IWAKI PUMPS MDG-M4 series, MDG-M4T6B115L, MDG-M4T6B220H, MDG-M4S6B220, MDG-M4S6B115L Instruction Manual

...

IWAKI Magnet Gear Pump

MDG-M4 (built-in type)

Instruction Manual

Read this manual before use of product

This instruction manual includes descriptions of the correct

handling of the pump, maintenance and inspection procedures

and troubleshooting. You are requested to read the manual

carefully so that the pump can safely be used to the full extent

of its capacity for a long period of time.

Contents

Item

■

Safety Instruction ............................................ 3

■

Page

① Inspection after Unpacking ............................. 4

② Principle of operation ...................................... 4

③ Pump Identification Codes .............................. 5

④ Names of Parts and Structure .......................... 6

⑤ Precautionary measures .................................. 7

⑥ Installation, Piping and Wiring ....................... 9

⑦ Operation .........................................................11

⑧ Maintenance and Inspection ............................13

⑨ Disassembling and Reassembling ...................14

⑩ Causes of Trouble and Troubleshooting ..........16

⑪ Performance and Sizes ....................................17

⑫ Repair Service .................................................19

Export Restrictions

Technical information contained in this instruction manual might be treated as controlled

technology in your countries, due to agreements in international regime for export control.

Please be reminded that export license/permission could be required when this manual is

provided, due to export control regulations of your country.

— 2 —

Safety Instruction

CautionElectrical Shock

CautionElectrical Shock

CautionElectrical Shock

Prohibited

CautionElectrical Shock

GroundingWear protective

Prohibited

CautionElectrical Shock

Prohibited

CautionElectrical Shock

Prohibited

CautionElectrical Shock

Prohibited

CautionElectrical Shock

Prohibited

CautionElectrical Shock

Prohibited

CautionElectrical Shock

Prohibited

CautionElectrical Shock

CautionElectrical Shock

CautionElectrical Shock

CautionElectrical Shock

CautionElectrical Shock

No Remodeling

Prohibited

GroundingWear protective

CautionElectrical Shock

GroundingWear protective

gear

CautionElectrical Shock

CautionElectrical Shock

CautionElectrical Shock

Warning

Turn off the power supply.

●

Working without disconnecting the power supply may

cause an electrical shock. Before engaging upon any

working procedures involving the pump, make sure to turn

the power supply switch off and to stop the pump and

other related devices.

Terminate operation!

●

When you detect or become aware of a dangerous sign or

abnormal condition during operation, terminate the

operation immediately and start it from the beginning

again.

For specified application only.

●

The use of a pump in an application other than those

clearly specified may result in injury or damage to the

pump. Use the pump strictly in accordance with the pump

specifications and application range.

No remodeling!

●

Never remodel a pump. Otherwise, a serious accident

may result. Iwaki will not be responsible for any accident

or damage of any kind which is caused by the user

remodeling the pump without first obtaining permission or

instructions from Iwaki.

Wear protectors.

●

If you touch or come in contact with any type of

hazardous chemical liquid, including but not limited to

chemicals, you may experience a serious injury. Wear

protective gear (protective mask, gloves, etc.) during the

pump operation.

Caution

Qualified operators only!

●

The pump operator and pump operation supervisor must

not allow any operators who have little or no knowledge

of the pump to run or operate the pump. Pump operators

must have a sound knowledge of the pump and its

operation.

Specified power only.

●

Do not operate the pump on voltage which is not specified

on the nameplate. Failure to do so may result in damage

or fire. Only the specified power level is to be applied.

Do not wet or dampen!

●

If the motor or wiring cable becomes wet or dampened

with the operating liquid by mistake, this may result in a

fire or cause an electrical shock. Install the motor and

wiring cable in positions which are not likely to become

wet or dampened with any liquid.

Ventilate!

●

Poisoning may result during an operation which involves

toxic or odorous liquid. Ventilate the operating site

sufficiently.

Spill-out accident!

●

Protective measures should be taken against any

accidental spill-out or leakage of the operating liquid as a

result of unexpected damage on the pump or the related

piping.

Caution

Damaged pump

●

Never operate a damaged pump. A damaged pump may

cause leakage or electrical shock.

Operating site must be free of water and

●

humidity

The pump is not designed to be water-proof or dust-proof.

The use of the pump in places where water splashes or

humidity is high may result in an electrical shock or short

circuit.

Do not damage or change power cable!

●

Do not scratch, damage, process, or pull the power cable

forcibly. An extra load onto the cable, such as heating the

cable or placing something heavy on the cable, may

damage the cable and finally cause a fire or an electrical

shock.

Do not cover the motor!

●

Running a covered motor may accumulate heat inside the

motor and cause a fire or a mechanical failure. Ventilate

the motor sufficiently.

Arrange grounding!

●

Do not operate the pump without connecting the

grounding wire. Otherwise, an electrical shock may

result. Make sure the grounding wire is connected with

the grounding terminal.

Caution

Install an earth leakage breaker (option)!

●

The operation of a pump without using an earth leakage

breaker may cause an electrical shock. Please purchase an

optional leakage breaker and install in the system.

Power cable cannot be replaced.

●

Never use a damaged or affected power cable. Otherwise,

a fire or an electrical shock may result. Handle the power

cable carefully, as it cannot to be replaced with a new

cable. (The pump unit itself must be replaced in that

circumstance.)

Limited operating site and storage

●

Do not install or store the pump in the following places:

*Places where a flammable gas or material is used or

stored.

*Places where the ambient temperature is extremely high

(40˚C or higher) or extremely low (0˚C or lower).

Do not drain the liquid in the site.

●

The liquid discharged out of the pump, including a

hazardous chemical liquid, must be drained into a special

container. Never drain such liquid directly onto the floor

in or near the operation site.

Disposal of used pump

●

Disposal of used or damaged pumps must be done in

accordance with the relevant local laws and regulations.

(Consult a licensed industrial waste products disposing

company.)

Explosion Protection

This s y mb ol ide nt i fies in format ion a bou t avoidi n g ex plosion s i n p ot e nt ia l ly

explosive atmo sp he re s i n a c co rd a n ce w it h E C Di r e ct ive 9 4/9/ EC (ATEX ).

— 3 —

InspectionafterUnpacking

①

Upon unpacking, check the following points to confirm that the product is what you

have ordered. If you find anything wrong, please contact the dealer you placed your

order with.

1

Do the model of pump, discharge, discharge pressure, voltage, and other items

shown on the nameplate correspond with those of the pump ordered by you?

2

Is the product not damaged or are the nuts and bolts not loosened during delivery?

Please examine by sight or touch.

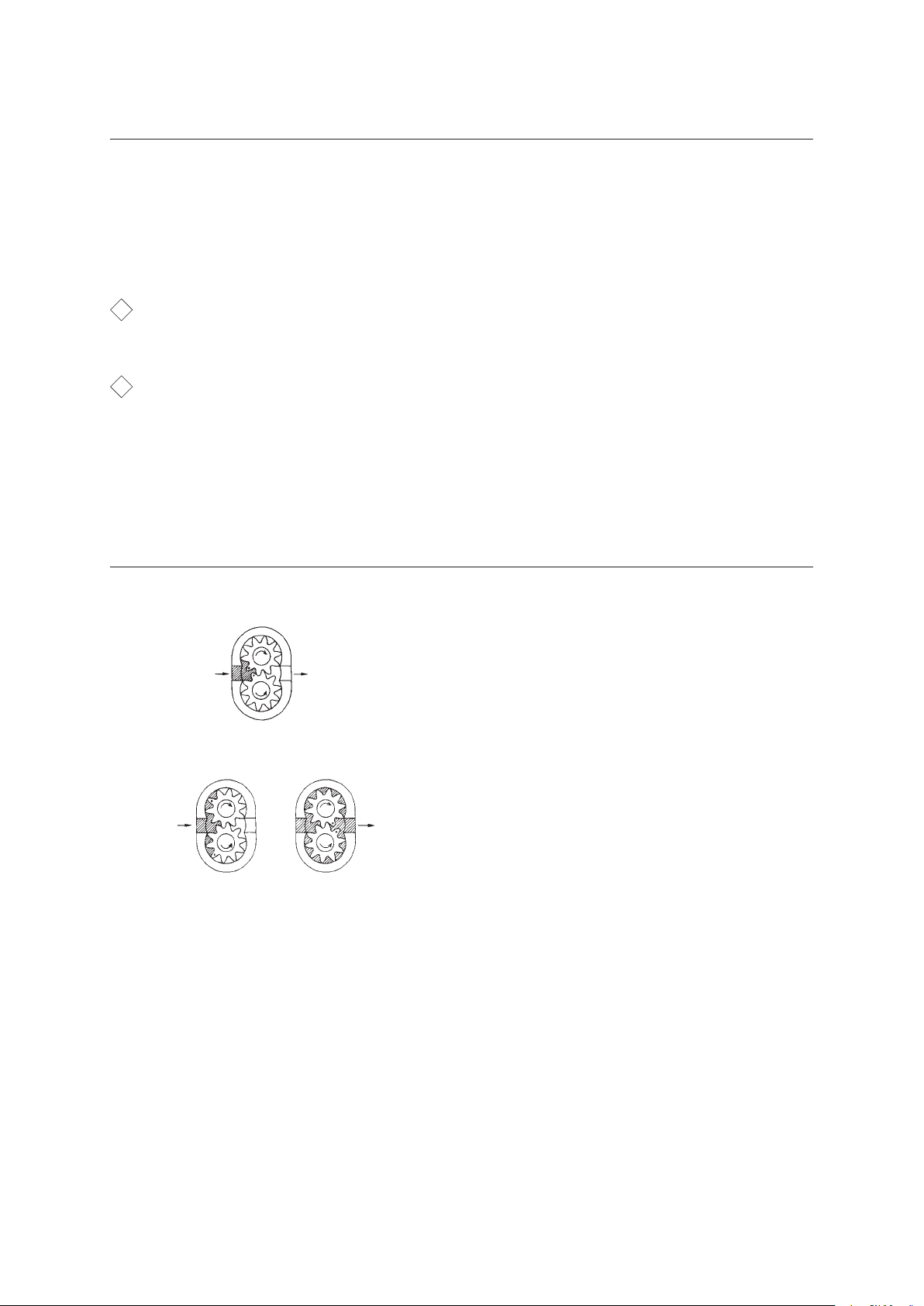

PrincipleofOperation

②

IN OUT

Fig.A

IN OUT

Fig.B Fig.C

The Iwaki Magnet Gear Pump comprises a

pair of gears driven by a magnet coupling

and casing in which the gears are fitted

exactly. (Fig. A)

Liquid introduced from the IN side feeds

into the grooves between the teeth of the

gears and is transferred to the OUT side by

rotation of the gears. (Fig. B)

This liquid is forced out of the grooves

between the gear teeth by meshing of the

gears. (Fig. C)

— 4 —

PumpIdentificationCodes

③

MDG - M4 S 6 B 115 H

① ② ③ ④ ⑤

① Represents the temperature range and viscosity limit of the liquid to be

handled.

S : Tem p er a tur e ............ b e tw e en 0 an d 5 0ºC

Vis co s ity .................. b e l ow 3 0mP a·s

T : Tem p er a tur e ............ b e tw e en 0 an d 9 5 ºC

Vis co s ity .................. b e l ow 8 0mP a·s(100 W mo tor)

below 200mPa·s(150W mo tor)

② Represents the m ax imu m discha rge pressu re.

6 : 0.6MPa

③ Connection

B : 1/4NPT

④ Li ne volta ge

115 : AC115V single phase

220 : AC220 ~ 240V single phase

⑤ Non-standard specif ication code

Without code : Equipped with a 100W motor

H : Equipped with a 150W motor

— 5 —

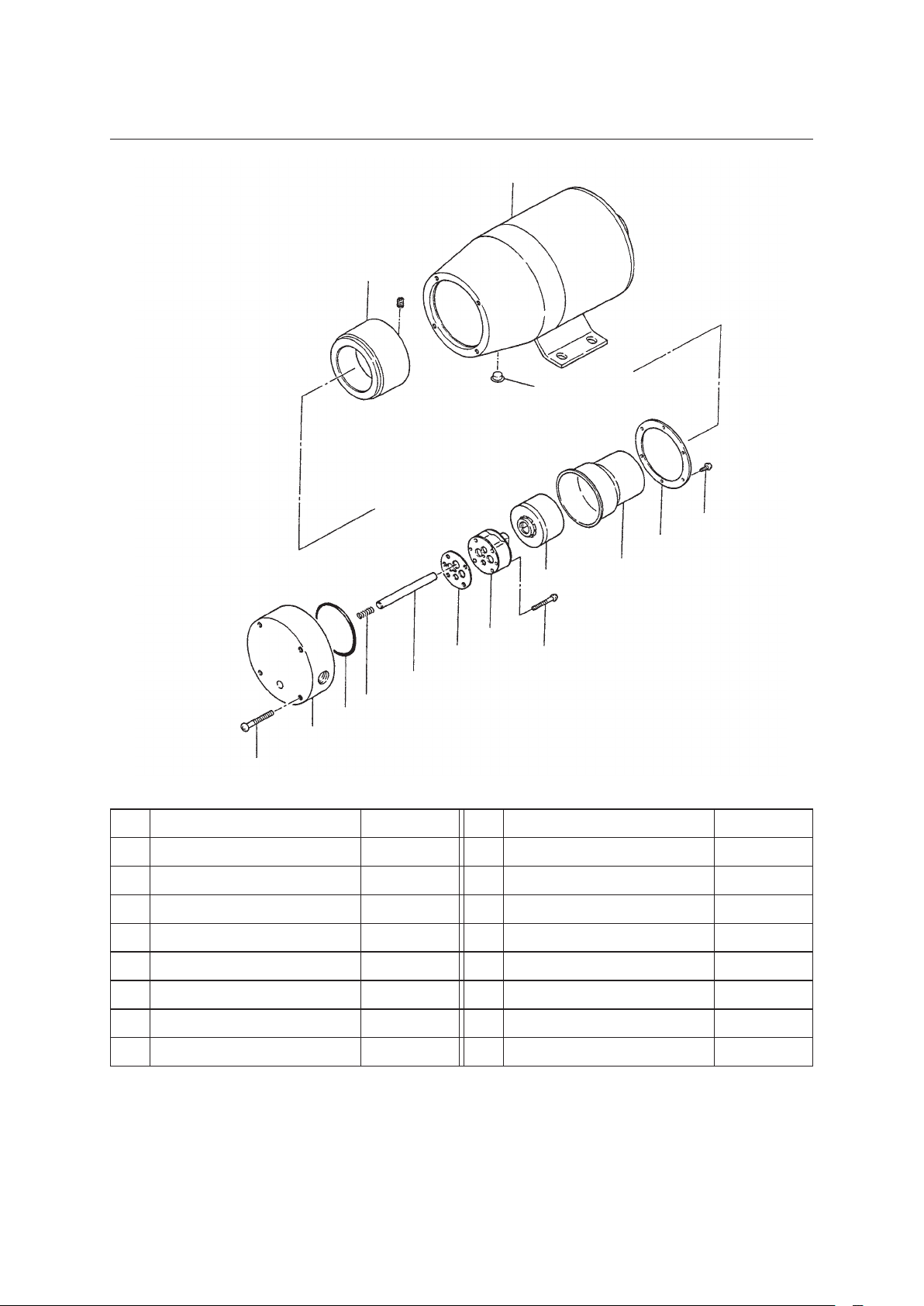

NamesofPartsandStructure

④

1

4

25

28

7

6

5

47

10

9

20

11

19

29

No. Name Number No. Name Number

1 Motor 1 19 Pump body 1

4 Driving magnet assy 1 set 20 Shaft spring 1

5 Rear casing 1 25 Cap 1

6 Magnet capsule 1 28 Screw M3×10 6

7 Mounting plate 1 29 Screw M4×35 4

9 Driving gear shaft 1 30 Screw M3×25 4

10 Gasket 1 47 Gear case unit 1 set

11 O ring 1

30

— 6 —

Loading...

Loading...