IWAKI PUMPS MDF-L250, MDF-L401lMDF-L422, MDF-L series, MDF-L505, MDF-L507 Instruction Manual

...Page 1

Read this manual before use of product

IWAKI Magnetic Drive Pump

Model MDF-L

Instruction Manual

Page 2

Thank you for selecting the IWAKI Magnetic Drive Pump type MDF-L. This instruction

manual has been prepared to ensure correct and safe handling of the pump. Please read this

manual carefully and thoroughly prior to operating the pump.

Pay special attention to the "Safety Instruction to Prevent Personal Injuries," "Warning," and

"Caution" messages included in this manual.

This instruction manual should be kept by each end user and within reach of the actual

operator, for quick reference when needed.

Contents

IMPORTANT INSTRUCTIONS ················································ 1~~5

Safety Instructions to Prevent Personal Injuries

OUTLINE OF PRODUCT······················································ 6~~14

1. Before Using Pump ·································· 7

2. Operating Principle ··································· 7

3. Identification Codes ·································· 8

4. Specifications

and Outer Dimensions ····························· 9

5. Names of Parts ······································ 11

PUMP OPERATION ···························································· 15~~30

1. Handling Instructions ····························· 16

2. Installation ·············································· 21

3. Piping ····················································· 22

4. Wiring ····················································· 26

5. Operation Step ······································· 27

MAINTENANCE ··································································· 31~~43

1. Causes of Trouble

and Troubleshooting ································32

2. Maintenance and Inspection ·················· 35

3. Spare Parts ············································ 39

4. Disassembly and Assembly ··················· 40

Please contact the IWAKI sales office or IWAKI dealer for any

inquiries or questions regarding this product.

Page 3

- 1 -

IMPORTANT INSTRUCTIONS

Important notes and statements for safe operation, preventing physical injury, and property damage,

are included on the body of the product and in the attached instruction manual.

Always Observe These Safety Instructions!

Safety Instruction to Prevent Personal Injuries

Warning

Ignoring this message can lead to improper

handling resulting in death or serious injury to the

operator.

Caution

Ignoring this message can lead to improper

handling resulting in injury to the operator or

damage to the product.

Page 4

- 2 -

Caution

Wear

protective gear

Caution

Prohibited

Power off

Caution

Prohibited

Caution

Prohibited

Wear

protective gear

Safety Section

WARNING

• Damaged or deteriorated tools are very dangerous. Use qualified and suitable

tools only.

• Use of protectors: When disassembling, assembling, and conducting maintenance

or when handling a dangerous type of liquid or a liquid of unknown property, be sure

to wear safety gloves, a helmet, and protective shoes. In addition, when handling

wet-end parts, always wear protective goggles, masks, etc.

• To prevent death or injury from a falling pump, make sure the rope or chain used

for lifting the pump is not accidentally cut or disconnected during installation. Make

sure the rope or the chain used to lift the pump has sufficient strength in relation to

the pump load. Also, be sure not to stand underneath a lifted or suspended pump.

• When fixing the pump with rope or chain, be sure to use special bolts (or rings) for

lifting. Never use any other points for lifting the pump.

• Always turn off the power supply prior to servicing the pump. Make special pro-

visions so that no other operator mistakenly turns on the power supply while someone is working on the pump. In a noisy or poor visibity environment, display a sign

near the power supply switch to notify others that someone is "WORKING" on the

pump. Power supply mistakenly turned on during maintenance may lead to personal

injury. Each operator must be especially careful of power supply operation.

• To ensure greater safety, check and make sure that there is no one near the

pump when switching on the power supply. The pump is not equipped with an

ON/OFF switch. Connecting the power cable supplies the power to the pump and

starts the operation.

• Run the pump at the specified power supply voltage on the nameplate only.

Otherwise, fire or electric shock may result.

• If the pump operation is stopped due to a power failure or closure of discharge

wire, turn off the power switch at once. After normal conditions return, turn the

switch on again.

• Do not use the pump for anything that it is not designed to do. User’s failure to

observe this instruction exempts IWAKI from any responsibility for personal injury or

damage to the equipment or facility caused by the pump’s misuse.

• When handling a toxic or odorant liquid, ventilate the working area well. In addi-

tion, the operator must wear protector gear (such as a safety mask, safety goggles,

and protective gloves).

Page 5

WARNING

• Do not allow toxic substances such as lubricants, solvents, or similar substances to flow into the local sewage system or river systems. Do not drain haz-

ardous liquids such as chemical solutions discharged out of the pump directly onto

the ground. Instead, drain such liquids into some kind of container. Observe the

laws and regulations related to the application, handling, and processing of hazardous substances.

• Do not pass under a raised pump.

Never pass under a raised pump. A serious injury could occur if the pump is accidentally dropped.

• No remodeling!

Remodeling of the pump by the user may result in serious personal injury, electric

shock, or damage to the pump. Do not attempt remodeling as it is very dangerous.

• Cautions when dangerous liquids are transferred.

When the pumps are used to transfer the dangerous liquids mentioned as below, the

pumps always must be checked and watched so that the liquids can not be leaked.

The operation of the pumps leaking the liquids may result in personal injury and/or

explosion, fire accidents.

• Explosive, fire-spreading and inflammable liquids

• Corrosive and stimulus toxic liquids

• Liquids detrimental to health

CAUTION

• Qualified operators only!

The pump operator and pump operation supervisor must not allow any operators who

have little or no knowledge of the pump to run operate the pump. Pump operators

must have a sound knowledge of the pump and its operation.

• For specified application only

The pump is designed and manufactured to the specifications agreed upon by the

user and IWAKI. The use of a pump in any application other than those clearly specified may result in injury or damage to the pump. Use the pump strictly in accordance

with the pump specifications and application range. If you change any specification,

contact IWAKI or your dealer.

• Ventilate!

Poisoning may result during an operation which involves toxic or odorous liquid.

Ventilate the operating site sufficiently.

- 3 -

Prohibited

No Remodeling

Safety Section

Prohibited

Caution

Page 6

CAUTION

• Spill-out prevention measures

Appropriate protective measures should be taken against any spill-out accidents

involving the operating liquid as a result of unexpected damage to the pump or the

piping. Never discharge hazardous liquid, including, but not limited to, chemical liquid, over the ground or floor on the pump operating site. Follow local rules and regulations in disposing of hazardous substances.

• Do not operate the pump dry.

Do not run the pump dry (without liquid inside the pump). Heat generated as a result

of abrasion between elements inside the pump during operation without liquid may

damage the inside of the pump. Operating the pump with the suction valve fully

closed will result in dry operation.

• Keep away from heat or flame.

Do not place any open flame or flammable object near the pump.

• Do not stand on the pump.

Do not stand on the pump or use the pump as a step under any circumstances.

Otherwise, you may experience a serious injury.

• Do not touch the pump.

When the pump is used to feed a hot liquid, do not touch the pump or the piping with

your bare hands during and immediately after operation as their surfaces are dangerously hot.

• Arrange grounding!

Do not operate the pump without connecting the grounding wire. Otherwise, an electrical shock may result. Make sure the grounding wire is connected with the grounding terminal.

• Install an earth leakage breaker

The operation of a pump without using an earth leakage breaker may cause an electrical shock. Please install an optional leakage breaker in the system.

• Do not install or store the pump in the following places.

• Places where flammable gas, dust or material is used or placed.

• Places where corrosive gas (chlorine gas or the like) is generated.

• Places where the ambient temperature is extremely high (40 °C or higher) or

extremely low, 0 °C or lower.

• Places where the pump is exposed to extreme dust or humidity. (Excluding the out-

door type)

• Places where vibrations occur.

- 4 -

Caution

Grounding

Caution

Prohibited

Prohibited

Prohibited

Electrical

Shock

Safety Section

Prohibited

Page 7

CAUTION

• Pump start-up

When connecting a power supply to the pump, make sure there is no person around

the pump. The pump has no ON/OFF switch. The pump starts operation when the

power is supplied by connecting the power supply cable.

• Foreign matter

Should foreign matter enter the pump, turn off the power at once and remove the

obstruction. Using the pump with foreign matter inside may cause damage to the

pump or a malfunction.

• Disposal of used pump

Disposal of used or damaged pumps must be done in accordance with local laws and

regulations. (Consult a licensed industrial waste products disposing company.)

• Handling of magnet coupling

The magnet used in the pump has a very high magnetic power. Be careful not to

allow your fingers to be seized by the magnet or to allow the magnet near any electronic device which may be affected by the magnet's power.

• Suspending pump operation for a prolonged period

When suspending pump operation for a prolonged period, drain the pump and clean

inside the pump. Take appropriate measures to prevent the entrance of foreign matter into the pump. If the pump is not operated for a period longer than one year,

replace the O ring and inspect inside the pump.

• Countermeasure for static electricity

When low electric conductivity liquid such as ultra-pure water and fluor inactive

liquid(e.g.FluorinertTM) are handled, the static electricity may be generated in pump,

which may cause static discharge and break down. Take countermeasure to avoid

and remove static electricity.

- 5 -

Caution

Caution

Safety Section

Page 8

OUTLINE OF PRODUCT

1. Before Using Pump ........................... 7

2. Operating Principle ........................... 7

3. Identification Codes .......................... 8

4. Specifications and

Outer Dimensions ................... 9

5. Names of Parts ............................... 11

- 6 -

Page 9

- 7 -

After unpacking, check the following points to confirm that

the delivered product and its accompanying parts and

elements are exactly what you ordered.

When lifting the pump please follow the procedure

mentioned "2. Installation" of "Pump operation".

[1] Do the model and frequency indicated on the nameplate

conform to your order?

[2] Prior to the installation of the MDF-LMKK pump

(using SiC liner ring and mouth ring), remove the

cardboard pad inserted inside the suction port.

[3] Has the pump unit or any part of it been damaged or

bolts and nuts been loosened during delivery?

[4] The fourth numeral of the MFG. No. shows the year the

product was manufactured.

(e.g.) ×××5×××

"5" shows the product was manufactured in the year

1995.

If you find anything wrong, please refer to the dealer you

placed your order with.

1. Before Using Pump

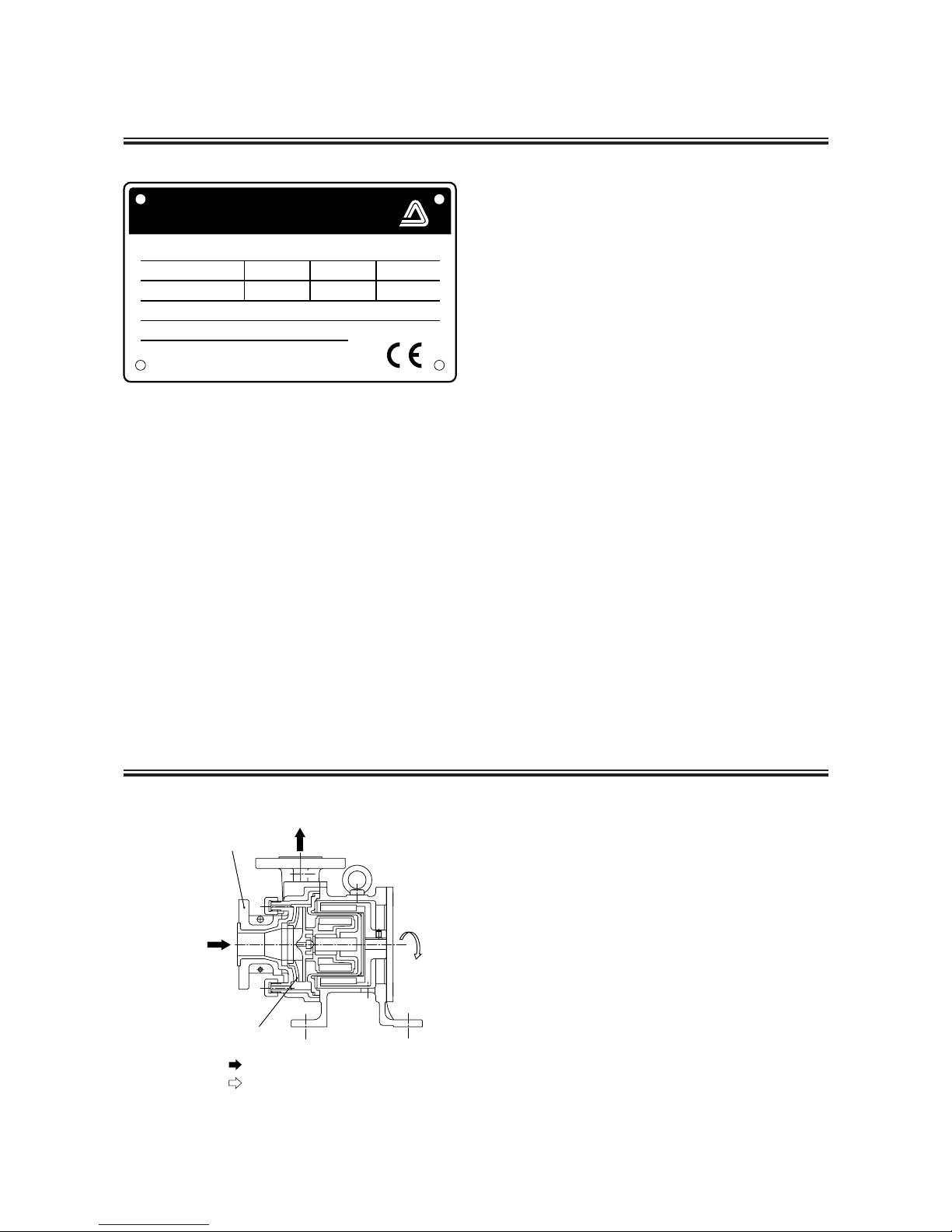

2. Operating Principle

The MDF-L pump is a magnet-driven centrifugal type

pump developed for various applications.

The impeller inside the pump chamber (front casing) is

rotated by magnetic force to transfer liquid from the suction

side to the discharge side.

The MDF-L type pump features excellent corrosion

resistance, durability, and safety, and serves as a chemical

pump for various processes. Most chemicals can be

handled by the pump.

Iwaki Magnet Pump

MODEL

HEAD (m)

CAPACITY (R/ min)

kW

5 0

Hz rpm

MFG.No.

IWAKI EUROPE GmbH

MADE IN JAPAN

MDF - L

Year:

2P406187

: Flow of liquid

: Direction of impeller rotation

Discharge side

Suction side

Impeller

Front casing

Page 10

MDF-L Type Series

Shows discharge port diameter

(42 shows 40)

0: 0.37 kW 1: 0.75 kW 2: 1.5 kW 3: 2.2 kW

5: 4 kW 7: 5.5 kW 10: 7.5 kW 15: 11 kW

CF: High density carbon/Alumina ceramics 99.5%

AA: Alumina ceramics 99.5%/Alumina ceramics 99.5%

* SiC/SiC is used in the model 6515.

KK: SiC/SiC

V: FKM E: EPDM A: AFLAS

®

FKM, AFLAS®: Fluoro rubber

EPDM: Ethylene propylene rubber

T, V, W: Standard

K, L: For high head applications

No mark: Standard

D, E: Pin-point contacting bearing system

(Standard models for 250, 401, 422, 423 and

425)

H, DH, EH:For up to 100 ˚C model (call it "H" type)

q Series

w Size of pump:

e Motor output

r Material of bearing/spindle

t Material of O ring and gasket

y Code of impeller

u Construction code

- 8 -

3. Identification Codes

Example:

MDF-L 42 5 CF V T - D

qwertyu

Page 11

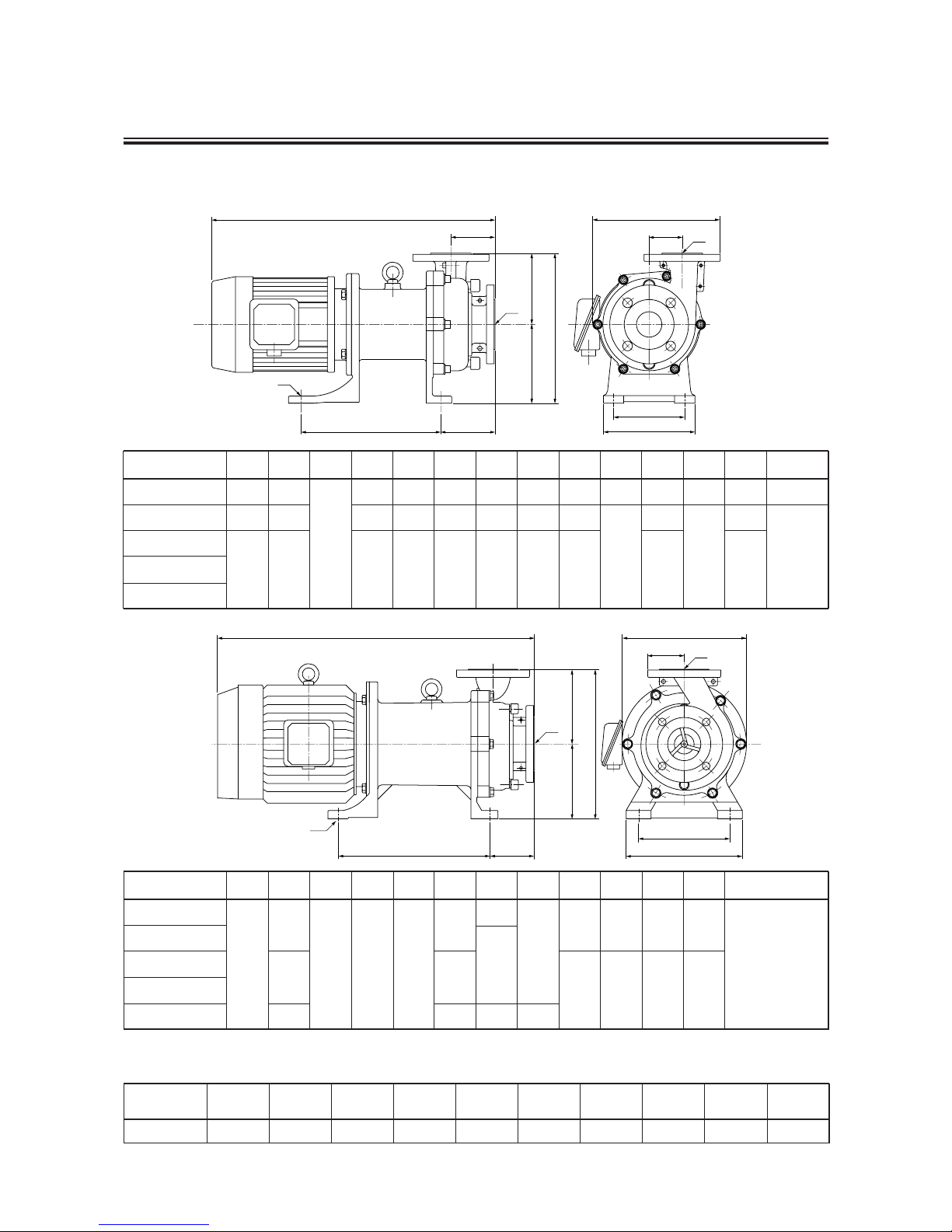

- 9 -

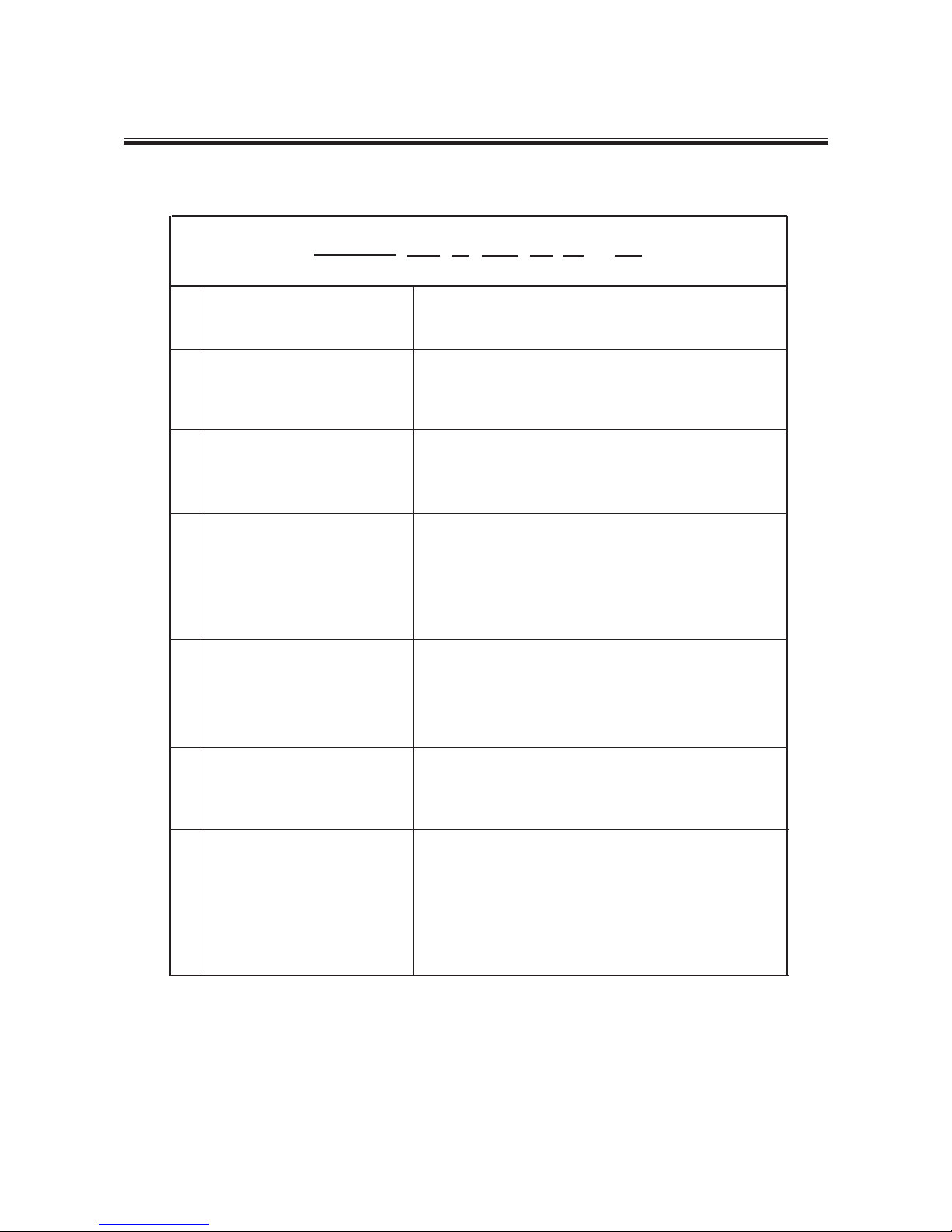

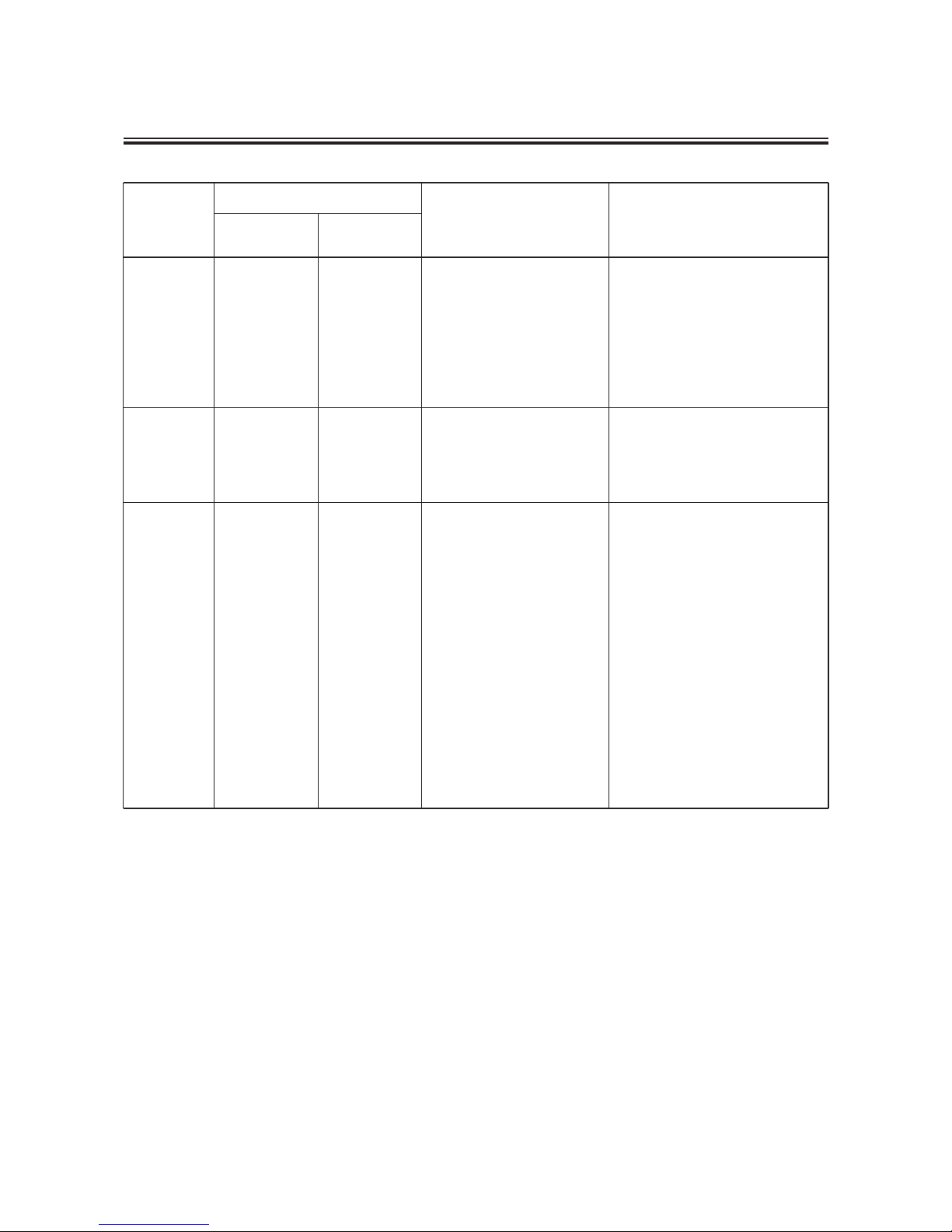

4. Specifications and Outer Dimensions

MM

Standard specifications

25×25

MDF-L401

Port Diameter

Suction Port ×

Discharge Port

Standard Performance

m-R/ min.

Model

Impeller

Code

Rated

speed

(min-1)

Motor

Output

kW

50Hz

K

12.2 - 50

T

7.3 - 150

V

5.6 - 150

W

3.0 - 150

K

16.8 - 100

T

4.5 - 200

V

8.3 - 200

W

4.8 - 200

K

T

V

W

K

L

T

V

W

T

V

W

T

V

W

K

T

V

W

T

V

W

K

T

V

W

T

V

W

40×40

50×40

50

×40

50

×40

65

×50

80

×65

MDF-L250

MDF-L422

MDF-L423

MDF-L505

MDF-L425

MDF-L507

MDF-L657

MDF-L6510

MDF-L6515

20 - 200

18 - 200

14 - 200

10.5 - 200

28.5 - 150

21.5 - 300

19.5 - 300

15 - 300

11.5 - 300

25.5 - 400

21 - 400

12 - 400

17 - 600

12.5 - 600

8.5 - 600

32.5 - 500

29 - 600

19.5 - 600

12.0 - 600

18.5 - 1000

10.5 - 1000

6.5 - 1000

30.5 - 800

26 - 1000

14.8 - 1000

9.5 - 1000

33 - 1000

24.8 - 1000

15 - 1000

2900

0.37

0.75

1.5

2.2

5.5

4

7.5

11

50Hz

Page 12

e

a

b

d

g

f

H

j

h

W

i

L

k

Model

Mass (kg)

250 401 422 423 425 505 507 657 6510 6515

- 10 -

Model

MDF-L250

MDF-L401

MDF-L422

MDF-L423

MDF-L425

W

205

233

251

H

237

275

295

L e

143

250

275

d

95

111

106

c

51

58

65

b

150

170

180

a

110

130

140

k

4-ø12

4-ø14

j

25

40

50

i

25

40

h

88

102

87

g

122

140

f

115

135

155

Model

MDF-L505

MDF-L507

MDF-L657

MDF-L6510

MDF-L6515

W

298

H

340

360

410

L f

180

230

e

285

365

450

d

90

108.5

108

b

280

a

220

k

4-ø14

j

65

80

i

50

65

h

80

100

g

160

180

MM

Mass

MM

Outer dimensions

e d

g

f

H

j

h

L

b

a

c

W

i

k

Page 13

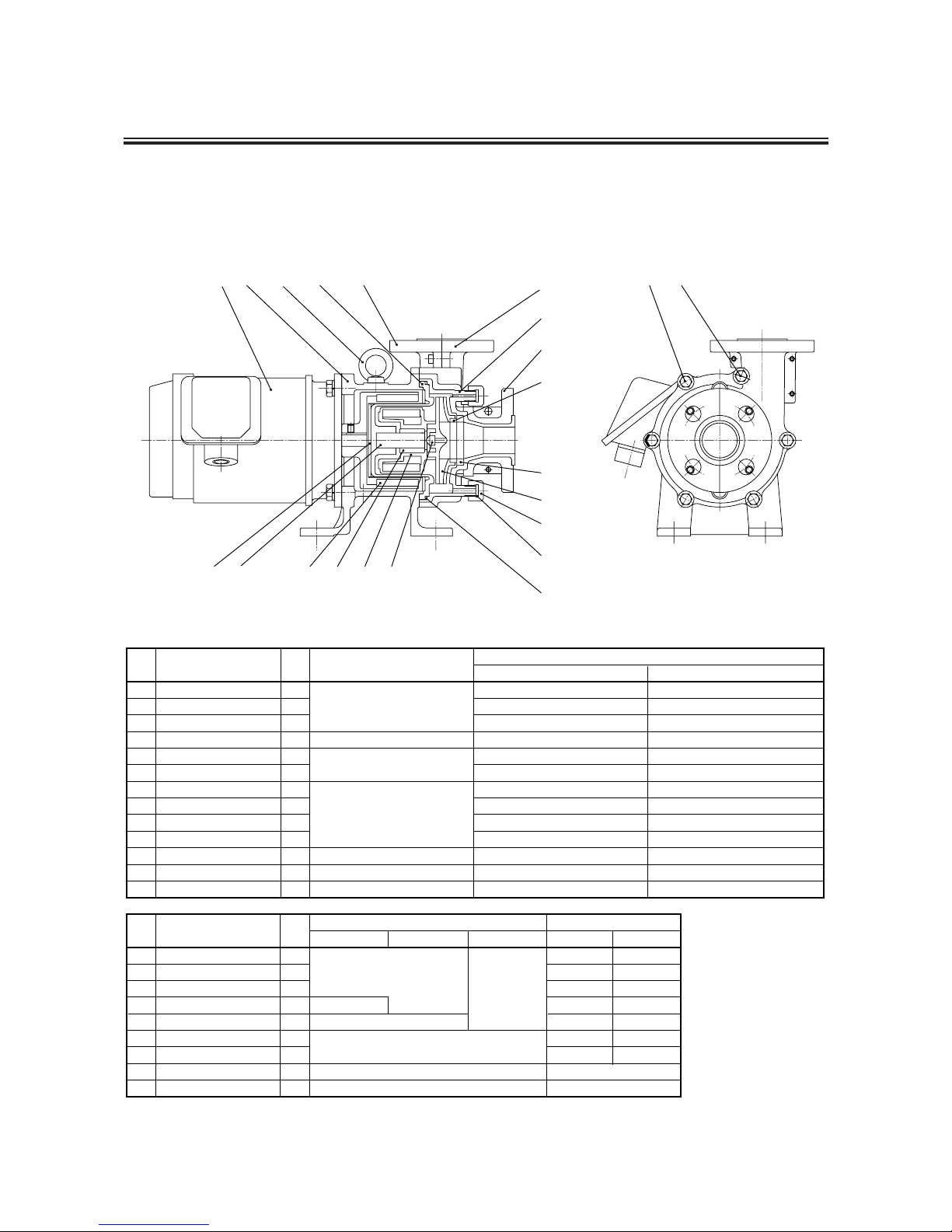

- 11 -

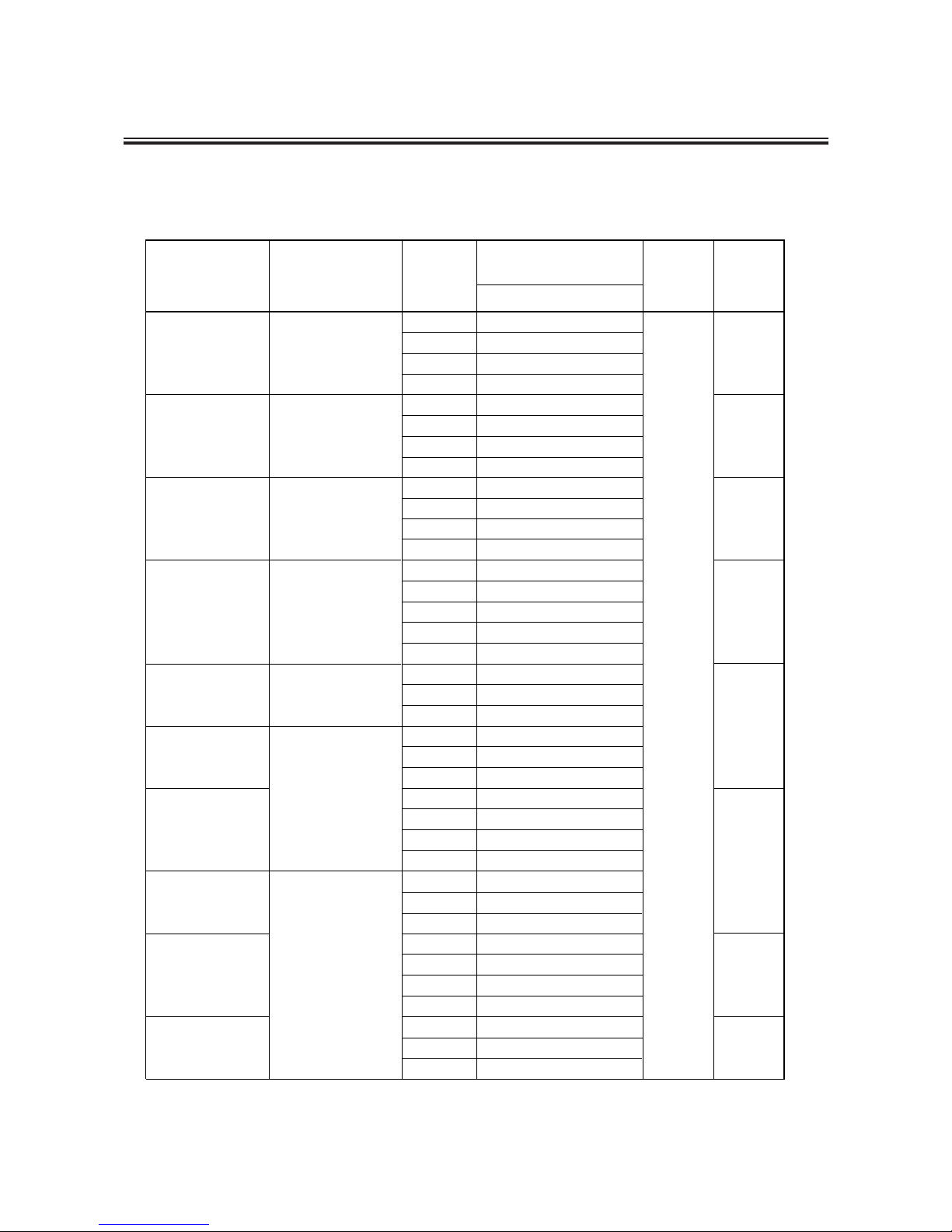

5. Names of Parts

MM

Names of Parts

• MDF-L250 and 401

No.

1

2

3

5

7

8

9

11

12

13

15

16

17

No.

18

19

20

21

22

23

24

25

26

Q'ty

1

1

1

1

1

1

2

1

1

1

2

Parts name

Material

M8×65, WITH SW, Q'TY5

FERRITE MAGNET+ALUMINUM ALLOY

STNLS STL

FC200

CFRETFE

PTFE

CFRETFE

M8×35, WITH SW, Q'TY1

M8×70, WITH SW, Q'TY5

M8×40, WITH SW, Q'TY3

Model 250

Model 401

Remarks

Front casing

Rear casing

Impeller

Drive magnet unit

Hex. head bolt

Hex. head bolt

Foot support

Cover A

Cover C

Cover B

Magnet capsule

Motor

Cap

Q'ty

Parts name

Remarks

Model 401Model 250

JIS B 2401

G 135

Only "H" type

Material

KK-EAA-ECF-D

PTFE

V: FKM E: EPDM A: AFLAS

Steel

STNLS STL

High density

carbon

Alumina ceramics 99.5%

SiC

®

1

1

1

1

1

1

2

1

1

Liner ring

Impeller thrust

Spindle

Bearing

Mouth ring

Oring

Gasket

Eye bolt

Rear casing cover

JIS B 2401

G 160

Only model 401

16

132

25

9

11

1

12

22

18

3

17

24

23

19

15

21520

26

87

Page 14

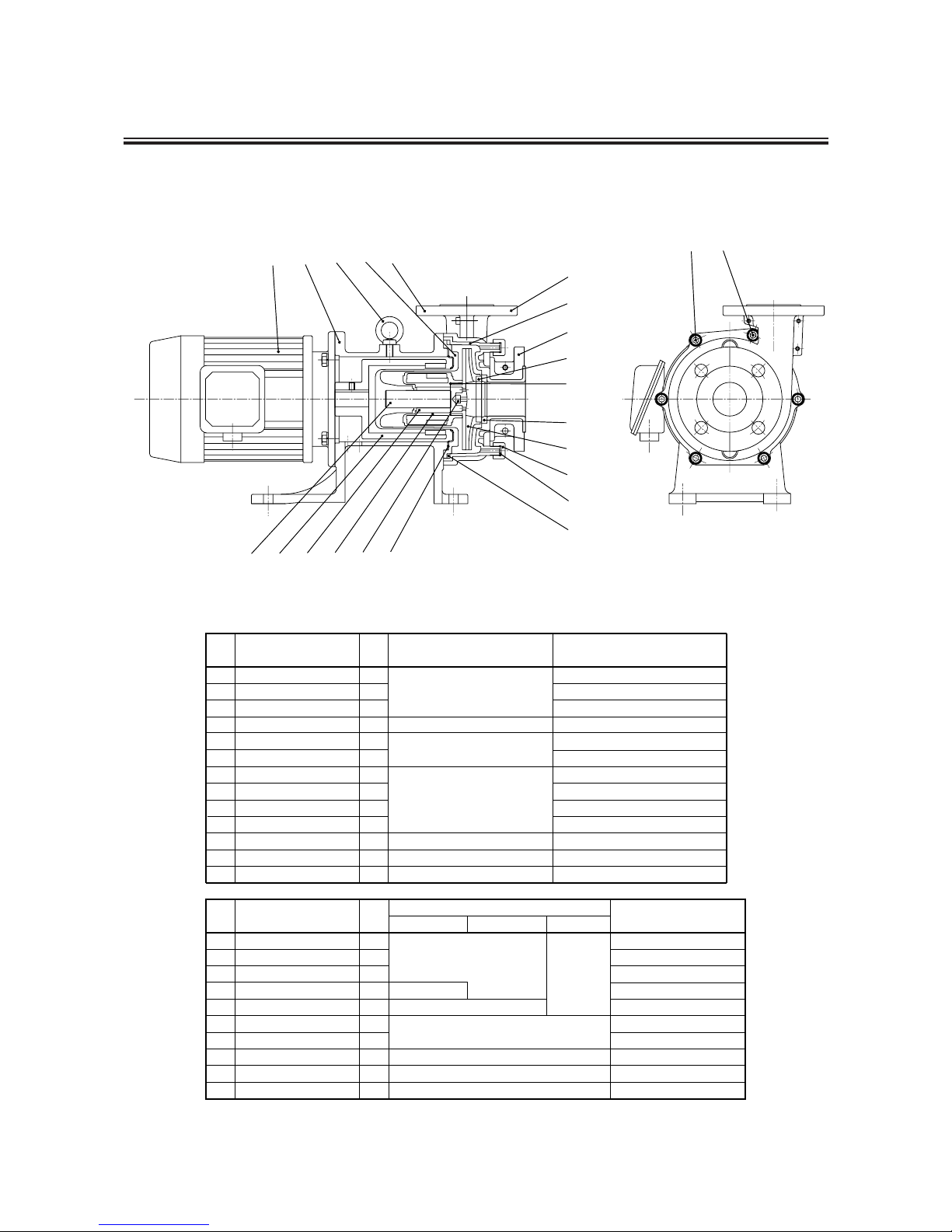

• MDF-L422, 423 and 425

- 12 -

No.

1

2

3

5

7

8

9

11

12

13

15

No.

18

19

20

21

22

23

24

25

29

Q'ty

1

1

1

5

1

1

1

2

1

1

Parts name

Material

M10×40 WITH SW

RARE EARTH MAGNET+FCD450

FC200

CFRETFE

CFRETFE

M10×75 WITH SW

Front casing

Rear casing

Impeller

Drive magnet unit

Hex. socket head bolt

Hex. socket head bolt

Foot support

Cover A

Cover C

Cover B

Magnet capsule

Motor

Cap

Q'ty

Parts name

Remarks

JIS B 2401 G 165

Material

KK-EAA-ECF-D

PTFE

V: FKM E: EPDM A: AFLAS

Steel

STNLS STL

High density

carbon

Alumina ceramics 99.5%

SiC

®

1

1

1

1

1

1

2

1

1

Liner ring

Impeller thrust

Spindle

Bearing

Mouth ring

O ring

Gasket

Eye bolt

Retainer ring

AS568-129

80

V, A: FKM E: EPDM

1

O ring

PTFE

16

17

1

1

2

STNLS STL

Remarks

80

29

87

20 5 211519

16

9

25

2

13

11

1

12

22

23

24

17

3

18

Page 15

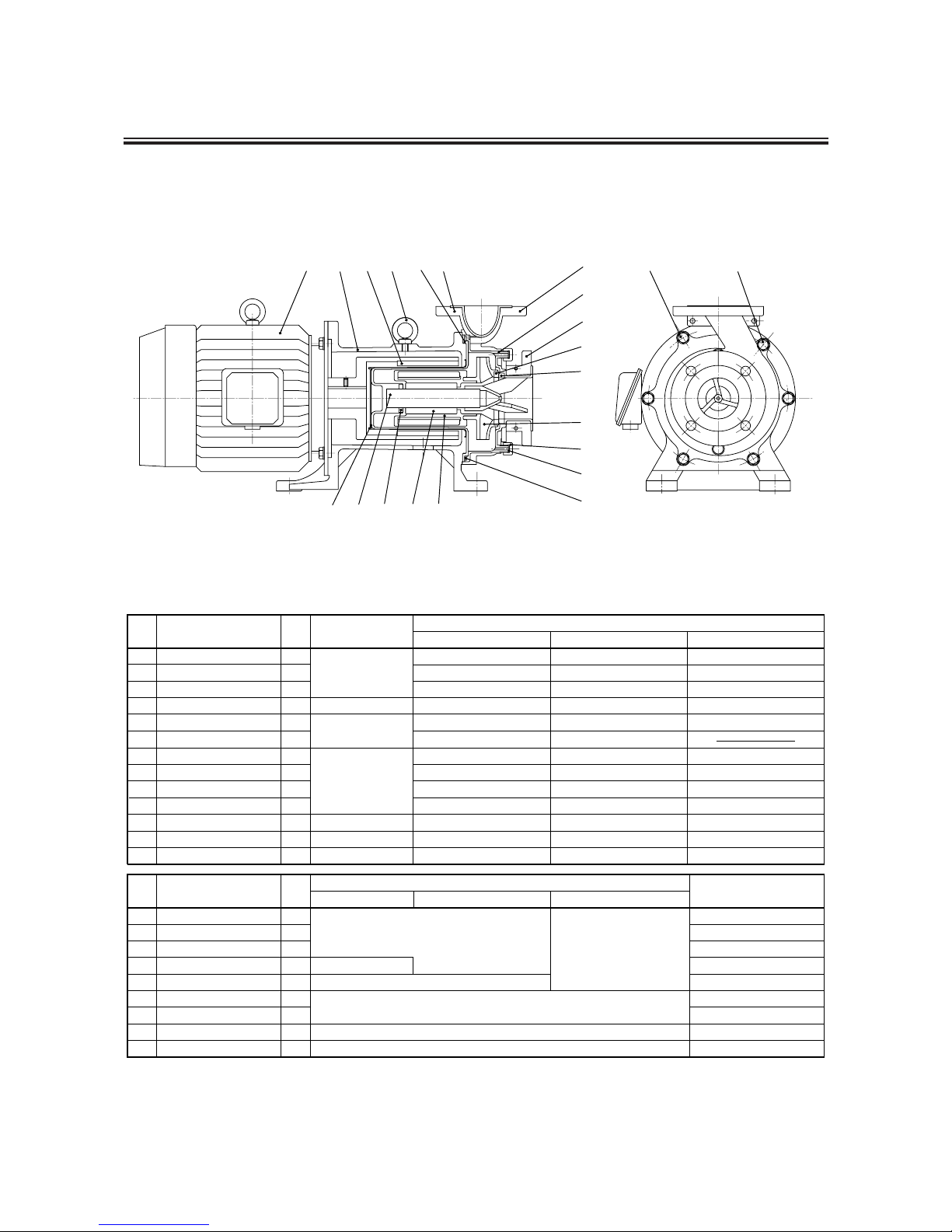

- 13 -

• MDF-L505, 507, 657, 6510 and 6515

No.

1

2

3

5

7

8

9

11

12

13

15

No.

18

19

20

21

22

23

24

25

26

Q'ty

1

1

1

1

1

2

1

1

Parts name

Material

M12×50, WITH SW, Q'TY 5

FERRITE+SS400

FC200

CFRETFE

CFRETFE

M12×90, WITH SW, Q'TY 1

Model 505 and 507

Remarks

Front casing

Rear casing

Impeller

Drive magnet unit

Hex. head bolt

Hex. head bolt

Foot support

Cover A

Cover C

Cover B

Magnet capsule

Motor

Cap

Q'ty

Parts name

Remarks

JIS B 2401 G 230

Material

KKAACF

Alumina ceramics 99.5%

PTFE

V: FKM E: EPDM A: AFLAS

Steel

STNLS STL

High density carbon

SiC

®

1

1

1

1

1

1

2

1

1

Liner ring

Rear thrust ring

Spindle

Bearing

Mouth ring

O ring

Gasket

Eye bolt

Rear casing cover

PTFE

16

17

1

1

2

STNLS STL

M12×50, WITH SW, Q'TY 5

M12×100, WITH SW, Q'TY 1

Model 657 and 6510 Model 6515

M12×90, WITH SW, Q'TY 6

*

Note: In model 6515 AA, Spindle and Bearing made of SiC are used.

Model 505 has a rear casing cover only "H" type.

The larger models above model 507 have a rear casing cover as standard equipment.

In model 6515, Drive magnet made of rare earth magnet is used.

2026

16 9 5 25 2 13

8

7

19 21 15

23

24

17

3

11

1

12

22

18

Page 16

MM

Description on Main Unit Body and Label

- 14 -

Pump unit (liquid feeding section)

Non-self priming type: Before operating the

pump, feed priming

liquid through the

suction or dischargeside

port.

Motor nameplate

Use only the power voltage specified on the

nameplate. (Follow applicable local power

regulations when used outside of Japan.)

"Arrow" indicator label

The arrow indicates the rotating

direction of the motor.

Always make sure that the motor

runs in the direction the arrow

indicates. (Refer to Preparation

for start-up [6] in the Pump

operation chapter.)

Motor (Driving section)

This motor provides power to the

pump unit.

Base

Setting should be fixed.

Discharge port

Suction port

Drain port

Liquid discharge port

Drain the discharged liquid into a

suitable container and follow the

applicable local regulations in

disposing of the liquid. Never

allow the discharged liquid to run

directly onto the ground.

"Never Operate Dry" indicator label

Operating the pump without liquid will

cause damage inside the pump. Never

operate the pump without liquid.

CAUTION

When cleaning the pump, be careful not to wipe the labels or the pump body

with solvent.

Specifications nameplate

Pump must be operated only under

the specified conditions.

Page 17

PUMP OPERATION

1. Handling Instructions ...................... 16

2. Installation ....................................... 21

3. Piping .............................................. 22

4. Wiring .............................................. 26

5. Operation Step ............................... 27

- 15 -

Page 18

[1] Handle the pump carefully.

Strong impacts caused by dropping the pump on the floor or striking it may result in damage or faulty

performance.

[2] Priming water

Be sure to fill the pump unit with feeding liquid as priming water before pump operation.

[3] Do not operate the pump in the following places.

• Places where the temperature falls below 0 ˚C

• Places where corrosive gas or explosive gas is generated

• Places exposed to splashing water

• Places where the ambient temperature is 40 ˚C or above

• Places where the humidity is excessively high. (Permissible humidity: 35~85%RH)

• Places filled with or likely to be filled with explosive or corrosive atmosphere.

• Danger due to dust, fire, earthquake and/or any externally imposed shock.

[4] Keep the pump away from fire.

To prevent fire and explosions, do not place dangerous or inflammable substances near the pump.

[5] If pump is damaged

Do not operate a damaged pump, otherwise there may be electricity leakage or electric shocks.

(Observe all the following instructions

to prevent injuries and accidents.)

- 16 -

1. Handling Instructions

Caution

¡Read the following information prior to installing the pump.

¡Protective wear:

When operating the pump or working near it, with the pump system loaded with chemical liquid,

always wear protective clothing, face guard, goggles, and gloves. Further precautionary

measures must be taken depending upon the type of liquid used.

¡Operating the pump dry (without supplying liquid to it) may cause seizure on wear of the

inside of the pump section.

¡Do not repair the pump beyond the range specified in this instruction manual.

The pump must be repaired by trained and qualified operators only.

Page 19

[6] No remodeling

Never try to remodel the pump. This may cause a serious accident or damage.

[7] Limitation to disassembly or repair

Users are allowed to disassemble and repair the pump to the degree of the given description in "Disassembly

and Assembly" in this manual.

[8] No dry running operation

Dry operation of the pump (pump operation without liquid inside) may cause damage to the pump internally.

Never operate the pump dry. In the case of MDF-L type, the sliding parts are self-lubricated and self-cooled. If

the pump is operated dry or with the suction-side valve closed, damage may result.

* Countermeasures to be taken in case of dry operation

1. Turn off the power switch of the pump immediately and leave the pump as it is for more than 1 hour.

2. Prime the pump and fill the pump with liquid.

(Note that the pump should be supplied with liquid after leaving the pump empty for more than 1 hour.

Sudden supply of liquid may cause a crack in a part due to quenching effects.)

[9] Dry operation compatible type pump

The dry running operation compatible type pump (with D at the end of the model identification) can endure

continuous dry running operation of not longer than 1 hour. Longer dry running operations, if repeated

frequently, may result in wear of the sliding parts which rapidly affects the normal functioning of the inner part

of the pump. The pump is designed so as not to develop cracks as a result of sudden cooling down with liquid

immediately after dry operation. However, it is recommended that the pump be left as it is for about 20 minutes

before running it with liquid.

* Pumps with E at the end of the model identification or without any symbol cannot endure dry running

operation.

[10] Points to be noted when starting and stopping pump

Pay close attention to the following points to avoid water hammer action when starting and stopping pump

operation. When the discharge-side piping is very long, extra attention is required.

(1) When starting the pump, first prime it. Then, close the discharge valve completely and turn on the power

switch. After starting up the pump, open the discharge valve gradually and set it to the desired operation

level.

(2) When stopping the pump, first close the discharge valve slowly. Turn off the power switch only after

completely closing the discharge valve.

In this procedure, never try to stop the pump quickly using a solenoid

valve, etc. Quick closure may cause water hammer action, and the

excessive pressure will destroy the pump.

- 17 -

Caution

Page 20

505 "H" type

507/657/6510 Standard

[11] Allowable pressure limit

See the table 1~5 for allowable pressure limits of each model.

See that the discharge pressure does not exceed the allowable pressure limit.

- 18 -

425 Standard

"H" type

MDF-L250

Standard

0.3

0.16

MPa

0 ˚C 90 100

Temperature

MDF-L422/423/425

0.45

0.4

MPa

0 ˚C 100

Temperature

422/423

Standard

"H" type

MDF-L401

Standard

0.3

0.24

MPa

0 ˚C 90 100

Temperature

MDF-L505/507/657/6510

0.5

0.4

0.3

MPa

0 ˚C 70 90 100

Temperature

Table 1

Table 4Table 3

Table 2

NOTE

MDF-L6515

0.6

0.5

MPa

0 ˚C 70 100

Temperature

Standard

Table 5

NOTE

*AFLAS®O ring

Above 10 ˚C

505 Standard

Page 21

[12] Use of slurry liquid

In principle, slurry liquid pumping is not possible. However, pumps with ceramic bearings (AA, and KK types

only) can handle the pumping of slurry liquid with a density of 5wt% or less, grain size of 50 µm or less, and

hardness of 80Hs or less. Prior to pumping such slurry liquid, be sure to confirm the operation feasibility with

the supplier.

[13] Influence of specific gravity and viscosity of liquid on pump performance

If the specific gravity or viscosity of the liquid is higher than that of pure water, the shaft power, discharge

volume, and pump head may vary somewhat. The delivered pump has been prepared to meet the specifications

ordered by the user. To change the operating conditions after delivery, be sure to contact the supplier.

[14] Intermittent operation

Frequent start/stop switching considerably shortens the service life of the pump. Try to limit the switching

frequency to six times or less per hour.

[15] Temperature humidity fluctuation

Temperature fluctuation may not change the performance of the pump itself. However, the liquid may change

in terms of its viscosity, pressure, or corrosion resistance. Pay special attention to changes in liquid

characteristics as a result of temperature fluctuation.

* The liquid temperature range for the pump using the O ring supplied by AFLAS®is 10~90 ˚C.

* Refer to the corrosion resistance table for the temperature ranges recommended for various types of liquid.

For inquiries or consultation, contact the dealer you placed your order with.

* Some types of pumps can be operated in the temperature range of 90~100 ˚C. For details, contact your

dealer.

[16] Disengagement of magnet coupling

Though the motor is running, the liquid is not circulated. (The pressure gauge on the discharge side points to "0"

point approximately.)

When the magnet coupling disconnects, stop the pump within 1 minute. If operation is continued with the

coupling in the disconnected mode, the power of the coupling will decrease considerably.

[17] Removal of grease (For AA type only)

Fluorocarbon grease is applied over the bearing in the AA type pump. The grease may, depending on the type

of liquid, melt into the liquid. Contact your dealer if you do not want the application liquid to be mixed with the

grease.

- 19 -

Liquid temperature range: 0~100 ˚C (pure water)

< 90~100 ˚C for the model MDF-L 250, 401 and 505 with code symbol "-H", "-EH", or "-DH" >

Ambient temperature range: 0~40 ˚C

Humidity range: 35~85%RH

Page 22

[18] Operation within range of drooping head capacity curve

In the case of a pump which generates a drooping head capacity curve in a low-capacity range, do not operate

the pump in the section where the line droops to the left. (Refer to the standard performance curve to verify the

head capacity.) If the drooping section (left side) of the head capacity curve is part of the pump operation

specifications, design the piping with the following points in mind.

q The discharge piping should have no water tank or air trap.

w The discharge amount should be adjusted with the valve installed near the discharge port.

- 20 -

Page 23

2. Installation

- 21 -

[1] Installation position

• Install the pump as close to the suction tank as possible and in the lowest position available (for flooded

suction).

• If the suction port of the pump is to be positioned higher than the suction tank (for suction lift), be sure to

arrange for a foot valve in the priming pipe and suction pipe.

* The lift head depends upon the liquid properties, temperature, and length of the suction piping. For details of

the setup, consult IWAKI or your dealer.

[2] Indoor and outdoor use

The pump can be operated either indoors or outdoors. However, safety measures should be taken so as not to

expose the motor and power distribution unit to flooding or other natural hazards.

[3] Installation site

Select an installation site that is flat and free of vibrations caused by nearby machines. Space sufficient for

maintenance work should be provided.

M Lifting

When lifting the pump, please pay attention to the following points.

• Pump must be lifted horizontally using two bolts located at pump and motor.

• In the case that there is no lifting bolt at the motor, rope or such kind materials should be tightenly winded to the

motor to lift the pump horizontally.

• Please use lifting chain or rope which has enough strength enduring pump weight.

• To prevent any human body accident caused by the pump drop, please do not enter under the lifted pump.

M Foundation preparation (before pump installation)

[1] The area for anchoring the pump must be greater than the area of the base. If the anchoring area is not enough,

the base may be destroyed due to a concentrated load on it.

[2] If pump operation is to be subject to vibration (resonation with the piping, for example), provide an expansion

joint between the pump and the piping. Otherwise, the piping, gauge, etc., may be damaged.

[3] Installation advice

• Use anchor bolts to fasten the pump base firmly.

• Install the pump horizontally.

• Sufficient space is required to allow cool air from the motor fan to circulate.

• Allow ample space around the pump for easy and efficient maintenance work.

Page 24

Tightening torque for piping flange of pump. (In the cace of steel flange with rubber gasket.)

Recomended bolt size and tightening torque for piping flange are as follows.

MDF-L250 : Bolt size is M12 and tightening torque is 42 N·m.

MDF-L401, 422, 423, 425, 505, 507, 657, 6510 and 6515 : Bolt size is M16 and tightening torque is 78.4

N·m.

Load of piping and momentum of piping for MDF-L.

The permissible stress and moment applicable to pump connection arrangement are as shown below.

The piping should be designed and worked so that stress and moment, higher than those values indicated in the table,

should not be applied to the pump.

Z

X

Y

X

Z

Y

3. Piping

- 22 -

Table 9 : Piping loadings

Forces of discharge piping Forces of suction piping

Direction of load

Mx

My

Mz

Direction of load

Fx

Fy

Fz

kN

0.89

0.58

0.71

kN

1.33

0.89

1.07

Dia. of pipe

25, 40, 50 65, 80

Load

kN·m

0.46

0.35

0.23

kN·m

0.95

0.72

0.47

Dia. of pipe

25, 40, 50 65, 80

Load

Direction of load

Fx

Fy: compression

Fy: tension

Fz

kN

0.71

0.89

0.44

0.58

kN

1.07

1.33

0.67

0.89

Dia. of pipe

25, 40, 50 65

Load

Mx

My

Mz

Direction of load

kN·m

0.35

0.46

0.23

kN·m

0.72

0.95

0.47

Dia. of pipe

25, 40, 50 65

Load

Moments of discharge piping Moments of suction piping

Page 25

- 23 -

Example of piping

(1) Discharge pipe (Support the pipe to keep the

pump free of piping load.)

(2) Valve

(3) Check valve

(4) Pressure gauge

(5) Motor

(6) Pump

(7) Air vent pipe

(9) Drain ditch

(10) Vacuum gauge

(11) Suction pipe (pipe diameter: D)

(The horizontal section should be as short as

possible and there should be an ascending

gradient of 1/100 toward the pump.)

(12) Pipe support

(13) Pump drain

(14) Suction pipe (pipe diameter: D)

(15) 2D, 500 mm or above

(16) Expansion joint

(17) Piping for flushing (Discharge side)

(18) Piping for flushing (Suction side)

15

1

2

12

3

4

12

16

5

6

7

2

17

2

1011

12

2

14

16 13

18

2

9

Page 26

Good

No good

Good

Good conditions Unacceptable conditions

No good

Good

No good

Good

No good

Air trap

Air trap

- 24 -

M Suction piping

[1] The suction pipe should employ the flooded suction method if possible. The shortest pipe possible, with the

minimum number of bends, should be used. Arrange a proper support under the suction pipe such as an

expansion joint or the like so that the weight and thermal stress of the pipe are not applied to the pump.

[2] Attach the coupling on the suction pipe carefully so as not to allow air inside the line. Air in the suction pipe

may damage the system.

[3] If suction is not good (e.g., the suction tank is a vacuum, the suction head is large, or the suction pipe is long),

the condition NPSHa > NPSHr + 0.5 m should be established. For the NPSHr level, refer to the standard

performance curve.

[4] When using an elbow pipe on the suction side, install a straight pipe with a length of at least 500 mm or 8 times

the suction port diameter before the pump suction port. Provide the largest radius possible for the R of the bend.

[5] Do not allow any projection where air may be trapped along the suction pipe. The suction pipe should have an

ascending gradient of 1/100 toward the pump.

Air trap

Air trap

Page 27

- 25 -

[6] If the diameters of the pump suction port and the suction pipe are different, use an eccentric reducer pipe.

Connect the eccentric reducer pipe so that the upper surface is level. In any case, never use a suction pipe with a

diameter smaller than that of the suction port.

[7] It is also recommended, in the case of flooded suction, that a gate valve be installed on the suction pipe for

easier overhaul inspection of the pump. Keep the gate valve fully open during ordinary pump operation; it is

required to be closed only during an overhaul inspection.

[8] When circulating a dangerous liquid, arrange the flushing pipes so that internal cleaning is possible when

disassembling the pump.

[9] The diameter of the suction pipe must be larger than that of the pump suction port.

[10] The end of the suction pipe should be located 500 mm or more below the surface of the liquid.

[11] A screen should be provided at the inlet in the suction tank to prevent the entry of foreign matter into the suction

pipe. The end of the suction pipe should be 1~1.5 D (D: diameter of suction pipe) or more away from the

bottom of the suction tank. Note that the entry of foreign matter may cause the pump to malfunction.

[12] In the case of the suction lift method, install a foot valve on the suction pipe.

Note: The items [10], [11], and [12] above are applied to the suction lift method.

M Discharge piping

[1] Use a support so that the weight of the pipe is not applied to the pump as load.

[2] If a method other than flooded suction is employed, install a priming pipe.

[3] If the pipe is too long the piping resistance may increase, hampering the pump's performance. The diameter of

the pipe should be determined by calculating the piping resistance.

[4] A check valve should be installed if any one of the following conditions is present. When selecting the check

valve, consider the check valve pressure limit (including the influence of water hammer or back flow onto the

pump).

q The discharge piping is very long

w The discharge lift exceeds 15 m

e The end of the discharge pipe is 9 m higher than the surface of the suction tank

r Several pumps are connected parallel to one another on the same piping

Page 28

[5] It is recommended that a valve be installed on the discharge pipe for the adjustment of discharge volume and for

the prevention of overload onto the motor. When installing both a check valve and a valve, the check valve

should be positioned between the pump and the valve.

[6] Do not fail to install a pressure gauge on the discharge piping.

[7] Install an air bleeding valve if the discharge pipe is very long horizontally.

[8] Install a drain valve for the drainage of liquid if there is a chance that the liquid in the discharge pipe might

freeze.

- 26 -

[1] Use an electromagnetic switch that conforms with the specifications (voltage, capacity, etc.) of the pump motor.

[2] If using the pump outdoors, waterproof the wiring to protect the switches from rainwater.

[3] Electromagnetic switches and push buttons should be installed reasonably distant from the pump.

[4] For starting up a pump with a motor of 5.5 kW or higher, be sure to use a Star Delta starter, soft starter or

invertor.

*Refer to the instruction manual of the motor issued by the motor maker for detailed handling instructions.

Electrical connections

ATTENTION

The electrical connection should be carried out by an authorized electrician in accordance with

local regulations. Please make sure that the electrical data on the nameplate of the motor

correspond to the electricity supply on which it will be used. Motors must be connected to a motor

protection switch.

4. Wiring

Page 29

5. Operation Step

M Operation instructions

[1] Never operate the pump dry or with the suction-side valve closed. Otherwise, the inside of the pump will be

damaged.

[2] In the event of cavitation, stop the pump within a minute.

In addition, do not continue pump operation with the air mixed into the suction side.

[3] If the magnet coupling disconnects, stop the pump within a minute. The power of the magnet coupling is

reduced if operation is continued with the coupling disconnected.

[4] The temperature fluctuation should not exceed 80 ˚C through the operation modes of starting, stopping, and

operating the pump.

[5] Before starting operation, close the discharge valve fully to prevent water hammer action upon start-up.

[6] Note that pump operation with the discharge valve closed fully over a long time will raise the temperature of the

liquid inside the pump and finally damage the pump.

[7] In the event of a service power failure, turn off the power switch immediately and close the discharge valve.

[8] Make sure that intolerable pressure levels are not applied to the pump. Refer to "page 18 [11] Allowable

pressure limit" in "1. Handling Instruction."

[9] Maximum pump surface temperature

The max. pump surface temperature of each model is shown in the table. Arrange protective measures in

accordance with the temperature levels.

- 27 -

Maximum surface temperature

when ambient temperature

is at 40 ˚C. (˚C)

MDF-L250

401

422, 423, 425

505, 507

657, 6510

6515

Model

Liquid temp (˚C)

100

90

90

90

90

90

95

2900

Rated speed

(min

-1

)

Page 30

[10] Sound generated by pump

The level of sound generated by each type of pump is shown in the table. Arrange a muffling measures in

accordance with the sound level. The procedure for sound measurement conforms to the EN 31201 (ISO11201).

- 28 -

(dB)

M Preparation for start-up

Preparations should be made, as described below, in the case of initial operation after installation and in the case of

restarting of operation after a long period of inactivity.

[1] Thoroughly clean the inside of the pump and pipe. Then, supply liquid.

[2] Tighten the flange connecting bolts and the installation bolts on the base.

[3] After priming the pump, close the discharge valve fully.

Also, make sure the air-vent valve and flushing piping valve are closed.

[4] In the case of the flooded suction method, measure the pressure in the flood pipe to confirm that the pump is

filled with liquid.

[5] In the case of the suction lift method, prime the pump.

[6] Run the motor instantaneously to check for correct direction of motor rotation. The motor should run in the

direction indicated with the arrow on the pump. If the direction is reversed, exchange any two wires of the

three-phase power wires.

Model

Sound

Level

MDF-L2507540180422, 423, 42580505, 50780657, 6510856515

85

Page 31

Points to be observed during operation.

If pump enters continuous operation mode, check flow

meter and confirm that pump operation is as per

specifications.

Remarks

• Suction valve-Fully opened

• Discharge valve-Fully opened

• Confirm pump is filled with liquid. If pump is not filled

with liquid, fill it in accordance with steps [4] and [5] of

'Preparation for start-up'. After priming completely,

close the discharge valve fully.

• Supply power immediately to run the pump only when

checking the rotating direction of the pump. (Correct

direction of pump operation is indicated with arrow on

the pump. Check the direction of motor fan by looking

at the fan through the fan cover.)

• Observe carefully to see if the motor fan slowly and

smoothly stops rotating when the power switch is turned

off.

Note: If the motor fan does not stop smoothly, it is

possible that the pump is locked inside.

In this case, contact your IWAKI dealer.

• Open valve carefully while paying attention to

amperemeter, to prevent motor from being overloaded

from excessive opening of valve.

* Within 1 minute, open the discharge valve gradually and

adjust the discharge pressure while checking the reading

of the pressure gauge on the discharge side. (Otherwise,

adjust the flow rate while checking the reading of the

flowrate meter.)

Caution

Total discharge pressure is increased to shut-off

pressure after start of normal pump operation,

open discharge valve gradually to set.

Operation Step

• Close or open the valve.

• Prime the pump

• Check the motor for correct rotating direction.

Switch on the power and then immediately switch off the

power.

• Turn on the power and start the pump. Then, adjust the

discharge pressure and discharge volume.

Following discharge volumes should be noted during pump operation.

MDF-L250 and 401: 10r/min. or above

MDF-L422 and 423: 20r/min. or above

MDF-L425, 505, 507, 657, 6510, and 6515: 50r/min. or above

• In case of automatic drive, too, close discharge valve before start-up and open valve slowly after start-up.

Caution

Do not run pump longer than 1 minute against a fully closed discharge valve.

M Operation

Operate the pump by following the steps given below.

- 29 -

No

1

2

3

4

• If flow meter is not available, check the values of

discharge pressure, suction pressure, and electric current

with reference to piping resistance.

5

Page 32

3 Points to be observed when stopping pump

• If the pump operation is stopped during cold weather, liquid in pump may freeze and damage pump. When

circulating a dangerous liquid, carry out internal cleaning by using flushing piping. Then drain the liquid

fully.

• Be sure to remove all liquid after stopping pump. In case of short-term suspension of operation, which

does not allow for removal of liquid, use band heater, etc., to prevent liquid inside from freezing.

• In event of power failure, turn off power switch and close discharge valve.

M Stoppage

- 30 -

1

2

Check/Operation Step

• Close discharge valve gradually.

• Turn off the power and stop pump operation.

Remarks

• Do not cause sudden closure with solenoid valve,

etc., otherwise pump may be destroyed by water

hammer action which is likely in case of long

discharge piping.

• Observe carefully whether the motor fan slowly

and smoothly stops rotating.

Caution

If not, check inside of pump.

Page 33

MAINTENANCE

1. Causes of Trouble

and Troubleshooting ........................ 32

2. Maintenance and Inspection ........... 35

3. Spare Parts ..................................... 39

4. Disassembly and Assembly ............ 40

- 31 -

Page 34

1. Causes of Trouble and Troubleshooting

- 32 -

Problem

Liquid is not

lifted.

Discharge

volume is

small.

When Discharge

Valve is Opened

Pressure gauge

and vacuum

gauge indicate

‘zero’.

Points of

pressure gauge

and vacuum

gauge swing

but return to

zero at once.

Pointer of

vacuum gauge

indicates a high

value.

When Discharge

Valve is Closed

Water goes

down at once

when priming

is carried out.

Pressure is

reduced if

discharge valve

is opened after

start-up step.

Pointer of

pressure gauge

never rises.

Cause

K Not enough priming wa-

ter

K Dry operation.

K Foreign matter is clog-

ging foot valve.

K Air enters through suction

pipe or gasket section.

K Magnet coupling has dis-

connected.

K Speed of pump is too low.

K Pump rotates in reverse

direction.

K Strainer is clogged with

foreign matter and liquid

passage is blocked.

Inspection and Measures

K Stop pump, feed sufficient

priming water, and restart

pump.

K Clean foot valve.

K Check whether seat is clogged

with foreign matter.

K Check again whether conn-

ecting flange in suction piping

is sealed airtight.

K Check whether suction liquid

level is abnormally lowered.

K Measure electric current level

to check for overload condition.

K Check whether the voltage

level is normal.

K Check for foreign matter

between impeller and casing.

K Check wiring and motor and

make necessary repairs.

K Exchange wires.

K Eliminate the foreign matter in

strainer.

Symptom on pump

Refer to "1. Causes of Trouble and Troubleshooting". Consult supplier for more information.

If you find any troubles, turn off the power supply immediately.

Page 35

- 33 -

Problem

Discharge

volume is

small.

When Discharge

Valve is Closed

Pointers of

pressure gauge

and vacuum

gauge indicate

normal values.

Pointer of

pressure gauge

indicates low

value and that

of vacuum

gauge indicates

extraordinarily

low value.

When Discharge

Valve is Opened

Pointer of

vacuum gauge

indicates

extraordinarily

high value.

Pointers of

pressure gauge

and vacuum

gauge swing.

Pointer of

vacuum gauge

indicates a high

value while

that of pressure

gauge indicates

normal value.

Pointer of

pressure gauge

indicates high

value while

that of vacuum

gauge indicates

normal value.

Pointers of

pressure gauge

and vacuum

gauge indicate

low values.

Cause

K Air is trapped in suction

pipe.

K Inlet section of impeller

unit is clogged with

foreign matter.

K Air enters through suction

pipe or gasket section.

K Discharge side of pump is

clogged with foreign

matter.

K There is an air trap or

resistance in suction pipe.

K There is portion in dis-

charge pipe that causes

resistance, or actual head

and loss of head are too

high.

K Rotation direction is re-

versed.

Inspection and

Countermeasures

K Inspect setup condition of

suction pipe and modify it if

necessary.

K Disassemble unit partially and

eliminate foreign matter.

K Check connecting section of

suction pipe and tighten it if

necessary.

K Eliminate foreign matter in the

pump.

K Eliminate foreign matter or

scale inside pipe.

K Check whether there is

protruding section in suction

pipe and take necessary

measures.

K Check actual head and piping

loss of discharge pipe and take

necessary measures.

K Exchange wires.

Symptom

Page 36

- 34 -

Problem

Motor is

overheated.

Discharge

volume is

suddenly

lowered.

Pump

vibrates.

When Discharge

Valve is Closed

When Discharge

Valve is Opened

Pointer of

vacuum gauge

indicates high

value.

Cause

K Voltage is lowered.

K Overload.

K Ambient temperature is

high.

K Strainer is clogged with

foreign matter.

K Foundation is defective.

K Anchor bolt is loose.

K Suction pipe is closed.

Cavitation is caused.

K Wear or melting of pump

bearing.

K Magnet capsule or spindle

is damaged.

K Dynamic balance of drive

magnet assembly fluctuates.

K Impeller and/or magnet

capsule is in contact with

fixing section.

K Wear of motor bearing.

Inspection and

Countermeasures

K Check whether the voltage and

frequency levels are adequate.

K Check whether the specific

gravity and viscosity of liquid

are adequate.

K Improve air ventilation.

K Eliminate foreign matter.

K Reinstall.

K Retighten bolts.

K Clean, and eliminate cause of

cavitation.

K Replace.

K Replace.

K Eliminate cause or replace.

K Replace.

K Replace bearing or motor.

Symptom

Page 37

2. Maintenance and Inspection

M Daily inspection

[1] Check whether the pump operates smoothly, without generating any abnormal noise or vibration.

[2] Check the level of the liquid in the suction tank and the suction pressure.

[3] Compare the discharge pressure and electric current measured during operation with the values indicated on the

motor nameplate for the verification of normal pump load.

* Note that the values indicated on the pressure gauge vary in proportion to the specific gravity of the liquid.

The cock of the pressure gauge or vacuum gauge must be opened only when measurement is carried out. It

must be closed upon the completion of each measurement. If the cock remains open during pump operation,

the meter mechanism may be affected by abnormal pressure caused by water hammer action.

[4] If a spare pump is available, activate it from time to time to keep it ready for use any time.

[5] Check to be sure there is no liquid leakage in the pump before operating it. If leakage is detected, never try to

operate the pump.

[6] Check to be sure the discharge pressure, discharge flow rate, and motor power supply voltage do not fluctuate

during pump operation. If considerable fluctuation of the respective values occurs, refer to "1. Causes of

Trouble and Troubleshooting" for correct measures.

M Periodic inspection

To ensure efficient and smooth operation of the pump, carry out periodic inspections by the following procedures

described below.

The overhauling and repair work for IWAKI pumps must be performed by qualified and trained personnel. User’s

failure to observe this instruction exempts IWAKI from the responsibility for personal injury or damage to the

equipment or facility which result from its misuse.

- 35 -

Page 38

Every 6 months

* Inspection record

should be kept.

Inspection Timing

- 36 -

Part Name

Drive magnet unit

Rear casing

Magnet capsule

Impeller

Front casing

Spindle

Check Points

K Are there slide-scratches?

K Is housing fixed normally? Is hex. socket set screw loose?

K Are inner perimeter of magnet and motor shaft coaxial?

(Max. eccentricity: 1/10 mm)

K Are there slide-scratches in bore?

K Are there cracks on liquid end part?

K Wear of thrust ring.

K Wear of spindle tip. (MDF-L 250, 401, 422, 423 and 425)

K Stains in rear casing.

K Are there a slide-scratches in the rear section or in the

cylindrical body?

K Are there cracks in resin of rear section or in cylindrical

body?

K Wear of bearing. (Measure dimensions.)

K Condition of fixed with impeller.

K Wear of mouth ring. (Measure dimensions.)

K Wear of impeller thrust. (MDF-L 250, 401, 422, 423 and

425)

K Are there cracks?

K Are there cavitation marks (such as mouth ring condition,

wear, seizure)?

K Stains or clogging inside impeller.

K Dimensional change in impeller.

K Stains in liquid contacting part.

K Are there cracks?

K Are there wear, slide-scratches, or cracks in thrust ring?

K Is drain clogged?

K Are there expansion or cracks on O ring?

K Slide-scratches in unlikely position.

K Are there cracks?

K Wear of abrasive section.

Page 39

* If the difference between the inner diameter of the bearing and the outer diameter of the spindle exceeds 1 mm, either

the bearing or the spindle whichever has the greater wear, should be replaced regardless of the values in the above

table. In the case of a ceramic bearing type pump, the spindle and the bearing should be replaced simultaneously.

* Initial wear may appear in the sliding parts in the first stages of operation. This should not be mistaken for an

abnormal condition.

M Wear limit of mouth ring

M Wear limits of bearing and spindle

Unit: mm

- 37 -

Model

Part

Inner diameter

of bearing

Outer diameter

of spindle

MDF-L

250

Upon

Shipment

18

18

Upon

Replace-

ment

19

17

MDF-L

401, 422

423, 425

Upon

Ship-

ment

26

26

Upon

Replace-

ment

27

25

MDF-L

505

Upon

Shipment

28

28

Upon

Replace-

ment

29

27

MDF-L

507, 657, 6510

Upon

Ship-ment

36

36

Upon

Replace-ment

37

35

MDF-L

6515

Upon

Shipment

34

34

Upon

Replace-

ment

35

33

Upon Shipment 2 mm

Mouth ring

Impeller

MDF-L505, 507, 657,

6510, 6515

9

7

Model

Thickness upon shipment

Thickness upon replacement

MDF-L250, 401, 422,

423, 425

8

6

* The step between the surfaces of the mouth ring and the impeller upon shipment is 2 mm. The wear limit of the

mouth ring is reached when this step is reduced to 0 mm. Replace the mouth ring then.

Unit: mm

Page 40

M Wear limits of tips of impeller thrust and spindle

(only for pumps with D or E at the end of model identification)

Pumps whose model identification codes have D or E at the end are designed to result in contact between the impeller

thrust tip and the spindle tip in the event of an abnormal operating condition (cavitation, dry operation, etc.). If the tips

are worn out beyond the wear limit level, the pump is subject to serious damage. The condition of the tips in contact

must be checked if an abnormal profile such as dry operation or cavitation lasts a total of over 3 hours.

- 38 -

M Wear checking steps

[1] Remove the rear casing from the foot support

and insert the magnet capsule attached to

impeller can into the rear casing.

[2] Rotate the impeller slowly by hand, with it

positioned on the rear casing.

• Tips are not worn out beyond wear limit

The impeller and magnet capsule will continue

to rotate smoothly.

• Tips are worn out beyond wear limit

The impeller and magnet capsule will not

continue to rotate smoothly. The contact at the

A section or B section, as shown in the figure of

the left, does not allow for the continuous

smooth rotation of the impeller and the magnet

capsule because the tips of the two elements are

excessively worn. In this case, replace the

impeller and rear casing with new ones.

Foot support

Rear casing

Impeller

Impeller thrust

A section

B section

Spindle

Rear casing

Magnet capsule

Page 41

3. Spare Parts

Appropriate spare parts are necessary to ensure long, continuous operation of the pump. It is recommended that

consumable parts be kept at hand constantly. When placing an order, supply the following information.

q Name of part and part number (in accordance with the drawings in this instruction manual)

w Pump model number and manufacturing number (as indicated on the pump nameplate)

e Drawing number if you have received the IWAKI-approved drawing

- 39 -

Circle around a number indicated the part is consumable.

CFRETFE

CFRETFE

CFRETFE

CFRETFE

No.

Part Name

Material

MDF-L

250

Rear

casing

2

MFL

1393

Alumina

ceramics 99.5%

MFL

1394

MFL

1430

MFL

1432

MFL

1433

MFL

0034

MFL

0035

MFL

0036

CF

AA

KK

CF

AA

KK

Magnet

capsule

15

AA

KK

Gasket

O ring

Spindle

SiC

CFRETFE

FKM

EPDM

Aflas

®

FKM

EPDM

Aflas

®

MFL

1437

MFL

1438

MFL

0071

MFL

0073

MFL

0074

MFL

1515

MFL

1516

MFL

1517

MFL

1550

MFL

1551

MFL

1552

MFL

1564

MFL

1565

MFL

1566

MFL

0227

MFL

0229

MFL

0230

MFL1502

MFL1503

MFL

0135

MFL

0254

MFL0298

MFL0316

MFL0317

MFL

0404

MFL

0405

MFL

0445

MFL

0447

MFL

0428

MDF-L

401

MDF-L

422

MDF-L

423

MDF-L

425

MDF-L

505

MDF-L

507

MDF-L

657

MDF-L

6510

MDF-L

6515

MFL0031

MFL0032

MFL0033

MFL

0080

MFL

0081

MFL

0082

MFL0130

MFL0131

MFL0132

MFL0280

MFL0281

MFL0282

MFL

0134

MFL0327

MFL

0456

MFL

0255

MFL0318

MFL0328

MFL

0406

MFL

0429

MFL0299

AA

CF

KK

Impeller

3

CFRETFE

CFRETFE

MFL

0457

MFL

0457

CF

Alumina

ceramics 99.5%

*

1

+

21

@4

@3

@0

Page 42

4. Disassembly and Assembly

- 40 -

Caution

• When disassembling the pump, put a mark on each lead in order to prevent the pump

from reversing rotation after rewiring, if you disconnect leads from the motor.

• Since the magnet used in the pump is very powerful, be careful not to get your fingers

caught between the elements during the disassembly and assembly processes. Also,

pay attention to prevent metal pieces or metal powder from adhering onto the pump.

• Do not bring any electronic device that may be impacted by strong magnetic power into

the pump magnetic field.

• Prior to disassembly or assembly, close the suction valve and discharge valve fully.

• The piping and the pump often retain liquid. When a dangerous liquid is handled, wear

protectors (goggles, rubber gloves, etc.) when disconnecting the pipes.

M Disassembly

[1] Disassemble only after thoroughly washing out the

liquid inside the pump by use of flushing piping,

remove the cap to discharge the liquid from the pump.

Then, clean the inside of the pump.

Warning

Wear protectors (goggles, rubber gloves, etc.).

Certain liquids are dangerous. They may hurt your

eyes and skin.

[2] Remove the front casing from the foot support.

Remove the hex socket bolts (or hex bolts) and take

out the front casing from the foot support.

Be careful with the spindle which remains pressed-fit

in the front casing.

Caution

Strong impacts may crack the spindle or casing.

Do not hit them with a tool.

* Note on MDF-L250, 401, 422, 423 and 425

The spindle is integrated with the rear casing, not

pressed into the front casing.

* During disassembly, discharge the liquid from the

casing and clean the inside of the pump.

MDF-L250, 401, 505, 507, 657, 6510 and 6515

MDF-L422, 423

and 425

MDF-L505, 507, 657, 6510 and 6515

Spindle

MDF-L250, 401, 422, 423 and 425

Front casing

Front casing

Drain cap

Page 43

- 41 -

*Note on MDF-L 422, 423 and 425

The impeller is fixed to the magnet capsule by screwing. When removing the impeller from the magnet capsule,

hold the magnet capsule by hand and rotate the impeller counterclockwise (from the impeller side).

If thread part is too tight and the impeller is not disconnected from the magnet capsule, put the magnet capsule with

the impeller on hot water (about 90 ºC) for 5 minutes. And then rotate the impeller counterclockwise. Beware of

scald while this procedure.

Caution

When disassembling and reassembling MDF-L 422, 423 and 425 magnet capsule and impeller, pay attention

to followings.

• The O ring is inserted between the impeller and thread part of the magnet capsule. This O ring prevents

that the impeller comes loose from thread part of the magnet capsule, even if the pump rotates reverse

direction. When replacing the impeller and/or the magnet capsule, confirm the pump rotating direction is

correct before reassembling the impeller and the magnet capsule without O ring.

• If the impeller and the magnet capsule are reassembled with O ring, there is possibility that the impeller is

not screwed into thread part of the magnet capsule completely. This may cause pump damage.

[4] Remove the rear casing.

Insert a flat-head screwdriver into the perimeter of the rear casing and pull the rear casing forward while lifting it

slightly up.

* Pay extra attention not to scratch the sealing surface.

Do not hit them with a tool.

*Note on MDF-L250, 401, 422, 423 and 425

The spindle is integrated with the casing, not pressed

into the front casing.

*During disassembly, discharge the liquid from the

casing and clean the inside of the pump.

[3] Pull out the impeller and magnet capsule

assembly toward yourself.

Be careful not to scratch the surface of each part.

Since the magnet capsule is strongly magnetized, store

it in a place free of metal pieces or metal powder.

Handle the front casing, magnet capsule, and impeller

with extra care so as not to scratch the sliding surface

and sealing surface.

*Note on MDF-L250, 401, 505, 507, 657, 6510 and

6515

Then disconnecting the impeller from the magnet

capsule, hold the magnet capsule by hand and strike

the rear of the impeller gently with a resin hammer.

When the impeller is tightly pressed in and

disconnection is difficult, warm the impeller and

magnet capsule in hot water (about 90 ˚C) for 5

minutes prior to striking the impeller with the hammer.

Impeller

Magnet capsule assembly

Rear casing

Page 44

[5] Replacement of spindle

The spindle is pressed into the front casing. Pay attention to the following points when replacing the spindle.

a. Hold the worn spindle in one hand and hit the perimeter of the front casing (cast part) lightly and evenly with a

resin hammer to remove the spindle from the casing. In this step, never strike the seal surface of the front casing

or the spindle.

b. Wipe off the stains on the front casing. Then, insert a new spindle into the casing by hand and strike it gently

with the resin hammer to press it in.

* Do not disassemble the spindle section unless it is seriously worn and needs to be replaced.

* If the spindle does not come off easily, warm the front casing in hot water (about 90 ˚C) before pulling it out for

replacement.

* In the case of the MDF-L250, 401, 422, 423 and 425, the casing and the spindle are integrated. It is not possible to

replace only the spindle.

M Assembly

The pump should be assembled by carrying out the steps of disassembly in reverse. Pay attention to the following

points.

¡ Replacement of O ring and gasket

When replacing the O ring or gasket, be sure to install a new one. In addition, see that the O ring or gasket is not

twisted or pressed by another part.

* The sealing section should be cleaned free of dust or scratches before installation.

¡ Fastening Bolts

Fasten the bolts in diagonal order by applying the fastening torque shown in the following table. Apply an equal

torque to each bolt.

- 42 -

Model

MDF-L 250

MDF-L 401

MDF-L 422, 423, 425

MDF-L 505, 507

MDF-L 657, 6510

MDF-L 6515

Type

Hex. head bolt

Hex. socket head bolt

Fastening torque

N·m

12.5

24.5

Size of bolts

M8×35L, M8×65L

M8×40L, M8×70L

M10×40L, M10×75L

M12×50L, M12×90L

M12×50L, M12×100L

M12×90L

¡ Ceramics bearing (AA type)

Apply fluorocarbon grease inside the bearing and the perimeter of the spindle. Otherwise, it will wear out in a short

time.

* Note on MDF-L 250, 401, 505, 507, 657, 6510 and 6515

[1] Install the rear casing onto the foot support.

[2] Attach the impeller onto the magnet capsule. If this is difficult, warm the magnet capsule in hot water (about

90 ˚C) for 5 minutes before attaching it.

Hex. head bolt

42.0

Page 45

[3] Check that there is no metal piece or other matter adhering onto the magnet capsule. Then, insert the magnet

capsule and impeller slowly into the rear casing.

* Note that the magnetic force of the magnet capsule is very strong.

[4] Confirm there is no dust or scratches on the seal surface of the front casing. Then, attach the O ring onto the front

casing.

[5] Insert the spindle attached on the front casing into the through hole of the magnet capsule and rear casing so that

the front casing and rear casing will be assembled.

[6] Fasten the hex. head bolts in diagonal order, applying an equal torque to each.

* Note on MDF-L 422, 423 and 425

[1] Attach the impeller to the magnet capsule.

Rotate the impeller clockwise, and screw the impeller on the magnet capsule.

Caution

• When replacing the impeller and /or the magnet capsule, confirm the pump rotating direction is correct

before reassembling the impeller and the magnet capsule without O ring.

• If the impeller and the magnet capsule are reassembled with O ring, there is possibilitiy that the impeller is

not screwed into thread part of the magnet capsule completely. This may cause pump damage.

[2] Insert the impeller and the magnet capsule unit to the rear casing. Then, the rear casing, the impeller and the

magnet capsule set is installed onto the foot support.

Caution

• Since the magnet used in the pump is very powerful, be careful

not to get your fingers caught between elements by inserting

wood pieces or plastic pieces between the rear casing and the

foot support.

[3] Confirm there is no dust or scratches on the seal surface of the front casing. Then, attach the O ring onto the front

casing.

[4] Attach the front casing onto the foot support.

[5] Fasten the hex. socket head bolts in diagonal order, applying an equal torque to each.

- 43 -

Impeller

Spacer

Page 46

T313-2 99/9

( )Country codes

IWAKI CO.,LTD. 6-6 Kanda-Sudacho 2-chome Chiyoda-ku Tokyo 101-8558 Japan

TEL:(81)3 3254 2935 FAX:3 3252 8892(http://www.iwaki-pumps.co.jp/)

Germany : IWAKI EUROPE GmbH

Italy : IWAKI Italia S.R.L.

Denmark : IWAKI Pumper A/S

France : IWAKI France S.A.

Switzerland: IWAKI (Schweiz) AG

U.K. : IWAKI PUMPS (UK) LTD

Sweden : IWAKI Sverige AB

Finland : IWAKI Suomi Oy

Austria : IWAKI (Austria) GmbH

Norway : IWAKI Norge AS

Holland : IWAKI Holland B.V.

Spain : IWAKI Iberica Pumps,S.A.

Belgium : IWAKI Belgium n.v.

TEL: (49)2154 9254 0 FAX:2154 1028

TEL: (39)02 9903931 FAX:02 99042888

TEL: (45)48 24 2345 FAX:48 24 2346

TEL: (33)1 69 63 33 70 FAX:1 64 49 92 73

TEL: (41)32 3235024 FAX:32 3226084

TEL: (44)1743 231363 FAX:1743 366507

TEL: (46)8 511 72900 FAX:8 511 72922

TEL: (358)9 2742714 FAX:9 2742715

TEL: (43)2236 33469 FAX:2236 33469

TEL: (47)66 80 66 86 FAX:66 80 66 87

TEL: (31)297 241121 FAX:297 273902

TEL: (34)943 630030 FAX:943 628799

TEL: (32)1430 7007 FAX:1430 7008

Singapore : IWAKI Singapore Pte. Ltd.

Indonesia : IWAKI Singapore (Indonesia Branch)

Malaysia : IWAKIm Sdn. Bhd

Taiwan : IWAKI Pumps Taiwan Co.,Ltd.

Thailand : IWAKI (Thailand) Co.,Ltd.

Hong Kong : IWAKI Pumps Co.,Ltd.

China :

IWAKI Pumps Co.,Ltd. (Shanghai office)

China :IWAKI Pumps Co.,Ltd. (Beijing office)

China :

IWAKI Pumps Co.,Ltd. (Guangzhou office)

Australia : IWAKI Pumps Australia Pty. Ltd.

U.S.A. : IWAKI WALCHEM Corporation

TEL: (65)763 2744 FAX:763 2372

TEL: (62)21 392 8288 FAX:21 392 8088

TEL: (60)3 703 8807 FAX:3 703 4800

TEL: (886)2 2776 5900 FAX:2 2740 2812

TEL: (66)2 322 2471 FAX:2 322 2477

TEL: (852)2 607 1168 FAX:2 607 1000

TEL: (86)21 5234 0776 FAX:21 5234 0775

TEL: (86)10 6262 6678 FAX:10 6262 6551

TEL: (86)20 8130 0605 FAX:(86)20 8130 0601

TEL: (61)2 9899 2411 FAX:2 9899 2421

TEL: (1)508 429 1440 FAX:508 429 13864

Loading...