Jabsco 29120-2000, 29090-2000 User Manual

Manual Toilets

Model:

29120-2000

Manual Toilet,

Regular Bowl

Applications

You may install JABSCO

Regular and Compact bowl

manually operated marine

toilets in both power and

sailing craft, either above or

below the waterline, for use

on sea, river, lake or canal.

Your installation may

discharge the waste either

overboard (provided that

your national and local

regulations allow this), or

into a treatment system

or into an on-board holding

tank (U.S.C.G. Marine

Sanitation Devices Type

I, II and III).

JABSCO manual toilets are

designed specifically for

marine use. Consult ITT

Industries Jabsco for advice

about possible non-marine

applications.

Model:

29090-2000

Manual Toilet,

Compact Bowl

Features

Design

▼ Reversible pump mounting allows re-assembly for left hand operation

by installer.

▼ Powerful self-priming, double-acting piston pump.

▼ Strong swirl action for efficient flushing.

▼ Crevice free contours and skirted base for added cleanliness and

hygiene.

▼ Contoured handle and conveniently positioned flush control lever for

ease of use.

▼ Angled pump housing and long stroke for easier pumping.

▼ Spring assisted top valve closure for easier priming.

▼ Automatic vacuum breaker operated by flush control lever for easier

bowl emptying.

▼ Constant 38mm (1

▼ Aortic joker valve combines full 38mm (1

flow prevention.

▼ Multi-angle discharge elbow for ease of installation.

▼ Accessible mounting points for faster installation.

▼ All fastenings face front or top for superbly simple servicing without

need for special tools.

▼ Renewable external seal housing for quick, clean replacement of seal

and piston rod guide.

▼ Positively located gaskets ensure correct re-assembly.

▼ Dual function base plug combines winter drain point with easy

cleaning access.

1

2") bore waste path minimises blockages.

/

1

2") bore with automatic back-

/

Optional re-assembly

by installer for left

hand operation.

Materials

▼ Luxury wooden seat and cover with tough baked enamel coating.

▼ Hygienic white ceramic bowl for ease of cleaning.

▼ Pump and base moulded in ABS or polypropylene with selected parts

in acetal resin, fitted with 316 passivated stainless steel fastenings,

brass weights and neoprene seals and gaskets.

Performance

▼ Flushing pump self-primes from dry up to 1 metre (3ft) below the

base.

▼ Waste pump discharges up to 3 metres (9ft) above the base.

Dimensions

▼ See the Dimensional Drawing on the back page.

1

Installation Instructions

Installation Instructions

YOUR TOILET is just one part of a system. Correct

installation of the whole system is essential if you

want the toilet to perform properly, operate

reliably and safely, and give satisfactory length of

life. The toilet is delivered assembled for righthanded operation. If you wish, both Regular and

Compact Bowl models may be re-assembled with

the pump on the left hand side. The seat and lid

is delivered boxed and unfitted for its protection.

NB: Key numbers, e.g. ('Key 31'), are references to the

exploded view diagram on the back page.

1. Re-assembly for left hand use

If you wish to change the pump mounting from right to left

hand, do so before installing the toilet.

▼ Pull off the hose (key 4) that runs from the pump to the bowl.

▼ Remove the 4 screws (key 31) that secure the pump assembly to

the base.

▼ Lift off the pump assembly and leave the base valve gasket (key

16) on its 3 locating pegs.

▼ Remove the 4 bolts (key 11) that secure the bowl to the base.

▼ Rotate the bowl 180° and re-secure it, using the nylon washers

(key 14) to protect the ceramic from the stainless steel washers

and nuts (key 13,12).

▼ Rotate the pump assembly 180° and re-secure it.

▼ Rotate the push-fit intake elbow (key 6) 180° and refit the hose

between the pump and the bowl.

2. Location

▼ Select a location that will give sufficient clearance all round and

above the toilet. Ensure that there is room to operate the pump

and that there is access to the drain plug at the end of the base.

▼ The mounting surface must be flat, rigid and strong enough to

support a man's weight and should be at least 50mm (2") wider

and 50mm (2") deeper than the base of the toilet.

▼ You will need sufficient clearance below the mounting surface to

be able to secure the mounting bolts.

▼ The seat and lid should be able to swing up and over at least

110°, so that they will not fall forward when the craft heels or

pitches. When they are swung up they must be supported so

that the hinges are not strained

4. Through Hull Fittings

YOU WILL need:

■■ 19mm (

▼ Follow the seacock manufacturer's own instructions concerning

▼ Ensure the inlet seacock is positioned where it will be below the

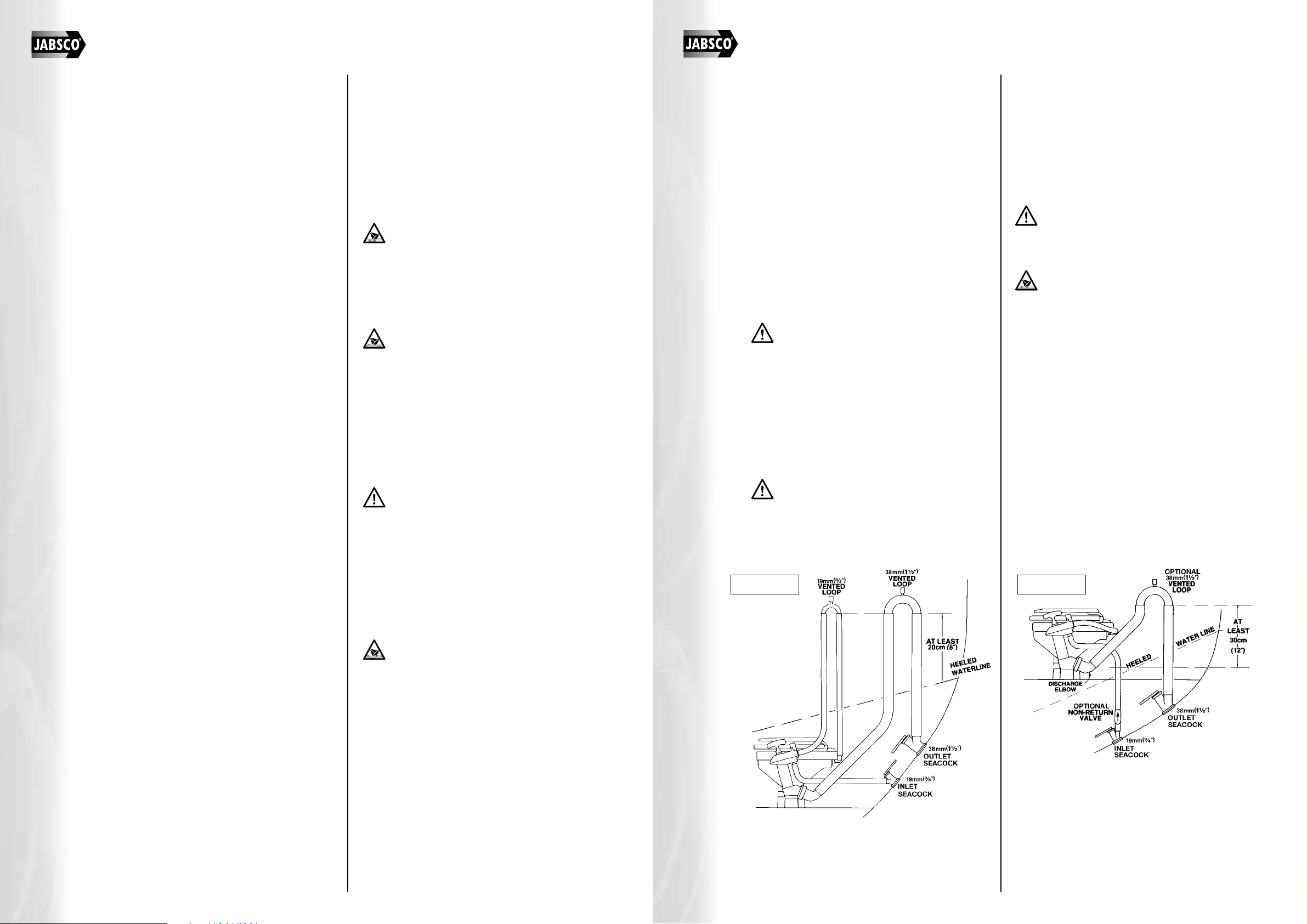

If the installation of the toilet results in it being connected to ANY

through-hull fitting that may possibly be below the waterline at ANY

time, whether when the craft is at rest, underway and heeling or

rolling or pitching, you must install the toilet in accordance with

these Installation Instructions. If you do not, water may flood in,

causing the craft to sink, which may result in loss of life.

FOLLOW THESE INSTRUCTIONS!

If the toilet is connected to ANY through-hull fittings and if the toilet

or pipework is damaged, water may flood in causing the craft to sink,

which may result in loss of life.

Therefore, if you are making connections between the toilet and ANY

through-hull fittings that may possibly be below the waterline at ANY

time, full bore seacocks MUST be fitted to those hull fittings, to allow

them to be shut off.

The seacocks MUST also be positioned where they are easily

accessible to all users of the toilet. If, for any reason, it is not possible

to do this, then secondary full bore marine quality valves MUST be

fitted to the hoses where they are easily accessible.

USE SEACOCKS!

3

/4") bore seacock for the flushing water inlet, and, if you

are discharging the waste overboard, a 38mm (1

seacock for the waste outlet.

materials and methods of installation.

waterline at all times when the craft is underway, and also

ensure that any outlet seacock is both aft of, and higher than,

the inlet seacock.

1

/2") bore

HAZARD RISK:

Through Hull Fittings.

HAZARD RISK:

Accidental Damage.

CAUTION: Use lever operated, full bore marine

seacocks and valves. The use of screw-down gate

valves is not recommended.

5. Pipework - selection of

correct method

YOU MUST select the correct method for the inlet pipework from 2

options and for the outlet pipework from 4 options, according to

whether the toilet is above or below the waterline, and to whether it

discharges the waste overboard or into an on-board holding tank.

5.1 Pipework - General

instructions for all options

▼ Rotate the intake seal (key 5) so that the elbow points upwards.

YOU WILL need:

■■ Spiral reinforced smooth bore flexible hoses for both the 19mm

3

/4") id inlet and the 38mm (11/2") id outlet pipework

(

■■ Two stainless steel worm-drive hose clips for every hose tail

connection (4, 6 or 8).

▼ Secure the hose runs so that the hoses cannot move and chafe,

and so that they do not exert any leverage on the hose tail

fittings to which they are connected, as this may cause adjacent

joints to leak.

▼ Avoid sharp bends in the hoses that may cause them to become

kinked.

▼ Keep all pipework lengths as short as possible, whilst complying

with these instructions. Unnecessary inlet or outlet hose length

just makes the toilet harder to pump.

▼ If it is difficult to fit the hose onto the hose tails of the toilet or

seacocks, lubricate it with water, or soften the hose by dipping

the end of it in hot water.

CAUTION: Do not apply flame to the hose. Do not

apply flame or any heat to the plastic hose tails on the

toilet. Do not use oils, greases or synthetic lubricants.

Do not apply sealing compounds to any hose

connections. Do not over tighten hose clips. Any of

these actions may result in cracking or breakage of the

plastic parts of the toilet.

▼ Secure the ends of all hoses to the hose tails with two stainless

steel worm-drive hose clips, ensuring that all inlet connections

are airtight and that all outlet connections are watertight.

▼ The Discharge Elbow (key 34) may be rotated 360° to suit your

installation. Always slacken the 2 securing screws, adjust the

discharge elbow to the required position and re-tighten the 2

securing screws BEFORE you connect the hose to it.

CAUTION: Failure to follow this procedure may result in

leaks between the discharge elbow and the pump

cylinder.

▼ Replace the white hose with a longer length of 19mm (

hose and arrange it to form an anti-syphon loop whose highest

point is at least 20cm (8") above the highest possible waterline,

and fit the Vented Loop at the highest point.

▼ Secure the ends of all hoses with two stainless steel worm-drive

hose clips.

CAUTION: Do not position the ventilated anti-syphon

loop between the inlet seacock and the flushing pump

inlet, as it will make the flushing pump difficult to

prime, harder to pump and may prevent it from

working at all.

HAZARD RISK:

Bowl Rim Below Waterline

If the toilet is connected to ANY through-hull fittings, and if the rim

of the bowl falls below the waterline, water may flood in causing the

craft to sink, which may result in loss of life.

Therefore, if the rim of the toilet is less than 20cm (8") above the

waterline when the craft is at rest, or if there is ANY possibility that the

rim of the bowl may be below the waterline at ANY time, a ventilated

anti-syphon loop MUST be fitted in any pipework connected to a

through-hull fitting, irrespective of whether inlet or outlet.

USE VENTED LOOPS!

SPECIAL NOTE 1: The smaller bore inlet pipework is more hazardous

than the larger outlet pipework. Unless there is a ventilated antisyphon loop in the inlet pipework, water will flow into the bowl

whenever both the inlet seacock is open and the rim of the bowl is

below the actual waterline. Although moving the Flush Control Lever

(key 23) to the "Shut" position will restrict the flow, this lever CANNOT

be relied upon as a shut-off valve.

SPECIAL NOTE 2: Making a loop in the hose without fitting a vent

may be just as hazardous as no loop at all, because water may syphon

over a loop. It is the vent that actually prevents the syphon.

5.2 Inlet Pipework - 2 options

Option 1: Toilet below the waterline

Option 2: Toilet always above the heeled waterline

Figure 1. Figure 2.

3

/4") id

3. Mounting

YOU WILL need:

■■ 4 x 8mm (5/16") diameter stainless steel bolts of length to suit the

thickness of the mounting surface.

■■ 4 stainless steel nuts, preferably self-locking. If you do not use

self-locking nuts you will need some nut-locking compound.

■■ 8 large stainless steel washers not more than 21mm (

diameter.

■■ A small tube of white silicone sealant.

▼ Offer up the toilet in the selected position and, using the holes

in the base as a guide, mark the positions for the 4 bolt holes

on the mounting surface. Remove the toilet and drill 4 vertical

holes of 9mm diameter through the mounting surface.

▼ Apply a bead of white silicone sealant to the outer rim of the

bottom base.

▼ Bolt down the toilet and tighten the fastenings securely. If you

are not using self-locking nuts, use nut-locking compound.

13

/16")

2

HAZARD RISK:

Pipework Becomes Loose

If the toilet is connected to ANY through-hull fittings and if the

pipework becomes disconnected, either from a through-hull fitting or

seacock, or from the toilet or any secondary valve, water may flood

in and may cause the craft to sink, which may result in loss of life.

Therefore the ends of ALL flexible hoses fitted directly or indirectly

between the toilet and ANY through-hull fitting that may possibly be

below the waterline at ANY time, MUST be secured to the hose tails

to which they are connected, using two stainless steel worm-drive

hose clips.

USE HOSE CLIPS!

YOU MUST fit a 19mm (3/4") Vented Loop fitting, Jabsco part number

29015-0000.

▼ Run the inlet hose by the most direct route from the inlet

seacock to the flushing pump inlet tail.

▼ Remove the white hose supplied with the toilet, which connects

the flushing pump outlet tail to the elbow (key 6).

YOU MAY need A 19mm (3/4") non-return valve, Jabsco part number

29295-0011

▼ Run the inlet hose by the most direct route from the inlet

seacock to the flushing pump inlet tail.

▼ For maximum convenience of use, install a 19mm (

non-return valve next to the inlet seacock, which will ensure that

the pump remains primed in between usages.

3

/4") in-line

3

Loading...

Loading...