IXOM CHLORGUARD User Manual

DOCUMENT No. CHL07-M

PART No. CHL01

REVISION 3.1.6

20/12/2015

CHLORGUARD USER'S MANUAL

Page 2

IMPORTANT INFORMATION

The equipment described in this manual is designed to be used in conjunction with liquefied chlorine

gas which is hazardous to personnel safety. It is important that persons employed in the vicinity of a

chlorine installation be given an appropriate level of training in chlorine safety practices and know the

location of safety equipment. Orica has wall charts and handbooks available which describe safe

practice in storing and handling chlorine.

This manual is provided for information purposes only.

All information included herein is subject to change without notice.

Orica should not be held responsible for any damages, direct or indirect, arising from or related to use

of this manual.

Page 3

TABLE OF CONTENTS Page

1 General ...................................................................................... 5

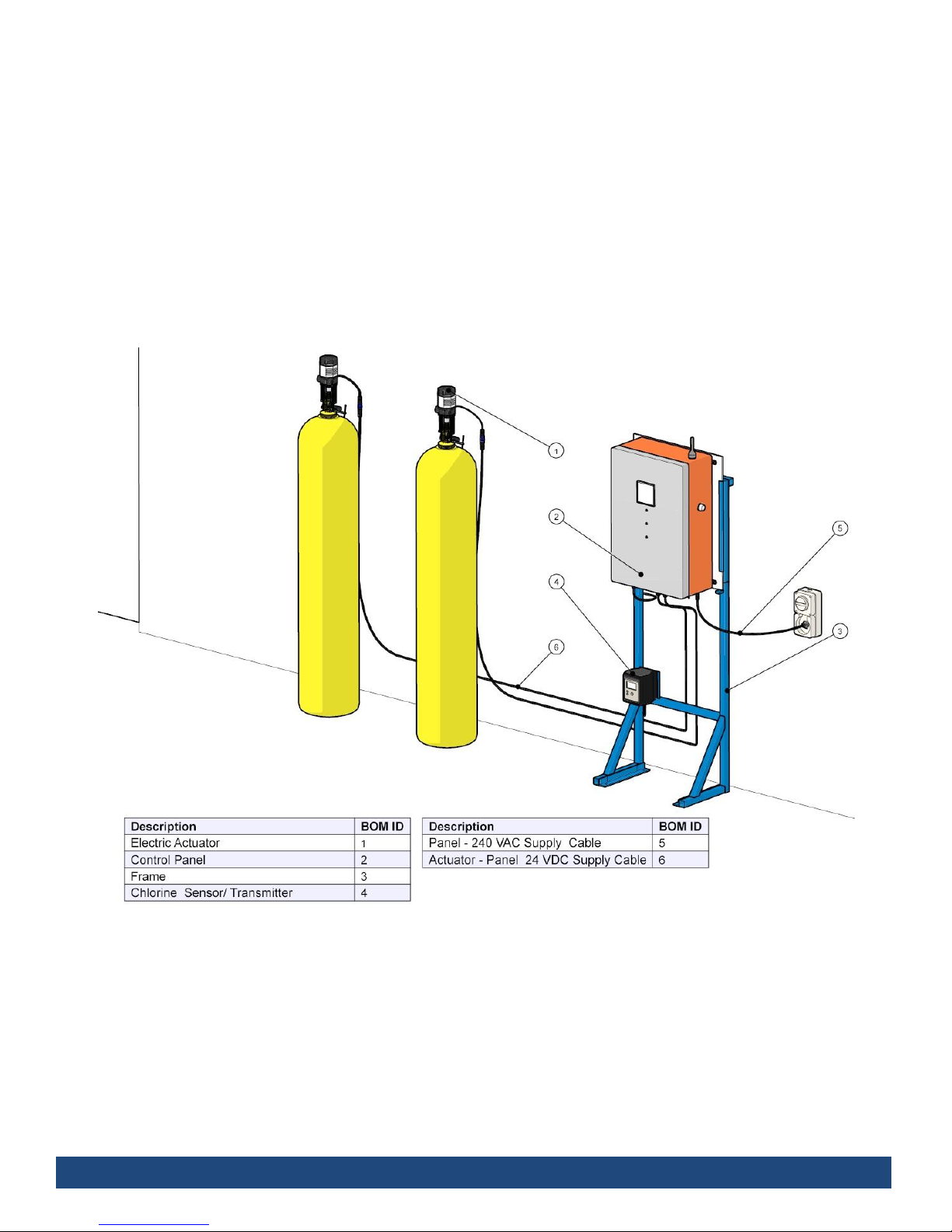

1.1 Typical Setup (70 kg cylinders) ..................................................................... 5

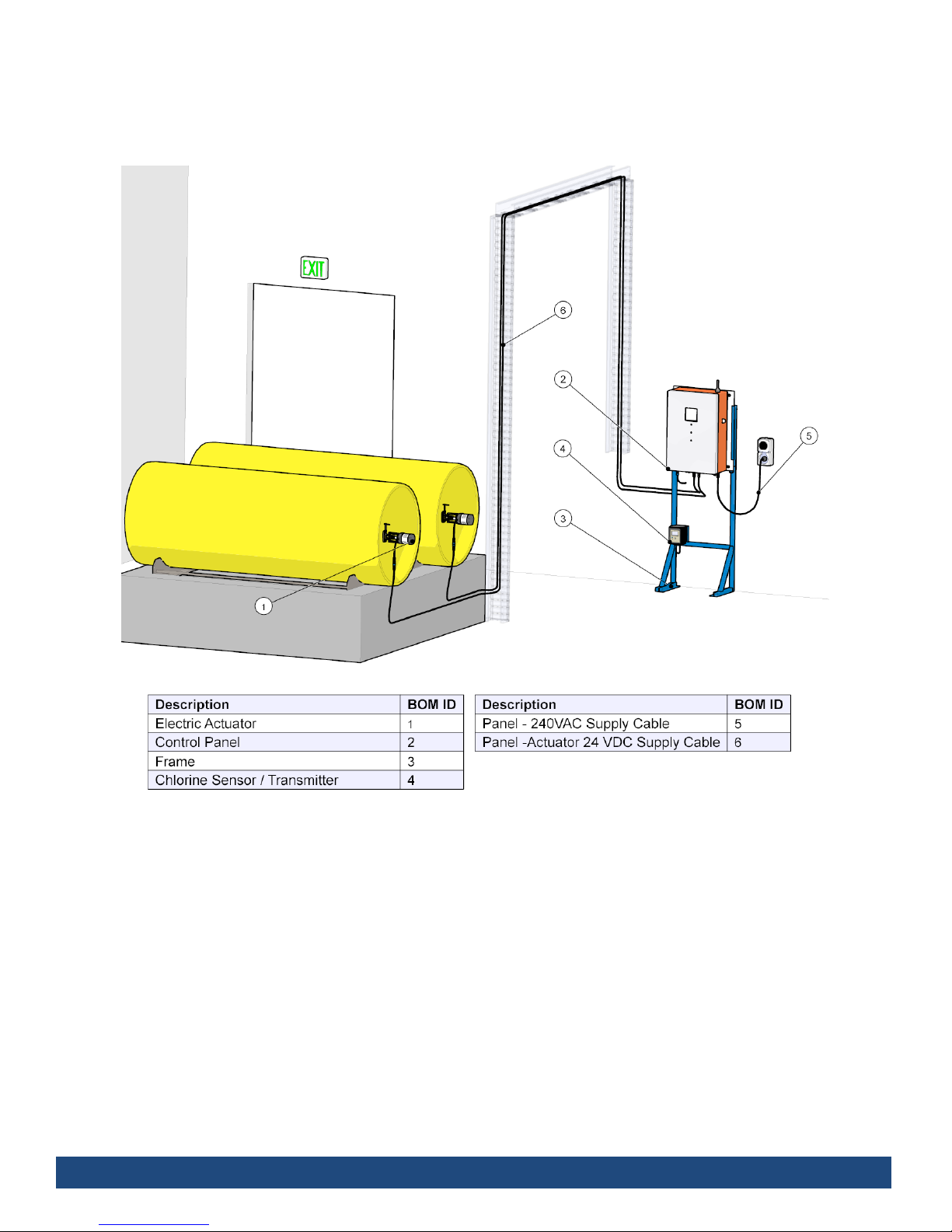

1.2 Typical Setup 920Kg Drums.......................................................................... 6

2 Key Components ...................................................................... 7

2.1 Control Panel ................................................................................................ 8

2.1.1 DC (UPS) power supply ........................................................................................ 11

2.1.2 PLC (Programmable Logic Controller) .................................................................. 11

2.1.3 GMS wireless module ........................................................................................... 11

2.1.4 Warning LED’s: Visual Alarm ................................................................................ 11

2.2 Support Bracket .......................................................................................... 12

2.3 Connecting Transmitting Key ...................................................................... 12

2.4 Actuator Types ............................................................................................ 13

2.5 Chlorine Transmitter & Sensor .................................................................... 13

3 OPERATION ............................................................................ 15

3.1 Overview ..................................................................................................... 15

3.1.1 Power Supply ........................................................................................................ 15

3.1.2 Battery Back-Up .................................................................................................... 15

3.1.3 PLC Programmable Logic Controller ..................................................................... 15

3.1.4 DC (UPS) power supply ........................................................................................ 15

3.1.5 Chlorine Sensor/Transmitter ................................................................................. 15

3.1.6 Closing Actuators .................................................................................................. 16

3.1.6.1 Electric Actuators ................................................................................................................. 16

3.1.6.2 Pneumatic Actuators ............................................................................................................ 16

3.1.6.3 Air Regulator ........................................................................................................................ 16

3.1.6.4 Air Pressure Switch .............................................................................................................. 16

4 Functional Description ........................................................... 17

4.1 Control Panel .............................................................................................. 17

4.1.1 PLC- Programmable Logic Controller.................................................................... 17

4.1.2 Back-Up Power Supply ......................................................................................... 17

4.1.3 Relay Interface ...................................................................................................... 18

4.1.4 GSM Modem ......................................................................................................... 18

4.1.5 Solenoid Valve (Pneumatic Version Only) ............................................................. 18

4.1.6 Pressure Switch (Pneumatic Version Only) ........................................................... 18

4.1.7 SCADA Digital Outputs ......................................................................................... 19

4.1.8 Mains Power Input ................................................................................................ 22

4.1.9 Chlorine Sensor Pin Inputs ................................................................................... 22

4.1.10 Electric Actuator Pin Inputs ................................................................................... 22

4.1.11 Pneumatic Actuator Inputs .................................................................................... 23

4.1.12 Chlorine Transmitter/Sensors ............................................................................... 23

Page 4

4.1.13 Electric Actuator and Support Bracket Assembly .................................................. 23

4.1.14 Electric Actuator Fitted to Standard Chlorine Valve ............................................... 24

4.1.15 Electric Actuator Fitted to Chlorine Institute Yoke & Siemens Vacuum Regulator . 26

4.1.16 Electric Actuator Fitted to International Yoke & Acromet/Prominent Vacuum

Regulator ............................................................................................................................ 27

4.1.17 Pneumatic Actuator and Support Bracket Assembly ............................................. 28

4.1.18 Pneumatic Actuator Fitted to Chlorine Institute Yoke and Siemens Vacuum

Regulator ............................................................................................................................ 29

4.1.19 Pneumatic Actuator Fitted to International Yoke and Acromet/Prominent Vacuum

Regulator ............................................................................................................................ 30

4.1.20 PLC Touch Screen Operation Menus.................................................................... 31

5 Appendices ............................................................................. 37

Page 5

1 GENERAL

Features of the ChlorGuard System

ChlorGuard provides an automatic emergency isolation system for chlorine cylinders and drums.

Operation of the system is initiated by an integral PLC and a Chlorine Sensor/Transmitter local to the

chlorine container. Further means of initiation can be by remote manual push buttons and trip inputs

from the user’s process.

1.1 Typical Setup (70 kg cylinders)

Page 6

1.2 Typical Setup 920Kg Drums

Page 7

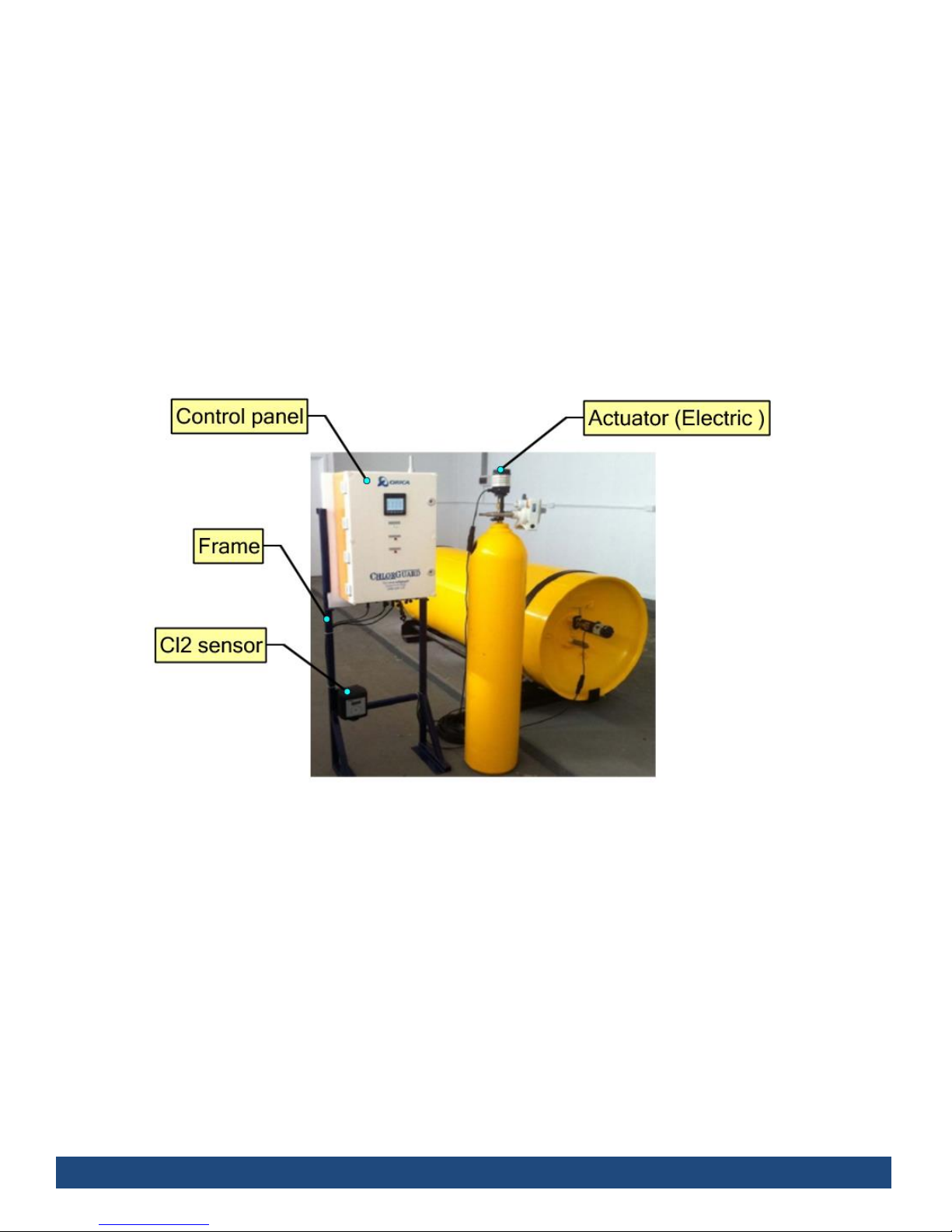

2 KEY COMPONENTS

The chlorguard system includes the following key components

A. Control panel

B. Actuator (Electric or Pneumatic)

C. Cl2 sensor

D. Frame (support of control panel)

E. Air Systems (only if the systems is pneumatic)

F. Support bracket

G. Connecting Transmitting Key

The following chlorguard assembly diagram to ilustrates the main components of the system:

Page 8

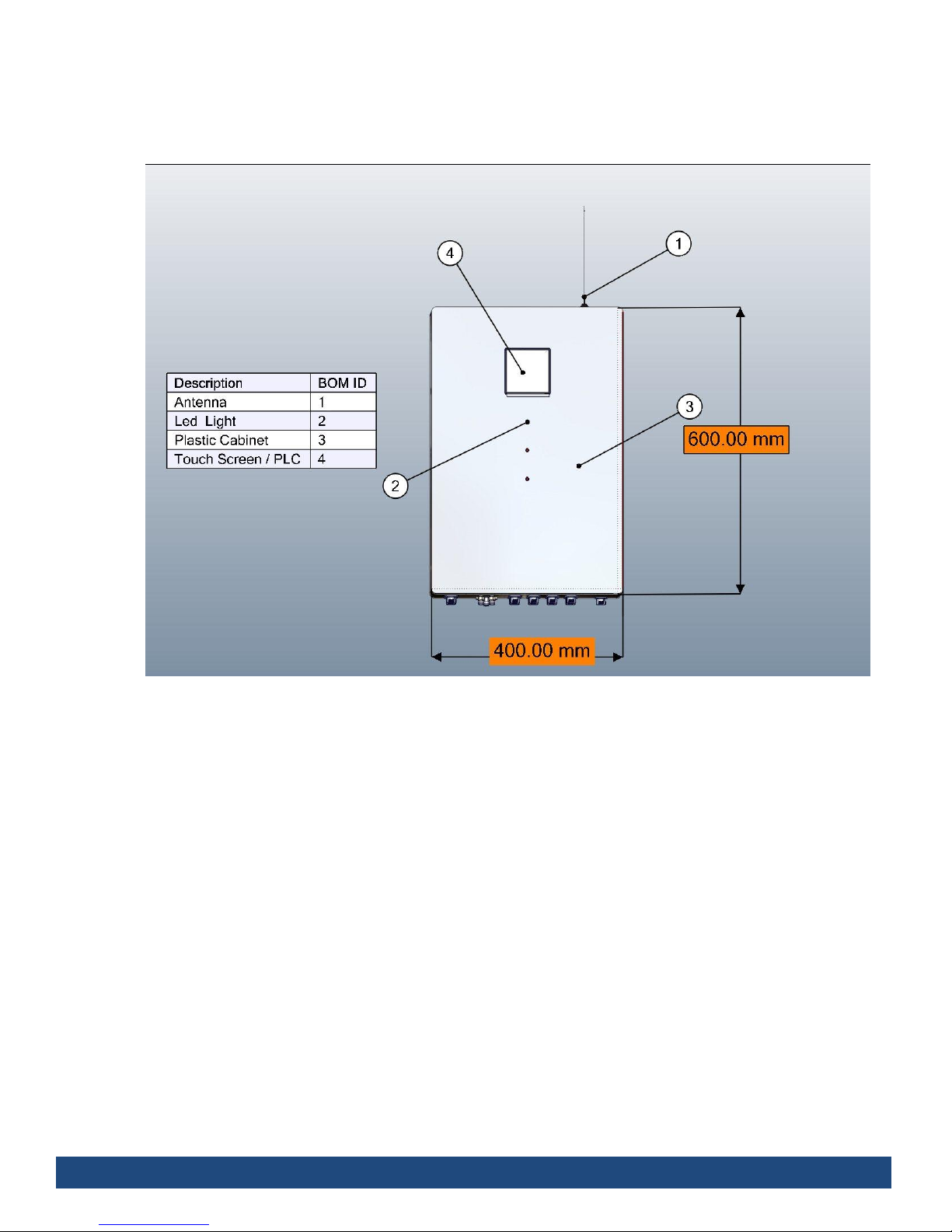

2.1 Control Panel

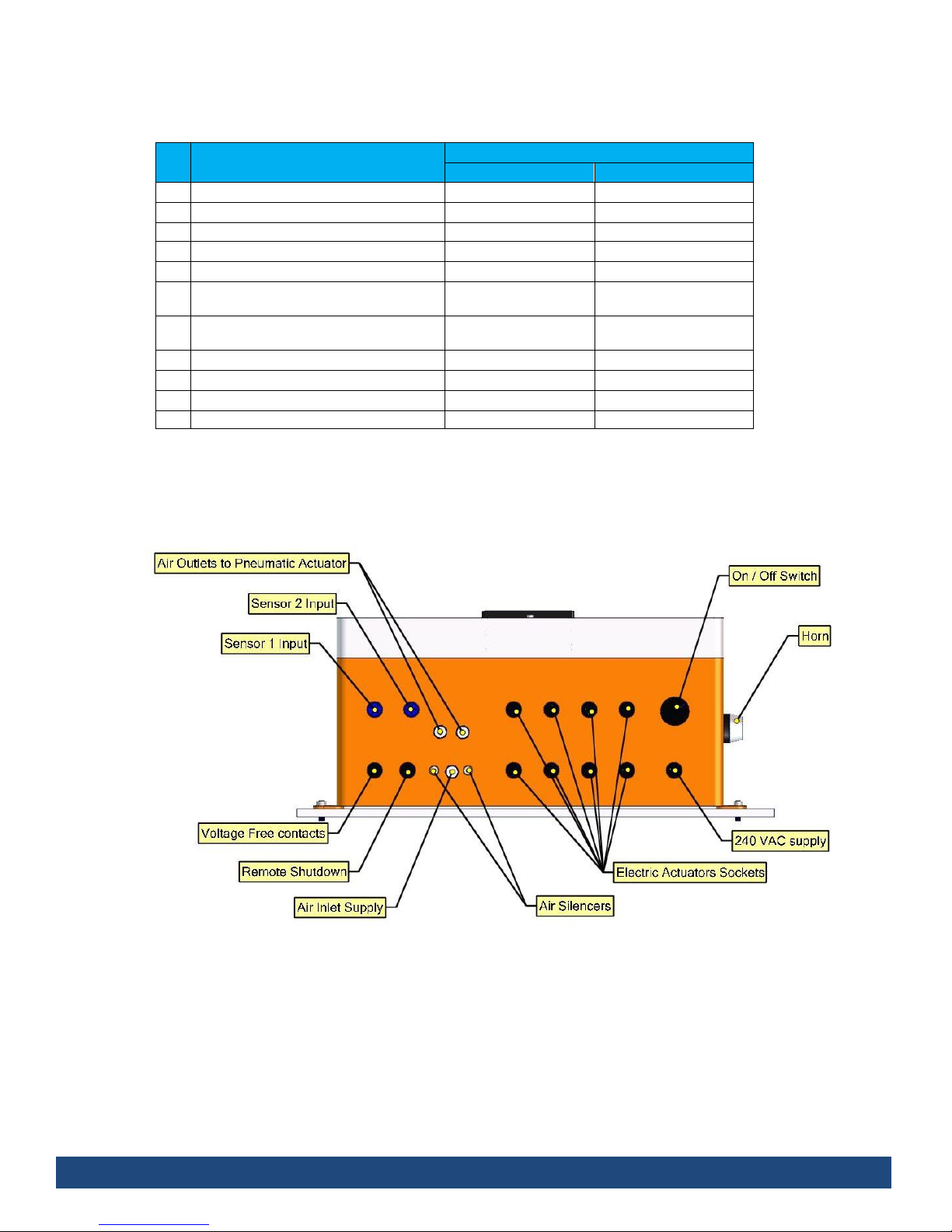

The Control Panel cabinet includes ports for:

Power

Sensors

Up to 8 Actuators (electrical or pneumatic)

Pneumatic solenoid valve input and output.

External devices (SCADA, Alarms etc.)

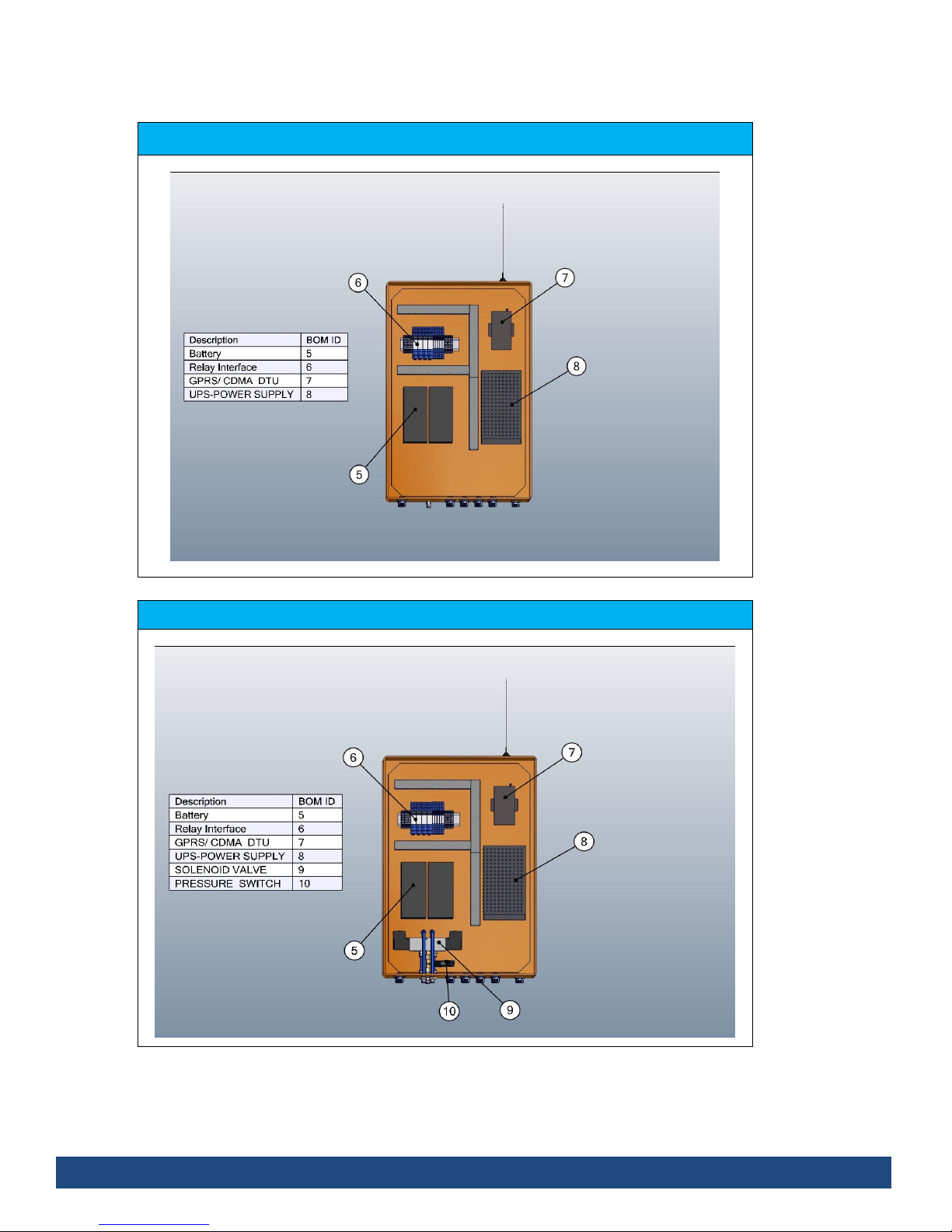

The Control Panel internal distribution design differs in the cabinet regarding if the actuator is electric

or pneumatic ; they’re illustrated in the following drawings:

Page 9

Control Panel Electric

Front View

Control Panel Pneumatic

Front View

Page 10

The following are the list of all components inside the cabinet :

Components

Control Panel

electronic

Pneumatic

a

Cabinet-plastic box

b

DC (UPS) power supply

c

PLC (Programable Logic Controller)

d

GMS wireless module

e

Battery

f

Relays (Auxiliary relay, base of the

relay and auxiliary relay)

g

Warning LED’s:

Visual Alarm (3 Flashing light)

h

Connectors (Hearvy load connector)

i

Pressure switch

j

Solenoid Valve

k

Sockets and plugs

The connection points the Control Panel are shown if the diagram below.

Page 11

2.1.1 DC (UPS) power supply

The DC Uninterrupted Power Supply (UPS) provides reliable 24 VDC Power Supply load to the

ChlorGuard system.

2.1.2 PLC (Programmable Logic Controller)

The ChlorGuard PLC includes a touch screen that provides system

information and access to menus within the program for those

authorised.

2.1.3 GMS wireless module

The GSM transfers information on the status and alarm conditions of the ChlorGuard system for

up to 4 operator phone contacts if required. Important information such as chlorine releases and

alarms are immediately transferred by wireless to operators letting them know when and how

much chlorine is in the work area. Operators can use their phones to log into the ChlorGuard

system to check the status of the system at any time.

2.1.4 Warning LED’s: Visual Alarm

Indicating lights on the front of the panel include the following.

The other indication light such as Low air pressure, etc., is show in the PLC screen.

Page 12

Allowance made to connect up a flashing “Warning Light” and “Audible” alarm connection so the

Customer can connect to.

2.2 Support Bracket

The patented support bracket has capability of attachment to both the pneumatic or electric type

actuators and is made from mild steel and powder coated.

Electric Support Bracket

Pneumatic Support Bracket

2.3 Connecting Transmitting Key

A small key which connects the actuator to the valve spindle.

Electric Actuator Key

Pneumatic Actuator Key

Loading...

Loading...