OPERATING MANUAL FOR IXOLIFT 400 SERIES

LIGHTWEIGHT

NON-POWERED

ACCESS PLATFORM

• MAX. WORKING HEIGHT 3974 MM

• SAFE WORKING LOAD 150 KG

• WEIGHT 140-239 KG

IXOLIFT 400W

IXOLIFT 400S

1

OPERATING MANUAL FOR IXOLIFT 400S / 400W / 400WS

INDEX

1. TECHNICAL SPECIFICATIONS 3

2. FEATURES 4

3. OPERATING INSTRUCTIONS 5

4. CHECKS PRIOR TO USE 6

5. CORRECT USE OF STABILISERS 7

6. TRANSPORTATION 7

7. LIST OF LABELS 8

8. LABELS 9

9. EC CONFORMITY CERTIFICATE 11

VERSION 1.1

2

OPERATING MANUAL FOR IXOLIFT 400S / 400W / 400WS

1. TECHNICAL SPECIFICATIONS

IXOLIFT 400W IXOLIFT 400S IXOLIFT 400WS

Safe Working Height

Safe Working Load (SWL)

Maximum Platform Height

Minimum Platform Height

Platform Size

Stowed Height

Stowed Lenght

Stowed Width

Max. Lenght with Stabilisers Out

Max. Width with Stabilisers Out

Classification

3974 mm

150 kg

1974 mm

974 mm

526 mm x 556 mm

1970 mm

1198 mm

728 mm

- 1500 mm

- 1668 mm

Indoor Rated

Indoor & Outdoor

Rated

Total Weight

228 kg 140 kg 239 kg

3

OPERATING MANUAL FOR IXOLIFT 400S / 400W / 400WS

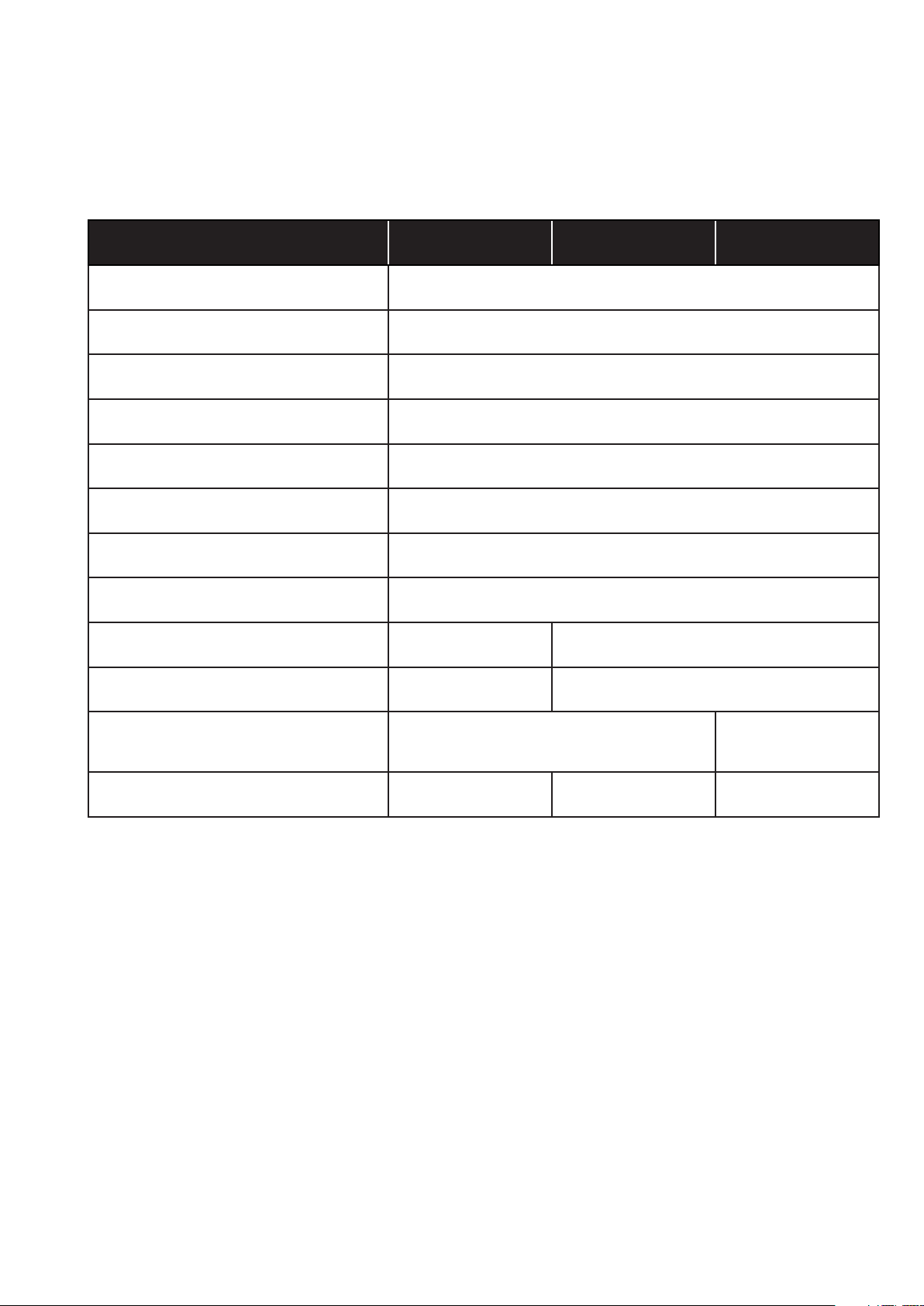

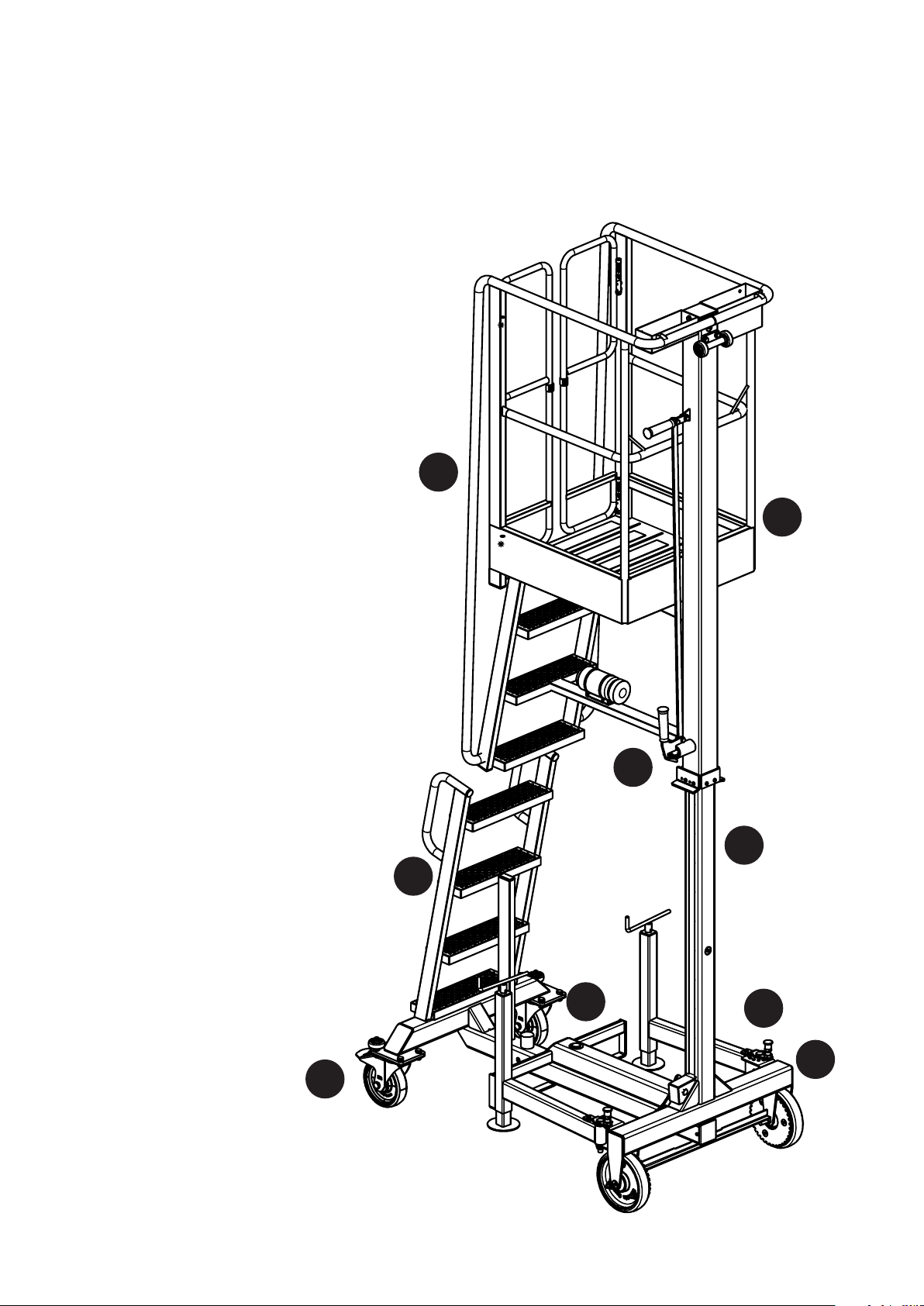

2. FEATURES

1. Automatic, anti-surfing brakes

2. Advanced gas spring hoisting mechanism

3. Lockable swivel castor wheels

4. Automatic finger protection system

5. Automatically closing gates

6. Tool boxes

7. Safety harness connector points

8. Anti-slip platform floor

9. Fork lift points

10. Enforced platform sides for ratchet straps

11. Extra wheels for horizontal transportation (400S only)

12. Bubble level

13. Raising handle with a shoot bolt

14. Operating Manual

15. Raising / Emergency lowering handle

16. Lowering handle

5

6

16

8

10

11

7

3

12

14

15

2

13

4

9

IXOLIFT 400S

4

1

OPERATING MANUAL FOR IXOLIFT 400S / 400W / 400WS

3. OPERATING INSTRUCTIONS

1. ALWAYS READ the Operating Manual

2. CHECK the unit condition - DO NOT USE a damaged unit

3. APPLY brakes on castor wheels

4. ONLY USE on HARD and LEVEL surface

5. LEVEL the unit

IXOLIFT 400W:

a) ALWAYS CHECK bubble level

IXOLIFT 400S / 400WS:

a) DEPLOY STABILISERS and lock in position (400WS: when used outdoors)

b) ADJUST STABILISERS to stabilise the unit

c) ALWAYS CHECK bubble level

3

14

12

12

6. Pull the raising handle to raise the basket to required height

7. Ensure that the shoot bolt is in a locked position

8. Enter basket - DO NOT EXCEED the maximum safe working load (SWL = max 150 kg)

9. Ensure gates are fully closed

10. If using a safety harness fasten it to unit’s safety harness connection points

11. Lift the lowering handle to lower the basket

12. DO NOT ATTEMPT to move the unit whilst operatives are in the basket

13. DO NOT PLACE loads on guardrails

14. KEEP ALL PERSONS CLEAR whilst working

15. APPLY WHEEL BRAKES WHEN NOT IN USE

16. EMERGENCY LOWERING, use the raising handle

5

13

16

3

15

15

7

17. KEEP ALL PERSONS CLEAR whilst lowering

5

OPERATING MANUAL FOR IXOLIFT 400S / 400W / 400WS

4. CHECKS PRIOR TO USE

1. All guard rails and hand rails must be

securely fitted and undamaged.

Gates must be lubricated and operate

freely.

2. All steps must be securily fitted and free

from dents and bends.

Remove debris to ensure maximum grip.

3. Check Level is on the unit and working

correctly.

1

4. All four castor wheels must be

undamaged and rotate freely.

7

5. Wheel brakes must be eective on both

castors.

6. Handle must be clean and undamaged.

Regularly grease* to ensure smooth

function.

NOTE! The lifting mechanism is based

on a gas spring built into the mast. The

gas spring must be replaced every 5

years.

7. Platform must be clear, clean and

undamaged.

8. Decent post must be clean

and undamaged.

9. IXOLIFT 400S & 400WS: Stabilisers must

deploy fully and winding handle must be

clean and free from damage

allowing rotation.

Grease* using grease points

on both stabilisers.

5

2

3

6

8

9

4

* We recommend WÜRTH

MULTI-PURPOSE GREASE

IV for greasing.

IXOLIFT 400S

6

OPERATING MANUAL FOR IXOLIFT 400S / 400W / 400WS

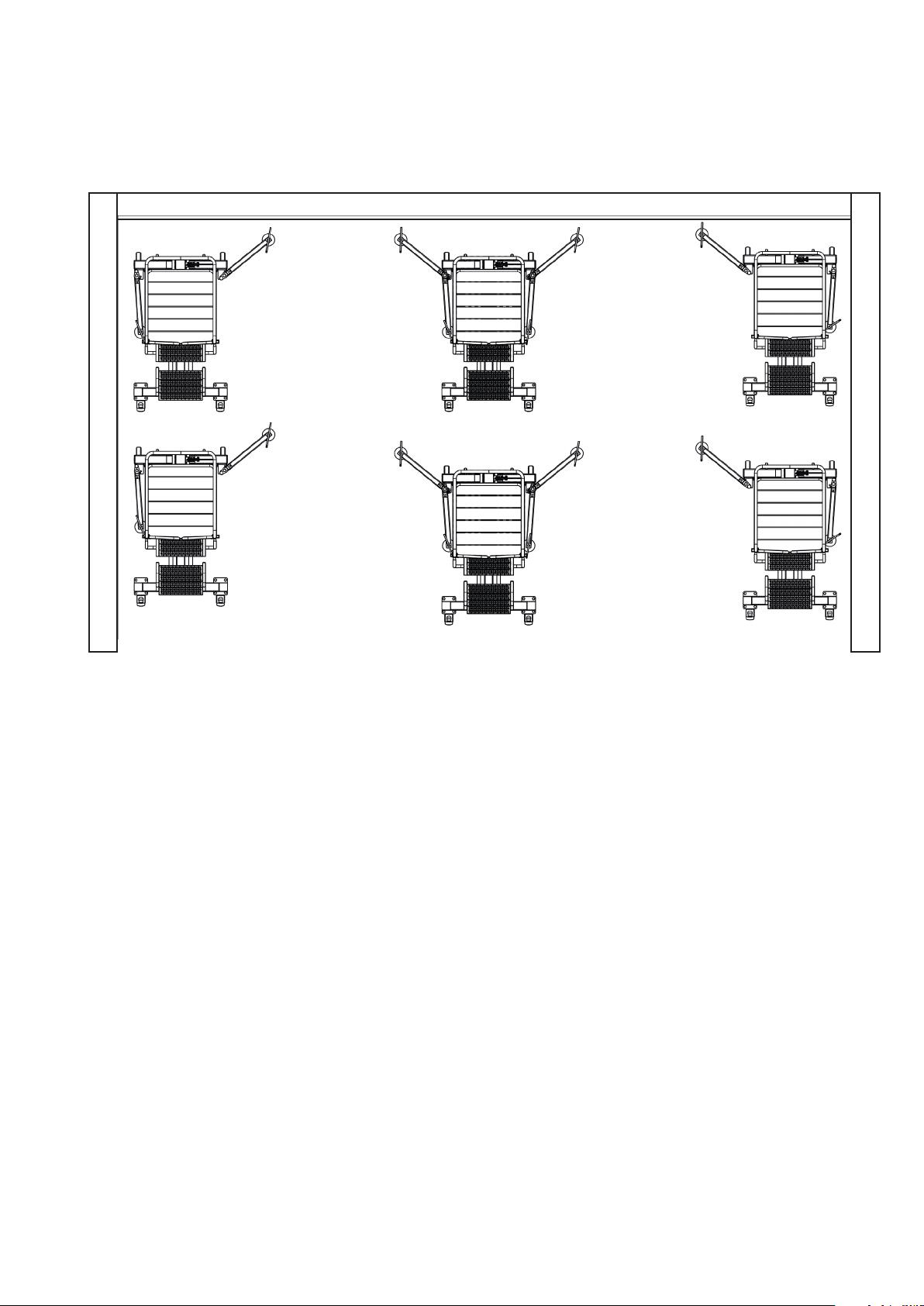

5. CORRECT USE OF STABILISERS

WALL

6. TRANSPORTATION

IXOLIFT 400S / 400W / 400WS - TRANSPORT IN VERTICAL POSITION

Apply castor wheel brakes

Lock anti-surfing brakes by raising the basket to the first locking position

Lift with forklift. Lifting points are marked on the mast side end of the unit.

Fasten the unit securely to the vehicle or pallet using ratchet straps utilizing the enforced

basket sides marked with decals.

IXOLIFT 400S - TRANSPORT IN HORIZONTAL POSITION

Apply castor wheel brakes and tilt the unit to its back.

The extra wheels in mast top will ease the maneuvering of the unit.

First lift the extra mast top wheels onto a pallet or into the vechicle and lift manually from

the other end of the unit.

Fasten the unit securely to the vehicle using ratchet straps.

7

OPERATING MANUAL FOR IXOLIFT 400S / 400W / 400WS

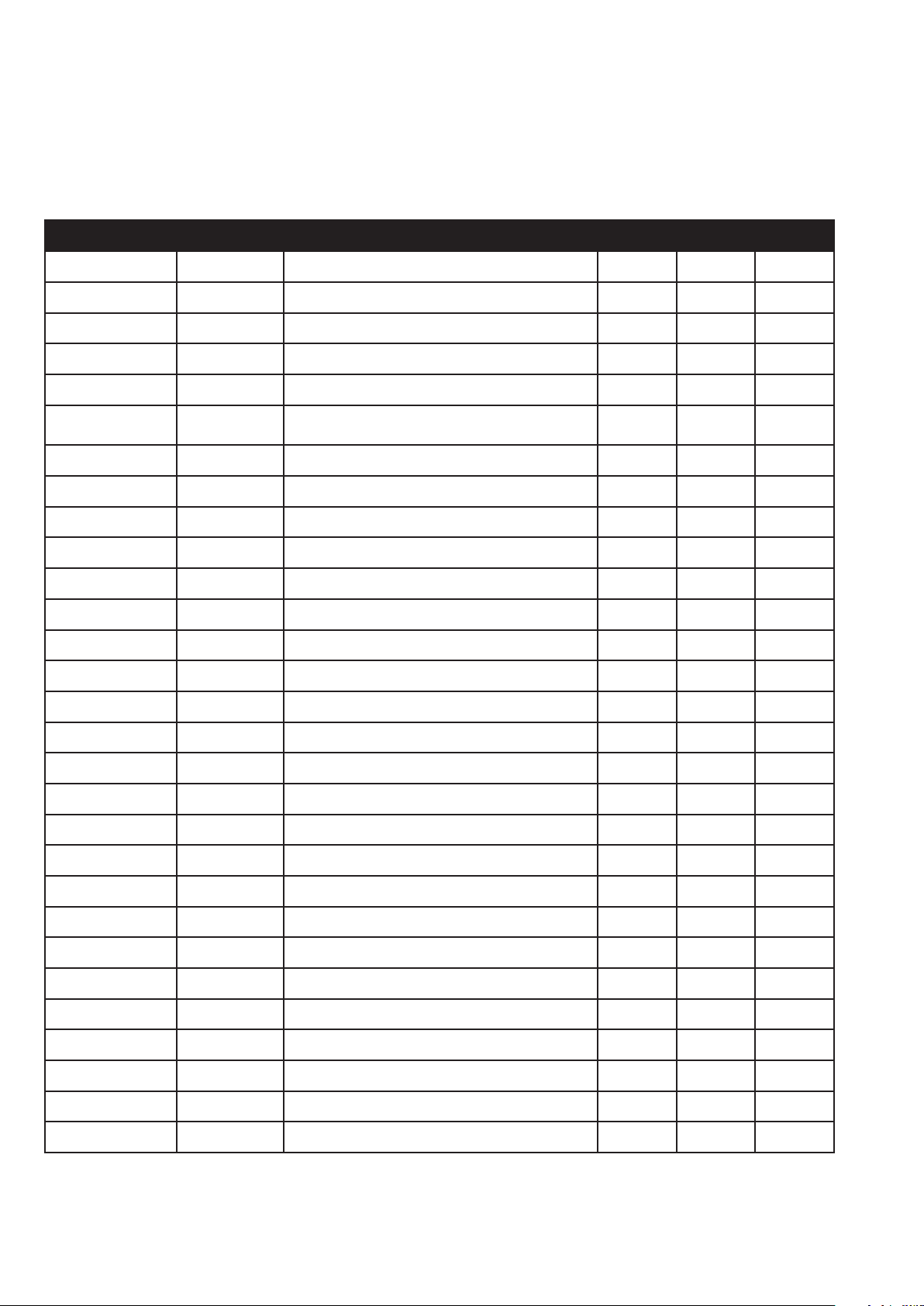

7. LIST OF LABELS

LABEL NUMBER QUANTITY LABEL TEXT 400W 400S 400WS

IXO400-002S 2 ALWAYS DEPLOY STABILISERS ✓

IXO400-002WS 2 DEPLOY STABILISERS WHEN USED OUTDOORS ✓

IXO400-003 1 LIFT HANDLE TO LOWER STEPS ✓ ✓ ✓

IXO400-004 1 PULL HANDLE TO RAISE STEPS ✓ ✓ ✓

IXO400-005 2 KEEP SHUT WHILST WORKING ✓ ✓ ✓

IXO400-006 2

IXO400-007 1 APPLY WHEEL BRAKES + ARROW LEFT ✓ ✓ ✓

IXO400-008 1 APPLY WHEEL BRAKES + ARROW RIGHT ✓ ✓ ✓

IXO400-009 1 ADJUST STABILISERS + ARROW LEFT ✓ ✓

IXO400-010 1 ADJUST STABILISERS + ARROW RIGHT ✓ ✓

IXO400-011 1 FORKLIFT POINTS + ARROWS DOWN ✓ ✓ ✓

IXO400-012 2 STRAP DOWN HERE DURING TRANSPORTATION ✓ ✓ ✓

IXO400-013 1 SWL 150 KG ✓ ✓ ✓

IXO400-014S 1 TYPE PLATE (400S) ✓

IXO400-014W 1 TYPE PLATE (400W) ✓

IXO400-014WS 1 TYPE PLATE (400WS) ✓

IXO400-015W 1 OPERATING INSTRUCTIONS (400W) ✓ ✓

IXO400-015S 1 OPERATING INSTRUCTIONS (400S) ✓

IXO400-015WS 1 OPERATING INSTRUCTIONS (400WS) ✓

IXO400-016 6 STABILISER WARNING STRIPES ✓ ✓

DO NOT SIT, CLIMB OR PLACE LOADS ON

HANDRAILS

✓ ✓ ✓

IXO400-017 2 DO NOT USE WITHOUT STABILISERS ✓ ✓ ✓

IXO400-018 2 IXOLIFT 400 SMALL ✓

IXO400-019 2 IXOLIFT 400 LARGE ✓

IXO400-020 1 OPERATING MANUAL ✓ ✓ ✓

IXO400-021 1 LEVEL ✓ ✓ ✓

IXO400-022 1 FOR INDOOR USE ONLY ✓ ✓

IXO400-023 1 ONLY USE ON HARD AND LEVEL SURFACE ✓ ✓ ✓

iXO400-024 2 WARNING STRIPES FOR STEPS ✓ ✓ ✓

IXO400-027 2 SAFETY HARNESS ANCHORING POINT ✓ ✓ ✓

8

OPERATING MANUAL FOR IXOLIFT 400S / 400W / 400WS

MANUFACTURER

I

TILLINMÄENTIE 3

FI-02330 ESPOO, FINLAND

MODEL

IXOLIFT 400S

SERIAL NO

YEAR

2016

SWL

150 kg

UNIT WEIGHT

140 kg

PLATFORM HEIGHT

LOWERED

974 mm

RAISED

1974 mm

MACHINERY DIRECTIVE 2006/42/EC

AND EN 280/2013 AND EN 1004/26

STANDARDS WHERE APPLICABLE

TECHNICAL FILE

IXOLIFT400v01

MANUFACTURED IN FINLAND

CONFORMITY

MAX. WIND

0 m/s

MANUFACTURER

I

TILLINMÄENTIE 3

FI-02330 ESPOO, FINLAND

MODEL

IXOLIFT 400W

SERIAL NO

YEAR

2016

SWL

150 kg

UNIT WEIGHT

228 kg

PLATFORM HEIGHT

LOWERED

974 mm

RAISED

1974 mm

MACHINERY DIRECTIVE 2006/42/EC

AND EN 280/2013 AND EN 1004/26

STANDARDS WHERE APPLICABLE

TECHNICAL FILE

IXOLIFT400v01

MANUFACTURED IN FINLAND

CONFORMITY

MAX. WIND

0 m/s

MANUFACTURER

I

TILLINMÄENTIE 3

FI-02330 ESPOO, FINLAND

MODEL

IXOLIFT 400WS

SERIAL NO

YEAR

2016

SWL

150 kg

UNIT WEIGHT

239 kg

PLATFORM HEIGHT

LOWERED

974 mm

RAISED

1974 mm

MACHINERY DIRECTIVE 2006/42/EC

AND EN 280/2013 AND EN 1004/26

STANDARDS WHERE APPLICABLE

TECHNICAL FILE

IXOLIFT400v01

MANUFACTURED IN FINLAND

CONFORMITY

MAX. WIND

12.5 m/s

8. LABELS

ALWAYS

DEPLOY STABILISERS

DEPLOY STABILISERS

WHEN USED OUTDOORS

IXO400-002S

IXO400-002WS

KEEP SHUT WHILST WORKING

PLACE LOAD ON HANDRAILS

APPLY WHEEL

DURING TRANSPORTATION

DO NOT SIT, CLIMB OR

BRAKES

IXO400-007

ADJUST STABILISERS

ADJUST STABILISERS

STRAP DOWN HERE

OPERATING MANUAL

PULL HANDLE

TO RAISE BASKET

+

150 KG

APPLY BRAKES

IXO400-005

IXO400-006

APPLY WHEEL

BRAKES

IXO400-008

IXO400-009

IXO400-010

IXO400-012

IXO400-020

IXO400-004

IXO400-013

FOR INDOOR USE ONLY

IXO400-022

LEVEL

IXO400-021

ONLY USE ON HARD

AND LEVEL SURFACE

IXO400-023

SAFETY HARNESS

ANCHORING POINT

IXO400-0027

LIFT HANDLE

TO LOWER BASKET

IXO400-003

9

OPERATING MANUAL FOR IXOLIFT 400S / 400W / 400WS

8. LABELS CONTINUED

OPERATING

INSTRUCTIONS

ALWAYS READ

THE OPERATING MANUAL

CHECK THE UNIT CONDITION:

DO NOT USE A DAMAGED UNIT

MAX WIND 12.5 M/S

APPLY BRAKES ON

SWIVEL CASTOR WHEELS

ONLY USE ON HARD

AND LEVEL SURFACE

LEVEL THE UNIT

DEPLOY STABILISERS

AND LOCK IN POSITION

WHEN USED OUTDOORS

ADJUST STABILISERS

TO STABILISE THE UNIT

ALWAYS CHECK

BUBBLE LEVEL

PULL THE LEVER AT THE

BOTTOM OF THE MAIN POST

TO RAISE THE BASKET

TO REQUIRED HEIGHT

ENSURE THAT THE

SHOOT BOLT IS

IN A LOCKED POSITION

ENTER BASKET - DO NOT

EXCEED THE MAXIMUM

SAFE WORKING LOAD 150 KG

ENSURE GATES ARE

FULLY CLOSED

IF USING A SAFETY HARNESS

FASTEN IT TO UNIT’S

SAFETY HARNESS

CONNECTION POINTS

DO NOT ATTEMPT TO MOVE

THE UNIT WHILST OPERATIVES

ARE IN THE BASKET

DO NOT PLACE LOADS

ON GUARDRAILS

KEEP ALL PERSONS CLEAR

WHILST WORKING

APPLY WHEEL BRAKES

WHEN NOT IN USE

IXO400-015WS

OPERATING

INSTRUCTIONS

INDOOR USE ONLY

ALWAYS READ

THE OPERATING MANUAL

CHECK THE UNIT CONDITION:

DO NOT USE A DAMAGED UNIT

APPLY BRAKES ON

SWIVEL CASTOR WHEELS

ONLY USE ON HARD

AND LEVEL SURFACE

LEVEL THE UNIT

ALWAYS CHECK

BUBBLE LEVEL

PULL THE LEVER AT THE

BOTTOM OF THE MAIN POST

TO RAISE THE BASKET

TO REQUIRED HEIGHT

ENSURE THAT THE

SHOOT BOLT IS

IN A LOCKED POSITION

ENTER BASKET - DO NOT

EXCEED THE MAXIMUM

SAFE WORKING LOAD 150 KG

ENSURE GATES ARE

FULLY CLOSED

IF USING A SAFETY HARNESS

FASTEN IT TO UNIT’S

SAFETY HARNESS

CONNECTION POINTS

DO NOT ATTEMPT TO MOVE

THE UNIT WHILST OPERATIVES

ARE IN THE BASKET

DO NOT PLACE LOADS

ON GUARDRAILS

KEEP ALL PERSONS CLEAR

WHILST WORKING

APPLY WHEEL BRAKES

WHEN NOT IN USE

IXO400-015W

OPERATING

INSTRUCTIONS

INDOOR USE ONLY

ALWAYS READ

THE OPERATING MANUAL

CHECK THE UNIT CONDITION:

DO NOT USE A DAMAGED UNIT

APPLY BRAKES ON

SWIVEL CASTOR WHEELS

ONLY USE ON HARD

AND LEVEL SURFACE

LEVEL THE UNIT

ALWAYS DEPLOY STABILISERS

AND LOCK IN POSITION

ADJUST STABILISERS

TO STABILISE THE UNIT

ALWAYS CHECK

BUBBLE LEVEL

PULL THE LEVER AT THE

BOTTOM OF THE MAIN POST

TO RAISE THE BASKET

TO REQUIRED HEIGHT

ENSURE THAT THE

SHOOT BOLT IS

IN A LOCKED POSITION

ENTER BASKET - DO NOT

EXCEED THE MAXIMUM

SAFE WORKING LOAD 150 KG

ENSURE GATES ARE

FULLY CLOSED

IF USING A SAFETY HARNESS

FASTEN IT TO UNIT’S

SAFETY HARNESS

CONNECTION POINTS

DO NOT ATTEMPT TO MOVE

THE UNIT WHILST OPERATIVES

ARE IN THE BASKET

DO NOT PLACE LOADS

ON GUARDRAILS

KEEP ALL PERSONS CLEAR

WHILST WORKING

APPLY WHEEL BRAKES

WHEN NOT IN USE

IXO400-015S

FORKLIFT POINTS

IXO400-011

DO NOT USE WITHOUT STABILISERS - INDOOR USE ONLY

IXO400-017

10

OPERATING MANUAL FOR IXOLIFT 400S / 400W / 400WS

9. EC DECLARATION OF CONFORMITY

MANUFACTURER IXOLIFT LTD.

Tillinmäentie 3 B118

FI-02330 ESPOO

FINLAND

PERSON AUTHORISED

TO COMPILE THE Mikael Stendahl

TECHNICAL FILE

DESCRIPTION IXOLIFT 400

Serial Number _________

TECHNICAL FILE

REFERENCE IXOLIFT400v01

DECLARATION I Declare that the equipment

described herein is in conformity with

Machinery Directive 2006/42/EC

Harmonised standards used: EN 280:2013

except 5.6.2.

Other technical standards and specifications

used: EN 1004:2005

SIGNATURE ___________________

Mikael Stendahl

DATE 31/03/2016

11

MANUFACTURED IN FINLAND

IXOLIFT LTD.

Tillinmäentie 3

FI-02330 ESPOO

FINLAND

+358 50 506 7339

sales@ixolift.com

www.ixolift.com

12

Loading...

Loading...