IXXAT CANlink II Hardware Manual

Hardware Manual

CANlink II

RS232-CAN Converter

The expert for industrial and automotive communication

IXXAT

Headquarter US Sales Office

IXXAT Automation GmbH IXXAT Inc.

Leibnizstr. 15 120 Bedford Center Road

D-88250 Weingarten USA-Bedford, NH 03110

Tel.: +49 (0)7 51 / 5 61 46-0 Phone: +1-603-471-0800

Fax: +49 (0)7 51 / 5 61 46-29 Fax: +1-603-471-0880

Internet: www.ixxat.de Internet: www.ixxat.com

e-Mail: info@ixxat.de e-Mail: sales@ixxat.com

Support

In case of unsolvable problems with this product or other IXXAT products

please contact IXXAT in written form by:

Fax: +49 (0)7 51 / 5 61 46-29

e-Mail: support@ixxat.de

Copyright

Duplication (copying, printing, microfilm or other forms) and the electronic

distribution of this document is only allowed with explicit permission of

IXXAT Automation GmbH. IXXAT Automation GmbH reserves the right to

change technical data without prior announcement. The general business

conditions and the regulations of the license agreement do apply. All rights

are reserved.

Handbuchnummer: 4.01.0032.20000

Version: 1.3

Contents

1 Lead-in ........................................................................................7

1.1 Overview ............................................................................. 7

1.2 Features............................................................................... 8

1.3 Versions............................................................................... 8

1.4 Block diagram ..................................................................... 9

1.5 Support ............................................................................. 10

1.6 Returning hardware.......................................................... 10

2 Aluminum housing version.......................................................11

2.1 Connector allocation......................................................... 11

2.1.1 Power supply (X1)...................................................................11

2.1.2 Serial interface RS232 (X2) ......................................................12

2.1.3 CAN (X3) ................................................................................12

2.2 Ground connections ......................................................... 13

3 Industrial DIN rail version .........................................................14

3.1 Connector allocation......................................................... 14

3.1.1 Power supply (X1)...................................................................15

3.1.2 Serial interface RS232 (X2) ......................................................15

3.1.3 CAN (X3) ................................................................................16

3.2 Ground connections ......................................................... 16

4 Description of functions ...........................................................17

4.1 Introduction ...................................................................... 17

4.2 RS232-CAN gateway ......................................................... 17

4.3 RS232-CANopen gateway ................................................. 18

4.4 Data structure of the configuration files.......................... 22

4.4.1 General settings [General] .......................................................23

4.4.1.1 Product name (ProductName)....................................23

4.4.1.2 Version number (TemplateVersion) ............................23

4.4.1.3 Operation mode (OperationMode) ............................23

4.4.1.4 Timeout ....................................................................23

4.4.2 User settings [User] .................................................................23

4.4.2.1 Configuration name (ConfigAlias) ..............................23

4.4.3 RS232 settings [RS232] ...........................................................23

4.4.3.1 Baudrate (RS232baudrate).........................................23

4.4.3.2 Number of databits (Databits) ...................................24

Copyright IXXAT Automation GmbH

3

CANlink II - Manual, V1.3

Contents

4.4.3.3 Parity (Parity)............................................................. 24

4.4.3.4 Flow control (Handshake).......................................... 24

4.4.4 CANlink settings [CANlink] ......................................................24

4.4.4.1 Baudrate (CANbaudrate) ...........................................24

4.4.4.2 Frame format (FrameFormat)..................................... 24

4.4.4.3 Send identifier (SendID)............................................. 25

4.4.4.4 Receive identifier (ReceiveID)...................................... 25

4.4.5 COPlink settings [COPlink]....................................................... 25

4.4.5.1 Baudrate (CANopenBaudrate).................................... 25

4.4.5.2 CANopen node number (CANopenNode)...................25

4.4.5.3 Heartbeat time (HBTime)........................................... 25

4.4.5.4 Receive PDO (RxPDO) ................................................25

4.4.5.5 Receive PDO type (RxPDOtype)...................................26

4.4.5.6 Transmit-PDO (TxPDO) ..............................................26

4.4.5.7 Transmit-PDO type (TxPDOtype).................................26

4.4.5.8 Byte stream flow control (ByteStreamExtension)........26

4.5 Default configuration ........................................................27

5 Download tool..........................................................................29

5.1 Configuration with Windows console program................29

5.1.1 Creating a configuration file ................................................... 30

5.1.2 Download of a configuration ..................................................30

5.1.3 Displaying the current configuration .......................................31

5.1.4 Saving the current configuration ............................................. 32

6 Configuration tool....................................................................33

6.1 Configuration with Windows application .........................33

6.1.1 Default configuration ............................................................. 33

6.1.2 Loading and saving a configuration ........................................34

6.1.3 Setting up a connection..........................................................34

6.1.4 Reading the current configuration........................................... 36

6.1.5 Downloading a configuration .................................................37

6.1.6 Disconnecting......................................................................... 37

6.2 Configuration cable ...........................................................37

7 Displays.....................................................................................38

7.1 Normal mode .....................................................................38

7.1.1 Power LED.............................................................................. 38

Copyright IXXAT Automation GmbH

4

CANlink II - Manual, V1.3

Contents

7.1.2 CAN LED.................................................................................38

7.1.3 COP LED .................................................................................38

7.1.4 RS232 LED..............................................................................38

7.2 Configuration mode ......................................................... 39

7.3 Error state ......................................................................... 39

8 Notes on EMC ...........................................................................40

8.1 Aluminum version............................................................. 40

8.2 Industrial DIN-rail version – shield concept ...................... 40

Appendix..........................................................................................41

Technical specifications............................................................ 41

Sources of data sheets............................................................. 41

EC conformity declaration....................................................... 42

Copyright IXXAT Automation GmbH

5

CANlink II - Manual, V1.3

Lead-in

1 Lead-in

1.1 Overview

Congratulations on your purchase of the IXXAT CANlink II, a high-quality electronic component developed and manufactured according to the latest technological standards.

This manual is intended to familiarize you with your CANlink II. Please read this

manual before initial startup.

The CANlink II enables devices with only one serial port a simple, configurable

access to CAN and CANopen networks. CANlink II provides two operation modes

for this purpose.

In the CAN operation mode (CANlink), received CAN data are transmitted transparently to the RS232 interface. Data received via RS232 are mapped into CAN

telegrams and transmitted. One configurable identifier each is available for

transmission and reception.

In the CANopen operation mode (COPlink), the CANlink operates as a CANopen

node, where the serial data are stored as a byte stream object in the manufacturer-specific object dictionary range.

The supported CANopen features are:

• 1 server SDO expedited, non-expedited, no CRC check

• 1 TX PDO static mapping

• 1 RX PDO static mapping

• Emergency message

• Heartbeat producer

• NMT slave

The communication interfaces and operation modes are configured by means of

a configuration file, which is saved on the device via a loading program.

The CANlink II is available in two housing versions, a plastic housing for DIN rail

mounting or as a desktop device in a robust aluminum housing.

Copyright IXXAT Automation GmbH

7

CANlink II - Manual, V1.3

Lead-in

1.2 Features

• Supply voltage 9-36 V

• CAN bus interface in accordance with ISO 11898-2, optional galvanic isolation

• Serial interface (RS232) up to 115 kbaud

• Fujitsu 16 bit microcontroller

• Two housing versions available

1.3 Versions

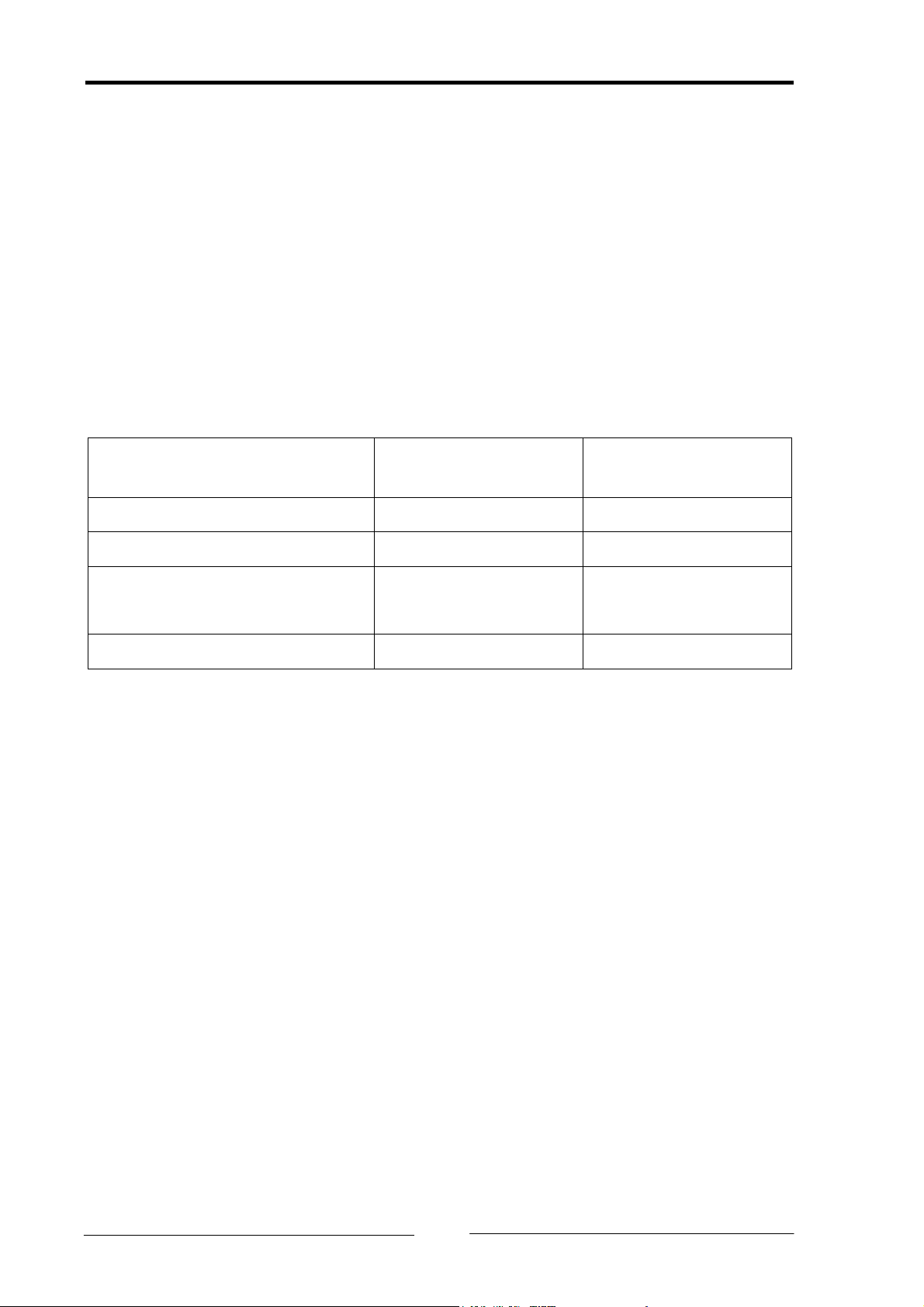

The following versions of the CANlink II are available:

Housing

Supply voltage

Bus interface

Galvanic isolation

Industrial

DIN rail

Industrial

aluminum

Plastic Aluminum

9 V – 36 V 9 V – 36 V

high speed

(ISO 11898-2)

high speed

(ISO 11898-2)

optional optional

Copyright IXXAT Automation GmbH

8

CANlink II - Manual, V1.3

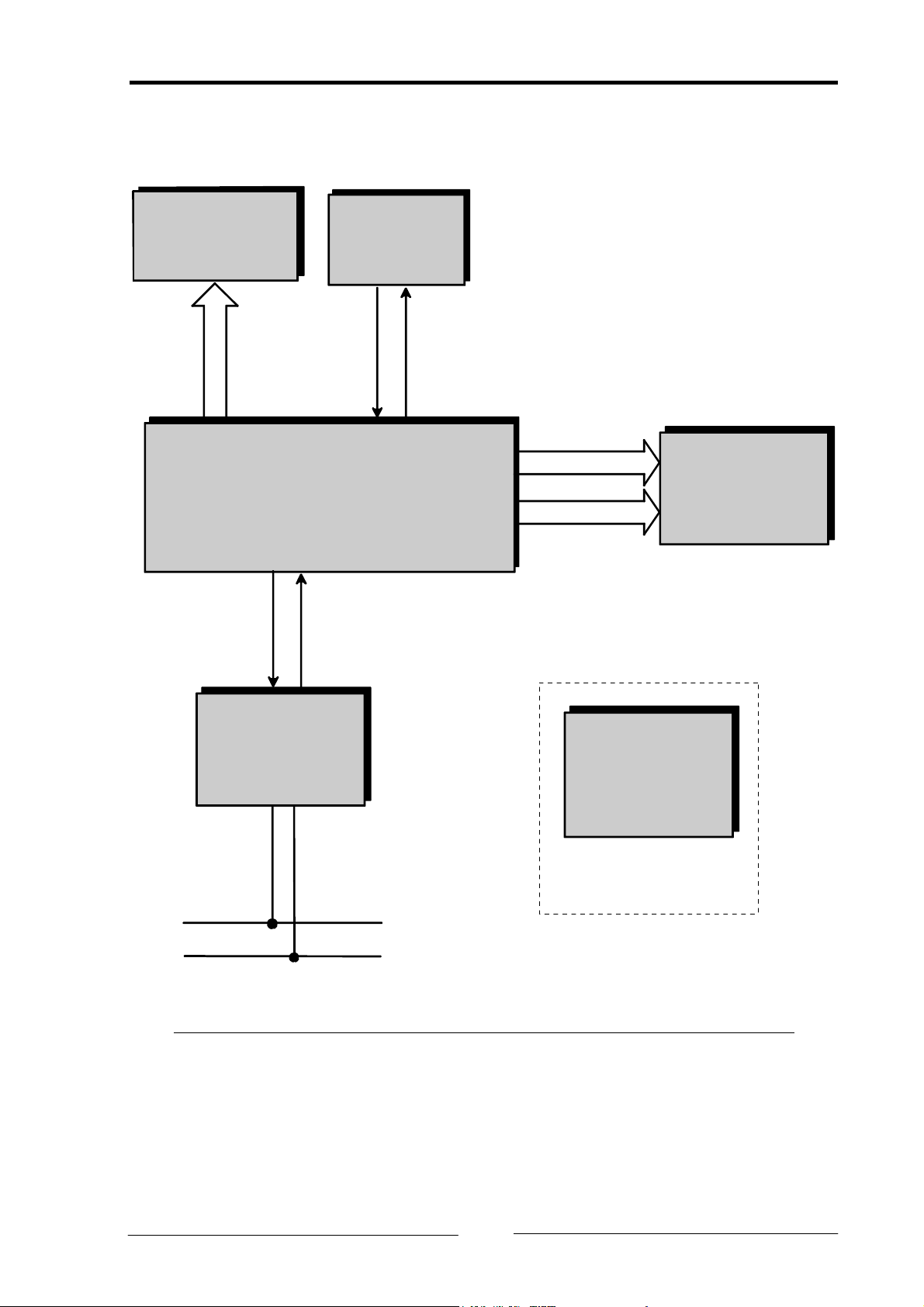

1.4 Block diagram

Lead-in

Full RS232

transceiver

optional RS485

s

e

n

i

L

2

3

2

S

R

Microcontroller

internal

RS232

Adapter

RxD

MB90F543

CAN

TxD

D 0..15

A 0..17

Optional

Data

Memory

CAN Bus

Interface

High Speed

CAN High

CAN Low

CAN Bus

In dustrial

Range

(9V -36 V )

Power Supply

Fig. 1-1: Block diagram CANlink II

Copyright IXXAT Automation GmbH

9

CANlink II - Manual, V1.3

Lead-in

1.5 Support

For more information on our products, FAQ lists and installation tips, please refer

to the support section of our website (http://www.ixxat.de), which also contains

information on current product versions and available updates.

If you have any further questions after studying the information on our website

and the manuals, please contact our support department. The support section on

our website contains the relevant forms for your support request. In order to facilitate our support work and enable a fast response, please provide precise information on the individual points and describe your question or problem in detail.

If you would prefer to contact our support department by phone, please also

send a support request via our website first, so that our support department has

the relevant information available.

1.6 Returning hardware

If it is necessary to return hardware to us, please download the relevant RMA

form from our website and follow the instructions on this form.

In the case of repairs, please also describe the problem or fault in detail on the

RMA form. This will enable us to carry out the repair quickly.

Copyright IXXAT Automation GmbH

10

CANlink II - Manual, V1.3

Aluminum housing version

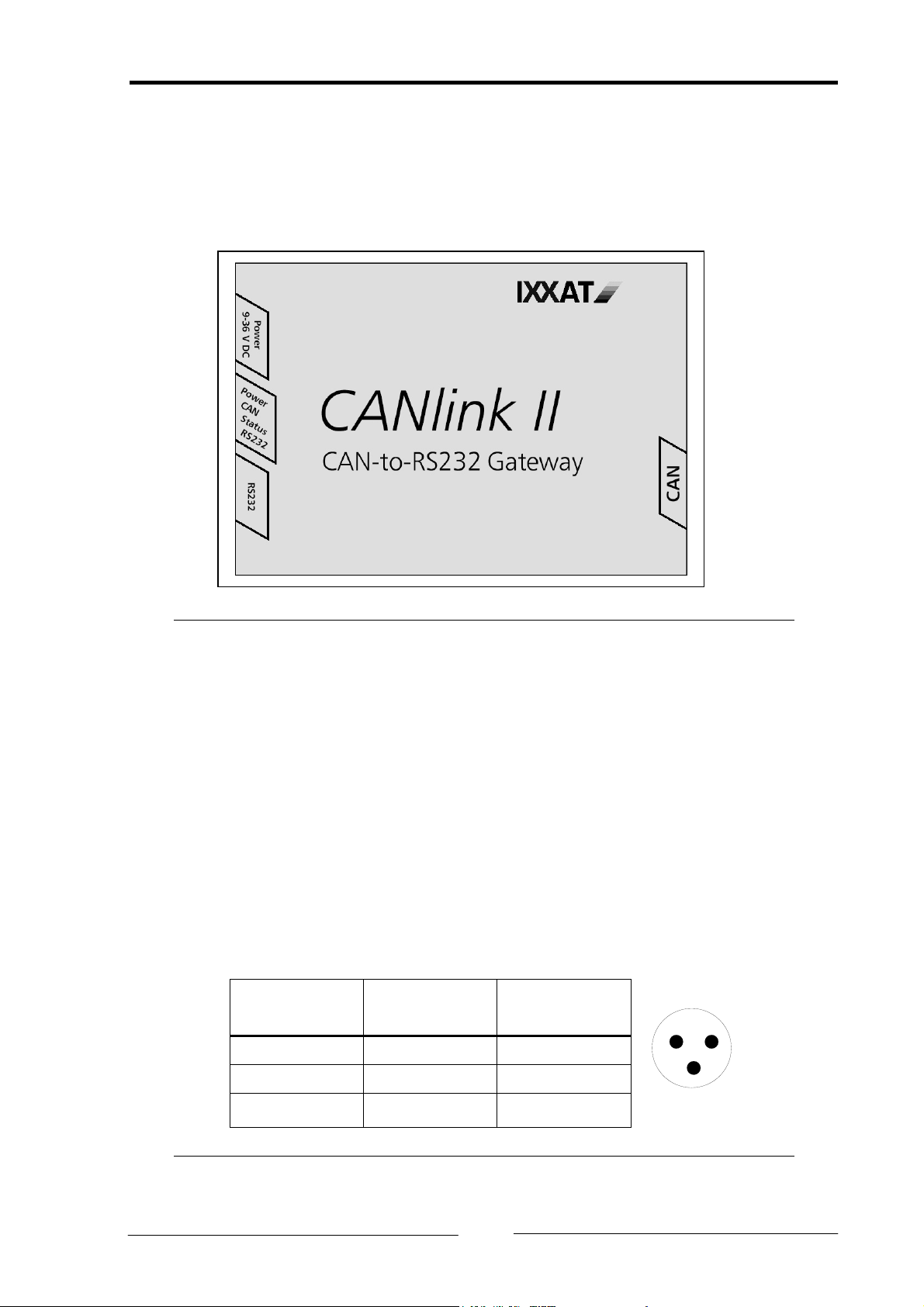

2 Aluminum housing version

2.1 Connector allocation

X1

LED

X2 X3

Fig. 2-1: Connector arrangement aluminum version

2.1.1 Power supply (X1)

The device is supplied with direct voltage of 9 V - 36 V. A pre-fabricated cable for

power supply is included in the scope of delivery. The connection allocation is

shown in Table 2-1.

The CANlink II is protected against polarity reversal, under-voltage and overvoltage. In the event of polarity reversal or under-voltage, it is switched off, with

over-voltage an internal fuse is triggered.

Pin no.

X1

1 PWR (+) White

2 GND (-) Brown

3 Shield Shield

Table 2-1: Pin allocation Power

Copyright IXXAT Automation GmbH

Signal Lead color

123

1

11

CANlink II - Manual, V1.3

Aluminum housing version

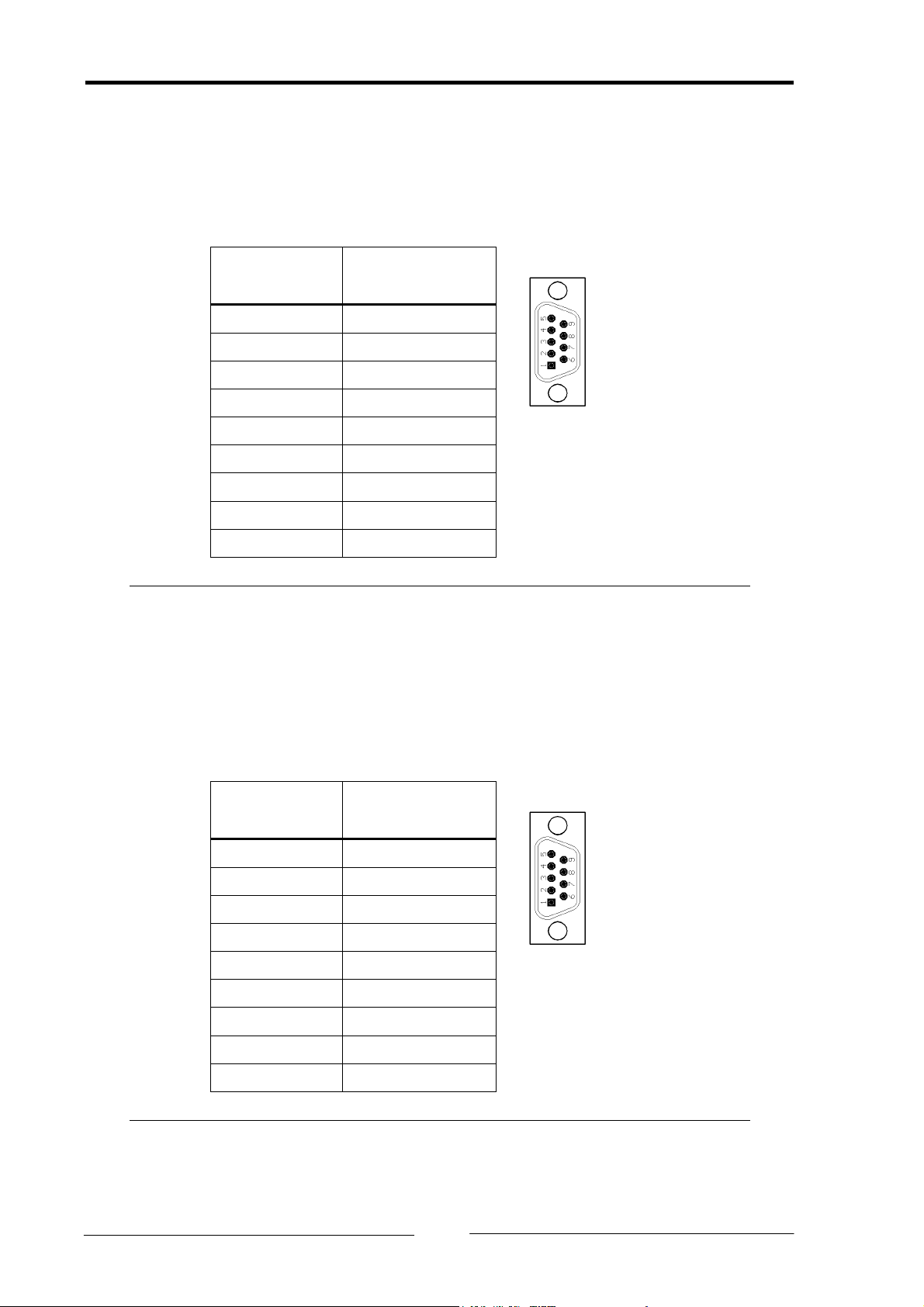

2.1.2 Serial interface RS232 (X2)

The signals of the serial port are connected to the 9-pin Sub-D connector X2 (see

table 2-2). The pin allocation complies with the standard for DTE devices. For

configuration of the device with a PC, you require a laplink cable.

Pin no.

Signal

X2

1 DCD

2 RX

3 TX

4 DTR

5 GND

6 DSR

7 RTS

8 CTS

9 RI

Table 2-2: Pin allocation RS232

2.1.3 CAN (X3)

CAN is available on connector X3 with a bus interface according to ISO 11898-2.

The signals of the bus interface are connected to the 9-pin Sub-D connector X3

(see Table 2-3). The pin allocation complies with the standard CiA DS102

Pin no.

Signal

X3, X4

1 2 CAN Low

3 GND

4 5 6 7 CAN High

8 9 -

Table 2-3: Pin allocation CAN

Copyright IXXAT Automation GmbH

12

CANlink II - Manual, V1.3

Aluminum housing version

2.2 Ground connections

In the galvanically isolated version, the GND of CAN (X3) is isolated from the rest

of the circuit, the GND of the serial port (X2) is connected to the GND of the

power supply (X1).

In the version without galvanic isolation, all GND connections (X1, X2, X3) are

connected with each other.

The shield connections of CAN (X3), serial port (X2) and power supply (X1) are

connected with each other both in the version with and in the version without

galvanic isolation.

Copyright IXXAT Automation GmbH

13

CANlink II - Manual, V1.3

Loading...

Loading...