IWAKI AMERICA WMD-100 Series, WMD-100R, WMD-100F, WMD-100RT, WMD-100FY Instruction Manual

...

IWAKI AMERICA

MAGNETIC DRIVE PUMP

WMD-100 SERIES

INSTRUCTION MANUAL

Thank you for having selected an Iwaki America WMD-100 Series magnetic drive pump. This

instruction manual deals with the correct handling, maintenance, inspection, and troubleshooting

procedures for the WMD-100 magnetic drive pump. Please read through it carefully to ensure

the optimum performance, safety and long service of your pump.

Contents

Item Page

1 Unpacking and Inspection.........................................................................................1

2 Identification.............................................................................................................1

3 Specifications............................................................................................................2

4 Handling...................................................................................................................2

5 Installation and Operation..........................................................................................3

6 Assembly..................................................................................................................4

7 Maintenance and Inspection......................................................................................5

8 Parts Description and Exploded View........................................................................6

9 External Dimensions and Weight...............................................................................7

P/N 180184.E 11/28/05

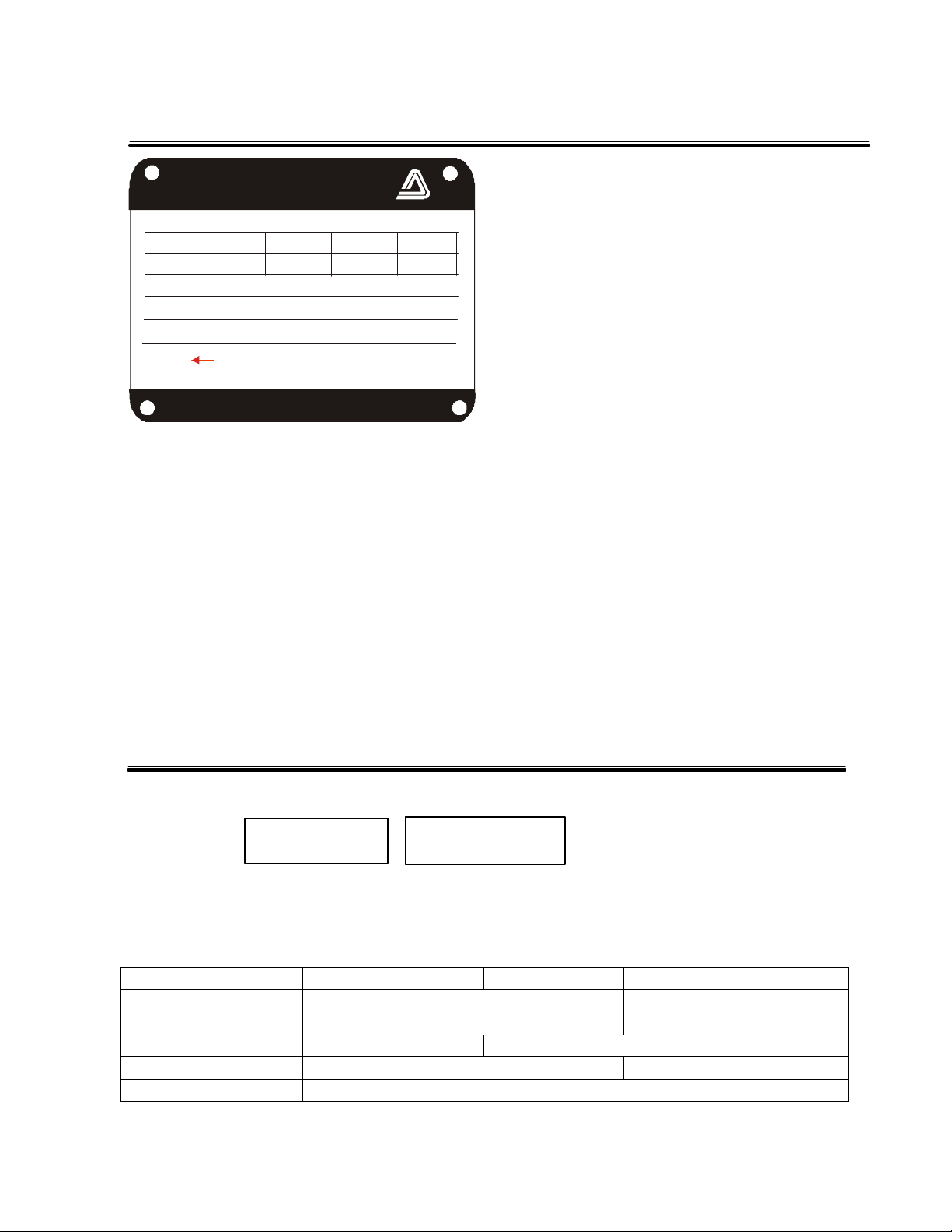

1 Unpacking and Inspection

CAPACITY (GPM)

IMPELLER DIAMETER

HOLLISTON, MASSACHUSETTS

DIRECTION OF ROTATION

Iwaki

Mag-Drive Pump

MODEL

HEAD (FT.)

SERIAL NO.

WMD-100

HP

DO NOT RUN PUMP DRY

www.iwakiwalchem.com

Hz.

RPM

Open the package and check that the product

conforms to your order. Also, check each of the

following points. For any problem or

inconsistency, contact your distributor at once.

1. Check that the model number indicated on the

nameplate conforms to the specifications of

your order.

2. Check that all the accessories you ordered are

included.

3. Check that the pump body and parts have not

been accidentally damaged or that any bolts

have not been loosened in transit.

2 Model Identification Guide

1 2

WMD-100 R RT F

1. Series name

2. Materials of construction

R RT F

Materials Glass fiber reinforced polypropylene

Connections Hose 1" I.D. conn. 1" NPT male

Bearings Alumina Ceramic/Rulon Silicon Carbide

O-ring FKM (Viton)

(GFRPP)

1

Carbon fiber reinforced

fluoroplastic

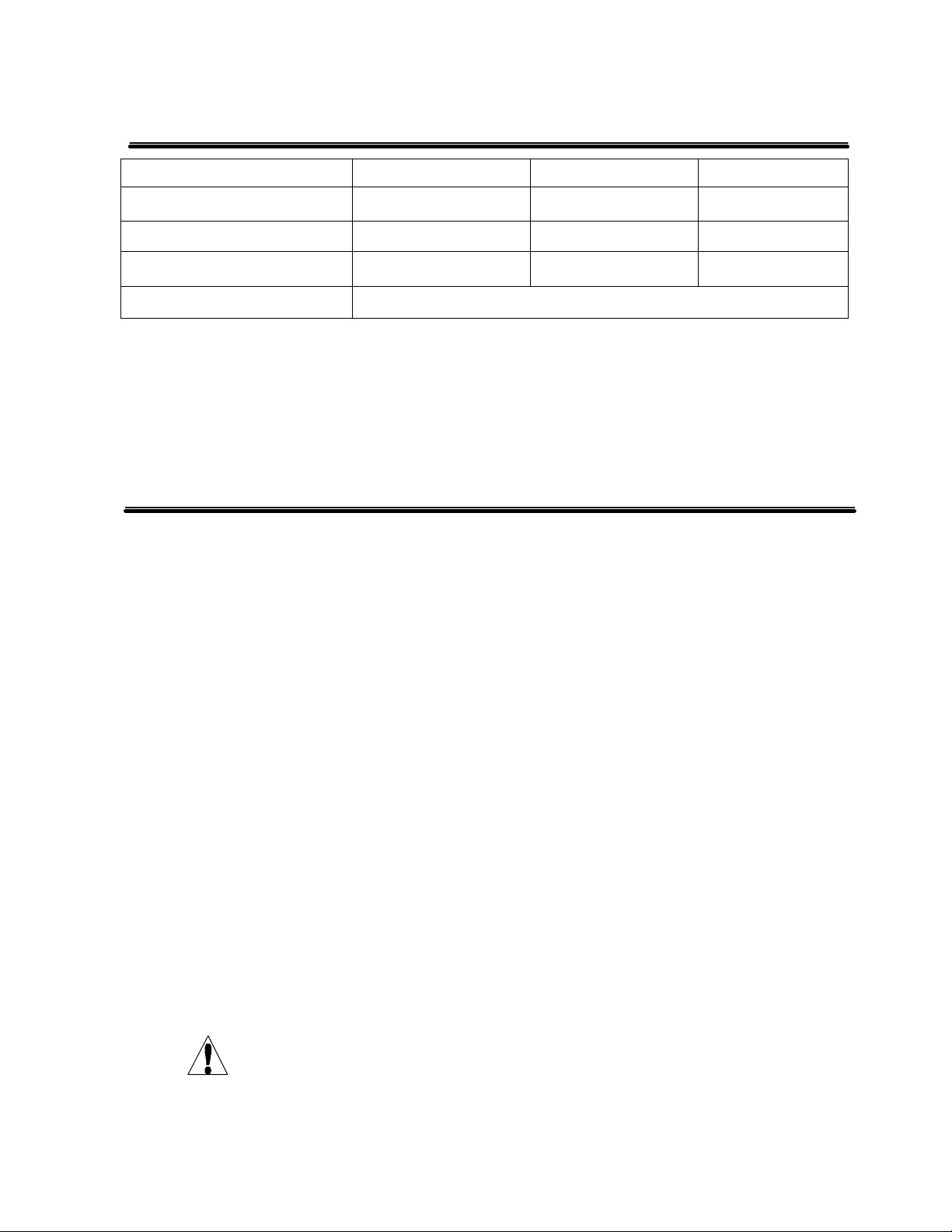

3 Specifications

WMD-100R(T) WMD-100FY WMD-100FZ

Specific gravity limit 1.2 1.3* 1.9*

Max capacity gpm (L/min) 36 (136) 36 (136) 28 (106)

Max head ft (m) 41.5 (12.6) 38 (11.6) 27 (8)

Motor output hp (kw) 1/3 (.25)

Notes:

1. Fluid temperature range: 32-176°F (0-80°C)

2. *Limit of specific gravity at maximum flow when fluid viscosity is 1 CP. Specific gravity fluids up

to 2.2 can be handled with appropriate trimming of impeller. Consult factory for recommended trim.

4 Handling Instructions

1. Do not operate the pump dry.

The sliding parts used in the WMD-100 series pump are lubricated and cooled by the fluid being

pumped. Never operate the pump dry or with the valves on the suction side closed. Otherwise, the

inside of the pump will be damaged. If the pump is unavoidably or accidentally operated dry, with

no obvious damage, allow the pump to cool down for a minimum of one hour before attempting to

restart. Do not allow fluid to enter the pump cavity until the pump has cooled down. Sudden or

rapid cooling of the pump may cause damage to the bearing system. A dry run operation device is

recommended for the prevention of dry pump operation.

2. Starting

Prior to starting the pump, make sure that the power is turned off. Then carry out priming to fill the

pump cavity with liquid.

Next, close the valves on the discharge side. Now you can turn the power on and start up the pump.

When the pump has reached full speed and line pressure is stable, the discharge valves can be

opened to the desired settings.

3. Stopping

When stopping the pump, first close the discharge valve gradually. When it is completely closed,

turn off the power switch so that the pump stops. Never stop the pump suddenly by quickly closing

a valve (i.e., solenoid or hydraulic valves).

Caution

Quick valve closure may cause water hammer which can cause severe damage to the pump.

2

Loading...

Loading...