IWILL DP400 Motherboard

User’s Manual

DP400 Motherboard

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

II

User’s Manual

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

DP400 Motherboard

Federal Communications Commission (FCC) Statement

This equipment has been tested and found to comply with the limits for a Class B digital

device, pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful interference in a residential installation. This equipment

generates, uses, and can radiate radio frequency energy and, if not installed and used in

accordance with the instructions, may cause harmful interference to radio communications. However, there is no guarantee that interference will not occur in a particular

installation. If this equipment does cause harmful interference to radio or television reception, which can be determined by turning the equipment off and on, the user is encouraged to try to correct the interference by one or more of the following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and the receiver.

• Connect the equipment onto an outlet on a circuit different from that to which the

receiver is connected.

• Consult the dealer or an experienced radio/TV technician for help.

Shielded interconnect cables and shielded AC power cable must be employed with this

equipment to insure compliance with the pertinent RF emission limits governing this

device. Changes or modifications not expressly approved by the system’s manufacturer

could void the user’s authority to operate the equipment.

Declaration of Conformity

This device complies with part 15 of the FCC rules. Operation is subject to the following

conditions:

• This device may not cause harmful interference, and

This device must accept any interference received, including interference that may cause

undesired operation.

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

User’s Manual

III

DP400 Motherboard

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Disclaimer

The information in this document is subject to change without notice. The manufacturer

makes no representations or warranties with respect to the contents hereof and specifically

disclaims any implied warranties of merchantability or fitness for any particular purpose.

Furthermore, the manufacturer reserves the right to revise this publication and to make

changes from time to time in the content hereof without obligation of the manufacturer to

notify any person of such revision or changes.

Trademark Recognition

Microsoft and Windows are registered trademarks of Microsoft Corp.

Intel and Xeon are registered trademarks of Intel Corporation.

Other product names used in this manual are the properties of their respective owners and

are acknowledged.

Copyright

• Portions © Intel Corporation

This publication, including all photographs, illustrations and software, is protected under

international copyright laws, with all rights reserved. Neither this manual, nor any of the

material contained herein, may be reproduced without the express written consent of the

copyright holders.

© January 2002

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

IV

User’s Manual

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

DP400 Motherboard

Contents

1: Introduction.................................................................... 1.1

Manual Structure............................................................................. 1.1

Manual Features.............................................................................. 1.2

If The Motherboard Is Already Installed ............................................ 1.2

If You Need To Install This Motherboard ............................................1.2

Critical Topics ................................................................................. 1.3

Packing List.................................................................................... 1.4

Pre-Use Checklist ............................................................................ 1.5

2: Key Features & Components .............................................. 2.1

Motherboard Layout ........................................................................ 2.2

Key Features & Components ............................................................. 2.4

Intel 860 Chipset...........................................................................2.5

CPU Sockets .................................................................................. 2.5

System Memory Sockets ..................................................................2.6

The AGP Slot.................................................................................2.7

PCI Expansion Slots ....................................................................... 2.8

Drive Connectors ...........................................................................2.9

IDE Drive Connectors...................................................................2.9

Floppy Disk Drive Connector..........................................................2.9

Other Connectors ......................................................................... 2.10

WTX Power Connectors............................................................... 2.10

CPU & System Cooling Fan Connectors .......................................... 2.10

WOL: Wake On LAN ................................................................... 2.11

CD-In & AUX Audio Connectors.................................................... 2.12

IRDA...................................................................................... 2.12

Chassis Intrusion Switch Connector.............................................. 2.13

Front Panel Connectors.............................................................. 2.13

Battery Connector .................................................................... 2.14

I/O Ports ...................................................................................... 2.14

PS/2 Ports .............................................................................. 2.14

USB Ports ...............................................................................2.15

LAN Port................................................................................. 2.15

Parallel Port ............................................................................ 2.15

Serial (COM) Ports .................................................................... 2.16

Audio Jacks & AC ‘97 Audio........................................................ 2.16

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

User’s Manual

V

DP400 Motherboard

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Jumpers ..................................................................................... 2.17

JP4 Flash Protect ..................................................................... 2.17

JP6 Clear CMOS ........................................................................ 2.17

Software Features.......................................................................... 2.18

Using the Power Installer 2 Disc .................................................... 2.18

Driver Software ........................................................................... 2.19

Utility Software........................................................................... 2.20

3: Motherboard Configuration ............................................... 3.1

The Default Configuration................................................................ 3.1

Hardware Configuration: Jumper Settings .......................................... 3.1

Jumper JP4: BIOS Flash Protect ....................................................3.2

Jumper JP6: Clear CMOS Memory ...................................................3.4

Firmware Configuration: The CMOS Setup Utility .................................3.6

Using the CMOS Setup Utility........................................................ 3.6

Reconfiguring the Motherboard ........................................................ 3.8

Hardware Reconfiguration ............................................................... 3.8

Firmware Reconfiguraton ................................................................3.8

4: Installing the Motherboard ............................................... 4.1

Pre-installation Preparation............................................................. 4.1

Installing CPUs..............................................................................4.2

Processor Selection .....................................................................4.2

Installation Video ......................................................................4.2

Installing The Processor...............................................................4.3

Installing the Heatsink Retention Mechanisms .................................4.6

Installing the Heatsink................................................................4.8

Installing the Processor Wind Tunnel............................................ 4.10

Installing System Memory ............................................................. 4.12

Memory Specifications ............................................................... 4.12

Memory Configuration Options .................................................... 4.12

Installing Memory Modules......................................................... 4.14

System Memory Recognition ....................................................... 4.14

Installing the Motherboard in a System Housing............................... 4.16

Motherboard Installation Procedure ............................................. 4.16

Connecting Front Panel Components ............................................ 4.18

EEB 3.0 Housing Installation...................................................... 4.18

Completing System Configuration ................................................... 4.19

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

VI

User’s Manual

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

DP400 Motherboard

5: System Configuration ....................................................... 5.1

Installing or Connecting Internal Peripherals .................................... 5.1

Installing an AGP Card....................................................................5.2

AGP Configuration ...................................................................... 5.2

Display Drivers ...........................................................................5.2

Connecting Internal Devices ............................................................5.3

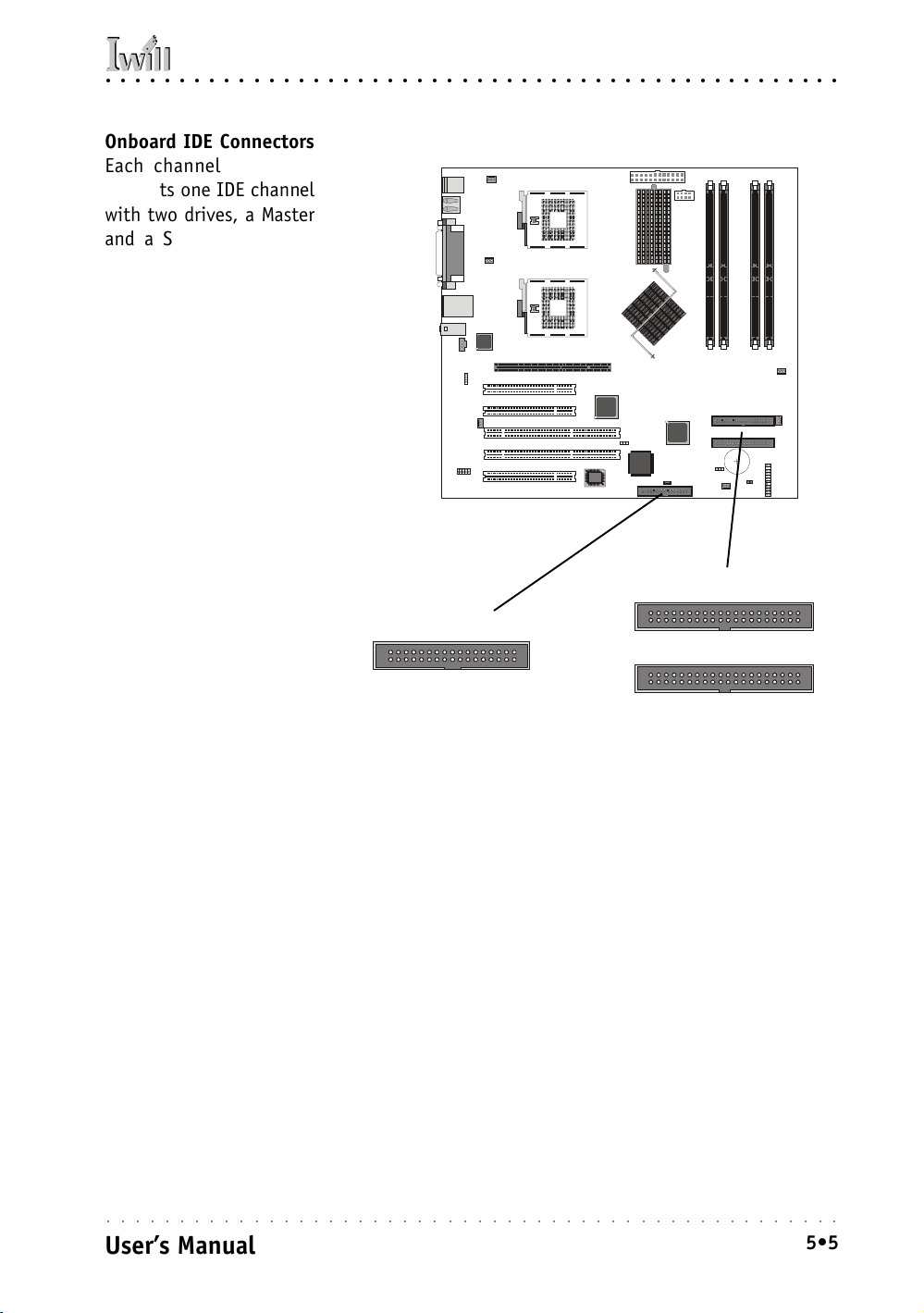

Connecting IDE Devices ...............................................................5.3

Connecting a Floppy Disk Drive......................................................5.4

Connecting External System Peripherals ............................................ 5.6

Connecting a Display Monitor ..........................................................5.6

Connecting a Keyboard & Mouse.......................................................5.6

Configuring the CMOS Setup Utility .................................................. 5.8

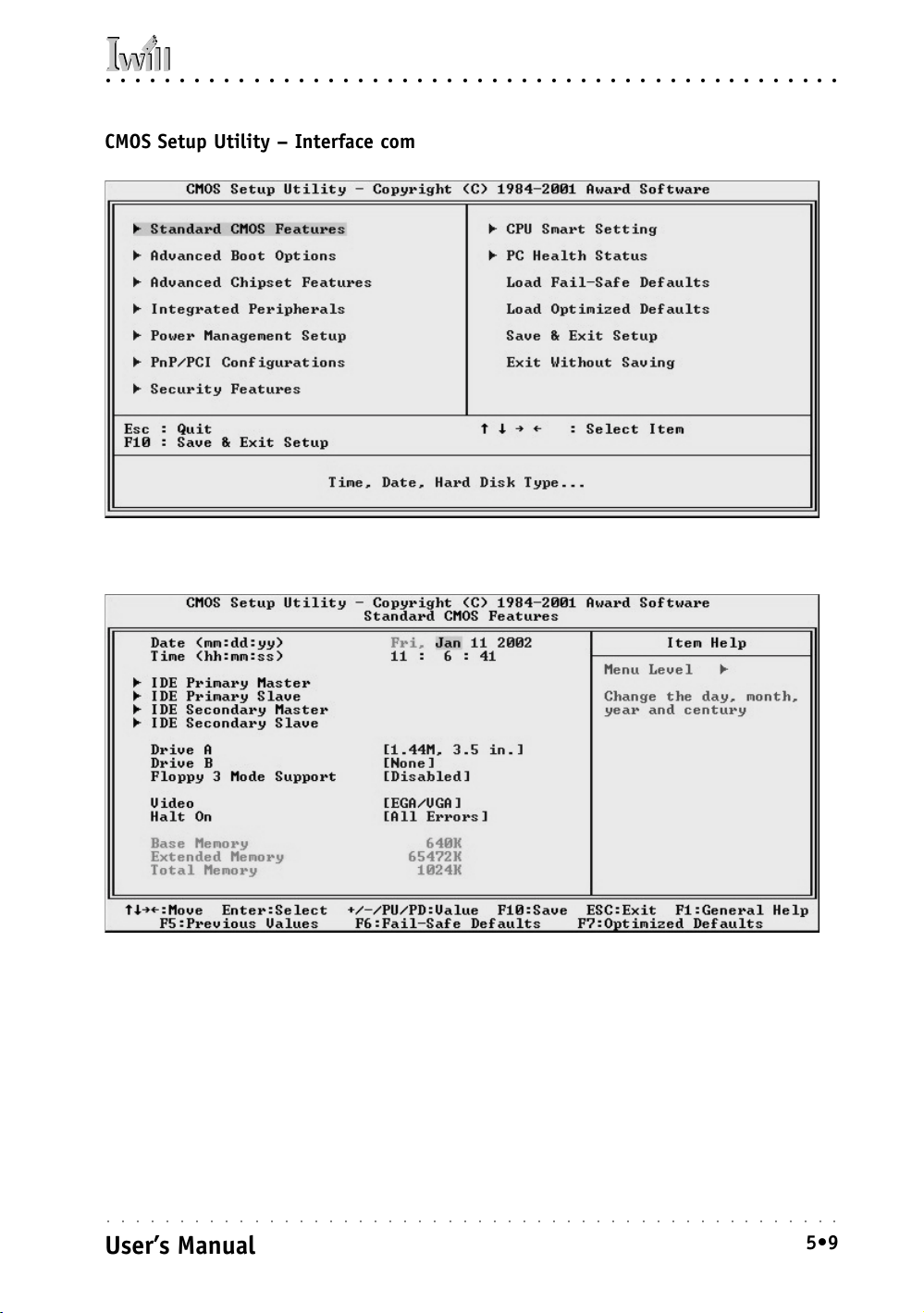

The CMOS Setup Utility User Interface...............................................5.8

Running the CMOS Setup Utility ....................................................5.8

CMOS Setup Utility Program Sections .............................................. 5.10

Standard CMOS Features ............................................................ 5.12

Advanced Boot Options ............................................................. 5.13

Advanced Chipset Features ......................................................... 5.14

Integrated Peripherals............................................................... 5.15

Power Management Setup .......................................................... 5.16

PnP/PCI Configurations ............................................................. 5.17

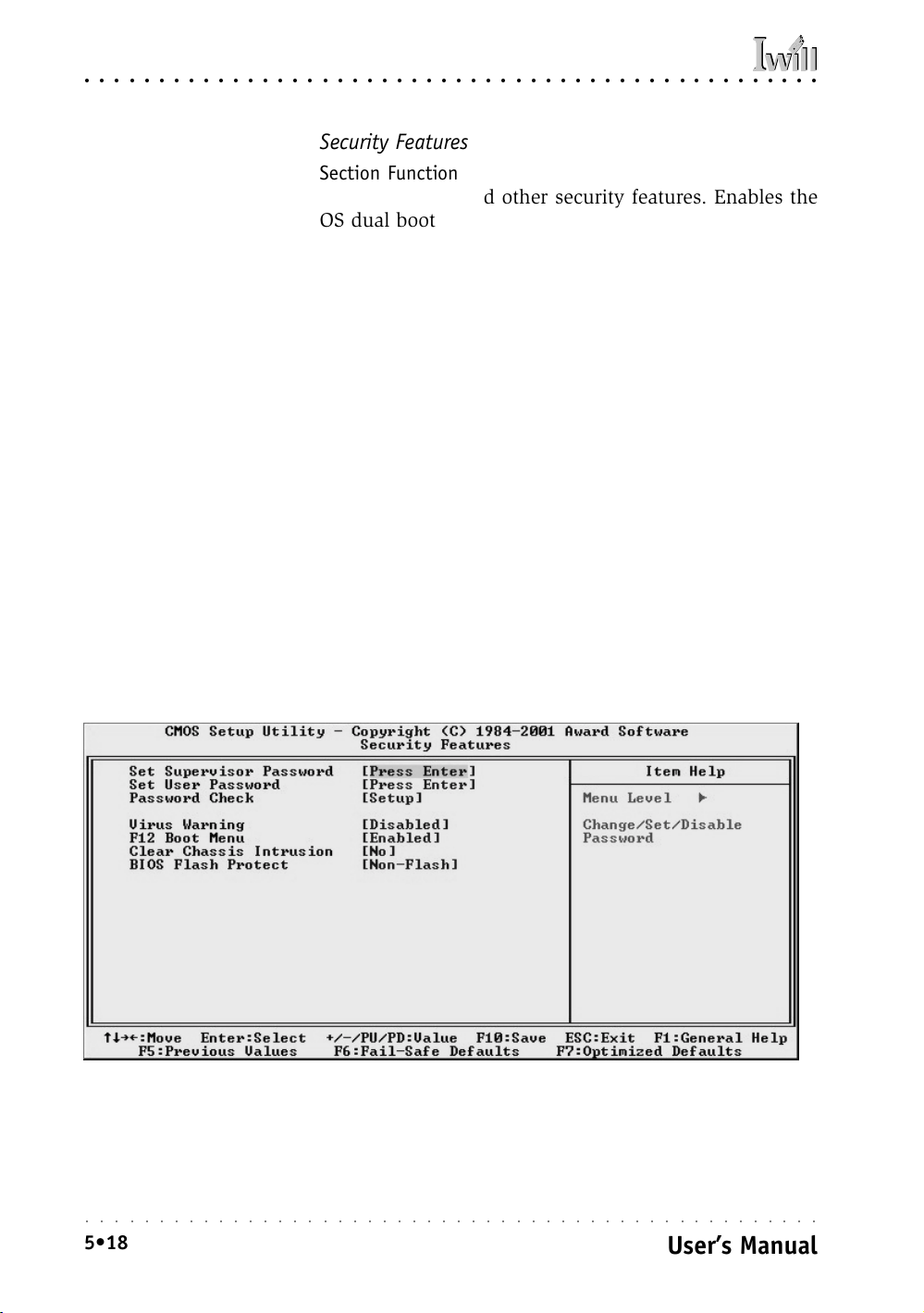

Security Features...................................................................... 5.18

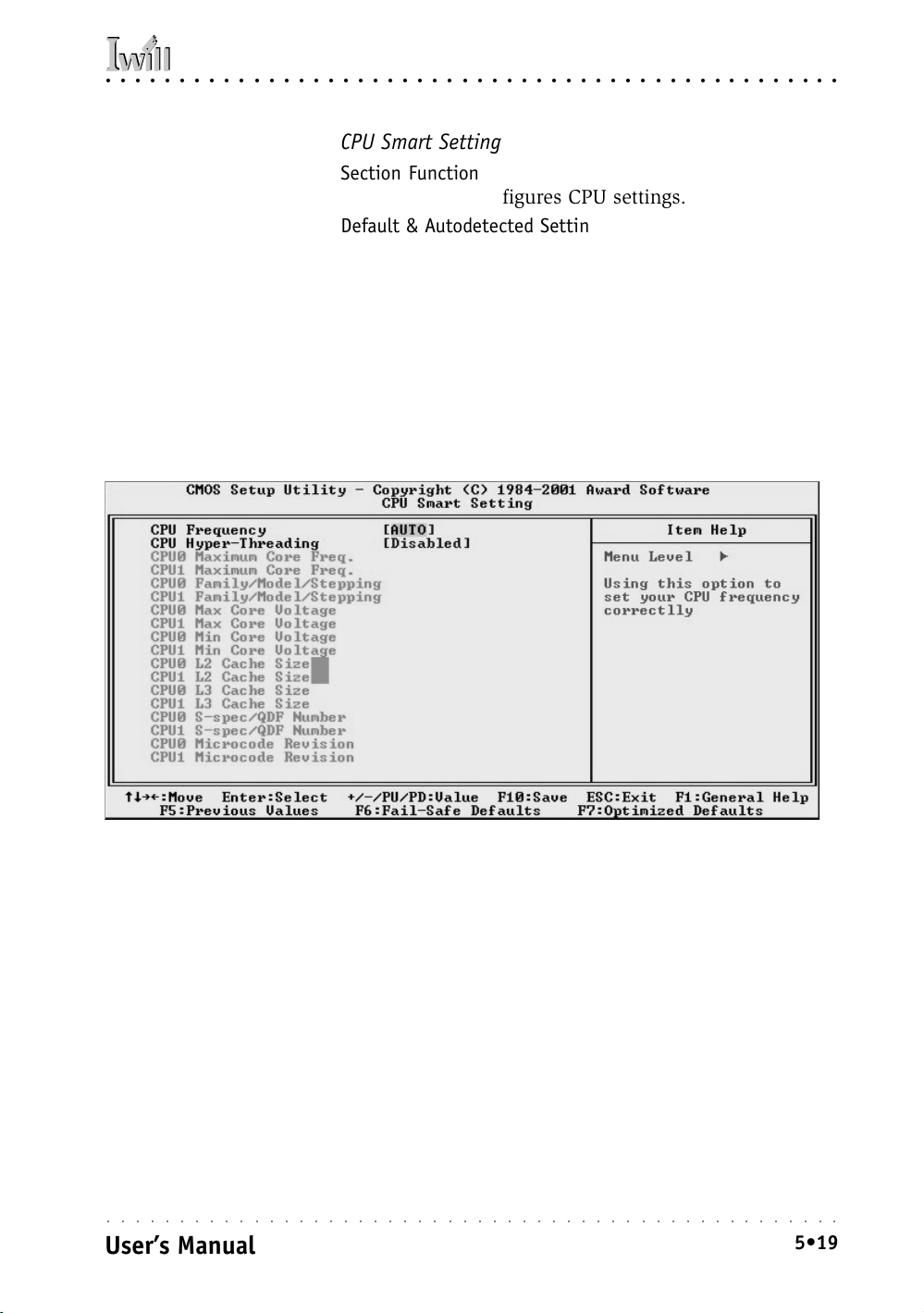

CPU Smart Setting .................................................................... 5.19

PC Health Status ...................................................................... 5.20

Load Fail-Safe Defaults.............................................................. 5.21

Load Optimized Defaults ............................................................ 5.21

Save & Exit Setup..................................................................... 5.21

Exit Without Saving .................................................................. 5.21

Installing an OS & Support Software ............................................... 5.22

Installing an Operating System ...................................................... 5.22

Multi-boot Option..................................................................... 5.22

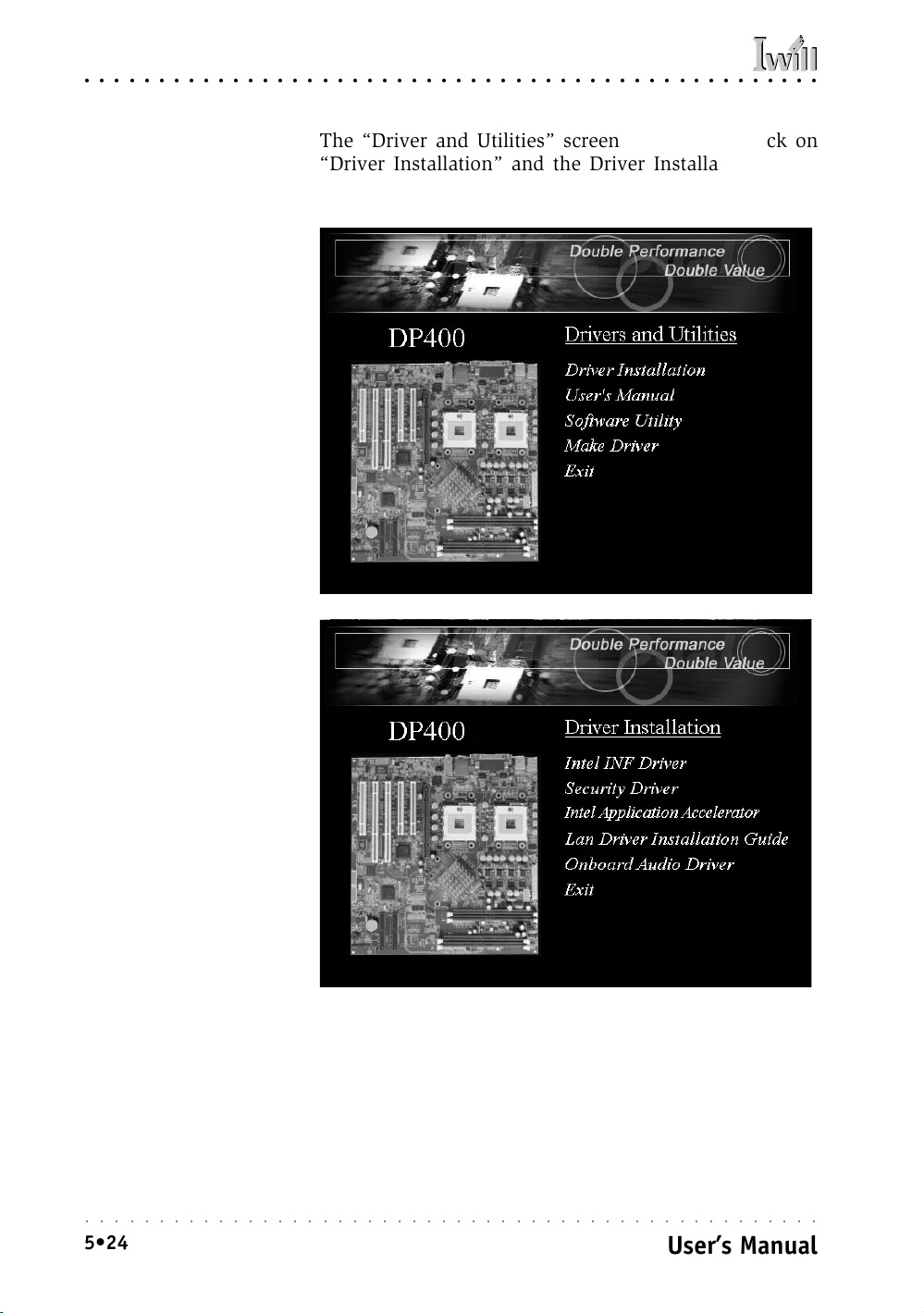

Installing the Support Software ..................................................... 5.22

Installing Windows Drivers ......................................................... 5.23

Making Driver Discs ................................................................... 5.25

Making & Installing Linux Drivers ................................................ 5.26

Installing the Utility Software ....................................................... 5.26

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

User’s Manual

VII

DP400 Motherboard

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

6: Using the Motherboard..................................................... 6.1

Using System Features..................................................................... 6.1

Front Panel System Controls & Indicators .......................................... 6.1

System Controls .........................................................................6.1

Indicator LEDs ...........................................................................6.3

Additional System Features .............................................................6.3

LAN Indicator LEDs .....................................................................6.3

Wake-on LAN (WOL)....................................................................6.3

Installing & Configuring An IR Port .................................................. 6.4

Performance Optimization ............................................................... 6.6

System Memory .............................................................................6.6

Disk Subsystems ............................................................................6.6

Processor Upgrades & Adjustments ................................................... 6.6

Troubleshooting .............................................................................. 6.7

Hardware Problems.......................................................................... 6.7

General Hardware Troubleshooting .................................................... 6.7

Hardware Configuration Problems .....................................................6.8

Plug and Play Problems ............................................................... 6.9

Replacing the System Configuration Record .......................................6.9

Loading Optimized Defaults.............................................................6.9

7: Technical Specifications ................................................... 7.1

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

VIII

User’s Manual

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

1: Introduction

What’s In This Chapter:

Introduction

Manual Structure

Manual Features

Critical Topics

Packing List

Pre-Use Checklist

1: Introduction

This is the User’s Manual is for the DP400 motherboard.

Please read this chapter before you use your motherboard

and identify which parts of the manual you will need to

refer to, if any. Please pay particular attention to the Critical Topics section.

Manual Structure

This manual has seven chapters covering the following

topics:

Chapter 1: Introduction

Explains the manual structure and conventions and indi-

cates the most important topics in the manual. In addition, there is a list of what you should find in the

motherboard package and some pointers on things to do

before you configure or install the board.

Chapter 2: Key Features & Components

Details the motherboard’s hardware features and impor-

tant components and indicates their locations. Describes

the support software that comes with the board on the

Power Installer 2 support CD-ROM disc.

Chapter 3: Motherboard Configuration

Lists the motherboard’s default configuration and con-

figuration options.

Chapter 4: Installing The Motherboard

Has information on how to prepare and install the

motherboard. Includes installing CPUs and system

memory and housing installation considerations.

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

User’s Manual

1•1

DP400 Motherboard

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Chapter 5: System Configuration

Covers connecting system peripherals to the motherboard,

initial BIOS configuration using the CMOS Setup utility,

OS options and software installation.

Chapter 6: Using The Motherboard

Explains system operation features that derive from the

motherboard. Has information on performance optimization and troubleshooting.

Chapter 7: Technical Information

Lists the motherboard’s technical specifications.

Manual Features

This User’s Manual is intended to be useful and informative while also making it easy to quickly find specific

information or specifications. The manual has icons and

notes in the sidebar to note important topics, indicate

warnings or further explain and illustrate points. We

suggest that most users review the manual to become

familiar with the motherboard. Expert users may want to

review topics selectively, as needed.

If The Motherboard Is Already Installed

You may receive the motherboard installed in a working

system. If this is the case, you should still probably review the sections on configuring and using the board,

especially if an Operating System is not installed yet.

If You Need To Install This Motherboard

We recommend that only experienced users and technicians install this motherboard. Otherwise, we suggest

having a qualified computer technician install and configure the system. This service is usually provided at a

nominal fee by better computer stores and service companies.

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

1•2

User’s Manual

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

1: Introduction

Critical Topics

Many users do not read through the entire User’s Manual.

While this may not be necessary for experienced users or

if the motherboard is already installed, there are some

topics which are particularly important and deserve your

specific attention. Some topics cover information critical

to the proper installation and use of the motherboard.

For the DP400 motherboard, please review the sections

on the following topics:

• CPU backplate installation

Please see Chapter 4.

• Xeon processor retention module installation

Please see Chapter 4.

• Dual processor installation

Please see Chapter 4.

• System memory installation requirements

Please see Chapter 4.

• Rear I/O Panel Shield

Please see Chapter 4.

• Required BIOS configuration

Please see Chapter 5.

• Support software installation

Please see Chapter 5.

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

User’s Manual

1•3

DP400 Motherboard

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Packing List

The DP400 motherboard package includes the following

items:

• DP400 motherboard

• ATA-66/100 IDE connector cable

Connects IDE devices to one of the onboard IDE

connectors.

• Floppy Disk Drive connector cable

Connects floppy disk drives to the onboard floppy

disk connector.

• Rear I/O Panel Shield

Covers the area around the rear panel I/O ports when

the board is installed in a system housing.

• 2 CPU Back Plates

Mount on the underside of the motherboard and

provide mounting points for the heatsink retention

modules and a thermal buffer.

• 2 Heatsink Retention Modules

Secure the CPU heatsink on top of the CPU.

• 2 CRIMM spacer modules

Install in unused system memory RIMM sockets.

• 3 Jumper Caps

Extra caps in case original caps are lost.

• Power Installer 2 support CD-ROM disc

Includes support software, drivers and bundled soft-

ware utilities.

• User’s Manual

• Quick Installation Guide

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

1•4

User’s Manual

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

1: Introduction

Pre-Use Checklist

Before you install and use the motherboard, please do

the following:

• Check Package Contents

Please compare the package contents to the Packing

List on the previous page and confirm that all items

are present and undamaged.

• Missing or Damaged Accessories

If anything is missing, please contact your vendor.

• Motherboard Damage

If the motherboard has been visibly damaged, return the complete package to your vendor with proof

of purchase.

• Prepare Minimum System Components

If you are installing the board in a new system, you’ll

need at least the following internal components;

• 2 Intel Xeon processors of identical specification

• At least two RIMM memory modules

• 1.5V AGP video display card

• Desired storage devices (hard disk, CD-ROM, etc.)

You will also need whatever external system peripherals

you intend to use, which will normally include at least a

keyboard, a pointing device and a video display monitor.

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

User’s Manual

1•5

DP400 Motherboard

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

1•6

User’s Manual

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

2: Key Features & Components

Chapter Topics:

Hardware Features

Motherboard Layout

Key Features & Components

Software Features

Driver Software

Utility Software

2: Key Features & Components

This chapter explains the location and function of this

motherboard’s key features and components. In addition,

it details the software that comes on the Power Installer 2

support CD-ROM disc. Please review this chapter if you

are installing the motherboard. It is also useful for reference regarding feature functions after the board is installed in a working system.

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

User’s Manual

2•1

DP400 Motherboard

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

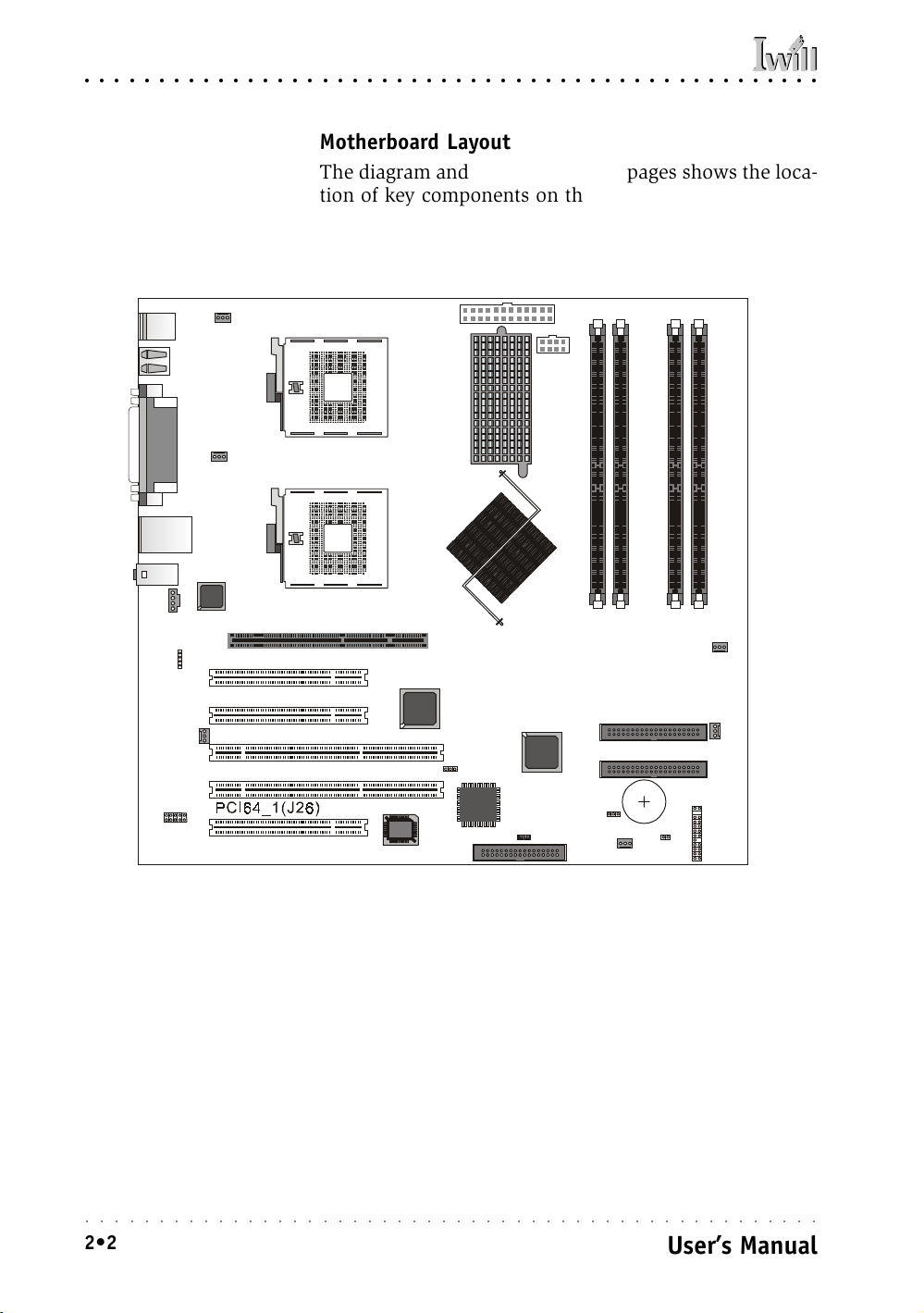

Motherboard Layout

The diagram and key on these two pages shows the location of key components on the motherboard.

PWR-WTX

CPU0-FAN

(J2A1)

CPU0

(J37A1)--A

PWR-WTX

(J37B1)--B

CPU1-FAN

(J1B1)

CD_In(J15)

AUX

(J18)

FAN-4

(J21)

IRDA

(J28)

CPU1

PCI0(J19)

PCI1(J20)

PCI64_0(J24)

PCI2(J29)

AGP PRO(J16)

FLOPPY(J33)

JP4

WOL

(J31)

RIMM3,2

(J7,J8)

Secondary(J22)

Primary(J25)

CMOS

(JP6)

FAN_3(J32)

RIMM1,0

(J9,J10)

FAN_2(J17)

FAN_1(J23)

Case

(J30)

J27

Front Panel

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

2•2

User’s Manual

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

2: Key Features & Components

Motherboard Layout Key

Component Function

CPU O, CPU 1 Socket 603 CPU sockets

CPU0-FAN, CPU1-FAN CPU cooling fan power connectors

PWR-WTX -A & -B Power connectors for WTX power supply

RIMM 0, 1, 2, 3 Memory sockets for PC600 or PC800 DRDRAM modules

AGP PRO AGP universal connector for 1.5V AGP 4X & Pro 50

PCI 0, 1, 2 32-bit PCI expansion slots

PCI64 0, 1 64-bit PCI expansion slots

PRIMARY, SECONDARY IDE drive connectors

FLOPPY Floppy disk drive connector

CD_In CD-ROM drive audio-in connector

AUX Auxiliary audio-in connector

IRDA IR port module connector

WOL Wake-On-LAN connector

JP4 BIOS Flash Protection jumper

CMOS (JP6) Clear CMOS jumper

Case Case Intrusion connector

Front Panel Housing front panel feature connector

FAN 1, 2, 3, 4 Housing cooling fan connectors

Rear panel I/O ports See figure on next page

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

User’s Manual

2•3

DP400 Motherboard

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

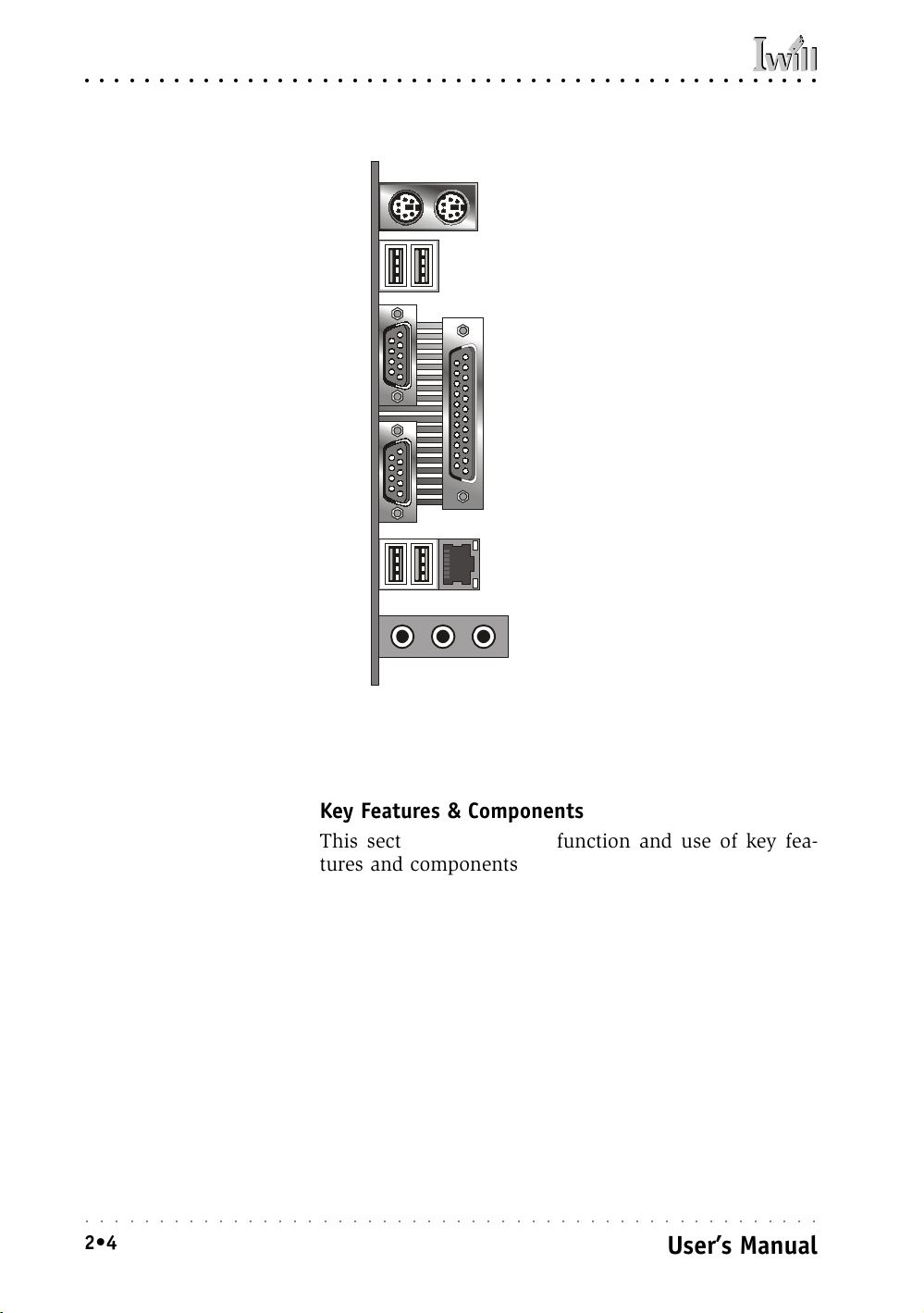

Rear I/O Panel Ports:

This figure show the ports

on the rear I/O panel. The

ports include, from top to

PS/2 Keyboard, PS/2 Mouse

bottom:

PS/2 ports

USB2, USB1

Two USB ports

Parallel & Serial ports

LAN & two USB ports

Audio ports

Serial 1 (COM1)

The ports have standard

color-coding as follows:

Parallel

PS/2 Keyboard: Purple

PS/2 Mouse: Green

Serial 2 (COM2)

USB Ports: Black

Serial Ports: Teal

Parallel Port: Burgundy

LAN jack: None

USB4, USB3, LAN RJ-45

Line-In jack: Light Blue

Line Out jack: Lime

Mic, Line Out, Line In

Mic In jack: Pink

Key Features & Components

This section explains the function and use of key features and components on the motherboard. It also indicates where to look in the manual for additional information on configuring and using them.

This motherboard uses an extended ATX form factor

PCB in a design that integrates many features onto the

board including several external ports.

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

2•4

User’s Manual

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

2: Key Features & Components

Intel 860 Chipset

This motherboard uses the Intel 860 Chipset. It is a highpowered chipset intended for workstation applications.

The components of the Intel 860 Chipset include the following devices mounted on the board:

• 82860 Memory & Graphics Controller Hub (MCH)

• 82801BA I/O Controller Hub (ICH2)

• 82802 AB Firmware Hub (FWH)

• 82806 AA 64-bit Bus Master PCI Expander (P64H)

The chipset provides host bus, memory, AGP, and I/O

interfaces.

CPU Sockets

Function: The System CPUs install in these sockets. You

can install either one or two CPUs, as needed.

Description: The Socket 603 CPU sockets support all Intel

Xeon CPUs that use this socket. The motherboard comes

with hardware to attach the heatsink and fan/wind tunnel assembly required by the Xeon CPU.

More Information: See the section in Chapter 4 on “In-

stalling CPUs” for information supported CPUs and their

installation procedure. Technical specifications are listed

in Chapter 7.

Socket 603 CPU Sockets:

Single CPU installs in

socket CPU0 only.

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

User’s Manual

CPU0

CPU1

2•5

DP400 Motherboard

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

System Memory Sockets

Function: The RIMM system memory sockets are for installing DRDRAM system memory modules.

Description: There are four RIMM memory module sockets on the motherboard. These sockets are for PC600 or

PC800 DRDRAM memory modules. The sockets function

independently, allowing a variety of memory configurations up to a total of 2GB.

More Information: See the section on Installing System

Memory in Chapter 4 for configuration specifications and

installation instructions. Technical specifications are listed

in Chapter 7.

RIMM Sockets:

System memory sockets for

PC600 or PC800 DRDRAM

modules.

See Chapter 4 for important installation information.

RIMM 1, 0RIMM 3, 2

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

2•6

User’s Manual

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

2: Key Features & Components

The AGP Slot

Function: The AGP slot is for installing an AGP interface

video display card.

Description: The AGP slot is a high-speed slot exclusively

designed for an AGP video display card. The AGP slot

supports two types of AGP card:

• AGP 4X – 266MHz data transfer, maximum 1064MB/

second data throughput

• AGP Pro50

The slot only supports 1.5V devices. Do not use a 3.3V

AGP card with this motherboard. The AGP slot is extended to include support for AGP Pro50 cards using up

to 50 watts of power.

More Information: See the section “Connecting & In-

stalling Internal Peripherals” in Chapter 4. Technical speci-

fications are listed in Chapter 7. Also, see the Advanced

Chipset Features section of “Configuring the CMOS Setup

Utility” in Chapter 5 for information on setting the AGP

memory aperture size.

AGP Pro Slot:

For AGP 4X & Pro 50 1.5V

cards only. Do not use

3.3V cards.

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

User’s Manual

AGP slot is for both AGP 4X & AGP Pro 50 cards

2•7

DP400 Motherboard

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

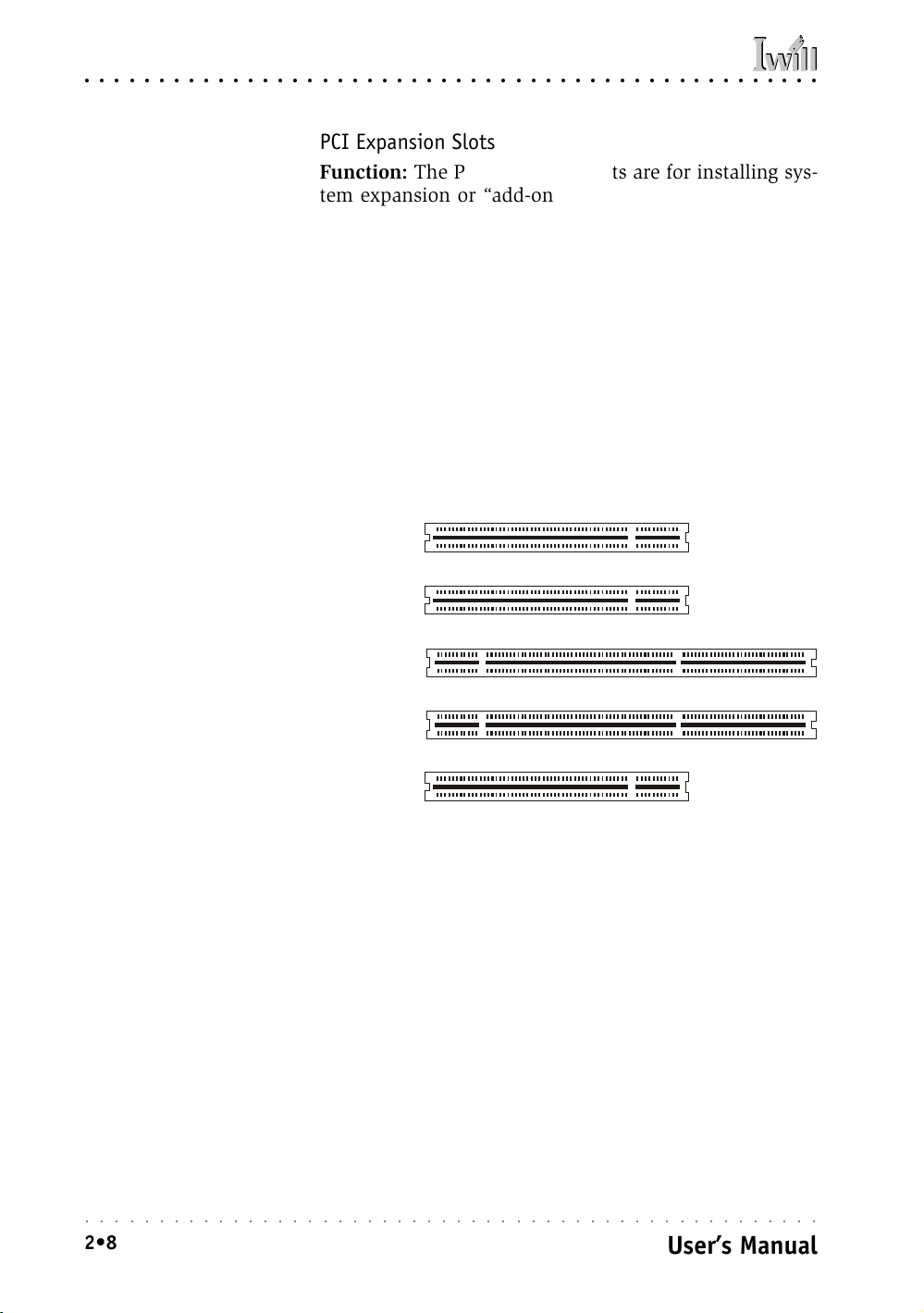

PCI Expansion Slots

Function: The PCI expansion slots are for installing system expansion or “add-on” cards to add additional sys-

tem hardware.

Description: This motherboard has five Bus Master capable PCI expansion slots, including three 32-bit 33MHz

slots and two 64-bit 66MHz slots. The slots provide two

levels of fast high-bandwidth pathway between the

motherboard and expansion cards.

More Information: See the section “Connecting & In-

stalling Internal Peripherals” in Chapter 5. Technical speci-

fications are listed in Chapter 7.

PCI Expansion Slots

All slots are Bus Master

capable. The 64-bit slots

require 64-bit cards.

PCI 0

PCI 1

PCI64 0

PCI64 1

PCI 2

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

2•8

User’s Manual

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

2: Key Features & Components

Drive Connectors

There are three drive connectors on the motherboard for

connecting IDE and floppy disk drives.

IDE Drive Connectors

Function: The two IDE connectors, marked ‘Primary’ and

‘Secondary’, are for connecting IDE drives to the

motherboard.

Description: The IDE controller on the motherboard sup-

ports IDE devices running in all modes up through ATA-

100. There are two IDE drive connectors. Each connector supports two drives, a ‘Master’ and a ‘Slave’ which

connect to the motherboard with a ribbon cable. The

supplied cable supports transfer modes through ATA-100.

More Information: See the section on “Connecting In-

ternal Peripherals” in Chapter 5 for instructions on connecting IDE drives. Technical specifications are listed in

Chapter 7.

IDE Drive Connectors

The channels are labeled

on the board.

Secondary

Floppy Drive Connector

Primary

Floppy Disk Drive Connector

Function: The floppy disk drive connector, marked

‘Floppy’, is for connecting one floppy disk drive to the

motherboard.

Description: The floppy disk drive connector supports

connecting one floppy disk drive to the motherboard.

The ‘Floppy’ drive connector uses a standard FDD ribbon cable. The floppy disk drive connected to the end of

the cable will function as Drive A:.

More Information: See the section on “Connecting In-

ternal Peripherals” in Chapter 4 for instructions on connecting a floppy disk drive. Technical specifications are

listed in Chapter 7.

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

User’s Manual

2•9

DP400 Motherboard

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

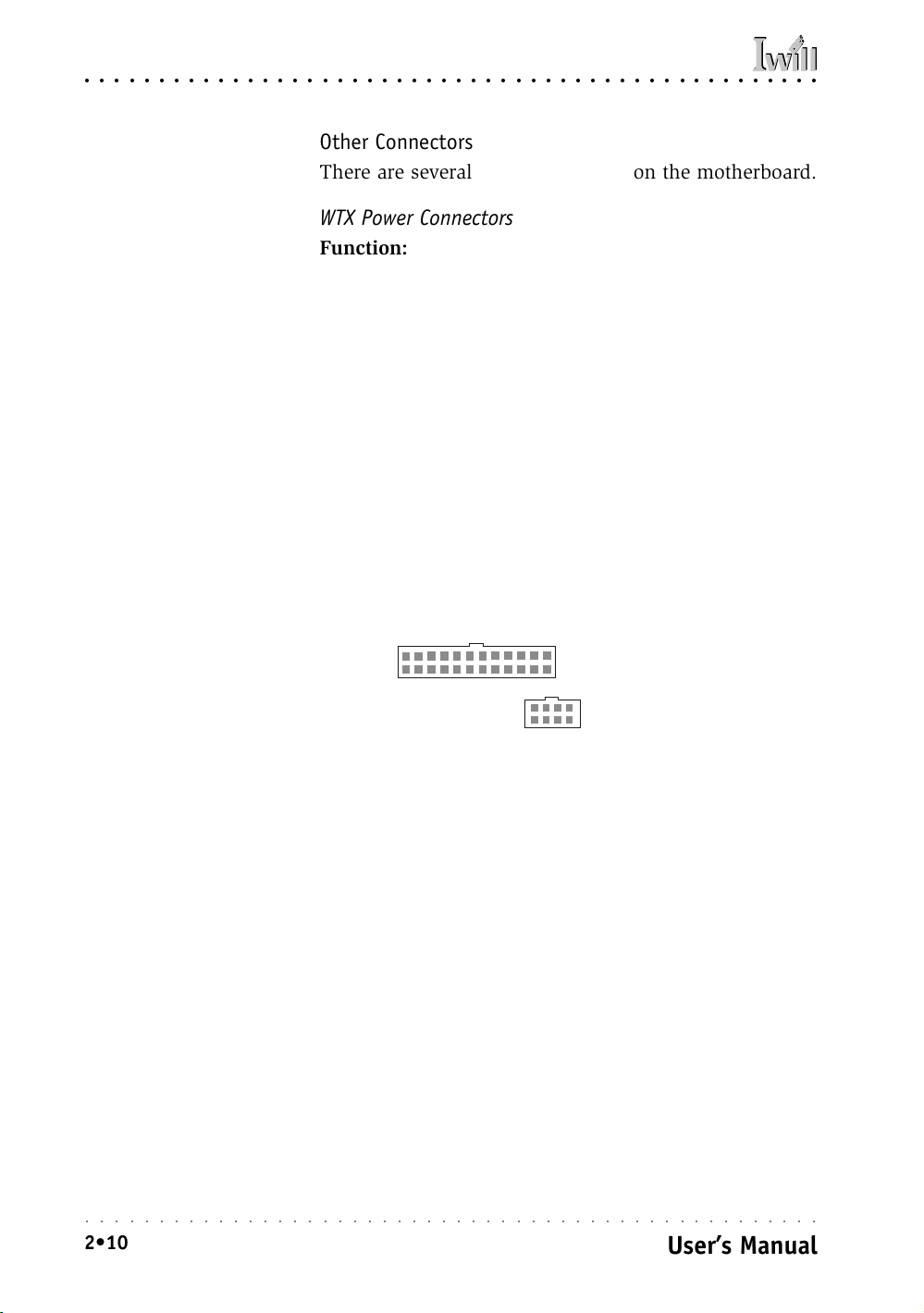

Other Connectors

There are several other connectors on the motherboard.

WTX Power Connectors

Function: Connectors for leads from the system power

supply.

Description: There are two power connectors on the

motherboard for the required WTX power supply. The

power supply leads plug into the connectors. The connector design prevents incorrect orientation. These are

not standard ATX connectors. The 24-pin and 8-pin connectors are for a minimum 430-watt WTX power supply

that complies with the Intel Xeon processor power supply design guidelines.

More Information: Please refer to the following URL –

http://www.iwill.net/dp400/IT002A430WSW.pdf – for

more information on the required power supply specifications.

WTX Power Connectors:

These are for the required

WTX power supply.

2x12 24-pin connector

2x4 8-pin connector

CPU & System Cooling Fan Connectors

Function: Power connectors for CPU and system housing cooling fans.

Description: There are two CPU cooling fan connectors

and four system housing cooling fan connectors. All connectors are 3-pin headers. The system housing fan connectors support fan tachometer monitoring. The processor heat sink fans are not speed controlled.

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

2•10

User’s Manual

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

2: Key Features & Components

The system fans use the motherboard fan speed control,

which consists of three states: Off, Normal speed, and

High speed. In Normal speed mode, the system fans run

at normal speed until the thermal sensor senses the temperature exceeds the High speed fan threshold temperature. The system fans then run at High speed when the

temperature threshold is exceeded. You can set the threshold temperature in the PC Health section of the CMOS

Setup Utility. You can set the threshold to 40°C to force

continuous operation of the system fans in high-speed

mode in the S0 and S1 sleep states.

More Information: Please see the PC Health Status section of “Configuring the CMOS Setup Utility” in Chapter

5 for information.

Cooling Fan Connectors:

The cooling fan power

connectors all use the

Fan power connectors

(orientation varies)

same 3-pin connector. The

System Fan connectors are

speed controlled, the CPU

Fan connectors are not.

WOL: Wake On LAN

Function: A connector for the lead from a Network Interface Card that supports the Wake On LAN feature.

Description: This feature enables the system to “wake

up” from Suspend mode when it receives a signal over a

LAN it is connected to. It works with the onboard LAN

port and will also work with an additional PCI NIC that

supports this feature by connecting the card to the WOL

connector on the motherboard.

The motherboard supports Wake on LAN through the

PCI bus PME# signal and the onboard Intel 82550 LAN

controller. This signal will wake up the computer only

when it is plugged into an AC power source and the system is in a supported sleep state.

More Information: Please see the Power Management

Setup section of “Configuring the CMOS Setup Utility”

Wake On LAN Connector:

This connector is for an

in Chapter 5 for information.

Wake On LAN connector

additional NIC. The

onboard LAN port supports

WOL without using this

connector.

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

User’s Manual

2•11

DP400 Motherboard

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

CD-In & AUX Audio Connectors

Function: Connectors for audio-in cables from internal

peripherals.

Description: The two audio-in connectors on the

motherboard are for audio cables from optical drives such

as a CD-ROM or DVD-ROM drive or a modem/telephony

device. The connectors provide an audio input connection between a device and the integrated AC ‘97 audio

subsystem.

More Information: Please see the Connecting internal

peripherals section in Chapter 5.

Audio-In Connectors:

The CD-In connector is for

CD-ROM or other optical

drives. Use the AUX connector for an additional

drive or a modem/telephony device.

CD-In audio-in connector

AUX audio-in connector

IRDA Connector:

The IRDA connector is for

both IrDA and ASKIR port

modules. You must use the

CMOS Setup Utility to configure the board to use the

IR feature.

IRDA

Function: Connector for an Infrared (IR) port module.

Description: The IRDA connector supports both IrDA and

ASKIR infrared port modules. Follow module instructions

to install.

More Information: Please see the Integrated Peripherals

section of “Configuring the CMOS Setup Utility” in Chapter 5 for information.

IRDA connector

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

2•12

User’s Manual

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

2: Key Features & Components

Chassis Intrusion Switch Connector

Function: Connector for Chassis intrusion switch.

Description: The hardware monitor subsystem supports

a chassis security feature that detects if the chassis (system housing) cover is removed. When the cover is removed, a signal is sent to the hardware monitor component. The chassis intrusion circuit is powered by the system power supply when the computer is connected to

AC power or by the onboard battery when it is not.

This feature uses a mechanical switch on the chassis that

connects to the chassis intrusion connector on the

motherboard. When the chassis cover is removed the

motherboard circuitry will detect the intrusion.

More Information: See the “System Features” section in

Chapter 6.

Chassis Intrusion:

This 2-pin connector con-

Chassis Intrusion Switch connector

nects to the lead from a

chassis-mounted chassis

intrusion switch.

Front Panel Connectors

Function: Multifunction pin header connector for system housing front panel features.

Description: This connector supports the following front

panel features:

• Reset Switch

• IDE device activity LED

• System ACPI Suspend switch

• System Power LED

• Keyboard lock

• Housing-mounted speaker

More Information: See Chapter 4 “Installing the Board

In A System Housing” and Chapter 6, “System Features”.

Front Panel Connector:

Leads from the front panel

Front Panel feature connector

IDE LED ACPIReset

Power On

features connect to this

header.

KL

Speaker

Keyboard Lock

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

User’s Manual

System LED

2•13

DP400 Motherboard

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Battery Connector

Function: Housing for system support battery.

Description: An external lithium coin-cell battery pow-

ers the real-time clock and CMOS memory. When the

computer is not plugged into a wall socket, the battery

has an estimated life of three years. When the computer

is plugged in, the standby current from the power supply

extends the life of the battery.

More Information: See the Standard CMOS Features section of “Configuring the CMOS Setup Utility” in Chapter

5 to adjust the real-time clock settings.

Battery & Housing:

The battery is a CR2032

System support battery

Lithium coin cell.

I/O Ports

There are several external Input/Output ports on the rear

edge of the motherboard. Please refer to the Rear I/O

Panel Ports illustration for the port locations. The ports

are color-coded for easy identification.

PS/2 Ports

Function: Connecting PS/2 devices to the system.

Description: The PS/2 ports are for a system keyboard

and mouse or other pointing device. Do not connect or

disconnect PS/2 devices when the system is turned on.

More Information: See the Advanced Boot Options section of “Configuring the CMOS Setup Utility” in Chapter

5 for information on adjusting related settings.

PS/2 Ports:

Do not plug or unplug devices when the system is

turned on.

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

2•14

PS/2 Mouse

PS/2 Keyboard

User’s Manual

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

2: Key Features & Components

USB Ports

Function: Connecting USB 1.1 devices to the system.

Description: These four ports are for USB devices. Each

pair of ports is controlled by a separate USB root hub.

The ports are for “Type A” USB cable connectors. You

can connect or disconnect USB cables when the system

is turned on.

More Information: See the Integrated Peripherals section of “Configuring the CMOS Setup Utility” in Chapter

USB Ports:

There are four USB ports.

Each pair of ports has its

own Host Controller and

Root Hub.

5 for information on adjusting port settings.

USB ports are paired 1/2, 3/4

LAN Port

Function: Connecting a CAT 5 LAN cable to the system.

Description: This is an RJ-45 connector for standard Cat

5 LAN cabling with RJ-45 jacks. The connector is for the

onboard LAN controller. You can connect or disconnect

a LAN cable when the system is turned on.

More Information: See the System Features section of

Chapter 6 for information LED modes.

LAN RJ-45 Jack:

Left-hand LED = Activity

RJ-45 LAN jack

(on top of USB3, 4 ports)

Right-hand LED = Link

Parallel Port

Function: Connecting a device with a parallel interface

to the system.

Description: The parallel port is generally used to connect a printer to the system. The port supports common

parallel port modes and allows bidirectional communication. Use an IEEE 1284 compliant cable with the default ECP mode configuration.

More Information: See the Integrated Peripherals section of “Configuring the CMOS Setup Utility” in Chapter

5 for information on adjusting port settings.

Parallel port:

The default mode is ECP,

configured as EPP 1.9,

DMA 3. 1284 compliant.

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

User’s Manual

Front Panel feature connector

2•15

DP400 Motherboard

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Serial (COM) Ports

Function: Connecting Serial devices.

The two serial ports have 9-pin connectors. They can

operate at speeds up to 115,200bps. You can configure

the port speed in the computer’s Operating System. Do

not connect or disconnect a serial cable when the system

is turned on.

More Information: See the Integrated Peripherals section of “Configuring the CMOS Setup Utility” in Chapter

5 for information on adjusting port settings.

Serial Ports:

The default configuration

is Serial 1 = COM1 and Serial 2 = COM2. Installing

an IR port requires disabling COM2.

Audio Jacks & AC ‘97 Audio

Function: Jacks for connecting external audio devices to

the onboard AC ‘97 audio subsystem.

Description: There are three audio jacks:

• Line Out

For the two stereo speakers.

• Line In

Audio input connector for an external audio source.

• Mic

Microphone connector for a computer microphone.

More Information: See the Integrated Peripherals section of “Configuring the CMOS Setup Utility” in Chapter

5 for information on AC ‘97 audio settings.

Serials ports 1 & 2

External Audio Jacks:

The onboard AC ‘97 audio

supports stereo speakers,

Line In (Light Blue)

Line Out (Lime)

audio input and a microphone.

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

2•16

Mic

User’s Manual

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

2: Key Features & Components

Jumpers

There are two jumper switches on this motherboard.

Jumpers function like switches to establish a hardware

configuration setting.

JP4 Flash Protect

Function: Sets protection method to prevent accidental

overwriting of installed system BIOS.

Description: A 3-pin jumper.

More Information: See Chapter 3 for configuration in-

formation.

JP4 Flash Protect:

Prevents the accidental

JP4 Flash Protect

overwriting of the system

BIOS.

JP6 Clear CMOS

Function: Clears the CMOS Setup Utility configuration

record stored in the real-time clock’s CMOS memory.

Description: A 3-pin jumper.

More Information: See Chapter 3 for configuration in-

formation and the Troubleshooting section in Chapter 6.

JP6 Clear CMOS:

Leads from the front panel

JP6 Clear CMOS

features connect to this

header.

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

User’s Manual

2•17

DP400 Motherboard

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Software Features

This motherboard comes with driver software and

bundled utility software on the supplied Power Installer

2 CD-ROM disc. The Installing OS & Support Software

section in Chapter 5 explains how to install the software

required to support this motherboard and profiles the

bundled utilities.

Using the Power Installer 2 Disc

You can run the Power Installer 2 CD-ROM install interface under Microsoft Windows NT 4.0, 2000 or XP. The

disc’s install interface should load automatically and you

then click on the model name of this motherboard.

Power Installer 2:

DP400

Main installation screen

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

2•18

User’s Manual

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

2: Key Features & Components

Driver Software

This motherboard requires that you install driver software to support the onboard hardware. You will need to

install the following:

• Intel 860 chipset support software

Various drivers that support the chipset and enhance

system performance.

• LAN driver software

Driver software for the

• Audio driver software

SoundMax audio driver that supports the onboard

AC ‘97 audio.

Please see “Installing OS & Support Software” in Chapter

5 for more information.

Power Installer 2:

DP400

Driver installation screen

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

User’s Manual

2•19

DP400 Motherboard

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Utility Software

The Power Installer 2 disc also has two utility programs

on it, Adobe Acrobat Reader and McAfee Anti-Virus.

• Acrobat Reader

Acrobat Reader allows you to read documents in

the Adobe PDF format, including online documents

on the Power Installer 2 disc and a wide range of

other content. The reader is free and can be upgraded at the Adobe web site – www.adobe.com –

when new versions become available.

• McAfee Anti-Virus

This is anti-virus software from one of the leading

vendors.

• Processor Installation Video

This is an MPEG format video from Intel that ex-

plains in detail how to install the Intel Xeon processor and its heatsink and Processor Wind Tunnel

cooling components. The video is viewable with any

player that can view MPEG format, including Windows Media Player. We highly recommend viewing

this video on another computer first if you will install processors on the motherboard yourself. Clicking on the item in the installer window runs the

video automatically under Windows NT, Windows

2000 or Windows XP.

Power Installer 2:

Utility installation screen

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

2•20

User’s Manual

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

3: Motherboard Configuration

In This Chapter:

The Default Configuration

Hardware Configuration: Jumper Settings

Firmware Configuration: The BIOS CMOS Setup Utility

Reconfiguring the Motherboard

Hardware Reconfiguration

Firmware Reconfiguration

3: Motherboard Configuration

This chapter deatils the motherboard’s default configuration and configuration options. Please review the contents of this chapter to find out information on the default configuration or alternative configuration options

to change the default configuration.

The motherboard will operate properly in the default

configuration. Please make certain that any configuration changes you make will not adversely affect system

operation.

The Default Configuration

The default configuration is set at the time of manufacture. The configuration is comprised of the hardware configuration settings and the default firmware settings in

the BIOS CMOS Setup Utility.

Hardware Configuration: Jumper Settings

This motherboard is mainly configured in firmware, which

simplifies configuration. There are very few hardware settings. The hardware settings are configured using standard jumper switches. The motherboard has only two

jumper switches, JP4, Flash BIOS Protection and JP6,

Clear CMOS.

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

User’s Manual

3•1

DP400 Motherboard

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Jumper JP4: BIOS Flash Protect

The system BIOS and CMOS Setup Utility are stored in

Flash memory on the motherboard, which provides permanent storage, but is rewritable, allowing for BIOS updates. Jumper JP4 controls the protection scheme that

prevents accidental damage to or rewriting of the data

stored in Flash memory.

JP4 has three setting options which allow the BIOS to be

protected either by a firmware setting in the Security Features section of the CMOS Setup Utility or by the jumper’s

hardware setting. The firmware setting option is more

convenient, so it is the default setting for this jumper.

The setting options are listed in the table below.

JP4: BIOS Flash Protect

Setting Function

Short 1-2 Protection mode selected in BIOS CMOS Setup Utility [Default]

Short 2-3 Protection enabled in hardware

Open [Remove Cap] No BIOS Flash Protection

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

3•2

User’s Manual

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

3: Motherboard Configuration

BIOS CMOS Setup Utility – Security Features

The Security Features section of the CMOS Setup Utility has

a BIOS Flash Protect item that controls BIOS flash protection. The default setting is “Non-Flash”. The optional set-

ting is “Flashable”. See the section on “Configuring the

CMOS Setup Utility in Chapter 5 for information on how to

use this program.

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

User’s Manual

3•3

DP400 Motherboard

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Jumper JP6: Clear CMOS Memory

JP6 is a jumper switch, but it does not set a hardware

configuration setting. The BIOS CMOS Setup Utility creates a system configuration record that is stored in CMOS

memory in the real-time clock chip. If the configuration

record data becomes corrupted or is destroyed, or if the

CMOS Setup Utility settings are changed to an unusable

configuration, the motherboard may not run properly or

at all. JP6 provides a means to delete the configuration

data stored in CMOS memory and reset the configuration

to the CMOS Setup Utility’s Optimized Defaults.

JP6: Clear CMOS Memory

Setting Function

Short 1-2 Normal operation [Default]

Short 2-3 Clear CMOS memory – see instructions

Follow this procedure to clear CMOS memory. The jumper

is beside the coin battery. If necessary, refer to the board

diagram and key in Chapter 2 for the location of the JP6

jumper.

1. Turn off and unplug the system. Remove the system

housing cover (see documentation if necessary).

2. Set JP6 to the Clear CMOS position by placing the

jumper cap over pins 2 and 3 for one minute.

3. Return the jumper cap to the Normal position.

4. Replace the system housing cover, plug in the system and turn it on.

5. Run the CMOS Setup utility and load the Optimized

Defaults. You can then enter any custom settings

you require.

6. Save the settings as you exit the program and restart

the computer.

The system should now operate normally.

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

3•4

User’s Manual

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

3: Motherboard Configuration

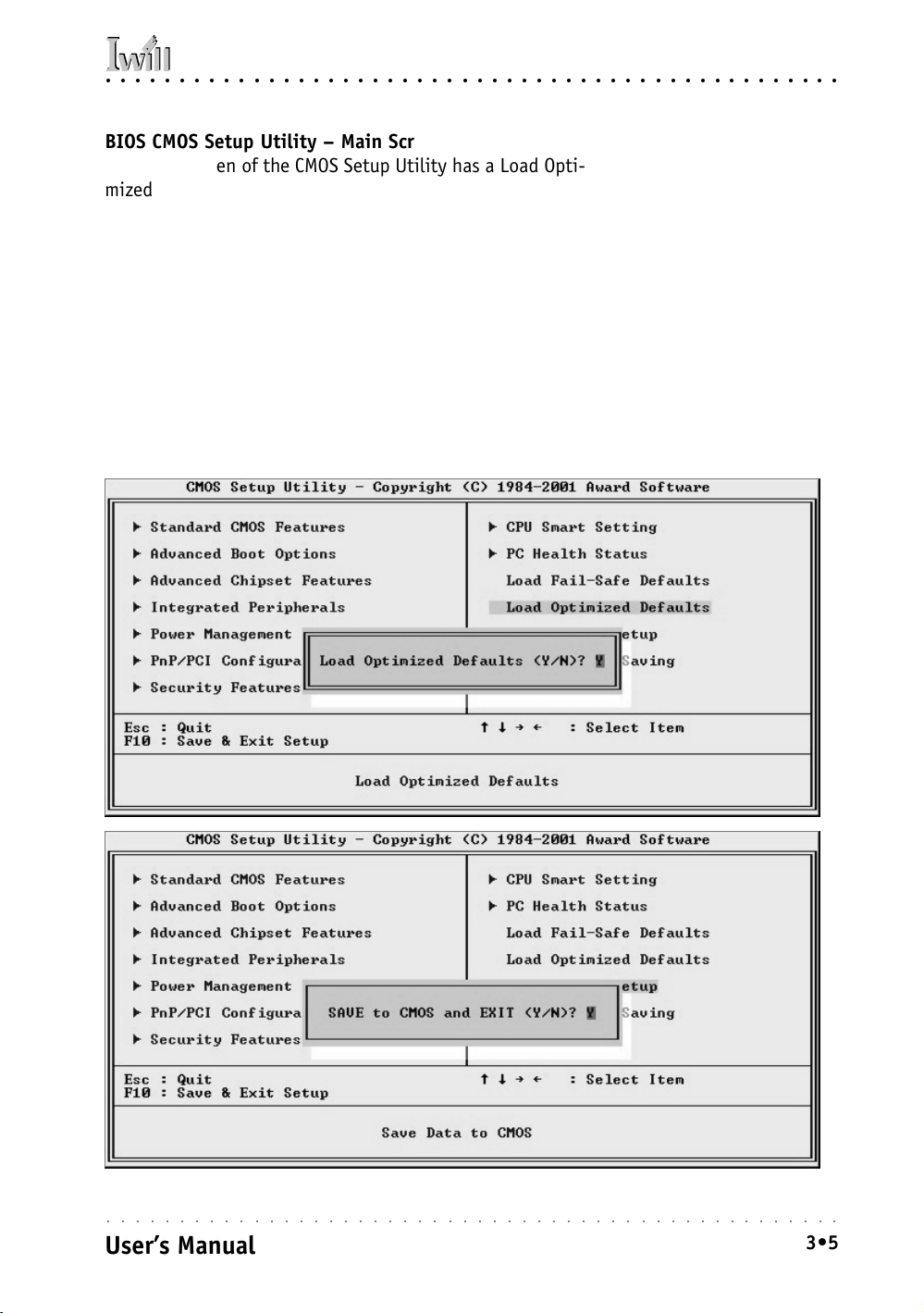

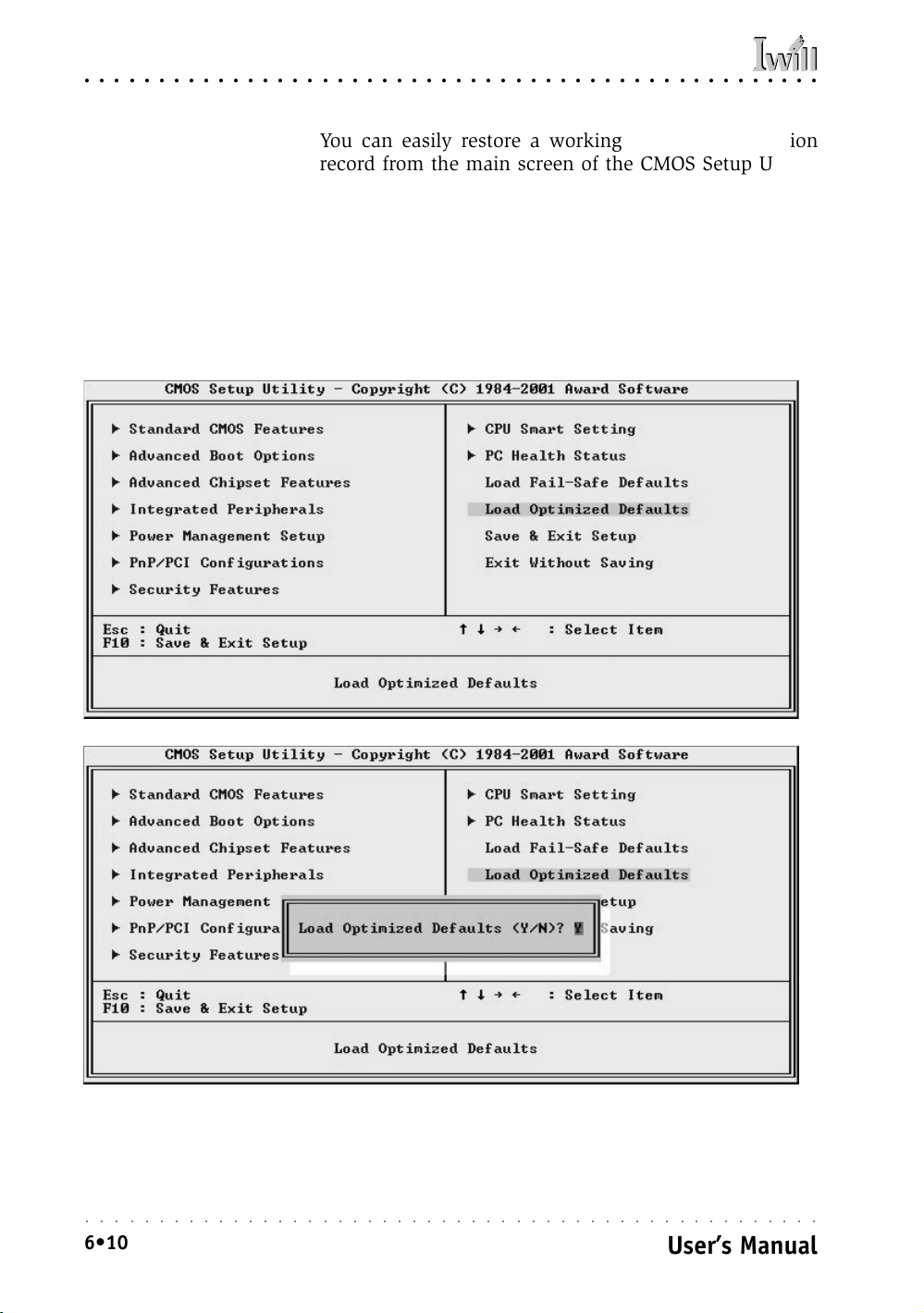

BIOS CMOS Setup Utility – Main Screen

The main screen of the CMOS Setup Utility has a Load Optimized Defaults item that loads the default operation settings. After you perform the Clear CMOS procedure, loaad

the defaults as follows:

1. Select Load Optimized Defaults and press the Enter key.

2. A message will appear asking you to confirm.

3. Type a Y to confirm and press the Enter key again.

4. Make other settings you require.

5. Select Save & Exit Setup and press the Enter key.

The system will restart and use the new settings.

See the section on “Configuring the CMOS Setup Utility in

Chapter 5 for information on how to use this program.

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

User’s Manual

3•5

DP400 Motherboard

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Firmware Configuration: The CMOS Setup Utility

The BIOS CMOS Setup Utility a configuration record of

system settings. This record is based on the “Optimized

Defaults that are stored with the utility in Flash memory

and can be reloaded at any time.

Many of these settings are either recommended or required for the motherboard to operate properly. Other

settings are customizable and can be changed to suit your

specific system configuration and operation requirements.

A number of the variable settings, such as CPU and IDE

device settings are set to be automatically detected in the

default configuration. While these settings can also be

established manually, automatic detection is more convenient, safe and reliable. We strongly recommend that

you leave all auto-detection settings undisturbed unless

you have a specific reason not to and you are certain of

what you are doing. Incorrect configuration of the CMOS

Setup Utility can result in unreliable operation or a failure of the motherboard to work at all.

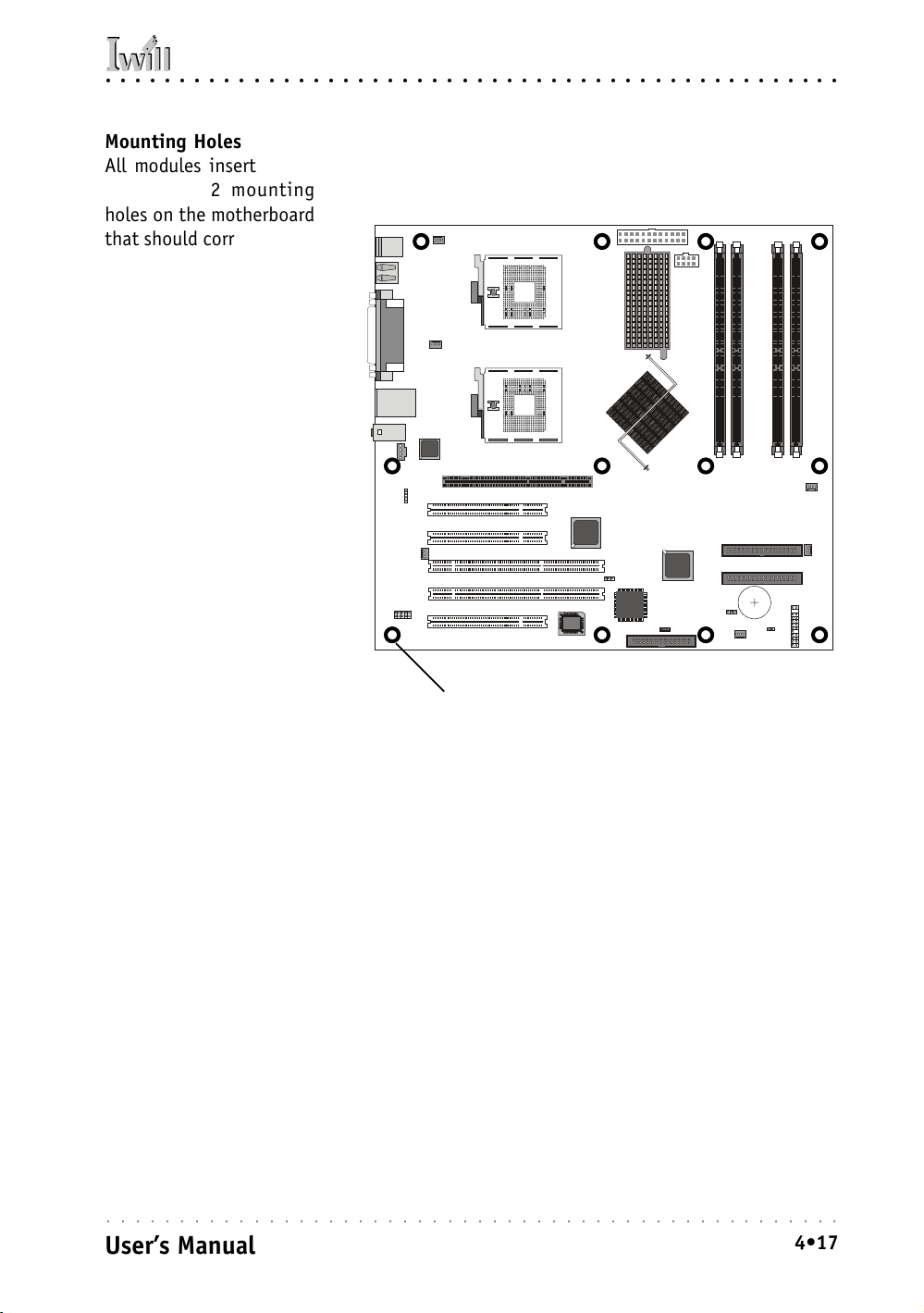

Using the CMOS Setup Utility

Please refer to the “Configuring the CMOS Setup Utility”

section in Chapter 5 for information on using the utility

and some settings you might want to customize. The utility

does not run under an Operating System. You must load

it during the Power On Self Test (POST) while the computer is starting up by press the Delete key or the Del key

on the system keyboard’s numeric keypad.

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

3•6

User’s Manual

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

3: Motherboard Configuration

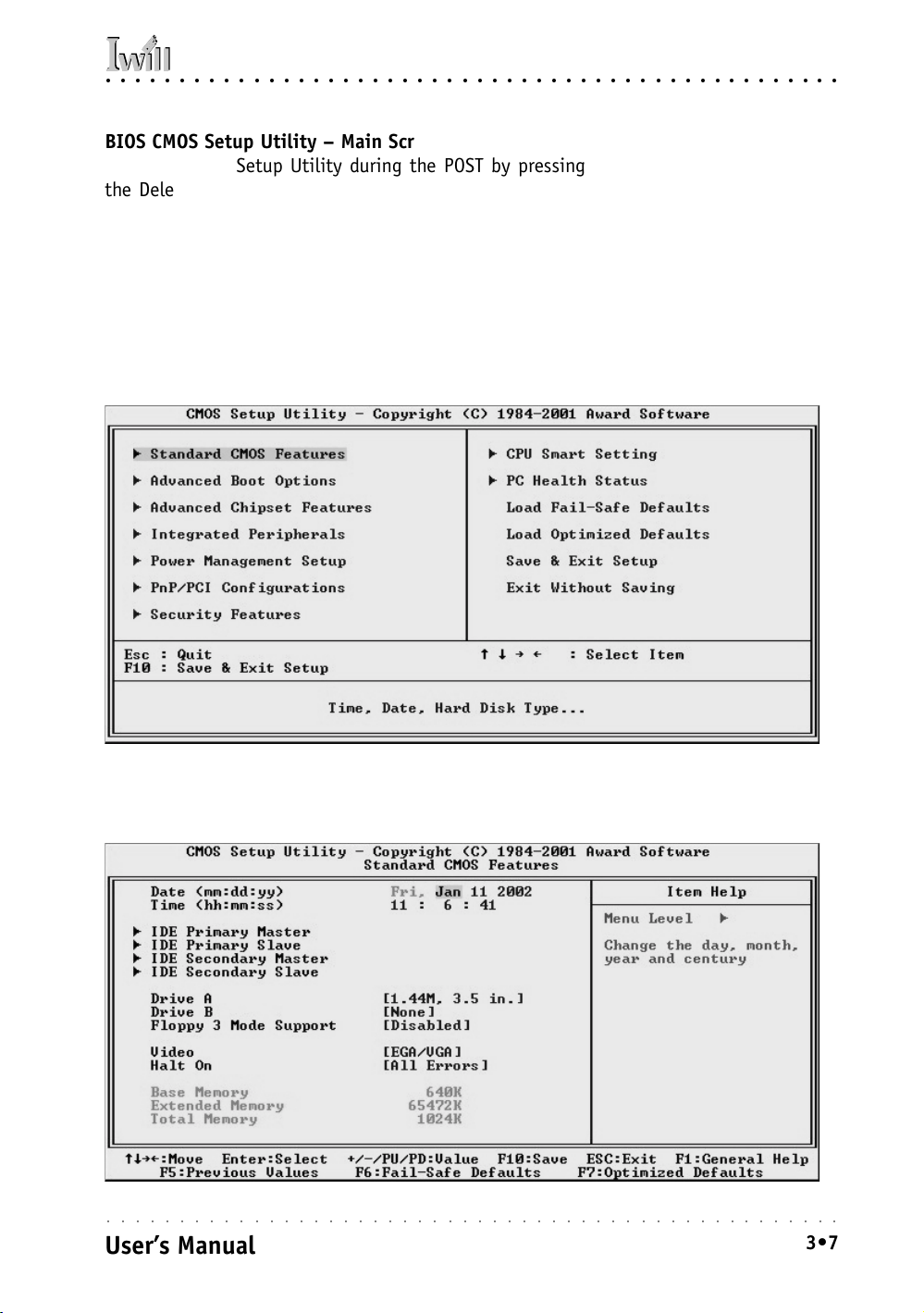

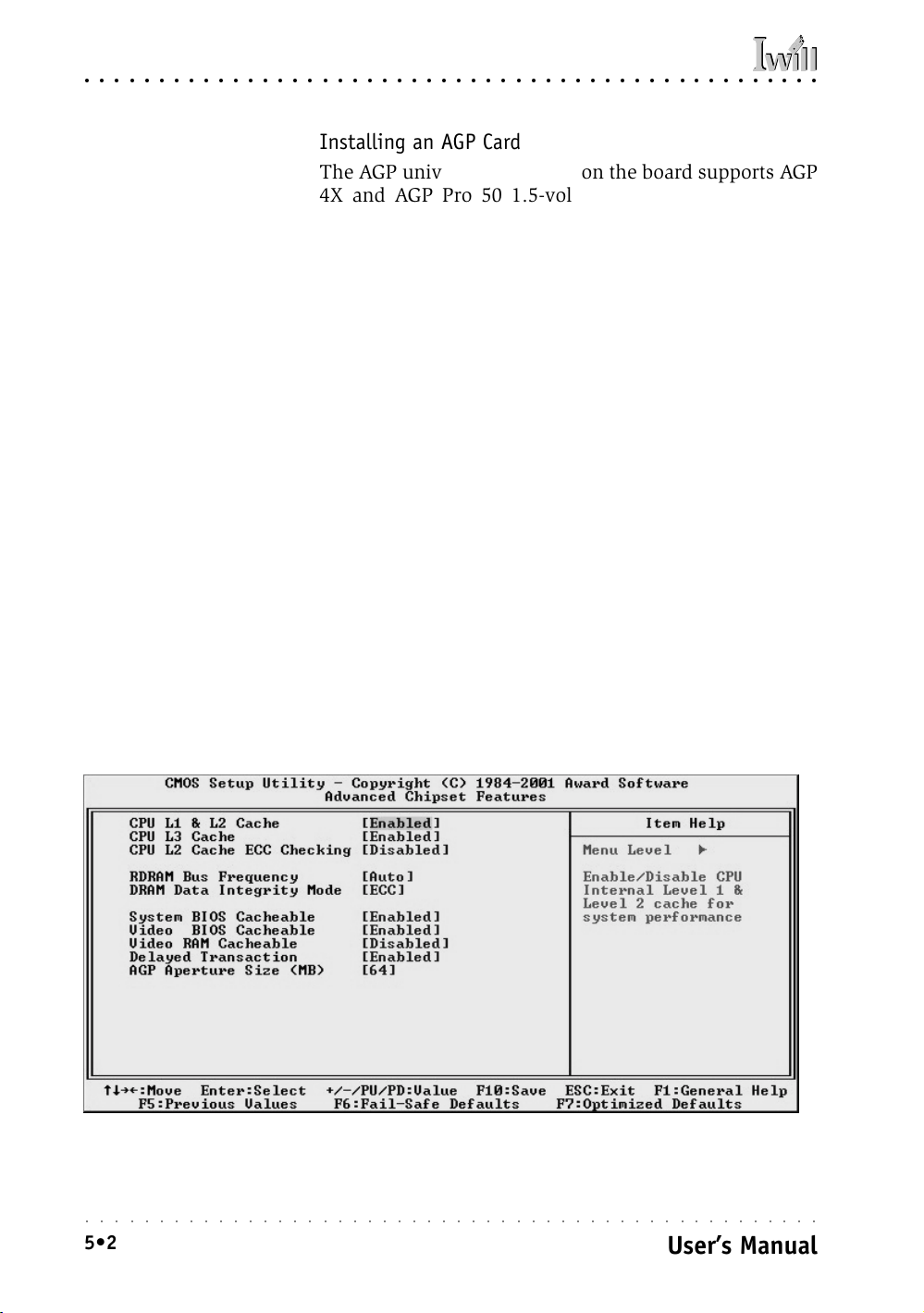

BIOS CMOS Setup Utility – Main Screen

Load the CMOS Setup Utility during the POST by pressing

the Delete or Del key. The utility interface commands are

explained at the bottom of each screen and “General Help”

is available by pressing the F1 key. See the section on “Con-

figuring the CMOS Setup Utility in Chapter 5 for information

on how to use this program.

The main screen has a basic list command instructions at the

bottom of the screen and displays a function description of

the highlighted item.

Sections marked by an arrow on the main screen list command

instructions at the bottom of the screen.

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

User’s Manual

3•7

DP400 Motherboard

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Reconfiguring the Motherboard

You can change the default configuration (as shipped) of

this motherboard as needed. However, since this

motherboard very few hard configuration options and

the CMOS Setup Utility is configuration is mostly either

required, recommended or automatic, there will probably be little reason to do so.

Hardware Reconfiguration

We recommend leaving the two jumper settings at the

default settings unless you need to perform the Clear

CMOS procedure. It is much more convenient to control

the BIOS Flash Protection feature using the CMOS Setup

Utility.

Firmware Reconfiguraton

You can initially specify or customize the CMOS Setup

Utility settings when you first configure the system (as

covered in Chapter 5) to meet your requirements. Other

than doing this, there should be no need to reconfigure

the CMOS Setup Utility unless the system configuration

changes or the configuration record stored in CMOS

memory becomes corrupted and unusable, which is not

common. If you need to completely recreate the system

configuration record, follow the Clear CMOS procedure

described in this chapter.

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

3•8

User’s Manual

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

4: Installing The Motherboard

In This Chapter:

Pre-Installation Preparation

Installing CPUs

Installing System Memory

Installing the Motherboard in a System Housing

Motherboard Installation Procedure

EEB 3.0 Housing Installation

Completing System Configuration

4: Installing the Motherboard

This chapter covers preparing the motherboard for installation, installing the board in a system housing or

“chassis” and installing or connecting other internal system components.

There are a number of important topics in this chapter

and we strongly urge that you review it before attempting to install the motherboard.

Pre-installation Preparation

Before you install the motherboard you will need to do

the following:

• Install one or two Intel Xeon CPUs

• Install Rambus system memory modules

Both of these require specific procedures that you must

follow precisely to insure that the components are successfully installed and work properly. Please review the

instructions in this section in detail and follow them carefully. The procedures are not complex.

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

User’s Manual

4•1

DP400 Motherboard

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Installing CPUs

This motherboard uses the Intel Xeon processor. Both

single and dual CPU configurations are supported on this

motherboard.

To install an Intel Xeon CPU on the motherboard it is

very important to precisely an entirely follow the procedure for installing both the CPU and its cooling assembly. Failure to do so can result in either improper operation or damage to the CPU and possibly the motherboard.

To install an Intel Xeon processor on this motherboard

you will need to do the following:

• Install the Xeon processor in a Socket 603

• Install the Heatsink Retention Mechanisms

• Install a Xeon-specific Heatsink

• Install the Processor Wind Tunnel assembly

Please follow the procedure detailed below to install one

or two Xeon processors on the board. Intel boxed Xeon

processors come with full installation instructions. If you

have these, please also read and follow those instructions carefully.

Required Tools:

• Philips-head screw driver

(Crosshead)

• Flathead screw driver

Processor Selection

This motherboard supports all Xeon processors and the

BIOS automatically detects the required settings and configures the CMOS Setup Utility accordingly. If you install

two Xeon processors, they must have identical specifications.

Installation Video

There is a Xeon processor installation video from Intel

in MPEG format on the Power Installer 2 support CDROM disc. You can access it from the Power Installer 2

interface in the Software Utility section. It is listed as

“Processor Installation”. We strongly recommend that you

view this video on another computer if you have not

installed a Xeon processor before. The video will play

with any software that can play the MPEG format, including Windows Media Player.

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

4•2

User’s Manual

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

4: Installing The Motherboard

Processor Installation

Video:

There is an instructional

video from Intel on the

Power Installer 2 disc that

fully details the Xeon processor installation procedure. You can access the

video in the Software Utility section of the disc interface. The video will play

with any software that

supports the MPEG format.

We suggest viewing it on

another computer before

installing a CPU.

Note:

If you are only installing

one CPU, install it in the

CPU0 socket.

Installing The Processor

Installing a Xeon processor in the Socket 603 is the simplest part of the procedure. It is very important, however, to carefully handle the processor by the side edges

and always fully observe precautions against electrostatic

discharge.

Please follow the installation procedure as illustrated on

the next two pages. The illustrations are generic and do

not specifically represent this motherboard.

Xeon Processor package

(Clockwise from lower left):

• Xeon processor

• TIM applicator

• Heatsink

• Procesor Wind Tunnel

• Retention Mechanisms

• Heatsink clips

• Mounting screws

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

User’s Manual

4•3

DP400 Motherboard

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

The processor installation procedure is as follows:

1. Raise the retaining lever of the processor locking

mechanism to a perpendicular position.

Step 1:

Raise the retaining lever

Step 2:

Align the Pin 1 corners

Raise the socket lever to the

vertical position

2. Align the processor to the socket by matching the

Pin 1 corner of the socket (marked with a triangle)

to the Pin 1 corner on the Socket 603 (marked by a

triangular hole in the Pin 1 corner).

Match the Pin 1 positions on

the socket and the processor

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

4•4

User’s Manual

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

4: Installing The Motherboard

3. Carefully insert the Xeon processor in the socket re-

ceptacles, taking care not to bend any pins.

Step 3:

Insert the processor

Step 4:

Secure the retaining lever

Gently press the processor

into the socket. Make sure the

retaining lever is vertical.

4. Lower the locking mechanism’s retaining lever and

secure it in place to secure the processor in the

socket. Grasp the processor by the edges and gently

pull upwards to insure it is properly inserted. The

processor shouldn’t move.

Presss the retaining lever

back down into the horizontal

position and make sure it

latches in place.

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

User’s Manual

4•5

DP400 Motherboard

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

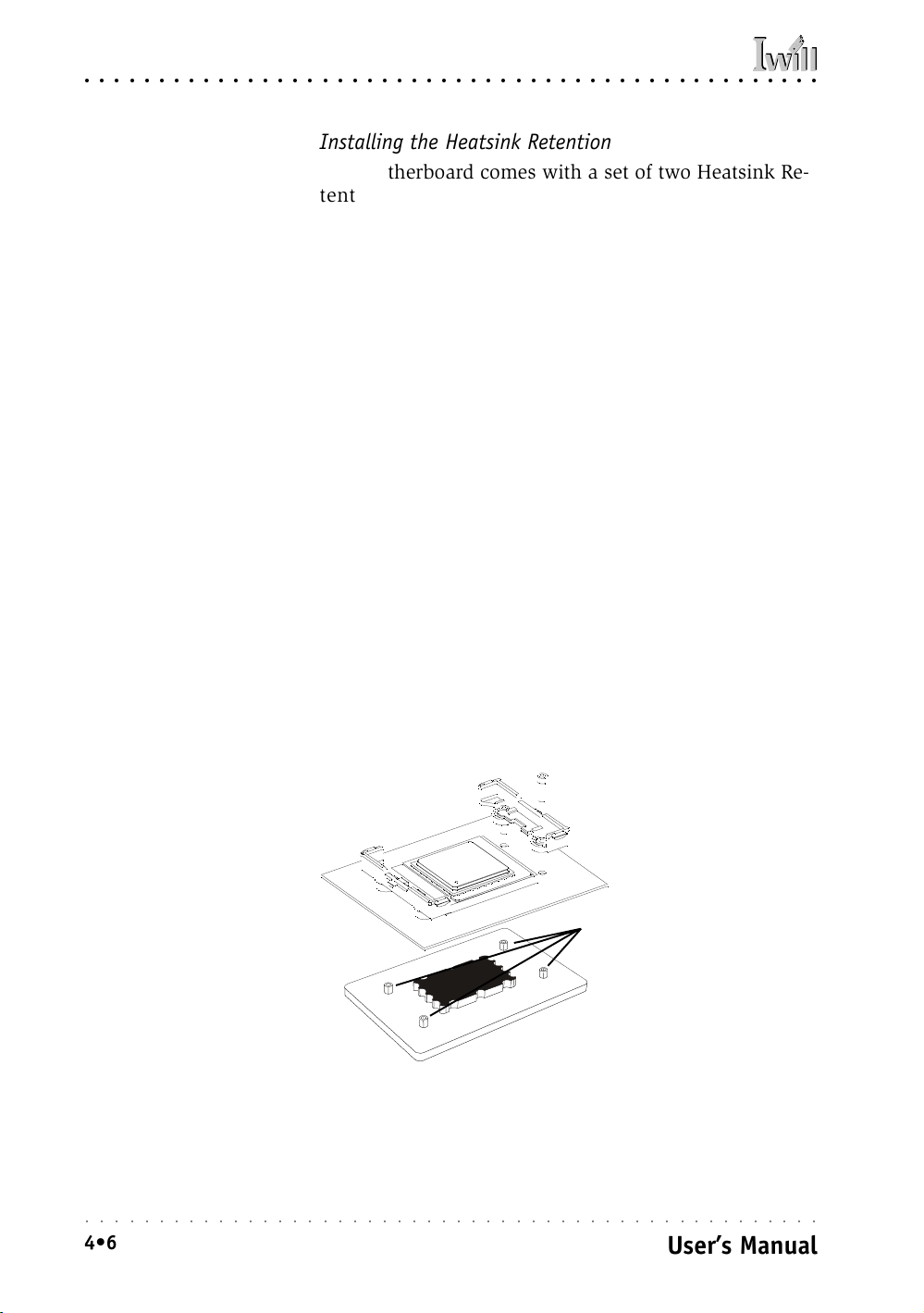

Installing the Heatsink Retention Mechanisms

The motherboard comes with a set of two Heatsink Retention Mechanisms. You must attach these to the

motherboard before installing the processor heatsink. If

you are installing a boxed Intel Xeon processor, it will

also come with two Retention Mechanisms, you can use

either set.

The mechanism attaches to the motherboard with the

supplied screws which screw into either a supplied CPU

Backplate or into the standoffs of an EEB 3.0-compliant

system housing (chassis).

We’ve assumed here that you are installing the

motherboard in a non EEB 3.0 chassis and therefore

will use a supplied CPU Backplate. If this is not the

case, please first install system memory as described

later in this chapter. Then install the Heatsink Retention

Mechanisms, Heatsink and Processor Wind Tunnel after the board is installed.

To install the supplied heatsink retention mechanisms,

do as follows:

1. Align the four standoffs on a CPU Backplate (mounting nuts attached to the plate) to Retention Mechanism mounting holes around one of the CPU sockets on the motherboard.

Step 1:

Align the CPU backplate

Mounting standoffs

CPU Backplate

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

4•6

User’s Manual

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

4: Installing The Motherboard

2. Align a Retention Mechanism to two of the mount-

ing holes in the board so that the mechanism is facing in towards the CPU socket.

Step 2:

Position the Retention

Mechanism

Step 3:

Attach the mechanism &

CPU Backplate with screws

Position the mechanism

facing in towards the CPU

socket.

3. Insert one of the supplied screws in each hole in the

mechanism so that it inserts in a matching standoff

on the CPU Backplate. Tighten the screws until they

are snug. Don’t overtighten the screws.

Insert & tighten the mounting screws so that they screw

into the CPU backplate

4. Repeat the same procedure to attach the second Re-

tention Mechanism on the opposite side of the CPU

socket. The mechanisms should hold the CPU

Backplate securely against the underside of the

motherboard.

If you are installing two CPUs, repeat this procedure on

the CPU1 socket.

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

User’s Manual

4•7

DP400 Motherboard

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Installing the Heatsink

Once you have attached a set of Retention Mechanisms,

you must install a Heatsink. The Heatsink attaches to the

Retention Mechanisms with the two supplied Heatsink

retaining clips.

Apply Thermal Interface Material

Before you install the heatsink you must apply the Thermal Interface Material (TIM) that is supplied in an applicator with boxed intel Xeon processors (or an exact

equivalent) to the heat spreader on the installed CPU.

We assume here that you have TIM in an Intel-supplied

applicator. To apply TIM to the CPU do as follows:

1. Apply all of the TIM in the applicator to the center

of the square heat spreader plate in the middle of

the CPU.

2. Do not spread the TIM around. When you place the

Heatsink on top of the CPU the material will disperse evenly.

Apply TIM

Apply all of the Thermal

Interface Material to the

center of the processor

heat spreader plate

Position the Heatsink

place the Heatsink on top

of the CPU so that it fits

into the Retention Mechanisms.

Don’t spread the TIM out with

the applicator tip. The

Heatsink will disperse it.

Next, install the processor Heatsink as detailed below.

Install the Heatsink

To install a processor Heatsink do as follows:

1. Place the Heatsink on top of the Xeon CPU so that it

fits into the recesses in the Retaining Mechanisms.

The Heatsink base is rectangular and will only fit

into the mechanism frame in the correct orientation.

Don’t spread the TIM out with

the applicator tip. Wiggle the

Heatsink a little after you

position it to disperse the

Thermal Inteface Material.

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

4•8

User’s Manual

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

4: Installing The Motherboard

2. Place a heatsink retaining clip on one of the Reten-

tion Mechanisms so that the large outer center tab

is on the outside and fits over the extension on the

Retention Mechanism. The inner center tab should

clip over the edge of the Heatsink.

Position Heatsink Clips

Position a clip on each Retention Mechanism.

Attach Heatsink Clips

Press the clip ends onto

Retention Mechanism.

position the clip so that the

large tab is on the outside

and fits over the mechanism

extension there

3. Hold the clip down against the mechanism and press

down on one end of the retaining clip so that the

tab on the end clips securely over the extension on

that end of the mechanism.

4. Press the other end of the retaining clip down so

that it clips securely over the extension at the other

end of the mechanism. The spring tension of the

clip should now hold that side of the heatsink securely against the Retention Mechanism.

Hold the clip down in the

middle while you press the

each end of the clip onto the

Retention Mechanism

5. Repeat the procedure above on the Retention Mecha-

nism on the other side of the Heatsink.

After you install the two retaining clips, the Heatsink

should be securely attached.

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

User’s Manual

4•9

DP400 Motherboard

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

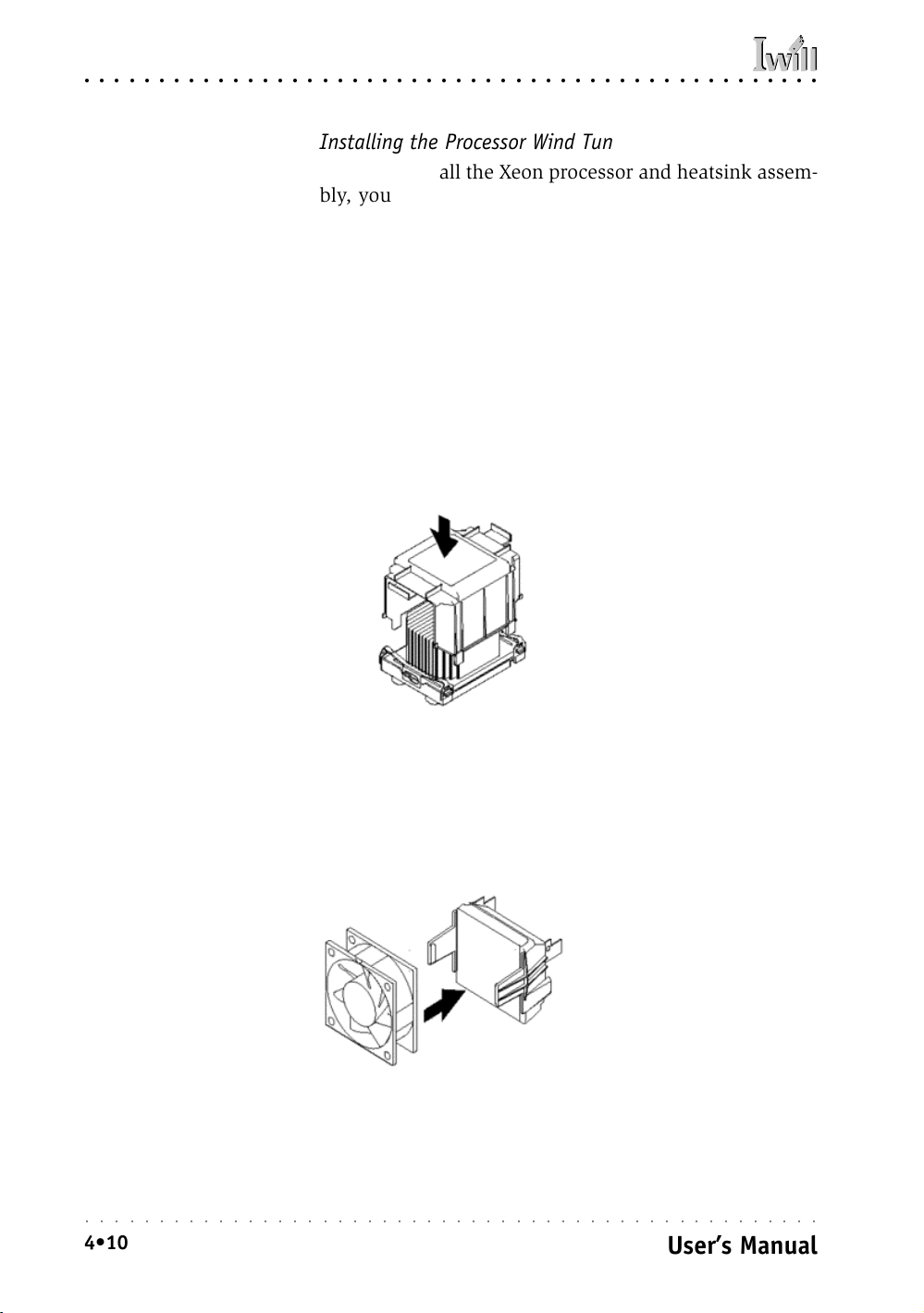

Installing the Processor Wind Tunnel

After you install the Xeon processor and heatsink assembly, you must install the Processor Wind Tunnel (PWT)

assembly. The PWT has three parts:

• Shroud

• Fan Assembly (fan with mounting frame)

• PWT End Cap

You install these components separately and in order as

follows.

Install Shroud

First install the PWT shroud:

1. Clip the shroud onto the retaining mechanisms at

the corners. It should fit onto the mechanism corners and the flexible tabs should snap into place.

Step 1:

Attach the PWT shroud

Step 1:

Clip the fan mount onto

the fan

Press the shroud down onto

the Retention Mechanisms

untl it snaps into place

Attach Fan Assembly

Next attach the cooling fan:

1. Clip the fan mounting frame onto the cooling fan.

Orient the fan so that it will blow air into the PWT

Shroud.

Orient the fan so that it

blows toward the Heatsink

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

4•10

User’s Manual

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

4: Installing The Motherboard

2. Insert the fan mounting frame tabs into the holes on

the forward side of the PWT Shroud. The plastic

tabs should snap securely into place.

Step 2:

Insert the PWT fan mount

into the PWT shroud

Step 3:

Insert the PWT end cap

into the PWT shroud

Press the fan mount into the

shroud so that it snaps into

place securely

Attach End Cap

1. Insert the End Cap tabs into the holes on the rear

side of the PWT Shroud. The plastic tabs should

snap securely into place.

Press the end cap into the

shroud so that it snaps into

place securely

Connect Power Lead

Plug the fan power lead onto the CPU Fan power connector for that CPU socket. The entire CPU installation is

then complete.

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

User’s Manual

4•11

DP400 Motherboard

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Installing System Memory

This section details the procedure for installing system

memory on the motherboard. Correct memory configuration is critical for proper system operation. Please review this section carefully and follow the configuration

guidelines precisely.

Memory Specifications

The motherboard has four RIMM module sockets. The

sockets operate in pairs. This motherboard uses Rambus

DRDRAM RIMM modules for system memory. The system memory specification are:

• Rambus DRDRAM RIMM modules

• PC600 or PC800

• Maximum 2GB total system memory

Memory Configuration Options

This motherboard has specific memory configuration requirements. These include:

• All sockets must have either RIMM or CRIMM modules installed in them.

• Module configurations are limited as specified.

• Any capacity RIMM may be used in any socket as

long as total memory does not exceed 2GB.

• Modules should all be the same speed (PC600 or

PC800) for best system performance.

Module Types

There are two modules types:

• RIMM

• CRIMM

The RIMM (Rambus Inline Memory Module) is a Rambus

DRDRAM memory module. The CRIMM (Continuity

Rambus Inline Memory Module) is not a memory module. CRIMMs must be installed in all sockets that do not

have RIMMs installed in them. No sockets can remain

empty in this memory design.

Module Configurations

The figures on the next page illustrate the allowed module configurations. Do not install modules in any other

configuration. Please note the configurations indicate

module positioning, not capacity. You can install any

mixture of module capacities that does not exceed 2GB.

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

4•12

User’s Manual

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

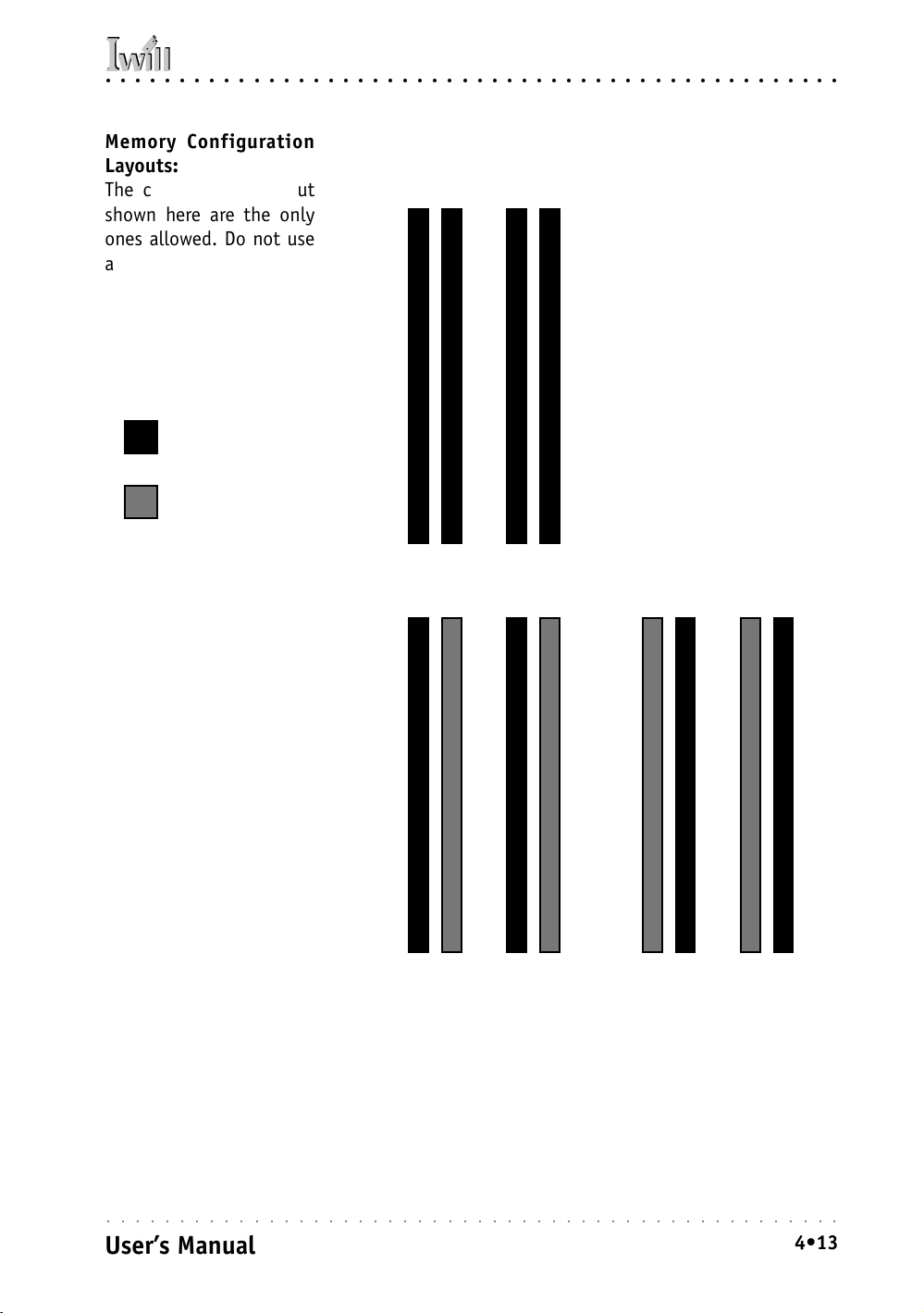

4: Installing The Motherboard

Memory Configuration

Layouts:

The configuration layout

shown here are the only

ones allowed. Do not use

any other layout of RIMM

and CRIMM modules. All

sockets MUST have some

kind of module installed.

RIMM module

CRIMM module

Each bank of two sockets

muct have at least one RIMM

installed

0123

0123 0123

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

User’s Manual

4•13

DP400 Motherboard

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Installing Memory Modules

Installing RIMM or CRIMM modules is simple. The modules insert in the sockets and are held in place by the

socket retaining arms. The edge connectors on the modules are of different widths and there are key notches in

the center of each module. These ensure that you can not

insert a module incorrectly.

Before you install any modules, you should review the

configuration requirements and choose a configuration.

You should then prepare the required number of RIMM

and CRIMM modules.

To install either type of module follow this procedure:

1. Align the module to the socket so that the edge

connectors on the module match the socket sections.

2. Hold the module perpendicular to the motherboard

and press the edge connector into the socket.

3. Press the module fully into the socket so that the

socket retaining arms swing up and engage the retention notches at each end of the module.

Following the configuration pattern you have chosen,

repeat this procedure until all modules are installed. Recheck the configuration pattern guide and confirm that