IXXAT CANio 500 Quick Start Manual

Quickstart Manual

CANio 500

I/O-to-CAN Gateway

English

HMS Technology Center Ravensburg GmbH

Helmut-Vetter-Straße 2

D-88213 Ravensburg

Germany

Tel.: +49 751 56146-0

Fax: +49 751 56146-29

Internet: www.hms-networks.com

E-Mail: info-ravensburg@hms-networks.com

Support

In case of unsolvable problems with this product or other HMS products

please fill in support form in the support are on www.ixxat.com.

Further international support contacts can be found on our webpage

www.ixxat.com

Copyright

Duplication (copying, printing, microfilm or other forms) and the electronic

distribution of this document is only allowed with explicit permission of

HMS Technology Center Ravensburg GmbH. HMS Technology Center

Ravensburg GmbH reserves the right to change technical data without

prior announcement. The general business conditions and the regulations

of the license agreement do apply. All rights are reserved.

Registered Trademarks

All trademarks mentioned in this document and where applicable third

party registered are absolutely subject to the conditions of each valid

label right and the rights of particular registered proprietor. The absence

of identification of a trademark does not automatically mean that it is not

protected by trademark law.

Document number: 4.01.0098.20000

Version: 1.3

Content

Copyright IXXAT Automation GmbH

3

CANio 500 Quickstart Manual, version 1.3

1 General information ....................................................................... 5

1.1 Highlights ................................................................................ 5

1.2 Designs and device variants ................................................. 6

2 Connector assignments ................................................................. 6

2.1 Connector (X1) power supply 6-32 V DC .............................. 6

2.2 Connector (X2) CAN ............................................................... 7

2.3 Connector (X3) digital ............................................................ 7

2.4 Connector (X4) analog ........................................................... 9

3 LED displays ................................................................................... 9

3.1 PWR - LED .............................................................................. 9

3.2 CAN - LED ............................................................................. 10

3.3 USR 1/2 - LED ....................................................................... 10

4 Description of functions .............................................................. 10

4.1 Introduction .......................................................................... 10

4.2 Galvanic isolation ................................................................ 10

4.3 Digital outputs ...................................................................... 10

4.4 Digital inputs .......................................................................... 11

4.4.1 Digital inputs 1-4 .................................................................... 11

4.4.2 Additional digital input on connector (X1) .............................. 11

4.5 Analog outputs ...................................................................... 11

4.6 Analog inputs ....................................................................... 12

4.6.1 0 - 10 V input range ................................................................ 13

4.6.2 ±5V input range ...................................................................... 13

4.6.3 ±100 mA input range .............................................................. 14

4.7 Power supply PWR(+) .......................................................... 14

5 Software ........................................................................................ 15

5.1 CANio 500 as a CAN module ............................................... 16

5.1.1 CAN – Identifier ...................................................................... 16

5.1.2 CAN baudrate ........................................................................ 16

5.1.3 Node number ......................................................................... 16

5.1.4 Setting the digital outputs ....................................................... 16

5.1.5 Control of the analog outputs ................................................. 17

5.1.6 Digital inputs ........................................................................... 18

Content

Copyright IXXAT Automation GmbH

4

CANio 500 Quickstart Manual, version 1.3

5.1.7 Digital inputs: edge events ..................................................... 19

5.1.8 Analog inputs ......................................................................... 20

5.1.9 Value of the power supply PWR(+) ........................................ 20

5.1.10 Heartbeat message .............................................................. 21

5.1.11 Emergency messages .......................................................... 22

5.1.12 Error management................................................................ 25

5.1.13 Factory settings .................................................................... 25

5.1.14 Reserved CAN identifiers ..................................................... 26

5.1.15 Steering the state machine of the CANio 500 ...................... 26

6 General ......................................................................................... 29

6.1 Support ................................................................................. 29

6.2 Returning hardware.............................................................. 29

6.3 Note on disposal of used devices ....................................... 29

6.4 Note on EMC ......................................................................... 30

6.5 FCC Compliance ................................................................... 30

6.6 EC DECLARATION OF CONFORMITY ................................. 31

General information

Copyright IXXAT Automation GmbH

5

CANio 500 Quickstart Manual, version 1.3

1 General information

The CANio 500 is a universal interface for analog and digital signals.

This manual is intended to help you to learn more about the CANio 250.

Please read this manual before using the CANio 250 for the first time. Therefore it is restricted to the essential topics. For further details – mainly with respect to the application software – the corresponding manuals are provided

online.

1.1 Highlights

Power supply 6 - 32 V DC

Power consumption 1.2 Watt (without load connected to the outputs)

CAN bus connection according to ISO 11898-2 with galvanic isolation

Communication as CAN node or CANopen device

4 digital inputs

4 digital outputs, high-side switch, short-circuit protection

4 analog inputs, 12-bit, precision typical 3%, device variants:

o 0 … +10 V

o -5 … +5 V

o -100 … +100 mA

4 analog outputs, 12-bit, precision typical 0.5%, output ranges pro-

grammable via software:

o 0 … +5 V

o 0 … +10 V

o -5 … +5 V

o -10 … +10 V

o -10.8 … +10.8 V

Monitoring of the power supply

Additional digital input on power supply connector

All inputs are protected for voltages up to 60 V

2 LEDs (both two-colored) controllable via software

1 LED for the CAN bus status

1 LED for the power supply

Robust aluminum housing

Temperature range -40 °C to 70 °C

Connector assignments

Copyright IXXAT Automation GmbH

6

CANio 500 Quickstart Manual, version 1.3

1.2 Designs and device variants

The CANio 500 is available in the following variants of the analog inputs:

Order number

Designs and device versions

1.01.0098.00000

CANio 500 with 4 analog inputs 0 … +10 V

1.01.0098.00001

CANio 500 with 4 analog inputs -5 … +5 V

1.01.0098.00002

CANio 500 with 4 analog inputs -100 … +100 mA

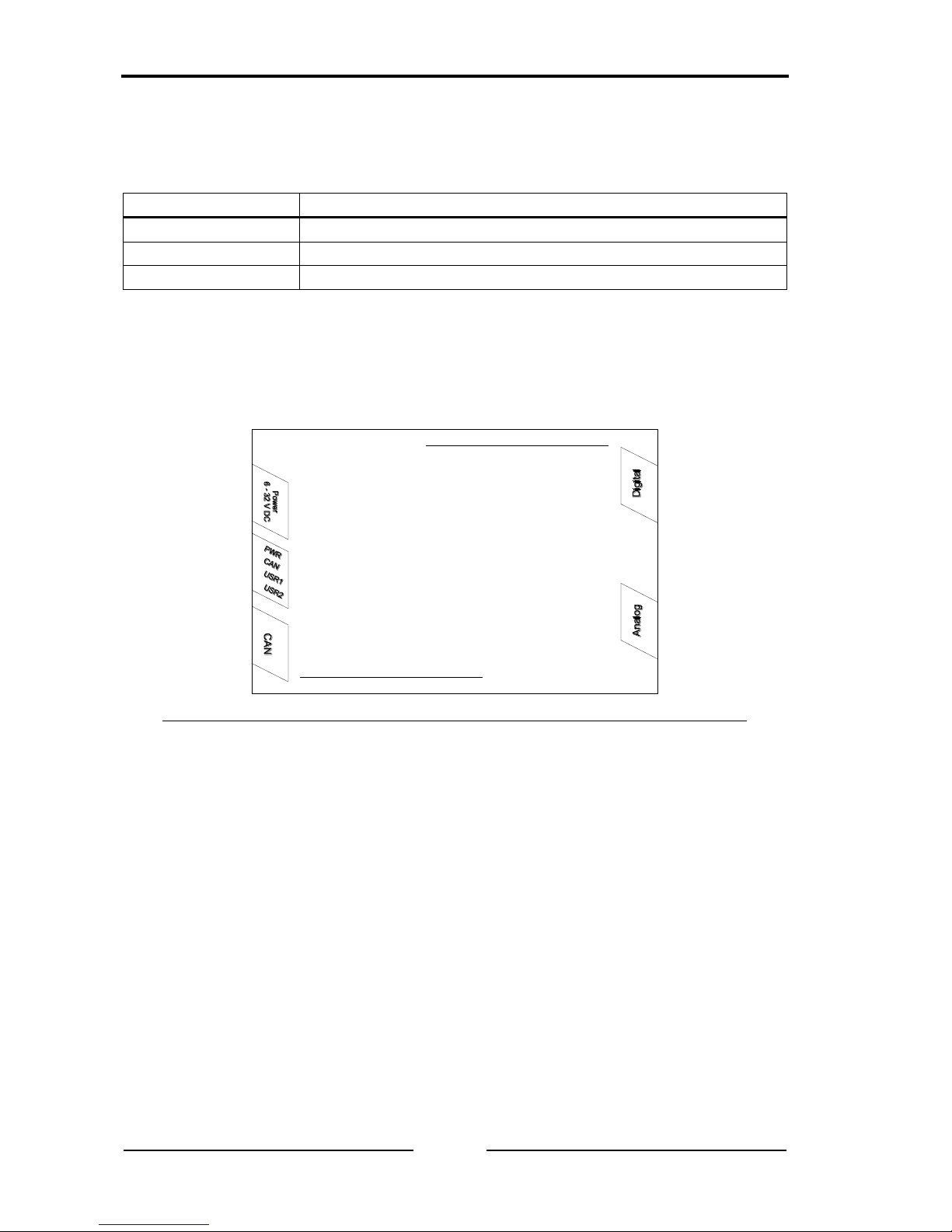

2 Connector assignments

X1 X3

LED

X2 X4

Figure 2-1: Connector assignments

2.1 Connector (X1) power supply 6-32 V DC

The CANio 500 is supplied with DC voltage of 6 V – 32 V The scope of supply

includes made-up cable for power supply. The terminal assignment is given in

table 2-1.

The type of connector is: Binder cable socket 99-0976-100-03

The CANio 500 is protected against reverse polarity, undervoltage and overvoltage. It is switched off in the case of reverse polarity or undervoltage. The

CANio survives overvoltage up to 60 V and load dump undamaged. In the

event of voltages above this, an internal fuse may be tripped. If the internal

fuse is tripped, the CANio 500 is no longer operational and must be returned to

IXXAT for repair.

CANio 500

I/O-to-CAN Gateway

Connector assignments

Copyright IXXAT Automation GmbH

7

CANio 500 Quickstart Manual, version 1.3

The additional digital input is also connected on this connector.

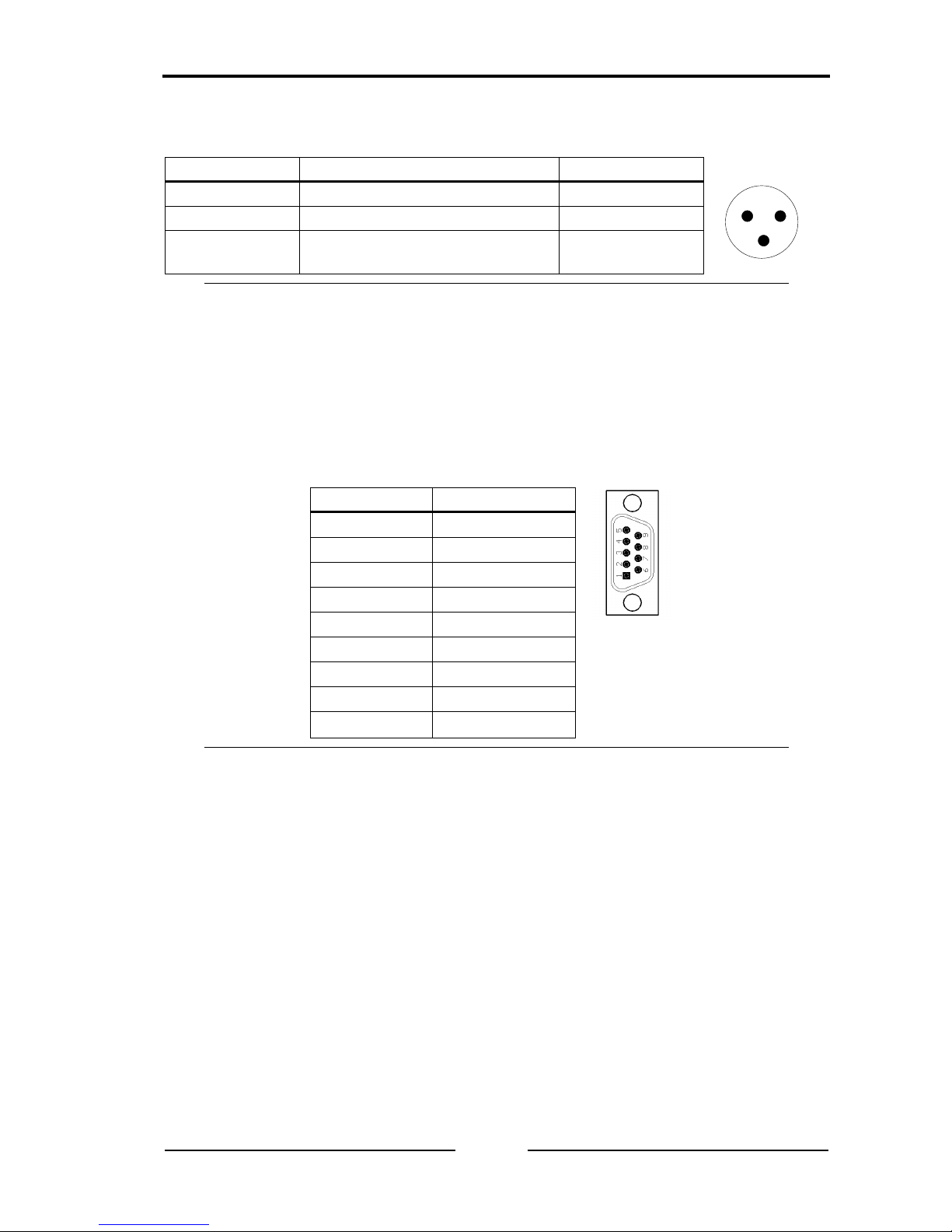

Pin no. X1

Signal

Wire color

1

123

1

PWR (+)

white

2

GND (-)

brown

3

Additional digital input on power supply connector

Shield

Table 2-1: Pin assignment power supply

2.2 Connector (X2) CAN

CAN is available on connector X2 with a bus connection according to ISO

11898-2. The signals of the bus connection are available on the 9-pin D-Sub

connector (pins, male) (see table 2-2).

Pin no. X2

Signal

1

-

2

CAN Low

3

GND_GND

4

-

5

-

6 - 7

CAN High

8

-

9

-

Table 2-2: Pin assignment CAN connector D-Sub 9

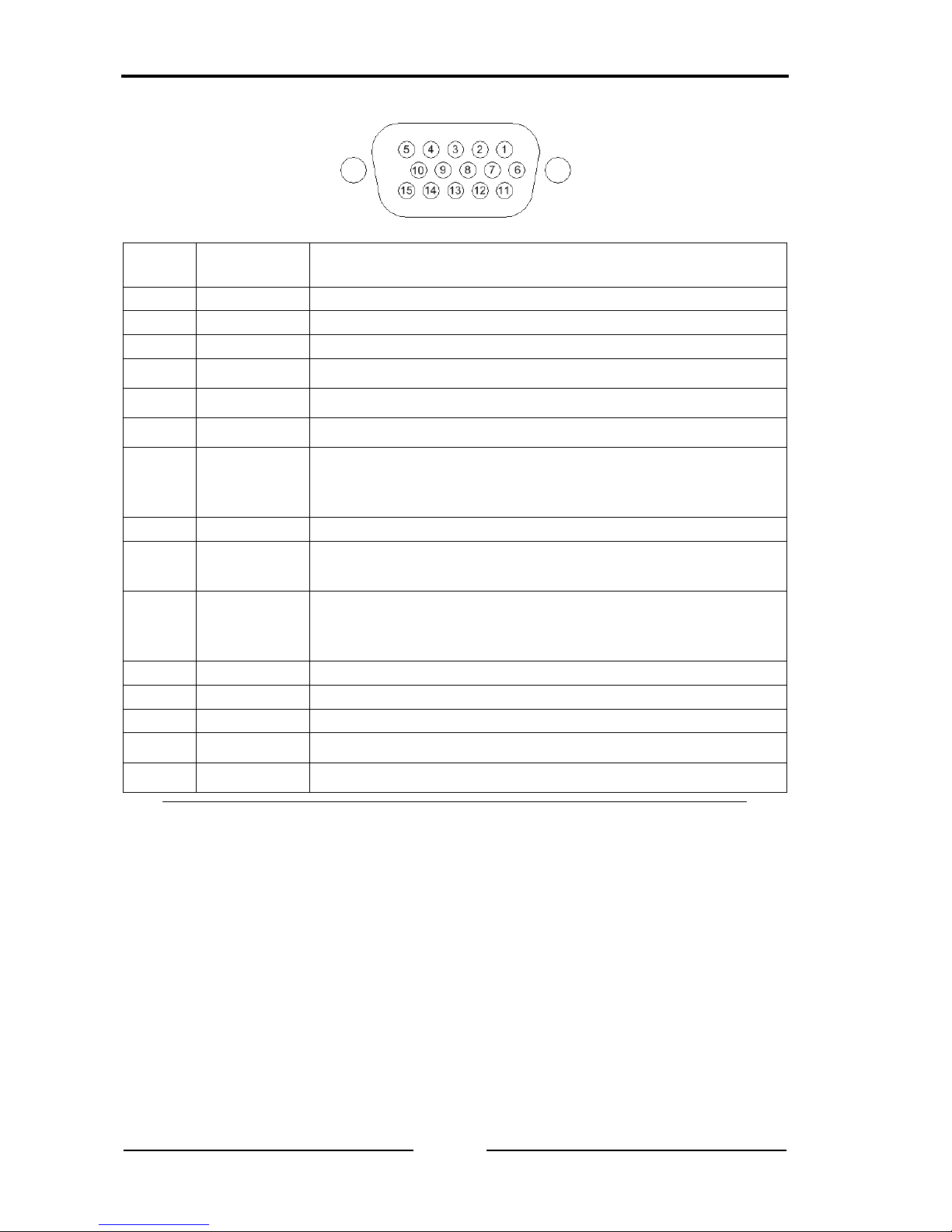

2.3 Connector (X3) digital

The digital signals are available on connector X3. Connector X3 is designed as

a 15-pin high density D-Sub HDF15 (socket, female) (see table 2-3).

The functions of the digital inputs and outputs are described in chapters 4.3

and 4.4.

Connector assignments

Copyright IXXAT Automation GmbH

8

CANio 500 Quickstart Manual, version 1.3

Pin

no. X2

Signal

Description

1

DIG_IN1

Digital input 1

2

DIG_IN2

Digital input 2

3

GND

Ground

4

DIG_OUT1

Digital output 1, high-side switch supplied with VBAT_IN.

5

DIG_OUT2

Digital output 2, high-side switch supplied with VBAT_IN.

6

VREF_IN

Reference input for digital inputs

7

VREF_OUT

Output. Here a voltage is available according to the power

supply PWR(+). This output can be connected to the

VREF_IN input.

8

Reserved

This connection must remain open

9

VBAT_IN

Power supply for the high-side switches of the digital outputs.

10

VBAT_OUT

Output (1 A protected). Here a voltage is available according to the power supply PWR(+). This output can be connected to the VBAT_IN input.

11

DIG_IN3

Digital input 3

12

DIG_IN4

Digital input 4

13

GND

Ground

14

DIG_OUT3

Digital output 3, high-side switch supplied with VBAT_IN.

15

DIG_OUT4

Digital output 4, high-side switch supplied with VBAT_IN.

Table 2-3: Pin assignment digital interface connector D-Sub HDF15

LED displays

Copyright IXXAT Automation GmbH

9

CANio 500 Quickstart Manual, version 1.3

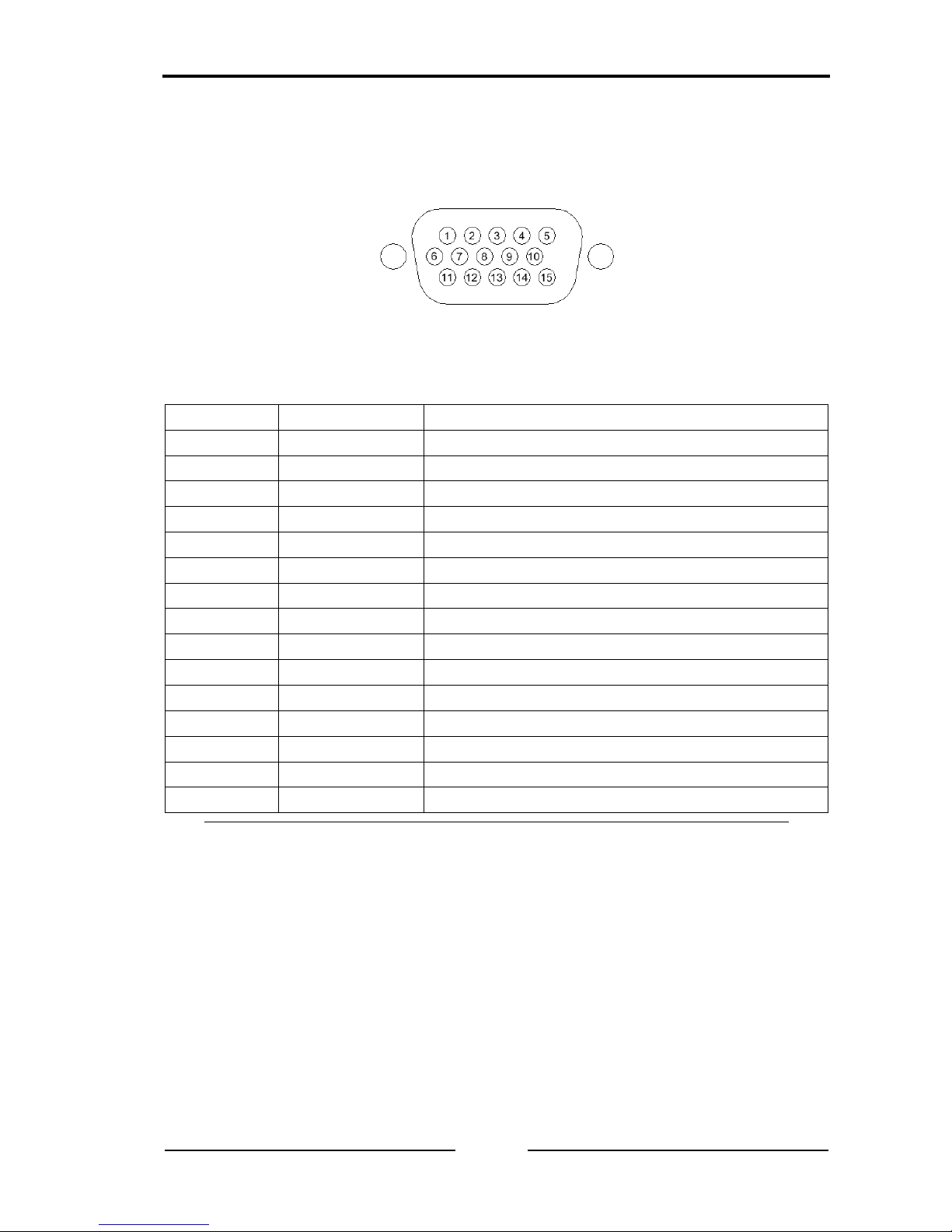

2.4 Connector (X4) analog

The analog signals are available on connector X4. Connector X4 is designed

as a 15-pin high density D-Sub HDM15 (pins, male) (see table 2-4).

The functions of the analog inputs and outputs are described in chapters 4.5

and 4.6.

Pin no. X4

Signals

Description

1

ANA_IN1_P

Analog input 1 positive (+)

2

ANA_IN2_P

Analog input 2 positive (+)

3

GNDA

Analog ground

4

ANA_IN3_P

Analog input 3 positive (+)

5

ANA_IN4_P

Analog input 4 positive (+)

6

ANA_IN1_M

Analog input 1 negative (-)

7

ANA_IN2_M

Analog input 2 negative (-)

8

GNDA

Analog ground

9

ANA_IN3_M

Analog input 3 negative (-)

10

ANA_IN4_M

Analog input 4 negative (-)

11

ANA_OUT1

Analog output 1

12

ANA_OUT2

Analog output 2

13

GNDA

Analog ground

14

ANA_OUT3

Analog output 3

15

ANA_OUT4

Analog output 4

Table 2-4: Pin assignment analog interface connector D-Sub HDM15

3 LED displays

The CANio 500 has four two-colored LEDs (see Figure 2-1). The LEDs react

as follows according to the operating mode of the CANio 500.

3.1 PWR - LED

The Power-LED (PWR) is lit green when the CANio 500 is connected to the

power supply. The Power-LED (PWR) is lit red when the power supply is connected with reverse polarity.

Description of functions

Copyright IXXAT Automation GmbH

10

CANio 500 Quickstart Manual, version 1.3

3.2 CAN - LED

The CAN-LED displays the status of the CANopen State Machine (green) and

the error status. In the 'CAN BUS OFF' status, no more communication is possible and the CAN - LED is permanently lit red.

3.3 USR 1/2 - LED

The User-LEDs (USR 1/2-LED), which can be freely programmed by the user,

can be switched via CAN messages. More information is given in chapters

5.1.4 and Error! Reference source not found..

4 Description of functions

4.1 Introduction

The CANio 500 allows monitoring or setting of analog and digital signals via a

CAN network.

4.2 Galvanic isolation

In the case of galvanic isolation, the ground of CAN (GND_CAN) is isolated

from the rest of the circuit.

The ground of the power supply [GND (-)] and of the digital and analog interfaces are connected to each other.

4.3 Digital outputs

High-side switches are used for the 4 digital outputs. The digital outputs can

be switched with a CAN message. More information is given in chapter 5.1.4.

The high-side switch can switch up to 34 V. In addition, they offer current limitation, thermal monitoring and surge protection up to 60 V (load dump). They

can also operate with inductive loads. The sum of the currents across all four

outputs should not exceed 1 A. Otherwise current limitation may be triggered.

The high-side switch modules are operated with the voltage VBAT_IN, which

is to be connected on the digital connector (X3). The power supply PWR(+) is

led out again on the connector for the digital interfaces (X3) (VBAT_OUT) and

can then be connected to the pin VBAT_IN via a bridge on connector (X3). If

other voltages are used, the bridge remains open and any voltage between 0

to 34 V can be supplied to the pin VBAT_IN. The pin VBAT_IN is used as a

power input for all 4 digital outputs. If the pin VBAT_IN remains open, the digital outputs have no function.

The voltage output VBAT_OUT is protected against overcurrent and shortcircuiting via a resettable fuse. If the fuse is triggered in the event of an over-

Loading...

Loading...