IXYS MCD161-22IO1, MCD161-20IO1, MCC161-22IO1, MCC161-20IO1 Datasheet

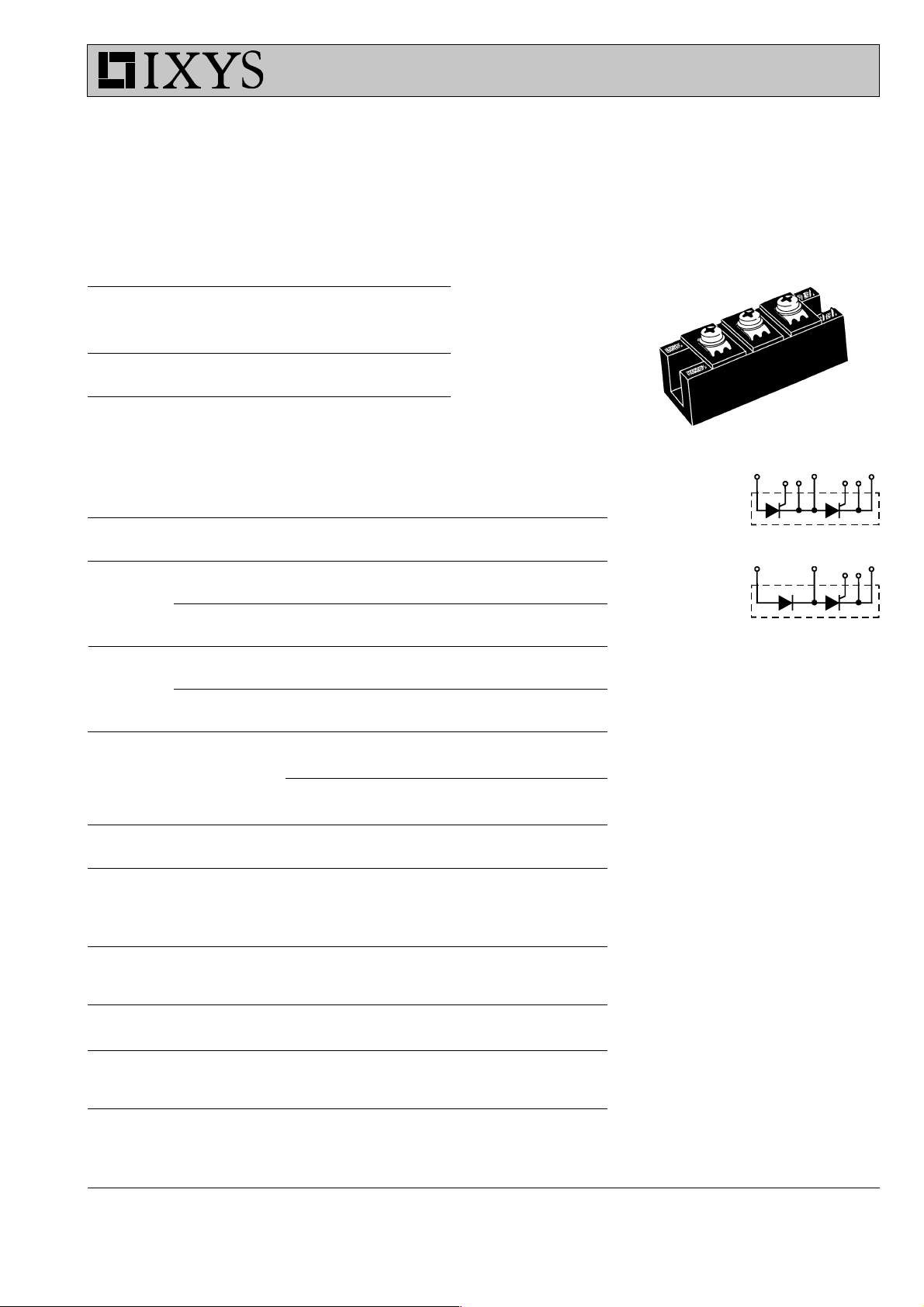

MCC 161

MCD 161

High V oltage Thyristor Module

High V oltage High Voltage

V

RSM

V

DSM

VV

2100 2000 MCC 161-20io1 MCD 161-20io1

2300 2200 MCC 161-22io1 MCD 161-22io1

Symbol Test Conditions Maximum Ratings

I

TRMS

I

TAVM

I

TSM

2

dt TVJ = 45°C t = 10 ms (50 Hz) A2s

òi

(di/dt)

(dv/dt)

P

GM

P

GAV

V

RGM

T

VJ

T

VJM

T

stg

V

ISOL

M

d

Weight Typical including screws g

V

RRM

V

DRM

Type

TVJ = T

VJM

TC = 85°C; 180° sine A

TVJ = 45°C; t = 10 ms (50 Hz) A

VR = 0 t = 8.3 ms (60 Hz) A

= T

T

VJ

VJM

VR = 0 t = 8.3 ms (60 Hz) A

t = 10 ms (50 Hz) A

300

165

6000

6400

5250

5600

A

180000

VR = 0 t = 8.3 ms (60 Hz) A2s

= T

T

VJ

VJM

VR = 0 t = 8.3 ms (60 Hz) A2s

cr

TVJ = T

VJM

f = 50 Hz, tP = 200 ms

VD = 2/3 V

IG= A, non repetitive, IT = I

diG/dt = A/ms

TVJ = T

cr

RGK = ¥; method 1 (linear voltage rise)

TVJ = T

IT = I

0.5 500

0.5

; VDR = 2/3 V

VJM

VJM

TAVM

t = 10 ms (50 Hz) A2s

repetitive, IT =A A/ms

DRM

DRM

500 150

TAVM

tP = 30 msW

tP = 500 msW

50/60 Hz, RMS t = 1 min V~

£ 1 mA t = 1 s V~

I

ISOL

Mounting torque (M6) Nm/lb.in.

2.25-2.75/20-25

Terminal connection torque (M6) Nm/lb.in.

170000

137000

128000

1000

120

60

10

-40 ...125

125

-40 ...125

3000

3600

4.5-5.5/40-48

A/ms

V/ms

8

W

V

°C

°C

°C

125

I

TRMS

I

TAVM

V

= 2x 300 A

= 2x 165 A

= 2000-2200 V

RRM

2

1

3671542

7

6

3

MCC

31542

MCD

Features

●

International standard package

●

Direct Copper Bonded Al2O3 -ceramic

base plate

●

Planar passivated chips

●

Isolation voltage 3600 V~

●

UL registered, E 72873

●

Keyed gate/cathode twin pins

Applications

●

Motor control

●

Power converter

●

Heat and temperature control for

industrial furnaces and chemical

processes

●

Lighting control

●

Contactless switches

Advantages

●

Space and weight savings

●

Simple mounting

●

Improved temperature and power

cycling

●

Reduced protection circuits

4

5

Data according to IEC 60747 and refer to a single thyristor/diode unless otherwise stated.

IXYS reserves the right to change limits, test conditions and dimensions

© 2000 IXYS All rights reserved

1 - 2

Symbol Test Conditions Characteristic Values

, I

I

RRM

DRM

V

T

V

T0

r

T

V

GT

I

GT

V

GD

I

GD

I

L

I

H

t

gd

t

q

Q

S

I

RM

R

thJC

R

thJK

d

S

d

A

a Maximum allowable acceleration m/s

TVJ= T

IT=A; T

For power-loss calculations only (TVJ = T

VD= 6 V; TVJ = 25°CV

VD= 6 V; TVJ = 25°CmA

TVJ= T

TVJ= T

; VR = V

VJM

300 1.36

RRM

= 25°CV

VJ

)V

VJM

40

0.8

1.6

mA

mW

2

TVJ = -40°CV

2.6

150

TVJ = -40°CmA

;VD = 2/3 V

VJM

;VD = 2/3 V

VJM

DRM

DRM

200

0.25

10

V

mA

TVJ = 25°C; VD = 6 V; tP = 30 ms 200 mA

diG/dt = 0.45A/ms; IG = 0.45 A

TVJ= 25°C; VD = 6 V; RGK = ¥ mA

TVJ= 25°C; VD = 1/2 V

diG/dt = A/ms; IG = A

TVJ = T

dv/dt = 20 V/ms; IT = 160 A; -di/dt = 10A/ms

TVJ= T

-di/dt = A/ms; IT =A A

0.5 0.5

; VR = 100 V; VD = 2/3 V

VJM

VJM

50 300 235

DRM

; tP = 200 ms typ. 150 ms

DRM

per thyristor; DC current K/W

per module K/W

per thyristor; DC current K/W

per module K/W

Creeping distance on surface mm

Creepage distance in air mm

150

550

0.155

0.078

0.225

0.113

12.7

9.6

2

ms

mC

50

MCC 161

MCD 161

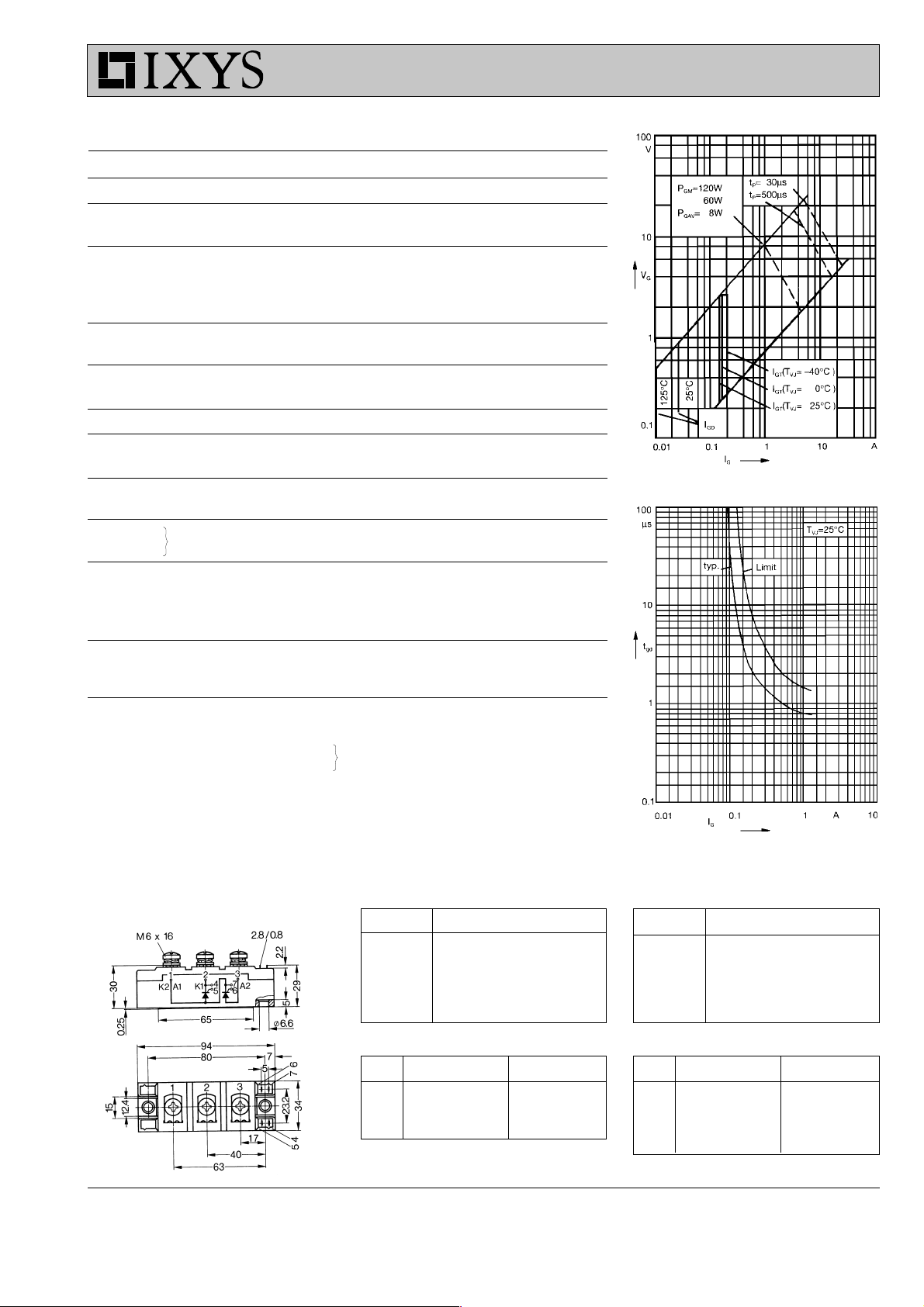

Fig. 1 Gate trigger characteristics

2

Optional accessories for modules

Keyed gate/cathode twin plugs with wire length = 350 mm, gate = yellow, cathode = red

Type ZY 180L (L = Left for pin pair 4/5) UL 758, style 1385,

Type ZY 180R (R = right for pin pair 6/7) CSA class 5851, guide 460-1-1

R

Dimensions in mm (1 mm = 0.0394")

for various conduction angles d:

thJC

d R

thJC

(K/W)

DC 0.155

180° 0.167

120° 0.175

60° 0.197

30° 0.226

Constants for Z

iR

calculation:

thJC

(K/W) ti (s)

thi

1 0.0072 0.001

2 0.0188 0.08

3 0.129 0.2

Fig. 2 Gate trigger delay time

R

for various conduction angles d:

thJK

d R

thJK

(K/W)

DC 0.225

180° 0.237

120° 0.245

60° 0.262

30° 0.296

Constants for Z

iR

calculation:

thJK

(K/W) ti (s)

thi

1 0.0072 0.001

2 0.0188 0.08

3 0.129 0.2

4 0.07 1.0

© 2000 IXYS All rights reserved

2 - 2

Loading...

Loading...