IWAKI AMERICA MX-401, MX-400, MX-402H, MX-402, MX-403 Instruction Manual

...

IWAKI AMERICA

MAGNETIC DRIVE PUMP

MX-(F)250 to 505 SERIES

INSTRUCTION MANUAL

Thank you for selecting an Iwaki America MX Series magnetic drive pump. This instruction manual

explains the correct handling, maintenance, inspection and troubleshooting procedures for your pump.

Please read through it carefully to ensure the optimum performance, safety and long service of your

pump.

TABLE OF CONTENTS

1 Unpacking and Inspection ..................................................................................................... 1

2 Model Identification Guide ................................................................................................... 2

3 Specifications......................................................................................................................... 3

4 Handling ................................................................................................................................ 8

5 Installation, Piping, and Wiring ........................................................................................... 10

6 Operation ............................................................................................................................. 15

7 Maintenance and Inspection ................................................................................................ 18

8 Troubleshooting ................................................................................................................... 21

9 Parts Description and Exploded View ................................................................................. 23

10 Disassembly and Assembly of Pump ................................................................................... 26

11 Spare Parts ........................................................................................................................... 30

12 Weights and Dimensions ..................................................................................................... 31

This product is patent pending.

180242 Rev. I March 2015

MODEL

HEAD (FT.)

CAPACITY (GPM)

IMPELLER DIAMETER

HOLLISTON, MASSACHUSETTS

www.iwakiamerica.com

Iwaki America

Mag-Drive Pump

HP Hz.

RPM

SERIAL NO.

DIRECTION OF ROTATION

DO NOT RUN PUMP DRY

MX-

1 Unpacking and Inspection

Open the package and check that the product conforms to your order. Also, check each of the following

points. For any problem or inconsistency, contact your distributor at once.

1. Check that the model number and the HP indicated on the nameplate conform to the specifications of

your order.

2. Check that all the accessories you ordered are included.

3. Check that the pump body and parts have not been accidentally damaged or that any bolts or nuts

have not been loosened in transit.

1

MX

-

250

CFV

6

1 2 3 4

2 Model Identification Guide

MX(F)250-403(H)

1 Series Symbol

MX GFRPP casing

MX-F CFRETFE casing

2 Pump Size

250 1” x 1” 0.5HP

251 1” x 1” 1.0HP

400 1.5” x 1.5” 0.75HP

401 1.5” x 1.5” 1.5HP

402H 2” x 1.5” 2.0HP

403H 2” x 1.5” 3.0HP

505 2.5" x 2" 5.0HP

3 Materials of Bearing/Spindle/O-ring

MX

CV, CE Carbon/Alumina ceramic/FKM (EPDM)

RV, RE PTFE/Alumina ceramic/FKM (EPDM)

AV,AE Alumina ceramic/Alumina ceramic/FKM (EPDM) models MX-250 to MX-401

MX-F

CFV High density carbon/High purity alumina ceramic/FKM

RFV PTFE/High purity alumina ceramic/FKM

KKV SiC/SiC/FKM

AFV High Purity Alumina Ceramic/High Purity Alumina Ceramic/FKM

4 Impeller Mark

MX

5 50Hz only

6 60 Hz only

7 larger impeller

MX-F

T,V,W 50 Hz only

X,Y,Z 60 Hz only

2

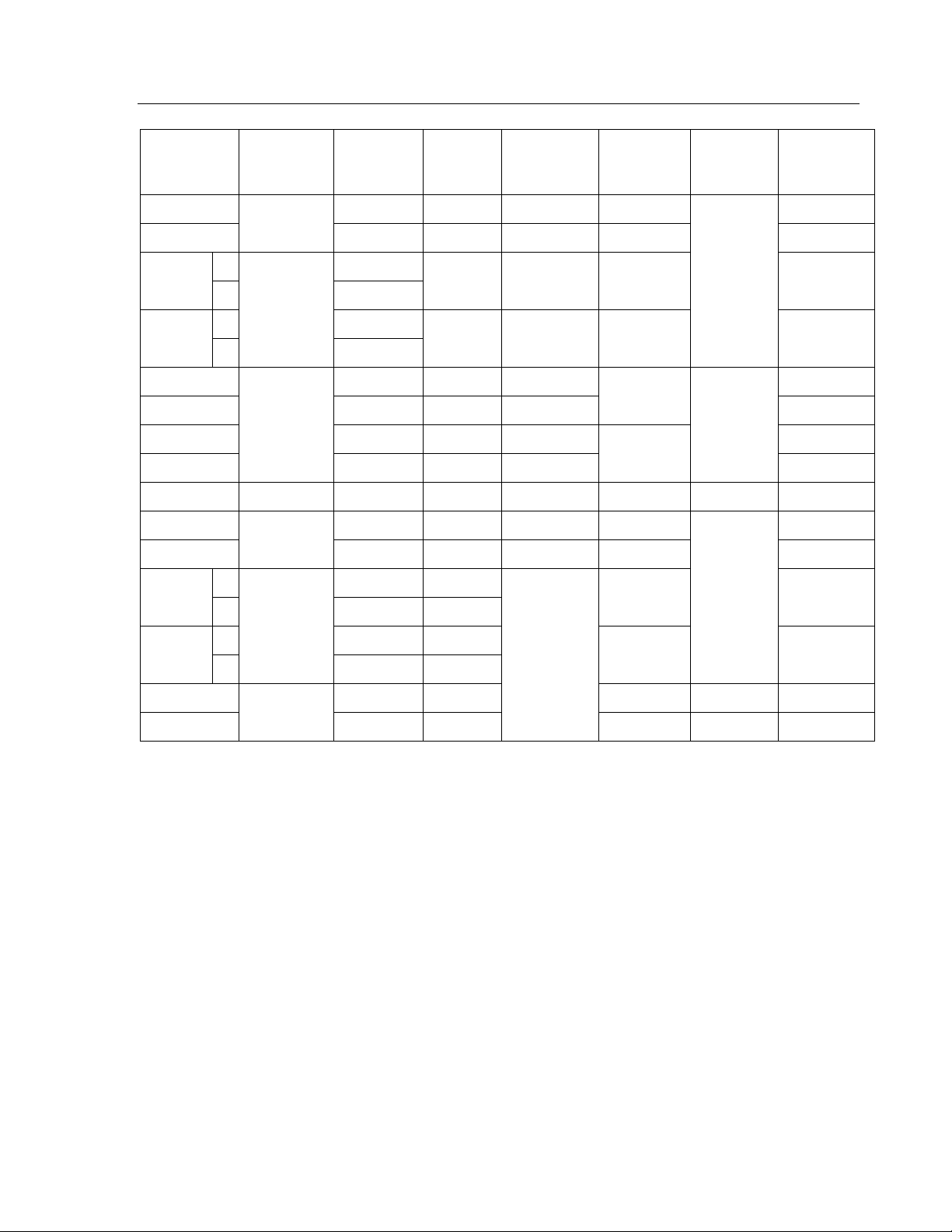

Model

Suct x Disch

Max.

Discharge

Pressure

(ft)

Max Flow

(GPM)

Specific

Gravity

Motor

output @

50/60Hz

Motor

Frame

Weight (less

motor) lbs.

MX-250

1” x 1”

53

40

1.0

0.5 HP

56C

17.0

MX-251

75

40

1.0

1 HP

22.5

MX-400

6

1.5” x 1.5”

39

70

1.2

0.75 HP

13.7

7

43

MX-401

6

59

80

1.2

1.5 HP

22.5

7

68

MX-402

2” x 1.5”

73

107

1.2

2 HP

145TC

29.8

MX-402H

99

45

1.0

29.8

MX-403

101

130

1.2

3 HP

32.0

MX-403H

126

70

1.0

32.0

MX-505

2.5" x 2"

86

225

1.2

5 HP

184TC

59.5

MX-F250

1” x 1”

48

43

1.2

0.5 HP

56C

17.0

MX-F251

69

40

1.0

1 HP

22.5

MXF400

V

1.5” x 1.5”

43

65

1.2

0.75 HP

13.7

X

34

65

MXF401

V

68

86

1.5 HP

22.5

X

50

75

MX-F402

2” x 1.5”

70

120

2 HP

145TC

29.8

MX-F403

93

130

3 HP

145TC

32.0

3 Specifications

Note 1: The specific gravity limit values shown above are with maximum impellers. The specific gravity limit

varies with the diameter. For details, contact your local distributor.

3

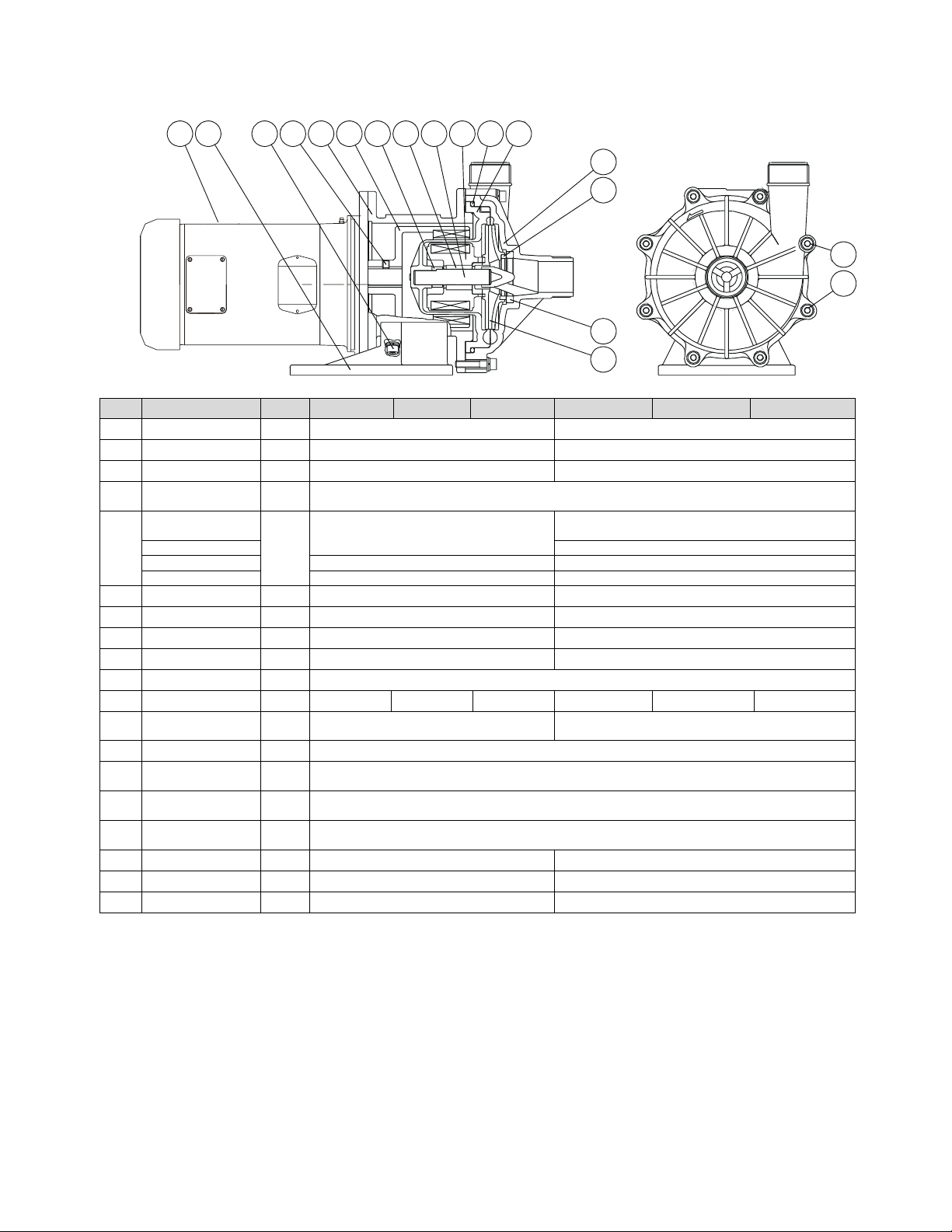

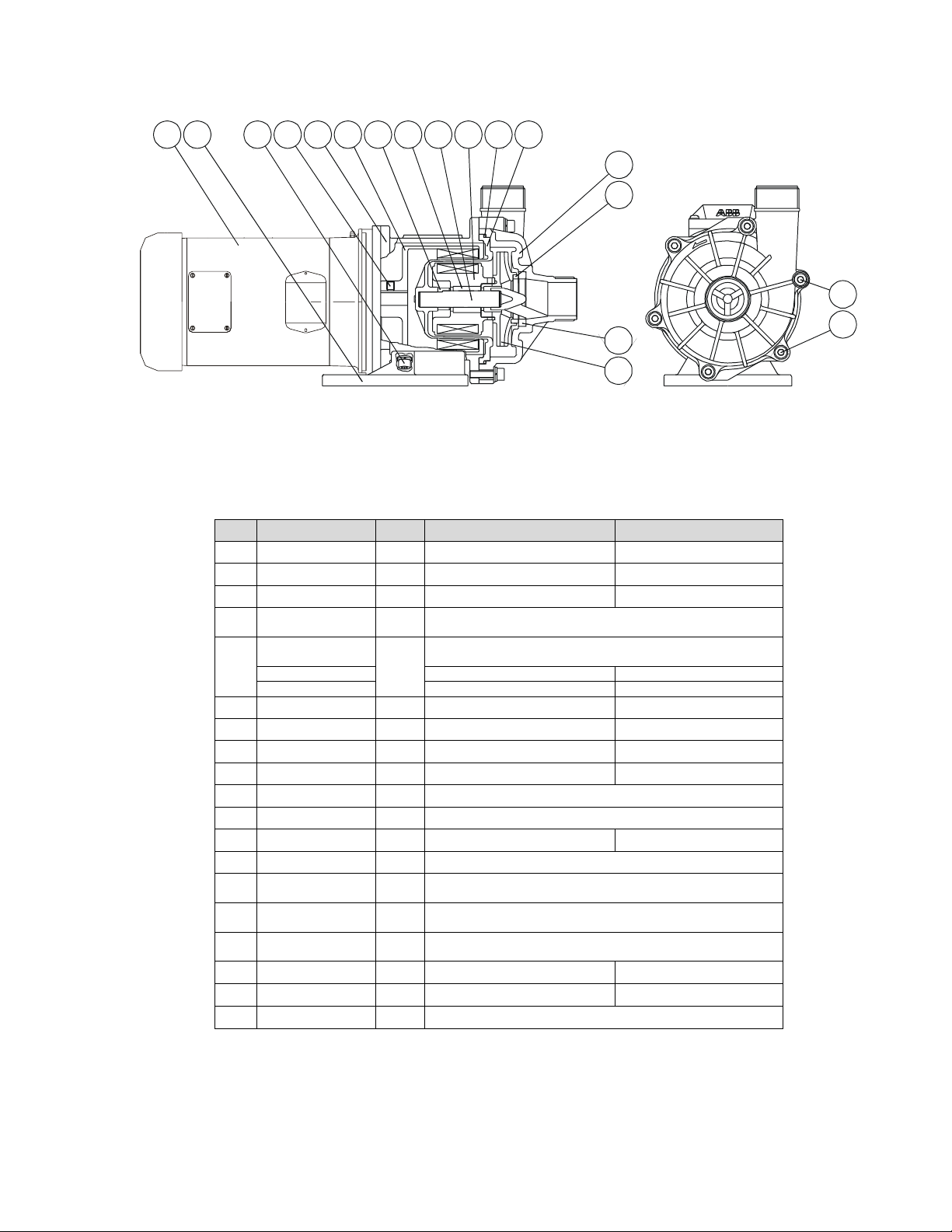

No.

Name

Qty

MX-250

MX-251

MX-401

MX-F250

MX-F251

MX-F401

1

Front casing 1 GFRPP

CFRETFE

2

Mouth ring 1 Filler charged fluororesin

PTFE or SiC

3

Impeller

1

GFRPP

CFRETFE

4

O-ring*

1

FKM/EPDM

JIS B 2401 G165

5

Bearing

AF

1

Carbon

Alumina Ceramic

CV, CF

HD Carbon

RV, RF

Filler charged fluororesin

PTFE

AV, KK

Alumina ceramic

SiC

6

Magnet capsule

1

Ferrite mag. + polypropylene

CFRETFE + Ferrite

7

Spindle 1 Alumina Ceramic 99.5%

Alumina ceramic or SiC

8

Rear thrust

1

CFRPPS

CFRETFE

9

Rear casing

1

GFRPP

CFRETFE

10

Drive magnet unit

1

Ferrite mag. + aluminum alloy

11

Motor 1 0.5 HP

1 HP

1.5 HP

0.5 HP

1 HP

1.5 HP

12

Base

1

GFRPP

GFRPP

13

Motor adapter

1

FC200

14

Hex head bolt

4

Steel

M8 x 20 w/PW, SW

15

Hex head bolt

6

SS

M8 x 35 w/PW, SW

16

Hex head bolt

2

SS

M8 x 50 w/PW, SW

18

Flange kit

2

GFRPP

CFRETFE

19

Liner ring 1 Alumina ceramic 99.5%

Alumina Ceramic 99.5% or SiC

21

Hex head screw 2 Steel M8 x 10

Steel M8 x 10

12 14 21 13 10 8

5

7

6

4

9

1

2

19

3

16

15

11

MX-(F)250, MX-(F)251, MX-(F)401

* Additional o-ring materials available upon request.

4

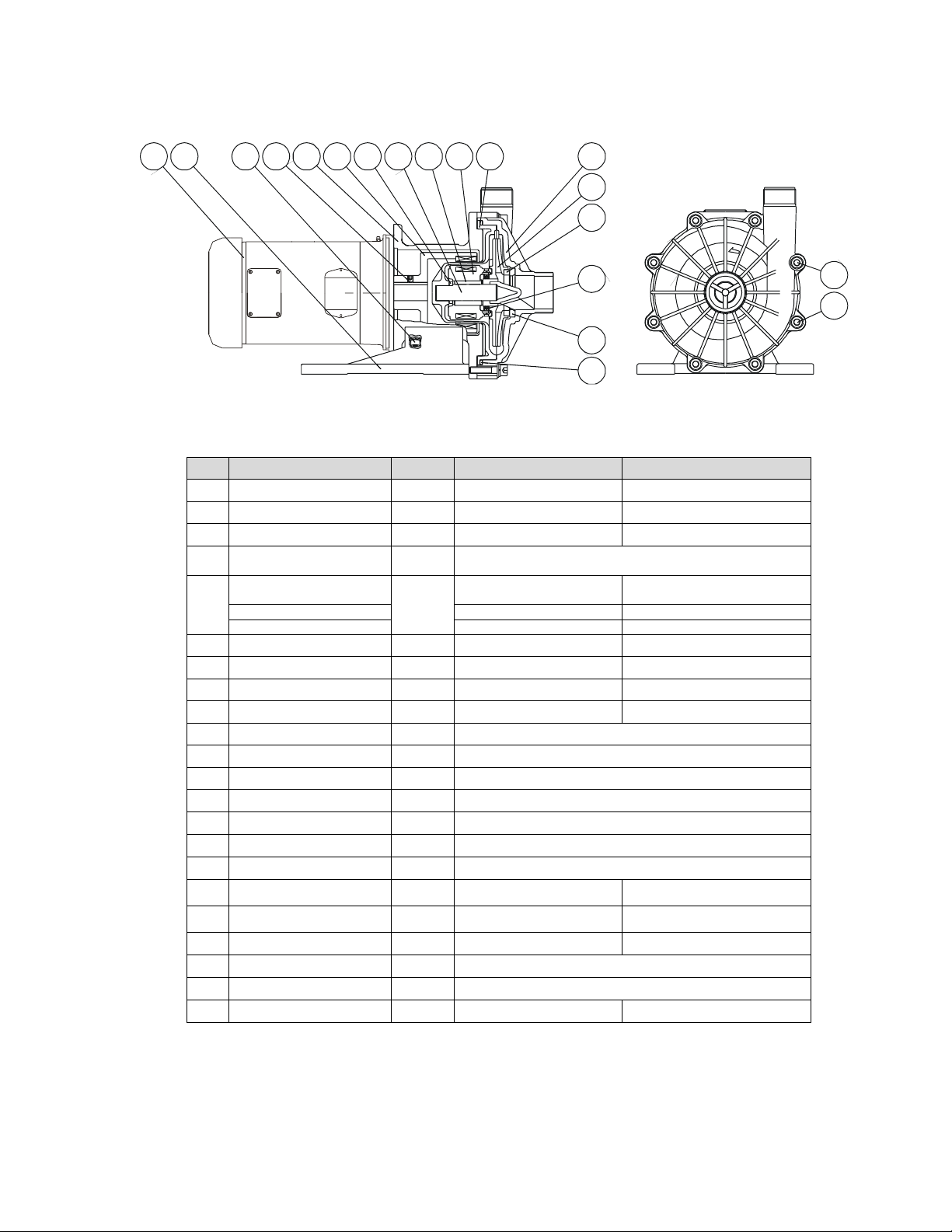

11

12

15

16

3

19

2

1

14 21 13

10

8

5

7

6

4

9

No.

Name

Qty

MX400

MX-F400

1

Front casing 1 GFRPP

CFRETFE

2

Mouth ring

1

Filler charged fluororesin

PTFE/SiC

3

Impeller 1 GFRPP

CFRETFE

4

O-ring*

1

FKM / EPDM

JIS B 2401 G135

5

Bearing

CV, CF

1

HD Carbon

RV, RF

Filler charged fluororesin

PTFE

KK

----

SiC

6

Magnet capsule

1

Ferrite + polypropylene

Ferrite + CFRETFE

7

Spindle 1 Alumina ceramic 99.5%

Alumina ceramic or SiC

8

Rear thrust 1 CFRPPS

CFRETFE

9

Rear casing 1 GFRPP

CFRETFE

10

Drive magnet unit

1

Ferrite + FCD450

11

Motor

1

1 or 1.5 HP

12

Base

1

GFRPP

GFRPP

13

Motor adapter

1

FC200

14

Hex bolt

4

Steel

M8 x20 w/PW, SW

15

Hex head bolt

4

SS

M8 x 30 w/SW

16

Hex head bolt

2

SS

M8 x 40 w/PW, SW

18

Flange kit 2 GFRPP

CFRETFE

19

Liner ring 1 Alumina ceramic 99.5%

Alumina ceramic or SiC

21

Hex head screw

2

Steel M8 x 10

MX-(F)400

*Additional o-rings materials available upon request.

5

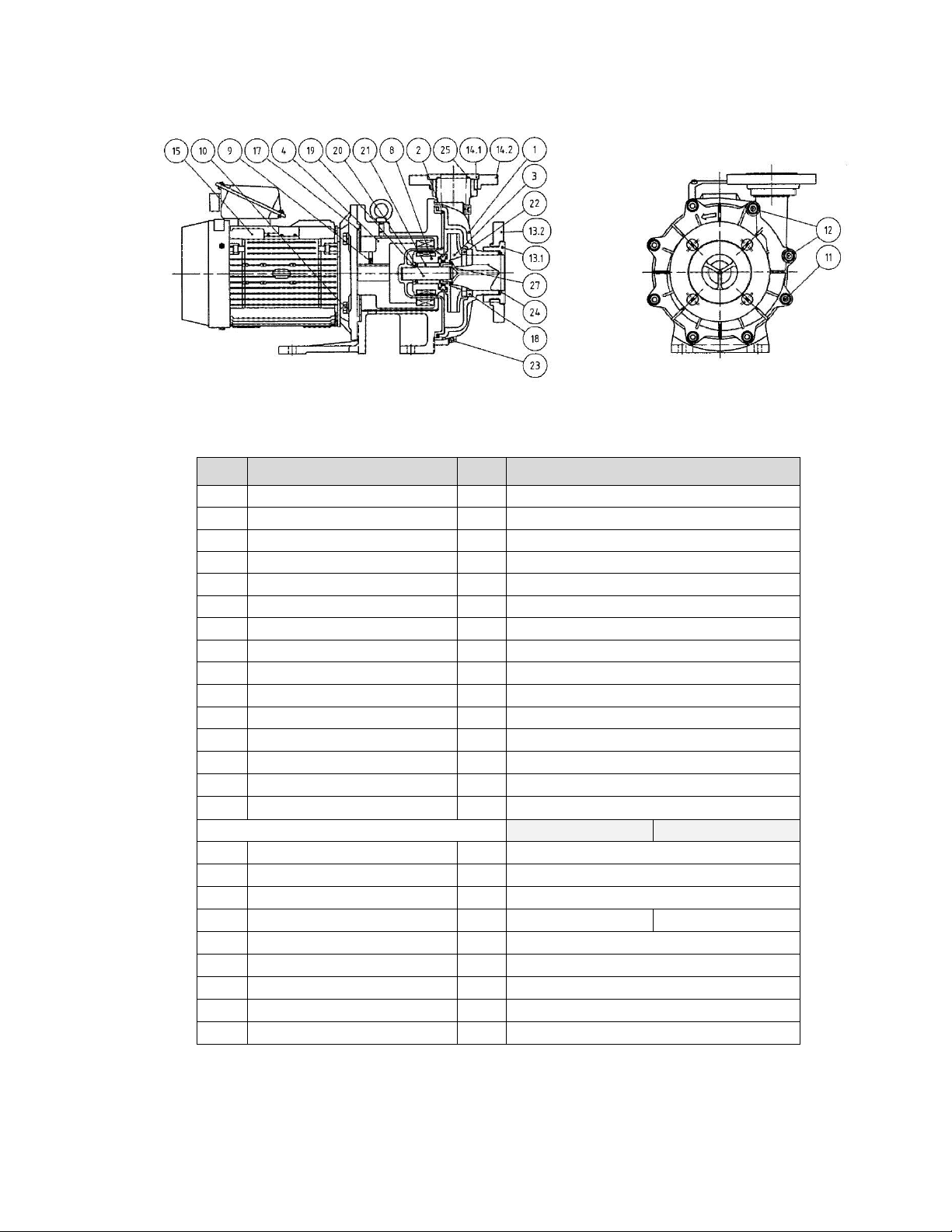

11

12

15

16

14

21 13 10

8

7 5

6 9

4

19

17

2

3

1

No.

Name

Qty

MX-402(H), 403(H)

MX-F402, F403

1

Front casing 1 GFRPP

CFRETFE

2

Mouth ring

1

Filler charge fluororesin

PTFE or SiC

3

Impeller 1 GFRPP

CFRETFE

4

O-ring*

1

FKM / EPDM

JIS B 2401 G195

5

Bearing

CV, CF

1

Carbon

HD Carbon

RV, RF

Filler charge fluororesin

PTFE

AV, KK

Alumina ceramic

SiC

6

Magnet capsule

1

Ferrite mag. + polypropylene

Ferrite mag. + CFRETFE

7

Spindle 1 Alumina ceramic 99.5%

Alumina ceramic or SiC

8

Rear thrust 1 CFRPEEK

CFRPFA

9

Rear casing 1 GFRPP

CFRETFE

10

Drive magnet unit 1 Ferrite mag. + aluminum alloy

11

Motor

1

2 + 3 HP

12

Base

1

GFRPP

13

Motor adapter

1

FC200

14

Hex head bolt 4 Steel M8 x 20 w/PW, SW

15

Hex head bolt

7

SS M10 x 55 w/ SW

16

Hex head bolt

1

SS M10 x 60 w/PW, SW

17

Lock pin 2 CFRPPS

CFRETFE

18

Flange kit, discharge

2

GFRPP

CFRETFE

19

Liner ring

1

Alumina ceramic 99.5%

Alumina ceramic or SiC

20

Motor bolt

4

SS 3/8 x 3/4”

21

Hex head screw

2

Steel M8 x 10

22

Flange kit, suction

1

GFRPP

CFRETFE

MX-(F)402(H), MX-(F)403(H)

*Additional o-ring materials available upon request.

6

No.

Name

Qty

MX-505

1

Front casing

1

GFRPP

2

Rear casing

1

GFRPP

3

Impeller

1

GFRPP

4

Drive magnet unit 1 Rare earth magnet +FCD450

8

Magnet capsule 1 Rare earth magnet +PP

9

Hex socket set screw 2 Steel M8 x 10

10

Hex head bolt 4 Stainless Steel M12 x 35, SW

11

Hex socket head bolt

6

Stainless Steel M10 x 45, PW, SW

12

Hex socket head bolt

2

Stainless Steel M10 x 75, PW, SW

13.1

Flange IN Inner

1

GFRPP

13.2

Flange IN Outer

1

GFRPP

14.1

Flange Out Inner

1

GFRPP

14.2

Flange Out Outer 1 GFRPP

15

Motor

1

17

Adapter

1

FC200

CV/CE

RV/RE

18

Liner ring 1 Alumina Ceramic 99.5%

19

Rear thrust

1

CFRPEEK

20

Spindle

1

Alumina Ceramic 99.5%

21

Bearing 1 Carbon

PTFE

22

Mouth ring

1

PTFE

23

O Ring 1 V:FKM E:EPDM JIS B 2401 G230

24

O Ring 1 V:FKM E:EPDM JIS B 2401 G70

25

O Ring 1 V:FKM E:EPDM JIS B 2401 G55

27

Lock Pin

2

GFRPPS

MX-505

7

CAUTION

Do not run pump dry

When the pump is operated for the first time after it was installed or after it was disassembled and

repaired, fill the pump chamber with the liquid to be pumped. If the pump runs dry without any liquid,

rubbing parts of pump will seize. The moving or rotating parts of MX pumps are lubricated and

cooled by the pumped liquid. The pump will be damaged if run dry or with the suction side valve

fully closed. If the pump runs dry by mistake, switch off the power and leave it for more than one

hour to cool it down slowly.

Keep pump away from fire

To prevent fire and explosions, do not place dangerous or inflammable substances near to pump.

No remodeling

Remodeling the pump can cause risk of injury or electrical shock.

!

4 Handling

Precautions on handling

1. Precautions when pump is started or stopped

When discharge line is long and to avoid water hammer, pay attention to the following:

a. When pump is started

After priming, close the discharge valve before power is switched on. After the

pump is started, gradually open the discharge valve to get the desired duty

point.

b. When pump is stopped

Gradually close the discharge valve and switch off the power. Never close the

discharge line suddenly with a solenoid valve. Sudden close of discharge line

causes water hammer resulting in pump damage.

2. Do not install or store pump in the following places.

Where the temperature falls below 0 deg. C.

Where there is corrosive or explosive gas.

Where water is splashed (except the pump equipped with weather-proof motor)

Where ambient temperature exceeds 40 deg. C.

Where humidity exceeds 85% (Allowable humidity: 35 to 85%RH)

3. Prime pump

The pump is not self-priming. Before the pump is started, prime the pump with pumped liquid.

Dry running causes seizure and quick wear of parts.

8

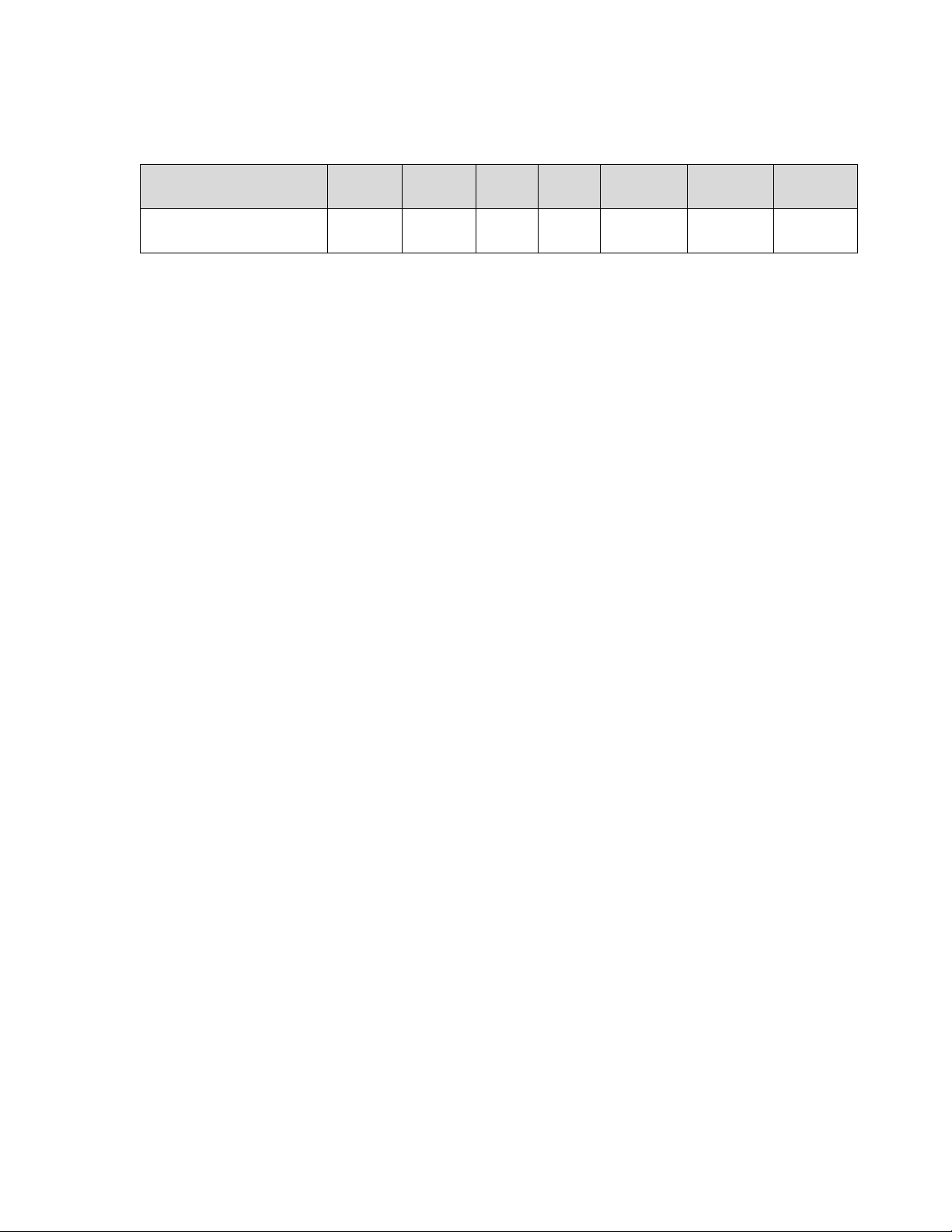

Model MX-

(F)250

(F)251

(F)400

(F)401

(F)402, 403

402H,

403H

505

Max. allowable pressure PSI

(MPa)

36.3

(0.25)

47.9

(0.33)

31.9

(0.22)

40.6

(0.28)

62.4

(0.43)

72.5

(0.5)

47.9

(0.33)

4. Pump allowable pressure

Pump allowable pressure is shown below. Do not allow discharge pressure to exceed the

allowable pressure.

5. Liquids to be transferred

a. Liquid containing slurry

Slurry cannot be handled except for type A or KK (with alumina ceramic bearing)

which can handle slurry liquid up to 5% concentration, slurry size of 50 micron m or

below and hardness up to 80Hs. Contact Iwaki America if you wish to handle slurry

liquid.

b. Performance influenced by specific gravity and viscosity of liquid

Liquid which is heavier or more viscous than water influences the shaft power,

discharge capacity and head.

The pump you purchased is made according to the specifications you gave us when

ordered. If you wish to change the conditions, please contact us.

c. Alumina ceramic bearing (types AV, AE) may be worn in a short time depending on

the characteristics of liquid (low viscosity etc.). Please contact Iwaki America if you

have any questions.

d. Influence by temperature

Pump performance is not influenced by the change of liquid temperature; however, the

temperature will affect the viscosity, vapor pressure and chemical corrosion. Refer to

the chemical resistance table for the permissible temperature for specific chemical

liquids.

Temperature of liquid to be handled: 0 – 80 deg. C (for water)

Permissible ambient temperature: 0 – 40 deg. C

Permissible humidity: 35 – 85% RH

6. Intermittent operation

Frequent stopping and starting may cause pump damage. Keep the start/stop frequency to within

six times an hour.

7. Disconnection of magnet coupling

If the magnet coupling is disconnected, stop the pump within a minute. If the pump runs with

the magnet coupling disconnected, the power of coupling will be decreased.

9

Loading...

Loading...