Page 1

IWAKI Air Pump

APN-085-D4

Instruction Manual

Read this manual before use of product

Page 2

Thank you for selecting an IWAKI APN-085-D4 air pump. This

instruction manual deals with "Safety Instructions", "Outline",

"Installation", "Operation" and "Maintenance" sections.

Please read through this instruction manual to ensure the optimum performance, safety and service of your pump.

Contents

Safety Instructions ······················································· 1

Outline 1. Unpacking & Inspection····························· 3

2. Operating principle ·································· 3

3. Identification code···································· 4

4. Specifications ········································· 4

5. Outer dimension ······································ 5

6. Performance curve ··································· 6

7. Overview & Label ···································· 6

8. Part names & Str ucture ······························ 7

Installation 1. Before installation ···································· 8

2. Installation/Tubing/Electrical wiring ············ 10

Operation 1. Before operation ····································· 13

2. Pump operation ······································ 14

Maintenance 1. Troubleshooting ······································ 16

2. Maintenance & Inspection ························· 16

3. Wear part replacement ······························ 18

This instruction manual should be kept on hand by the end user

for quick reference.

Contact us or your nearest distributor if you have any questions.

Important Instruction

For the Safe and

Correct Handling of the Pump

● "Safety Instruction" section deals with important details about

handling of the product. Before use, read this section carefully for

the prevention of personnel injury or property damage.

● Observe the instructions accompanied with "WARNING" or

"CAUTION" in this manual. These instructions are very important for protecting pump users from dangerous situations.

● The symbols on this instruction manual have the following meanings:

Nonobservance or misapplication of the

WARNING

CAUTION

Indicates a prohibited action or procedure. Inside or near this circle, a concrete and practical image of the activity to be avoided is

depicted.

Indicates an important action or procedure which must be performed or carried out without fail. Failure to follow the instructions herein can lead to malfunction or damage to the pump.

Export Restrictions

Technical information contained in this instruction manual might be

treated as controlled technology in your countries, due to agreements

in international regime for export control.

Please be reminded that export license/permission could be required

when this manual is provided, due to export control regulations of your

co untr y.

contents of “Warning” section could lead to

a serious accident which may result in death.

Nonobservance or misapplication of the

contents of “Caution” section could lead to

personal injury or property damage.

Types of Symbols

Page 3

Electrical shock

Prohibited

Prohibited

Safety Instructions

Prohibited

Prohibited

Caution

Caution

Prohibited

WARNING

● Turn off power before service

Risk of electrical shock. Be sure to turn off

power to stop the pump and related devices

before service is performed.

● Do not use the pump in any condition

other than its intended purpose

The use of the pump in any conditions other

than those clearly specified may result in

failure or injury. Use this product in specified

conditions only.

● Do not modify the pump

Alternations to the pump carries a high

degree of risk. It is not the manufacturer's

responsibility for any failure or injury resulting

from alterations to the pump.

● Wear protective clothing

Always wear protective clothing such as an

eye protection, chemical resistant gloves, a

mask and a face shield during disassembly,

assembly or maintenance work.

● Use specified power only

Do not apply power other than that specified on the nameplate. Otherwise failure or

fire may result. Ensure the pump is properly

grounded.

No remodeling

Wear protectors

CAUTION

● Qualified personnel only

The pump should be handled or operated

by a qualified personnel with a full understanding of the pump.

● Ventilation

Fumes or vapours can be hazardous with

certain solutions. Ensure proper ventilation

at the operation site.

● Do not install or store the pump:

1. Where ambient temperature falls below

0°C or exceeds 40°C.

2. Under a flammable/corrosive atmos-

phere.

● Spill precautions

Ensure protection and containment of

solution in the event of plumbing or pump

damage (secondary containment).

● Keep electric parts and wiring dry

Risk of fire or electric shock. Install the

pump where it can be kept dry.

- 1 -

Page 4

Prohibited

Electrical shock

Electrical shock

Prohibited

Safety Instructions

CAUTION CAUTION

●

Do not use a damaged pump

Use of a damaged pump could lead to an

electric shock or death.

●

Stop operation

If you notice any abnormal or dangerous

conditions, suspend operation immediately

and inspect/solve problems.

●

Preventative maintenance

Follow instructions in this manual for

replacement of wear parts. Do not disassemble the pump beyond the extent of the

instructions.

●

Do not damage the power cable

Do not pull, knot, or crush the power cable.

Damage to the power cable could lead to a

fire or electrical shock if cut or broken.

●

Do not use the pump in a wet location

The pump is not waterproof. Use of the

pump in wet or extremely humid locations

could lead to electric shock or short circuit.

●

Damaged power cable

Do not use any damaged power cable for

the prevention of a fire or electrical shock.

The cable is not replaceable, so that the

whole pump unit needs to be replaced

when the cable is damaged.

●

Disposal of a used pump

Dispose of any used or damaged pump in

accordance with local rules and regulations.

If necessary, consult a licensed industrial

waste disposal company.

- 2 -

Page 5

Outline

Before use, check the specification, limitation and hazardous

nature of the pump.

1. Unpacking & Inspection

Open the package and check that the product conforms

to your order. If any problem or inconsistency is found,

immediately contact your distributor.

1. Check the nameplate to see if the information such as

model codes, discharge capacity and discharge pressure

are as ordered.

2. Check for transit damage, deformation and loose bolts.

2. Operating principle

The APN- 085-D4 is a diaphragm type air pump and is

designed to be built into various devices such as a gas

analyser and for contamination-free gas compression,

vacuum and deliver y.

The rotary motion of the motor is converted through a

connecting rod to the reciprocation of the diaphragm in

the pump chamber, where gas is transferred from the inlet

to outlet.

IN OUT

Valve

Diaphragm

Connecting rod

- 3 -

Page 6

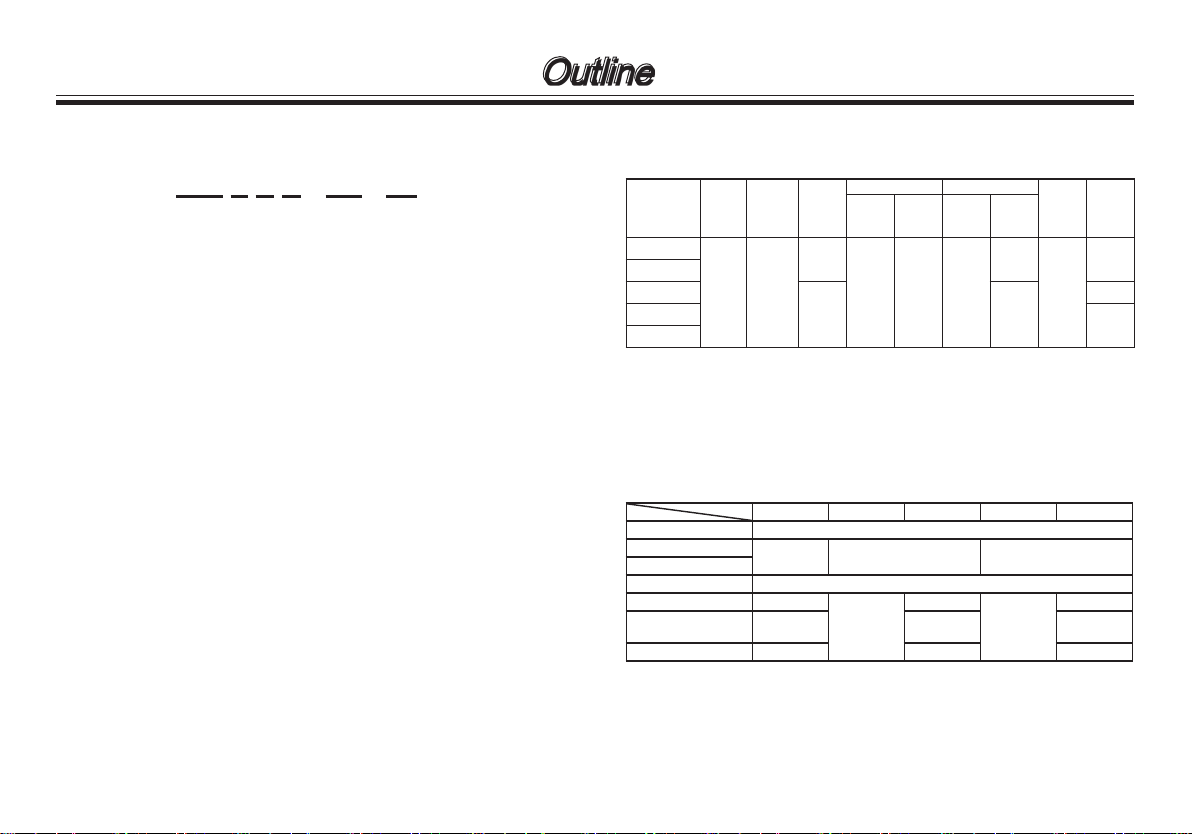

Outline

3. Identification code

APN - 085 L V X - D4 - 02

a b c d e f

a. Pump size

b. Pump head

No code : Corrosive resistant (Molded diaphragm )

L : High vacuum (Horizontally oriented)

H : High vacuum (Vertically oriented)

c. Diaphragm/Valve materials

N : NBR

E : EPDM

V : FKM

d. Pump connection

No code : ø8 tube connection

X :

Rc1/4 female thread connection (JIS taper pipe thread)

X1 :

G1/4 female thread connection (JIS parallel pipe thread)

e. Motor

D4 : 24V BLDC motor (with 1-5VDC control signal)

f. Special specification

No code : Standard

01-99 : Special design

4. Specifications

■ Pump Performance at 24VDC (power voltage) and 5VDC (control signal)

Max. dis-

Max. air

Typ e

APN-085V

APN-085E

APN-085LV/HV

APN-085LE/HE

APN-085LN/HN

NOTE1. Observe the maximum discharge pressure of 0.08MPa.

NOTE2. Allowable gas temperature range is 0-40°C.

NOTE3. Allowable ambient temperature range is 0-40°C. Observe the

NOTE4. Both the inlet and outlet of the pump are Rc1/4 female thread

ow

pressure

(L/min)

6 0.08

lowest starting temperature at the start of operation.

connections (JIS taper pipe thread) or G1/4 female thread

connections (JIS parallel pipe thread).

charge

(MPa)

Max.

vacuum

(kPa)

61.3

34.66

■ Wet end material

Parts

Pump head GFRPP

Diaphragm

Valve

Valve seat GFRPP

Retainer plate GFRPPS

Screw

Gasket (X1 type) FKM FKM FKM

GFRPP : Glass fiber reinforced polypropylene

NBR : Nitrile Butadiene Rubber

FKM : Fluorine-contained rubber

EPDM : Ethylene propylene diene monomer

GFRPPS : Glass fiber reinforced polypropylene sulfide

SUS304 : Austenite stainless steel

Model

LN/HN V LV/ H V E LE/HE

NBR FKM EPDM

SUS30 4

equiv

Motor Connection

Power

Rated

con.

current

(A)

GFRPPS

SUS30 4

equiv

Tub e Thread

(W)

15 1.2 ø8

-

Rc1/4

Rc1/4

or

G1/4

-

Weight

(kg)

1.3

GFRPPS

Lowest

starting

temp.

(°C)

10

5

0

SUS30 4

equiv

- 4 -- 4 -

Page 7

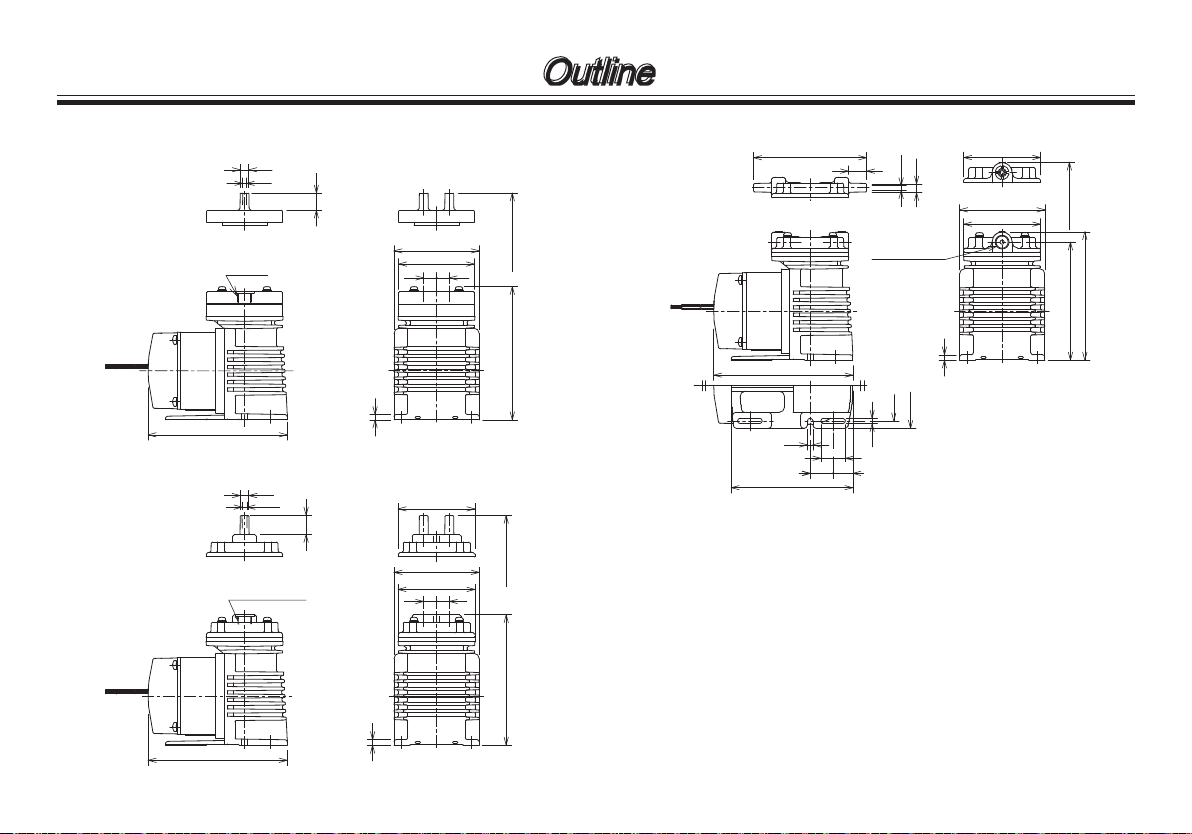

5. Outer dimension

■

APN-085

ø8

ø4

APN-085- L type

2-Rc1/4

Outline

■

APN-085L

17

80

ø71

12

Total length(136)

12

106

17

APN-085- L type

ø8

ø4.8

2-Rc1/4 or 2-G1/4

ø72

80

ø72

Total length (121)

111

(121)

■

APN-085H

(130)

ø4.8

APN-085- H type

2-Rc1/4 or 2-G1/4

(130)

(125)

5

ø8

18

5

ø72

80

ø72

12 12

Total length (140)

(122)

(130)

5.5

114

21.5

5.5

23

18.5

5

80

66

- 5 -- 5 -

Page 8

Outline

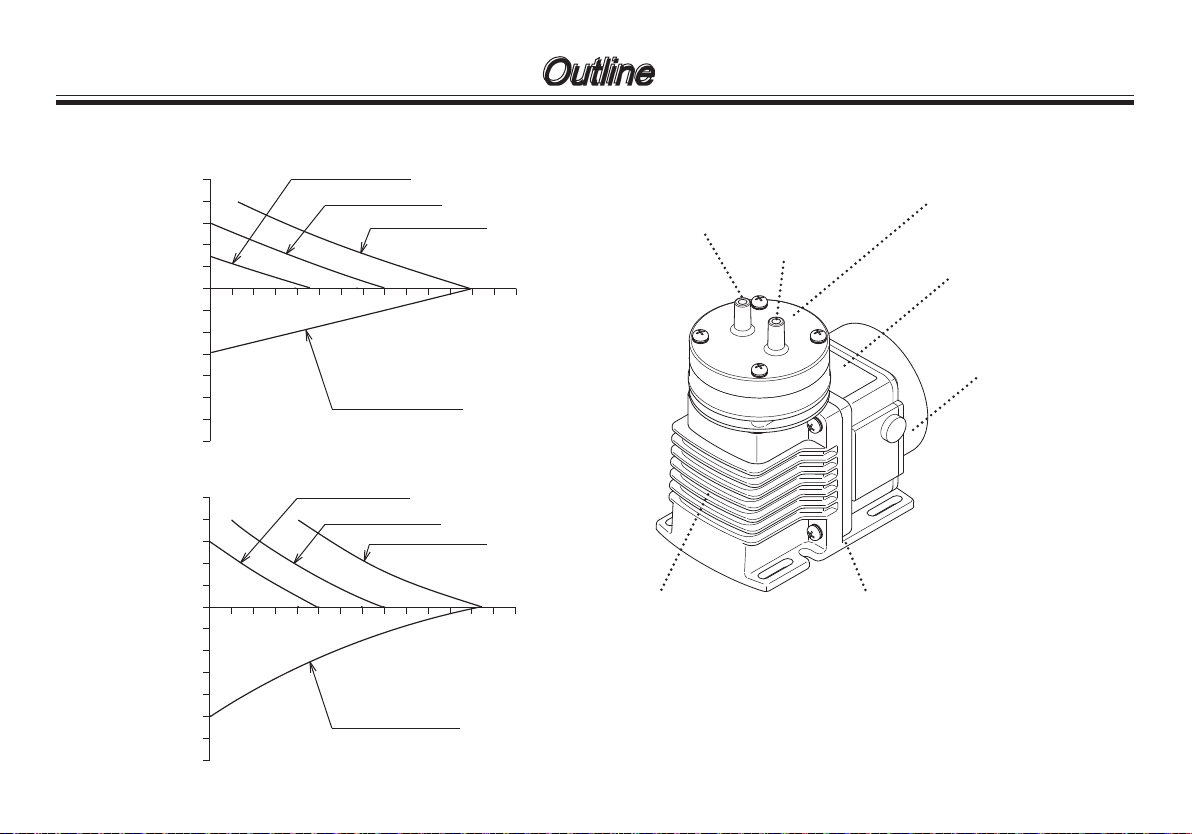

6. Performance curve

■

APN-085

Discharge pressure

(MP a)

Vacuum pressure

(kPa) [abs]

■

APN-085 L/H

Discharge pressure

(MP a)

Vacuum pressure

(kPa) [abs]

0.1 0

0.08

0.06

0.04

0.02

101.3

87. 98

74.6 5

61.32

47. 99

34.66

21.33

8.00

0.10

0.08

0.06

0.04

0.02

101.3

87.98

74.65

61.32

47.99

34.66

21.33

8.00

0

1 2 3 4 5 6

0

1 2 3 4 5 6

Vacuum 74.65k Pa [abs]

Vacuum 87.98kPa [a bs]

Vacuum 101.3kPa [a bs]

Discharge pressure 0MPa

Vacuum 74.65k Pa [abs]

Vacuum 87.98kPa [a bs]

Vacuum 101.3kPa [a bs]

Discharge pressure 0MPa

AIR FLOW

(L/min)

AIR FLOW

(L/min)

7. Overview & Label

Outlet

Pump body

(Driven unit)

An installation location

should be free from liquid spillage.

- 6 -- 6 -

Pump head

Inlet

Nameplate

Model and MFG. No.

(Production number) are

described.

Motor

Base

Anchor the pump with

bolts.

Page 9

Outline

8. Part names & Structure

■ APN-085

No. Part names Q'ty No. Part names Q'ty

1 Pump head 1 19 Connecting rod 1 set

2 Valve 1 20 Bracket 1

3 Valve seat 1 40 Motor 1

4 Diaphragm 1 62 Screw 4

40

3

4

62

2

1

19

20

■ APN-085 L/H

5

4

40

No. Part names Q'ty No. Part names Q'ty

1 Pump head 1 19 Connecting rod 1 set

2 Valve 1 20 Bracket 1

3 Valve seat 1 38 Gasket* 2

4 Diaphragm 1 40 Motor 1

5 Retainer plate 1 61 Screw 1

18 Under retainer plate 1 62 Screw with washer 4

The Gasket is provided to the X1 type (APN-085 with G1/4 female

thread connection) only.

61 3

2

62

38

1

18

19

20

- 7 -

Page 10

Installation

1. Before Installation

Read through this instruction manual before use. Carry

out installation work with a full understanding.

CAUTION

● Do not operate the pump in a flammable atmosphere

Do not place explosive or flammable material near

the pump.

● Do not use a damaged pump

Use of a damaged pump could lead to an electric

shock or death.

● Do not install the pump in a

place where the pump can

get wet. Avoid using wet gas,

or internal condensation will

build up and consequently

result in the shor t lives of the

valve and diaphragm.

● Do not install the pump in a

corrosive or flammable gas

atmosphere. Keep good ventilation in a working area.

● Ambient temperature should

not fall below 0°C or exceed

40°C. Observe the allowable

gas temperature range of 0

and 40°C.

- 8 -

Page 11

Installation

?V

Risk of burn

Provide a filter

● Observe the rated voltage

specified on the name plate.

Applying any voltage than

the rated one may result in

failure.

● Surface temperature may

rise high in operation but it

dose not mean failure.

Do not touch the pump body

directly or place the objects

which may be deformed by

heat close to the pump.

● Do not use the pump in

a dusty place. Be sure to

provide the inlet with a filter

to prevent foreign matters

from getting into the pump.

Otherwise, the pump performance may reduce or the

lives of the valves and diaphragm remarkably shorten.

● Do not tube two or more

pumps in series. It may prevent the motor from starting

and lead to a burn out.

- 9 -

Page 12

Installation

2. Installation/ Tubing/ Electrical wiring

WARNING

If you notice any abnormal or dangerous conditions, suspend

operation immediately and inspect/solve problems.

2.1 Installation

1. Do not expose the pump to

direct sunlight, vibration and

wind & rain.

2. Keep good ventilation. The

pump should always be free

from the possibility of getting

wet.

3. Ambient temperature should

not fall below 0°C or exceed

40°C. Observe the allowable

maximum ambient humidity

of 90%RH.

4. Install the pump in a clear

and level place.

Select a convenient place

for maintenance and inspection.

5. Pump fixation

Set the pump baseplate on a

concrete foundation and fasten

anchor bolts tightly to prevent

the pump from vibrating during

operation.

CAUTION

Do not install the pump on a

unstable place.

2. 2 Tu bing

1. The short tubing with the mini-

mum bends is optimal to reduce

resistance.

2. Use vinyl tubes resistant to the

pumping pressure.

CAUTION

Do not have tubing bent or

pressed. Otherwise, the tube

end may break.

- 10 -

Page 13

Installation

3. Tube size

Select proper tube size, otherwise liquid leaks and failure

may result.

CAUTION

Use of a wrong tube size bears the risk of coming off,

causing an air leak.

4. Valve installation

Install valves on both discharge and suction lines.

• Suction valve:

For adjustment of an air flow and a vacuum.

• Discharge valve:

For maintenance and shutoff.

5. Tube connection

Push the tubes into the inlet and outlet as far as they will go.

NOTE: If suction line connection is imperfect, the pump sucks

air and it prevents the pump from bringing out full performance.

2.3 Electrical wiring

Electrical wiring must be performed by a qualified electrician.

We are not responsible for personal injury or proper ty damage due to nonobser vance of this warning. Contact us or your

nearest distributor for wiring as necessary.

■

Before wiring

1. Confirm that power is disconnected before work.

2. Wiring work should be done in accordance with local elec-

tric codes. Use the recommended wiring accessories.

3. Observe the rated voltage specified on the name plate.

4. When an external fuse is used and has blown out, always

investigate and solve root causes. Replace the fuse before

resuming operation.

Be sure to unplug the pump before investigating the cause

of blowout. If the fuse blows frequently, starting current may

be a root cause. In this case review the system.

- 11 -

Page 14

AC power

Pump

DC power

supply

Good

AC power

Pump

No good

DC power

supply

Installation

5. For wire lead colours, red

age. Yellow

signal. The black

and black leads are for external variable

lead is common for both the power and

and black are for power volt-

the signal. Observe the maximum signal voltage of 5.5VDC.

CAUTION

Observe polarity, otherwise failure or malfunction may

result. Note that rotational direction of the motor does not

change by reversing polarity.

Red: 24VDC (+)

Black: GND (-)

Yellow: 1-5VDC external variable signal(+)

Orange: Encoder output (Max output current: 3mA)

6. In order to make ON-OFF operation, install a switch between

the DC power supply and the pump. Installing it between the

DC power supply and the AC power source, the pump may

not run.

Wiring example

7. After wiring work, check that the system is free from the

inductive noise at start-up.

8. Noise accompanies the high-speed switching of the drive

circuit. Check it does not affect peripheral devices.

9. If a power source is shared with inductive loads such as a

solenoid relay, take protective measures against surge.

■ Rated current & Starting current

Model Rated current Starting current

APN-085 -D4 1.2 A 4A or below

- 12 -

Page 15

Operation

1. Before operation

Suction pressure

No load operation

● Dropping or subjecting the

pump to strong impact, failure may result.

Handle the pump with care.

● The pump can not start

with full discharge/suction

pressure. Remove pressure

before operation.

● After a long period of stop-

page, pump performance at

the beginning of operation

becomes occasionally unstable. In this case, warm the

pump up for 10 minutes with

no discharge line pressure.

Suction valve

Keep a discharge

valve full open.

Suction valve

Do not increase suction

line pressure

● Always use a suction valve

to adjust an air flow.

● If the compressed air (higher

pressure than atmospheric

pressure) is transferred to

the pump, the lives of the

valve, diaphragm and bearing may be sharply reduced.

Always keep atmospheric or

lower pressure in the suction

line.

● Injection point must be below

the pump position. Or siphon

action/back flow may result.

- 13 -

Page 16

Operation

● Do not use solvents such as

benzine, alcohol, thinner for

maintenance or cleaning,

otherwise a coat discolours

or comes off.

2. Pump operation

■ Start-up

1. Before pump operation, check that each tube connection is

secured.

2. Check that a suction line is connected to the inlet and a dis-

charge line to the outlet.

CAUTION

If a suction line and a discharge line are connected the

other way around, pumping process is inverted.

3. Check that the pump is firmly fixed on a mounting position.

■ Operation

Operate the pump according to the following steps.

No. Procedure Points to be Checked

1 Check tubing, wir-

ing and voltage.

2 Open valves. • Fully open both discharge and

3 Supply power to the

pump.

4 Adjust air flow. • Provide a running-in period before

• See "2.2 Tubing" and "2.3

Electrical wiring" sections.

• Check the spec label to see if

power supply voltage is correct.

suction lines.

• Check the item 1 and 2. Then turn

on power and start the pump.

• Smooth starting may not be

obtained when ambient temperature is 10ºC or below. In this case,

run the pump with no discharge

line pressure for a few minutes to

warm it up.

full scale operation.

• Always adjust an air flow by a suction valve.

- 14 -

Page 17

Operation

5 Points to be

checked during

operation

• After starting, check a pressure

gauge to see if suction and discharge line pressure are correct

and an air flow meter to see if the

specified air flow is obtained.

• Keep a suction line pressure at or

below atmospheric pressure.

• In case electric power has failed

while the pump is running, switch

off main power. Otherwise, the

motor may not restart or may burn

out depending on a line pressure

at the time of power recovery.

■ Stop and Storage

Before a long period of stoppage (1 week or more):

● Release pressure and turn off main power.

● Make sure both supply air and gas are stopped.

Before resuming operation:

● Warm up the pump under no load operation. Operation

may occasionally be upset in the beginning.

● Follow the "

■ Operation" table to resume operation.

- 15 -

Page 18

Maintenance

1. Troubleshooting

Turn off power on sensing danger and check the following. In case trouble can not be solved, contact us or your

nearest distributor.

Phenomenon

Causes

Pump does not run.

Pump stops running.

Poor air ow or discharge pressure

No power distribution Check wiring.

Motor trouble (disconnection or capacitor failure)

Wrong tubing or poor connection

Pump head mounting screws are loose.

Diaphragm insertion is loose.

Diaphragm is damaged.

Filter is clogged.

Valve is worn.

Higher suction pressure than atmospheric

Eccentric shaf t has worn.

Connecting rod bearing has worn.

Motor bearing has worn.

Voltage reduction

Bracket tightening screws are loose.

Condensation in the pump head.

Pump makes noise.

Replace the motor.*

Check and x tubing.

Tighten the screws.

Tighten diaphragm.

Replace diaphragm.

Remove foreign matters.

Replace the valve.

Reduce suction pressure.

Replace the connecting rod unit.*

Replace the connecting rod unit.*

Replace the motor.*

Increase voltage to the rated level.

Secure them.

Dry up the pump.

Contact us for the measures marked with *.

Measures

2. Maintenance & Inspection

Handling of the pump, maintenance and inspection should

be carried out within the descriptions of this instruction

manual.

We are not responsible for personal injury or property damage due to nonobservance of this warning. Contact us or

your nearest distributor as necessary.

■ Daily inspection

Pay attention to the following items during operation. Stop

operation on sensing danger and solve problems on the

Troubleshooting section. If pump performance has remarkably

reduced, replace wear parts.

No. Check that... Measure

• Apply correct voltage and

1 pump operation is normal.

there is no noise or vibra-

2

tion problem.

there is no air leak or air

3

ingress from pump parts

and tubing connections.

amperage.

• Adjust discharge/suction

pressure.

• Unusual noise/vibration

may occur when pump

operation is not normal.

• Retighten connections.

- 16 -

Page 19

Maintenance

■ Wear parts

If pump performance has remarkably reduced, replace diaphragms and valves with new ones. Wear part duration varies

with the pressure, temperature and characteristics of gas/

liquid.

The estimated life below is calculated based on continuous

operation with clean water at ambient temperature (Room temperature range is 0-40°C.).

Application Load range

Gas transfer All range 8000hr 8000hr

* The above lives are reference values and not warranted.

Estimated life

Valve Diaphragm

■ Cleaning

Turn off power and wait until the pump has cooled down. Then

clean off the surface of the pump with a wet cloth. Use a neutral detergent for greasy dirt as necessary and dry it with a dry

cloth.

Check the pump surface has dried up before operation.

CAUTION

Risk of electrical shock. Do not wet electric parts or wiring.

■ Storage

Protect the pump from dust during storage.

Do not store the pump:

• Where ambient temperature falls below 0°C or exceeds 40°C.

• Under a flammable or corrosive atmosphere.

• Under heavy dust or high humidity.

• Under direct sunlight or wind & rain.

• Under vibration.

- 17 -

Page 20

Maintenance

3. Wear part replacement

For a long period of operation wear parts need to be

replaced periodically.

CAUTION

● Turn off power before service

Risk of electrical shock. Be sure to turn off power to

stop the pump and related devices before service is

performed.

● Do not touch the pump or pipe with bare hands

Risk of burning. The surface temperature of the

pump or pipe gets high in or right after operation.

● Wear protective clothing

Always wear protective clothing such as an eye protection, chemical resistant gloves, a mask and a face

shield during disassembly, assembly or maintenance

work.

See page 7 "8. Part names & Structure" as necessary.

■ Diaphragm replacement

<APN-085>

1. Unscrew all the pump head

fixing screws and take out

the pump head, valve and

valve seat.

2. Catch the diaphragm nut

with a special spanner and

turn the diaphragm anticlockwise so as to detach it

from the con rod (Fig.1).

3. Mount a new diaphragm into

the rod and fasten as far as

it will rotate with the spanne r.

4. Push down the diaphragm

until it bottoms out and then

mount and secure the valve

seat, valve and pump head

onto the bracket with the

screws by 1.39N•m.

Screw

Pump

head

Valve

Mating

points

Valve seat

Diaphragm

Bracket

Diaphragm

Special

spanner

Bracket

Con rod

Fi g.1

- 18 -

Page 21

Maintenance

■ Valve replacement

<APN-085>

1. Unscrew all the pump head

fixing screws and take out

the pump head and valve.

2. Replace the old valve with

new one. Always check the

mating points and fit the

valve and the pump head in

place.

3. Supply air into the pump

head unit through the inlet

and check the air is discharged through the outlet.

4. Push down the diaphragm

until it bottoms out and then

secure the pump head unit

onto the bracket with the

screws by 1.39N•m.

NOTE1. Do not loosen the motor fixing screws during mainte-

nance work.

NOTE2. Contact your nearest distributor for the replacement of

the connecting rod and the motor.

Valve

Pump head

Valve seat

- 19 -

Page 22

■ Diaphragm replacement

<APN-085L/H>

1. Unscrew all the pump head

fixing screws and take out

the pump head, valve and

valve seat.

2. Remove the diaphragm

fixing screw and detach

the retainer plate and diaphragm.

3. Place a new diaphragm onto

the under retainer plate.

4. Place the retainer plate

onto the diaphragm. Apply

the LOCTITE® 222 to the

diaphragm fixing screw and

tighten it by 1.98N•m so as

to secure the retainer plate.

5. Push down the diaphragm

until it bottoms out and then

mount and secure the valve

seat, valve and pump head

onto the bracket with the

screws by 1.98N•m.

Pump

head

Valve

Valve seat

Diaphragm

fixing screw

Retainer

plater

Diaphragm

Under

retainer plate

Bracket

Screw

Mating

points

Con rod

■ Valve replacement

<APN-085L/H>

1. Unscrew the pump head fixing screws and take out the

pump head and valve.

2. Replace the old valve with

new one. Always check the

mating points and fit the

valve and the pump head in

place.

3. Supply air into the pump

head unit through the inlet

and check the air is discharged through the outlet.

4. Push down the diaphragm

until it bottoms out and then

secure the pump head unit

onto the bracket with the

screws by 1.39N•m.

- 20 -

Valve

Pump head

Valve seat

Page 23

- 21 -

Page 24

Australia IWAKI Pumps Australia Pty. Ltd.

Austria IWAKI EUROPE GmbH

Belgium IWAKI Belgium n.v.

China IWAKI Pumps (Shanghai) Co., Ltd.

China

China

China

IWAKI Pu mps (Guangdong) Co., Ltd .

GFTZ I WAKI Engine ering & Trading (Gu angzhou)

GFTZ IWAKI Engineering & Trading (Beijing)

Denmark IWAKI Nordic A/S

Finland IWAKI Suomi Oy

France IWAKI France S. A.

Germany IWAKI EUROPE GmbH

Holland

IWAKI Europe GmbH, Netherlands Branch

Hong Kong IWAKI Pumps Co., Ltd.

Indonesia

IWAKI Singapore (Indonesia Branch)

IW A KI C O. , LTD. 6- 6 Kanda-Sudacho 2- chome Chiyoda-ku Tokyo 101-85 58 Japa n

TEL : (61)2 9899 2411 FAX : 2 98 99 2421

TEL : (49)2154 925 40 FAX : 2154 92 54 48

TEL : (32)1367 0200 FA X : 1367 2030

TEL : (86)21 627 2 7502 FAX : 21 62 72 6929

TEL : (86)750 38 66228 FAX : 75 0 3866278

TEL : (86)20 8 435 0603 FAX : 2 0 8435 9181

TEL : (86)10 64 42 7713 FAX : 10 6442 7 712

TEL : (45)4 8 24 2345 FAX : 48 24 23 46

TEL : (358)9 2 745810 FAX : 9 2742715

TEL : (33)1 69 63 3 3 70 FAX : 1 64 49 92 7 3

TEL : (49)2154 925 4 0 FAX : 215 4 9254 48

TEL : (3 1)74 242 00 11 FAX : 2154 9 254 48

TEL : (852)2 6 07 1168 FAX : 2 6 07 1000

TEL : (62)21 69 0 6606 FAX : 21 6 90 6612

TEL:(81)3 3254 2935 FAX:3 3252 8892(http://ww w.iwakipumps.jp)

Italy

IWAKI Europe GmbH, Italy Branch

Korea IWAKI Korea Co.,Ltd.

Malaysia IWAKIm Sdn. Bhd.

Norway IWAKI Norge AS

Singapore IWAKI Singapore Pte. Ltd.

Spain

IWAKI Europe GmbH, Spain Branch

Sweden IWAKI Sverige AB

Switzerland IP Service SA

Tai w an IWAKI Pumps Taiwan Co., Ltd.

Tai w an

IWAKI Pu mps Taiwan (Hsin -chu) Co., Ltd . TEL : (886)3 573 5797 FAX : (8 86)3 573 5798

Thailand IWAKI (Thailand) Co.,Ltd.

U.K. IWAKI Pumps (UK) LTD.

U.S.A . IWAKI AMERICA Inc.

Vietnam IWAKI pumps V ietnam Co.,Ltd.

( )Count ry cod es

TEL : (39)0 444 371115 FAX : 044 4 335350

TEL : (82)2 263 0 4800 FAX : 2 2630 4 801

TEL : (60)3 78 03 8807 FAX : 3 7803 48 00

TEL : (47)23 38 49 0 0 FA X : 23 38 49 01

TEL : (65) 6316 2028 FAX : 6316 3221

TEL : (34)93 37 70 19 8 FAX : 93 47 40 991

TEL : (46)8 511 72900 FAX : 8 511 72922

TEL : (41)26 674 9300 FAX : 26 674 9302

TEL : (886) 2 8227 6900

FAX : 2 8227 6 818

TEL : (66)2 32 2 2471 FAX : 2 32 2 2477

TEL : (44)1743 231363 FAX : 1743 366 507

TEL : (1)508 429 1440 FAX : 508 429 138 6

TEL : (84)613 933 456 FAX : 613 93339 9

T761-2 '14/01

Loading...

Loading...