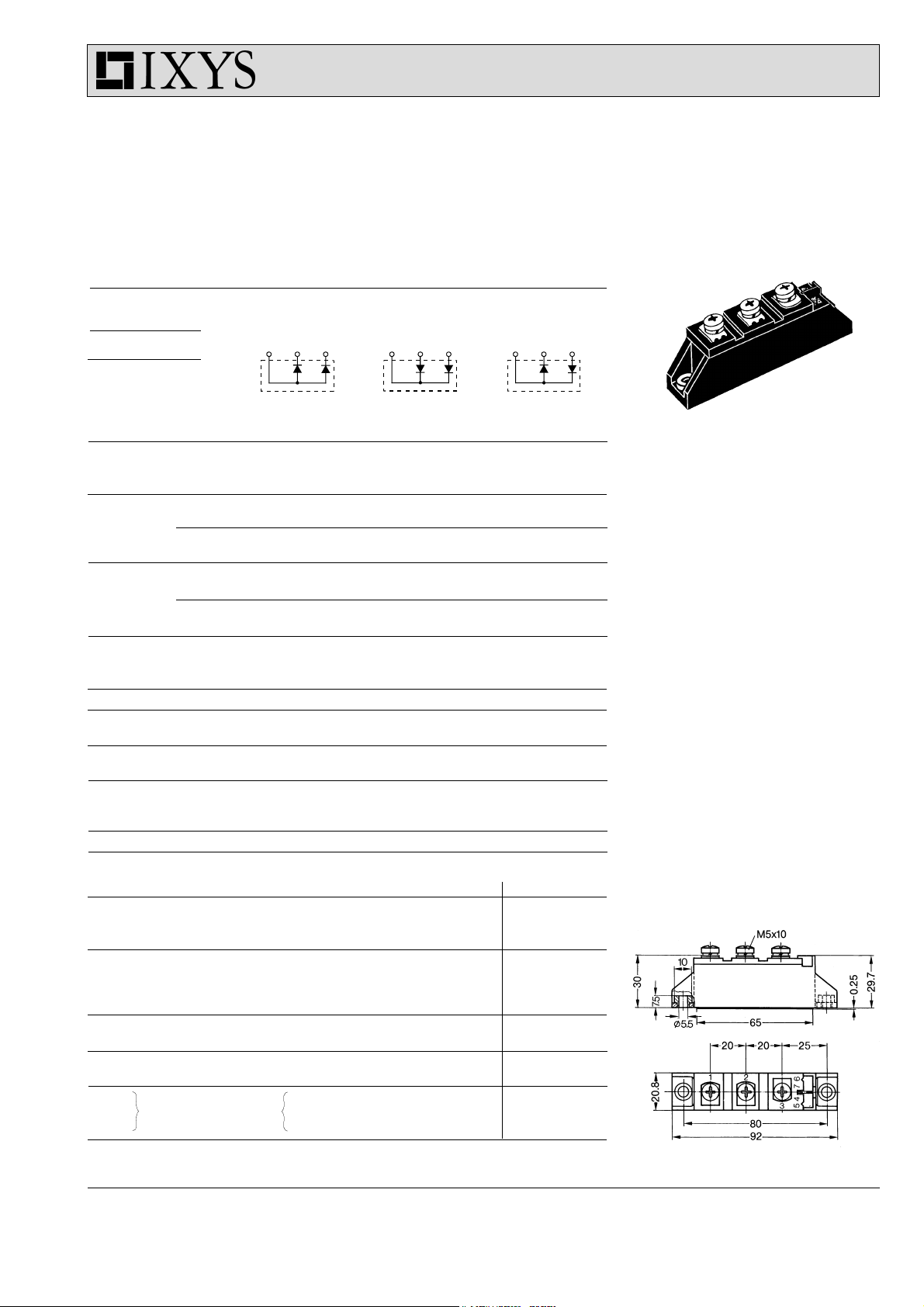

IXYS MEA75-12DA, MEK75-12DA, MEE75-12DA Datasheet

Fast Recovery

Epitaxial Diode

(FRED) Module

MEA 75-12 DA

MEK 75-12 DA

MEE 75-12 DA

V

I

t

RRM

FAV

rr

= 1200 V

= 75 A

= 250 ns

Preliminary data

V

RSM

V V MEA75-12 DA MEK 75-12 DA MEE 75-12 DA

1200 1200

Symbol Test Conditions Maximum Ratings

I

FRMS

I

FAV

I

FRM

I

FSM

I2t T

T

VJ

T

stg

T

Hmax

P

tot

V

ISOL

M

d

d

S

d

A

a Maximum allowable acceleration m/s

Weight g

V

RRM

T

= °CA

75 107

case

T

= °C; rectangular, d = 0.5 A

75 75

case

t

< 10 µs; rep. rating, pulse width limited by T

P

T

= 45°C; t = 10 ms (50 Hz), sine A

VJ

T

= 150°C; t = 10 ms (50 Hz), sine A

VJ

= 45°C; t = 10 ms (50 Hz), sine A

VJ

T

= 150°C; t = 10 ms (50 Hz), sine A

VJ

T

= 25°CW

case

50/60 Hz, RMS t = 1 min V~

I

≤ 1 mA t = 1 s V~

ISOL

Mounting torque (M5) Nm/lb.in.

Terminal connection torque (M5) Nm/lb.in.

Creep distance on surface mm

Strike distance through air mm

Type

123 123 123

VJM

TBD

A

1200

t = 8.3 ms (60 Hz), sine A

1300

1080

t = 8.3 ms (60 Hz), sine A

1170

7200

t = 8.3 ms (60 Hz), sine A2s

7100

5800

t = 8.3 ms (60 Hz), sine A2s

5700

-40...+150

-40...+125

110

°C

°C

°C

280

3000

3600

2.50-4/22-35

2.50-4/22-35

12.7

9.6

2

2

50

90

s

s

2

TO-240 AA

3

2

1

Features

●

International standard package

with DCB ceramic base plate

●

Planar passivated chips

●

Short recovery time

●

Low switching losses

●

Soft recovery behaviour

●

Isolation voltage 3600 V~

●

UL registered E 72873

Applications

●

Antiparallel diode for high frequency

switching devices

●

Free wheeling diode in converters

and motor control circuits

●

Inductive heating and melting

●

Uninterruptible power supplies (UPS)

●

Ultrasonic cleaners and welders

Advantages

●

High reliability circuit operation

●

Low voltage peaks for reduced

protection circuits

●

Low noise switching

●

Low losses

Symbol Test Conditions Characteristic Values (per diode)

typ. max.

I

R

V

F

V

T0

r

T

R

thJH

R

thJC

t

rr

I

RM

Data according to IEC 60747

IXYS reserves the right to change limits, test conditions and dimensions

T

= 25°CV

VJ

T

= 25°CV

VJ

T

= 125°CV

VJ

100 1.85

IF = A; T

300 2.58

IF = A; T

For power-loss calculations only V

DC current K/W

DC current K/W

IF = A T

150 250 300

VR = V T

600 22

-di/dt = A/µsT

200 33

= V

R

RRM

= 0.8 • V

R

= 0.8 • V

R

= 125°CV

VJ

T

=25°CV

VJ

= 125°CV

VJ

T

=25°CV

VJ

RRM

RRM

2.17

2.64

0.5

34

mA

2

mA

mA

1.48

3.65

mΩ

0.550

0.450

= 100°Cns

VJ

= 25°CA

VJ

= 100°CA

VJ

© 2000 IXYS All rights reserved

Dimensions in mm (1 mm = 0.0394")

015

D6 - 5

MEA 75-12 DA MEE 75-12 DA

MEK 75-12 DA

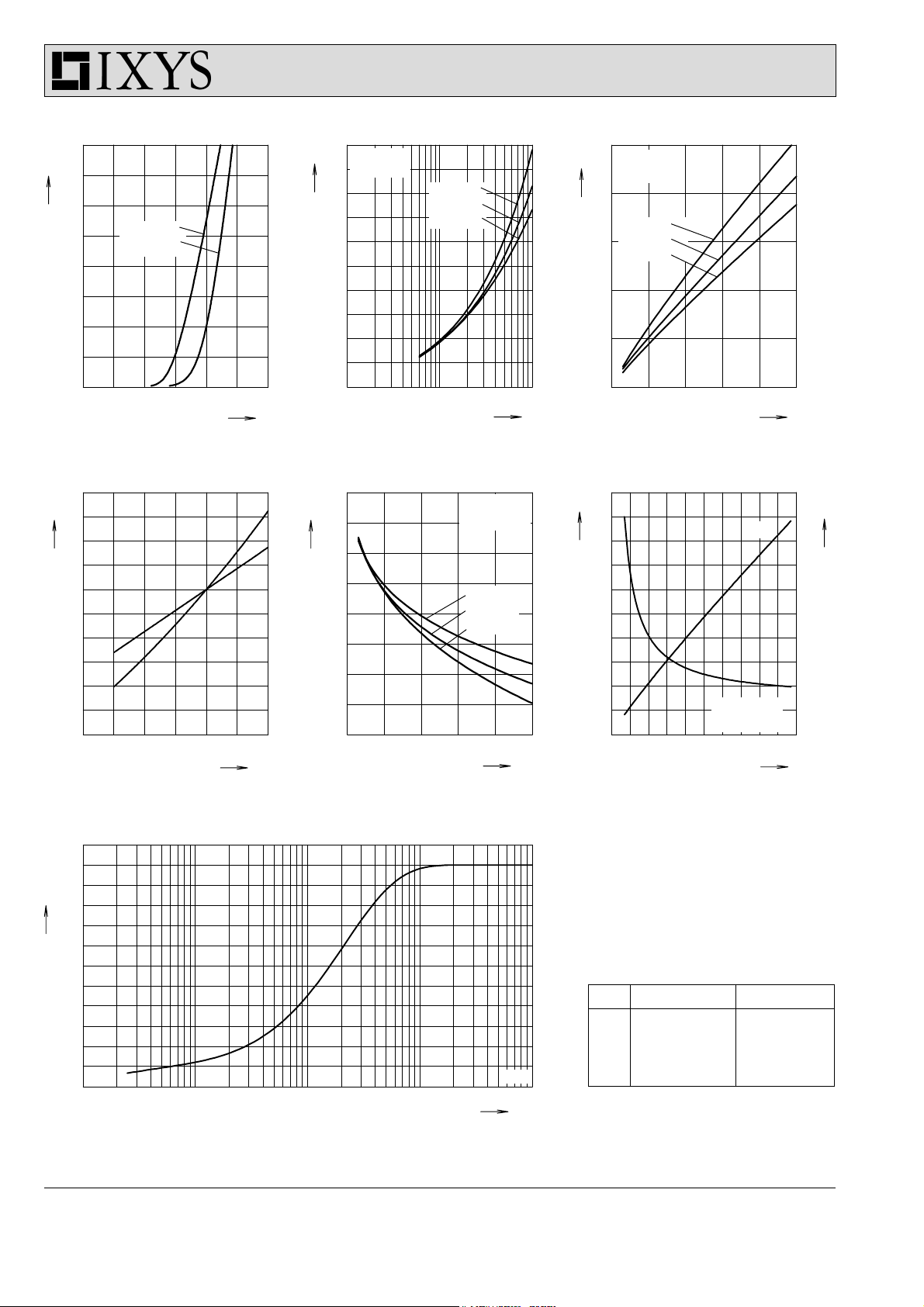

200

A

175

150

I

F

125

TVJ=125°C

TVJ= 25°C

100

75

50

25

0

0123

V

V

F

Fig. 1 Forward current IF versus

voltage drop VF per leg

1.4

1.2

K

f

1.0

I

0.8

RM

Q

r

0.6

0.4

0 50 100 150

°C

T

VJ

Fig. 4 Dynamic parameters Qr, I

versus junction temperature T

Q

10

µC

8

r

6

TVJ= 100°C

VR = 600V

IF= 150A

IF= 100A

IF= 70A

I

RM

100

A

80

60

TVJ= 100°C

VR = 600V

IF= 150A

IF= 100A

IF= 70A

4

2

0

10 100 1000

A/µs

-diF/dt

Fig. 2 Reverse recovery charge Q

versus -diF/dt

350

ns

300

t

rr

250

200

TVJ= 100°C

VR = 600V

IF= 150A

IF= 100A

IF= 70A

r

40

20

0

200 600 10000 400 800

-di

Fig. 3 Peak reverse current I

versus -diF/dt

100

A

80

V

FR

60

40

20

t

fr

F

A/µs

/dt

RM

2.0

µs

V

FR

1.6

t

fr

1.2

0.8

0.4

TVJ= 100°C

IF = 150A

150

200 600 10000 400 800

RM

Fig. 5 Recovery time trr versus -diF/dt Fig. 6 Peak forward voltage VFR and t

VJ

-di

A/µs

/dt

F

0

0 200 400 600 800 1000

diF/dt

versus diF/dt

0.0

A/µs

fr

0.6

K/W

0.5

0.4

Z

thJH

0.3

0.2

0.1

0.0

0.001 0.01 0.1 1 10

s

Fig. 7 Transient thermal impedance junction to heatsink

D6 - 6

Constants for Z

iR

calculation:

thJH

(K/W) ti (s)

thi

1 0.037 0.002

2 0.138 0.134

3 0.093 0.25

75-12 DA

t

4 0.282 0.274

016

© 2000 IXYS All rights reserved

Loading...

Loading...