TRN1 | TRN2

Operating Instruction Manual

Iwata Revolution Series and NEO For Iwata Series airbrushes deliver soft, eortless coverage at low air pressures.

Fine atomization is achieved with the smallest of air compressors, making these airbrushes a simple choice for medium

spray applications and for anyone wanting to start airbrushing for the rst time.

1

NEED ASSISTANCE

If you have any issues or warranty service questions, contact your

local ANEST IWATA aliate before returning to your place of purchase.

ANEST IWATA-MEDEA, INC.

Portland, Oregon U.S.A.

+1-503-253-7308 (M-F)

info@iwata-medea.com

www.iwata-airbrush.com

ANEST IWATA SOUTH-EAST ASIA CO., LTD.

Bangkok, Thailand

+66-(0)-2643-2870

www.anest-iwatasoutheastasia.com

ANEST IWATA SOUTH AFRICA (PTY) LTD.

Johannesburg, Republic of South Africa

+27-11-463-2169/2265/2223

www.anest-iwata.co.za

ANEST IWATA CORPORATION

Yokohama, Japan

+81-(0)45-591-1111

www.anest-iwata.co.jp

ANEST IWATA STRATEGIC CENTER

Cardano al Campo, Italy

+39-0331-733120

www.anest-iwataeu.com

ANEST IWATA SHANGHAI

Shanghai, China

+86-(0)21-6407-9713 / 15 / 16

www.anest-iwata-sh.com

ANEST IWATA RUS LLC

Moscow, Russia

+7-495-938-77-28

www.anestiwata.ru

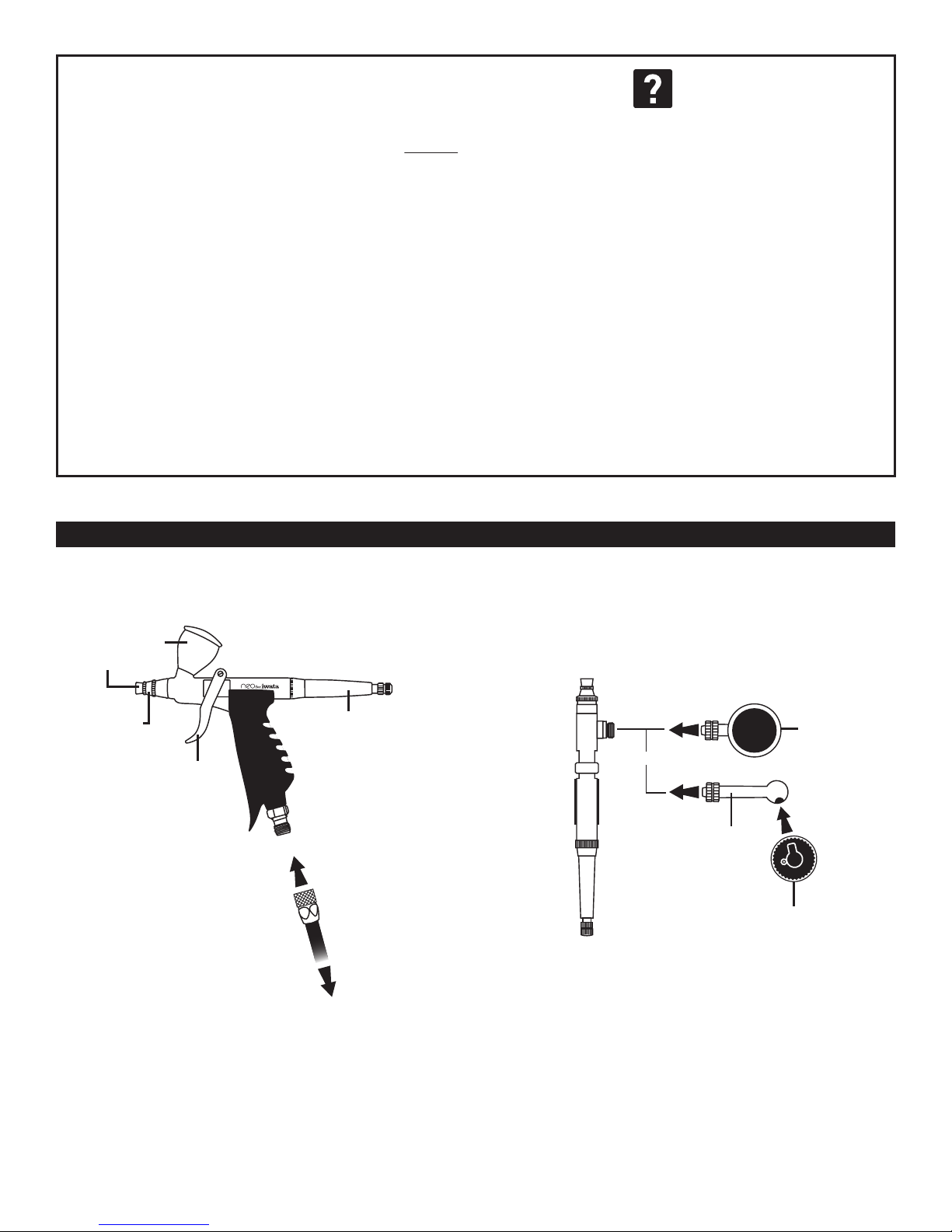

ASSEMBLY

1. Screw the air hose onto the airbrush (Iwata air hose sold separately).

2. Screw the air hose onto the compressor.

color cup

needle cap

TRN1

TRN1 GRAVITY FEED

TRIGGER AIRBRUSH

ANEST IWATA AUSTRALIA PTY LTD.

Mt. Druitt, NSW

+61-(02)-9853-2000

www.anest-iwata.com.au

ANEST IWATA (U.K.) LTD.

Neots Cambs, England

+44-(0)1480-405419

www.anest-iwata.co.uk

ANEST IWATA MOTHERSON LTD.

Uttar Pradesh, India

+91-(0)120-4600500 / 14 / 17

www.aircompressors.com

CENTURY TRADING CO., LTD.

Seoul, Korea

82-2-2163-0300

www.centrading.co.kr

TRN2 SIDE FEED

TRIGGER AIRBRUSH

nozzle cap

trigger

TO AIRBRUSH

TO COMPRESSOR

handle

air hose

side feed

cup

OR

side feed

adapter

bottle

2

GENERAL OPERATION

Quick Start Guide

For further in-depth instruction and information, please go to

www.iwata-neo.com

Fine-Line Spray

1. Depress the main lever to start air flow.

2. Position the airbrush close to the surface, between 1/16 and 1/2 inch is

common.

3. Pull the main lever back slightly to start the flow of paint.

Line thickness can be controlled by adjusting the distance between the

airbrush and the surface and also by varying the paint flow by manipulating

the main lever’s position.

Wide-Line and Background Spraying

1. Depress the main lever.

2. Position the airbrush further away from the surface, from 1 to 6 inches is

common.

3. Pull the main lever back much farther releasing more paint to cover the

bigger area.

Increase the distance between the airbrush and painted surface to co nt rol t he

line’s width. Increasing the air pressure will also affect the spray width.

Air Pressure

For the NEO, working pressures generally vary between 10 and 60 psi, depending on what type of work is being done and what textures are desired.

A good working

MAINTENANCE

Cleaning the Airbrush (TRN2)

1. Remove the paint bottle.

2. Attach a bottle containing the appropriate cleaning solution. (Note:

Medea Airbrush Cleaner works great for water-based media.)

3. Spray until the solution sprays clear.

4. Remove the bottle of cleaning solution.

5. Spray air until the airbrush sprays dry.

6. Attach a bottle containing the next color.

7. Repeat cleaning procedure when nished.

Cleaning the Airbrush (TRN1)

1. Dump out the color cup’s excess paint.

2. Rinse the cup with the appropriate cleaning solution. (Note: Medea

Airbrush Cleaner works great for water-based media.)

3. Use a paper towel to wipe out any left-over paint.

4. Fill the bottom of the cup with cleaner.

5. Spray cleaner until the spray is clear.

6. Add the next color to the color cup.

7. Repeat cleaning procedure when nished.

Cleaning the Needle (TRN2, TRN1)

Before removing the needle, clean the airbrush as recommended.

1. Unscrew the handle from the airbrush body.

2. Loosen the needle chucking nut.

3. Gently pull the needle straight out.

4. Fold a soft cloth damp with cleaner over the needle.

5. Rotate the needle to gently wipe the residual paint off.

6. Carefully insert the needle into the airbrush until it seats fully against

the nozzle.

CAUTION: The most probable time to damage the needle is when the

needle passes through the main lever. If the needle stops abruptly, retract

and examine the trigger mechanism for proper assembly and re-insert

the needle.

pressure may average around 15-25 psi. The viscosity of the paint and

your desired spray characteristics will also af fect your ideal pressure. As a

general rule, larger amounts of paint or thicker paints, will be sprayed with

higher pressures.

WARNING: Do not exceed 100psi.

Paint Preparation

For non-airbrush-ready paints, proper preparation, including ltering

the paint through a nylon mesh, is recommended for best performance.

Paint should be thinned with its proper solvent. It is best to prepa re paint

relatively thin and make repeated passes across the work to achieve the

desired shade. This will also improve the

quality of your work and decrease the cleaning time of your airbrush.

Safety Tips

• Always spray in a well-ventilated area.

• Do not spray solvent-based (flammable) paints around open flames.

• Use the appropriate respirator to safely lter out the paint vapors par-

ticular

to the kind of paint you are using.

• Wear eye protection to prevent paint contact with eyes.

• Never use air pressure that exceeds the airbrush’s limit (100 psi).

Before Each Session

Spray water or the appropriate clea ning solution through the airbrush to

make sure the airbrush is working properly.

After Each Session

Or any time the airbrush becomes clogged:

1. Increase the air pressure.

2. Spray cleaning solution for a short time.

3. Clean the needle if necessary

Cleaning the airbrush this way helps clean the paint passage, the nozzle

and the needle thoroughly.

Periodically

To ensure smooth main lever action lubricate the needle and the main

lever

mechanism when necessary.

1. Unscrew the handle.

2. Loosen the needle chucking nut.

3. Remove the needle.

4. Coat the needle lightly at the front where the taper starts with a highquality

lubricant, like Medea Super Lube.

5. Wipe the needle with a soft, clean cloth, leaving a light coat of lube

behind.

6. Re-insert the needle gently into the airbrush.

7. Tighten the needle chucking nut.

8. Screw the handle onto the airbrush body.

Use a tiny drop of lube on the main lever’s piston. DO NOT over-lube the

needle

or the main lever mechanism, since it is possible to transfer excess lube

into the nozzle causing severe paint flow problems. DO NOT use light

machine oil or WD-40 for lubrication. These will cause the needle to stick

as it moves through the needle packing o-ring.

7. Tighten the needle chucking nut nger tight.

• Pull the main lever back and forth to visually conrm the needle’s abil-

ity to move.

8. Screw the handle back onto the airbrush body.

Never remove the nozzle unless it is damaged or clogged.

Always keep your airbrush clean. Never leave paint in your airbrush as dried paint can

clog a nozzle. Although engineered from durable, high-quality materials, the nozzle is

small and delicate. Accidental damage caused by cross-threading, over-tightening,

dropping the airbrush, forcing a needle or tools into the nozzle and normal wear are

not covered under the warranty. Replacement parts and repair services are available

through your local aliate.

IMPORTANT NOZZLE INFORMATION

CAUTION: If it becomes absolutely necessary to dismantle the airbrush

remember that in most situations tools are not needed.

NEVER soak your entire airbrush in any liquid. NEVER

store your airbrush with spray medium or cleaning

agents in the uid cup.

3

31

NEO FOR IWATA — TRN1, TRN2

33

30A

30B

5A

2

TRN1

3

29A

29B

TRN2

4

19

5B

32

12

11

10

9

8

15

7

13

16

17

24

14

27

6

23

20

22

18

28

25

21

26

PRICE ITEM TRN2 TRN1 ALSO

# ITEM DESCRIPTION CODE # N 5000 N 5500 FITS

1 Needle Cap A N 110 2 n n

2 Nozzle Cap N3 A N 140 3 opt n

N5 A N 140 4 n opt

3 Nozzle N3 C N 080 3 opt n

N5 C N 080 4 n opt

4 Nozzle Cap O-ring A N 150 4 n x

5A Head Base A N 135 3 x n

5B Head Base A N 135 4 n x

6 Head Base Packing (PTFE) A N 150 5 n n

7 Main Body Ring Screw A N 131 2 n n

8 Needle Packing (PTFE) A N 150 7 n n

9 Needle Packing Screw A N 125 2 n n

10 Slide Cam A N 130 1 n n

11 Spring Side Cam A N 130 2 n n

12 Main Body R ing A N 131 1 n n

13 Needle Chucking Guide A N 115 2 n n

14 Needle Spring A N 135 2 n n

15 Spring Guide A N 170 2 n n

16 Needle Chucking Nut A N 120 2 n n

PRICE ITEM TRN2 TRN1 ALSO

# ITEM DESCRIPTION CODE # N 5000 N 5500 FITS

17 Needle N3 A N 075 3 opt n

N5 A N 075 4 n opt

18 Handle Cap Set D N 090 2 n n

19 Trigger With Trigger Screw A N 100 2 n n

20 Air Piston Set A N 010 1 n n

21 Air Valve Set C N 020 2 n n

22 Grip Mount/Ex tension D N 160 1 n n

23 Grip B N 160 2 n n

24 Bottle Adapter C N 040 1 n x

25 Side Cup Lid 0.50 oz / 15 ml A N 095 2 n x

26 Side Cup 0.50 oz / 15 ml A N 070 6 n x

27 Side Cup Lid 0.24 oz / 7 ml A N 095 3 n x

28 Side Cup 0.24 oz / 7 ml D N 070 5 n x

29A Fluid Gravity Cup w/O-ring 0.05 oz / 1.50 ml C N 070 1 x n NEO CN

29B O-ring For Fluid Gravity Cup 0.05 oz / 1.50 ml A N 071 2 x n NEO CN

30A Fluid Gravity Cup w/O-ring 0.24 oz / 7 ml D N 070 2 x n NEO CN

30B O-ring For Fluid Gravity Cup 0.24 oz / 7 ml A N 071 3 x n NEO CN

31 Fluid Gravity Cup Lid 0.24 oz / 7 ml A N 095 4 x n NEO CN

32 Spanner A N 165 1 x n NEO CN/

NEO BCN

33 Spanner A N 165 2 n x

n = yes x = no opt = optional

4

REPLACEMENT PARTS AND ACCESSORIES

Nozzle

In time, the nozzle may wear or be damaged and may need to be replaced.

1. Unscrew the handle.

2. Loosen the needle chucking nut.

3. Gently pull the needle part way back. It doesn ’t need to be fully pulled

out.

4. Unscrew the needle cap and the nozzle cap.

5. Unscrew the nozzle counter-clockwise with the provided wrench.

6. Screw the new nozzle into the airbrush body with your ngers.

7. Slightly tighten the nozzle with the provided wrench.

• DO NOT OVER TIGHTEN!

8. Screw the needle cap and nozzle cap onto the airbrush body.

9. Push the needle all the way forward until it seats with the new nozzle.

10. Tighten the needle chucking nut.

11. Screw the handle onto the airbrush body.

TIP: Keep a spare nozzle on hand for unforeseen accidents.

WARRANTY

Needle

Needles are subject to easy physical damage because of the long tapered,

extremely ne tip. If the needle point becomes severely bent, it must be

straightened before pulling it back through the nozzle. If not, the bent

needle might damage the nozzle

as it’s pulled through.

TIP: Keep a spare needle on hand for unforeseen accidents.

All Iwata airbrushes are warranted against all manufacturing defects of material and manufacture or workmanship for a period of FIVE years

from date of purchase. This warranty does not cover needles, nozzles, o-rings and internal packings since these parts need to be replaced

occasionally due to normal wear. Any other parts or materials that are or become defective so as not to be usable within this period will be

repaired or replaced. This warranty does not cover damage caused by negligence or airbrushes which have been altered or abused in any way.

Copyright © 2018 ANEST Iwata-Medea, Inc. All rights reserved.

NEOTRIGGER-IM-KMD

Loading...

Loading...