Page 1

~PORTANTSAFETYINSTRUCTIONS

Putting sewing systems into operation

which these sewing machines will be built into, have conformed with

Technical service for those sewing systems

!.Observe

machine.

2.Read a

In addition, keep this instruction

3.Use the machine after it has been ascertained

country.

4.AII safety devices mu

without the specified safety devices is

S.This machine sha

6.For your personal protection, We recomme

7

.For

receptacle.

7-1

7-2

7-3 For

7-4 When leaving the working place

7-5 When using clutch motors

8.1f you should allow oil, grease, etc. used with the machine and devices to come in contact with your

skin

doctor.

9.

Tampering with the live

IO.Repair, remodeling

specially skilled personnel. Only

ll.General

l2.Repair

or

Whenever you find a failure

l3.Before making

air

be

expelled. Exceptions to this

technicians

14.Periodically clean the machine

the bas

ll

the

the following,

For threading needle(s), looper,

For

folder, cloth guide etc.

repair

or

swallow any

and

under

cylinder,

cut

off. Existing residual

ic

safety measures, including,

instructions, including,

st

be in position when the machine is ready for work

ll

be operated by

turn

off the

rep lacing part(s)

work.

maint

enance

maintenance works

the

audit

and

repair

the

air

or

specially skilled personnel.

of

of

such liquid by mistake, immediately wash the contacted areas

parts

and

adjustment

and

inspection works have to

guidance

and

maintenance works on

compressor bas to be det.ached from

air

needle, presser foot,

and

of

are

is

prohibited until it bas been ascertained

is

also proh.ibited.

but

but

not limited to this instruction Manual before you use the machine.

Manual

appropriate

power

without

devices, regardless

spare

of

of

any

pressure

only adjustments

throughout

so

that you may read

that

not

allowed.

ly-trained operators.

nd

that

you

switch

spreader

or

when the working place

app

works must only be done

parts

electrical components

specially skilled personnel.

of

electrical components, immediately stop

after disconnecting

or

etc.

and

lying brake,

designated by

the period

that

the sewing systems

the

safety regulations in your county.

not limited to the following ones, whenever you u

it

at

anytime when necessary.

it conforms with safety rules/standards valid

or

in operation. The operation

wear

safety glasses.

disconnect the power plug

replacing bobbin.

throat

the

and

plate, looper, spreader, feed dog, needle guard,

is

unattended.

it

has to be waited until the

of

whether the machine

by

appropriately trained technicians

JACK Can

be

done by appropriately trained personnel.

sha

ll

be conducted by qualified electric technicians

machine equipped with pneumatic parts such as an

the

machine

the

performance checks

of

use.

be

used for repairs.

and

air

compressor from

of

the

machine from the

motor

stopped totally.

and

consult a medical

is

powered, is prohibited.

the

machine.

the compressed

done

by

air

the

machine bas to be

appropriately trained

supply bas to

se

in

eyes

in

the

your

or

or

IS.

Grounding

be operated in

l6.An

appropriate

connected to a 2rounded receptacle.

l7.The machine is only allowed to be us ed for

l8.Remodel

safety measures.

machine.

l9.Warning hints are marked with

the

machine

an

environment

power plug has to

or

modify the machine in accordance with

JACK

is

always necessary for the normal operation

that

is

free from strong noise sources such as high-frequency welder.

be

attached to

the

assumes

Danger

Items requiring special attention

of

no

responsibility for

the

two shown symbols.

injury

to

operator

of

the

the

machine by electric technicians. Power plug has to be

purpose intended.

the

safety rules/standards while taking all the effective

damage

or

service

Other

used

caused by remodeling

staff

v

machine. The machine has to

are

not

allowed.

or

modification of the

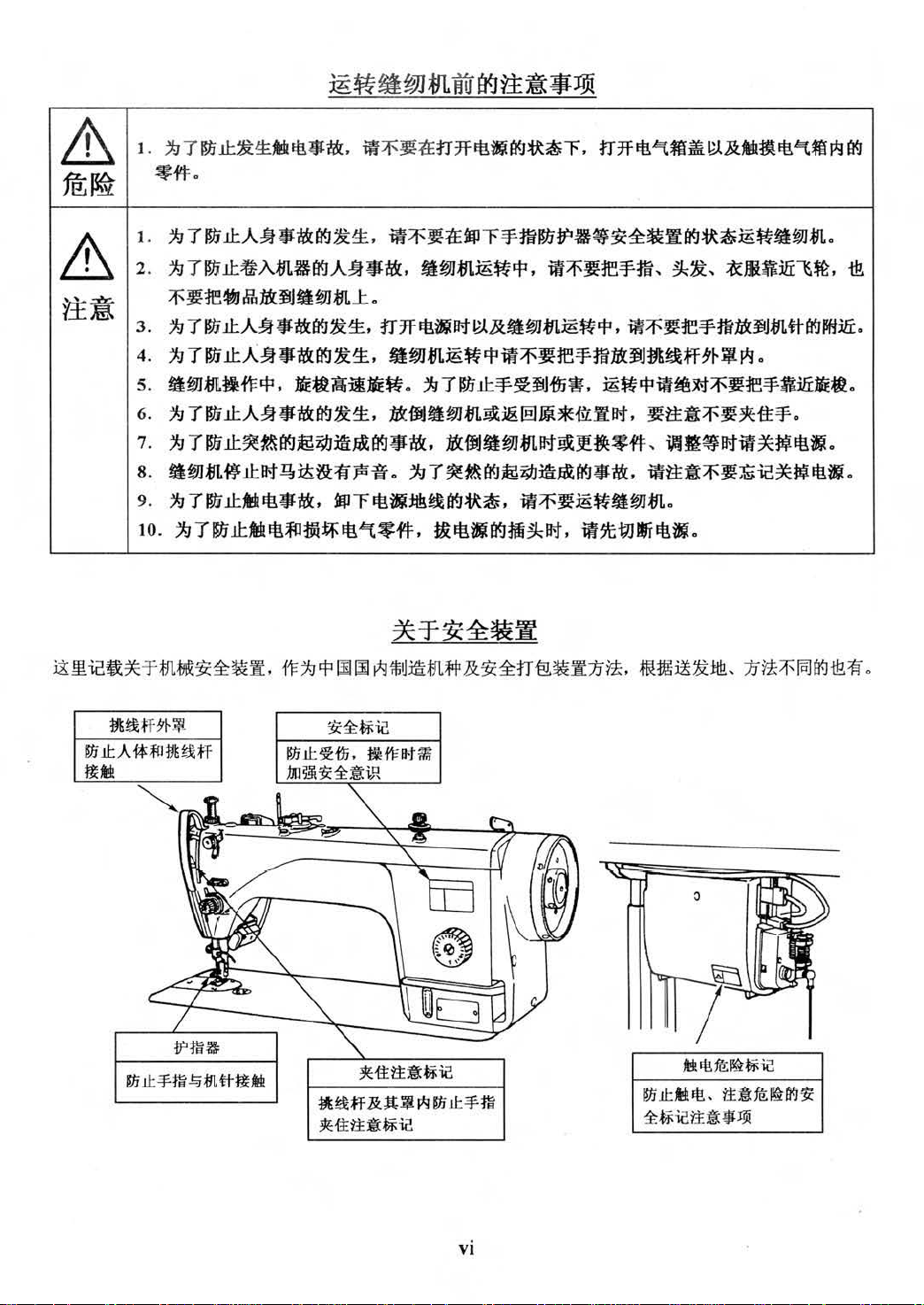

Page 2

&

~~

&

1.

~7~~~~

M~$~.

~~~~fl~~~

.. #.

1.

~T~~A~

2.

~T~~$Afia~A~•~·

::

p~re~

-~

~£~. ~~~~~~~m~~a~~~~~~~*~~~mm.

~:tt~~

J~mm...t.

~~*~·fl*~~-~~&Mm~~·~~

•mm~~~.

~~~re~m,~~,~ma~~~.~

~-

3.

~T~~A~-~~~~.n*~-~~&•mm~~~.~~~re~mtt~m~~~~.

4.

~r~~A~-~~~~

s.

•mm~*~·

6.

~r~~A~-~~~~.

1.

~Y~~~~~~~~~~-~.tt••mm~~£~*-ftl:

s.

Mmm~~~~~~~F~·~Y~~~~~~~~-~.~tt·~~~~**~~

9.

~T~~M~•~·

10.

~T~~il!~~~t+~~~#.

~-~~~~.~Y~~~~~~~.~~~~~M~~re~3~~~.

.

•mm~~~~~~re¥mtt~m~~*~~.

tt••mm~~§~*~~~.

~~~-~~~~~.~~~~~•mm.

t£~-~~~111.

~;tWIT~~.

~~-~~~~•·

,

~•~~~**~~.

~r*~~•

~~~•~fm•~~••·~~~oo~~~-m~&~~n~••~~

.

••~~~,~~~~~&~.

.

~~U

f & ~~

~'{ttl:fj;~iG

1*1

Vi

li:-'Fm

vi

~

.t1:

til

f@.

,

r.u~

fg:

~~iCY£~~~

~

Er~

:rc

Page 3

l.To

~

avo

id

electrical shock hazards, ne

components mo

FOR

unt

ed inside the electrical box.

SAFE OPERATION

ith

er

open

the

cover

of

the electrical box nor touch

the

&

l.To avoid personal injury, never

devices removed.

2.To prevent possible personal injuries caused by being caught in

head

an

d clothes away from the handwheel while the machine is in ope

place nothing around it.

3.To avoid personal injury, never

power switch or operate the machine.

4.To avo

S.The hook rotates

6.To avoid possible persona l injuries, be careful n

7.To

8.The motor does not produce noise while the machine

9.To avoid elec

JO.To

id

personal injury, neve r put

machi

ne

is

in

opera

tion.

at

h high speed while the machi

to hands, be s

addit

ion

tilting /rai sing the machine head.

avoid possible accidents because of

machine when tilting the m

the machine, etc.

to

abrupt start

the power supply removed.

prevent possible accidents because

turn

OFF the power switch in

, be

ure

to keep your hands away from

sure

to

turn

OFF the power to

of the machine, be sure to

tri

cal shock h

operate

put

your

your

abrupt

ac

hine b

ead

azards, never

prior

to the connection/disconnection

the

machine with

hand und er the needle when you

fin

gers

into

ne

is

the

vicinity

the mac

or performing

turn

operate

of

electric shock

hine when replacing

ot

to allow yo

start

of

OFF the power to

the sewing machine with the ground wire for

any

the

in

operation. To prevent possible injury

of

the machine,

rep

laceme

is

at

rest.

or

damaged el

of

the

finger

the

mac hine, keep you

thread

ur

take-up cover while the

the

book

the

fing

ers

turn

OFF

nt

of

To

avo

id possible accidents due

the

machi ne.

ectr

of

the power plu

guard

or

safety

fin

gers,

rat

ion. In addition,

turn

"ON" the

during operation .. In

bobbin.

in the machine when

the

power to the

parts,

adjustment of

ical componeot(s),

g.

vii

Page 4

3~1JJ1Ifll

·

·····

····················

············

·····

·······

··················································································1

~~fit~

t.

~m

2.

~~m

3.

•

4.

~~A<J~~

1Jll~

5.

6.

~;fl:ilb:fitA<J~ll

7.

~tt~:fit

s. m

9.

;f:t

10.

fil~*l:t.A<J~~

11.

.ffi~.ffijJ

12.

J:~~~1J~

13.

Jif~!l:lr~1Jt!··

14.

~

;t1

t

Htr

A<J

tt

it

$ tjji .......•.......•.•..

...

.......................................

A<J

i9.J

~

~~·····

7t

jtfj

·

···········

IJt.

t¥.1 ~ •···········

····

·······································································

(8990

SS,

899l

SS)

(

8990SS,

(~~)

tt

~J

~~:n~

JL\

99

~~1i1;i.;:

a<Jiq~·······

a<J~)I1J~

····

···········

···

····

····

·······················

··

·························

····

··

·············

.........................................

···

·········

·······

31i:1J

···············

·

············

~t'f!!~!!~!!I'!!

·····························································································

···

·········

.•.

••.••.•...•••...•.•.•..•..........

............

··········

··

............................

....

...

·

·· ······

····

· ·

....

.................

··

·····································

·············

...................

..

8991SS) ......................................

(

8990SS,

···········

············

·

··········

·

·······

···········

· ··

···

··············································································

I'

I'!P

·!!·

!!!!!!-

!!

!!-

!!

!!-

!!!!!!1'1'1'!!

8991SS) .....................

···························

· ·

····

···

····

·········

··········

············

.....

!! !!-1'!!

···············

·······

············

......................

····

·1'··

·· ·· ······

···

· ·······

··•···•····••••

.....................................................

·················

· · ·

·········

· ·

·········

···

····················

··

······················

........

...

···············

··•·••···················•········· 2

.

.................................

·

·······

·········

·····

·

···

····· ·····

3

4

5

·········

····················

...........................................

......

...............................

···

····

·············

·······································

·······

·········

···

·

··

······ ··· ······

....

..........

....

.....

...................

·~~""

". '"'···

···--

····

··

··

······ s

·

·····

·· ·· ·

·······

··

····

········10

·· ··

··

··l

11

··

·····

12

-

·····

-

·····-··-·-·

13

5

6

7

s

9

O

15

.

~~-··· · ·

16.

m~:ffm~

17

.

.:tn.~.Wll:~:Wt¥.1~·

18

.

-~

.ffiJJ~tr~

19.

Wf~t¥.1~-

20.

-~·*·····················

21.

•

ti

-=¥-

22.

m~:ff

23

.

.:tn.

tt.!:ii~

24.

ra1

):E.

7J

25

.

~$~

26.

£5$89fi'i.J~

27

..

*!lt¥.111J11.-~

•

2 8.

~#f¥.*-

t.ffi

······

·······

·· ·

····

·

···············

:fit89~~·······

···

···············

··

·········

i9.J

{!lj

til

··········

.......................

~t¥.1

~~···

··························

t¥.J

ifli/Jt.~ffil~/Jt.

····

·

··

···

········ ················

.:tn.~····

1Jifl~71-·······

....................

··

·············

...

........................

···

·

·············

····················

··

··

····

··

····

··························

.........

...................................

·····

·

······

····

··········

..

..............................................................

······

· ··

·············

·································································

........

.....

·····

········

...............................

····

···

·

··········

........

..................................................

·······················································

··

···············

..

······························································ ...

········

·····

····

···

-····-··

··································

.. ···············

······

···

·····

.............................

····

·····

························

···

·

············

···

·

······

................

··· · ·

···········

····

· · ·

··

··

···

····················································

···········

..................

.. ····

·····················

···

······

··············

..................................................................

·

··

·····

······

···················

......................

·

····

····················

.......

··

·· ..

...........................................

...

......................

......

....

.......

·····

······························

...............................................

......

.......................

····

·············

.......................................

······

.. ·················

·····

··

···················

···

······

·······

·····

·

·······

····

···············

··

·········14

15

··

········

·······

15

.....

..........

..

17

18

18

19

21

..

22

····

········

······

23

24

···············

······

··

· ··

25

·········

26

· ····

···

·

27

....

28

viii

Page 5

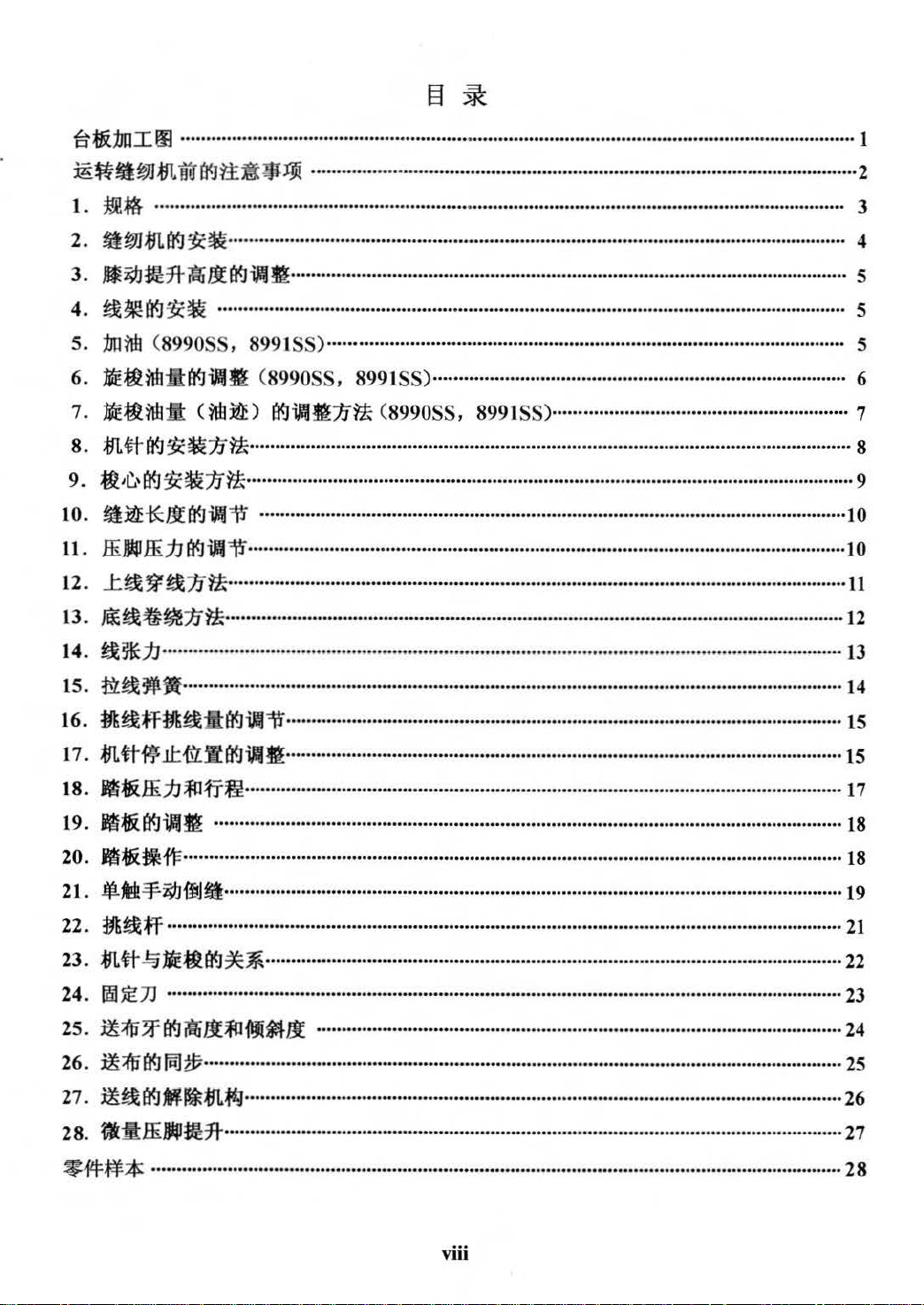

CONTENTS

SCHEMATIC

BEFORE OPERATI

1.

SPECIFICATIO

2.

INSTALLATION··················································································································· 4

3.

ADJUSTING

4.

INSTALLING

LUBRICATIO N(8990SS, 8991SS)·····················································································5

5.

6. ADJUSTING

7. ADJ

8.

9. SETTING

10. ADJUSTING

11

. PRESSER

12. THREADING

13 . WINDING THE BOBBIN TRREAD··· ................................................................................. J2

UST

(8990SS, 8991SS)··················································································································7

ATTACUING

DIA

GRAM OF

ON·········································································

NS

················································································································ 3

THE

HEIGHT

THE

THREAD STAND··············································································· 5

THE

AMOUNT

ING THE AMOUNT

THE

NEEDLE·································································································8

THE

BOBBIN INTO

TUE

STITCH

FOOT

PRESSURE .............................................................................................. 10

THE

MACHINE HEAD ...............................................................................

THE

LENGTH

MACHINE TABLE······························ ....................

····

··································· 2

OF

THE

OF

OIL

OF

OIL(OIL

THE

KNEE

IN

BOBBIN CASE .............................................

...............................................................................

LIFTE

THE

SPLASHES)IN THE HOOK

R·····················································5

HOOK

(8990SS, 8991SS)··················6

....

....

....... 9

JO

I

Jl

14. THREAD

15. TOREAD TAKE-tJP SPRING ............................................................................

16.

ADJUSTING

17.

ADJl

18. PEDAL

1

9.

ADJUSTMENT

20. PEDAL

21

. ONE-TOUCH TYPE REVERSE

22. WIPER ··································································································································21

23. NEEDLE-TO-HOOK

24. COUNTER KNIFE ...............................................................................................................

25. HEIGHT AND TILT

26.

ADJl

27. THREAD TENSION RELEASE RELEASING MECHANISM ....................................... 26

MICRO-LIFTING MECHANISM

28.

TENSION ..............................................................................................................

THE

THREAD TAKE-UP

TSTING THE NEEDLE S

PRESSURE

OPERA'

iSTfNG

THE

AND

PEDALSTROKE

OF

THE

PEDAL ........................................................................................ J8

I.l0N···················

RELATIONSHIP

OF

THE

FEED

TIMING

TOP POS

··················································

FEED STIT

FEED DOG ........................................................................

STROK£

mON

............................................................

................................................................. 15

.....................................................................

·······································18

CHING MECRANISM ............................ 19

........................................................................

......................................................................................

OF

THE

PRESSER FOOT ......................................

......

............ 14

..

13

15

17

22

23

24

25

27

PARTS

BOOK

......................................................................................................................... 28

ix

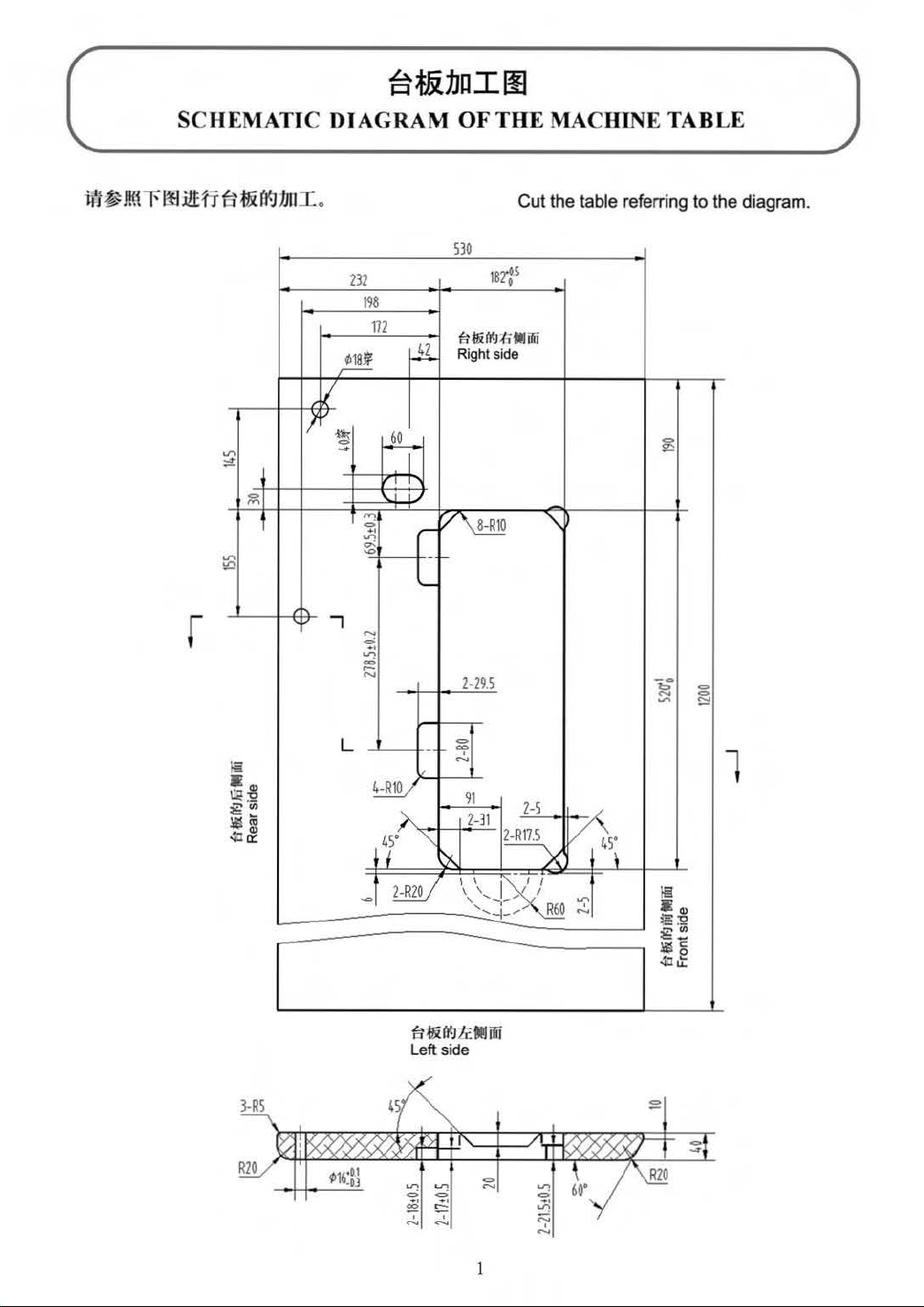

Page 6

S

CHE

~*&1.mil!J

MATIC DIAGRAI\tl OF THE MACHINE TABLE

Cut the table referring to the diagram.

SJO

m

198

172

~

~

1Btis

Er~(J{J

;fi"

Right side

t'li"Ai

v

II

~

C>

,....

...,..

"'"!

C>

.,

OJ")

<>-

...,

~

J

" I I

..J

I

,....-

'--

- r

v

~

'\

~

r

}§

•

ill!

~

;g<Jl

$ lii

40

~

..,

L

......

<=>

.......

~

"'

4-R10

'""

4

5"

I

2-R20

Z-29.5

""'

<>;>

-

.....

91

2-31

'\

~

I I

\

'-.-,_....

'

....

-!_........

~~ftt:JtcMffii

Left side

Z-5

2

-R17.5

1-x

~-/i

I

R60

L"

v

":"

"'

45

C>

1r

C>

......

!;:::!

l

.

\

!§

.Q)

~:2

~!!

~a

40U:

Page 7

•

ii1iPr~f'JJ~Uft

·

ss••~·

•

:liW~ffl~W.tflZ~,

•

frt~j:gj!Jt~~;g:(!(J~~.

•

i1Hiff1iA

•

iWrdtlV..

•

ttffia~:f~~.

•

iiHdu

•

-wf:f~re~f'JJ.trl!IUlitrff!J,

•

*~f'JJ.trl~~fl".trl~~{fiJ.5:fi.t~f'JJ.tfl~l;fji¥J3f~.

~~±E

ttffi>ri~

It~~~~~

V..

~

~Bl

~~wm~

A

CAUTIO

~

~ J:~~~¥J~~Kfi.

(

trt5)

0

~mz~•-~ttM~~~--

i~HE..trl~trtFF-~o

:U=~Mo

~ ~

lE

~ o

lE

rdfl:it~

•~~:f~~m

~~H~

1¥1

ME~

.•

JErdfl~~~~mm~,rg~tJ3ftt~3f~o

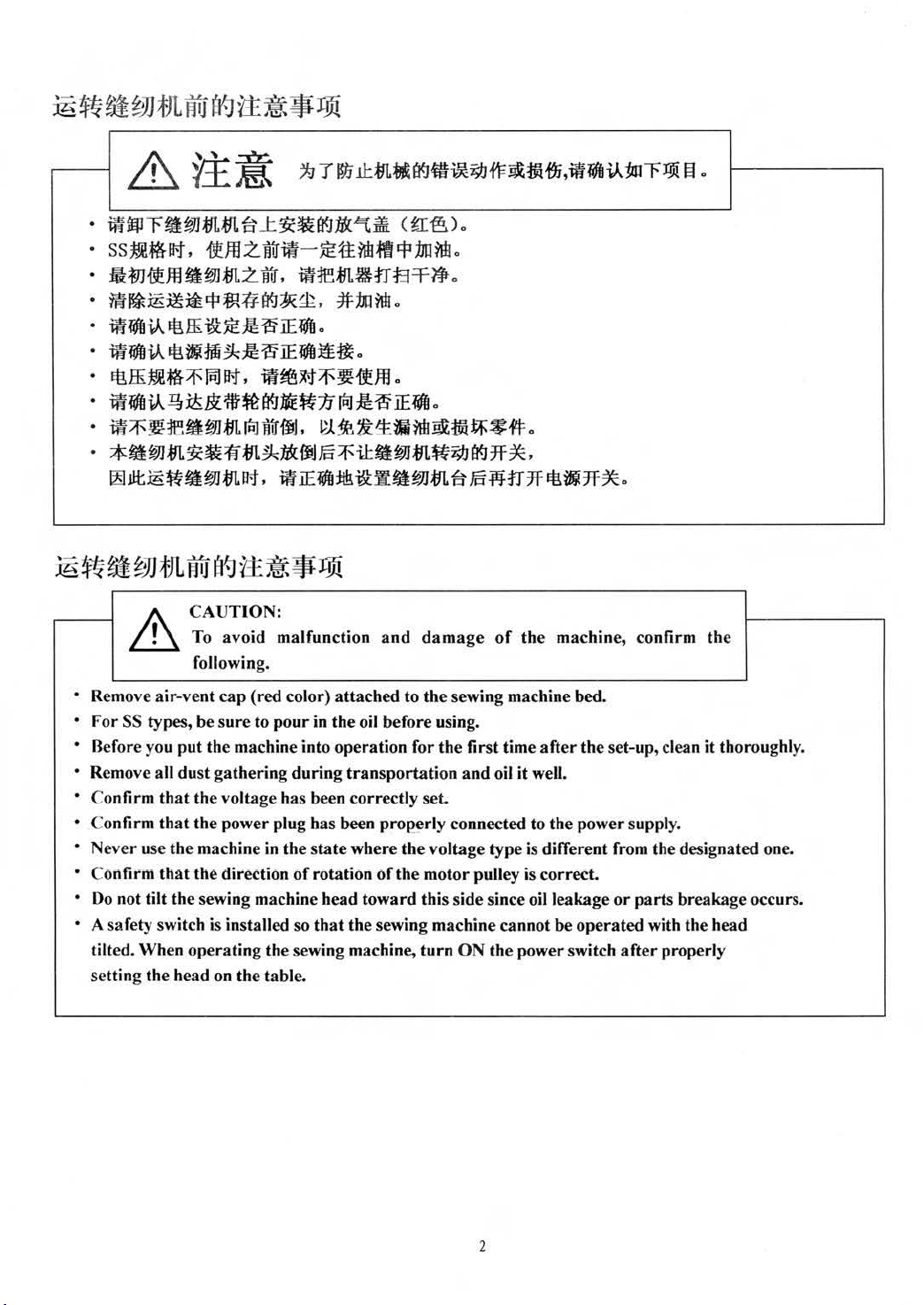

N:

To avoid malfunction

following.

0

0

:1J

JiU

:J!~

lE

rdfl

o

PJ.~~1:.~~M~tvl~~#o

and

damage

of

the

machine, confirm the

• Remove air-vent

• For SS types, be s

• Before you

• Remove all dust gathering

• Confirm

• Confirm

• Never use

• Confirm

•

Oo

• A safety switch is in

tilted. When operating the sewing machine,

setting

that

that

that

not tilt the sewing machine head toward this side since

the

cap

(red color) attached to

ure

to

pour

in the oil before using.

put

the machine into operation f

during

the voltage has been correctly set.

the

pow

er

plug bas been properly connected to the pow

the

machine

the direction

head on the table.

in

the state where

of

sta

lled so

transportation

rotation

that

of

the

sewing machine cannot be operated with the head

the

or

the

voltage type is different from tbe designated one.

the

motor pulley is correct.

turn

sewing machine bed.

the

first time aft

and

oil it well.

ON

the power switch

oil

leakage

er

the set-up, clean it thoroughly.

er

suppl

y.

or

parts

breakage occurs.

after

properly

2

Page 8

}Hiif

~~;J,illi}jt

41.k

'tf·

~

L\:

JJt

1\!!J.IHJV

ol

II~I

I~I,

·.~il.!r

(

l~t;JJ.WJI·)

ttifHr~

-ftJf.ltdE~

Ifl:ftM!.t

m~.R-t

1\l!JII-I'Ililh

1. SPECIFICATIONS

8990SS

-Alt:tfif4,

~if,ljfij7f

13

7;tJ;btl

JACK

New

I

tWM,

~

Defrix

8991SS 8990DS

cp

J1J*4

5000

tj

·

*5mm

DBxl #9-#18

lOmm

(.tir-/f.t)

15

30.7

mm

ti~

300mm

Oil No.1

517mm

tfl.illl

Xl78mm

rom

(~::k)

~M

4000

899LDS

tt

I

-A~t~t4,

~i\11jfij:7f

x~~ti~

--

8990SS

Application

spee

Sewing

Stitch l

Need

Presser

foot

Needle bar stroke

Rota

Arm

Arm

Lubricating oil

*The

maximum sewing speed is 4000 rpm when the stitch length

d

ength

le

life(

by

knee

litter)

ry hoo

k

pocket size

bed

size 517mm

General fabrics, light-weight

medium-weight materials

Lubricated rotary

JACK

I

Max

.5000

New

Defrix Oil No.I

rpm

8991SS

IOmm

hook

and

*Max.

DBxl #9-#18

(standard)

30.7

is

8990DS

General fabris, light-weight materials

5mm

15

mm

(max.)

mm

Lubrication-feer rotary

300mm

X178mm

not less than 4 mm.

I

Max.4000

--

899I DS

rpm

hook

3

Page 9

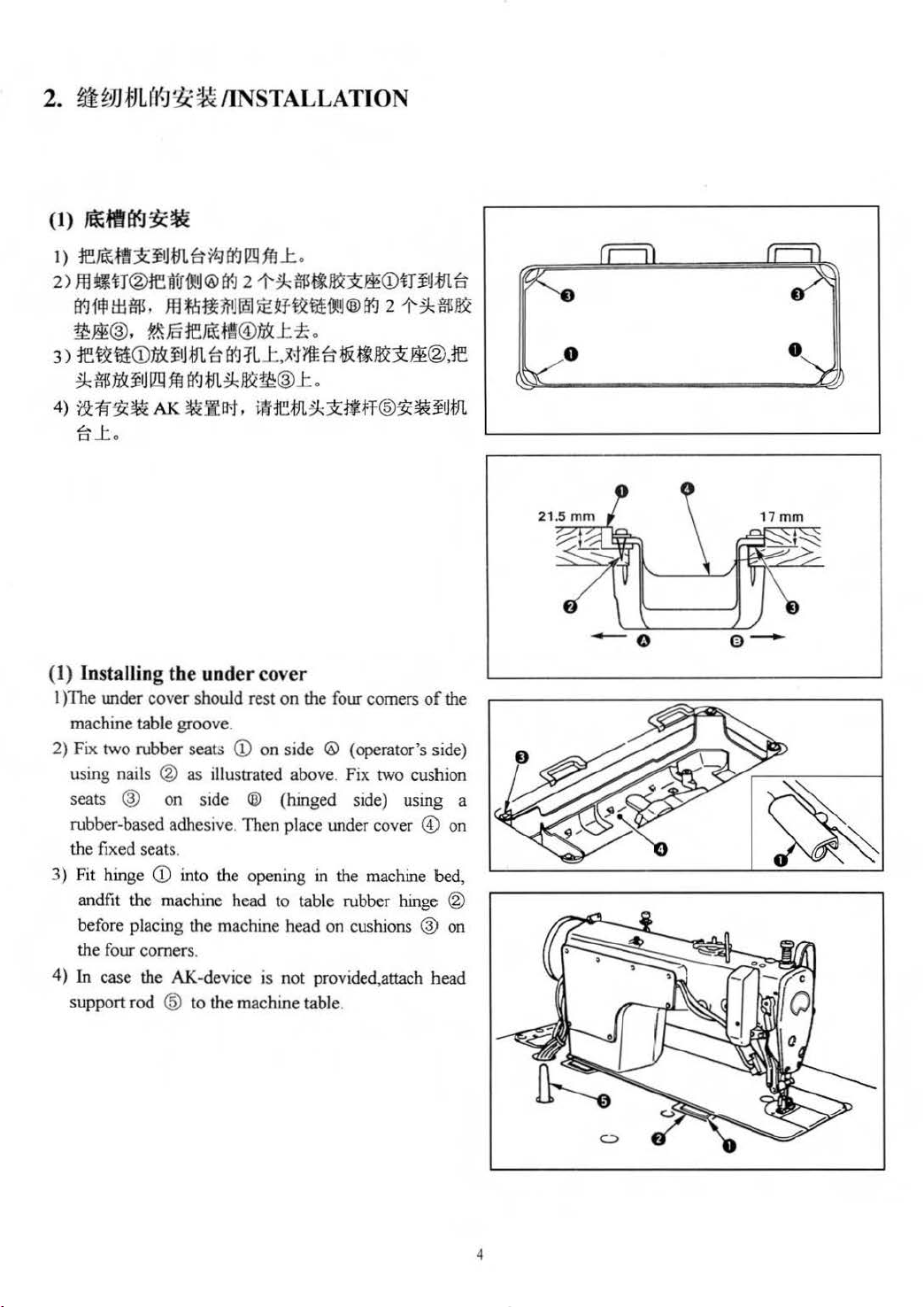

2.

~~9J

tJLI

Y-J~~

(1)

~fll¥1~~

1 >

re~ttt~

2)

ffl~H®:JelitriJ!tl®rfJ

~~~•·

m§!®

3)

re~•CD$¥1J;fn.Eirf.J1L

~B$¥1J

4)

Yiif:f(~

~J:

¥tl

m~•~~~*~•ru®rt-J21-~•~

,

?t.t.Fo:te~tll!

1m

ffi

AK

.

IINSTALLATION

m

~

7t1

rt-J

ll!l

ffl.t .

21-~Hi!.fi~j:§!(D~H,J-11LE1

@$.t~.

J:

.~fiEEi~.ti~~~®.1e

~m~JIQW:®.t.

~::llB;J",

i~1e.fJl.~~tijt.ff@:f(~¥

~fJL

(1) Installing the under cover

I )The under cover should rest on the four comers

machine table groove.

2) Fix two rubber seat.;

using nails ® as illustrated above. Fix two cushion

seats ® on side ® (hinged side) using a

rubber-based adhesive . Then place under cover

the fixed seats.

3)

Fit hinge

andfit the machjne head to table rubber hinge @

before placing the machine head on cusruons ® on

the four comers.

4)

In

support rod @ to the machine table.

CD

into the opening

case the AK-device is not provided,attach head

CD

on side ® (operator's side)

in

the machine bed,

of

@)

the

on

- o

e-

4

Page 10

A.

_

WARNING:

Turn

OFF

s

tart

of

the

the power

sew

in machine.

before s

tarting

the

work

so as to prevent accidents

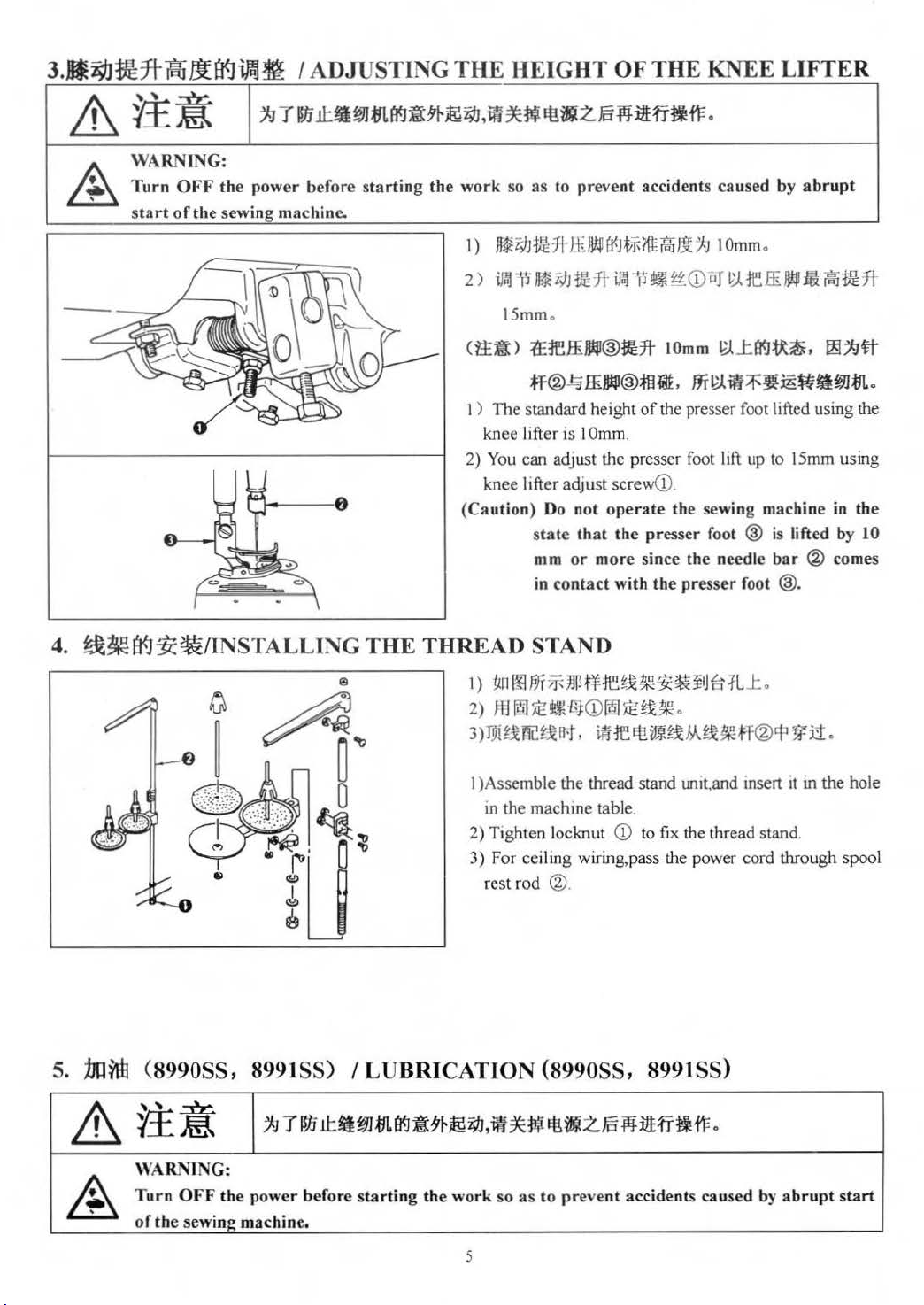

1)

~

i)I

Jt1HrH~llt4Jfi(JtJf-ftti%13t.fJ

2)~~-~-*~~•~CD~~reffi~~~•*

15mm.

caused

IOmm

by abrupt

.

4.

~~o<Jhttps://manualmachine.com/INSTALLING

THE

(tj:~) .tE1effi

~®~

1 )

The

standard height

knee lifter

2) You can ad

knee lifter adj u

(Ca

ution) Do

THREAD

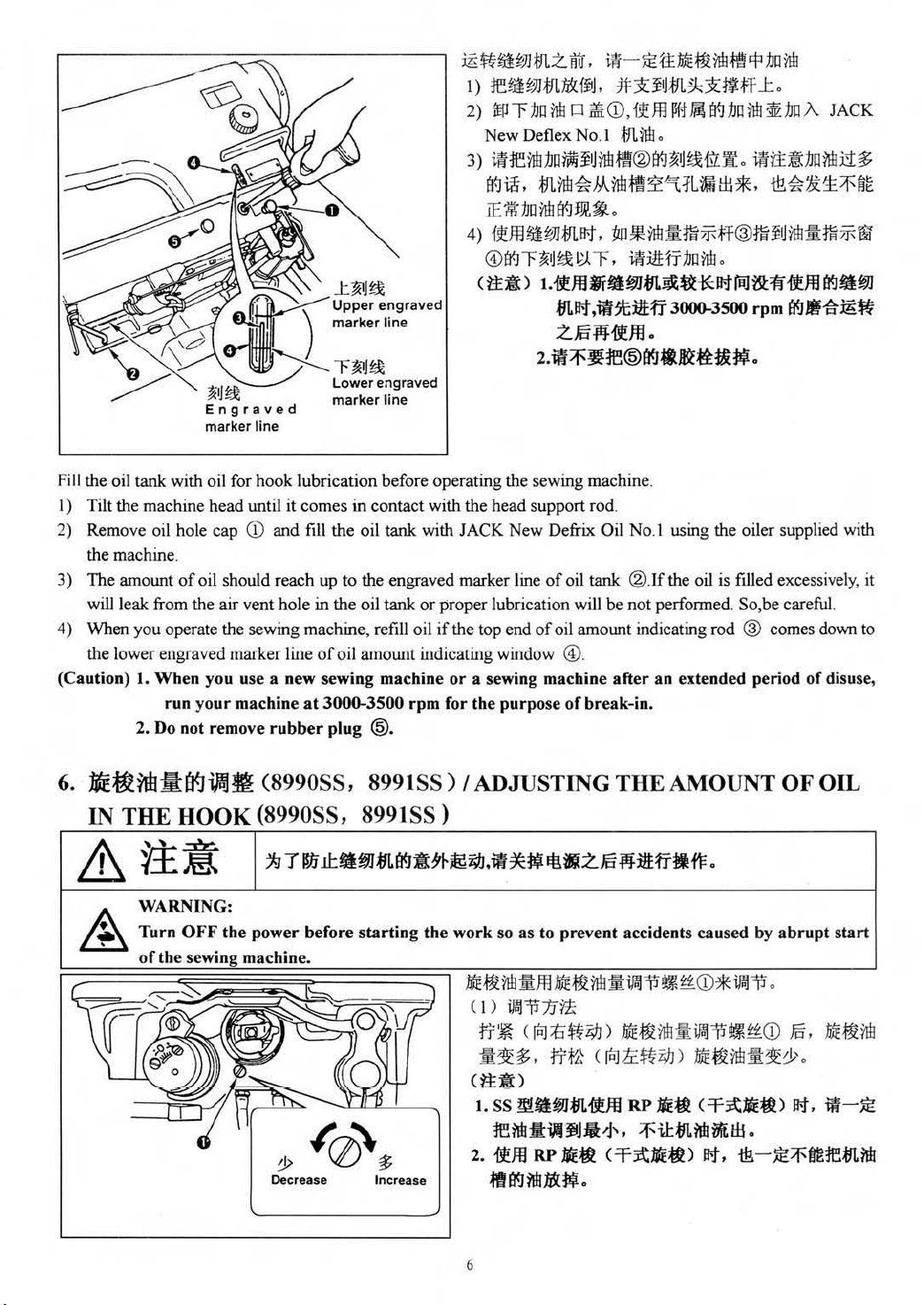

1)

~n

~fjf~JJ

2)

JfJ

1ti1

3)

rm~x

reu

1 )Assemble the thread stand unit,and insert

m the machine table.

2) Tigh

3) For ceiling wiring,pass the power cord through spool

ten locknut

r

es

t rod ®.

lJW®~

ffi~®~~.mt».

is

I Omm.

just

not

s

tate

that

mm

or

contact

in

ft

lOmm

of

the presser foot lifted using the

the presser foot lift

st

screweD.

operate

the

more since

with

the

presser

the

the

presser

sew

foot ® is lifted by 10

needle

1»-..t

fl<J~

~~~~

up

to 15mm using

ing machine in

bar

foot @.

STAND

I

Stf1e;:l~3C~~~Jf:t.fL.t.

~

t~

·

r.J

CD

l!m

frt.

~ ~ ~

~~He

CD

.

rt!

im!~x»Jx~H

to

ftx the thread stand.

®cr

~.

f!i

~~mm

® comes

~

i1.

it

in the hole

~#

.

the

5.

j]u~

&

~

(8990SS, 8991SS) I LUBRICATION (8990SS, 8991SS)

¥.£~

'~

WA

RNING:

Turn

OFF

of the sewing machine.

~r~~~m

the powe

r before

mfl<1a*&

sta

rtin

g the

~~~-~-~~~-fi~~

work

5

so as to

preve

nt accidents ca u

-

sed

by

abrupt

start

Page 11

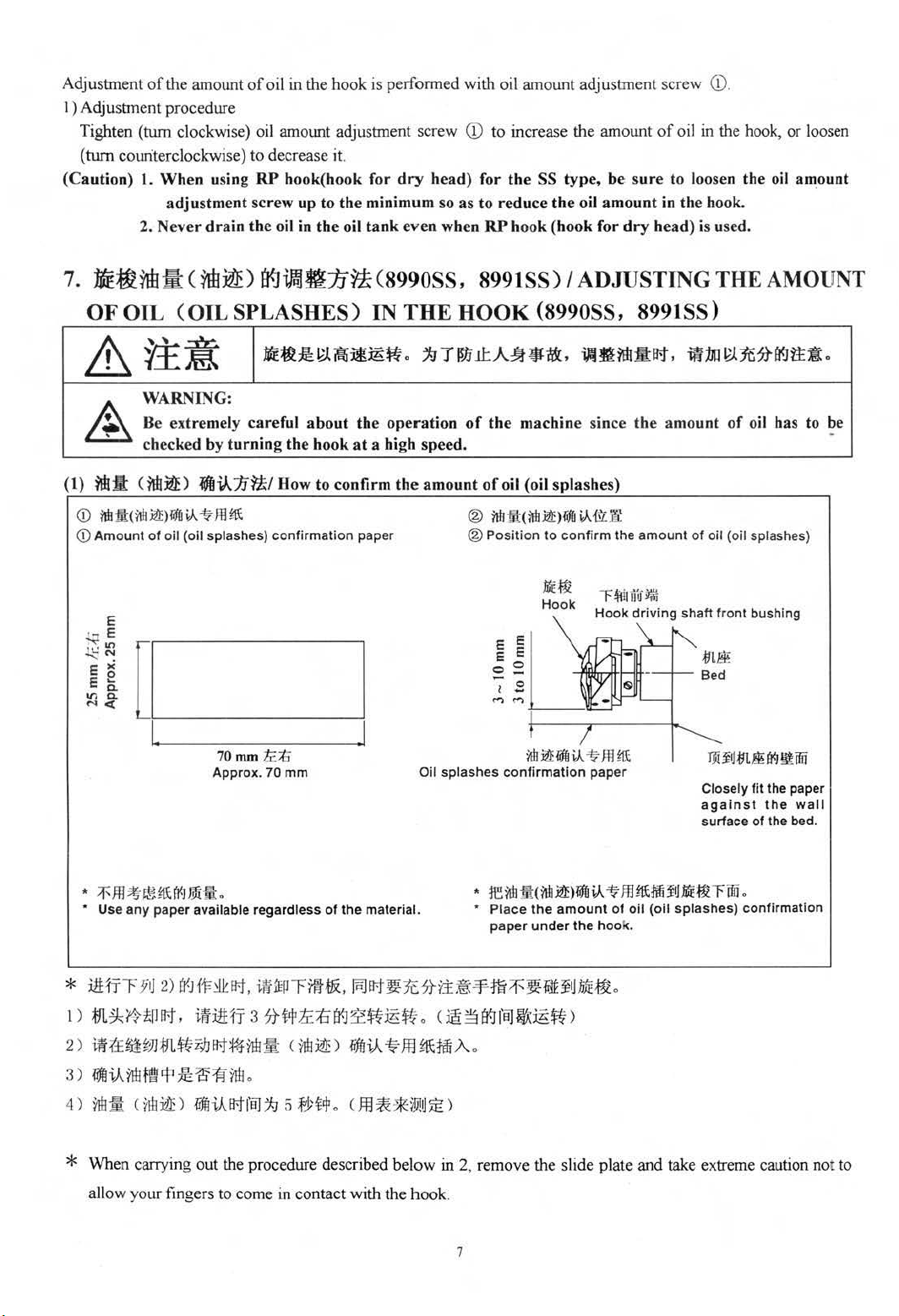

Fill

the oil

tank

with oil for

I ) Tilt the machine head until it

2) Remove oil hole cap

the machine.

3)

The amount

will leak from the

4) When you operate the sewing machine, refill oil

the lower engraved marker line

(Caution)

of

oil should reach up

1.

When you use a new sewing machine

run yo

2. Do not remove

CD

air vent

ur

machine

hook

lubrication before operating the sewing machine.

comes

in contact with the head support rod.

and fill the oil

bole

in the oil

of

at

3000-3500

rubber

plug @.

tank

with JACK

to

the engraved marker line

tank

or

oil amowlt indicating window @

rpm

~••mm~~.

l)

1EfibJJ.t!LfiXfftJ,

2)

lEfJ"""f:br:J~

New

3)

ii:IE1\fJ1Jr:J#UiJ~.m®atJ~

~~

IE

#fJil~~~~.

4)

f~fflU~JJmat.

®atJ"""F~~J~

c

tt~)

D

Deflex No.1

.

m~~M~-~~~~~*·

t.

ifJO

m~t-t

2..6-NifJO.

2.lti~~:IE®£1CJ.~ttt£~.

New

Defrix Oil No.I using the oiler supplied with

of

oil tank ®.If the oil is filled excessively, it

proper

if

lubrication will be

the top end

or

a sewing machine

for the purpose

of

oil amount indicating rod ® comes down to

of

•-~tt••~M~~~

#:J(i

~.t!L

~~f,Uf

iWi

CD,

ft.J=§

llft

1M~

m~.

Ij

~-fl'Lft.

tm*~:l:fli7F;ff®fli¥

I2J.

r,

iRliHr1Jo~.

JT!lmm!~U~¥drt1Blti:ff

,ift]tlltff

after

break-in.

3000-3500 rpm

not

perfonned

an

extended period of disuse,

.t.

1Jil1W

iUUA

ii!ttt~:bll¥!lli1§f;

&~~~~~

. So,be careful.

JACK

1J

rm:!:m7Fw

if.m

e9!lfm

I'J(Jlffil-lg~

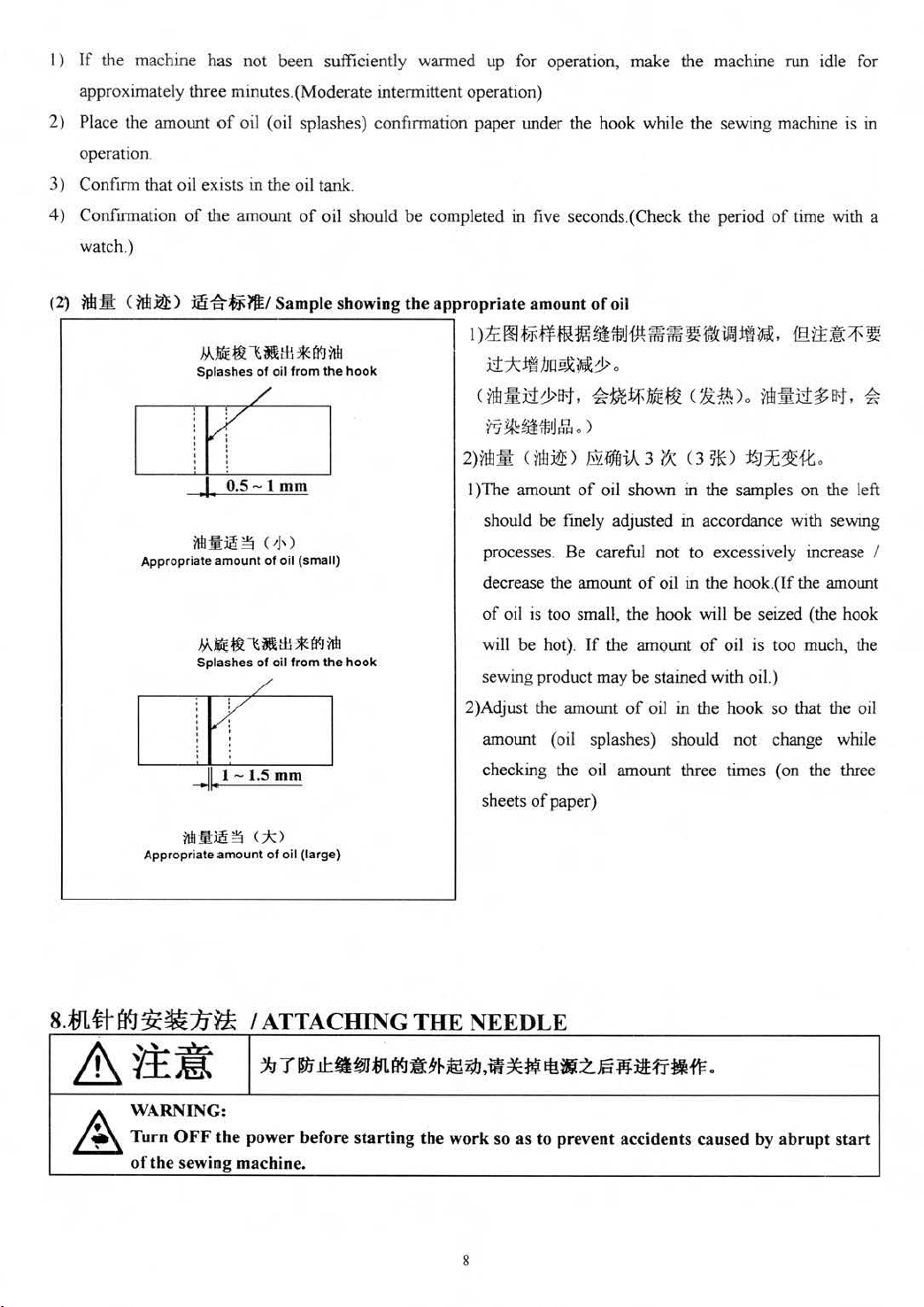

6.

lE~rmill¥.JiiAJ.

IN THE HOOK

WARNING:

A

Turn

OFF

of

the sewing machine.

(8990SS,

899ISS)

(8990SS, 8991SS)

the

power before

starting

I ADJUSTING THE AMOUNT OF OIL

the

work so as to prevent accidents caused

··~:!:JOJitE·~·~~~~

(I)

~~

1J ¥t

Decrease

Incr

ease

rr~ <[Q]::b~~)

•

~$

.

rr~<~

(tj:ft)

1. ss

~tutmmu

re

~

:1:\\1

JjJ

2.

i!Jti RP

flt£1CJ?1iJJD(~.

6

JIE~ ( =f~:Jti~)

•

!J,

••

~"~>

RP

•

::f'

by

abrupt

CD

*~~

rm:fl!:

~~~~

••rmg~&

:lti~

c=t=-~Jti~)

11:

m

~

rAt

at,

.

CD

l±i

•

&-

JE~fm1E!11.?1il

~.

••rm

.

Jt-t,

iif-JE

start

Page 12

Adjusbnent

I)

Adjustment procedure

Tighten

(turn counterclockwise) to decrease

(Ca

ution) 1. When using

7.

:Mf~rffiit

OF

&¥£~

&\

(1)

?lli:fit

<D

Amount

of

the amount

(tum clockwise) oil amount adjusbnent screw

adjustment

2.

Never drain

(

OIL

' checked

(OIL

...

~

WARNING:

Be

extre

($UIJH)

of

oil

(oil splashes)

of

oil in the

RP

screw

the

oil in the oil tank

rffi~)

I¥J~f!/JW(8990SS,

SPLASHES) IN

~~~~~~~~.~T~~A~$~.

mely careful

by turning

?Of!V..1Jf!l

How

confirmation

hook

it.

hook(hook

up

to

the

about

the hook

to

con firm

at

is performed with oil

CD

for

dry

head)

minimum so

even

as

when

to

8991SS) I ADJUSTING THE AMOUNT

the

a hi gh

paper

THE

operation

the

HOOK (8990SS, 8991SS)

of

spee

d.

amount

®

amount

to

increase the amount

for

the

reduce

RP

hook

the mac

of

oil (oil

Position

adjus

SS

type,

the

oil

(hook

~-~-~.~m~~~~~~

hine

splashes)

to

confirm

bne

be sure

amount

for

dry hea

since

the

nt screw

of

the amount

amount

CD

oil

in

to

loosen

in the hook.

d) is used.

of

oil

.

the hook, or loosen

the

oil

amount

.

of

oil has to be

-

(oil splashes)

E

~

E

n

•

• Use

* iiHJ'F 111 2)

I )

z)m~umm*~B1~~~<~~)•~•m~•A.

3)

4)

[1!-------~

70

mm

ft.;f;

Approx. 70 mm Oil

>Fffi~~~(

tfl

~lt!rJrr.t,

·~nlltfN9'~~~1r!

~lt

rl:

F-JJ1

any

Hil:.

paper available regardl

tr'.lft~B1.

i!litHr 3

Offiil£)

1iffl~ftt

ess

illffEIJrffi

?t~li:;ba<J~~iE~.

J.

i'8J

;9 5 .fy~cp.

of

the

material.

:tJX.

~ftt~JE

Oll~B

splashes

•

•

?tr£g.:p11J:f'!H

C

~3a<Jf8Jf.i::iE~)

lt~Y!tl

~)

~~

Hook

nn~liffiV-

confirmation

reit!lill

<nn~>li1HV-

Place

the

paper

under

~

T~111u·f;1,t

Hook

-

~m~

paper

amount

the

hoo

t¥1JJiJE~.

driving

~

ffl

fft:tilif'1..16Ett

of

oil

(oil

k.

shaft front bushing

fit the paper

Closely

against

surface

the

of

the bed.

rffii.

splashes)

confirmation

wall

* When carrying out the procedure described

allow your fingers to come in contact with the

below

in 2, remove the slide plate

hook

.

7

and

take extreme caution not to

Page 13

I) If the machine has not been sufficie

approximately three minutes.(Moderate intermittent operation)

nt

ly warmed up for operation, make the machine

run

idle for

2) Place the amount of oil (o

operation.

3) Conftrm that oil exists

4) Confirmation

watch.)

(2)

7111:1!:

(

of

711!~) ~*~1l/

Splashes

in the oil

the amount

lAME~~~

of

/

: 1 v

·

V:

' '

' '

: i

.1.

0.5-1

itb:ID:

~

iate

amou

~ ( tj\ )

nt

of

Appropr

il

splashes) c

tank

of

oil should

Samp

le showing the appropriate

l±l

:liE

B<J

from

mm

oil

$tb

the

(small)

oil

onfmn

be

hook

ation paper under the hook while the sewing machine is

completed

in

ftve seconds.(Check the period

amount

1 )

li:

00

t

'F

jj:);:::tj

(

~~ct

r5~~11i~£.)

2)

~ik

O!b

I )The amount

should

processes. Be careful not

decrease the amount

of

oil is too small, the hook will be seized (the hook

of

oil

#ttH~

!l

~

#Jtl

-fJH/ff

~ ~ 1t~

J

JQ~(f;ty

~~.~-~--

~)

be

.

(~~).~ti1$~.~

JSY1

ifH.A

3 (

J;:

0 5i0

of

oil shown

finely adjusted in accordance with sewing

in

the samples on the left

to

excessivel y increase I

of

oil in the hook.(If the amount

of

if.j

.tW

l1it

• m

:1:$)

5£~-ft.

time wi

t.E

~

.

th

/F

in

a

Jl:

M.~~~~l±l*rfJith

Splashes

__jj.

)tb:!i~ ~ <;~)

Appropriate :amount

s.m#a<J~~:!Jf!

...

&¥±~

~

~

WARNING:

Turn

OFF the

of

the sewing machine.

of

oil

from

the hook

I -

1.5

mm

of

oil

(large)

I ATTACHING THE NEEDLE

~Tm~•m•~

power

before

starting

will be hot).

sewing product may be stained

2)Adjust the amount

amount (oil splashes) should not change while

checking the oil amount three times (on the three

sheets

of

paper)

If

the amount

of

of

oil is too much, the

with oil.)

oil in the hook so that the oil

•*m~~~•*•~~~•ff•~·

the

work

so as to prevent accidents caused by

abrupt

start

8

Page 14

~Wftffl

DBxl ~ DPx5

~JlJL#.

i~.ftH~~B'~fliWJ,

1'fi*'HI(J

:t

~

I

I

I

I

~

I

I

,_,.

c~:i:) 1fffl*

•re-mtt-~~~~••~•.

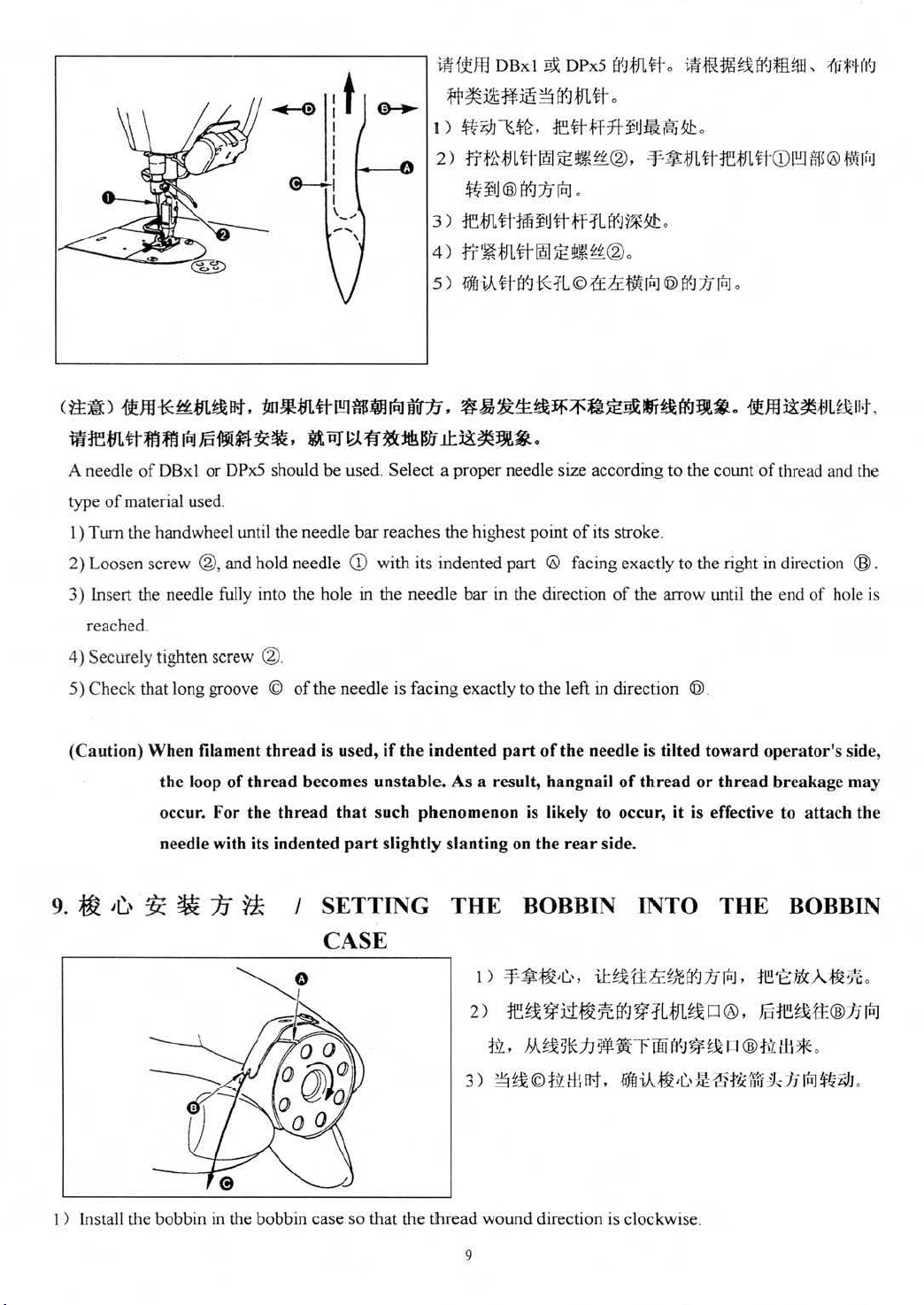

A needle

type

of

I)

TWTI

2)

Loosen

3)

Insert the needle fully into the hole

~.m~

a:t. W~*m*[!!J~.iJinlmrn.

of

DBx I or DPx5 should

material used.

the

hand

wheel until the needle

screw ®,and hold needle

~~~w•*•~~~••

be

used.

Select

bar reaches

CD

with its indented part @ facing exactly to the right

in

the

:fr~:i*

1 )

2)

3 )

4)

5)

~ilt

~

({-]

,fJL

* 0

~Z))JlS~,

rrt~;fJLHm!}:Et~f'i'®,

~

ilj

:Jet

JL

tr

n=~tJLtt-~~t~~£®.

fiffliA#B<J*1L©1£~fY'iia.J@B<J/Jr~

~:&-~~~:Ef::f'~~~*f~(J<Jl:l•·

1E.#ff7f-$rJifkrl~B!.!:

®

({-]

1J

laJ

0

ffi $

1j

*

.jf

1l

fj{J

~ ~

o

-¥~H1LtHemti"CD[!!Jfl'

0

o

1fffll3:~MJL

f

)®~

~11H,

HiiJ

o

a proper needle size according

the highest

needle

bar

point

of

in the direction

its

stroke

of

to

the count

.

the arrow until the end

of

thread and the

in

direction ®.

of

hole is

reached.

4) Securely tight

5)

Check

(Caution) When filament t

9.

~

~~'

en scr

that long groove ©

the

loop of

occur.

needle with its indented

!i.

~

for

1J

ew

®.

of

hre

thread

the thread

~

the needle

ad is use

becomes un

that

is

facing

d,

if

the

stab

such phenomenon

part

slightly slanting on the

I SETTING

CASE

exactly to the left

indent

ed

part

of

le. As a result, hangnail

is likely to occur, it is effective to attach the

THE

2)

3)~~©~ili~.

BOBBIN INTO

I )

¥~~~C.·, iH:

re~~rl~:Jift-J~:t

152,

h\?2.Bt0J

in

the needle is tilted toward

rear

side.

5!li

direction @.

operator

of

thread

or

thread breakage may

THE

H!lr:~JtB<J/Jr:;J,

LtJL

~IJ®,

~r

rnHI

0

~ ~

®iA•~~~~m~h~~~

1~E;iD{.A;f3l

m1~~1tt:®hltrJ

I I@

.fil.

's

side,

BOBBIN

:/6.

/11 *.

o

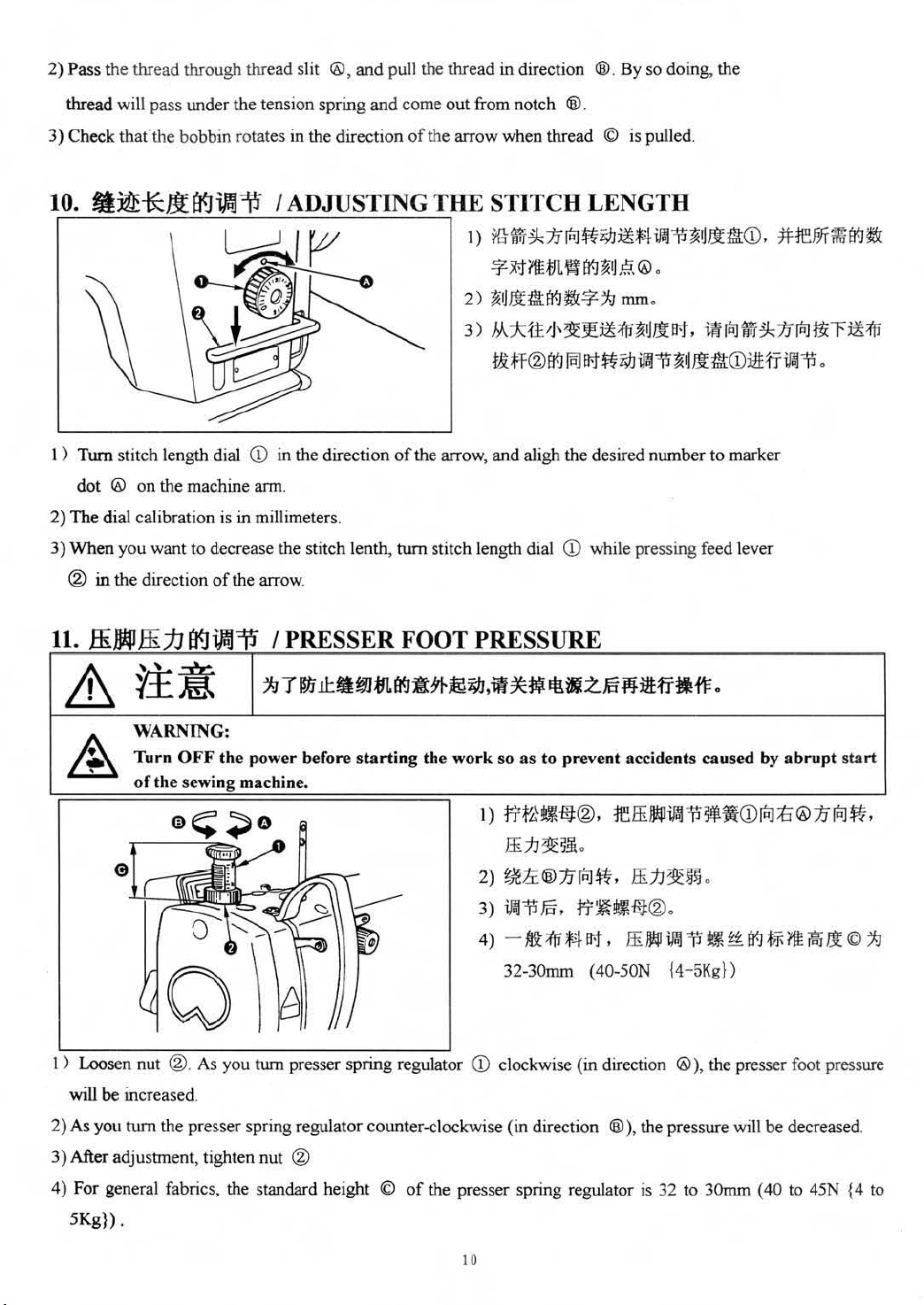

I)

In

stall the bobbin in the bobbin

case

so

that

the

t!hread

9

wound

direction is clockwise.

Page 15

2) Pass the thread through thread slit

®,

and

pull the thread in direction ®.

By

so

doing, the

thread will pass under the tension spring

3) Check tha

10.

I )

Tum

dot

Th

2)

Wh

3)

® in the direct ion

fthe

bobbin rotat

ff:it!

*ll

a<JiAJ

stitch length dial

® on the machine arm.

e dial calibration is in millimeters.

en

you

want to decrease the stitch lenth,

of

es

in the direction

iJ

I ADJUSTING T

CD

in the direction

the arrow.

and

come

out

from notch ®.

of

the arrow when thread © is pulled.

HE

STITCH LENGTH

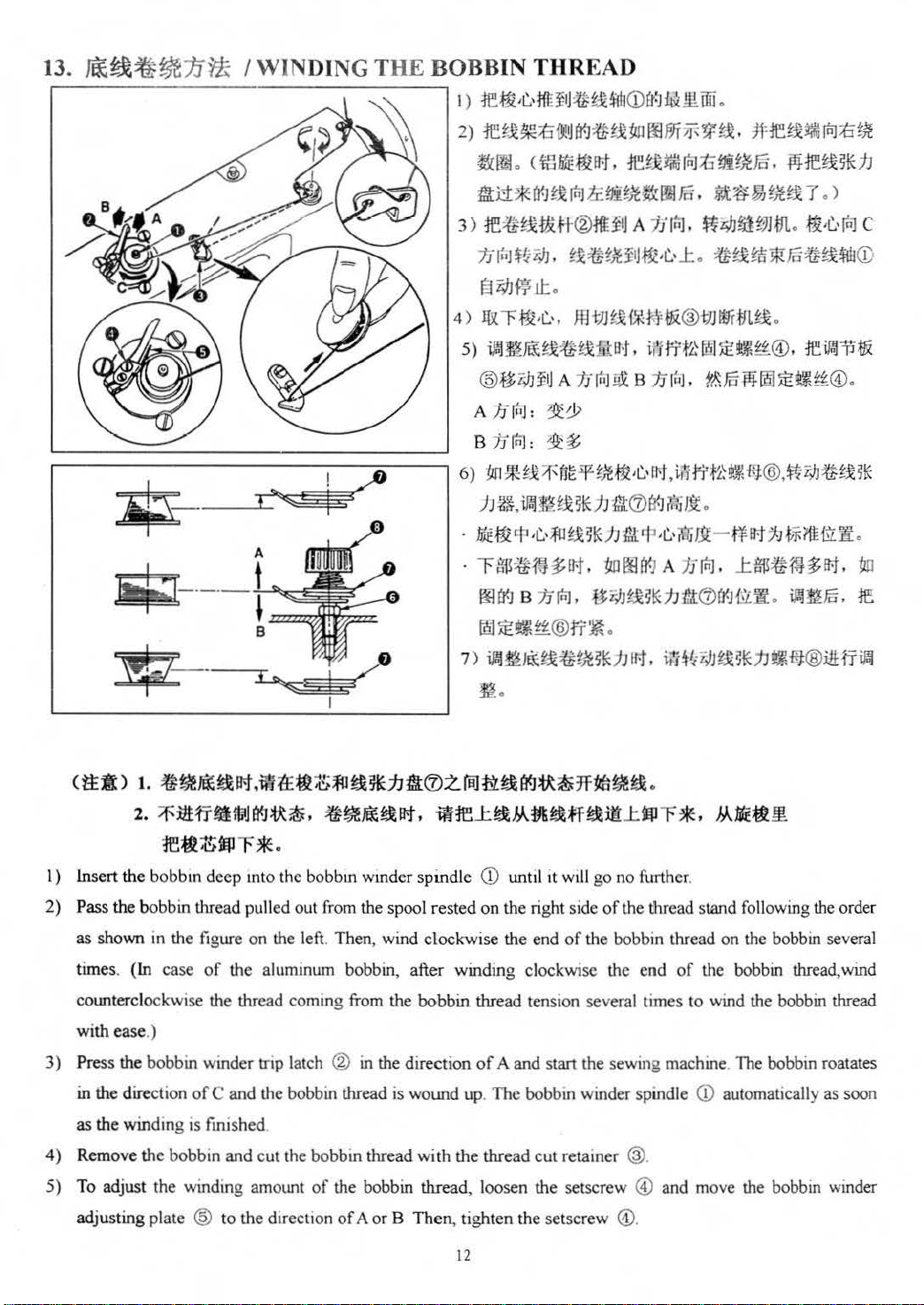

I )

illWrf

~

:IJ

rtJ

~~i9J~:M

-*"

M

?tUJL

~

(f.J~rL~.

2)

~!Jf.ffiEr-1~-*"~

3)M*tt~~

•H®(f.J~~~i9J~~~~-CD~~-~

of

the arrow, and aligh the desired number to marker

tum

stitch length dial

~~~~J.t~.-rtlft~:IJ~~~~~

CD

while pressing feed lever

iP.li5

®.

mm.

~!JJ.t

fit

CD'

:tHEJi.JT

~

.

Et-J

~

11

.

JliJJ14J

.ffi

jJ

a<J~Ti

£, WARNIN G:

_

Turn OFF

of

the sewing machine.

I)

Loosen nut ®.

will

be

increased.

tum

2) As you

the presser spring regulator counter-clockwise (in direction

I PRESSER FOOT PRESSURE

the

power before startin

As

you

turn

g the

work

presser spring regulator

so as to prevent accidents

1 >

n't.HJ-e:®.

ffit.J~

2)

~

le®1J~~.

3)

ir.J~€.

~--~M~.

32-30mm (40-SON {4-5Kg})

CD

clockwise (in direction

reJI!J141•

5!

.

ffijj~~~

:rr~t'-HJ®

ffi

!J141•Ti~*Et-J~m•J.t©~

®),the

caus

ed by

abrupt

Ti~J(CD

.

.

®),the

pressure will be decreased.

rtJ

:ti

presser foot pressure

sta

®/Jrtl

~,

rt

3)

After adjustment, tighten nut ®

4) For general fabrics, the standard height ©

5K

g}).

of

the presser spring regulator is 32 to 30mm ( 40

10

to

45N { 4

to

Page 16

12.

_t~~~:JJ~

I THREADING

THE

MACIDNE HEAD

~

~

¥±~

.'

~

WARNING:

Turn

OFF

the

of

the

sewing machine.

~T·k~-m~a*&~~~-~SZfi~-~-~.

power before

starting

the work so as to prevent accidents caused

0

<

tl:

>

(Note)

by

abrupt

::ftJMelft~!lli

Do

not

pass this

thread

through

section().

O

start

$

11

Page 17

13.

~~~~

1J¥!

I WINDING

THE

BOB

BIN

THREAD

I)

le~·L.•

2)~~-~-~~~~oom~9Y.~re~•~~~

ff

U~:¥1:~!ffh

<D

tf.J

ibiill.

iiD

.

~~.<m~~~.~~~~~~~Fc.

~i1*1'f.J~xlnl

3)

1E~~1£#®-Mf..flj

1Ji

nJ$

!iliiJ

§

MW

4)~~-~.

s>~•

6)

-

-

7 )

~~$~hl~.~~~~~~~®.re~~•

@-~~A~~~B~~

A

:1JrQ:J

=

B

:1Jrnl

:

1m*~:;

)J

~5.

illft~~

~-~~~~*h•~~n&-n~~~m&~

~n~w~~. ~OO~Anlnl . .te~mJ~.

~~B:1J

~~t~f:~®rr~

ir.l~J~J&;ffi~~~lUJ

.t

df!~~m~Fn.

A 1iliiJ,

,

~x~t~jiJ~·L.·.t

~~~HJHxT.)

~4JriiWJt11.

.

~tHi!i'~Uci~~H!lJ

ll:.

mm~~M•®

~&

~~

Ffielf-m-!3l·t·rt-t,i~f-i't~t~-f{t®,tirJJ~~x5K

~lUJ

:W.:

(J)

i¥J

inJ,

8~Y~h·~~&•.~mfi.e

.

IM',

~~m~

.

~ffi~~~-~@.

~·~I~

.

iat~i"JJ~5~1J-HJ;

~~~*h

.

.

~·L.·~

@

C

~

.

~

i8:tr~

••

<t:EA)

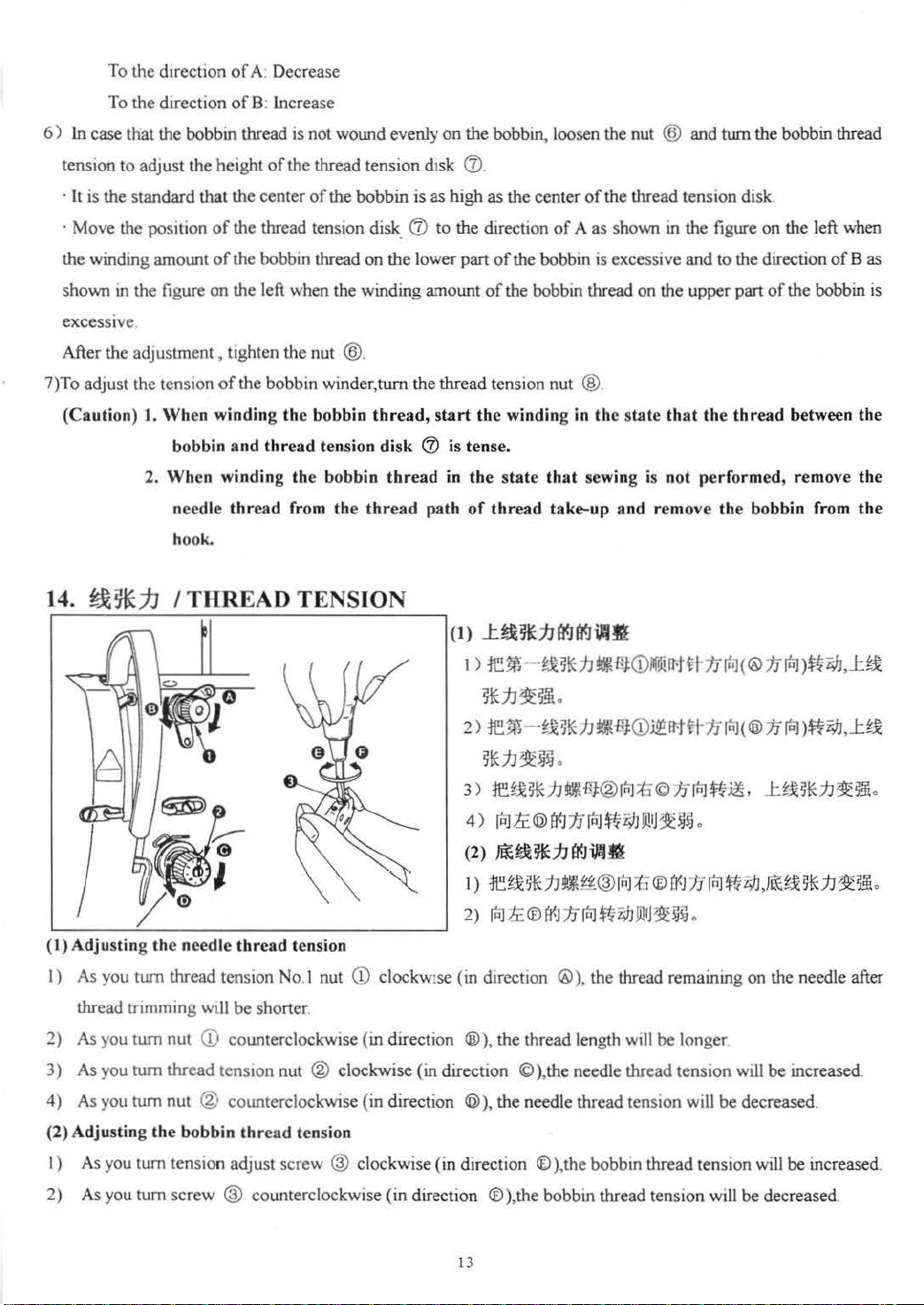

I)

insert the bobbin deep mto the bobbm wmder spindle

2) Pass the bobbin thread pulled out from the spool rested on the right side

as

times.

counterclockwise the thread coming from the bobbin thread tension several times to wind the bobbin thread

with ease.)

3) Press the bobbin winder trip latch

in the direction

as

4)

Remove the bobbin and cut the bobbin thread with the thread

5) To adjust the winding amotmt

t.

$~~~1Pt,iiHE;ti45lt'l~*iJfl®Z.raJtt~(J(J~~1f1tii~~.

~

~•ff•~~~~.•~•~~Pt.•re~~Mm~~~-~~~*·M~~•

re~~lll

shown in the figure on the left. Th en, wind clockwise the end

(In case

the winding is fmished

-

F*·

CD

until it wi

of

the aluminum bobbin, after winding clockwise the end

® in the direction

of

C and the bobbin thread

of

the bobbin thread, loosen the setscr

is

wound up. The bobbm winder spindle

of

A and

stan

cut

ll

go no further.

of

the thread stand following the order

of

the bobbin thread on the bobbin several

of

the bobbin thread, wind

the sewing machine. The bobbin roatates

<D

automatically as soon

retainer ®.

ew

® and move the bobbin winder

adjusting plate

@ to the direction

of A orB

Then, tighten the setscr

12

ew

@.

Page 18

To the direction

of

A. Decrease

the direction

To

6)

In case that the bobbin thread is not wound evenly

to

tension

·

It

· Move the position

the winding amount

shown

excessive.

After the

7)To adjust the tension

(Ca

14.

adJust the height

is the standard that the

in

the figure

adjustment.

utio

n)

J.

Wh

bobbin

Wh

2.

needle

hook.

~*.7J

I THREAD TENSION

of

B: increase

of

the thread

center

of

of

the thread tension

of

the bobbin thread

on

the left when the winding amount

tighten

of

en w

inding the

en

winding th

the

nut @.

the bobbin winder,

and

thread

e bo

thread from the thread path of thread take-up

tension d1s

the

bobbin

disk

on

bobbin

thread,

tension disk

bbin

on

k 0 .

is as

high

(J)

to

the direction

the lower part

tum

the

thread tension nut ®.

start

(J)

is tense.

thread

in the s

(I)

the

bobbin, loosen the nut @ and

as

the

center

of

the thread tension

of A as

of

the bobbin

of

the bobbin thread on the upper part

the

winding in the state that the

tate that sewing is not

_t~~j](fj(f]i.flfl

shown in the figure

is

excessive

and

and

performed,

remove the

tum

the bobbin thread

disk

.

on

the left when

to the direction

of

the bobbin

thread

between

remove

bobbin

from the

of

Bas

is

the

the

(t) Adj u

I)

2) As you

3)

4) As you

(2)

I)

st

ing the n

As you turn thread tension No.I nut

thread trimming

turn

As you

Adju

As you

turn

tum

sting the bo

tum

eed

le

thread tension

wt

ll

be

shorter

nut

CD

counterclockwise (in direction

thread

tens

tOn

nut @ counterclockwise (in direction @ ), the needle thread tension will

bbin

thr

ead tension

tension adjust

CD

clockw1se

nut

® clockwise (in direction

screw

® clockwise (in direction

1)

:te~-!x5~JJ~~~

5*JJ~5!

2)

rem

5!E.7J~~~

3)~Y*hS~®Iul~ChluJ~~.

4)

[Q)le:@a91JrR'J~z;lj)J!IJ*~~

(2)

Ji£~~11

1 >

retx5*

2)

[ti)

(in djrection ®

®),the

.

- t

..

BtEJJ~~Q)j!ft1tUflnl<®7rluJ>~rJJ.J:~

.

(fj

.:7J

~

£ ®

ft-J

}J

),

thread length will

©),the

needle thread tension will

®)

,the bobbin thread tension will

<D

K~rr·tvt-1JrtJ<®7rlnl>*zJJ.J:t~

J:Y*.7J~~.

.

iAJff

~~®inJ;tJ

[ti)

t~fJJ)J!Ij~~~

the thread remaining on the needle after

®

be

(j{J

1i

o

longer

rtJ

~

M

be

decreased.

,JtHx

5*JJ

be

increased.

be

increase<i

~5,;

.

2)

As you

tum

screw

® counterclockwise (in direction

13

®),the

bobbin thread tension will

be

decreased.

Page 19

15.

15!~~-

( 1)

Changing

the

/TH

stroke

READ TAKE-

of

thread

take-up

UPS

spring

PRING

<1>

Jf

i&~tifi.JICDacJrrf£111

1 >

rrt~~s~JJ

2)

re~~~JJH®~:ti®tr.J

3)

rfil~®f(~1Jfnl-1:1i;I:JJill

(2)

Jfi&~tifi~•CDB<JffiJJB1,

1)

rrt~~

2)

rrt'~~x5lCJJH

3)

fEJ~

4)

rPJ1L®f(-J1JfriJ~l;JJ!Jli

f:l

~~~~~~®.

f

(~1J~~i;I:JW1J~

j~;J'.

ri:

~~~®Jrrf~*.1J%~(ffi.1lf)

!i!

l~t~~@itHfif~~

5*

fJ

ff@~

;(:J

@

(f.]1J

~

J~~.

CD

I) Loosen setscrew ®.

2)

As

you tum tension post @ clockwise (in direction @),the stroke

of

the thread take-up spring will be

increased.

3) As you turn the knob counterclockwise (in direction ®),the stroke will be decreased.

(2)

Changing

the

pressure

of

thread

take-up

spring

CD

.

:k.

@.

.

~i;I:J

D!IJ~~!Ji

.

I) Loosen setscrew

2) Loosen setscrew

(

~,and

@.

remove thread tension (asm.) @.

3) As you tum tension post @ clockwise (in direction @), the pressure will be increased.

4) As you tum the post counterclockwise (in direction ®), the pressure will be decreased.

(ti:Alt)

JK8991-DS ,

~~. ~fi-J<iPI!fB<J~~~.

~~fi-·1PI·~~I¥J:1!1JJE

timzM.

!l•1ia<J~~rrfl5:J:;J'B<J~~fli!J3'&*~4.

.

m~~~~~nu~.m~~~~~~M

:!&:

12 ili * .

When the thread take-up

midway, th

tension

DF

:#l~f;§~*ffl

~~••£~$a~~·~*~£~~.ra$a~~.

1J

~£:

~1t=f

J:tttftt,

tt~~~~t:Jifi,

fdfti.\~~--B<JffiJJiPI!f

~-!i:B<J

-ftffl:bo?\bldfitl:ttf,

IT~.&!ie~ll!~~~.

.E

'

jE_tf;l(R]®/JrtiJtil±I.Ta'

~~~~~••B<JffiJJ.~jr.m

-

JN:-11Jt4

t0-J3mm

ii:;(:J~~~.

X

•

~E~~)9i-liz;IJ~~HN:J5

•

The

thread take-up

up

to

the last.

of

read

the

is

fed

thread

spr

out from

take-up

ing moves

0 since the

spring

is

O

up

to

high.

~~~~f;l-~1,\l!fa<J

0

spr

ing works

~JA<;Yft

•

14

Page 20

(Caution)

For

the Models

JK899lDS

and

-DF,

the

fully-dry hook is

adopted

. Comparing with the sewing

machine using

thread

increases. As a result,

To

jud

works

the direction

does not

stroke

general

16.

m

~

ff

&it~

A

--~

WARNING:

Turn

of

the

the

existing hook, the sewing machine tends to be affected by the adjustment

take-up spring .

ge

the

work

of

up to

the

last before needle

of ® after

work

up to

of

the

thread

fabrics, a

1J6

~I

take-up

stro

B<J

~rm~~•moo•*&~~*•*~~~~-~~~-

OFF

the

power before

sewing machin e.

If

the

thread

thread

the

the

ke

breakage,

thread

last,

of

~

tak

e-up

thread

the

pressure

decrea

spring

10 to 13 mm is proper.

is excessively small,

T-i

I ADJUSTING THE THREAD TAKE-UP

starting

take-up

balloon stitching etc. may occur.

spring,

of

se

the

spring

confirm

is pulled

the

thread

pressure

does

not

whether

out

from ® when pulling out needle

take-up

of

the

the

spring

thread

spring

STROKE

the

work

so

as

to prevent accidents caused

of

work

sufficiently,thread running

or

not the thread take-up spring

thread

ha s been performed. When it

take-up

does not work properly. For the

spr

ing. In addition, the

by

abrupt

start

the

in

l

2)•~•M~.re~~-oo~~®~~~~~.m~

3)~~-ro~~~©~-~~~~~~~~~~m

I)

When sewing heavy-weight materials, move thread guide

of

thread pulled

2) When sewing light-weight materials, move thread guide

of

thread pulled out by the thread take-up.

3) Norm ally, thread guide

17.

:tfl.#

&it~

--~

out

by the thread take-up.

ID

is positioned in a way that marker line © is aligned with the center

w.tt{f[•B<J~~

I ADJUSTING

~Tm~~•mooa*&~~~·*~~~~-~-~-

)B~~M~.e~~-

!!~*·

1iE:l

~'J'

.

CD

to the left (in direction

CD

to the right (in direction

THE

NEEDLE STOP POSITION

ID~~®~~~

®)to

increase the length

®)to

decrease the length

of

8~.m~

the screw.

WARNING:

A

Turn

OFF

of

the

sewing machine.

the

power before

start

ing

the

work

so as to prevent accidents caused by

15

abrupt

start

Page 21

\

(1)

W~

J§

a<J~

11:-&

~

1 )

t=r-

r1Ur~

m

tt

w .tt

lliit:&&:

Er.J

8

~

~J.

~ ® -i~ll-JEr.Jmft.

2)~mtt~~~~W.t1:1flit.~~-~ill.~*Rffi

l:rn

:iJHf

iJWf.i

•

A. lti

J ©

EB

1J

r~

:tt

i;IJ.fJl

B.

[DJ©Er.J1JJriJ

~i9.Jfil#

m.tt7'r

~t·

f!P

.UJ!l:

f¥ll:fi:iR

4HB~u

litr.

.

£ ®

~

~.tt

ctt~)

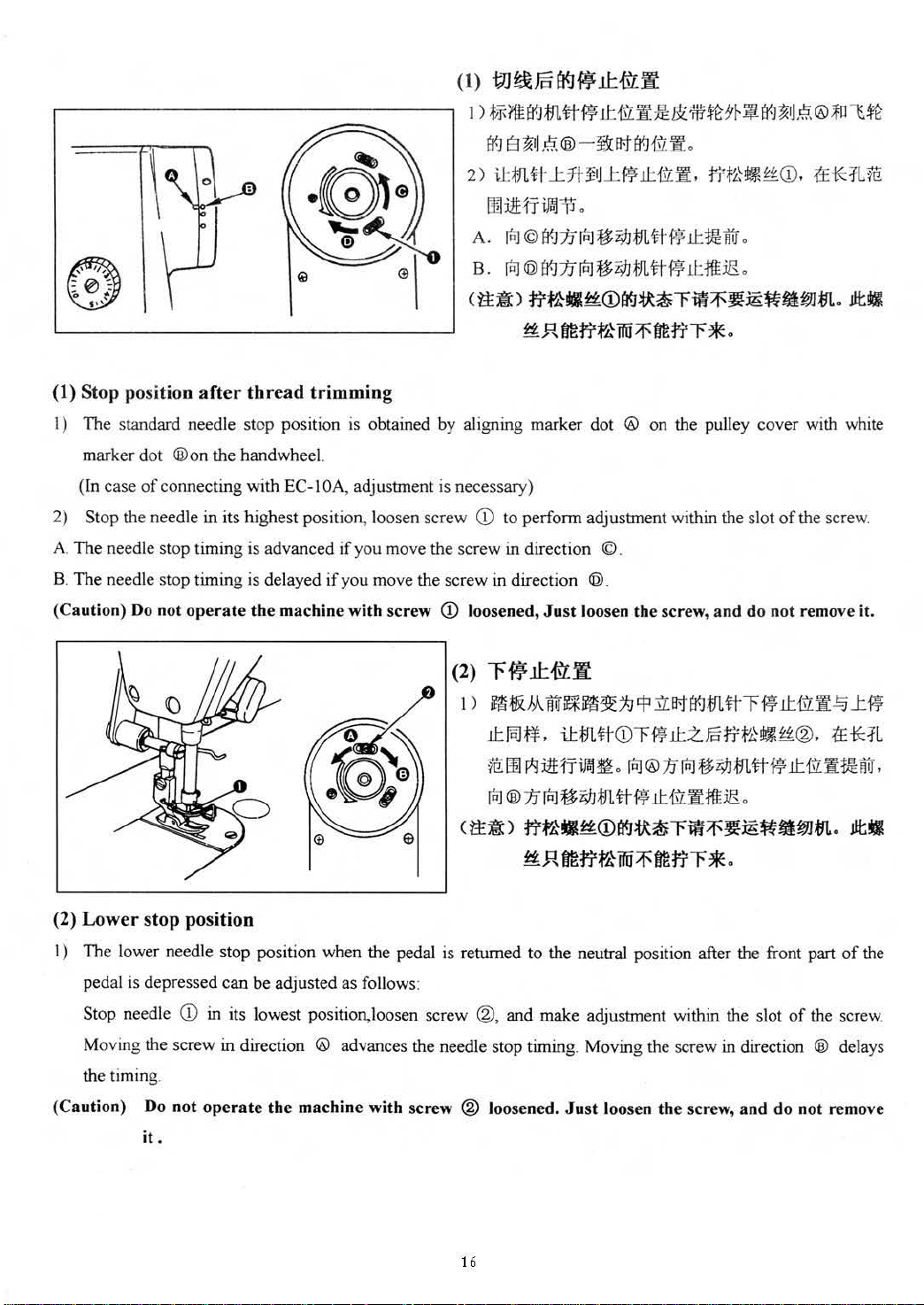

(1) Stop position

1)

The standard needle stop position is obtained by aligning marker dot ® on the pulley cover with white

marker dot

(In case

2) Stop the needle

A.

Th

B. The needle stop timing is delayed

(

Caut

of

e needle stop timing is advanced

ion)

Do

after

thread

®on

the handwheel.

connecting with

in

its highest position, loosen screw

not

operate

the

trimming

EC-1 OA, adjustment is necessary)

if

you move the scr

if

you move the screw in direction ©.

machine with screw ~ loosened, Just loosen the screw, and do n

(2)

\)

~~•*~~~

*

.R

fm~~ffii

ill

to perform adjustment within the slot

ew

in

direction ©.

"f

w

11:

-&•

~~Mlitr~~~~~

.tt~~.

Mm

JriJ

®

ftmttill~W

~•fi~•

1J

JriJ

• M

{JI.

~~

~~ ~

~

fm

tr~

*·

ft~~m

.tt~~tr

.[DJ®~Jril

tt-~

•i9.Jmtt~JJ:1fl

.tt

lli:rt

m

~~~~m.

of

the screw.

ot remov

tt~w.ttm•~~

~•~®.~*~

j[i.

~•

e it.

~

••litr

.

ctt~)~

(2)

Lower

I ) The lower needle stop position when the pedal is returned to the neutral position after the front part

pedal

Stop needle

Moving the screw

the timing .

(Caution) Do

stop position

is

depressed can be adjusted as follows:

ill

in its lowest position,loosen screw

in

direction ® advances the needle stop timing. Moving the screw

not ope

it.

rate

the

machine with screw ® loosened.

®,

16

~•* ~

*

.R

fm~tl

and make adjustment within the slot

~~~~~~~

ffii~fm

Just

loosen the

~ ~

*.

screw,

~~~mm

in

direction ® delays

and

do not remove

of

the screw.

.~

of

•

the

Page 22

18.

~~ff7J

WARNING:

A

Turn OFF

lUff~

the power

of the sewing machine.

I PEDAL PRESSURE AND PEDAL STROKE

before starting

the

work

so

as

to

(1)

•*~il.ffi.1J

1)

~~~rf~~.ffi:f.Jifnri

2)

~5!'fl.JH3

3)

~

jiJ

:tJ

'ffiiJ.ffi.:f.J~Ao

(2)

•*~~.1JB<Jilld~

I ) ffl ~

2)

3)

(3)

~ii~H®:ti:~¥

~

iJWiJ

rr~iJWf.i~H

trt~t~HBS.JJ~~o

•*~·trfla<Jilldl!

prevent

accidents caused by a

brupt

(t(]i}ld~

'

H!'fl~CD:itHTiiW:P

~¥1J

tt:1J!tlffi:f.J~~o

~ H ®

i'iJ

I2J.

1tHr

.ffi.iJ

~A

o

1J

ti:iJ!

tl

l¥JfLI*J,trf:i~'J'.,

iJal

i:l

0

o

start

(1) Adjusting the pressure required to depress the front

I) This pressure can be changed by altering the mounting position

2)

Th

e pressure decreases when you hook the spring on the left side.

3) The pressure increases when you hook the spring on the right side.

(2) Adjusting the pressure

I) This pressure can be adjusted using regulator screw

2) The pressure increases as

3)

The

pressure decreases

(3) Adjusting

The pedal stroke decreases when you insert connecting rod @ into the left hole.

the

pedal stroke

as

requir

you

you

ed to depress the back

turn

the r

egu

lator screw in.

turn

the screw out

®.

part

of the pedal

of

pedaling pressure adjust spring

part

of

the pedal

CD

.

17

Page 23

19.

~:tfiB<Jlm~

WAR.'IING:

&.

Tu

rn

of

the sewing machine.

I ADJUSTMENT

OFF

the power before

start

OF

THE PEDAL

ing the wo

rk

(1)

(.oJ

so as to

it~

ij'l{

prev

ent accidents caused by

ff(fl~~

J.;

:t.nt•J.fti;/J~

~

i!Wil

{&

@.

abrupt

il

:

fl.J~:f1

1

M.ff

Q)

start

.fll

20.

~

:tfi

~f'F

I PEDAL

OP

ERATION

.ia:1~H®PX;

(2)

l?lti

1)

if.'.l1i:ii~H(I'~

2)

t-rr~u~r-TJt:#.~.®.ttiVJ:itf~H®*ffw.l"'P

-

JHx.

~(I(]

1tJ

1l

K&f!Prif!;J.c.l(~

i'J'ltfii'fJ

(1) Insta lling the connecting rod

Move pedal @ to the right

arrows so that motor control lever

® are straightened .

rod

(2) A

dju

sting tbe pedal angle

I)

The

pedal tilt can

length

of

the connecting r

2) Loosen adjust screw

connecting rod ®

(1)

~~:(:f

I )

rtl

ntr~~

2)

rrm~rlwr~~·::.kJ~it~~J

•mH~~.

3 )

*£~r~Ul!H&r~

p.}

JU

4

t&~d1:

ff!UM&/lJ{l':it~~JJ

~8M*~€~~i!UMl

m

.

be

.

~@I~

or

left as illustrated by the

CD

and connecting

freely adjusted by changing the

od

@),

and adjust the length

®.

®.

<f§.

~.

mm

p;~

.tt

~

< m 'ft

ll;

#JJJ[

.

.

~1E

r §l9J

..t

w

Ltsx"F

of

4 )

~·JRT~~tR::J;JtJHxfJJff®

*

f~t

iJ

li

zvJIEJWi.W:f~~f:I:B1

~ff~. ~m~~~~~. ~ffi~~h~*®.~~

~~

~u~

:t&

~

t;J

~l

Z;IJ

11=

.

•

~~l'f]

•M•

-~m

·~m

(I)

The pedal

I) The machine runs at low sewing speed when you lightly depress the front part

Fl

Z;JJf&tlfli!:f,

••m~~i!U~~~Fom~•~••m.m~~w~.

mw~~~~~~~~~~~@m~m~~~~~

.m~~m~~~~~z~.~•mft®m~~.

is

operated in the following four steps:

.Je~:tJijS@I

!:f

Jl:ifl~D!

IJ~iHJJ.#L

f~JfiHs*Fof¥

.

~tt~a-~••·

18

11

-.•

o

.

{Ef¥

rt.#rt;HxZ.fnJJ~Jm

of

the pedal ®.

Page 24

2)

The machine

automation reverse feed stitching

feed stitching.)

3)

The

machine

4)

The

machine trims threads when

*

If

your machine

thread trimming

if

you further depress the back part, the thread trimmer is actuated.

nms

at

stops

(with its

is

provided with

step. The

high

sewing

needle

presser foot goes up

speed

has

up

you

the

when you further depress

been

preset,

the

or

down)

when

fully

depress

Auto-lifter , an addition

the

when

the

machine runs at high

you

reset

the

pedal

back part

you

of

the

pedal ®.

step

is given between the machine stop and

lightly depress

front part

speed

toit

s original

the

back part

of

the

pedal®.

after it completes reverse

position©

of

the pedal @,

(If

the

.

and

• While machine

sewmg.

•

The

machine will perform normal thread trimming even

following high

•

The

machine will completely

immediately after

• When the machine stops with its needle down, and

the

pedal

21. itl

fM!

or

once

.

:=f-l;t]

in

automatic back sewing,

low speed

the

fflj

it

sewing

perform

machine

started

I ONE-TOUCH TYPE REVERSE FEED STITCHING

if

the

.

thread trimming even

thread

trimming action.

MECHANISM

pedal put

if

(1)

I)

2 )

3)

(1) How to

1 )The moment switch lever

2)The machine performs reverse feed stitching as long as

3 )The machine resumes normal feed stitching the moment

to

the

neutral place, machine will stop after back

if

you depress

if

you reset

you want to bring

ttffl1ir!

19:

"f

**1£

ffCD,

1-E

tiC

F

0'~

r11

I'BJ

ilHr

-=F--t~Jf

performs reverse

the

switch lever is

the

switch lever

SLilP~1J iE(Q]~g~J

operate

is

the

back

part

of

the

pedal immediately

the

pedal to its neutral position

the

needle up,depress the back part

til~JJfJU'L

{~1)

feed

sti

held

depressed

released

§jj o

tching

.

f!

P

(J!Jfiit

0

J

o

CD

is pressed, the machine

.

.

of

(2)

1f;X:

~[§!)

Heigh

t

of

the

switch

&¥±~

A

I)

2l fF

~~

;X:(l)if

'~

WARNING:

Turn

OFF

of

the sewing machine.

~~-~®

2

t~ffi:

~T~~~

the

power

. k~BM*~~~~~-~

'I'6T

before

~ffffL

~moo•*~

starting

the

~~~-~

work

so

0

19

~~m

as

to prev ent acc idents caused by

~-~~~

0

abrupt

start

Page 25

3)

~:fe7l

I)

Loosen setscrew ® and move the switch itself up and down to adjust the height.

2)

Switch

3)

In

machine head and lower switch base

•

r&WHf~

The following functions can be performed by one-touch operation using optional switch (23632656)

(I)

Needle up I down compensating stitching ••• Every time the switch is pressed, needle up/down compensating

stitching

(2) Back compensating stitching

speed (This is effective only when the constant-dimension stitching pattern is selected on the

(3) Function to cancel once reverse feed stitching at the end

automatic reverse feed stitching

(4) Thread trimming function

(5) Presser lifting function

(6)

:;X:CD

tr.Jlli:J!

CD

can be used in two positions by turning

addition, when you desire to lower the position

( ~

is

performed.

One stitch compensating stitching •

performed.

:f'fF

~rr-t.

?'~~~)

••• When the switch is pressed, automatic presser lifting can be executed.

i~rrtlf'~WJ;fJL'ffiHitf.J~~t~~®.

@ .

I Optional switch (separately-available)

f.t

P~

:iM!'q

7f

( I )

~l~

tt-H~~~JJ

< 2 )

fill

f'.it

CP-1600

(3)

~a*f~J~

t1lz!f)(

¥~

(4)

t]J~r)Jfi~

<5

>

EE

iltilfn:

(

6)

I

tt-1H~~~JJ

••• Every time the switch

at

the end

••• When the switch is pressed, thread trimming is performed.

of

••

Every time the switch

~-Fff*~®o

it.

of

switch

~

< 23

:fH~

f'.ii

f*ft~J::i2H4!7

1

0

•••

fi-

J;tJti~

sewing onJy can be canceled once.

CD,

loosen setscrew ® located in the back

63

2656 )

•••

~JJ

ix~WlrJJee

~7f

•••

•••

is

CD

~;~.

r

tf.J

J;IJ

'BJt~-~ff:'ldlH

••

•

tJ

~-

~R

•••

:1E

Fo:iittY.W~

~:rF~Fo

ffJti(

-

(X;Jf~iiHT

pressed, reverse feed stitching

of

sewing ••• When the switch

is

pressed, one stitch compensating stitching

f

J:'

?~

7f

* .

\t-~11l~~~IJ.t~~~

~7f7t:zFo.

o

ffilltil

E!

Z9Jtt1t

ti~

ilf

t;t

JfJ

!f!-

M ~ :i1Hr

-F

~

!f.t~Z;!J{'\=

t;t

f~

.i!UiHr

r--~tr.Jra*

0

1

ft-;~~~§.i!~.'lJ

fill

o

)

o

0

f:ii

o <

CD

is

performed at low

CP-1600 panel.)

is

pressed,

of

the

o

9-i:f

{E

E!

Mf~J~

.

the

next

is

•

~~{tf:7f~I¥Jlttll

&¥±

A

~

"'liTh

WARNfNG:

Turn

OFF

of

the sewing machine.

Connection

~T~~~~

the

power

befor

oftbe

e s

optional switch

m~

•*m~~~**~zFo~*ff~~o

tarting the

iW

~JJ

t;t

lnsert the cord

connector

polarity).

The pin is provided with the inserting direction.

protruding portion @ upward.

work

so

1e:i2tw:J14

®.

iw

re~ur,®®WJ

nr

:EI

7f*

=~~

CD

20

as

to preve

B'~

Efit•,Hru

<

15!:

1=Ht>Z

J:tmA.o

of

the optional switch into ® and @

coming from the machine head.(There

Af

tu.

nt

accidents cau sed

iJ

M

~

~ M l'~

tJ1

~ffiFi

I*

fl-

tr.J

tiil

by

tf.J

A 1r

abr

upt

4 P

1al~MD

rQ)

~

~.m

Insert it

start

B<.J

5:E

• f!f

of

is

with

®

4P

no

Page 26

22.

ijt~:ff

I WIPER

&¥±~

A Turn

'~

WARNING:

'

of

the

OFF

sew

ing

~Tm~~mmooa*®~~~N*~~fi~mff•~

the

powe

r before

machine.

starting

the

work

so

as

to preve

<t)

m~*fB<J-&w

~~ffQ~m•$M~~m~F~~tt~ff~~

1 >

Jf.J

i[·~·Jill:iJ~$J

~j(J~

I

J/'J.

2>mm~ff~®mm~H.

jE!JEt.Hfl¥J5jL.I:§.gM

3)

'f

if

JfJ

(1) Positioning

A

djus

t the position

thickness

is as

I )Turn the handwheel in the

2)Adju

Tighten wiper adjust screw

3)When the wiper

of

follows.

to align white marker dot

marker d

the w1per and the cent

pressed and fixed by

ot

st

the distance betwee n the flat part

nt

accidents

-

~~. it-

@.

jjE~

:

HHN . ~#

the

wiper

of

the material sewn. The ad

@ on the machine arm.

er

wiper coll

is

unnecessary, tum wiper switch @

OFF.

·

caused by

u~8~rJ.St:

~~~~~~-~®

il

tJlt!-ri-

''L'~j~~ffi~e

:Yd'!~

1JH:UfJ

the wiper accordi

nonn

CD

of

the

®

F ~

justme

al directi0n

on the handwheel with

need

le to I mm.

so

that the wiper

ar @.

abrupt

CD

of

start

.

xtrtf..tJL~

.

Jmm.

@.

ng

to the

nt procedure

of

rotation

is

21

Page 27

23

.

:tfl.

tr

!::jmf~

l¥1

~~

I NEEDLE-TO-HOOK RELA

TIONSIDP

&tt~

A

, m

I

WARNING:

Turn OFF

of

the sewi

ng machine.

~Tm~~-m~•*®~~~N-~~S~*ff~*·

the pow

er

before starting the w

ork

so as to preve

<I>

lfrtr:

I)

~M~~. 1Htffll;f-3§

5:E

~~

f:f:

(

7Jc

}:E

fl-

2)

CDB

fl-111)

~Jr~ffil.~Fcrr~#ff~~~~t'-f:f:<D.

~

Att-111~tt-

~r~~Fc~~#ff«W~~

c

7Jc

}:EME

3) (DB

t~l!1)

ff

®

J::

-r

~.

(

DA

#IJ1)n'fi~

ff®J::fi-B<J1Jjn],

nt accidents caused by abrupt st

:

9J

rF1f~~

•m

1J

<D.

ff

?a!

ll

)

:fE

#ff®B<:ltiJtx®J1iiHt.ffFf';;i;±)C@

ff®~

;tl

a

(1(]:!(~-&W)

~t£ 3 :m.D.if~~~~~f:f:JF4J~~.f:E#

*

B<J

1J

jn]

,

1E.1£t

3

*Mf~fl!il

re~~cnmtt-ffr~*®~

trfO

J$i

~.

~

r

.r

:l

.•

~

J5n't'£tt-.ff~!M

~~©~mtt-

J

~! ® ~fiE#

~t~f:f:,

ffr~*®

•f:f:

<D.

ff

""f

~lifJ~~{:Eft

~

:;tc@

art

(F)

4 )

.f£Jlt;jj\~r.

:tJLtr~bJE;f?i~fRJIW-if.\1~:>9

Fcrr~~f:f:.

<~

tl~

• 8990DS, 899lDS ~

11r%1m

(1) Adju

I)

Tum

(Adjusting the needle bar

2) (For

@. then tighten

(

For

®,

(Adjusting position

3)

(For

ascending needle bar ® with the bottom

(For a DA

ascending needle bar

4) After making the adjustments mentioned in the above steps, align hook blade point @

needle ® . Provide a clearance

securely tighten setscrews in the hook .

(Caution )

~M~~~. ~-~ME;tl~.~

~ilit

r :

11418001

st the timing between the needle

the hand wheel to bright the needle

a

DB

needle) Align marker line ®

se

tscrew

aDA

needle) Align marker line © on needle bar ® with the bottom end

then tighten setscrew

of the hook

a

DB

needle) Loosen the three hook setscrews,

needle) Loosen the three hook setscrews, tw11 the handwheel and align marker line @ on

heig

ffl

ht)

CD

.

CD.

®)

1».

r~:l