Page 1

CCAANN@@nneett NNTT 220000//442200

GGeenneerriicc PPrroottooccooll ffoorr GGaatteewwaayy MMooddee

SOFTWARE DESIGN GUIDE

4.02.0332.20000 1.5 en-US ENGLISH

Page 2

Important User Information

Liability

Every care has been taken in the preparation of this document. Please inform HMS Industrial Networks of any

inaccuracies or omissions. The data and illustrations found in this document are not binding. We, HMS Industrial

Networks, reserve the right to modify our products in line with our policy of continuous product development. The

information in this document is subject to change without notice and should not be considered as a commitment by

HMS Industrial Networks. HMS Industrial Networks assumes no responsibility for any errors that may appear in this

document.

There are many applications of this product. Those responsible for the use of this device must ensure that all the

necessary steps have been taken to verify that the applications meet all performance and safety requirements

including any applicable laws, regulations, codes, and standards.

HMS Industrial Networks will under no circumstances assume liability or responsibility for any problems that may

arise as a result from the use of undocumented features, timing, or functional side effects found outside the

documented scope of this product. The effects caused by any direct or indirect use of such aspects of the product

are undefined, and may include e.g. compatibility issues and stability issues.

The examples and illustrations in this document are included solely for illustrative purposes. Because of the many

variables and requirements associated with any particular implementation, HMS Industrial Networks cannot assume

responsibility for actual use based on these examples and illustrations.

Intellectual Property Rights

HMS Industrial Networks has intellectual property rights relating to technology embodied in the product described in

this document. These intellectual property rights may include patents and pending patent applications in the USA

and other countries.

CAN@net NT 200/420 Software Design Guide

4.02.0332.20000 1.5 en-US

Page 3

Table of Contents

Page

1 User Guide ........................................................................................................................... 3

1.1 Related Documents ............................................................ .... .... ...................................... 3

1.2 Document History ............ .... .... ................................................................................. .... ...3

1.3 Trademark Information..................................................................... .... .... ........................ 3

1.4 Conventions................................................................. .... .. .. ...........................................4

2 TCP Server Function ............................................................................................................ 5

3 ASCII Protocol...................................................................................................................... 6

3.1 Basic Message Format ..................................................................... .. ...............................6

4 Message Types .................................................................................................................... 7

4.1 Message................................... .... .... .............................................................................. 7

4.2 Cyclic Message ........ .... .... ..................................................................................... .... .... ...8

4.2.1 CYC INIT ..... .... .... . ... . ... . ... . ... . ... . ... . ... . .... ... . ... . .... .... .... .... .... . ... . ... . ... . ... . ... . ... . ... . ... . .. 8

4.2.2 CYC UPDATE . .... .... .... . ... .... . ... . ... . ... . ... . ... . ... . ... . .... .... .... .... .... .... .... .... . ... . ... . ... . ... . ... . . 9

4.2.3 CYC STOP ... . ... . ... . ... . .... ... . ... . .... .... .... .... .... . ... . ... . ... . ... . ... . ... . ... . ... . ... . .... .... .... .... .... . .. 9

4.3 CAN Commands........................................ .... .... ............................................................. 10

4.3.1 Initializing the CAN Controller . . ... . ... . ... . ... . ... . ... . .... .... .... .... .... .... .... . ... . ... . ... . ... . ... . ... . .. 11

4.3.2 Configuring the Filter.. . ... . ... . .... .... .... .... .... . ... . ... .... . ... . ... . ... . ... . ... . ... . ... . .... .... .... .... .... 14

4.3.3 Starting the CAN Controller ... . ... . ... . ... . ... . ... . ... . .... .... .... .... .... . ... . ... .... . ... . ... . ... . ... . ... . ... 16

4.3.4 Stopping the CAN Controller ... . ... . ... . .... .... .... .... .... . ... . ... . ... . ... . ... . ... . ... . .... ... . ... . .... .... .. 16

4.3.5 Requesting the Status. .... ... . .... .... .... .... .... . ... . ... . ... . ... . ... . ... . ... . .... ... . .... .... .... .... .... . ... . 17

4.4 Device Commands....................... .. .. ............................................................................... 19

4.4.1 DEV IDENTIFY... .... .... . ... . ... . ... . ... . ... . ... . ... . ... . ... . ... . .... .... .... .... .... . ... . ... . ... . ... . ... . ... . ... . 19

4.4.2 DEV VERSION . . ... . ... . ... . .... .... .... .... .... .... .... . ... . ... . ... . ... . ... . ... . ... . .... .... .... .... .... .... .... .. 19

4.4.3 DEV PROTOCOL .. . ... . ... . ... . ... . ... . ... . ... . ... . .... .... .... .... .... . ... . ... . ... . ... . ... . ... . ... . ... . ... . .... .. 19

4.4.4 DEV INTERFACES ... .... .... .... .... .... .... . ... . ... . ... . ... . ... . ... . ... . .... .... .... .... .... . ... .... .... . ... . ... . 19

4.5 Events....................... .... .. .. ..................................................................................... .... .. 20

4.6 Responses ................................. .... ............................................................................... 20

4.6.1 Positive Response. .... .... .... . ... . ... . ... . ... . ... . ... . ... . ... . ... . .... .... .... .... .... . ... . ... . ... . ... . ... . ... . . 20

4.6.2 Negative Response .. ... . ... . .... .... .... .... .... . ... .... . ... . ... . ... . ... . ... . ... . ... . .... .... .... .... .... . ... ... 20

4.6.3 Device Response .. . ... . ... . ... . ... . .... .... .... .... .... .... . ... . ... . ... . ... . ... . ... . ... . ... . ... . .... .... .... .... . 20

4.7 PING REQUEST .............................................................. .... .... ........................................ 21

5 How to Handle Incoming Messages ................................................................................. 22

6 Example ............................................................................................................................. 23

7 List of Error Codes ............................................................................................................. 24

CAN@net NT 200/420 Software Design Guide

4.02.0332.20000 1.5 en-US

Page 4

This page intentionally left blank

Page 5

User Guide 3 (26)

1 User Guide

Please read the manual carefully. Make sure you fully understand the manual before using the

product.

1.1 Related Documents

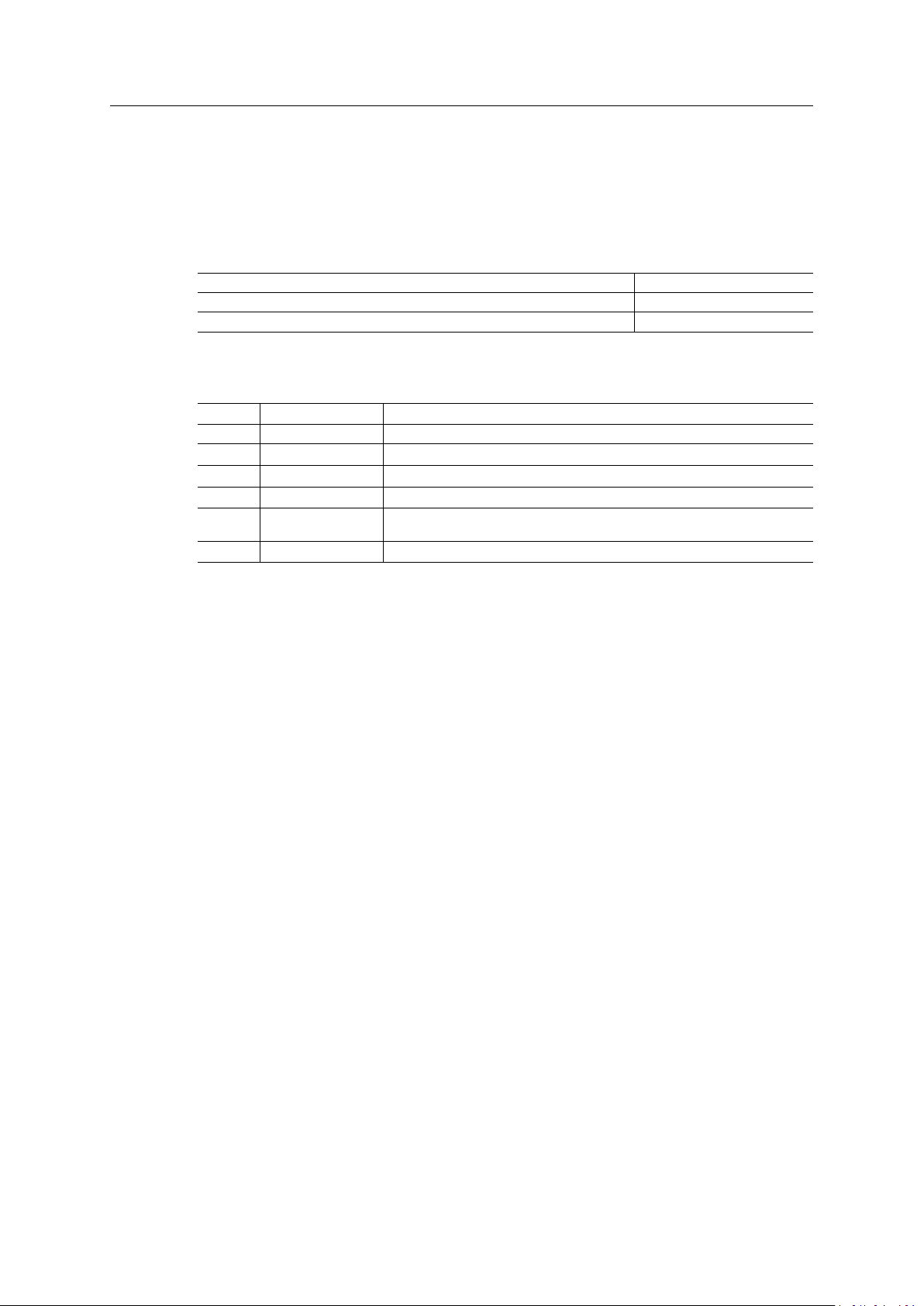

Document

Installation Guide VCI Driver

User Manual CAN@net NT

1.2 Document History

Author

HMS

HMS

Version

1.0 June 2016

1.1

1.2

1.3

1.4 January 2019

1.5

Date

October 2016 Adjusted filter examples in 4.2 CAN commands

July 2017 Added information about CAN@net NT 420

April 2018 Adjusted PING REQUEST and title

March 2019 Layout changes

Description

First release

Minor corrections in chapter 4, added command for cyclic message, updated error

codes

1.3 Trademark Information

Ixxat®is a registered trademark of HMS Industrial Networks. All other trademarks mentioned in

this document are the property of their respective holders.

CAN@net NT 200/420 Software Design Guide

4.02.0332.20000 1.5 en-US

Page 6

User Guide 4 (26)

1.4 Conventions

Instructions and results are structured as follows:

► instruction 1

► instruction 2

→ result 1

→ result 2

Lists are structured as follows:

• item 1

• item 2

Bold typeface indicates interactive parts such as connectors and switches on the hardware, or

menus and buttons in a graphical user interface.

This font is used to indicate program code and other

kinds of data input/output such as configuration scripts.

This is a cross-reference within this document: Conventions, p. 4

This is an external link (URL): www.hms-networks.com

This is additional information which may facilitate installation and/or operation.

This instruction must be followed to avoid a risk of reduced functionality and/or damage

to the equipment, or to avoid a network security risk.

CAN@net NT 200/420 Software Design Guide

4.02.0332.20000 1.5 en-US

Page 7

TCP Server Function

2 TCP Server Function

In the Gateway mode the device is acting as a TCP server and transmits and receives data on the

TCP port that is defined with the CAN-Gateway Configurator. The default TCP port is 19228.

Connection:

• Server exclusively accepts a single connection.

• Additional connection requests are rejected.

• Server exchanges data and commands with the ASCII protocol.

The server receives Ethernet ASCII protocol messages, extracts the original CAN message and

transmits the CAN message to the selected CAN bus. Received CAN messages are packed into the

ASCII protocol and forwarded to the connected Ethernet TCP/IP client. The server also handles

commands.

The device automatically starts the protocol server after power-up. When a connection to the

server is closed or lost, the device is restarted and waiting for a new connection.

5 (26)

CAN@net NT 200/420 Software Design Guide

4.02.0332.20000 1.5 en-US

Page 8

ASCII Protocol 6 (26)

3 ASCII Protocol

The ASCII protocol is used to pack data (CAN messages) and commands for the transfer over

Ethernet TCP/IP network.

The ASCII-Protocol in Version 2.0 supports 6 different message types:

• Messages (both directions)

• CAN Commands (from client to server)

• Device Commands (from client to server)

• Events (from server to client)

• Responses (from server to client)

• Ping Request

Commands have to be confirmed. Before a new command can be transmitted an answer has to

be received.

3.1 Basic Message Format

Basic Rules of ASCII Protocol:

• Messages are coded with ASCII characters exclusively.

• Valid characters:

– letters from a to z (no national characters)

– no distinction between upper and lower case

– numbers from 0 to 9

• Messages start with a valid ASCII character and are terminated dependent on the settings in

the CAN-Gateway Configurator with

\r\n, \r, or \n (End-Of-Line).

• Directly after End-Of-Line the next message can follow.

• Messages containing invalid characters are discarded.

• Message contents (e.g. CAN identifier, CAN data) are noted in HEX notation. Other formats

are not supported. HEX specifier (0x...) is omitted.

• ASCII protocol message consists of groups of ASCII characters, each group separated by a

space character (0x20).

• More than one consecutive space characters (0x20) are reduced to a single space character.

• No space characters before and after a CAN message

• The groups of ASCII characters describe different types of messages or commands contained

in the ASCII-Protocol message.

• The single characters of an ASCII-Protocol message are transmitted over the TCP connection

in readable order; beginning with the “message type” group of ASCII characters and ending

with the termination \n.

CAN@net NT 200/420 Software Design Guide

4.02.0332.20000 1.5 en-US

Page 9

Message Types

4 Message Types

4.1 Message

Used to exchange CAN messages between the device and the Ethernet TCP/IP host and to

exchange information in both directions, to and from the device.

When a device receives a message on the CAN bus:

• CAN message is packed into an ASCII protocol message of type Message and transmitted

over Ethernet TCP/IP.

When device receives an ASCII-Protocol message of type Message from Ethernet TCP/IP:

• Message is unpacked and translated into a CAN message.

• CAN message is transmitted to the CAN bus.

Make sure, that the CAN controller is in running state before a message is transmitted (see CAN

Commands, p. 10). Otherwise the message is discarded. If the device is in running state and no messages

can be transmitted (e. g. invalid bus connection) the device discards one message every 10 ms to prevent

a data jam.

M <port> <format> <identifier> [<data-byte>] | dlc=<dlc>]

7 (26)

Parameter

Parameter

port

format Message format according to CFT:

identifier Message identifier (in HEX)

data-byte Only in data messages.

dlc Only in remote frames (RTR) in Classic CAN mode, valid values 0–8

Description

CAN port number (NT 200: 1...2, NT 420: 1...4)

• C – Controller type (C – CAN, F — CAN FD)

• F – Frame Format (S – Standard, E – Extended)

• T – Frame Type (D – Data, R – RTR)

Remote frames (RTR) are only supported by Classic CAN.

Classic CAN: up to 8 (blank separated) data bytes (in HEX)

CAN FD: up to 64 (blank separated) data bytes (in HEX)

Example

Classic CAN data message:

M 1 CSD 100 55 AA 55 AA

CAN FD data message:

M 2 FED 18FE0201 01 02 03 04 05 06 07 08

Classic CAN remote frame:

M 1 CSR 101 dlc=05

Return Value

None

CAN@net NT 200/420 Software Design Guide

4.02.0332.20000 1.5 en-US

Page 10

Message Types

4.2 Cyclic Message

With the cyclic messages commands it is possible to send CAN messages from the CAN@net NT

cyclically, precisely timed and with high frequency, whereas the application data must only be

updated by ASCII commands if required.

• up to 16 cyclic messages are possible

• configuration only via ASCII command

• each message can be configured and the transmission started and stopped individually

Valid Order of Use

► Make sure, that all cyclic messages are stopped (see CYC STOP, p. 9).

► Define the cyclic message (see CYC INIT, p. 8).

► To start the transmission, update the cyclic message (see CYC UPDATE, p. 9).

4.2.1 CYC INIT

Initializes a cyclic message. The command can only be executed when the message is not yet

transmitted.

8 (26)

CYC INIT <msg_num> <port> <time> <count>

Parameter

Parameter

msg_num

port

time

count

Description

Message number, valid values: 0–15

CAN port number (NT 200: 1...2, NT 420: 1...4)

Message cycle time in units of 0.5 ms, valid values: 1–65535 (= 0.5 ms to 32767.5 ms)

Maximum number of transmit repetitions, if a further update message is missing after the

start of the transmission. Valid values: 0–65535. Value 0 sets endless transmission. After

an update message the count is restarted. If the count expires, the cyclic message is

stopped.

Example

CYC INIT 0 1 200 10 "01 02 03 04 05 06 07 08"

CYC INIT 15 2 2000 0

Return Value

Return value Description

R ok

R ERR <error-number> <error-description>

Function succeeded

See List of Error Codes, p. 24

Remark

To start the transmission, call CYC UPDATE.

CAN@net NT 200/420 Software Design Guide

4.02.0332.20000 1.5 en-US

Page 11

Message Types

4.2.2 CYC UPDATE

Starts the transmission of an initialized cyclic message and updates the cyclic message . The

command can only be executed if the message is initialized.

CYC UPDATE <msg_num> <can-message>

Parameter

Parameter

msg_num

can-message

Example

CYC UPDATE 0 M 0 CSD 101 21 22 23 24 25 26 27 28

CYC UPDATE 15 M 0 CSD 101 21 22 23 24 25 26 27 28

Return Value

None

4.2.3 CYC STOP

9 (26)

Description

Message number, valid values: 0–15. Message must be initialized.

Updated CAN message, for information about the message format see Message, p. 7.

Specify value 0 for the port.

Stops the cyclic transmission of the message.

CYC STOP <msg_num>

Parameter

Parameter

msg_num

Description

Message number, valid values: 0–15.

Example

CYC STOP 0

CYC STOP 15

Return Value

Return value Description

R ok

R ERR <error-number> <error-description>

Function succeeded

See List of Error Codes, p. 24

CAN@net NT 200/420 Software Design Guide

4.02.0332.20000 1.5 en-US

Page 12

Message Types

4.3 CAN Commands

Fig. 1 CAN states

The commands that are used to control the CAN controller on the device and to modify the

settings of filter table are described in the following chapters.

10 (26)

Valid Order of Use

► Stop the CAN controller (see Stopping the CAN Controller, p. 16).

► Initialize the CAN controller (see Initializing the CAN Controller, p. 11).

→ Filter settings are deleted and all messages are rejected.

► Configure the filter (see Configuring the Filter, p. 14).

► Start the CAN controller (see Starting the CAN Controller, p. 16).

► Stop the CAN controller (see Stopping the CAN Controller, p. 16).

CAN@net NT 200/420 Software Design Guide

4.02.0332.20000 1.5 en-US

Page 13

Message Types

4.3.1 Initializing the CAN Controller

Make sure, the CAN controller is not in running state before initialization.

With the initialization the CAN controller loses its filter settings and all messages are

rejected. Configure the filter after initialization.

CAN INIT

Initializes the CAN controller with the baud rate value.

The following baud rates are possible (in kBd):

• CAN: 5, 10, 20, 50, 100, 125, 250, 500, 800, 1 000

• CAN FD arbitration phase: 5, 10, 20, 50, 100, 125, 250, 500, 800, 1 000

• CAN FD data phase: 500, 1 000, 2 000, 4 000, 5 000, 6 667, 8 000, 10 000

CAN <port> INIT <mode> <baudA> <baudD> <iso>

11 (26)

Parameter

Parameter

port

mode Operational mode

baudA Classic CAN: Baud rate value in KBaud like 125

baudD Baud rate in KBaud for data phase (only with CAN FD)

iso

Description

CAN port number (NT 200: 1...2, NT 420: 1...4)

STD = Standard

LISTEN = Listen only

CAN FD: Baud rate value in KBaud for arbitration phase

ISO or nonISO (only with CAN FD)

Example

CAN 1 INIT STD 125

CAN 2 INIT LISTEN 250

CAN 3 INIT STD 500 2000

CAN 4 INIT STD 500 2000 nonISO

Return Value

Return value

R ok

R ERR <error-number> <error-description>

Description

Function succeeded

See List of Error Codes, p. 24

Remark

When the controller is initialized, configure a filter with CAN FILTER ADD and start the controller.

CAN@net NT 200/420 Software Design Guide

4.02.0332.20000 1.5 en-US

Page 14

Message Types

12 (26)

CAN INIT CUSTOM

Initializes the CAN controller with user defined baud rates via register values for brp, sjw, tseg1

and tseg2. For CAN FD values tdo and iso must additionally be set, as well as all register values

for the data phase.

If customized register values are used, check in CAN-Gateway Configurator if the values result in a usable

baud rate.

Classic CAN:

CAN <port> INIT CUSTOM <mode> <brp>/<sjw>/<tseg1>/<tseg2>

CAN FD:

CAN <port> INIT CUSTOM <mode> <brp>/<sjw>/<tseg1>/<tseg2>�

<brp>/<sjw>/<tseg1>/<tseg2>/<tdo> <iso>

Parameter

Parameter

port

mode Operational Mode

brp Baud rate prescaler

sjw

tseg1 Time segment 1

tseg2 Time segment 2

tdo Transceiver delay offset (only with CAN FD)

iso

Description

CAN port number (NT 200: 1...2, NT 420: 1...4)

STD = Standard

LISTEN = Listen only

Synchronization jump width

ISO or nonISO (only with CAN FD)

Example

Classic CAN:

CAN 1 INIT CUSTOM STD 16/1/12/2

CAN 2 INIT CUSTOM LISTEN 16/1/12/2

CAN FD:

CAN 3 INIT CUSTOM STD 16/1/12/2 4/1/12/2/8

CAN 4 INIT CUSTOM STD 16/1/12/2 4/1/12/2/8 nonISO

Return Value

Return value Description

R ok

R ERR <error-number> <error-description>

Function succeeded

See List of Error Codes, p. 24

Remark

When the controller is initialized, configure a filter with CAN FILTER ADD and start the controller.

CAN@net NT 200/420 Software Design Guide

4.02.0332.20000 1.5 en-US

Page 15

Message Types

13 (26)

CAN INIT AUTO

Automatic baud rate detection is only possible with Classic CAN. CAN FD does not

support automatic baud rate detection.

Starts the automatic baud rate detection. The CAN controller tries to auto detect a baud rate on

the bus, based on the following possible baud rates in kBd: 5, 10, 20, 50, 100, 125, 250, 500, 800,

1 000. If a baud rate is detected the controller is initialized.

CAN <port> INIT AUTO <mode> <timeout>

Parameter

Parameter

port

mode Operational Mode

timeout

Description

CAN port number 1...2 (with NT 200), 1...4 (with NT 420)

STD = Standard

LISTEN = Listen only

Maximum waiting time in msec for the receiving of a CAN data message or a CAN error

message, valid values: 1 to 1 million

Example

CAN 1 INIT AUTO STD 100

CAN 2 INIT AUTO LISTEN 100

Return Value

Return value Description

R ok

R ERR <error-number> <error-description>

Function succeeded

See List of Error Codes, p. 24

Remark

CAN INIT AUTO checks up to 12 baud rates. In case of low bus activity and a high timeout the

baud rate detection may take several seconds. Check the status of the baud rate detection with

CAN STATUS AUTO. When the baud rate is detected, configure a filter with CAN FILTER ADD and

start the controller.

CAN@net NT 200/420 Software Design Guide

4.02.0332.20000 1.5 en-US

Page 16

Message Types

4.3.2 Configuring the Filter

Make sure, that the CAN controller is in stopped state before configuring the filter.

CAN FILTER CLEAR

Deletes all filter entries for 11 and 29 bit identifiers.

CAN <port> FILTER CLEAR

Parameter

Parameter

port

Example

CAN 1 FILTER CLEAR

Return Value

Return value Description

R ok

R ERR <error-number> <error-description>

Description

CAN port number 1...2 (with NT 200), 1...4 (with NT 420)

14 (26)

Function succeeded

See List of Error Codes, p. 24

CAN FILTER ADD

If a message passes several filters, the message is received several times.

Adds one pair of identifier/mask values to the message filter list. The filter works as a positive

filter list. Received messages that match the registered identifier/mask values are passed through.

All other messages are discarded.

The mask value specifies the bit-position of the identifier, which must be checked (1 means “to

be checked”).

Binary representation of mask:

• binary positions with value 1 are relevant for the filter

• binary positions with value 0 are not relevant for the filter

Binary representation of identifier:

• Defines the values for the positions that are marked as relevant (1) in mask.

• Values in positions that are marked as not relevant (0) in mask are ignored.

CAN <port> FILTER ADD <type> <identifier> <mask>

CAN@net NT 200/420 Software Design Guide

4.02.0332.20000 1.5 en-US

Page 17

Message Types

Parameter

Parameter

port

type

identifier Value for the identifier to match (in HEX)

mask Value for the mask (in HEX)

Description

CAN port number 1...2 (with NT 200), 1...4 (with NT 420)

Message format type: STD or EXT

Example

CAN 1 FILTER ADD STD 100 700

Return Value

Return value Description

R ok

R ERR <error-number> <error-description>

Example for 11 bit Identifiers

hex bin

Identifier

Mask

Result 0x1XX (0x100–0x1FF)

0x100 0001:0000:0000

0x700 0111:0000:0000

Any identifier between 0x100 and 0x1FF passes the filter, as only the first 3 bits of the mask are

marked as relevant.

Function succeeded

See List of Error Codes, p. 24

0001:XXXX:XXXX

15 (26)

Example for 29 bit Identifiers

hex bin

Identifier

Mask

Result

0x10003344 0001:0000:0000:0000:0011:0011:0100:0100

0x1F00FFFF 0001:1111:0000:0000:1111:1111:1111:1111

0x1FXXFFFF 0001:0000:XXXX:XXXX:0011:0011:0100:0100

Any identifier between 0x10003344 and 0x10FF3344 passes the filter.

Further Examples

Identifier Mask Valid message identifiers which pass the filter

0x100 0x7FF 0x100

0x700 0x700 0x700–0x7FF

0x000 0x000 0x000–0x7FF

Remark

To allow all messages to pass the filter, add CAN <port> FILTER ADD STD 0 0 and CAN

<port> FILTER ADD EXT 0 0 to the message filter list.

CAN@net NT 200/420 Software Design Guide

4.02.0332.20000 1.5 en-US

Page 18

Message Types

4.3.3 Starting the CAN Controller

Sets the CAN controller in running state.

CAN <port> START

Parameter

Parameter

port

Description

CAN port number 1...2 (with NT 200), 1...4 (with NT 420)

Example

CAN 1 START

Return Value

Return value

R ok

R ERR <error-number> <error-description>

4.3.4 Stopping the CAN Controller

Sets the CAN controller in stopped state for (re-)configuration.

16 (26)

Description

Function succeeded

See List of Error Codes, p. 24

With the command STOP the locally buffered transmit messages of the CAN controller are

discarded.

CAN <port> STOP

Parameter

Parameter

port

Description

CAN port number 1...2 (with NT 200), 1...4 (with NT 420)

Example

CAN 1 STOP

Return Value

Return value Description

R ok

R ERR <error-number> <error-description>

Function succeeded

See List of Error Codes, p. 24

CAN@net NT 200/420 Software Design Guide

4.02.0332.20000 1.5 en-US

Page 19

Message Types

4.3.5 Requesting the Status

CAN status responses always include the CAN channel number.

CAN STATUS

Reads the CAN status value. Can only be used in stopped and in running state.

CAN <port> STATUS

Parameter

Parameter

port

Example

CAN 1 STATUS

Return Value

The command CAN Status returns CAN status information.

Description

CAN port number 1...2 (with NT 200), 1...4 (with NT 420)

17 (26)

R CAN <port> <BEOTI> <num>

port

BEOTI

num

Example return values Description

R CAN 1 ----- 100

R CAN 2 –E-T- 24

R ERR <error-number> <error-description>

CAN port number 1...2 (with NT 200), 1...4 (with NT 420)

Five character string:

B — bus off status

E — error warning level

O — data overrun detected

T — transmit pending

I — Init (stopped) state, otherwise running state

Number of free message buffers for transmission (maximally 100)

CAN port 1, 100 free message buffers for transmission

CAN port 2, error warning level, transmit pending, 24 free

message buffers for transmission

See List of Error Codes, p. 24

Remark

The buffer (organized as FIFO) can store maximally 100 messages. If the buffer is full, new

messages are discarded.

CAN@net NT 200/420 Software Design Guide

4.02.0332.20000 1.5 en-US

Page 20

Message Types

CAN STATUS AUTO

Reads the CAN baud rate detection status.

CAN <port> STATUS AUTO

Parameter

Parameter

port

Description

CAN port number 1...2 (with NT 200), 1...4 (with NT 420)

Example

CAN 1 STATUS AUTO

R busy

CAN 1 STATUS AUTO

R 125

Return Value

Return value

R stopped

R busy

R <baud-rate>

R failed

R timeout

R ERR <error-number> <error-description>

18 (26)

Description

Not yet started

Baud rate detection running

Detected baud rate in kBd

Not detected or unknown baud rate

No bus traffic

See List of Error Codes, p. 24

Remark

Make sure that a baud rate is detected before configuring a filter and starting the controller.

CAN@net NT 200/420 Software Design Guide

4.02.0332.20000 1.5 en-US

Page 21

Message Types

4.4 Device Commands

The ASCII protocol supports the following DEV (device) commands:

• DEV IDENTIFY

• DEV VERSION

• DEV PROTOCOL

• DEV INTERFACES

4.4.1 DEV IDENTIFY

Identifies the device.

DEV IDENTIFY

Return Value

Return value Description

R CAN@net NT 420

R ERR <error-number> <error-description>

19 (26)

Identity of the device

See List of Error Codes, p. 24

4.4.2 DEV VERSION

Reads the firmware version number of the device.

DEV VERSION

Return Value

Return value

R V1.00.00

R ERR <error-number> <error-description>

4.4.3 DEV PROTOCOL

Reads the ASCII protocol version number of the device.

DEV PROTOCOL

Return Value

Return value Description

R V2.0

R ERR <error-number> <error-description>

4.4.4 DEV INTERFACES

Reads the types of all available fieldbus interfaces.

Description

Firmware version number of the device

See List of Error Codes, p. 24

ASCII protocol version number of the device

See List of Error Codes, p. 24

DEV INTERFACES

Return Value

Return value Description

R CAN CAN

R CAN

R ERR <error-number> <error-description>

CAN@net NT 200/420 Software Design Guide

See List of Error Codes, p. 24

4.02.0332.20000 1.5 en-US

Page 22

Message Types

4.5 Events

The following events are transmitted to the host if the CAN controller changes the status.

20 (26)

E <port> ERRORWARNING SET

E <port> ERRORWARNING RESET

E <port> BUSOFF

The error status of the CAN controller and the error counter are defined according to ISO 118981:2015.

4.6 Responses

4.6.1 Positive Response

A positive response is always R ok.

4.6.2 Negative Response

R ERR <error-number> <error-description>

For a list of error codes see List of Error Codes, p. 24.

Example

R ERR 1 invalid baudrate

4.6.3 Device Response

CAN controller reached Error Warning level.

CAN controller under-run Error Warning level.

CAN controller reached Bus Off state.

Device responses depend on the request command.

Examples

R V1.00.00

R CAN CAN

CAN@net NT 200/420 Software Design Guide

4.02.0332.20000 1.5 en-US

Page 23

Message Types

4.7 PING REQUEST

Monitors the connection between host and CAN@net NT (heartbeat mechanism).

The CAN@net NT answers to a PING REQUEST with a PING RESPONSE. The first PING REQUEST

activates the connection monitoring. If no further PING REQUEST is received in the defined time

(set in parameter timeout in seconds, default value are 3 seconds), the CAN@net NT is

disconnected and reset.

PING REQUEST <timeout>

Parameter

Timeout in seconds (1...255), default value: 3 s

Example

PING REQUEST 10

Return Values

R PING RESPONSE

R ERR <error-number> <error-description>

21 (26)

CAN@net NT 200/420 Software Design Guide

4.02.0332.20000 1.5 en-US

Page 24

How to Handle Incoming Messages 22 (26)

5 How to Handle Incoming Messages

The communication from and to the device is handled asynchronous.

Example

A CAN status command/response sequence can be interrupted by incoming CAN messages.

tx: CAN 1 STATUS

rx: M 1 CSD 123 02 22 33

rx: M 2 CSD 345 02 55 AA

rx: R CAN 1 ----- 100

This is especially the case when working with more than one CAN controller. The ASCII message

parser on the host side has to take care on that and handle receiving ASCII messages on an event

basis.

The host message parser has to distinguish the following types of messages:

• CAN message, like M 2 CSD 01 C4 97 00 00 00 00 00 00

• Positive response (R ok)

• Negative response (R ERR <error-number> <error-description>)

• Device response, like R CAN CAN

• Events like E 1 BUSOFF

• CAN status response, like R CAN 1 ----- 100

CAN Message

Receiving CAN messages follows the definition of transmitting messages in Message, p. 7.

Example

M 1 CSD 100 55 AA 55 AA

M 2 CED 18FE0201 01 02 03 04 05 06 07 08

CAN@net NT 200/420 Software Design Guide

4.02.0332.20000 1.5 en-US

Page 25

Example 23 (26)

6 Example

The following example shows an initialization of both CAN channels. The direction is shown by rx.

(transmitted by user) and tx. (received by user).

tx: DEV VERSION

rx: R V0.10.04

tx: DEV INTERFACES

rx: R CAN CAN

tx: CAN 1 STOP

rx: R ok

tx: CAN 1 INIT STD 250

rx: R ok

tx: CAN 1 FILTER ADD STD 345 7F0

rx: R ok

tx: CAN 1 START

rx: R ok

tx: CAN 2 STOP

rx: R ok

tx: CAN 2 INIT STD 250

rx: R ok

tx: CAN 2 FILTER ADD STD 123 7F0

rx: R ok

tx: CAN 2 START

rx: R ok

tx: CAN 1 STATUS

rx: R CAN 1 ----- 100

tx: CAN 2 STATUS

rx: R CAN 2 ----- 100

tx: M 1 CSD 123 01 22

tx: M 2 CSD 345 01 55

rx: M 1 CSD 345 01 55

rx: M 2 CSD 123 01 22

CAN@net NT 200/420 Software Design Guide

4.02.0332.20000 1.5 en-US

Page 26

List of Error Codes 24 (26)

7 List of Error Codes

Error number Error description

0

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16 CAN <port_num> parameter is missing

17 DEV parameter is missing

18

19

20

21

22

23

24

25

- -

27 CYC parameter is missing

28

29

30

31

32

33

Unknown error ‘<error_code>’

CAN <port_num> baud rate not found

CAN <port_num> stop failed

CAN <port_num> start failed

CAN <port_num> extended filter is full

CAN <port_num> standard open filter set twice

CAN <port_num> standard filter is full

CAN <port_num> invalid identifier or mask for filter add

CAN <port_num> baud rate detection is busy

CAN <port_num> invalid parameter type

CAN <port_num> invalid CAN state

CAN <port_num> invalid parameter mode

CAN <port_num> invalid port number

CAN <port_num> init auto baud failed

CAN <port_num> filter parameter is missing

CAN <port_num> bus off parameter is missing

CAN <port_num> invalid parameter brp

CAN <port_num> invalid parameter sjw

CAN <port_num> invalid parameter tSeg1

CAN <port_num> invalid parameter tSeg2

CAN <port_num> init custom failed

CAN <port_num> init failed

CAN <port_num> reset failed

CAN <port_num> filter parameter is missing

CYC message <msg_num> stop failed

CYC message <msg_num> init failed

CYC message <msg_num> invalid parameter port

CYC message <msg_num> invalid parameter msg_num

CYC message <msg_num> invalid parameter time

CYC message <msg_num> invalid parameter data

CAN@net NT 200/420 Software Design Guide

4.02.0332.20000 1.5 en-US

Page 27

This page intentionally left blank

Page 28

last page

© 2019 HMS Industrial Networks

Box 4126

300 04 Halmstad, Sweden

info@hms.se 4.02.0332.20000 1.5 en-US / 2019-03-06 / 12176

Loading...

Loading...