSTALLATION OF MACHINE HEAD)

脚踏

把防震橡胶垫放到台板上,然后把机头放在上面,用固定螺丝、垫片、螺母4固定好。

(Put rubber cushion on the table ,place the machine head on the rubber

cushion and fix it to the table using screws ,plain washersand nuts4.)

3.加油方法(LUBRICATION)

(1)把No.1新机油加入到所指的孔处。(每周1~2次)

(2)拧松安装螺钉,放倒缝纫机,把润滑脂加到螺旋齿轮和涡轮4上。

(3)每周检查一次机座安装台内的加油毛毡上面是否吸满油,不够时请加油。同时请往

曲轴部上也加油

(1)Apply New Dwfrix Oil No.1to the components shown by the arrows .

(once or twice a week)

(2)Loosen connecting screw ,tilt the head backward and apply some grease

to driving worm grease 4and gear .

( 3 ) Check , approximately once a week ,that oil amount is sufficient to

reach the top of the oil felt placed inside the bed mounting base .If the

amount of oil is insufficient, add an adequate amount of oil,At the time ,

also apply oil to crank rod.

- 3 -

Page 4

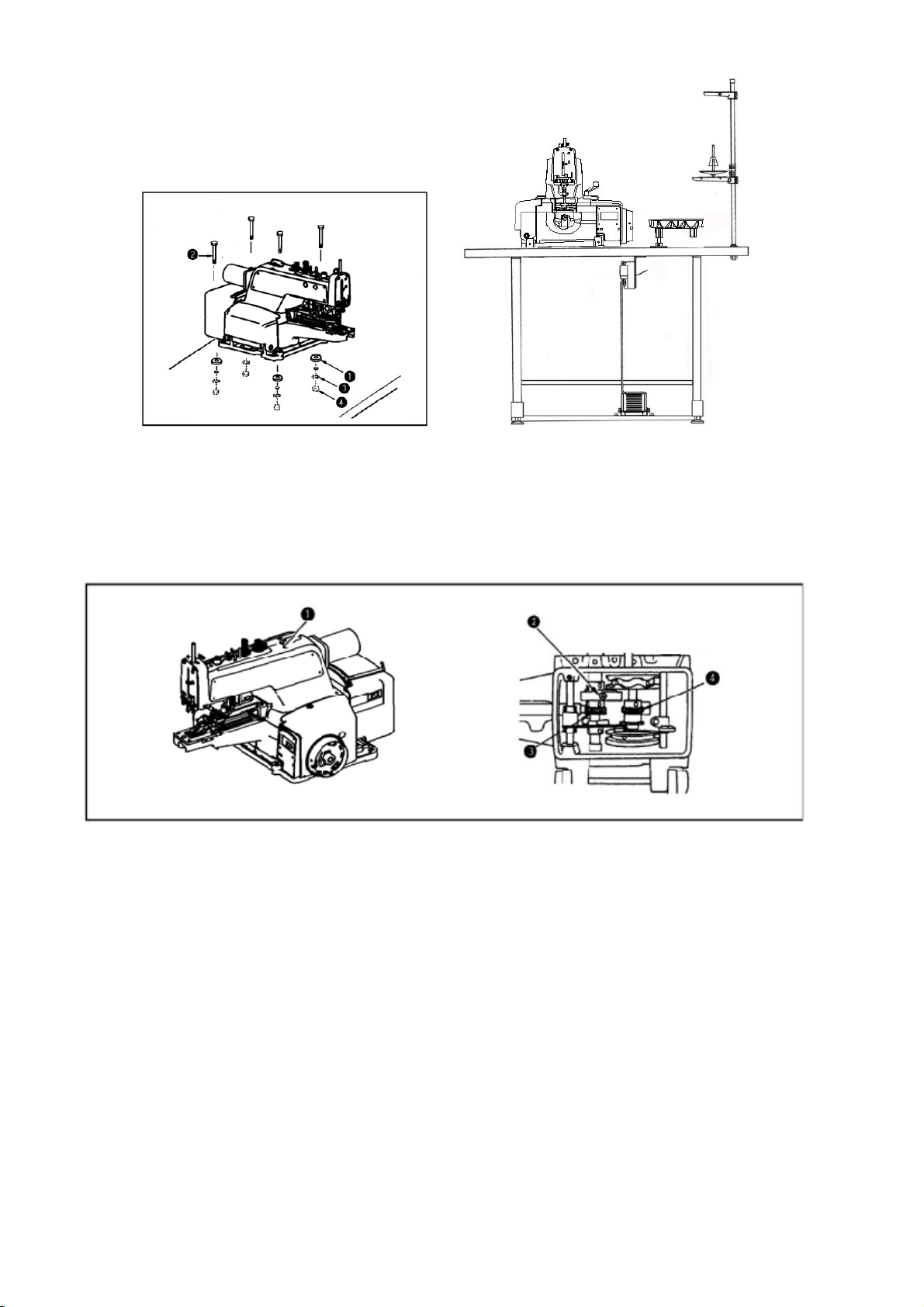

4.机针安装方法 (ATTACHING THE NEEDLE)

★标准机针为使用TQ×7#14

(1)拧松机针固定螺钉,手拿机针把机

针长沟转到面前。

(2)把机针插进针杆孔的深处。

(3)拧紧机针固定螺丝。

★Use a standard needle ofTQ×7#14

(1)Loosen sarew .

(2)Insert needle up into the

needle hole in the needle bar until

it comes in contact with the deepest

end of the needle hole.

5.针杆罩的安装方法 (ATTACHING THE NEEDLE BAR GUARD)

(1)拧松固定螺丝,并把它卸下。

(2)把针杆罩 安装到第二道线器的下

面。

(3)用固定螺丝固定起来。

(1)loosen screwand remone the

thread guide No.2.

(2)Place needle bar guard under

the thread guide No.2.

(3)Fix the thread guideNo.2 and

needle bar guard together using

screw.

6.纽扣盘的安装方法(ATTACHING THE BUTTON TRAY ASSEMBLY)

把纽扣盘插进机座前部的孔上,并把固

定螺丝拧紧固定。

Insert the posts of button tray

in the hole on the right of the

machine sub-base and tighten each

setscrew.

- 4 -

Page 5

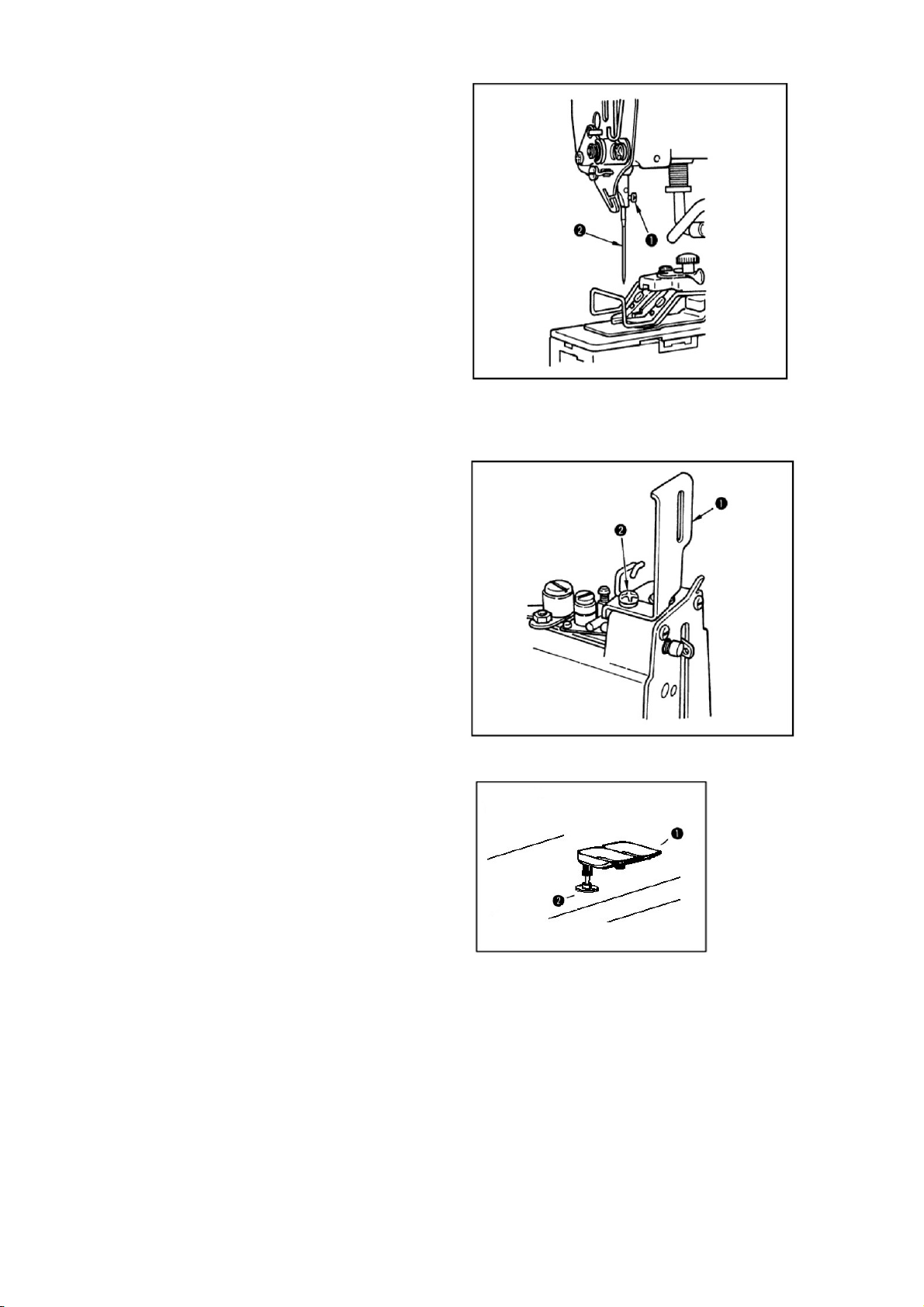

7.上线穿线方法(THREADING THE MACHINE )

如图所示的顺序进行穿线,从针孔的前侧向后侧按松线螺母A,把线拉出约60~70mm左

右。(Thread the machine in order of to18 as illustrated and pass the thread

through the needle eye from the front for 60 to 70 mm as you depress nipper

releasing knurted thumb nut A)

8.线张力(THREAD TENSION ADJUSTMENT)

第一线张力螺母是调整钉扣强度用

的,仅能调节极小的张力。

第二线张力调整螺母是调整背面的

紧线程度的,其张力比第一线张力螺母

强,根据使用的机线、布料、纽扣厚度等

情况,进行调整。

向右转动各线张力螺母之后,线张力变

强,向左转动则张力变弱。

Tension post No.1 is used to adjust the thread tension to sew on the

button and a relatively low tension will be enough. Tension post No.2

is used to adjust the thread tension applied to the root of the button

sewing stitches.

This tension must be determined according to the type of thread ,fabric

and thickness of the button and must be higher than that of tension post

No.1.turn the tension nuts clockwise to increase or counterclockwise

to reduce the thread tension .

- 5 -

Page 6

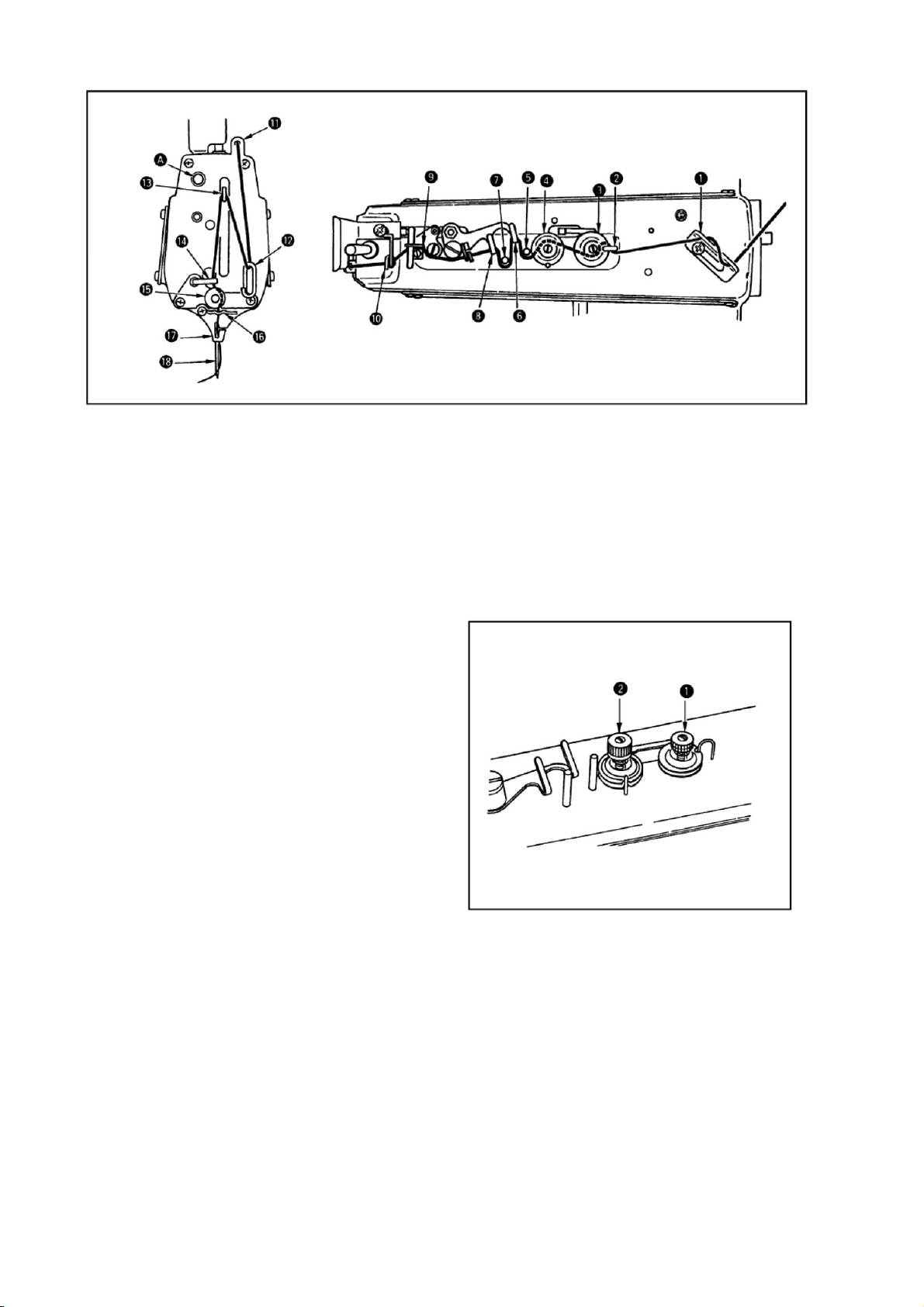

9.线调节杆的调整(ADJUSTMENT OF THE THREAD PULL -OFF LEVER)

调节线调节杆时时,请把螺

丝刀插进左侧面板上的孔中,拧松

固定螺丝,然后左右移动调节杆

的活动滑块 进行调整。缝制结

束,如果线头从A部前头的孔中露

出时,请把线调节杆活动滑块向

左移动,如果线头从B部箭头的孔

中露出时,请把滑块向右移动,不

让线头露出来。

To adjust the thread pull-off lever,insert a screwdriver through an opening

in the machine arm side cover (left),loosen screw and adjust the position

of nipper bar block (rear)to the left or the right . If the end of the

thread is drawn from arrow hole A in the button after sewing ,change the

position of nipper bar block (rear) to the left .Move the lever to the right

when the thread end comes out from arrow hole B .

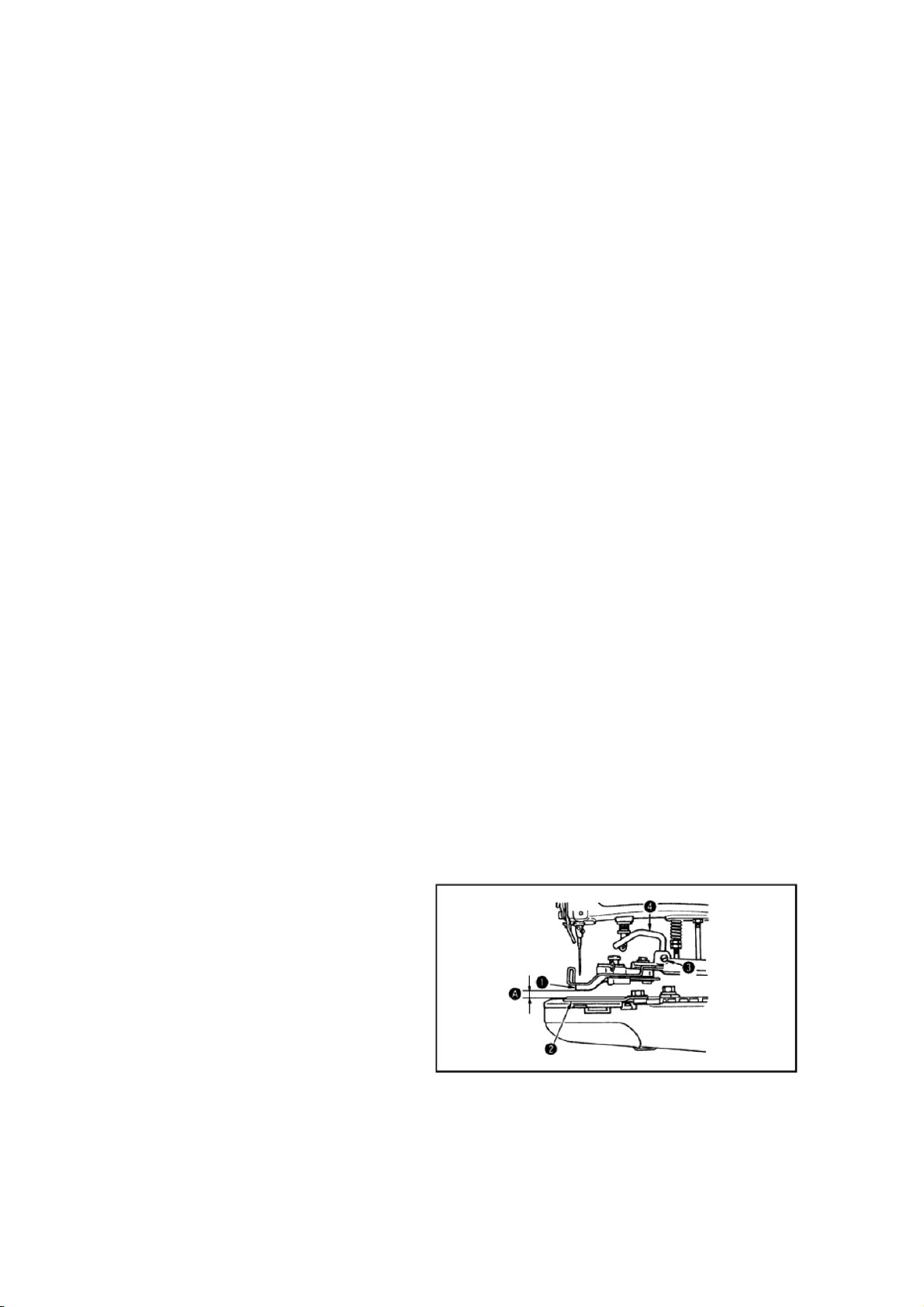

10.针导向器的位置(POSITION OF THE NEEDLE GUIDE )

在针杆最下点,拧松螺丝,左右移动针

导向器,把机针和针导向器的间隙调

整为0.05~0.1mm

Loosen screw and provide a 0.05 to

0.1mm clearance between the needle

guide and the needle by moving

the needle guide to the left or

the right when the needle is in the

lowest position .

11.机针和弯针的关系(NEEDLE -TO-LOOPER RELATION)

- 6 -

Page 7

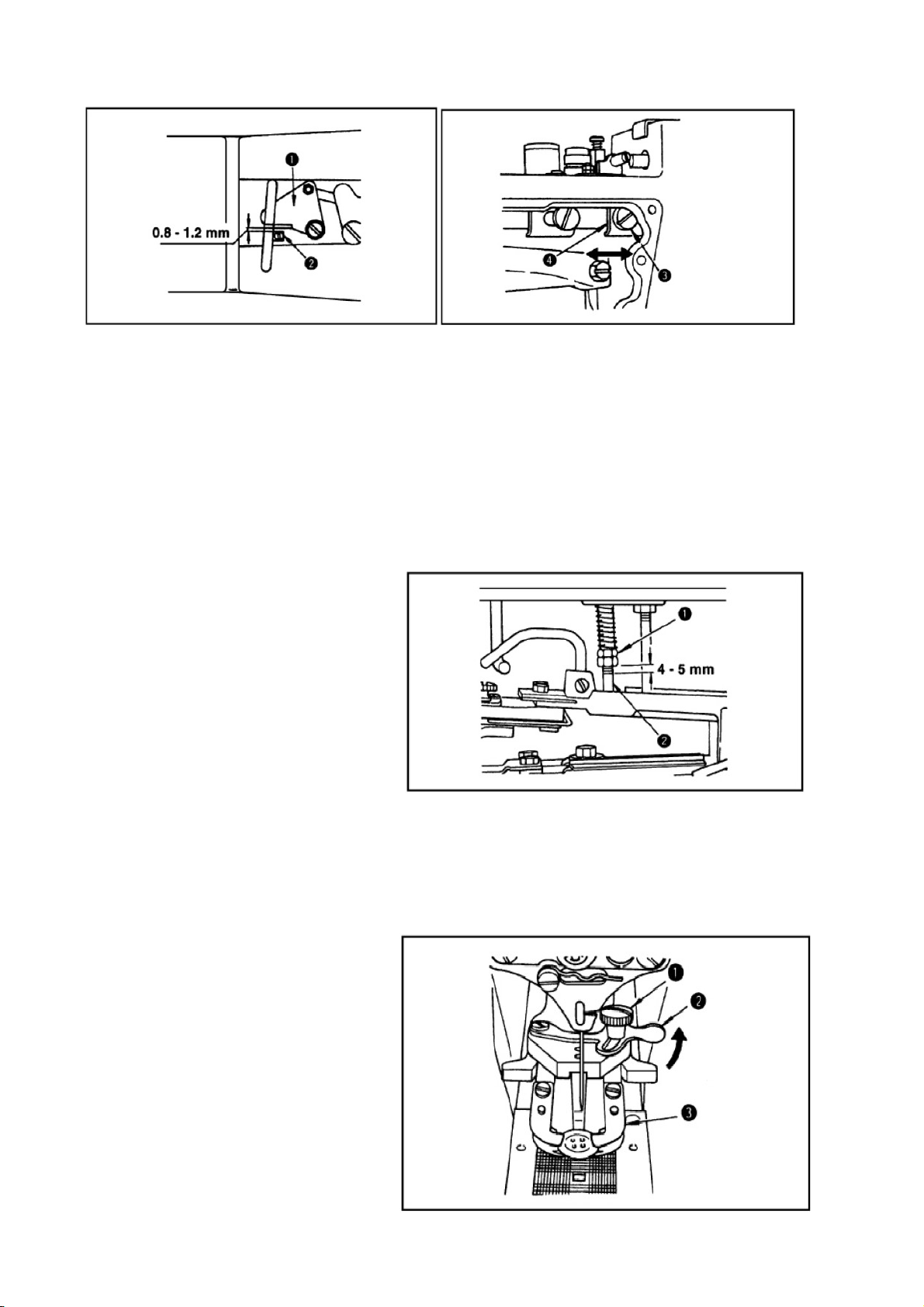

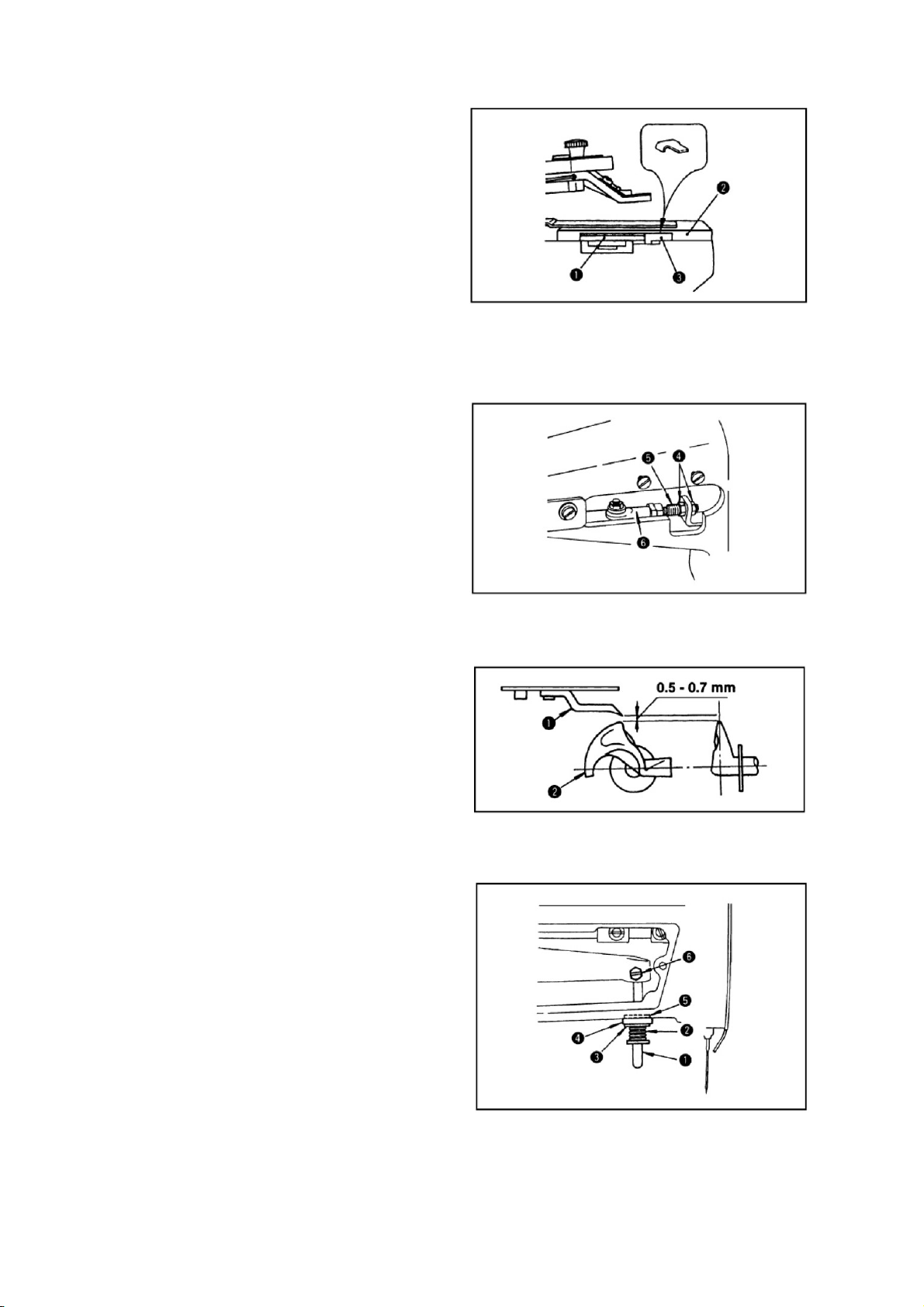

★机针和弯针按照如下方法进行调整

(1)按转动方向驱动手轮,让针杆落到最下点,然后拧松固定螺丝(决定针杆高度)

(2)TQx1机针时,使用上方的2条刻线,TQx7机针时,使用下方的2条刻线,把其中的上

刻线A对准针杆下端块的下端,然后拧紧固定螺丝。这时应让机针固定螺丝4进入到避

免与针杆下端块相碰的沟槽里。(决定弯针的位置)

(3)拧松固定螺丝5,转动手轮,把针杆的2条一组的刻线中的下刻线B对准针杆下端块

的下端。

(4)在此状态,把弯针的针尖6对准机针的中心,然后拧紧固定螺丝5.

(5)拧松固定螺丝7,把弯针间隙调整为0.01~0.1mm,在拧紧螺丝7.

★ Adjust the needle-to-looper relation as follows :

(1 )Depress the pedal fully forward ,turn the needle driving pulley in the

normal sewing direction to bring down the needle bar to the lowest point of

its stroke and loosen screw

(Adjusting the needle bar height )

(2)Adjust the height of the needle bar using top two lines engraved on the

needle bar for the TQx1 needle and using the bottom two lines for the TQx7

needle .Align the upper line A with the bottom end face of needle bar bushing

(lower) and tighten screw in the way that needle clamp screw 4 rests in

the slot of the needle bar bushing (lower )

(3) Looper screws 5 and turn by hand the needle driving pully until lower

line B of two lines aligns with the bottom end face of needle bar bushing

(lower)

(4) By keeping the machine in this state ,align looper blade 6 with the

center of the needle and tighten screws 5

(5) Loosen screws 7 and provide a 0.01to 0.1 mm clearance between the

looper and the needle .tighten screws7.

12.爪扣装置的高度(HEIGHT OF THE BUTTON CLAMP)

在断开位置,纽扣爪脚的地面和布

压脚下板上面的间隔A,1377E标准为

9mm。

The standard clearance A between the

bottom face of button clamp jaw lever

and the top face of feed plate is 9

mm for 1377E.Loosen screw and

adjust the height of button clamp

lfting hook4.

- 7 -

Page 8

13. 拨针器的调整(ADJUSTMENT OF THE NIPPER )

运转时,把拔针器的方块和拔的间隙调整为0.8~1.2mm ,不让拔针器压住机线。调

节方法是,拧松固定螺钉,左右移动拔针器活动滑块4。

Provide a 0.8 to 1.2 mm clearance between nipper and nipper block to

prevent the nipper from nipping the thread while stitching .Loosen screw

and move nipper bar block 4 to the left or the right .

14. 压脚压力的调节(WORK PRESSING FORCE )

压脚的压力,以在转动螺母2个螺

母的下端和压脚压力调节杆的螺

丝部间隙为4-5mm时为准。

The standard work pressing force is

obtained by providing a 4 to 5 mm

clearance between the bottom face

of nut and the bottom end of the

screw of pressure adjusting bar.

15. 压脚压力的调节(ADJUSTMENT OF THE BUTTON CLAMP STOP LEVER)

在断开状态,拧紧固定螺丝,用

爪脚打开拔杆开关打开爪脚 ,

把纽扣设定到正确的位置。让纽扣

容易放进取出,然后拧紧螺丝。

Set the machine for stop -motion

state ,loosen clamp screw place a

button correctly in the sewing

position and adjust button clamp

stop lever to permit the button

properly to rest on button clamp

jaw levers .tighten clamp screw

after determining the distance

between the left and right jaw

levers

- 8 -

Page 9

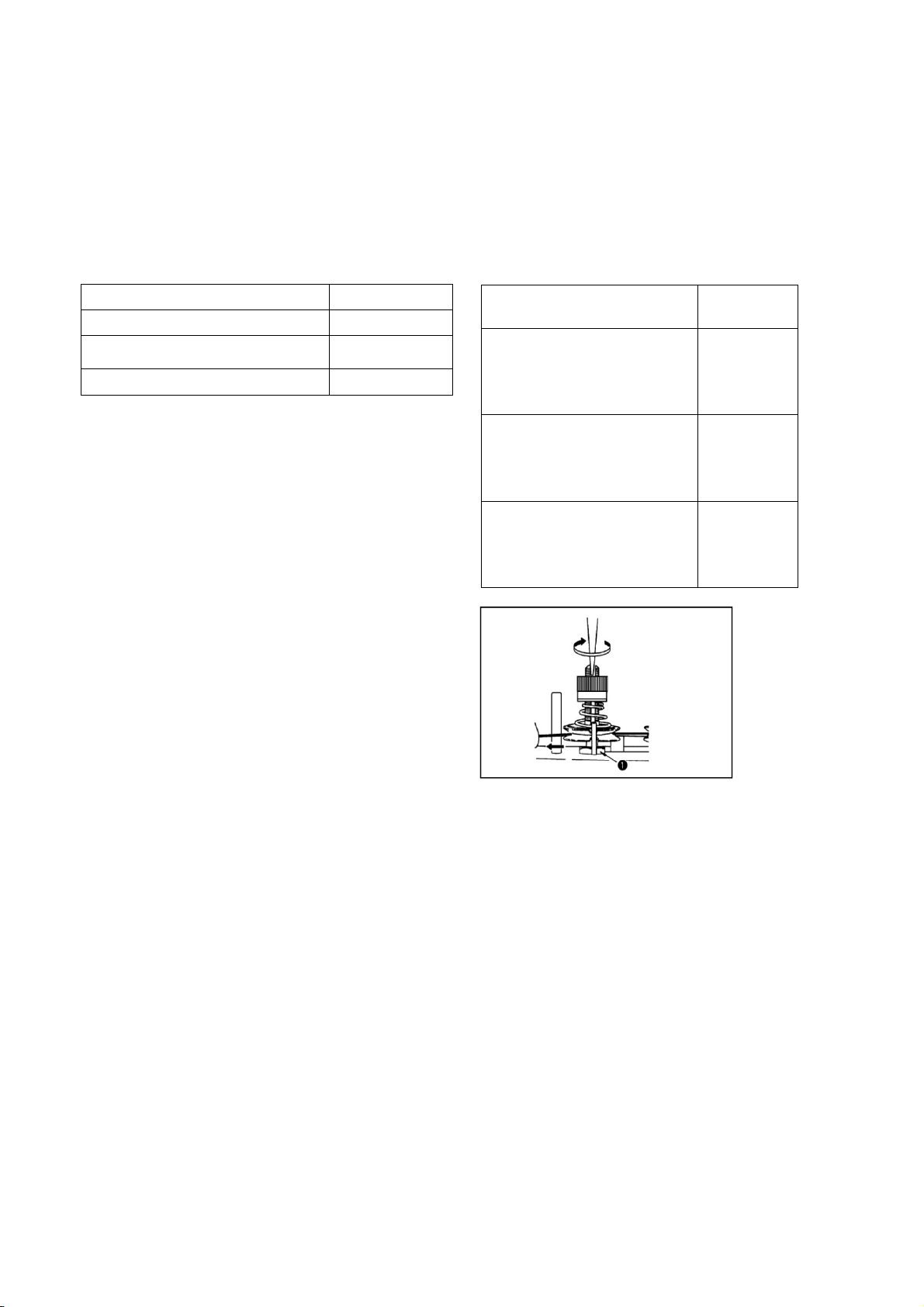

16. 松线同步时间的调整(TIMING OF THREAD TENSION RELEASE)

沿箭头方向拉机线,转动手轮,有一个第二线张力盘浮起,机线迅速拔出的点。此时,从

针杆上端块上面到针杆上面到 针杆上端的高度为T1377E使用53~56mm时为标准。

特别是频繁发生下列现象时,进行如下调节:

拧松螺母,把螺丝刀插入第二线张力杆,沿箭头方向转动的话,针杆高度变低,向相反

方向转动,则变高。

现象 针杆高度

1.布料里侧的紧线不好时 稍稍高一点

2.断开时,机针中途断线时 稍稍高一点

3.经常断线时 稍稍低一点

1.when the stitch made on

the wrong side of the

workpiece is too loose;

Turn the needle driving pully as you draw

the thread in the direction of the arrow as

illustrated abd you will find a piont at which

the tension disc on the tension post No.2

release the thread ,At this moment, the

standard distence from the top end of the

needle bar to the top of the needle bar

bushing is 53 to 56 mm for T1377E .Perfom

2.When the thread is

broken at the time of stop

-motion;

3.When the thread is

broken frequently

Phenomenon Height of

needle bar

Make the

needle bar

slightly

higher

Make the

needle bar

slightly

higher

Make the

needle bar

slightly

lower

the following adjustments especially when

the undermentioned troubles occur

frequently.

Loosen nut , insert the blade of a

screwdriver to the top slot of the tension post

No.2 and turn it in the direction of the arrow

to lower the needle bar ,(to reduce the said

distance ),and vice versa .Your adjustments

is required when following troubles are

freqently;

- 9 -

Page 10

17. 切线装置(AUTOMATIC THREAD TRIMMER)

★移动刀位置的调整

压脚上升到最高处时,切线连接板

(前)和针板槽沟面的间隔标准为

12.5mm。调整到12.5mm时,请使用附属

品的定位尺,放到缝纫机,卸下防油

板,拧松螺母4(2个),前后移动连接

螺丝5,进行调整。另外,拧紧螺母4

时,请注意切线连接头6应基本保持水

平。

★Position of the moving knife

When the machine stops in the state

of “stop -motion”and its button

clamp assembly rests in the highest

position ,there must be a standard

clearance of 12.5mm between thread

trimming connecting link (front)

and the end face of the slit in throat plate

.this clearance is determined by gauge 3

which is stored in the accessory box ;tilt the

head backwards ,remove the bed oil shield ,

Loosen two nuts 4 and adjust the clearance

by moving connecting screw 5in the axial

direction .When you tighten two nuts

4,ensure that joint 6stays in the horizontal

position .

★L型提升杆的安装方法

按移动反弹弹簧、分离垫片、分

离垫4、分离垫片5的顺序安装到L型提升

杆上。确定完全分离之后让机梁的凸部

和分离垫片端面紧密结合,不要有任何

松动,用螺丝6拧紧固定。

- 10 -

Page 11

(Electric control part)

电控部分

- 11 -

Page 12

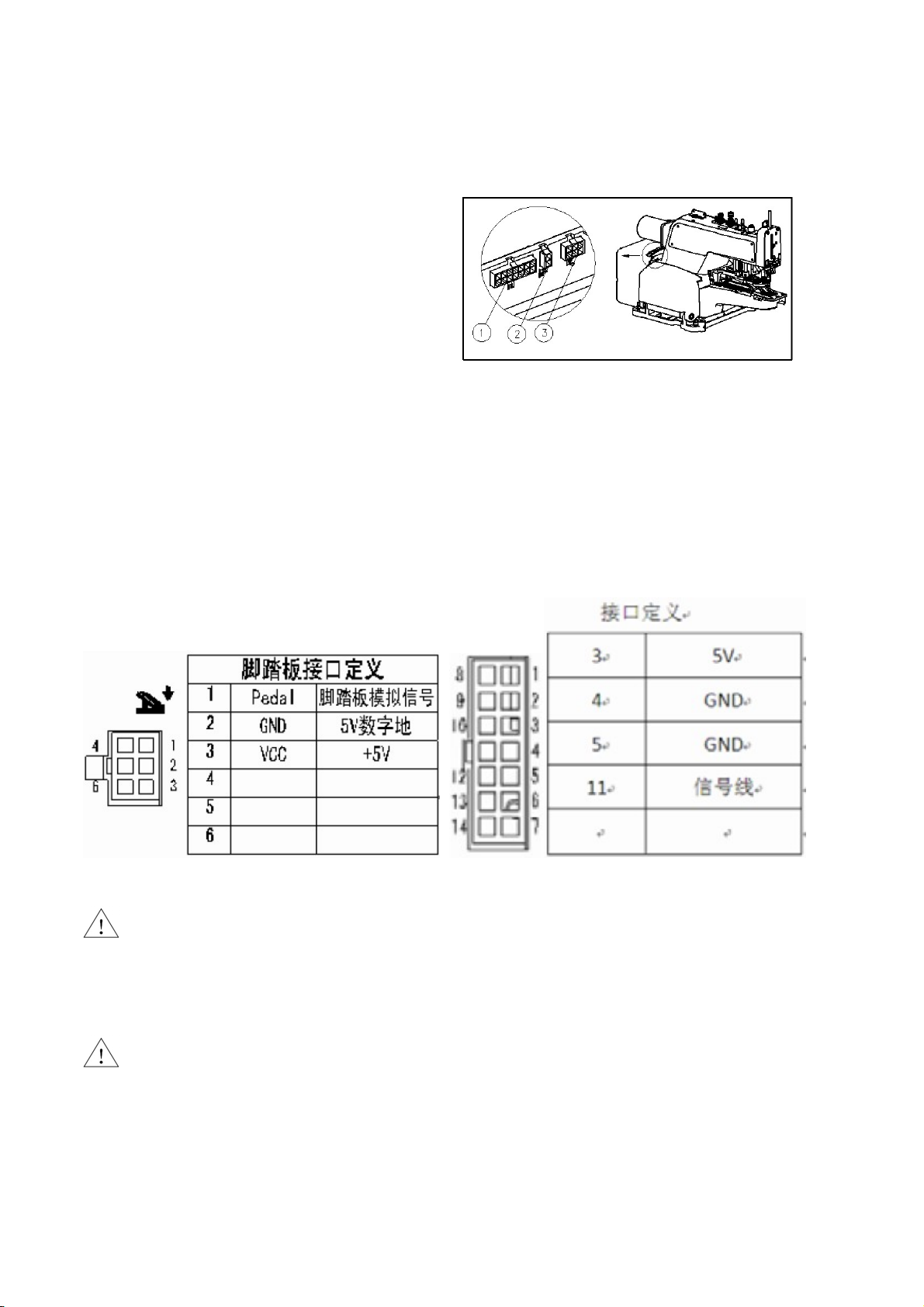

第1 章 产品接口

1. 1 接口插头连接

将脚踏板及机头的各连接插头安

插到控制器后面对应的插座上如图11 所示,各插座名称如图1-2 所示。

连接好,请检查插头是否插牢.

例图1-2 所示。连接好,请检

查插头是否插牢.LED灯和传感

器插座;②抬压脚电磁铁插

例图1-1 AHE 系列控制器图

座;脚踏板插座。

Connect the pedal and the nose of the plug placed behind the controller

corresponding to the socket as shown in figure 1-1, the name of the socket as

shown in figure 1-2. Connection is good, please check whether the plug is

stuck. Example shown in figure 1-2. Connection is good, please check whether

the plug is stuck. LED lights and sensors socket; (2) the presser foot

electromagnet socket; The pedals socket.

图1-2 控制器接口定义

:使用正常的力量插不进去时,请检查插头与插座是否匹配,插入方向

或针的方向是否正确!照明灯接口和传感器接口都是1*2 的接口,请注意区

分。

:When using normal power plug is not in, please check whether the plug and

socket match, the direction of the needle insertion direction or whether it

is right! Light interface and sensor interfaces are 1 * 2, please pay

attention to distinguish.

- 12 -

Page 13

1.2 接线与接地(Wiring and grounding )

必须要做好系统的接地工程,请合格的电气工程人员予以施工。产品通电

及投入使用前,必须确保电源插座AC 输入端已安全可靠的接地。系统的接地

线为黄绿线,该地线请务必可靠连接至电网安全保护接地上,以保证安全使

用,并可防止出现异常情况。

Must prepare system grounding engineering, please qualified electrical

engineering construction. Product power and put into use before, must ensure

that the power socket AC input is safe and reliable grounding. Grounding line

is yellow green line in the system, the ground please reliable connection to

the network security protection on the ground, to ensure the safe use, and

can prevent the abnormal situation.

:所有电源线、信号线、接地线等接线时不要被其它物体压到或过度扭

曲,以确保使用安全!

All power cables, signal lines, grounding line don't pressed to by other

objects such as wiring or excessive distortion, to ensure the safety of use!

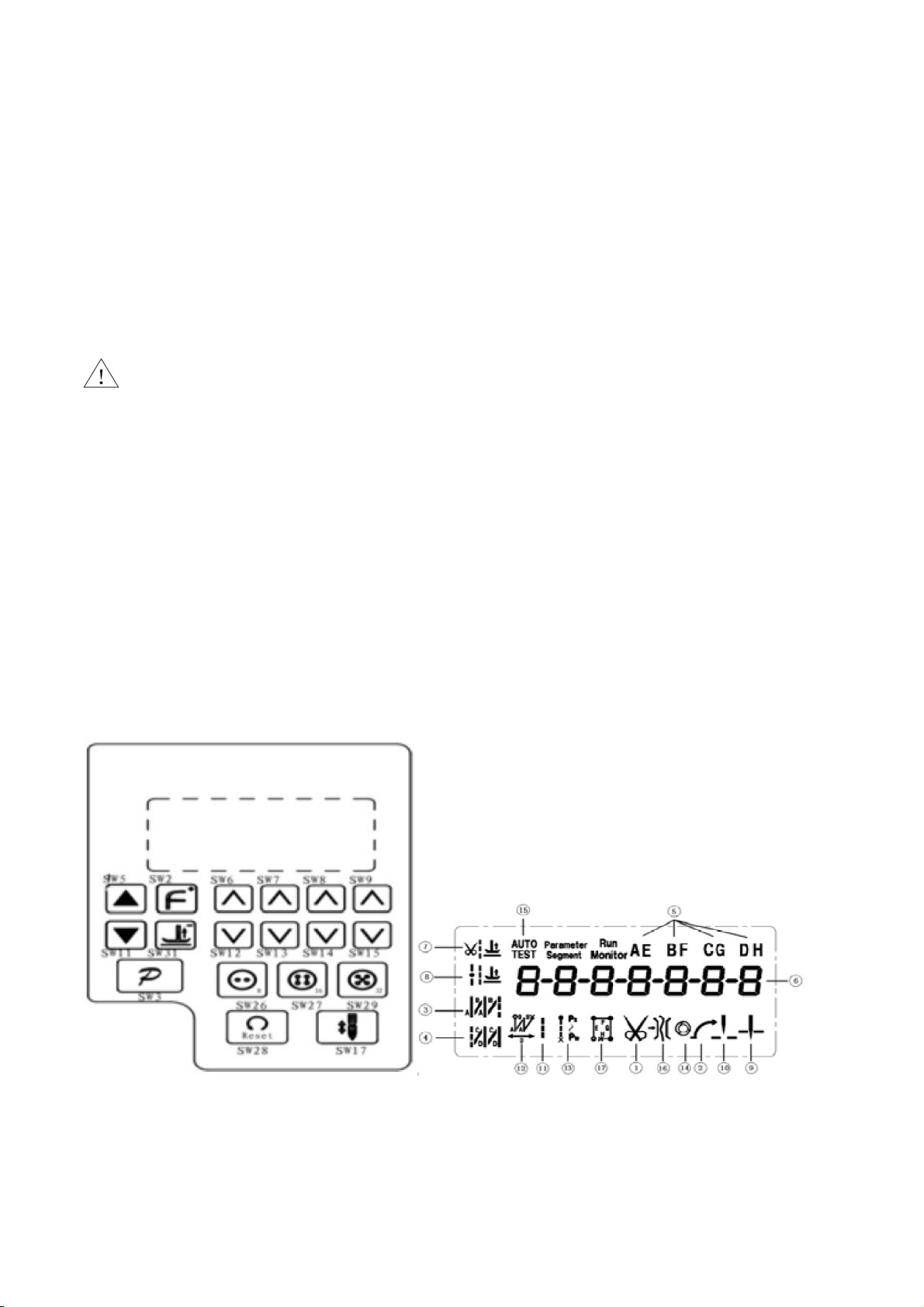

第 2 章 操作面板使用说明(Chapter 2 operation panel instructions )

2.1 操作面板的显示说明(The operation panel display)

根据系统工作状态,操作面板的液晶屏模块将显示当前的缝纫模式、各种参数、前/后

固缝设置,以及抬压脚、停针位、剪线、慢速起缝等液晶字符。H-12 操作面板液晶屏功

能图标显示说明如下所示。

Based on the system working

status,operation panel of the LCD panel

module will display the current sewing

patterns, all kinds of parameters,

before/after solid seam Settings, as well

as the presser foot, needle, thread, such

as slow up seam LCD characters. H - 12

operation panel LCD screen function icon

is displayed as shown below.

图2-1 H-12 操作面板外观界面 图2-2 H-12 操作面板液晶显示屏图示

- 13 -

Page 14

The index icon description

1

2

Soft start function 4

Count/parameter

values displayed

3

After trimming the

presser foot

2.2 操作面板各按键功能说明

The index icon description

Many pieces

5

6

Free seam

Automatic

test

- 14 -

Page 15

2.2 Operation panel each key-press function description

Theserial

number

1

2

3

4

appearance name Functional description

Confirm and

Return key

Key input parameters confirmed a key,

and backs up one level menu until the

sewing operator working condition. In

addition, but also with other key

press at the same time Implement

composite function, can enter advanced

parameters and feature set.

Press the key, LCD screen icon

bright, showed that the soft start,

Soft start

effective click the icon to go out

again, show closed soft start

function.

Presser

Foot Lift

Press the key, LCD screen icon is

displayed

, electromagnet presser

foot lift at the same time, press the

button again, the LCD panel icon shows

no .

8 pin key

Press the button, the system into 8

needles sewing patterns

5

16 pin key

Press the button, the system into 16

needles sewing patterns

6

32 pin key

Press the button, the system into 32

needles sewing patterns

7

Reset

button

Press the button, the system

automatically search for the origin

8

The speed

of increase

or decrease

in key

Long press can quickly adjust system.

Further into the parameters set

pattern, through and the P key

combination mode switch can be set on

a few parameters.

- 15 -

Page 16

第 3 章 系统参数设置说明

3.1 技术员参数表

参数编号 参数范围 典型值 参数描述 备注

100 100~800

101 200~5000 1500 自由缝最高速(全局最高限速)

102 200~5000

104

108 100~800

13A 0~800

13E

140 0/1 0

149 0~10 0

164

165 XXXX

200

~800

0~800

-

200

3000

200

400

300

5

起缝速度

多段缝最高速;自动测试速度

Reset 速度

慢速起缝速度

踏板抬压脚确认时间

压脚抬起延迟时间

上电自动找停车位:

0:不找;1:找

压脚缓放开关(0 关闭缓放,非0

为缓放开启)

密码

恢复出厂设置

速度

踏板参数

习惯设定

注:16X 参数操作须长时间按住 键大约3-5 秒。

- 16 -

Page 17

Chapter 3 system parameter setup instructions

3.1 The technician parameter table

1.Long press , can modify the technician parameter table;

2.Press the corresponding key and or and keys can choose

parameter number and change the corresponding parameter values;

3.Finally to press the key , exit parameters setting mode, back to the

sewing pattern.

The serial

number

range

Typical

values

Parameters to describe note

100 100~800 200 The sewing speed

101 200~5000 1500

102 200~5000 3000

The maximum speed limit on free

seam top speed (global)

Many pieces most high speed;

Automatic test speed

104 200~800 200 Reset speed

108 100~800 400 Sewing speed slow

13A 0~800 300 Pedal presser foot set the time Pedal

Presser foot lift the delay time

13E 0~800 5

Electricity automatically find a

140 0/1 0

parking space: 0: don't look for;

1: find a

Presser foot slowly let go off (0

149 0~10 0

closed slowly, non-zero for slow

opening)

164 - password

165 XXXX Restore the factory Settings

speed

speed

paramet

er

Used to

set

Note: 16 x parameter operation is to be a long time holding down the key

about 3 to 5 seconds.

- 17 -

Page 18

3.2 系统员参数表

参数编号 参数范围 典型值 参数描述

244 0~800

100

放压脚延迟时间(ms)

249 0~600 120 剪线后自动抬压脚抬起保持时间100ms

24A 0~60 7 8针设置

24B 0~60

15

16针设置

24C 0~60 31 32针设置

24D 0/1 1 针数切换时自动复位

24E

278

279

0/1 1

1~500

1~100

后踩踏板时是否停车,1为停车

150 抬压脚全出力时间

3 抬压脚chopping开通时间

27A 1~100 5 抬压脚chopping关闭时间

27B 1~600

10

抬压脚chopping关闭时间

3.2 System parameter table

1.Long hold keys to electricity, enter the technician 1xx parameter

table ;

2.And then press the key not to put at the same time, press the or

key, member can modify system parameter table 2xx;

3.Press the corresponding key number and change parameters, key

and key can modify;

4.Finally press the P button , that is, save and exit parameters setting

mode and return to normal sewing patterns.

Parameter number range values Parameters to describe

244 0~800 100

249 0~600

120

24A 0~60 7

24B 0~60 15

24C 0~60 31

24D

0/1 1

24E 0/1 1

278

1~500

279 1~100

27A

1~100

27B 1~600

150

3

5

10

Put the presser foot delay time (ms)

Presser foot lift the hold time 100 ms

8 needle set

8 needle set

8 needle set

Automatic reset pin number when switching

When the pedal is after parking, 1 for

parking

Presser foot all output time

Presser foot chopping opening time

Presser foot chopping closing time

Presser foot chopping closing time

3.3 监控参数表

- 18 -

Page 19

参数编号 参数描述 参数编号 参数描述 参数编号 参数描述

010 针数计数 022 相电流 027

011 记件数 023 初始角度 028

013 霍尔状态

024

机械角度 029 DSP软件版本号

电机累计运行

时间

机头交互量电

压采样值

020 母线电压 025 踏板电压采样值 030-037 历史故障代码

021 机头转速 026 机头传动比实际值

3.3 Monitoring parameter table

1.First press the keys , then press the key , can enter the monitor

model, parameters, 024 LCD screen display by default;

2.Press the key and the corresponding numbe or key or key

and key can select parameters, can real-time monitoring the corresponding

parameters;

3.Finally press the P button , that is, save and exit parameters setting

mode and return to normal sewing patterns.

Paramete

r number

Parameters

to describe

Parameter

number

Parameters to

describe

Parameter

number

Parameters

to

describe

010

011

Pin number

counting

022

Remember

the number 023

Phase current

027

The initial

point of 028

Total run

time

Voltage

sampling

values

013

Hall state

024

Mechanical

point of view 029

DSP

version

number

020

021

Bus voltage

The nose of

speed

025

026

Step voltage

sampling values

Ratio of the

actual value

030-037

Historical

fault code

3.4 故障代码表

若系统出现报错或报警,请首先检查如下项:

1、先确认机器的连接线是否连接完好;2、确认电控和机头是否匹配;3、确认恢复出厂

- 19 -

Page 20

是否准确。

故障代码 代码含义 解决措施

E r r - 0 1 硬件过流 关闭系统电源,30 秒后重新接通电源,控制器若仍不能正常工

E r r - 0 2 软件过流

E r r - 0 3 系统欠压 断开控制器电源,检查输入电源电压是否偏低(低于176V)。若

E r r - 0 4 停机时过压 断开控制器电源,检查输入电源电压是否偏高(高于264V)。若

E r r - 0 5 运行时过压

E r r - 0 6 电磁铁

回路故障

E r r - 0 7 电流检测

回路故障

E r r - 0 8 电机堵转 断开控制器电源,检查电机电源输入插头是否脱落、松动、破

E r r - 0 9 制动回路故障 关闭系统电源,检查电源板上白色的制动电阻接头是否松动或脱

E r r - 1 0 HMI 通讯故障 检查控制面板与控制器的连线是否脱落、松动、断裂,将其恢复

E r r - 1 1 机头停针

信号故障

E r r - 1 2 电机初始角度

检测故障

E r r - 1 3 电 机 HALL 故障 关闭系统电源,检查电机传感器接头是否松动或脱落,将其恢复

E r r - 1 4 DSP 读 写

EEPROM 故障

E r r - 1 5 电机超速保护

E r r - 1 6 电机反转

E r r - 1 7 HMI 读 写

EEPROM 故障

E r r - 1 8 电机过载

E r r - 2 3 电机堵转扇区

错误

作,请更换控制器并通知厂方

电源电压偏低,请在电压恢复正常后重新启动控制器。若电压恢

复正常后,启动控制器仍不能正常工作,请更换控制器并通知厂

方。

电源电压偏高,请在电压恢复正常后重新启动控制器。若电压恢

复正常后,启动控制器仍不能正常工作,请更换控制器并通知厂

方。

关闭系统电源,检查电磁铁连线是否正确,是否有松动、破损等

现象。若有则及时更换。确认无误后重启系统,若仍不能工作,

请更换控制器并通知厂方。

关闭系统电源,30 秒后重新接通电源观察是否能正常工作。重

试几次,若该故障频繁出现,请更换控制器并通知厂方。

损,是否有异物缠绕在机头上。排除后重启系统仍不能正常工

作,请更换控制器并通知厂方。

落,将其插紧后重启系统。若仍不能正常工作,请更换控制器并

通知厂方。

正常后重启系统。若仍不能正常工作,请更换控制器并通知厂

方。

检查机头同步信号装置与控制器的连线是否松动,将其恢复正常

后重启系统。若仍不能正常工作,请更换控制器并通知厂方。

请断电后再尝试2-3 次,若仍报故障,请更换控制器并通知厂方

。

正常后重启系统。若仍不能正常工作,请更换控制器并通知厂

方。

断开控制器电源,检查电机电源输入插头是否脱落、松动、破

损,是否有异物缠绕在机头上。排除后重启系统仍不能正常工

作,请更换控制器并通知厂方。

3.4 The fault code tableIf the system error or alarm, please first check the

following items:1、Make sure the machine problem is in good contact;2、

Confirm that electrical control and the nose match; 3、Confirm back the

factory are accurate.

- 20 -

Page 21

Fault code Code meaning The measures

E r r - 0 1 Hardware flow Shut down the system power supply, 30 seconds to

E r r - 0 2 Software flow

connect the power supply, controller, if still doesn't

work, please replace the controller and notify the

manufacturer

E r r - 0 3 The system

under voltage

Disconnect the controller power supply, check whether

the input power supply voltage is low (less than 176

v). If the supply voltage is low, after the voltage is

back to normal, please restart the controller. If the

voltage is back to normal after starting controller

still does not work, please replace the controller and

notify the manufacturer

E r r - 0 4 When stop

overvoltage

E r r - 0 5 The runtime

overvoltage

Disconnect the controller power supply, check whether

the input power supply voltage is too high (above 264

v). If the supply voltage is on the high side, after

the voltage is back to normal, please restart the

controller. If the voltage is back to normal after

starting controller still does not work, please

replace the controller and notify the manufacturer.

E r r - 0 6

electromagnet

Shut down the system power supply, check that the

magnet wire is correct, whether there is loose and

Circuit fault

broken. If there is change in time. After restart the

system, if still cannot work, please replace the

controller and notify the manufacturer.

E r r - 0 7 Current

detection

Circuit fault

Shut down the system power supply, 30 seconds to see

if turning on the power supply can work normally. Try

again a few times, if the fault occur frequently,

please replace the controller and notify the

manufacturer.

E r r - 0 8 Motor blocked Disconnect the controller power supply, check whether

the motor power input plug fall off, looseness,

breakage, whether there is foreign body coil on the

nose. Rule out after restart the system still does not

work, please replace the controller and notify the

manufacturer.

E r r - 0 9 Braking circuit

fault

Shut down the system power supply, check whether joint

on white braking resistor power panel loose or fall

off, insert the tight after restart the system. If it

still doesn't work, please replace the controller and

notify the manufacturer.

E r r - 1 0 HMI

communication

failures

Check the connection to the control panel and the

controller whether fracture, fall off, loose, it

returned to normal after restart the system. If it

still doesn't work, please replace the controller and

notify the manufacturer.

E r r - 1 1 The nose needle

Signal failure

Check whether the nose synchronous signal device and

the connection to the controller is loose, it returned

to normal after restart the system. If it still

doesn't work, please replace the controller and notify

the manufacturer.

E r r - 1 2 Motor fault

initial Angle

measure

E r r - 1 3 Motor HALL

fault

- 21 -

Please try again when the power is 2-3 times, if still

at fault, please replace the controller and notify the

manufacturer

Shut down the system power supply, check that the

motor sensor connector is loose or fall off, it

Page 22

E r r - 1 4 DSP block read

and write

EEPROM failure

E r r - 1 5 Electrical

overspeed

protection

E r r - 1 6 Motor reversal

E r r - 1 7 HMI block read

and write

EEPROM failure

E r r - 1 8 Motor overload

E r r - 2 3 Motor locked-

rotor sector

errors

returned to normal after restart the system. If it

still doesn't work, please replace the controller and

notify the manufacturer.

Disconnect the controller power supply, check whether

the motor power input plug fall off, looseness,

breakage, whether there is foreign body coil on the

nose. Rule out after restart the system still does not

work, please replace the controller and notify the

manufacturer.

第4 章 特殊功能操作说明

4.1 上停针位调整

1

2

3

控制系统在恢复出厂后,可根据需要重新设置

上针位!

第一步:先按下 键不放,再按下

键,即进入监控模式,默认为024 号监控参

数,液晶屏显示当前角度,如为0°表明此位

置为系统当前默认的上停针位置。

第二步:转动手轮,让挑线杆到上停针位置或

希望调整到的合适位置,此时液晶屏显示调整

后的上停针位,如124.

第三步:长按 待出现“----”后放开,等

出现“8888”后保存成功。

Chapter 4 special function instructions

4.1 The needle on an adjustment

Control system after the restore factory,

can according to the need to reset the

1

- 22 -

needle!First step: the first press the

key , press the key again, namely

Page 23

2

3

4.2 一键恢复机头厂家参数值

into monitor mode, the default value is no.

024 monitoring parameters of liquid crystal

screen display the current point of view,

such as 0 ° show that the location of the

needle on the system of the current default

location.

Step 2: turn the handwheel, let the take-up

on the needle position or want to adjust to

the appropriate location, the LCD shows the

adjusted on the needle position, such as

124.

Step 3: long press to appear after the "-"

let go, such as a "8888" after successfully

saved.

如果希望恢复机头厂家的出厂参数,可按照

如下步骤:第一步:先按下 键不放,再按

1

下 键,即进入监控模式,默认为024 号监

控参数。

第二步:长按 键3 秒钟以上,开始一键恢

复机头厂家参数,液晶屏显示横杠,表明正

2

在恢复参数,此时控制器切勿断电或拔出操

作面板插头。

待数码管显示8,表明机头厂家恢复参数完成

3

4.3 自动测试

自动测试:同时按 键和 号键两次后,LCD 显示闪烁的 ,点踩踏板即可实现自

动测试;同时按 键和 号键,退出自动测试。

4.2 A key to restore the nose manufacturer parameter values

If you want to restore the nose manufacturer factory

parameters, can according to the following steps:

1

- 23 -

first step: first press the button

the key

value is no. 024 monitoring parameters.

, namely into monitor mode, the default

, then press

Page 24

2

3

Step 2: long press more than 3 seconds, start a

recovery head manufacturer parameters, LCD shows

rung, that recovering parameters, the controller do

not power or pull out plug operation panel.

For eight digital tube display, which indicates that

the nose manufacturer parameters to complete

recovery

4.3 Automatic test: at the same time according to the and keys after

twice, LCD display flashing , points pedal can realize automatic test;

According to and keys at the same time, out of automatic test.

- 24 -

Page 25

零件样本

(Parts Book)

- 25 -

Page 26

- 26 -

Page 27

1、纽钳机构部件/

Button clamp mechanism components

序号 零件件号 名称 数量 DESCRIPTION

1 ----- 抬压脚组件 1 PICK-UP DEVICE ASM.

2 40902001 钮针提升杆 1 BUTTON CLAMP LIFTING HOOK

3 402S14006 螺钉 1 SCREW 15/64-28 L=9

4 409S12001 螺钉 2 SCREW 3/16-32 L=13.5

5 40928001 垫圈 2 WASHER 5×10.5×1

6 300145 钮钳座 1 BUTTON CLAMP HOULDER

7 409S11002 螺钉 1 SCREW 9/64-40 L=3.5

8 4091200100 纽钳杆座组件 1 HINGE SCREW D=5.5 H=3

9 40912002 钮夹控制座 1 JAW LEVER HOLDER

10 409S20002 轴位螺钉 1 HINGE SCREW D=5.5 H=1.8

11 409S20003 钮夹螺钉 1 CLAMP SCREW A

12 40912003 钮夹止动杆 1 SNAP FASTENER CLAMP STOP LEVER

13 409S16001 螺母 1 NUT

14 40901003 钮夹滑块 1 BUTTON CLAMP SLIDE

15 409S20004 钮夹止动销 2 BUTTON CLAMP STOP PIN

16 40912005 左钮夹钳夹 1 BUTTON CLAMP LEVER JAW(LEFT)

17 40912006 钮扣左弹簧压板 1 BUTTON HOLDING SPRING LEFT

18 409S20005 轴位螺钉 2 HINGE SCREW D=6.35 H=3.9

19 409S11002 螺钉 1 SCREW 9/64-40 L=3.5

20 40927001 钮夹弹簧 1 BUTTON CLAMP SPRING

21 40912008 右钮夹钳夹 1 BUTTON CLAMP LEVER JAW RIGHT

22 40912009 钮夹右弹簧压板 1 BUTTON HOLDING SPRING RIGHT

23 402S14006 螺钉 1 SCREW 15/64-28 L=9

24 409S30002 钮钳调压杆 1 BUTTON CLAMP PRESSUER ADJUSTIN

25 40927002 钮夹压力弹簧 1 PRESSUER ADJUSTING SPRING

26 409S16003 螺母 2 NUT M6

27 40927003 手指保护架 1 FINGER GUARD

28 30128010 垫圈 2 WASHER

29 40902002 合叶销 1 HINGE PIN

30 H05002 卡簧 2 SNAP PIN

31 401S16002 螺母 2 NUT M6

32 409S30001 钮钳塞销 1

33 402S11007 螺钉 2 SCREW 11/64-40 L=3.5

34 413S14004 螺钉 2 SCREW M3

PICK-UP DEVICE STOPPER PIN

- 27 -

Page 28

- 28 -

Page 29

2、机壳部件/

Arm & miscellaneous cover components

序号 零件件号 名称 数量 DESCRIPTION

1 4091206200 面板盖组件 1 FACE PLATE COMPL

406S11009

2

40927004

3

40902003

4

409S11004

5

40913002

6

7 4091301400 3号线张力器组件 1 THREAD TENSION NO.3 ASM.

8 40913015 3号线张力调节座 1 TENSION ADJUSTING BASE NO.3

9 40913016 线张力盘 1 THREAD PRESSER PLATE

10 40927020 弹簧 1 TENSION SPRING B

11 409S30017 线张力器螺栓 1 THREAD TENSION STUD

12 409S16026 张力调节螺母 2 THREAD TENSION NUT

H05002

13

406S11009

14

15 40912203 罩壳安装座 1 RUBBER PLUG

16 301805 左盖板 1 SIDE COVER RIGHT

17 40937008 安全标签 1 SAFETY LABEL

18 301807 右盖板 1 SIDE COVER LEFT

S05024

19

20 409S11009 螺钉 2 SCREW

40930008

21

22 P02002 GB/T117-1986销6×32 2 GUIDE PIN

23 409S30018 连接螺栓 1 SET SCREW

24 40912080 防油底板 1 BED OIL SHELD

25 41711014 电线夹 3 WIRE CLIP

26 4091100100 钮扣盘 1 BUTTON TRAY ASM

27 417S30025 螺栓M4X6 2 SCREW

28 41711014 电线夹 3 WIRE CLIP

40228001

29

30 40911007 左侧盖 1 SIDE COVER LEFT

31 40912081 底座活动盖 1 LOOPER COVER

32 40912067 侧盖弹簧片 2 SIDE COVER SPRING

409S11006

33

409S11007

34

35 40923013 滴油毡 1 OIL DRIP FELT

409S20006

36

61910003

37

40926002

38

39 40902019 左侧盖轴 1 SIDE COVER HINGE SHAFT LEFT

40 417S30009 螺钉 10 SCREW

41 40911011 电机罩壳 1 SIDE COVER

42 402S14006 螺钉 1 SCREW M6 L=6

43 40122017 橡皮塞 1 RUBBER PLUG

45 40112008 安全板支架 2 SAFETY PLATE

46 40911006 安全板 2 SAFETY PLATE

47 409S11008 螺钉 2 SCREW M4 L=6

48 40928002 垫圈 1 SPRING WASHER 5.0×110

49 402S20032 轴位螺钉 1 HINGE SCREW D=6 H=2.5

50 40128001 波形垫圈 2 SPRING

51 40912020 安全板安装座 1 SAFETY PLATE INSTALLING BASE

52 401S16004 螺母 1 NUT SM15/64-28

421S10013

53

421s30002

54

S10009

55

300941 纽扣盘固定座

56

S05083

57

40911012

58

40933002

59

40901022

60

螺钉 4 SCREW

第三夹线弹簧 1 TENSION SPRING

夹线螺栓 1 NIPPER RELEASING STOP

螺钉 1 SCREW

第四线导向装置 1 THREAD GUIDE NO.4

GB/T896-1986挡圈3 1 E-RING 3.2

螺钉 8 SCREW

拼装螺钉 4 SCREW M8 L=30

LED灯(TD-5)

弹性垫圈 1 SPRING WASHER 6.5×14.0×17

螺钉 2 SCREW M4 L=6

螺钉 2 SCREW

螺钉 1 SHOULDER SCREW D=6 H=2.7

扎带(小)

凸轮指示销

螺钉M5×8 2 SCREW

木螺钉 3 WOOD SCREW

螺钉M6×12 1 SCREW

螺钉M5×30 3 SCREW

电控罩壳 1 MOTOR COVER

电控 1 CONTROL BOX

油盘 1 OIL RESERVOIR

1

LED LAMP

4

RIBBON

2

CAM INDECATING PIN

1 BUTTON TRAY BASE

- 29 -

Page 30

- 30 -

Page 31

3、下轴部件/

Looper shaft mechanism components

序号 零件件号 名称 数量 DESCRIPTION

1 ----- 挡圈组件 1 THRUST COLLAR .ASM

40908002

2

409S11012

3

409S11010

4

40912021

5

40909001

6

409S17001

7

40909002

8

40912022

9

4090500100

10

40903003

11

409S20008

12

13 401S14001 螺钉 1

14 ----- 针板组件 1 THROAT PLATE SET

40901005

15

16

40928004

17

409S11031

40919003

18

409S11011

19

4091900100

20

409S20009

21

22 ----- 分线三角凸轮 1 ASSY LOOP POSITIONING FINGER C

40910001

23

24 409S14002 螺钉 2 SCREW 11/64-40 L=3.5

25 ----- 连接轴组件 1 ASSY CAM AND LOOPER SLEEVE

40902006

26

409S15004

27

40910002

28

29 409S14002 螺钉 2 SCREW 11/64-40 L=2.8

40903004

30

31 401S14001 螺钉 1

40902026

32

33 ----- 挡圈组件 1 THRUST COLLAR ASM, D=11.11,W=1

40908001

34

409S14003

35

409S14003

36

40925002

37

38 409S14001 螺钉 2 SCREW 1/4-40 L=6

39 40924001 端面轴承 1 THRUST BALL BEARING

40903005

40

41 ----- 蜗轮蜗杆组件 1 WORM WHEEL ASM.

40925011

42

409S14003

43

40925001

44

409S14003

45

40917001

46

409S11009

47

挡圈 1 THRUST COLLAR D=7.94 W=7

螺钉 1 SCREW 9/64-40 L=6.1

螺钉 1 SCREW

导向线杆(打捆针导向器) 1 NEEDLE GUARD

插入导向滑板 1 POSITONGNING FINGER YOKE SLIDE

螺钉 2 SCREW M4 L=9

导向卡箍(压铁插孔) 1 YOKE SLIDE INSERT

滑块(轭铁片) 1 YOKE SLIDE

环形定位杆 1 ASSY LOOP POSITIONING FINGER L

滚珠 1 LOOP POSITIONNING FINGER CAM RO

轴位螺钉 1 HINGE SCREW D=6.35 H=2.4

SCREW

针板 1 THROAT PLATE ASM.

轴承垫圈

螺钉

定刀 1 COUNTER KNIFE

螺钉 2 SCREW1/8-44 L=3.0

动刀 1 MOVING KNIFE ASM.

螺钉 1 HINGE SCREW D=6 H=0.85

后凸轮 1 LOOP POSITIONING FINGER CAM

连接轴 1 CAM AND LOOPER SLEEVE

螺钉 2 SCREW 15/64-28 L=4.0

后凸轮 1 LOOP POSITIONGNING FINGER CAM RE

下轴前套 1 LOOPER SHAFT BUSHING FRONT

下轴 1 LOOPER SHAFT

挡圈 1 THRUST COLLAR ASM, D=11.11,W=10

螺钉 1 SCREW 1/4-40 L=5

螺钉 1 SCREW 1/4-40 L=5

勾线轴齿轮 1 LOOPER SHAFT DRIVER GEAR ASM.

下轴后套 1 LOOPER SHAFT BUSHING REAR

蜗杆 1 WORM

螺钉 2 SCREW 1/4-40 L=7

凸轮轴从动齿轮 1 CAM SHAFT ASM.

螺钉 2 SCREW 1/4-40 L=6

钩圈 1 LOOPER

螺钉 3 SCREW M4 L=9

BEARING WASHER

1

1 SCREW

SCREW

- 31 -

Page 32

- 32 -

Page 33

4、绕线和过线部件

Nipper & tension parts components

/

序号 零件件号 名称 数量 DESCRIPTION

409S11013

1

40912024

2

409S20013

3

409S16005

4

409S16006

5

4091202500

6

409S20011

7

40927007

8

409S30004

9

409S20012

10

40927008

11

40909003

12

409S20013

13

4091300400

14

409S20014

15

4091202700

16

40926006

17

40926007

18

409S11014

19

40912029

21

40912030

22

40912031

23

409S11014

24

4091300600

25

26 409S16007 调节螺母 1 TENSION NUT

27 40912032 夹线器防松盘 1 ROTATION STOPPER

28 40927009 夹线器弹簧 1 THREAD TENSION SPRING

29 40912033 松线板 1 THREAD TENSION DISK PRESSER

30 40913007 夹线板 2 THREAD TENSION NO.1

31 409S30006 第二夹线杆 1 TENSION POST NO.2

32 409S16008 夹线板松线杆 1 TENSION RELEASE PIN

40926008

33

P03009

34

409S11014

35

40928004

36

40912034

37

4091300800

38

39 409S16009 调节螺母 1 THREAD TENSION NUT

40 40927010 夹线器弹簧 1 FIRST THREAD TENSION SPRING

41 40913007 夹线板 2 THREAD RENSION DISK NO.1

42 409S30007 第一夹线杆 1 THREAD RENSION POST NO.2

40913009

43

40913010

44

409S16024

45

409S11013

46

40912100

47

409S30008

48

40928005

49

409S11015

50

409S11016

51

40927011

52

409S30009

53

57 40913012 2号导线钩 1 THREAD GUIDE

40928005

58

螺钉 1 SCREW M6 L=12

针杆防护罩 1 NEEDLE BAR GUARD

轴位螺钉 1 SHOULDER SCREW

螺母 2 NUT

松线螺母 1 NUT

导线装置 1 NIPPER COMPL

松线销 1 LOOPER SHAFT BUSHING REAR

夹线杆拉伸弹簧 1 NIPPER BAR BLOCK SPRING

弹簧销 1 NIPPER BAR BLOCK SPRING SCREW

螺钉 1 HINGE SCREW D=4 H=20

夹线座弹簧 1 HIPPER SLIDE BLOCK SPRING

夹线座 1 NIPPER BLOCK

螺钉 1 SHOULDER SCREW D=7.94 H=15

引线杆组件 1 THREAD PULL OFF LEVER ASM.

驱动杆轴位螺钉 1 SHOULDER SCREW D=7.94 H=8

夹线杆驱动杆组件 1 NIPPER BAR ACTUATING LEVER ASM.

导线杆 2 THREAD GUIDE PIN

夹线杆底座弹簧销 1 NIPPER BAR BLOCK SPRING PIN

螺钉 1 SCREW

夹线杆驱动块 1 NIPPER BAR BLOCK

拨线杆驱动块 1 TENSION LEVER ROCKING PIECE

夹线杆 1 NIPPER BAR

螺钉 1 SCREW

2号夹线杆组件 1 TENSION POST ASM NO.2

螺母 1 NUT M6

弹性圆柱销 1 SPRING PIN 3×16

螺钉 1 SCREW

垫圈 1 WASHER

释压杆 1 THREAD TENSION RELEASING LEVER

1号夹线器组件 1 ASSY HTREAD RENSION NO.1

导线钩 1 THREAD GUIDE

二眼线板 1 THREAD GUIDE NO.1

螺母 1 NUT M4

螺钉 1 SCREW M5 L=14

夹线杆滑块 1 NIPPER BAR BEARING BLOCK

调节螺钉 1 ADJUSTING SCREW

垫圈 1 WASHER 5.5×10×0.8

螺钉 1 SCREW M6 L=12

螺钉 1 SCREW

2号钳杆弹簧 1 THREAD TENSION SPRING

夹线杆拉伸弹簧销 1 NIPPER BAR SPRING SCREW

垫圈 1 WASHER 5×10.5×1

- 33 -

Page 34

- 34 -

Page 35

5、送料盘部件/

Feed plate components

序号 零件件号 名称 数量 DESCRIPTION

40915001

1

409S12003

2

40909004

3

40912036

4

40903010

5

409S16012

6

400110

7

409S20015

8

409S30010

9

400111

10

40937001

11

409S16013

12

40903012

13

409S11003

14

40912208

15

421S10005

16

409S30019

17

18 401S14001 螺钉 3

40912040

19

40901006

20

400110

21

409S20015

22

409S30012

23

24 40904003 交叉送料调节杠杆 1 CROSSWISE FEED LEVER

R01002

25

40926010

26

40926010

27

40926010

28

401846

32

401847

33

401848

34

38 40912205 送料调节盘底座 1 PLATE BASE

39 40937010 刻度盘贴膜 1 GRADUATE PLATE

41 40912206 调节手柄 1 HANDLE AND INDICATOR SPRING

42 403S11027 螺钉 2 SCREW M4 L=6

45 40904004 调节手柄连接杆 1 INDICATOR SPRING CONNECTING LI

409S20016

46

47 40902022 凸轮轴 1 CAM SHAFT

48 40910019 十字纵向送料盘 1 LENGRHWAISE FEED CAM(X)

40903040

50

40910006

51

40910004

52

409S20035

53

409S14005

54

40912087

58

40903039

59

409S14005

60

61 409S11005 螺钉 1 SCREW M5 L=8

63 40923015 油毡 1 FEED SHOULDER SCREW FELT

66 61910003 扎带(小) 3 CABLE BAND

68 40930007 磁铁 1 MAGNET

69 40930003 信号轮 1 SINGLE WHEEL

70 40912108 传感器安装座 1 HALL SWITCH HOLDER

71 ----- 霍尔开关 1 HALL SWITCH

72 417S30033 螺栓(带垫圈)M4×8 2 SCREE

73 407S17003 十字沉头螺钉M3×4 1 SCREE

75 40903043 定位套 1 POSITONING SLEEVE

76 409S14003 螺钉 2 SCREW 1/4-40 L=5

送料板 1 FEED PLATE SMALL BUTTON

螺钉 2 SCREW 3/16-28 L=6

交叉送料滑块 1 LNDICATOR PIN BEARING BLOCK

交叉送料指示板 1 CROSSWISE FEED INDICATOR

交叉送料轴承座 1 CROSSWISE FEED INDICATOR PIN

螺母 1 NUT M=6

滑板连接杆 1 SLIDE PLATE CONNNECTING LINK

轴位螺钉 1 HING SCREW D=6.35 H=4.8

双头螺栓 1 STUD

连接杆 1 INTERMEDI CONNECTING LINK

交叉送料刻度盘 1 CROSSWISE FEED GRADVATED PLATE

螺母 1 NUT M5

送料凸轮滚子 3 CAM ROLL

螺钉

手柄

螺钉M3×6

送料凸轮滚子螺栓 3 CAM ROLL SCREW STUD

连接杆 1 SPACER PLATE

送料底板 1 FEED PLATE

滑板连接杆 1 INTERMEDI CONNECTING LINK

轴位螺钉 1 HING SCREW D=6.35 H=4.8

交叉送料轴位螺钉 1 HING SCREW FOR CROSSWISE FEED

铆钉 5 RIVET

杆销 1 FEED STUD A

杆销 1 FEED STUD B

杆销 1 FEED STUD C

送料调杆滑块 1 LENGTHWISE FEED LEVER SLIDE

送料调节杠杆左 1 FEED LEVER L

送料调节杠杆右 1 FEED LEVER R

轴位螺钉 2 SHOULDER SCREW D=6.35 H=9.7

凸轮轴右套 1 CAM SHAFT BUSHING LEFT

交叉送料凸轮 1 FEED CAM ASM.

纵向送料凸轮(一字) 1 LENGRHWAISE FEED CAM(-)

轴位螺钉 1 SHOULDER SCREW D=6.35 H=4.8

螺钉 2 SCREW 9/32-28 L=13.5

垫圈 1 WASHER

凸轮轴右轴套 1 CAM SHAFT BUSHING RIGHT

螺钉 5 SCREW 9/32-28 L=13.5

2

SCREW

1

HANDLE AND INDICATOR SPRING

2

SCREW

SCREW M6×12

- 35 -

Page 36

- 36 -

Page 37

6、钮钳提升部件

Button clamp lifter components

/

序号 零件件号 名称 数量 DESCRIPTION

40901033

1

40903016

2

40902009

3

40922001

4

5 40928014 垫圈 2 WASHER 8.5×18.0×1.2

40927012

6

40927013

7

8 4090201100 钮钳提升杆钩 1 BUTTON CLAMP LIFTING ROD A

40912042

9

10 40903020 钮钳提升杆滚筒 1 L TYPE LIFTING BAR ROLLER

40928021

11

12 409S16014 螺母 1 NUT 9/64-40

L01002

13

4030500500

14

N01004

15

N01004

16

409S30013

17

409S16015

18

19 40912089 后切线连接杆 1 CONNECTING LINK REAR

20 409S20036 轴位螺钉 1 HINGE SCREW D=6.35 H=3.2

21 409S20037 轴位螺钉 1 HINGE SCREW D=7.94 H=4

22 409S16013 螺母 1 NUT 3/16-32

23 401S16002 螺母 1 NUT 15/64-28

24 40912044 切线杠杆 1 THREAD TRIMMING LEVER

409S11021

24

25 40912090 切线连杆 1 THREAD TRIMMING LINK

409S20023

26

S05023

27

28 409S20038 轴位螺钉 1 HINGE SCREW D=6.35 H

29 401S16002 螺母 1 NUT 3/16-32

30 40912091 电磁铁连杆 1 MAGNET CONNECT POLE

31 40912092 电磁铁安装板 1 MAGNET HOLEDER

32 417S30306 带弹垫螺钉M5X15 4 SCREW M5 L=15

33 417S30033 螺栓(带垫圈)M4×8 4 SCREW M4 L=8

34 409S20039 电磁铁销钉 1 PIN

35 413S16003 螺母M4 2 NUT M4

36 40930005 电磁铁 1 ELECTROMAGNET

40912032

37

38 401S16002 螺母 1 NUT

39 409S20040 轴位螺钉 1 SHOULDER SCREW D=7.94 H=3.1

401S16002

40

40901036

41

42 4091210000 连杆 1 CRANK ROD

43 40128034 垫圈 1 WASHER

44 40928022 垫圈 2 WASHER

抬压杠杆 1 LIFTING LEVER

轴套 1 BUSHING

针棒杠杆轴 1 NDDELE BAR LEVER

橡胶垫 2 CUSHION

弹簧 1 SPRING

弹簧 1 SPRING

切线连杆 1 CONNECTING LINK FRONT

垫圈 1 WASHER

螺钉 1 JOINT STUD

切线连接球体 1 FEED ADJUSTING JOINT

螺母 2 NUT M5

螺母 2 NUT M5

连接螺钉 1 CONNECTING SCREW

螺母 2 NUT M8 TYPE1

螺钉 2 SCREW M5 L=14

轴位螺钉 1 HINGE SCREW D=6.35 H

螺钉 1 SCREW M6 L=10

垫圈 1 WASHER

螺母 1 NUT M5

切线杠杆座 1 THREAD TRIMMING LEVER BASE

- 37 -

Page 38

- 38 -

Page 39

7、推针滑轮轴部件/

Needle driving pulley shaft components

序号 零件件号 名称 数量 DESCRIPTION

1 40903034 滑轮轴左套 1 PULLEY SHAFT BUSHING LEFT

2 40603020

403S14004

3

40925004

4

409S14001

5

6 40902051 滑轮轴 1 NEEDLE DRIVING PULLEY SHAFT

7 40903024 滑轮轴右套 1 PULLEY SHAFT BUSHING RIGHT

9 401S14001 螺钉 1 SCREW

10 1383300400 电机转子组件 1 Rotor components

11 1383300900 电机光栅组件 1 Gratings components

12 13833003 电机定子总成 1 Stator components

13 1383300700 电机罩壳组件 1 Motor cover components

14 302443 手轮 1 PULLEY

15 403S14004 螺钉M6 2 SCREW M6

40910021

16

409S14003

17

40910020

18

挡圈

螺钉 2 SCREW M6

滑轮轴齿轮 1 DRIVING GEAR(A) ASM.

螺钉 2 SCREW 1/4-40 L=6

平衡凸轮 1 BALANCE CAM

螺钉 2 SCREW

偏心轮 1 ECCENTRIC CAM

2 THRUST COLLAR

- 39 -

Page 40

- 40 -

Page 41

8、针杆驱动机构部件

Needle bar driving mechanism components

/

序号 零件件号 名称 数量 DESCRIPTION

101S11006

1

40902027

2

40903026

3

40913013

4

40909017

5

409S11024

6

7 40903035 针杆上套 1 NEEDLE BAR BUSHING UPPER

40909016

8

9 ----- 针杆轴承座 1 NEEDLE BAR SLIDE BLOCK B

10 ----- 针杆轴承座 1 NEEDLE BAR SLIDE BLOCK C

11 41017001 机针 1 NEEDLE TQ×1 #16

40905007

12

L02008

13

409S20025

14

40928013

15

16 ----- 连杆组件 1 CRANK ROD ASM.

409S11009

17

40912046

18

40905009

19

40910009

20

40910009

21

409S14001

22

40923008

23

24 40923014 油毡 1 OIL RETAINNING FELT

40923008

25

40923008

26

螺钉 1 SCREW 1/8-44 L=4.5

针杆 1 NEEDLE ROD

针杆下套 1 NEEDLE BAR BUSHING LOWER

导线 1 NEEDLE BAR BALACE

针棒轴衬座 1 NEEDLE BAR CLAMP

螺钉 1 SCREW M4 L=12

针杆轴承座 1 NEEDLE BAR SLIDE BLOCK A

针杆杠杆 1 NEEDLE BAR DRIVING LEVER

螺钉 2 SCREW M6 L=14

轴位螺钉 1 SHOULDER SCREW D=9.53 H=8

垫圈 1 WASHER

螺钉 2 SCREW 11/64-40 L=8.5

盖板 1 THRUST HOLDER

连杆 1 CRANK ROD

偏心轮 1 ECCENTRIC CAM

螺钉 1 SCREW 1/4-40 L=6

螺钉 1 SCREW 1/4-40 L=8.5

油线 1 OIL WICK

油线 0.01 OIL WICK

油线 0.1 OIL WICK

- 41 -

Page 42

九、附件组件/ Accessory parts components

- 42 -

Page 43

九、附件组件/ Accessory parts components

序号 零件件号 名称

1 10131002 螺丝刀(大) 1 SCREW DRIVER LARGE

2 10131003 螺丝刀(中) 1 SCREW DRIVER MIDDLE

3 10131004 螺丝刀(小) 1 SCREW DRIVER SMALL

4 20131038 小油壶(尖嘴) 1 OILER

5 40931019 定位尺 1 GAUGE

6 30131010 内六角扳手(3mm) 1 INNER WERNCH 3mm

7 30131012 内六角扳手(4mm) 1 INNER WERNCH 4mm

8 20131047 内六角扳手(5mm) 1 INNER WERNCH 5mm

9 30131006 扳手(8mm~10mm) 1 Wrench 8mm~10mm

10 40931025 扳手(9mm-11mm) 1 Wrench 9mm~11mm

11 40931031 单盘线架 1 COTTON STAND ASSY 2DTHF

12 40131017 机头罩 1 MACHINE COVER

13 40931009 M6×70 螺钉 4 SCREW M6 L=70

14 --------- 橡胶垫 4 WASHER 6.2×13×1

15 40912024 针杆护罩 1 NDDELE BAR GUARD

16 N01007 螺母 M6 4 NUT M6

409s11008 螺钉 2 SCREW

402s20032 轴位螺钉 1 SHOULDER SCREW

s05035 M5×25 螺钉 3 SCREW

40912020 安全板安装座 1 THE MOUNTING SEAT

17

18 20131051 镊子 1 TWEEZERS

19 --------- 脚踏 1 Pedals

20 40931028 说明书 1 INSTRUCTION MANUAL & PARTS LIST

21 40931021 支撑杆 1 SUPPORT

22 --------- 脚踏连杆 1 Pedals connecting rod

23 403S30020 木螺钉 6 Wood screw

24 300841 纽扣盘底座 1 Button plate of the base

25 41017004 TQ*7 16#机针 3 NEEDLE TQ×7#16-12

26 4091100100 纽扣盘组件 1 Button plate

40928002 垫圈 2 WASHER

40112008 安全板安装板 1 SAFETY BOARD MOUNTING PLATE

40128029 弹簧垫圈 Ø8 4 SPRING WASHER

401s16003 螺帽 1 NUT

40911006 安全板 1 SAFETY BOARD

数

量

DESCRIPTION

- 43 -

Loading...

Loading...