IWAKI PUMPS MDG-M4 series, MDG-M4T6B115L, MDG-M4T6B220H, MDG-M4S6B220, MDG-M4S6B115L Instruction Manual

...

IWAKI Magnet Gear Pump

MDG-M4 (built-in type)

Instruction Manual

Read this manual before use of product

This instruction manual includes descriptions of the correct

handling of the pump, maintenance and inspection procedures

and troubleshooting. You are requested to read the manual

carefully so that the pump can safely be used to the full extent

of its capacity for a long period of time.

Contents

Item

■

Safety Instruction ............................................ 3

■

Page

① Inspection after Unpacking ............................. 4

② Principle of operation ...................................... 4

③ Pump Identification Codes .............................. 5

④ Names of Parts and Structure .......................... 6

⑤ Precautionary measures .................................. 7

⑥ Installation, Piping and Wiring ....................... 9

⑦ Operation .........................................................11

⑧ Maintenance and Inspection ............................13

⑨ Disassembling and Reassembling ...................14

⑩ Causes of Trouble and Troubleshooting ..........16

⑪ Performance and Sizes ....................................17

⑫ Repair Service .................................................19

Export Restrictions

Technical information contained in this instruction manual might be treated as controlled

technology in your countries, due to agreements in international regime for export control.

Please be reminded that export license/permission could be required when this manual is

provided, due to export control regulations of your country.

— 2 —

Safety Instruction

CautionElectrical Shock

CautionElectrical Shock

CautionElectrical Shock

Prohibited

CautionElectrical Shock

GroundingWear protective

Prohibited

CautionElectrical Shock

Prohibited

CautionElectrical Shock

Prohibited

CautionElectrical Shock

Prohibited

CautionElectrical Shock

Prohibited

CautionElectrical Shock

Prohibited

CautionElectrical Shock

Prohibited

CautionElectrical Shock

CautionElectrical Shock

CautionElectrical Shock

CautionElectrical Shock

CautionElectrical Shock

No Remodeling

Prohibited

GroundingWear protective

CautionElectrical Shock

GroundingWear protective

gear

CautionElectrical Shock

CautionElectrical Shock

CautionElectrical Shock

Warning

Turn off the power supply.

●

Working without disconnecting the power supply may

cause an electrical shock. Before engaging upon any

working procedures involving the pump, make sure to turn

the power supply switch off and to stop the pump and

other related devices.

Terminate operation!

●

When you detect or become aware of a dangerous sign or

abnormal condition during operation, terminate the

operation immediately and start it from the beginning

again.

For specified application only.

●

The use of a pump in an application other than those

clearly specified may result in injury or damage to the

pump. Use the pump strictly in accordance with the pump

specifications and application range.

No remodeling!

●

Never remodel a pump. Otherwise, a serious accident

may result. Iwaki will not be responsible for any accident

or damage of any kind which is caused by the user

remodeling the pump without first obtaining permission or

instructions from Iwaki.

Wear protectors.

●

If you touch or come in contact with any type of

hazardous chemical liquid, including but not limited to

chemicals, you may experience a serious injury. Wear

protective gear (protective mask, gloves, etc.) during the

pump operation.

Caution

Qualified operators only!

●

The pump operator and pump operation supervisor must

not allow any operators who have little or no knowledge

of the pump to run or operate the pump. Pump operators

must have a sound knowledge of the pump and its

operation.

Specified power only.

●

Do not operate the pump on voltage which is not specified

on the nameplate. Failure to do so may result in damage

or fire. Only the specified power level is to be applied.

Do not wet or dampen!

●

If the motor or wiring cable becomes wet or dampened

with the operating liquid by mistake, this may result in a

fire or cause an electrical shock. Install the motor and

wiring cable in positions which are not likely to become

wet or dampened with any liquid.

Ventilate!

●

Poisoning may result during an operation which involves

toxic or odorous liquid. Ventilate the operating site

sufficiently.

Spill-out accident!

●

Protective measures should be taken against any

accidental spill-out or leakage of the operating liquid as a

result of unexpected damage on the pump or the related

piping.

Caution

Damaged pump

●

Never operate a damaged pump. A damaged pump may

cause leakage or electrical shock.

Operating site must be free of water and

●

humidity

The pump is not designed to be water-proof or dust-proof.

The use of the pump in places where water splashes or

humidity is high may result in an electrical shock or short

circuit.

Do not damage or change power cable!

●

Do not scratch, damage, process, or pull the power cable

forcibly. An extra load onto the cable, such as heating the

cable or placing something heavy on the cable, may

damage the cable and finally cause a fire or an electrical

shock.

Do not cover the motor!

●

Running a covered motor may accumulate heat inside the

motor and cause a fire or a mechanical failure. Ventilate

the motor sufficiently.

Arrange grounding!

●

Do not operate the pump without connecting the

grounding wire. Otherwise, an electrical shock may

result. Make sure the grounding wire is connected with

the grounding terminal.

Caution

Install an earth leakage breaker (option)!

●

The operation of a pump without using an earth leakage

breaker may cause an electrical shock. Please purchase an

optional leakage breaker and install in the system.

Power cable cannot be replaced.

●

Never use a damaged or affected power cable. Otherwise,

a fire or an electrical shock may result. Handle the power

cable carefully, as it cannot to be replaced with a new

cable. (The pump unit itself must be replaced in that

circumstance.)

Limited operating site and storage

●

Do not install or store the pump in the following places:

*Places where a flammable gas or material is used or

stored.

*Places where the ambient temperature is extremely high

(40˚C or higher) or extremely low (0˚C or lower).

Do not drain the liquid in the site.

●

The liquid discharged out of the pump, including a

hazardous chemical liquid, must be drained into a special

container. Never drain such liquid directly onto the floor

in or near the operation site.

Disposal of used pump

●

Disposal of used or damaged pumps must be done in

accordance with the relevant local laws and regulations.

(Consult a licensed industrial waste products disposing

company.)

Explosion Protection

This s y mb ol ide nt i fies in format ion a bou t avoidi n g ex plosion s i n p ot e nt ia l ly

explosive atmo sp he re s i n a c co rd a n ce w it h E C Di r e ct ive 9 4/9/ EC (ATEX ).

— 3 —

InspectionafterUnpacking

①

Upon unpacking, check the following points to confirm that the product is what you

have ordered. If you find anything wrong, please contact the dealer you placed your

order with.

1

Do the model of pump, discharge, discharge pressure, voltage, and other items

shown on the nameplate correspond with those of the pump ordered by you?

2

Is the product not damaged or are the nuts and bolts not loosened during delivery?

Please examine by sight or touch.

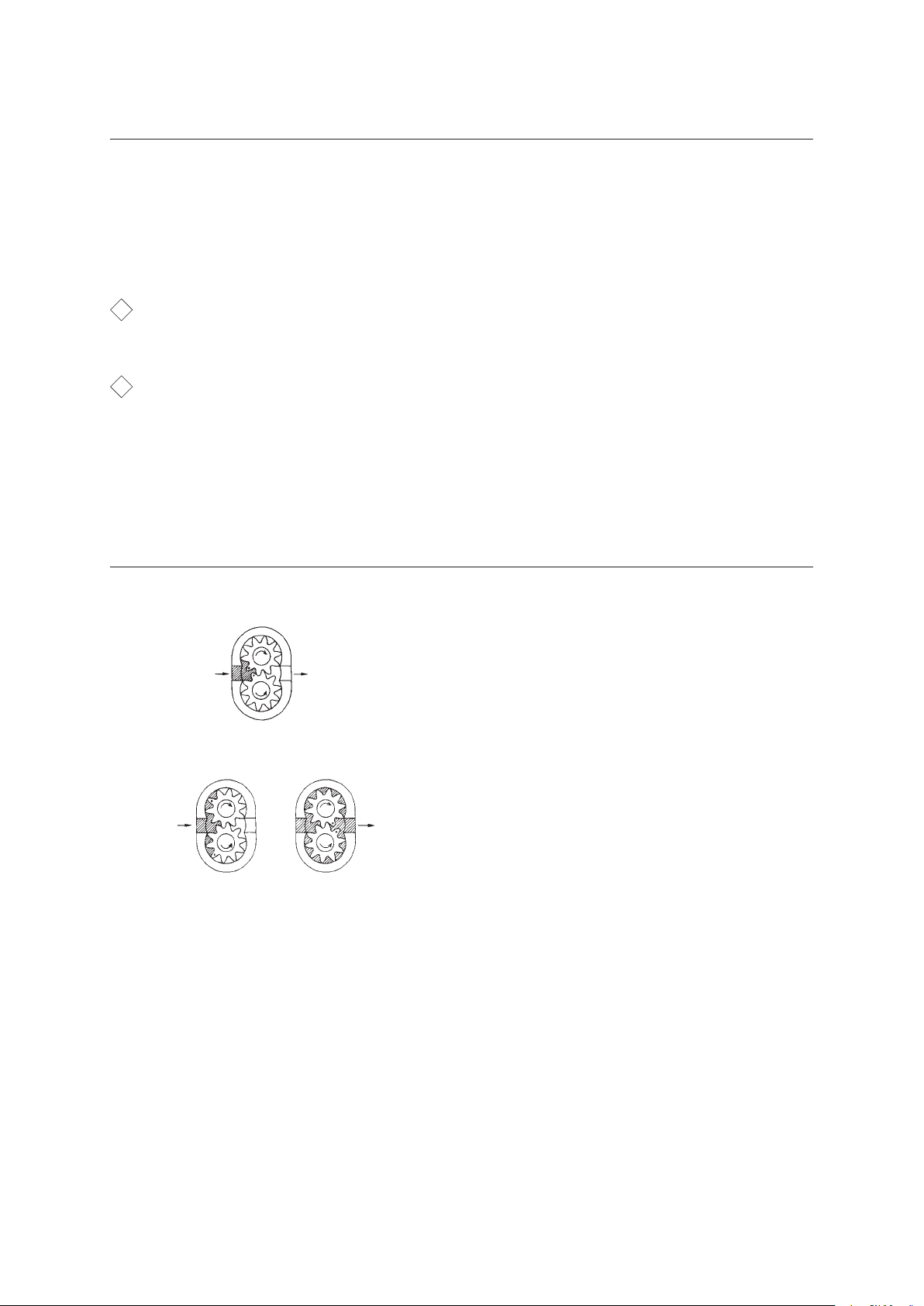

PrincipleofOperation

②

IN OUT

Fig.A

IN OUT

Fig.B Fig.C

The Iwaki Magnet Gear Pump comprises a

pair of gears driven by a magnet coupling

and casing in which the gears are fitted

exactly. (Fig. A)

Liquid introduced from the IN side feeds

into the grooves between the teeth of the

gears and is transferred to the OUT side by

rotation of the gears. (Fig. B)

This liquid is forced out of the grooves

between the gear teeth by meshing of the

gears. (Fig. C)

— 4 —

PumpIdentificationCodes

③

MDG - M4 S 6 B 115 H

① ② ③ ④ ⑤

① Represents the temperature range and viscosity limit of the liquid to be

handled.

S : Tem p er a tur e ............ b e tw e en 0 an d 5 0ºC

Vis co s ity .................. b e l ow 3 0mP a·s

T : Tem p er a tur e ............ b e tw e en 0 an d 9 5 ºC

Vis co s ity .................. b e l ow 8 0mP a·s(100 W mo tor)

below 200mPa·s(150W mo tor)

② Represents the m ax imu m discha rge pressu re.

6 : 0.6MPa

③ Connection

B : 1/4NPT

④ Li ne volta ge

115 : AC115V single phase

220 : AC220 ~ 240V single phase

⑤ Non-standard specif ication code

Without code : Equipped with a 100W motor

H : Equipped with a 150W motor

— 5 —

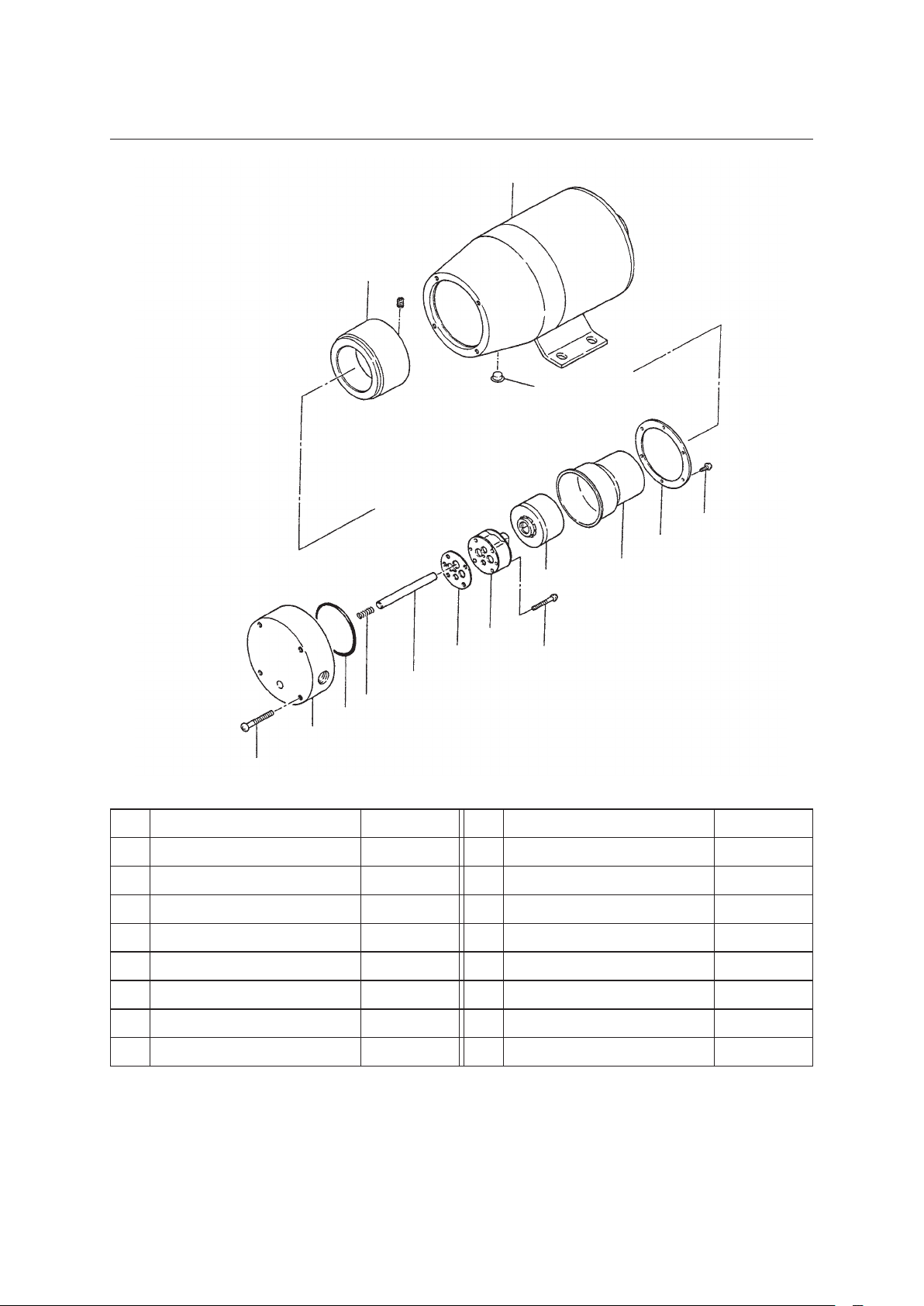

NamesofPartsandStructure

④

1

4

25

28

7

6

5

47

10

9

20

11

19

29

No. Name Number No. Name Number

1 Motor 1 19 Pump body 1

4 Driving magnet assy 1 set 20 Shaft spring 1

5 Rear casing 1 25 Cap 1

6 Magnet capsule 1 28 Screw M3×10 6

7 Mounting plate 1 29 Screw M4×35 4

9 Driving gear shaft 1 30 Screw M3×25 4

10 Gasket 1 47 Gear case unit 1 set

11 O ring 1

30

— 6 —

Precautionarymeasures

Highly viscous

⑤

1

Do not operate the pump dry.

The pump should not be operated

dry or while the suction side is

closed. This will wear out the gears

and bearings.

2

Range of liquid temperatures

The pump can be used with liquids

in the following temperature range.

The performance will change

depending on the temperature of the

liquid.

● Type S : 0 ~ 50ºC

liquid

● Type T : 0 ~ 95ºC

In case the liquid being handled is

a solvent, the gears may swell to

force the pump to stop, in the worst

case. For further information,

please contact us.

3

Liquid viscosity

Highly viscous liquid cannot be

transferred.

● Type S : up to 30mPa·s

● Type T : 80mPa·s(with a 100W

motor)

200mPa·s(with a 150W

motor)

— 7 —

4

Do not use the pump for transferring

Slurry liquid

slurry liquid or liquid which begins

to crystallize when stationary.

5

Do not splash water on the motor.

This may cause an electric leak or

burning.

6

Do not cover the motor unit tightly

with a cover, etc. Avoid operating

the pump at an ambient temperature

above 40ºC. The relative humidity

should be below 85%. Do not splash

water on the motor. It may cause an

electric leak or damage by fire.

— 8 —

Installation,PipingandWiring

⑥

Flooded suction

■

Installation

1

Choose a place which has an

ambient temperature below40°C

and a relative humidity lessthan

85%, and is convenient for

maintenance and checking. The

pump must not be installed

outdoors without suitable

protection.

2

To prevent dry running, install the

pump in a position lower than the

surface of the liquid in the tank on

Priming method

(In case the pump chamber is wet)

①There is no liquid in the suction piping

(This is not allowed for the T type).

0.3m

②There is liquid inside the suction piping.

the suction side (Flooded suction).

3

In case it is necessary to install an

S type pump in a position in which

the inlet of the pump remains

higher than the liquid surface (a

suction lift), refer to the

illustrations opposite. In this

position, the pump does not suck if

the pump chamber is not wet.

(The T type pumps do not function

on a suction lift.)

5m

— 9 —

4

For fixing the pump, use M6 small

screw. In the event floor on which

the pump is installed is resonant and

causes a loud noise, fix the pump

with rubber mountings.

■

Piping

1

In order to reduce the friction

resistance of liquid, the piping

should be as short and with as few

bends as possible.

2

The inlet and outlet joints of the

pump should be completely sealed

with sealing tape, etc. To prevent

them from sucking air. If sealing is

incomplete on the suction side, in

particular, air is sucked in and the

performance of the pump is lowered.

3

For connection, use a thick hose

which can withstand pump pressure.

Since the hose on the suction side,

particularly, tends to be crushed by

sucking force, the use of for example,

a Teflon hose is recommended. (In

the case of hot liquid, particular care

should be taken.)

■

Wiring

1

Use proper wiring connections. Wiring should be carr ied out in accordance

with the technical standa rd of electric installation and interior wir ing

regulations, referring to the opposite diagram.

2

Make sure to include a ground wire or a ground terminal i n the wi r ing.

● Rated Electric Current Value 50/60Hz

Model of Pump Rated Voltage (V) Rated Current (A)

MDG-M4[S/T]6B115 115 1.5 / 1.7

MDG-M4[S/T]6B220

220 ~ 240

MDG-M4T6B220H 1.4 / 1.5

— 10 —

0.70 / 0.84

Operation

⑦

■

NotesonOperation

1

Dry running is strictly prohibited. This will damage the inside of the pump.

2

The pump should not be operated with closed valves. If this happens, the bearing

will abnormally worn away.

3

In case liquid which solidifies or causes precipitation is handled, the pump should

be flushed clean when it is out of operation.

4

In cold weather, the pump should be kept warm so as not to be frozen.

5

When operation is restarted after having been stopped for a long time, the same

points as in starting up should be confirmed.

■

Startingup

The following items must be checked when starting up the pump.

No. Item Remarks

● Conrm piping and electrical wiring,

Conrmation of piping,

1

wiring and voltage

2 Conrmation of valves

Conf irmat ion of liquid

3

in pump

4 Starting up

referring to descriptions in piping and wiring

sections.

● Confirm that power voltage is appropriate.

● Valves on suction side and discharge side

should be fully opened.

● When S type pump is used for suction lift,

prime pump sufficiently. T ty pe pumps cannot

be used for suction lifting. Fill piping with

liquid before starting operation.

● After confirming items 1~3 above, start

operation.

● During operation, watch for items listed in

following section.

— 11 —

■

NotesonDuringOperation

The following points must be checked while the pump is in operation. If something

abnormal occurs, stop the operation immediately and take proper measures by

referring to the section ‘‘Causes of Trouble and Troubleshooting’’ (Page 16). In case

the pump still cannot be restored to normal condition, please contact your supplier.

No. Check Point Remarks

Is pump transferring

1

liquid properly?

Is there abnormal noise

2

or vibration?

Is liquid leaking or air

3

being sucked out from

joints of pump?

● Whether liquid is transferred.

● Whether suction and discharge pressures are at

normal levels.

● If pump does not function normally,

abnormal noise or vibration tends to be

generated.

● Base on which pump is mounted sometimes

becomes resonant, increasing noise. If

separation of pump from base decreases

noise, anti-vibration measure such as

anti-vibration rubber should be mounted.

● Clamp connections more tightly.

● If many air bubbles are found in discharged

liquid, air is being sucked out. Examine

piping and clamp connection more tightly.

Is temperature of pump

unit surface, motor

4

surface, etc., abnormally

high?

● Pump unit surface temperature is same as

that of liquid handled.

● Temperature of motor surface is within

about 40°C above ambient temperature.

Sometimes it is too hot to touch, but it is

normal if temperature is within this range.

— 12 —

MaintenanceandInspection

⑧

■

DailyInspection

1

Pay attention to the operating condition, referring to ‘‘Notes on Operation During

Operation’’. When any of the consumable parts reaches its replacement time or the

performance is noticeably lowered, substitute the gear case unit and the driving

gear shaft with new ones.

■

ConsumableParts

No. Part Number Raplacement Time

47

9

10 Gasket 1 at every maintenance

The above replacement periods have been estimated based on the length of time in

which the initial flow rate of clear water at normal temperature under a pressure of

0.5MPa loweres by 20%.

Gear Case

Unit

Driving

Gear

shaft

1 set

5,000 hours

1

— 13 —

DisassemblingandReassembling

⑨

Pump unit

Screw

Motor

■

DisassemblingProcedure

1

Unscrew 4 screws (29) to detach the pump unit from the motor unit.

2

Unscrew the screws (28) and remove the mounting plate (7), rear casing (5) and

magnet capsule (6) in this order.

3

Unscrew the screws (30) and remove the gear unit (47), gasket (10), drive gear

shaft (9) and shaft spring (20) in this order.

4

Remove the O ring (11).

● Put the dismantled parts in a clean place. Take care that they do not get scratched.

Particular care is required for the magnet capsule (6) which contains powerful

magnets and easily attracts iron powder, etc. Its storage should be chosen

carefully.

— 14 —

■

ReassemblingProcedure

Follow the disassembling steps in reverse, while attending to the following points.

1

Position the gasket (19) corresponding to the gear case u nit (47) as il lustr ated.

2

In at taching the gear un it (47), tighten the small screws (30) uniformly.

(Clamping torque : 1N·m)

3

If the O r i ng is flawed, replace it with a new one.

4

When the life of any of the consumable parts expires, replace the gear case

unit (47), gasket (10) a nd d r ive gear shaft (9) simultaneously.

gasket(10)

gear case unit(47)

— 15 —

CausesofTroubleandTroubleshooting

⑩

Causes

Troubles

Motor

Motor start

not increase

but rpm does

Motor stops

Liquid

cannot be

pumped up

Magnet

Too much

started.

cannot be

current is

generated.

and excess

while in

operation.

cient.

is insuf-

or pumping

coupling

comes off.

noise or

vibration.

Liquid leaks.

Contact is bad or broken somewhere in wiring.

Motor malfunctions. (Break malfunctioning of capacitor,etc.)

Thermal protector activated by overload.

Earth leakage circuit breaker activated by leak.

Dry running.

Air gets in through inlet port.

Inlet pipe is crushed.

Pressure in inlet portion is lowered to saturated vapor pressure of liquid.

Plug is out of socket.

○

○

○

○

○

○

○

○

○

○

Viscosity of liquid handled is too high.

○

○

Foreign matter sticks to gears.

Gear is damaged.

Magnet capsule hits rear casing.

Gears are locked because liquid temperature is too high.

Seal is damaged.

Bolt is loosened.

Valve is closed.

○

○

○

○

○

○

○

○

○

○

○

○

○

○

High resistance of piping.

Performance of pump lowered by decrease in liquid temperature.

○

○

○

Insert plug into socket.

Examine and repair defective part.

Countermeasure

Repair or replace.

Conrm pump is lled with liquid.

Inspect wiring and motor,and repair or replace.

Lower viscosity of liquid handled and/or discharge pressure.

Open valve.

Tighten bolt.

Replace gear.

Lower viscosity.

Substitute with crush-proof pipe.

Disassemble and remove foreign matter.

Take necessary steps to prevent air from getting in.

Lower either liquid temperature or piping resistance.

Replace seal.

Increase thickness of seal.

Alter piping to reduce resistance.

Disassemble and repair or replace parts.

— 16 —

Raise liquid temperature or change specication.

PerformanceandSizes

⑪

■

Performance

Motor Specications

Rated

Current

(V)

φ

115

φ

φ

115

φ

(A)

1.5/1.7

0.70/0.84

1.5/1.7

0.70/0.84

1.4/1.5 150/180

Rated

Output

(W)

100

Model of Pump

MDG-M4S6B115L

MDG-M4S6B220

MDG-M4T6B115L

MDG-M4T6B220

MDG-M4T6B220H

Diameter

1/4NPT

Maximum

Flow rate

(ℓ/min)

4/4.8

3.8/4.6 8.00

Maximum

Discharge

Pressure

(MPa)

0.6

Attainable

Degree of

Vacuum

kPa (abs.)

Rated

Voltage

1

5.33

1

220~240

1

1

220~240

〔Note〕 1. Above is the performance on a test of clean water at 25ºC.

(The discharge changes depending on the temperature of liquid handled.

Further i nformat ion will be supplied on request.)

2. The pumps can be used in an ambient temperature between 0 and 40ºC.

Type

2P

Induction

Motor

Capacitor

Run

Type

Weight

(kg)

7.9

8.2

3. Maximum operat ing noise is 60dB or below.

(1 m away from the front of pump, A scale)

— 17 —

■

OuterSizes

● Models MDG-M4

E

40 107 89

242

□

2-Rc1/4

OUTIN

122.5

65

120122

110

130

● Models MDG-M4

E

40 107

119

239

□H

120

2-Rc1/4

OUTIN

132.5

65

89

110

130

— 18 —

RepairService

⑫

■

Repair

In case something unusual comes to your notice while you are using the pump, stop

operation immediately and check whether anything is out of order. (Refer to the

chapter on ‘‘Causes of Trouble and Troubleshooting’’.)

1

For repair work, please contact us or the dealer with whom you placed your order.

2

Before requesting repair, peruse this instruction manual again and recheck the

product.

3

When you request repair, the following information is needed:

① Model code and manufacturing number.

② Period of use and conditions under which the product has been used.

③ Details of the problem.

In the event you return your pump, please ship it only after thoroughly washing the

inside to prevent residual liquid from flowing out in transit, which is very dangerous.

— 19 —

Australia IWAKI Pumps Australia Pty. Ltd.

Austria IWAKI EUROPE GmbH

Belgium IWAKI Belgium n.v.

China IWAKI Pumps (Shanghai ) Co., Ltd.

China

China

China

IWAKI Pumps (Guangdong) Co., Ltd.

GFTZ IWAKI Engineering & Trading (Guangzhou)

GFTZ IWAKI Engineering & T rading (Beijing )

Denmark IWAKI Nordic A/S

Finland IWAKI Suomi Oy

France IWAKI France S.A.

Germany IWAKI EUROPE GmbH

Holland

IWAKI Europe GmbH, Netherlands Branch

Hong Kong IWAKI Pumps Co., Ltd.

Indonesia

IWAKI Singapore (Indonesia Branch)

IWAKI CO.,LTD. 6-6 Kanda-Sudacho 2-chome Chiyoda-ku Tokyo 101-8558 Japan

TEL : (61)2 9899 2411 FAX : 2 9899 2421

TEL : (49)2154 92540 FAX : 2154 9254 48

TEL : (32)1367 0200 FAX : 1367 2030

TEL : (86)21 6272 7502 FAX : 21 6272 6929

TEL : (86)750 3866228 FAX : 750 3866278

TEL : (86)20 8435 0603 FAX : 20 8435 9181

TEL : (86)10 6442 7713 FAX : 10 6442 7712

TEL : (45)48 24 2345 FAX : 48 24 2346

TEL : (358)9 2745810 FAX : 9 2742715

TEL : (33)1 69 63 33 70 FAX : 1 64 49 92 73

TEL : (49)2154 9254 0 FAX : 2154 9254 48

TEL : (31)74 2420011 FAX : 2154 9254 48

TEL : (852)2 607 1168 FAX : 2 607 1000

TEL : (62)21 690 6606 FAX : 21 690 6612

TEL:(81)3 3254 2935 FAX:3 3252 8892(http://www.iwakipumps.jp)

Italy

IWAKI Europe GmbH, Italy Branch

Korea IWAKI Korea Co.,Ltd.

Malaysia IWAKIm Sdn. Bhd.

Norway IWAKI Norge AS

Singapore IWAKI Singapore Pte. Ltd.

Spain

IWAKI Europe GmbH, Spain Branch

Sweden IWAKI Sverige AB

Switzerland IP Service SA

Taiwan IWAKI Pumps Taiwan Co., Ltd.

Taiwan

IWAKI Pumps Taiwan (Hsin-chu) Co., Ltd. TEL : (886)3 573 5797 FAX : (886)3 573 5798

Thailand IWAKI (Thailand) Co.,Ltd.

U.K. IWAKI Pumps (UK) LTD.

U.S.A. IWAKI AMERICA Inc.

Vietnam IWAKI pumps Vietnam Co.,Ltd.

( )Country codes

TEL : (39)0444 37111 5 FAX : 0444 335350

TEL : (82)2 2630 4800 FAX : 2 2630 4801

TEL : (60)3 7803 8807 FAX : 3 7803 4800

TEL : (47)23 38 49 00 FAX : 23 38 49 01

TEL : (65)6316 2028 FAX : 6316 3221

TEL : (34)93 37 70 198 FAX : 93 47 40 991

TEL : (46)8 511 72900 FAX : 8 511 72922

TEL : (41)26 674 9300 FAX : 26 674 9302

TEL : (886)2 8227 6900

FAX : 2 8227 6818

TEL : (66)2 322 2471 FAX : 2 322 2477

TEL : (44)1743 231363 FAX : 1743 366507

TEL : (1)508 429 1440 FAX : 508 429 1386

TEL : (84)613 933456 FAX : 613 933399

T367-3 '15/04

Loading...

Loading...