Iwata Kustom Hi-Line TH, Kustom Hi-Line CH, Kustom Revolution TR, Kustom Micron CM, Kustom Eclipse CS Manual & Parts Manual

Micron CMHi-Line TH Revolution TR Hi-Line CH Eclipse CS

K U S T O M S E R I E S M A N UA L & P A R T S G U I D E

Iwata-Medea, Inc. • P.O. Box 14397 • Portland, Oregon 97293

tel: (503) 253-7308 • fax: (503) 253-0721 • info@medea-artool.com

— w w w . I W AT A A I R B R U S H . c o m —

part no. K 910

Congratulations on the purchase of your Iwata

Kustom

™

— a versatile, reliable and high

performance airbrush! Kustom painting takes pole position with the new Iwata Kustom airbrush series

that sports large cups and shines in atomizing solvent-based paints.

T E F L O N PA C K I N G S • L A R G E C U P S

P R E - S E T H A N D L E S & TA L L T R I G G E R S

distinguish these airbrushes as Kustom!

ONLY FROM IWATA-MEDEA

Iwata airbrushes are designed for the demanding professional. Modern, precision machining and carefully selected

materials are employed in the manufacturing process to ensure consistent high performance and long life. Each Iwata

airbrush is spray-tested before shipment to assure maximum performance and adherence to Iwata’s strict quality

standards. To maintain your Iwata Kustom airbrush at its peak performance, proper care and attention must be observed.

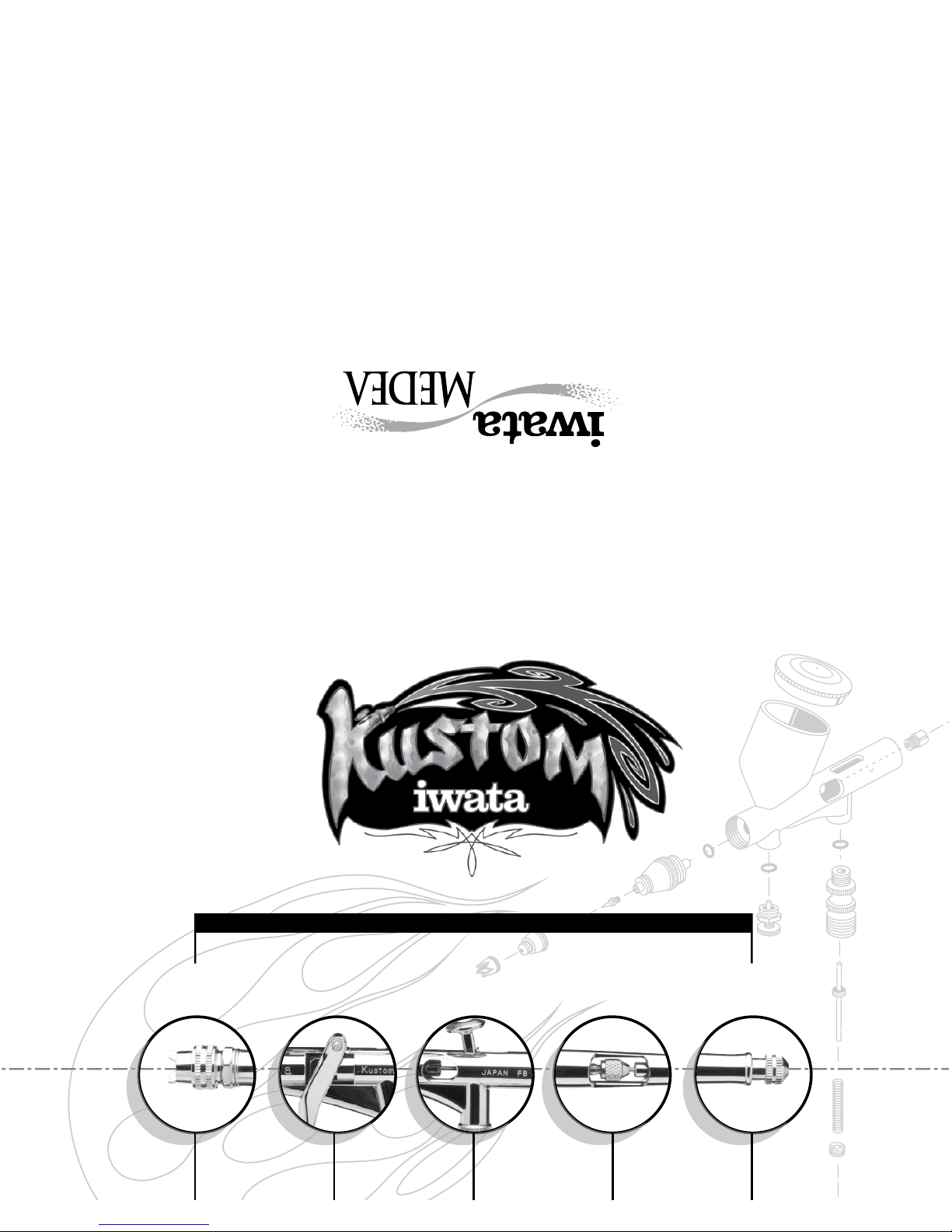

K9200 Features:

Unique high-precision fan-pattern spray-head system;

• "Fan-Pattern" air cap

(requires 1 HP or larger compressor)

• "Round-Pattern" air cap

• Pre-set handle

MAC Valve (Micro Air Control) •

Spray-gun trigger design •

0.50mm nozzle •

• Teflon needle packings

• Large 1/2 oz. (14ml) removable gravity-feed fluid cup

• Pistol-Grip Filter included - see page 15

Iwata Kustom Hi-Line TH Airbrush

The first airbrush to create both round-pattern and fan-pattern sprays,

the Kustom Hi-Line TH stands alone among its peers. Triggering the

imagination of auto-body touch-up and Kustom painters, the Kustom TH

delivers unprecedented fan pattern control with a minimum of

overspray — giving it a unique advantage over mini touch up guns.

The fan-pattern air cap produces an oval spray pattern — perfect for

creating smoother blends, gradations and backgrounds because the

paint is atomized more consistently across the entire width of the spray.

Great for small areas such as chip repair, fender wells, door jams and

other hard-to-reach areas.

The Kustom TH also features an interchangeable round-pattern air cap,

producing a round spray pattern with concentrated spray at its center,

which is preferable for freehand graphics and fine line detail.

FAN ROUND

TH Spray Patterns

These features, and more, distinguish the Kustom TH as the ultimate airbrush for creative versatility.

4

5

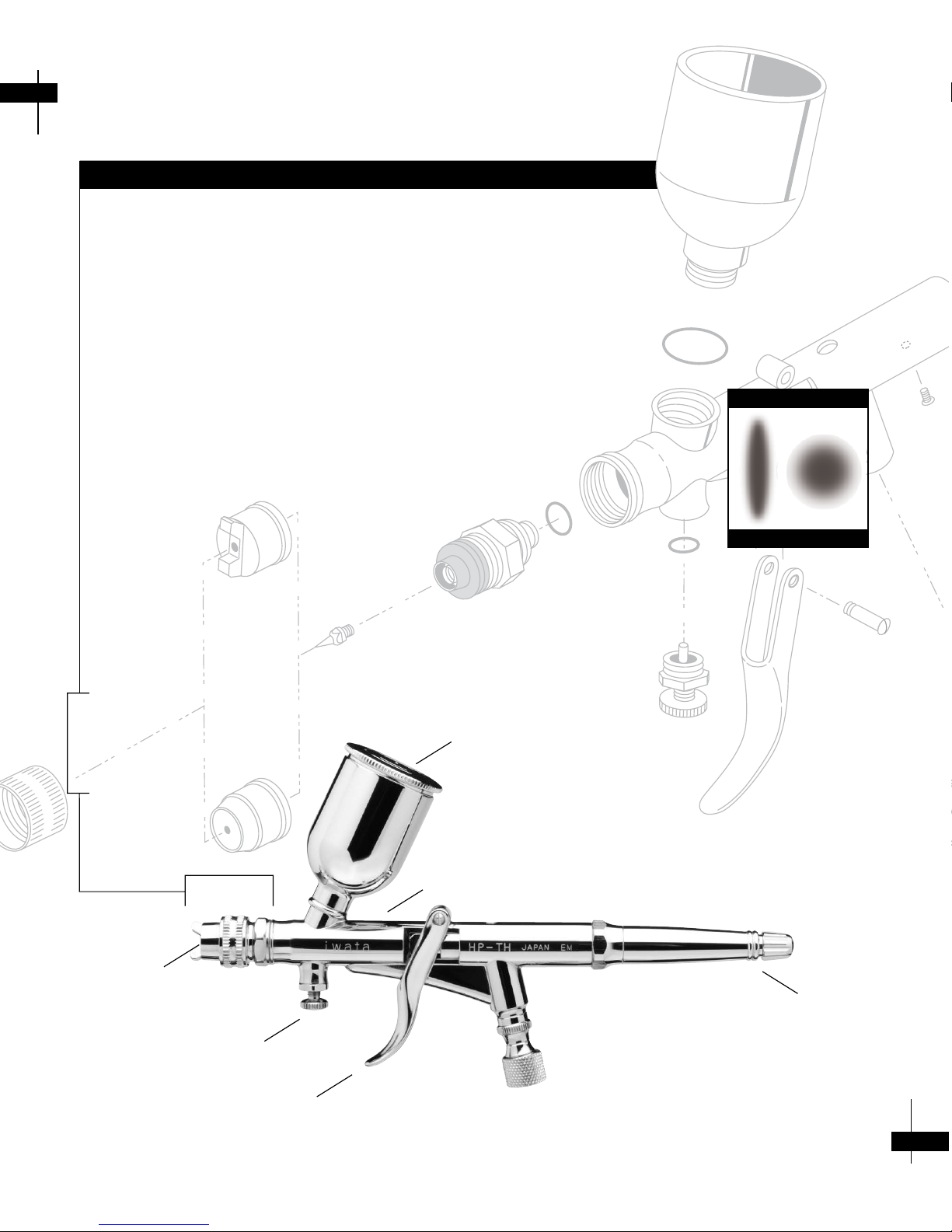

Iwata Kustom Revolution TR Airbrush

Triggering the passion of spray-gun users, the Kustom

Revolution TR airbrush proves easy to use. The long trigger

provides commanding control of the airbrush spray.

K9400 Features:

• 0.30mm nozzle

• Teflon needle packings

• Large 3/4 oz. (21ml) gravity fluid removable cup

• Spray-gun trigger design

• Pre-set handle

• Pistol-Grip Filter included - see page 15

Iwata Kustom Hi-Line CH Airbrush

A preferred airbrush for users who need ultimate control

of fine-line work and medium background spraying, the

Kustom Hi-Line CH boasts a MAC valve that supplies precise

air control to the head of the airbrush for ultimate control.

K9100 Features:

• 0.30mm nozzle

• Teflon needle packings

• Large 1/2 oz. (14ml) gravity fluid cup

• Taller trigger for extreme control of trigger action and paint flow

• Pre-set handle

• MAC Valve for precise air-pressure control

• Pistol-Grip Filter included - see page 15

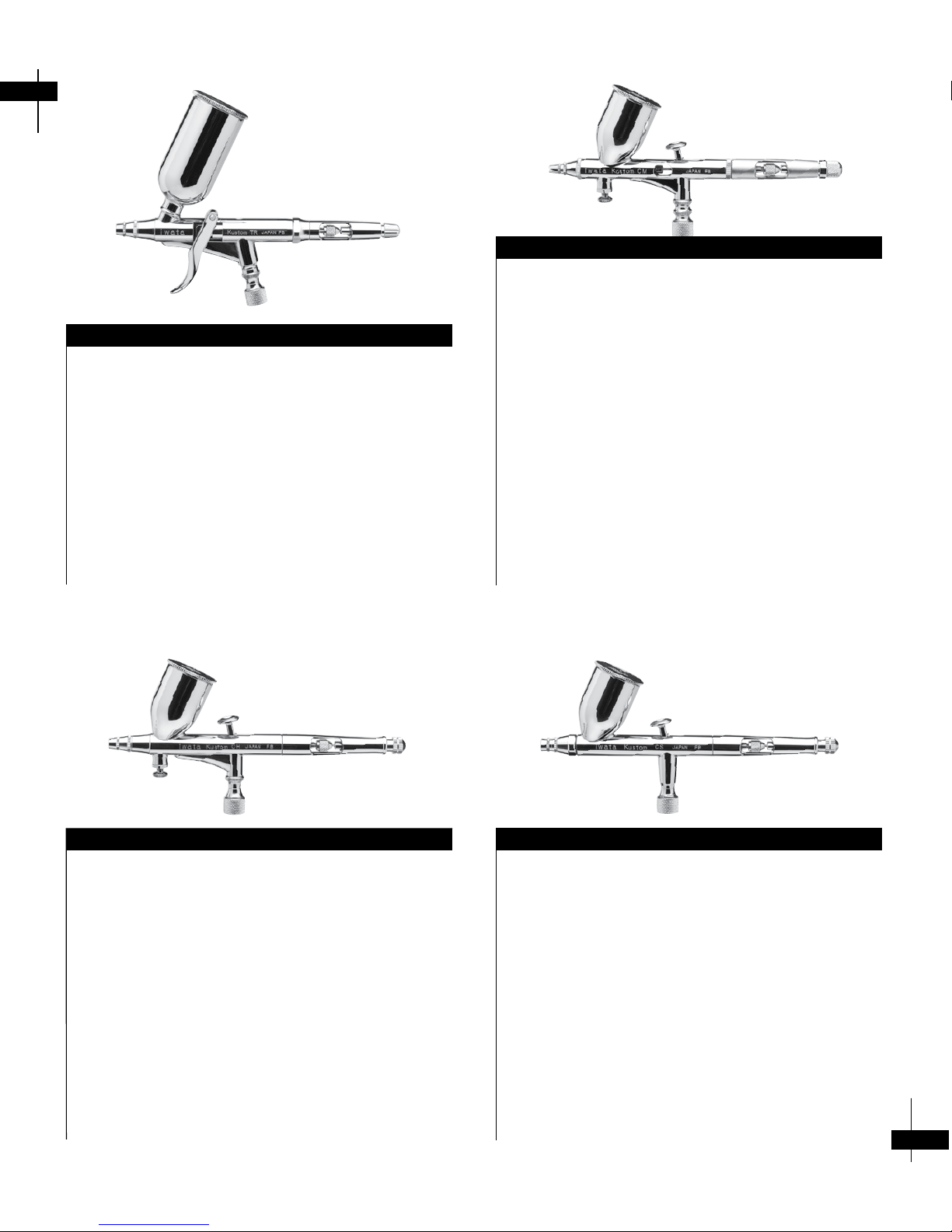

Iwata Kustom Micron CM Airbrush

The MAC Daddy of all airbrushes, the Kustom Micron CM is

framed around the Iwata Custom Micron airbrush. The new

Kustom Micron CM airbrush provides extreme control of

ultra fine-line spray, silky-smooth atomization and ultimate

paint-flow control with hand-tuned, hand-adjusted

performance. Iwata Micron airbrushes are world-renown

as the professional’s choice for the utmost of fine line detail.

K9000 Features:

• 0.23mm "Matched Head System"

• Teflon needle packings

• Large 1/2 oz. (14ml) gravity fluid cup

• Taller trigger for extreme control of trigger action and paint flow

• Pre-set handle

• MAC valve for precise air pressure control

• Pistol-Grip Filter included - see page 15

Iwata Kustom Eclipse CS AirbruIsh

The workhorse of the Kustom line, the Kustom Eclipse CS

features a large general-purpose nozzle/needle combination.

Still maintaining fine-line control, the Kustom Eclipse CS

creates wide background sprays with fine atomization and

control. Designed to spray metallic, pearlescent and base

coat paints.

K9300 Features:

• 0.35mm nozzle

• Teflon needle packings

• Large 1/2 oz. (14ml) gravity fluid cup

• Taller trigger for extreme control of trigger action and paint flow

• Pre-set handle

• Pistol-Grip Filter included - see page 15

6

7

— G E T T I N G S T A R T E D —

Compressor

Choose an appropriate compressor for your Kustom airbrush.

The Iwata Sprint Jet or Smart Jet compressors are a good beginner’s

choice and will provide approximately 25 - 30 psi of air pressure

to your Kustom TR, CM, CH and CS airbrushes. The high powered

Iwata Power Jet Pro, Power Jet and Power Jet Lite compressors can

be controlled to provide 5 - 45 psi to your Kustom airbrush, and

are the ideal air sources to utilize all of the Kustom airbrush series’

unique potential.

PLEASE NOTE: The TH fan pattern air cap requires a 1 HP or larger

compressor.

Assembly and Spray Test

Carefully screw the Pistol-Grip Filter (#40) onto the air valve of your

Kustom airbrush and hand tighten. Next, screw airhose to bottom of

the Pistol-Grip Filter and hand tighten. CAUTION: Be especially careful

to not cross-thread or over-tighten connections or you may damage

the filter. Finally, screw the airhose onto the compressor and lightly

tighten with a wrench.

DO NOT OVERTIGHTEN!

Check to ensure that you can pull the main lever (#14 on CM, CH

and CS) or trigger (#14 on TH and TR) fully back. If trigger action is

limited, unscrew the adjusting knob at the back end of the pre-set

handle (#39) to allow the main lever (or trigger) to be fully pulled

back, or adjust as needed.

Turn the compressor on, and if using an Iwata Power Jet Pro, Power

Jet or Power Jet Lite compressor, adjust the pressure to 25 psi. Check

for any air leaks at airhose connections.

If your airbrush is equipped with a Micro Air Control (MAC) valve (#16

on TH, CM and CH), adjust valve to wide open position, allowing air to

flow when the main lever is pushed down, or trigger is pulled back.

Pointing the airbrush away from you, press down on the main

lever (or pull trigger) to start the flow of air through the airbrush

and clear it of any residue. To further ensure a clean airbrush, add

a small amount of the appropriate cleaner or solvent into the

color cup and spray it through the airbrush by pushing down and

pulling back on the main lever (or pull trigger) to open the nozzle

(#6) of the airbrush. Fully allow the all the cleaner to spray through

the airbrush. CAUTION: Check paint manufacturer’s label for details.

Not all paints and cleaners are compatible with one another, and

the appropriate cleaner must be used to ensure that your airbrush

is properly maintained.

CAUTION: Always wear appropriate respirator or spray mask and

protective clothing. Spray in a well ventilated area.

Fine Line Spray

To spray a fine line, depress and pull the main lever (#14 on CM, CH

and CS) or pull trigger (#14 on TH and TR) back slightly while positioning the airbrush close to the surface (approximately 1/16 - 1/2

inch). The thickness of the line can be controlled by varying the

distance of the airbrush from the surface and adjusting the amount of

paint flow by the position of the main lever (or trigger).

Wide Line and Background Spraying

For wider lines and background spray, depress and pull the main

lever (or pull trigger) further back to release more paint. Increase the

distance between the airbrush and surface (from 1/2 - 6 inches is

common) to control spray width. Increasing the air pressure will also

affect the spray width. Kustom airbrushes will spray a background

width of approximately 2” (TR, CM, CH and CS) to 4” (TH).

The TH is equipped with a fan air cap (#5A) creating an oval spray

pattern, as opposed to a circle. The fan air cap produces a superior

spray pattern for backgrounds, smoother blends and gradations. To

use the fan air cap, loosen the cover ring (#4) and position the tabs on

the fan air cap up-and-down for a horizontal spray pattern, and sideto-side for a vertical spray pattern. The round pattern air cap (#5B) can

be substituted to create a circle spray pattern for finer detail work.

Cutaway Handle

The cutaway handle (#39) is a special feature on the Kustom TR, CM,

CH and CS. Its purpose is two-fold;

1) A wider background spray pattern can be accomplished by

pulling the exposed needle chucking nut (#37) back to fully

open the nozzle, while

simultaneously depressing the main lever

(#14 on CM, CH and CS) or trigger (#14 on TR), passing more paint

through the nozzle.

2) Free up paint clogs that may have formed at the tip of the

airbrush by pulling the exposed needle chucking nut back to

fully open the nozzle while simultaneously depressing the main

lever or trigger .allowing the clog to be sprayed out.

Stippling

Iwata Kustom TR, CM, CH and CS airbrushes are designed to produce

a wide range of stippling textures. Stippling is achieved by removing

the needle cap (#1) and nozzle cap (#2) and adjusting the air pressure

between 5 and 50 psi. Lower air pressure will give you coarse stipple

whereas a higher pressure will provide a fine stipple effect. Paint

viscosity will also affect the stippling texture. At low air pressure the main

lever (or trigger) may need to be pumped to create a coarse stipple.

Air Pressure

Working pressures vary from between 10 to 45 psi, depending on what

type of work is being done and what textures are desired. The viscosity

of the paint and your desired spray characteristics will also have an

effect on which pressure is ideal. As a general rule, larger amounts of

paint or thicker paints will be sprayed with higher pressures.

Paint Preparation

Proper preparation and filtering the paint through a nylon mesh is

recommended for best performance. Paint should be thinned with

its proper solvent. It is best to prepare the paint relatively thin and

make repeated passes across the work to achieve the desired shade.

This will also improve the quality of your work and decrease the

cleaning time of your airbrush.

— G E N E R A L O P E R AT I O N —

8

9

Loading...

Loading...