Page 1

Read this manual before use of product

IWAKIController

ModelFDC-1

InstructionManual

Page 2

Thank you for purchasing Iwaki Controller Model FDC-1.

This controller is an exclusive use for Iwaki pneumatic bellows pump. This document provides

“Notice and warnings”, “Overview”, “Set up”, “Operation” and “Maintenance”, and explains

handling and how to operate the controller.

To make sure for your safety and correct use, please read this manual entirely before using the

controller, and comprehend thoroughly for each clause.

Contents

NOTICE AND WARNING FOR HUMAN SAFETY ························ 1

OVERVIEW ··················································································· 3

1. Unpacking and inspection ····················································· 4

2. Specification ·········································································· 4

3. External dimensions ······························································ 5

4. Names and explanations of component devices ··················· 6

5. Explanation of work ······························································· 7

6. Main functions ······································································· 8

SETUP ··························································································· 9

1. Installation ·········································································· 10

2. Connection ·········································································· 10

Operation ···················································································· 17

1. How to operate ···································································· 18

2. How to set controller ···························································· 18

3. Operation screen ································································· 21

4. Setting confirming and setting change procedure ··············· 22

5. Pump operation ··································································· 22

6. Alarm reset procedure ························································· 23

Maintenance ··············································································· 24

1. Troubleshooting ··································································· 25

Please keep this document at customer’s site in order to review

whenever it is necessary. For additional information, please inquire

our local representatives in your area, or call us directly.

Page 3

−1−

Important Instruction

Types of Symbols

Indicates that “Warning” or “Caution” must be exercised. Inside this

triangle, a concrete and practical image provided as a warning or cau-

tion message is depicted.

Indicates a prohibited action or procedure. Inside or near this circle, a

concrete and practical image of the activity to be avoided is depicted.

Indicates an important action or procedure which must be performed

or carried out without fail. Failure to follow the instructions herein

can lead to malfunction or damage to the pump.

Nonobservance or misapplication of the

contents of the “Caution” section could lead to

serious physical injury to the user or serious

damage to the product.

Warning

Nonobservance or misapplication of the

contents of the “Warning” section could lead to

a serious accident, including death or injury.

Caution

For the Safe and Correct Handling of the Pump

• Read the "Safety Instructions" sections carefully to prevent accidents involving your customers

or other personnel and to avoid damage or loss of other assets. Always follow the instructions

and advice found in these sections.

• Observe and abide by the instructions described in this manual. These instructions are very

important for protecting pump users from potentially dangerous conditions and situations related

with the use of the pump system.

• The symbols relate to the following meanings described below:

Page 4

Safety Section

WARNING

• For specified application only

Model FDC-1 is the exclusive use controller designed for IWAKI pneumatic drive bellows pump FA, FF, FH, FW and FS Series. Do not use this controller for other pumps

or application.

• Do not disassemble and remodel

Do not disassemble and remodel the controller.

CAUTION

• Qualified operator only

The controller must be operated or maintained by the person who has enough knowledge of the product and experience of handling of product.

• Place to be installed and stored

This controller is not explosion-proof design. Do not install or store the controller at

flammable atmosphere. Do not install or store the controller at corrosive

atmosphere.Otherwise, it may be failed or cause accident.

• Precautions for wiring proximity switches

Wrongly wired proximity switches (Right and Left) may cause the seizure of contacts.

Pay attention to the wiring.

• Specified voltage only

Do not use the controller with other voltage than specified one. Otherwise it may

causes fire or electrical shock.

- 2 -

Caution

No Remodeling

Prohibited

Prohibited

Prohibited

Prohibited

Page 5

−3−

OVERVIEW

1. Unpacking and inspection.................... 4

2. Specification......................................... 4

3. External dimensions............................. 5

4. Names and explanations

of component devices......... 6

5. Explanation of work.............................. 7

6. Main functions...................................... 8

Page 6

−4−

1) Please inspect immediately on the followings as soon as you receive the product, and inquire the shop you ordered if

any objectionable was found.

(1) Identify if the model number described on the front panel is the same as you ordered.

(2) Check if there is any damage(s) suffered from accident(s) during transportation.

(3) Confirm all of accessories were included. (if specified)

*Standard accessories: one each connector (CN1~CN6), total 6 connectors and a set of contact for the connectors.

*Optional accessories: Cable exclusively used for Electro- pneumatic regulator. (Only if ordered as an optional)

General

Spec.

Power supply DC24V + / - 10%

Power Consumption 24VA or less

Ambient temp. 0 ~ 50 °C

Ambient humidity 85% or less (No condensing)

Input

Spec.

Leak sensor input

Voltage between electrodes DC24V + / - 10%

Operating resistance Detect:0~15kohm (25k ohm or more: no detection)

Proximity switch input

Input signal Proximity Switch (negative logic operation)

ON voltage level 3V or less

OFF voltage level 5V or more

External start input

Input signal Potential free contact or NPN open collector output

ON voltage level 3V or less

OFF voltage level 18V or more

External alarm reset

input

Input signal Potential free contact or NPN open collector output

ON voltage level 3V or less

OFF voltage level 18V or more

Output

Spec.

Solenoid valve

operation output

Output NPN open collector output

Output load voltage DC 24V + / - 10%

Output load current 1A (MAX)

Leak alarm output

Time-up alarm output

Life alarm output

Fast alarm output

Output NPN open collector output

Output load voltage DC 24V + / - 10%

Output load current 1A (MAX)

Electro-pneumatic

Regulator control output

Output signal Analog signal

Voltage range 0 ~ 10V

Resolution 8bit D/A converter

1. Unpacking and inspection

2. Specification

Page 7

−5−

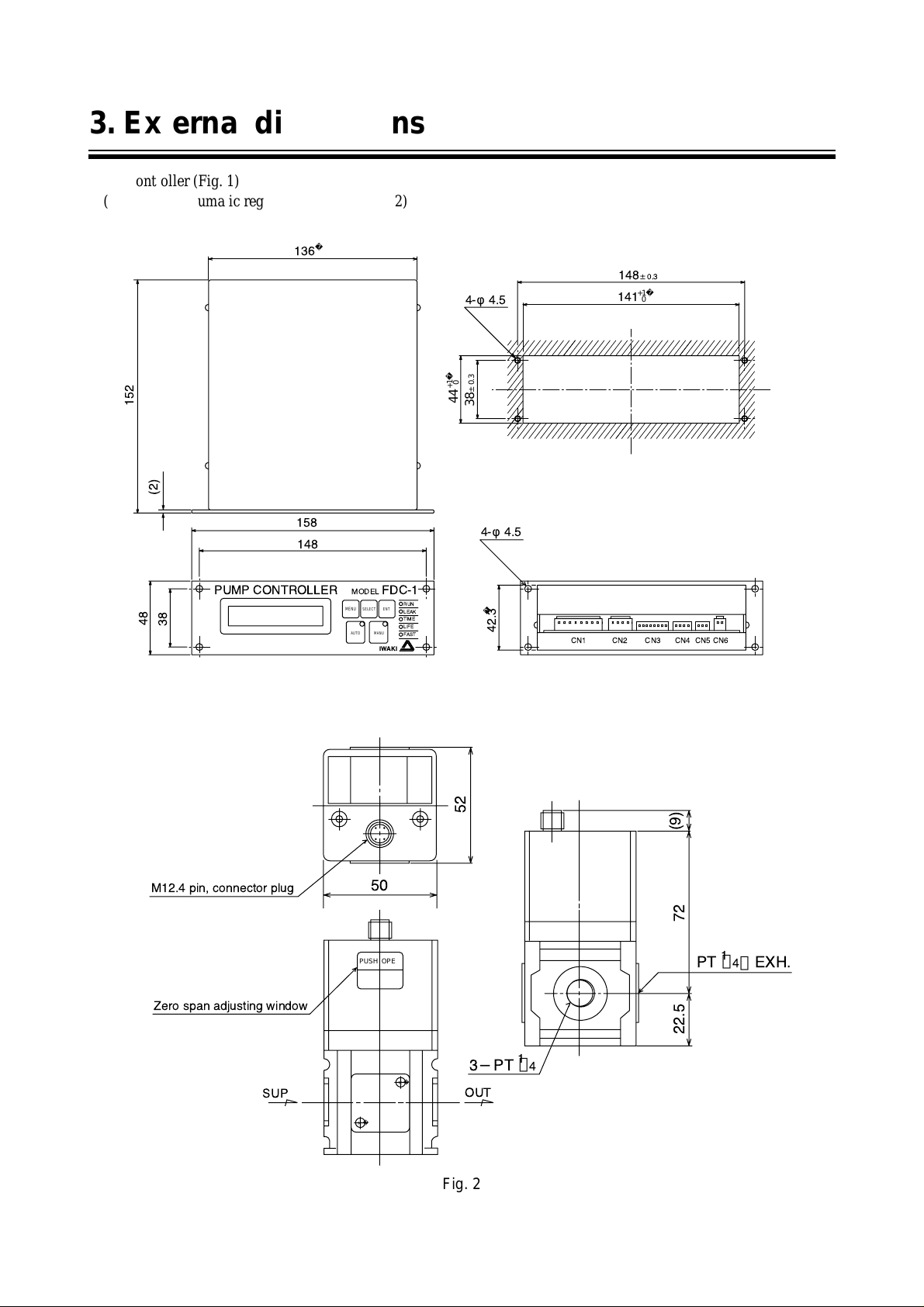

Fig. 1

PUMP CONTROLLER MODEL FDC-1

IWAKI

RUN

LEAK

TIME

LIFE

FAST

CN1 CN2 CN3 CN4 CN5 CN6

141

+1

0

148

±

0.3

4-φ4.5

4-φ4.5

44

+1

0

38±0.3

136

152

158

SELECT

MENU

ENT

AUTO MANU

148

38

48

42.3

(2)

Fig. 2

50

3−PT

1

/

4

PT

1

/

4

,

EXH.

52

(9)

72

22.5

×

×

OUT

SUP

PUSH OPEN

Zero span adjusting window

M12.4 pin, connector plug

(1) Controller (Fig. 1)

(2) Electro-pneumatic regulator (Option) (Fig. 2)

3. External dimensions

Page 8

−6−

Fig. 3

PUMP CONTROLLER MODEL FDC-1

IWAKI

;

;

;

;

;

;

;

;

;;;;

;

;

;;

;

;

;

;;

;

;

;

;

;

;

;

;

;;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;;;;

;

;

;

;

;

;

;

;;;

;

;

;

;

;

;;

;

;;

;;;

;

;

;;;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;;;

;

;

;

;;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;;;;;

;

;

;

;

;

;;;

;

;

;

;

;

;;

;;;

;

;

;

;

;;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;;;;

;

;

;

;

;

;

;

;;;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;;

;

;

;

;

;

;

;

;

;

;;;;

;

;

;;

;

;

;

;

;

;

;

;

;

;;

;

;

;

;

;

;

;;

;

;

;

;

;

;

;;

;

;

;

;;;;;

;

;

;

;

;

;

;

;;

;

;

;

;;;

;;

;

;;

;

;

;;

;

;

;

;;;

;;

;

;

;

;;

;;;

;

;

;

;;;;

;

;

;

;

;

;;;;

;

;

;

;

;;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;;

;

;;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;;

;

;

;

;

;

;;;

;

;;;

;

;

;

;;;

;

;

;

;

;

;

;

;

;;

;

;

;

;

;;;

;

;

;

;

;;;

;

;

;

;

;

;

;

;;;

;

;

;

;;;

;

;;;

;

;

;

;

;;;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;;

;

;

;

;

;

;

;;

;

;;;

;;;;

;

;

;

;

;

;

;;;

;

;

;

;;;

;;

;

;

;;;

;;;

;

;

;

;

;

;

;

;;

;

;

;

;

;

;

;

;

;

;

;;

;

;;

;;;

;

;

;;;

;

;

;

;

;

;

;

;

;

;;;

;

;

;

;;

;;;

;

;

;

;;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;;

;

;

;

;

;

;

;;

;

;

;

;

;

;

;

;

;;;

;

;

;;;;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;;

;

;;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;;

;

;

;

;;

;

;

;

;

;

;

;

;

;

;

;

;

;;;

;

;

;

;;;

;

;

;

;;;;

;

;

;

;

;

;

;

;

;

;

;

;

;

;;;

;

;

;

;

;

;

;

;;;;

;

;

;

;;

;;

;

;

;

;

;

;;

;

;;

;

;

;

;

;

;

;

;

;;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;;

;

;

;;

;

;

;

;

;

;

;

;

;

;;;

;

;

;

;

;

;

;

;

;;

;

;

;

;

;;;

;

;

;

;

;

;

;

;;;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;;;

;

;

;

;

;

;;

;;;

;

;

;

;;;

;

;;

;

;

;

;

;

;;;

;

;

;

;;;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;;;

;

;

;

;

;

;;

;;;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;;

;

;

;

;;;

;

;;

;

;

;

;

;;;;

;

;

;

;;;

;;

;

;;

;

;

;;;;

;

;

;

;

;

;

;;

;

;

;

;

;

;

;

;

;

;;

;

;

;

;

;

;

;

;

;

;

;

;

;;

;

;

;;

;

;;

;;;

;

;

;

;;;;

;

;

;

;

;

;

;;;;

;

;

;

;;

;;;

;

;

;

;;;;

;

;

;

;

;

;

;

;;;

;

;

;

;;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;;;;

;;

;

;

;

;

;

;

;

;

;

;;

;

;

;

;

;

;

;

;;

;;;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;;;

;

;

;

;

;

;

;

;;

;;

;

;

;

;

;

;

;

;;

;

;

;

;

;

;

;

;

;

;

;

;

;

;;;

;

;

;

;

;

;

;

;

;;

;

;

;

;;;

;

;

;

;

;

;

;;

;

;;

;

;

;

;;;

;

;

;

;

;;;

;

;

;

;;;;

;

;

;

;

;

;

;;;;

;

;

;

;

;

;

;

;

;

;

;

;

;

;;;;

;

;

;

;

;

;

;;

;

;

;;

;

;

;

;;

;;;

;

;

;;;;;

;

;

;

;

;

;

;

;

;

;

;

;

;;;

;

;

;;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;;

;

;

;;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;;

;

;;

;

;

;

;

;

;

;

;

;

;

;

;

;

;;

;

;

;

;

;;;

;

;

;

;

;

;

;

;

;;

;

;

;

;

;

;

;;

;

;

;

;

;

;

;;;

;

;

;

;

;

;

;

;;

;

;

;

;

;

;;;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;;

;

;

;

;;;

;

;

;

;;;

;;

;;;;;

;

;

;

;

;

;

;

;;;

;

;

;

;;

;;;

;

;

;

;;;;

;

;

;

;

;

;

;

;;;

;

;

;

;;;

;;

;

;

;

;

;

;;;

;;

;

;

;

;

;

;

;

;;;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;;

;

;

;

;;;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;;

;

;

;

;;

;

;

;

;

;

;

;;

;

;

;

;

;

;

;

;

;

;

;

;

;

;;;;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;;;

;;

;

;

;

;

;

;

;

;

;;

;

;

;

;

;

;

;

;

;

;

;;;;

;

;

;

;

;;

;;;

;

;

;

;;;;

;

;

;

;

;

;

;

;;;

;

;

;

;;;

;;

;

;

;

;

;

;;;

;

;

;

;

;;;

;;

;

;

;

;;;

;

;

;

;

;

;

;

;;;;

;

;

;

;;;

;

;

;

;;;

;

;

;

;

;

;

;

;

;;

;

;

;

;

;;

;

;

;

;;;

;

;

;;;

;

;

;

;

;

;

;;

;

;

;

;

;

;

;

;;

;

;

;

;

;

;

;

;;;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;;

;

;

;

;

;

;

;

;

;;;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;;

;;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;;

;

;;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;;

;

;

;

;

;

;

;

;

;

;

;

;

;

;;

;

;;

;;;

;

;

;

;

;

;

;

;;;;;

;

;

;;;

;;

;

;

;

;

;

;

;

;;

;

;

;

;

;

;

;;;;

;

;

;

;

;

;

;

;

;

;

;

;

;

;;;

;

;

;

;

;

;

;

;;;

;

;

;;

;

;

;

;

;

;

;;;

;

;

;

;

;

;;

;;;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;;;

;

;

;

;;

;

;

;

;

;

;

;;

;

;

;

;

;

;

;

;

;

;;;

;

;

;

;;;

;

;

;

;

;

;

;;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;;;;

;

;

;

;

;

;

;

;;;

;

;

;

;;;

;;

;

;

;

;

;

;;;

;

;

;

;

;

;

;

;;

;

;

;

;;;

;;

;

;

;

;

;

;;;;

;

;

;

;;;

;;

;

;

;

;

;

;

;

;

;

;;

;

;

;

;

;

;

;

;;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;;

;

;

;

;

;

;

;

;

;

;;

;

;

;

;

;

;

;

;;;

;

;

;;

;

;

;

;;;

;

;

;

;;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;;;;

;;

;

;

;

;

;

;

;

;

;

;;

;

;

;

;

;

;

;

;

;

;;;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;;;;

;

;

;

;;

;

;

;

;

;

;

;

;;

;

;

;

;

;

;

;

;

;

;;

;;;

;

;

;

;;;;

;

;

;

;

;

;

;;

;

;

;

;

;

;;;

;;

;

;

;

;

;

;;;

;

;

;

;

;

;

;

;

;

;

;

;

;;;

;

;

;

;;;

;

;;;;;

;

;

;

;

;

;

;

;

;

;

;

;;

;

;

;

;

;

;

;

;;;

;

;

;

;

;;

;

;;;

;

;

;

;;

;

;

;

;

;

;

;

;;;

;

;

;

;;

;;

;

;

;

;

;

;

;

;;;

;

;

;

;

;

;

;

;;;

;

;;;

;;

;

;

;

;

;

;

;

;

;

;

;

;

;

;;;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;;;

;

;

;

;

;;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;;;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;;;

;

;

;

;

;

;

;

;;

;

;

;

;;;

;;

;

;;;

;

;;;;;

;

;

;

;

;

;;

;

;;

;

;

;

;

;

;

;;;

;

;

;

;;;;

;

;

;

;

;

;

;

;;;

;

;

;

;

;

;

;;

;

;

;

;

;

;

;

;

;

;;

;;;

;

;

;

;;;;

;

;

;

;

;

;

;

;;;

;

;

;

;;;

;

;

;

;

;

;;

;

;;;

;

;

;

;

;

;

;

;

;

;

;

;

;;

;

;

;

;

;

;

;

;

;;;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;;

;

;

;

;

;

;

;;;

;

;

;

;

;;

;

;

;

;

;

;

;

;

;;;

;

;

;

;;;

;;

;

;

;

;;;

;;

;

;

;

;

;

;

;

;;

;

;

;

;;;

;

;

;

;

;

;;;

;;;;

;

;

;;;

;;

;

;;;;;

;

;

;

;

;;;

;

;

;

;

;

;;

;

;

;

;;;

;

;

;;;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;;

;;;

;

;

;

;;;;

;

;

;

;

;

;;

;;;

;

;

;

;;;

;

;

;

;

;

;

;;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;;;;;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;;;;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;;;;

;

;

;

;

;

;

;

;

;

;

;;;

;

;

;

;

;

;;

;

;

;

;

;

;;;

;

;

;

;

;

;

;

;;;

;

;

;

;

;

;

;

;;

;

;;

;

;

;

;

;

;

;

;

;

;

;

;

;;;

;

;

;;;

;

;

;

;;;

;

;

;

;;;

;

;

;

;

;

;

;

;

;

;

;

;;;

;

;

;

;;;;

;

;

;

;

;

;;

;;

;

;

;

;

;;;

;

;

;

;

;

;

;;;;;

;

;

;

;;

;;

;

;

;

;

;

;;

;

;

;

;

;

;

;

;

;;;

;

;

;

;;;

;;

;

;

;

;

;

;

;

;

;

;

;

;

;

;;;

;;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;;

;

;

;

;

;

;

;;;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;;;

;

;

;

;

;

;

;

;;;

;

;

;

;

;

;

;

;;

;

;

;

;;;

;

;

;

;

;

;

;

;;;

;

;

;

;

;

;

;

;;

;

;;

;;;

;

;

;

;;

;

;;

;

;

;

;

;

;;;;

;

;

;

;;;

;

;

;

;

;

;

;

;

;

;

;;

;

;

;

;

;

;;;;

;

;;;

;

;

;

;;;

;

;

;

;

;

;

;

;

;

;

;

;

;

;;;;;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;;

;

;

;

;

;

;

;

;;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;;

;

;

;

;

;

;

;

;

;

;

;;

;

;

;

;;;

;

;;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;;

;

;

;

;

;

;

;

;

;

;

;;;

;

;

;;

;

;

;

;

;

;

;

;

;

;;

;

;

;

;

;

;

;;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;;;

;

;

;

;;

;

;

;

;

;

;

;;

;

;

;

;

;

;

;

;;

;;;

;

;

;

;;;;

;

;

;

;

;

;

;

;

;;

;

;

;

;;;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;;;

;

;

;

;

;

;;;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;;

;

;

;

;

;

;

;

;;

;;

;

;

;;;

;

;

;

;

;

;

;

;;

;

;

;

;;

;

;

;

;

;;;

;

;

;

;;;

;

;

;

;

;

;

;

;

;

;

;;

;

;

;;;

;

;;

;

;

;

;

;

;

;;;;

;

;

;

;

;

;

;

;

;

;

;

;

;;;;;

;

;

;

;

;

;;;

;

;

;

;;

;

;;

;

;;;

;

;

;;;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;;

;

;

;;;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;;;

;

;

;

;

;

;

;

;

;

;

;;

;

;

;

;

;;;

;

;

;

;

;

;

;

;;;

;

;

;

;

;

;

;

;;

;

;

;

;;;

;;

;

;

;

;

;

;;;

;

;

;

;

;

;

;;;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;;

;;;

;

;

;;

;;;

;

;

;

;

;

;

;

;;;

;

;

;

;;;

;;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;;

;

;

;

;

;

;

;;

;

;

;

;

;

;

;

;

;;;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;;;;;

;

;;

;

;;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;;

;

;

;

;

;

;

;

;;

;

;

;

;

;

;

;

;

;

;

;

;;;

;;

;

;

;

;;;;;;

;

;

;

;

;

;

;;

;

;

;

;;;

;

;

;

;

;

;

;

;;;;

;

;

;

;

;;

;

;

;

;

;

;;

;

;

;

;;;

;

;;

;

;

;

;

;

;

;

;;;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;;;

;;

;

;

;

;;;

;

;

;

;

;

;

;

;;;

;

;

;

;

;

;;;

;;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;;;;

;

;;;

;

;

;

;;

;

;

;

;

;;;

;

;

;

;

;;

;

;

;

;

;

;

;

;;

;

;

;

;

;

;

;;;

;;

;

;

;

;

;

;

;;;

;

;

;

;;;

;

;

;

;

;

;;

;

;

;;

;

;

;;;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;;;

;

;

;

;

;

;

;;;

;

;

;

;;

;

;

;

;

;

;

;

;

;;;;

;

;

;

;;

;;

;

;;

;

;

;

;

;;;

;

;

;

;

;;;

;

;

;

;;;

;

;

;

;;

;

;

;

;

;

;

;

;

;;;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;;

;

;;;

;

;;

;

;

;

;;;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;;;

;

;;;;;

;

;

;

;;

;

;

;

;

;

;;;

;

;

;

;

;

;

;

;;;

;

;

;;

;

;

;

;

;

;

;

;

;

;

;

;

;;

;

;

;

;

;

;

;

;;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;;;;

;

;

;

;

;

;

;

;;;

;

;

;

;

;

;

;

;

;

;

;;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;;;

;;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;;

;

;

;;

;

;

;

;;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;;

;

;

;

;

;

;

;

;

;

;

;

;;;

;

;

;

;

;

;

;

;

;

;;;

;

;

;

;;;

;

;

;

;

;

;

;

;

;

RUN

LEAK

TIME

LIFE

FAST

CN1 CN2 CN3 CN4 CN5 CN6

SELECT

MENU

ENT

AUTO MANU

①

②

⑦

⑥

④③

⑤

⑨⑩⑧

⑪

①

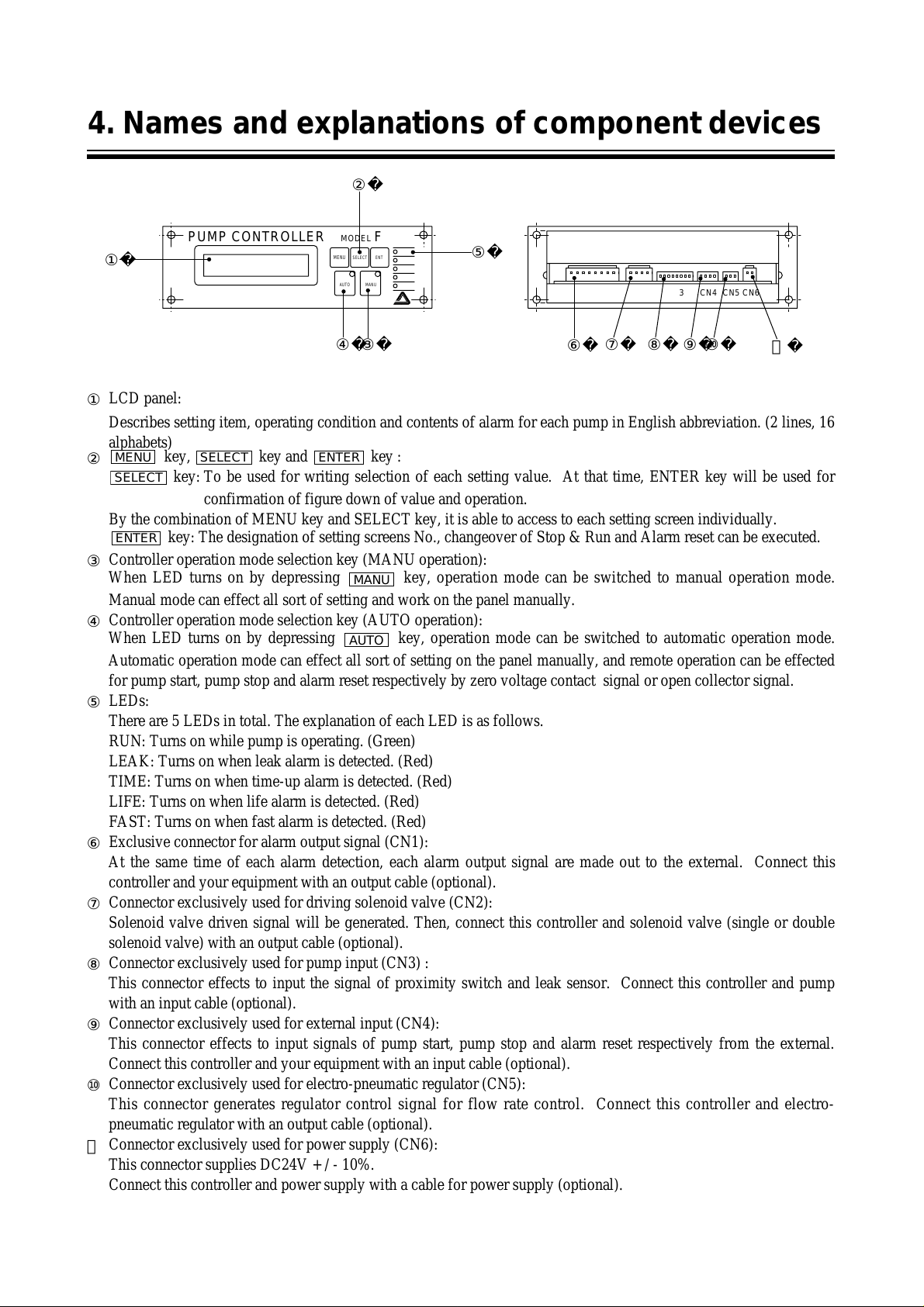

LCD panel:

Describes setting item, operating condition and contents of alarm for each pump in English abbreviation. (2 lines, 16

alphabets)

②

key, key and key :

key: To be used for writing selection of each setting value. At that time, ENTER key will be used for

confirmation of figure down of value and operation.

By the combination of MENU key and SELECT key, it is able to access to each setting screen individually.

key: The designation of setting screens No., changeover of Stop & Run and Alarm reset can be executed.

③

Controller operation mode selection key (MANU operation):

When LED turns on by depressing key, operation mode can be switched to manual operation mode.

Manual mode can effect all sort of setting and work on the panel manually.

④

Controller operation mode selection key (AUTO operation):

When LED turns on by depressing key, operation mode can be switched to automatic operation mode.

Automatic operation mode can effect all sort of setting on the panel manually, and remote operation can be effected

for pump start, pump stop and alarm reset respectively by zero voltage contact signal or open collector signal.

⑤

LEDs:

There are 5 LEDs in total. The explanation of each LED is as follows.

RUN: Turns on while pump is operating. (Green)

LEAK: Turns on when leak alarm is detected. (Red)

TIME: Turns on when time-up alarm is detected. (Red)

LIFE: Turns on when life alarm is detected. (Red)

FAST: Turns on when fast alarm is detected. (Red)

⑥

Exclusive connector for alarm output signal (CN1):

At the same time of each alarm detection, each alarm output signal are made out to the external. Connect this

controller and your equipment with an output cable (optional).

⑦

Connector exclusively used for driving solenoid valve (CN2):

Solenoid valve driven signal will be generated. Then, connect this controller and solenoid valve (single or double

solenoid valve) with an output cable (optional).

⑧

Connector exclusively used for pump input (CN3) :

This connector effects to input the signal of proximity switch and leak sensor. Connect this controller and pump

with an input cable (optional).

⑨

Connector exclusively used for external input (CN4):

This connector effects to input signals of pump start, pump stop and alarm reset respectively from the external.

Connect this controller and your equipment with an input cable (optional).

⑩

Connector exclusively used for electro-pneumatic regulator (CN5):

This connector generates regulator control signal for flow rate control. Connect this controller and electropneumatic regulator with an output cable (optional).

⑪

Connector exclusively used for power supply (CN6):

This connector supplies DC24V + / - 10%.

Connect this controller and power supply with a cable for power supply (optional).

AUTO

MANU

ENTER

SELECT

ENTER

SELECT

MENU

4. Names and explanations of component devices

Page 9

−7−

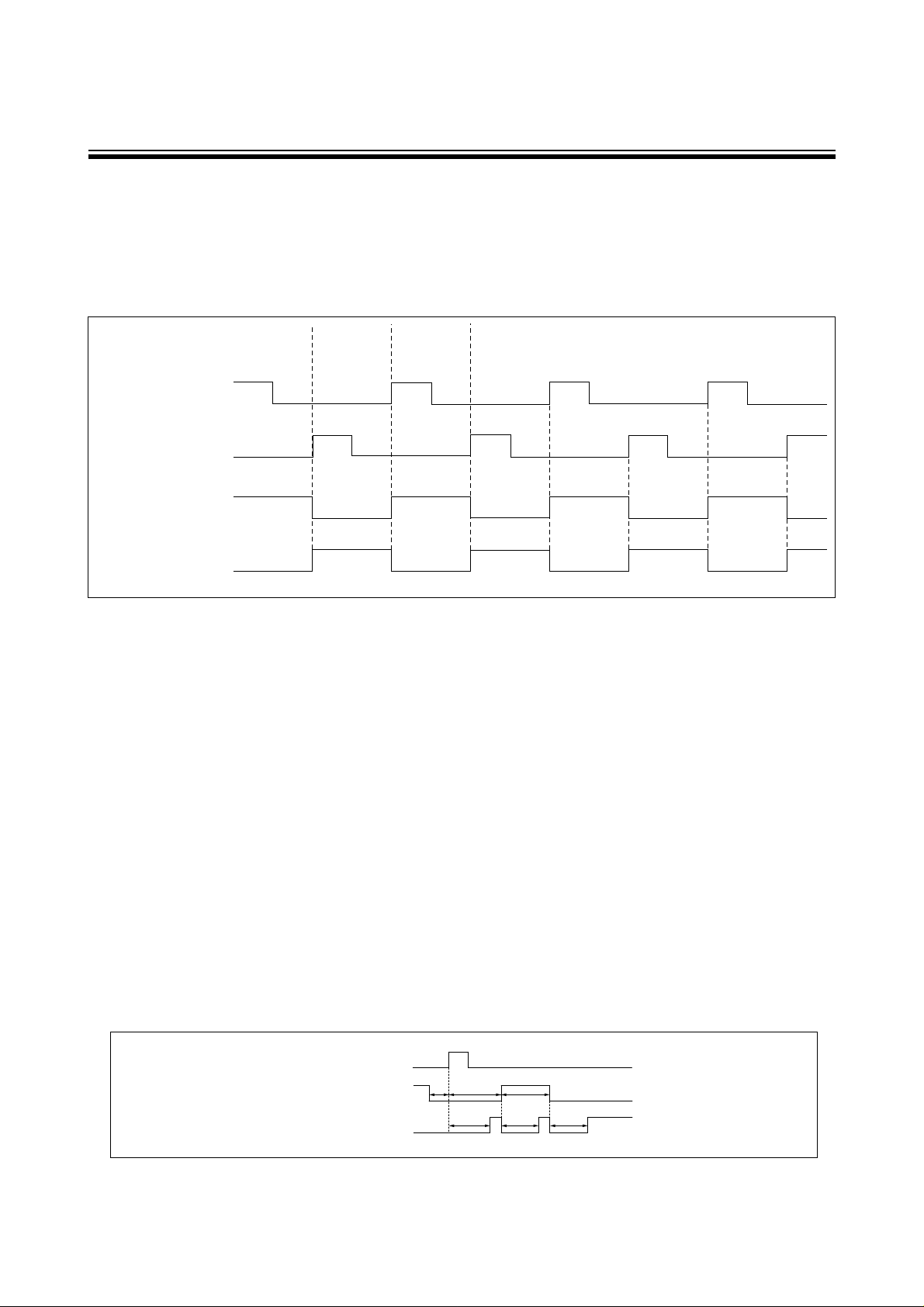

(1) Pump operation:

① When proximity switch R input is on, solenoid valve operation output keeps ON condition.

② Even if proximity switch R input is off, solenoid valve operation output keeps ON condition.

③ At the condition of proximity switch L input is on, solenoid valve operation output becomes off.

④ Then, until proximity switch R input comes on, solenoid valve operation output keeps off condition.

⑤ The above operations (①~④) shall be repeated in order.

②

①

Proximity switch L

Proximity switch R

Solenoid valve

operation output L

Solenoid valve

operation output R

(2) Flow rate control:

1 shot flow rate for F pump has been arranged; discharge capacity shall be “pump stroke rate times 1 shot flow rate”.

When the flow rate was set arbitrarily, stroke rate shall be converted automatically within the controller. Comparing

this converted stroke rate and operating cycle of proximity switch, which is effected to input into controller while

pump is operating, control voltage (DC0~10V) to Electro-pneumatic regulator (ER1) shall be adjusted. Varying

secondary air pressure of electro-pneumatic regulator (ER1), discharge capacity shall be controlled.

(3) Leak alarm:

This function effects to stop pump with alarm signal when pump brings about leakage.

It detects leakage and makes output signal by that leaked liquid conducts between electrodes (C1- C2 or D1-D2) of

which set up corresponding to each bellows (left and right).

Receiving this alarm, the controller effects warning, and put control signal off to Electro-pneumatic regulator

simultaneously. Then, it makes stop pump.

On this occasion, pneumatic pressure to drive inside of pump shall be released and becomes no-pressure only when

Electro-pneumatic regulator (optional) is being used.

(4) Time up alarm:

This function effect to alarm when pump stops or stroke speed becomes abnormally slow down for some reason.

Output for solenoid valve still keeps operating condition, though. Time set for criterion of warning shall be

executed on setting screen No.8.

It makes output as an alarm in case of whatever longer stroke time (t1, t2 and t3), than preset time t0. When all of

t1, t2 and t3 become shorter than t0, this alarm shall be reset automatically, and starts operation again.

5. Explanation of work

t1 t2

t3

t0 t0 t0

Proximity switch L

Proximity switch R

Time up alarm

Page 10

−8−

(5) Life alarm:

This function effects to alarm and notice when accumulated count number becomes beyond the fixed total count

number which was set manually.

Output for solenoid valve and Electro-pneumatic regulator (optional) still keep operating condition, though.

Total count number setting can be executed at setting screen No.9, and also, it is able to reset by manual reset or

reset signal from the externals. After input of reset, Life alarm detection is neglected for 2 minutes. After 2 minutes

past, it detects again if pump is operating condition.

(6) Fast alarm:

This function effects to alarm when pump stroke became abnormally faster than the preset stroke rate for some

reasons. Output for solenoid valve and Electro-pneumatic regulator (optional) still keep operating condition,

though.

Stroke rate setting for criterion of warning shall be executed on setting screen No.10.

If actual operating stroke becomes slower than the fixed stroke, then it resets automatically. Also it is able to reset

by reset signal from manual reset device. After reset signal input, it neglects detection for 2 minutes. After

2minuites, it may start again if it is in alarm condition.

① Possible to fix a specified flow rate control against the load fluctuation at discharge side.

② Possible to set flow rate freely.

③Possible to display stroke rate, flow rate and total count number while pump is operating.

④ In case of bellows broken, leak alarm will be output to the externals. Pump stops simultaneously with alarm output.

⑤ Possible to set necessary time set for 1 shot of pump operation. When the time for 1 shot of pump is beyond the

setting time, time up alarm will be output to the externals.

⑥ Possible to set total counts number of pump. When count number for 1 shot of pump is beyond the setting number,

life alarm will be output to the externals.

⑦ Possible to set maximum counts stroke rate. When count number for stroke is beyond the setting number while its

operation, first alarm will be outputting to the externals.

⑧ Possible to set alarm reset for start / stop of pump by signals from the externals.

⑨ Possible to select operation mode of controller from MANU and AUTO.

⑩ In case of proximity switch broken, possible to operate pump by timer mode until proximity switch is replaced.

6. Main functions

Page 11

−9−

SETUP

1. Installation.......................................... 10

2. Connection......................................... 10

Page 12

−10−

(1) Installation to instrument panels (see the illustration):

Fig. 4

• Cutout (W141 x H44mm) on instrument panel.

• Tap 4 screw holes (W148 x H38mm) for fitting.

• Insert the controller into the hole, and fix firmly with M4 screws.

• Install with enough room toward the depth.

PUMP CONTROLLER MODEL FDC-1

IWAKI

RUN

LEAK

TIME

LIFE

FAST

CN1 CN2 CN3 CN4 CN5 CN6

141

+1

0

148

±

0.3

4-φ4.5

4-φ4.5

44

+1

0

38±0.3

136

152

158

SELECT

MENU

ENT

AUTO MANU

148

38

48

42.3

(2)

1. Installation

WARNING

• Do not install or store at explosion atmosphere, such places causing particulate or corrosion

gases (such as chlorine gas).

It may cause fire or harm to human body.

2. Connection

Execute wiring and piping referring illustrations 5 & 6 of which shows electrical wiring of controller and piping

drawing of air and charts 2 ~ 7 as well as an instruction of pump.

Caution: In case of wrong wiring, it may cause breakdown or wrong operation of controller and

pump. Please pay special attention!

Page 13

−11−

CN 1

GND

GND

GND

CN 3

CN 2

◯

−

◯

+

LR

FA・FF・FH・FW・FS pump

C1

C2

D1

D2

SV

ER

CN 4

GND

CN 5

CN 6

GND

FR

Leak alarm

DC+24V output

Time up alarm

DC+24V output

Life alarm

DC+24V output

DC+24V output

Fast alarm

SV output R

DC+24V output

DC+24V output

SV output L

Leak detection input

DC+24V output

Proximity switch input R

DC+24V output

Proximity switch input L

Red (Brown)

White (Black)

Black (Blue)

Red (Brown)

White (Black)

Black (Blue)

Proximity switch

input R

Proximity switch

input L

Electrode

Electrode

Your device

External start input

External alarm reset input

Electro-pneumatic reguleter

DC+24V output

Electro-pneumatic reguleter

DC0-+10V output

Electro-pneumatic reguleter GND

DC+24V supply

GND supply

DC+24V

power source

SV: Electro-magnetic valve

(Single solenoid valve)

ER: Electro-pneumatic regulater

FR: Manual regulater

Note: L and R are in reverse for air piping of FS pump.

Fig. 5 Wiring for single solenoid valve.

Page 14

−12−

CN 1

CN 3

CN 2

◯

−

◯

+

LR

C1

C2

D1

D2

WSV

ER

CN 4

CN 5

CN 6

FR

Leak alarm

DC+24V output

Time up alarm

DC+24V output

Life alarm

DC+24V output

DC+24V output

Fast alarm

SV output R

DC+24V output

DC+24V output

SV output L

GND

GND

GND

Leak detection input

DC+24V output

Proximity switch input R

DC+24V output

Proximity switch input L

Red

(Brown)

White

(Black)

Black

(Blue)

Red

(Brown)

White

(Black)

Black

(Blue)

FA・FF・FH・FW・FS pump

Proximity switch

input R

Proximity switch

input L

Electrode

Electrode

GND

GND

External start input

External alarm reset input

Electro-pneumatic reguleter

DC+24V output

Electro-pneumatic reguleter

DC0-+10V output

Electro-pneumatic reguleter GND

DC+24V supply

GND supply

DC+24V

power source

WSV: Electro-magnetic valve

(Double solenoid valve)

ER: Electro-pneumatic regulater

FR: Manual regulater

Note: L and R are in reverse for air piping of FS pump.

Fig. 6 Wiring for double-solenoid valve.

Your device

Page 15

−13−

CN1 Chart 2

OUTPUT

Purpose of wiring Wiring objects

Pin No. Marker Tube No.

1P 1 Leak alarm

Connection between FDC-1 and

your equipment

2P 2 COM (DC+24V)

3P 3 Time up alarm

4P 4 COM (DC+24V)

5P 5 Life alarm

6P 6 COM (DC+24V)

7P 7 Fast alarm

8P 8 COM (DC+24V)

OUTPUT

Purpose of wiring

Pin No. Marker Tube No.

1P 9 Solenoid valve output R2P 10 Solenoid valve output R+

3P 11 Solenoid valve output L4P 12 Solenoid valve output L+

Connection between FDC-1 and

Solenoid valve (Note)

Wiring objects

Note: In case of connection with single solenoid, it is no matter to connect pin Nos. 3P and 4P

1P

2P

3P

4P

5P

6P

7P

8P

FDC-1 Controller inside

DC+24V

Fig. 7 Output scheme

Your equipment side

Inside circuit

CN2 Chart 3

Page 16

−14−

INPUT

Purpose of wiring

Pin No. Marker Tube No.

1P 21 External input (pump start, stop)

2P 22 GND

3P 23 External input (alarm reset)

4P 24 GND

Connection between FDC-1 and

your equipment

Wiring objects

(Brown) (Black) (Blue) : FH, FA type pump proximity switch

(Red) (White) (Black) : FF, FW, FS type pump proximity switch

Note: Proximity switch L & R signify Left and Right respectively from the view of pump inlet port.

For FH-40R, FA-40VE, L & R are Upper side and Lower side respectively.

INPUT

Purpose of wiring Wiring objects

Pin No. Marker Tube No.

1P 13 Leak sensor C1, D1

Connection between FDC-1 and

pump

2P

14 Leak sensor C2, D

2

3P 15 Proximity switch R (Brown) [Red]

4P 16 Proximity switch R (Black) [White]

5P 17 Proximity switch R (Blue) [Black]

6P 18 Proximity switch L (Brown) [Red]

7P

19 Proximity switch L (Black) [White]

8P 20 Proximity switch L (Blue) [Black]

CN3 Chart 4

CN4 Chart 5

1P

2P

3P

4P

DC+24V

NPN Open collector

Your equipment side

Start signal

Alarm reset signal

or

or

Potential free

contact

Inside of FDC-1

Same as above

Fig. 8 CN4 Input scheme

Inside

circuit

Page 17

−15−

INPUT

Purpose of wiring

Pin No. Marker Tube No.

1P 25 Power supply for Electro-pneumatic regulator (Red)

2P 26 Input signal for Electro-pneumatic regulator (White)

3P 27 GND for Electro-pneumatic regulator (Black)

Connection between FDC-1 and

Electro-pneumatic regulator

Wiring objects

INPUT

Purpose of wiring

Pin No. Marker Tube No.

1P 28 DC24V Power supply +

2P 29 GND

Connection between FDC-1 and

power supply (Note)

Wiring objects

Note: Please provides DC24V power supply with 1A or more.

CN5 Chart 6

Note: Wiring is not needed when electro-pneumatic regulator is not used.

CN6 Chart 7

Chart 8 Table of wiring devices

FDC-1 side

connector

Contact

Wire

Remarks

Cross section mm2AWG

CN1 VHR-8N BVH-21T-P1.1 0.5 20 8 wires, 5m or less

CN2 VHR-4N BVH-21T-P1.1 0.5 20 4 wires, 5m or less

CN3 XHP-8 BXH-001T-P0.6 0.3 22 8 wires, 5m or less

CN4 XHP-4 BXH-001T-P0.6 0.3 22 4 wires, 5m or less

CN5 XHP-3 BXH-001T-P0.6

0.3mm2, Outer dia. φ5.9 4 wires shield cord、5m or less

CN6 VHR-2N BVH-21T-P1.1 0.5 20 2 wires, 5m or less

Note 1: Use the connector and pin made by J.S.T. Mfg. Co., Ltd.

2: For the wiring of CN5, use Omron made XS2C-D422 as electro-pneumatic regulator side I/O connector. Refer

to Chart 9) for connection.

Chart 9 Wiring of electro-pneumatic regulator

FDC-1 side

connector

Electro-pneumatic regulator

side I/O connector

1P 1P

2P 4P

3P 3P

Note: Connect shield cord to 3P of FDC-1 side connector XHP-3.

Page 18

−16−

Caution

• Proximity switch cord of FF, FW and FS pumps consists of three wires of black, white and red. Wrong connection

of them will cause the failure of proximity switch.

Caution

1. Standard proximity switch can not be used to handle flammable liquid such as solvent or so. Ask IWAKI for

explosion-proof proximity switch.

2. Electrode can not be used to handle flammable liquid. If used, it may spark resulting in fire.

Caution

• Use power source of DC24V plus minus 10% range.

■Air piping

Figure 5 and 6 show electrical wiring and air piping schemes. Make the air piping according to following procedures

referring to the schemes.

(1) Precautions for air piping

a) Bad quality air will give bad influence to the performance and life of the equipments.

Supply clean air which contains no solid matters, water and oil.

b) Flush pipes before they are connected. When the seal tape is used for piping, pay attention so that the tape can be

get into the pipe.

c) Install a regulator before the electro-pneumatic regulator (option) and adjust supplied air pressure to get the stable

performance.

d) If the electro-pneumatic regulator is not used, connect pipe from manual regulator

(FR) on Fig. 5 and 6 to the solenoid valve.

Note: The secondary side set pressure of manual regulator must not exceed the max. supply air pressure of the pump.

Refer to the instruction manual of the used pump.

(Pay attention to the pumped liquid temperature range.)

(2) Piping of electro-pneumatic regulator

Install the electro-pneumatic regulator between the manual regulator and the solenoid valve. Refer to the

instruction manual of the electro-pneumatic regulator for details.

The first side set pressure of electro-pneumatic regulator : Between the max. supply air pressure of pump and the

max. supply air pressure of pump + 0.05 MPa (Pay attention to the pumped liquid temperature range.)

Page 19

−17−

OPERATION

1. How to operate................................... 18

2. How to set controller.......................... 18

3. Operation screen ............................... 21

4. Setting confirmation and

setting change procedure ........... 22

5. Pump operation.................................. 22

6. Alarm reset procedure ....................... 23

Page 20

−18−

1. How to operate

① Confirm if pump, solenoid valve, alarm devices and electro-pneumatic regulator are connected correctly each other,

and if it is connected DC24V as well.

(Adjust voltage to DC24V with the help of transformer if it is an abnormal voltage.)

② Supply air to preliminary inlet of electro-pneumatic regulator with manual regulator.

2-1 Flow of setting

Flow of setting is as follow.

Setting Pump Sensor

Power on

No. 1

No. 2

No. 3

No. 4

No. 5

No. 6

No. 7

No. 8

No. 9

No. 10

No. 11

Selecting Timer

NO

Selecting Sensor

YES

No. 3

No. 8

No. 9

No. 10

No. 11

No. 2

NO

No. 12

No. 3

No. 9

No. 11

No. 3

No. 9

No. 11

No. 12

YES

Setting Electro-pneumatic

regulator presence

Setting 1 shot of pump

discharge

Setting necessary pump

discharge

Setting maximum air supply

pressure for Electro-pneumatic

regulator

Completion of setting

(Control of constant discharge)

Setting key protect for setting

operation

Setting standard No. of stroke

of detection

Setting standard No. of count

of detection for Life alarm

Setting standard time of

detection for Time up alarm

Setting air supply pressure

when pump starts

Setting minimum air supply

pressure for Electro-pneumatic

regulator

Setting 1 shot of pump

discharge

Setting standard time of

detection for Time up alarm

Setting standard count number

of detection for Life alarm

Setting standard stroke rate of

detection for First alarm

Setting key protect for setting

operation

Completion of setting

(Normal operation)

Setting Electro-pneumatic

regulator presence

No. 5

No. 6

No. 7

Setting maximum air supply

pressure for Electro-pneumatic

regulator

Setting air supply pressure

when pump starts

Setting minimum air supply

pressure for Electro-pneumatic

regulator

Setting Pump stroke rate

Setting 1 shot of pump

discharge

Setting standard count number

of detection for Life alarm

Setting key protect for setting

operation

Completion of setting

(Timer mode)

Setting Pump stroke rate

Setting 1 shot of pump

discharge

Setting standard count number

of detection for Life alarm

Setting key protect for setting

operation

Completion of setting

(Timer mode)

2. How to set controller

Page 21

−19−

2-2 Setting

• Initial screen (At power on)

PUMPCONTROLLER

IWAKIPUMPS

After indicated on screen, it scrolls automatically to screen No.1.

• Setting screen No.1 (Setting the pump drive system)

1.DRIVEMODE

SENSOR?TIMER?

• The setting object mode is flickering.

• Select the setting object with key, and enter by key.

A specified flow rate control,Normal operation →SENSOR

→

Setting screen No.2

Timer mode →TIMER →Setting screen No.12

ENTER

SELECT

• Setting screen No.2 (Setting the presence of electro-pneumatic regulator)

2.E−PRegSET

Yes? No?

• The setting object mode is flickering.

• Select the presence (Y / N) of Electro-pneumatic regulator.

• Select the setting object with key, and enter by key.

A specified flow rate control →Yes →Setting screen No.3

Normal operation

→

No →Setting screen No.8

ENTER

SELECT

• Setting screen No.3 (Setting 1 shot discharge capacity of pump)

3.1Shotdcapa.

dc=****.*cc/shot

• Setting 1 shot discharge capacity of pump to ****.* area.

• Set 1 shot discharge capacity of each pump as shown in Chart 8.

•Every time depressing key, each input value is

sequentially indicated as 1 →2 →3

→

........

→9 →0 →

1

......

.

Then the required value can be settled by depressing ENTER key.

After the settlement of the first figure, by depressing ENTER key to

decrease the figure, and then input each required value as the same

step as above.

SELECT

Pump type Logical value of 1 shot discharge capacity [cc / shot]

FF-10H 93

FF-20H 185

FF-40H 500

FH-10R 85

FH-20R 190

FH-40R 500

FF-10 93

FF-20 204

FA-40VE 500

FW-20 200

FW-40 500

FW-80 1000

FS-15 63

FS-30 138

FS-60 284

Chart 10

Page 22

−20−

• Setting screen No.5 (Setting the maximum air pressure being supplied by Electro-pneumatic regulator)

5.E−PRegPres.

MAX.=0.**MPa

• Setting the maximum air pressure being supplied by Electropneumatic regulator in 0.** area.

• Input of value shall be processed as same as Setting screen No.3.

• Electro-pneumatic regulator supplies air as the setting value is to be

the upper limit.

• For the protection of pump, do not set the value exceeding the

maximum air pressure supply of pump.

• Setting screen No.6 (Setting the minimum air pressure being supplied by Electro-pneumatic regulator)

6.E−PRegPres.

MIN.=0.**MPa

• Setting the minimum air pressure being supplied by Electropneumatic regulator in 0.** area.

• Input of value shall be processed as same as Setting screen No.3.

• Electro-pneumatic regulator supplies air as the setting value must be

the lowest limit.

• Setting screen No.7 (Setting the air pressure being supplied at the start of pump operation)

7.STARTPres.

sp=0.**MPa

• Setting the required air pressure at the start of pump operation.

• Input of value shall be processed as same as Setting screen No.3.

• For the protection of pump, do not set the value exceeding the

maximum air pressure supply of pump.

• Setting screen No.8 (Setting the standard time of Time Up alarm detection)

8.TIMEUPALARM

T=**.*Sec

• Setting the standard time of Time Up alarm detection in **.* area.

• Input of value shall be processed as same as Setting screen No.3.

• In case pump operates slower than the setting value, then the alarm

will be output.

• Setting screen No.9 (Setting the standard count number of Life alarm detection)

9.LIFEALARM

L=****×100000count

• Setting the standard count number of Life alarm detection in ****

area.

• Input of value shall be processed as same as Setting screen No.3.

• In case pump operates exceeding the setting value, then the alarm

will be output.

• Setting screen No.10 (Setting the standard stroke rate of Fast alarm detection)

10.FASTALARM

F=***.*spm

• Setting the standard count number of Fast alarm detection in ***.*

area.

• Input of value shall be processed as same as Setting screen No.3.

• In case pump operates faster than the setting value, then the alarm

will be output.

• Setting screen No.4 (Setting the required flow rate of pump)

4.FLOWRATESET

fr

=***.*L/min

• Setting the required flow rate of pump in ****.* area.

• Input of value shall be processed as same as Setting screen No.3.

• For the protection of pump, do not set the value exceeding the

maximum discharge capacity.

Page 23

−21−

• Setting screen No.11 (Setting the key protect of setting operation)

11.KEYPROTECT

Yes? No?

• Setting the key protect of setting operation.

• This function is to prevent the setting change by wrong operation

once the setting has been executed.

• The selection procedure shall be the same as Setting screen No.2.

• When it is necessary to change the setting, refer “4-2 Setting

change”.

• Setting screen No.12 (Setting the stroke rate at Timer mode)

12.STROKERATE

SR=***.*spm

• Setting the pump stroke rate at Timer mode.

• This function is to operate ON/OFF of the solenoid valve

compulsory, so as to become the settled stroke number.

• Pump may operate intermittently depending on stroke rate to be set.

• Setting screen No.13 (Reset of the accumulation count of pump)

13.COUNTRESET

Yes? No?

• This function is used whenever it is required to reset the

accumulation count, in case of changing pump, etc.

• The selection procedure shall be the same as Setting screen No.2.

• Unless the accumulation count is not to be reset at changing pump,

etc., the Life alarm may alert.

Stroke rate, flow rate and accumulation count can be displayed on LCD screen of controller.

PUMPSTROKE

***.*spm

FLOWRATE

**.*L/min

TOTALCOUNTS

*********counts

• Display of stroke rate

• Display of accumulation count

SELECT

• Display of flow rate

Press key

SELECT

Press key

SELECT

Press key

3. Operation screen

Page 24

−22−

4. Setting confirmation and setting change procedure

4-1 Setting confirmation:

Confirm if the screen is the operation screen, then press key.

LCD screen of the controller is displayed as shown left. Then, input

[01] in “No. **” area.

Input of value shall be processed as same as Setting screen No.3.

Every time pressing key, display comes out in the order of

setting. If it is necessary to confirm each screen individually, input the

required setting screen No. into the “No.**” area.

ENTER

MENU

CHANGENo.

No.**

4-2 Setting change:

In case of setting the key protect for setting operation, it is able to

cancel the key protect for setting operation using key +

key in the operation screen. After the cancellation, press

key. Then LCD screen of the controller displays as

mentioned left.

Input the required Setting screen No. into “No.**”.

Input of value shall be processed as same as setting screen No.3.

If “01” is input, all of setting are reset again.

MENU

ENTER

SELECT

CHANGENo.

No.**

After the completion of cancel procedure, LCD screen of the

controller displays as mentioned left and the operation screen is

automatically displayed.

Note : After the change is done, set the key protect according to

setting screen No.11.

CHANGEOK!!

5-1 Manual operation (if necessary) :

Confirm if the screen shows the operation mode.

Confirm that LED of key lights on, and then press

key.

LCD screen of the controller displays as mentioned left.

Select START or STOP by key, and then enter by

key.

Select START?

...................

pump start

Select STOP?

......................

pump stop

ENTER

SELECT

ENTER

MANU

14.DRIVEMODE

START? STOP?

5-2 Automatic operation (If it is necessary to operate from your equipment using an

external signal)

Non-voltage contact signal or open collector signal from the externals can operate this controller, as well.

Automatic operation for pump start, pump stop and alarm reset are available by an external signal.

Confirm if the screen displays the operation mode.

Automatic operation is practicable if LED of key lights on when pressed key.

AUTO

AUTO

5. Pump operation

Page 25

−23−

When each alarm (leak alarm, time up alarm, life alarm and fast alarm) outputs, LED corresponding to each alarm lights

on and displayed on LCD screen of the controller as mentioned below.

LEAK ALARM TIME UP ALARM LIFE ALARM FAST ALARM

Leak alarm

Time up alarm

Life alarm Fast alarm

RESET

RESET

RESET RESET

6. Alarm reset procedure

In case of LED of key lights on, by depressing key, alarm shall be reset.

In case of LED of key lights on, non-voltage contact signal or open collector signal from the externals shall

reset alarm.

Other work shall not be accepted until all of alarms are released.

AUTO

ENTER

MANU

5-3 To change operation mode

Press key and key simultaneously to release the key protection. After the protection is released,

press either key or key to change to operation mode. After the change, set the key protection

according to item 4-2 “setting change” on page 22.

AUTO

MANU

ENTER

SELECT

WARNING

• When the pump is stopped and air piping is removed or bolts on pump are loosened, it may

happen the inside liquid spauts due to the residual pressure. Pay attention to liquid spauting.

Page 26

−24−

MAINTENANCE

1. Troubleshooting ................................. 25

Page 27

−25−

1. Troubleshooting

Symptom Causes Check point & countermeasure

Pump does not start Defective electrical

wiring line

Confirm wiring between FDC-1 and solenoid valve for pump.

Confirm wiring between FDC-1 and proximity switch.

NO and NC proximity sensor of pump supply are being input to FDC-1

as right and left reversed.

Defective pump proximity sensor.

After power on to FDC-1, confirm output voltage of proximity sensor

without supplying air to pump.

FF pump: voltage between white and black is approx. 24V.

FH, FA pump: voltage between black and blue is approx. 24V.

FS pump: voltage between white and black is approx. 24V.

FW pump: voltage between white and black is approx. 24V.

If the above voltages close to 0V, it seems defective.

Electrode (leak sensor) is conducted.