IWAKI Magnetic Drive Pump

MX Series (MX-250/-505)

Instruction Manual

Read this manual before use of product

(Asia Edition)

Thank you for selecting an Iwaki MX Series Magnetic Drive Pump. This instruction manual

deals with "Safety instructions", "Outline", "Installation", "Operation" and "Maintenance"

sections. Please read through this manual carefully to ensure the optimum performance, safety

and service of your pump.

Contents

Important instructions ························································ 1

Safety instructions ····························································· 2

Outline 1. Unpacking & Inspection ..................................................7

2. Product outline .................................................................7

3. Model code .......................................................................8

4. Specification .....................................................................9

5. Dimension ......................................................................10

6. Part names ......................................................................11

7. Overview ........................................................................15

Installation 1. Before installation ..........................................................17

2. Installation/Pipework/Wiring ........................................19

Operation 1. Operational precautions..................................................26

2. Before operation .............................................................27

3. Operation ........................................................................27

Maintenance 1. Troubleshooting ..............................................................30

2. Maintenance & Inspection .............................................31

3. Spare & Wear parts ........................................................34

4. Dismantlement & Assembly ..........................................35

This instruction manual should be kept on hand by the end user for

quick reference.

Contact us or your nearest dealer if you have any questions.

Impor tant instr uctions

For the Safe and

Correc t Hand ling of the Pump

● "Safety Inst r uct ion" section deals with import a nt details about handling of the product. Before

use, read this section carefully for the prevention of personal injury or propert y dam age.

● Obser ve the instructions accompanied with "WAR N I NG" or "CAU TION" in this manual. These

instr uct ions are very impor t ant for protecting users from da ngerous situations.

● T he symbols on this inst r uction manual have the following meanings:

Nonobservance or misapplication of “ Warning” sec-

WARNING

tions could lead to a serious accident which may

result in death.

Nonobservance or misapplication of “Caution” sec-

CAUTION

tions could lead to personal injury or proper t y dam age.

Types of Symbols

Indicates that “Warn ing” or “Caution” must be exercised. Inside this triangle, a concrete and practical image provided as a warning or caution message is depicted.

Indicates a prohibited action or procedure. Inside or near this circle, a concrete and

practical image of the activity to be avoided is depicted.

Indicates an import ant action or procedure which must be performed or carr ied out

without fail. Failure t o follow the instructions herein can lead to malfu nction or

damage to the pump.

Export Restrictions

Technical information contained in this instruction manual might be treated as controlled

technology in your countries, due to agreements in international regime for export control.

Please be reminded that export license/permission could be required when this manual is

provided, due to export control regulations of your country.

- 1 -

Safety instructions

Prohibited

No Remodeling

WARNING

● Turn off power before work

Be sure to turn off all the related power supplies prior to any inspection/

maintenance and installation works. Working on the pump with power ON,

any rotating part may catch the hand, finger, hair, or clothes, and it may

result in serious injury. Make sure no one turns on power by mistake while

working on the pump, otherwise it may result in a serious accident. If your

working area is noisy or dark, let other people know about the situation by

displaying a notice such as “POWER OFF (Maintenance)” near a power

switch.

● Stop operation

Turning off power

If you notice any abnormal or dangerous conditions, suspend operation immediately and inspect/solve problems.

● Do not use the pump in any condition other than its intended purpose

The use of the pump in any conditions other than those clearly specied

may result in failure or injury. Use this product in specied conditions only.

● Do not modify the pump

Alterations to the pump carries a high degree of risk. It is not the manufacturer’s responsibility for any failure or injury resulting from alterations to the

pump.

● Wear protective clothing

Always wear protective clothing such as an eye protection, chemical resistant gloves, a mask and a face shield during disassembly, assembly or

maintenance work. The specic solution will dictate the degree of protection. Refer to MSDS precautions from the solution supplier.

Wear protective

gear

- 2 -

Safety instructions

Prohibited

Fire ban

WARNING

● Use strong ropes (chains) for lifting up the pump

Serious injury may result if lifting ropes (chains) break. Check lifting ropes

(chains) are strong enough before use. Observe the maximum weight.

● Use eye bolts

Chain the pu mp via eye bolts to lift it up. Otherwise the pump may accidentally fall down, resulting in serious injury.

● Do not lift the pump by gripping any plastic parts (pump unit, flange or base)

The pump can drop unintentionally as a plastic part breaks, resulting in

serious injury.

● When handling dangerous liquid

For handling harmful liquids as mentioned below, be sure to conduct daily

inspection and maintenance for the prevention of liquid leakage. Otherwise

personal injury, explosion or fire may result.

1. Explosive or flammable liquid

2. Corrosive or stimulus toxic liquid

3. Health hazardous liquid

● Do not damage a power cable

Do not pull, knot, or crush the power cable. Damage to the power cable

could lead to a re or electrical shock if cut or broken.

● Do not operate the pump in a flammable atmosphere

Do not place explosive or ammable material near the pump.

Prohibited

Prohibited

● Do not catch the finger

Magnetic force of the pump is powerful. Take care not to catch the finger in

the bracket.

- 3 -

Safety instructions

Prohibited

CAUTION

● Qualified personnel only

The pump should be handled or operated by qualified personnel with a full

understanding of the pump. Any person not familiar with the product should

not take part in the operation or management of the pump.

● Use specified power only

Do not apply power other than that specied on the nameplate. Otherwise,

failure or re may result. Ensure the pump is properly grounded.

● Do not run pump dry

Do not run pump dry (Operation without liquid). Friction heart builds up during dry running operation and damages internal parts. If the pump is operated with a suction side valve closed or without priming, the pump runs dry.

● Ventilation

Fumes or vapours can be hazardous with certain solutions. Ensure proper

ventilation at the operation site.

● Do not install/store the pump:

• In a ammable/explosive/corrosive atmosphere.

• In a dusty/humid environment.

• Where ambient temperature can exceed 0-40°C.

• Under mechanical vibrations.

• In direct sunlight or wind & rain.

● Spill precautions

Ensure protection and containment of solution in the event of plumbing or

pump damage (secondary containment).

Prohibited

● Do not stand on the pump

Do not use the pump as a platform. Injury or damage may result when the

pump turns over.

- 4 -

Prohibited

Safety instructions

CAUTION

● Do not touch the pump or pipe with bare hands

Risk of burning. The surface temperature of the pump or pipe rises high

along with liquid temperature in or right after operation.

● Grounding

Risk of electric shock! Always properly ground the pump. Conform to local

electric codes.

● Install a GFCI (earth leakage breaker)

An electrical failure of the pump may adversely affect other devices on the

same line. Purchase and install an earth leakage breaker separately.

● Starting

The pump doesn’t have an ON-OFF switch. The pump starts as a power

cable is plugged in.

● Foreign matter

When foreign matters enter the pump, turn off power at once and remove

them. Using the pump with foreign matters may result in failure.

● Static electricity

Caution

Grounding

Electrical shock

When low electric conductivity liquids such as ultra-pure water and fluor

TM

inactive liquid (e.g. Fluorinert

) are handled, static electricity may generate in the pump and may cause static discharge. Take countermeasures to

remove static electricity.

● Preventative maintenance

Follow instructions in this manual for replacement of wear parts. Do not

disassemble the pump beyond the extent of the instructions.

● Do not use a damaged pump

Use of a damaged pump could lead to an electric shock or death.

● Disposal of a used pump

Dispose of any used or damaged pump in accordance with local rules

and regulations. If necessary, consult a licensed industrial waste disposal

company.

Prohibited

- 5 -

Outline

1. Unpacking & Inspection ........................7

2. Product outline ......................................7

3. Model code ...........................................8

4. Specification .........................................9

5. Dimension ...........................................10

6. Part names ......................................... 11

7. Overview .............................................15

- 6 -

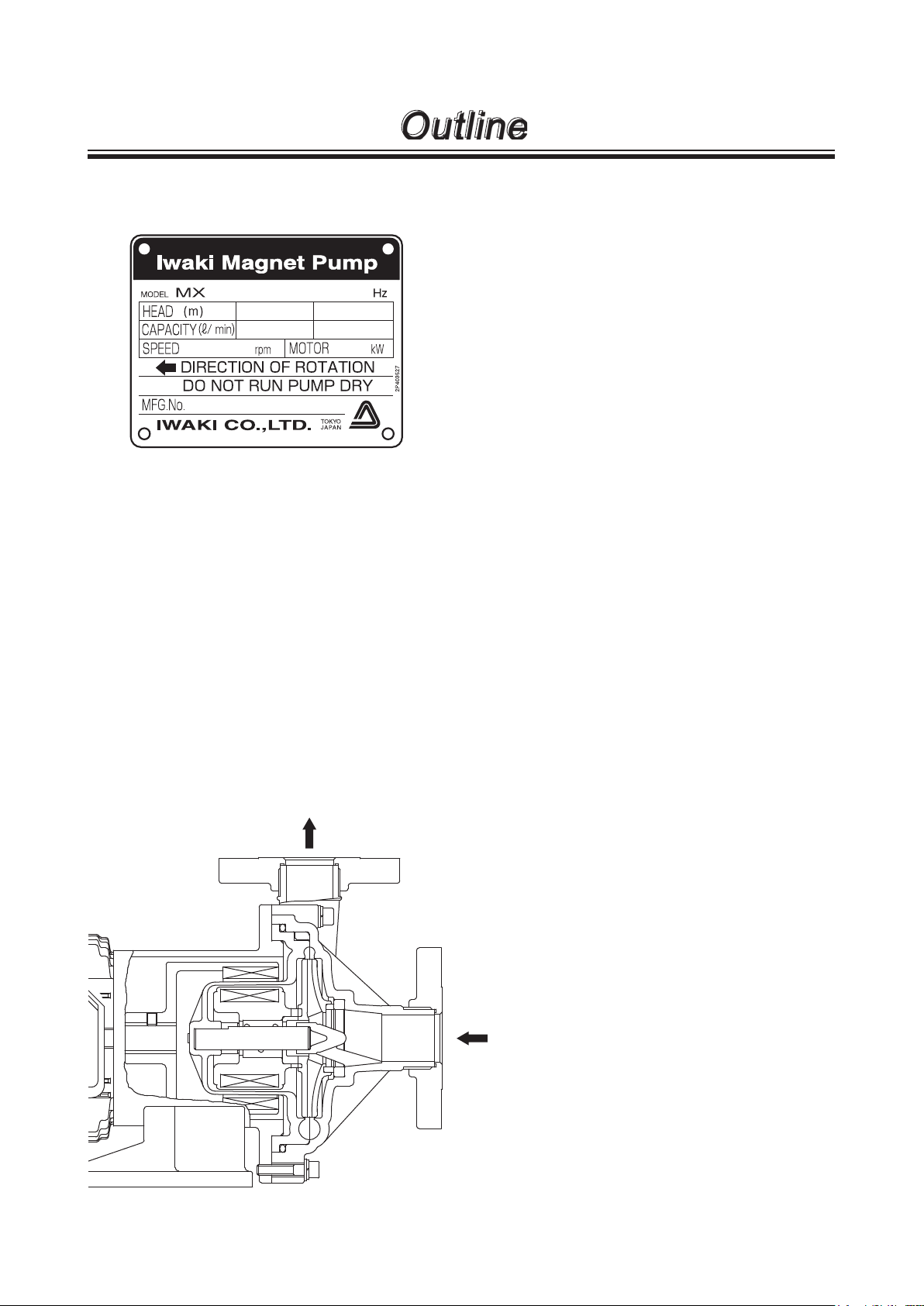

1. Unpacking & Inspection

Outline

On unpacking the product, check the following

points. If you find any problems, contact your

nearest distributor.

1. Check the information on nameplate (model

code, flow rate, head and voltage) to see if the

product is delivered as per order.

2. Check for transit damage, deformation, and loose

bolts.

2. Product outline

The MX is a magnetic drive centrifugal pump capable of handling various liquid.

■ Principle of operation

The magnetic force between drive and driven

magnets rotates the impeller in the pump chamber,

where a liquid is transferred from the inlet to outlet.

- 7 -

Outline

3. Model code

MX - 400 C V 6 C - 2 S

a b c d e f g

a. Pump I.D. and motor output

Code Pump I.D. (Inlet × Outlet) Motor output

250

251 0.75kW

400

401 0.75kW

402/402H

403/403H 2.2kW

505 65A × 50A 3.7kW

*The motor is 2-pole, 3-phase.

b. Sliding parts

C: Carbon bearing × Alumina ceramic spindle

R: Filled PTFE bearing × Alumina ceramic spindle

A: Alumina ceramic bearing × Alumina ceramic spindle (available for MX-250/-251/-400/-401)

25A × 25A

40A × 40A

50A × 40A

0.37kW

0.37kW

1.5kW

c. O ring materials

V: FKM

E: EPDM

A: Aflas

d. Impellers

3, 5, 7 : 50Hz

4, 6 : 60Hz

*The code “7” is used with an IE2 high efficiency motor. Applicable models are the MX-250/-251/-400/-401.

*The code “3“ and “4“ are used with an IE3 premium efficiency motor. An applicable model is the MX-401.

e. Motors

No code: Totally-enclosed-fan-cooled motor for indoor use

C: Totally-enclosed-fan-cooled motor for outdoor use

A: Increased safety motor

f. Motor power voltage

2: 200/220V 2: 200/220V 2: 200/220V

4: 380/400/415V (50Hz) or 440V(60Hz) 6: 380V 6: 380V

9: 460V 7: 400/440V 7: 400/440V

®

MX-250/-251/-400/-401

(3-phase standard motor)

MX-402(H)/-403(H)

(3-phase IEC motor)

8: 415V 9: 460V

9: 460V

(3-phase IEC motor)

MX-505

g. Special version

S : Special version

- 8 -

Outline

4. Specification

Model Inlet × Outlet S.G. limit

MX-250 25×25 1.0 0.37kW

MX-251 25×25 1.0 0.75kW

MX-400 40×40 1.2 0.37kW

MX- 401 40×40 1.2 0.75kW

MX-402 50×40 1.2 1.5kW

MX-402H 50×40 1.0 1.5kW

MX-403 50×40 1.2 2.2kW

MX-403H 50×40 1.0 2.2kW

MX-505 65×50 1.2 3.7kW

■ Pump weight

Model MX-250/-400 MX-251/-401 MX-402/-402H MX-403/-403H MX-505

MX 13.5kg 18.5kg 30.5kg 33kg 53.5kg

MX (IE3) - 22kg 38kg 43kg 64kg

Motor

output

- 9 -

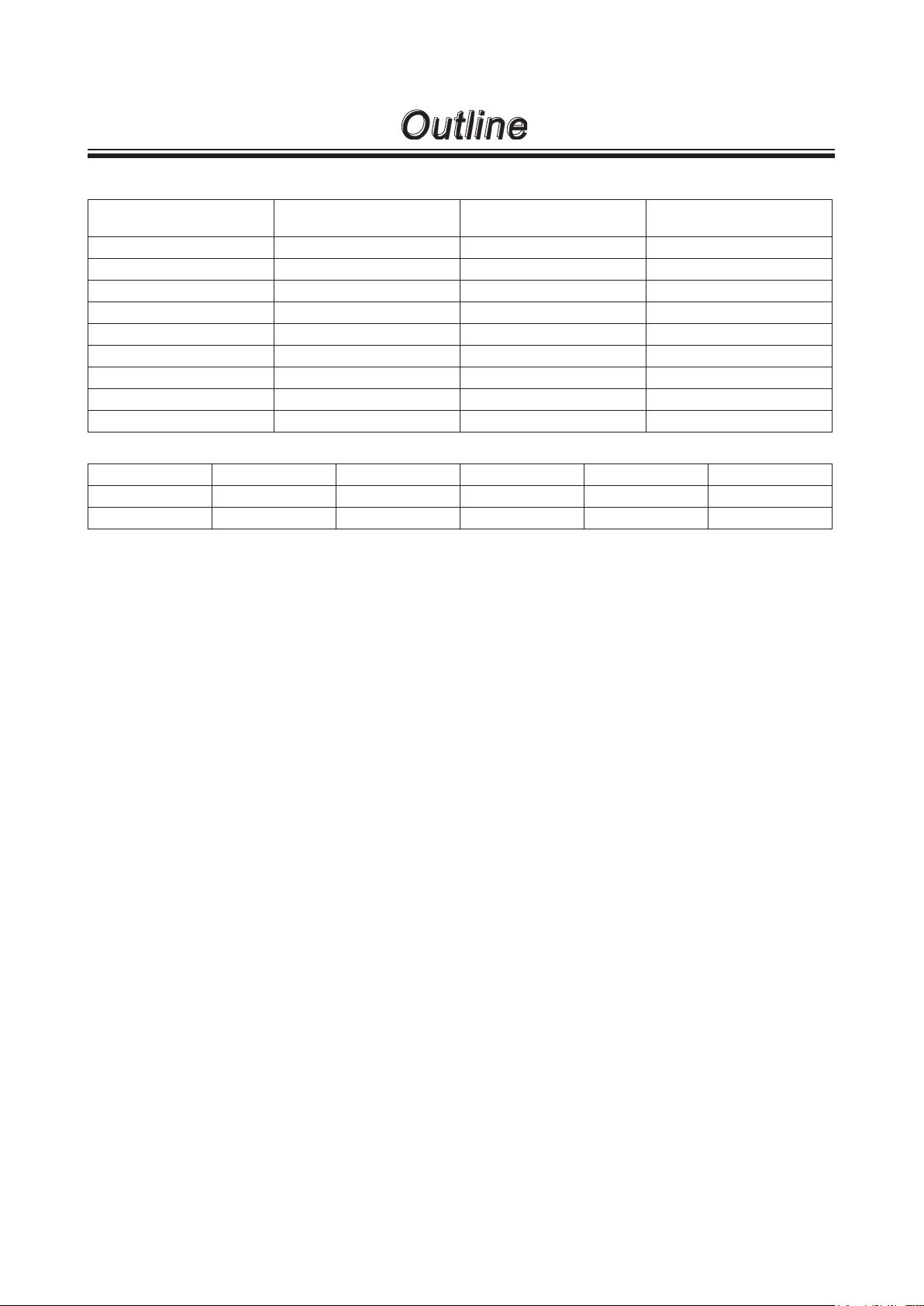

5. Dimension

MX-250/-251/-400/-401/-402(H)/-403(H)

Outline

MX-505

f

H

d e

c

L

g

f

W

b

a

b

4×k

H

d e

c

L

g

a

W

4×k

Model W H L a b c d e f g k

MX-250 160 247.5 411 130 65 130 115 140 90 163 12

MX-251 160 247.5 444 130 65 130 115 140 90 171 12

MX-251 (IE3) 160 247.5 446 130 65 130 115 140 90 171 12

MX-400 140 219 411 110 54 98 95 130 87 150 12

MX- 401 160 249 457 130 72 130 115 140 103 184 12

MX-401 (IE3) 160 249 459 130 72 130 115 140 103 184 12

MX-402(H)/-403(H) 260 274 516 208 80 200 120 160 89 157 14×36

MX-402(H)/-403(H)(IE3) 260 274 514/543 208 80 200 120 160 89 157 14×36

MX-505 180 330 601 140 96 220 150 180 95 175 14

NOTE: Actual dimensions may differ from the above information depending on model identification codes.

- 10 -

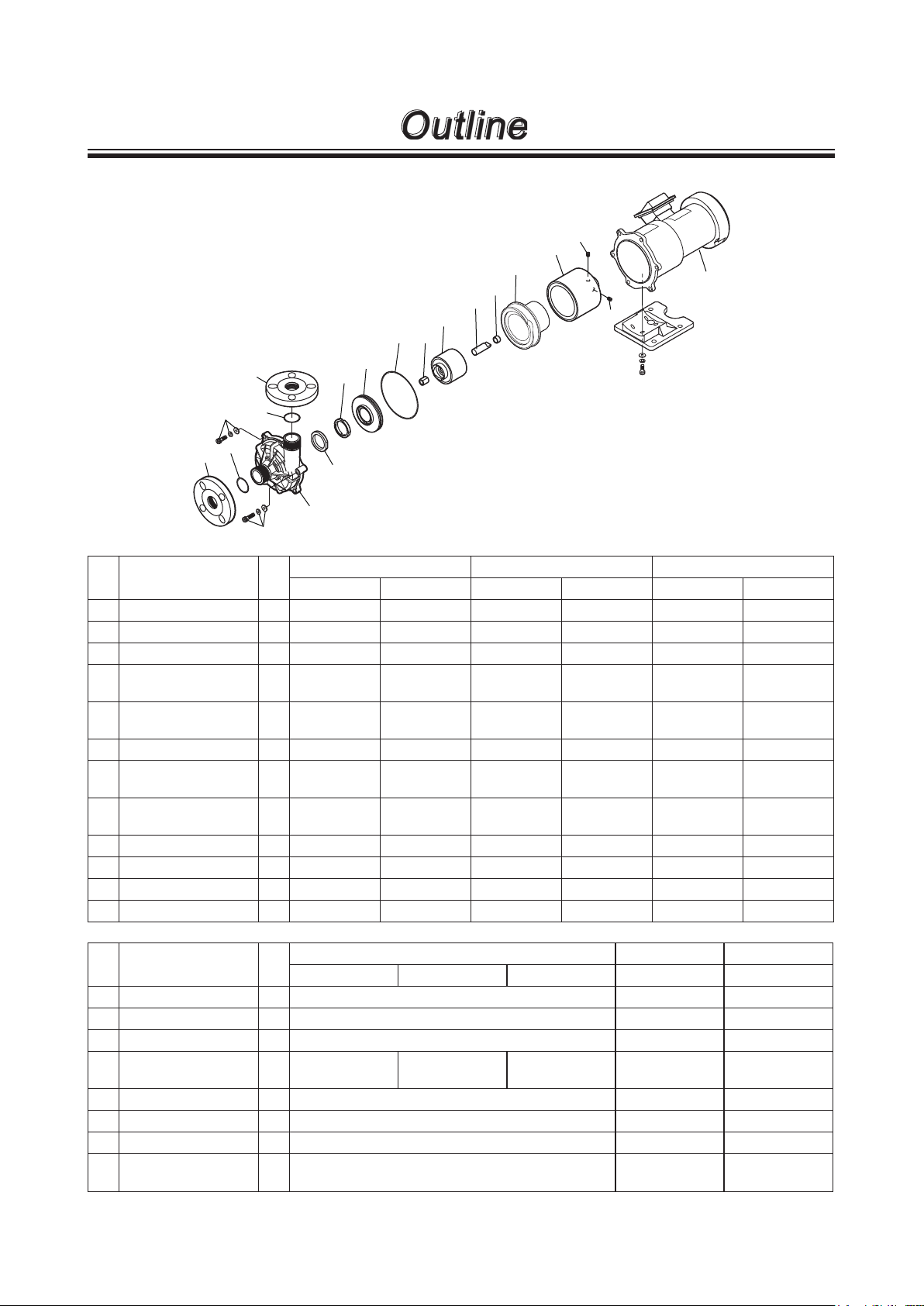

6. Part names

MX-250/-251/-401

13

Outline

9

5

2

19

20

8

21

23

13

24

11

24

1

12

3

22

18

9

27

15

16

No. Names Q'ty

Materials Remarks Materials Remarks Materials Remarks

MX-250 MX-251 MX-401

1 Front casing 1 GFRPP GFRPP GFRPP

2 Rear casing 1 GFRPP GFRPP GFRPP

3 Impeller 1 GFRPP GFRPP GFRPP

5 Drive magnet unit 1

8 Magnet capsule 1

Ferrite mag.

+aluminum alloy

Ferrite mag.

+PP

Ferrite mag.

+FCD450

Ferrite mag.

+PP

Ferrite mag.

+FCD450

Ferrite mag.

+PP

9 Hex socket set screw 2 Steel M8 × 10 Steel M8 × 10 Steel M8 × 10

11 Hex soch head bolt 6

12 Hex soch head bolt 2

Stainless

steel

Stainless

steel

M8 × 35,

with PW, SW

M8 × 50,

with PW, SW

Stainless

steel

Stainless

steel

M8 × 35,

with PW, SW

M8 × 50,

with PW, SW

Stainless

steel

Stainless

steel

M8 × 40,

with PW, SW

M8 × 50,

with PW, SW

13 Flange 2 GFRPP GFRPP GFRPP

15 Motor 1

16 Base 1 GFRPP GFRPP GFRPP

17 Adapter 1 FC200 FC200 FC200

No. Names Q'ty

CV/CE RV/RE AV/AE Remarks Remarks

Materials MX-250/-251 MX-401

18 Liner ring 1 Alumina ceramics 99.5%

19 Rear thrust 1 CFRPPS

20 Spindle 1 Alumina ceramics 99.5%

21 Bearing 1

High density

carbon

Filled PTFE

Alumina ce-

ramics

22 Mouth ring 1 Filled PTFE

23 O ring 1 V: FKM E: EPDM JIS B 2401 G165 JIS B 2401 G165

24 O ring 2 V: FKM E: EPDM JIS B 2401 G25 AS568-129

27 Hex soch head bolt 4 Steel

M8 × 20,

with PW, SW

M8 × 20,

with PW, SW

- 11 -

MX-400

13

Outline

15

9

5

2

19

20

8

23

21

13

24

11

24

3

22

18

27

9

16

1

12

No. Names Q'ty Materials Remarks No. Names Q'ty

1 Front casing 1 GFRPP 18 Liner ring 1

CV/CE RV/RE AV/AE

Materials Remarks

Alumina ceramics 99.5%

2 Rear casing 1 GFRPP 19 Rear thrust 1 CFRPPS

3 Impeller 1 GFRPP 20 Spindle 1

Drive mag-

5

net unit

Magnet cap-

8

Hex socket

9

set screw

Hex soch

11

head bolt

Hex soch

12

head bolt

sule

Ferrite magnet

1

+aluminum alloy

Ferrite magnet

1

+PP

21 Bearing 1 Carbon

22 Mouth ring 1 Filled PTFE

2 Steel M8 × 10 23 O ring 1 V: FKM E: EPDM

4

2

Stainless

steel

Stainless

steel

M8 × 30,

with PW, SW

M8 × 40,

with PW, SW

24 O ring 2 V: FKM E: EPDM

Hex soch

27

head bolt

Alumina ceramics 99.5%

Filled

PTFE

4 Steel

13 Flange 2 GFRPP

15 Motor 1

16 Base 1 GFRPP

17 Adapter 1 FC 200

Alumina

ceramics

99%

JIS B 2401

G135

AS568-129

M8 × 20,

with PW, SW

- 12 -

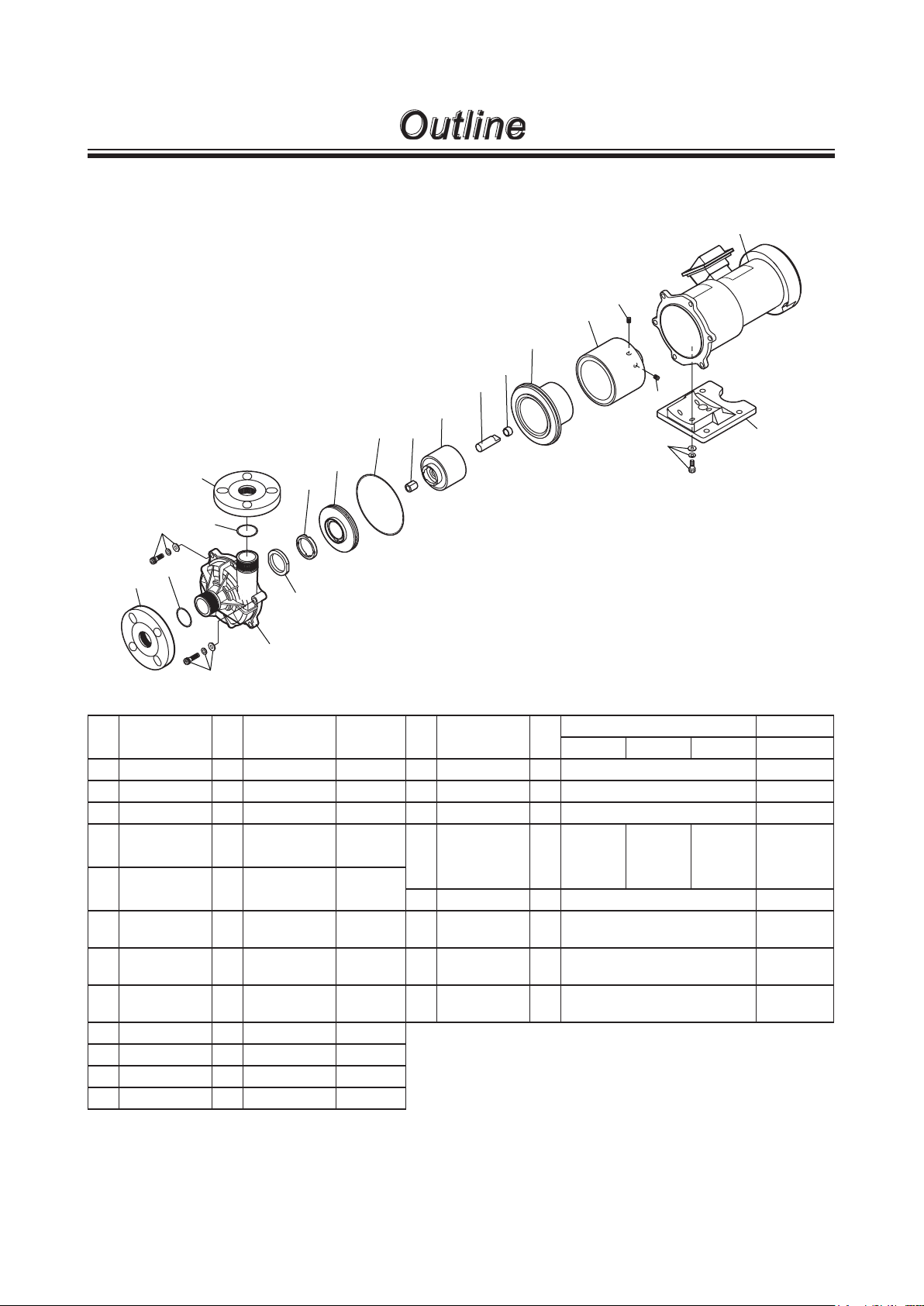

MX-402(H)/-403(H)

Outline

8

23

21

20

19

15

10

9

4

17

2

9

18

3

27

16

26

27

22

Materials Remarks

CV/CE RV/RE

Alumina ceramics 96%

14

25

11

24

13

1

12

No. Names Q'ty Materials Remarks No. Names Q'ty

1 Front casing 1 GFRPP 18 Liner ring 1

2 Rear casing 1 GFRPP 19 Rear thrust 1 CFRPEEK

3 Impeller 1 GFRPP 20 Spindle 1

Drive mag-

4

net unit

Magnet cap-

8

Hex socket

9

set screw

Hex head

10

Hex soch

11

head bolt

Hex soch

12

head bolt

sule

bolt

Rear earth

1

magnet

21 Bearing 1 Carbon Filled PTFE

+FCD450

Rear earth

1

magnet

+PP

22 Mouth ring 1 Filled PTFE

23 O ring 1 V: FKM E: EPDM

2 Steel M8 × 10 24 O ring 1 V: FKM E: EPDM

4

7

1

Stainless

steel

Stainless

steel

Stainless

steel

M10 × 30*,

with SW

M10 × 45,

with PW, SW

M10 × 60,

with PW, SW

25 O ring 1 V: FKM E: EPDM

Hex soch

26

head bolt

27 Lock pin 2 GFRPPS

Alumina ceramics 99.5%

4 Steel

13 Flange in 1 GFRPP

14 Flange out 1 GFRPP

15 Motor 1

16 Base 1 GFRPP

17 Adapter 1 FC200

JIS B 2401

G195

AS568-

136

AS568-

129

M8 × 20,

with PW, SW

*IE3 motor: M10×25

- 13 -

MX-505

13.1

13.2

Outline

10

9

4

17

2

9

19

20

21

27

8

3

27

14.1

14.2

11

25

24

12

23

22

1+18

15

No. Names Q'ty Materials Remarks No. Names Q'ty

1 Front casing 1 GFRPP 18 Liner ring 1

Materials

CV/CE RV/RE

Alumina ceramics 99.5%

2 Rear casing 1 GFRPP 19 Rear thrust 1 CFRPEEK

3 Impeller 1 GFRPP 20 Spindle 1

Alumina ceramics 99.5%

Rear earth

4 Drive magnet unit 1

magnet

21 Bearing 1 Carbon Filled PTFE

+FCD450

22 Mouth ring 1 Filled PTFE

23 O ring 1 V: FKM E: EPDM

25 O ring 1 V: FKM E: EPDM

27 Lock pin 2 GFRPPS

8 Magnet capsule 1

Hex socket set

9

screw

10 Hex head bolt 4

Hex soch head

11

12

bolt

Hex soch head

bolt

Rear earth

magnet

+PP

2 Steel M8 × 10 24 O ring 1 V: FKM E: EPDM

M12 × 35,

with SW

M10 × 45,

with PW, SW

M10 × 75,

with PW, SW

6

2

Stainless

steel

Stainless

steel

Stainless

steel

13.1 Flange in inner 1 GFRPP

13.2 Flange in outer 1 GFRPP

14.1 Flange out inner 1 GFRPP

14.2 Flange out outer 1 GFRPP

Remarks

JIS B 2401

G230

JIS B 2401

G70

JIS B 2401

G55

15 Motor 1

17 Adapter 1 FC200

- 14 -

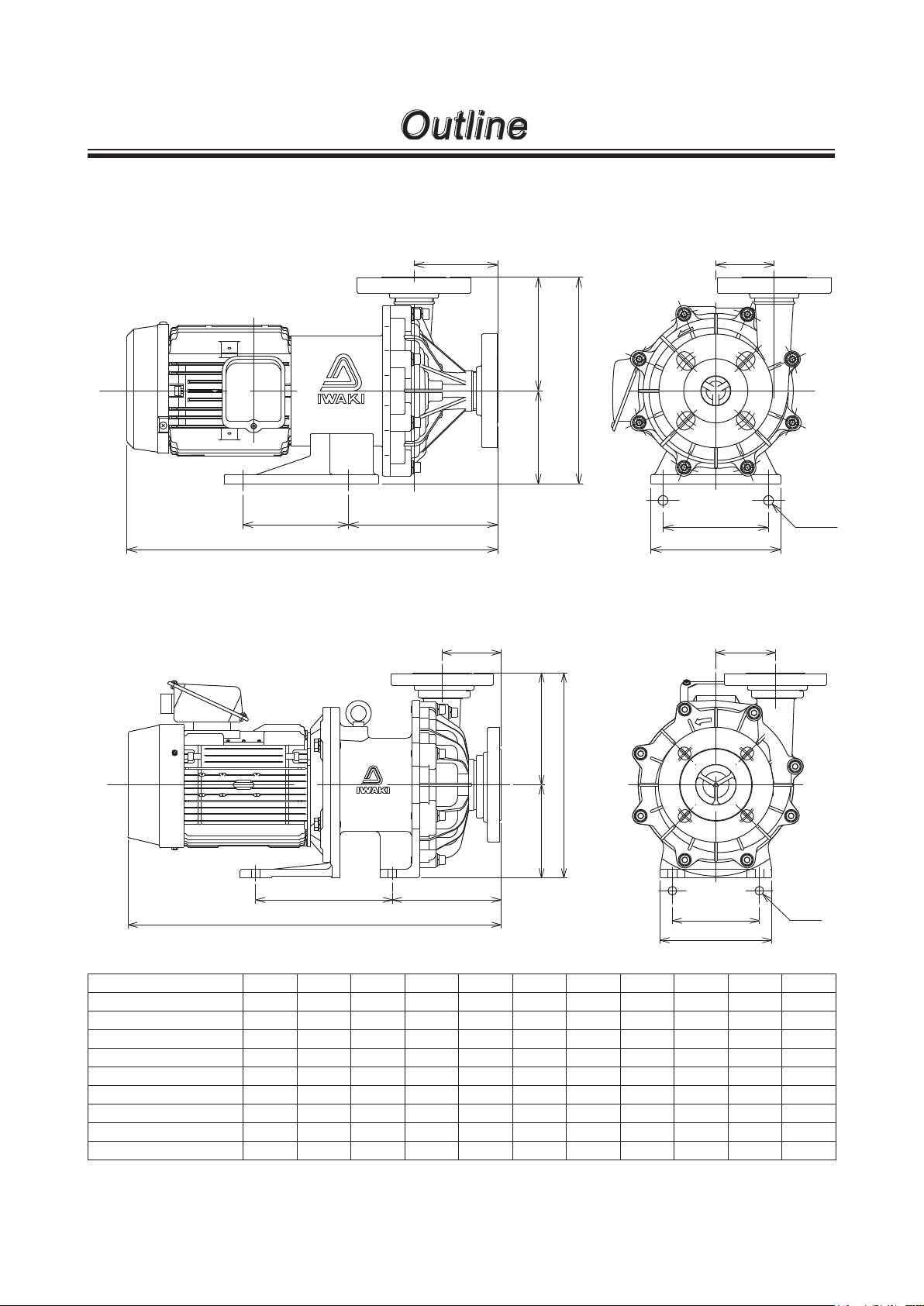

7. Overview

Outline

Pump unit

Not capable of self-priming.

Prime the pump via inlet or

outlet before operation.

Outlet

Motor nameplate

Apply the power voltage specified on the

nameplate (follow an applicable local

power regulation.)

"Arrow" label

The arrow indicates a rotational direction of

the motor. Make sure the motor runs in a correct direction. Refer to page 27, "2. Before

operation".

Motor (Drive unit)

The motor power is transmitted to

the pump.

Base

Be sure to fix the base.

Pump nameplate

Operate the pump in accordance

Inlet

with specifications.

"Do not run pump dry" label

Operating the pump without liquid

damages internal parts.

CAUTION

Wet a cloth with tap water and wring it out for cleaning the pump. Use a neutral detergent for greasy dirt and then rub with a dry cloth. Do not wipe nameplates, labels or

pump body with any solvent.

- 15 -

Installation

1. Before installation ...............................17

2. Installation/Pipework/Wiring ...............19

- 16 -

Installation

CAUTION

● Do not run pump dry

Do not run pump dry (operation without priming water or with a suction valve

closed). Otherwise, internal parts are excessively worn by friction heat and

fatal pump damage results.

* If the pump runs dry by mistake, turn off power and leave it for more than

one hour to cool it down. Quick cooling can give rise to cracks on parts.

* An Iwaki dry run protector, the DR, is recommended for the prevention of

dry running.

● Do not operate the pump in a flammable atmosphere

Do not place explosive or ammable material near the pump.

● Do not modify the pump

Alterations to the pump carries a high degree of risk. It is not the manufacturer’s responsibility for any failure or injury resulting from alterations to the

pump.

Prohibit

Prohibit

Prohibit

1. Before installation

Always observe the following points.

■ Precautions for starting/stopping the pump

(In case the pump is in flooded suction system.)

Follow the procedures below when starting/stopping the pump for the prevention of water hammer.

Take extra care when a discharge line is long.

When starting the pump

First, prime the pump. Then turn on power to start operation with a discharge valve fully closed.

And then gradually open the valve and adjust a flow rate to a specified point.

When stopping the pump

Gradually close a discharge valve. Turn off power and stop the pump after the valve is fully closed.

NOTE: Do not close a discharge valve sharply. Otherwise an excessive pressure may dam-

age the pump, when using a solenoid valve, set it to close slowly.

■ Do not install or store the pump:

• Where ambient temperature can exceed 40 ºC or falls below 0 ºC.

• Where ambient humidity can exceed 85%RH or falls below 35%RH.

• In a corrosive/explosive environment.

• In direct sunlight or wind & rain (except outdoor-use type).

• Under mechanical vibration.

- 17 -

Installation

■ Always prime the pump

The MX is not a self-priming pump. Prime the pump every time the pump is operated. Do not run pump dry

(operation without liquid.), or internal parts seizing or excessive wear results.

■ Maximum operating pressure

Do not allow a discharge pressure to exceed the limits below.

Model MX-250 MX-251 MX- 400 MX-401

Pressrue limits (MPa) 0.25 0.33 0.22 0.28 0.43 0.5 0.33

MX-402

/-403

■ Liquid conditions

Slurry

The MX series can not send slurry except the pumps with a SiC bearing and a SiC spindle (sliding parts

code: A).

The A type can handle slurry up to 5% (concentration), 50μm (particle size) and 80Hs (hardness).

Contact us for details.

Performance change

Shaft power, discharge capacity and pump head vary depending on specic gravity and viscosity. The

pump is designed for a specied liquid. If you made a change to the liquid property, contact us.

SiC bearing

A SiC bearing can be worn greater than other materials depending on liquid property including liquid viscosity. Contact us for detail.

Temperature change

Viscosity, vapour pressure and corrosive nature vary with liquid temperature. Always take account of temperature change.

MX-402(H)

/-403(H)

MX-505

►Allowable liquid temperatrue: 0-80°C (clean water)

►Allowable ambient temperature: 0-40°C

►Allowable ambient humidity: 35-85%RH

NOTE: Contact us for the allowable liquid temperature range at each liquid type.

■ Intermittent operation

Frequent ON-OFF operation damages the pump in a short time. Do not make ON-OFF operation more than

six times per hour.

■ Disconnection of magnet coupling

Stop the pump immediately when the magnet coupling is disconnected. Otherwise magnetic force reduces.

■ Ascending area of a spike curve (in a performance curve)

When a specified point falls on an ascending area of a spike curve (generally, a flow is small in this area.

See the standard performance curves), check and observe the following points.

• There should be no possibility of trapping air in a supply tank or a discharge line.

• A discharge valve should be installed near the pump outlet to adjust a flow rate.

- 18 -

Installation

2. Installation/ Pipework/ Wiring

If you notice any abnormal or dangerous conditions, suspend operation immediately

and inspect/solve problems.

WARNING

● Turn off power before work

Be sure to turn off power to stop the pump and related devices before work.

Make sure no one turns on power by mistake while working on the pump,

otherwise it may result in a serious accident. If your working area is noisy or

dark, let other people know about the situation by displaying a notice such as

"POWER OFF (Maintenance)" near a power switch.

Do not lift the pump by gripping any plastic parts (pump unit, flange or base)

●

The pump can drop unintentionally as a plastic part breaks, resulting in seri-

Turning off power

ous injury.

● Electrical wiring

Electrical work should be performed by a qualified electrician. Otherwise,

personal injury or property damage may result.

■ Carrying in and out

When carrying in and out the pump, observe the following points.

• Do not lift the pump by holding plastic parts such as a pump unit, a flange or a base.

• Mount the pump horizontally on a pump base.

Caution

- 19 -

Installation

■ Installation

Arrange pump and pipework based on the following piping layout for a long period of operation.

1

16

12

12

15

5

9

17

7

2

1011

12

2

6

15

2

2

14

13

Installation location

• Install the pump as close to a supply tank. Keep a liquid level in the tank higher than the pump at any time

(flooded suction application).

• In case the pump is installed above a liquid level (suction lift application), lay on a priming line and mount a

foot valve to the bottom of a suction line.

1. Discharge pipe

2

3

4

( Support pipework to keep the pump free of

piping weigh.)

2. Gate valve

3. Check valve

4. Pressure gauge

5. Motor

6. Pump

7. Air vent/ priming line

9. Drain ditch

10. Vacuum gauge

11. Suction pipe (Pipe diameter: D)

( Horizontal sections should be shortest and

laid on a rising gradient of 1/100 toward the

pump)

12. Pipe support

13. Suction pipe (Pipe diameter: D)

14. 2D or 500mm or more

15. Expansion joint

16. Flushing line (Discharge side)

17. Flushing line (Suction side)

NOTE: The maximum suction lift varies with liquid characteristics, specific gravity, liquid

temperature and suction line length. Contact us for detail.

Outdoor use motors (Indoor use motors can not be installed out of doors)

Outdoor use motors can also be used in doors. Protect the motor and electrical power distribution equipment from possible damage due to an accidental outflow or act of providence.

Installation space

• Select a level location, free from vibration, that won’t hold liquid.

• Allow sufficient space around the pump for easy access and maintenance.

CAUTION

Fix the pump firmly. Support piping so as not to directory weigh on the pump.

- 20 -

■ Foundation work

Installation

Foundation bolt

Shim

Base

Liner

Concrete

• Installation area should be larger than the footprint of the pump. Or a plastic base may break

due to a concentrated load.

• If piping vibrates sympathetically with the

pump in operation, provide an expansion joint

between the pump and the piping to reduce

vibration.

■ Tightening torque between the pump and pipework

Connect the pump to pipework via inlet and outlet flanges according to the tightening torque below. The

table is based on use of metal pipe flanges with rubber gaskets. Tighten bolts diagonally at even torque.

Model Bolt size Tightening torque

MX-250/-251/-400/-401/-402/-403/-505 M16 20N•m

■ Piping load and momentum

Try not to apply a heavy load to the inlet and outlet flanges. Permissible piping weight and moment to the

pump are as below.

Y

Z

Y

Z

X

X

- 21 -

Installation

Permissible stress to outlet flange Permissible stress to inlet flange

Pipe dia. (mm)

kN

40, 50

Load direction

Fx

Fy

Fz

40, 50

Load direction

Mx

25

Load

Load direction

Fx

Fy: compression

Fy: tension

Fz

Permissible moment to outlet flange Permissible moment to inlet flange

Load direction

Mx

0.10 0.15

0.15 0.20

0.10 0.10

0.10 0.15

Pipe dia. (mm)

25

Moment

kN·m

0.02 0.05

Pipe dia. (mm)

25

Load

kN

0.10 0.10

0.10 0.15

0.10 0.15

Pipe dia. (mm)

25

Moment

kN·m

0.05 0.10

40, 50, 65

40, 50, 65

My

Mz

0.05 0.10

0.05 0.10

My

Mz

0.02 0.05

0.05 0.10

■ Suction line

1. Always build up a flooded suction system. Have a suction line shortest with the minimum number of

bends. Support piping by pipe supports so that the pump is not subject to piping weight or thermal stress.

2. Make sure joints on a suction line are secure and air doesn't come in. If air is entrained into a suction line,

liquid may not be pumped or the pump may break at its worst.

3. When the inner pressure of a supply tank is negative, or a suction lift or a suction line is long, apply the

following formula.

NPSHa>NPSHr+0.5m (See the standard performance curve for NPSHr.)

4. If a bent pipe is installed in a suction line, lay a straight line (length: 500mm or longer, or 8 times longer

than the inlet I.D. of the pump) between a pump inlet and the bent pipe. Also, have the curvature radius of

the bent pipe largest.

5. Do not allow any arched line where air may be trapped. A suction line should be laid on a rising gradient

of 1/100 toward the pump.

6. If the inlet I.D. of the pump is different from that of a suction pipe, use an eccentric reducer pipe. Upper

side should always be level. Air may be trapped if it is mounted upside down.

- 22 -

Installation

7. In flooded suction, install a gate valve on a suction line for easier overhaul & inspection. Keep this valve

open at any time during operation.

8. Install a flushing line for cleaning the pump after handling a harmful liquid.

9. A suction pipe I.D. should be equal to or larger than a pump inlet I.D.

Suction lift application

10. One end of a suction line should always be at least 500 mm lower than a liquid level in a supply tank for

the prevention of air ingress.

11. Provide a screen in a supply tank for the prevention of foreign matter interfusion (Clean the screen peri-

odically.). The distance between the end of a suction line and the bottom of a suction tank should be 1.5

times wider than a suction line I.D.

12. Be sure to install a foot valve at one end of a suction line.

Good conditions Unacceptable conditions

Trapped air

Trapped air

Trapped air

- 23 -

Installation

■ Discharge line

1. Support discharge piping so as not to directory weigh on the pump.

2. Lay a priming line when the pump is not under a flooded suction system.

3. Pipe resistance rises too high to obtain an intended flow if a discharge pipe I.D. is too long. Always take

account of the increment of pipe resistance.

4. Install a check valve in the following cases.

When selecting a check valve, check its maximum operating pressure to make sure it tolerates a possible

pressure rise due to water hammer or backflow.

• A discharge line is too long.

• Actual discharge head (static discharge head plus discharge pipe resistance) is more than 15m.

• The end of a discharge line is 9m higher than a liquid level in a supply tank.

• Several pumps are running in parallel.

5. Install a gate valve on a discharge line to adjust a flow rate and to protect a motor from overload. If you

are to install a check valve as necessary, it should be mounted in between the pump and the gate valve.

6. Install a pressure gauge on a discharge line.

7. Install an air vent line when a discharge line is laid long in a horizontal direction.

8. Drain

Install a drain valve if there is the risk of liquid freezing in the discharge line.

■ Wiring

Electrical wiring and any work on power source must be performed by qualified persons only. It is not the

manufacturer’s responsibility for any injury and damage due to noncompliance with this notice. Contact us

as necessary.

1. Install an electromagnetic switch according to motor specifications (voltage, capacity, etc.).

2. Electromagnetic switches and push buttons should be installed away from the pump.

3. If the pump is used out of doors, protect switches from rainwater.

- 24 -

Operation

1. Operational precautions ......................26

2. Before operation .................................27

3. Operation ............................................27

- 25 -

Prohibit

Operation

1. Operational precautions

CAUTION

● Never run pump dry or shut off a suction valve during operation. Otherwise

the pump fails in a short period.

● Check the rotational direction of the pump. Clockwise seen from the motor

end is a correct direction. Operation in a reverse direction may cause

pump damage.

● Stop the pump immediately when it is running under cavitation. Do not

continue to run the pump when air is entrained from a suction line.

● Stop the pump immediately if the magnet coupling is disconnected.

Magnetic force reduces if the pump keeps on running for more than one

minute in this condition.

Keep liquid temperature change within 80˚C at any time during operation or stop.

●

● Start the pump with a discharge valve fully closed in order to avoid water

hammer.

● Closed-discharge operation should be within one minute. If the pump runs

with a discharge valve closed for a long time, the liquid temperature inside

the pump rises and damages the pump.

● If power is interrupted while the pump is running, switch off the pump

immediately and close a discharge valve.

● Take extra care for a discharge pressure not to exceed the pump limit. See

page 18, "Maximum operating pressure".

● The surface temperature of the pump or pipe rises high along with liquid

temperature in or right after operation. Take preventive measures.

Model Liquid temperatuer Surface temperature (at ambent 40°C)

MX-250/-251/-400/-401/-402(H)/-403(H)/-505 80°C 80°C

● Noise level

Model MX-250/-400 MX-251/- 401

Noise level 70dB 75dB 80dB 85dB

MX-402(H)/-403(H)

MX-505

Caution

Caution

In case the pump noise affects human health or communication to secure

a safety, provide a noise reduction cover. Be careful not to reduce cooling

effect by a motor fan.

- 26 -

Operation

2. Before operation

Take the next steps to start the pump at the first operation or after a long period of storage.

1. Clean the inside of piping and a supply tank.

2. Retighten flange fixing bolts and base fixing bolts.

3. Prime the pump and shut off a discharge valve. Check an air vent line and a flushing line are closed.

4. Run the motor for a moment (within a second) in order to check if the motor rotates to the direction pointed by an arrow label (clockwise seen from a motor fan). If the motor rotates in reverse, interchange two of

three phase wires at random.

3. Operation

■ Starting process

Operate the pump by the following procedure.

Operation procedure Remarks

• Open valves. • Open suction valves fully.

1

2

• Prime the pump. • Prime the pump unit and then close a discharge valve.

• Check the motor for correct

rotating direction.

Turn on power and then

3

immediately (within one second) switch off the power.

• Turn on power and start the

pump to adjust discharge

pressure and capacity.

Observer the minimum discharge capacity. See below.

4

• Open discharge valves fully.

• Supply power to run the pump only for checking a rotational direction. (The

correct direction is indicated with an arrow on the motor.)

• Check if the motor fan smoothly stops after the power is turned off.

CAUTION

If the motor fan does not stop smoothly, internal parts may

contact each other. Check the inside of the pump.

• Run the pump with a discharge valve closed. Once a pressure gauge points

the max discharge pressure, open the discharge valve gradually to obtain a

specified discharge pressure (or discharge capacity).

NOTE: Start to open/close a discharge valve gradually to adjust dis-

charge pressure within one minute after the pump starts to run.

Always check a discharge pressure gauge (or adjust discharge

capacity by checking a flow meter).

CAUTION

Opening a valve sharply, the motor may be overloaded.

Always open a valve while checking ammeters.

- 27 -

Operation

Operation procedure Remarks

Do not operate the pump below the minimum discharge capacity.

►The minimum discharge capacity: 10

• Observe the minimum discharge capacity for the prevention of continuous closed-discharge operation. This

4

rule holds true to not only manual operation but also automatic operation.

CAUTION

Do not run the pump longer than one minute with a discharge valve fully closed.

< Points to be checked>

Check a flow meter and con-

5

firm that pump operation is

as per specifications during

operation.

/min MX-250/-251/-400/- 401

20

/min MX-402(H)/-403(H)

50

/min MX-505

• If a flow meter is not available, calculate a flow rate from discharge pressure,

suction pressure and current value, taking account of pipe resistance.

CAUTION

In case of trouble, turn off power immediately and solve problems. See “1.

Troubleshooting”.

■ Stopping process

Operation Procedure Remarks

• Close a discharge valve

gradually.

1

• Turn off power and stop

2

pump operation.

<Leaving the pump stop>

• Liquid in the pump may freeze and consequently damage the pump in winter. Drain liquid before storage. When

draining harmful liquid, be sure to flush the inside of the pump and piping afterwards.

3

• Use a heater to prevent liquid from freezing when the pump is temporarily stopped in an extremely cold region.

• In the event of a power failure, turn off power and close a discharge valve.

• Do not close a discharge valve sharply whether manually or automatically.

Otherwise, the pump may be damaged by water hammer action which tends to

occur with a long a discharge line. When using a solenoid valve, set it to close

slowly.

• Check that the motor stops slowly and smoothly. If it does not stop smoothly,

inspect the inside of the pump.

- 28 -

Maintenance

1. Troubleshooting ..................................30

2. Maintenance & Inspection...................31

3. Spare & Wear parts ............................34

4. Dismantlement & Assembly ................35

- 29 -

Maintenance

1. Troubleshooting

If you can not find out the root cause of failure, contact us.

Symptom

Troubles

Liquid can not

be discharged.

Discharge

capacity is too

low.

Motor is overheated.

Discharge

capacity is rapidly reduced.

Pump vibrates.

When a discharge

valve is closed.

The pump can not be

primed.

After starting, pressure drops sharply as

a discharge valve is

opened.

Discharge pressure

does not rise.

Pressure & vacuum

are normal.

Pressure is low and

vacuum is very low.

When a discharge

valve is opened.

The readings of pressure/vacuum gauges

drop to zero.

The readings of pressure/vacuum gauges

fluctuate and drop to

zero.

Vacuum is high.

Vacuum is very high.

The readings of pressure gauge & vacuum gauge fluctuate.

Vacuum is high but

pressure is normal.

Vacuum is normal

but pressure is high.

Pressure and vacu-

um are low.

Vacuum is high. • A suction line clogs with

• Priming liquid level is too

low.

• Dry running

• A foot valve doesn't close

due to foreign matter clogging.

• Air ingress through a

suction line or a sealing

surface.

• A disconnection of the

magnet coupling

• Low pump speed

• The pump rotates in

reverse.

• The strainer is clogged

with foreign matters.

• Air pocket in suction line

• Foreign matters are

clogged at impeller inlet.

• Air ingress from a suction

line or a sealing surface.

• Discharge line clogs with

foreign matters.

• Resistance such as air

pocket in suction line.

• Actual head is too high or

pipe resistance is too large.

• Motor rotates in reverse. • Interchange motor wiring.

• Power voltage is low.

• Overload

foreign matters.

• Poor foundation

• Loose mounting bolts.

• Cavitation occurs.

• Pump bearing is worn or

melted.

• Magnet capsule or spindle

is broken.

• Dynamic balance of drive

magnet is upset.

• The rotating part hits

against other parts.

• Motor bearing is worn.

Cause

Point to be checked

&

Countermeasures

• Stop and prime the pump

and resume operation.

• Clean the foot valve and

a seat.

• Check if suction line connections are completely

sealed.

• Check if liquid level in

supply tank is not too low.

• Check amperage to see

if the motor is not overloaded.

• Check if foreign matters

do not lock the impeller or

magnet capsule.

• Check if voltage is normal.

• Check wiring or motor.

• Correct wiring.

• Remove foreign matters.

• Check and correct suction

line.

• Remove foreign matters.

• Check suction line con-

nections and retighten as

necessary.

Remove foreign matters or

•

scale from pump/piping.

• Check if there is no

arched pipework.

• Check actual head and

pipe resistance.

• Check voltage or frequency.

• Check specific gravity and

viscosity of liquid.

• Keep good ventilation.

• Remove foreign matters.

• Reinstall the pump.

• Retighten the bolts.

• Remove the cause of

cavitation.

• Replace as necessary.

• Replace as necessary.

• Remove the cause.

Replace as necessary.

• Replace as necessary.

• Replace bearing or motor.

- 30 -

Maintenance

2. Maintenance & Inspection

WARNING

● Access limitation

The magnet drive pump has a pair of strong magnets. The strong magnet field

could adversely affect the persons who are assisted by electronic devices

such as the pacemaker.

● Turn off power before service

Risk of electrical shock. Be sure to turn off power to stop the pump and related

Prohibited

devices before service is performed.

● Wear protective clothing

Always wear protective clothing such as an eye protection, chemical resistant

gloves, a mask and a face shield during disassembly, assembly or mainte-

nance work. The specic solution will dictate the degree of protection. Refer to

MSDS precautions from the solution supplier.

CAUTION

● Do not catch the finger

Magnetic force of the pump is powerful. Take care not to catch the finger in

the bracket.

■ Daily inspection

1. Always check for leakage before pump operation. Do not run the pump when liquid leaks.

2. Check whether the pump runs without abnormal noise or vibration.

Turning off power

Wear protective

gear

Caution

3. Check a liquid level in a supply tank and a suction pressure.

4. Check that discharge capacity and a motor current value are as per specifications on the nameplate during operation.

NOTE A discharge pressure is in proportion to the specific gravity of liquid. The cock of a

pressure gauge or a vacuum gauge should be opened only when measurement is

carried out. Close it right after measurement. If the cock remains open during pump

operation, its meter mechanism may be adversely affected by the abnormal pressure rise caused by water hammer action.

5. If a spare pump is stored, run it from time to time to keep it ready for operation at any time when needed.

6. Check discharge pressure, discharge capacity, and motor power supply voltage to see if they do not fluc-

tuate during pump operation. See page 30 "1. Troubleshooting" as necessary.

- 31 -

Maintenance

■ Periodic inspection

To ensure efficient and smooth operation, perform periodic inspection. Be careful not to damage internal

sliding parts and plastic parts when dismantling the pump.

The magnetic force of a drive and a driven magnet is strong. Be careful not to catch the finger. Do not put

electrical devices such as a watch and a mag card close to those magnets.

Interval

Every six months

(Maintain an

inspection record)

Part names

(Drive magnet unit)

Drive magnet

Hex. socket set screw

Rear casing

Rear thrust

(Magnet capsule unit)

Magnet capsule

Bearing

(Impeller unit)

Impeller

Mouth ring

Inspection items

● Wear trace

● If the drive magnet is correctly

mounted by hex. socket set

screws and they are not loose.

● Decentering of magnet and

motor shaft (Max.1/10mm)

● Wear tracks on an inner surface

● Cracks

● Wear of the rear thrust

● Contamination in rear casing

● Wear tracks on the rear end or

side face of the magnet capsule

● Cracks on the rear end or side

face of the magnet capsule

● Wear of the bearing

● Loose fit of the impeller unit

● Wear of the mouth ring

● Cracks

● Contamination in the impeller

● Impeller deformation

Measures

○ Finding wear trace, contact us.

○ Reset the drive magnet to the

motor shaft and retighten the

screws.

○ Retighten the hex. socket set

screws or replace the drive

magnet (Contact us).

○ Contact us.

○ Replace as necessary.

○ Contact us.

○ Remove contamination.

○ Contact us.

○ Contact us.

○ Replace as necessary.

○ Replace or contact us.

○ Replace as necessary.

○ Replace as necessary.

○ Remove contamination.

○ Replace as necessary.

Front case

Rear case

Liner ring

Spindle

● Contamination

● Cracks

● Wear, cracks and wear tracks

on a liner ring

● Swelling or a crack on O ring

● Wear tracks on an unlikely portion

● Cracks

● Wear degree

- 32 -

○ Remove contamination.

○ Replace as necessary.

○ Contact us.

○ Replace as necessary.

○ Contact us.

○ Replace as necessary.

○ Replace as necessary.

Maintenance

■ Wear limits of bearing and spindle

Check wear degree of the bearing and spindle.

Model

Bearing inner diameter 18 19 24 25

Spindle outer diameter 18 17 24 23

* If the clearance between the bearing (#21) and the spindle (#20) exceeds 1 mm, either of them, whichever

has greater wear, should be replaced regardless of the wear limit. For the pumps with the SiC spindle and

SiC bearing (MX-250/-251/-400/-401), replace the both parts at the same time (the whole magnet capsule

unit of #8 needs changed to the new one to replace the bearing).

* Sliding parts may suffer initial wear in an initial operation phase but this is not abnormal.

■ Wear limit of mouth ring

Check wear degree of the mouth ring.

Model

MX-250/-251/-400/-401 MX-402/-402(H)/-403/-403(H)/-505

Before use Wear limit Before use Wear limit

Mouth ring thickness

Initial thickness Wear limit

MX-250/-251/-400/-401/-402(H)/-403(H) 8mm 6mm

MX-505 9mm 7mm

* The mouth ring (#22) is 2 mm (3m for MX-250) forward from the impeller (#3) when shipped. Before the

step has reduced to 0 mm, replace the impeller unit.

Max 2mm

Mouth ring

Impeller

- 33 -

Maintenance

3. Spare & Wear parts

Appropriate spare parts are necessary for a long period of continuous operation. We recommend

that wear parts be always in stock. Place an order for spares with the following information.

1. Part names and part number (See the diagram below.)

2. Pump model identification code and manufacturing number (See pump nameplate.)

3. Drawing number if you have our approval drawing

■ Spare parts list

No. Part name MX-250 MX-251 MX-400 MX-401 MX-402 MX-403 MX-402H MX-403H MX-505

1 Front casing unit MX0109 MX0125 MX0131 MX0799 MX0804 MX0983

2 Rear casing MX0110 MX0126 MX0132 MX0802 MX0807 MX0967

IE1 M X0111 - MX0127 - MX0176 MX0184 MX0190 MX0191 MX0969

29 Impeller unit 50Hz

29 Impeller unit 60Hz

Magnet capsule unit C

8

(carbon)

Magnet capsule unit R

8

(PTFE)

Magnet capsule unit A

8

(Alumina ceramic)

O ring (for casing) V M X 0116 MX0129 MX0 116 MX0180 MX0 974

23

O ring (for flange) V M X 0117 MX013 0 MX0181 MX0978

24

O ring (for flange) V - - MX0130 MX0976

25

20 Spindle MX0 118 MX0182

19 Rear thrust MX0 119 MX0183

13

Flange

14 - - MX0299

27 Lock pin - MX0308

Note1: The O ring part numbers above are for FKM and EPDM. Contact us for the Aflas® O ring.

Note2: The maximum duration of the above parts (except #23, #24 and #25 O rings) is about 20,000 hours, however, it is based

on the operation with clean water at ambient temperature and can change with liquid properties and temperature.

For the #23, #24 and #25 O rings, they should be replaced every time the pump head is opened.

Note3: The #20 spindle, #21 bearing and #22 mouth ring must be replaced when the wear limit has come. Note the whole

magnet capsule unit (#8) needs to be changed to the new for the replacement of the bearing, and the whole impeller unit (#29) for the replacement of the mouth ring.

13

24

11

24

13

12

IE2 MX0991 MX0935 MX0993 MX0937 M X0176 MX0184 MX0190 MX0191 MX0969

IE3 - MX0120 - MX1016 MX0176 MX018 4 MX0190 MX0191 MX0969

IE1 MX0112 - MX0128 - MX017 7 MX0185 MX0185 MX0176 MX0968

IE3 - MX0121 - M X1017 MX0177 MX0185 MX0185 MX0176 MX0968

MX0 113 MX0122 M X0113 MX0122 M X0178 MX0186 MX0178 MX0186

MX0 114 MX0123 M X0114 MX0123 M X0179 MX0187 MX0179 MX0187

MX0 115 MX0124 M X011 5 MX0124 - - - - -

E MX0207 MX0235 MX0207 MX0302 MX0973

E MX0205 MX0233 MX0300 MX0977

E - - MX0233 MX0975

MX0204 MX0232 MX0298

2

19

20

8

8

21

23

29

3

22

18

1

14

25

11

24

13

12

29

3

27

22

18

1

8

8

23

21

27

13.1

20

13.2

2

19

14.1

27

29

14.2

11

25

24

22

1+18

12

(13.1) MX0980

(13.2) MX0979

(14.1) MX0982

(14.2) MX0981

23

3

27

19

8

20

8

21

2

MX-402/-403/-402H/-403HMX-250/-251/-400/-401 MX-505

- 34 -

Maintenance

Prohibited

4. Dismantlement & Assembly

WARNING

● Access limitation

The magnet drive pump has a pair of strong magnets. The strong magnet field

could adversely affect the persons who are assisted by electronic devices

such as the pacemaker.

● Turn off power before service

Risk of electrical shock. Be sure to turn off power to stop the pump and related devices before service is performed.

Turning off power

● Wear protective clothing

Always wear protective clothing such as an eye protection, chemical resistant

gloves, a mask and a face shield during disassembly, assembly or maintenance work. The specific solution will dictate the degree of protection. Refer to

Wear protective

gear

MSDS precautions from the solution supplier.

CAUTION

● Do not catch the finger

Magnetic force of the pump is powerful. Take care not to catch the finger in

the bracket.

► Mark each wire so that the wires can be connected correctly to the motor.

► Do not disassemble the pump beyond the extent shown on this manual.

► Make sure to close suction and discharge valves before dismantling/assembling the pump. Clean the

inside of the pump as well.

► Magnetic force of the pump is strong. Be careful not to catch the finger in parts. Do not allow iron

pieces or powders to stick to a drive and a driven magnet.

► A pair of strong magnets is mounted in the pump and its magnetic force may affect magnetic disks/

cards or wrist watches. Do not bring them close to the pump.

Caution

- 35 -

Maintenance

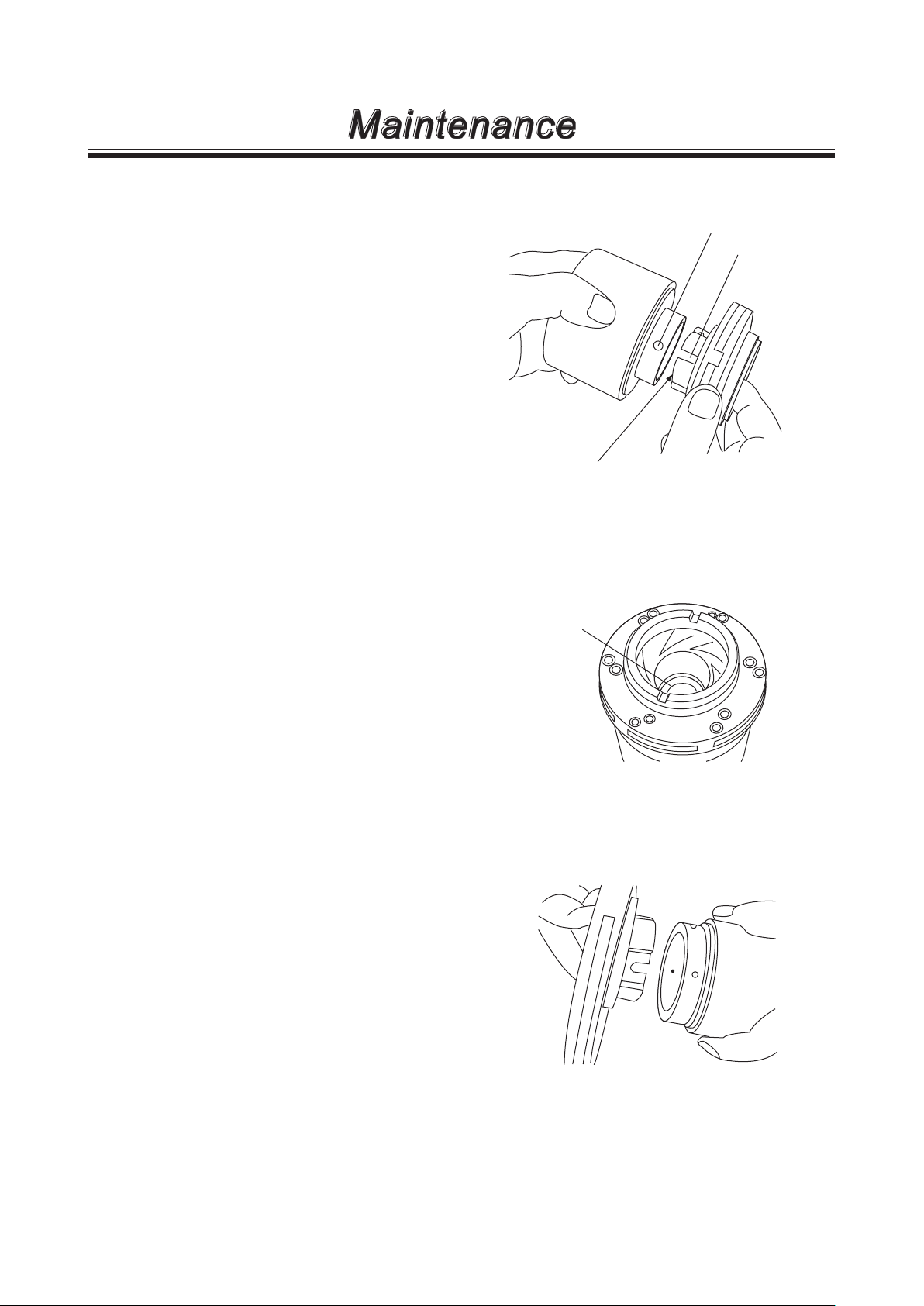

■ Disassembly (pump head)

1. Remove hex. socket head bolts from the front

casing and remove it from the motor bracket.

At this time drain and collect residual liquid and

decontaminate wet ends.

2. Pull out the combination of an impeller unit and a

magnet capsule unit. Be careful not to catch the

finger in the impeller unit and the bracket.

Magnet capsule unit

Impeller unit

3. Detach the impeller unit from the magnet capsule

unit as necessary. Be careful not to damage the

units.

a. MX-250/-251/-400/-401

Slightly tap the back of the impeller unit by a

plastic hammer while holding the magnet capsule unit. If it is hard to remove, warm them in

hot water (about 90°C) for five minutes.

Be careful not to get scalded with hot water..

- 36 -

Maintenance

b. MX-402(H)/-403(H)/-505

Turn two lock pins 90 degrees anticlockwise

using a flathead screwdriver and then push

them off inwards. Tap the end of driver handle

if necessary.

The lock pins can also be turned by using a

4mm hex. wrench from the inner surface of

the magnet capsule unit. In this case turn the

wrench clockwise. Note the pins will be damaged if they are turned in a reverse direction.

After unlocking, push it off from the outside by

using a bar.

Lock pin

After the lock pins are removed, detach the

impeller unit from the magnet capsule unit by

slightly tapping the back of the impeller unit

with a plastic hammer. If the impeller unit is

hardly removed, warm it in hot water (approx.

90°C) for five minutes and tap the back slightly. Be careful not to scald in hot water.

The impeller unit can not be separated from

the magnet capsule unit unless the lock pins

are removed. Do not use excessive force to

remove the impeller unit.

4. Slide the top of a flathead screw driver in

between the rear casing and the motor bracket to

pull out the casing. Pay attention not to scratch

the O ring surface.

Rear casing

- 37 -

Maintenance

■ Assembly (pump head)

1. Mount the impeller unit to the magnet capsule

unit.

a. MX-250/-251/-400/-401

Slide the impeller unit down into the magnet

capsule unit as far as it will go, locating the

U-shape holes under the through holes.

Through-hole

U-shape hole

The end of

press-fitting part

Check that the end of press-fitting parts has

come at a bearing surface. If the impeller unit

can not be fitted to the magnet capsule unit,

warm the magnet capsule unit in hot water

(about 90°C for five minutes) for softening. Be

careful not to get scalded with hot water.

b. MX-402(H)/-403(H)/-505

The mating surface on the magnet capsule

unit has two hole sizes. Large holes (stepped

holes of I.D. 6mm and 12mm) are for the lock

pins and the small holes (I.D. 3mm) are for

cooling. Slide down the impeller unit into the

magnet capsule as far as it will go, locating

the U-shape holes under the smaller holes. If

it is hard to combine them, warm the magnet

capsule unit in hot water (approx. 90°C) for 5

minutes. Be careful not to scald at this time.

Check no clearance between the

bearing surface

and the pressfitting parts.

- 38 -

Maintenance

After fitting the impeller unit, insert two lock

pins all the way seated in the lock pin holes

from an inner surface.

Use a flathead screwdriver to turn the pins

90 degrees clockwise from the outside while

holding the pins from the inside. Once it

clicks, the impeller unit is secured.

If the screw groove is deformed and can not

be used, the pins can be turned from the

inner surface with a 4mm hex. wrench. In

this case turn the wrench anticlockwise. Note

these plastic pins may be broken if it is turned

in reverse.

Lock pin

2. Insert the combination of the impeller unit and

the magnet capsule unit into the rear casing

slowly.

Do not allow foreign matters such as iron pieces

to adhere to the magnet capsule unit.

3. Mount the rear casing with the combined units in

it to the bracket.

CAUTION

Magnet force is very powerful. Place plastic or wooden spacers between the rear

casing and the motor bracket so as not to

catch the fingers.

Pay extra attention to for MX-402/-403 in

this point.

Bracket

Spacer

Impeller

- 39 -

Maintenance

4. Fit an O ring to the front casing. Check that sealing surfaces are free of dust or scratches. Make sure that

an O ring is in place and will not be out of a groove.

Mount the front casing to the rear casing according to a pair of mating parts (except the MX-400/-505).

Note that the MX-402 and -403 have two pairs of mating parts.

Rear casing

5. Fasten the front casing to the motor bracket.

Tighten the hex. socket bolts evenly. Tightening torque is shown below.

Model Tightening torque

MX-250/-251/-400/-401 11.8N•m

MX-402/-402(H)/-403/-403(H)/-505 14.7N•m

Mating parts

Front casing

- 40 -

Maintenance

■ Disassembly (loose flange)

<MX- 505>

1. Turn the combination of the outer and inner flange

counter clockwise to detach it from the pump inlet/

outlet. Use a belt wrench if necessary.

■ Assembly (loose flange)

<MX- 505>

1. Fit an O ring into the groove of the inner flange.

2. Combine the inner flange and the outer flange, using

the mating parts as a guide.

3. Turn the combination of the flanges clockwise until it

will not turn further.

NOTE: O ring may come out of the groove.

Keep it in place while tightening the

flanges.

Inner flange

Mating parts

Outer flange

Mating parts

O ring

O ring

Outer flange

Inner flange

Front casing

Mating parts

Mating parts

O ring

Gloove

- 41 -

European ofce

TEL: +49 2154 9254 0 FAX: +49 2154 9254 48

Germany

TEL: +49 2154 9254 50 FAX: +49 2154 9254 55

Holland

TEL: +31 74 2420011 FAX: +49 2154 9254 48

Italy

/ IWAKI Europe GmbH (Italy Branch)

TEL: +39 0444 371115 FAX: +39 0444 335350

Spain

/ IWAKI Europe GmbH (Spain Branch)

TEL: +34 93 37 70 198 FAX: +34 93 47 40 991

Belgium

TEL: +32 13 670200 FAX: FAX: +32 13 672030

Denmark

TEL: +45 48 242345 FAX: +45 48 242346

Finland

TEL: +358 9 2745810 FAX: +358 9 2742715

France

TEL: +33 1 69 63 33 70 FAX: +33 1 64 49 92 73

/ IWAKI Europe GmbH

/ IWAKI Europe GmbH

/ IWAKI Europe GmbH (Netherlands Branch)

/ IWAKI Belgium N.V.

/ IWAKI Nordic A/S

/ IWAKI Suomi Oy

/ IWAKI France S.A.

IWAKI CO.,LTD. 6-6 Kanda-Sudacho 2-chome Chiyoda-ku Tokyo 101-8558 Japan

Norway

/ IWAKI Norge AS

TEL: +47 23 38 49 00 FAX: +47 23 38 49 01

Sweden

/ IWAKI Sverige AB

TEL: +46 8 511 72900 FAX: +46 8 511 72922

U.K.

/ IWAKI Pumps (U.K.) LTD.

TEL: +44 1743 231363 FAX: +44 1743 366507

U.S.A.

/ IWAKI America Inc.

TEL: +1 508 429 1440 FAX: +1 508 429 1386

Argentina

TEL: +54 11 4745 4116

Singapore

TEL: +65 6316 2028 FAX: +65 6316 3221

Indonesia

TEL: +62 21 6906606 FAX: +62 21 6906612

Malaysia

TEL: +60 3 7803 8807 FAX: +60 3 7803 4800

/ IWAKI America Inc. (Argentina Branch)

/ IWAKI Singapore Pte Ltd.

/ IWAKI Singapore (Indonesia Branch)

/ IWAKIm SDN. BHD.

http://www.iwakipumps.jp

TEL: +81 3 3254 2935 FAX: +81 3 3252 8892

Australia

/ IWAKI Pumps Australia Pty Ltd.

TEL: +61 2 9899 2411 FAX: +61 2 9899 2421

China (Hong Kong)

TEL: +852 2607 1168 FAX: +852 2607 1000

China (Guangzhou) / GFTZ IWAKI Engineering & Trading Co., Ltd.

TEL: +86 20 84350603 FAX: +86 20 84359181

China

/ IWAKI Pumps (Shanghai) Co., Ltd.

TEL: +86 21 6272 7502 FAX: +86 21 6272 6929

Korea

/ IWAKI Korea Co., Ltd.

TEL: +82 2 2630 4800 FAX: +82 2 2630 4801

Taiwan

/ IWAKI Pumps Taiwan Co., Ltd.

TEL: +886 2 8227 6900 FAX: +886 2 8227 6818

Thailand

TEL: +66 2 322 2471 FAX: +66 2 322 2477

Vietnam

/ IWAKI Pumps Vietnam Co., Ltd.

TEL: +84 613 933456 FAX: +84 613 933399

/ IWAKI Pumps Co., Ltd.

/ IWAKI (Thailand) Co., Ltd.

T452-8 '15/07

Loading...

Loading...