Iwata IS 50 Instruction Manual

PROBLEMS AND REMEDIES

Parts marked with *, are particularly difficult for the operator to handle . If it is necessary to replace these parts, please contact the retailer.

WARNING Indicates a potentially hazardous situation which, if not avoided, may result in serious injury or loss of life.

CAUTION Indicates a potentially hazardous situation which, if not avoided, may result in minor or moderate injury or

property damage.

OTHER SAFETY SYMBOLS

INDICATES THAT ATTENTION MUST BE PAID TO...

A brief explanation is in the symbol or near to it.

This example indicates, “pay attention to any possible electrical discharge”.

INDICATES SPECIFIC DANGEROUS OPERATIONS THAT MUST NOT BE CARRIED OUT

A brief explanation is in the symbol or near to it.

This example indicates, “do not touch”.

INDICATES SPECIFIC IMPORTANT OPERATIONS THAT MUST BE CARRIED OUT

A brief explanation is in the symbol or near to it.

This example indicates, “ground the compressor”.

SUPPLEMENTARY NOTES

IMPORTANT

Indicates necessary procedures that must be followed to ensure safe, correct and efficient use of the product.

IMPORTANT INFORMATION

Distributed by: ANEST IWATA Corporation _ 3176,Shinyoshida-cho, Kohoku-ku, Yokohama, 223-8501 Japan_ Made in Taiwan

Instruction Manual

MJ1624-00ERIV.00

OIL-FREE MINI COMPRESSOR IS 50

ANEST IWATA will not accept responsibility for any damage or injury caused by failure to observe warnings and instructions contained within this instruction manual.

CHECKING THE PRODUCT

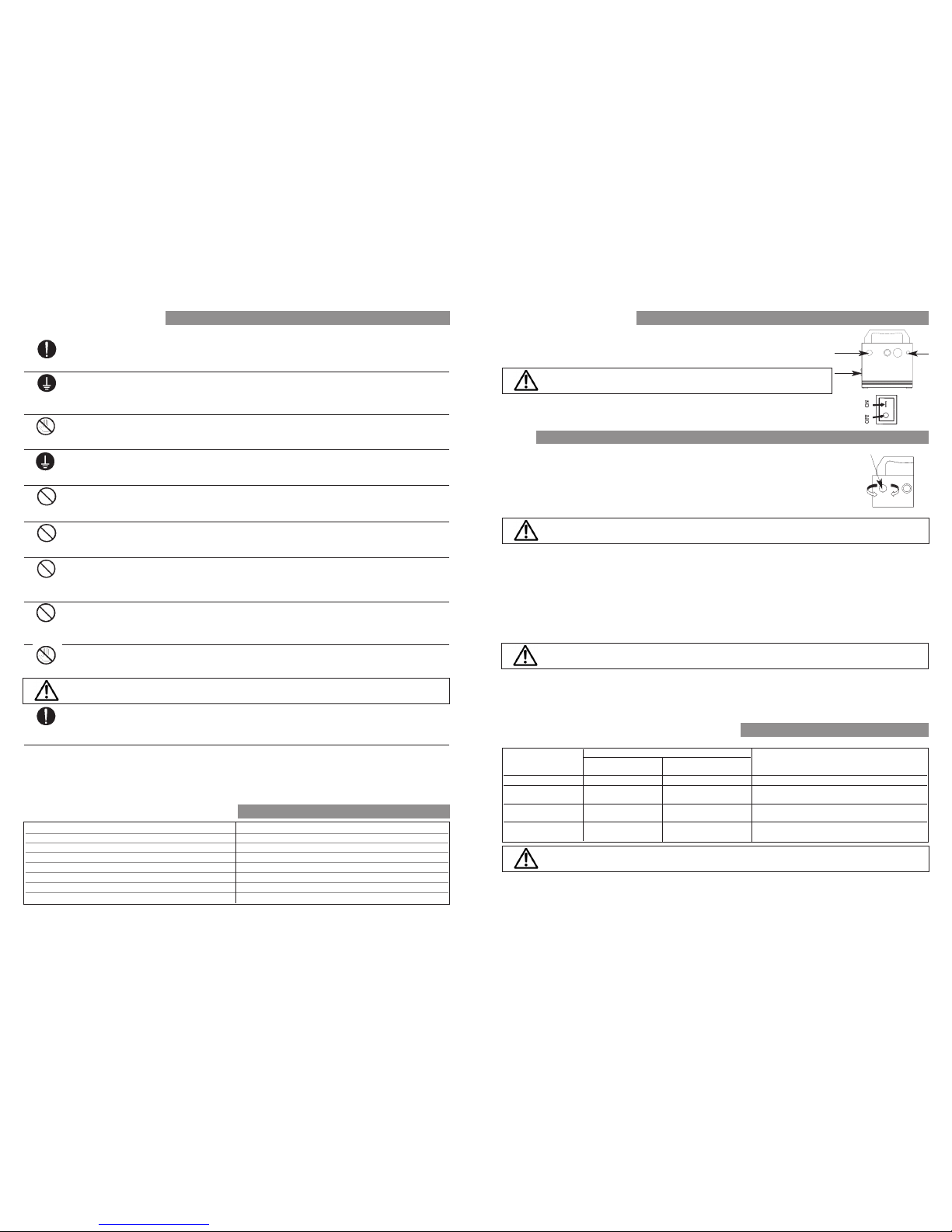

INSPECTION OF PRODUCT COMPONENT NAMES

Check that the model name you have purchased is

the same as that indicated on the plate, found on the

back of the compressor.

Ensure that the product has not been damaged during

transportation.

INSPECTION OF ACCESSORIES

Check that the following accessories are included:

Instruction manual_4 m spiral air hose_

moisture grip filter.

Pressure regulator

knob

Airbrush holder

Handle

Air

outlet

Power

Switch

Pressure gauge

FRONT VIEW

SIDE VIEW

Problem Cause Remedy

The power switch is off. Switch the power switch on.

The engine does Switch power switch off, discharge air

not work. Safety system is activated. pressure and switch on again after 15 min-

utes.

Reduced voltage. Contact local electricity company.

Seizure of compressor * Repair

Pressure does not increase Air escapes from each connection Tighten or replace necessary parts.

or takes a long time to or from hoses.

increase.

Incorrect positioning. Stabilise the 4 feet.

Presence of anomalous

noises or vibrations.

Worn internal parts of the compressor. * Repair

Loose parts. Tighten them.

IMPORTANT

This product should be operated only by an adequately trained operator, for safe use and maintenance of the equipment. Any

misuse or handling other than those indicated in this Instruction Manual is not covered by guarantee. ANEST IWATAdisclaims all

responsibility for any accident or damage caused by failure to observe the operational and safety procedures in this manual. In

the interest of user friendliness, this manual contains information in a brief and concise form.

For any additional information you may require regarding spray gun operations, or if any missing parts or any damage during

transportation is found, please contact your nearest ANEST IWATACompany (see last cover page).

Before use, adjustment or maintenance, it is important to read this instruction manual very carefully. This manual must be stored in

a safe place for any future reference that may be necessary.

GB

ANEST IWATA Italia S.r.l.

46, Corso Vigevano 10155, Torino (Italy)

Tel. diretto +39 011 - 24 80 868 - Fax: +39 011 - 85 19 44

info@anest-iwata.it www.anest-iwata.it

ANEST IWATA Iberica

Calle de Les Teixidores, 3-5

08918 - Badalona (Barcelona)

Tel.:+34 933 20 59 93 - Fax.:+34 933 20 59 65

info@anest-iwata.es www.anest-iwata.es

ANEST IWATA Europe s.r.l.

NIEDERLASSUNG DEUTSCHLAND

Mommsenstrasse 5, 04329 Leipzig

Telefon: +49 0341 241 4430 - Fax: +49 0341 241 443 29

info@anest-iwata.de www.anest-iwata.de

ANEST IWATA Europe S.r.l.

46, Corso Vigevano 10155, Torino Italy

Direct Tel. +39 011 - 22 74 402

Fax +39 011 - 22 74 406

info@anest-iwataeu.com

www.anest-iwataeu.com

ANEST IWATA Scandinavia

Ögärdesvägen 6C, 433 30 PARTILLE - Sweden

Tel. +46 (0)31 - 340 28 60 - Fax +46 (0)31 - 340 28 69

info@anest-iwata.se www.anest-iwata.se

ANEST IWATA France

25 rue de Madrid - 38070 St Quentin Fallavier - France

Tél. +33 (0)4 - 74 94 59 69 - Fax +33 (0)4 - 74 94 34 39

info@anest-iwata.fr www.anest-iwata.fr

ANEST IWATA U.K.

Unit 10 Little End Road - Eaton Socon

St. Neots - CAMBRIDGESHIRE

PE19 8JH

Tel.: +44 (0) 1480 405419 Fax: +44 (0) 1480 217610

enquiries@anest-iwata.co.uk www.anest-iwata.co.uk

European Sales Branches:

32

SAFETY WARNINGS

INSTALL IN A SECURE WORKING ENVIRONMENT

• Install the equipment in areas free from gas and inflammable substances (Acetylene, Propane etc.), which could cause explosions of fires.

SWITCH OFF MAIN ELECTRIC SOURCE

• Before inspecting the product, turn the main electric source off by removing the plug from the electric socket or by using the power switch. Otherwise, it could cause electric shock.

DO NOT TOUCH

• Do not touch moving parts while the main electric source is active, to avoid causing injury to hands.

GROUND PRODUCT WITH A GROUNDING CABLE

• Correctly ground the product with a grounding cable.

ONLY USE FOR SUPPLYING AIR

• Do not use the compressor to supply any type of gas, other than air, to avoid the risk of fires or explosions.

NEVER CONNECT TO RESPIRATORS

• Never connect respirators to compressed air outlet, to avoid serious injury or irreversible damage to the operator.

NEVER USE FOR SUPPLYING AIR TO MEDICAL EQUIPMENT

• Never connect to medical equipment directly. (Connect a protection system when using with medical equipment). Otherwise the health

or life of the operator could be put at risk.

INSTALL IN A SECURE WORKING ENVIRONMENT

• Never install the compressor where it could come into contact with atmospheric elements. The material used to manufacture the product is not water resistant. If electrical parts come into contact with water, it could lead to a short circuit and cause fire.

DO NOT TOUCH

• Do not directly touch any part of the system whilst it is in operation, or immediately after, to avoid burns.

OBSERVE THE RECOMMENDED WORKING TEMPERATURE

• The recommended working temperature is between 0~40°C. Use at above or below the recommended temperature could cause malfunction and damage the equipment.

IMPORTANT SPECIFICATIONS

HOW TO OPERATE

•

First of all, make sure that the electric power switch is switched off (OFF), then connect the electric cable to

to the electric socket.

• Switch the electric power switch on (ON) and make sure that the compressor works correctly.

• Allow it to run for 5 minutes, making sure that it does not create any anomalous noises or vibrations.

Connect the electric power cable plug directly to the electric socket. Use of an extension lead could

create a reduction in voltage, causing the engine to stall. You are advised to refrain, as far possible,

from using extension leads for the electrical connection.

USE

• Connect the air hose and airbrush to the compressor.

• Make sure that the power switch is switched off (OFF) and connect the electric power cable plug directly to the electric socket.

• Activate the electric power switch (ON) to operate the compressor.

PRESSURE SETTING

• Use the pressure regulator knob on the compressor to calibrate air pressure. Turn the regulator knob

clockwise to increase pressure and anti-clockwise to reduce pressure.

Make sure that the compressor, air hose and airbrush are securely connected. Accidental disconnection of the air hose whilst in

operation, could cause bodily injury.

Before switching the compressor on, make sure there isn’t any residual pressure inside the air hose. Residual pressure could

cause the engine to stall.

To avoid burns, do not touch the surfaces of the compressor (except the parts necessary to switch it on) whilst in operation.

If you detect any anomalous vibrations or unusual noises caused by product failure, switch the equipment off immediately and

do not switch it on again until the problem has been resolved.

• To disactivate the compressor, switch the power switch off (OFF) and pull the airbrush trigger to completely discharge residual air pressure from the compressor.

Always discharge residual air pressure from the air hose completely, after use. Never direct the air discharge towards the human

body, to avoid inflammation of eyes or skin.

MAINTENANCE AND INSPECTION

• Carry out the following operations periodically to guarantee the correct working order of the equipment.

Before carrying out any maintenance procedures, always disconnect the compressor from the main electric source, by removing the electric cable plug from the socket, to avoid injury or electric shock.

Before carrying out any maintenance procedures, always discharge residual air pressure from the compressor completely, so

that parts under pressure are not forcefully released during disassembly, causing injury.

CAUTION

CAUTION

CAUTION

CAUTION

CAUTION

OPERATION PERIODICAL MAINTENANCE REFER TO

Daily Every 100 hours

Every 6 months

Complete inspection X How to operate page 3

Inspect air pressure X How to operate page 3

regulator knob

Check for unusual noises

or vibrations X Problems and Remedies page 4

Check mini filter

anti-condenser X Clean mini filter

Air

outlet

Pressure

regulator

knob

Pressure regulator knob

Power

Switch

Power

switch

-

+

Model IS-50 (Silver Jet)

Motor: W 110-140

Max. pressure: bar 1,3

Air flow: L/min 9

Weight: kg 2,9

Dimensions : mm 150 x 155 x 180

Spiral hose: 4 m (code HPA-CH41)

Moisture grip filter: VIMFA450

Loading...

Loading...