Page 1

Iwaki

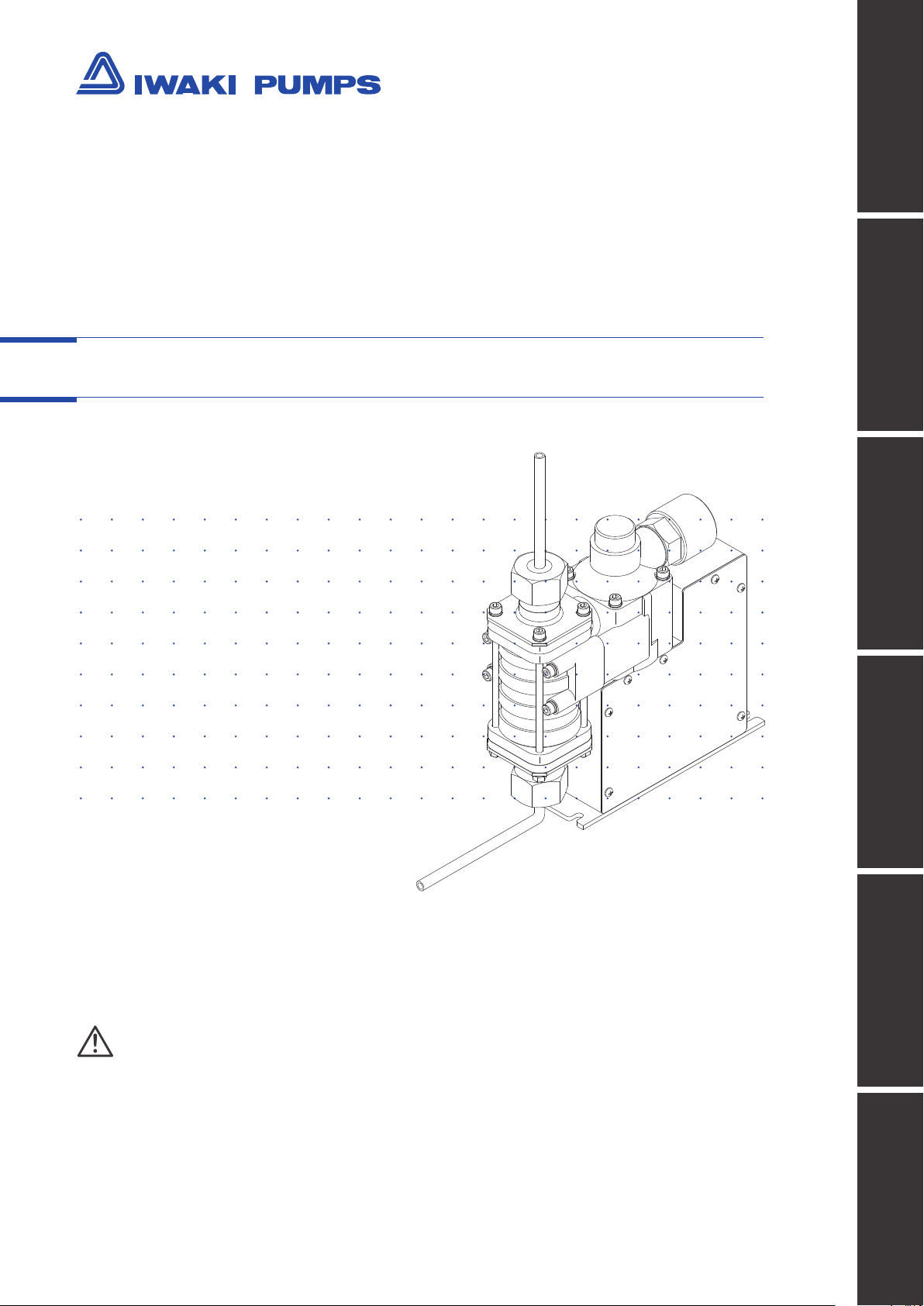

Photoresist Dispensing Pump

PDS-105 RA/RB

Safety instructions Overview Installation Operation Maintenance

Instruction manual

Thank you for choosing our product.

Please read through this instruction manual before use.

This instruction manual describes important precautions and instructions for the product. Always keep it on hand for quick reference.

©2011 IWAKI CO., LTD.

Specication

Page 2

Order conrmation

Open the package and check that the product conforms to your order. If any problem or

inconsistency is found, immediately contact your distributor.

a. Check if the delivery is correct.

Check the nameplate to see if the information such as model codes and production number are as or-

dered.

MODEL

Model code

Production number

1P417431

b. Check if the required number of accessories is provided.

<Attached accessories>

• R-03-PB8F signal wire connector (one each)

• R-03-PB5F motor wire connector (one each)

c. Check if the delivery is damaged or deformed.

Check for transit damage and loose bolts.

Order conrmation

2

Page 3

Contents

Order conrmation .......................................................................................................................................... 2

Safety instructions .................................................................... 5

Warnings ........................................................................................................................................................ 6

Cautions ......................................................................................................................................................... 7

Precautions for use ...................................................................................................................................... 8

Overview .................................................................................... 9

Introduction ................................................................................................................................................... 9

Pump structure & Operating principle ........................................................................................................ 9

Discharge process ................................................................................................................................ 9

Suction process .................................................................................................................................. 10

Part names ................................................................................................................................................... 11

Identication codes .................................................................................................................................... 12

Installation ...............................................................................13

Before installation ....................................................................................................................................... 13

Installation/Piping/Wiring .......................................................................................................................... 14

Installation ................................................................................................................................................ 14

Piping ....................................................................................................................................................... 14

Wiring ....................................................................................................................................................... 15

Applicable motor drivers .......................................................................................................................... 16

Operation ..................................................................................17

Pump setting ............................................................................................................................................... 17

Pulse input & Motor rotation ..................................................................................................................... 17

Number of pulses & Flow volume ....................................................................................................... 17

Number of pulses & Flow rate ............................................................................................................. 17

Return to origin ......................................................................................................................................... 18

Home sensor output is "OFF" ............................................................................................................. 18

Home sensor output is "ON" ............................................................................................................... 18

Operation programming ........................................................................................................................... 18

Time based control (when using an Oriental Motor SG9200-2 pulse controller) ................................ 19

Flow based control (when using a pulse signal as a start signal) ....................................................... 20

Pump operation ........................................................................................................................................... 21

Contents

3

Page 4

Maintenance ............................................................................ 22

Troubleshooting .......................................................................................................................................... 22

Inspection .................................................................................................................................................... 23

Daily inspection ........................................................................................................................................ 23

Specication/Outer dimension .................................................................................................................. 24

Specication ............................................................................................................................................. 24

Pump ................................................................................................................................................... 24

Stepping motor .................................................................................................................................... 25

Encoder (RB type) ............................................................................................................................... 25

Home sensor ....................................................................................................................................... 25

Pressure sensor .................................................................................................................................. 25

Outer dimension ....................................................................................................................................... 26

PDS-105R A/B .................................................................................................................................... 26

4

Contents

Page 5

Safety instructions

Fire ban

Read through this section before use. This section describes important

information for you to prevent personal injury or property damage.

■ Symbols

In this instruction manual, the degree of risk caused by incorrect use is noted with the follow-

ing symbols. Please pay attention to the information associated with the symbols.

Indicates mishandling could lead to a fatal or serious

WARNING

CAUTION

accident.

Indicates mishandling could lead to personal injury or prop-

erty damage.

Safety instructions

A symbol accompanies each precaution, suggesting the use of "Caution", "Prohibited actions"

or specic "Requirement".

Caution marks Prohibited marks Requirement marks

Caution

Electrical

shock

Prohibited

Do not rework

or alter

Requirement

Wear

protection

Export Restrictions

Technical information contained in this instruction manual might be treated as controlled tech-

nology in your countries, due to agreements in international regime for export control.

Please be reminded that export license/permission could be required when this manual is

provided, due to export control regulations of your country.

Safety instructions

5

Page 6

Requirement

WARNING

Turn off power before work

Risk of electrical shock. Be sure to turn off power to stop the pump and

related devices before service is performed. Let other people know about

the situation by displaying a notice such as "POWER OFF (Maintenance)"

near the power switch.

Stop operation

If you notice any abnormal or dangerous conditions, suspend operation

Requirement

Prohibited

Do not remodel

Wear

protectors

immediately and inspect/solve problems.

Do not use the pump in any condition other than its intended purpose

The use of the pump in any conditions other than those clearly specied

may result in failure or injury. Use this product in specied conditions only.

Do not modify the pump

Alterations to the pump carries a high degree of risk. It is not the manufac-

turer's responsibility for any failure or injury resulting from alterations to the

pump.

Wear protective clothing

Always wear protective clothing such as an eye protection, chemical re-

sistant gloves, a mask and a face shield during disassembly, assembly or

maintenance work. The specic solution will dictate the degree of protec-

tion. Refer to MSDS precautions from the solution supplier.

6

Requirement

WARNING

Spill precautions

Ensure protection and containment of solution in the event of plumbing or

pump damage (secondary containment).

Page 7

CAUTION

Qualied personnel only

The pump should be handled or operated by qualied personnel with a

Safety instructions

Requirement

Prohibition

Requirement

Prohibition

full understanding of the pump. Any person not familiar with the product

should not take part in the operation or maintenance of the pump.

Use specied power only

Do not apply any power other than that specied on the nameplate. Other-

wise, failure or re may result. Ensure the pump is properly grounded.

Ventilation

Fumes or vapours can be hazardous with certain solutions. Ensure proper

ventilation at the operation site.

Do not install or store the pump:

• In a ammable atmosphere.

• In a dusty/humid environment.

• In a corrosive atmosphere.

Flushing before operation

Requirement

Requirement

Requirement

Requirement

Flush the inside of the pump and piping with pure water or the liquid to be

delivered before the start of operation.

Static electricity

When low electric conductivity liquids such as ultra-pure water and fluor

TM

inactive liquid (e.g. Fluorinert

) are handled, the static electricity may be

generated in the pump and may cause static discharge. Take counter-

measures to remove the static electricity.

Before returning product

Be sure to drain chemicals and clean the inside of the pump before return

so that a harmful chemical does not spill out in transit.

Disposal of a used pump

Dispose of any used or damaged pump in accordance with relevant regu-

lations. Consult a licensed industrial waste products disposing company.

CAUTION

7

Page 8

Precautions for use

• Electrical work should be performed by a qualied electrician. Otherwise,

personal injury or property damage could result.

• Do not install the pump:

–In a ammable atmosphere.

–In a dusty/humid place.

– In a corrosive atmosphere.

• Allow sufficient space around the pump for easy access and maintenance.

• Use care handling the pump. Do not drop. An impact may affect pump

performance. Do not use a pump that has been damaged to avoid the risk

of electrical damage or shock.

Caution

Caution

Caution

• The pump is not waterproof. Do not operate the pump while wet with solu-

tion or water. Failure or injury may result. Immediately dry off the pump if it

gets wet.

• Do not close discharge line during operation. Solution may leak or piping

may break.

• Solution in the discharge line may be under pressure. Release the pres-

sure from the discharge line before disconnecting plumbing or disassembly

of the pump to avoid solution spray.

• Wear protective clothing when handling or working with pumps. Consult

solution MSDS for appropriate precautions. Do not come into contact with

residual solution.

Caution

Caution

Requirement

Caution

Precautions for use

8

Page 9

Overview

Pump working principle, part names and identication codes are described in this section.

Introduction

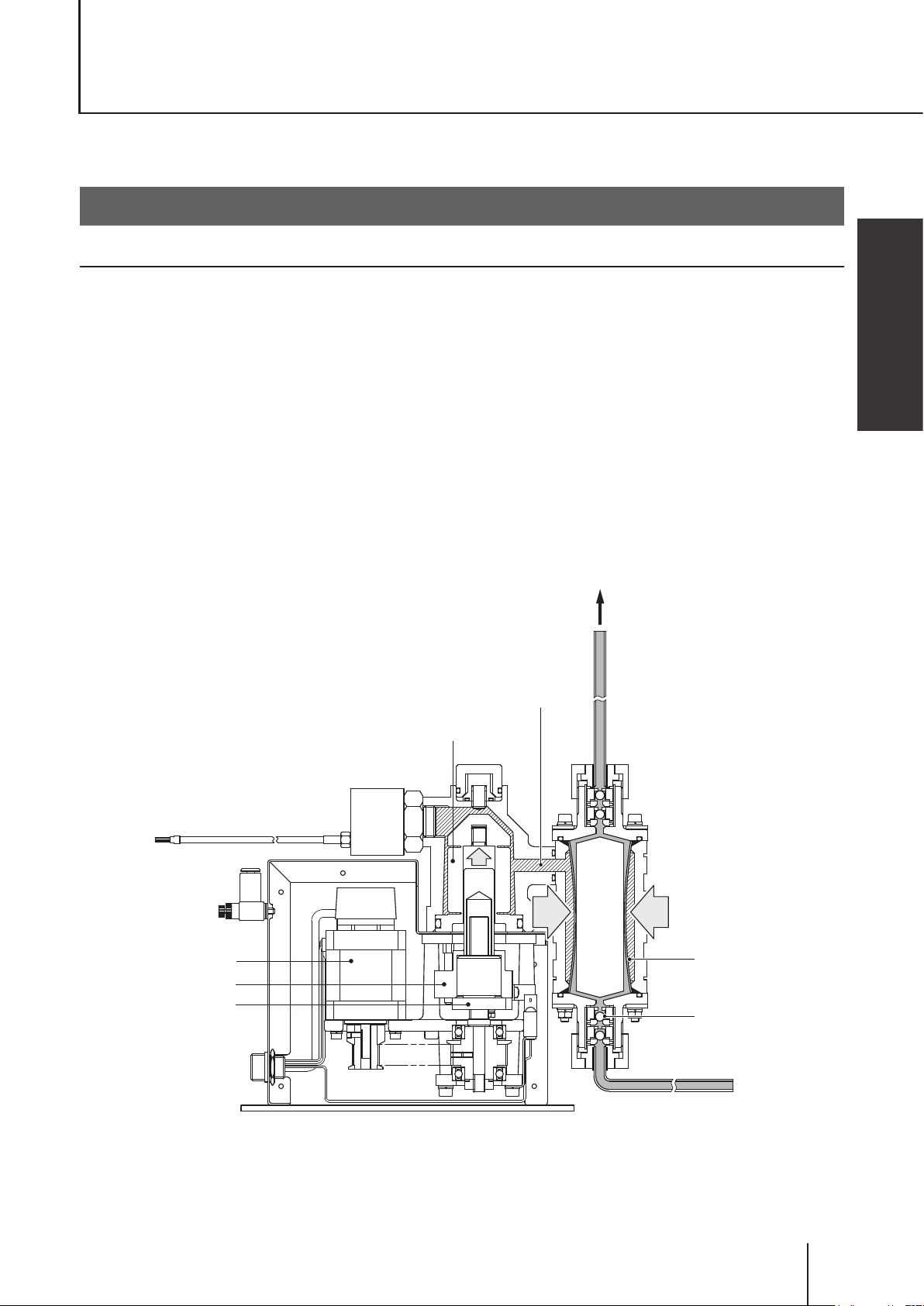

Pump structure & Operating principle

The rotational motion of the stepping motor is changed to linear motion by the direct drive unit. Liquid is loaded

into the pump head and then delivered to a discharge line as the bellows reciprocates.

Principle of operation

● The bellows expands and contracts as the ball screw reciprocates.

● The reciprocating motion of the bellows compresses or expands the shape of the tubephragm via hydraulic

uid.

● Volumetric change is created in the tubephragm.

● Liquid is taken in as the tubephragm expands and is pushed out as it contracts in sync with the action of the

check valves (pump head valves).

Overview

■ Discharge process

Stepping motor

Cylinder

Ball screw

OUT

Hydraulic fluid

Bellows

Tubephragm

Check valve

Introduction

9

Page 10

■ Suction process

IN

10

Introduction

Page 11

Part names

Pressure sensor

Monitors hydraulic pressure.

Outlet

Overview

Base

Always anchor it with bolts.

Speed controller joint

Used for air purge.

Motor-Driver wiring terminal

Used for connecting a motor driver.

Inlet

Nameplate

Signal line terminal

Used for connection with user's PLC.

*Do not clean the pressure sensor, speed controller or nameplate with a solvent such as benzine or thinner.

Shows a model code and MFG number.

Part names

11

Page 12

Identication codes

Each code represents the following information.

PDS - 1 05 RA - K T W2 - 01

a b c d e f g h

a. Series name

b. Product classication

1: Pump

c. Flow rate

05: 5.0ml/shot (max discharge capacity)

d. Drive unit

RA: Compact type (with no encoder)

RB: Compact type (with an encoder)

e. Wet end O ring

K : Kalrez®

f. Pressure sensor

P : Positive pressure sensor (0-1000kPa)

T : Compound pressure sensor (-100 - 300kPa)

g. Inlet/outlet I.D.

W2: 1/4" (ø6.35×ø4.35mm) PFA tube connection

M6: ø6×ø4 [mm] PFA tube connection

h. Special version

No code: Standard

01: Custom design (coded in ascending order)

Identication codes

12

Page 13

Installation

This section describes the installation of the pump, piping and wiring. Read through

this section before work.

Points to be observed

Observe the following points when installing the pump:

• Be sure to turn off power to stop the pump and related devices before service is performed.

• Be careful for the power not to be turned on while service is performed.

• If you notice any abnormal or dangerous conditions, suspend operation immediately and

inspect/solve problems.

• Do not install the pump in a ammable atmosphere.

Observe the following points during wiring work:

Electrical work should be performed by a qualied electrician. Always observe applica-

•

ble codes or regulations.

Do not perform wiring work while the power is on. Otherwise, an electrical shock or

•

short circuit may result. Be sure to turn off power before wiring work.

Be careful for the power not to be turned on during work.

•

Installation

Before installation

A driver in a user's PLC and other related devices are necessary for operation. Purchase

these devices including a motor driver separately as needed. The following diagram is a gen-

eral system example. Congure your system in accordance with an actual service condition.

User's PLC

Controller

Solenoid valve

Motor driver

Air-operated

Pump

valve

Nozzle

Silicon wafer

Chemical liquid

Before installation

13

Page 14

Installation/Piping/Wiring

NOTE

Do not hold the pump head to lift the pump unit up, or the pump head may deform and a leak may result.

Installation

Observe the following points during installation.

● Installation location

Mount the pump indoors. Allow sufcient space around the pump for easy access and maintenance.

● Mounting position

• Install the pump as close to a supply tank as possible in a ooded suction system.

• Make sure the discharge-line end-nozzle is positioned higher than a chemical liquid level.

Nozzle

Chemical liquid

● Mounting direction

Always direct the outlet upward. Keep the pump head in a vertical position with the check valves upright.

Otherwise, performance may be reduced.

● Anchoring

Fix the pump with four M4 mounting screws (with PW and SW).

Piping

Observe the following points during pipework.

● Pipe connection

Both inlet and outlet of the pump have PFA tube joints. Secure every joint properly to eliminate any possibility

of air ingress, or performance may be reduced.

● Fitting and Tube

Take account of corrosion and pressure resistance when selecting ttings and tubes.

● Pipe resistance

Keep a piping length shortest with the minimum number of bends.

Installation/Piping/Wiring

14

Page 15

Wiring

Observe the following diagram.

24VDC

SG9200-2 Pulse Controller

PLC

GND

YesNo

Use of a pulse controller:

24VDC

10 11 12

1 2 3 4 5 6 7 8 9

CN2

1

3

2

CN1

ORIENTAL MOTOR

CSD5807N2-P driver

GND

1 2 3 4 5

CN3

Terminal assignment

Driver connector PIN1 (Blue motor lead)

Driver connector PIN2 (Red motor lead)

Driver connector PIN3 (Orange motor lead)

Driver connector PIN4 (Green motor lead)

Driver connector PIN5 (Black motor lead)

A

B

No.

Motor line connectors

E

C

D

Installation

Input of a pulse signal rotates the motor clockwise

(seen from the motor output shaft).

Input of a pulse signal rotates the motor counterclockwise

(seen from the motor output shaft).

CW pulse input

−

1

2

CCW pulse input

+

−

3

4

+

Motor driver CN2 terminal assignment

● Photocoupler ON: HALF Step

When at “photocoupler is ON”, the current to the motor stops,

All Windings

+

5

● Photocoupler OFF: FULL Step

allowing the motor shaft to be rotated by hand.

Signal

Off Signal

Step Angle

−

+

−+−

6

7

8

● A signal is output whenever the motor excitation sequence

returns to step “0” in synchronization with the input pulse signal

● Photocoupler ON: Automatic Current Cutback Release

Automatic Current

Cutback Release Signal

9

10

(output transistor is ON).

Excitation Timing

+

11

Encoder A phase + Line driver output

Terminal assignment

A

No.

Signal line connectors

● A signal is output every 10 pulses in full step mode and every

20 pulses in half step mode.

Signal

−

12

Encoder A phase - Line driver output

B

GND (common)

Encoder B phase + Line driver output

C

Sensor output (open collector)

Encoder B phase - Line driver output

D

5-24VDC (home sensor power)

5VDC (encoder power)

F

E

H

G

Note: An encoder is equipped only to the B type.

*When using an Oriental motor SG9200-2 pulse controller, consult its instruction manual as well.

Wiring Diagram

Installation/Piping/Wiring

15

Page 16

Applicable motor drivers

See the table below for applicable ORIENTAL MOTOR's motor drivers.

Product name

CR D5107PB 24VDC

CR D507- K D 24VDC Built in

Rated power

voltage

Driver type

Pulse-train

input

Pulse input

type

1 pulse/

2 pulse

(I/O,

RS485)

Driver type Cable Attached connector

PCB

BOX

• Cable set

LCS04SD5 (0.6m)

• Motor lead connector

LCS5N06B (0.6m)

LCS5N10B (1m)

<Accessories>

• In/out cable connector

• Motor lead connector

• MOREX 51103-0200

• MOREX 51103-1200

• MOREX 51103-0500

• MOREX 50351-8100 (contact)

• PHOENIX CONTACT MC1,5/3STF-3,5 power line connector

CSD5807N-P 24VDC

SD 5107P3 24VDC

RK D507- A 100VAC

Pulse-train

input

Pulse-train

input

Pulse-train

input

2 pulse PCB

2 pulse PCB

1 pulse/

2 pulse

BOX

• Driver cable set

LCS01CSK5 (0.6m)

• Driver cable set

LCS04SD5 (0.6m)

• Motor lead connector

LC5N06B (0.6m)

LC5N10B (1m)

CC05PK5 5m motor cable

CC10PK5 10m motor cable

CC20PK5 20m motor cable

• AMP 171822-3

• AMP 1-171822-2

• AMP 171822-5

• MOREX 51103-0200

• MOREX 51103-1200

• MOREX 51103-0500

• MOREX 50351-8100 (contact)

• Control signal in/out connector

Case: MOREX 54311-1201

Connector: MOREX 54306-2019

Installation/Piping/Wiring

16

Page 17

Operation

This section describes pump operation. Observe instructions in this manual. See manufacturer's instruction manual for the motor driver.

Pump setting

First, program operation of the pump.

Pulse input & Motor rotation

The pump lets out liquid at the input of the CCW direction command pulse and takes in liquid at the input of the

CW direction command pulse.

At factory default setting, the motor-driven cylinder (sensor dog) is at the origin where a home sensor output

turns ON. Be sure the cylinder returns to the origin before operation. See the next page for detail.

■ Number of pulses & Flow volume

Number of input pulses Calculated ow volume

2400 1ml

4800 2ml

7200 3ml

9600 4ml

12000 5ml

■ Number of pulses & Flow rate

Number of input pulses per sec Calculated ow rate

2400 pps 1ml/sec

4800 pps 2ml/sec

7200 pps 3ml/sec

9600 pps 4ml/sec

Operation

Pump setting

17

Page 18

Return to origin

Program the origin return behaviour to ensure the motor-driven cylinder to come back to origin before opera-

tion every day. The behaviour should be different depending on whether the home sensor output is ON or OFF

at an input of an origin return signal. See the programming chart below for detail.

■ Home sensor output is "OFF"

Input of an origin return

signal (from PLC)

Home sensor output

signal (from pump)

Pump behaviour

Discharge

process

Suction

process

Origin

Offset interval (max 600 pulses from origin)

■ Home sensor output is "ON"

Input of an origin return

signal (from PLC)

Home sensor output

signal (from pump)

Pump behaviour

Discharge

process

Suction

process

Origin

Offset interval (max 600 pulses from origin)

Operation programming

Operational behaviour can be programmed into two different control modes; Time-based control (via a pulse

controller) and Flow-based control (via a pulse controller or user's PLC). In either mode, the pump runs through

the routine of a discharge process, pause state, suction process and waiting state. See the following charts to

program operation in individual modes.

NOTE

• The cylinder can contract beyond the origin for the offset interval (600 pulses below the origin). Do not ex-

ceed the limit.

• The motor may step out if the waiting time is too short. "Step out" means the motor rotates out of a specified

step angle and number of pulses.

• The maximum discharge flow rate is 4ml/sec, however, discharge pressure may rise sharply depending on liquid

viscosity and piping layout, and may overload the bellows. Observe the maximum discharge pressure.

• The maximum suction flow rate is 3ml/sec, however, suction pressure may fall sharply depending on liquid vis-

cosity and piping layout, and may trigger cavitation. Reduce the flow rate as necessary.

18

Pump setting

Page 19

■ Time based control (when using an Oriental Motor SG9200-2 pulse controller)

An ORIENTAL MOTOR SG9200-2 pulse controller is needed for discharge-time control and an OMROM

H3RN-1 Off-delay timer for suction-time control. A discharge process is made for a discharge time; a time period

when the pump is receiving the discharge signal from the pulse controller, and a suction process starts as re-

ceiving a suction signal from the Off-delay timer. Provide with the pulse controller a pause time [T1] of 0.5 sec or

more between the end of a discharge process and the start of a suction process and a waiting time (at least 1/2

of a set suction time) [T2] between the end of the suction process and the start of the next discharge process.

NOTE

Observe the formula below when determining a discharge ow rate and a discharge time. Or the pump may break:

Discharge ow rate (see page 24) × Discharge time = 5.0ml (max disch. capacity per shot: see page 24) or less

<When a discharge ow rate × a discharge time = 5.0ml>

Discharge signal

(from pulse controller)

Home sensor output signal

(from pump)

Valve delay (user-selectable)

Control signal of discharge-

line air-operated valve

(valve ON during signal input)

Suction signal

(from Off delay timer)

Pump behaviour

Discharge

process

Suction

process

Pause time [T1] : 0.5 sec or more

<When the same discharge ow rate × a discharge time < 5.0ml>

A discharge process will becomes shorter.

Discharge signal

(from pulse controller)

Home sensor output signal

(from pump)

Valve delay (user-selectable)

Operation

Waiting time [T2] : 1/2 of suction time or more

Control signal of discharge-

line air-operated valve

(valve ON during signal input)

Suction signal

(from Off delay timer)

Discharge

Pump behaviour

process

Suction

process

Pause time [T1] : 0.5 sec or more

Discharge time

Waiting time [T2] : 1/2 of suction time or more

Pump setting

19

Page 20

■ Flow based control (when using a pulse signal as a start signal)

Use the pulse controller or user's PLC to program a discharge and a suction ow rate as well as a pause time

[T1] of 0.5 sec or more between the end of a discharge process and the start of a suction process and a wait-

ing time (at least 1/2 of the time taken to nish suction process per set ow rate) [T2] between the end of the

suction process and the start of the next discharge process as well. The programmed behaviour starts at an

input of pulse signal.

(from pulse controller/PLC)

Control signal of discharge-

Pump behaviour

Pulse signal

Home sensor output signal

(from pump)

line air-operated valve

(opens during signal input)

Discharge

process

Suction

process

Valve delay (user-selectable)

Precedent valve close (user-selectable)

Pause time [T1] : 0.5 sec or more

Waiting time [T2] : 1/2 of suction time or more

20

Pump setting

Page 21

Pump operation

Filter ushing

1

Check that lter has been ushed in user's system.

NOTE

See manufacturer's manual for lter ushing.

Degassing

2

Eliminate air from the lter cartridge before operation. Air in a lter or a pipeline reduces a ow rate.

NOTE

See manufacturer's manual for degassing.

Open a suction and a discharge line fully.

3

NOTE

Do not close a valve on a suction line or a discharge line during operation. It may pose a leak or blow

out the pump or a pipe.

Operation

4

Start operation along a programmed behaviour.

Operation

Pump operation

21

Page 22

Maintenance

This section describes troubleshooting, inspection, specication and dimensions.

Points to be observed

Observe the following points during maintenance work:

• Follow instructions in this manual for replacement of wear parts. Do not disassemble the

pump. Contact us when repairs are needed.

• Always wear protective clothing such as an eye protection, chemical resistant gloves, a

mask and a face shield during disassembly, assembly or maintenance work. The specific solution will dictate the degree of protection. Refer to MSDS precautions from the

solution supplier.

• Solution in the discharge line may be under pressure. Release the pressure from the

discharge line before disconnecting plumbing or disassembly of the pump to avoid solution spray.

• Risk of electrical shock. Be sure to turn off power to stop the pump and related devices

before service is performed.

Troubleshooting

First check the following points. If the following measures do not help remove problems, contact your distributor.

States Possible causes Check items Solutions

The pump

does not run.

Liquid can not

be pumped up.

* Solutions marked with * are conducted by us.

Faulty wiring If wiring between the motor and mo-

tor driver is correct? See page 15.

Power voltage is too

low.

An inapplicable mo-

tor driver is used.

Motor failure If the motor steps out, abnormal

Air ingress through a

suction line

A failed O ring seal Check for a leak point or a loose

Clogging in a pipe or

the pump

Malfunction of an air-

operated valve

A ball valve is stuck

on a valve seat.

If a rated power voltage is applied

to the motor driver? See page 16.

If an applicable motor driver is

used? See page 16.

noise and vibration are found?

Check for an air-ingress point. • Seal the point by tightening a

bolt.

Flush the pipe and the pump to

determine clogging points.

If supply air pressure is correct? • Observe the rated supply air

If a solenoid valve is damaged? • Replace as necessary.

If liquid ows back from the suction

line end.

• Correct wiring and resume opera-

tion.

• Observe the rated voltage of the

driver.

• Use an applicable motor driver.

• Check the motor. Replace as

necessary.*

If motor has failed, related electric

devices may also have failed, so

inclusive inspection is necessary.

pipe joint.

• Tighten the bolt. Replace O ring

as necessary.*

• Determine a cause of clogging.

Repair will be needed if the pump

is clogged.*

pressure.

• Replace the check valve as nec-

essary.*

Troubleshooting

22

Page 23

States Possible causes Check items Solutions

No home sen-

sor signal

No pressure

sensor signal

No encoder

signal

* Solutions marked with * are conducted by us.

Faulty wiring If the signal and power lines are

connected in place? See page 15.

Home sensor failure Use a tester to check the voltage

between GND and signal output

terminals. The result should be:

0V at sensor "ON"

Power voltage at sensor "OFF"

Faulty wiring If the signal and power lines are

connected in place? See page 15.

Pressure sensor fail-

ure

Faulty wiring If the signal and power lines are

Encoder failure A counter does not work. • Replace as necessary*

Use a tester to check the voltage

between GND and signal output

terminals. The result should be:

1V when pump is stopped

Above 1V when pump is running

connected in place? See page 15.

• Correct wiring and resume opera-

tion.

• Replace as necessary*

• Correct wiring and resume opera-

tion.

• Replace as necessary*

• Correct wiring and resume opera-

tion.

Inspection

Perform daily inspection to keep pump performance and safety.

Daily inspection

Check for a leak or any other abnormality during operation. If you notice any abnormal condition, suspend

operation immediately and inspect/solve problems according to "Troubleshooting".

Maintenance

Inspection

23

Page 24

Specication/Outer dimension

Specication

Information in this section is subject to change without notice.

■ Pump

Item Spec

Max discharge capacity 5.0 [ml/shot]

Max discharge pressure*

4&6

Pressure resistance 300 [kPa]

Discharge ow rate 0.1-4.0 [ml/sec]

Suction ow rate*

1

Resolution 0.01 [ml]

Discharge accuracy ±0.3 [%]F.S

Linearity*

5

Allowable liquid viscosity Max.200 [mPa·s]

Allowable surface temperature*

Number of pulses per discharge capacity*

2

3

Ambient temperature 10-40 [ºC]

Ambient humidity 30- 45 [%RH]

Allowable liquid temperature 15-25 [ºC]

Weight 3 [kg]

*1 Suction pressure may be too low (negative) and trigger cavitation depending on operating conditions such as liquid

viscosity, piping layouts and suction flow rate (max. 3ml/sec). Adjust the suction flow rate as necessary.

*2 The allowable surface temperature is based on operation at ambient of 22±1ºC, with full stroke length and 1 shot/min.

*3 The number of pulses per discharge capacity is a reference value with half stepping (0.36° per pulse).

*4 Set the discharge ow rate not to exceed the max discharge pressure.

*5 When handling viscous liquid, linearity may reduce depending on piping layout. In this case linearity can be maintained

by closing a discharge-side air operated valve after liquid is completely discharged. Determine an optimal delay time in

accordance with operating conditions.

*6 Do not close a valve on a suction line or a discharge line during operation. It may pose a leak or blow out the pump or a

pipe.

150 [kPa]

0.1-3.0 [ml/sec]

±0.5 [%]F.S

Max.30 [ºC]

2400 [pulse/ml]

Specication/Outer dimension

24

Page 25

■ Stepping motor

Items Spec

Manufacturer ORIENTAL MOTOR Co, Ltd.

Model PK545-NB or equivalent

Maximum holding torque 0.23 N·m

Rated current 0.75 A/Phase

Step angle 0.72°

Insulation resistance B class (130ºC)

The above date is based on use of an ORIENTAL MOTOR CSD5807N2-P driver.

■ Encoder (RB type)

Items Spec

Manufacturer Microtech Laboratory Inc.

Model MGH-20-500-E

Supply voltage 5 VDC ± 0.5

Consumption current 60 mA or below

Detection Incremental

Number of output pulses 500

Output phase 2-phase (A and B)

Output type Line driver

■ Home sensor

Items Spec

Manufacturer OMRON

Model EE-SX670A

Supply voltage 5-24 VDC ± 10%

Sensor logic Normally open

Output type Open collector

Dark-ON

Output operation

■ Pressure sensor

Manufacturer Nidec Copal Corporation

Rated pressure

Supply voltage 10.8-30 VDC

Consumption current 20 mA or below

Output type

Pilot lamp

Sensor

Items Spec

Model

PA-850-103G-NGF

PA-850-302R-NGF

103G: 0-1000 kPa

302R: -100 - 300 kPa

Analogue voltage

Main circuit

Pressure

Sensor

Power voltage +

L (not used)

Sensor out

Common -

Power voltage + (brown)

Analogue out (white)

Switch out (black)

Specication

Common - (blue)

Earth (shielded)

Output voltage 1-5 VDC

Specication/Outer dimension

25

Page 26

Outer dimension

■ PDS-105R A/B

(2000)

(182)

105

60

OUT

(100)(182)

23

44

30

Tube size

W2 1/4" PFA tube

M6 ø6×ø4 PFA tube

(189)

175

7 161

(R)

213.5

(100)

IN

44

30

13.5

50

Specication/Outer dimension

26

Page 27

27

Specication

Page 28

Australia IWAKI Pumps Aust ralia Pty. Ltd.

Austria IWAKI EUROPE Gmb H

Belgium IWAKI Belgium n.v.

China IWAKI Pumps (Shanghai) Co., Ltd.

China IWAKI Pu mps (Guandong) Co., Ltd.

China

China

GFTZ I WAKI Engine ering & Trading (Gu angzhou)

GFTZ I WAKI Enginee ring & Trading (Be ijing)

Denmark IWAKI Nordic A/S

Finland IWAKI Suomi Oy

France IWAK I France S.A.

Germany IWAKI EUROPE GmbH

Holland IWAKI EUROPE NL Branch

Hong Kong IWAKI Pumps Co., Ltd.

Indonesia

IWAKI Si ngapore (I ndonesia Br anch)

TEL : (61)2 9899 2411 FAX : 2 989 9 2421

TEL : (49)2154 925 4 0 FAX : 2154 925 4 48

TEL : (32)1367 0200 FAX : 1367 203 0

TEL : (86)21 627 2 7502 FAX : 21 6272 69 29

TEL : (86)750 38 66228 FAX : 750 38 66278

TEL : (86)20 8 435 0603 FAX : 20 84 35 9181

TEL : (86)10 64 42 7713 FAX : 10 6442 7712

TEL : (45)4 8 24 2345 FAX : 48 24 2 346

TEL : (358)9 2 745810 FAX : 9 2742715

TEL : (33)1 69 63 3 3 70 FA X : 1 64 49 92 73

TEL : (49)2154 925 4 0 FAX : 2154 925 4 48

TEL : (31)547 293 160 FAX : 547 292 3 32

TEL : (852)2 6 07 1168 FAX : 2 607 1000

TEL : (62)21 69 0 6606 FAX : 21 690 6 612

IWAKI CO.,LTD. 6-6 Kanda-Sudacho 2-chome Chiyoda-ku Tokyo 101-8558 Japan

Italy IWAKI Italia S.R.L .

Korea IWAKI Korea Co.,Ltd.

Malaysia IWAKIm Sdn. Bhd.

Norway IWAKI Norge AS

Singapore IWAKI Singapore Pte. Ltd.

Spain IWAKI Iberica Pumps, S.A .

Sweden IWAKI Sverige AB

Switzerland IWAKI (Schweiz) AG

Tai wan IWAKI Pumps Taiwan Co., Ltd.

Tai wan

IWAKI Pu mps Taiwan (Hsin -chu) Co., Ltd . TEL : (886)3 57 3 5797 FAX : (8 86)3 573 5798

Thailand IWAKI (Thailand) Co.,Ltd.

U.K. I WAKI Pumps (UK) LTD.

U.S.A . IWAKI AMERICA Inc.

Vietnam IWAKI pumps Vietnam Co.,Ltd.

TEL:(81)3 3254 2935 FAX:3 3252 8892

TEL : (39)0 444 371115 FAX : 0 444 335 350

TEL : (82)2 263 0 4800 FA X : 2 2630 4801

TEL : (60)3 78 03 8807 FA X : 3 7803 480 0

TEL : (47)23 38 49 0 0 FAX : 23 3 8 49 01

TEL : (65) 6316 2028 FAX : 6316 3221

TEL : (34)9 43 630030 FAX : 943 6 28799

TEL : (46)8 511 72900 FAX : 8 511 72922

TEL : (41)26 674 9300 FAX : 26 674 9302

TEL : (886) 2 8227 6900

TEL : (66)2 32 2 2471 FAX : 2 32 2 2477

TEL : (44)1743 231363 FAX : 1743 366507

TEL : (1)508 429 1440 FAX : 508 42 9 1386

TEL : (84)613 933 456 FAX : 613 93339 9

( )Country codes

FAX : 2 8227 6 818

T787-1 '12/10

Loading...

Loading...