IWAKI PUMPS MD-15FZ-220N, MD-30FZ-220N, MD-15FX-220N, MD-15FY-220N, MD-30FY-220N Instruction Manual

...Page 1

IWAKI Magnetic Drive Pump

MD-F type

Instruction Manual

Read this manual before use of product

Page 2

Thank you for selecting an Iwaki MD-F type Magnetic Drive Pump.

This instruction manual deals with "Safety Instructions", "Outline",

"Installation", "Operation" and "Maintenance" sections.

Please read through this instruction manual to ensure the optimum performance, safety and service of your pump.

Contents

Safety Instructions ··········································································1

Outline 1. Unpacking & Inspection ·······································3

2. Operating principle ···············································3

3. Specification & Identification code ······················4

4. Outer dimensions ··················································5

5. Performance curves ·············································6

6. Overview & Label ················································6

7. Part names & Structure ·········································7

Installation 1. Before installation ·················································8

2. Installation/Piping/Electrical wiring ·················11

Operation 1. Before operation ··················································15

Maintenance 1. Troubleshooting ··················································17

2. Maintenance & Inspection ·································17

This instruction manual should be kept on hand by the end user

for quick reference.

Contact us or your nearest dealer if you have any questions.

Important Instruction

For the Safe and

Correct Handling of the Pump

● "Safety Instruction" section deals with important details about

handling of the product. Before use, read this section carefully for

the prevention of personnel injury or property damage.

● Observe the instructions accompanied with "WARNING" or

"CAUTION" in this manual. These instructions are very important for protecting pump users from dangerous situations.

● The symbols on this instruction manual have the following meanings:

Nonobservance or misapplication of the

WARNING

CAUTION

Indicates a prohibited action or procedure. Inside or near this circle, a concrete and practical image of the activity to be avoided is

depicted.

Indicates an important action or procedure which must be performed or carried out without fail. Failure to follow the instructions herein can lead to malfunction or damage to the pump.

For exportation

Technology related to the use of goods in this instruction manual falls

in the category of technology contained in the Foreign Exchange

Order Attachment, which includes complementary export control of

technology. Please be reminded that export license, which is issued

by the Ministry of Economy, Trade, and Industry could be required,

when this is exported or provided to someone even in Japan.

contents of “Warning” section could lead to

a serious accident which may result in death.

Nonobservance or misapplication of the

contents of “Caution” section could lead to

a personal injury or damage to the product.

Types of Symbols

Page 3

Power off

Safety Instructions

Prohibited

Prohibited

Prohibited

No modification

No dismantlement

Caution

Caution

Wear protectors

Prohibited

Prohibited

● Turn off the power.

Risk of electrical shock. Dismantling/

assembling the pump unit without turning off the power may cause an electrical

shock. Before engaging in any maintenance

or inspection work, be sure to turn off the

pump and related devices.

● Terminate operation.

On sensing any abnormality, stop operation

immediately and inspect/solve problems.

● For specified application only

The use of the pump in any application

other than those clearly specified may result

in injury or damage. Use the pump in a

specified condition.

● No dismantlement/modification

Do not dismantle/modify the pump. We are

not responsible for any accidents or damage

due to modification.

● Wear protective clothing.

Always wear protective clothing such as

safety goggles and protective gloves during

pipework or dismantlement.

WARNING

CAUTION

● Restriction on operator

The pump should be handled by a qualified

person with a full understanding.

● Specified power only

Do not apply any power other than the

specified one on the nameplate. Otherwise

damage or fire may result.

● Do not wet the pump.

If a liquid spills over electric parts or wires, a

fire or electrical shock may result. Install the

pump in a place free from liquid spillage.

● Ventilation

Poisoning may result when handling a toxic

or odorous liquid. Keep good ventilation in a

work area.

● Countermeasure against efflux

Take a protective measure against the accidental efflux caused by pump or pipe breakage.

● Damaged pumps.

Do not use any damaged pump. Using a

damaged pump may lead to an electric leak

or shock.

- 1 -

Page 4

Prohibited

Safety Instructions

Caution

Prohibited

Electrical shock

Prohibited

Caution

Earthing

CAUTION CAUTION

● Do not place the pump close to water.

The pump is not dust-/water-proof construction. The use of the pump in a humid place

or a place where the pump can get wet may

result in electrical shock or short-circuit.

● Do not damage the power cable.

Risk of fire or electrical shock. Do not

scratch, modify, or pull the power cable.

The cable can also be damaged when it is

heated or loaded with a heavy thing.

● Do not cover the motor during operation.

Or heats builds up and fire or mechanical

failure may result.

● Earthing

Risk of electrical shock. Always earth the pump.

● Install an earth leakage breaker.

An electrical failure of the pump may adversely affect related devices. Purchase and

install an earth leakage breaker separately.

● Power cable is not replaceable.

Do not use any damaged power cable for

the prevention of a fire or electrical shock.

The cable is not replaceable, so that the

whole pump unit needs to be replaced when

the cable is damaged.

● Limited operating site and storage

Do not install or store the pump in the following places where...

1. Ambient temperature exceeds 40°C or

falls below 0°C.

2. Under a flammable/corrosive atmosphere.

● Do not drain a harmful chemical liquid

directly on the ground or the floor.

Use a container.

● Disposal of the used pump

Dispose of any used or damaged pump

in accordance with relevant regulations.

Consult a licensed industrial waste products

disposing company.

● Static electricity

When low electric conductivity liquids such

as ultra-pure water and fluor inactive liquid

(e.g. Fluorinert

TM

) are handled, the static

electricity may generate in the pump and

may cause static discharge. Take countermeasures to remove the static electricity.

- 2 -

Page 5

Outline

Before use, check the specification, limitation and hazardous

nature of the pump.

1. Unpacking & Inspection

On unpacking the product, check the following points. If

you find any problems, contact your nearest distributor.

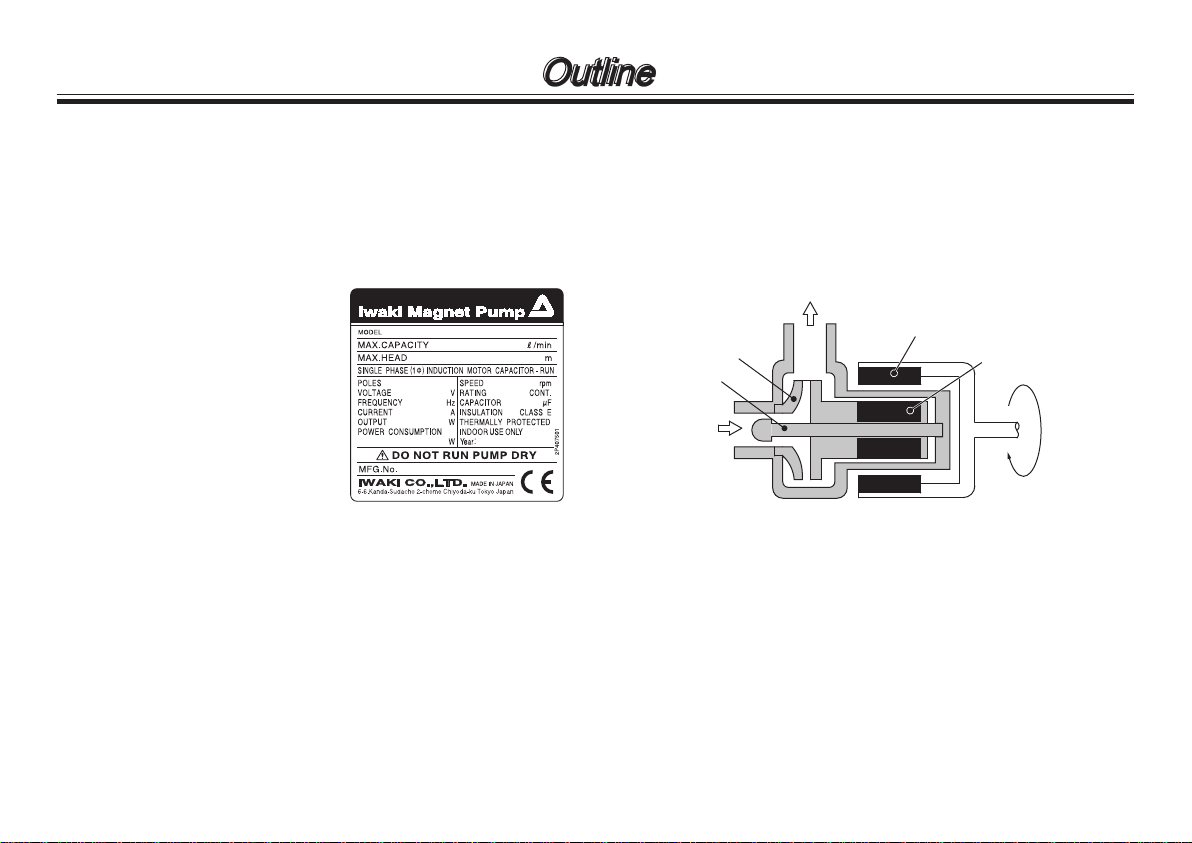

1. Check the information on the

nameplate such as model, discharge capacity, discharge head

and voltage to see that the product is delivered as per order.

2. Check for transit damage, deformation, and loose bolts.

2. Operating principle

The MD-F is a magnetic drive centrifugal pump.

The magnetic force of the motor drives the impeller magnet and rotates the impeller in the pump chamber, where a

liquid is transferred from the inlet to outlet.

Outlet

Drive magnet

Impeller

Spindle

Inlet

Driven magnet

- 3 -

Page 6

Outline

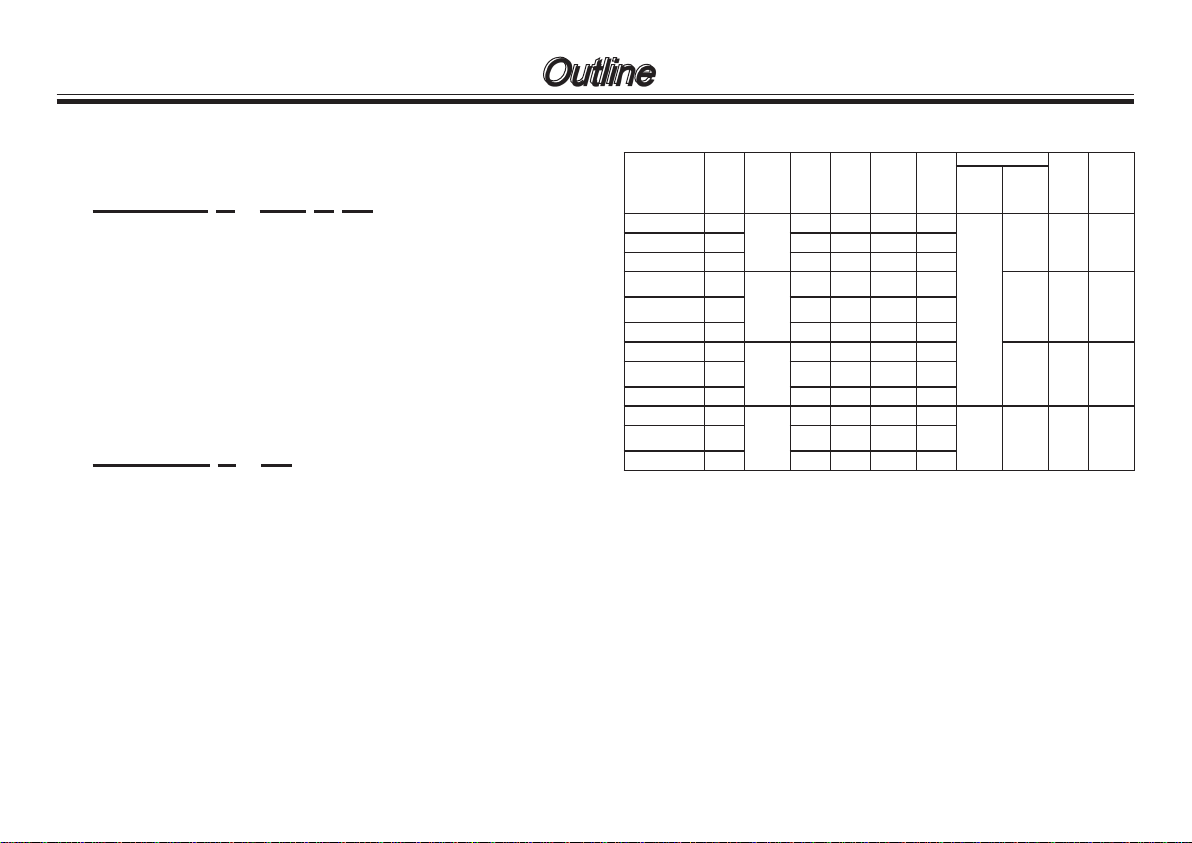

3. Specification & Identification code

Identification code

MD - 15F X - 220 N 01

a b c d e

a. Series model MD-15F/ -30F/ -55F/ -100F

b. Impeller type X, Y, Z

c. Power voltage 220: 220/240V (50Hz)

d. Motor type N: New type motor)

e. Special version No code: Standard

01-99: Special design

MD - 55F X - 01

a b c

a. Series model MD-55F/ -100F

b. Impeller type X, Y, Z

c. Special version No code: Standard

01-99: Special design

NOTE: Special design is different from standard in power cable

length, outlet direction, plug shape or terminal treatment.

Specification 50/60Hz

Max

Max

Impeller

Model

MD-15FX-220N X

MD-15FZ-220N Z -/10 -/3.1 -/2.5-6 -/1.9

MD-30FX-220N X

MD-30FY-220N Y 10/12 6/8

MD-30FZ-220N X -/11 -/7 -/5.5-7 -/1.9

MD-55FX X

MD-55FZ Z -/55 -/6.0 -/4.5-25 -/2.0

MD-100FX X

MD-100FZ Z -/115 -/8.5 -/6.5-55 -/1.9

type

Connec-

ow

tion

(L/min)

10/- 4.1/- 3-5/- 1.2/-

NPT 1/2

13/15 8/11

NPT 1/2

65/- 7.8/- 6.4-30/- 1.3/-

R1

125/- 10.5/- 7.5-65/- 1.2/-

R1

head

(m)

Norm

ow

(m-L/min)

5.5-8/

8.5-9.5

4.5-6.5/

6-8

3.8-30

/6.4-32

6-60/

8-70

Max SG

1.5/1.3

1.9/1.5

2.0/1.3

2.0/1.3

Power

(V)

220/240

(1ph)

220/240

(1ph)

220/380

(3ph)

400/440

(3ph)

Motor

Rated

output

(W)

10 1.8 0.06MD-15FY-220N Y 9/10 3/4 2-5/3-7 1.9/1.3

45 4.0 0.17

90 5.4 0.12MD-55FY Y 60/65 5.4/7.8

260/-

260/265

-/265

NOTE:

a. Performance data is based on pumping of clear water at

ambient temperature.

b. The maximum flow is obtained at zero discharge head, and

the maximum head is obtained at the maximum pressure.

c. The maximum viscosity is up to 30mPa•s (at SG 1.0).

d. Allowable liquid temperature is 0-80°C.

* Note that the liquid temperature is based on pumping clean

water and it changes with liquid property and operating conditions.

e. Non freezing

Mass

(kg)

8.5 0.17MD-100FY Y 115/135 8.5/11.5

Max

operating

pressure

(MPa)

- 4 -

Page 7

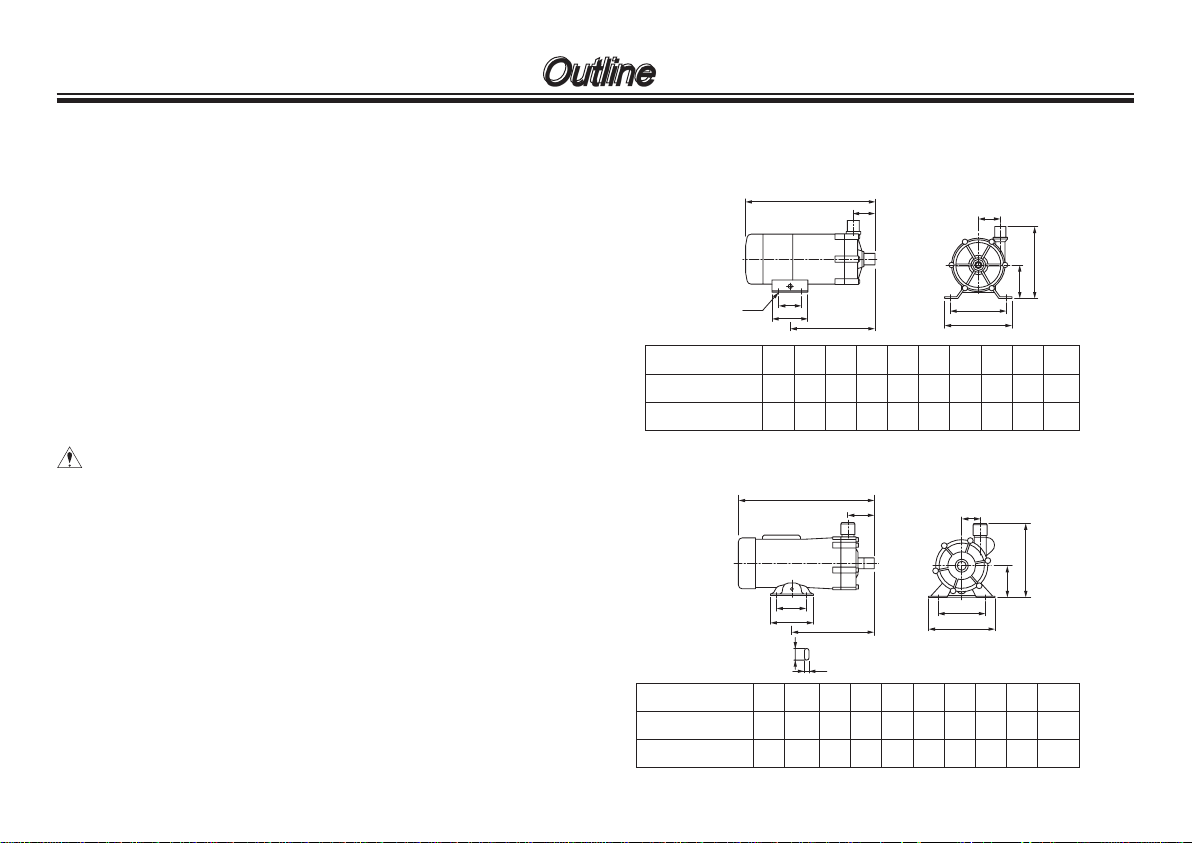

Outline

MD-15F-N

MD-30F-N

Model

W H Labc d e f G

95

120

120

130

186

231–405064681005560

34 28.5

38.5

123.5

15239

L

e

i

a

b

G

C

W

f

d

H

MD-55F

MD-100F

Model

W H Labc d e f G

120

156

155

174.3

270

320407064100

100

1106575

58.3 39.543198.5

19563

L

e

a

b

G

C

W

f

d

H

27

9

f. The maximum specific gravity is obtained at or near the

maximum flow. Note that the limitation varies with a duty

point, ambient or liquid viscosity.

g. Motor type

MD-15F/-30F/-55F: Single-phase capacitor-run induction

motor

MD-100F: Single-phase capacitor-run induction

motor or 3-phase induction motor

* The pump stops when the motor temperature becomes

extremely high due to ambient or liquid temperature rise or

overload operation. The pump resumes operation after temperature falls to a normal.

* For the IEC motor, consult your nearest distributor.

CAUTION

● If pump stops frequently, turn off power and check for

impeller damage or clogging. See “Troubleshooting” on

page 17.

● Do not dismantle the motor. Contact us for inspection.

4. Outer dimensions

● MD-15F-N/ -30F-N

● MD-55F/ -100F

- 5 -

Page 8

Outline

15

10

5

0 2 4 6 8 10 12

15

10

5

0 2 4 6 8 10 12

50Hz 60Hz

MD.30FX

MD.30FX

MD.30FY

MD.15FY

MD.15FZ

MD.30FZ

MD.30FY

MD.15FX

MD.15FY

15

10

5

0 25 50 75 100 125 150

15

10

5

0 25 50 75 100 125 150

50Hz

60Hz

MD.100FX

MD.100FY

MD.55FX

MD.55FY

MD.100FY

MD.100FZ

MD.55FY

MD.55FZ

5. Performance curves

● MD-15F-N/ -30F-N

Flow rate Flow rate

* Performance data is based on pumping of clear water at ambi-

ent temperature.

● MD-55F/ -100F

Head Head

* Performance data is based on pumping of clear water at ambi-

ent temperature.

Flow rate Flow rate

6. Overview & Label

Pump unit (Liquid feeding unit)

Not capable of self-priming. Always prime

the pump before operation.

Inlet

- 6 -

Outlet

Specification label

Use the pump according to the specifications on the label.

Motor (drive unit)

Do not wet the

pump and motor

units.

Base

Fix the pump securely.

Page 9

7. Part names & Structure

101

2 8 3 5

15

6

1

9

No. Part names Q'ty Materials Remarks

1 Front casing 1 CFRETFE

2 Bearing 2 SiC

3 Rear casing 1 CFRETFE

5 O ring 1 FKM

6 Impeller 1 CFRETFE

8 Spindle 1 SiC

9 Thrust ring 2 SiC

15 Machine screw 6 Stainless steel

101 Motor 1

Outline

- 7 -

Page 10

Installation

1. Before Installation

Read through this instruction manual before use. Carry

out installation work with a full understanding.

WARNING

● Risk of electrical shock. Dismantling/assembling the

pump unit without turning off the power may cause

an electrical shock. Before engaging in any maintenance or inspection work, be sure to turn off the

pump and related devices.

● Electrical work or wiring must be carried out by a

qualified person according to local laws or regulations.

CAUTION

● Do not drop the pump.

● A strong magnet is inside the pump. Do not bring a

watch or floppy disk which may be adversely affected by a magnetic force.

● Do not run pump dry. If the pump runs without a liquid, friction heat damages the pump.

● Dropping or subjecting the pump to

strong impact, failure may result.

Handle the pump with care.

● The pump is not capable of self-

priming. Always prime the pump

before operation.

● Allowable liquid temperature range

is 0-80°C. Non-freezing. Note

the range may change with liquid

property.

- 8 -

Page 11

Installation

● A strong magnet is inside the

pump. Do not use the pump with

any liquid which contains metals

such as iron and nickel.

CAUTION

Do not install or store the pump in

the following places where...

1. Ambient temperature exceeds

40°C or falls below 0°C.

2. In a dusty/humid place or cor-

rosive atmosphere.

3. Under direct sunlight or wind &

rain.

● Observe the maximum ambient

humidity of 90%. The motor is not

water-/dust-proof. Do not wet the

motor, or it may fail.

● Banned solutions

• Halogenated hydrocarbons such

as trichloroethylene and carbon

tetrachloride

• Ether and low-grade ester

• Slurry (Never use slurry, which

wears out the pump bearings.)

● Do not place dangerous or am-

mable goods near the pump for

your safety.

● An electrical failure of the pump

may adversely affect related

devices. Purchase and install an

earth leakage breaker separately.

● Non-condensing. Do not wet the

motor.

● Do not dismantle/modify the pump.

We are not responsible for any

accidents or damage due to modification.

- 9 -

Page 12

Installation

● Do not use any damaged pump.

Using a damaged pump may lead

to an electric leak or shock.

● Do not get the motor wet. The

pump is not dust-/water-proof or

rust-proof construction.

● Risk of fire or electrical shock. Do

not scratch, modify, twist or pull the

power cable. The cable can also

be damaged when it is heated or

loaded with a heavy thing. Stop

operation and contact us if the

power cable is damaged.

● Risk of burning. Do not touch the

motor. Motor surface temperature

rises high during operation.

● Noise level during operation is as below.

Model Noise level Model Noise level

MD-15FX

55dB

MD-15FZ MD-55FZ

MD-30FX

60dB

MD-30FZ MD-100FX

*Noise level is measured in A scale at a distance of 1m.

MD-55FX

55dBMD-15FY MD-55F Y

MD-100FX

75dBMD-30F Y MD-100FY

- 10 -

Page 13

Installation

30cm

or

more

2. Installation/ Piping/ Electrical wiring

Stop working upon sensing danger or abnormality in

work.

CAUTION

● Wear protective clothing.

Always wear protective clothing such as safety goggles and protective gloves during pipework or dismantlement.

● A qualied operator only

The pump must be handled or operated by a quali-

ed person with a full understanding of the pump.

Any person who is not familiar with this product

should not take part in operation or management.

2.1 Installation

1. Installation location

Select a convenient place for

maintenance and inspection.

Observe the allowable room temperature of 0-40°C and ambient

humidity of 90%RH.

2. Mounting position

This pump is not capable of selfpriming. Flooded suction application is ideal. The pump should be

installed 30cm lower than the suction liquid level, or bearing may be

worn soon by entrained air.

3. Outlet direction

Always direct the outlet upward or

entrained air can not be expelled.

Do not mount the pump vertically.

4. Pump fixation

Secure the pump by fixing the

base. Do not install the pump

vertically.

- 11 -

Direct the outlet upward

Page 14

Installation

2.2 Piping

1. In order to minimize the piping resistance, have piping shortest with the minimum bends. For the prevention of cavitation,

have the suction piping bore wide as much as possible.

2. Use a corrosion-/pressure-resistant vinyl tube, otherwise

the suction hose can be crushed by the suction force (especially for hot liquid). A braided tube or Teflon tube is recommended.

3. For the MD-55F & -100F, be sure

to remove a cushion from the

outlet before pipework. Be careful

not to damage the wet ends, especially SiC parts.

4. Select a suitable tube bore for

secure connection.

5. Install valves on both discharge

and suction lines.

• Suction-side valve:

For easy pump removal and

maintenance.

• Discharge-side valve:

For adjustment of the flow rate

and discharge head.

Dischargeside valve

Suction-side valve

- 12 -

Page 15

Installation

Brown

Blue

Thermal protector

Power source

Yellow/Green

Auxiliary coil

Capacitor

Main coil

Thermal protector

Thermal

protector

Power

source

Rotor

(220V)

Red

Gray

W2

U1

White

Blue

U2

V1

Black

Yellow

V2

W1

2.3 Electrical wiring

Electrical wiring must be done by qualified person who has a

full knowledge of safety. We are not responsible for the injury

or damage accident due to nonobservance of this warning.

Contact us or your nearest distributor for wiring as necessary.

■

Before wiring

1. Confirm that the power is disconnected before work.

2. Wiring work should be done in accordance with electric

work requirements. Use the recommended wiring accessories and follow electrical installation requirements.

3. Apply the specified power voltage. See the spec label.

4. The pump doesn't have the ON-OFF switch. The pump

starts as the power cable is plugged in.

5. Earth the pump by an earthing wire.

6. When a leakage breaker is used.

Always solve the root cause when a leakage breaker operates. Replace the fuse and resume operation. Be sure to

unplug the pump before investigation.

■

Connection diagram

● Single-phase capacitor-run induction motor

(MD-15/-30/-50/-100F types)

● 220/380V 3-phase motor

(MD-100F type)

- 13 -

Page 16

● 400/440V 3-phase motor

Thermal protector

Thermal

protector

Power

source

(380V)

Red

Gray

W2

U1

White

Blue

U2

V1

Black

Yellow

V2

W1

Thermal protector

Thermal

protector

Power

source

(MD-100F type)

Installation

■

Rated current & Starting current (50/60Hz)

Model

MD-15FX-220N 0.18 / - - - 0.3 / 0.29 - MD-15FY-220N 0.18 / 0.2 - - 0.4 / 0.4 - -

MD-15FZ-220N - / 0.2 - - 0.4 / 0.4 - MD-30FX-220N 0.41 / 0.49 - - 0.4 / 0.4 - MD-30FY-220N 0.37 / 0.37 - - 1.2 / 1.25 - MD-30FZ-220N - / 0.32 - - 1.2 / 1.25 - -

MD-55FX 1.0 / - - - 1.2 / 1.25 - MD-55FY 1.0 / 0.9 - - 1.1 / 1.0 - MD-55FZ - / 0.9 - - 1.1 / 1.0 - -

MD-100FX 1.93 / - 1.18-0.69 / - 0.62-0.6 / - 3.8- 4.3 / - 3.8-2.2 / - 1.9-2.2 / -

MD-100FY

MD-100FZ

220/240V

Single phase

1.93-1.93 /

1.85-1.83

- /

1.85-1.83

Rated current Starting current

220/380V

3 phases

1.18 -0.69 /

1.17-0.67

- / 1.17-0.67 - / 0.6-0.58 - / 3.6-4.0 - / 3.7-2.1 - / 1.85-2.1

400/440V

3 phases

0.62-0.6 /

0.6-0. 5 8

220/240V

Single phase

3.8-4.3 /

3.6-4.0

220/380V

3 phases

3.8-2.2 /

3.7-2.1

400/440V

3 phases

1.9-2.2 /

1.85-2.1

- 14 -

Page 17

1. Before operation

CAUTION

● Before operation, check that the pump is firmly

installed in piping via the inlet and outlet and the

pump is securely fixed.

● Do not run pump dry. If the pump runs without a liquid, the pump is damaged by friction heat.

● Do not run the pump with a discharge/suction valve

closed.

● Do not open the discharge valve or suction valve at

once, otherwise the magnetic coupling may disconnect (In this case turn off the power.).

Operation

■

Operation

After installation, piping and wiring work are completed, operate the pump in accordance with the following procedures.

No. Procedure Points to be checked

1 Check piping, wir-

2 Open or close a

3 Prime the pump

4 Supply power to the

5 Adjust discharge

ing and voltage.

valve.

chamber.

pump.

capacity & discharge head to

specified level.

• See "2.2 Piping" and "2.3

Electrical wiring" sections.

• Check the spec label to see if the

power supply voltage is correct.

• Fully open a suction-side valve.

• Fully close a discharge-side valve.

• Prime the pump with liquid (In suc-

tion lift application).

• Check the item 1, 2 and 3. Then

turn on power and start the pump.

Open a discharge-side valve gradually till the flow and head reach

a specified level. Do not open or

close the valve at once.

Note: Do not keep the discharge-

side valve closed more than 1

minute.

Note: Check that the pump trans-

fers a liquid without trouble.

If there is a problem, turn

off the power immediately

and solve the cause. See

"Troubleshooting" section.

- 15 -

Page 18

Operation

No. Procedure Points to be checked

6 Points to be

checked during

operation

■

Shutdown

No. Procedure Description

1 Close a discharge-

side valve.

2 Turn off power. Check if the motor stops rotating

■

Before a long period of storage

Remove the liquid from the pump before it is stored for a long

time. In addition, run the pump with clean water for 5 minutes

every 3 months to prevent the motor bearing from being stuck.

• Do not allow foreign matters to

enter the pump. Foreign matters

may cause impeller to be locked,

hindering liquid circulation. In this

case turn off power immediately

(Contact us).

• Turn off power when the leakage

breaker operates. Investigate the

root cause on the Trouble shooting

section of page 17.

Close the discharge-side valve

gradually. Do not use the solenoid

valve.

smoothly as turning off power. If

it is not smooth, check the motor.

Contact us for detail.

■

Drainage

WARNING

● Turn off power before work.

● Always wear protective clothing such as safety gog-

gles and protective gloves during pipework or dismantlement.

CAUTION

● Do not get wet with chemical when removing the

hose. Do not wet the motor or electric parts.

● Do not drain a harmful chemical liquid directly on

the ground or the floor. Always use a container.

■

Procedure

1. Turn off power. Make sure no one turns on the power while

working on the pump.

2. Close the discharge- and suction-side valves fully.

3. Place a container under the pump and loosen the hose

clamp. Pull out hoses from the inlet and outlet. Be careful

not to get wet with chemicals.

4. Unfix and take out the pump.

5. Drain residual chemicals through the inlet. Do not drain a

harmful chemical liquid directly on the ground or the floor.

Use a container.

- 16 -

Page 19

Maintenance

1. Trouble shooting

Handling of the pump, maintenance and inspection should

be carried out within this instruction manual. Do not handle the pump beyond the descriptions in this manual.

We are not responsible for any personal injury or property

damage due to nonobservance of this warning. Contact us

or your nearest distributor as necessary.

Phenomenon

Causes

Wrong wiring Inspect wiring. Rewire as

Motor failure

Air is trapped.

Air suction from the inlet

Dry running

Too high SG or viscosity

Impeller magnet hits the

rear casing

Impeller is damaged.

Foreign matters on the

impeller.

O ring is damaged

Pump head mounting

screws are loose.

The pump does not run.

Poor discharge head

Overcurrent

Noise and vibration problem

Leakage

necessary.

Contact us.

Eliminate air.

Check suction piping.

Prime the pump before

operation.

Replace with suitable pump.

Contact us.

Contact us.

Contact us.

Contact us

Tighten the mounting

screws.

Measure

2. Maintenance & Inspection

WARNING

● Always wear protective clothing such as safety goggles and protective gloves during pipework or dismantlement.

CAUTION

● Do not get wet with chemical when removing the

hose. Do not wet the motor or electric parts.

● Do not drain a harmful chemical liquid directly on

the ground or the floor. Always use a container.

■

Retightening

After a long period of operation or storage, the pump head

mounting screws may be loose. Tighten the mounting screws

as necessary, but then do not deform the plastic pump head.

■

Daily inspection

Always check for abnormality in vibration, noise, current value,

and discharge capacity. Stop operation on sensing any abnormality. And solve problems on the trouble shooting section.

- 17 -

Page 20

Maintenance

15

1

5

3

6

11

101

■

Wear parts

● Replace wear parts before the end of estimated life.

● The estimated life is calculated based on the continuous

operation with ambient temperature clean water and changes with operating conditions.

● We are note responsible for damage due to use of slurry.

● Replace O ring with new one every time dismantling the

pump despite of the estimated life.

No. Parts Estimated life

1 Front casing

3 Rear casing

5 O ring

6 Impeller

101 Motor

10,000hours

- 18 -

Page 21

Australia IWAKI Pumps Australia Pty. Ltd.

Austria IWAKI EUROPE GmbH

Belgium IWAKI Belgium n.v.

China IWAKI Pumps (Shanghai) Co., L td.

China

China

China

IWAKI Pumps (Guangdong) Co., Ltd.

GFTZ IWAKI Engineering & Trading (Guangzhou)

GFTZ IWAKI Engineering & T rading (Beijing )

Denmark IWAKI Nordic A/S

Finland IWAKI Suomi Oy

France IWAKI France S.A.

Germany IWAKI EUROPE GmbH

Holland

IWAKI Europe GmbH, Netherlands Branch

Hong Kong IWAKI Pumps Co., Ltd.

Indonesia

IWAKI Singapore (Indonesia Branch)

IWAKI CO.,LTD. 6-6 Kanda-Sudacho 2-chome Chiyoda-ku Tokyo 101-8558 Japan

TEL : (61)2 9899 2411 FAX : 2 9899 2421

TEL : (49)2154 92540 FAX : 2154 9254 48

TEL : (32)1367 0200 FAX : 1367 2030

TEL : (86)21 6272 7502 FAX : 21 6272 6929

TEL : (86)750 3866228 FAX : 750 3866278

TEL : (86)20 8435 0603 FAX : 20 8435 9181

TEL : (86)10 6442 771 3 FAX : 10 6442 7712

TEL : (45)48 24 2345 FAX : 48 24 2346

TEL : (358)9 27 45810 FAX : 9 274271 5

TEL : (33)1 69 63 33 70 FAX : 1 64 49 92 73

TEL : (49)2154 9254 0 FAX : 2154 9254 48

TEL : (31)547 293 160 FAX : 547 292 332

TEL : (852)2 607 1 168 FAX : 2 607 1000

TEL : (62)21 690 6606 FAX : 21 690 6612

TEL:(81)3 3254 2935 FAX:3 3252 8892(http://www.iwakipumps.jp)

Italy

Korea IWAKI Korea Co.,Ltd.

Malaysia IWAKIm Sdn. Bhd.

Norway IWAKI Norge AS

Singapore IWAKI Singapore Pte. Ltd.

Spain

Sweden IWAKI Sverige AB

Switzerland IP Service SA

Taiwan IWAKI Pumps Taiwan Co., Ltd.

Taiwan

Thailand IWAKI (Thailand) Co.,Ltd.

U.K. IWAKI Pumps (UK) LTD.

U.S.A. IWAKI AMERICA Inc.

Vietnam IWAKI pumps Vietnam Co.,Ltd.

IWAKI Europe GmbH, Italy Branch

TEL : (39)0444 3711 15 FAX : 0444 335350

TEL : (82)2 2630 4800 FAX : 2 2630 4801

TEL : (60)3 7803 8807 FAX : 3 7803 4800

TEL : (47)23 38 49 00 FAX : 23 38 49 01

TEL : (65)6316 2028 FAX : 6316 3221

IWAKI Europe GmbH, Spain Branch

TEL : (34)93 37 70 198 FAX : 93 47 40 991

TEL : (46)8 511 72900 FAX : 8 511 72922

TEL : (41)26 674 9300 FAX : 26 674 9302

TEL : (886)2 8227 6900

IWAKI Pumps Taiwan (Hsin-chu) Co., Ltd. TEL : (886)3 573 5797 FAX : (886)3 573 5798

TEL : (66)2 322 247 1 FAX : 2 322 2477

TEL : (44)1743 231363 FAX : 1 743 366507

TEL : (1)508 429 1440 FAX : 508 429 1386

TEL : (84)613 933456 FAX : 613 933399

( )Country codes

FAX : 2 8227 6818

T865 '13/10

Loading...

Loading...