Page 1

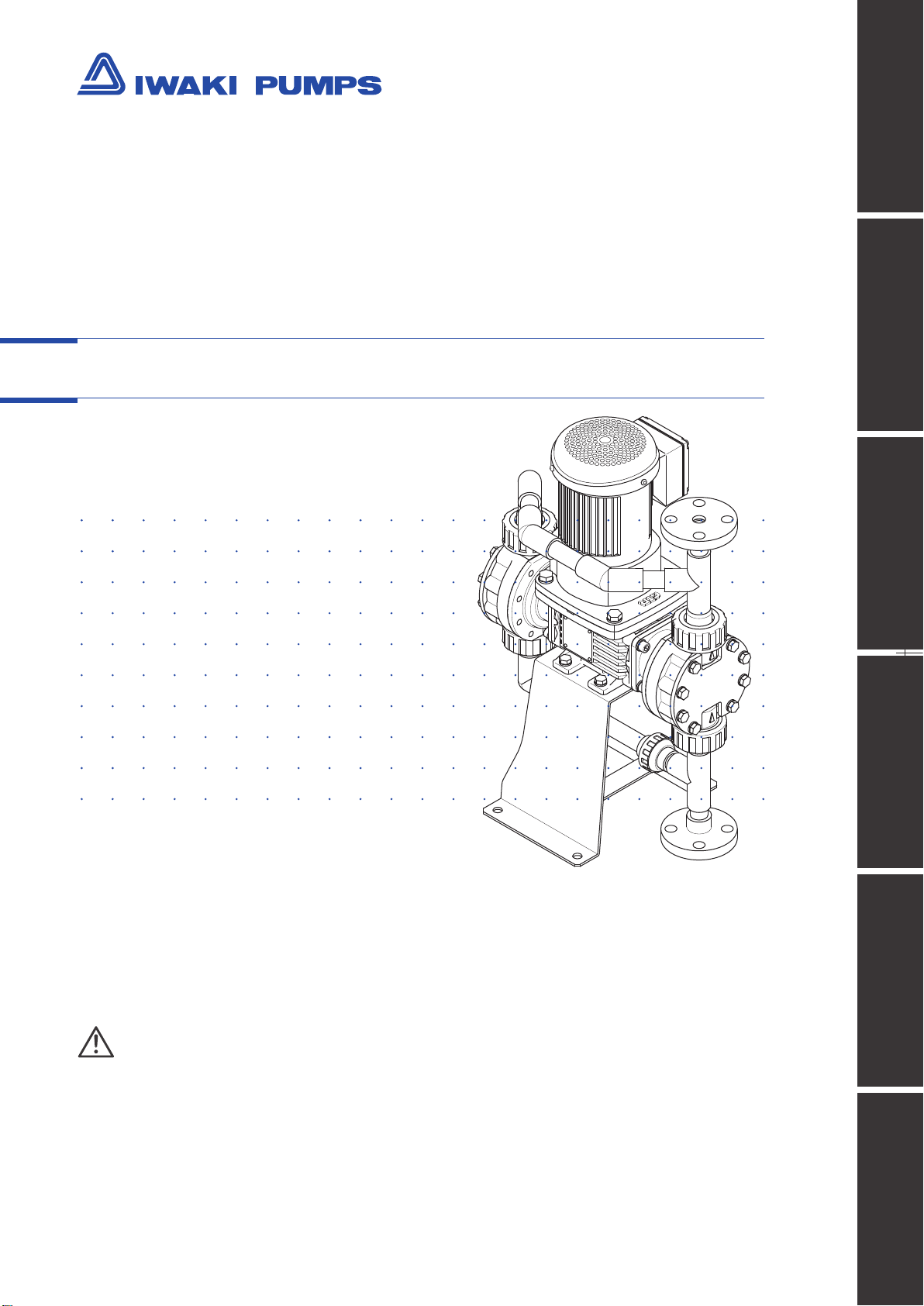

IWAKI Metering Pump

TD series

Safety instructions Overview Installation Operation Maintenance Specication

Instruction manual

Thank you for choosing our product.

Please read through this instruction manual before use.

This instruction manual describes important precautions and instructions for the product. Always keep it on hand for quick reference.

©2011 IWAKI CO., LTD.

Page 2

Order conrmation

Open the package and check that the product conforms to your order. If any problem or

inconsistency is found, immediately contact your distributor.

a. Check if the delivery is correct.

Check the nameplate to see if the information such as model codes, discharge capacity and discharge

pressure are as ordered.

b. Check if the delivery is damaged or deformed.

Check for transit damage and loose bolts.

Order conrmation

2

Page 3

Contents

Order conrmation ..........................................................................................................................................2

Safety instructions .................................................................... 5

Warnings ........................................................................................................................................................6

Cautions .........................................................................................................................................................8

Precautions for use ....................................................................................................................................10

Overview ...................................................................................11

Introduction ................................................................................................................................................. 11

Pump structure & Operating principle ...................................................................................................... 11

Pump mechanism ....................................................................................................................................12

Flow pulsation reduction mechanism ..................................................................................................12

Part names ...................................................................................................................................................13

Pump ........................................................................................................................................................13

TD .......................................................................................................................................................13

Identication codes ....................................................................................................................................14

Installation ...............................................................................15

Pump mounting ...........................................................................................................................................15

Before installation .....................................................................................................................................15

Pipework ......................................................................................................................................................16

Piping layout .............................................................................................................................................16

Necessary devices ...................................................................................................................................17

Relief valve ..........................................................................................................................................17

Back pressure valve ............................................................................................................................17

Strainer ................................................................................................................................................17

Pressure gauge ...................................................................................................................................17

Pump inlet/outlet connections ..................................................................................................................18

Tube connection ..................................................................................................................................18

Union connection ................................................................................................................................18

Piping precautions ....................................................................................................................................19

Prohibited piping .................................................................................................................................19

Slurry delivery ..........................................................................................................................................20

Wiring ...........................................................................................................................................................21

Inverter-Motor ...........................................................................................................................................21

Inverter-Grid power ..................................................................................................................................21

IPM motor terminal box ............................................................................................................................22

Contents

3

Page 4

Operation ................................................................................. 23

Before operation .........................................................................................................................................23

Operation .....................................................................................................................................................24

Starting procedure ...................................................................................................................................24

Inverter operation .....................................................................................................................................25

Start/Stop of operation ........................................................................................................................25

Flow rate adjustment ...........................................................................................................................25

Before stoppage .......................................................................................................................................26

Resumption after a long period of stoppage ............................................................................................26

Maintenance ............................................................................ 27

Troubleshooting ..........................................................................................................................................27

Inspection ....................................................................................................................................................29

Daily inspection ........................................................................................................................................29

Periodic inspection ...................................................................................................................................29

Maintenance of IPM motor .......................................................................................................................29

Oil replacement (drive unit) ......................................................................................................................30

Replacement procedure ......................................................................................................................31

Wear part replacement ...............................................................................................................................32

Before assembly/disassembly ..................................................................................................................33

Exploded view .............................................................................................................................................34

Pump head ...............................................................................................................................................34

TD-01/-03 VC/V6 ................................................................................................................................34

TD-05/-1 VC/V6/VS ............................................................................................................................36

TD-01/-03 VS ......................................................................................................................................38

TD-2/-4/-6/-8 VC/V6/VS .....................................................................................................................40

TD-01/-03 S6 ......................................................................................................................................42

TD-05/-1 S6 ........................................................................................................................................44

TD-2/-4/-6/-8 S6 .................................................................................................................................46

Specications/Outer dimensions ..............................................................................................................48

Specications ...........................................................................................................................................48

Pump ...................................................................................................................................................48

Inverter ................................................................................................................................................49

Outer dimensions .....................................................................................................................................50

FF type ................................................................................................................................................50

HH type ...............................................................................................................................................51

UU type ...............................................................................................................................................51

Performance curves .................................................................................................................................52

TD-VC/-V6 ...........................................................................................................................................52

TD-S6 ..................................................................................................................................................54

TD-VS .................................................................................................................................................56

Contents

4

Page 5

Safety instructions

Read through this section before use. This section describes important

information for you to prevent personal injury or property damage.

■ Symbols

In this instruction manual, the degree of risk caused by incorrect use is noted with the follow-

ing symbols. Please pay attention to the information associated with the symbols.

Indicates mishandling could lead to a fatal or serious

WARNING

CAUTION

accident.

Indicates mishandling could lead to personal injury or prop-

erty damage.

Safety instructions

A symbol accompanies each precaution, suggesting the use of "Caution", "Prohibited actions"

or specic "Requirements".

Caution marks Prohibition mark Requirement mark

Caution

Electrical

shock

Prohibited

Do not rework

or alter

Fire ban

Requirement

Wear

protection

Grounding

Export Restrictions

Technical information contained in this instruction manual might be treated as controlled tech-

nology in your countries, due to agreements in international regime for export control.

Please be reminded that export license/permission could be required when this manual is

provided, due to export control regulations of your country.

Safety instructions

5

Page 6

Requirement

WARNINGS

Turn off power before service

Risk of electrical shock. Be sure to turn off power to stop the pump and

related devices before service is performed.

Stop operation

If you notice any abnormal or dangerous conditions, suspend operation

Requirement

Prohibited

Do not remodel

Wear

protectors

immediately and inspect/solve problems.

Do not use the pump in any condition other than its intended purpose

The use of the pump in any conditions other than those clearly specied

may result in failure or injury. Use this product in specied conditions only.

Do not modify the pump

Alterations to the pump carries a high degree of risk. It is not the manufac-

turer's responsibility for any failure or injury resulting from alterations to the

pump.

Wear protective clothing

Always wear protective clothing such as an eye protection, chemical re-

sistant gloves, a mask and a face shield during disassembly, assembly or

maintenance work. The specic solution will dictate the degree of protec-

Prohibited

tion. Refer to MSDS precautions from the solution supplier.

Stay out from under suspended loads

Risk of personal injury. Keep away from the pump while it is lifted up.

WARNINGS

6

Page 7

WARNINGS

Do not stand on the pump

Do not use the pump as a platform. Injury or damage may result when the

Safety instructions

Prohibited

Caution

Requirement

Prohibited

pump turns over.

Do not get access to the inside of the driven unit during operation

Risk of personal injury. A reciprocating diaphragm/shaft may catch the fin-

ger or hand.

Qualied personnel only

The pump should be handled or operated by qualified personnel with a

full understanding of the pump. Any person not familiar with the product

should not take part in the operation or management of the pump.

Closed-discharge operation is not allowed

Do not close a discharge line during operation. Otherwise, overpressure

will cause liquid leakage or break the pump and piping. Note for the TD

series, a discharge valve is not used for controlling a ow rate.

Requirement

Do not use grid power directory to the pump

Always use an applicable inverter for powering the pump, or fire may

result.

WARNINGS

7

Page 8

Fire ban

CAUTIONS

Use specied power only

Do not apply power other than that specied on the nameplate. Otherwise,

Requirement

Prohibited

Requirement

Caution

failure or re may result. Ensure the pump is properly grounded.

Do not install/store the pump:

• In a ammable/explosive/corrosive atmosphere.

• In a dusty/humid environment.

• Where ambient temperature can exceed 0-40ºC.

• Under mechanical vibrations.

Spill precautions

Ensure protection and containment of solution in the event of plumbing or

pump damage (secondary containment).

Do not touch the pump or pipe with bare hands

Risk of burning. The surface temperature of the pump or pipe rises high

along with liquid temperature in or right after operation.

Electrical

shock

Requirement

Do not bring the pump close to a ammable substance

Keep the pump away from a ammable substance for the prevention of

re. Do not allow a leak of lubricating oil. Observe local rules and regula-

tions for handling of oils.

Install a GFCI (earth leakage breaker)

An electrical failure of the pump may adversely affect other devices on the

same line. Purchase and install an earth leakage breaker separately.

Foreign matter

When foreign matters enter the pump, turn off power immediately to re-

move them. Using the pump with foreign matters may result in failure.

CAUTIONS

8

Page 9

CAUTIONS

Preventative maintenance

Follow instructions in this manual for replacement of wear parts. Do not

Safety instructions

Requirement

Prohibited

Requirement

Prohibited

disassemble the pump beyond the extent of the instructions.

Do not use a damaged pump

Use of a damaged pump could lead to an electric shock or death.

Disposal of a used pump

Dispose of any used or damaged pump in accordance with local rules

and regulations. If necessary, consult a licensed industrial waste disposal

company.

Do not cover the pump with cloth

The motor temperature may build up and a re or an electric/mechanical

failure may result.

Non freezing

Frozen liquid may damage the pump and piping. Drain liquid before leav-

Requirement

Requirement

ing it for a long time or use measures to prevent liquid from freezing in

winter.

Pressure removal

Solution in the discharge line may be under pressure. Release the pres-

sure from the discharge line before disconnecting plumbing or disassem-

bly of the pump to avoid solution spray.

CAUTIONS

9

Page 10

Precautions for use

• Electrical work should be performed by a qualied electrician. Otherwise,

personal injury or property damage may result.

• Shipping inspection with tap water is conducted on every pump. Be sure to

dry off the pump head before operation, or residual water may cause unde-

sirable reaction when having contact with some chemicals.

• Use care handling the pump. Do not drop. An impact may affect pump

performance. Do not use a pump that has been damaged to avoid the risk

of electrical damage or shock.

• The pump is not waterproof. Do not operate the pump while wet with solu-

tion or water, or failure or injury may result. Immediately dry off the pump if

it gets wet.

Caution

Requirement

Caution

Caution

• Do not clean the pump or nameplate with a solvent such as benzine and

thinner. This may discolour the pump or erase printing. Use a dry or a

damp cloth or a neutral detergent.

• Drain liquid before leaving the pump for a long time.

Caution

Requirement

Precautions for use

10

Page 11

Overview

Pump characteristics, features and part names are described in this section.

Introduction

The TD series is the mechanically-driven diaphragm pump. Its pulse-reduction design en-

sures low ow pulsation without the need of an air chamber. A wide selection range of wet

ends allows for delivery of acid, alkaline, viscous liquid, slurry and solvent in various plants or

built-in applications.

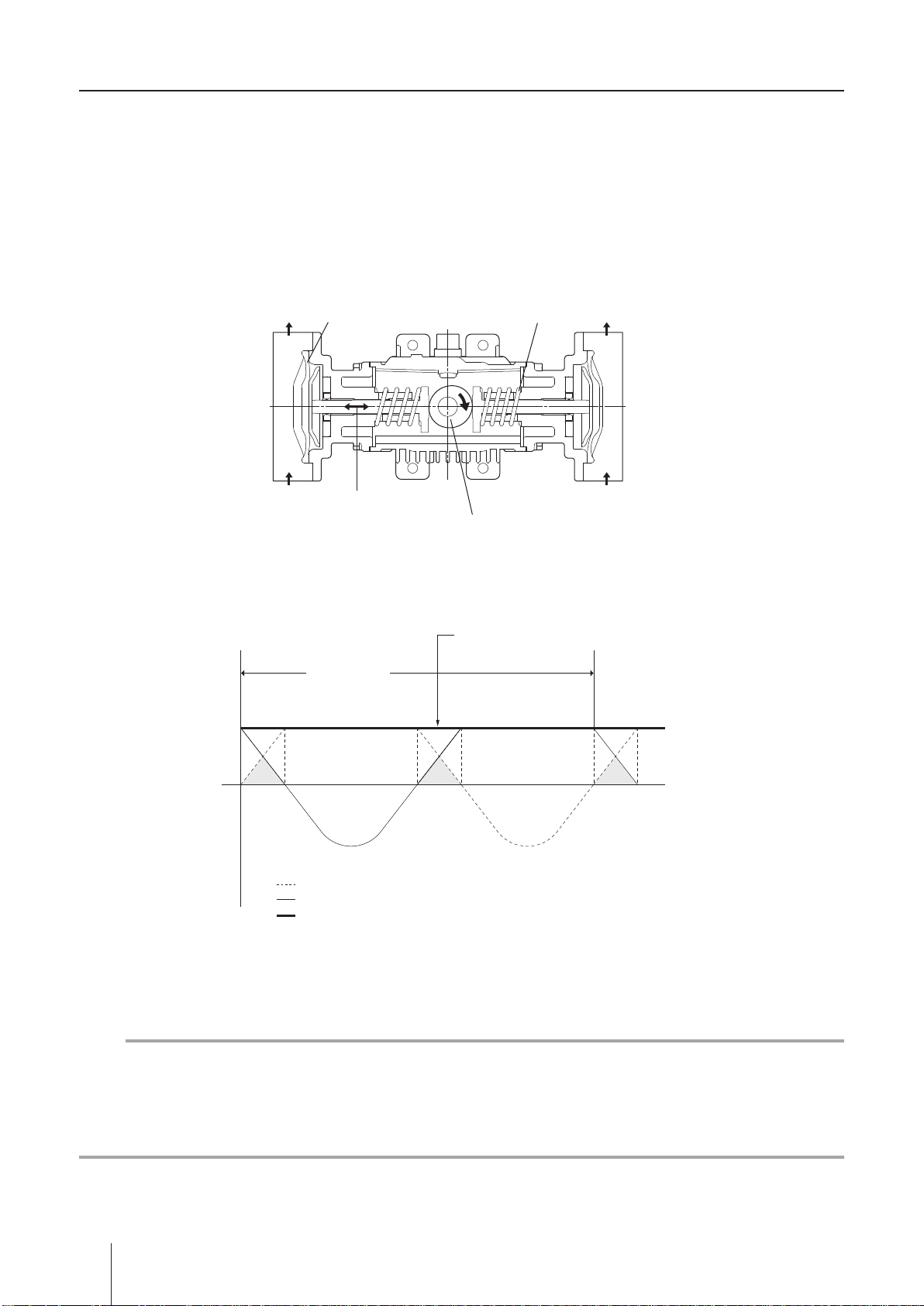

Pump structure & Operating principle

Motor rotation is transmitted to an eccentric cam via a reduction gear and then converted to reciprocating

motion. Volumetric change occurs in the pump chamber as the diaphragm moves back and forth, so liquid is

delivered through the outlet with the assistance of the suction and discharge check valves.

Suction process

When the diaphragm moves back, negative pressure in the pump head opens the suction check valve to take

in liquid while closing the discharge check valve.

Overview

Discharge process

When the diaphragm moves forward, positive pressure in the pump head opens the discharge check valve to

deliver liquid while closing the suction check valve.

Motor

Outlet

Check valve

Pump head

Inlet

Diaphragm

Gear unit

Pump shaft

: Liquid flow

: Motor rotation

: Diaphragm reciprocation

: Valve movement

Introduction

11

Page 12

Pump mechanism

0

■ Flow pulsation reduction mechanism

The reduction mechanism consists of the two factors. One is the use of a highly-precise constant-velocity cam,

which makes a trapezoidal waveform of each discharge. The other is the phase shift of two different discharge,

The rear head moves out of phase with the front by 180 degrees to make a constant synthesized waveform.

The ow rate of the TD can change with a motor rotation speed (inverter frequency).

* Note suction pulsation is not reduced.

Constant-velocity cam and Phase shift

Inlet

Discharge/Suction waveform

Discharge process

Pump shaft

One cycle

Front head

SpringOutlet Diaphragm

Constant-velocity cam

Constant synthesized waveform

Rear head

Outlet

Inlet

Suction process

Discharge/Suction volume of the front head

Discharge/Suction volume of the rear head

Total discharge volume consists of both heads

NOTE

The mechanically-driven diaphragm pump including the TD by its nature involves flow pulsation during op-

eration. The reduction mechanism can reduce but can't eliminate the pulsation completely, and the pulsation

becomes greater as a discharge pressure gets higher. This is because the diaphragm transiently depressed

under a high pressure as with every other mechanically-driven diaphragm pumps.

12

Introduction

Page 13

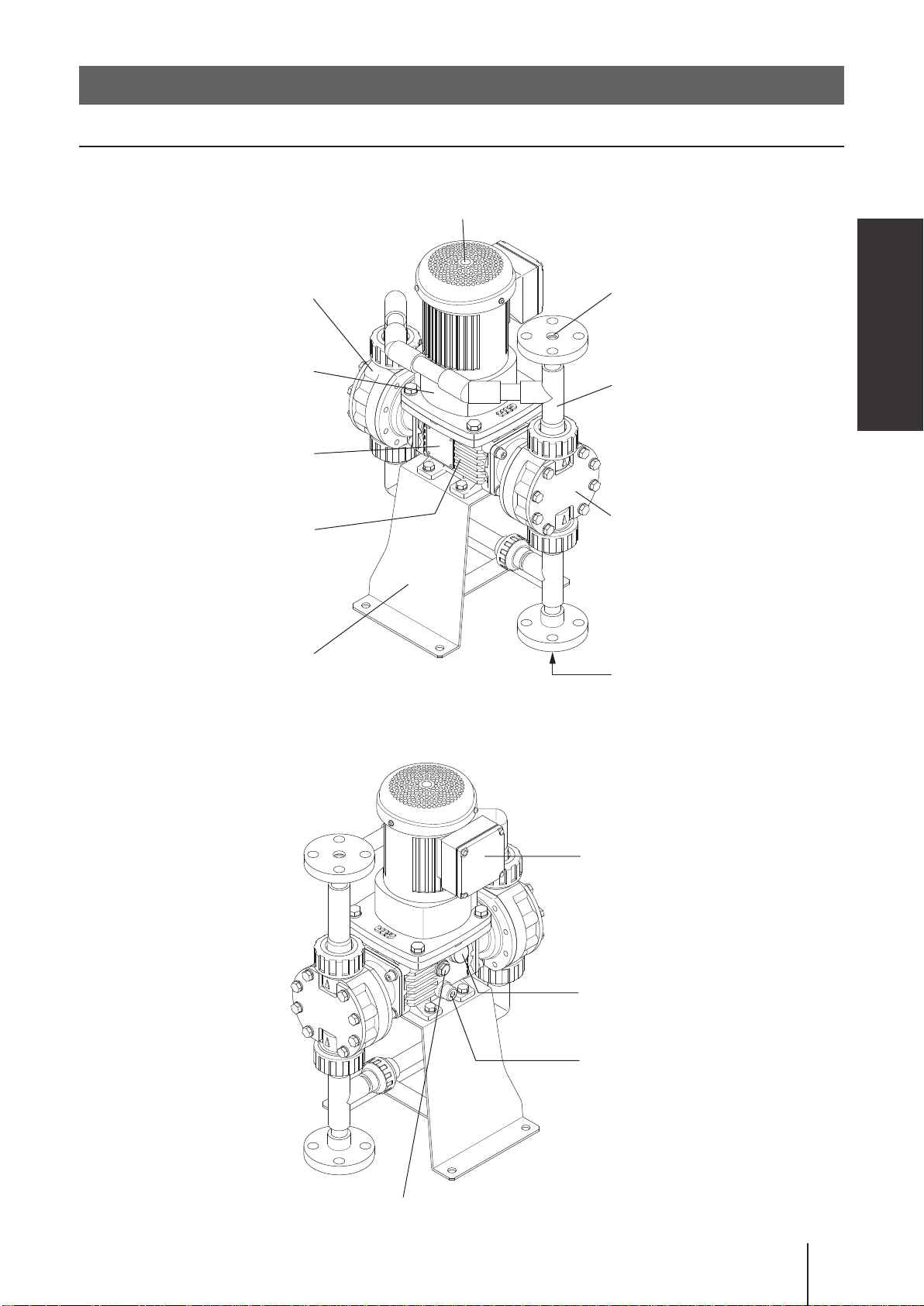

Part names

Pump

■ TD

Rear pump head

Motor

Overview

Outlet

Gear unit

Nameplate

Driven unit

Baseplate

Pipe unit

Front pump head

Inlet

Oil gauge

Terminal box

Oil-filler cap

Oil-drain port

Part names

13

Page 14

Identication codes

Each code represents the following information.

TD - 2 VC FF 1 S - 02 S

a b c d e f g h i

a. Series name

TD

b. Drive unit

M : High-efciency IPM fan motor

No code : High-efciency IPM fanless motor

c. Diaphragm size

01, 03, 05, 1, 2, 4, 6, 8

d. Wet end materials

Code Pump head Valve Valve seat O ring Valve gasket Diaphragm

VC PVC CE

V6 PVC SUS316

VS PVC SUS316 SUS304 EPDM PTFE PTFE+EPDM

S6 SUS316/SCS14 SUS316 SUS316 - PTFE PTFE+EPDM

*DS stands for diaphragm size

FKM: 01-1 (*DS)

PVC: 2-8 (*DS)

EPDM: 01-1 (*DS)

PVC: 2-8 (*DS)

FKM PTFE PTFE+EPDM

EPDM PTFE PTFE+EPDM

Material code

PVC : Polyvinyl chloride SUS316 : Austenitic stainless steel

SUS304 : Austenitic stainless steel SCS14 : Stainless cast steel (SUS316)

CE : Alumina ceramics FKM : Fluorine-contained rubber

EPDM : Ethylene-propylene rubber PTFE : Polytetrauoroethylene

e. Connection type

FF : JIS ange

UU : Union

HH : Tube

* These three connection codes are standard options. Other codes such as FU or UH can be selectable as necessary. In

this case the rst code represents the inlet and the second code the outlet, e.g. FU means JIS ange inlet + union outlet.

*Any union connection is not available for the pumps with 2, 4, 6 and 8 diaphragm sizes and of the S6 type.

*Any tube connection is not available for the pumps with 2, 4, 6 and 8 diaphragm sizes and of the S6 type.

f. Connection direction

1 : Horizontal inlet and outlet

2 : Vertical inlet and outlet

3 : Horizontal inlet and Vertical outlet

4 : Vertical inlet and Horizontal outlet

*The 3rd option is available only for pumps with UU or HH connection type.

g. Special version (pump head)

No code : Standard S : Custom design (e.g. special check valves or pipe I.D.)

h. Motor

0.2 : 0.2kW

i. Special version (drive unit)

No code : Standard S : Custom design (e.g. special motors or baseplates)

14

Identication codes

Page 15

Installation

This section describes the installation of the pump, piping and wiring.

Read through this section before installation is performed.

Points to be observed

Observe the following points when installing the pump:

• Be sure to turn off power to stop the pump and related devices before installation is per-

formed.

• If you notice any abnormal or dangerous conditions, suspend operation immediately and

inspect/solve problems.

• Do not place explosive or ammable material near the pump.

• Do not use a pump that has been damaged to avoid the risk of electrical damage or

shock.

• Use care handling the pump. Do not drop. An impact may affect pump performance.

• Keep the pump as level and as low as possible when it must be lifted up.

• Fumes or vapours can be hazardous with certain solutions. Ensure proper ventilation at

the operation site.

• Observe information on the appropriate drawing and specification sheet.

Pump mounting

Before installation

Check if installation doesn't adversely affect facility, surrounding equipment and the pump. Install the pump according to the following instructions to ensure the optimum performance, safety and service.

• Allow sufcient space around the pump for easy access and maintenance.

• Select a level location, free from vibration, that won't hold liquid. Always use a level gauge.

• Install the pump as close to a supply tank in a ooded suction system.

• Avoid installing the pump:

- In direct sunlight or wind & rain.

- In a dusty/humid place.

- In a corrosive atmosphere.

- In a place where proper ventilation is not maintained.

Installation

Pump mounting

15

Page 16

Pipework

Pipework must be done according to the following instructions to ensure the optimum performance, safety and service.

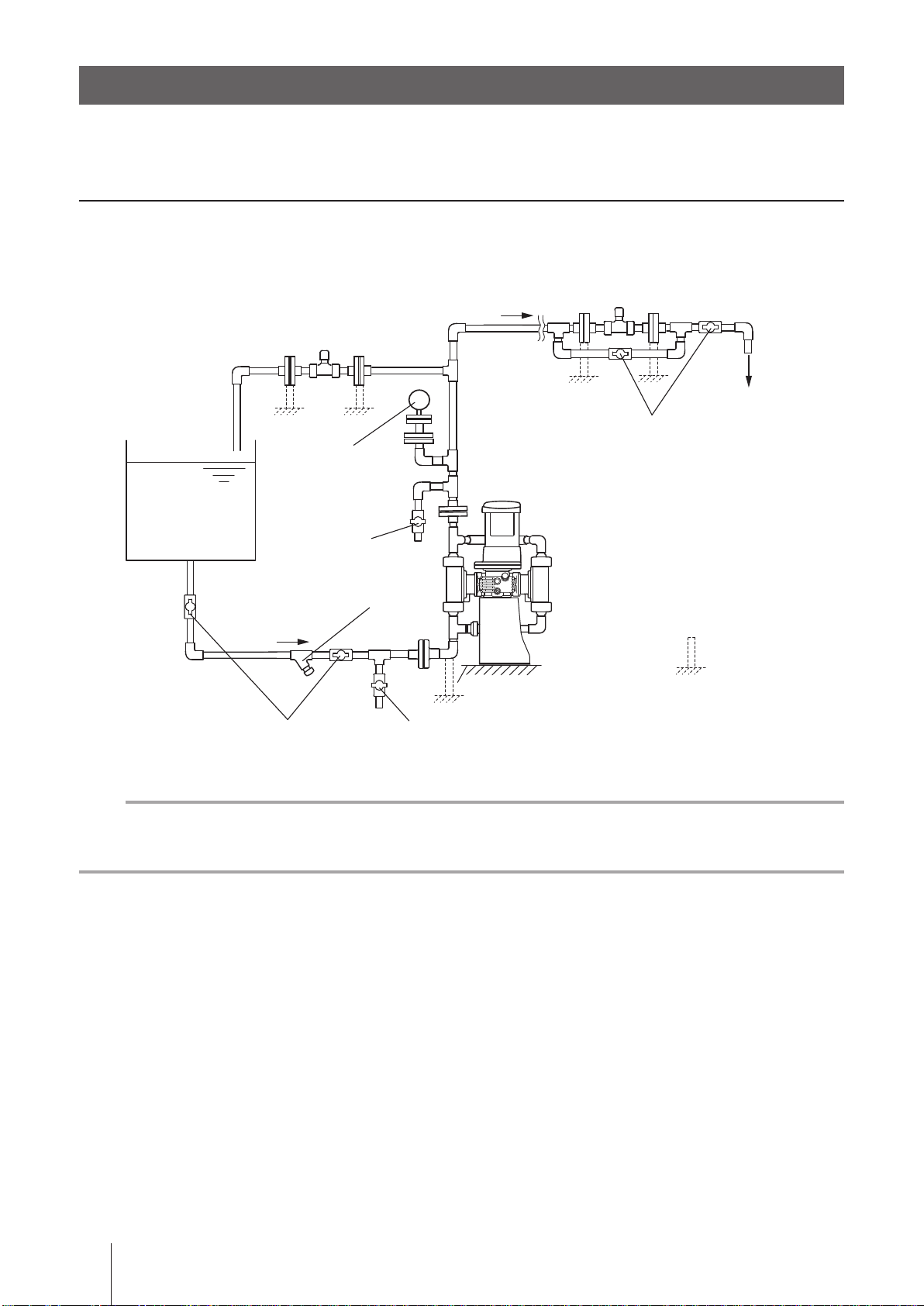

Piping layout

Arrange pump and pipework based on the following piping layout for a long period of operation.

Back pressure valve

Discharge line

Relief valve

(overfeeding prevention)

Injection point

: Pipe support

Flooded suction

Supply tank

Discharge pressure

monitoring gauge

Air vent valve

Y shaped strainer

Suction line

Suction valve

(shut off valve)

P

Maintenance valve

Drain valve

NOTE

• Design an optimal layout to meet NPSHr, especially when planning to deliver slurry.

• If pipework directory weighs on the pump, the pump may be damaged. Be sure to install pipe supports.

16

Pipework

Page 17

Necessary devices

The following devices are needed to the metering pump. Be sure to install, or personal injury or property damage may result.

■ Relief valve

The metering pump by nature keeps working, exceeding the limit pressure of discharge line if it is blocked. This

may damage the pump/piping system and burn out the motor. Install a relief valve close to the pump and x its

set pressure below the maximum allowable pressure of the pump/discharge line.

■ Back pressure valve

Discharge line pressure must be 0.03MPa or higher than suction line pressure. Otherwise, check valve may

not check ow and overfeeding may result. Install a back pressure valve on the discharge line to keep the mini-

mum pressure difference as necessary.

■ Strainer

Provide a 40-mesh strainer at the end of a suction line and clean it periodically. Otherwise, clogging may

result.

Installation

■ Pressure gauge

Install a pressure gauge to monitor the discharge line pressure.

Glossary

Overfeeding is the condition that check valves in the pump head stay open and liquid continues flowing

into discharge line. Always keep the discharge line pressure 0.03MPa or higher than a suction line pres-

sure.

Pipework

17

Page 18

Pump inlet/outlet connections

Arrange the pump inlet and outlet according to a piping system in which the pump is incorporated.

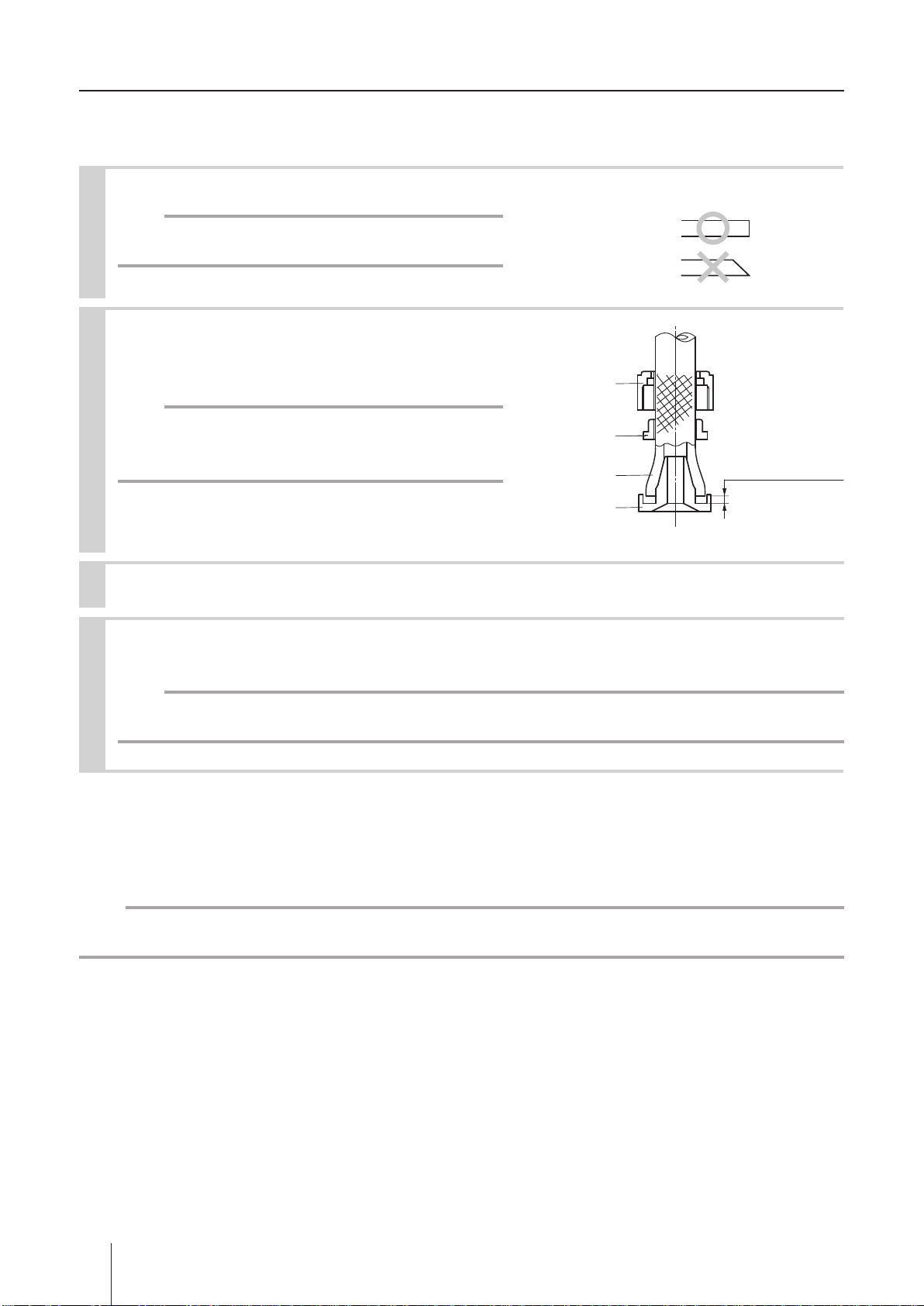

■ Tube connection

Cut the tube ends at.

1

NOTE

Otherwise a leak may result.

Pass a tube into the tting nut and stopper and

2

then slide it down to the tube adapter as far as

it will go.

NOTE

The tube end must come within at least 2mm from the

bottom of the adapter.

Fitting nut

Stopper

Tube

Tube adapter

Tube end (Side view)

Within 2mm

from the bottom

Place an O ring into the inlet/outlet unit (part # 70/71).

3

Secure the tube end (with the tube adapter) on the inlet/outlet unit by hand-tightening the

4

tting nut.

NOTE

The plastic tting nut may be broken if tightened too much.

■ Union connection

Connect the union socket (72) to a plastic ange or joint of your piping system. Use an adhesive to secure the

connection.

NOTE

Do not allow an extra amount of adhesive to enter the pump.

18

Pipework

Page 19

Piping precautions

• Foreign matters such as sand and scale may enter pipework while service is performed. They may cause

fatal damage to the pump. Be sure to blow them out before operation. Also, do not apply adhesive too much

or leave a screw or nut.

• If pipework directory weighs on the pump, the pump may deform. Be sure to install pipe supports.

• Flange connection must be free from any tension or distortion, or a leak or pipe damage may result.

• The suction line I.D. should be equal to or wider than the I.D. of the pump inlet.

• Always keep the inlet of the pump below the liquid level of the supply tank (ooded suction).

• The pump suffers greater pressure loss as the piping length gets longer. Excessive piping resistance may

damage the pump depending on operating conditions such as liquid viscosity, liquid specic gravity and pip-

ing length. Contact us for detail.

■ Prohibited piping

The suction line I.D. is smaller than the

I.D. of the pump inlet. Risk of cavitation.

Suction lift application may adversely affect flow accuracy.

Installation

P

The suction line is too long. Risk of cavitation,

air ingress or greater flow pulsation.

P

P

P

Arched suction line may adversely affect flow accuracy.

P

Pipework

19

Page 20

Slurry delivery

The TD can deliver slurry with some limitations. Contact us for allowable particle size and concentration.

• Branch a drain line from the discharge line.

PP

Drain

• Do not allow any inverted arch line in pipework where slurry can stay.

• Reduce (optimise) the suction and the discharge line I.D. as long as the NPSHr is satised in order to obtain

the maximum possible speed of ow.

• Install a ushing line (tap water) for removing slurry from the pump and piping after delivery.

• Do not use a back pressure valve. The valve may be damaged or clogged by slurry.

• With no use of a back pressure valve, the minimum differential pressure (0.03MPa or higher discharge pres-

sure than suction pressure) may not be satised and overfeeding may occur. In this case extend the dis-

charge line upwards to increase the pressure to the necessary level.

• If the relief valve has opened to release overpressure and been contaminated by slurry, take apart and clean

the inside to remove slurry.

• If an injection point at the end of discharge line is located at a lower position than a tank liquid level, siphon

will take place. In this case extend the rising part of discharge line over the liquid level and then separate the

falling part of it before the tank liquid level.

Tank liquid level

Pipework

20

Flushing line

Extension

P

Set apart the falling part of

discharge line before a tank

liquid level to prevent siphon.

Injection point

Drain

Page 21

Wiring

NFB

Wiring for the inverter and the motor.

Points to be observed

Observe the following points during wiring work:

Do not use grid power directory to the pump. Always use an applicable inverter for pow-

•

ering the pump, or fire may result.

Electrical work should be performed by a qualied electrician. Always observe applica-

•

ble codes or regulations.

Do not perform wiring work while electric power is on. Otherwise, an electrical shock or

•

a short circuit may result. Be sure to turn off the power before wiring work.

Inverter-Motor

Electrically connect the inverter and the motor through the U, V and W lines. See the diagram below for detail.

Wiring diagram

Inverter output terminal

Motor terminal

U/ T1 V/T2 W/T3

↓ ↓ ↓

U V W

Black Gray White

Installation

NOTE

• Connect an electric conduit to the ø21.5mm hole of the motor-terminal box to cover the Inverter-Motor wiring.

• Always check the U, V and W lines are properly connected. Miswiring leads to signicant pulsation in a discharge line.

• Do not extend the U, V and W lines longer than 50m. Do not use a shielded cable for the lines.

Inverter-Grid power

Electrically connect the inverter with a grid power through the R, S and T lines. See manufacturer's manuals

for details of the inverter. Install a NFB for easy maintenance.

R

S

T

GND

R

S

T

INV

U/T1

V/T2

W/T3

U

Black

V

Gray

W

White

Green/Yellow

Motor

NFB: Non-Fuse Breaker

INV: Inverter

Wiring

21

Page 22

IPM motor terminal box

53

80

Use an electric conduit for the Inverter-Motor wiring. See the dimension below for detail. A conduit connection

hole of I.D. 21.5mm is made on a 4mm thick terminal box.

Aluminium terminal box

80

4

ø21.5

Motor

Unit: mm

22

Wiring

Page 23

Operation

This section describes pump operation and programming. Run the pump

after pipework and wiring are completed.

Before operation

Always check the following items before the rst-time operation or resuming operation after a

long period of stoppage.

Points to be observed

Observe the following points during operation:

• The pump should be handled or operated by qualified personnel with a full understand-

ing of the pump. Any person not familiar with the product should not take part in the

operation or maintenance of the pump.

•

Risk of burning. The surface temperature of the pump or motor rises up to 80ºC in or

right after operation.

•

Do not close a discharge line during operation. Otherwise, liquid leakage or pump head/

motor/piping breakage may result due to overpressure.

•

Do not close a suction line during operation. Otherwise, internal parts are excessively

worn by friction heat and fatal pump damage results.

• Risk of electrical shock. Be sure to turn off power to stop the pump and related devices

before service is performed.

• Check for transit damage, loose bolts and an oil leak.

• Check the motor rated voltage corresponds to the power voltage supplied to the inverter. See motor name-

plate.

• Electrical wiring must be correct. See the "Wiring" section on page 21 and inverter manufacturer's manual.

• Check a liquid level in the supply tank.

• Check if the discharge and suction lines are laid correctly.

• Check the oil gauge on the driven unit. An oil level should be at the middle of the gauge (marked in red).

Red mark

Operation

Before operation

23

Page 24

Operation

Read this section before operation.

Starting procedure

Start the pump by the following procedure.

Open the suction and discharge valves.

1

Turn on the inverter power.

2

Push the RUN key to start the pump.

3

See page 25 for detail.

NOTE

Set the frequency dial to about 10Hz at the start. Increase the drive frequency as necessary in later steps.

Check the rotational direction of the motor.

4

Clockwise seen from the motor end (positive rotation) is the correct direction.

NOTE

For the pumps with a fanless motor, check output from the pump. Signicant output pulsation may be a

sign of reverse motor rotation. Correct motor wiring as necessary.

Expel air from the pump head.

5

Open an air vent line to expel air while taking in liquid into the pump head. Close the line after the pump

head is lled with liquid.

Check the pump operation for abnormality.

6

In cold climates, an electric current to the motor can double at the start of operation. This overcurrent re-

sults when gear-oil temperature is too low. Run the pump with no discharge pressure until the oil warms

up.

Turn the frequency dial to a desired position.

7

Increase a ow to a specied rate. See page 25 for detail.

Use a calibration cylinder to measure discharge capacity.

8

Repeat measurement. The pump and system are ok when the measured discharge capacity does not

change.

NOTE

Observe the above instructions to keep the optimal operating conditions. If you notice any abnormal or dangerous

conditions, suspend operation immediately and inspect/solve problems. See page 27 "Troubleshooting" or contact us.

Operation

24

Page 25

Inverter operation

See below for the basic operation of the VF-nC3M transistor inverter with default setting. See manufacturer's

manual for other programming including external frequency control.

Frequency display

RUN key

■ Start/Stop of operation

Use the RUN key to start and the STOP key to stop the motor.

STOP key

Frequency dial

Operation

■ Flow rate adjustment

This pump does not have a stroke length knob that general metering pumps have for adjusting a ow rate. The

TD changes a ow rate with the inverter, controlling a motor speed.

NOTE

Observe the allowable control frequency range at each model, or the IPM motor may break. Note that the

following data is based on operation at the maximum discharge pressure (see page 48).

TD-01/-03/-05/-1/-2/-4: 6-60Hz

TD-6/-8: 10-60Hz

Turn the frequency dial clockwise to increase and anticlockwise to decrease Hz and a

1

ow rate.

Operation Drive frequency Details

Power is turned ON

The dial is turned

to 60Hz

Power is turned OFF

0.0Hz

A ow rate is changed to 60.0Hz.

The drive frequency is stored after the inverter is

turned off.

Operation

25

Page 26

Before stoppage

• After everyday operation, release the liquid and pressure from the pump and pipework and turn off power.

• Before a long period of stoppage, flush the inside of the pump and pipework with clean water or cleaning liq-

uid. Completely drain and depressurize them afterwards.

• Frozen liquid may damage the pump and piping. Remove liquid completely in winter.

• Band heaters can be used to keep the pump and piping warm when suspending operation just for a short

period of time in winter.

Resumption after a long period of stoppage

When operation is resumed after a long period of stoppage (one week later), do not run the pump without com-

missioning. Always check a tank liquid level and run the pump according to the starting procedure on page 24.

26

Operation

Page 27

Maintenance

This section describes troubleshooting, maintenance, wear part replace-

ment, exploded views and specications.

Points to be observed

Observe the following points during maintenance work:

• Follow instructions in this manual for replacement of wear parts. Do not disassemble the

pump beyond the extent of the instructions.

• Always wear protective clothing such as an eye protection, chemical resistant gloves, a

mask and a face shield during disassembly, assembly or maintenance work.

• Risk of electrical shock. Be sure to turn off power to stop the pump and related devices

before/during service is performed. See below.

Risk of burning. Do not touch the pump or pipe with bare hands. The surface temperature

•

of the pump or pipe rises high along with liquid temperature in or right after operation.

Troubleshooting

First check the following points. If the following measures do not help remove problems, contact your nearest distributor.

States Possible causes Solutions

Motor does not

starts to run.

Flow is too low.

Flow is too high.

Flow uctuates.

Grid power is directly connected to the motor.

Disconnection

Power fuse has blown. Inspect/solve the root cause of the blowout.

Power voltage reduction

Overpressure (discharge line) Check a discharge line or check valves.

Out of frequency range.

Inverter is not working. Repair the inverter. Replace as necessary.

NPSHr is not satisfied.

A check valve and valve seat have been worn.

Foreign matters in the check valve Take apart and clean the valve.

Clogged suction line or strainer Take apart and clean them.

Air ingress from the suction line.

Different liquid is used.

A relief valve is open. Check/reset the set pressure.

Damaged diaphragm Replace with new one.

Damaged gaskets or O rings Replace with new ones.

Minimal differential pressure of 0.03MPa is

not kept and overfeeding results.

Different liquid is used.

NPSHr is not satisfied.

A check valve and valve seat have been worn.

Use an inverter. Replace motor if necessary.

Replace/reconnect motor wires as necessary.

Inspect/solve the root cause of the reduction.

Observe the allowable frequency. See page 25.

Review the pump and piping system to meet

the NPSHr.

Replace with new ones.

Check for loose connections and retighten

as necessary.

Check liquid characteristics and pump specification.

Keep the minimal differential pressure. Use

a back pressure valve as necessary.

Check liquid characteristics and pump specification.

Review the pump and piping system to meet

the NPSHr.

Replace with new ones.

Maintenance

Troubleshooting

27

Page 28

States Possible causes Solutions

gaseous liquid Take measures to reduce gas.

No discharge

Great pulsation

Discharge pres-

sure is too low.

Liquid leaks.

Air ingress

from:

No discharge

from:

A leak from: a damaged diaphragm Replace with new one.

Reverse motor rotation. Use an inverter or correct wiring.

A check valve and valve seat have been worn.

Foreign matters in the check valve Take apart and clean the valve.

Suction line vibration is too big. Support the suction lines.

A check valve and valve seat have been worn.

Foreign matters in the check valve Take apart and clean the valve.

Pressure gauge has failed. Replace with new one.

Clogging in a pressure gauge Remove clogging.

A relief valve is open. Check/reset the set pressure.

Damaged diaphragm Replace with new one.

Overpressure (discharge line)

Damaged diaphragm Replace with new one.

Damaged gaskets or O rings Replace with new ones.

Misarranged valve assembly Rebuild it in correct order.

Loose connection of the inlet and outlet Tighten them as necessary.

Loose pump-head-fixing-bolts Tighten them as necessary.

Motor failure Replace with new one.

a suction line (imperfect

joint or sealing)

an empty tank

Clogged suction line or strainer

Foreign matters in a check valve

A damaged check valve

and valve seat

Check for an imperfect joint/sealing and

retighten as necessary.

Rell the supply tank. Degassing is required

before resuming operation.

Take apart and clean them.

Take apart and clean the valve.

Replace with new ones.

Replace with new ones.

Replace with new ones.

Inspect/solve the root cause of overpressure.

NPSHr is not satisfied.

A noise level is too

high.

Oil leaks. Damaged gaskets or O rings Replace with new ones.

No suction

Motor temperature

is too high (80ºC

or more).

Damaged driven unit Repair or replace with new one.

Overpressure (discharge line) Inspect/solve the root cause of overpressure.

Oil level, grade or quality is wrong. Check if it is proper. Replace as necessary.

A check valve and valve seat have been worn.

Foreign matters in the check valve Take apart and clean the valve.

Clogged suction line or strainer Take apart and clean them.

Air ingress from a suction line.

Damaged diaphragm Replace with new one.

Damaged gaskets or O rings Replace with new ones.

Entrained air in the pump head. Perform degassing.

Misarranged valve assembly Rebuild it in correct order.

Overpressure (discharge line) Inspect/solve the root cause of overpressure.

Target frequency is too high or low. Reset the dial to a proper position.

Review the pump and piping system to

meet the NPSHr.

Replace with new ones.

Check for loose connections and retighten

as necessary.

Troubleshooting

28

Page 29

Inspection

Perform daily and periodic inspection to keep pump performance and safety.

Daily inspection

Check the following points. Upon sensing abnormality, stop operation immediately and remove problems according to "Troubleshooting".

When wear parts come to the life limit, replace them with new ones. Contact your distributor for detail.

No. Inspection items Points to be checked

1 Noise and vibration

Air ingress from pump head joints

2

and a suction line

3 Pressure gauge/Flow meter/Ammeter

4 Oil gauge on the driven unit • If an oil level is proper and oil is not leaked or deteriorated.

5 Spare pump condition

• If abnormal noise or vibration occurs. They are signs of abnor-

mal operation.

• If leakage occurs.

• If pump head bolts or nuts are loose. Tighten with a torque

wrench as necessary.

• If the rated discharge pressure, flow rate and a motor load current on the spec labels are observed. If not, remove problems.

• If it is usable. Run it from time to time to keep it ready for opera-

tion at any time when needed.

Periodic inspection

Check wear parts such as valve set (a check valve, valve guide, valve seat and valva gasket), diaphragm and

tubing for heavy damage or wear at least every 6 months.

Part names Points to be checked Measures

Check valve, valve guide,

valve seat, valve gasket,

O ring

If they are damaged or worn.

Replace as soon as possible if pump performance has reduced. Note their lives change with

operating conditions such as liquid characteristics.

Replace as soon as possible if pump perform-

Diaphragm If it is damaged or worn.

If it is hardened or discoloured

by ultraviolet-ray or chemical

Tubing

liquid.

If it is damaged by high pressure.

ance has reduced. Note its life changes with operating conditions such as liquid characteristics.

Replace as soon as possible if pump performance has reduced. Note its life changes with operating conditions such as liquid characteristics.

Maintenance of IPM motor

An IPM gear motor used in the TD series pump is the combination of a motor and a reduction gear unit, and

the NLGI #0 extreme pressure lithium base grease is used in the gear unit. This long life grease can be used

up to 10,000 hours of operating time or 3-5 years of useful life, but then needs replaced after either period has

passed. Note replacement of the grease must be conducted by a skilled engineer. Contact us or your distributor.

Maintenance

Inspection

29

Page 30

NOTE

• Tighten the pump head bolts (parts# 20) when a leak is found from the pumphead-bracket seal. See the

exploded view pages for the rated tightening torque at each pump model. If it can't stop a leak, replace the

diaphragm.

• A leak from the vent hole is the sign of diaphragm rupture. Stop the pump immediately and replace the dia-

phragm.

Pumphead-Bracket seal

Pump head

Pump head bolt

Bracket

Vent hole

Oil replacement (drive unit)

Replace the lubricating oil in the drive unit every 4000 hours operation or 1 year after delivery, whichever

comes first.

• When the rst time the pump is used, replace the oil after 500 hours of running-in period to remove initial

abrasion powder. Or abnormal wear may be caused.

• The specied oil volume is about 220mL.

NOTE

Always use the oil brand below. Otherwise, pump damage or in the worst case fair may result.

Specied oil brand

Oil company Brand name

SUMICO LUBRICANT CO., LTD. Molyoil F320

30

Inspection

Page 31

■ Replacement procedure

Prepare a container to receive used oil in advance.

Remove the oil cap.

1

Remove the drain plug.

2

Use a container to collect used oil.

Oil cap

Drain plug

Replace the drain plug after the drive unit is emptied.

3

Remove old seal tape from the drain-plug threads and apply new one before retting the plug.

Rell gear oil.

4

The specied oil volume is about 220ml. Always check an oil level comes to the middle of the oil gauge,

or the driven unit may fail to operate properly.

Maintenance

Red mark

Inspection

31

Page 32

Wear part replacement

To run the pump for a long period, wear parts need to be replaced periodically.

Contact your distributor with the following information for wear part replacement.

1. Part names and part number (see the "Exploded view" section.)

2. Pump model identification code and manufacturing number (see pump nameplate.)

3. Drawing number if you have our approval drawing

Precautions

• Solution in the discharge line may be under pressure. Release the pressure from the

discharge line before disconnecting plumbing or disassembly of the pump to avoid solution spray.

• When dismantling the pump, pay attention to the residual liquid in the pump head.

• Always wear protective clothing such as an eye protection, chemical resistant gloves, a

mask and a face shield during disassembly, assembly or maintenance work.

• Follow instructions in this manual for replacement of wear parts. Do not disassemble the

pump beyond the extent of the instructions.

• Risk of electrical shock. Be sure to turn off power to stop the pump and related devices

before service is performed.

32

Wear part replacement

Page 33

Before assembly/disassembly

• Inch the motor or rotate the motor fan by hand to extend the pump shaft to the maximum length when removing the diaphragm.

• Inch the motor or rotate the motor fan by hand to contract the pump shaft to the minimum length when replacing the pump head to the bracket.

• When a new diaphragm is mounted, clean the diaphragm-side retainer surface and apply the grease; Dow

Corning Toray MOLYKOTE® HP-500. Always apply a screw burning protective agent to the diaphragm shaft.

• Observe the mounting direction of the valve assembly. If the outlet valve assembly is mounted upside down,

the pump falls into closed-discharge operation and excessive pressure may damage the pump or cause per-

sonal injury when it bursts.

• Always fasten the pump head to the specied tightening torque (see the exploded view pages) in diagonal

order. Repeat the procedure once again to make sure the possibility of a leak is eliminated.

31

24

1

6

4 2

3

5

1

8

4

6

5

3

7

2

Maintenance

Wear part replacement

33

Page 34

Exploded view

Pump head

■ TD-01/-03 VC/V6

Tube : HH3

Union : UU3

73

72

76*

Front head

Observe the

mounting direction.

Observe the

mounting direction.

85

84

83

76*

CAUTION

20

CAUTION

Flange : FF1

FF4

77

76*

71

10*

9

5*

3*

2*

4*

7*

22

21

Flange : FF2

78

76*

FF3

Valve set

216*

31

30*

1

7*

5*

3*

Valve set

2*

4*

9

10*

Rear head

Rotate anticlockwise

to remove

diaphragm.

Diaphragm

Pump shaft

Retainer

Apply the specied

grease onto the surface. See page 33 for

detail.

70

76*

72

73

76*

70

Union : UU3

78

Flange : FF1

FF3

85

Tube : HH3

* The parts denoted by an asterisk are wear parts and need replaced periodically (every time the service life has passed).

See the next page for the estimated life of each part based on operation with clean water at room temperature.

*The front and rear pump heads consist of the same component parts and assembly sequence.

Exploded view

34

84

83

76*

Flange : FF2

FF4

CAUTION

Take care not to drop the valve set or not to get

wet with residual chemicals in the pump head

when removing the inlet pipe unit (70).

Inch the motor or rotate the motor

fan by hand to extend the pump

shaft to the maximum length when

mounting the diaphragm. Fasten the diaphragm into the shaft

through the retainer until it bottoms

out and will not turn further.

Page 35

Parts list

No. Part names # of parts Materials Estimated life

1 Pump head 1 PVC 2* Valve 2

3* Valve guide 2 PVC 8000hrs or 1 YR

4* Valve seat 2

5* Valve gasket 2 PTFE 8000hrs or 1 YR

7* O ring 2

9 Fitting 2 PVC -

10* O ring 2

20 Hexagon bolt 4 Stainless steel -

21 Spring washer 4 Stainless steel -

22 Plain washer 4 Stainless steel -

30* Diaphragm 1 PTFE+EPDM 4000hrs or 6 months

31 Retainer 1 SUS304 70 Inlet pipe unit 1 PVC 71 Outlet pipe unit 1 PVC 72 Union socket 2 PVC 73 Nut 2 PVC -

2: FF1/FF3/

76* O ring

77 Flange elbow unit 1 PVC -

78 Flange unit

83 Tube adapter 2 PVC -

84 Stopper 2 SS400 85 Fitting nut 2 CFRPVDF -

216* Oil seal 1 NBR 8000hrs or 1 YR

*The parts with an estimated life are wear parts and need to be replaced periodically.

* The listed number of parts is required to consist of one single pump head except for parts # 70 and 71.

HH3/UU3

1: FF2/FF4

1: FF1/FF2

2: FF3

VC V6

Alumina ceramics SUS316

VC V6

PVC PVC

VC V6

FKM EPDM

VC V6

FKM EPDM

VC V6

FKM EPDM

PVC -

8000hrs or 1 YR

8000hrs or 1 YR

8000hrs or 1 YR

8000hrs or 1 YR

8000hrs or 1 YR

NOTE

Retighten the bolts/parts evenly to the following torque.

Tightening torque

Part No. Torque

#9 5 N•m

#20 2.9 N•m

Exploded view

Maintenance

35

Page 36

■ TD-05/-1 VC/V6/VS

Flange : FF1

77

Tube : HH3

85

Union : UU3

73

72

76*

Front head

84

83

76*

Flange : FF2

FF3

78

FF4

76*

76*

71

CAUTION

Observe the mounting direction.

CAUTION

Observe the mounting direction.

73

Union : UU3

Flange : FF1

72

76*

FF3

10*

9

5*

3*

2*

4*

7*

22

21

20

76*

78

85

Tube : HH3

84

Valve set

1

7*

5*

3*

2*

4*

9

10*

76*

83

Flange : FF2

214*

218

31

30*

Valve set

70

217*

FF4

Rear head

Rotate anticlockwise

to remove diaphragm.

Pump shaft

Retainer

Apply the specied

Diaphragm

grease onto the

surface. See page

33 for detail.

70

Inch the motor or rotate the motor fan by hand

to extend the pump shaft to the maximum length

when mounting the diaphragm. Fasten the diaphragm into the shaft through the retainer until it

bottoms out and will not turn further.

CAUTION

Take care not to drop the valve set or not to get

wet with residual chemicals in the pump head

when removing the inlet pipe unit (70).

* The parts denoted by an asterisk are wear parts and need replaced periodically (every time the service life has passed).

See the next page for the estimated life of each part based on operation with clean water at room temperature.

*The front and rear pump heads consist of the same component parts and assembly sequence.

36

Exploded view

Page 37

Parts list

No. Part names # of parts Materials Estimated life

1 Pump head 1 PVC 2* Valve 2

3* Valve guide 2 PVC 8000hrs or 1 YR

4* Valve seat 2

5* Valve gasket 2 PTFE 8000hrs or 1 YR

7* O ring 2

9 Fitting 2 PVC -

10* O ring 2

20 Hexagon bolt 6 Stainless steel -

21 Spring washer 6 Stainless steel -

22 Plain washer 6 Stainless steel -

30* Diaphragm 1 PTFE+EPDM 4000hrs or 6 months

31 Retainer 1 SUS304 70 Inlet pipe unit 1 PVC 71 Outlet pipe unit 1 PVC 72 Union socket 2 PVC 73 Nut 2 PVC -

2: FF1/FF3/

76* O ring

77 Flange elbow unit 1 PVC -

78 Flange unit

83 Tube adapter 2 PVC -

84 Stopper 2 SS400 85 Fitting nut 2 CFRPVDF -

214* Oil seal assy 1 - 8000hrs or 1 YR

217* Oil seal gasket 1 Nonasbestos

218 Hex socket head bolt 4 Steel -

*The parts with an estimated life are wear parts and need to be replaced periodically.

* The listed number of parts is required to consist of one single pump head except for parts # 70 and 71.

NOTE

Retighten the bolts/parts evenly to the following torque.

Tightening torque

Part No. Torque

#9 9 N•m

#20 2.9 N•m

HH3/UU3

1: FF2/FF4

1: FF1/FF2

2: FF3

Alumina ceramics SUS316 SUS316

VC V6 VS

VC V6 VS

FKM EPDM SUS304

VC V6 VS

FKM EPDM EPDM

VC V6 VS

FKM EPDM EPDM

VC V6 VS

FKM EPDM EPDM

PVC -

8000hrs or 1 YR

8000hrs or 1 YR

8000hrs or 1 YR

8000hrs or 1 YR

8000hrs or 1 YR

Every time the oil seal

assy is dismantled.

Maintenance

Removal of the Oil seal assy

Screw in the attached two M4 hex sock head

bolts as below to remove the oil seal assy.

M4×25 hex sock head bolt

Oil seal assy

Exploded view

37

Page 38

■ TD-01/-03 VS

Tube : HH3

85

Union : UU3

73

72

76*

Front head

84

83

76*

Flange : FF1

FF4

77

76*

71

10*

Flange : FF2

78

76*

FF3

CAUTION

Observe the mounting direction.

CAUTION

Observe the mounting direction.

72

73

Union : UU3

Flange : FF1

20

76*

FF3

22

21

78

Tube : HH3

9

3*

2*

4*

5*

7*

76*

85

Valve set

7*

3*

2*

4*

5*

9

10*

83

84

216*

31

30*

1

Valve set

76*

Flange : FF2

70

FF4

Rear head

Rotate anticlockwise

to remove

diaphragm.

Pump shaft

Diaphragm

Retainer

Apply the specied

grease onto the surface. See page 33 for

detail.

Inch the motor or rotate the motor

fan by hand to extend the pump

shaft to the maximum length when

mounting the diaphragm. Fas-

70

ten the diaphragm into the shaft

through the retainer until it bottoms

out and will not turn further.

CAUTION

Take care not to drop the valve set or not to get

wet with residual chemicals in the pump head

when removing the inlet pipe unit (70).

* The parts denoted by an asterisk are wear parts and need replaced periodically (every time the service life has passed).

See the next page for the estimated life of each part based on operation with clean water at room temperature.

*The front and rear pump heads consist of the same component parts and assembly sequence.

38

Exploded view

Page 39

Parts list

No. Part names # of parts Materials Estimated life

1 Pump head 1 PVC 2* Valve 2 SUS316 8000hrs or 1 YR

3* Valve guide 2 PVC 8000hrs or 1 YR

4* Valve seat 2 SUS304 8000hrs or 1 YR

5* Valve gasket 2 PTFE 8000hrs or 1 YR

7* O ring 2 EPDM 8000hrs or 1 YR

9 Fitting 2 PVC -

10* O ring 2 EPDM 8000hrs or 1 YR

20 Hexagon bolt 4 Stainless steel -

21 Spring washer 4 Stainless steel -

22 Plain washer 4 Stainless steel -

30* Diaphragm 1 PTFE+EPDM 4000hrs or 6 months

31 Retainer 1 SUS304 70 Inlet pipe unit 1 PVC 71 Outlet pipe unit 1 PVC 72 Union socket 2 PVC 73 Nut 2 PVC -

2: FF1/FF3/

76* O ring

77 Flange elbow unit 1 PVC -

78 Flange unit

83 Tube adapter 2 PVC -

84 Stopper 2 SS400 85 Fitting nut 2 CFRPVDF -

216* Oil seal 1 NBR 8000hrs or 1 YR

*The parts with an estimated life are wear parts and need to be replaced periodically.

* The listed number of parts is required to consist of one single pump head except for parts # 70 and 71.

HH3/UU3

1: FF2/FF4

1: FF1/FF2

2: FF3

EPDM 8000hrs or 1 YR

PVC -

NOTE

Retighten the bolts/parts evenly to the following torque.

Tightening torque

Part No. Torque

#9 5 N•m

#20 2.9 N•m

Maintenance

Exploded view

39

Page 40

■ TD-2/-4/-6/-8 VC/V6/VS

71

Front head

7*

Rear head

CAUTION

Observe the mounting direction.

29

20

CAUTION

Observe the mounting direction.

70

3*

2*

4*

5*

5*

3*

2*

4*

7*

218

217*

214*

31

30*

1

Rotate anticlockwise

to remove diaphragm.

74*

Pump shaft

Retainer

Apply the specied

Diaphragm

grease onto the surface. See page 33 for

CAUTION

Take care not to drop the valve set or not to get

wet with residual chemicals in the pump head

when removing the inlet pipe unit (70).

Inch the motor or rotate the motor fan by hand

to extend the pump shaft to the maximum length

when mounting the diaphragm. Fasten the dia-

detail.

phragm into the shaft through the retainer until it

bottoms out and will not turn further.

* The parts denoted by an asterisk are wear parts and need replaced periodically (every time the service life has passed).

See the next page for the estimated life of each part based on operation with clean water at room temperature.

*The front and rear pump heads consist of the same component parts and assembly sequence.

40

Exploded view

Page 41

Parts list

No. Part names # of parts Materials Estimated life

1 Pump head 1 PVC -

2* Valve 2

Alumina ceramics SUS316 SUS316

VC V6 VS

8000hrs or 1 YR

3* Valve guide 2 PVC 8000hrs or 1 YR

4* Valve seat 2

VC V6 VS

PVC PVC SUS304

8000hrs or 1 YR

5* Valve gasket 2 PTFE 8000hrs or 1 YR

7* O ring 2

VC V6 VS

FKM EPDM EPDM

8000hrs or 1 YR

20 Hexagon bolt 8 Stainless steel -

29 Reinforcing plate 1 SS400 -

30* Diaphragm 1 PTFE+EPDM 4000hrs or 6 months

31 Retainer 1 SUS304 70 Inlet pipe unit 1 - -

71 Outlet pipe unit 1 - -

74* O ring 1

VC V6 VS

FKM EPDM EPDM

8000hrs or 1 YR

214* Oil seal assy 1 - 8000hrs or 1 YR

217* Oil seal gasket 1 Nonasbestos

Every time the oil seal

assy is dismantled.

218 Hex socket head bolt 4 Steel -

*The parts with an estimated life are wear parts and need to be replaced periodically.

* The listed number of parts is required to consist of one single pump head except for parts # 70 and 71.

NOTE

Retighten the pump head mounting bolts evenly to the following torque in diagonal order.

Tightening torque

Part No. Torque

#20 12 N•m

Removal of the Oil seal assy

Screw in the attached two M4 hex sock head

bolts as below to remove the oil seal assy.

M4×25 hex sock head bolt

Suction line mounting

Hand-tighten the pump nut (a) and (b), and then joint nut. If the joint nut

is fastened rst, a poor ow rate or poor suction head may result.

Maintenance

Oil seal assy

Pump nut (b)

Joint nut

Pump nut (a)

Exploded view

41

Page 42

■ TD-01/-03 S6

Flange : FF2

FF3

Front head

71

75*

9

Flange : FF1

FF4

71

Hold the fitting (#9) with a spanner when tightening the pipe unit

(#70/71) to the pump head.

CAUTION

Observe the mounting direction.

20

CAUTION

Observe the mounting direction.

21

5*

3*

2*

5*

4*

5*

Valve set

216*

30*

1

5*

3*

2*

Valve set

5*

4*

5*

9

75*

31

70

Rotate anticlockwise

to remove

diaphragm.

Diaphragm

70

Rear head

Pump shaft

Retainer

Apply the specied

grease onto the

surface. See page

33 for detail.

Flange : FF1

FF3

Flange : FF2

FF4

Inch the motor or rotate the motor fan by

hand to extend the pump shaft to the maximum length when mounting the diaphragm.

Fasten the diaphragm into the shaft through

the retainer until it bottoms out and will not

turn further.

CAUTION

Take care not to drop the valve set or not to get

wet with residual chemicals in the pump head

when removing the inlet pipe unit (70).

* The parts denoted by an asterisk are wear parts and need replaced periodically (every time the service life has passed).

See the next page for the estimated life of each part based on operation with clean water at room temperature.

*The front and rear pump heads consist of the same component parts and assembly sequence.

42

Exploded view

Page 43

Parts list

No. Part names # of parts Materials Estimated life

1 Pump head 1 SUS316 2* Valve 2 SUS316 8000hrs or 1 YR

3* Valve guide 2 SUS316 8000hrs or 1 YR

4* Valve seat 2 SUS316 8000hrs or 1 YR

5* Valve gasket 6 PTFE 8000hrs or 1 YR

9 Fitting 2 SUS316 -

20 Hexagon bolt 4 Stainless steel -

21 Spring washer 4 Stainless steel -

30* Diaphragm 1 PTFE+EPDM 4000hrs or 6 months

31 Retainer 1 SUS304 70 Inlet pipe unit 1 SUS316 -

71 Outlet pipe unit 1 SUS316 -

75* Gasket 2 PTFE 8000hrs or 1 YR

216* Oil seal 1 NBR 8000hrs or 1 YR

*The parts with an estimated life are wear parts and need to be replaced periodically.

* The listed number of parts is required to consist of one single pump head except for parts # 70 and 71.

NOTE

Retighten the bolts/parts evenly to the following torque.

Tightening torque

Part No. Torque

#9 25 N•m

#20 2.9 N•m

#70 25 N•m

#71 25 N•m

Exploded view

Maintenance

43

Page 44

■ TD-05/-1 S6

Flange : FF2

FF3

71

Flange : FF1

FF4

Front head

CAUTION

Observe the mounting direction.

75*

5*

3*

2*

5*

4*

5*

71

Hold the fitting (#9) with a spanner when tightening the pipe unit

(#70/71) to the pump head.

9

Rear head

Valve set

218

30*

1

217*

214*

31

CAUTION

Observe the mounting direction.

21

20

Flange : FF1

FF3

5*

3*

2*

Valve set

5*

4*

5*

9

75*

Flange : FF2

FF4

70

70

Rotate anticlockwise

to remove

diaphragm.

Pump shaft

Retainer

Diaphragm

Apply the specied

grease onto the surface. See page 33 for

detail.

Inch the motor or rotate the motor fan by hand

to extend the pump shaft to the maximum length

when mounting the diaphragm. Fasten the diaphragm into the shaft through the retainer until it

bottoms out and will not turn further.

CAUTION

Take care not to drop the valve set or not to get

wet with residual chemicals in the pump head

when removing the inlet pipe unit (70).

* The parts denoted by an asterisk are wear parts and need replaced periodically (every time the service life has passed).

See the next page for the estimated life of each part based on operation with clean water at room temperature.

*The front and rear pump heads consist of the same component parts and assembly sequence.

44

Exploded view

Page 45

Parts list

No. Part names # of parts Materials Estimated life

1 Pump head 1 SUS316 2* Valve 2 SUS316 8000hrs or 1 YR

3* Valve guide 2 SUS316 8000hrs or 1 YR

4* Valve seat 2 SUS316 8000hrs or 1 YR

5* Valve gasket 6 PTFE 8000hrs or 1 YR

9 Fitting 2 SUS316 -

20 Hexagon bolt 6 Stainless steel -

21 Spring washer 6 Stainless steel -

30* Diaphragm 1 PTFE+EPDM 4000hrs or 6 months

31 Retainer 1 SUS304 70 Inlet pipe unit 1 SUS316 -

71 Outlet pipe unit 1 SUS316 -

75* Gasket 2 PTFE 8000hrs or 1 YR

214* Oil seal assy 1 - 8000hrs or 1 YR

217* Oil seal gasket 1 Nonasbestos

218 Hex socket head bolt 4 Steel -

*The parts with an estimated life are wear parts and need to be replaced periodically.

* The listed number of parts is required to consist of one single pump head except for parts # 70 and 71.

Every time the oil seal

assy is dismantled.

NOTE

Retighten the bolts/parts evenly to the following torque.

Tightening torque

Part No. Torque

#9 25 N•m

#20 3.5 N•m

#70 25 N•m

#71 25 N•m

Maintenance

Exploded view

45

Page 46

■ TD-2/-4/-6/-8 S6

Front head

81

82

71

75*

80

8

Rear head

CAUTION

Observe the mounting direction.

CAUTION

Observe the mounting direction.

20

6*

3*

2*

6*

4*

6*

21

Valve set

30*

6*

3*

2*

Valve set

6*

4*

6*

8

80

214*

217*

218

31

1

Rotate anticlockwise to remove

diaphragm.

Pump shaft

Retainer

Apply the specied

Diaphragm

grease onto the surface. See page 33 for

detail.

75*

Inch the motor or rotate the motor fan by hand

to extend the pump shaft to the maximum length

when mounting the diaphragm. Fasten the diaphragm into the shaft through the retainer until it

bottoms out and will not turn further.

70

82

81

CAUTION

Take care not to drop the valve set or not to get

wet with residual chemicals in the pump head

when removing the inlet pipe unit (70).

* The parts denoted by an asterisk are wear parts and need replaced periodically (every time the service life has passed).

See the next page for the estimated life of each part based on operation with clean water at room temperature.

*The front and rear pump heads consist of the same component parts and assembly sequence.

46

Exploded view

Page 47

Parts list

No. Part names # of parts Materials Estimated life

1 Pump head 1 SUS316/SCS14 -

2* Valve 2 SUS316 8000hrs or 1 YR

3* Valve guide 2 SUS316 8000hrs or 1 YR

4* Valve seat 2 SUS316 8000hrs or 1 YR

6* Valve gasket 6 PTFE 8000hrs or 1 YR

8 Valve support 2 SUS316 -

20 Hexagon bolt 8 Stainless steel -

21 Spring washer 8 Stainless steel -

30* Diaphragm 1 PTFE+EPDM 4000hrs or 6 months

31 Retainer 1 SUS304 70 Inlet pipe unit 1 SUS316 -

71 Outlet pipe unit 1 SUS316 -

75* Gasket 2 PTFE 8000hrs or 1 YR

80 Hex socket head bolt 8 Stainless steel -

81 Hexagon bolt 8 Stainless steel -

82 Spring washer 8 Stainless steel -

214* Oil seal assy 1 - 8000hrs or 1 YR

217* Oil seal gasket 1 Nonasbestos

218 Hex socket head bolt 1 Steel -

*The parts with an estimated life are wear parts and need to be replaced periodically.

* The listed number of parts is required to consist of one single pump head except for parts # 70 and 71.

Every time the oil seal

assy is dismantled.

NOTE

Retighten the pump head mounting bolts evenly to the following torque in diagonal order.

Tightening torque

Part No. Torque

#20 12 N•m

Removal of the Oil seal assy

Screw in the attached two M4 hex sock head

bolts as below to remove the oil seal assy.

M4×25 hex sock head bolt

Oil seal assy

Maintenance

Exploded view

47

Page 48

Specications/Outer dimensions

Specications

Information in this section is subject to change without notice.

■ Pump

TD-VC/-V6/-S6

TD- 01/-M01 TD-03/-M03 TD-05/-M05

Flow rate*

1

l/h 9 18 30 60 138 252 378 510

l/min 0.15 0.3 0.5 1 2.3 4.2 6.3 8.5

Max discharge press. MPa 1.0 0.5 0.4 0.3

Repeatability ±2% FS

Linearity ±2% FS

Max allowable

viscosity*

2

(Newtonian liquid)

1

*

Represents the discharge capacity based on pumping clean water at 25ºC and the max discharge pressure, and may

increase as the pressure reduces.

2

*

Flow rate reduces by about 10-30% of the rated values above when viscous liquid is delivered.

VC 300mPa•s

V6 500mPa•s

S6 500mPa•s 1000mPa•s

TD-1/- M1 TD-2/-M2 TD-4/-M4 TD- 6/-M6 TD-8/-M8

TD-VS

Flow rate

TD- 01/-M01 TD-03/-M03 TD-05/-M05

l/h 7.2 14.4 24 48 138 252 378 510

l/min 0.12 0.24 0.4 0.8 2.3 4.2 6.3 8.5

TD-1/- M1 TD-2/-M2 TD-4/-M4 TD- 6/-M6 TD-8/-M8

Max discharge press. MPa 1.0 0.5 0.4 0.3

Repeatability ±2% FS

Linearity ±2% FS

Max allowable

viscosity

VS 300-1000mPa•s

(Newtonian liquid)

*

The above information is based on operation with silicone oil (Newtonian liquid) of 1000mPa•s at 25°C with our plumbing

system and may change with plumbing conditions or when a different liquid is used.

*

When liquid viscosity gets lower, a ow rate increases and repeatability becomes worse.

Specications/Outer dimensions

48

Page 49

TD-VC/-V6/-S6/-VS

TD- 01/-M01 TD-03/-M03 TD-05/-M05

TD-1/- M1 TD-2/-M2 TD-4/-M4 TD- 6/-M6 TD-8/-M8

Flow control method Motor rpm control

Turndown ratio 1:10 1:6

Control

range

Frequency Hz 6-60 10-60

Stroke rate*

1

spm 12-120 7-72 12-120 15-90 20-120

Reduction ratio 1:15 1:25 1:15 1:20 1:15

Stroke length mm 1.2 2.3 1.2 2.3 6

Diaphragm effective dia. mm ø30 ø60 ø72 ø100

Outlet 15A 25A

Inlet 15A

15A (VS:25A)

25A