Page 1

IWAKI

Electromagnetic Metering Pump

ES-B/C Type (Asia version)

Instruction Manual

Read this manual before use of product

Page 2

Thank you for selecting the IWAKI's electromagnetic metering pump ES series. This instruction manual deals with "Safety Instructions", "Outline", "Installation", "Operation" and

"Maintenance" sections.

Please read through this manual carefully to ensure the optimum performance, safety and

service of your pump.

Contents

Important instructions ····························································· 1

Safety instructions ·································································· 2

Outline 1. Safety and Caution Notes ················································ 5

2. Principle of Operation ····················································· 5

3. Specifications ·································································· 6

Installation 1. Unpacking ········································································ 8

2. Location ··········································································· 8

3. Supply Tubing ·································································· 9

4. Discharge Tubing ····························································· 9

5. Electrical ·········································································· 9

Operation 1. Priming ·········································································· 11

2. Adjustment ····································································· 11

3. Calibration ····································································· 12

Maintenance 1. Diaphragm Replacement ··············································· 14

2. Valve Replacement ························································ 14

3. Tubing ············································································ 14

4. Troubleshooting ····························································· 15

5. Model code ···································································· 16

6. Dimensions ···································································· 17

7. Exploded view ································································ 19

8. Parts list ········································································· 20

Contact us or your nearest dealer if you have any questions.

Page 3

Important instructions

For the Safe and

Correct Handling of the pump

●

"Safety Instr uct ion" section deals with important details about handling of the product. Before

the use of the pump, read this section carefully for the prevention of personnel injury or loss.

●

Observe the instr uct ions accompanied with "WARN I NG" or "CAUTION" in this manual. These

instructions are very important for protecting pump users from dangerous situations.

●

The symbols on this instruction manual have the following meanings:

Nonobservance or misapplication of the contents of

WARNING

“Warning” section could lead to a serious accident

which may result in death.

Nonobservance or misapplication of the contents of

CAUTION

“Caution” section could lead to a personal injury or

damage to the product.

Types of Symbols

Indicates that “War n ing” or “Caution” must be exercised. Inside this tr iangle, a concrete and practical image provided as a warn ing or caution message is depicted.

Indicates a prohibited action or procedure. Inside or near this circle, a concrete and

practical image of the activity to be avoided is depicted.

Indicates an imp or t a nt ac t ion or proce du re which must b e p er for med or ca r ried out

without fail. Failure to follow the instr uctions herein can lead to malfu nction or

damage to the pump.

- 1 -

Page 4

Safety instructions

Electrical Shock

Prohibited

No Remodeling

Wear protective

gear

Prohibited

WARNING

●

Turn off power

Working on the pump while the power is ON, you may be shocked. Be sure

to turn off the pump and related devices before any work.

●

Terminate operation

Finding any abnormal condition, stop the operation immediately and

inspect/solve problems.

●

For specified application only

The use of the pump in any application other than those clearly specified

may result in injury or damage. Use the pump in a specified condition.

●

No modification

Do not modify the pump. We are not responsible for any accidents or damage due to modification.

●

Wear protective clothing

Always wear protective clothing such as safety goggles, protective gloves

when arranging piping or dismantling the pump.

●

Do not place the pump close to water

The pump is not water-proof construction. The use of the pump in a humid

place or a place where the pump can bet wet, electrical shock or short-circuit may result.

CAUTION

●

Restriction on pump operator

The pump should be handled by a qualified person with a full understanding of the pump.

●

Specified power only

Do not apply any power other than the specified one on the nameplate.

Otherwise damage or fire may result.

●

Do not run pump dry

Prohibited

Prohibited

Do not run pump dry. Parts friction heat is generated and damages the

pump if the pump runs without liquid.

●

Do not wet the pump

If a liquid spills over electric parts or wires, a fire or electrical shock may be

caused. Install the pump in a place free from liquid spillage.

- 2 -

Prohibited

Do not wet

or dampen

Page 5

Safety instructions

Caution

Prohibited

Electrical Shock

Electrical Shock

Prohibited

Caution

CAUTION

●

Ventilate

Poisoning may result when handling toxic or odorous liquid. Ventilate the

operating site sufficiently.

●

Countermeasure against efflux

Take a protective measure against the accidental efflux caused by the

pump or piping breakage.

●

Damaged pumps

Do not use any damaged pump. Using a damaged pump could lead to an

electric leak or shock.

●

Do not damage power cable

Do not scratch, damage, modify, or pull the power cable. Heating the cable

or placing a heavy thing on it may damage the cable and may result in a

fire or electrical shock.

●

Install an earth leakage breaker

Risk of electrical shock. Do not run the product without an optional leakage

breaker. Secure a leakage breaker to reduce the risk of electrical shock.

Purchase separately.

●

Damaged power cable

Caution

Do not use any damaged power cable for the prevention of a fire or electrical shock. Handle the power cable with care.

●

Wear parts replacement

Replace wear parts in accordance with instructions. Do not dismantle the

pump beyond the extension described on this manual.

●

Limited operating site and storage

Do not install or store the pump in the following places...

1. Ambient temperature is beyond 0-40 dig.C.

2. Under a flammable atmosphere.

●

Pump disposal

Any used or damaged pump must be disposed of in accordance with local

laws and regulations. (Consult a licensed industrial waste products disposing company.)

- 3 -

Page 6

Outline

1.Safety and Caution Notes

2.Principle of Operation

3.Specifications

- 4 -

....................................

...............

......................

5

5

6

Page 7

Outline

1. Safety and Caution Notes

Avoid areas where ambient temperature exceeds 40 degrees Celsius or falls below 0 degrees Celsius, or

where the pump or tubing would be exposed to direct sunlight.

Disconnect the pump from electrical power source before performing any maintenance.

When working on or around a metering pump, always wear proper protective clothing and equipment as rec-

ommended by the supplier of the liquid being pumped.

Depressurize the discharge tubing before disconnecting the tubing or performing any maintenance on the

pump.

2. Principle of Operation

The ES series electromagnetic metering pump consists of a pump unit, a driving unit, and a control unit.

The drive unit is an electromagnetic solenoid. When the solenoid coil is energized by the control unit the

armature shaft moves forward due to the magnetic force of the solenoid. The shaft is attached to a PTFE

faced diaphragm which is part of the pump unit. The diaphragm is forced into the pump head cavity decreas-

ing volume and increasing pressure which forces liquid in the pump head out through the discharge check

valves. When the solenoid coil is de-energized, a spring returns the armature to its starting position. This

action pulls the diaphragm out of the head cavity increasing volume and decreasing pressure. Atmospheric

pressure then pushes liquid from the supply tank through the suction check valves to refill the pump head.

- 5 -

Page 8

Outline

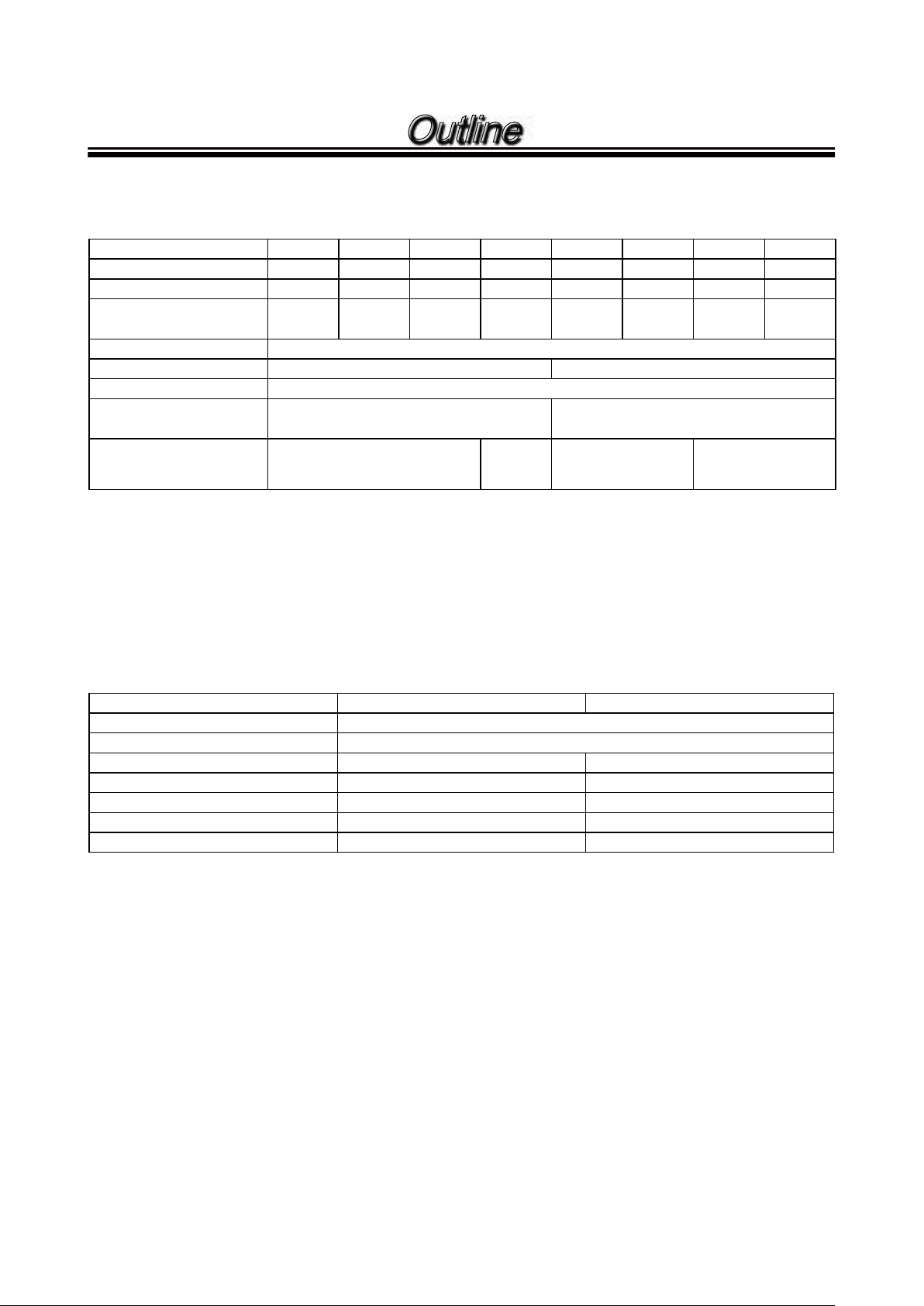

3. Specifications

Capacity/Pressure Rating

Model B11 B16 B21 B31 C16 C21 C31 C36

Max. capacity L/H 2.28 3.9 5.7 12.0 4.8 7.8 16.2 24.0

Max. capacity ml/min 38 65 95 200 80 130 270 400

Max. discharge pressure

MPa

Stroke rate 0 - 353 spm

Stroke length 1.00 mm (Fixed stroke length) 1.25 mm (Fixed stroke length)

Power supply 207 - 253VAC, 50Hz single phase

Average power consumption

Connection tubing

ID×OD

• Max. capacity is measured with clean water under the Max. discharge pressure. Actual discharge capacity

may increase if the discharge pressure is low.

• Operating conditions

Ambient temperature: 0 - 40 degrees Celsius

Relative humidity : 35 - 90 % non-condensing

1.0 0.7 0.4 0.2 1.0 0.7 0.35 0.2

16 watt 22 watt

4×9 or 6×8mm

8×13 mm

or

9×12mm

4×9 or 6×8mm

8×13 mm or

9×12mm

Liquid End Materials

Liquid End Part VH VC

Pump head PVC

Diaphragm PTFE (bonded to EPDM)

Valve ball Hastelloy C276 Alumina Ceramics

Valve seat EPDM FKM

Valve guide PVC PVC

Gasket PTFE PTFE

O ring EPDM FKM

PTFE: Polyterafluoroethylene

EPDM: Ethylene propylene diene monomer

FKM: Fluoroelastmer

- 6 -

Page 9

Installation

1.Unpacking

2.Location

3.Supply Tubing

4. Discharge Tubing

5. Electrical

- 7 -

..........................................

.............................................

...........................................

...................................

............................

8

8

9

9

9

Page 10

Installation

1. Unpacking

Open the shipping carton and inspect contents for damage. If any items are messing or damaged, contact

your local distributor to arrange for replacement.

2. Location

Choose a location for the pump which is clean, dry, close to an electrical outlet, and allows convenient

access to frequency control and tubing connections. Avoid areas where ambient temperature exceeds 40

deg.C or falls below 0 deg.C, or where the pump or tubing would be exposed to direct sunlight.

Flooded suction (mounting the pump below the level of liquid in the supply tank) is strongly recommended,

especially when pumping liquids that readily generate gas bubbles (See Figure 1). Sodium hypochlorite and

hydrogen peroxide are common examples of such liquids.

If flooded suction mounting is not possible, a shelf adjacent to (but not directly above) the supply tank often

works well (See Figure 2).

The supply tank or cover can also be used if it is provisions for mounting a pump (See Figure 3).

In any cases, the total suction lift should not exceed 1.0m.

Figure 1

Flooded Suction

Figure 2

Shelf Mount

- 8 -

Figure 3

Tank M ou nt

Page 11

Installation

3. Supply Tubing

The supply tubing run should be as short as possible. For flooded suction mounting, install a shout-off

valve with an appropriate tubing connector at the tank outlet. Cut a length of tubing from the coil supplied

and install between the shut-off valve and the pump inlet fitting. For suction lift applications, install a foot

valve on one end of suction tubing and cut the tubing to a length such that the foot valve hangs vertically

about 25mm above the bottom of the tank. Avoid any loops in the tubing run that could form a vapour trap.

Running the tubing through a length of PVC pipe will help to keep tubing straight.

4. Discharge Tubing

The discharge tubing run is less critical and can be any length required to reach the application point. Avoid

sharp bends or kinks in the tubing and protect the tubing from sharp edges that could chafe or cut it. Install a

check valve (optionally available) at the injection point and connect the discharge tubing to the check valve.

CAUTION

Any check valve using Hastelloy or other metal springs in liquid end is not usable for

chemicals (such as HCL) which corrode the Hastelloy or other metal springs. Ask IWAKI

for a special check valve for this application.

5. Electrical

Connect the pump power cord to a GROUNDED outlet supplying proper voltage. Avoid branch circuits that

also supply power to heavy machinery or other equipment that could generate electrical interference.

Be sure to equip the power cord with a noise filter. The DENSEI-LAMBDA MBS1205-22 is recommended.

Refer to manufacturer's instruction for the noise filter before use.

- 9 -

Page 12

Operation

1.Priming

2.Adjustment

3.Calibration

- 10 -

.............................................

......................................

.......................................

11

11

12

Page 13

Operation

CAUTION

● Do not operate the pump with a completely closed discharge-side valve. Operating

the pump with the discharge-side valve fully closed may lead to liquid leakage or

pipe rupture. In addition, more than 30 minutes of closed-discharge operation causes

abnormal heat in the pump. This can lead to failure such as leakage when the pump

head, valve case or so is deformed or the pump head is loosened. Make sure not to

operate the pump with the discharge-side valve closed.

● Do not run the pump dry. A pump, which has been run dry, may experience liquid

leakage during its liquid feeding operation. Make it a rule to run the pump after supplying liquid inside the pump.

* Dry operation of the pump over a long time (longer than 30 minutes) causes the

pump to overheat and the pump unit (pump head, valve guide etc.) to become deformed or the pump head attachment to become loose, which may result in liquid

leakage trouble.

● Keep the pump head firmly assembled. If the installation bolts on the pump head are

loosened, liquid leakage may result.

* Fasten the 4 hex. socket bolts tightly before starting the initial pump operation. (The

bolts may be loosened during storage or transportation of the pump, depending

upon the condition of each.)

* Fastening torque: 2.16N•m (B11•16•21, C16•21)

2.55N•m (B31, C31•36)

Tighten all the bolts fully by applying an equal amount of torque in a diagonal order

among the bolts.

1. Priming

Install the pump as described above. With the pump turned on, set frequency at 100%. If the pump is

equipped with an air vent valve, open the knob 1/2 turn. Liquid should move through the suction tubing and

into the pump head. When liquid starts running through the vent tubing, close the air vent knob and continue

with output adjustment described below. If the pump has no air vent valve, disconnect the discharge tubing

from the injection valve. When liquid enters the discharge tubing at the pump head, set frequency to 0% to

stop the pump and reconnect the discharge tubing to the injection valve.

2. Adjustment

If less than full output is required, set the frequency to the approximate percentage of maximum desired.

- 11 -

Page 14

Operation

3. Calibration

If exact output calibration is required, first prime and adjust the pump as above. Then connect a calibra-

tion column to the suction side of the pump. Turn the pump on for one minute and read the amount of liquid

pumped from the column. Adjust the frequency up or down as necessary and check the output again. When

the desired output is reached, disconnect the calibration column and reconnect the suction tubing (See

Figure 4).

Figure 4

Calibration

- 12 -

Page 15

Maintenance

1.Diaphragm Replacement

2.Valve Replacement

3.Tubing

4.Troubleshooting

5.Model Code

6.Dimensions

7.E x p l o d e d V i ew

8.Parts List

...............................................

....................................

.....................................

.........................................

........................

.............................

................................

..............

14

14

14

15

16

17

19

20

- 13 -

Page 16

Maintenance

CAUTION

● Before working on the pump, disconnect the power cord, depressurize the discharge

tubing and drain or flush any residual liquid for the pump head and valves.

1. Diaphragm Replacement

Remove the power cord from the electrical outlet and disconnect the suction tubing, discharge tubing, and

air vent tubing. Remove the four head bolts with a 4mm or 5mm hex wrench. Unscrew the diaphragm and

remove its retainer (small disk behind the diaphragm). Install the new retainer and diaphragm on the shaft.

Turn the diaphragm clockwise until it bottoms on the shaft. Replace the pump head and tighten the head

bolts to a torque of 2.16/2.55 N•m.

2.16N•m (B11•16•21, C16•21)

2.55N•m (B31, C31•36)

2. Valve Replacement

Remove the suction and discharge tubing. Remove the suction fitting, the valve ass'y (consists of 2 × valve

ball, 2 × valve seat, 2 × valve guide, 1 × gasket & 1 × O ring). Install the new valve ass'y. Be sure both valve

seats are in the same orientation. Refer to Figure 5, below. Tighten the suction fitting. Similarly remove and

replace the discharge valve ass'y.

Gasket

Valve Guide

Ball

Valve Seat

FLOW

Figure 5

Valve Ass'y Orientation

3. Tubing

Check ends of tubing for splits, cracks or thin spots. Examine the full length of tubing for damage due to

chafing, abrasion, stress cracks, excessive temperature or exposure to ultraviolet light (direct sunlight or

mercury vapour lamps). If any signs of deterioration exist, replace the entire length of tubing. It is a good idea

to replace discharge tubing on a regular preventive schedule every 12 months.

- 14 -

Page 17

Maintenance

4. Troubleshooting

CAUTION

● Before working on the pump disconnect the power cord, depressurize the discharge

tubing and drain or flush any residual liquid from the pump head and valves.

Problem Possible Cause Corrective Action

Pump does not start - Faulty wiring

- Correct wiring

- Improper voltage

- Electronic control unit is damaged.

Pump does not prime - Air in suction tubing

- Valve gasket is not installed

- Valve ass'y direction is wrong

- Pump is air locked

- Suction or discharge valve is clogged

with foreign matter

- Adhesion of valve onto valve seat

Output fl uctuates

Liquid leaks - Fitting or coupling nut is loose

- Suction or discharge valve is clogged

with foreign matter

- Air is trapped in pump

- Overfeeding

- Diaphragm is damaged

- Pump head is loose

- Diaphragm is damaged

- Connect to proper voltage source

- Replace control unit

-

Reroute suction tubing to eliminate air trap

- Install valve gasket

- Reassemble valve ass'y

- Open air vent valve

- Disassemble, inspect, clean

- Disassemble, inspect, clean

- Disassemble, inspect, clean

- Open air vent valve

- Install injection valve or back pressure valve

- Replace diaphragm

- Tighten

- Tighten pump head bolts

- Torque: 2.16N•m (B11•16•21, C16•21)

2.55N•m (B31, C31•36)

- Replace diaphragm

- O ring or valve gasket missing

- Instal O ring or valve gasket

Check if the pump head mounting bolts are not loosened every 3 months. Tighten them

diagonally on the following tightening torques as necessary. The mounting bolts may

loosen during operation (An extent of looseness depends on operating condition.).

Tightening torque of the pump head mounting screw

Torque Torque Parts name

ES-B11 • 16 • 21 2.16N • m M4 hex. socket head bolts

ES-B31 2.55N • m M4 hex. socket head bolts

ES-C16 • 21 2.16N • m M4 hex. socket head bolts

ES-C31 2.55N • m M4 hex. socket head bolts

ES-C36 2.55N • m M5 hex. socket head bolts

- 15 -

Page 18

Maintenance

5. Model Code

ES-B 16 VC-230 N 3

Series name

ES: With manual stroke speed control (without stroke length adjustment)

Drive unit symbol

Average power consumption: B 16W, C 22W

Diaphragm effective diameter

11: 10mm 16: 15mm 21: 20mm 31: 30mm 36: 35mm

Liquid end material symbol

See the table of Liquid End Materials presented page 6.

VH: Hastelloy ball valves

VC: Ceramic ball valves

Power-supply voltage

230: 207-253VAC

Control unit type

N: Manual stroke speed control

Connection Tubing inside diameter (ID) × Outside diameter (OD)

1: ø4 × ø9mm

3: ø6 × ø8mm

4: ø8 × ø13mm

5: ø9 × ø12mm

ES-B11, B16, B21, C16, C21

ES-B31, C31, C36

- 16 -

Page 19

6. Dimensions (ES-B type)

Maintenance

Dimensions in mm

Model A B C D E F G H J L

ES-B11

ES-B16

ES-B21

ES-B31 81.5 26 2 90 16 5 - 172 8 158

81.5 22 2 90 37 5 150 184 28 175

P&Q

Tubing

Ø4×Ø9

or

Ø6×Ø8

Ø8×Ø13

or

Ø9×Ø12

Mounting hole Dimensions in mm

ModelRTVZX

ES all variations 88 16 10 32 6.2

W

100

100

- 17 -

Page 20

(ES-C type)

Maintenance

L

E

Q

H

G

D

POWER CORD (2000)

R

X

UT

P

A

Y

V

B

S

Z

F

W

J

Dimensions in mm

Model A B D E F G H J L

ES-C16

ES-C21

105 27 100 37 8 160 194 36 196.5

ES-C31 105 29 10 0 16 8 182 186.5 18 177.5 Ø8×Ø13

ES-C36 105 28.5 100 16 8 181.5 186.5 18.5 177 116

P&Q

Tubing

Ø4×Ø9

or

Ø6×Ø8

or

Ø9×Ø12

W

116

116

Mounting hole Dimensions in mm

Model RXUTVYZS

ES all variations 100 7 8 37 15 18 12 95

- 18 -

Page 21

Maintenance

7. Exploded View

Models with thermoplastic liquid end materials and air vent valve

23

26

4

4

6

14

111

13

12

111

13

12

17

19

25

A

10

27

5

ES-B31,

C31, C36

44

45

46

D

55

56

38

42

41

39

B

47

18

9

7

48

43

52

B

53

C

17

14

111

13

12

111

13

12

1

A: Air Vent Ass'y

B: Valve Ass'y

C: Drive Unit

D: Control Unit

3

4

Notice: Actual fitting nut(4) may differ from illustrated ones.

- 19 -

Page 22

8. Parts List (ES-B type)

Maintenance

Item Description Material

Head, 11 1

1

3

4

5 Air vent body B PVC 1

6 Lock nut PVC 1

7

9

10 Air vent body A

11 Valve guide PVC 4

12 Valve seat EPDM/FKM 4

13 Valve ball HC/CE 4

14 Gasket PTFE 2

17 O-ring, S14 EPDM/FKM 2

18 Spacer:0.2,0.3,0.5,0.7mm Brass 1

19 Bolt, M4X40 SUS316 equivalent

23 Adjusting Screw PVC 1

25 O-ring, P4 FKM-A 1

26 O-ring, P10A FKM-A 1

27 O-ring, P7 FKM-A 1

38 Gasket EPDM 1

39

41 Cord Nut POM 1

42 Case Gasket NBR 1

43 Control unit case PPE 1

44 Control unit cover PPE 1

45 SF Gasket EPDM 1

46 SF Knob PE 1

47 Screw 4x25 SUS304 equivalent 1

48 Terminal Gasket NBR 1

53 Pump body PPG 1

52 Plug

55 Cap Gasket EPDM 1

56 Screw, M3x35 SUS304 equivalent

Head, 16

Head, 21

Head, 31

Fitting,

Fitting, φ 6 x φ 8

Fitting, φ 8 x φ 13

Fitting, φ 9 x φ 12

Fitting nut, φ 4 x φ 9

Fitting nut,

Fitting nut, φ 8 x φ 13

Fitting nut, φ 9 x φ 12

Diaphragm, 11 1

Diaphragm, 16

Diaphragm, 21

Diaphragm, 31

Retainer, 11 1

Retainer, 16

Retainer, 21

Retainer, 31

Cord Gasket E

φ

4 x φ 9

φ

6 x φ 8

VH/VC

VH/VC

VH/VC

VH/VC

PVC 1

φ

6mm

PVC

PVC

PVC

PTFE+EPDM

PPS

NBR 1

B11 B16 B21 B31

Q'ty per Item

1

1

3

1

1

1

1

1

4

1

1

1

2

2

1

1

- 20 -

Page 23

(ES-C type)

Maintenance

Item Description Material

Head, 16 1

1

3

4

5 Air vent body B PVC 1

6 Lock nut PVC 1

7

9

10 Air vent body A PVC 1

11 Valve guide PVC 4

12 Valve seat EPDM/FKM 4

13 Valve ball HC/CE 4

14 Gasket PTFE 2

17

18 Spacer:0.2,0.3,0.5,0.7mm Brass 1

19

23 Adjusting Screw PVC 1

25 O-ring, P4 FKM-A 1

26 O-ring, P10A FKM-A 1

27 O-ring, P7 FKM-A 1

38 Gasket EPDM 1

39

41 Cord Nut POM 1

42 Case Gasket NBR 1

43 Control unit case PPE 1

44 Control unit cover PPE 1

45 SF Gasket EPDM 1

46 SF Knob PE 1

47 Screw 4x25 SUS304 equivalent 1

48 Terminal Gasket NBR 1

53 Pump body PPG 1

52 Plug

55 Cap Gasket EPDM 1

56 Screw, M3x35 SUS304 equivalent

Head, 21

Head, 31

Head, 36

Fitting,

Fitting, φ 6 x φ 8

Fitting, φ 8 x φ 13

Fitting, φ 9 x φ 12

Fitting nut, φ 4 x φ 9

Fitting nut, φ 6 x φ 8

Fitting nut, φ 8 x φ 13

Fitting nut, φ 9 x φ 12

Diaphragm, 16

Diaphragm, 21

Diaphragm, 31

Diaphragm, 36

Retainer, 16 1

Retainer,

Retainer, 31

Retainer, 36

O-ring, S14

O-ring, P16 2

Bolt, M4X35

Bolt, M5X35 4

Cord Gasket E φ

φ

4 x φ 9

21

VH/VC

VH/VC

VH/VC

VH/VC

VH/VC

6mm

PVC

PVC

PVC

PTFE+EPDM

PPS

EPDM/FKM

SUS316 equivalent

NBR 1

C16 C21 C31 C36

1

Q'ty per Item

2

1

2

2

1

1

1

1

3

1

1

4

1

1

1

1

1

- 21 -

Page 24

U.S.A . : IWAKI America Inc.

Australia : IWAKI Pumps Australia Pty. Ltd.

Singapore : IWAKI Singapore Pte. Ltd.

Indonesia : IWAKI Singapore (Indonesia Branch)

Malaysia : IWAKIm Sdn. Bhd.

Tai wan : IWA KI P ump s Tai w an C o. , Lt d .

Thailand : IWAKI (Thailand) Co.,Ltd.

Hong Kong : IWAKI Pumps Co., Ltd.

China :

GFTZ IWAKI Engineering & Trading Co., Ltd.

China : IWAKI Pumps Co., Ltd. (Beijing office)

China : IWAKI Pumps (Shanghai) Co., Ltd.

Philippines : IWAKI Chemical Pumps Philippines, Inc.

Korea : IWAKI Korea Co.,Ltd.

Vietnam :

IWAKI Pumps Vietnam Joint Venture Co.,Ltd.

IWAKI CO.,LTD. 6-6 Kanda-Sudacho 2-chome Chiyoda-ku Tokyo 101-8558 Japan

TEL : (1)508 429 1440 FAX : 508 429 1386

TEL : (61)2 9899 2411 FAX : 2 9899 2421

TEL : (65)763 2744 FAX : 763 2372

TEL : (62)21 690 6607 FAX : 21 690 6612

TEL : (60)3 7803 8807 FAX : 3 7803 4800

TEL : (886)2 8227 6900 FAX : 2 8227 6818

TEL : (66)2 320 1303 FAX : 2 322 2477

TEL : (852)2 607 1168 FAX : 2 607 1000

TEL : (86)20 8435 0603 FAX : 20 8435 9181

TEL : (86)10 6442 7713 FAX : 10 6442 7712

TEL : (86)21 6272 7502 FAX : 21 6272 6929

TEL : (63)2 888 0245 FAX : 2 843 3096

TEL : (82)2 3474 0523 FAX : 2 3474 0221

Germany : IWAKI EUROPE GmbH

Italy : IWAKI Italia S.R.L.

Denmark : IWAKI Pumper A/S

Sweden : IWAKI Sverige AB

Finland : IWAKI Suomi Oy

Norway : IWAKI Norge AS

France : IWAKI France S.A.

U.K. : IWAKI PUMPS (UK) LTD.

Switzerland : IWAKI (Schweiz) AG

Austria : IWAKI (Austria) GmbH

Holland : IWAKI Holland B.V.

Spain : IWAKI Iberica Pumps, S.A.

Belgium : IWAKI Belgium n.v.

TEL : (84)613 933456 FAX : 613 933399

TEL:(81)3 3254 2935 FAX:3 3252 8892(http://www.iwakipumps.jp)

TEL : (49)2154 9254 0 FAX : 2154 1028

TEL : (39)02 990 3931 FAX : 02 990 42888

TEL : (45)48 24 2345 FAX : 48 24 2346

TEL : (46)8 511 72900 FAX : 8 511 72922

TEL : (358)9 2742714 FAX : 9 2742715

TEL : (47)66 81 16 60 FAX : 66 81 16 61

TEL : (33)1 69 63 33 70 FAX : 1 64 49 92 73

TEL : (44)1743 231363 FAX : 1743 366507

TEL : (41)32 3235024 FAX : 32 3226084

TEL : (43)2236 33469 FAX : 2236 33469

TEL : (31)297 241121 FAX : 297 273902

TEL : (34)943 630030 FAX : 943 628799

TEL : (32)1430 7007 FAX : 1430 7008

T630 '07/05

Loading...

Loading...