Page 1

IWAKI Auto-Dampener

PDA-W

Instruction Manual

Read this manual before use of product

This is patent pending product

.

Page 2

We thank you for selecting IWAKI Auto-dampener PDA-W series. This instruction

manual, which is divided into five sections of "Safety", "Outline of product", "Instal-

lation", "Operation" and "Maintenance", deals with the correct handling and opera-

tion procedures for the auto-dampener. To make maximum use and to ensure safe

and long time operation of the auto-dampener, please read this manual thoroughly

and carefully prior to operating the auto-dampener.

Contents

Safety section

.................................................................................................

Outline of product

1. Unpacking and inspection

2. Outline of product

3. Model code

4. Specification

5. Dimensions and mass

6. Structure and names of parts

7. Main parts and labelling

Installation

...................................................................................................

1. Before use

2. Installation

3. Piping

Operation

...................................................................................................

1. Preparation for operation

2. Operation

3. Stopping

Maintenance

..................................................................................................

1. Troubleshooting

2. Maintenance and inspection

3. Consumable parts

...........................................................................................

..............................................................................

...............................................................................................

............................................................................................................

.........................................................................................................

......................................................................................

.......................................................................

...................................................................................

............................................................................................................

............................................................................................................

....................................................................................................................

.............................................................................

.............................................................................................................

.................................................................................

.......................................................................

....................................................

...................................................................

1

4

5

5

5

6

7

8

9

10

11

11

12

14

15

15

16

17

18

19

19

This instruction manual should be kept on hand by end users for quick reference. It is recommended that each user, after reading the instruction manual thoroughly, keep it in a position close to the pump system and where it may be easily accessed by operator at any time

whenever necessary.

Contact us if you have any questions.

Page 3

Important instruction

For the Safe and Correct Handling of the Auto-dampener

● Before use of the auto-dampener, read this "Safety Section" to prevent accidents and to avoid the

damage or loss of assets.

● Observe and abide by the instructions described in this "Safety Section".

These instructions are very important for protecting pump users or other persons from hazard or

loss of assets.

● Meaning of symbols

Following two symbols describe the extent of hazards and loss which may be brought if the

instructions are not observed or if the auto-dampener is wrongly used.

Non observance or misapplication of the contents of the

Warning

Caution

"Warning" could lead to death or injury.

Non observance or misapplication of the contents of the

"Caution" could lead to injury or damage.

Types of Symbols

Prohibited action or procedure is indicated.

Inside or near this circle, a concrete activity to be prohibited is

depicted.

Action or procedure which must be performed without fail is

indicated. Inside this circle, a concrete activity to be performed

is depicted.

-

1 -

Page 4

Safety instruction

WARNING

● Power off

Be sure to turn off power prior to any inspection/maintenance and

installation works. Be careful power is not turned on unintentionally

while working on the dampener. In a noisy or dark place, display a sign

of "Men Working" near the power supply switch.

● Do not remodel the auto-dampener

Never remodel the auto-dampener. Remodeling may cause serious

injury or damage due to electrical shock. We are not responsible for

any accident or damage arise from modification.

● Prohibited installation/storage place

To avoid fire or injury, do not install or store the dampener in:

• Flammable atmosphere.

• Dusty place.

• Corrosive atmosphere.

Power off

No remodeling

Prohibited

● Ventilation

Risk of poisoning. Keep your working site ventilation when handling a

toxic/odoriferous liquid.

● Wear protective clothing

Be sure to wear protective clothing such as safety goggles, protective

gloves etc. during maintenance and/or inspection.

● Returns

When the dampener is sent back to IWAKI, drain the liquid out of the

dampener and clean thoroughly with water to prevent any accidents in

transportation.

-

2

-

Wear protective

gear

Page 5

Safety instruction

CAUTION

● Countermeasure against static electricity

When low electric conductivity liquid such as the ultra-pure water and

the fluor inactive liquid (e.g. Fluorinert™) are handled, static electricity

may generate in the pump, which may cause a static discharge and the

pump breakage. Take a countermeasure for removing static electricity.

● When pump is stopped

• When pump is stopped, release pressure on the discharge side first.

Otherwise the bellows may be deformed due to the residual pressure

on the pump discharge side.

• If a valve is provided on the discharge side, do not close the valve

when pump is stopped to avoid impactive pressure resulting in deformation of bellows or connecting plate.

● Pump at halt

• Do not supply air to both the right and left air-supply ports at the same

time to prevent the bellows from deformation.

• If the pump or dampener is stopped for a long time with the liquid

inside, the gas may be generated to penetrate the bellows and corrode the metallic parts. When the pump or dampener is stopped for 2

days or more, operate them for about 10 minutes a day to replace the

air.

Prohibited

Prohibited

● Air exhaust port

Do not choke (make tube dia. smaller) air exhaust port to avoid bellows

deformation due to residual air.

● Before operating the pump & dampener

Fully open pump suction and discharge valves. Confirm that liquid is

filled in piping.

● Supply air pressure

Do not supply air exceeding 0.5 MPa to prevent bellows from deformation.

● Prohibited liquids

Do not handle the following liquids.

• Liquid easily crystallizes

• Liquid containing slurry

• Solvent naphtha, stripping agents or solvents

● Disposal of used dampener

Disposal of used or damaged dampener must be done in accordance

with local laws and regulations. (Consult a licensed industrial waste

products disposing company.)

● Do not close a discharge valve which is positioned beyond the

dampener in operation.

Impactive pressure may deform the pump and dampener.

Prohibited

Prohibited

Prohibited

-

3 -

Page 6

Product outline

1. Unpacking and inspection

2. Outline of product

3. Model code

4. Specification

5. Dimension and mass

6. Structure and names of parts

7. Main parts and labelling

-

4

-

..................................................

................................................

.......................................

........................

.................................

............................

..................

5

5

5

6

7

8

9

Page 7

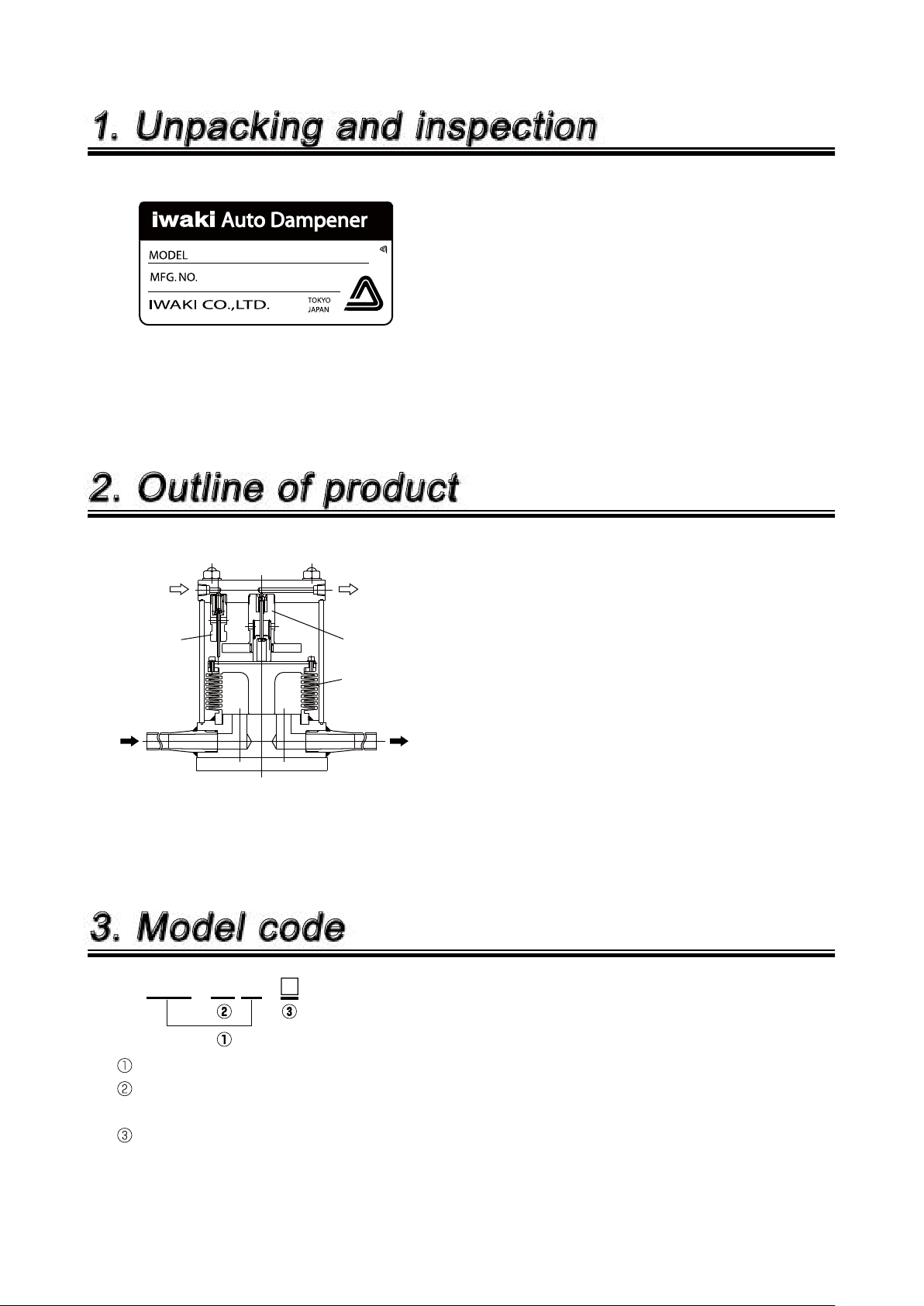

Inlet

Pressure

adjusting valve

Pressure

adjusting valve

Air supply

Bellows

Outlet

Air exhaust

1. Unpacking and inspection

After unpacking the product, check the following

points to ascertain that the product is exactly your

ordered one.

(1) if the model code on the nameplate is the same as

your order.

(2) if the product is not broken or bolts and nuts are not

loosened during transportation.

2. Outline of product

IWAKI auto-dampener the PDA-W series are

exclusively designed for the pneumatic driven bel-

lows pump to dampen the liquid pulsation.

The liquid discharged from the pump is transferred

to outlet through bellows. At this moment, the sup-

ply air is automatically adjusted by the pressure

regulating valve and this functions to dampen the

liquid pulsation.

3. Model code

PDA - 20 W -

Series code

Capacity (Max. discharge capacity of corresponding pump)

20 : 20 L/min. 40 : 40 L/min. 80 : 80 L/min.

Special version

No symbol : Standard version With symbol : Special version

-

-

5 -

5

-

Page 8

4. Specification

Model PDA-40W PDA-80W

Applied pump

Temp. ran g e (

Max. liquid press. (MPa)

Supply air press. (MPa)

Pulsation press width (Mpa)

Liquid pipe connection

Air piping connection

Wet end material

● Notes on operation

(1) Do not handle the liquid which is apt to be crystallized or contains solids.

Otherwise life of parts is shortened.

(2) Do not use the product exceeding the max. allowable liquid and air pressure.

Otherwise the pump or dampener may fail.

(3) If the AC-3 controller is used to drive the pump, use the solenoid valve of double solenoid and 2-position type. If

single solenoid type is used, good dampening effect can not be obtained.

Note: Performance and dimensions may be changed without prior notice.

)

10-100 101-150 151-180 10-10 0 101-150 151-180

0.5 0.5

0.2-0.5 0.15-0.3 0.15-0.2 0.2-0.5 0.15-0.3 0.15-0.2

PFA tube ø19 mm ø 16 mm PFA tube ø25 mm ø 22 mm

PDA-20W

FW-20, FS-30

0.3 0.2 0.5 0.3 0.2

Within 0.06 (in case liquid viscosity is within 1 - 50 mPa•s)

Rc 1/4 (Female)

PTFE, PFA

FW-40, FS-60 FW-80

10-80

0.2-0.5

-

-

6

-

6 -

Page 9

5. Dimension and mass

■

PDA-20, 40, 80W

PDA-20W

PDA-40W

PDA-80W

ABCD E FGHMass (kg)

348 148 215 191

388 188 255 229

408 208 323 266

ø

19 × ø16

ø

25 × ø22

ø

25 × ø22

18 33 135 7

23 36 162 12

25 38 188 17

-

7 -

-

7

-

Page 10

6. Structure and names of parts

■

PDA-20, 40, 80W

No Name Q'ty Material Remarks

Bellows unit 1 PTFE, PFA

1

Cylinder 1 A6063 Fluor coat

2

Plate 1 A5052 Fluor coat

3

OUT guide 1 SUS304

4

Slider 1 PPS

5

Stud bolt 4 SUS304 PTFE coat

6

Valve A 2 SUS304

7

Pin nut 1 SUS304

8

Pin 1 SUS304

9

Spring A 1 SUS304WPB

10

Spring B 2 SUS304WPB

11

Cover 1 A5052 Fluor coat

12

Spacer 1 PVC

13

IN guide 1 SUS304

14

Val ve seat 2 F K M

15

No Name Q'ty Material Remarks

Slider pin 1 SUS304

16

O-ring 2 FKM

17

Cap nut 4 SS Fluor coat

18

Plate washer 4 SS Fluor coat

19

O-ring 1 FKM S-10

20

Stopper 1 SUS304

21

Spacer A 1 PVC

22

Electrode holder 2 SUS304

23

O-ring 2 FKM P-3

24

Hex screw 2 SS

25

Bellows plate 1 SUS304

26

Bellows flange 2 SUS304

27

Hex bolt 6 SS

28

Spring washer 6 SS M4

29

*

M3

12

×

*

O-ring

PDA-20W

PDA-40W

PDA-80W

S-135

172

194. 5

×

3

×

2

-

8 -- 8 -

Page 11

7. Main parts and labelling

OUT label

Air exhaust port

Nameplate

shows model and MFG.No.

OUT label

Discharge port

Cover

Fix the cover at installation

IN label

Air supply port

IN label

Suction port

-

-

9 -

9

-

Page 12

Installation

1. B ef o r e u s e

2. Installation

3 Piping

-

10

..........................................................

-

.................................................

..................................................

11

11

12

Page 13

1. Before use

(1) Do not stop the supply air to the dampener while discharge piping is pressurized.

Otherwise the bellows may be deformed. Also, the pulsation reduction effect can not be received.

(2) Do not use the dampener at a higher pressure than the specified pressure of the pump.

The dampener may fail if it continuously operates exceeding the max. allowable liquid pressure and the max.

allowable supply air pressure. (Refer to 4. Specification)

(3) Do not handle the liquid which is apt to crystallize or contains slurry.

These liquids shorten the life of bellows.

(4) Pay attention to stripping agents or solvents.

• Some strippers may cause the cracks in a short time in the bellows or in piping (PFA material).

(Guarantee period is different for these liquids. Ask IWAKI.)

• Risk of fire. Do not connect the electrodes with any device including our controllers when using solvent.

WARNING

Do not connect the electrodes with any device including our controllers when using a solvent. Solvents may catch fire due to a electric spark.

(5) Surface temperature of the dampener

WARNING

The temperature of the dampener or pipe surfaces becomes very high while a high temperature liquid is pumped. Do not touch them with bare hands. Always wear protective

clothing.

Model

PDA-20W

PDA-40W

PDA-80W

Liquid temp. Room temp.

180 deg.C 74 deg.C 20 deg.C

180 deg.C 66 deg.C 20 deg.C

80 deg.C 20 deg.C

Cylinder surface temp.

40 deg.C

2. Installation

(1) Connect tubes to Inlet and outlet of the dampener horizontally.

(2) Install the dampener between the pump and the filter, as close to the pump. Keep the tube length

between the dampener and the pump less than 1 meter.

(3) Keep a space around the dampener for maintenance work.

(4) Mount the dampener and the pump securely on a flat foundation.

-

11 -

-

11

-

Page 14

Attached to tube

To pipe line

Attached to tube

To pipe line

Tube fitting

Tube fitting

3. Piping

Piping example

Discharge side

Pressure

gauge

(PG2)

Solenoid

Suction side

Pressure

reducing valve

Air supply source

(to seal air)

Pump

valve

Tak e i n

Dampener

IN OUT

Filter

Pressure

gauge

(PG2)

Exhaust

: Liguid piping

: Air piping

■

Liquid piping

(1) There is the distinction of suction and discharge

side tubes of dampener. Pay attention to the con-

nection. "I" is marked for suction side and "O"

for discharge side.

(2) Keep the pump and the dampener free of any

excessive load such as piping weight when tub-

ing each devise. Support tubing to protect the

dampener from tubing vibration.

(3) In case that high temperature liquid is handled,

piping must be done so that the dampener can

not be affected by the expansion and shrinkage

of the pipe because of the heat.

(4) Install the filter in the discharge piping.

(5) Employ the tube which has the pressure resist-

ance more than that of specified max. pressure of

the dampener.

(6) For mounting of pipe joints, pay attention so

that the air can not be sucked in. Especially, the

air sucked in suction piping causes unstable or

impossible discharge.

(7) PFA tubes are equipped for suction and dis-

charge ports. Tube diameters are:

PDA-20W : 19 × 16 mm

PDA-40W : 25 × 22 mm

PDA-80W : 25 × 22 mm

Use the tube fittings which correspond to tube

diameters(See the left draw.).

Note. Pipe line tubes should have larger bore

than the suction/discharge bore.

-

12

12 -

-

-

Page 15

■

Air piping

CAUTION

Use the instrument air which is dust free and dehumidified as supply air. If the supply

air contains foreign matters, water, or oil, the pressure adjusting valves may malfunction

and air may leak from the air exhaust port.

(1) Air piping should be connected to the dampener on the discharge tube beyond the pressure reducing

valve.

CAUTION

Pipe diameter must be the same as that of the pump (solenoid valve). If the pipe diameter to the dampener is small, necessary air can not be supplied to the dampener inlet

because of pressure down, which will bring reduction of dampening effect or deformation of the bellows.

CAUTION

Install a pressure reducing valve for each combination of the pump/dampener. If only a

pressure reducing valve control several combinations of pump/dampener, the pulsation

reduction effect will reduce or the bellows are deformed because of the pressure down

at dampener inlet.

(2) In case that air adjusting valve is installed

If the valve (marked with * on the illustration below) is installed in the air piping for adjusting a stroke

rate of the pump, install it not to interrupt the air supply to the dampener as shown on the illustration

below.

To pump (solenoid valve)

*

(Good)

*

Air supply source

Pressure reducing valve

(3) When the pressure reducing valve is installed for the pump and the damper separately.

The set pressure for the damper should be equal to the damper.

(No good)

To the auto-dampener

-

13 -

-

13

-

Page 16

OPERATION

1. Preparation for operation

2. Operation

3. Stopping

-

14

-

...................................................

.....................................................

........................

15

15

16

Page 17

1. Preparation for operation

When the pump is operated first time together with the dampener, check the followings.

(1) Check to see if no damage, loosened bolts or leakage are found on dampener (pump).

(2) Air pressure adjustment

This auto-dampener automatically adjusts the air pressure to be sealed depending on handled liquid pressure, which

requires no adjustment on the dampener.

2. Operation

Order Operation Check items

Start pump. Confirm if liquid is discharged normally.

1

Adjust pump discharge capacity and pressure.

2

Refer to Operating Instruction of pump for details of pump operation.

3

If no abnormality is found, start full operation.

4

Confirm by pressure gauge if air pressure does not

exceed specified pump pressure.

CAUTION

Right after the pump starts, the dampener exhausts air intermittently. This is because

the pressure adjusting valves function until load fluctuation is gone. Note that this is not

abnormal. Installing the muffler into the exhaust port, the exhaust noise can be reduced.

(Fitting bore: RC1/4)

CAUTION

Check that pneumatic pressure is applied to auto-dampener while pump operation. If

pneumatic pressure is not applied, pulsation dampening effect may be reduced or bellows

may be deformed.

In case the bellows of dampener is broken, it may happen the pumped liquid gets into

pneumatic piping. Take suitable protective measure in the system.

CAUTION

When the pump operates at 30 spm or below, the air is exhausted from the dampener in

sync with operation.

-

15 -

-

15

-

Page 18

CAUTION

Do not run the pump in time-lag operation. In the time-lag operation, the bellows of autodampener may fail in a short time. Also pulsation dampening effect can not be obtained.

When the auto-dampener is used, the time-lag should be zero.

Time-lag operation: When proximity switches detects the bellows movement and the

switching-over signal is transferred to the solenoid valve, the

switching-over signal is outputted with time lag. This is called "timelag operation". IWAKI controllers (AC-1, FD, SC and FDC) can not

operate the pump in time-lag operation. Pay attention to the timelag operation if the pump is operated by programmable controller or

so.

3. Stopping

(1) Stop the pump according to the procedure mentioned in operating instructions of the pump and controller. The air

is eliminated from the dampener after stoppage.

(2) Add the supply air to the auto-dampener while pump is stopped.

CAUTION

If air supply is interrupted when discharge piping is pressurized, the bellows may be

deformed. Be sure to release the residual pressure.

(3) Before the pump is stopped for a long time, confirm that pressure is released from the dampener and then stop the

air supply.

-

16

-

Page 19

Maintenance

1. Troubleshooting

2. Maintenance & inspection

3. Consumable parts

-

17

-

........................................

....................................

......................

18

19

19

Page 20

1. Troubleshooting

Trouble

Large pulsation

(Beyond specified range)

Air is mixed in

the liquid.

Liquid leaks.

Air leaks

(Cylinder)

Air leaks

(Air exhausting

part)

Cause Countermeasure

● Too high discharge pres-

sure.

● Air pressure adjusting valve

at intake or exhaust side is

clogged.

● Wor n valve se at .

● Too low supply air pressure

to dampener.

● Broken bellows inside

dampener

● Broken bellows.

(Air is mixed in discharged

liquid.)

● Stud bolts are not tightened

enough.

● Deterioration or deforma-

tion of O-ring.

● Air pressure adjusting valve

at exhaust side is clogged.

○ Check filter and replace.

○ Disassemble and clean. (*)

○ Replace valve seat. (*)

○ Keep the supply air pressure

to dampener.

○ Replace bellows unit. (*)

○ Replace bellows unit. (*)

○ Tighten.

○ Replace O-ring(*)

○ Disassemble and clean. (*)

Inspection & check items

a. Filter blinding or drying

b. If filter is wetted enough.

a. Check air filter.

a. Refer to item Air Piping on

Installation section.

a. If specified air pressure is

added to dampener.

b. If the dampener is not used

beyond specified pressure

a. If specified air pressure is

added to dampener.

b. If the dampener is not used

beyond specified pressure.

c. If residual pressure is

released.

a. Refer to Periodic Inspec-

tion on Maintenance and

Inspection.

a. Check air filter.

Note: Items marked (*) are done by IWAKI.

-

18

-

Page 21

2. Maintenance & inspection

WARNING

● Wear protectors

When piping is removed or pump is disassembled/assembled, wear protective gear

such as safety goggles and protective gloves etc.

● Release pressure inside piping

If pressure is not released from piping, liquid may be splashed. Release residual pressure before maintenance works start.

● Interruption of supplied air

Interrupt air supply to dampener before maintenance works start.

● Power off

Always turn off power supply prior to maintenance works. Display a sign near power

supply switch to notify other person that someone is "WORKING".

Turned on, by mistake, power supply during maintenance works may lead to personal

injury. Each operator must pay special attention.

■

Routine inspection

a. Confirm if the liquid is discharged normally from dampener (pump).

b. Confirm the vibration width of pressure gauge to see no change in discharge capacity and pressure.

c. Confirm if pipe does not vibrate abnormally.

■

Periodical inspection (Make the inspection once a month or more.)

If the air leakage through cylinder part is confirmed, stop the pump after pump discharge side pressure is released

to leave it until it is cooled down. And then, securely tighten the cap nuts of dampener.

Tightening torque

PDA-20W PDA-40W

6.4 N m 6.4 N m 12.7 N m

PDA-80W

3. Consumable parts

Repair is done by IWAKI.

No. Q'ty/unit

11

Bellows unit

15 2Valve seat

Note1: The quantity shows the number of the parts which required to a dampener.

Note2: Time to be replaced is just for your reference. It is not guaranteed.

Note3: The durability of consumable parts depends on pressure, temperature and characteristics of liquid.

Time to be replacedParts

One year (Continuous operation)

-

19 -

Page 22

: IWAKI EUROPE GmbH

Germany

: IWAKI Italia S.R.L.

Italy

: IWAKI Nordic A/S

Denmark

: IWAKI Sverige AB

Sweden

: IWAKI Suomi Oy

Finland

: IWAKI Norge AS

Norway

: IWAKI France S.A.

France

: IWAKI PUMPS (UK) LTD.

U.K.

: IWAKI (Schweiz) AG

Switzerland

: IWAKI (Austria) GmbH

Austria

: IWAKI Holland B.V.

Holland

: IWAKI Iberica Pumps, S.A.

Spain

: IWAKI Belgium n.v.

Belgium

TEL : (49)2154 9254 0

TEL : (39)02 990 3931

TEL : (45)48 24 2345

TEL : (46)8 511 72900

TEL : (358)9 2742714

TEL : (47)66 81 16 60

TEL : (33)1 69 63 33 70

TEL : (44)1743 231363

TEL : (41)26 674 9300

TEL : (43)2236 33469

TEL : (31)297 241121

TEL : (34)943 630030

TEL : (32)1367 0200

FAX : 2154 1028

FAX : 02 990 42888

FAX : 48 24 2346

FAX : 8 511 72922

FAX : 9 2742715

FAX : 66 81 16 61

FAX : 1 64 49 92 73

FAX : 1743 366507

FAX : 26 674 9302

FAX : 2236 33469

FAX : 297 273902

FAX : 943 628799

FAX : 1367 2030

IWAKI CO.,LTD. 6-6 Kanda-Sudacho 2-chome Chiyoda-ku Tokyo 101-8558 Japan

U.S.A.

Australia

Singapore

Indonesia

Malaysia

Taiwan

Thailand

Hong Kong

China

China

China

China

Philippines

Korea

TEL:(81)3 3254 2935 FAX:3 3252 8892(http://www.iwakipumps.jp)

: IWAKI America Incorporated

: IWAKI Pumps Australia Pty. Ltd.

: IWAKI Singapore Pte. Ltd.

: IWAKI Singapore (Indonesia Branch)

: IWAKIm Sdn. Bhd.

: IWAKI Pumps Taiwan Co., Ltd.

: IWAKI (Thailand) Co.,Ltd.

: IWAKI Pumps Co., Ltd.

: IWAKI Pumps (Guandong) Co., Ltd.

: GFTZ IWAKI Engineering & Trading (Guangzhou)

: IWAKI Pumps Co., Ltd. (Beijing)

: IWAKI Pumps (Shanghai) Co., Ltd.

: IWAKI Chemical Pumps Philippines, Inc.

: IWAKI Korea Co.,Ltd.

TEL : (1)508 429 1440

TEL : (61)2 9899 2411

TEL : (65)6316 2028

TEL : (62)21 690 6606

TEL : (60)3 7803 8807

TEL : (886)2 8227 6900

TEL : (66)2 322 2471

TEL : (852)2 607 1168

TEL : (86)750 380 9018

TEL : (86)20 8435 0603

TEL : (86)10 6442 7713

TEL : (86)21 6272 7502

TEL : (63)2 888 0245

TEL : (82)2 3474 0523

FAX : 508 429 1386

FAX : 2 9899 2421

FAX : 6316 3221

FAX : 21 690 6612

FAX : 3 7803 4800

FAX : 2 8227 6818

FAX : 2 322 2477

FAX : 2 607 1000

FAX : 750 380 9078

FAX : 20 8435 9181

FAX : 10 6442 7712

FAX : 21 6272 6929

FAX : 2 843 3096

FAX : 2 3474 0221

T389-2 '06/11

Loading...

Loading...