Page 1

CAN FD Repeater

CAN-CR100, CAN-CR110/FO, CAN-CR120/HV, CAN-CR300

USER MANUAL

4.01.0210.20000 1.4 en-US ENGLISH

Page 2

Important User Information

Disclaimer

The information in this document is for informational purposes only. Please inform HMS Industrial Networks of any

inaccuracies or omissions found in this document. HMS Industrial Networks disclaims any responsibility or liability

for any errors that may appear in this document.

HMS Industrial Networks reserves the right to modify its products in line with its policy of continuous product

development. The information in this document shall therefore not be construed as a commitment on the part of

HMS Industrial Networks and is subject to change without notice. HMS Industrial Networks makes no commitment

to update or keep current the information in this document.

The data, examples and illustrations found in this document are included for illustrative purposes and are only

intended to help improve understanding of the functionality and handling of the product. In view of the wide range

of possible applications of the product, and because of the many variables and requirements associated with any

particular implementation, HMS Industrial Networks cannot assume responsibility or liability for actual use based on

the data, examples or illustrations included in this document nor for any damages incurred during installation of the

product. Those responsible for the use of the product must acquire sufficient knowledge in order to ensure that the

product is used correctly in their specific application and that the application meets all performance and safety

requirements including any applicable laws, regulations, codes and standards. Further, HMS Industrial Networks will

under no circumstances assume liability or responsibility for any problems that may arise as a result from the use of

undocumented features or functional side effects found outside the documented scope of the product. The effects

caused by any direct or indirect use of such aspects of the product are undefined and may include e.g. compatibility

issues and stability issues.

CAN FD Repeater User Manual

4.01.0210.20000 1.4 en-US

Page 3

Table of Contents

Page

1 User Guide ........................................................................................................................... 3

1.1 Target Audience............ ............................................. ........ ........ ..................................... . 3

1.2 Document History .. ............................................. ........ ........ ..................................... ........ 3

1.3 Trademark Information .... ........ ........ ............................................. ........ ........ .................... 3

1.4 Conventions.......................... ........ ........ ............................................. ........ ........ .............4

2 Safety Instructions .............................................................................................................. 5

2.1 Information on EMC ...... .................................................................. ........ ........ ................. 5

2.2 General Safety Instructions ...................................... ........ ........ ..........................................5

2.3 Intended Use.. ..................................... ........ ........ ............................................. ........ .......5

3 Scope of Delivery ................................................................................................................ 5

4 Product Description ............................................................................................................ 6

4.1 Features ...... ........ ........ ............................................. ........ ........ ...................................... 6

4.2 Automatic Error Detection ........ ........ ............................................. ........ ........ .................... 6

5 Configuration....................................................................................................................... 7

5.1 Configuring the Lock Time ..................... ........ ........ ............................................................7

5.2 Extending the Recessive Bit........ ..................................... ........ ........ ................................... 8

6 Installation........................................................................................................................... 9

6.1 Mounting the Device ......... ..................................... ........ ........ ..........................................9

6.2 Connectors .... ..................................... ........ ........ ............................................. ........ .......9

7 Operation........................................................................................................................... 11

7.1 LEDs .. ............................................. ........ ........ ..................................... ........ ........ ........ 11

8 Technical Data ................................................................................................................... 12

9 Support/Return Hardware................................................................................................ 13

9.1 Support ........... ........ ........ .................................................................. ........ ........ ........... 13

9.2 Return Hardware ............ ........ ........ ............................................. .................................. 13

CAN FD Repeater User Manual

4.01.0210.20000 1.4 en-US

Page 4

10 Disposal.............................................................................................................................. 13

A Regulatory Compliance ..................................................................................................... 15

A.1 EMC Compliance (CE) .......................................... ........ ........ ..................................... ...... 15

A.2 FCC Compliance Statement ...... ........ ........ ............................................. ........ ........ ........... 15

A.3 RoHs Directive ................ ........ ........ ............................................. ........ ........ .................. 16

A.4 Disposal and recycling................................................. ........ ........ .................................... 16

CAN FD Repeater User Manual

4.01.0210.20000 1.4 en-US

Page 5

User Guide 3 (18)

1 User Guide

Please read the manual carefully. Make sure you fully understand the manual before using the

product.

1.1 Target Audience

This manual addresses trained personnel who are familiar with CAN, CAN FD and the applicable

standards. The contents of the manual must be made available to any person authorized to use

or operate the product.

1.2 Document History

Version

1.0

1.1

1.2

1.3 May 2019

1.4

Date

February 2018 First release

February 2018

March 2019 Layout changes, added description for lock time and extending the recessive bit

July 2020 Added FO connector type to technical data and description of automatic error

Description

Minor corrections

Corrections bit rate

detection

1.3 Trademark Information

Ixxat®is a registered trademark of HMS Industrial Networks. All other trademarks mentioned in

this document are the property of their respective holders.

CAN FD Repeater User Manual

4.01.0210.20000 1.4 en-US

Page 6

User Guide 4 (18)

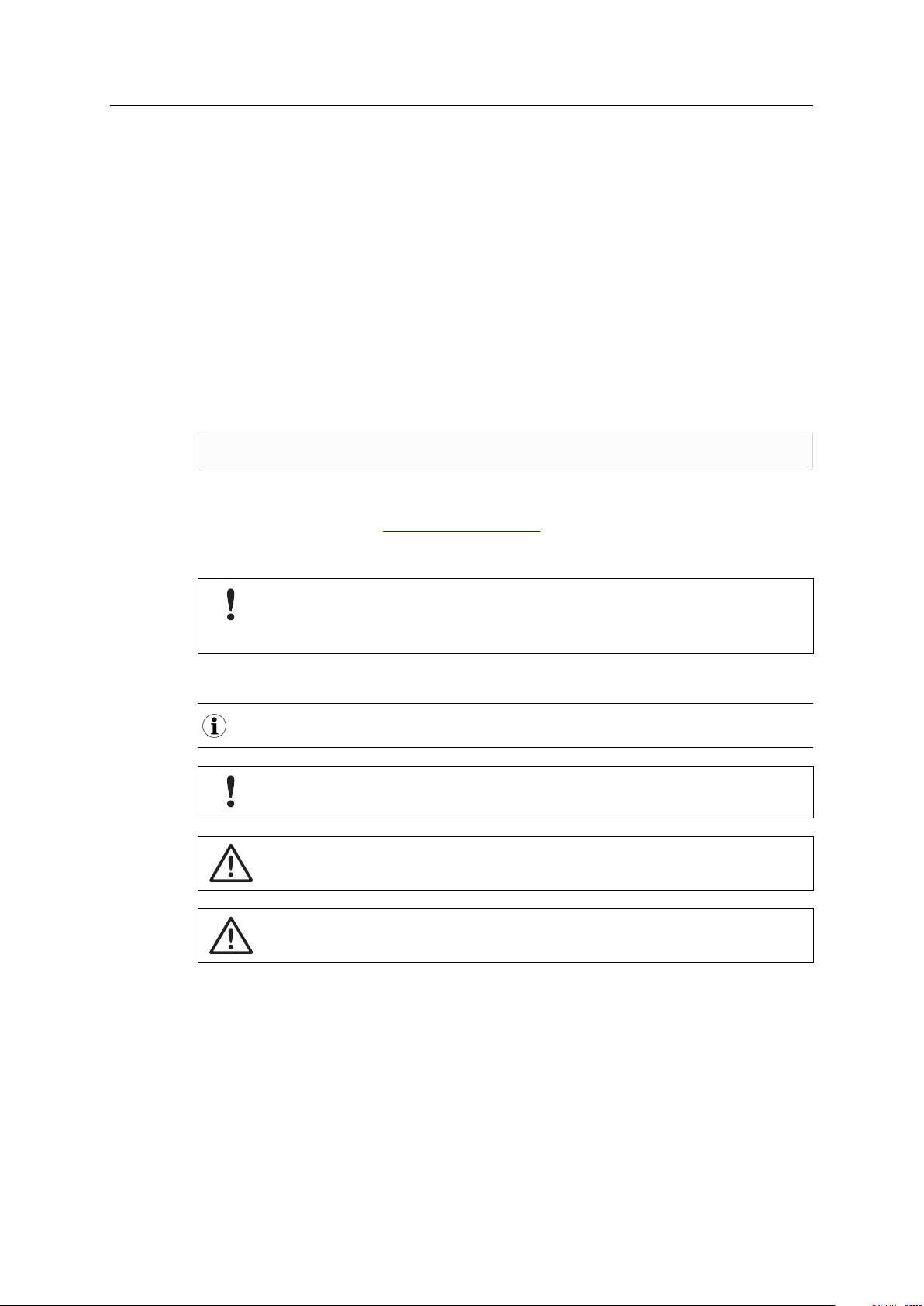

1.4 Conventions

Instructions and results are structured as follows:

► instruction 1

► instruction 2

→ result 1

→ result 2

Lists are structured as follows:

• item 1

• item 2

Bold typeface indicates interactive parts such as connectors and switches on the hardware, or

menus and buttons in a graphical user interface.

This font is used to indicate program code and other

kinds of data input/output such as configuration scripts.

This is a cross-reference within this document: Conventions, p. 4

This is an external link (URL): www.hms-networks.com

Safety advice is structured as follows:

Cause of the hazard!

Consequences of not taking remediate action.

How to avoid the hazard.

Safety signs and signalwords are used dependent on the level of the hazard.

This is additional information which may facilitate installation and/or operation.

This instruction must be followed to avoid a risk of reduced functionality and/or damage

to the equipment, or to avoid a network security risk.

Caution

This instruction must be followed to avoid a risk of personal injury.

WARNING

This instruction must be followed to avoid a risk of death or serious injury.

CAN FD Repeater User Manual

4.01.0210.20000 1.4 en-US

Page 7

Safety Instructions 5 (18)

2 Safety Instructions

2.1 Information on EMC

Risk of interference to radio and television if used in office or home environment!

Make sure, that DIN rail is connected to the ground.

Use exclusively included accessories. Use exclusively shielded cables.

Make sure, that the shield of the CAN cable is connected.

If necessary, enlarge distance between source of interference (e.g. motors, frequency inverter) or

drain of interference and device to avoid interference.

2.2 General Safety Instructions

► Protect product from moisture and humidity.

► Protect product from too high or too low temperature (see Technical Data, p. 12).

► Protect product from fire.

► Do not paint the product.

► Do not modify or disassemble the product. Service must be carried out by HMS Industrial

Networks.

► Store products in dry and dust-free place.

2.3 Intended Use

The devices are used to establish a physical coupling of two or more segments of a CAN or CAN

FD bus system. It is possible to implement tree or star topologies, as well as long drop lines. With

a galvanically isolated repeater network segments can be electrically decoupled.

The devices cannot be used to extend a CAN/CAN FD system because in terms of signal the

repeater corresponds to a line with delay time.

3 Scope of Delivery

Included in scope of delivery:

• CAN FD Repeater

• User Manual CAN FD Repeater

CAN FD Repeater User Manual

4.01.0210.20000 1.4 en-US

Page 8

Product Description 6 (18)

4 Product Description

4.1 Features

CAN-CR100

• 2 x CAN/CAN FD interfaces according to ISO 11898-2

• ISO CAN FD and nonISO CAN FD

• variant with integrated bus termination resistor and variant without bus termination resistor

available

• 1 kV isolation voltage

CAN-CR120/HV

• 2 x CAN/CAN FD interfaces according to ISO 11898-2

• ISO CAN FD and nonISO CAN FD

• variant with integrated bus termination resistor and variant without bus termination resistor

available

• 3 kV isolation voltage

CAN-CR110/FO

• 2 x CAN/CAN FD interfaces:

– 1 x CAN interfaces according to ISO 11898-2

– 1 x FO interface (F-SMA connector)

• ISO CAN FD and nonISO CAN FD

• variant with integrated bus termination resistor and variant without bus termination resistor

available

• 1 kV isolation voltage

HMS Industrial Networks offers cable assemblies (F-SMA) in various lengths to connect two CAN-CR110/

FO.

CAN-CR300

• 4 x CAN/CAN FD interfaces according to ISO 11898-2

• ISO CAN FD and nonISO CAN FD

• variant with integrated bus termination resistor and variant without bus termination resistor

available

• 1 kV isolation voltage

4.2 Automatic Error Detection

The Ixxat CAN FD Repeater automatically disconnects a defective segment from the network,

allowing the remaining network to continue working. After successful troubleshooting the

segment is automatically reconnected.

A segment is detected as defect and therefore disconnected if a dominant bus level is detected

on the channel for more than 1.4 ms. If a recessive level is detected again on the channel, the

segment is reconnected automatically.

CAN FD Repeater User Manual

4.01.0210.20000 1.4 en-US

Page 9

Configuration 7 (18)

1

5 Configuration

To operate the CAN repeater no software installation is required. The CAN repeater is configured

via DIP switches (1).

Fig. 1 DIP switches

5.1 Configuring the Lock Time

The CAN transceiver transmits data and receives these transmitted data again after a certain

delay, the so-called loop delay. For example, if the transceiver transmits a dominant bit and after

that a recessive bit, the transceiver only sees the recessive bit in its receive output after the loop

delay. The size of the loop delay depends on several factors, like for example the number of CAN

nodes in the network. The higher the capacity load is, the higher is the loop delay. To avoid bit

errors caused by this delay, the configured lock time must be higher then the loop delay.

► Use a screwdriver or similar tool to set the DIP switches.

► Observe, that the setting depends on the bit rate and the capacitive load of the network

(the higher the capacity load, the higher the value).

► Configure the lock time with DIP switches 1 and 2.

► Observe the following reference values:

– for networks with less than 32 nodes the lock time is about 200 ns

– for networks between 32 and 64 nodes the lock time is about 400 ns

– for networks with more than 64 nodes the lock time is about 800 ns and with this

setting the bit rate is limited to maximal 500 kbit/s

Valid Lock Time Combinations

DIP switch 1 DIP switch 2 Lock time

Off Off 200 ns (default)

On

Off

On On 1600 ns

Off

On 800 ns

400 ns

CAN FD Repeater User Manual

4.01.0210.20000 1.4 en-US

Page 10

Configuration 8 (18)

5.2 Extending the Recessive Bit

Due to the internal structure the CAN transceiver shortens recessive bits on the network, and

thus dominant bits are extended. At high bit rates this might cause errors. To extend the

recessive bits may improve the error rate, as the bits then are closer to their nominal value on

the network. If the recessive bits are extended with the DIP switches, the extension is made

independently of the bit rate, also at low bit rates.

► Use a screwdriver or similar tool to set the DIP switches.

► Extend the recessive bit with DIP switches 3 and 4.

Valid Combinations

DIP switch 3 DIP switch 4 Recessive bit extension

Off Off 0 ns (default)

On

Off

On On 30 ns

Off

On 20 ns

10 ns

CAN FD Repeater User Manual

4.01.0210.20000 1.4 en-US

Page 11

Installation 9 (18)

1

2

3

1

2

4

5

6 Installation

6.1 Mounting the Device

Fig. 2 Mounting on DIN rail

► Make sure that the lock time is configured (see Configuration, p. 7).

► Make sure, that the device is not connected to power supply.

► Hook the device onto the upper lip of the rail and push downwards (1).

► Push the device towards the rail until it snaps into place (2).

6.2 Connectors

Fig. 3 Connectors

1 CAN 1

2 CAN 3

3 Power

4 CAN 2

5 CAN 4

The CAN connectors and the power connector are fixed and can not be removed.

CAN FD Repeater User Manual

4.01.0210.20000 1.4 en-US

Page 12

Installation 10 (18)

6.2.1 Power Connector

Pin Allocation

Pin no. Signal

1 +9 V to +36 V DC

2 0 V

3

4

—

—

6.2.2 CAN Connector

Pin Allocation

Pin no. Signal

1

2

3 CAN GND

4

If a D-Sub 9 connector is used, observe the following pin allocation of the D-Sub 9 connector.

CAN high

CAN low

Shield

Pin no.

1

2

3 CAN GND

4

5

6

7

8

9

Signal

—

CAN low

—

—

—

CAN high

—

—

The shield of the CAN connector is connected to the ground via a 10 nF capacitor. The ground of

the device is connected to the DIN rail after mounting the device on the DIN rail. The ground of

the CAN connector (CAN GND) is connected via a 10 nF capacitor to the device ground.

For best noise immunity, ground the shields of the CAN cables.

CAN FD Repeater User Manual

4.01.0210.20000 1.4 en-US

Page 13

Operation

PWR

1

2

3

CAN

4

7 Operation

7.1 LEDs

Fig. 4 LED array

LEDs PWR 2/3/4 do not have any function.

The LEDs CAN 3/4 are activated only with CAN-CR300.

7.1.1 Power LED

Power LED PWR 1 indicates the status of the power supply.

11 (18)

LED state

Off

Green

Red

7.1.2 CAN LEDs

With CAN-CR100, CAN-CR120/HV and CAN-CR110/FO the LEDs CAN 1 and 2 indicate the status of

the CAN connections.

With CAN-CR300 LEDs CAN 1, 2, 3 and 4 indicate the status of the CAN connections.

LED state

Off

Green or green

flashing

Red flashing CAN communication, but errors Each CAN circuit transmits and reads back the transmitted

Red Dominant-lock External device applies a permanent dominant level to the

Description

No power

Power ok Device fully functional

Device is reset

Description

No CAN communication

CAN communication

Comments

Device not connected to power supply, or fuses of device

or internal power supply damaged

After power-up the device is set into reset, LEDs are red

during reset (normal duration: about 200 ms). Or power

supply is damaged, internal voltage is below necessary

level.

Comments

No CAN communication, device not connected to CAN

LED is triggered when a dominant bit is transmitted to the

respective CAN port.

bits. An error occurs, if the repeater transmits a dominant

bit, but measures a recessive bit.

CAN.

CAN FD Repeater User Manual

4.01.0210.20000 1.4 en-US

Page 14

Technical Data 12 (18)

8 Technical Data

Weight

Operating temperature -20 °C to +70 °C

Storage temperature

Power supply

Housing material Polyamid

CAN/CAN FD transceiver

CAN bus termination resistor 120 Ohm (only with variants with integrated bus termination resistor)

CAN bit rates

CAN FD bit rates

Protection class

Relative humidity 10 to 95 %, non-condensing

Approx. 150 g

-40 °C to + 85 °C

+9 V to +36 V DC

Microchip MCP2562FD

Up to 1 Mbit/s

500 kbit/s up to 4 Mbit/s

IP20

CAN-CR100

Dimensions 22.5 x 105 x 114 mm

Current consumption at 24 V Typ. 70 mA, max. 100 mA

Galvanic isolation

CAN propagation delay (typical) Typ. 175 ns (35 m bus length)

1 kV DC/1 sec, 500 V AC/1 min

CAN-CR120/HV

Dimensions 22.5 x 105 x 114 mm

Current consumption at 24 V Typ. 70 mA, max. 100 mA

Galvanic isolation

CAN propagation delay (typical) Typ. 175 ns (35 m bus length)

3 kV DC/1 sec, 1500 V AC/1 min

CAN-CR110/FO

Dimensions 22.5 x 105 x 120 mm

Current consumption at 24 V Typ. 70 mA, max. 100 mA

Galvanic isolation

CAN propagation delay (typical) Typ. 300 ns (60 m bus length) between wire connection of a FO Repeater through

FO transmitter

FO receiver

FO connector F-SMA connector

FO line Multi mode fiber optic cables (only glass);

Maximal line length between two

FO repeaters

1 kV DC/1 sec, 500 V AC/1 min

the fiber optic cable to the wire connection of a second FO Repeater (not including

the signal delay time of the fiber optics: approx. 5 ns/m)

Broadcom HFBR 1404Z, 820 nm

Broadcom HFBR 2402Z, 820 nm

Recommended: 50/125 μm, 62.5/125 μm,

also compatible with: 100/140 μm, 200 μm (consider max. line length)

50/125 μm: 1500 m

62.5/125 μm: 2000 m

CAN-CR300

Dimensions 22.5 x 105 x 114 mm

Current consumption at 24 V Typ. 90 mA, max. 125 mA

Galvanic isolation

CAN propagation delay (typical) Typ. 175 ns (35 m bus length)

1 kV DC/1 sec, 500 V AC/1 min

CAN FD Repeater User Manual

4.01.0210.20000 1.4 en-US

Page 15

Support/Return Hardware

9 Support/Return Hardware

9.1 Support

► For problems or support with the product request support at www.ixxat.com/support.

► If required use support phone contacts on www.ixxat.com.

9.2 Return Hardware

► Fill in the form for warranty claims and repair on www.ixxat.com/support/product-returns.

► Print out the Product Return Number (PRN resp. RMA).

► Pack product in a physically- and ESD-safe way, use original packaging if possible.

► Enclose PRN number.

► Observe further notes on www.ixxat.com.

► Return hardware.

13 (18)

10 Disposal

► Dispose of product according to national laws and regulations.

► Observe further notes about disposal of products on www.ixxat.com.

CAN FD Repeater User Manual

4.01.0210.20000 1.4 en-US

Page 16

This page intentionally left blank

Page 17

Appendix A: Regulatory Compliance 15 (18)

A Regulatory Compliance

A.1 EMC Compliance (CE)

The product is in compliance with the Electromagnetic Compatibility Directive. More information

and the Declaration of Conformity is found at www.ixxat.com.

A.2 FCC Compliance Statement

This device complies with Part 15 of the FCC Rules. Operation is subject to the following two

conditions:

• This device may not cause harmful interference.

• This device must accept any interference received, including interference that may cause

undesired operation.

Product name

Model

Responsible party HMS Industrial Networks Inc

Address 35 E. Wacker Dr, Suite 1700

Phone

Any changes or modifications not expressly approved by HMS Industrial Networks could

void the user's authority to operate the equipment.

This equipment has been tested and found to comply with the limits for a Class A digital

device, pursuant to part 15 of the FCC Rules. These limits are designed to provide

reasonable protection against harmful interference when the equipment is operated in a

commercial environment. This equipment generates, uses, and can radiate radio

frequency energy and, if not installed and used in accordance with the instruction

manual, may cause harmful interference to radio communications. Operation of this

equipment in a residential area is likely to cause harmful interference in which case the

user will be required to correct the interference at his own expense.

CAN Repeater

CAN-CR100, CAN-CR110/FO, CAN-CR120/HV, CAN-CR300

Chicago , IL 60601

+1 312 829 0601

CAN FD Repeater User Manual

4.01.0210.20000 1.4 en-US

Page 18

Appendix A: Regulatory Compliance 16 (18)

A.3 RoHs Directive

The product is in compliance with the RoHs Directive 2002/95/EC (Restriction of the use of

certain hazardous substances in electrical and electronic equipment).

A.4 Disposal and recycling

You must dispose of this product properly according to local laws and regulations. Because this

product contains electronic components, it must be disposed of separately from household

waste. When this product reaches its end of life, contact local authorities to learn about disposal

and recycling options, or simply drop it off at your local HMS office or return it to HMS.

For more information, see www.hms-networks.com.

CAN FD Repeater User Manual

4.01.0210.20000 1.4 en-US

Page 19

This page intentionally left blank

Page 20

last page

© 2020 HMS Industrial Networks

Box 4126

300 04 Halmstad, Sweden

info@hms.se 4.01.0210.20000 1.4 en-US / 2020-07-15 / 19312

Loading...

Loading...